Allen-Bradley 2711P-K4M5A8, 2711P-K4M20D8, 2711P-K4M5D8, 2711P-K4M20A8, 2711P-K4C5A8 User Manual

...Page 1

User Manual

Original Instructions

PanelView Plus 6 Terminals

Catalog Numbers 2711P-K4M5A8, 2711P-K4M5D8, 2711P-K4M20A8, 2711P-K4M20D8, 2711P-K4C5A8, 2711P-B4C5A8, 2711P-K4C5D8,

2711P-B4C5D8, 2711P-K4C20A8, 2711P-B4C20A8, 2711P-K4C20D8, 2711P-B4C20D8, 2711P-K6M5A8, 2711P-T6M5A8, 2711P-B6M5A8,

2711P-K6M5D8, 2711P-T6M5D8, 2711P-B6M5D8, 2711P-K6M20A8, 2711P-T6M20A8, 2711P-B6M20A8, 2711P-K6M20D8, 2711P-T6M20D8,

2711P-B6M20D8, 2711P-K6C5A8, 2711P-T6C5A8, 2711P-B6C5A8, 2711P-K6C5D8, 2711P-T6C5D8, 2711P-B6C5D8, 2711P-K6C20A8,

2711P-T6C20A8, 2711P-B6C20A8, 2711P-K6C20D8, 2711P-T6C20D8, 2711P-B6C20D8, 2711P-K6C5A9, 2711P-T6C5A9, 2711P-B6C5A9,

2711P-K6C5D9, 2711P-T6C5D9, 2711P-B6C5D9, 2711P-K6C20A9, 2711P-T6C20A9, 2711P-B6C20A9, 2711P-K6C20D9, 2711P-T6C20D9,

2711P-B6C20D9, 2711P-K7C4D8, 2711P-T7C4D8, 2711P-B7C4D8, 2711P-T7C4D8K, 2711P-K7C4A8, 2711P-T7C4A8, 2711P-B7C4A8,

2711P-K10C4D8, 2711P-T10C4D8, 2711P-B10C4D8, 2711P-K10C4A8, 2711P-T10C4A8, 2711P-B10C4A8, 2711P-K12C4D8, 2711P-T12C4D8,

2711P-B12C4D8, 2711P-T12C4D8K, 2711P-K12C4A8, 2711P-T12C4A8, 2711P-B12C4A8, 2711P-K15C4D8, 2711P-T15C4D8, 2711P-B15C4D8,

2711P-K15C4A8, 2711P-T15C4A8, 2711P-B15C4A8, 2711P-K7C4D9, 2711P-T7C4D9, 2711P-B7C4D9, 2711P-K7C4A9, 2711P-T7C4A9,

2711P-B7C4A9, 2711P-K10C4D9, 2711P-T10C4D9, 2711P-B10C4D9, 2711P-K10C4A9, 2711P-T10C4A9, 2711P-B10C4A9, 2711P-K12C4D9,

2711P-T12C4D9, 2711P-B12C4D9, 2711P-K12C4A9, 2711P-T12C4A9, 2711P-B12C4A9, 2711P-K15C4D9, 2711P-T15C4D9, 2711P-B15C4D9,

2711P-K15C4A9, 2711P-T15C4A9, 2711P-B15C4A9

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

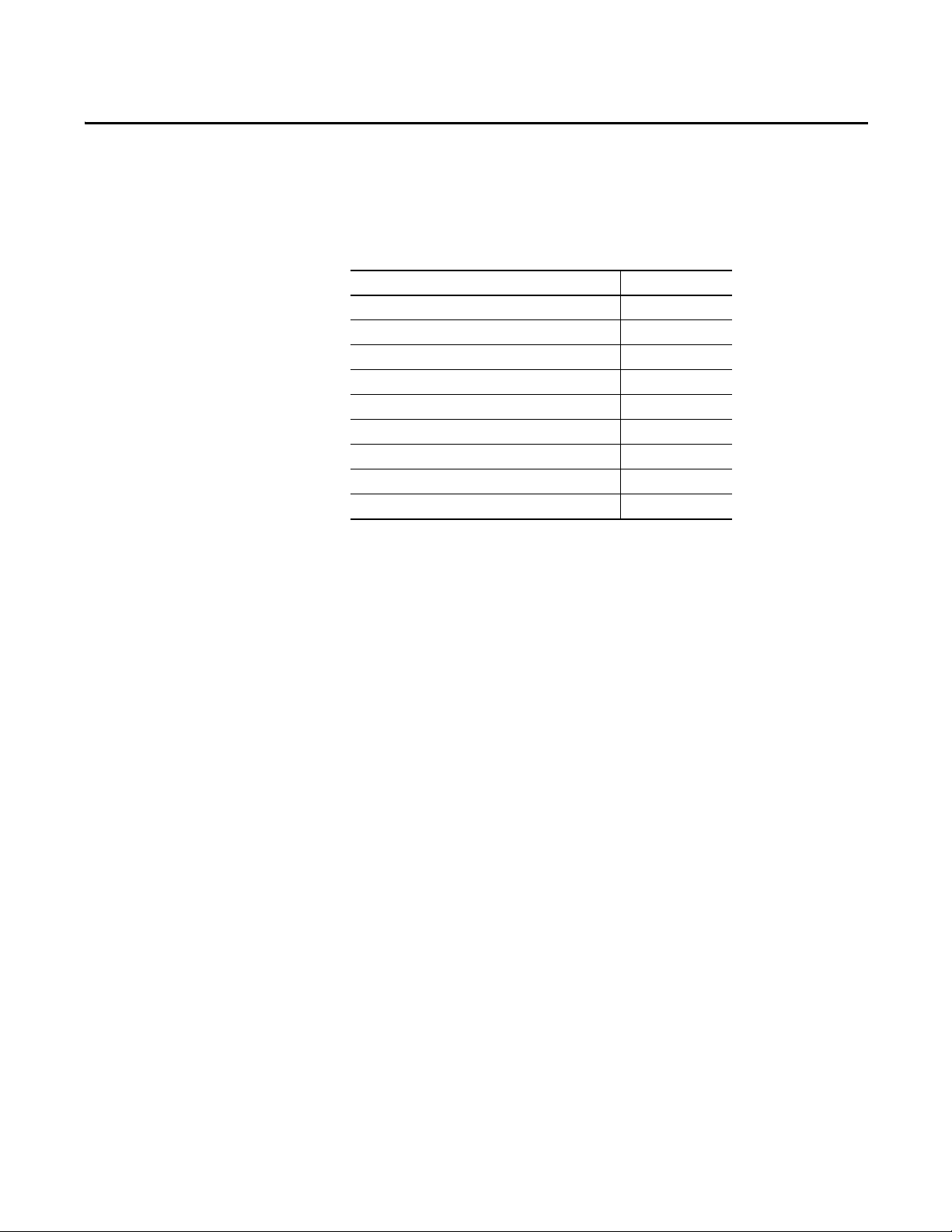

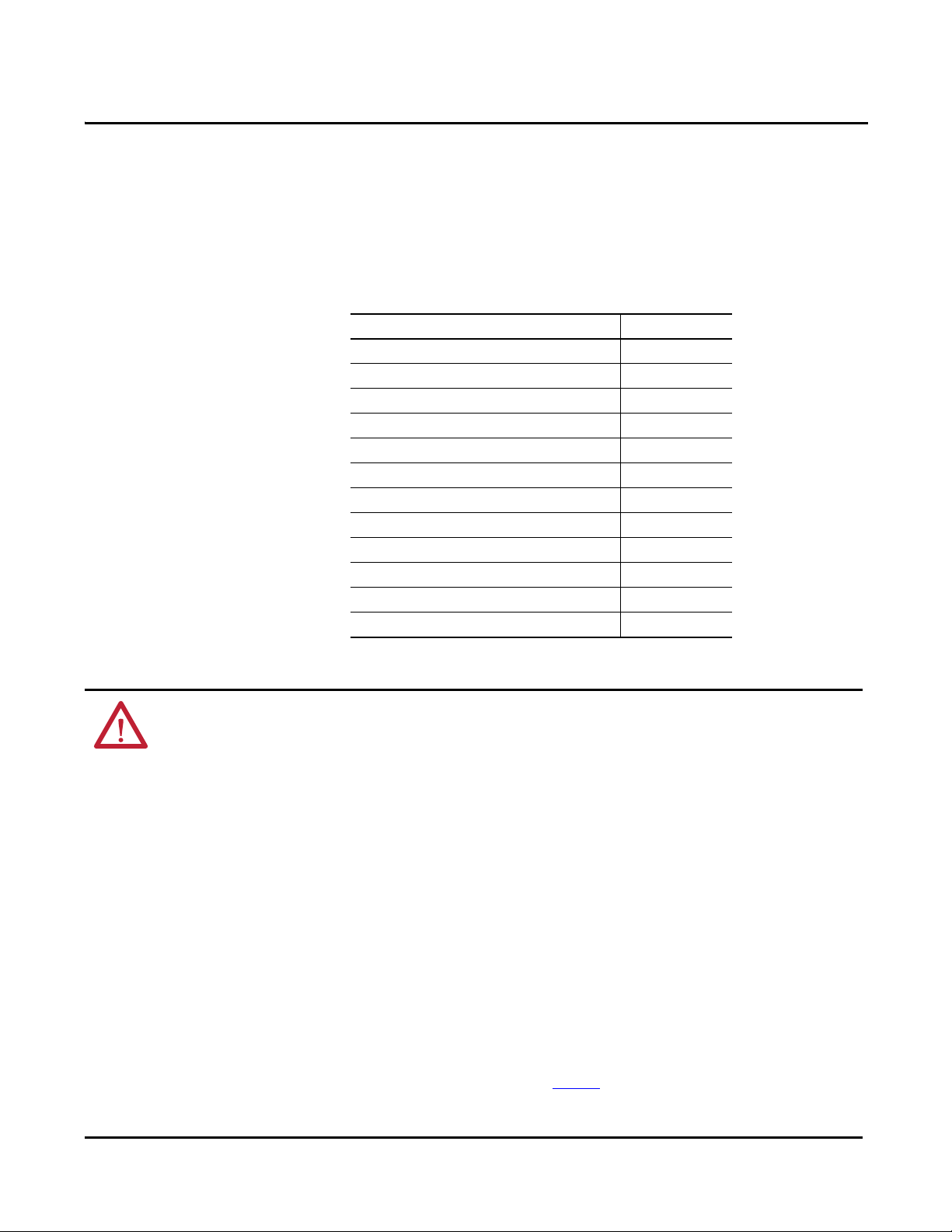

This table contains the changes made to this revision.

Top ic Pag es

Added information about free user memory available for PanelView Plus 6

terminals.

17, and 20…23

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 5

Table of Contents

Preface

Overview

Install Terminal

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Firmware Upgrades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

About the Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Windows CE Operating System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Open versus Closed System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Start-up Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Desktop Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Software Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

400 and 600 Terminal Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

700 to 1500 Terminal Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

400/600 Terminal Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

700 to 1500 Terminal Selections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 2

Mounting Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Panel Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Panel Cutout Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Product Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mount the 400/600 Terminal in a Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Mount the 700 to 1500 Terminal in a Panel . . . . . . . . . . . . . . . . . . . . . . . . 35

Remove and Install the Power Terminal Block. . . . . . . . . . . . . . . . . . . . . . 37

DC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

AC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Initial Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Reset the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Configuration Mode

Chapter 3

Access Configuration Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Terminal Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Load and Run Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Start-up Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Desktop Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Communication Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Ethernet Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

File Management. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Display Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Input Device Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Configure Print Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Check Integrity of Application Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Configure Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 5

Page 6

Table of Contents

Windows CE Operating System

View and Clear the System Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Enable or Disable the Alarm Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Time and Date Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Regional Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Font Linking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Chapter 4

Windows CE 6.0 Standard Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Windows CE 6.0 with Extended Features . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Windows Explorer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Taskbar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Input Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Windows Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Backup and Restore. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Hardware Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Keypad Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Touch Properties. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Display Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Logo Manager. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

User Accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Network Server Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Printer Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

PDF Reader. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Image Viewer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Chapter 5

Install and Replace Components

Required Tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Install or Replace the Logic Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Install or Replace a Communication Module . . . . . . . . . . . . . . . . . . . . . . 121

Replace the Display Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Replace the Bezel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Replace the Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Replace the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Install the AC Power Supply Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Remove the Product ID Label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Replace the Keypad Legend Inserts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Load an SD Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Clean the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 137

Chapter 6

Terminal Connections

6 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

USB Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

Ethernet Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Serial Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Page 7

Firmware Upgrades

Table of Contents

DH-485/DH+ Communication Module . . . . . . . . . . . . . . . . . . . . . . . . . 147

ControlNet Communication Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Controller Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Chapter 7

Terminal Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Download Firmware Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Firmware Upgrade Wizard. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Upgrade Terminal Firmware from a Storage Device. . . . . . . . . . . . . . . . 157

Upgrade Terminal Firmware over the Network. . . . . . . . . . . . . . . . . . . . 160

Chapter 8

Troubleshooting

Fonts Resident on Terminal

Outdoor Installations for High-bright

Displays

Index

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Terminal Does Not Start Properly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Start-up Messages and Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Check Terminal Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Ethernet Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Program Launcher ActiveX Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Application Does Not Run . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Configuration Mode Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

File System Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Advanced Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Access Maintenance Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Restore Factory Defaults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Appendix A

True Type Fonts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Appendix B

Important Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Using an Antiglare Overlay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Using a Solar Visor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Selecting an Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Backlight Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Orientation of the Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 9

Preface

This manual describes how to install, configure, operate, and troubleshoot

PanelView Plus 6 terminals. It does not provide procedures on how to create

applications that run on the terminal.

You need to do the following:

• Use FactoryTalk

HMI application to run in the terminal.

• Create ladder logic to interact with the HMI application.

®

View Studio for Machine Edition software to create an

Additional Resources

Package Contents

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

PanelView Plus Specifications Technical Data, publication

2711P-TD005

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com

Provides technical specifications, environmental

specifications, and certifications for the PanelView Plus 6

platform.

Provides general guidelines for installing a Rockwell

Automation® industrial system.

Provides declarations of conformity, certific ates, and other

certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

This product is shipped with the following items:

• Terminal with FactoryTalk View Machine Edition runtime software

installed and activated

• Product information

• Mounting levers for installing 400 and 600 terminals

• Mounting clips for installing 700 to 1500 terminals

• Panel cutout template

Firmware Upgrades

For the latest firmware upgrades and other downloads for PanelView Plus 6

terminals, go to http://www.rockwellautomation.com/support

and click

Firmware Updates.

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 9

Page 10

Preface

Notes:

10 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 11

Overview

Top ic Pa ge

Windows CE Operating System 12

Open versus Closed System 12

Desktop Access 13

Software Support 13

400 and 600 Terminal Features 14

700 to 1500 Terminal Features 17

400/600 Terminal Selections 20

700 to 1500 Terminal Selections 21

Accesso ries 22

Chapter 1

About the Terminals

PanelView Plus 6 terminals are operator interface devices that run HMI

machine-level applications in an industrial environment. The displays range in

size from 4 to 15 inches. These devices are used to monitor, control, or display

information graphically, letting operators quickly understand the status of their

application.

This platform is programmed by using common development software that

provides multilingual support, and integrates into systems with Rockwell

Automation controllers including preferred Logix controllers.

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 11

Page 12

Chapter 1 Overview

Windows CE Operating System

PanelView Plus 6 terminals run the Windows CE operating system (OS),

providing the foundational OS elements for the majority of user needs.

For users with more complex application requirements, some of the terminals

offer optional, extended features and file viewers.

