Page 1

User Manual

PanelView 5500 Terminals

Catalog Numbers 2715-T7CD, 2715-T7CA, 2715-B7CD, 2715-B7CA, 2715-T9WD,2715-T9WA, 2715-T10CD,

2715-T10CA, 2715-B10CD, 2715-B10CA, 2715-T12WD, 2715-T12WA, 2715-T15CD, 2715-15CA, 2715-B15CD,

2715-B15CA, 2715-T19CD, 2715-T19CA

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, ArmorBlock, CompactLogix, ControlFLASH, ControlLogix, FLEX, Kinetix, PanelView, POINT I/O, RSLinx, Stratix 6000, Studio 5000 Logix Designer, Studio 5000 View Designer, Rockwell Software, and

Rockwell Automation are trad emarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Table of Contents

Preface

Overview

Install the PanelView 5500 Terminal

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Product Release Notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

About the PanelView 5500 Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Operator Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Touch Gestures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

EtherNet/IP Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Typical Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Product Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Ethernet Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

North American Hazardous Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Required Circuit Port Parameters for USB Peripheral Devices . . . 20

Mounting Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mounting Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Panel Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Panel Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Product Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Prepare for Panel Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Mount the Terminal in a Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Remove and Replace the Power Terminal Block . . . . . . . . . . . . . . . . . . . . 31

Connect to DC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Connect to AC Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Connect to a Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Ethernet Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Device Level Ring Network Topology. . . . . . . . . . . . . . . . . . . . . . . . . . 35

Linear Network Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Star Network Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Initial Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Update the Firmware Before You Use the Terminal . . . . . . . . . . . . . 38

Configure Terminal Settings

Chapter 3

Runtime Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Entering Data Using Virtual Keyboards. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Log On to the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Log Off of the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Settings Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 3

Page 4

Table of Contents

Configure the IP Address of the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Use DHCP to Assign an IP Address For the Terminal . . . . . . . . . . . 48

Assign a Static IP Address For the Terminal. . . . . . . . . . . . . . . . . . . . . 49

Configure a DNS Address For the Terminal . . . . . . . . . . . . . . . . . . . . . . . . 50

Configure the Ethernet Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

View the Network Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Adjust the Brightness of the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Configure the Display Screen Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Calibrate the Touch Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Disable Downloads to the Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Change the HMI Device Name. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

View the Firmware Revision. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Display Terminal Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Reboot the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Change the Date and Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

View General Information for the Configured Controller . . . . . . . . . . . 63

Chapter 4

Monitor and Manage Control System

Alarms

Install and Replace Components

Update Firmware

Alarm Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Alarm Help Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

View the Alarm Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Manage the Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Alarm Detail-pane Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Filter the Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Chapter 5

Connect to USB Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

USB Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Insert an SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Replace the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Install a Protective Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Clean the Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Remove the Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Chapter 6

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Firmware Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Get the Terminal Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Install the ControlFLASH Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Update the Firmware by Using ControlFLASH Software. . . . . . . . . . . . 85

Verify the Firmware Update. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 5

Chapter 7

Table of Contents

Troubleshooting

Index

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

View Diagnostic Information for the Configured Controller . . . . . . . . 91

Troubleshooting Profiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Import a Troubleshooting Profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Export a Troubleshooting Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Terminal Does Not Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Terminal Restarts Intermittently . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Touch Screen Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Display Issues . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Ethernet Issues. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Cannot Download Application to Terminal. . . . . . . . . . . . . . . . . . . . . . . . 97

Performance Is Slow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Resistance to Chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Clean the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Remove Paint and Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Equipment Wash Downs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Ship the Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Restore Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 5

Page 6

Table of Contents

Notes:

6 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 7

Preface

IMPORTANT

IMPORTANT

This manual describes how to install, configure, operate, and troubleshoot the

PanelView™ 5500 terminals. It does not provide procedures on how to create

applications that run on the terminals or ladder logic that runs in the controller.

Other tasks that you must do include:

• Configure the Ethernet settings and update the firmware of the terminal.

You must configure the Ethernet settings and update the firmware

before you can download a View Designer project and use the

terminal. See Initial Startup on page 37

• Create an application by using the Studio 5000 View Designer™

application.

• Create a project for the controller by using the Studio 5000 Logix

Designer® application.

.

Package Contents

This product is shipped with the following items:

• PanelView 5500 terminal

• Mounting levers for panel installation

• Removable power terminal blocks (AC or DC)

• Product information sheet

• Cutout template

This product can contain open source packages. The open source declarations are

part of the .nvs file. You can view the open source declarations by opening the .nvs

file with a text reader such as Notepad.

Do not modify the .nvs file. The .nvs file is used in firmware upgrades and a

modified .nvs file can cause the firmware upgrade to fail.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 7

Page 8

Preface

Product Release Notes

Product release notes are available online within the Product Compatibility and

Download Center.

1. From the Quick Links list on http://www.ab.com

, choose Product

Compatibility and Download Center.

2. Click the Download icon and search for your product.

3. Click the download icon to access product release notes.

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PanelView 5500 Terminals Technical Data, publication

2715-TD001

EtherNet/IP Embedded Switch Technology Application

Guide, publication ENET-AP005

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Guidelines for Handling Lithium Batteries Technical Data,

publication AG-5. 4

Safety Guidelines for the Ap plication, Installation, and

Maintenance of Solid-State Controls, publication SGI-1.1

Product Certifications website, http://www.ab.com

Provides specifications and certifications for the PanelView 5500 terminal.

Provides information on how to install, configure, and maintain linear, star, and Device Level Ring (DLR) networks using

Rockwell Automation® EtherNet/IP devices with embedded switch technology.

Provides general guidelines for installing a Rockwell Automation industrial system.

Provides guidelines to store, handle, install, and dispose of lithium batteries.

Provides general guidelines for the application, installation, and maintenance of solid-state equipment.

Provides declarations of conformity, certificates, and other certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature/

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

. To order paper copies of

8 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 9

Chapter 1

Overview

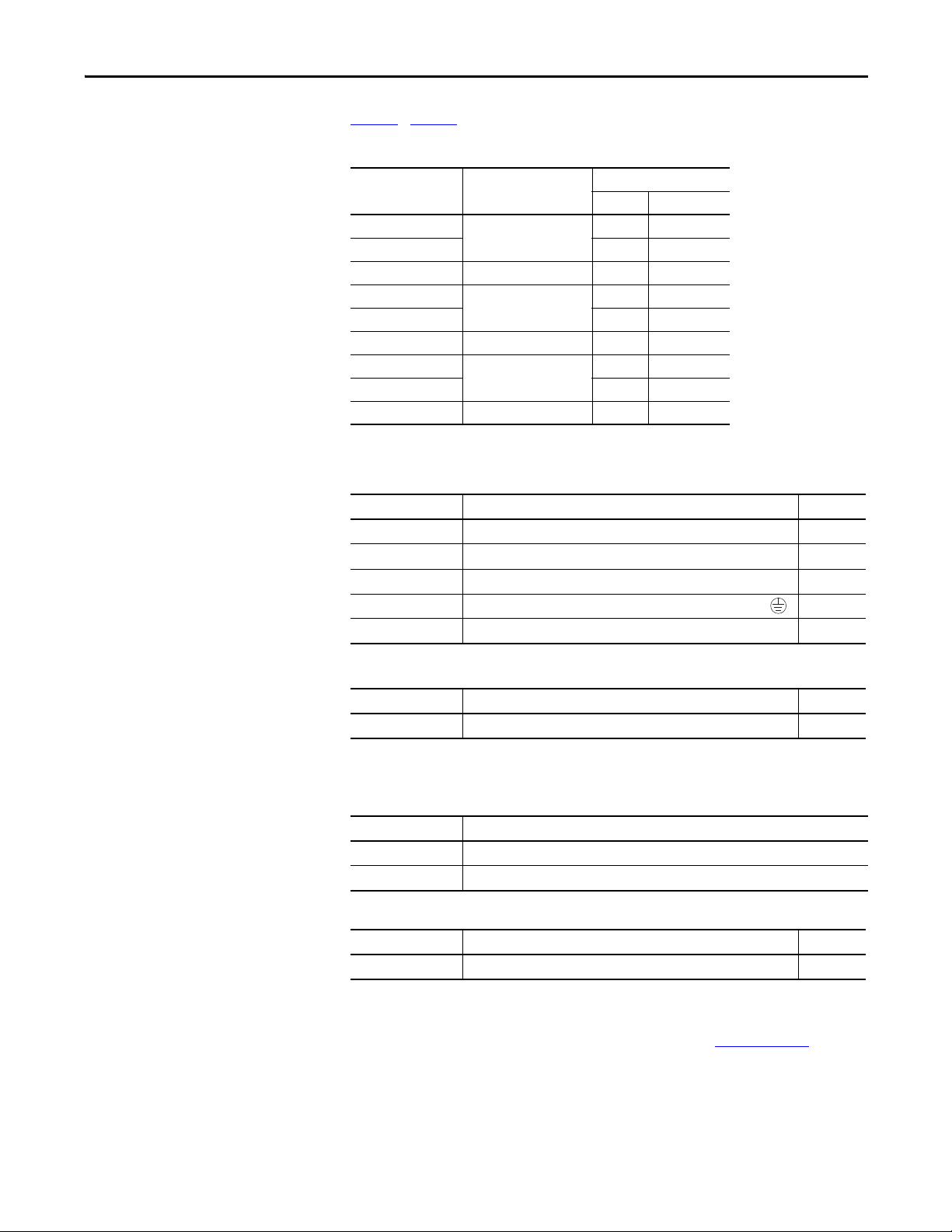

Topic Page Topic Page

About the PanelView 5500 Terminals 9 EtherNet/IP Communication 14

Hardware Features 10 Typical Configuration 14

Operator Control 10 Catalog Number Explanation 14

Touch Gestures 12 Product Selections 14

Studio 5000 Environment 12 Accessories 15

About the PanelView 5500 Terminals

The PanelView 5500 terminals

are operator interface devices for

monitoring and controlling

devices that are attached to

ControlLogix® L7 and

CompactLogix™ L1, L2, and L3

controllers over an EtherNet/IP

network. Animated graphic and

text displays provide operators a

view into the operating state of a machine or process. Operators interact with the

control system by using the touch screen or keypad of the terminal.

The PanelView 5500 terminals include these features and capabilities:

• Tightly integrated control and design environment allows information to

be shared between the PanelView 5500 terminal and the Logix platforms.

• The Studio 5000 environment provides one point of access for both View

Designer and Logix Designer applications.

• Connection to one ControlLogix L7 or CompactLogix L1, L2, or L3

controller with revision 27 firmware or later.

• Supports a maximum of 50 user-defined screens (this will increase in

future firmware).

• Supports a maximum of 500 Logix-based alarms (this will increase in

future firmware).

• Ethernet communication supporting Device Level Ring (DLR), linear, or

star network topologies.

• High-speed human machine interface (HMI) button control and easily

configured navigation menu.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 9

Page 10

Chapter 1 Overview

2

4

6

7

L1

L2

L3

L4

L5

L6

L8

L7

R9

R10

Esc

798

456

123

0

.

–

R11

R12

R13

R14

R16

R15

1

5

8

9

3

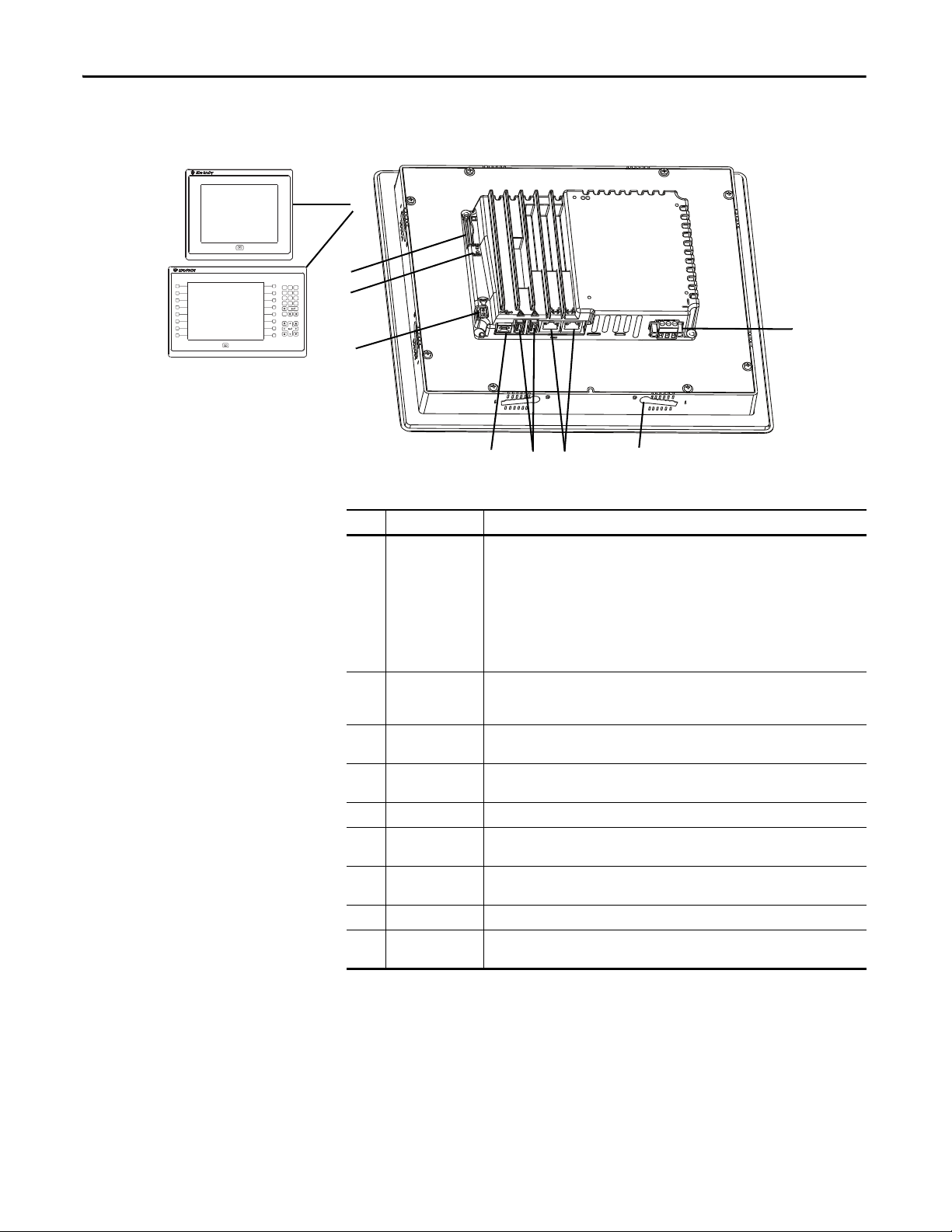

Hardware Features

The PanelView 5500 terminals are fixed hardware configurations providing a

range of display sizes and operator input options.

Table 1 - Hardware Features

Item Feature Description

TFT color graphic displays with a touch screen and navigation button in a range of

display sizes. Some models also have a keypad and function keys providing additional

operator input options.

