Allen-Bradley 3P-FCOVPD-B-FA, 23P-FCOVPD-B-FB, 23P-FC-RB200, 23P-FC-RB100, 23P-FC-RB300 Installation Instructions Manual

...Page 1

Installation Instructions

Original Instructions

PowerFlex DC Field Controller Overvoltage Protection Device

Catalog Numbers 23P-FCOVPD-B-FA, 23P-FCOVPD-B-FB, 23P-FCOVPD-D-FA, 23P-FCOVPD-D-FB, 23P-FC-RB100, 23P-FC-RB200, 23P-FC-RB300, 23P-FC-RB400,

23P-FC-RB500

Topi c Pag e

Product Advisories 2

Require d Tools an d Hardware 2

System Wiring Dia gram 2

Dampening Resistor 3

Optional External Discharge Resistor 3

Volt age Cla mp The rmost at 4

Voltage Clamp Nameplate Data 4

Product Dimensions and Weights 5

Minimum Mounting Clearances 8

Install the Voltage Clamp and Dampening Resistor 9

Additional Resources 11

The overvoltage protection device (voltage clamp) helps to provide protection against overvoltage for the PowerFlex® DC field controller when

used with a highly inductive load. An overvoltage can occur when the AC supply voltage is turned off before the field controller is disabled. The

resulting overvoltage can damage the field controller.

The voltage clamp (cat. no. 23P-FCOVPD-x-Fx) is composed of a pair of Silicon Controlled Rectifier (SCR) modules and a circuit board. The

circuit board detects the load voltage level. When a potentially damaging voltage level is detected, the voltage clamp activates the appropriate SCR,

based on the direct of current flow. The SCRs conduct the excess current and allow the resistance in the motor field to gradually decay. The voltage

clamp must not be used to discharge inductive loads routinely. The voltage clamp requires approximately 30 minutes to dissipate the energy from an

overvoltage condition before power can be reapplied to the device.

A dampening resistor (RB) must be installed in combination with the voltage clamp. The dampening resistor is required to dampen the overvoltage

that results from undershooting holding current when the voltage clamp SCR stops conduction. Dampening resistor kits (cat. no. 23P-FC-RBn00)

must be purchased separately. See Dampening Resistor on page 3

The voltage clamp enclosure is rated IP20 and the power terminals are rated IP00. The dampening resistor terminals are rated IP00. Therefore,

these devices must be enclosed in a protective enclosure or appropriate guards must be provided to help protect against an electric shock and/or

burn hazard.

for details.

Page 2

PowerFlex DC Field Controller Overvoltage Protection Device

U

V

W

C

D

PowerFlex DC

Field Controller

PE

RB

Voltage Clamp

C

D

RD

PE

L

RL

Load

Product Advisories

Qualified Personnel

ATT EN TI ON : Only qualified personnel familiar with DC drives, field controllers, motors and associated machinery should plan or implement the installation,

startup, and subsequent maintenance of the system. Failure to comply can result in personal injury and/or equipment damage.

Personal Safety

ATT EN TI ON : To avoid an electric shock hazard, verify that all power to the connected devices has been removed before you begin installation.

ATT EN TI ON : To avoid an electric shock hazard, the installer must provide guarding to shield exposed electrical equipment against accidental contact. Exposed

electrical components that carry potentially hazardous voltages are identified in this manual. When installing this equipment, consider the design and

placement of guarding to help prevent personal injury or equipment damage.

BURN HAZARD: Hot surfaces can cause severe burns. The dampening resistor assembly becomes hot during operation. To avoid a burn hazard, the installer

must provide guarding to shield exposed electrical equipment against accidental contact. After operation, allow time for the resistor assembly surfaces to cool

before you start maintenance.

Required Tools and Hardware

This table provides a list of customer-supplied tools and hardware that is required to install the voltage clamp.

Tools Hardware Hardware

Nut driver or torque wrench (10 mm, 13 mm, 15 mm).

Flat-nose and hexalobular screwdriver (T30).

M6 screws (8) for voltage clamp and dampening

resistor mounting.

