Allen-Bradley 22A-A2P3N104, 22A-V1P5N104, 22A-A4P5N104, 22A-V4P5N104, 22A-A8P0N104 Quick Start Manual

...Page 1

Quick Start

PowerFlex 4 Adjustable

Frequency AC Drive

FRN 2.xx

This Quick Start guide summarizes the basic steps needed to install,

start-up and program the PowerFlex 4 Adjustable Frequency AC Drive.

The information provided Does Not

intended for qualified drive service personnel only.

For detailed PowerFlex 4 information including EMC instructions,

application considerations and related precautions refer to the

PowerFlex 4

supplied with the drive or at

User Manual

, Publication 22A-UM001x on the CD

www.ab.com/manuals/dr.

General Precautions

replace the User Manual and is

ATTENTION:

time to discharge after removal of mains supply. Before working on

!

drive, ensure isolation of mains supply from line inputs [R, S, T (L1,

L2, L3)]. Wait three minutes for capacitors to discharge to safe voltage

levels. Failure to do so may result in personal injury or death.

Darkened display LEDs is not an indication that capacitors have

discharged to safe voltage levels.

ATTENTION:

if this parameter (A092 [Auto Rstrt Tries], A094 [Start At PowerUp]) is

!

used in an inappropriate application. Do not use this function without

considering applicable local, national and international codes,

standards, regulations or industry guidelines.

ATTENTION:

frequency AC drives and associated machinery should plan or

!

implement the installation, start-up and subsequent maintenance of the

system. Failure to comply may result in personal injury and/or

equipment damage.

ATTENTION:

sensitive parts and assemblies. Static control precautions are required

!

when installing, testing, servicing or repairing this assembly.

Component damage may result if ESD control procedures are not

followed. If you are not familiar with static control procedures,

reference A-B publication 8000-4.5.2, “Guarding Against Electrostatic

Damage” or any other applicable ESD protection handbook.

The drive contains high voltage capacitors which take

Equipment damage and/or personal injury may result

Only qualified personnel familiar with adjustable

This drive contains ESD (Electrostatic Discharge)

ATTENTION:

component damage or a reduction in product life. Wiring or application

!

errors, such as, undersizing the motor, incorrect or inadequate AC

supply, or excessive ambient temperatures may result in malfunction of

the system.

An incorrectly applied or installed drive can result in

Page 2

English-2

Mounting Considerations

•

Mount the drive upright on a flat, vertical and level surface.

–

Install on 35 mm DIN Rail.

or

–

Install with screws.

Minimum Panel Thickness Screw Size Mounting Torque

1.9 mm (0.0747 in.) m4 x 0.7 (#8-32) 1.56-1.96 Nm (14-17 lb.-in.)

•

Protect the cooling fan by avoiding dust or metallic particles.

•

Do not expose to a corrosive atmosphere.

•

Protect from moisture and direct sunlight.

Minimum Mounting Clearances

See page 12 for mounting dimensions.

25 mm

(1.0 in.)

120 mm

(4.7 in.)

120 mm

(4.7 in.)

Mounting Option A

No clearance required

between drives.

Mounting Option B

120 mm

(4.7 in.)

120 mm

(4.7 in.)

Ambient Operating Temperatures

Ambient Temperature Enclosure Rating Minimum Mounting

Minimum Maximum

-10°C (14°F)

40°C (104°F)

IP 20/Open Type Use Mounting Option A

IP 30/NEMA 1/UL Type 1

Clearances

(1)

Use Mounting Option B

50°C (122°F) IP 20/Open Type Use Mounting Option B

(1)

Rating requires installation of the PowerFlex 4 IP 30/NEMA 1/UL Type 1 option kit.

General Grounding Requirements

Important: Remove the MOV to ground jumper if the

drive is installed on an ungrounded distribution system.

Jumper

Location

CE Conformity

Refer to the PowerFlex 4

drive for details on how to comply with the Low Voltage (LV) and

Electromagnetic Compatibility (EMC) Directives.

Tighten screw after jumper removal.

