Allen-Bradley 2198-H003-ERS, 2198-H008-ERS, 2198-H015-ERS, 2198-H025-ERS, 2198-H040-ERS Design Manual

...Page 1

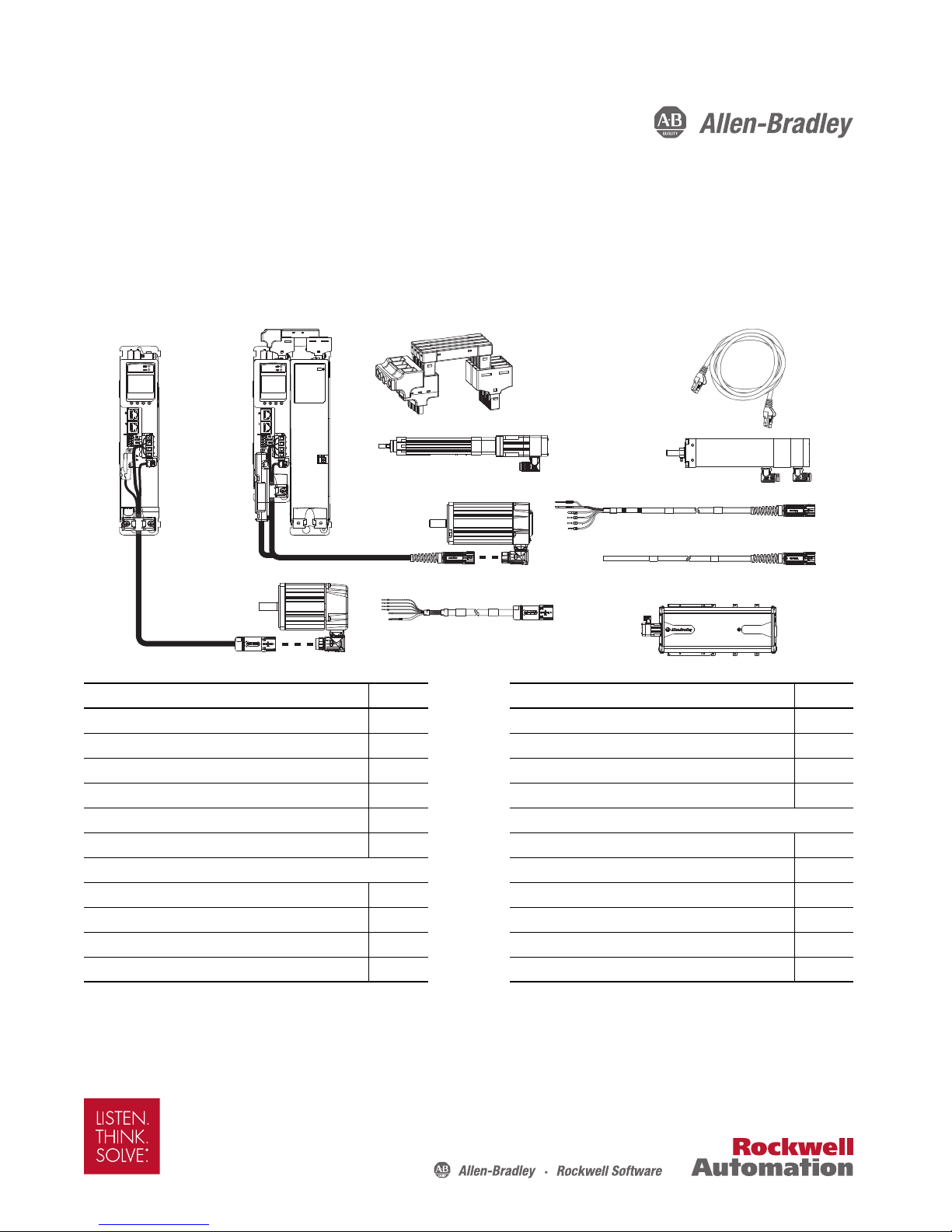

Design Guide

Interface Cables, Connector Kits,

and Other Drive Accessories

Kinetix 5500

Servo Drives

Kinetix VP

Rotary Motors

2090-Series Single Motor Cables

MP-Series

Rotary Motors

Kinetix VP and

MP-Series

Electric Cylinders

MP-Series Linear Stages

2090-Series Motor Power/Brake

and Feedback Cables

Kinetix 5500 Drive Systems

Catalog Numbers 2198-H003-ERS, 2198-H008-ERS, 2198-H015-ERS, 2198-H025-ERS, 2198-H040-ERS, 2198-H070-ERS,

2198-H003-ERS2, 2198-H008-ERS2, 2198-H015-ERS2, 2198-H025-ERS2, 2198-H040-ERS2, 2198-H070-ERS2, 2198-CAPMOD-1300

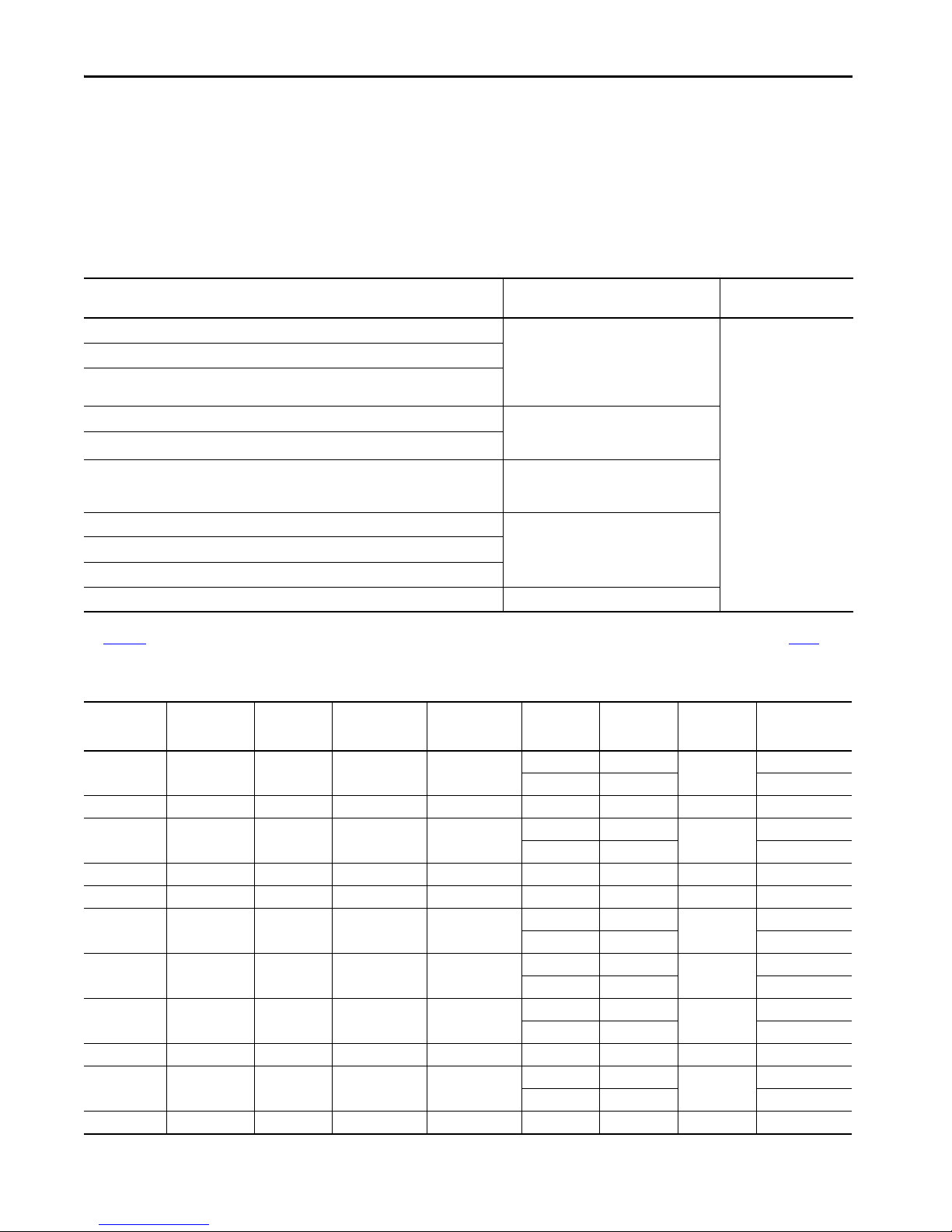

Topic Page Topic, continued Page

Introduction 2 MP-Series Low Inertia Motors 53

Safe Torque-off Configuration Options 3 MP-Series Medium Inertia Motors 64

Determine What You Need 6 MP-Series Food Grade Motors 72

Kinetix 5500 Shared-bus System Examples 10 MP-Series Stainless Steel Motors 77

2090-Series Single Motor Cable Overview 13 Linear Motion System Combinations

2090-Series Motor Power/Brake and Feedback Cables Overview 14 LDAT-Series Integrated Linear Thrusters 80

Rotary Motion System Combinations MP-Series Integrated Linear Stages 101

Kinetix VP Low Inertia Motors 16 Kinetix VP Electric Cylinders 105

Kinetix VP Food Grade Motors 32 MP-Series Electric Cylinders 108

Kinetix VP Hygienic Stainless Steel Motors 43 MP-Series Heavy Duty Electric Cylinders 110

Kinetix VP Stainless Steel Motors 52 Additional Resources 116

Page 2

Kinetix 5500 Drive Systems

Summary of Changes

This publication contains new and updated information as indicated in the following table.

Top ic Page

Added compatibility with CompactLogix™ 5480 controllers. 3

Added compatibility with Kinetix® VP (Bulletin VPAR) electric cylinders.

Added compatibility with Kinetix VP (Bulletin VPH) hygienic stainless-steel ser vo motors.

Added compatibility with 2198-DBRxx-F AC line filters. 9

Corrected motor-rated output values for VPF-B1153E and VPF-B1153F servo motors. 38

Added performance specifications for Bulletin VPH servo motors with Kinetix 5500 drives. 43, 47

Added performance specifications for Bulletin VPAR electric cylinders with Kinetix 5500 drives. 105

7, 8

Introduction

Use this publication if your application includes the Kinetix® 5500 drive family and Kinetix VP motors and actuators or

any of the other compatible Allen-Bradley® motors and actuators. LDAT-Series linear thrusters and MP-Series™ motor

and actuators require the 2198-H2DCK feedback converter kit. For more Kinetix drive and motor information, see the

Kinetix Motion Control Selection Guide, publication KNX-SG001

, or Motion Analyzer software.