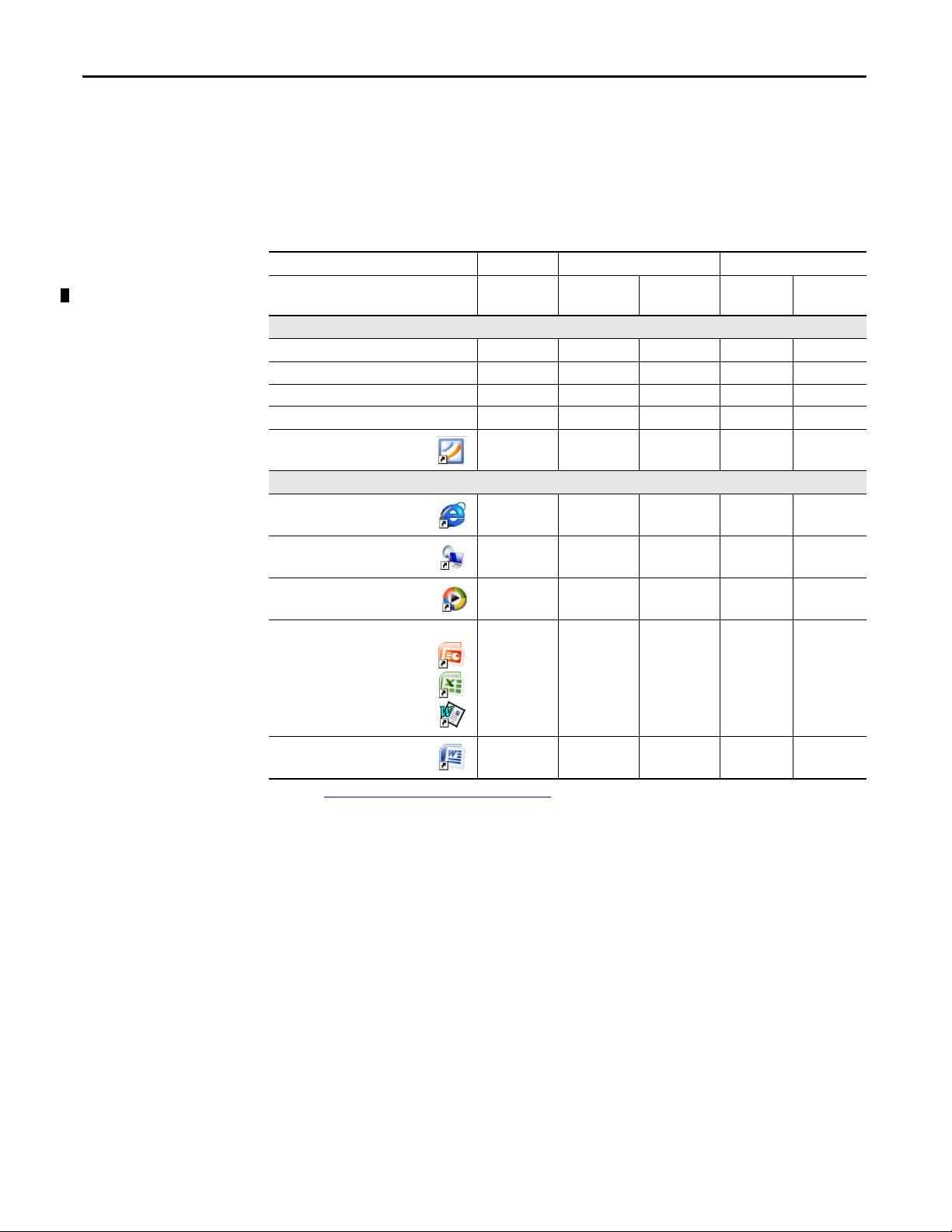

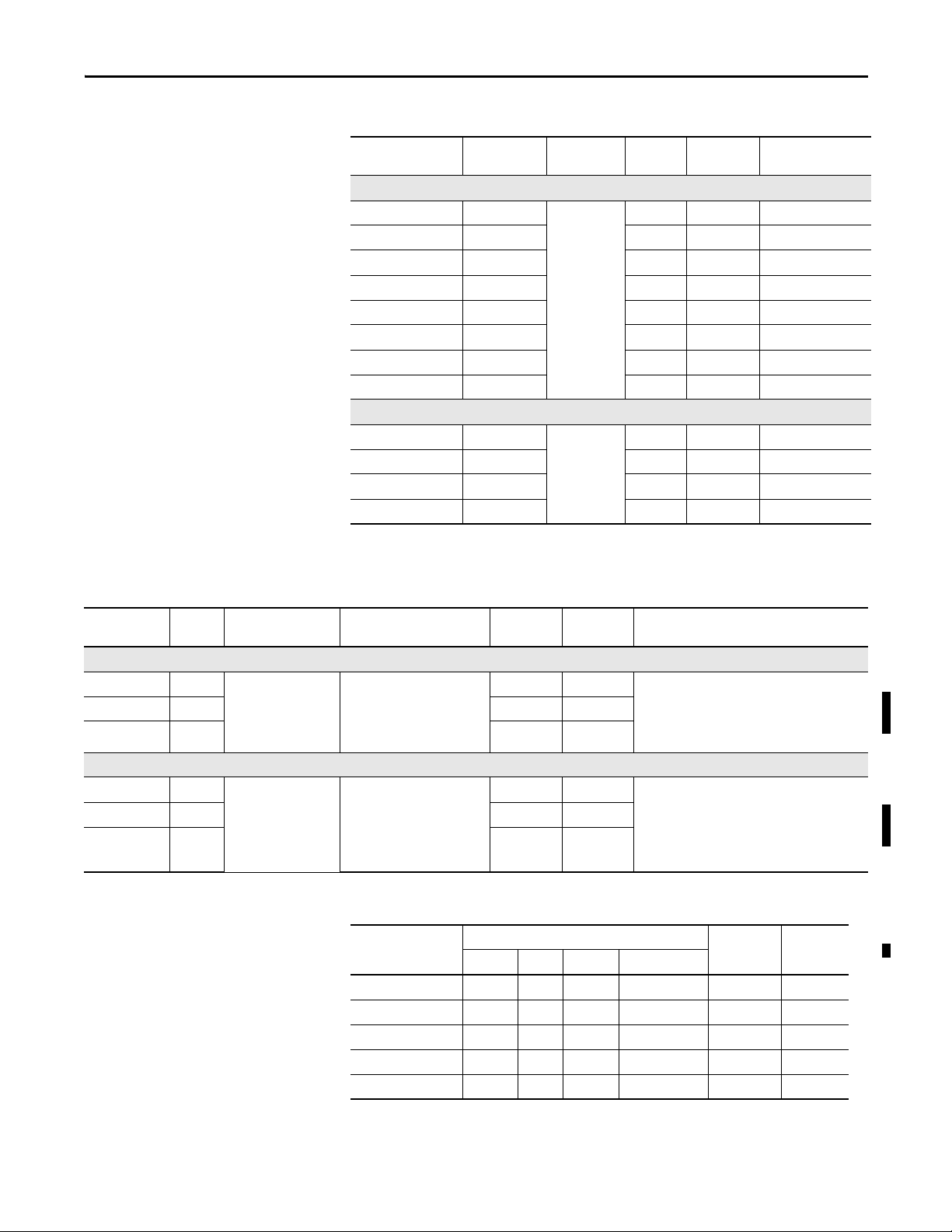

Table 1 - Operating System Features

Features 400 Terminals 600 Terminals 700 to 1500 Terminals

(2)

2711P-xxxx8

2711P-RP8x

—x

Cat. No. 2711P-xxxx8 2711P-xxxx8 2711P-xxxx9

Standard Features

FTP server x x x x x

VNC client/server x x x x x

ActiveX co ntrols

Third-party device support x x x x x

PDF reader x x x x x

Optional Extended Features

Web browser - Internet Explorer

Remote desktop connection

(1)

xxxxx

—— x—x

—— x

2711P-xxxx9

2711P-RP9x

Media player

Microsoft Office file viewers

• Power Point

• Excel

• Word

WordPad text editor — — x — x

(1) Refer to Display Factor yTal k View ME Station Inform ation on page 78 for a list of ActiveX controls loaded on a terminal.

(2) The remote desktop connection is not currently supported on PanelView Plus 6 - 600 terminals with extended features.

Open versus Closed System

—— x—x

—

—

—

—

—

—

x

x

x

—

—

—

x

x

x

The terminals can be configured to run an open or closed desktop environment:

• An open system launches the Windows Explorer desktop on startup. The

system is configurable via the control panel and supports Windows

operations.

• A closed system launches a FactoryTalk View Machine Edition application

on startup and restricts access to the Windows Explorer desktop.

All terminals are shipped as closed systems restricting access to the desktop. The

first time you start the system, the terminal launches FactoryTalk View ME

Station Configuration mode. At this point, you can change the start-up option

and allow desktop access.

12 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 13

Overview Chapter 1

TIP

IMPORTANT

Start-up Options

Desktop Access

You can configure the terminal to perform one of three actions at startup:

• Launch a FactoryTalk View Machine Edition HMI application.

• Launch the FactoryTalk View Machine Edition Configuration mode of

the terminal where you load and run applications, configure start-up

options and terminal settings, and enable or disable desktop access.

• Launch the Windows Explorer desktop.

The factory default state and start-up option following a firmware upgrade is to

launch the terminal in Configuration mode. Refer to Start-up Options on

page 51 for details on how to change the start-up option.

Any of the terminals can be configured to allow or restrict desktop access. From

the desktop, you can perform system and control panel operations, or run

third-party applications. Terminals with optional, extended features (catalog

numbers ending in 9) can additionally run viewers, media players, and launch the

web browser. You can even allow access temporarily to perform specific tasks,

then disable desktop access to prevent unauthorized changes.

All terminals are initially shipped with desktop access disabled.

Refer toDesktop Access on page 54

for details on how to modify desktop access.

Desktop access does not change the feature set of your terminal. If you have a

terminal with a catalog number ending in 8, opening the desktop does not

give you access to extended features and file viewers.

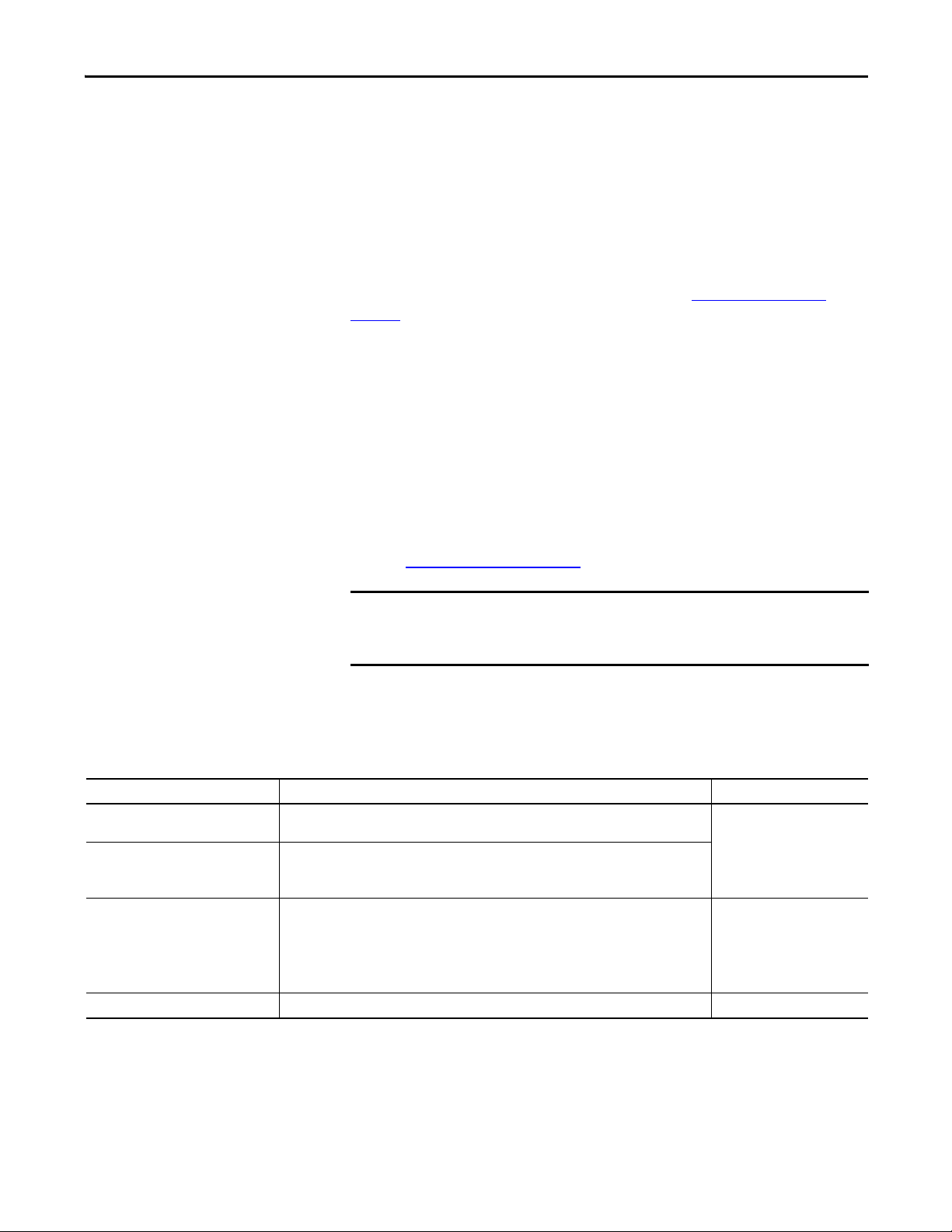

Software Support

Table 2 - PanelView Plus 6 Software Support

Software Description Version

FactoryTalk View Machine Edition Station Runtime environment for FactoryTalk View Machine Edition .mer applications. Machine Edition

FactoryTalk View Studio for

Machine Edition

FactoryTalk ViewPoint

(700 to 1500 terminals only)

Windows CE 6.0 OS Operating system that runs on all terminals. 6.0

Station is preloaded on each terminal and does not require FactoryTalk View activation.

Configuration software for developing HMI applications that run on PanelView Plus 6 terminals.

RSLinx® Enterprise software is included with FactoryTalk View Studio software and loaded during

installation.

Add-on capability provided with FactoryTalk View Studio software:

• This web-based, thin-client solution lets manufacturers or casual users monitor or download

changes to a running Machine Edition application from remote locations via an Internet

browser.

• A single license is embedded with each terminal supporting a single client connection to

terminal. No additional software is required.

The table lists software supported on the terminals.