R/L1

S/L2

T/L3

SHLD

User Manual

on the CD supplied with the

U/T1

V/T2

W/T3

Page 3

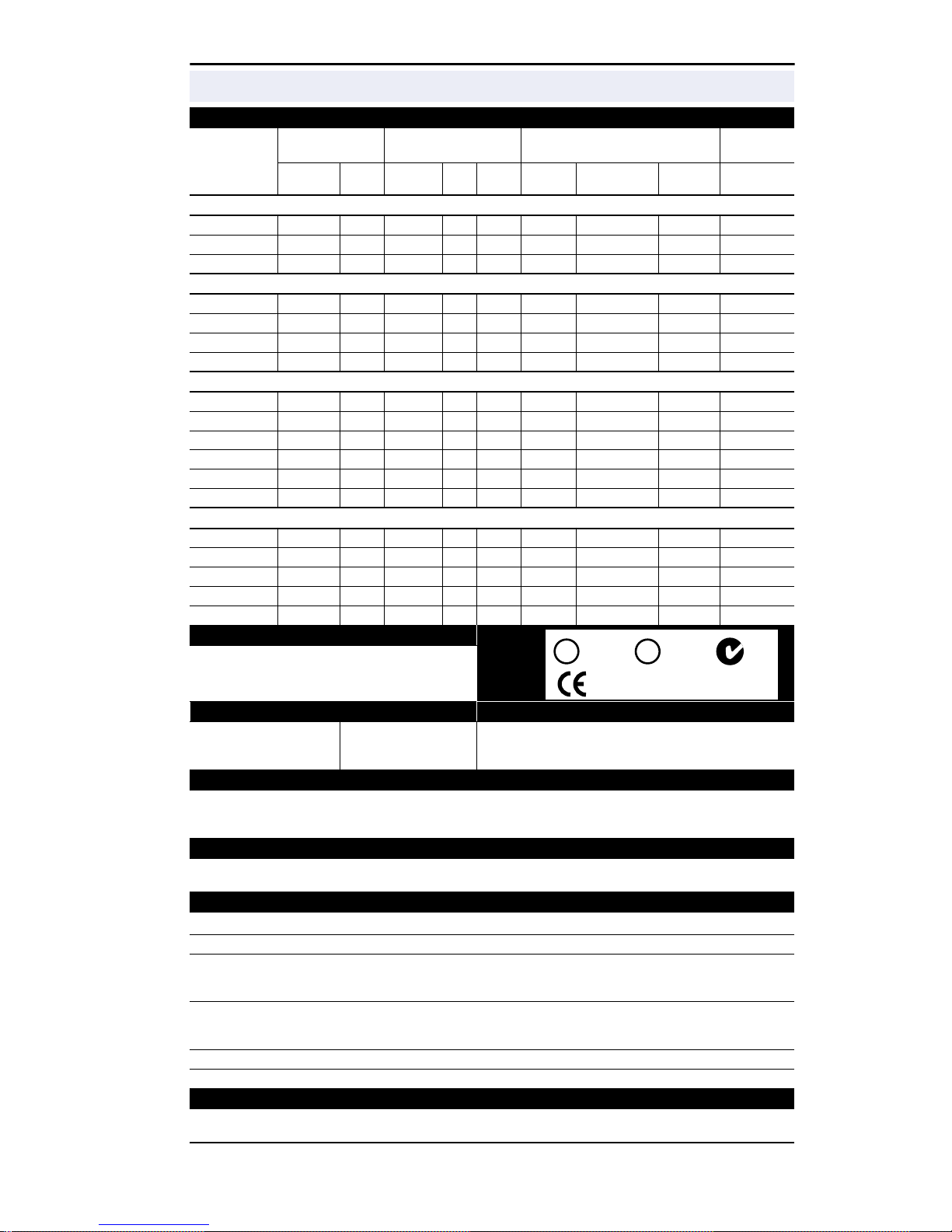

Specifications, Fuses and Circuit Breakers

Drive Ratings

Catalog

Number

Output Ratings Input Ratings Branch Circuit Protection

kW (HP) Amps

Voltage

Range kVA Amps Fuses

140M Motor

Protectors Contactors

100 - 115V AC 1-Phase Input, 0 - 230V 3-Phase Output

22A-V1P5N104 0.2 (0.25) 1.5 90-126 0.75 6.0 10 140M-C2E-C10 100-C09 25

22A-V2P3N104 0.37 (0.5) 2.3 90-126 1.15 9.0 15 140M-C2E-C16 100-C12 30

22A-V4P5N104 0.75 (1.0) 4.5 90-126 2.25 18.0 30 140M-D8E-C20 100-C23 50

200 - 240V AC – 1-Phase

(1)

Input, 0 - 230V 3-Phase Output

22A-A1P5N104 0.2 (0.25) 1.5 180-265 0.75 5.0 10 140M-C2E-B63 100-C09 25

22A-A2P3N104 0.37 (0.5) 2.3 180-265 1.15 6.0 10 140M-C2E-B63 100-C09 30

22A-A4P5N104 0.75 (1.0) 4.5 180-265 2.25 10.0 15 140M-C2E-C16 100-C12 50

22A-A8P0N104 1.5 (2.0) 8.0 180-265 4.0 18.0 30 140M-D8E-C20 100-C23 80

200 - 240V AC – 3-Phase Input, 0 - 230V 3-Phase Output

22A-B1P5N104 0.2 (0.25) 1.5 180-265 0.75 1.8 3 140M-C2E-B25 100-C09 25

22A-B2P3N104 0.37 (0.5) 2.3 180-265 1.15 2.5 6 140M-C2E-B40 100-C09 30

22A-B4P5N104 0.75 (1.0) 4.5 180-265 2.25 5.2 10 140M-C2E-C10 100-C09 50

22A-B8P0N104 1.5 (2.0) 8.0 180-265 4.0 9.5 15 140M-C2E-C16 100-C12 80

22A-B012N104 2.2 (3.0) 12.0 180-265 5.5 15.5 25 140M-C2E-C16 100-C16 115

22A-B017N104 3.7 (5.0) 17.5 180-265 8.6 21.0 35 140M-F8E-C25 100-C23 165

380 - 480V AC – 3-Phase Input, 0 - 460V 3-Phase Output

22A-D1P4N104 0.37 (0.5) 1.4 340-528 1.4 1.8 3 140M-C2E-B25 100-C09 30

22A-D2P3N104 0.75 (1.0) 2.3 340-528 2.3 3.2 6 140M-C2E-B40 100-C09 40

22A-D4P0N104 1.5 (2.0) 4.0 340-528 4.0 5.7 10 140M-C2E-B63 100-C09 60

22A-D6P0N104 2.2 (3.0) 6.0 340-528 5.9 7.5 15 140M-C2E-C10 100-C09 90

22A-D8P7N104 3.7 (5.0) 8.7 340-528 8.6 9.0 15 140M-C2E-C16 100-C16 145

Input/Output Ratings

Output Frequency:

Efficiency:

0-240 Hz (Programmable)

97.5% (Typical)

Digital Control Inputs (Input Current = 6mA)

SRC (Source) Mode:

18-24V = ON

0-6V = OFF

SNK (Sink) Mode:

0-6V = ON

18-24V = OFF

D

9

Approvals

E

6

T

6

S

X

I

L

U

UL508C

L

®

I

N

Q

D

E

C

T

O

N

Analog Control Inputs

4-20mA Analog:

0-10V DC Analog:

External Pot:

250 ohm input impedance

100k ohm input impedance

1-10k ohms, 2 Watt minimum

EMC Directive 89/336

LV: EN 50178, EN 60204

EMC: EN 61800-3, EN 50081-1, EN 50082-2

D

9

E

6

T

6

S

X

I

L

U

CSA 22.2

L

C

®

I

N

Q

D

E

C

T

O

N

Control Output

Programmable Output (form C relay)

Resistive Rating: 3.0A at 30V DC, 3.0A at 125V AC, 3.0A at 240V AC

Inductive Rating: 0.5A at 30V DC, 0.5A at 125V AC, 0.5A at 240V AC

Fuses and Circuit Breakers

Recommended Fuse Type:

Recommended Circuit Breakers:

UL Class J, CC, T or Type BS88; 600V (550V) or equivalent.