The purpose of this publication is to assist you in identifying the drive system components and accessory items you need

for your Kinetix 5500 drive and motor/actuator combination. Diagrams in this publication illustrate how many of the

common drive accessory items are used in a typical system. See the Kinetix Servo Drives Specifications Technical Data,

publication KNX-TD003

, for detailed accessory descriptions and specifications.

Drive/motor system combinations also include the following:

• Motor/cable combinations table

• Drive and motor performance specifications table

• Torque/speed curves with each motor matched to the drive that provides optimum performance

Performance specification data and curves reflect nominal system performance of a typical system with motor/drive at

rated ambient temperature and line voltage. For additional information on ambients, line conditions, and valid

combinations that are not shown in this publication, refer to the Motion Analyzer system sizing and selection tool.

IMPORTANT These system combinations do not include all possible motor/drive combinations. See the Motion Analyzer system sizing and

selection tool to verify compatibility. Access Motion Analyzer at https://motionanalyzer.rockwellautomation.com.

2 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 3

Kinetix 5500 Drive Systems

1585J-M8CBJM-x

Ethernet (shielded) Cable

Any Logix 5000™ Controller

(CompactLogix™ 5370 controller is shown)

Studio 5000 Logix Designer®

Application

(version 21.0 or later)

AC Inp ut Power

Safety

Device

2198-Hxxx-ERS Servo Drives

(top view)

2198-Hxxx-ERS Servo Drives

(front view)

Digital Inputs to Sensors and Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

Module Definition

Configured with

Motion-only

Connect ion

Safe Torque-off

(STO) Connectors

ControlLogix® 5570 Controllers or

GuardLogix® 5570 Safety Controllers

ControlLogix 5580 Controllers or

GuardLogix 5580 Safety Controllers

Compac tLogix 5370 Contro llers or

Compact GuardLogix 5370 Safety Controllers

CompactLogix 5380 or 5480 Controllers or

Compact GuardLogix 5380 Safety Controllers

Kinetix VP

Servo Motors

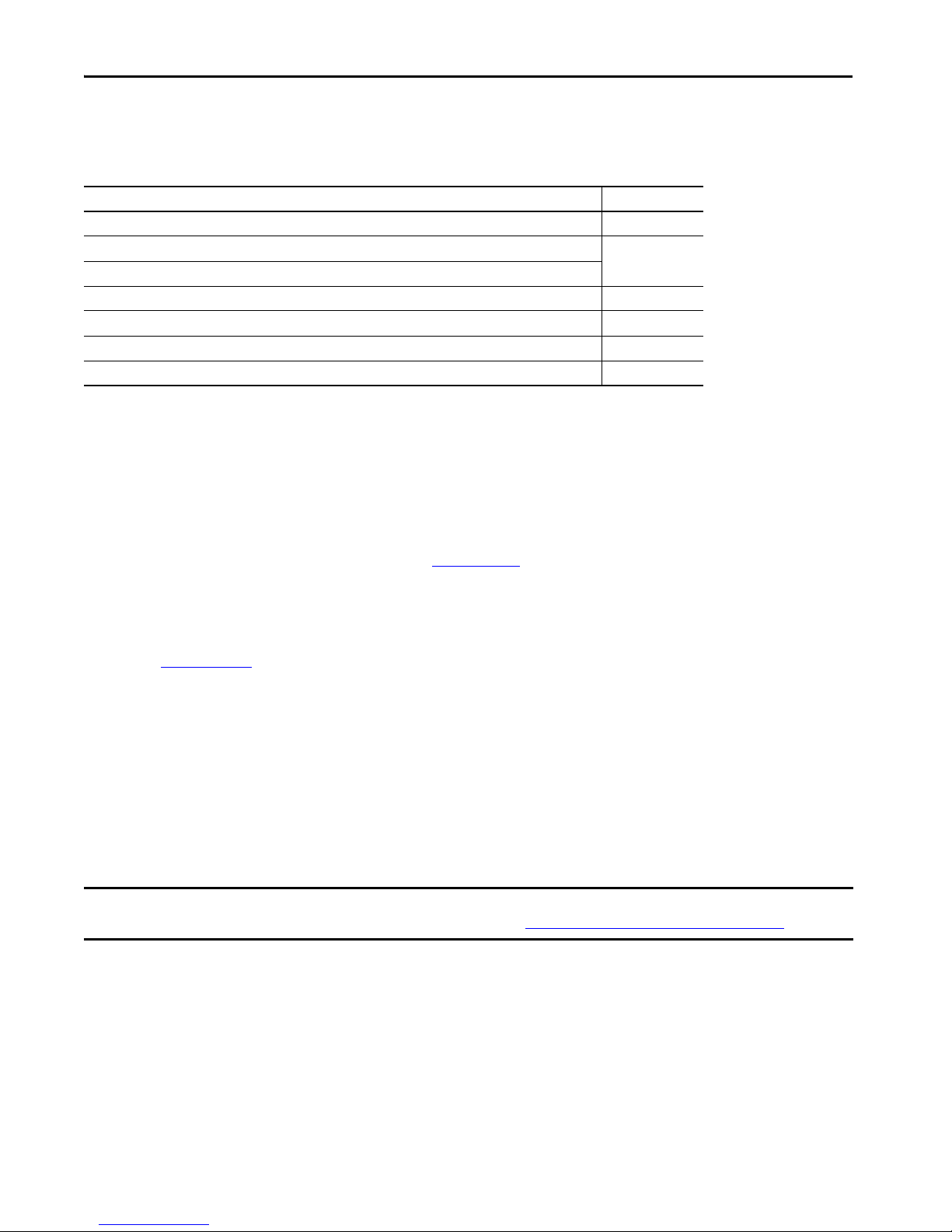

Safe Torque-off Configuration Options

Kinetix 5500 servo drives are available with safe torque-off over hardwired connections or integrated over the

EtherNet/IP™ network. These examples illustrate the safe torque-off configuration options.

Hardwired Safety Configuration

The 2198-Hxxx-ERS drives use the safe torque-off (STO) connector for wiring external safety devices and cascading

hardwired safety connections from one drive to another.

Safe Torque-off (hardwired) Configuration

00:00:BC:2E:69:F6

1 (Front)

2 (Rear)

Logix5585

0000

TM

DC INPUT

SAFETY ON

NET

LINK

OKFORCESDRUN

DC INPUT

AC OUTPUT

Allen-Bradley

Input

1606-XL

Power Supply

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 3

Page 4

Kinetix 5500 Drive Systems

1606-XL

Power Supply

Input

Allen-Bradley

LNK1LNK2NET OK

EtherNet/IP

1

2

1585J-M8CBJM-x

Ethernet (shielded) Cable

Compact GuardLogix 5370 Controller,

Compact GuardLogix 5380 Safety Controller or

GuardLogix 5570 Controller,

GuardLogix 5580 Safety Controller

(GuardLogix 5570 Safety Controller is shown)

Studio 5000 Logix Designer

Application

(version 24.0 or later)

AC Input Po wer

2198-Hxxx-ERS2 Servo Drives

(top view)

2198-Hxxx-ERS2 Servo Drives

(front view)

Digital Inputs to Sensors and Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

Kinetix VP

Servo Motors

1783-BMS

Stratix® 5700

Switch

Module Definition

Configured with

Motion and Safety

Conne ction

1734-AENTR

POINT Guard I/O™

EtherNet/IP Adapter

Safety

Device

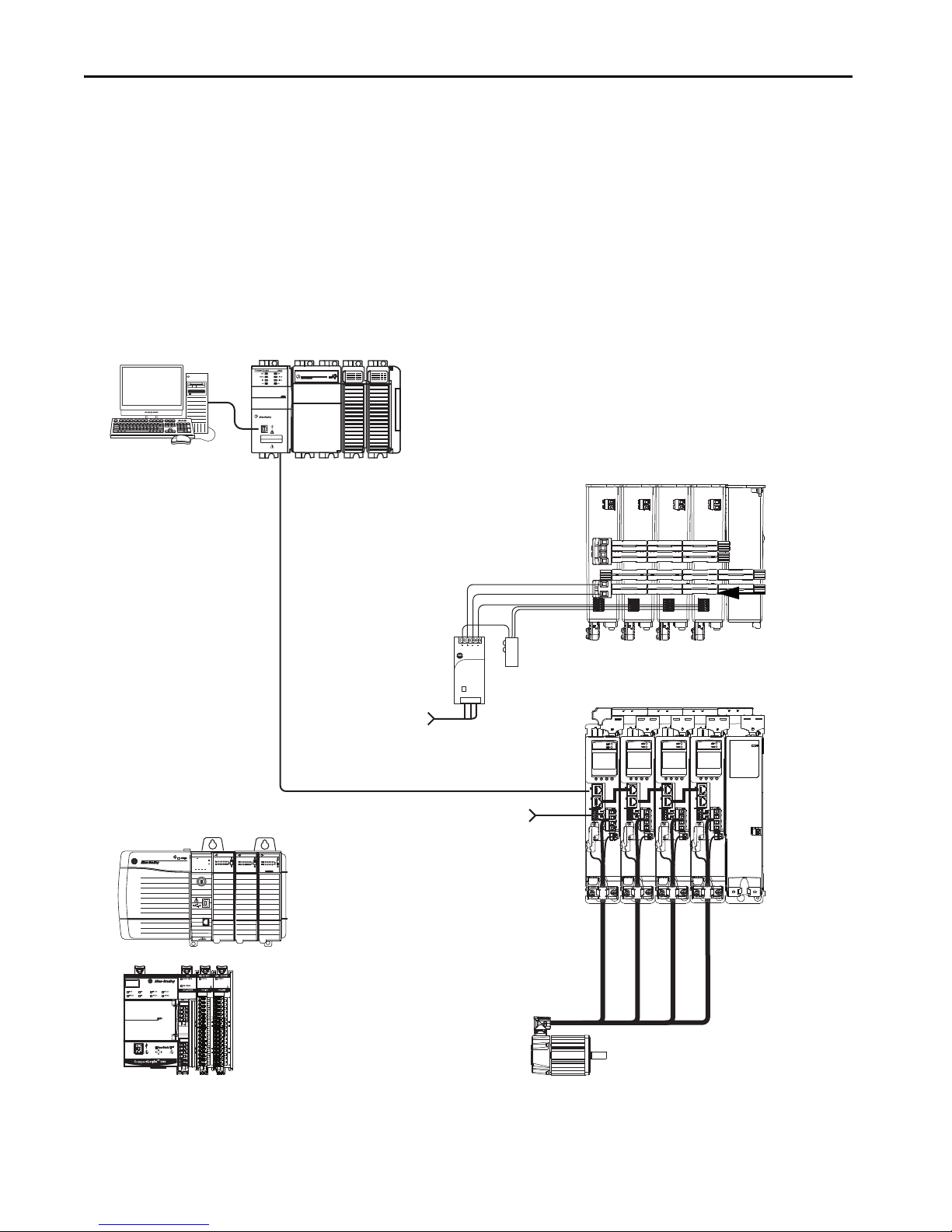

Integrated Safety Configurations

The GuardLogix 5570 or Compact GuardLogix 5370 safety controller issues the safe torque-off (STO) command over

the EtherNet/IP network and the 2198-Hxxx-ERS2 drive executes the STO command.