M8 bolt and washer for voltage clamp ground (PE)

terminal.

M6 bolts and washers (2) for device cat. no. 23P-FCOVPD-B-FA and

23P-FCOVPD-D-FA power terminals (C, D).

M10 bolts and washers (2) for device cat. no. 23P-FCOVPD-B-FB and

23P-FCOVPD-D-FB power terminals (C, D).

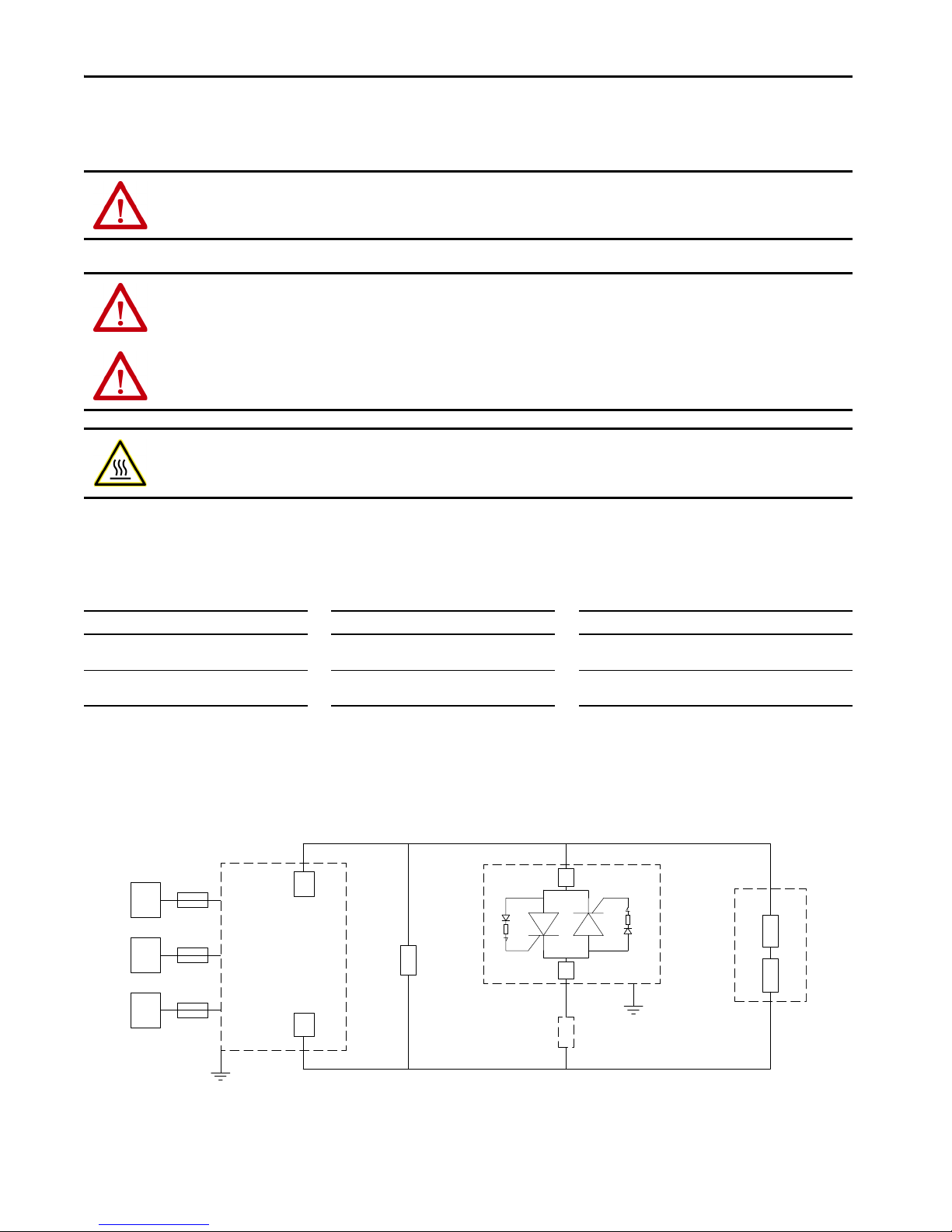

System Wiring Diagram

This diagram represents the recommended wiring configuration for a PowerFlex DC field controller, voltage clamp, required dampening resistor

(RB), and optional discharge resistor (RD).