1 Display/Keypad

2 Power

3Mounting slot

4 Ethernet ports

5 USB host ports Two USB 2.0 high-speed (type A) host ports.

6USB device port

7Audio out

8 Status indicators Light-emitting diode indicators on back of unit provide status and fault conditions.

Secure Digital (SD)

9

card slot

• 6.5-in. touch or touch with keypad

• 9-in. wide screen with touch

• 10.4-in. touch or touch with keypad

• 12.1-in. wide screen with touch

• 15-in. touch or touch with keypad

• 19-in. touch

AC or DC power input:

• 18…30V DC (isolated)

• 100…240V AC nom (85…264V AC)

The slots on the top, bottom, and sides of the terminal are used with mounting levers

to mount the device to a panel or enclosure. The number of slots varies by terminal size.

Two 10/100Base-T, Auto MDI/MDI-X, Ethernet ports for controller communication that

supports DLR network topology.

IMPORTANT: The USB device port is not functional. The port will be available in a

future s oftware release.

IMPORTANT: The audio out feature is not functional. The feature will be available in a

future s oftware release.

One SD card slot supports catalog number 1784-SDx SD card.

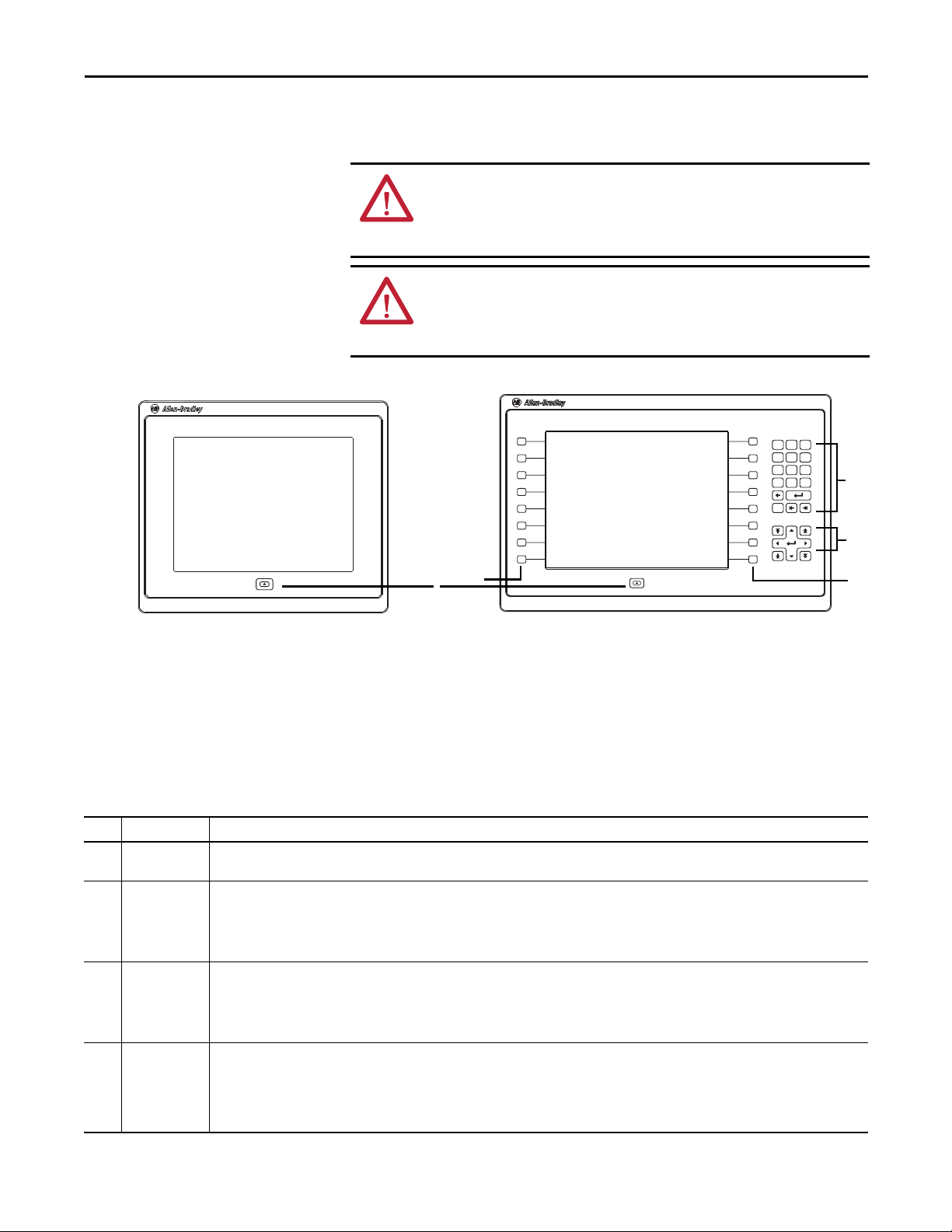

Operator Control

All PanelView 5500 terminals have a color display with a touch screen and

navigation key, or a touch screen, navigation key, and keypad for operator control.

• Analog, resistive, touch screens provide accurate, durable touch with

excellent reliability for control of industrial applications.

10 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 11

Overview Chapter 1

L1

L2

L3

L4

L5

L6

L8

L7

R9

R10

Esc

798

456

123

0

.

–

R11

R12

R13

R14

R16

R15

1

2

3

4

4

• Keypad models are similar except for the number of function keys to the

left (L#) and right (R#) of the display. Larger models have more keys.

ATT EN TI ON : The keypad and touch screen support input from a finger, stylus,

and gloved-hand for operation in dry or wet environments. The plastic stylus

must have a minimum tip radius of 1.3 mm (0.051 in.). Any other object or tool

can damage the keypad or touch screen.

ATT EN TI ON : Do not perform multiple operations simultaneously. Multiple

simultaneous operations can result in unintended operation.

– Touch only one operating element on the screen with one finger at one time.

– Press only one key on the terminal at one time.

The physical keypad on the PanelView 5500 terminal is used during runtime to

initiate actions, control navigation, and enter data. The terminal also supports a

virtual keyboard and numeric keypad that opens on PanelView 5500 terminal

screens during runtime.

The terminal also supports the use of a physical keyboard and mouse when

connected to the USB ports.

Table 2 - PanelView 5500 Terminal Keypad

Item Feature Description

Navigation

1

button

2 Numeric keypad

3 Navigati on keys

4

Function keys

6.5-in. terminal

10.4-in. terminal

15-in. terminal

Opens the navigation menu at the bottom of a screen and displays the contents of a project. The menu allows screen navigation and device

configuration.

Contains numeric, decimal, minus, and these keys:

• Backspace - deletes the character to the left of the insertion point.

• Enter - inputs the currently highlighted key or enters a blank line if the insertion point is in the text box of the virtual keyboard.

• Tab-left, Tab-right - selects the previous or next control or input element.

• Esc - cancels or dismisses a dialog.

Provides navigation control.

• Arrow keys - selects a key on the vir tual keyboard that is above, below, left, or right of the selected key. Arrow keys also move the cursor if the cursor

is in a text box.

• Home/End - moves the insertion point to the beginning or end of a text or numeric entry field.

• Page up/Page down - goes to the next or previous pages of a list.

Performs specific commands when configured for a screen or any of its graphic elements. For example, L1 can be configured to go to another screen.

• L1…L6 and R1…R6

• L1…L8 and R1…R8

• L1…L10 and R1…R10

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 11

Page 12

Chapter 1 Overview

Touch Gestures

Studio 5000 Environment

The PanelView 5500 terminal supports touch gestures to interact with screen

elements during runtime. Standard touch functions include these gestures:

•Tap – Briefly touch the target on the screen with your fingertip.

•Drag – Touch the target and move your fingertip across the screen without

losing contact.

For a list of actions you can perform by using touch gestures, see the View

Designer help.

Use the Studio 5000 environment to create HMI applications for the

PanelView 5500 terminal.

The Studio 5000 environment includes these applications:

•View Designer – you can create and design a project for a specific

PanelView 5500 terminal and download the project to the terminal.

You can create an application for any PanelView 5500 terminal and reuse

that same application across the entire platform.

•Logix Designer – you can develop control logic for a CompactLogix or

ControlLogix controller and download the logic to the controller.

12 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 13

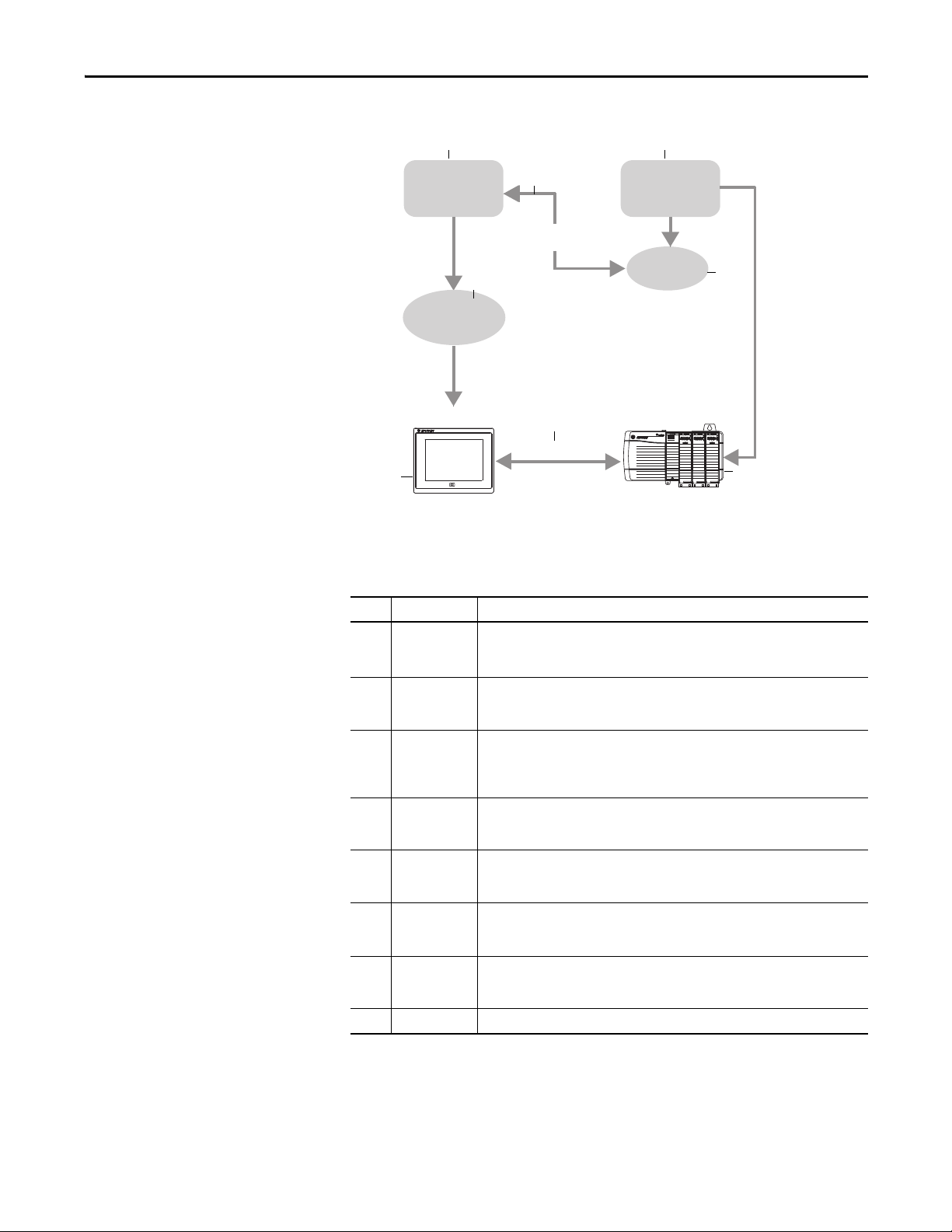

Figure 1 - How Studio 5000 Applications Work Together

LINK NET OK

1

2

3

4

5

7

6

8

View Designer

Application

Logix Designer

Application

Tag Bro wse r

Offline

ACD File

HMI Project

(VPD File)

HMI Device

Control ler

Runtime

Communication

Overview Chapter 1

The table describes how the View Designer and Logix Designer applications

work together to create an HMI runtime project.

Table 3 - Studio 5000 Applications and Tools

Item Component Description

View Des igner

1

application

2Tag browser

Logix Designer

3

application

4ACD file

HMI project

5

(VPD file)

6 HMI device

7Runtime

8 Controller A logic controller such as a ControlLogix or CompactLogix 5370 controller.

A Studio 5000 application that is used to build HMI projects.

View Designer projects are stored as .VPD files that can be downloaded to the PanelView

5500 terminal.

A tool that is used to search for and select tags within a Logix Designer ACD project file.

You can bind the tags to graphic element properties and properties of an HMI screen.

View Designer uses the tag browser to read data from an ACD file.

A Studio 5000 application that is used to develop control logic for an industrial

automation system. Logix Designer interfaces with controllers to read and write tag

information. Logix Designer projects are stored as .ACD files that can be downloaded to

the controller.

An Automation Controller Database (ACD) file. An ACD file is a Logix Designer project file

that contains the logic or code, including tags and data types, which runs within a

controller.

A View Project Database (VPD) file. A VPD project is a file that contains the operator

interface application, including HMI screens, controller references, and information about

the HMI device to run the application.

A Human Machine Interface (HMI) device, such as the PanelView 5500 terminal, which

runs the HMI project. At runtime, the HMI device communicates directly with the

controller.

The environment in which the runtime HMI project communicates with the controller.