In this example, a single GuardLogix safety controller makes the Motion and Safety connections with the

2198-Hxxx-ERS2 integrated safety drives.

IMPORTANT If only one controller is used in an application with Motion and Safety connections, it must be a GuardLogix 5570 or Compact

GuardLogix 5370 safety controller.

Motion and Safety Configuration (single controller)

4 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 5

Kinetix 5500 Drive Systems

1606-XL

Power Supply

Input

Allen-Bradley

LNK1LNK2NET OK

EtherNet/IP

1

2

LNK1LNK2NET OK

EtherNet/IP

1

2

1585J-M8CBJM-x

Ethernet (shielded) Cable

Studio 5000 Logix Designer

Application

(version 24.0 or later)

AC Input Po wer

2198-Hxxx-ERS2 Servo Drives

(top view)

2198-Hxxx-ERS2 Servo Drives

(front view)

Digital Inputs to Sensors and Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

Kinetix VP

Servo Motors

1734-AENTR

POINT Guard I/O

EtherNet/IP Adapter

1783-BMS

Stratix 5700

Switch

Motion Program

Module Definition

Configured with

Motion only

Connect ion

Safety Program

Module Definition

Config ured with S afety

only Connection

Safety

Device

Any Logix 5000™ Controller

(CompactLogix 5370 controller is shown)

Compact GuardLogix 5370 Controller,

Compact GuardLogix 5380 Safety Controller or

GuardLogix 5570 Controller,

GuardLogix 5580 Safety Controller

(GuardLogix 5570 Safety Controller is shown)

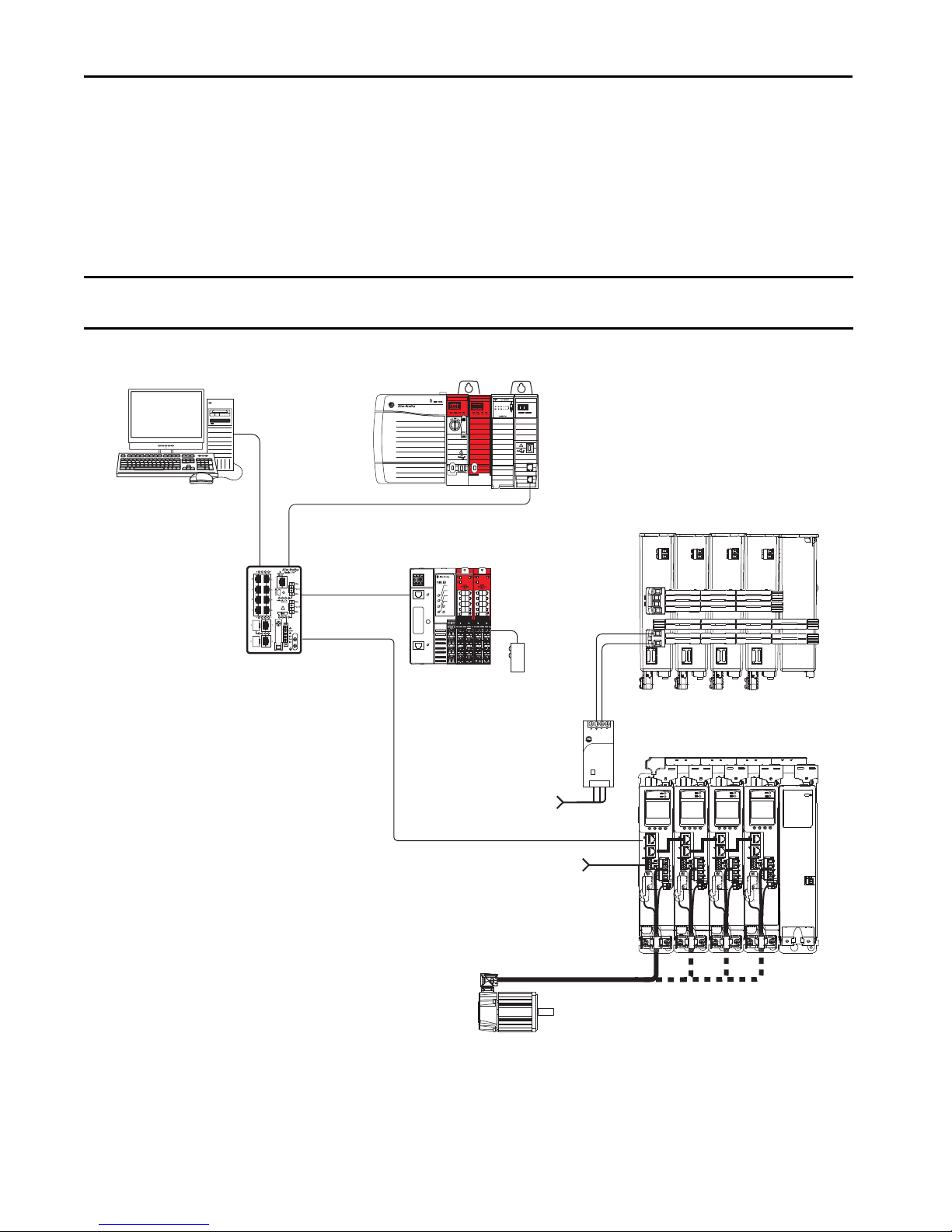

In this example, a non-safety controller makes the Motion-only connection and a separate GuardLogix safety controller

makes the Safety-only connection with the 2198-Hxxx-ERS2 integrated safety drives.

IMPORTANT If two controllers are used in an application with Motion-only and Safety-only connections, the Safety-only connection must

be a GuardLogix 5570 or Compact GuardLogix 5370 safety controller and the Motion-only connection must be a

ControlLogix5570 or CompactLogix 5370 controller.

Motion and Safety Configuration (multi-controller)

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 5

Page 6

Kinetix 5500 Drive Systems

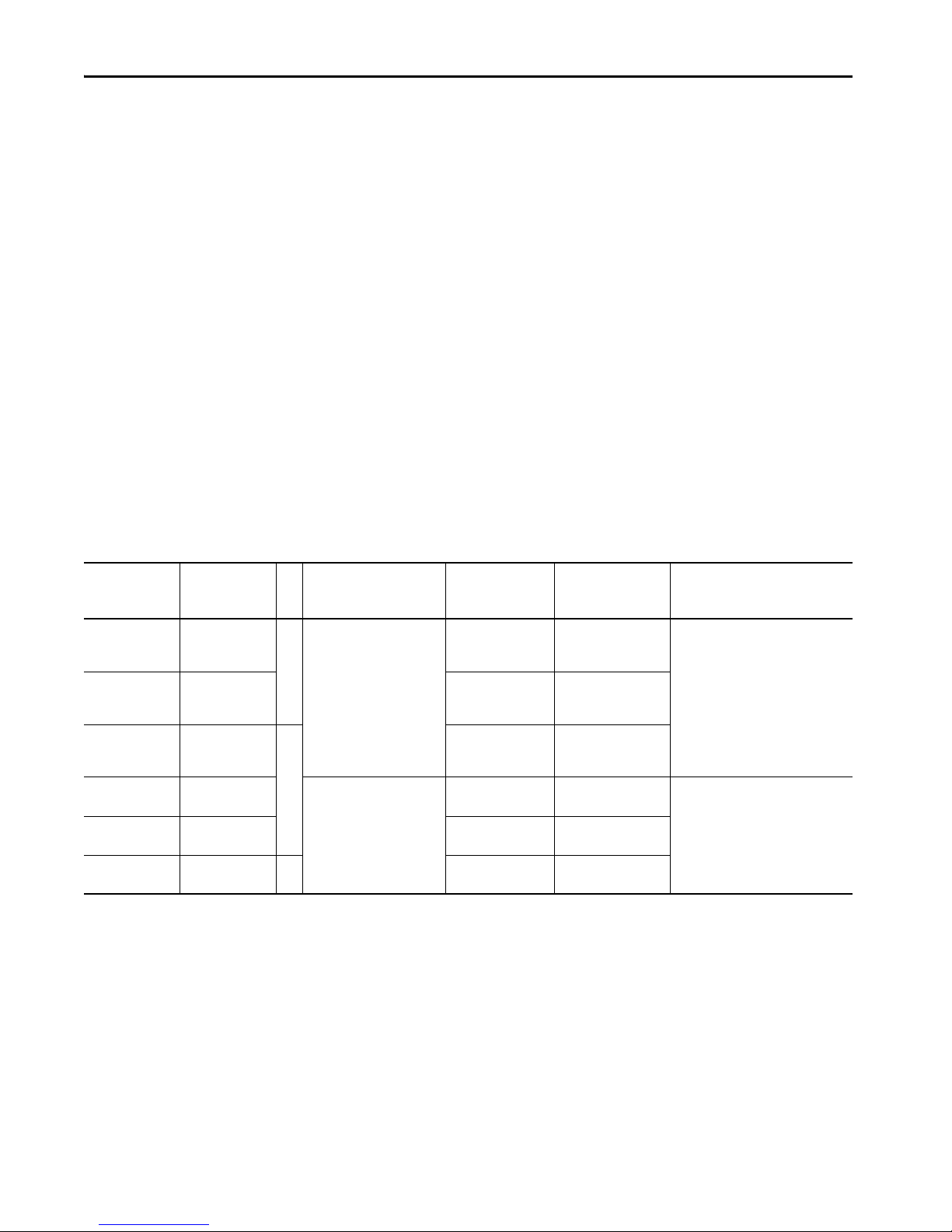

Determine What You Need

For each Kinetix 5500 drive system, the drive and motor/actuator catalog numbers are required to determine the motor

cable catalog number. Ethernet cables and a 24V DC power supply are also required.