2 Rockwell Automation Publication 23PFC-IN002A-EN-P - November 2018

Page 3

PowerFlex DC Field Controller Overvoltage Protection Device

Dampening Resistor

A dampening resistor (RB) must be installed with the voltage clamp to dampen the overvoltage that results from undershooting holding current

when the SCR stops conduction. Purchase and install the appropriate resistor kit that is listed in the Dampening Resistor (RB) Kits table, or use the

sizing information to install a customer-supplied resistor.

Dampening Resistor Sizing Calculations

The value of resistor RB is determined by the 500 mA SCR holding current at the rectified voltage value. The dielectric strength of resistor RB is at

least double the rectified voltage value and its power loss is two to three times (for margin) the power dissipation that is calculated, considering the

rectified nominal voltage of the load.

Size a customer-supplied discharge resistor (RB) as follows:

RB value = 1.35 * V_line / 500 mA

RB dielectric strength ≥ 2 * 1.35 * V_line

2

RB power = 2 * (V_load)

The available dampening resistor kits are shown in the Dampening Resistor (RB) Kits table. The resistor kits are sized with the value of resistor RB

as a function of V_line with a typical inductive load that is connected to the PowerFlex DC field controller. For most applications, the typical DC

output voltage is approximately 1.08 * V_line. By using the typical DC output voltage value as a guideline, the power dissipation value can be forced

to be a function of the AC input line voltage. Size a dampening resistor (RB) where V_load = 1.08 * V_line:

RB value = 1.35 V_line / 500 mA

RB dielectric strength ≥ 2 * 1.35 * V_line

RB power = 2 * (1.08 * V_line)

(RB power = 2 increases the power dissipation margin.)