• 6.10 or later

• 6.0 or later

1.2 or later

(400 and 600 terminals)

(700 to 1500 terminals)

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 13

Page 14

Chapter 1 Overview

5

7

8

9

10

12

11

6

3a

2

3b

4

1

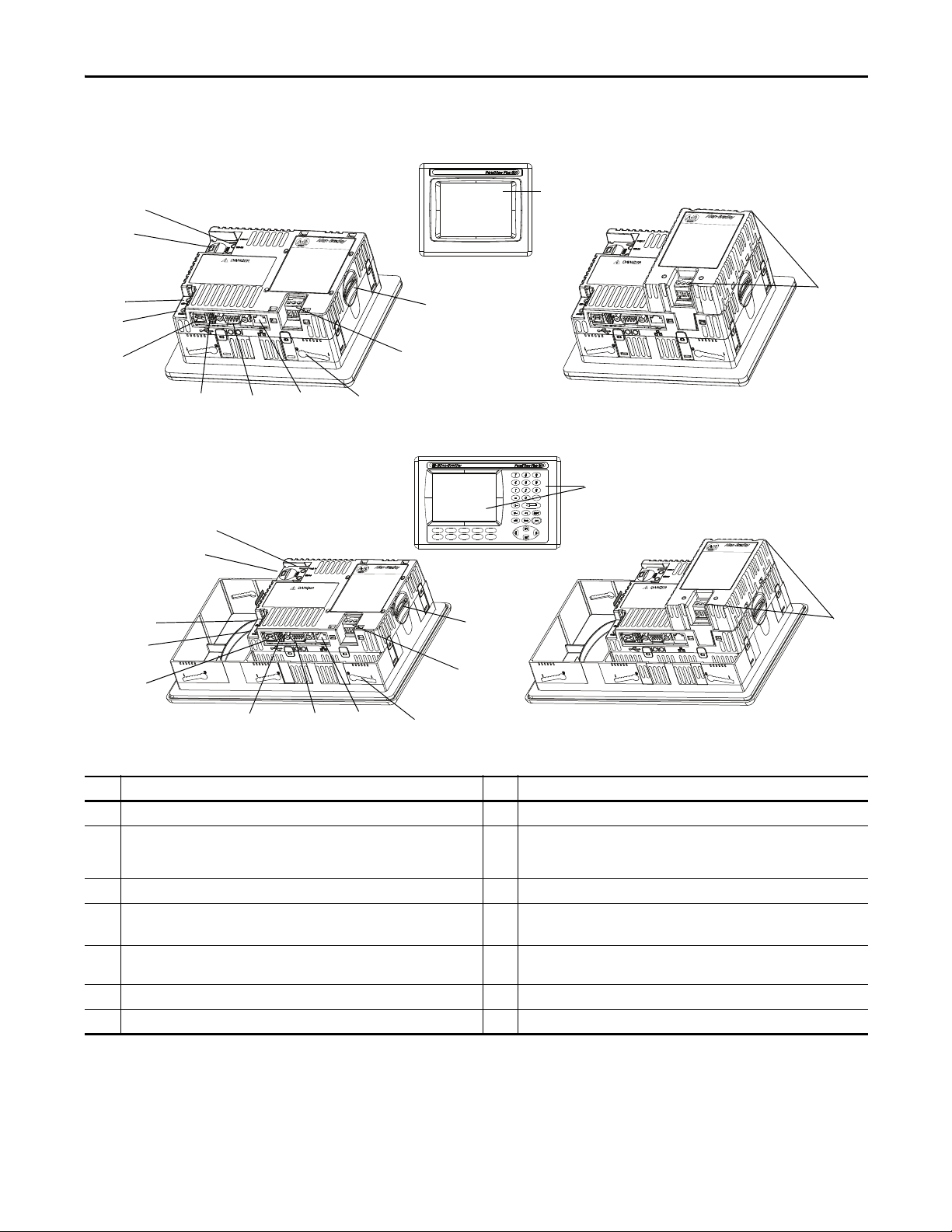

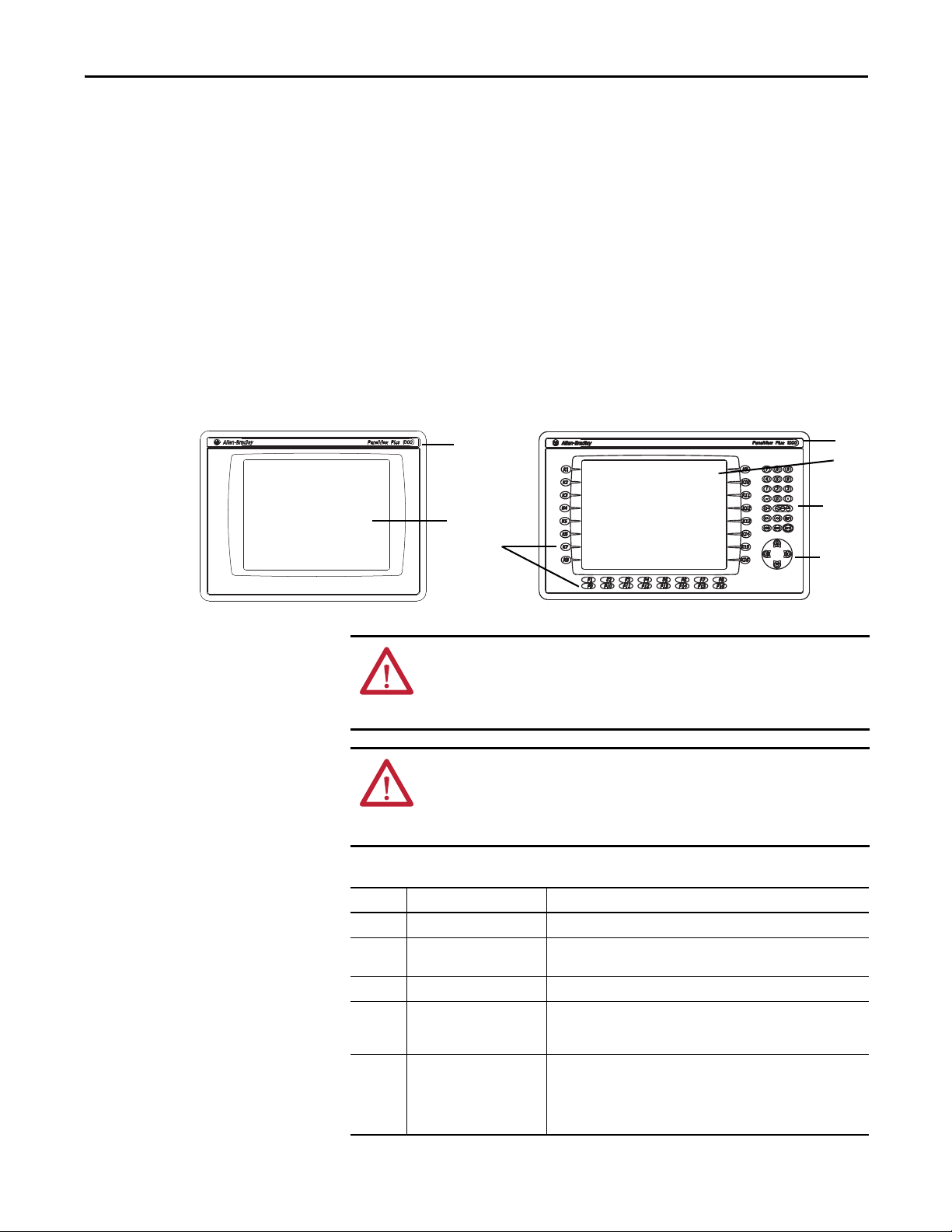

400 and 600 Terminal Features

Both the 400 and 600 terminals provide these communication options:

• RS-232 serial port only or

• Ethernet port and RS-232 serial port

Figure 1 - 400 Keypad or Keypad/Touch Terminals

Table 3 - PanelView Plus 6 - 400 Terminal Components

Item Component

1 3.5-in. grayscale or color display with one of these operator input options:

• Keypad

• Combination keypad and touch screen

2 Secure Digital (SD) card slot supporting cat. no. 1784-SDx cards

3a DC power input, nonisolated

24V DC nom (18…30V DC)

3b AC power supply module with AC power input

100…240V AC (50…60 Hz)

4 Mounting slots (four)

5 Ethernet port for controller communi cation, 10/100Base-T, Auto MDI/MDI-X

6 RS-232 serial port for controller communication, printing, or file transfers

7 One USB 2.0 high-speed (type A) host port for attaching USB peripherals including

mouse, keyboard, printer, and USB drives that are hot-swappable in nonhazardous

locations

8 One USB 2.0 high-speed (type B) device port for connecting a host computer

9 Reset switch to reset the terminal without having to power off and on

10 Default switch to access maintenance operations such as restoring factory defaults

11 Battery compartment

12 Indicators provide communication and fault status

(1)

(1)

(2)

14 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

(1) Presence of a DC power input or AC power supply module is catalog number dependent. Removing the

AC power supply module voids the terminal warranty.

(2) Presence of Ethernet port is catalog number dependent.

Page 15

Figure 2 - 600 Touch Terminals

8

9

10

12

11

5

7

6

3a

2

4

3b

1a

8

9

10

12

11

7

5

6

3a

2

4

3b

1b

Figure 3 - 600 Keypad or Keypad/Touch Terminals

Overview Chapter 1

F1

F4F3 F5

F2

F6

F9F8 F10

F7

Table 4 - PanelView Plus 6 - 600 Terminal Components

Item Component Item Component

1a 5.7-in. color or grayscale display with a touch screen 6 RS-232 serial port for controller communication, printing, or file transfers

1b 5.7-in. color or grayscale display with either a:

• Keypad

• Combination keypad and touch screen

2 Secure Digital (SD) card slot supporting cat. no. 1784-SDx cards 8 One USB 2.0 high-speed (type B) device port for connecting a host computer

3a DC power input, nonisolated

(1)

24V DC nom (18…30V DC)

3b AC power supply module with AC power input

(1)

100…240V AC (50…60 Hz)

4 Mounting slots (four on touch terminals; six on keypad terminals) 11 Battery compartment

5 Ethernet port for controller communication, 10/100Base-T, Auto MDI/MDI-X

(1) Presence of a DC power input or the AC power supply module is catalog number dependent. Removing the AC power supply module voids the terminal warranty.

(2) Presence of Ethernet port is catalog number dependent.

7 One USB 2.0 high-speed (type A) host port for attaching USB peripherals

including mouse, keyboard, printer, and USB drives that are hot-swappable in

nonhazardous locations

9 Reset switch to reset the terminal without having to power off and on

10 Default switch to access maintenance operations such as restoring factory

defaults

(2)

12 Indicators provide communication and fault status

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 15

Page 16

Chapter 1 Overview

F1

F2

F4F3 F5

F6

F7

F9F8 F10

1

2

3

4

5

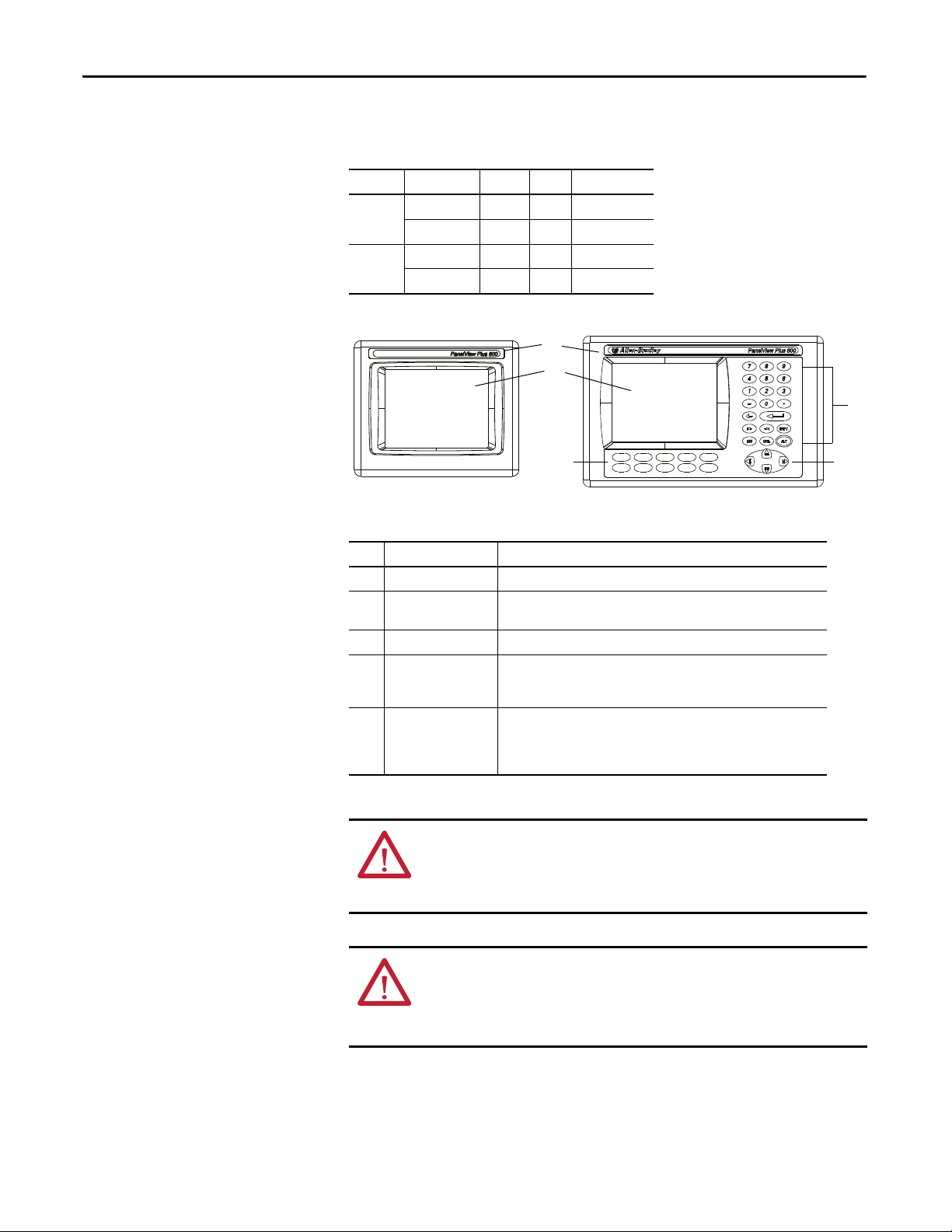

The terminals feature grayscale or color LCD displays with these input options.

Table 5 - Operator Input Options

Terminal Display Type Keypad Touch Key and Touch

400 Grayscale •

Color • •

600 Grayscale • • •

Color • • •

Table 6 - Display and Operator Input Features

Item Feature Description

1 Product label Product identification label can be replaced with custom label.

2 Display/touch screen Color or grayscale display with or without a resistive, 4-wire, touch screen

(catalog number dependent)

3 Numeric keypad 0…9, Backspace, Enter, Left and Right Tab, Esc, Shift, Ctrl, Alt keys

4 Navigation keys Use arrow keys for navigation. Use Alt+arrow to initiate these functions:

• Alt+left arrow (Home), Alt+right arrow (End)

• Alt+up arrow (Page Up), Alt+down arrow (Page Down)

5Function keys

Keys that can be configured in the application to per form operations. For

example, F1 can be configured to navigate to another screen.

400

• F1…F8

600

• F1…F10

ATT EN TI ON : Use a finger or gloved finger to operate the keypad. To operate the

touch screen, use a finger, gloved-finger or plastic stylus with a minimum tip

radius of 1.3 mm (0.051 in.). Using any other object or tool can damage the

keypad or touch screen.

ATT EN TI ON : Do not carry out multiple operations simultaneously. Doing so can

result in unintended operation:

• Touch only one operating element on the screen with one finger at one time.

• Press only one key on the terminal at one time.