During runtime, the HMI device runs the downloaded project, exchanges data with the

controller, animates displayed data, and responds to operator input.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 13

Page 14

Chapter 1 Overview

EtherNet/IP Communication

Typical Configuration

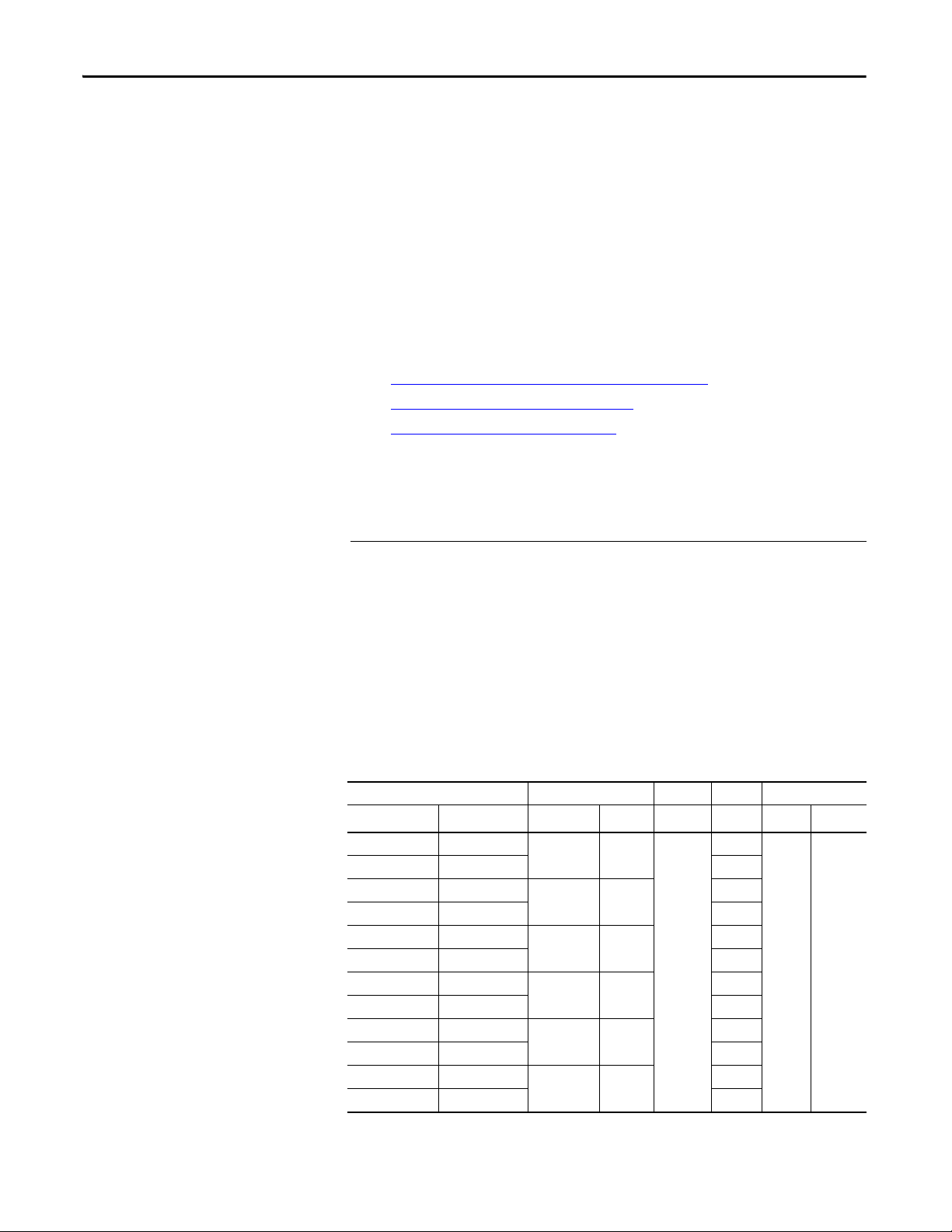

Catalog Number Explanation

The PanelView 5500 terminals contain EtherNet/IP embedded switch

technology. These terminals communicate with ControlLogix controllers over an

Ethernet connection with DLR or linear network topologies. Star technology is

also supported when using switches.

ThePanelView 5500 terminals can reside on EtherNet/IP networks that run

integrated motion and CIP Sync applications without affecting performance.

The terminal is not a consumer or producer of CIP Sync or motion packets.

Traditional DLR, linear, and star network topologies are supported. See these

topics for examples:

• Device Level Ring Network Topology on page 35

• Linear Network Topology on page 36

• Star Network Topology on page 37

Bulletin Input Type Display Size Display Type Power

||| |

2715- T = Touch 7 = 6.5-in. C = Color, standard aspect ratio A = AC

B = Keypad with Touch 9 = 9-in. W = Color, wide aspect ratio D = DC isolated

10 = 10.4-in.

12 = 12.1-in.

15 = 15-in.

19 = 19-in.

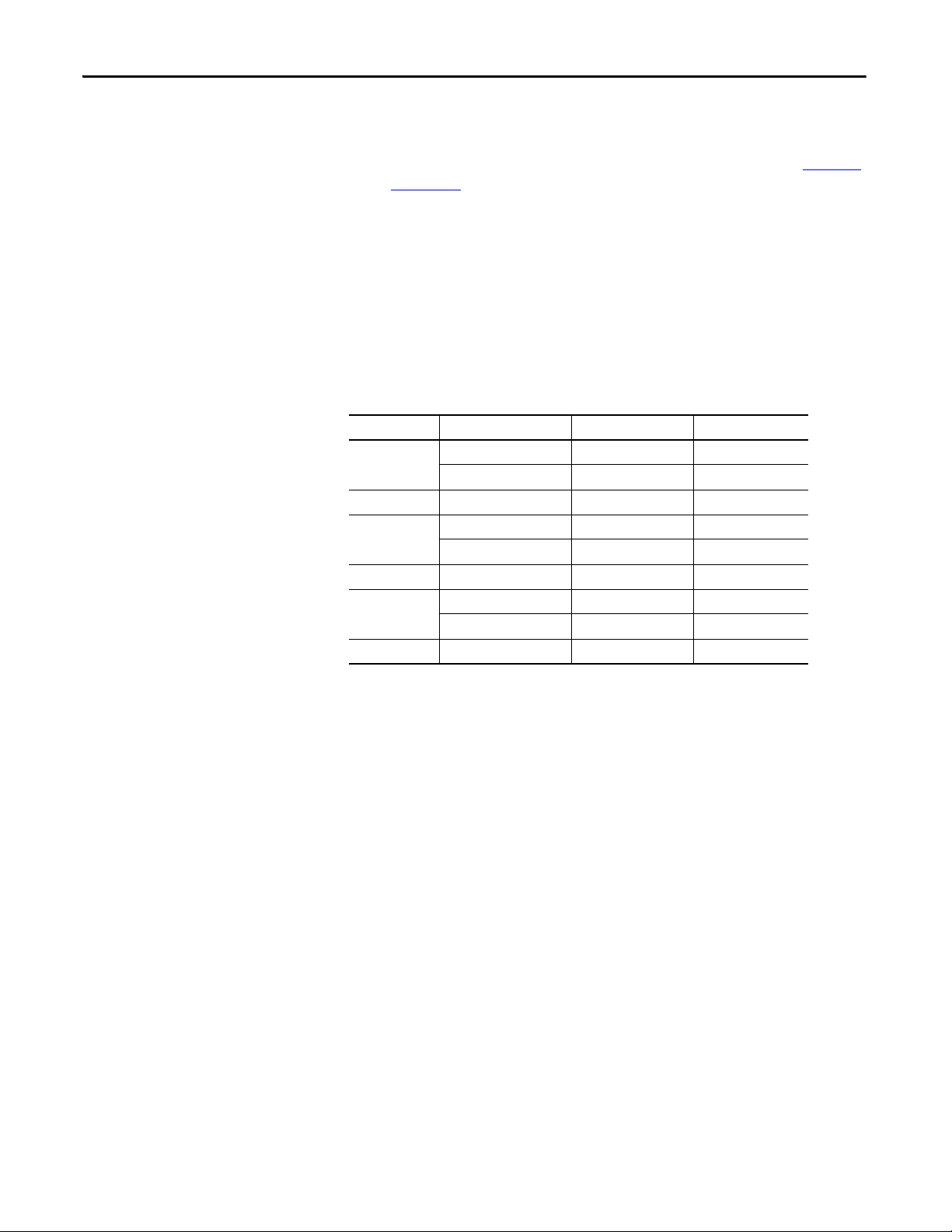

Product Selections

Cat. No. Display Ethernet Power Memory

Touch Key and Touch Size Type DLR AC or DC RAM User

2715-T7CD 2715-B7CD

2715-T7CA 2715-B7CA AC

2715-T9WD –

2715-T9WA – AC

2715-T10CD 2715-B10CD

2715-T10CA 2715-B10CA AC

2715-T12WD –

2715-T12WA – AC

2715-T15CD 2715-B15CD

2715-T15CA 2715-B15CA AC

2715-T19CD –

2715-T19CA – AC

(1) Memory that is available for you to store applicatio ns.

14 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

6.5-in.

9-in. wide

10.4-in.

12.1-in. wide

15-in.

19-in.

VGA

TFT Color

WVGA

TFT Color

SVGA

TFT Color

WXGA

TFT Color

XGA

TFT Color

SXGA

TFT Color

Yes

DC

DC

DC

DC

DC

DC

(1)

512 MB 250 MB

Page 15

Overview Chapter 1

Accessories

Ta b l e 4 …Ta b l e 8 list accessories for the PanelView 5500 terminals.

Table 4 - Protective Overlays

(1)

Cat. No.

2711P-RGT7SP

2711P-RGB7P •

2711P-RGT9SP 9-in. wide •

2711P-RGT10SP

2711P-RGB10P •

2711P-RGT12SP 12.1-in. wide •

2711P-RGT15SP

2711P-RGB15P •

2711P-RGT19P 19-in. •

(1) Three overlays are shipped with each catalog number.

Display Size

6.5-in.

10.4-in.

15-in.

Table 5 - Power Supplies and Power Terminal Blocks

Cat. No. Description Quantity

1606-XLP95E DIN-rail power supply, 24…28V DC output voltage, 95 W 1

1606-XLP100E DIN-rail power supply, 24…28V DC output voltage, 100 W 1

2711P-RSACDIN DIN-rail power supply, AC-to-DC, 100…250V AC, 50…60 Hz 1

2711P-RTBAP 3-pin AC power terminal block (gray with black labels for L1, L2N, and 10

2711P-RTBDSP 3-pin DC power terminal block (black with white labels for +, –, and GND) 10

Operator Input

Tou ch K ey and Tou ch

•

•

•

Ethernet Cables

Table 6 - Mounting Hardware

Cat. No. Description Quantity

2711P-RMCP

(1) Catalog number 2711P-RMCP mounting levers are used with the PanelView 5500 terminals. Do not use gray mounting levers; they

(1)

are not compatible with PanelView 5500 terminals.

Mounting levers (black) 16

Table 7 - Secure Digital (SD) Cards

Cat. No. Description

1784-SD1 1 GB SD card

1784-SD2 2 GB SD card

Table 8 - Battery Replacement

Cat. No. Description Quantity

2711P-RY2032 Lithium coin cell battery, CR2032 equivalent 1

See the Industrial Ethernet Media Brochure, publication 1585-BR001B, for

recommended Ethernet cables and media solutions.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 15

Page 16

Chapter 1 Overview

Notes:

16 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 17

Install the PanelView 5500 Terminal

Top ic Pa ge

North American Hazardous Locations 19

Mounting Considerations 21

Mounting Clearances 21

Panel Guidelines 22

Panel Cutout Dimensions 22

Product Dimensions 23

Prepare for Panel Mounting 24

Mount the Terminal in a Panel 28

Remove and Replace the Power Terminal Block 31

Connect to DC Power 32

Connect to AC Power 33

Connect to a Network 34

Initial Startup 37

Chapter 2

ATT EN TI ON : Do not use a PanelView 5500 terminal for emergency stops or

other controls critical to the safety of personnel or equipment. Use separate

hard-wired operator interface devices that do not depend on solid-state

electronics.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 17

Page 18

Chapter 2 Install the PanelView 5500 Terminal

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as

defined in IEC 60664-1), at altitudes up to 2000 m (6561 ft) without derating.

The terminals are intended for use with programmable logic controllers. Terminals that are AC powered must be connected to

the secondary of an isolating transformer.

This equipment is considered Group 1, Class A industrial equipment according to IEC CISPR 11. Without appropriate

precautions, there may be difficulties with electromagnetic compatibility in residential and other environments due to

conducted or radiated disturbances.

Korean Radio Wave Suitability Registration - When so marked this equipment is registered for Electromagnetic

Conformity Registration as business equipment (A), not home equipment. Sellers or users are required to take

caution in this regard.

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판 매자 또는 사용자는 이 점을 주의하

시기 바 라 며 , 가정외의 지역에서 사용하는 것을 목적으 로 합니다 .

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for

those specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting

from accessibility to live parts. The interior of the enclosure must be accessible only by the use of a tool. The terminals meet

specified NEMA, UL Type, and IEC ratings only when mounted in a panel or enclosure with the equivalent rating. Subsequent

sections of this publication may contain additional information regarding specific enclosure type ratings that are required to

comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by different types of

enclosure.

, for additional installation requirements.

ATTENTION: Wiring and Safety Guidelines

Use publication NFPA 70E, Electrical Safety Requirements for Employee Workplaces, IEC 60364 Electrical Installations in

Buildings, or other applicable wiring safety requirements for the country of installation when wiring the devices. In addition to

the NFPA guidelines, here are some other guidelines to follow:

• Connect the device and other similar electronic equipment to its own branch circuit.

• Protect the input power by a fuse or circuit breaker rated at no more than 15 A.

• Route incoming power to the device by a separate path from the communication lines.

• Cross power and communication lines at right angles if they must cross.

• Communication lines can be installed in the same conduit as low-level DC I/O lines (less than 10V).

• Shield and ground cables appropriately to avoid electromagnetic interference (EMI). Grounding minimizes noise from EMI

and is a safety measure in electrical installations.

For more information on grounding recommendations, refer to the National Electrical Code published by the National Fire

Protection Association.

18 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 19

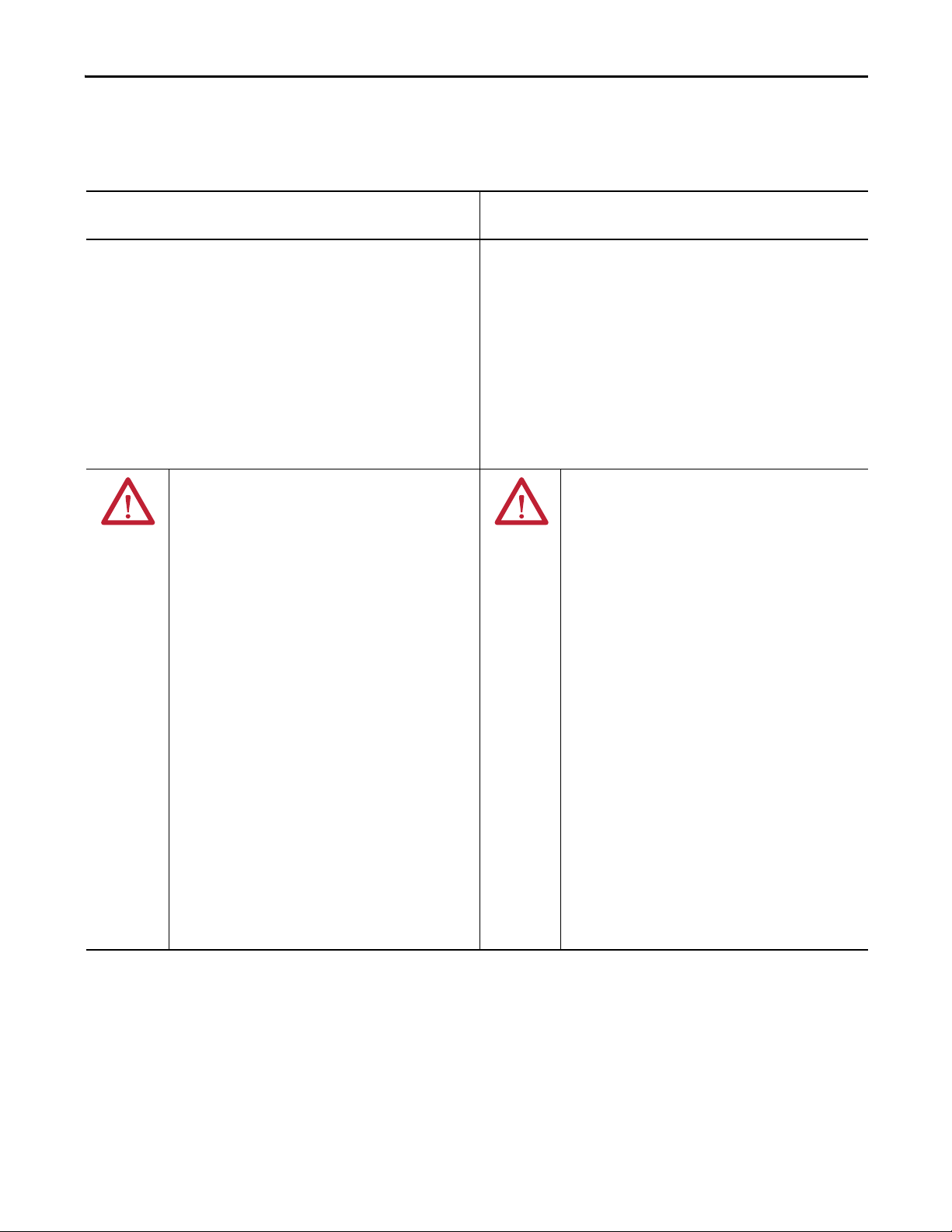

North American Hazardous Locations

Install the PanelView 5500 Terminal Chapter 2

The following information applies when operating this

equipment in hazardous locations.