• 2198-KITCON-DSL (2-pin) connector kits are used for motor feedback from Kinetix VP motors (highresolution absolute feedback). Kits are included with the drive and can also be purchased separately. Use these kits

with 2090-CSxM1DF or 2090-CSxM1DG cables.

• 2198-H2DCK feedback converter kits (2-pin, Hiperface-to-DSL, series B or later) feedback converter kits are

required for LDAT-series linear thrusters and MP-Series motors and actuators. Use these kits with

2090-CFBM7DF feedback cables.

• Shared-bus connector kits are required for shared-bus configurations.

Optional equipment includes the following:

• Kinetix 5500 capacitor module

• 2198-ABQE encoder output module

• Bulletin 2198 AC line filters

• Bulletin 2097 shunt resistors

Example diagrams of the required and optional equipment are provided.

Kinetix 5500 Servo Drives

Drive Cat. No.

(hardwired STO)

2198-H003-ERS 2198-H003-ERS2

2198-H008-ERS 2198-H008-ERS2

2198-H015-ERS 2198-H015-ERS2

2198-H025-ERS 2198-H025-ERS2

2198-H040-ERS 2198-H040-ERS2

2198-H070-ERS 2198-H070-ERS2 3

Drive Cat. No.

(integrated STO)

Input Voltage

Frame

1

195…264V rms, single-phase

195…264V rms, three-phase

324…528V rms, three-phase

2

195…264V rms, three-phase

324…528V rms, three-phase

Continuous Output

Power

kW

0.2 kW

0.3 kW

0.6 kW

0.5 kW

0.8 kW

1.6 kW

1.0 kW

1.5 KW

3.2 kW

2.4 kW

5.1 kW

4.0 kW

8.3 kW

7.0 kW

14.6 kW

Continuous Output

Current

A 0-pk

1.4

3.5

7.1

11.3

18.4

32.5

Featu res

• Single-axis, single or three-phase

• Multi-axis, three-phase bus-sharing

• Designed for optimum performance

with Kinetix VP servo motors

• Single cable technology

• Safe torque-off

• Single-axis, three-phase

• Multi-axis, three-phase bus-sharing

• Designed for optimum performance

with Kinetix VP servo motors

• Single cable technology

• Safe Torque-off

6 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 7

Kinetix 5500 Drive Systems

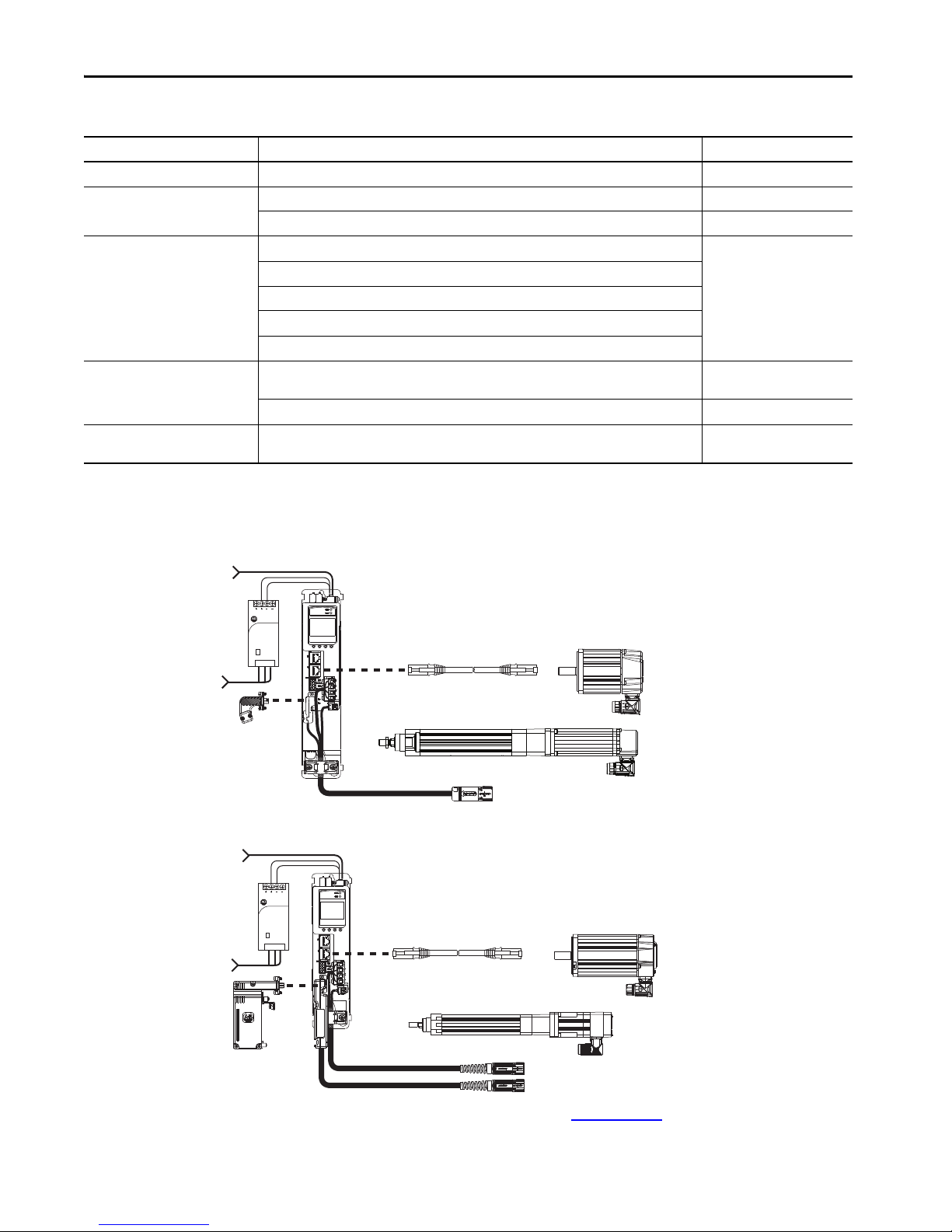

2198-KITCON-DSL Connector Kit

• Accepts DSL motor feedback from Kinetix VP

(Bulletin VPL, VPF, VPH, VPS) rotary motors

and Kinetix VP electric cylinders

• Feedback-only (DSL )

Bulletin 2090 Motor Power and Feedback Cables

MP-Series Linear Actuators

(MPAR-B3xxxx electric cylinder is shown)

MP-Series Rotary Motors

(MPL-Bxxxx motor is shown)

LDAT-Sxxxxxx-xDx

Linear Thrusters

2198-H2DCK Converter Kit

Converts 15-pin Hiperface feedback into 2-pin DSL feedback for:

• MP-Series rotary motors and linear actuators

• LDAT-Series linear thrusters

• Feedback-only (absolute single-turn/multi-turn Hiperface)

2-pin Motor Feedback

(MF) Connector

2198-Hxxx-ERSx Drive

(front view)

MP-Series Linear Actuators

(MPAS-B9xxx ballscrew linear stage is shown)

Kinetix VP Rotary Motors

(VPL-Bxxxx motor is shown)

MP-Series Linear Actuators

(MPAI-B3xxxx heavy-duty electric c ylinder is shown)

Induction Rotary Motors

(no feedback, V/Hz)

2090-CSBM1DF or 2090-CSBM1DG

Single Motor Cables

Kinetix VP Electric Cylinders

(Bulletin VPAR)

Feedback connections are made at the 2-pin motor feedback (MF) connector. These examples illustrate how you can use

the Bulletin 2198 connector kits for making these connections. These examples illustrate how you can use the Bulletin

2198 connector kits for making these connections.

Feedback Configuration Examples

IMPORTANT In 2198-H2DCK converter kit applications, you can replace the 2090-CPxM7DF power/brake cable with a 2090-CSBM1DF single

motor cable (and reuse the 2090-CFBM7DF feedback cable) to increase the maximum cable length to 50 m (164 ft). However,

this applies to only 18 and 14 AWG single cables. 2090-CSxM1Dx-10Axxx (10 AWG/M40 connector) single cables are not

compatible with 2090-CPBM7DF-10Axxx (10 AWG/M40 connector) power/brake cables.

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 7

Page 8

Kinetix 5500 Drive Systems

1606-XL

Power Supply

Input

Allen-Bradley

Bulletin 2090 Single Motor Cable

1585J-M8CBJM-x

Ethernet (shielded) Cable

1606-XLxxx

24V DC Control Power Supply

for Control, Digital Inputs,

and Motor Brakes

AC Inp ut Power

Single-phase or Three-phase

AC Input Power

2198-KITCON-DSL

Feedback Connector Kit

2198-Hxxx-ERSx

Kinetix 5500 Servo Drive

Kinetix VP Rotary Motors

(Bulletin VPL motor is shown)

Kinetix VP Linear Actuators

(Bulletin VPAR electric cylinder is shown)

1585J-M8CBJM-x

Ethernet (shielded) Cable

1606-XLxxx

24V DC Control Power Supply

for Control, Digital Inputs,

and Motor Brakes

AC Input Power

Single-phase or Three-phase

AC Input Po wer

Bulletin 2090 Motor Power/Brake

and Feedback Cables

2198-H2DCK (series B or later)

Feedback Converter Kit

2198-Hxxx-ERSx

Kinetix 5500 Servo Drive

MP-Series Rotary Motors

(Bulletin MPL low-inertia motor is shown)

MP-Series Linear Actuators

(Bulletin MPAR electric cylinder is shown)

High-resolution absolute

encoder feedback only.