16 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 17

Overview Chapter 1

1

2

3

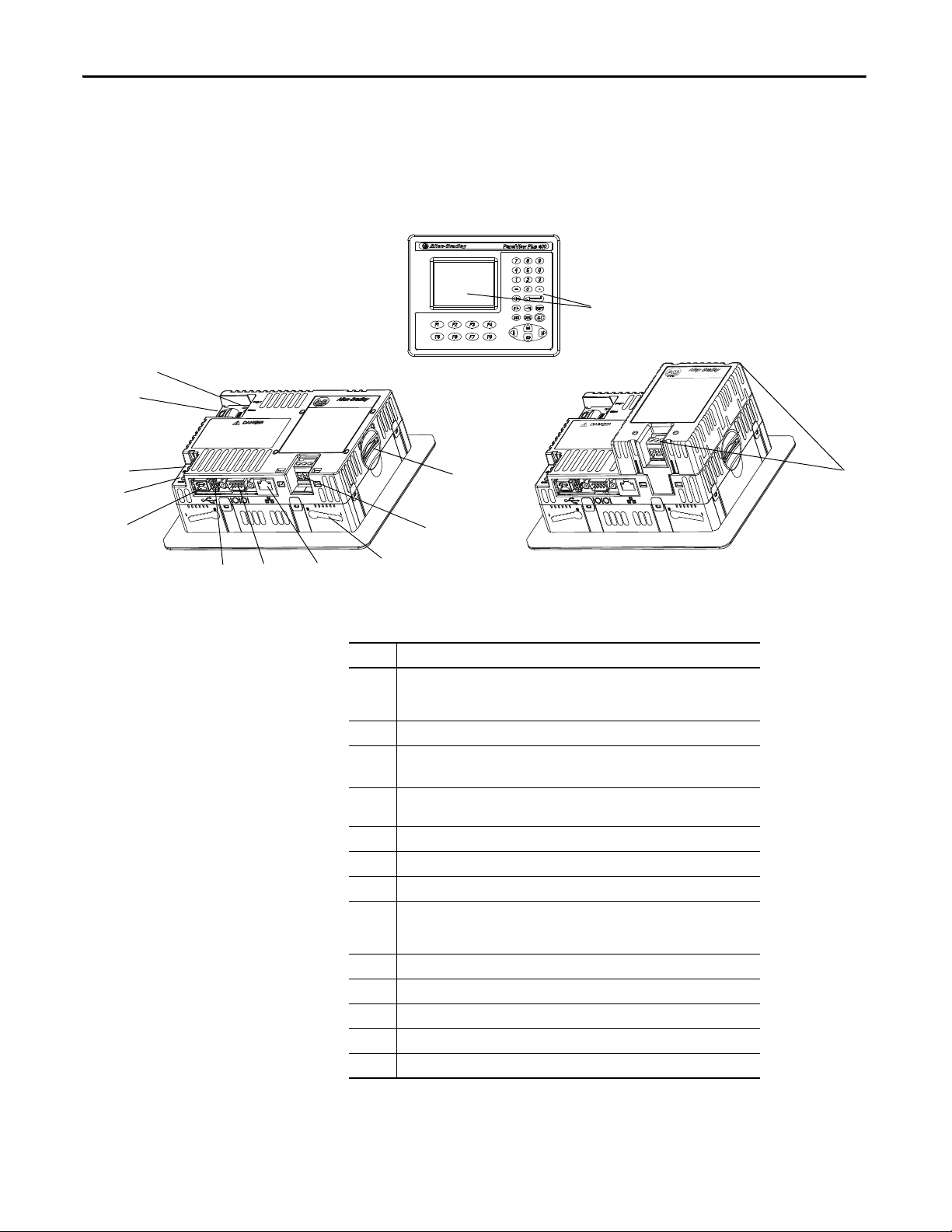

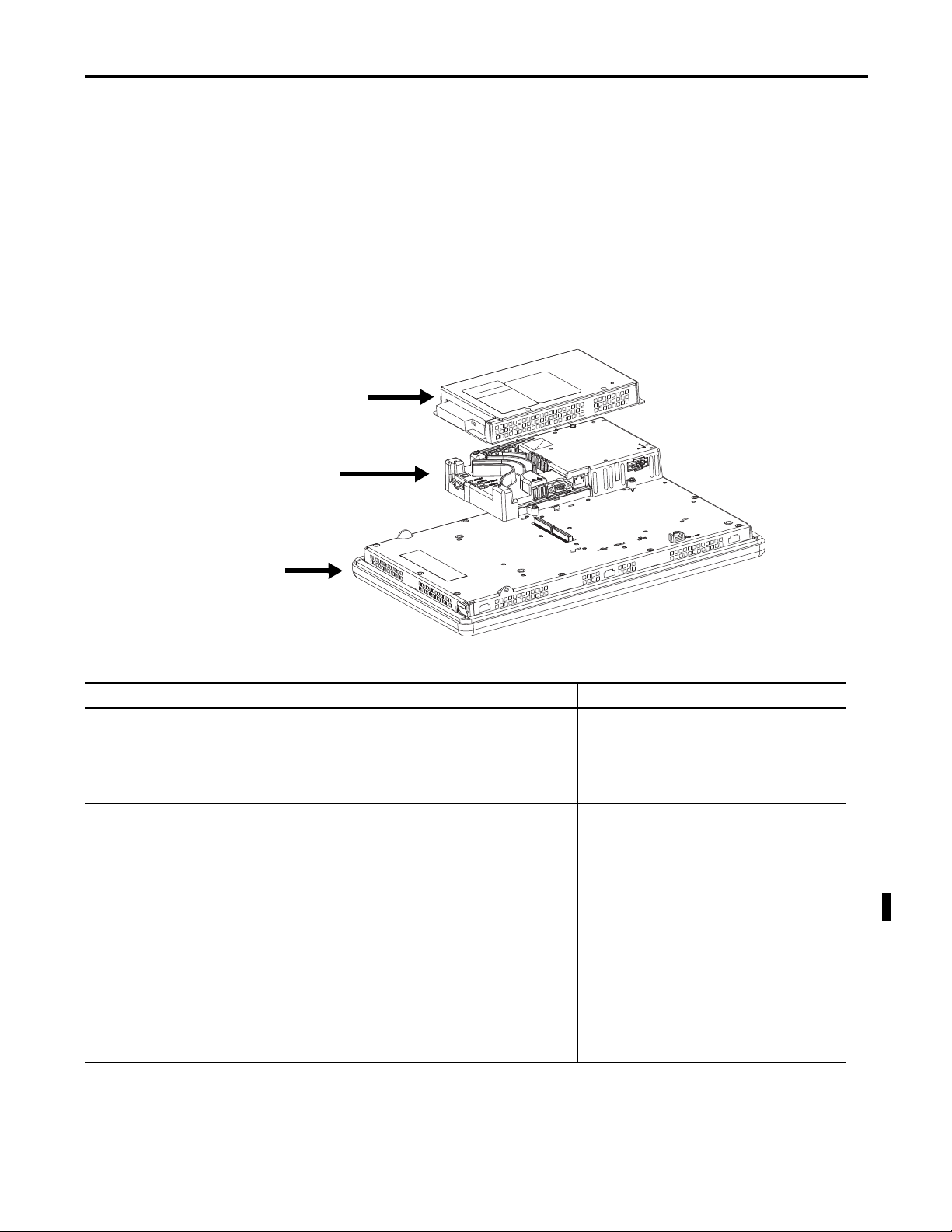

700 to 1500 Terminal Features

The larger 700 to 1500 terminals consist of modular components ordered

separately or as configured terminals. The modular components consist of the

following:

• Display module

• Logic module

• Optional communication module

These components provide for flexible configuration, installation, and upgrades.

You can order a factory-assembled unit with a single catalog number or separate

components for field installation.

Table 7 - Modular Components

Item Terminal Component Description Options for Environmental Conditions

1 Display module Flat panel, color graphic display in four sizes with keypad,

2 Logic module The logic module has these hardware features:

3 Communication module Optional module for communication with these networks:

touch-screen, or combination keypad/touch-screen input:

• 700 (6.5-in.)

• 1000 (10.4-in.)

• 1250 (12.1-in.)

• 1500 (15-in.)

• Power i nput, AC or DC

• RS-232 serial port

• Ethernet port

• 2 USB 2.0 host ports

• Network interface for optional communication module

• 512 MB RAM memory and 512 MB nonvolatile memory

(approx. 79 MB free user memory)

• Secure Digital (SD) card slot

• Battery-backed real-time clock

• Status indicators

• Reset switches

• Single PCI slot

• DH+

™/DH-485

• ControlNet scheduled and unscheduled

• Ethernet

Display modules are also available with these

characteristics:

• Marine-certified

• Conformal-coated

• High-bright display for outdoor use

• Built-in antiglare overlay

Logic modules are also available with these characteristics:

• Marine-certified

• Conformal-coated

Communication modules are also available with these

characteristics:

• Marine-certified

• Conformal-coated

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 17

Page 18

Chapter 1 Overview

1

2

3

4

5

6

7

9

8

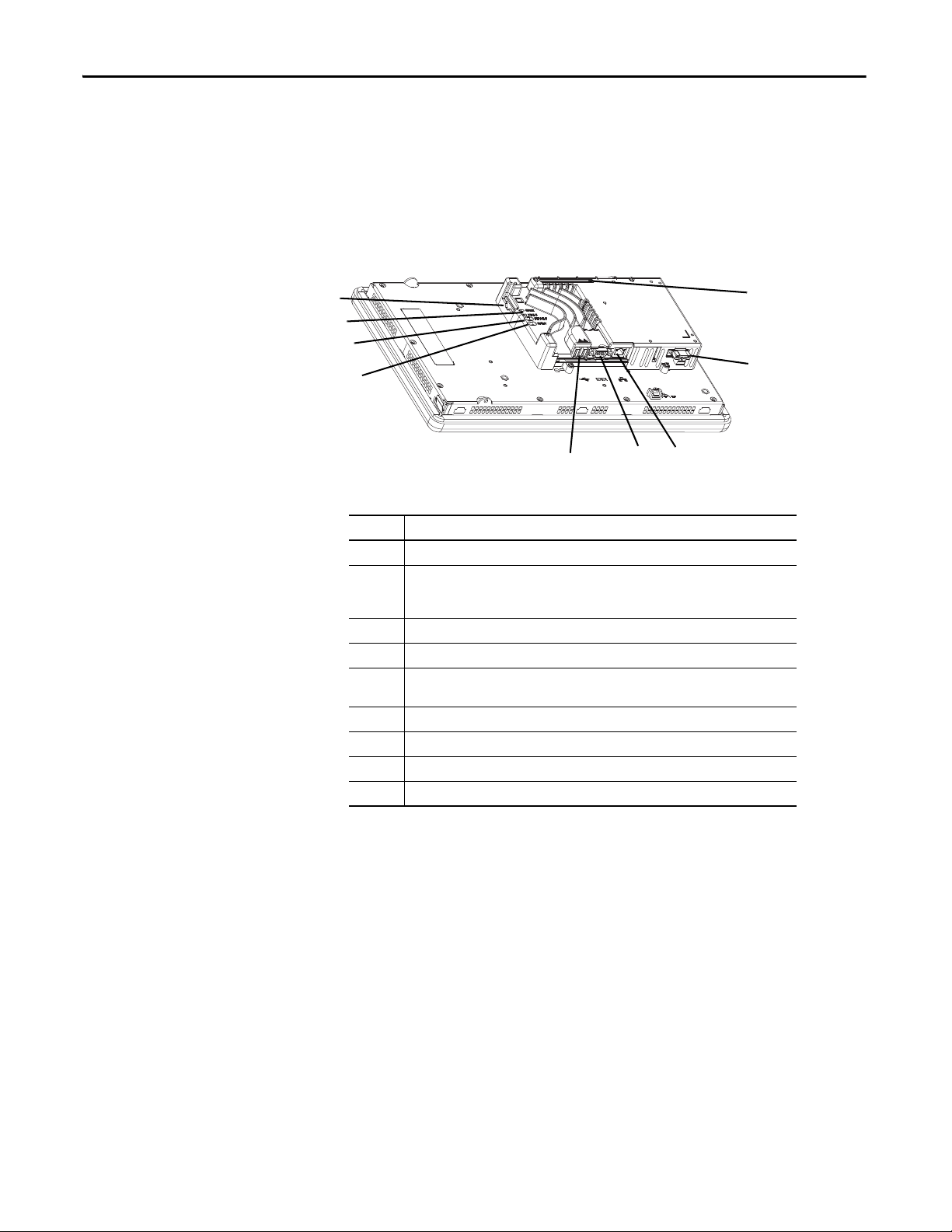

Configured Terminals

A configured terminal, ordered as a single-catalog number, has a display module

and logic module.

An optional DH+/DH-485, ControlNet, or Ethernet communication module

can be added later for additional network capabilities.

Table 8 - Logic Module Features

Item Feature

1 Network interface connector for optional communication module

2 AC or DC power input

• Isolated 18…32V DC

• 100…240V AC

3 Ethernet port for controller communication, 10/100 BaseT, Auto MDI/MDI-X

4 RS-232 serial port for file transfers, printing, and controller communication

5 Two USB 2.0 high-speed (type A) host ports for attaching USB devices including mouse,

keyboard, printer, and USB drives that are hot-swappable in nonhazardous locations

6 Reset switch to reset the terminal without having to power on and off

7 Default switch to access maintenance operations such as restoring factory defaults

8 Indicators provide communication and fault status

9 Secure Digital (SD) card slot supporting cat. no. 1784-SDx cards

(1) For DC applications using AC power, an external, remote AC-to-DC power supply, cat. no. 2711P-RSACDIN, is

available for DIN-rail mounting.

(1)

18 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 19

Overview Chapter 1

5

1

2

1

2

4

3

Operator Input

All 700 to 1500 display modules have TFT color, graphic displays with either

keypad, touch screen, or combination keypad/touch-screen input. Common

features and firmware provide for easy migration to a larger display:

• Eight-wire resistive touch screens are extremely accurate for operator

interfaces. When a point on the touch screen is pressed, the layers connect

and change the electrical current, which is then registered and processed.

• All keypad or combination keypad/touch-screen displays are similar except

for the number of functions keys.

To meet the requirements of specific environmental conditions, high-bright

displays, marine-certified displays, and conformal-coated displays are also

available. Plus, you can order field replaceable bezels.

ATT EN TI ON : Use a finger or gloved finger to operate the keypad. To operate the

touch screen, use a finger, gloved-finger or plastic stylus with a minimum tip

radius of 1.3 mm (0.051 in.). Using any other object or tool can damage the

keypad or touch screen.

ATT EN TI ON : Do not carry out multiple operations simultaneously. Doing so can

result in unintended operation:

• Touch only one operating element on the screen with one finger at one time.

• Press only one key on the terminal at one time.

Table 9 - Display Fe atures

Item Feature Description

1 Replaceable ID Label Product identification label can be replaced with custom label.

2 Display Analog resistive touch screen applies to touch-screen or combination

3 Numeric keypad 0…9, –, Backspace, Enter, Left and Right tab, Shift, Esc, Ctrl, Alt keys.

4 Navigation keys Use arrow keys for navigation. Use Alt+arrow to initiate these functions:

5 Fu nction keys

700 F1 …F10, K1…K12

1000 F1 …F16, K1…K16

1250 F1 …F20, K1…K20

1500 F1 …F20, K1…K20

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 19

keypad/touch-screen terminals.

• Alt+left arrow (Home), Alt+right arrow (End)

• Alt+up arrow (Page Up), Alt+down arrow (Page Down)

Keys that can be configured in the application to perform operations. For

example, F1 can be configured to navigate to another screen.

Replaceable legends are available to customize the function key labels.