ATTENTION: When marked, these products are suitable for use in

"Class I, Division 2, Groups A, B, C, D"; Class I, Zone 2, Group IIC

hazardous locations and nonhazardous locations only. Each

product is supplied with markings on the rating nameplate

indicating the hazardous location temperature code. When

combining products within a system, the most adverse

temperature code (lowest "T" number) may be used to help

determine the overall temperature code of the system.

Combinations of equipment in your system are subject to

investigation by the local Authority Having Jurisdiction at the time

of installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this equipment

unless power has been removed or the area is

known to be nonhazardous. Secure any external

connections that mate to this equipment by using

screws, sliding latches, threaded connectors, or

other means provided with this product.

• Substitution of components may impair suitability

for Class I, Division 2.

• Peripheral equipment must be suitable for the

location in which it is used.

• The battery in this product must be changed only

in an area known to be nonhazardous.

• All wiring must be in accordance with Class I,

Division 2 wiring methods of Article 501 of the

National Electrical Code and/or in accordance with

Section 18-1J2 of the Canadian Electrical Code,

and in accordance with the authority having

jurisdiction.

Informations sur l’utilisation de cet équipement en

environnements dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à

une utilisation en environnements de Classe I Division 2 Groupes A, B,

C, D dangereux et non dangereux. Chaque produit est livré avec des

marquages sur sa plaque d'identification qui indiquent le code de

température pour les environnements dangereux. Lorsque plusieurs

produits sont combinés dans un système, le code de température le

plus défavorable (code de température le plus faible) peut être utilisé

pour déterminer le code de température global du système. Les

combinaisons d'équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de

l'installation.

AVERTISSEMENT : RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher l'équipement.

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher les connecteurs. Fixer tous les

connecteurs externes reliés à cet équipement à

l'aide de vis, loquets coulissants, connecteurs

filetés ou autres moyens fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• Les équipements périphériques doivent s'adapter

à l'environnementdans lequel ils sont utilisés.

• S'assurer que l'environnement est classé non

dangereux avant de changer la pile ou le module

horloge temps réel de ce produit.

• Tous les systèmes de câblage doivent être de

Classe I, Division 2, conformément aux méthodes

de câblage indiquées dans les Articles 501 du

National Electrical Code (Code Electrique

National) et/ou conformément à la Section 181J2 du Canadian Electrical Code (Code Electrique

Canadien), et en fonction de l'autorité de

jurisdiction.

The terminals have a temperature code of T4 when operating in a 55 °C (131 °F) maximum ambient temperature. Do not

install product in environments where atmospheric gases have ignition temperatures less than 135 °C (275 °F).

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 19

Page 20

Chapter 2 Install the PanelView 5500 Terminal

Nonincendive Field

Wiring Apparatus

Associated Nonincendive Field Wiring Apparatus

PanelView 5500 Host Product

USB Peripheral Device

USB Peripheral Device

USB Host Port

USB Host Port

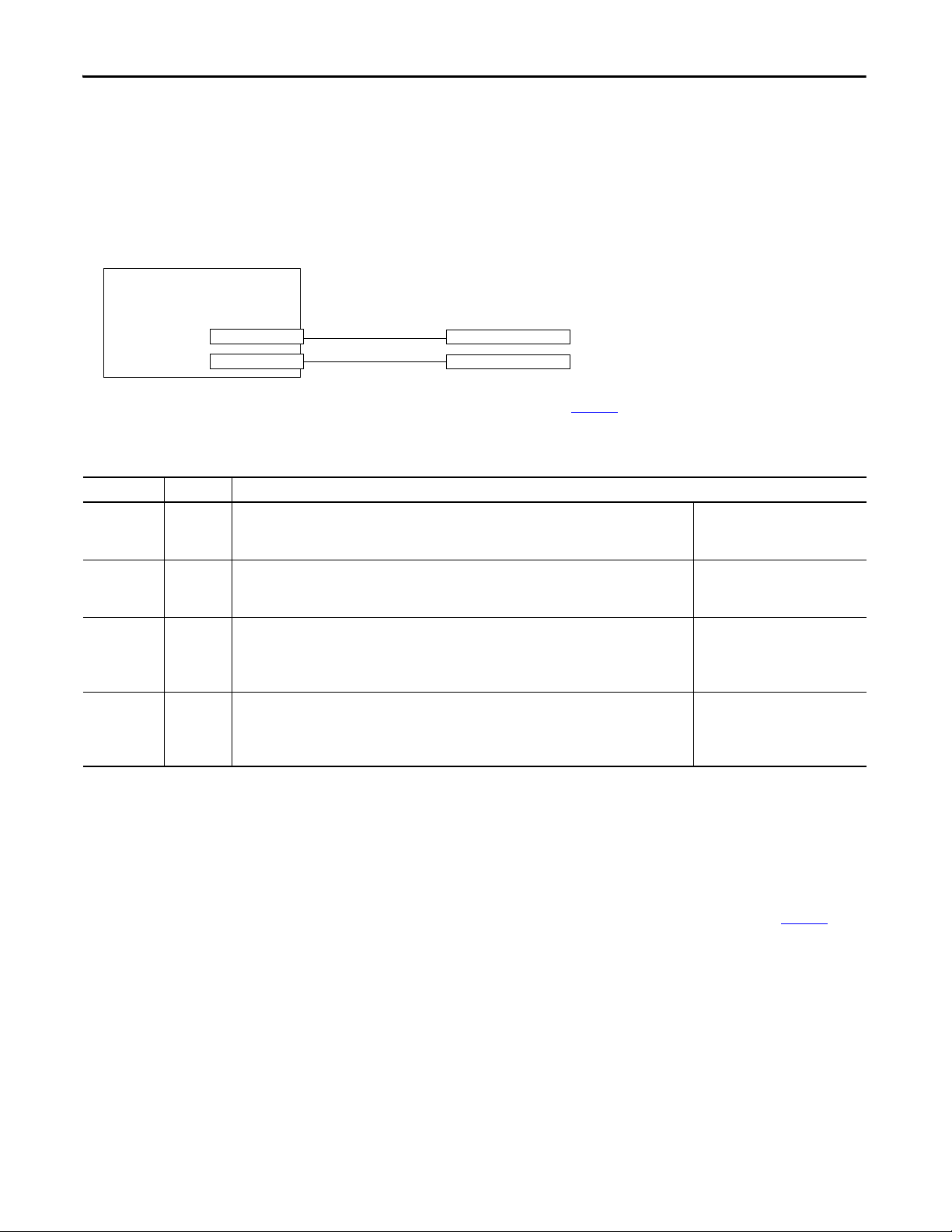

Required Circuit Port Parameters for USB Peripheral Devices

This product contains USB host ports that comply with hazardous location environments. Field-wiring compliance

requirements are provided in compliance with the National Electrical Code, Article 500.

Figure 2 - PanelView 5500 Control Drawing

PanelView 5500 terminals provide two, separately powered USB host ports. Ta b l e 9 defines the circuit parameters of these

USB host ports.

Table 9 - Circuit Parameters for USB Host Ports

Parameter Value Parameter Definition

V

oc (USB)

I

sc (USB)

C

a (USB)

L

a (USB)

5.25V DC

1.68 A

10 μF

15 μH

Open circuit voltage of each host USB port.

The maximum applied voltage rating, V

or equal to V

Maximum output current of each host USB port.

The maximum current, I

greater than or equal to I

This value is the maximum total capacitance that can be connected to each USB host port. The total

capacitance of each USB peripheral device and its associated cable must not exceed the indicated value.

The maximum total capacitance, C

device shall be less that or equal to C

This value is the maximum total inductance that can be connected to each USB host port. The total

inductance of each USB peripheral device and its associated cable must not exceed the indicated value.

The maximum total inductance, L

shall be less than or equal to L

oc (USB)

.

max (peripheral)

sc (USB).

max (peripheral)

, to which each USB peripheral device can be subjected shall be

i (peripheral)

a (USB)

i (peripheral)

.

a (USB)

, of each USB peripheral device shall be greater than

, and cable capacitance of each separate USB peripheral

.

, and cable inductance of each separate USB peripheral device

V

max (peripheral)

(as appropriate)

I

max (peripheral)

C

L

i (peripheral)

i (peripheral)

+ C

+ L

≥ V

oc (USB)

≥I

sc (USB)

cable(USB)

≤ L

cable

≤ C

a (USB)

a (USB)

Application Information

Per the National Electrical Code, the circuit parameters of associated field-wiring apparatus for use in hazardous locations

shall be coordinated with the host product such that their combination remains nonincendive. PanelView 5500 terminals

and the USB peripheral devices shall be treated in this manner.

The USB peripheral devices and their associated cabling shall have circuit parameters with the limits given in Tab l e 9

them to remain nonincendive when used with the PanelView 5500 USB host ports.

If cable capacitance and inductance are not known, use the following values from ANSI/ISA-RP 12.06.01-2003:

C

= 197 pF/m (60 pF/ft)

cable

L

= 0.7 μH/m (0.20 μH/ft)

cable

Nonincendive field wiring must be wired and separated in accordance with 501.10(B)(3) of the National Electrical Code

(NEC) ANSI/NFPA 70 or other local codes as applicable. This associated nonincendive field wiring apparatus has not

been evaluated for use in combination with another associated nonincendive field wiring apparatus.

20 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

for

Page 21

Install the PanelView 5500 Terminal Chapter 2

Acceptable Unacceptable

≤ 90°

From Vertic al

≤ 90°

From Vertical

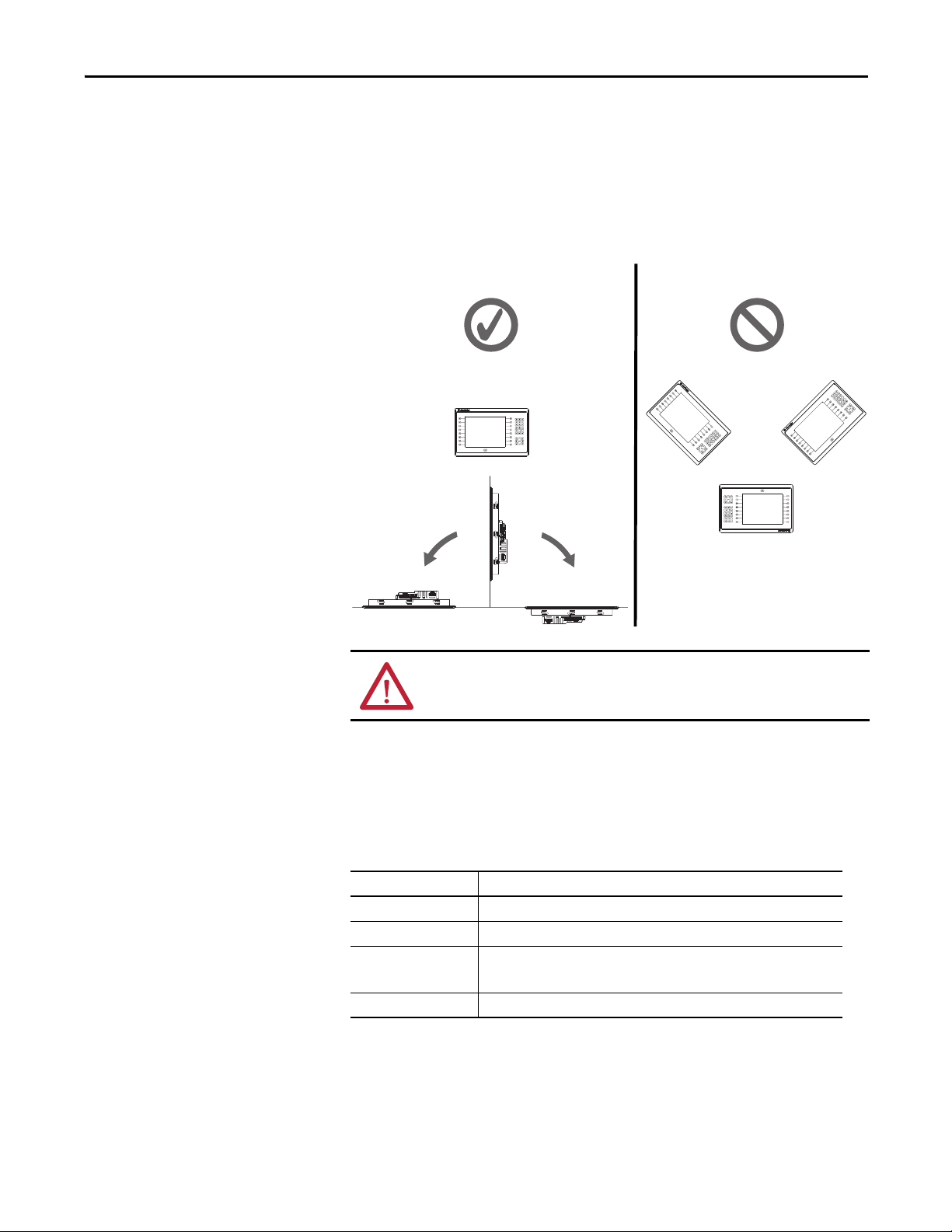

Mounting Considerations

Consider the following when mounting the terminal:

• Mount the terminal at a height suitable for operators. You can mount the

cabinet at a level other than the operator floor.