/ RB

2

/ RB

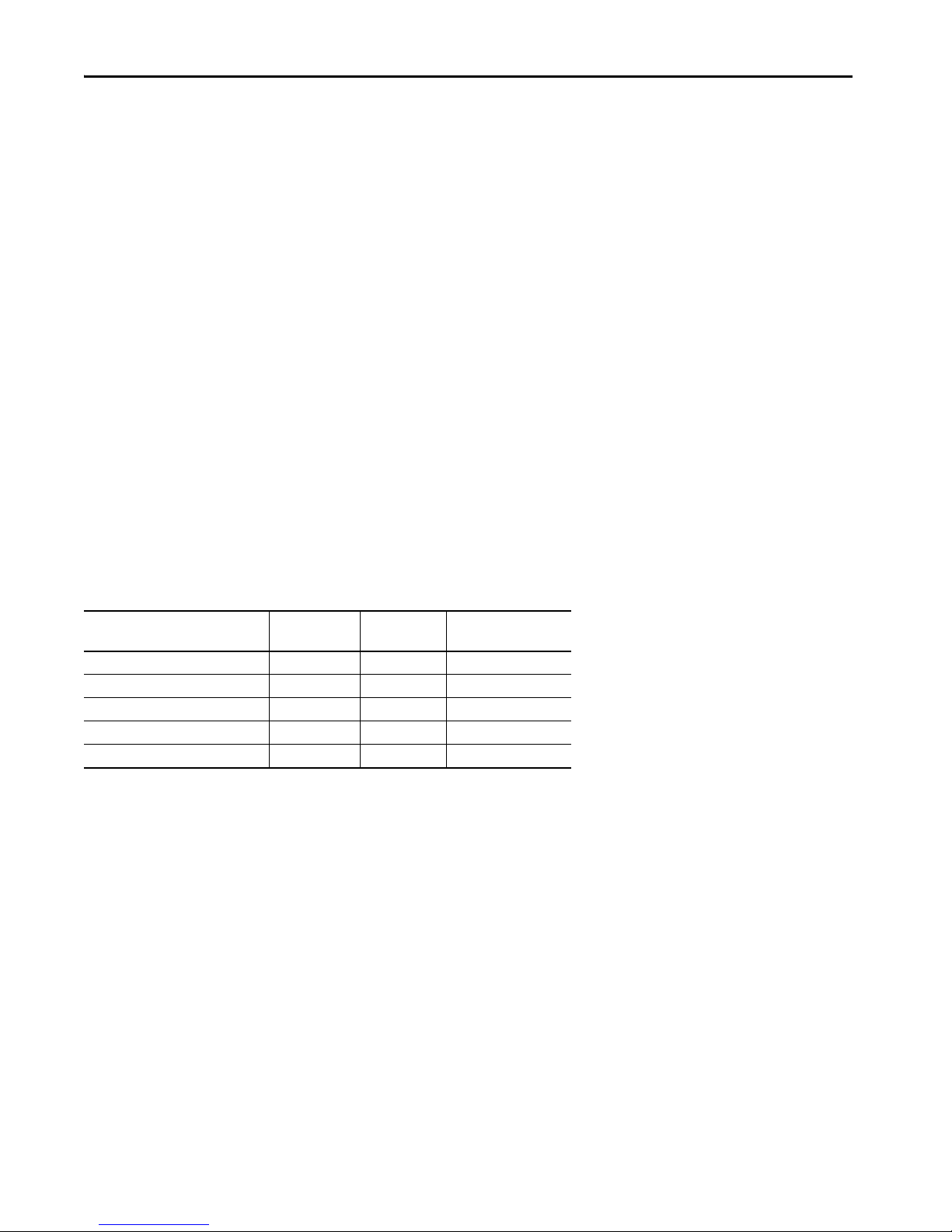

Dampening Resistor (RB) Kits

Field Controller AC Input Voltage Range

(Vrms)

60…100V 220 930 23P-FC-RB100

101…200V 390 930 23P-FC-RB200

201…300V 680 930 23P-FC-RB300

301…400V 1000 930 23P-FC-RB400

401…500V 1200 930 23P-FC-RB500

(1) Resistor kits are IP00 / Open Type and must be installed in an enclosure.

RB Resistor Value

Ohms

RB Resistor Size

Watts

RB Resistor Kit Cat. No.

(1)

Optional External Discharge Resistor

An external discharge resistor (RD) must be installed to reduce the load current discharge time if the load τ is greater than the rated operation time,

as calculated in the Calculate the Average Power Dissipation Value for Resistor RD section on page 4. The time constant for the load is calculated

as:

τ = L / R, where L is the load inductance and R is the internal resistance of the load

The addition of resistor RD decreases the discharge time constant: τ = L /(R + RD)

Optional External Discharge Resistor Calculations

Calculate the Resistance Value of Resistor RD

To calculate the resistance value of resistor RD, the inductance and resistance of the existing load must be known. The desired time constant of the

“updated circuit” is expressed as:

τ = L / (R + RD)

Solve for RD.

Rockwell Automation Publication 23PFC-IN002A-EN-P - November 2018 3

Page 4

PowerFlex DC Field Controller Overvoltage Protection Device

Cat No. 23P-FCOVPD-D-FA

UL Type OPEN/IP20

Rated Voltage : 600 VDC

Max rated current : 120A

MFD, in 2018 on week 20

制造于2018年,第20周

Product of Italy

Rockwell Automation, 1201 S. 2nd St., Milwaukee, WI 53204, USA

Serial Number:

J20A0001

*K20E0013*

IND. CONT.

LISTED

C

R

US

31KF

Series: A

25

Rated Operation Time : 60 sec Rated Recovery Time : 1800 sec

Calculate the Peak Power Rating Value for Resistor RD

Calculate the peak power rating value for RD in watts, where the initial current is equal to the load current.

RD_peak_Power = (I_load)

Solve for RD_peak_Power.

2

* RD

Calculate the Average Power Dissipation Value for Resistor RD

Calculate the average power dissipation for resistor RD.

The initial current, Io, of the discharge circuit is the load current. The load actually consists of an inductance and a resistance in series (though the

only visible object is the load coil).