Page 20

Chapter 1 Overview

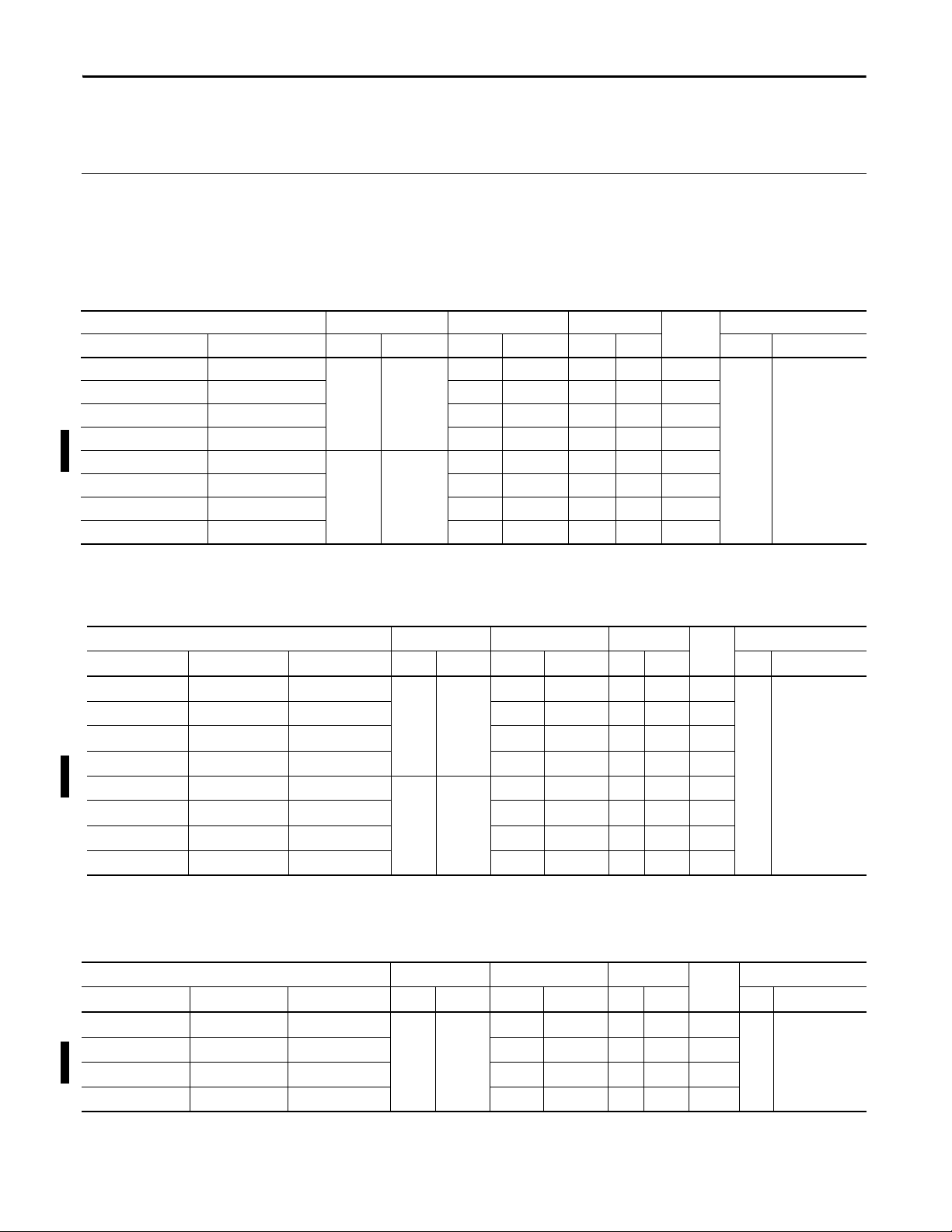

400/600 Terminal Selections

Bulletin Input Type Display Size Display Type Communication Power Operating System

|| || | | |

2711P- K = Keypad 4= 3.5 in. C = Color 5 = RS-232, USB A = AC 8 = Windows CE 6.0

B = Keypad and Touch 6 = 5.7 in. M = Grayscale 20 = Ethernet, RS-232, USB D = DC 9 = Windows CE 6.0 with extended features

T = Touch

The table shows the catalog number breakdown for the 400 and 600 terminals.

Table 10 - PanelView Plus 6 - 400 Terminals without Extended Features

Cat. Nos. Display Communication Ports USB Ports

Keypad Keypad and Touch Size Type RS -232 Ethernet Host Device RAM Nonvolatile

2711P-K4M5A8 — 3.5-in. Grayscale • • • AC

2711P-K4M5D8 — • • • DC

2711P-K4M20A8 — • • • • AC

2711P-K4M20D8 — • • • • DC

2711P-K4C5A8 2711P-B4C5A8 3.5-in. Color • • • AC

2711P-K4C5D8 2711P-B4C5D8 • • • DC

2711P-K4C20A8 2711P-B4C20A8 • • • • AC

2711P-K4C20D8 2711P-B4C20D8 • • • • DC

(1) The terminal s support FactoryTalk View Machine Edition software, version 6.10 or later, and the Windows CE 6.0 operating system.

Input

Power

256

Memory (MB)

(approx. 73 MB

free user memory)

(1)

512

Table 11 - PanelView Plus 6 - 600 Terminals without Extended Features

Cat. Nos. Display Communication Ports USB Ports

Keypad Touch Keypad and Touch Size Type RS-232 Ethernet Host Device RAM Nonvolatile

2711P-K6M5A8 2711P-T6M5A8 2711P-B6M5A8 5.7-in. Grayscale • • • AC

2711P-K6M5D8 2711P-T6M5D8 2711P-B6M5D8 • • • DC

2711P-K6M20A8 2711P-T6M20A8 2711P-B6M20A8 • • • • AC

2711P-K6M20D8 2711P-T6M20D8 2711P-B6M20D8 • • • • DC

2711P-K6C5A8 2711P-T6C5A8 2711P-B6C5A8 5.7-in. Color • • • AC

2711P-K6C5D8 2711P-T6C5D8 2711P-B6C5D8 • • • DC

2711P-K6C20A8 2711P-T6C20A8 2711P-B6C20A8 • • • • AC

2711P-K6C20D8 2711P-T6C20D8 2711P-B6C20D8 • • • • DC

(1) The terminals support FactoryTalk View Machine Edition software, version 6.10 or later, and the Windows CE 6.0 operating system.

Input

Power

Memory (MB)

256

free user memory)

(approx. 73 MB

Table 12 - PanelView Plus 6 - 600 Terminals with Extended Features

Cat. Nos. Display Communication USB Ports

Keypad Touch Keypad and Touch Size Type RS-232 Ethernet Host Device RAM Nonvolatile

2711P-K6C5A9 2711P-T6C5A9 2711P-B6C5A9 5.7-in. Color • • • AC

2711P-K6C5D9 2711P-T6C5D9 2711P-B6C5D9 • • • DC

2711P-K6C20A9 2711P-T6C20A9 2711P-B6C20A9 • • • • AC

2711P-K6C20D9 2711P-T6C20D9 2711P-B6C20D9 • • • • DC

Input

Power

Memory (MB)

256

free user memory)

(approx. 73 MB

(1)

512

(1)

512

(1) The terminals support FactoryTalk View Machine Edition software, version 6.10 or later, and the Windows CE 6.0 operating system with extended features and file viewers.

20 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 21

Overview Chapter 1

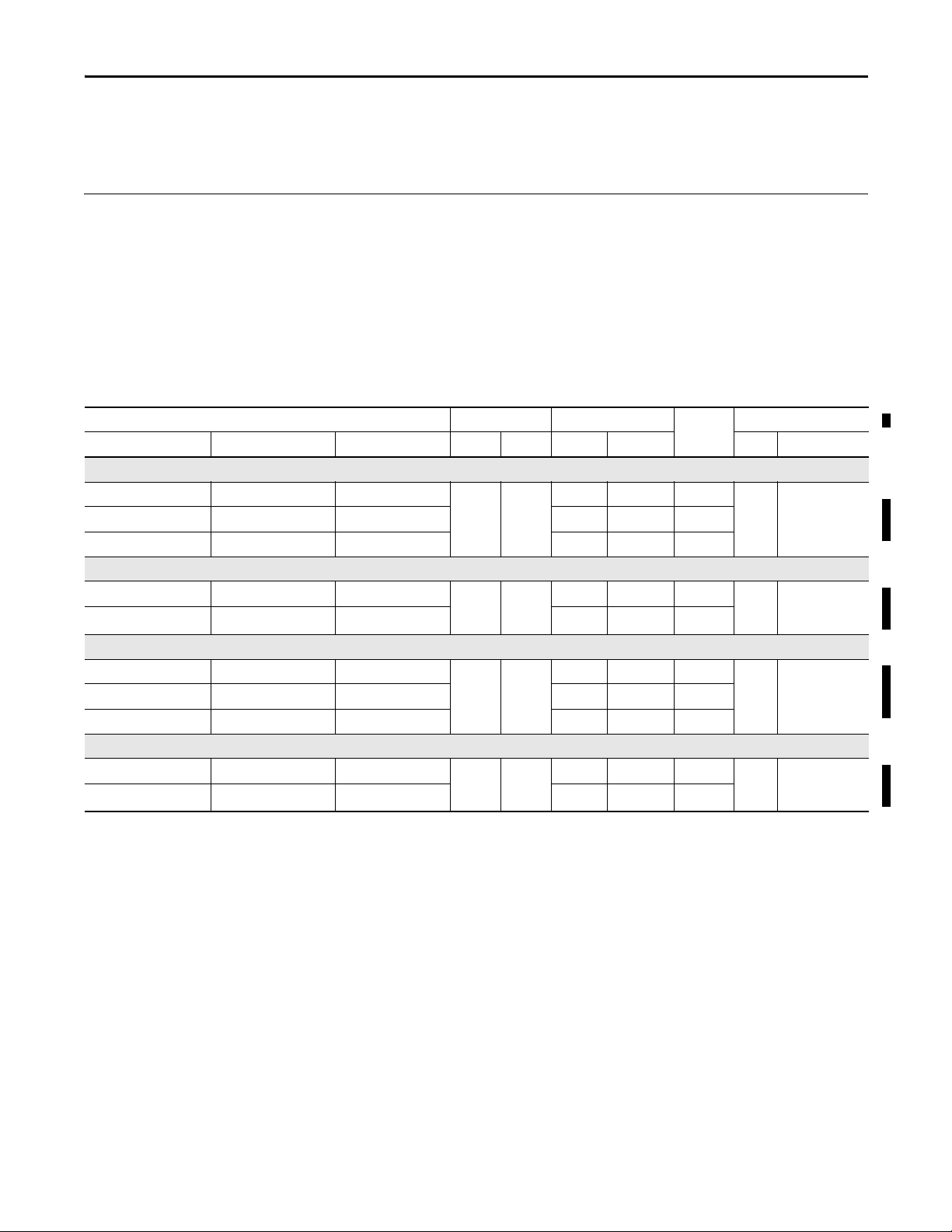

700 to 1500 Terminal

The table shows the catalog number breakdown for the 700 to 1500 terminals.

Selections

Bulletin Input Type Display Size Display Type Communication

|| || | | | |

2711P- K = Keypad 7 = 6.5 in. C = Color 4 = Ethernet, RS-232 & (2) USB A = AC 8= Windows CE 6.0 K = Conf ormal-Coated

T = Touch 10 = 10.4 in. D = DC 9 = Windows CE 6.0 with

B = Keypad/Touch 12 = 12.1 in.

15 = 15 in.

(1) Optional communication mo dules are available as separate catalog numbers.

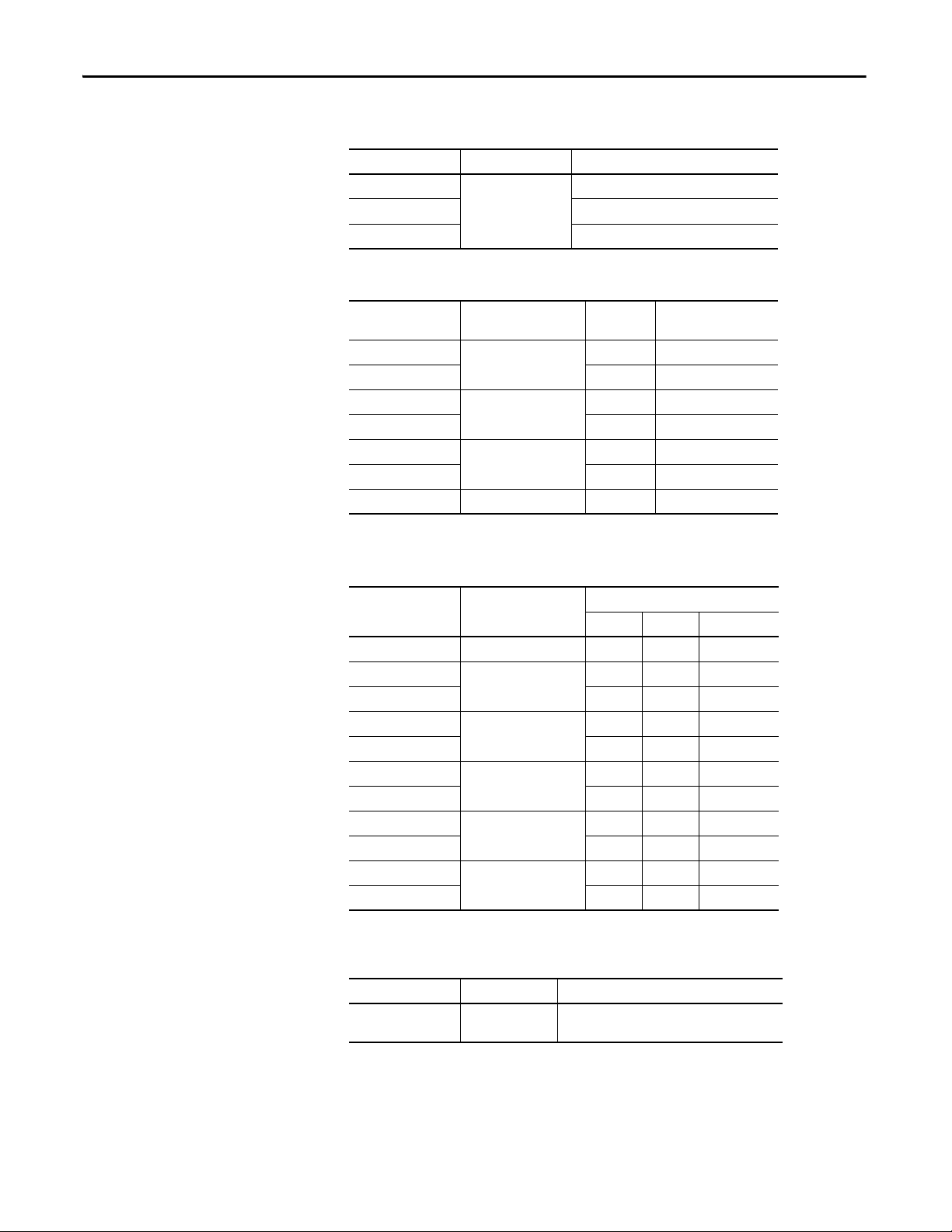

Table 13 - PanelView Plus 6 - 700 to 1500 Terminals without Extended Features

Cat. No. Display Communication

Keypad Touch Keypad/Touch Size Type RS-232 Ethernet RAM Nonvolatile

700 Model

2711P-K7C4D8 2711P-T7C4D8 2711P-B7C4D8 6.5-in. Color ••DC

– 2711P-T7C4D8K – ••DC

2711P-K7C4A8 2711P-T7C4A8 2711P-B7C4A8 ••AC

1000 Model

2711P-K10C4D8 2711P-T10C4D8 2711P-B10C4D8 10.4-in. Color ••DC

2711P-K10C4A8 2711P-T10C4A8 2711P-B10C4A8 ••AC

1250 Model

2711P-K12C4D8 2711P-T12C4D8 2711P-B12C4D8 12.1-in. Color ••DC

– 2711P-T12C4D8K – ••DC

2711P-K12C4A8 2711P-T12C4A8 2711P-B12C4A8 ••AC

1500 Model

2711P-K15C4D8 2711P-T15C4D8 2711P-B15C4D8 15-in. Color ••DC

2711P-K15C4A8 2711P-T15C4A8 2711P-B15C4A8 ••AC

(1)

Power Operating System Special Option

extended features

Input

Power

Memory (MB)

512

free user memory)

512

free user memory)

512

free user memory)

512

free user memory)

512

(approx. 79 MB

512

(approx. 79 MB

512

(approx. 79 MB

512

(approx. 79 MB

(1)

(1) The logic module supports FactoryTalk View Machine Edition software, version 6.0 or later, FactoryTalk ViewPoint software version 1.2 or later, and the Windows CE 6.0 operating system.