HMCP circuit breakers or equivalent.

Protective Features

Motor Protection:

Overcurrent:

Over Voltage:

I2t overload protection - 150% for 60 Secs, 200% for 3 Secs (Provides Class 10 protection)

200% hardware limit, 300% instantaneous fault

100-120V AC Input – Trip occurs at 405V DC bus voltage (equivalent to 150V AC incoming line)

200-240V AC Input – Trip occurs at 405V DC bus voltage (equivalent to 290V AC incoming line)

380-460V AC Input – Trip occurs at 810V DC bus voltage (equivalent to 575V AC incoming line)

Under Voltage:

100-120V AC Input – Trip occurs at 210V DC bus voltage (equivalent to 75V AC incoming line)

200-240V AC Input – Trip occurs at 210V DC bus voltage (equivalent to 150V AC incoming line)

380-480V AC Input – Trip occurs at 390V DC bus voltage (equivalent to 275V AC incoming line)

Control Ride Through:

Faultless Power Ride Through:

Minimum ride through is 0.5 Secs - typical value 2 Secs

100 milliseconds

Dynamic Braking

Internal brake IGBT included with all ratings 0.75 kW (1 HP) and larger. Refer to Appendix B of the PowerFlex 4

on CD for ordering information.

(1)

200-240V AC - 1-Phase drives are also available with an integral EMC filter. Catalog suffix changes from N104 to N114.

Power

Dissipation

IP20 Open

Watts

English-3

User Manual

Page 4

English-4

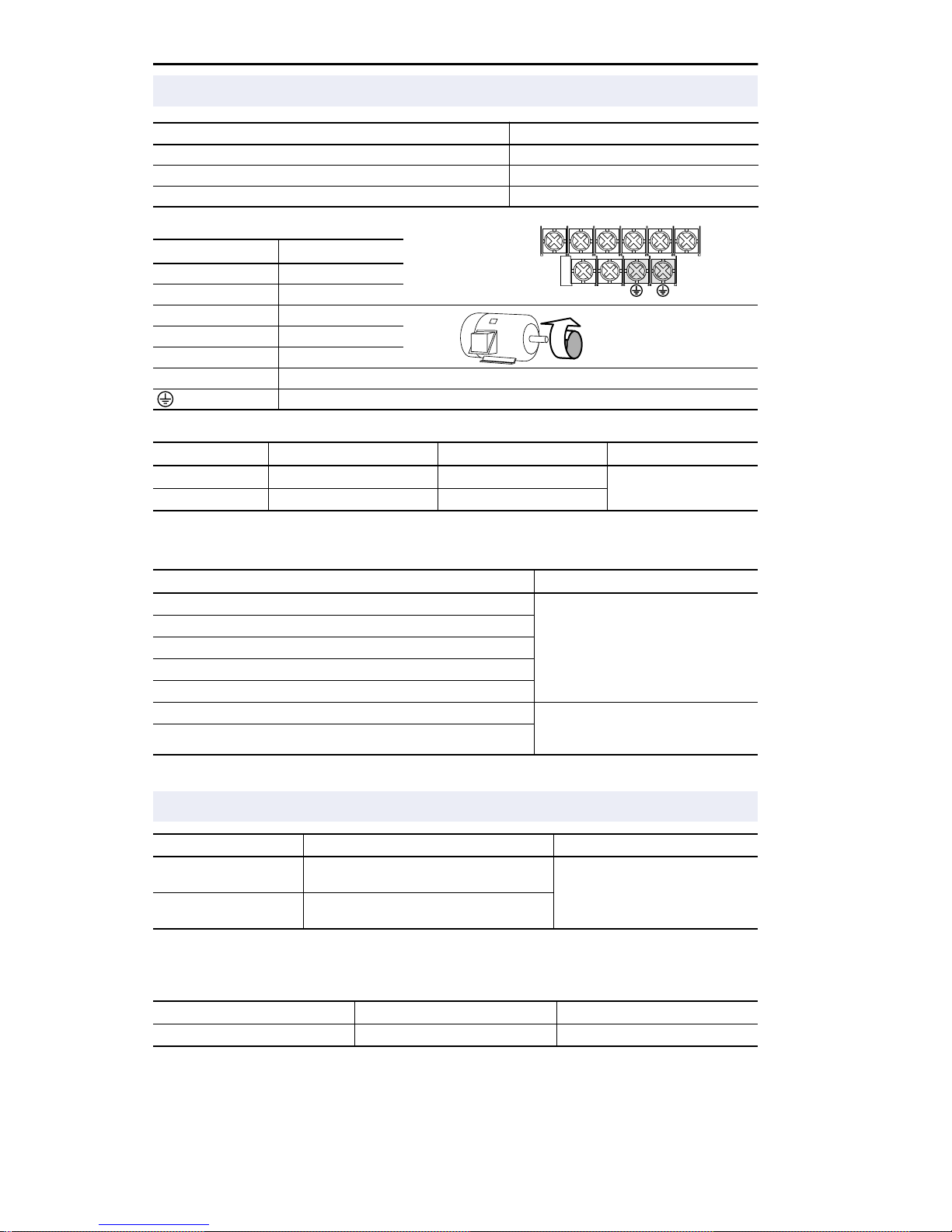

Power Wiring

Power Wire Rating Recommended Copper Wire

Unshielded 600V, 75°C (167°F) THHN/THWN 15 Mils insulated, dry location

Shielded 600V, 75°C or 90°C (167°F or 194°F) RHH/RHW-2 Belden 29501-29507 or equivalent