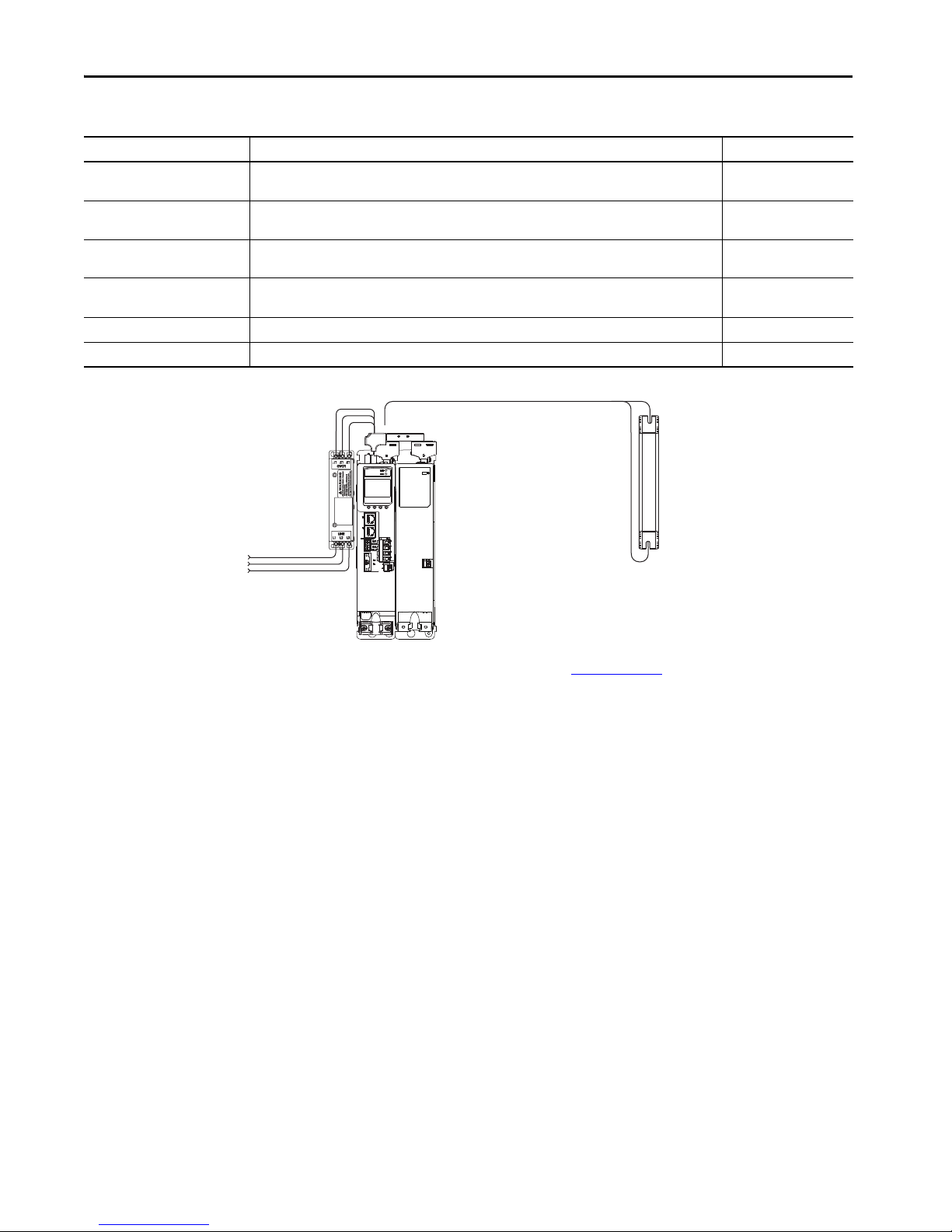

Required Drive Accessories

Drive Accessory Description Cat. No.

24V power supply 24V DC for control power and motor brakes. 1606-XLxxx

Ethernet network cables

Motor cables

Shared-bus connection system

Hiperface-to-DSL

feedback converter kit

(1) The 2198-KITCON-DSL feedback connector kit is required for Kinetix VP motors and actuators and is included with each Kinetix 5500 servo drive. Replacement kits are also available.

(2) The maximum cable length is reduced to 20 m (65.6 ft) for these systems and typical system performance, as documented in this publication, requires the motor and drive at 40 °C (104 °F) ambient

and rated line voltage.

(2)

Double-ended, non-flex, shielded. 1585J-M8CBJM-x

Double-ended, high-flex, shielded. 1585J-M8UBJM-x

Kinetix VP (Bulletin VPL, VPF, VPH, and VPS) rotary motors.

Kinetix VP (Bulletin VPAR) electric cylinders.

(1)

MP-Series (Bulletin MPL, MPM, MPF, and MPS) rotary motors with high-resolution absolute encoders.

MP-Series (Bulletin MPAS ballscrew, MPAR, and MPAI) linear actuators.

(1)

Refer to the specific drive/motor

combination for the motor

cables required for your system.

LDAT-Series linear thrusters.

Input wiring connectors and DC-bus T connectors for use between frame 1, 2, and 3 servo drives

(frame 3:2, frame 2:1, frame 1:1, and frame 2:2). Required for shared-bus configurations.

2198-H040-x-x

Input wiring connectors and DC-bus T connectors for use between frame 3 servo drives (frame 3:3). 2198-H070-x-x

Converts Hiperface high-resolution absolute encoder feedback to Hiperface DSL feedback. Required

for feedback connections to LDAT-Series linear thrusters and MP-Series motors and actuators.

2198-H2DCK

Kinetix 5500 Drive with Kinetix VP Motor

Kinetix 5500 Drive with MP-Series Motor or Actuator

Allen-Bradley

1606-XL

Power Supply

Input

Refer to the Kinetix Servo Drives Specifications Technical Data, publication KNX-TD003, for detailed descriptions and

additional specifications for the Kinetix 5500 drive family.

8 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 9

Kinetix 5500 Drive Systems

Single-phase or Three-phase

AC Inp ut Power

2097-Rx Shunt Resistor

Bulletin 2198 AC Line Filter

(required for CE)

2198-CAPMOD-1300

Capacitor Module

2198-Hxxx-ERSx

Kinetix 5500 Servo Drive

Bulletin 2198 shared-bus connection

system for bus-sharing configurations.

Optional Drive Accessories

Drive Accessory Description Cat. No.

Shared-bus connector kits 24V input wiring connectors, T-connectors, and bus bars for the 24V shared-bus connection system

Capacitor module

Encoder output module

AC line filters AC line conditioning for EMC.

Bulletin 2097 shunt resistor Panel-mount shunt resistor. 2097-Rx

External auxiliary encoders Allen-Bradley Integrated Motion encoder on the EtherNet/IP network provides a feedback-only axis. Bulletin 842E-CM

Capacitor bank for energy storage and/or to improve performance in applications that produce regenerative

energy and require shorter duty cycles (1360 μf).

The Allen-Bradley encoder output module is a DIN-rail mounted EtherNet/IP network-based standalone

module capable of outputting encoder pulses to a customer-supplied peripheral device.

• 2198-TCON-24VDCIN36

• 2198-xxxx-P-T

2198-CAPMOD-1300

2198-ABQE

• 2198-DBRxx-F

• 2198-DBxx-F

Kinetix 5500 Optional Accessories

Refer to the Kinetix Servo Drives Specifications Technical Data, publication KNX-TD003, for detailed descriptions and

additional specifications for the Kinetix 5500 drive accessories.

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 9

Page 10

Kinetix 5500 Drive Systems

Studio 5000 Logix Designer

Application

1585J-M8CBJM-x

Ethernet (shielded) Cable

1734-AENTR POINT I/O™

EtherNet/IP Adapter

PanelVie w™ Plus

Display Terminal

1585J-M8CBJM-OM15

0.15 m (6 in.) Ethernet cables

for drive-to-drive connections.

Kinetix 5500 Servo Drive System

2198-ABQE

Encoder Output Module

Line Scan

Cameras

CompactLogix 5370 Controller

2198-Hxxx-ERSx Drives

(front view)

Zero-stack Tab

and Cutout Engaged

In this example, the encoder output module outputs encoder pulses to cameras used in line-scan vision systems. The

module supports real and virtual axes for systems using the integrated motion on EtherNet/IP network.

Encoder Output Module Example

00:00:BC:2E:69:F6

1 (Front)

2 (Rear)

MOD

NET

OUTPUT-A OUTPUT-B

1734-AENTR

02

0

POINT I O

Module

Status

Network

Activity

Network

Status

Point Bus

Status

Link 1

Activity/

System

Status

Power

Field

Power

Link 2

Activity/

Status

Refer to the Kinetix Servo Drives Specifications Technical Data, publication KNX-TD003, for detailed descriptions and

additional specifications for the Kinetix 5500 drive accessories.