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 21

Page 22

Chapter 1 Overview

Table 14 - PanelView Plus 6 - 700 to 1500 Terminals with Extended Features

Cat. No. Display Communication

Keypad Touch Keypad/Touch Size Type RS-232 Ethernet RAM Nonvolatile

700 Model

2711P-K7C4D9 2711P-T7C4D9 2711P-B7C4D9 6.5-in. Color ••DC

2711P-K7C4A9 2711P-T7C4A9 2711P-B7C4A9 ••AC

1000 Model

2711P-K10C4D9 2711P-T10C4D9 2711P-B10C4D9 10.4-in Color ••DC

2711P-K10C4A9 2711P-T10C4A9 2711P-B10C4A9 ••AC

1250 Model

2711P-K12C4D9 2711P-T12C4D9 2711P-B12C4D9 12.1-in Color ••DC

2711P-K12C4A9 2711P-T12C4A9 2711P-B12C4A9 ••AC

1500 Model

2711P-K15C4D9 2711P-T15C4D9 2711P-B15C4D9 15-in. Color ••DC

2711P-K15C4A9 2711P-T15C4A9 2711P-B15C4A9 ••AC

Input

Power

Memory (MB)

512

512

512

512

(approx. 79 MB

free user memory)

(approx. 79 MB

free user memory)

(approx. 79 MB

free user memory)

(approx. 79 MB

free user memory)

(1)

512

512

512

512

(1) The logic module supports FactoryTalk View Machine Edition software, version 6.0 or later, FactoryTalk ViewPoint software version 1.2 or later, and the Windows CE 6.0 operating system with extended

features and file viewers.

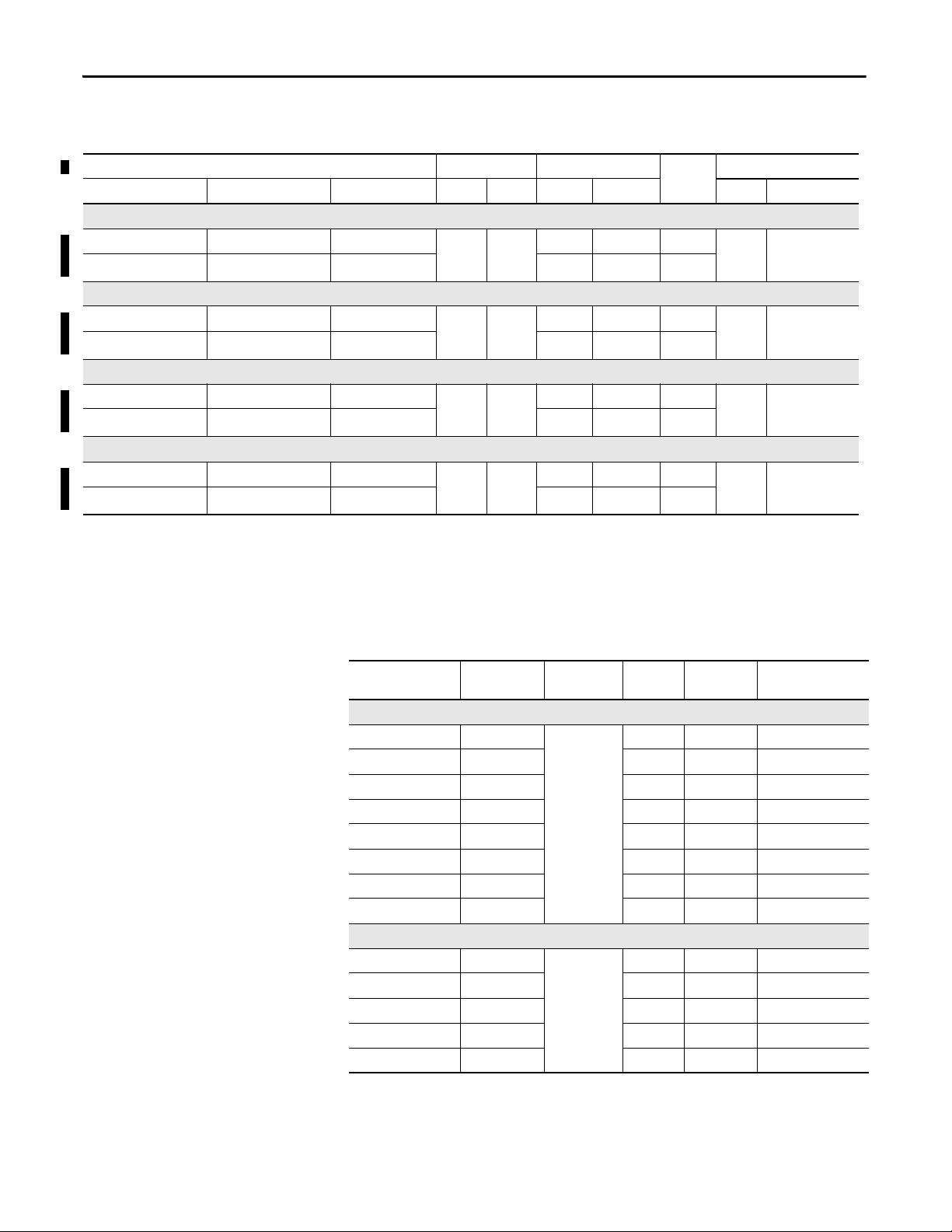

Accessories

Tables 15…28 list accessories for the PanelView Plus 6 terminals.

Table 15 - Display Modules - 700 to 1500 Terminals

Cat. No. Input Type Display Marine

Certified

700 Model

2711P-RDK7C Keypad 7-in. color

2711P-RDK7CK Keypad •

2711P-RDT7C Touch

2711P-RDT7CK Touch •

2711P-RDT7CM Touch •

2711P-RDB7C Keypad/Touch

2711P-RDB7CK Keypad/Touch •

2711P-RDB7CM Keypad/Touch •

1000 Model

2711P-RDK10C Keypad 10-4 in. color

2711P-RDT10C Touch

2711P-RDT10CM Touch •

2711P-RDB10C Keypad/Touch

2711P-RDB10CM Keypad/Touch •

Conformal

Coated

Built-in

Antiglare Overlay

22 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 23

Table 15 - Display Modules - 700 to 1500 Terminals

Overview Chapter 1

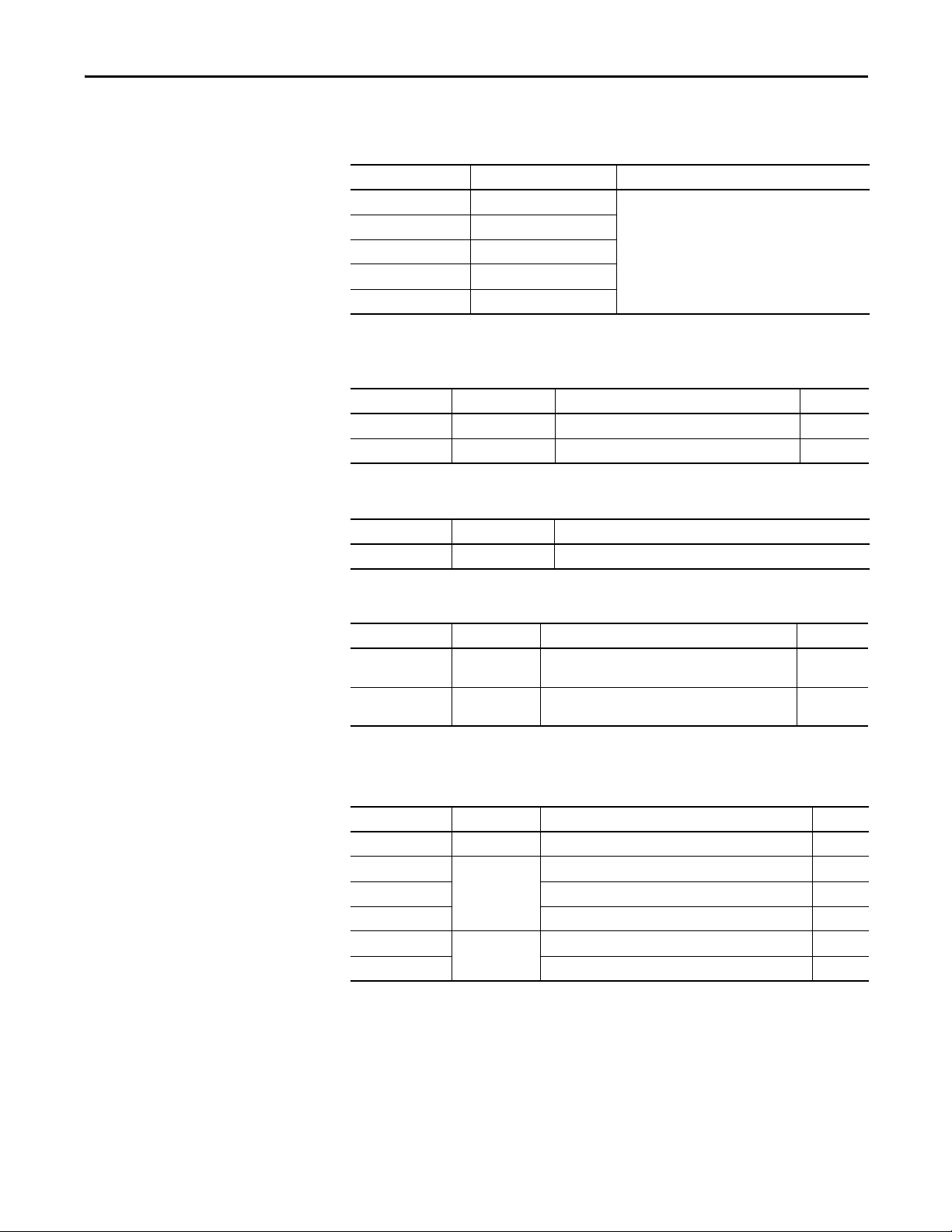

Table 16 - Logic Modules - 700 to 1500 Terminals

Cat. No. Input Type Display Marine

Certified

Conformal

Coated

Built-in

Antiglare Overlay

1250 Model

2711P-RDK12C Keypad 12.1-in. color

2711P-RDK12CK Keypad •

2711P-RDT12C Touch

2711P-RDT12CK Touch •

2711P-RDT12H

(1)

Keypad/Touch

2711P-RDT12AG Touch •

2711P-RDB12C Keypad/Touch

2711P-RDB12CK Keypad/Touch •

1500 Model

2711P-RDK15C Keypad 15-in. color

2711P-RDT15C Touch

2711P-RDT15AG Touch •

2711P-RDB15C Keypad/Touch

(1) H at end of cat. no. refers to 1250 High-bright display module.

Cat. No.

Power

Input

Memory

RAM/Nonvolatile

Communication

Marine

Certified

Conformal

Coated

Without Standard Features

2711P-RP8A AC

2711P-RP8D DC •

2711P-RP8DK DC ••

512 MB/512 MB

(approximately 79 MB

free user memory)

• Ethernet

• RS-232

• Network interface for

communication module

••Windows CE 6.0 operating system

• FactoryTalk View Machine Edition runtime,

version 6.0 or later

• FactoryTalk ViewPoint software,

version 1.2 or later

With Extended Features

2711P-RP9A AC

2711P-RP9D DC •

2711P-RP9DK DC ••

512 MB/512 MB

(approximately 79 MB

free user memory)

• Ethernet

• RS-232

• Network interface

communication module

••Windows CE 6.0 operating system

with extended features and file viewers

• FactoryTalk View Machine Edition runtime,

version 6.0 or later

• FactoryTalk ViewPoint software,

version 1.2 or later

Table 17 - Communication Modules - 700 to 1500 Terminals

Cat. No.

Ethernet DH+ DH-485 ControlNet

2711P-RN6 ••

2711P-RN6K •• •

2711P-RN15S ••

2711P-RN15SK ••

2711P-RN20

(1)

•

Communication

Included Software

Conformal

(2)

Coated

Marine

Certified

(1) All terminals have an Ethernet port. The cat. no. 2711P-RN20 module provides an additional Ethernet port.

(2) Scheduled and unscheduled communication.

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 23

Page 24

Chapter 1 Overview

Table 18 - Secure Digital (SD) Cards

Cat. No. Terminal Model Description

1784-SD1

1784-SD2 2 GB Secure Digital (SD) card

All terminals

2711C-RCSD USB to SD adapter for secure digit al card (SD)

1 GB Secure Digital (SD) card

700

(1)

Number of CCFL

Backlights

A and B 1

Table 19 - CCFL Backlight Replacements

Cat. No. Terminal Model Series

2711P-RL7C

2711P-RL7C2 C and D 1

2711P-RL10C

2711P-RL10C2 B and C 1

2711P-RL12C

2711P-RL12C2 C 1

1000

1250

A1

A and B 2

2711P-RL15C 1500 B 2

(1) These CCFL-backlight replacement catalog numbers do not apply to LED displays.

Table 20 - Antiglare Overlays

(1)

Cat. No.

Ter mina l Mo del

Keypad Touch Key/Touch

2711P-RGB4 400 grayscale or color • •

2711P-RGK6

600 grayscale or color

2711P-RGT6 •

2711P-RGK7

2711P-RGT7 •

2711P-RGK10

700 color

1000 color

2711P-RGT10 •

2711P-RGK12

2711P-RGT12 •

2711P-RGK15

2711P-RGT15 •

1250 color

1500 color

Operator Input

••

••

••

••

••

(1) Three overlays are shipped with each catalog number.

Table 21 - Solar Visor

Cat. No. Terminal Model Description

2711P-RVT12 1250 Solar visor for 1250 high-bright display module,

24 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

cat. no. 2711P-RDT12H

Page 25

Overview Chapter 1

Table 22 - Function Key Legend Kits

Cat. No. Terminal Model

2711P-RFK6 600 keypad

2711P-RFK7 700 keypad

2711P-RFK10 1000 keypad

2711P-RFK12 1250 keypad

2711P-RFK15 1500 keypad

(1) Applies to keyp ad and keypad/touch-screen termin als.

(1)

Description

Blank legend inserts and software

Table 23 - Mounting Hardware

Cat. No. Terminal Model Description Quantity

2711P-RTFC 400 or 600 Replacement mounting levers 8

2711P-RTMC 700 to 1500 Replacement Mounting clips 8

Table 24 - Replacement Battery

Cat. No. Terminal Model Description

2711P-RY2032 All terminals Replacement CR2032 coin-cell equivalent battery

Table 25 - Cables

Cat. No. Terminal Model Description Length

2711C-CBL-UU02

(1)

700 to 1500 Programming cable that connects the USB device port of

2 m (6.5 ft)

the terminal to a USB host port of a computer

6189V-USBCBL2 400 and 600 Programming cable that connects the USB device port of

1.8 m (6 ft)

the terminal to a USB host port of a computer

(1) Only for Series A terminals with a mini-USB port, type B.