Shielded Tray rated 600V, 75°C or 90°C (167°F or 194°F) RHH/RHW-2 Shawflex 2ACD/3ACD or equivalent

Power Terminal Block (A Frame Shown)

Terminal Description

R/L1, S/L2 1-Phase Input

BR+

R/L1, S/L2, T/L3 3-Phase Input

U/T1 To Motor U/T1

V/T2 To Motor V/T2

W/T3 To Motor W/T3

BR+, BR- Dynamic Brake Resistor Connection [0.75 kW (1 HP) ratings and higher]

Safety Ground - PE

=

BR-

Switch any two motor leads to

change forward direction.

Power Terminal Block Specifications

Frame Maximum Wire Size

A 3.3 mm2 (12 AWG) 0.8 mm2 (18 AWG)

2

B 5.3 mm

(1)

Maximum/minimum sizes that the terminal block will accept - these are not recommendations.

(10 AWG)

(1)

Minimum Wire Size

2

1.3 mm

(16 AWG)

(1)

V/T2T/L3S/L2R/L1 U/T1 W/T3

Torque

1.7-2.2 N-m (16-19 lb.-in.)

Input Power Conditions

Input Power Condition Corrective Action

Low Line Impedance (less than 1% line reactance)

Greater than 120 kVA supply transformer

Line has power factor correction capacitors

Line has frequent power interruptions

Line has intermittent noise spikes in excess of 6000V (lightning)

Phase to ground voltage exceeds 125% of normal line to line voltage

Ungrounded Distribution System

(2)

Refer to Appendix B of the PowerFlex 4

User Manual

on CD for accessory ordering information.

I/O Wiring Recommendations

(3)

•

Install Line Reactor

•

or Isolation Transformer

•

Remove MOV jumper to ground.

•

and Install Isolation Transformer with

grounded secondary if necessary.

(2)

Wire Type(s) Description Minimum Insulation Rating

Belden 8760/9460

(or equiv.)

Belden 8770

(or equiv.)

(3)

If the wires are short and contained within a cabinet which has no sensitive circuits, the use of shielded wire may not be

necessary, but is always recommended.

0.8 mm2(18AWG), twisted pair, 100% shield with

drain.

2

0.8 mm

(18AWG), 3 conductor, shielded for

remote pot only.

300V

60 degrees C

(140 degrees F)

I/O Terminal Block Specifications

Maximum Wire Size

1.3 mm2 (16 AWG) 0.13 mm2 (26 AWG) 0.5-0.8 N-m (4.4-7 lb.-in.)

(4)

Maximum / minimum that the terminal block will accept - these are not recommendations.

(4)

Minimum Wire Size

(4)

Torque

Refer to the PowerFlex 4

control cable length recommendations

User Manual

on CD for maximum power and

Page 5

Control Terminal Block

English-5

(1)

Important: I/O Terminal 01 is

always a coast to stop input except

when P036 [Start Source] is set to

“3-Wire” control. In three wire

control, I/O Terminal 01 is controlled

by P037 [Stop Mode]. All other stop

sources are controlled by P037

[Stop Mode].

Important: The drive is shipped with

a jumper installed between I/O

Terminals 01 and 11. Remove this

jumper when using I/O Terminal 01

as a stop input.

(2)

Two wire control shown. For three

wire control use a momentary input

on I/O Terminal 02 to

command a start. Use a maintained

input for I/O Terminal 03 to

change direction.

Relay N.O.

Relay Common

Relay N.C.

P036

[Start Source]

Keypad Per P037 Coast

3-Wire Per P037 Per P037

2-Wire Per P037 Coast

RS485 Port Per P037 Coast

R1

R2

R3

Stop

I/O Terminal 01

+24V

+10V

01 02 03 04 05 06

Stop

01

02

03

04

05

06

11

12

13

14

15

16

Refer to the PowerFlex 4

User Manual on CD for

detailed I/O wiring examples.

(1)

Stop

Start/Run FWD

Direction/Run REV

Digital Common

Digital Input 1

Digital Input 2

+24V DC

+10V DC

0-10V In

Analog Common

4-20mA In

RS485 Shield

(2)

Typical

SRC Wiring

Potentiometer

must be

1-10k ohm

2 Watt Min.

Typical

SNK Wiring

30V DC 125V AC 240V AC

R1 R2

Resistive 3.0A 3.0A 3.0A

Inductive 0.5A 0.5A 0.5A

R3

SNK

SRC

11 12 13 14 15

(1)

16

RS485

(DSI)

81

No. Signal Default Description Param.

R1 Relay N.O. Fault Normally open contact for output relay. A055

R2 Relay Common – Common for output relay.

R3 Relay N.C. Fault Normally closed contact for output relay. A055

Sink/Source DIP Switch Source (SRC)

01 Stop

(1)

Coast

02 Star t/Run FWD Not Active

03 Direction/Run REV Not Active

04 Digital Common –

Inputs can be wired as Sink (SNK) or Source (SRC) via DIP Switch

setting.

The factory installed jumper or a normally closed input

must be present for the drive to start.

Command comes from the integral keypad by default. To

disable reverse operation, see A095 [Reverse Disable].

(1)

P036

P036, P037

P036, P037,

A095

For digital inputs. Electronically isolated with digital inputs

from analog I/O.