During the current discharge, the energy that is stored in the magnetic field of the load inductance is dissipated in the internal load resistance and

the external optional added resistor RD.

E = Energy, Joules

P = Power, Watts (Joules/Second)

L = Inductance, Henrys

R = Resistance, Ohms

I = Current, amps

Io = Initial Current, amps

τ = Circuit Time Constant L/R, Seconds

2

E = ½ * L_load * Io

(The initial value of the energy stored load inductance)

τ = L / (RD + R_load)

P_rd = [E / 6 * τ] * [RD / (RD + R_load)]

P_rd = Average power dissipation of resistor RD over six time constants (discharge time of the circuit).

Solve for P_rd.

Voltage Clamp Thermostat

A thermal-trip interlock terminal block (TB1) is provided on the top of the voltage clamp. Use this terminal block to interlock the voltage clamp

with the field controller control circuit. The thermal trip circuit opens when the voltage clamp heat-sink temperature is too high. When the

thermostat is open, the field controller is disabled.

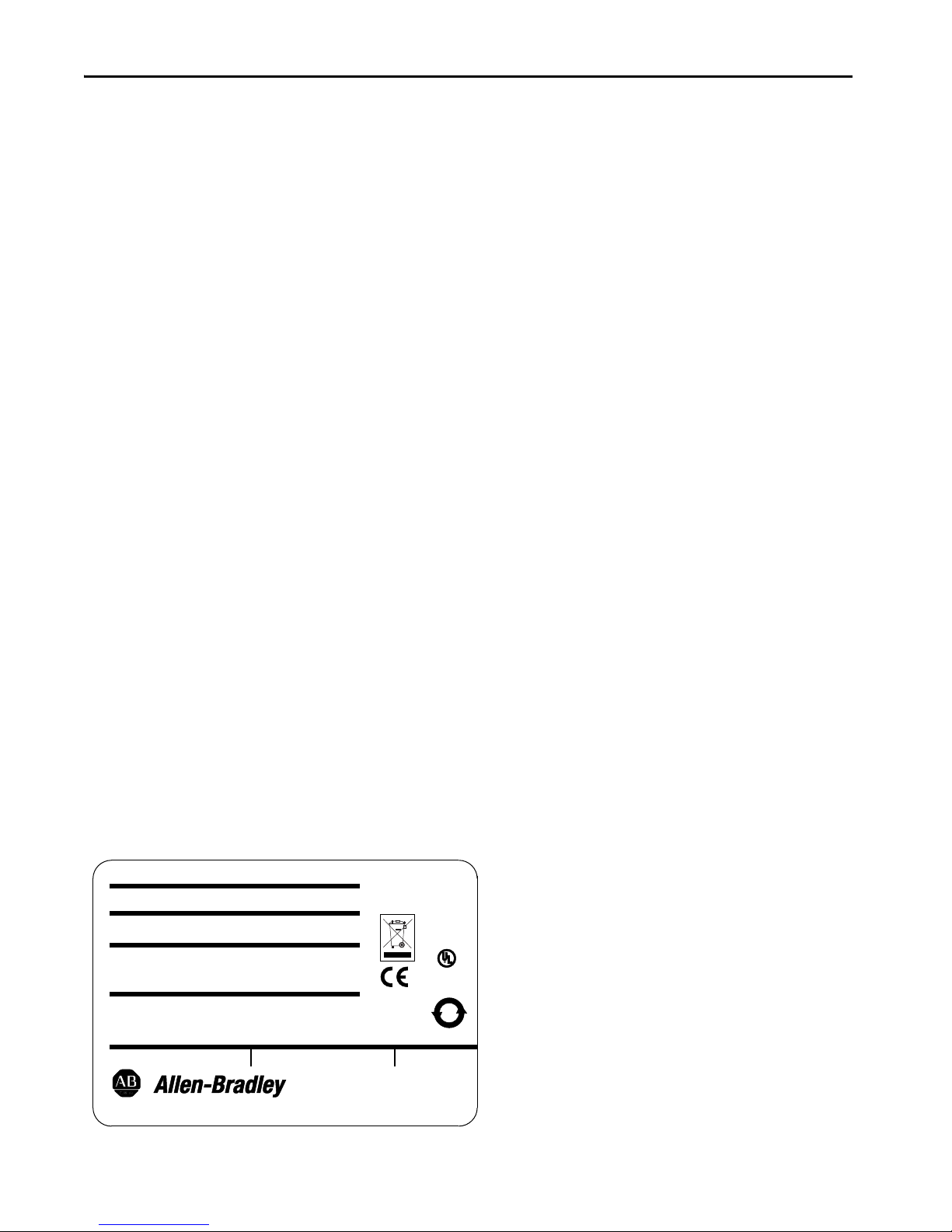

Voltage Clamp Nameplate Data

The voltage clamp contains a data nameplate label on the side of each module. This nameplate identifies the specific catalog number, serial number,

and applicable power data. Include this information when communicating with Rockwell Automation personnel about this product.

EXAMPLE ONLY

4 Rockwell Automation Publication 23PFC-IN002A-EN-P - November 2018

Page 5

PowerFlex DC Field Controller Overvoltage Protection Device

179.6 (7.1)

210 (8.3)

117 (4.6)

7 (0.3)

194 (7.6)

20

(0.8)

10

(0.4)

63.5

25

(1.0)

7 (0.27)

9 (0.35)

64

(2.52)

1.5

(0.06)

116

(4.56)

3 (0.12)

12.5 (0.5)

13

(0.5)

141 (5.6)

Dimensions are in millimeters and (inches)