Table 26 - Power Supply and Power Terminal Blocks

Cat. No. Terminal Model Description Quantity

2711P-RSACDIN All terminals DIN-rail power supply, AC-to-DC, 100…240V AC, 50…60 Hz 1

2711P-RVAC 400 and 600 AC power terminal block 10

2711P-6RSA AC module converts a DC-powered terminal to AC power 1

2711-TBDC DC power terminal block 10

2711P-RTBAC3 700 to 1500 AC power terminal block 10

2711P-RTBDC2 DC power terminal block 10

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 25

Page 26

Chapter 1 Overview

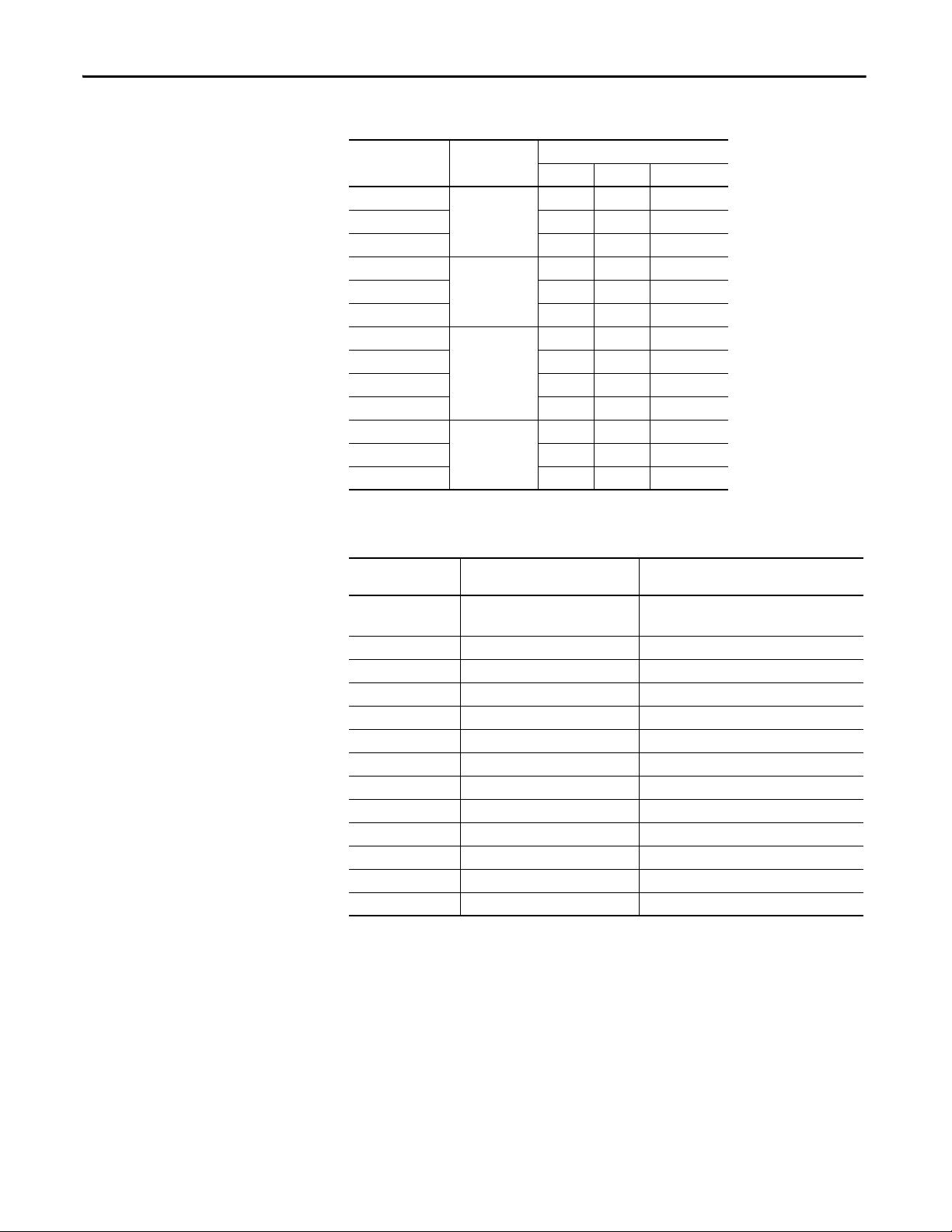

Table 27 - Bezel Replacements

Cat. No. Terminal Model

Keypad Touch Key/Touch

2711P-RBK7

2711P-RBT7 •

700

Operator Input

•

2711P-RBB7 •

2711P-RBK10

2711P-RBT10 •

1000

•

2711P-RBB10 •

2711P-RBK12

2711P-RBT12 •

2711P-RBT12H

(1)

1250

•

•

2711P-RBB12 •

2711P-RBK15

2711P-RBT15 •

1500

•

2711P-RBB15 •

(1) Applies to the cat. no. 2711P-RDT12H 1250 high-bright display module.

Table 28 - Adapter Plates

Cat. No.

2711P-RAK4 400 keypad or keypad/touch

600 touch

2711P-RAK6 600 keypad or keypad/touch PanelView Standard 600 keypad

2711P-RAK7 700 keypad or keypad/touch PanelView Standard 900 keypad

2711P-RAT7 700 touch PanelView Standard 900 touch

2711P-RAK10 1000 keypad or keypad/touch PanelView 1000/1000e keypad

2711P-RAT10 1000 touch PanelView 1000/1000e touch

2711P-RAK15 1500 keypad or keypad/touch PanelView 1200e/1400e keypad

2711P-RAT15 1500 touch PanelView 1200e/1400e touch

2711P-RAK12E 1250 keypad

2711P-RAT12E2 1250 touch

2711P-RAT12E 1250 touch

2711P-RAK12S 1250 keypad

2711P-RAT12S 1250 touch

Adapts This

PanelView Plus 6 Termin al

To Thi s Term ina l Cut out

PanelView Standard 550 keypad

(1)

(2)

(2)

(1)

or keypad/touch PanelView Standard 1400 keypad

(2)

PanelView 1200/1400e keypad

PanelView 1200 touch

PanelView 1200e/1400e touch

PanelView Standard 1400 touch

(1) Applies also to PanelView 1000/1000e keypad or keypad/touch terminals.

(2) Applies also to PanelView 1000/1000e touch terminals.

26 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 27

Install Terminal

Top ic Pa ge

Required Circuit Parameters for USB Peripheral Devices 29

Mounting Clearances 30

Panel Guidelines 30

Panel Cutout Dimensions 30

Remove and Install the Power Terminal Block 37

Mount the 400/600 Terminal in a Panel 33

Mount the 700 to 1500 Terminal in a Panel 35

Remove and Install the Power Terminal Block 37

DC Power Connections 38

AC Power Conn ection s 41

Initial Startup 43

Reset the Terminal 43

Chapter 2

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as defined

in IEC 60664-1), at altitudes up to 2000 m (6561 ft) without derating.

The terminals are intended for use with programmable logic controllers. Terminals that are AC powered must be connected to the

secondary of an isolating transformer.

This equipment is considered Group 1, Class A industrial equipment according to IEC CISPR 11. Without appropriate precautions, there

may be difficulties with electromagnetic compatibility in residential and other environments due to conducted or radiated

disturbances.

Korean Radio Wave Suitability Registration - When so marked this equipment is registered for Electromagnetic Conformity

Registration as business equipment (A), not home equipment. Sellers or users are required to take caution in this regard.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be accessible only by the use of a tool. The terminals meet specified

NEMA, UL type, and IEC ratings only when mounted in a panel or enclosure with the equivalent rating. Subsequent sections of this

publication may contain additional information regarding specific enclosure type ratings that are required to comply with certain

product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

, for additional installation requirements

• NEMA Standards 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by different

types of enclosure

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 27

Page 28

Chapter 2 Install Terminal

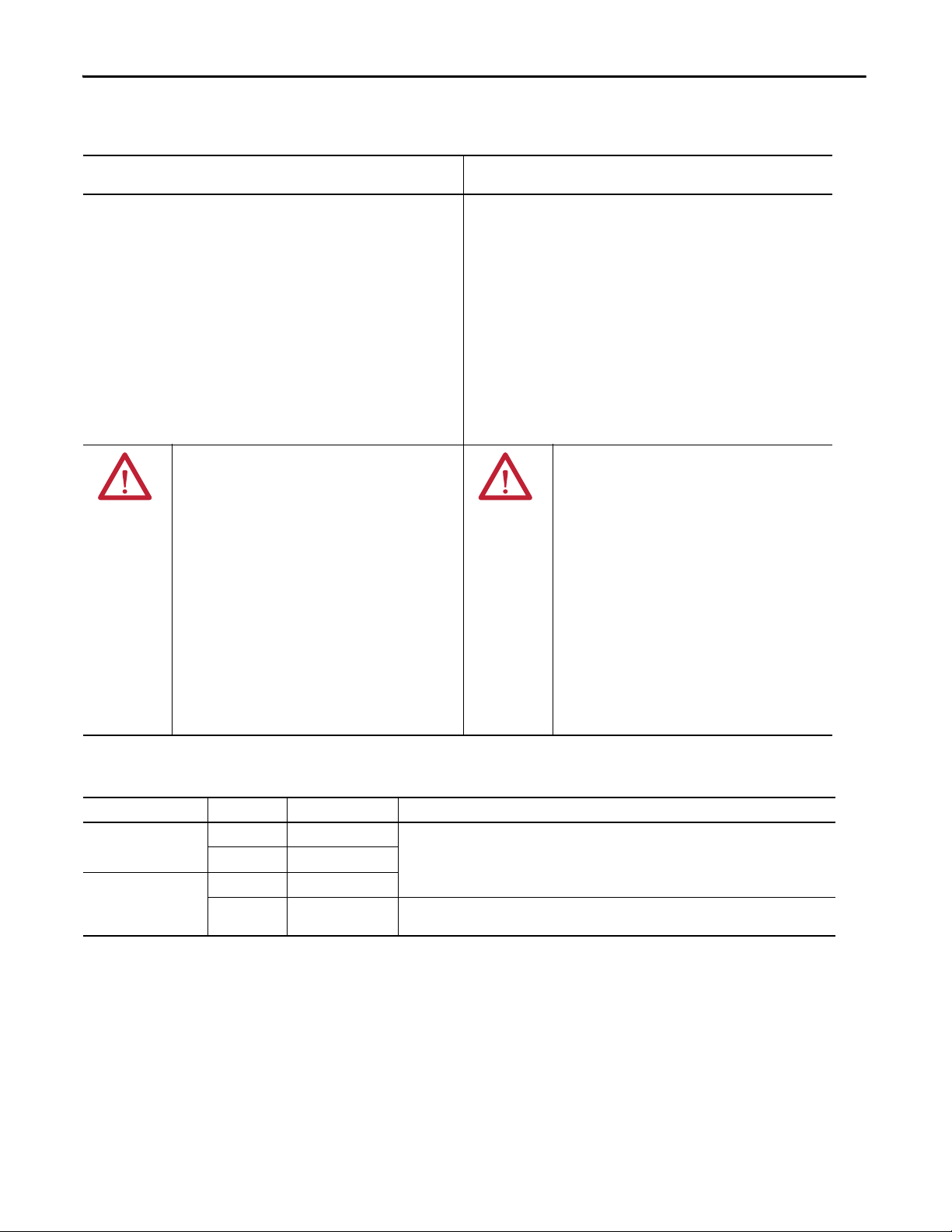

North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations.

When marked, these products are suitable for use in "Class I,

Division 2, Groups A, B, C, D"; Class I, Zone 2, Group IIC, Class II,

Division II, Groups F, G; Class III hazardous locations and

nonhazardous locations only. Each product is supplied with

markings on the rating nameplate indicating the hazardous

location temperature code. When combining products within a

system, the most adverse temperature code (lowest "T" number)

may be used to help determine the overall temperature code of the

system. Combinations of equipment in your system are subject to

investigation by the local Authority Having Jurisdiction at the time

of installation.

WARNING: EXPLOSION HAZARD

• Do not disconnect equipment unless power has been removed

or the area is known to be nonhazardous.

• Do not disconnect connections to this equipment unless

power has been removed or the area is known to be

nonhazardous.

• Substitution of components may impair suitability for Class I,

Division 2.

• Peripheral equipment must be suitable for the location in

which it is used.

• The battery or real-time clock module in this product must

only be changed in an area known to be nonhazardous.

• All wiring must be in accordance with Class I, Division 2, Class

II, Division 2, or Class III, Division 2 wiring methods of Articles

501, 502 or 503, as appropriate, of the National Electrical Code

and/or in accordance with Section 18-1J2 of the Canadian

Electrical Code, and in accordance with the authority having

jurisdiction.

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Lorqu'ils sont marqués, ces produits ne conviennent qu'à une

utilisation en environnements Classe I, Division 2, Groupes A, B, C

et D ; Cla sse I, Zone 2, Groupe IIC, Classe II, Divisio n II, Gro upes F et

G ; Classe III, dangereux ou non dangereux. Chaque produit est

livré avec des marquages sur sa plaque d'identification qui

indiquent le code de température pour les environnements

dangereux. Lorsque plusieurs produits sont combinés dans un

système, le code de température le plus défavorable (code " T " le

plus faible) peut être utilisé pour déterminer le code de

température global du système. Les combinaisons d'équipements

dans le système sont sujettes à inspection par les autorités locales

qualifiées au moment de l'installation.

AVERTISSEMENT : RISQUE D’EXPLOSION

• Couper le courant ou s'assurer que l'environnement est

classé non dangereux avant de débrancher l'équipement.

• Couper le courant ou s'assurer que l'environnement est

classé non dangereux avant de débrancher les connecteurs.

• La substitution de composants peut rendre cet équipement

inadapté à une utilisation en environnement de Classe I,

Division 2

• Les équipements périphériques doivent s'adapter à

l'environnement dans lequel ils sont utilisés.

• La batterie ou le module de l'horloge en temps réel de ce

produit doit être changé(e) uniquement dans un

environnement classé sans risque.

• Tous les systèmes de câblage doivent être de Classe I,

Division 2, Classe II, Division 2, ou Classe III, Division 2,

conformément aux méthodes de câblage indiquées dans

les Articles 501, 502 ou 503 du National Electrical Code

(Code Electrique National) et/ou conformément à la Section

18-1J2 du Canadian Electrical Code (Code Electrique

Canadien), et en fonction de l'autorité de jurisdiction.

Table 29 - Temperature Codes - PanelView Plus 6 Terminals

Terminal Model Input Power Temperature Code Description

400 and 600 terminals DC T4 Do not install terminals rated T4 in environments where atmospheric gases have ignition

AC T4

700 to 1500 terminals DC T4

AC T3 Do not install terminals rated T3 in environments where atmospheric gases have ignition

28 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

temperatures less than 135 °C (275 °F).

temperatures less than 200 °C (392 °F).

Page 29

Install Terminal Chapter 2

Nonincendive

Field-Wiring Apparatus

Associated Nonincendive Field-wiring Apparatus

PanelView Plus 6 Host Product

USB Peripheral Device

USB Peripheral Device

USB Host Port

USB Host Port

Required Circuit Parameters for USB Peripheral Devices

The terminals contain one or two USB host ports that comply with hazardous location environments. Field-wiring

compliance requirements are provided in compliance with the National Electrical Code, Article 500.