05 Digital Input 1 Preset Frequencies Program with A051 [Digital In1 Sel]. A051

06 Digital Input 2 Preset Frequencies Program with A052 [Digital In2 Sel]. A052

11 +24V DC –

12 +10V DC –

13 0-10V In

(3)

Not Active

14 Analog Common –

15 4-20mA In

(3)

Not Active

16 RS485 (DSI) Shield –

(3)

Only one analog frequency source may be connected at a time. If more than one reference is connected at the same

Drive supplied power for digital inputs.

Maximum output current is 100mA.

Drive supplied power for 0-10V external potentiometer.

Maximum output current is 15mA.

For external 0-10V input supply

(input impedance = 100k ohm) or potentiometer wiper.

For 0-10V In or 4-20mA In. Electronically isolated with

analog inputs from digital I/O.

For external 4-20mA input supply

(input impedance = 250 ohm).

Ter minal should be connected to safety ground - PE when

using the RS485 (DSI) communications port.

P038

P038

P038

time, an undetermined frequency reference will result.

Page 6

English-6

Prepare For Drive Start-Up

ATTENTION:

following start-up procedures. Some of the voltages present are at

!

incoming line potential. To avoid electric shock hazard or damage to

equipment, only qualified service personnel should perform the

following procedure. Thoroughly read and understand the procedure

before beginning. If an event does not occur while performing this

procedure,

supplied control voltages. User supplied voltages may exist even when

main AC power is not applied to the drive. Correct the malfunction

before continuing.

Power must be applied to the drive to perform the

Do Not Proceed. Remove All Power

including user

Before Applying Power to the Drive

1.

❏

❏

❏

❏

Confirm that all inputs are connected to the correct terminals and are

secure.

2.

Verify that AC line power at the disconnect device is within the rated

value of the drive.

3.

Verify that any digital control power is 24 volts.

4.

Verify that the Sink (SNK)/Source (SRC) Setup DIP Switch is set to

match your control wiring scheme. See page 5 for location.

Important:

❏

5.

Important:

Verify that the Stop input is present or the drive will not start.

The default control scheme is Source (SRC). The Stop

terminal is jumpered (I/O Terminals 01 and 11) to allow

starting from the keypad. If the control scheme is changed

to Sink (SNK), the jumper must be removed from I/O

Terminals 01 and 11 and installed between I/O Terminals

01 and 04.

If I/O Terminal 01 is used as a stop input, the jumper

between I/O Terminals 01 and 11 must be removed.

Applying Power to the Drive

6.

❏

❏

Apply AC power and control voltages to the drive.

7.

Familiarize yourself with the integral keypad features (see next page)

before setting any Program Group parameters.

Start, Stop, Direction and Speed Control

Factory default parameter values allow the drive to be controlled from

the integral keypad. No programming is required to start, stop, change

direction and control speed directly from the integral keypad.

Important:

If a fault appears on power up, refer to page 11 for an explanation of the

fault code. For complete troubleshooting information, refer to the

PowerFlex 4

To disable reverse operation, see A095 [Reverse Disable].

User Manual

on the CD supplied with the drive.

Page 7

Integral Keypad

English-7

➋

FAULT

➌

VOLTS

AMPS

HERTZ

➑

➏

➊

RUN

FWD

REV

➍

➐

PROGRAM

➎

➒

No. LED LED State Description

Run/Direction

➊

Status

Alphanumeric

➋

Display

Displayed Units Steady Red Indicates the units of the parameter value being displayed.

➌

Program Status Steady Red Indicates parameter value can be changed.

➍

Fault Status Flashing Red Indicates drive is faulted.

➎

Pot Status Steady Green Indicates potentiometer on Integral Keypad is active.

➏

Start Key Status Steady Green Indicates Start key on Integral Keypad is active.

➐

Steady Red Indicates drive is running and commanded motor direction.

Flashing Red Drive has been commanded to change direction. Indicates

Steady Red Indicates parameter number, parameter value, or fault code.

Flashing Red Single digit flashing indicates that digit can be edited.

Menu Description

Display Group (View Only)

Consists of commonly viewed drive operating

conditions.

Basic Program Group

Consists of most commonly used

programmable functions.

Advanced Program Group

Consists of remaining programmable functions.

Fault Designator

Consists of list of codes for specific fault

conditions. Displayed only when fault is present.

actual motor direction while decelerating to zero.

All digits flashing indicates a fault condition.

The Reverse key is also active unless disabled by A095

[Reverse Disable].

No. Key Name Description

➑

➒

Escape Back one step in programming menu.

Cancel a change to a parameter value and exit Program

Mode.

Select Advance one step in programming menu.

Select a digit when viewing parameter value.

Up Arrow

Down Arrow

Enter Advance one step in programming menu.

Potentiometer Used to control speed of drive. Default is active.

Start Used to start the drive. Default is active.

Reverse Used to reverse direction of the drive. Default is active.

Stop Used to stop the drive or clear a fault.

Scroll through groups and parameters.

Increase/decrease the value of a flashing digit.

Save a change to a parameter value.

Controlled by parameter P038.

Controlled by parameter P036.

Controlled by parameters P036 and A095.

This key is always active.

Controlled by parameter P037.

Page 8

English-8

Viewing and Editing Parameters

The last user-selected Display Group parameter is saved when power is removed and is

displayed by default when power is reapplied.

The following is an example of basic integral keypad and display functions. This example

provides basic navigation instructions and illustrates how to program the first Program

Group parameter.

Step Key(s) Example Displays

1. When power is applied, the last user-selected

Display Group parameter number is briefly

displayed with flashing characters. The display

then defaults to that parameter’s current value.

(Example shows the value of d001 [Output

Freq] with the drive stopped.)

FAULTPROGRAM

VOLTS

AMPS

HERTZ

2. Press Esc once to display the Display Group

parameter number shown on power-up. The

parameter number will flash.

3. Press Esc again to enter the group menu. The

group menu letter will flash.

4. Press the Up Arrow or Down Arrow to scroll

through the group menu (d, P and A).