Maximum weight 5.25 kg (11.6 lb)

Product Dimensions and Weights

These illustrations provide the approximate dimensions and weights for the voltage clamp and dampening resistor kits. Use these dimensions for

mounting these devices.

Voltage Clamp Catalog Numbers 23P-FCOVPD-B-FA and 23P-FCOVPD-D-FA

225 (8.9)

(2.5)

Rockwell Automation Publication 23PFC-IN002A-EN-P - November 2018 5

Page 6

PowerFlex DC Field Controller Overvoltage Protection Device

179.6 (7.1)

210 (8.3)

117 (4.6)

7 (0.3)

194 (7.6)

25

(1.0)

12.5

(0.5)

63.5

25

(1.0)

10.5 (0.4)

9 (0.35)

64

(2.52)

1.5

(0.06)

116

(4.56)

5 (0.2)

12.5 (0.5)

13

(0.5)

141 (5.6)

Dimensions are in millimeters and (inches)

Maximum weight 5.25 kg (11.6 lb)

Voltage Clamp Catalog Numbers 23P-FCOVPD-B-FB and 23P-FCOVPD-D-FB

225 (8.9)

(2.5)

6 Rockwell Automation Publication 23PFC-IN002A-EN-P - November 2018

Page 7

Dampening Resistor Dimensions

50 (2.0) 426 (16.8)

64 (2.5)

48 (1.9)

24 (0.9)

6.5 (0.3)

6.5 (0.26)

5.5 (0.2)

R7.0 (0.3)

102 (4.0)

124 (4.9)

115 (4.5)

120 (4.7)

526 (21.1)

502 (19.8)

(Name plate)

Dimensions are in millimeters and (inches)

Weig ht 3. 9 kg ( 8.6 lb )

PowerFlex DC Field Controller Overvoltage Protection Device

Rockwell Automation Publication 23PFC-IN002A-EN-P - November 2018 7

Page 8

PowerFlex DC Field Controller Overvoltage Protection Device

≥ 50 mm

(2.0 in.)

≥ 10 mm

(0.4 in.)

≥ 150 mm (6.0 in.)

≥ 150 mm (6.0 in.)

≥ 10 mm

(0.4 in.)

≥ 200 mm (7.9 in.)

≥ 200 mm (7.9 in.)

≥ 200 mm

(7.9 in.)

≥ 200 mm

(7.9 in.)

(Name plate)

(Name plate)

Minimum Mounting Clearances

The minimum clearances that are specified in this section must be provided to help avoid device overheating.