Figure 4 - PanelView Plus 6 Terminals Control Drawing

PanelView Plus 6 terminals provide one or two separately-powered USB host ports. Ta b l e 3 0 defines the circuit parameters

of the USB host ports.

Table 30 - Circuit Parameters for USB Host Ports

Parameter Value Parameter Definition

V

I

sc (USB)

C

a (USB)

L

a (USB)

oc (USB)

5.25V DC Open circuit voltage of the host USB port.

The maximum applied voltage rating, V

or equal to V

1.68 A Maximum output current of the host USB port.

The maximum current, I

greater than or equal to I

10 μF This value is the maximum total capacitance that can be connected to the USB host port. The total

capacitance of the USB peripheral device and its associated cable must not exceed the indicated value.

The maximum total capacitance, C

must be less that or equal to C

15 μH This value is the maximum total inductance that can be connected to the USB host port. The total

inductance of the USB peripheral device and its associated cable must not exceed the indicated value.

The maximum total inductance, L

must be less than or equal to L

oc (USB)

.

max (peripheral)

sc (USB).

max (peripheral)

, to which each USB peripheral device can be subjected must be

i (peripheral)

.

a (USB)

i (peripheral)

.

a (USB)

, of the USB peripheral device must be greater than

, and cable capacitance of the separate USB peripheral device

, and cable inductance of the separate USB peripheral device

V

max (peripheral)

as appropriate

I

max (peripheral)

C

i (peripheral)

L

i (peripheral)

+ C

+ L

≥ V

oc (USB)

≥ I

sc (USB)

cable(USB)

cable

≤ L

,

≤ C

a (USB)

a (USB)

Application Information

Per the National Electrical Code, the circuit parameters of associated field-wiring apparatus for use in hazardous locations

must be coordinated with the host product such that their combination remains nonincendive. PanelView Plus 6 terminals

and the USB peripheral devices must be treated in this manner.

The USB peripheral devices and their associated cabling must have circuit parameters with the limits given in Ta b l e 3 0

them to remain nonincendive when used with the PanelView Plus 6 USB host port.

If cable capacitance and inductance are not known, use the following values from ANSI/ISA-RP 12.06.01-2003:

C

= 197 pF/m (60 pF/ft)

cable

L

= 0.7 μH/m (0.20 μH/ft)

cable

Nonincendive field-wiring must be wired and separated in accordance with 501.10(B)(3) of the National Electrical Code

(NEC) ANSI/NFPA 70 or other local codes as applicable. This associated nonincendive field-wiring apparatus has not

been evaluated for use in combination with another associated nonincendive field-wiring apparatus.

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 29

for

Page 30

Chapter 2 Install Terminal

Mounting Clearances

Panel Guidelines

Plan for adequate space around the terminal, inside the enclosure, for ventilation

and connections. Consider heat produced by other devices in the enclosure. The

ambient temperature around the terminal must be 0…55 °C (32…131 °F).

Table 31 - Minimum Required Clearances

Product Area Minimum Clearance

Top 51 mm (2 in.)

Bottom 102 mm (4 in.)

Side 25 mm (1 in.)

Back 0 mm (0 in.)

A clearance of 102 mm (4 in.) is sufficient on the side of the terminal to insert

and remove an SD card, and on the bottom of terminal for connections.

The terminals are panel-mounted devices intended to mount in the door or wall

of a NEMA rated, UL Type rated, or IP rated enclosure:

• Supporting panels must have a mounting thickness of 1.5…4.8 mm

(0.060…0.188 in.).

• The material strength and stiffness of the panel must be sufficient to hold

the terminal and maintain an appropriate seal against water and dust.

• The panel surface must be flat and free of imperfections to maintain an

adequate seal and NEMA and UL Type ratings.

Panel Cutout Dimensions

Use the full size template shipped with your terminal to mark the panel cutout

dimensions.

Table 32 - Panel Cutout Dimensions

Terminal Input Type Height, mm (in.) Width, mm (in.)

400 Keypad or keypad/touch 123 (4.86) 156 (6.15)

600

700

1000

1250

1500

(1) Also applies to high-bright display module, cat. no. 2711P-RDT12H.

Keypad or keypad/touch 142 (5.61) 241 (9.50)

Touch 123 (4.86) 156 (6.15)

Keypad or keypad/touch 167 (6.57) 264 (10.39)

Touch 154 (6.08) 220 (8.67)

Keypad or keypad/touch 224 (8.8) 375 (14.75)

Touch 224 (8.8) 305 (12.00)

Keypad or keypad/touch 257 (10.11) 390 (15.35)

(1)

Tou c h

Keypad or keypad/touch 305 (12.00) 419 (16.50)

Touch 305 (12.00) 391 (15.40)

257 (10.11) 338 (13.29)

30 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 31

Install Terminal Chapter 2

a

b

c

d

a

b

d

c

1

6

1

6

6

1

a

b

c

d

Product Dimensions

Ta b l e 3 3 and Ta b l e 3 4 provide product dimensions for all PanelView Plus 6

terminals.

Figure 5 - PanelView Plus 6 - 400 Keypad or Keypad/Touch

Figure 6 - PanelView Plus 6 - 600 Touch

Figure 7 - PanelView Plus 6 - 600 Keypad or Keypad/Touch

F1

F6

F4F3 F5

F2

F9F8 F10

F7

Table 33 - PanelView Plus 6 - 400 and 600 Product Dimensions

Terminal Input Type

Height (a)

mm (in.)

Width (b)

mm (in.)

400 Keypad or keypad/touch 152 (6.0) 185 (7.28) 60 (2.35) 90 (3.54)

Keypad or keypad/touch 167 (6.58) 266 (10.47) 68 (2.68) 98 (3.86)

600

Touch 152 (6.0) 185 (7.28) 68 (2.68) 98 (3.86)

Depth (c)

mm (in.)

Depth (d) with AC module

mm (in.)

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 31

Page 32

Chapter 2 Install Terminal

d

c

d

c

a

a

b

b

The 700 to 1500 terminals look similar. The 1000 keypad and keypad/touch

terminals are shown for illustrative purposes.

Figure 8 - PanelView Plus 6 - 1000 Keypad, Keypad/Touch, Touch

Table 34 - PanelView Plus 6 - 700 to 1500 Terminal Dimensions

Terminal Input Type

700 Keypad or keypad/touch 193 (7.58) 290 (11.40) 55 (2.18) 83 (3.27)

Touch 179 (7.04) 246 (9.68) 55 (2.18) 83 (3.27)

1000 Keypad or keypad/touch 248 (9.77) 399 (15.72) 55 (2.18) 83 (3.27)

Touch 248 (9.77) 329 (12.97) 55 (2.18) 83 (3.27)

1250 Keypad or keypad/touch 282 (11.12) 416 (16.36) 55 (2.18) 83 (3.27)

Touch 282 (11.12) 363 (14.30) 55 (2.18) 83 (3.27)

Tou c h

(high-bright module)

1500 Keypad or keypad/touch 330 (12.97) 469 (18.46) 65 (2.55) 93 (3.65)

Touch 330 (12.97) 416 (16.37) 65 (2.55) 93 (3.65)

Height (a)

mm (in.)

282 (11.12) 363 (14.30) 74 (2.9) 101 (3.99)

Width (b)

mm (in.)

Depth (c)

Display to Logic Module

mm (in.)

Depth (d)

Display to Comm Module

mm (in.)

32 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 33

Install Terminal Chapter 2

6

1

1

2

3

4

5

6

Notch

Alignment Marks

Orientation of Slot Varies

Gasket

FAULT

COMM

FAULT

Mount the 400/600 Terminal in a Panel

The terminals were designed for single-person installation. No tools are required

except for those needed to make the panel cutout

Mounting levers secure the terminal to the panel. Four or six levers are required

depending on the terminal model. The levers insert into the mounting slots on

the top and bottom of the terminal.

Each mounting slot has six notches with alignment marks that are locking

positions for a lever. The thickness of the panel in which you mount the terminal

determines the locking position required to maintain the NEMA/UL Type seal.

Table 35 - Lever Locking Positions

Mounting Slot

Lever Lock

Position

1

2

3

4

5

6

Panel T hickness R ange

1.50…2.01 mm (0.060…0.079 in.) 16

2.03…2.64 mm (0.080…0.104 in.) 14

2.67…3.15 mm (0.105…0.124 in.) 12

3.17…3.66 mm (0.125…0.144 in.) 10

3.68…4.16 mm (0.145…0.164 in.) 8/9

4.19…4.80 mm (0.165…0.188 in.) 7

Typic al

Gauge

Follows these steps to mount the terminal in a panel.

ATT EN TI ON :

Disconnect all electrical power from the panel before making the panel cutout.

Make sure the area around the panel cutout is clear and that the panel is clean of

any debris, oil, or other chemicals.

Make sure metal cuttings do not enter any components already installed in the

panel and that the edges of the cutout have no burrs or sharp edges.

Failure to follow these warnings can result in personal injury or damage to panel

components.

1. Cut an opening in the panel by using the cutout template shipped with the

terminal or the cutout dimensions on page 30

.

2. Verify the sealing gasket is present on the terminal.

This gasket forms a compression type seal. Do not use sealing compounds.

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 33

Page 34

Chapter 2 Install Terminal

F1

F2

F4F3 F5

F6

F7

F9F8 F10

Flat Side of Lever

Mounting Slots

Mounting Levers

TIP

FAULT

COMM

FAULT

DEFAULT

RESET

Notch

Rotate lever until notch in lever aligns with

proper alignment mark on terminal.

Alignment Marks

6

1

1

3

4

2

1

35

4

62

3. Place the terminal in the panel cutout.

4. Insert all mounting levers into the mounting slots on the terminal.

Slide each lever until the flat side of the lever touches the panel surface.

5. When all levers are in place, slide each lever an additional notch or two

until you hear a click.

Refer to Table 35 on page 33

as a guide to determine the locking positions

for your panel thickness.

6. Rotate each lever in direction indicated until it is in the final position.

Levers rotate in same direction on top and bottom of terminal.

Follow the appropriate locking sequence for the optimal terminal fit.

FAULT

FAULT

COMM

DEFAULT

RESET

7. Inspect all levers to verify they are in the correct and same locked position.

ATTENTION: All levers must be locked to provide an adequate gasket

seal between the terminal and the panel. Rockwell Automation

assumes no responsibility for water or chemical damage to the terminal

or other equipment within the enclosure because of improper

34 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

installation.

Page 35

Install Terminal Chapter 2

IMPORTANT

Sealing Gasket

Mount the 700 to 1500 Terminal in a Panel

Mounting clips secure the 700 to 1500 terminals in a panel. The number of clips

varies by terminal size. Tools required for installation include panel cutout tools,

a small, slotted screwdriver, and a torque wrench for tightening the

mounting clips.

ATT EN TI ON :

Disconnect all electrical power from the panel before making the panel cutout.

Make sure the area around the panel cutout is clear and that the panel is clean of

any debris, oil, or other chemicals.

Make sure metal cuttings do not enter any components already installed in the

panel and that the edges of the cutout have no burrs or sharp edges.

Failure to follow these warnings can result in personal injury or damage to panel

components.

For outdoor installations using a high-bright display module, catalog number

2711P-RDT12H, refer to Appendix B on page 179

considerations.

Follow these steps to mount the terminal in a panel.

for important installation

1. Cut an opening in the panel by using the panel cutout template shipped

with the terminal or the cutout dimensions on page 30

2. Verify the terminal sealing gasket is properly positioned on the terminal.

This gasket forms a compression type seal. Do not use sealing compounds.

Be careful not to pinch the legend strip during installation.

.

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 35

Page 36

Chapter 2 Install Terminal

Mounting Clip Slot

Mounting Clip

1

2

3

4

5

6

7

8

Tor que Se que nce

6 Clips

246

513

Tor que S eq uen ce

4 Clips

14

3

2

Tor que Se que nce

8 Clips

3. Place the terminal in the panel cutout.

4. Slide the ends of the mounting clips into the slots on the terminal.

5. Tighten the mounting clip screws by hand until the gasket seal contacts the

mounting surface uniformly.

6. Tighten the mounting clips screws to a torque of 0.90…1.1 N•m

(8…10 lb•in) by using the specified sequence, making sure not to

overtighten.

ATT EN TI ON : Tighten the mounting clips to the specified torque to provide a

proper seal and to prevent damage to the product. Allen-Bradley assumes no

responsibility for water or chemical damage to the product or other equipment

within the enclosure because of improper installation.

36 Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017

Page 37

Install Terminal Chapter 2

Remove and Install the Power Terminal Block

The terminals are shipped with a power terminal block installed. You can remove

the terminal block for ease of installation, wiring, and maintenance.

WARNING: Explosion Hazard

If you connect or disconnect wiring while the power is on, an electrical arc can

occur. This could cause an explosion in hazardous location installations. Be sure

that power is removed and the area is nonhazardous before proceeding.

Failure to remove power can result in electrical shock or damage to the terminal.

The terminal blocks have different colors and markings for AC and DC power

connections. Always match the terminal block color to its mating connector. The

power terminal blocks are not intended for daisy chaining power.

Use a 0.6 x 3.5 mm flat blade screwdriver for terminal block wiring.

Table 36 - Wire Specifications for Power Input Terminal Block

Terminal Wire Type Dual-wire Size

400, 600

700 to 1500

(1) Two-wire max per terminal.

Stranded or solid

Cu 90 °C (194 °F)

0.3…1.3 mm

22…16 AWG

(1)

Single-wire Size Strip Length Screw Torque

2

0.3…2.1 mm

(22…14 AWG)

2

7 mm (0.28 in.)

0.45…0.56 N•m

(4…5 lb•in)

0.56 …0.90 N•m

(5…8 lb•in)

400 and 600 Terminals

Follow these steps to remove the terminal block from a 400 or 600 terminal.

1. Insert the tip of a small, flat-blade screwdriver into the terminal block

access slot.

2. Gently pry the terminal block to rotate it away from the terminal; this

releases the locking mechanism.

Follow these steps to replace the terminal block.

1. Press terminal block base in first with block leaning outward.

2. Gently push the top of the terminal block to rotate it into place; it snaps

when seated.

Rockwell Automation Publication 2711P-UM006E-EN-P - January 2017 37

Page 38

Chapter 2 Install Terminal

Three-position

AC Terminal Block

Two -p os it io n

DC Terminal Block

TIP

700 to 1500 Terminals

Follow these steps to remove the terminal block from a 700 to 1500 terminal.

1. Loosen the two screws that secure the terminal block.

2. Gently pull the terminal block away from the connector.

Follow these steps to install the terminal block.

1. Reattach the terminal block to the connector until seated.

2. Tighten the two screws that secure the terminal block to a torque of

0.40…0.51 N•m (3.5…4.5 lb•in).

DC Power Connections

Terminals with an integrated 24V DC power supply have these power ratings.

Table 37 - DC Power Ratings

Terminal Power Supply Input Voltage Power Consumption

400, 600 Nonisolated 24V DC nom (18…30V DC) 15 W max (0.6 A at 24V DC)

700 to 1500 Isolated 24V DC nom (18…32V DC) 70 W max (2.9 A at 24V DC)

The power supply is internally protected against reverse polarity. Connecting

DC+ or DC- to the earth/ground terminal can damage the device.

ATT EN TI ON : Applying an AC power source to a terminal with a DC power input

can damage the device.

External Power Supply

Use a dedicated 24V DC, safety extra-low voltage (SELV) or protective

extra-low voltage (PELV) power supply to power each PanelView Plus 6 device.