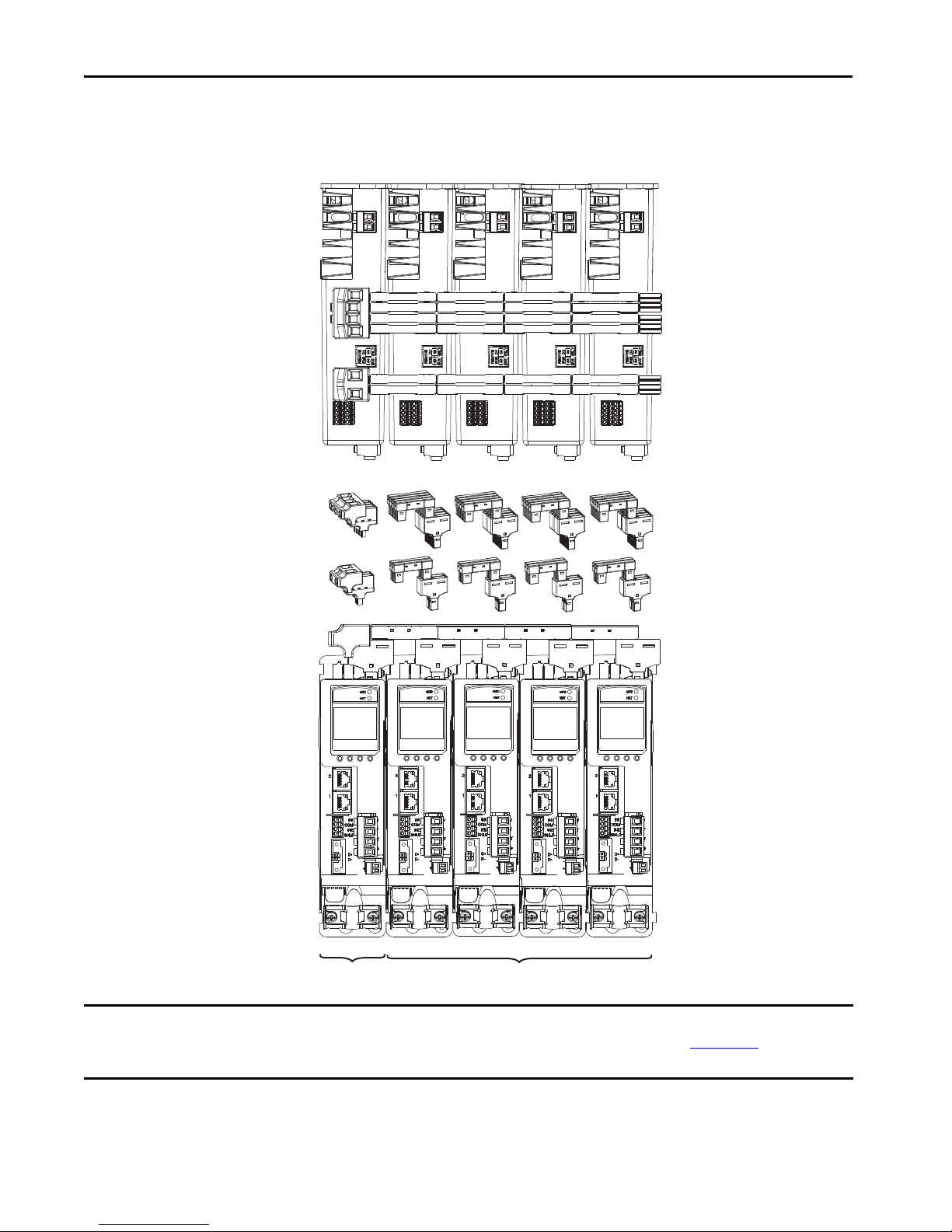

Kinetix 5500 Shared-bus System Examples

These system examples illustrate how Kinetix 5500 servo drives and shared-bus accessories are used in typical shared-bus

configurations. In these examples, frame 1 and 2 drives are used, so the shared-bus accessories are all catalog number

2198-H040-x-x.

Engaging the zero-stack tab and cutout from drive-to-drive makes efficient use of panel space for installations with

multiple drives. Engaging the zero-stack tab and cutout from drive-to-drive is required for shared-bus multi-axis drive

systems. This is done to make sure the drive connectors are spaced properly to accept the shared-bus connection system.

Zero-stack Tab and Cutout Example

Refer to the Kinetix Servo Drives Specifications Technical Data, publication KNX-TD003, for detailed descriptions and

catalog numbers for the shared-bus connector kits.

10 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 11

In this example, three-phase AC power and 24V control power is shared in a shared-AC configuration. All drives must

+

+

++

Kinetix 5500 Servo Drives (top view)

2198-H008-ERS (frame 1) Drives are Shown

Three-phase

Input Power

Kinetix 5500 Servo Drives (front view)

2198-H008-ERS (frame 1) Drives are Shown

Shared AC ( mains AC inpu t)

Shared 24V (control power input)

Shared-bus Connection System

(front view)

AC Inp ut

Connector

Control Power

Input Connector

Bus-bar Connectors and

AC Bus T-connectors

Bus-bar Connectors and

Control Power T-connectors

24V Control

Input Power

Axis 1 Axis 2

Axis 3

Axis 4 Axis 5

2198-H040-ADP-IN 2198-H040-AP-T

The 2198-H040-ADP-IN

connector kit also includes a

DC-bus T-connector, but is not

used in this configuration.

have the same power rating (catalog number).

Shared AC Installation Example

Kinetix 5500 Drive Systems

IMPORTANT In shared AC configurations, all drives must have the same power rating. Shared AC configurations do not support the

Bulletin 2198 capacitor module. Refer to the Kinetix 5500 Servo Drives User Manual, publication 2198-UM001

information, including restrictions on how many drives can be connected in the shared AC configuration.

, for system sizing

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 11

Page 12

Kinetix 5500 Drive Systems

++++

++

2198-H040-ERSx

Common-bus (converter)

(frame 2) Leader Drives

2198-H008-ERSx

Common-bus (inverter)

(frame 1) Follower Drives

2198-CAPMOD-1300 Capacitor Module

(optional component) Front View

2198-CAPMOD-1300 Capacitor Module

(optional component) Top View

2198-Hxxx-ERS

Kinetix 5500 Servo Drives are Shown

(top view)

Three-phase

Input Power

Shared AC (mains AC input)

Shared 24V (control power input)

Shared-bus Connection System

(front view)

AC Input

Conne ctor

Control Power

Input Connector

Bus-bar Connectors and

AC Bus T-connectors

Bus-bar Connectors and

Control Power T-connectors

24V Control Input Power

Axis 1

Axis 2

Axis 3

Axis 4

Axis 5

2198-H040-ADP-IN

DC Bus

Shared DC Bus

DC Bus

Connector

Bus-bar Connectors and

DC Bus T-connectors

2198-Hxxx-ERS

Kinetix 5500 Servo Drives are Shown

(front view)

Axis 6

2198-H040-ADP-T

2198-H040-DP-T

2198-KITCON-CAP1300

(ships with capacitor module)

In this example, three-phase AC input power is supplied to two converter drives with the same power rating. This parallel

converter configuration increases the DC power supplied to the inverter drives.

Shared AC/DC Bus Hybrid Installation Example

IMPORTANT In shared AC/DC hybrid configurations, the two converter drives must have the same power rating and must be greater than or

equal to the inverter drives. Refer to the Kinetix 5500 Servo Drives User Manual, publication 2198-UM001

information, including restrictions on how many drives can be connected in the shared AC/DC, shared DC (common bus), and

hybrid configurations.

12 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

, for system sizing

Page 13

Kinetix 5500 Drive Systems

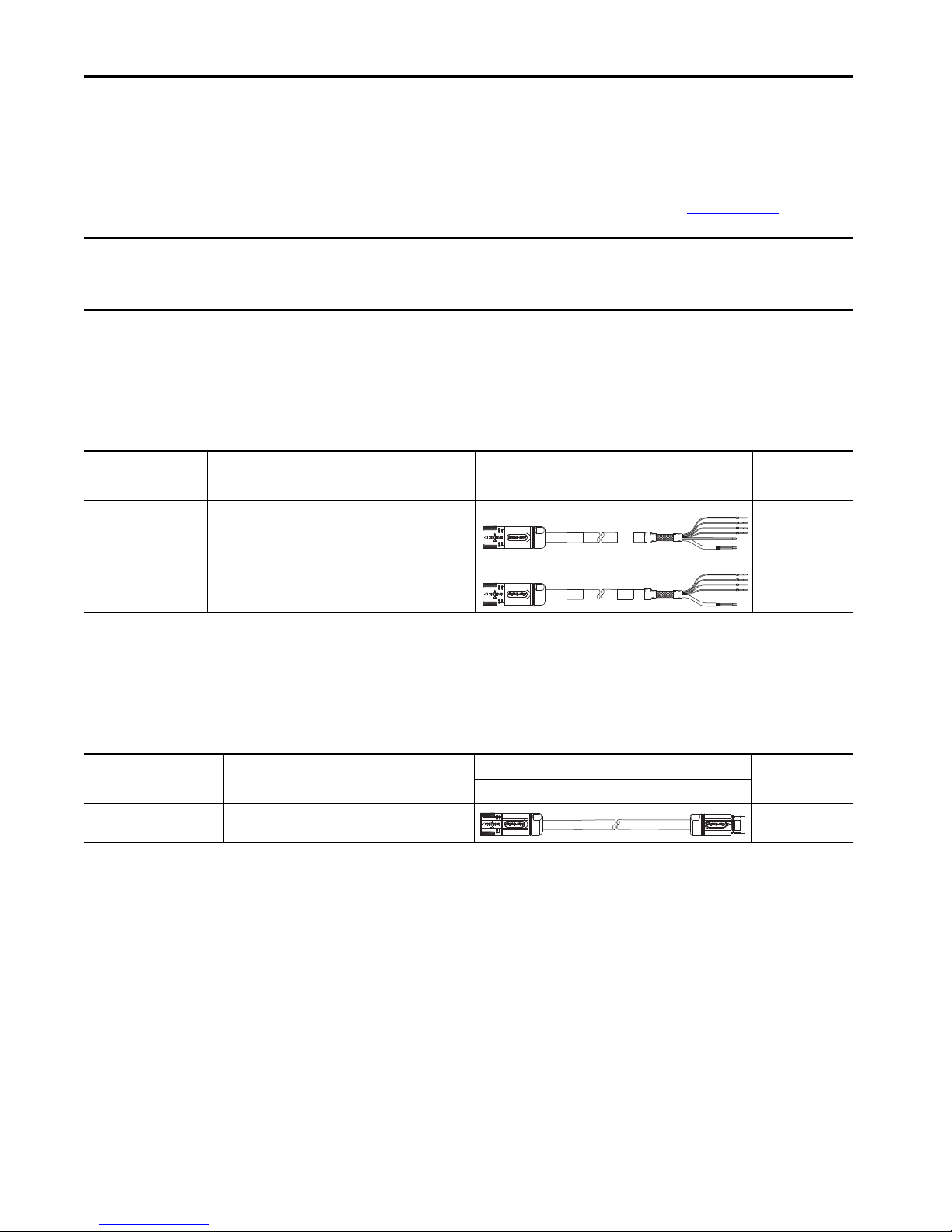

2090-Series Single Motor Cable Overview

These cables apply to Kinetix VP rotary motors and linear actuators. When using single cables, system performance of a

typical system with the motor at 40 °C (104 °F) and drive at 50 °C (122 °F) ambient applies. For maximum motor-cable

lengths with Kinetix 5500 drives, see the Kinetix 5500 Servo Drives User Manual, publication 2198-UM001

IMPORTANT Because of the unique characteristics of single cable technology, building your own cables, using field modified Rockwell

Automation® factory-delivered cable, or using third-party cables with Kinetix VP (Bulletin VPL, VPF, VPH, and VPS) motors and

Bulletin VPAR electric cylinders is not an option.