Voltage Clamp Clearances

Minimum clearance requirements for the voltage clamp are intended to be from device to device. Other objects can occupy this space; however,

reduced airflow can cause the voltage clamp to overheat. Air circulation through the device must not be impeded. The voltage clamp assembly must

be mounted in a vertical orientation (as shown here).

Dampening Resistor Clearances

Minimum clearance requirements for the dampening resistor are intended to be from device to device. The resistor assembly can be mounted

horizontally, or vertically. When mounted vertically, the terminal block must be below the resistor assembly (as shown here).

8 Rockwell Automation Publication 23PFC-IN002A-EN-P - November 2018

Page 9

PowerFlex DC Field Controller Overvoltage Protection Device

L2 L3

O

I

Install the Voltage Clamp and Dampening Resistor

Follow these steps to install the voltage clamp and dampening resistor with a PowerFlex DC field controller.

Remove Power from the PowerFlex DC Field Controller

ATTENTION: Remove power before making or breaking cable connections. When you remove or insert a cable connector with power applied, an electric arc can

occur. An electric arc can cause personal injury or property damage by:

• sending an erroneous signal to your system field devices, causing unintended machine motion

• causing an explosion in a hazardous environment

Electrical arcing causes excessive wear to contacts on both a module and its mating connector. Worn contacts can create electrical resistance.

• Remove and lockout all incoming power to the field controller and any connected devices.

L1

Mount the Voltage Clamp

The voltage clamp maximum weight is 5.25 kg (11.6 lb). Follow the steps to mount the voltage clamp.

IMPORTANT Mount the voltage clamp as close as possible to the PowerFlex DC field controller. The minimum clearances must be met (see Minimum Mounting

Clearances on page 8

1. Mark and verify the hole pattern on the panel on which you intend to mount the voltage clamp. See page 5

2. Partially install the lower M6 mounting screws into the mounting panel.

3. Lift the voltage clamp onto the screws that are installed in the panel.

4. Install the remaining screws into the panel and tighten all hardware to 7 N•m (62 lb•in).

for details).

or page 6 for dimensions.

Mount the Dampening Resistor

The dampening resistor weighs 3.9 kg (8.6 lb). Follow the steps to mount the dampening resistor.

1. Mark and verify the hole pattern on the panel on which you intend to mount the dampening resistor. See page 7

2. Partially install the four M6 mounting screws into the mounting panel.

3. Lift the dampening resistor assembly onto the screws that are installed in the panel.

4. Tighten all hardware to 7 N•m (62 lb•in).

for dimensions.

Rockwell Automation Publication 23PFC-IN002A-EN-P - November 2018 9

Page 10

PowerFlex DC Field Controller Overvoltage Protection Device

C

D

PE

Thermostat Terminal

Block (TB1)

Wire the Voltage Clamp

Use the information in this section and the System Wiring Diagram on page 2 to wire the power and ground (PE) connections on the voltage clamp.

Voltage Clamp Power, Ground, and Thermostat Terminal Identification

Voltage Clamp Power and Ground (PE) Terminal Specifications

Terminal Description Wire Size Cat. No. Terminal Bolt Size

23P-FCOVPD-B-FA,

C, D DC Power connections

PE Safety ground All M8 15 N•m (132.7 lb•in)

Same as the connected

PowerF lex DC fi eld cont roller.

23P-FCOVPD-D-FA

23P-FCOVPD-B-FB,

23P-FCOVPD-D-FB

M6 7 N•m (62 lb•in)

M10 25 N•m (221.2 lb•in)

Recommended

Torq ue

Voltage Clamp Thermostat Terminal Block and Wire Specifications

Wire Size

Term ina l

1

2

Flexible / Multi-core

2

)

(mm

0.14…1.5 26…14 0.5 N•m (4.4 lb•in)

AWG

Recommended Torque

Wire the Dampening Resistor

Use the information in this table and the System Wiring Diagram on page 2 to wire the dampening resistor.