• Use appropriate light. Do not operate the terminal in direct sunlight.

• Terminals are rated to operate at mounting angles between 0…180 degrees.

Figure 3 - Acceptable and Unacceptable Mounting Positions

6

1

1

6

6

1

Mounting Clearances

Plan for adequate space around the terminal, inside the enclosure, for ventilation

and cables. Consider the heat from other devices in the enclosure. The ambient

temperature around the terminal must be 0…55 °C (32…131 °F).

Table 10 - Minimum Required Clearances

Product Area Minimum Clearance

Top 51 mm (2 in.)

Bottom 102 mm (4 in.)

Side

Back 0 mm (0 in.)

6

6

6

1

1

1

1

1

1

6

6

6

ATT EN TI ON : Failure to follow these guidelines can result in personal injury or

damage to the panel components.

25 mm (1 in.)

102 mm (4 in.) is required to insert and remove an SD card or cable on one side

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 21

Page 22

Chapter 2 Install the PanelView 5500 Terminal

Panel Guidelines

Panel Cutout Dimensions

The terminals are panel-mounted devices that mount in the door or wall of a

NEMA, UL Type, or IP rated enclosure:

• Enclosure panels must meet the panel thickness requirements in Table 13

on page 24.

• The material strength and stiffness of the panel must be sufficient to hold

the terminal and maintain an appropriate seal against water and dust.

• The panel surface must be flat and free of imperfections to maintain an

adequate seal and NEMA, UL Type, or IP ratings.

Use the template that is shipped with your terminal to mark the cutout

dimensions.

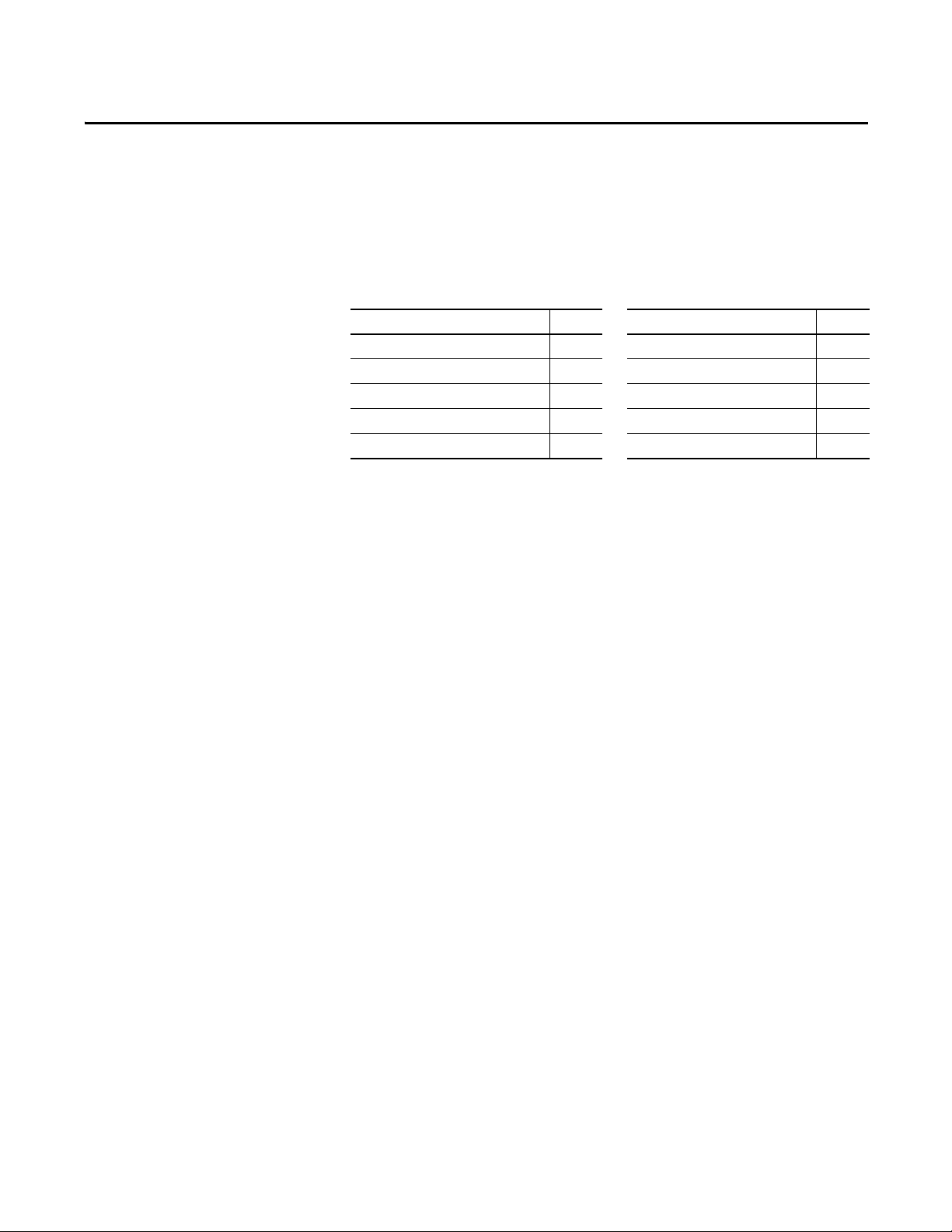

Table 11 - PanelView 5500 - Panel Cutout Dimensions

Terminal Size Input Type Height, mm (in.) Width, mm (in.)

6.5-in.

9-in. Touch 162 (6.38) 252 (9.92)

10.4-in.

12.1-in. Touch 218 (8.58) 312 (12.28)

15-in.

19-in. Touch 383 (15.08) 457 (17.99)

Keypad and touch 142 (5.59) 237 (9.33)

Touch 142 (5.59) 184 (7.24)

Keypad and touch 224 (8.82) 335 (13.19)

Touch 224 (8.82) 269 (10.59)

Keypad and touch 290 (11.42) 418 (16.46)

Touch 290 (11.42) 353 (13.90)

22 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 23

Install the PanelView 5500 Terminal Chapter 2

1

6

6

1

1

6

6

6

1

1

c

c

a

b

a

b

d

d

TIP

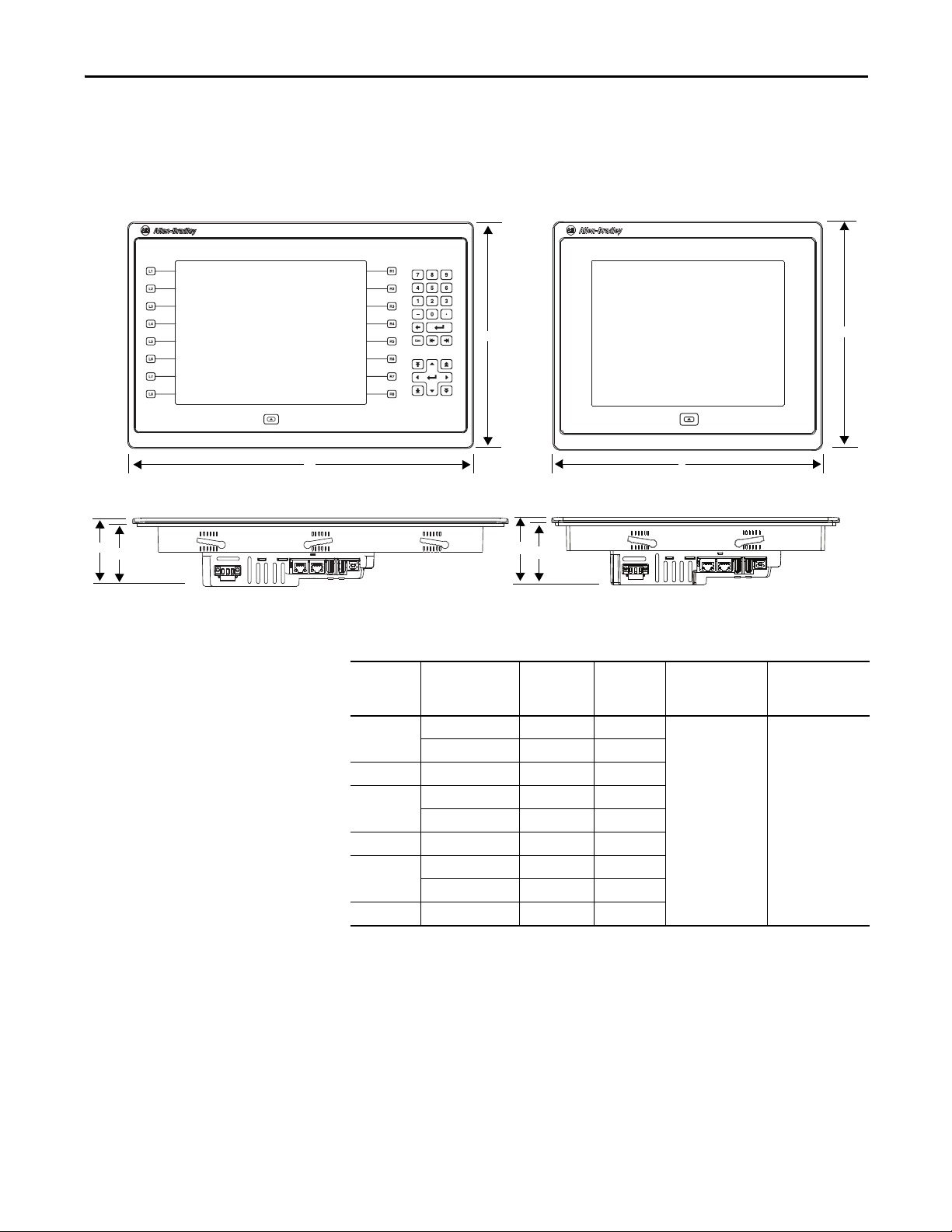

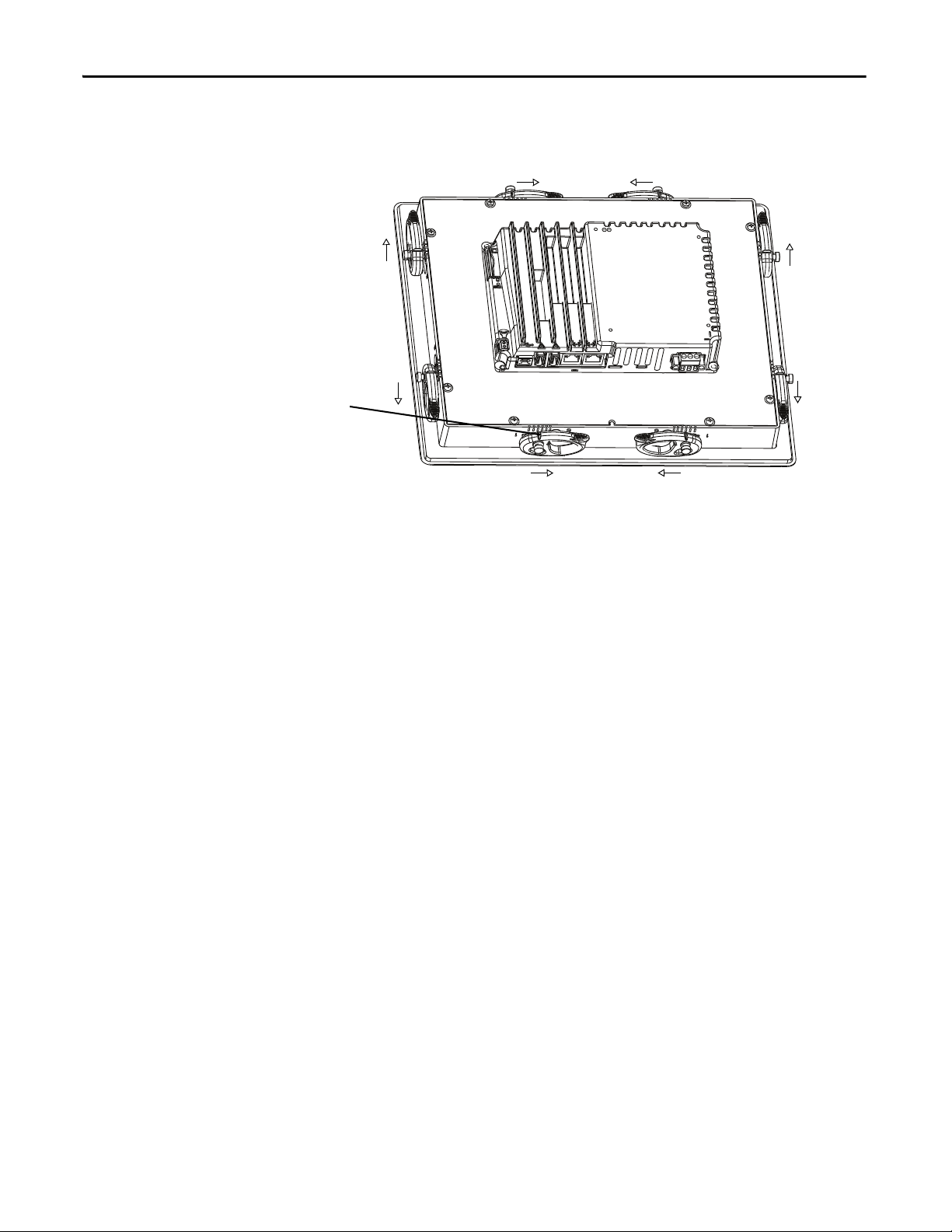

Product Dimensions

The table provides product dimensions. The 10.4-inch touch and combination

keypad with touch terminals are shown for illustrative purposes. All other

terminal sizes look similar.

Figure 4 - PanelView 5500 Terminal Dimensions (the 10.4-in. terminal is shown)

Table 12 - PanelView 5500 Terminal Dimensions

Ter min al

Size

6.5-in.

9-in. Touch 190 (7.48) 280 (11.02)

10.4-in.

12.1-in. Touch 246 (9.69) 340 (13.39)

15-in.

19-in. Touch 411 (16.18) 485 (19.09)

Input

Type

Height (a)

mm (in.)

Width (b)

mm (in.)

Keypad and touch 179 (7.05) 285 (11.22)

Touch 170 (6.69) 212 (8.35)

Keypad and touch 252 (9.92) 385 (15.16)

Touch 252 (9.92) 297 (11.69)

Keypad and touch 329 (12.95) 484 (19.06)

Touch 318 (12.52) 381 (15.00)

When mounted in a panel, the front of the bezel extends less than

6.36 mm (0.25 in.) from the front of the panel.

Overall Depth (c)

Mounted Depth

mm (in.)

69.6 (2.74) 63.6 (2.50)

(d)

mm (in.)