5. Press Enter or Sel to enter a group. The right

digit of the last viewed parameter in that group

will flash.

6. Press the Up Arrow or Down Arrow to scroll

through the parameters that are in the group.

7. Press Enter or Sel to view the value of a

parameter. If you do not want to edit the value,

press Esc to return to the parameter number.

8. Press Enter or Sel to enter program mode to

edit the parameter value. The right digit will

flash and the Program LED will illuminate if the

parameter can be edited.

or

or

or

or

or

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

9. Press the Up Arrow or Down Arrow to change

the parameter value. If desired, press Sel to

move from digit to digit or bit to bit. The digit or

bit that you can change will flash.

10. Press Esc to cancel a change. The digit will

stop flashing, the previous value is restored and

the Program LED will turn off.

Or

Press Enter to save a change. The digit will stop

flashing and the Program LED will turn off.

11. Press Esc to return to the parameter list.

Continue to press Esc to back out of the

programming menu.

If pressing Esc does not change the display,

then d001 [Output Frequency] is displayed.

Press Enter or Sel to enter the group menu.

or

VOLTS

AMPS

HERTZ

FAULTPROGRAM

VOLTS

AMPS

HERTZ

FAULTPROGRAM

Page 9

See the PowerFlex 4 User Manual on CD for more information on parameters.

English-9

Smart Start-Up with Basic Program Group Parameters

The PowerFlex 4 is designed so that start up is simple and efficient. The Program Group

contains the most commonly used parameters.

= Stop drive before changing this parameter.

No. Parameter Min/Max Display/Options Default

P031 [Motor NP Volts] 20/Drive Rated Volts 1 VAC Based on Drive Rating

Set to the motor nameplate rated volts.

P032 [Motor NP Hertz] 10/240 Hz 1 Hz 60 Hz

Set to the motor nameplate rated frequency.

P033 [Motor OL Current] 0.0/(Drive Rated Amps×2) 0.1 Amps Based on Drive Rating

Set to the maximum allowable motor current.

P034 [Minimum Freq] 0.0/240.0 Hz 0.1 Hz 0.0 Hz

Sets the lowest frequency the drive will output

continuously.

P035 [Maximum Freq] 0/240 Hz 1 Hz 60 Hz

Sets the highest frequency the drive will output.

P036 [Start Source] 0/5 0 = “Keypad”

Sets the control scheme used to start the drive.

(1)

When active, the Reverse key is also active

unless disabled by A095 [Reverse Disable].

P037 [Stop Mode] 0/7 0 = “Ramp, Clear Fault”

Active stop mode for all stop sources [e.g. keypad,

run forward (I/O Terminal 02), run reverse (I/O

Ter minal 03), RS485 port] except as noted below.

Important: I/O Terminal 01 is always a coast to

stop input except when P036 [Start Source] is set

for “3-Wire” control. When in three wire control, I/O

Ter minal 01 is controlled by P037 [Stop Mode].

(1)

Stop input also clears active fault.

1 = “3-Wire”

2 = “2-Wire”

3 = “2-Wire Level Sensitive”

4 = “2-Wire High Speed”

5 = “RS485 (DSI) Port”

1 = “Coast, Clear Fault”

2 = “DC Brake, Clear Fault”

3 = “DC Brake w/Shutoff, Clear Fault”

4 = “Ramp”

5 = “Coast”

6 = “DC Brake”

7 = “DC Brake w/Shutoff”

(1)

(1)

(1)

0

0

(1)

(1)

P038 [Speed Reference] 0/5 0 = “Drive Potentiometer”

Sets the source of the speed reference to the

drive.

Important: When A051 or A052 [Digital Inx Sel] is

set to option 2, 4, 5 or 6, and the digital input is

active, A051 or A052 will override the speed

reference commanded by this parameter. Refer to

Chapter 1 of the PowerFlex 4 User Manual on CD

for details.

P039 [Accel Time 1] 0.0/600.0 Secs 0.1 Secs 10.0 Secs

Sets the rate of accel for all speed increases.

P040 [Decel Time 1] 0.1/600.0 Secs 0.1 Secs 10.0 Secs

Sets the rate of decel for all speed decreases.

P041 [Reset To Defaults] 0/1 0 = “Idle State”

Resets all parameter values to factory defaults.

1 = “Internal Freq”

2 = “0-10V Input/Remote Potentiometer”

3 = “4-20mA Input”

4 = “Preset Freq 0-3”

5 = “RS485 (DSI) Port”

1 = “Reset Defaults”

0

0

Advanced Group Parameters

No. Parameter Min/Max Display/Options Default

A051

[Digital In1 Sel]

I/O Terminal 05

[Digital In2 Sel]

A052

I/O Terminal 06

A055 [Relay Out Sel] 0/9 0 = “Ready” (Not Faulted)

A056 [Relay Out Level] 0.0/9999 0.1 – 1 0.0

A067 [Accel Time 2] 0.0/600.0 Secs 0.1 Secs 20.0 Secs

A068 [Decel Time 2] 0.1/600.0 Secs 0.1 Secs 20.0 Secs

A069 [Internal Freq] 0.0/240.0 Hz 0.1 Hz 60.0 Hz

0/7 0 = “Not Used”

1 = “Accel 2 & Decel 2”

2 = “Jog”

3 = “Auxiliary Fault”

1 = “At Frequency”

2 = “Motor Running”

3 = “Reverse”

4 = “Motor Overload”

4 = “Preset Frequencies”

5 = “Local”

6 = “RS485 (DSI) Port”

7 = “Clear Fault”

5 = “Ramp Regulated”

6 = “Above Frequency”

7 = “Above Current”

8 = “Above DC Bus Volts”

9 = “Retries Exhausted”

4

0

Page 10

English-10

See the PowerFlex 4 User Manual on CD for more information on parameters.