2090-CSxM1DF cable conductors have flying-leads and lead preparation that is designed specifically for Kinetix 5500

servo drives. No on-site lead preparation is required. 2090-CSxM1DG cable conductors have flying-leads and lead

preparation that is designed for either Kinetix 5500 or Kinetix 5700 servo drives. No on-site lead preparation is required;

however, 2090-CSxM1DG cable leads are longer than 2090-CSxM1DF cable leads to accommodate either drive family.

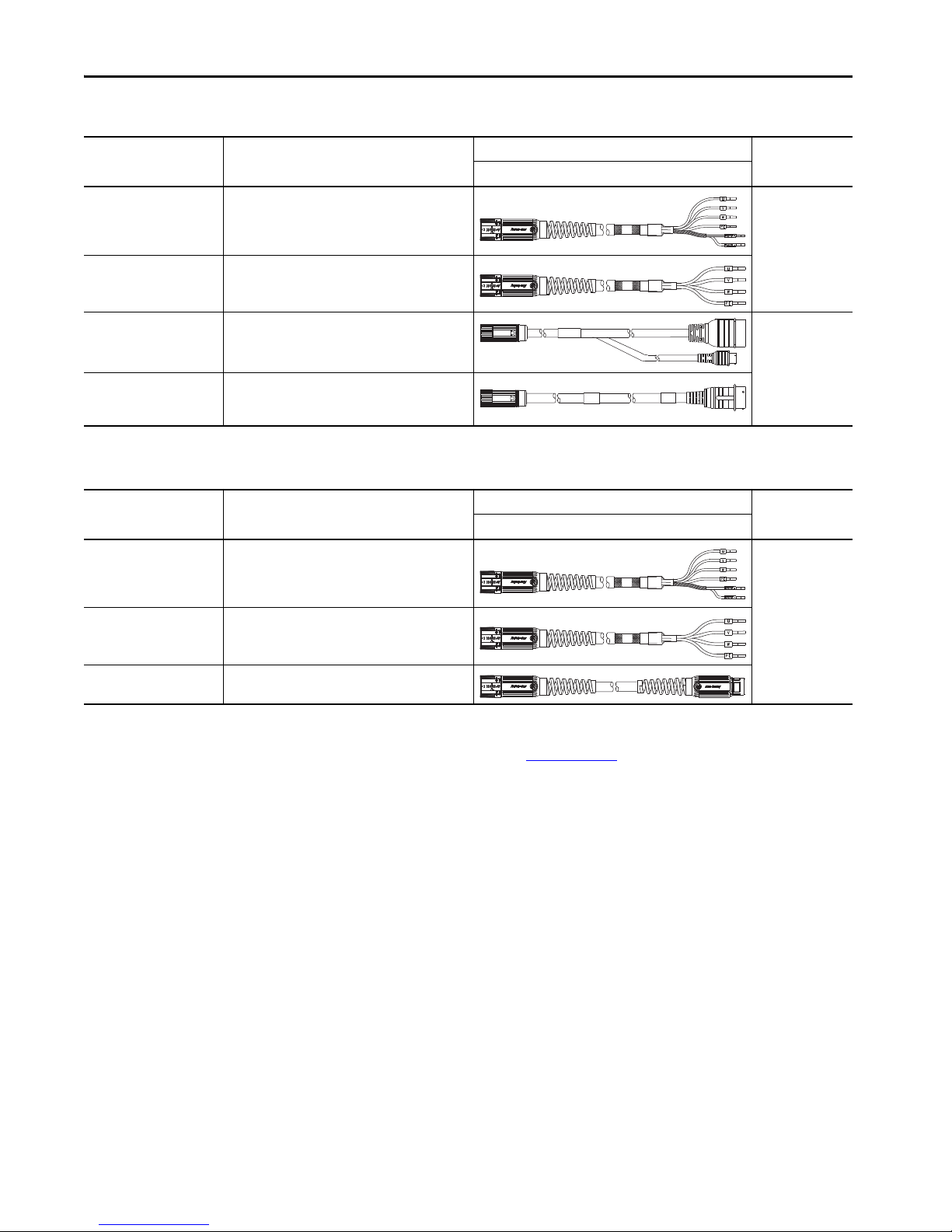

Single Motor Cable Descriptions

.

Single Cable Cat. No. Description

2090-CSBM1DF-xxAAxx

2090-CSBM1DF-xxAFxx

2090-CSBM1DG-xxAAxx

2090-CSBM1DG-xxAFxx

2090-CSWM1DF-xxAAxx

2090-CSWM1DG-xxAAxx

• Drive-end flying-leads (DF) (DG = longer lead lengths)

• Power/feedback/brake wires (SB)

• Standard, non-flex (AA)

• Continuous-flex (AF)

• Drive-end flying-leads (DF) (DG = longer lead lengths)

• Power/feedback wires only (SW)

Motor End Drive End

Cable Configuration

Motor Connector

SpeedTec DIN

Single extension cables provide continuous-flex cable technology between your standard (non-flex) cable and the

continuous-flex application. The IP rating for continuous-flex extension cables is consistent with the motor/actuator and

cable combination they are extending. Extension cables are available in lengths up to 30 m (98.4 ft). Extension power

cables are available in 18, 14, and 10 AWG.

Single Extension Cable Descriptions

Cable Cat. No. Description

2090-CSBM1E1-xxAFxx

(1) SpeedTec DIN connector (motor end) and male connector for extending SpeedTec DIN cable.

• Drive-end (male) connector, extension (E1)

• Motor-end SpeedTec DIN cable plug (M1)

(1)

Motor End Drive End

Cable Configuration

Motor Connector

SpeedTec DIN

Refer to the Kinetix Motion Accessories Technical Data, publication KNX-TD004, for cable specifications.

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 13

Page 14

Kinetix 5500 Drive Systems

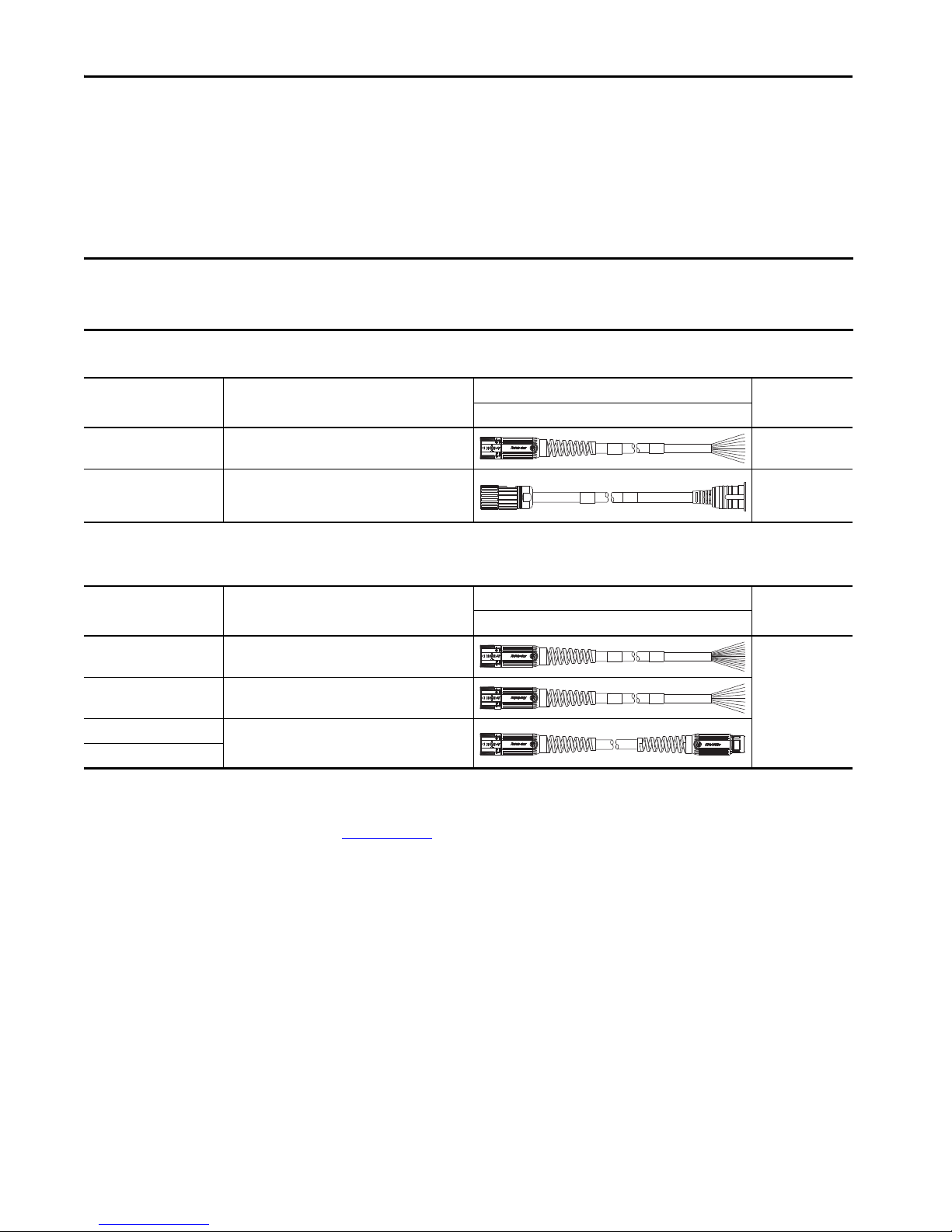

2090-Series Motor Power/Brake and Feedback Cables Overview

These cables apply to LDAT-Series linear thrusters and MP-Series motors and actuators with high-resolution absolute

encoders. When using these cables, system performance of a typical system with the motor/actuator at 40 °C (104 °F)

and drive at 40 °C (104 °F) ambient applies. Maximum motor power cable length is 20 m (65.6 ft) for Kinetix 5500 drive

systems using these cables.