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 23

Page 24

Chapter 2 Install the PanelView 5500 Terminal

IMPORTANT

6

1

1

2

3

4

5

6

Notch

Alignment Mark

Orientation of Slot Varies

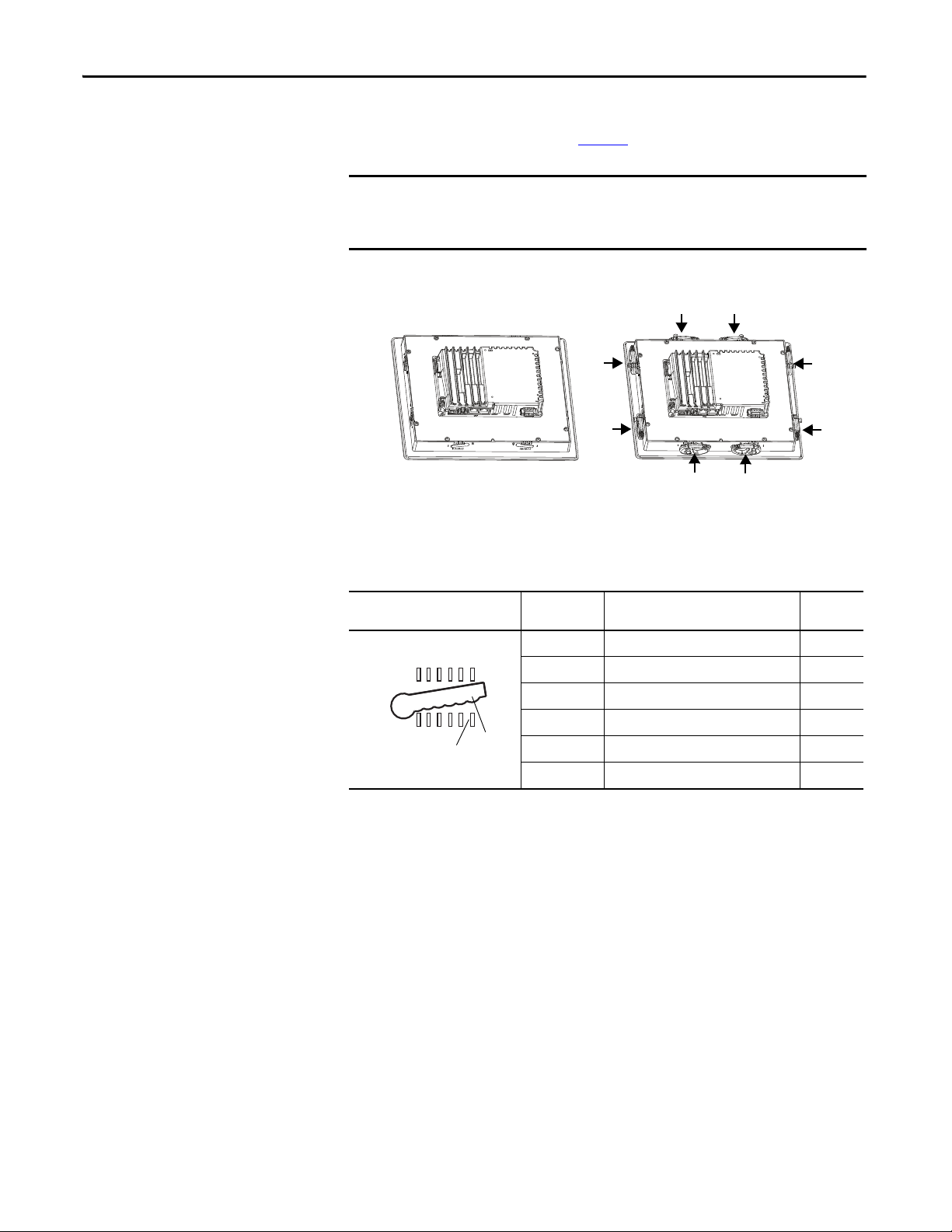

Prepare for Panel Mounting

Before mounting your PanelView 5500 terminal in a panel, read this section and

the entire installation procedure on page 28

.

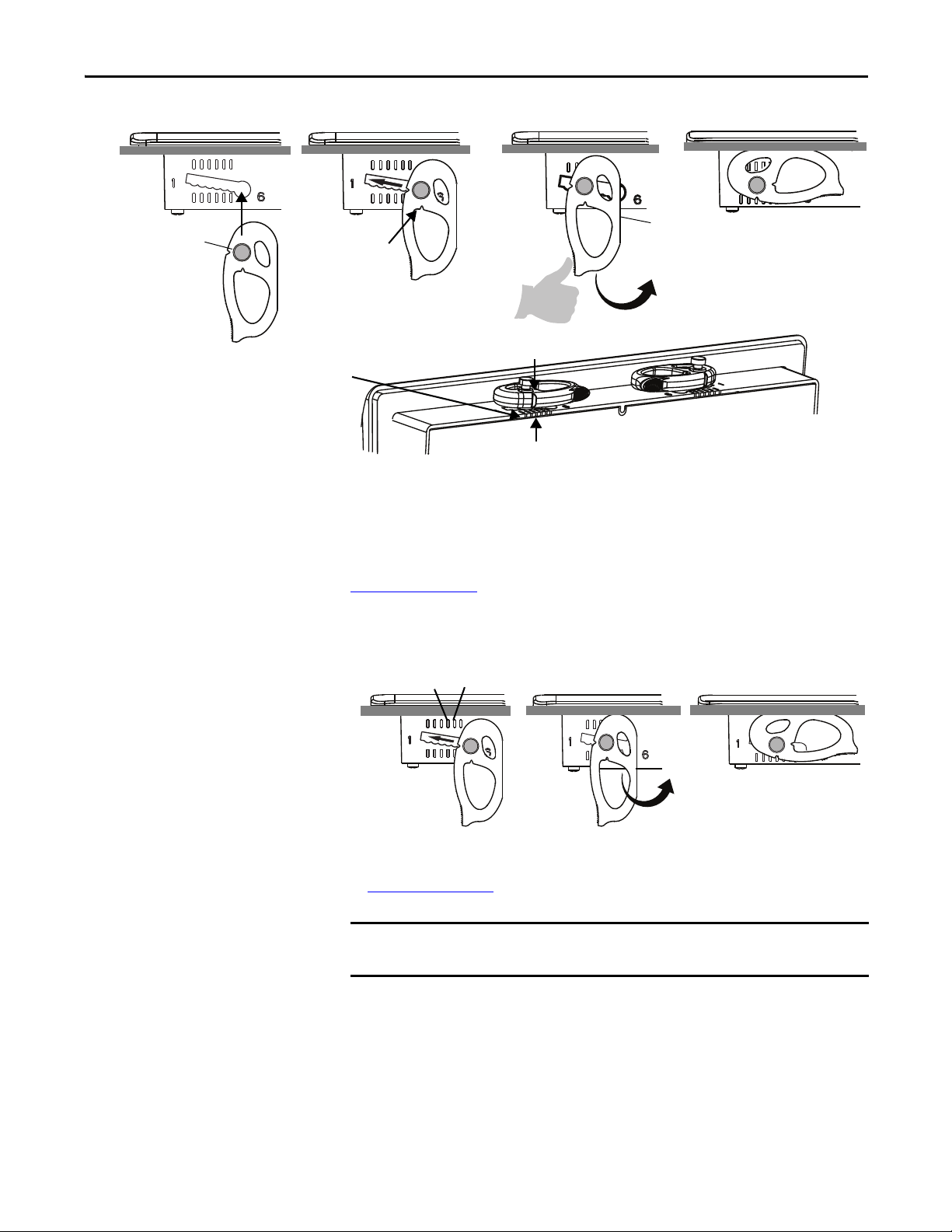

Catalog number 2711P-RMCP mounting levers (black) are used with PanelView

5500 terminals. Do not use gray mounting levers; they are not compatible with

PanelView 5500 terminals.

Mounting levers insert into the slots around the bezel to secure the terminal in

the panel. The number of levers varies by terminal size.

Each slot has six notches with alignment marks that are locking positions for a

lever. The thickness of the panel in which you mount the terminal determines the

locking position that is required to maintain a NEMA, UL Type, or IP seal.

Table 13 - Lever Locking Positions

Mounting Slot

Lever Lock

Position

1

2

3

4

5

6

Panel T hickness R ange

1.50…2.01 mm (0.060…0.079 in.) 16

2.03…2.64 mm (0.080…0.104 in.) 14

2.67…3.15 mm (0.105…0.124 in.) 12

3.17…3.66 mm (0.125…0.144 in.) 10

3.68…4.16 mm (0.145…0.164 in.) 8/9

4.19…4.80 mm (0.165…0.188 in.) 7

Typic al

Gauge

Always orient a lever vertically before inserting it into a slot. This is the only way

to slide the lever knob within the slot for positioning. After sliding the lever to a

specific notch, rotate the lever toward the panel to lock it in position. The flat

side of the lever must come into contact with the panel.

24 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 25

Install the PanelView 5500 Terminal Chapter 2

1

Flat Side

Knob on reverse

side of lever

inserts into

large end of slot

1234

The edge of the bezel has alignment indentations

to assist with the lever position.

The notch on the outside of the lever shows that

the lever is locked in position 3.

You can use an erasable marker or grease pencil to mark the

indentations for visibility of slot positions.

Inner notch on lever

shows current lever

position.

TIP

IMPORTANT

5

4

Initially, you secure the terminal in the panel by sliding each lever to a position

that is one or two notches greater than the final lock position. For example, if the

final lock position is 3, slide each lever to position 4 or 5.

Follow the locking sequence and lever orientations for each terminal as shown in

Figure 5 on page 27

.

If the lock position is 6, slide lever to large end of slot or insertion hole.

You then adjust each lever to its final lock position in the same sequence as shown

in Figure 5 on page 27

.

This process equalizes the pressure of the levers against the panel at a gradual

rate reducing the probability of broken clamps.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 25

Page 26

Chapter 2 Install the PanelView 5500 Terminal

Notch shows locked position.

31

2

4

8

6

7

5

This 10.4-in. touch terminal has all levers locked in position 3,

which is appropriate for a panel thickness of

2.67…3.15 mm (0.105…0.124 in.).

This figure shows the lever orientation and lock sequence for a 10.4-in. touch

terminal.

26 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 27

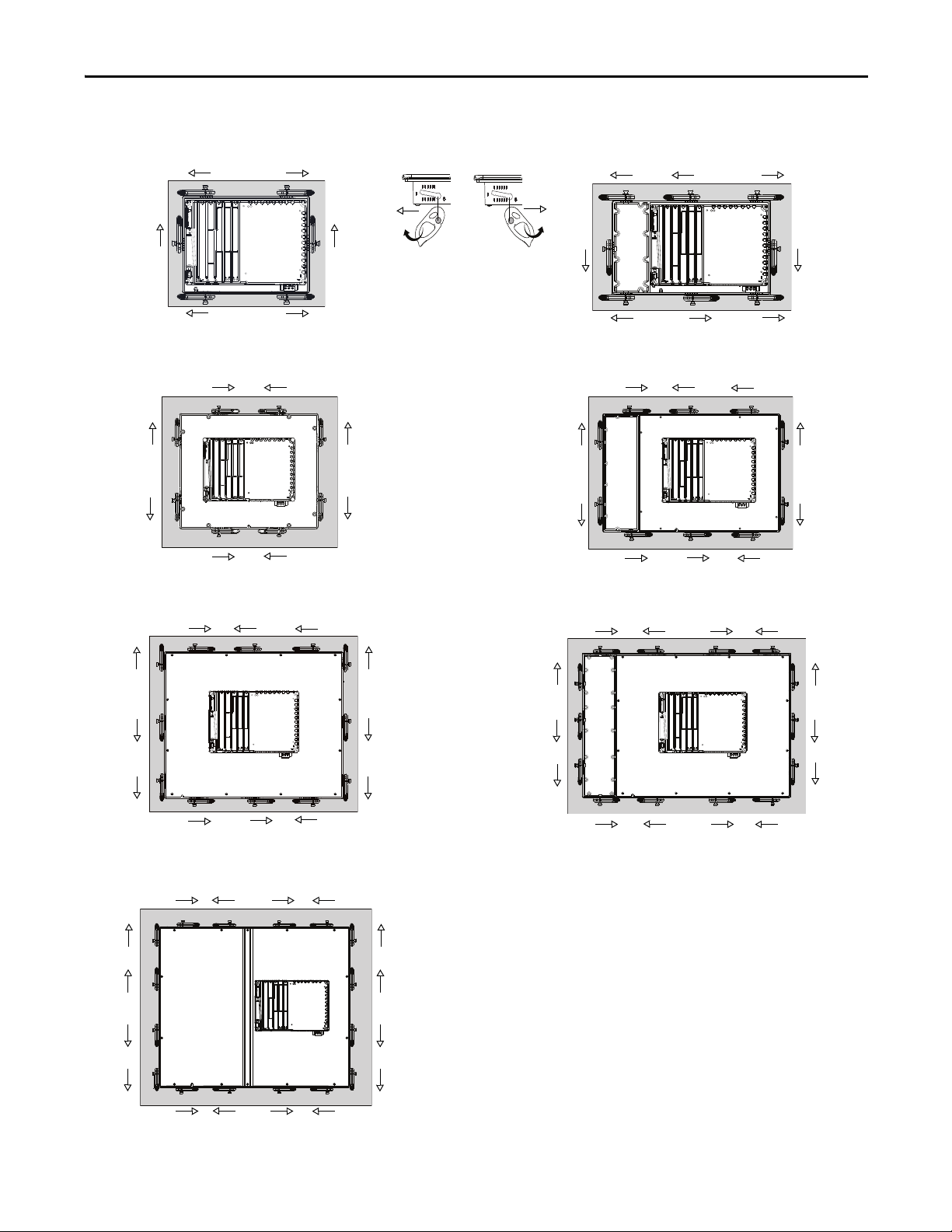

Figure 5 - Mounting Lever Orientation and Lock Sequence

ERR

STS

1

212

5

24

6

6.5-in. Touch Only - 6 Levers

6.5-in. Keypad and Touch - 8 Levers

2

7

4

8

8

29

3

10 1

7

5

4

5

9-in. and 10.4-in. Touch Only - 8 Levers

10.4-in. Keypad and Touch, 12.1-Touch Only - 10 Levers

3

1

6

24

5

6

8

7

3

1

6

3

1

IMPORTANT: The mounting lever orientations that are shown are required to

maintain NEMA, UL Type, and IP seals. If you require a NEMA, UL Type, or IP seal,

do not use a mounting lever in other orientations.