Dampening Resistor Terminal Block and Wire Specifications

Terminals Description Wire Size Wire Strip Length

Power connection from voltage clamp terminals C and D. 14 AWG 2.5 mm

2

12 mm (0.5 in.) 600V, 80 °C (176 °F)

Minimum Wire Insulation

Rating

Recommended Terminal

Tor que

1.5…1.8 N•m (0.6…0.7

lb•in)

10 Rockwell Automation Publication 23PFC-IN002A-EN-P - November 2018

Page 11

PowerFlex DC Field Controller Overvoltage Protection Device

Voltage Clamp Ratings

Cat. No. 23P-FCOVPD-B-FA 23P-FCOVPD-B-FB 23P-FCOVPD-D-FA 23P-FCOVPD-D-FB

Maximum rated supply system voltage (VAC) 200 200 500 500

Maximum rated load system current (A DC) 120 570 120 570

Thyristor module (or equivalent) SKKT132/16E MCC501-16io2 SKKT132/16E MCC501-16io2

Rated operation time (s) 60

Rated recovery time (s) 1800

Operation ambient temperature - °C (°F) 0…50 (32…122)

Transportation and storage temperature - °C (°F) -25…+55 (13…131)

Degree of protection IP20; except power terminals - IP00

Overvoltage catego ry III

Pollu tion de gree 2

Installation altitude above sea level (m) ≤ 1000

Thermal protection temperature threshold - °C (°F) 70 (158)

Thermal protection ratings (max.) 250V, 2 A

Weight - kg (lb) 3.7 (8.2) 5.25 (11.6) 3.7 (8.2) 5.25 (11.6)

Additional Resources

These documents contain additional information concerning related products from Rockwell Automation.

Resource Description

PowerFlex DC Field Controller Installation Instructions, publication 23PFC-IN001

PowerFlex DC Field Controller Programming Manual, publication 23PFC-PM001

PowerFlex DC Drive Technical Data, publication 20P-TD001

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Product Certifications website,

http://www.rockwellautomation.com/global/certification/overview.page

Provides general guidelines for installing a Rockwell Automation® industrial system.

You can view or download publications at http://www.rockwellautomation.com/global/literature-library/overview.page

technical documentation, contact your local Allen-Bradley distributor or Rockwell Automation sales representative.

Provides installation instructions for the PowerFlex DC Field Controller.

Provides information on how to start up, program, and troubleshoot the PowerFlex DC Field

Control ler.

Provides detailed information on:

• Basic product selection

• Field controller specifications

• Option specifications

• Circuit protection

Provides declarations of conformity, certificates, and other certification details.

. To order paper copies of

Rockwell Automation Publication 23PFC-IN002A-EN-P - November 2018 11

Page 12

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

1S7A92

At the end of its life, this equipment should be collected separately from any unsorted municipal waste.

Rockwell Automation Support

Use the following resources to access support information.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document, complete the

How Are We Doing? form at http://literature.rockwellautomation.com/idc/groups/literature/documents/du/ra-du002_-en-e.pdf

.

Technical Support Center

Knowledgebase Articles, How-to Videos, FAQs, Chat, User

Forums, and Product Notification Updates.

https://rockwellautomation.custhelp.com/

Local Technical Support Phone Numbers Locate the phone number for your country. http://www.rockwellautomation.com/global/support/get-support-now.page

Direct Dial Codes

Find the Direct Dial Code for your product. Use the code to

route your call directly to a technical support engineer.

http://www.rockwellautomation.com/global/support/direct-dial.page

Literature Library

Installation Instructions, Manuals, Brochures, and

Technical Data.

http://www.rockwellautomation.com/global/literature-library/overview.page

Product Compatibility and Download

Center (PCDC)

Get help determining how products interact, check

features and capabilities, and find associated firmware.

http://www.rockwellautomation.com/global/support/pcdc.page

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page

Allen-Bradley, PowerFlex, Rockwell Automation, and Rockwell Software are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

.

Publication 23PFC-IN002A-EN-P - November 2018

Copyright © 2018 Rockwell Automation, Inc. All rights reserved. Printed in U.S.A.

Loading...

Loading...