No. Parameter Min/Max Display/Options Default

A070

A071

A072

A073

[Preset Freq 0]

[Preset Freq 1]

[Preset Freq 2]

[Preset Freq 3]

(1)

To activate [Preset Freq 0] set P038 [Speed Reference] to option 4.

Input State of Digital In 1

(2)

When a Digital Input is set to “Accel 2 & Decel 2”, and the input is active, that input overrides the settings in this table.

(1)

0.0/240.0 Hz 0.1 Hz 0.0 Hz

(I/O Terminal 05)

0 0 [Preset Freq 0] [Accel Time 1] / [Decel Time 1]

1 0 [Preset Freq 1] [Accel Time 1] / [Decel Time 1]

0 1 [Preset Freq 2] [Accel Time 2] / [Decel Time 2]

1 1 [Preset Freq 3] [Accel Time 2] / [Decel Time 2]

Input State of Digital In 2

(I/O Terminal 06)

Frequency Source Accel / Decel Parameter Used

5.0 Hz

10.0 Hz

20.0 Hz

(2)

A078 [Jog Frequency] 0.0/[Maximum Freq] 0.1 Hz 10.0 Hz

A079 [Jog Accel/Decel] 0.1/600.0 Secs 0.1 Secs 10.0 Secs

A080 [DC Brake Time] 0.0/90.0 Secs 0.1 Secs 0.0 Secs

A081 [DC Brake Level] 0.0/(Drive Amps × 1.8) 0.1 Amps Amps × 0.05

A082 [DB Resistor Sel] 0/99 0 = Disabled

1 = 5% Duty Cycle

2 = 100% Duty Cycle

3-99 = % of Duty Cycle

0

A083 [S Curve %] 0/100% 1% 0% (Disabled)

A084 [Start Boost] 1/14 Settings in % of base voltage. 8

ariable Torque Constant Torque

V

7 (5 HP Drives)

1 = “30.0” 5 = “0.0 no IR Comp” 10 = “10.0”

2 = “35.0” 6 = “0.0” 11 = “12.5”

3 = “40.0” 7 = “2.5” 12 = “15.0”

4 = “45.0” 8 = “5.0” 13 = “17.5”

9 = “7.5” 14 = “20.0”

A088 [Maximum Voltage] 20/Rated Volts 1 VAC Rated Volts

A089 [Current Limit] 0.1/(Drive Amps × 1.8) 0.1 Amps Amps × 1.5

A090 [Motor OL Select] 0/2 0 = “No Derate” 1 = “Minimum Derate”

0

2 = “Maximum Derate”

A091 [PWM Frequency] 2.0/16.0 kHz 0.1 kHz 4.0 kHz

A092 [Auto Rstrt Tries] 0/9 1 0

A093 [Auto Rstrt Delay] 0.0/120.0 Secs 0.1 Secs 1.0 Secs

A094 [Start At PowerUp] 0/1 0 = “Disabled” 1 = “Enabled” 0

A095 [Reverse Disable] 0/1 0 = “Reverse Enabled” 1 = “Reverse Disabled” 0

A096 [Flying Start En] 0/1 0 = “Disabled” 1 = “Enabled” 0

A097 [Compensation] 0/3 0 = “Disabled”

1 = “Electrical”

2 = “Mechanical”

3 = “Both”

1

A098 [SW Current Trip] 0.0/(Drive Amps × 2) 0.1 Amps 0.0 (Disabled)

A099 [Process Factor] 0.1/999.9 0.1 30.0

A100 [Fault Clear] 0/2 0 = “Ready” 1 = “Reset Active Fault”

0

2 = “Clear Fault Queue”

A101 [Program Lock] 0/1 0 = “Unlocked” 1 = “Locked” 0

A102 [Testpoint Sel] 0/FFFF 1 Hex 400

A103 [Comm Data Rate]

A104 [Comm Node Addr]

A105 [Comm Loss Action] 0/3 0 = “Fault”

(3)

0/5 0 = “1200”

1 = “2400”

2 = “4800”

(3)

1/247 1 100

3 = “9600”

4 = “19.2K”

5 = “38.4K”

2 = “Stop”

1 = “Coast to Stop”

3 = “Continue Last Speed”

3

0

A106 [Comm Loss Time] 0.1/60.0 0.1 5.0

A107 [Comm Format]

(3)

0/2 0 = “RTU 8-N-1” 1 = “RTU 8-E-1”

0

2 = “RTU 8-O-1”

A110 [0-10V Analog Input

0.0/100.0% 0.1% 0.0

Low]

A111 [0-10V Analog Input

0.0/100.0% 0.1% 100.0

High]

A112 [4-20mA Analog Input

0.0/100.0% 0.1% 0.0

Low]

A113 [4-20mA Analog Input

0.0/100.0% 0.1% 100.0

High]

A114 [Slip Compensation] 0.0/10.0 Hz 0.1 Hz 2.0 Hz

(3)

Power to drive must be cycled before any changes will affect drive operation.

Page 11

See the PowerFlex 4 User Manual on CD for more information on parameters.