29 4

6

12

8

11

5

82 46

11

13

9

10

14

12

15-in. Keypad and Touch - 14 Levers

53 17

1

10

3

7

15-in. Touch Only- 12 Levers

19-in. Touch Only- 16 Levers

53 1 7

82 4 6

11

13

9

15

10

16

12

14

Install the PanelView 5500 Terminal Chapter 2

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 27

Page 28

Chapter 2 Install the PanelView 5500 Terminal

TIP

Gasket

Flat side

TIP

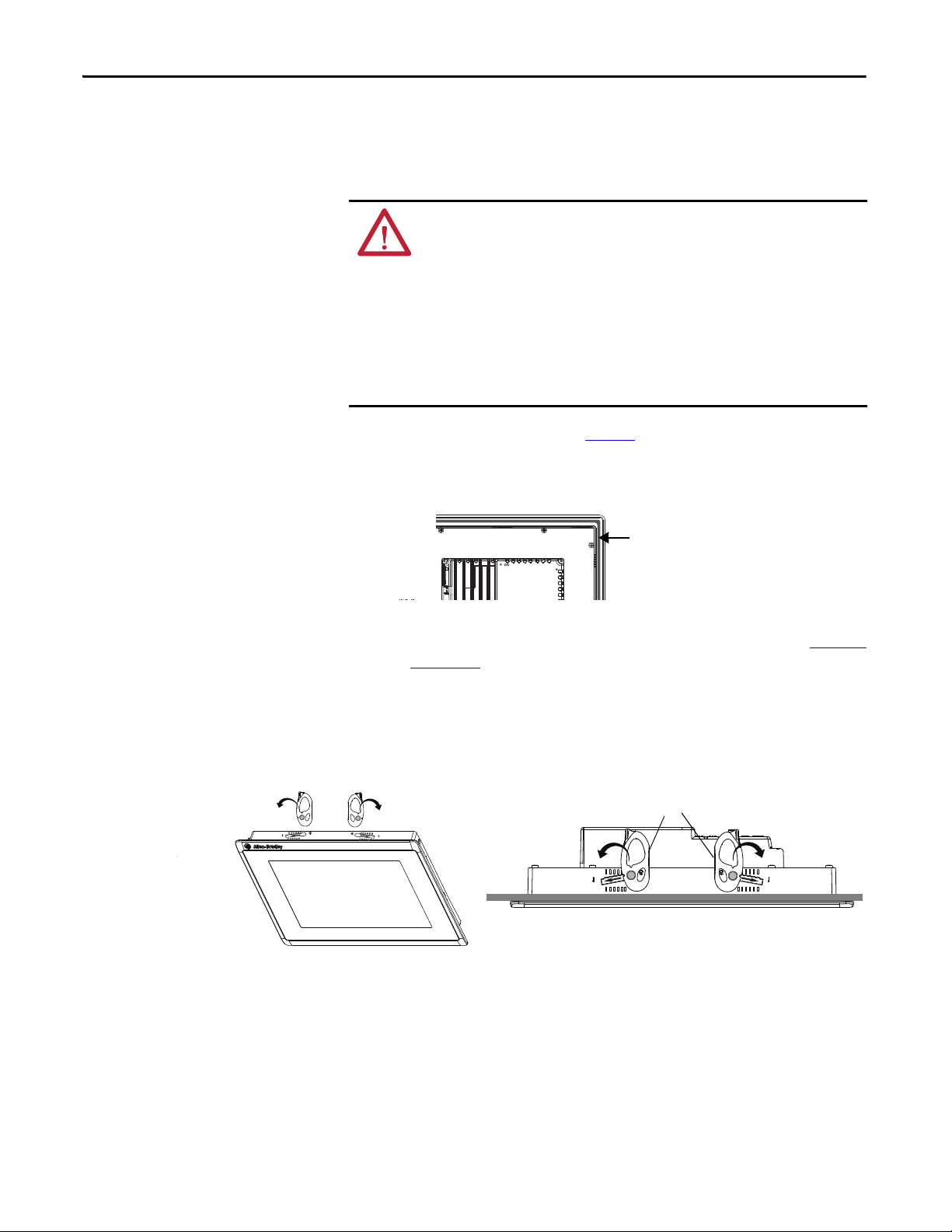

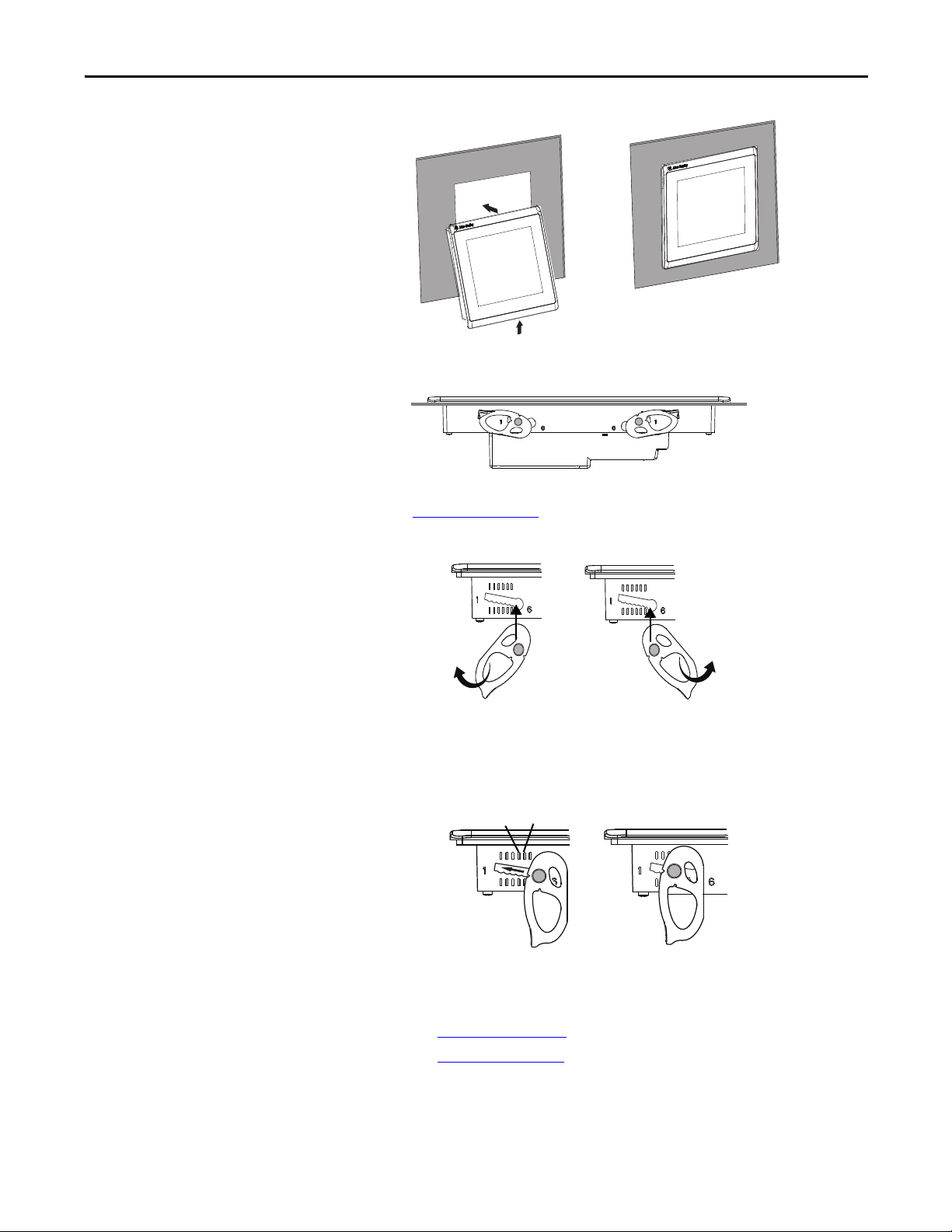

Mount the Terminal in a Panel

The PanelView 5500 terminals were designed for single-person installation. No

tools are required except for the tools needed to make the panel cutout.

Follows these steps to mount the terminal in a panel.

ATT EN TI ON :

Disconnect all electrical power from the panel before making the panel cutout.

Make sure that the area around the panel cutout is clear and that the panel is clean

of any debris, oil, or other chemicals.

Make sure that metal cuttings do not enter any components that are already

installed in the panel and that the edges of the cutout have no burrs or sharp

edges.

Failure to follow these warnings can result in personal injury or damage to panel

components.

1. Use the cutout dimensions on page 22

2. Verify that the sealing gasket is present on the terminal.

This gasket forms a compression type seal. Do not use sealing compounds.

to cut an opening in the panel.

3. Insert and stabilize the terminal in the panel cutout.

a. Insert levers in the top corner slots in the orientation shown in Figure 5

on page 27 and rotate the non-flat side of the levers toward panel.

The mounting levers for PanelView 5500 terminals are black (catalog

number 2711P-RMCP).

Do not use gray mounting levers; they are not compatible with

PanelView 5500 terminals.

b. Tilt the terminal toward the panel cutout and guide upward into the

cutout. Make sure that the levers stay intact.

The levers prevent the terminal from falling out of the panel.

28 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 29

Install the PanelView 5500 Terminal Chapter 2

TIP

5

4

c. Pull the top of the terminal toward you to verify that the levers are still

intact and the terminal is stabilized in the panel.

d. Insert the remaining levers in the slots by using the orientations in

Figure 5 on page 27

that are correct for your terminal.

The direction that you rotate the levers varies for each terminal size.

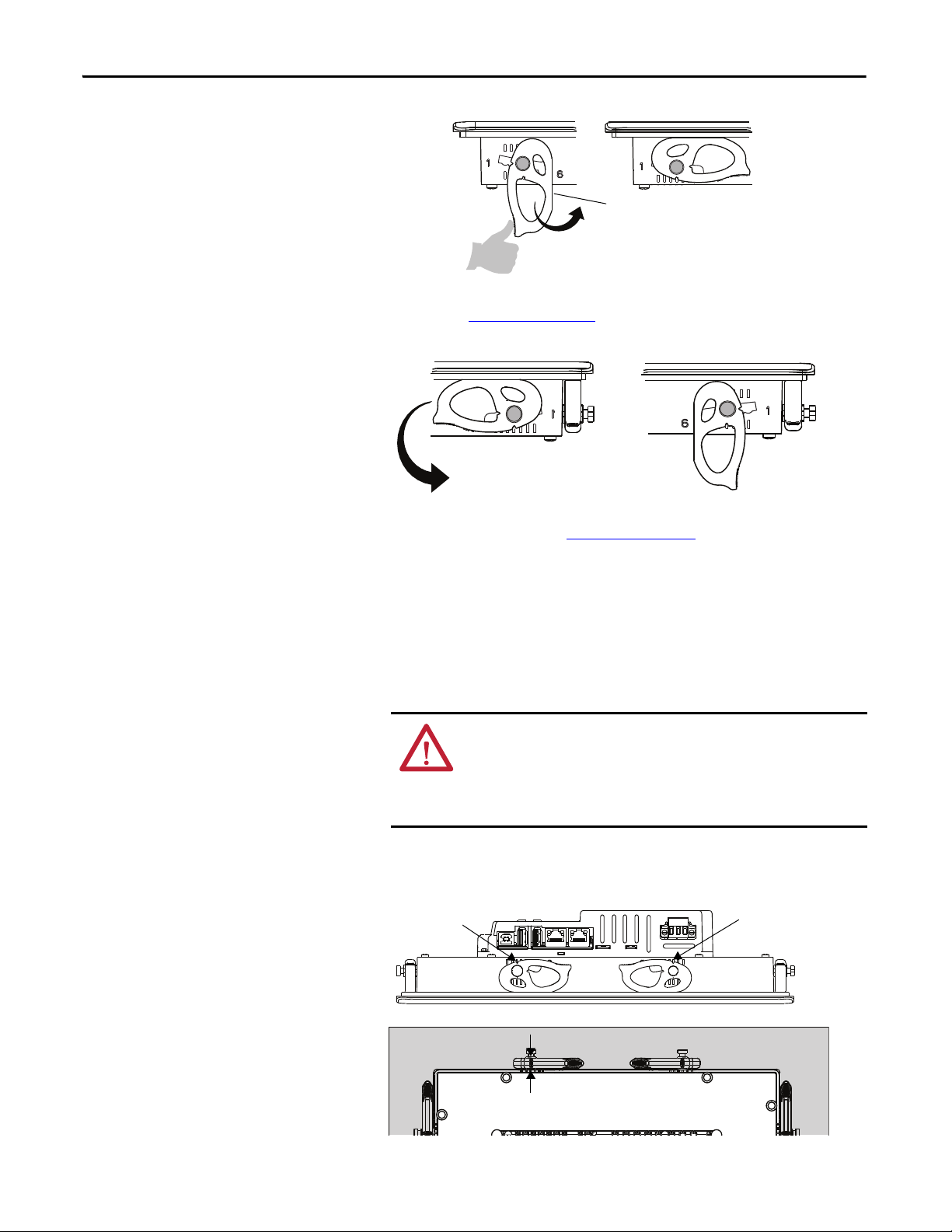

4. Slide and rotate each lever to a notch that is one or two positions greater

than the final lock position. Start with the first lever in the sequence.

For example, if the final lock position is 3, slide the lever to notch 4 or 5.

To help position the levers and identify the final slot position, use the

alignment marks or previous marks you made on the bezel.

a. See Table 13 on page 24

b. See Figure 5 on page 27

to get the final lock position of the levers.

to get the locking sequence.

c. Rotate each lever until its flat side comes in contact with the panel.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 29

Page 30

Chapter 2 Install the PanelView 5500 Terminal

TIP

Flat side

1

1

Outer Notch

Outer Notch

5. Adjust each lever to its final lock position shown in the same locking

sequence in Figure 5 on page 27

.

a. Unlock lever one in the sequence by rotating it away from the bezel.

b. With the lever positioned vertically to the slot, slide the lever to the

final locking position in Table 13 on page 24

.

The outer notch of the lever aligns with the bezel indentation.

c. Carefully rotate the lever back toward panel.

A broken lever does not damage the product.

d. Lock the remaining levers to their final position.

6. Inspect all levers and make sure each is in the correct locked position.

ATTENTION: All levers must be in the correct and same locked position

to provide an adequate gasket seal between the terminal and the panel.

Rockwell Automation assumes no responsibility for water or chemical

damage to the terminal or other equipment within the enclosure

because of improper installation.

The notch on the outside of lever shows its locked position.

These two views show levers that are locked in position 3.

30 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 31

Install the PanelView 5500 Terminal Chapter 2

1

1

AC Terminal Bl ock

DC Terminal Block

Remove and Replace the Power Terminal Block

The product has a 3-pin terminal block for power connections. You can remove

the terminal block for ease of installation, wiring, and maintenance.

WARNING: Explosion Hazard

If you connect or disconnect wiring while the power is on, an electrical arc can

occur. This can cause an explosion in hazardous location installations. Be sure

that power is removed and the area is nonhazardous before proceeding.

Failure to remove power can result in electrical shock or damage to the terminal.

The terminal block has different markings for AC and DC power connections.

Use a 0.6 x 3.5 mm flat blade screwdriver for terminal block wiring.

Table 14 - Wire Specifications for the Power Input Terminal Block

Wire Type Dual-wire Size

Stranded or solid

Cu 90 °C (194 °F)

(1) Two-wire maximum per terminal.