English-11

Display Group Parameters

No. Parameter Min/Max Display/Options

d001 [Output Freq] 0.0/ [Maximum Freq] 0.1 Hz

d002 [Commanded Freq] 0.0/ [Maximum Freq] 0.1 Hz

d003 [Output Current] 0.00/Drive Amps × 2 0.01 Amps

d004 [Output Voltage] 0/Drive Rated Volts 1 VAC

d005 [DC Bus Voltage] Based on Drive Rating 1 VDC

d006 [Drive Status] 0/1 (1 = Condition True) Bit 3

d007-

[Fault x Code] F2/F122 F1

d009

d010 [Process Display] 0.00/9999 0.01 – 1

d012 [Control Source] 0/9 Bit 1 = Speed Command

d013 [Contrl In Status] 0/1 (1 = Input Present) Bit 3 Bit 2 Bit 1 Bit 0

d014 [Dig In Status] 0/1 (1 = Input Present) Bit 3 Bit 2 Bit 1 Bit 0

d015 [Comm Status] 0/1 (1 = Condition True) Bit 3 Bit 2 Bit 1 Bit 0

d016 [Control SW Ver] 1.00/99.99 0.01

d017 [Drive Type] 1001/9999 1

d018 [Elapsed Run Time] 0/9999 Hrs 1 = 10 Hrs

d019 [Testpoint Data] 0/FFFF 1 Hex

d020 [0-10V Analog Input] 0.0/100.0% 0.1%

d021 [4-20mA Analog Input] 0.0/100.0% 0.1%

Decelerating Accelerating Forward Running

(See P038; 9 = “Jog Freq”) (See P036; 9 = “Jog”)

Reserved Stop Input Dir/Run REV Start/Run FWD

Reserved Reserved Digital In2 Sel Digital In1 Sel

Fault Occurred RS485 Option Transmitting Receiving

Bit 2 Bit 1 Bit 0

Bit 0 = Start Command

Fault Codes

To clear a fault, press the Stop key, cycle power or set A100 [Fault Clear] to 1 or 2.

No. Fault Description

F2 Auxiliary Input

F3 Power Loss Monitor the incoming AC line for low voltage or line power interruption.

F4 UnderVoltage

F5 OverVoltage

F6 Motor Stalled

F7 Motor Overload

F8 Heatsink OvrTmp

F12 HW OverCurrent

F13 Ground Fault Check the motor and external wiring to the drive output terminals for a grounded condition.

F33 Auto Rstrt Tries Correct the cause of the fault and manually clear.

F38 Phase U to Gnd Check the wiring between the drive and motor. Check motor for grounded phase.

F39 Phase V to Gnd

F40 Phase W to Gnd

F41 Phase UV Short Check the motor and drive output terminal wiring for a shorted condition.

F42 Phase UW Short

F43 Phase VW Short

F48 Params Defaulted The drive was commanded to write default values to EEPROM. Clear the fault or cycle power to

F63 SW OverCurrent

F64 Drive Overload Reduce load or extend Accel Time.

F70 Power Unit Cycle power. Replace drive if fault cannot be cleared.

F81 Comm Loss If adapter was not intentionally disconnected, check wiring to the por t. Replace wiring, port

F100 Parameter Checksum Restore factory defaults.

F122 I/O Board Fail Cycle power. Replace drive if fault cannot be cleared.

(1)

Auto-Reset/Run type fault. Configure with parameters A092 and A093.

(1)

Check remote wiring.

(1)

(1)

Monitor the incoming AC line for low voltage or line power interruption.

Monitor the AC line for high line voltage or transient conditions. Bus overvoltage can also be

caused by motor regeneration. Extend the decel time or install dynamic brake option.

(1)

Increase [Accel Time x] or reduce load so drive output current does not exceed the current set

by parameter A089 [Current Limit].

(1)

An excessive motor load exists. Reduce load so drive output current does not exceed the

current set by parameter P033 [Motor OL Current].

(1)

Check for blocked or dirty heat sink fins. Verify that ambient temperature has not exceeded

40°C (104°F) for IP 30/NEMA 1/UL Type 1 installations or 50°C (122°F) for Open type installations.

Check fan.

(1)

Check programming. Check for excess load, improper DC boost setting, DC brake volts set too

high or other causes of excess current.

Replace drive if fault cannot be cleared.

Replace drive if fault cannot be cleared.

the drive. Program the drive parameters as needed.

(1)

Check load requirements and A098 [SW Current Trip] setting.

expander, adapters or complete drive as required. Check connection. An adapter was

intentionally disconnected. Turn off using A105 [Comm Loss Action].

Page 12

English-12

T

Drive Dimensions

Dimensions are in millimeters and (inches). Weights are in kilograms and (pounds).

A

D

5.5 (0.22)

GE

B

C

F

Frame A B

A 80 (3.15) 185 (7.28) 136 (5.35) 67 (2.64) 152 (5.98) 59.3 (2.33) 140 (5.51) 1.4 (3.1)

B 100 (3.94) 213 (8.39) 136 (5.35) 87 (3.43) 180 (7.09) 87.4 (3.44) 168 (6.61) 2.2 (4.9)

(1)

Overall height of drive with IP 30/NEMA 1/UL Type 1 option kit installed.

(2)

Overall height of standard IP 20/Open Type drive.

(1)

CDE

(2)

FG

Shipping

Weight

PowerFlex 4 Frames – Ratings are in kW and (HP)

Frame 120V AC – 1-Phase 240V AC – 1-Phase 240V AC – 3-Phase 480V AC – 3-Phase

A 0.2 (0.25)

0.37(0.5)

B 0.75(1.0) 1.5 (2.0) 2.2 (3.0)

0.2 (0.25)

0.37 (0.5)

0.75 (1.0)

0.2 (0.25)

0.37 (0.5)

0.75 (1.0)

1.5 (2.0)

3.7 (5.0)

0.37 (0.5)

0.75 (1.0)

1.5 (2.0)

2.2 (3.0)

3.7 (5.0)

Optional Conduit Box – Dimensions are in millimeters and (inches)

79.1

64.1

(2.52)

(3.11)

35.6

(1.40)

∅ 22.2

(0.88)

20.7

(0.81)

40.0

(1.57)

59.2

(2.33)

∅ 22.2

(0.88)

34.0

(1.34)

25.6

(1.01)

40.6

(1.60)

Frame A Frame B

U.S. Allen-Bradley Drives Technical Support

el: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Publication 22A-QS001B-EN-P – May 2002

Supersedes December 2001 Copyright © 2002 Rockwell Automation, Inc. All rights reserved. Printed in Taiwan.

75.3

(2.96)

74.3

(2.93)

Loading...

Loading...