0.3…1.3 mm

22…16 AWG

(1)

Single-wire Size Strip Length Screw Torque

2

0.3…2.1 mm

(22…14 AWG)

2

7 mm (0.28 in.)

0.4…0.5 N•m

(3.5…4.4 lb•in)

To remove the terminal block, follow these steps.

1. Loosen the two screws that secure the terminal block.

2. Gently pull the terminal block away from the connector.

To install the terminal block, follow these steps.

1. Reattach the terminal block to the connector until seated.

ATTENTION: Do not use excessive force to press the terminal block into

position. The terminal blocks are keyed to fit the DC or AC connector. If

the terminal block does not fit into the connector, verify that you have

the correct terminal block. See Table 5 on page 15

.

2. Tighten the two screws that secure the terminal block to the connector.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 31

Page 32

Chapter 2 Install the PanelView 5500 Terminal

7 mm

20 mm

GNDDC+ DC–

Connect to DC Power

Terminals with a 24V DC power supply have these power ratings:

• 24V DC nominal (18…30V DC)

• 50 W maximum (2.1A at 24V DC)

ATT EN TI ON : The power supply is internally protected against reverse polarity.

Connecting DC+ or DC- to the earth ground terminal can damage the terminal.

Connecting AC power, or more than 30V DC, can also damage the terminal.

Terminals with a DC power input require a safety extra-low voltage (SELV) or

protective extra-low voltage (PELV) 24V DC power supply. Supported power

supplies include catalog numbers 1606-XLP95E, 1606-XLP100E,

or 2711P-RSACDIN.

ATT EN TI ON : Use a SELV or PELV supply as required by local wiring codes for

your installation. The SELV and PELV power sources provide protection so that

under normal and single fault conditions, the voltage between conductors and

earth ground does not exceed a safe value.

You can power the terminal from the same power source as other equipment by

using a DC power bus.

To connect the operator terminal to a DC power source, follow these steps.

1. Verify that the wiring is not connected to a power source.

2. Strip 7 mm (0.28 in.) of insulation from the ends of the wires.

3. Secure the DC power wires to the marked terminals (+ and –) on the

terminal block.

1

1

4. Secure the earth ground wire to the GND terminal on the terminal block.

The GND terminal must be connected to a low-impedance earth ground.

ATTENTION: The earth ground connection to ground is mandatory. This

connection is required for noise immunity, reliability, and

Electromagnetic Compliance (EMC) with the European Union (EU) EMC

Directive for CE-mark conformance. This connection is required for

safety by Underwriters Laboratory (UL).

5. Apply power to the operator terminal.

32 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 33

Install the PanelView 5500 Terminal Chapter 2

7 mm

20 mm

L1

L2/Neutral

Protective Ear th

to Ground Bus

Connect to AC Power

Terminals with an AC power supply have these power ratings:

• 100…240V AC (50…60 Hz)

• 105VA maximum

ATT EN TI ON : Improper wiring of the power terminals can result in voltage at

the communication connector shells.

Do not apply power to the terminal until all wiring connections have been made.

Failure to do so can result in electrical shock.

To connect the operator terminal to an AC power source, follow these steps.

1. Verify that the wiring is not connected to a power source.

2. Strip 7 mm (0.28 in.) of insulation from the ends of the wire.

3. Secure the AC power wires to the marked terminals (L1 and L2N) on the

terminal block.

1

1

4. Secure the protective earth ground wire to the marked terminal on the

terminal block.

The protective earth terminal must be connected to a low-impedance

earth ground.

ATTENTION: The earth ground connection to ground is mandatory. This

connection is required for noise immunity, reliability, and

Electromagnetic Compliance (EMC) with the European Union (EU) EMC

Directive for CE-mark conformance. This connection is required for

safety by Underwriters Laboratory (UL).

5. Apply power to the operator terminal.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 33

Page 34

Chapter 2 Install the PanelView 5500 Terminal

IMPORTANT

IMPORTANT

Link 1Link 2

1

1

Network Ports

Link 1

Link 2

Connect to a Network

The two Ethernet ports connect to controllers on an EtherNet/IP network by

standard Ethernet connections. These network topologies are supported:

• Device Level Ring Network Topology

• Linear Network Topology

• Star Network Topology

Each of these EtherNet/IP network topologies supports applications that use

Integrated Motion over an EtherNet/IP network, if necessary.

The terminal has dual-Ethernet ports but one device IP address.

Ethernet Ports

The Ethernet ports have two 10/100Base-T connectors for network

communication and supports MDI/MDI-X connections and DLR network

topology.

The terminal connects to an EtherNet/IP network by using a CAT5, CAT5E, or

CAT6 twisted-pair, Ethernet cable with RJ45 connectors.

To help prevent accidental disconnection of the Ethernet cable:

• To minimize vibration at the connector, and reduce the chance that

personnel that work inside the panel can accidentally disconnect the cable,

secure the Ethernet cable to the connector.

• Do not install the Ethernet cable too tightly. To prevent pulling on the cable

when the panel door is opened and closed, leave some slack in the cable.

The maximum cable length between the Ethernet ports and a 10/100Base-T port

on an Ethernet switch (without repeaters or fiber) is 100 m (328 ft).

WARNING: In hazardous locations, do not connect or disconnect any

communication cable with power applied to this device or any device on the

network. An electrical arc can cause an explosion in hazardous location

installations. Make sure that the power is off or the area is nonhazardous before

proceeding.

34 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 35

Install the PanelView 5500 Terminal Chapter 2

TIP

1

8

Yellow

Indicator

Green

Indicator

Table 15 - Ethernet Connector Pinout

Connector Pin Pin Name

1TD+

2TD-

View of RJ45

Conne ctor

3RD+

4Unused

5Unused

6RD-

7Unused

8Unused

Shield Connection

No direct connection

(AC coupled to chassis GND)

Each Ethernet port has two indicators that provide the activity status.

Table 16 - Ethernet Status Indicators

Indicator Color Description

Link Integrity Green On when a link is present.

Activity Yellow Blinks when activity is detected on Ethernet link.

Device Level Ring Network Topology

A Device Level Ring (DLR) network is a single-fault tolerant ring network that is

intended for the interconnection of automation devices. This topology is also

implemented at the device level. No additional switches are required.

A DLR network contains supervisor nodes and ring nodes. The PanelView 5500

terminal operates only as a ring node on the network.

When a fault occurs, the fault location is determined and the supervisor

reconfigures the network to continue sending data on the network. Once the

fault is corrected, the supervisor reconfigures the network to operate as a normal

ring (versus a faulted ring).

For more information on DLR network topology, see EtherNet/IP Embedded

Switch Technology Application Guide, publication ENET-AP005

.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 35

Page 36

Chapter 2 Install the PanelView 5500 Terminal

PanelView 5500 Terminal

Connected Via Two DLR Por ts

Computer Connected Via a 1783-ETAP EtherNet/IP Tap

ControlLogix Controller with

1756-EN3TR (or EN2TR) Module

Kinetix® 350 Drive Connected Via a

1783-ETAP EtherNet/IP Tap

Kinetix 6500 Drives

with Motors

1734-AENTR POINT I/O™ Adapter

with POINT I/O Modules

1794-AENTR FLEX™ I/O Adapter

with FLEX I/O Modules

PanelView 5500 Terminal Connected

Via O ne Ethe rnet Por t

Kinetix 350 Drive Connected

Via a 1783-ETAP EtherNet/IP Tap

Kinetix 350 Drive Connected

Via a 1783-ETAP EtherNet/IP Tap

Control Logix Controller wi th

1756-EN3TR (or EN2TR) Module

1794-AENTR FLEX I/O Adapter

with FLEX I/O Modules

1734-AENTR POINT I/O Adapter

with POINT I/O Modules

Compu ter

PanelView 5500 Terminal

Using Two-port DLR option

Figure 6 - PanelView 5500 Terminal in a DLR Topology Network

Linear Network Topology

A linear network topology is a collection of devices that are daisy-chained

together across an EtherNet/IP network. Devices that can connect to a linear

network topology use embedded switch technology to eliminate the need for a

separate switch, as required in star network topologies.

Figure 7 - PanelView 5500 Terminal in a Linear Topology Network

36 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 37

Install the PanelView 5500 Terminal Chapter 2

Compu ter

Stratix 6000™ Switch

1734-AENTR POINT I/O Adapter

with POINT I/O Modules

Kinetix 350 Drive

1732E-IB16M12R

ArmorBlock®

EtherNet/IP Module

ControlLogix Controlle r

with 1756-EN2T Module

PanelView 5500 Terminal

Connected Via One Ethernet Port

IMPORTANT

Star Network Topology

A star network topology is a traditional EtherNet/IP network that includes

multiple devices that are connected to each other via an Ethernet switch.

Figure 8 - PanelView 5500 Terminal in a Star Topology Network

Initial Startup

You must configure the Ethernet settings and update the firmware before you

can download a View Designer project and use the terminal. See Update the

Firmware Before You Use the Terminal on page 38.

If you attempt to configure the terminal settings without updating the firmware,

the Settings menu shows an update firmware message at the bottom of the screen.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 37

Page 38

Chapter 2 Install the PanelView 5500 Terminal

Update the Firmware Before You Use the Terminal

When power is turned on, the terminal goes through its startup sequence. The

Welcome screen displays with a Configure the Ethernet Network button.

To configure the Ethernet settings and update the firmware, follow these steps.

1. Boot up the terminal.

The Welcome dialog box displays.

2. Tap Configure the Ethernet Network.

The Internet Protocol (IP) Settings dialog box displays.

3. Configure the IP settings for the terminal.

• To obtain an IP address automatically, see Use DHCP to Assign an IP

Address For the Terminal on page 48.

• To configure IP settings manually, see Assign a Static IP Address For the

Te r m in al o n pa g e 49 .

38 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 39

Install the PanelView 5500 Terminal Chapter 2

4. Tap the Ethernet icon.

5. Configure the Ethernet ports for the terminal.

See Configure the Ethernet Ports on page 51

.

6. Update the firmware by using the ControlFLASH™ software.

Begin the update at Get the Terminal Firmware on page 84

.

You can now download a View Designer application to the terminal. After the

application is downloaded, the terminal resets then automatically launches the

application.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 39

Page 40

Chapter 2 Install the PanelView 5500 Terminal

Notes:

40 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

Page 41

Chapter 3

Configure Terminal Settings

Topic Page Topic Page

Runtime Environment 42 Configure the Display Screen Saver 54

Entering Data Using Virtual Keyboards 43 Calibrate the Touch Screen 55

Log On to the Terminal 45 Disable Downloads to the Terminal 57

Log Off of the Terminal 46 Change the HMI Device Name 58

Settings Menu 47 View the Firmware Revision 59

Configure the IP Address of the Terminal 48 Display Terminal Diagnostics 59

Configure a DNS Address For the Terminal 50 Reboot the Terminal 61

Configure the Ethernet Ports 51 Change the Date and Time 62

View the Network Diagnostics 52 View General Information for the

Configured Control ler

Adjust the Brightness of the Display 53

63

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 41

Page 42

Chapter 3 Configure Terminal Settings

1234567

8

9

System

Banner

Runtime Environment

During runtime, the PanelView 5500 terminal runs HMI projects. A project is

configured and downloaded to your terminal from the View Designer

application. The project launches each time the terminal restarts.

The terminal exchanges data values with the controller, animates the displayed

data, and responds when you press keys or touch a screen or element on a screen.

During runtime, you can perform these tasks:

• Navigate screens and their graphic elements

• View and manage alarms

• View and perform operations on a trend chart

• Display error information

• Configure terminal settings and view diagnostic information

Here is an example of a screen in a project that is downloaded to the terminal.

Item Name Description

1 Alarm summar y Indicates the number of unacknowledged alarms. Tap the icon to open the alarm

2Previous and next

buttons

3 Log On Tap this button to open the Logon dialog box.

4 Navigation button Tap this button to display the navigation menu at the bottom of the screen.

5Network diagnostics

42 Rockwell Automation Publication 2715-UM001A-EN-P - July 2015

shortcut

6 Controller diagnostics

shortcut

7 Time and date Displays the current time and date.

8 Screen Displays screens, shortcuts, and popups of a project that is created in the View

9 Navigation menu Displays menu items that you have access to when you are logged in. To display the

summary screen.

Tap the left arrow to display the previous screen; tap the right arrow button to display

the next screen.

Displays the status of Ethernet link 1 and Ethernet link 2. Tap the icon to open the

Network dialog box.

Displays the status of a connected controller. Tap the icon to open the Controllers

information screen.

Designer application.

navigation menu, press the Navigation button below the screen or in the system

banner above the screen. You can tab to menu items to open the screens of the

project. Tap a menu item to display that project in the screen.

The navigation menu also provides access to the Settings menu for the terminal.

Page 43

Configure Terminal Settings Chapter 3

1

3

2

10

11

4

9 76

5

8

Entering Data Using Virtual Keyboards

The virtual keyboard or virtual numeric keypad opens during runtime when text

or numeric input is required.

• The virtual keyboard opens on the PanelView 5500 terminal screen when

you tap a field or element that requires text or numeric input.

• The virtual numeric keypad opens on the PanelView 5500 terminal screen

when you tap a field or element that requires only numeric input.

Figure 9 - Virtual Keyboard

Table 17 - Virtual Keyboard Description

Item Feature Description

1 Text entry field Tap the letters, numbers, and character keys to enter text into this field. The tex t entry

2 Clear Tap this button to remove all characters that are entered in the text entry field.

3 Backspace Tap this key to delete one character to the left at a time.

4 éüç Tap this key to toggle between Roman characters and alpha-European characters.

5 Arrow keys Tap the left arrow key to move the cursor one space to the left. Tap the right arrow key to

6 Cancel Tap Cancel to cancel the entry.

7 OK Tap OK to complete the entr y.

8 Space bar Tap the space bar to enter a space in the text entry field.

9#?=

ABC

10 Shift Tap this key to toggle the keyboard between uppercase and lowercase letters. The

11 Caps lock Tap this key to toggle the keyboard between uppercase or lowercase letters. The keyboard

field is always active when the keyboard is open.

Numeric keys are not part of the alpha-European keyboard.

move the cursor one space to the right.

Tap this key to toggle between symbols and alpha-numeric characters:

• When in symbol mode, the key displays as ABC.

• When in alpha-numeric mode, the key displays as #?=.

keyboard returns to lowercase cha racters after one character has been entered.

remains in the selected state until you tap this key again.

Rockwell Automation Publication 2715-UM001A-EN-P - July 2015 43

Page 44

Chapter 3 Configure Terminal Settings

1

5

2

3

4

67

Figure 10 - Virtual Numeric Keypad

Table 18 - Virtual Numeric Keypad Description

Item Feature Description

1 Numeric entry field The numeric entry field into which you type the numeric value for the graphic

2 Min-Max value The displayed minimum and maximum values you can enter for the selected field or

3 Clear Tap the X to remove all numbers that are entered into the numeric entry field.