IMPORTANT To increase the maximum motor power cable length to 50 m (164 ft) and the system ambient to motor at 40 °C (104 °F) and

drive at 50 °C (122 °F), use the 2090-CSBM1DF (single) cable for motor power/brake, and the 2090-CFBM7DF cable for motor

feedback.

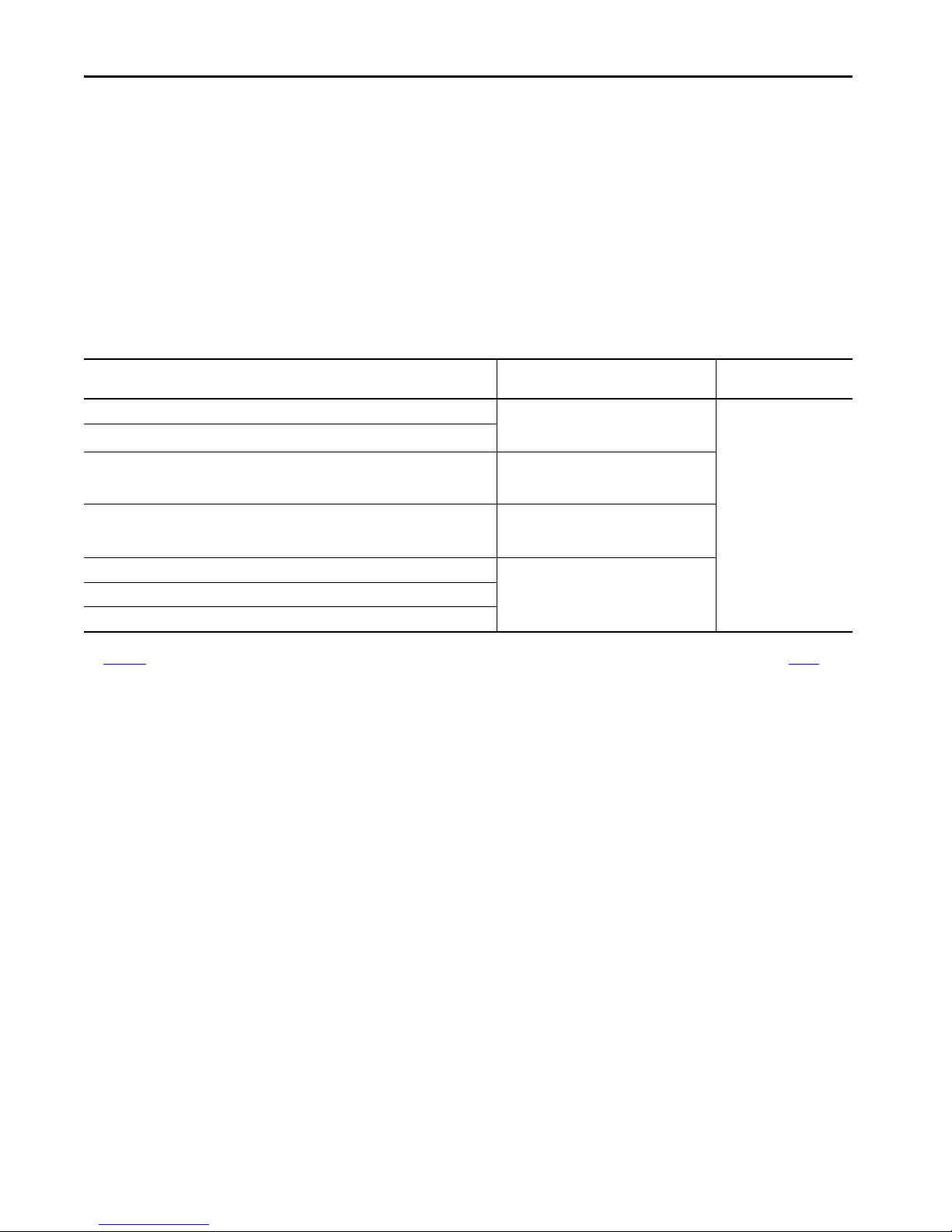

Feedback Cable Descriptions (standard, non-flex)

Standard Cable

Cat. No.

2090-CFBM7DF-CEAAxx

2090-CFBM4E2-CATR

(1) Threaded DIN connector (motor end) and bayonet connector for 2090-XXNFMP-Sxx cable.

Description

• Drive-end flying-leads (DF)

• High-resolution or resolver applications (CE)

• Drive-end bayonet (E2), transition (TR) cable

• Motor-end threaded DIN (M4)

• All feedback types (CA)

Motor/Actuator End Drive End

(1)

Cable Configuration

Motor/Actuator

Connector

SpeedTec DIN

(M7)

Threaded DIN

(M4)

Feedback Cable Descriptions (continuous-flex)

Continuous-flex Cable

Cat. No.

2090-CFBM7DF-CDAFxx

2090-CFBM7DF-CEAFxx

2090-CFBM7E7-CDAFxx

2090-CFBM7E7-CEAFxx

(1) SpeedTec DIN connector (motor end) and male connector for extending SpeedTec or threaded DIN cable.

Description

• Drive-end flying-leads (DF)

• High-resolution or incremental applications (CD)

• Drive-end flying-leads (DF)

• High-resolution or resolver applications (CE)

• Drive-end (male) connector, extension (E7)

• Motor-end SpeedTec DIN cable plug (M7)

(1)

Motor/Actuator End Drive End

Cable Configuration

Motor/Actuator

Connector

SpeedTec DIN

(M7)

Motor-end cable connector kits, for use when building your own cables are also available. Refer to the Kinetix Motion

Accessories Technical Data, publication KNX-TD004

, for more information.

14 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 15

Power/Brake Cable Descriptions (standard, non-flex)

Kinetix 5500 Drive Systems

Standard Cable

Cat. No.

2090-CPBM7DF-xxAAxx

2090-CPWM7DF-xxAAxx

Description

• Drive-end flying-leads (DF)

• Power/brake wires (PB)

• Drive-end flying-leads (DF)

• Power wire s only (PW)

• Drive-end bayonet (E2), transition (TR) cable

2090-CPBM4E2-xxTR

• Motor-end threaded DIN (M4)

• Power/brake wires (PB)

• Drive-end bayonet (E2), transition (TR) cable

2090-CPWM4E2-xxTR

• Motor-end threaded DIN (M4)

• Power wire s only (PW)

(1) Threaded DIN connector (motor end) and bayonet connector for 2090-XXNFMP-Sxx cable.

Power/Brake Cable Descriptions (continuous-flex)

Continuous-flex Cable

Cat. No.

2090-CPBM7DF-xxAFxx

Description

• Drive-end flying-leads (DF)

• Power/brake wires (PB)

Cable Configuration

Motor/Actuator End Drive End

(1)

(1)

Cable Configuration

Motor/Actuator End Drive End

Motor/Actuator

Connector

SpeedTec DIN

(M7)

Threaded DIN

(M4)

Motor/Actuator

Connector

SpeedTec DIN

2090-CPWM7DF-xxAFxx

2090-CPBM7E7-xxAFxx

(1) SpeedTec DIN connector (motor end) and male connector for extending SpeedTec or threaded DIN cable.

• Drive-end flying-leads (DF)

• Power wire s only (PW)

• Drive-end (male) connector, extension (E7)

• Motor-end SpeedTec DIN cable plug (M7)

(1)

(M7)

Refer to the Kinetix Motion Accessories Technical Data, publication KNX-TD004, for cable specifications.

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 15

Page 16

Kinetix 5500 Drive Systems

Kinetix 5500 (200V-class operation) Drives with Kinetix VP Low Inertia Motors

This section provides system combination information for the Kinetix 5500 drives (with 200 and 240V, nominal input)

when matched with Kinetix VP (200V-class) low-inertia motors. Single cable catalog numbers, system performance

specifications, and the optimum torque/speed curves are included.

Kinetix 5500 servo drives are capable of 200V or 400V-class operation. These system performance tables and torque/

speed curves reflect single-phase and three-phase drive operation with 200V-class motors; however, only 2198-H003ERSx, 2198-H008-ERSx, and 2198-H015-ERSx drives are capable of single-phase operation.

Bulletin VPL Motor Cable Combinations

Rotary Motor (200V-class)

Cat. No.

VPL-A063xx 2090-CSBM1Dx-18AAxx or

VPL-A0751E, VPL-A0752C, VPL-A0753C

VPL-A0752E, VPL-A0753E

VPL-A1001C

VPL-A1001M, VPL-A1002x, VPL-A1003x

VPL-A1152x, VPL-A1153x

VPL-A1303x, VPL-A1304x, VPL-A1306x

(1) Use 2090-CSxM1DF or 2090-CSxM1DG cables. Cable length xx is in meters, 01 (3.3)…50 (164) in 1.0 m (3.3 f t) increments. Refer to the Kinetix Motion Accessories Technical Data, publication

KNX-TD004

, for cable specifications. For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Single Motor Cable Overview beginning on page 13.

Single Cable Cat. No.

2090-CSWM1Dx-18AAxx (standard, non-flex)

2090-CSBM1Dx-18AFxx (continuous-flex)

2090-CSBM1Dx-14AAxx or

2090-CSWM1Dx-14AAxx (standard, non-flex)

2090-CSBM1Dx-14AFxx (continuous-flex)

2090-CSBM1Dx-18AAxx or

2090-CSWM1Dx-18AAxx (standard, non-flex)

2090-CSBM1Dx-18AFxx (continuous-flex)

2090-CSBM1Dx-14AAxx or

2090-CSWM1Dx-14AAxx (standard, non-flex)

2090-CSBM1Dx-14AFxx (continuous-flex)

(1)

Feedback Type

Multi-turn or Single-turn

Digital Encoder Feedback

16 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 17

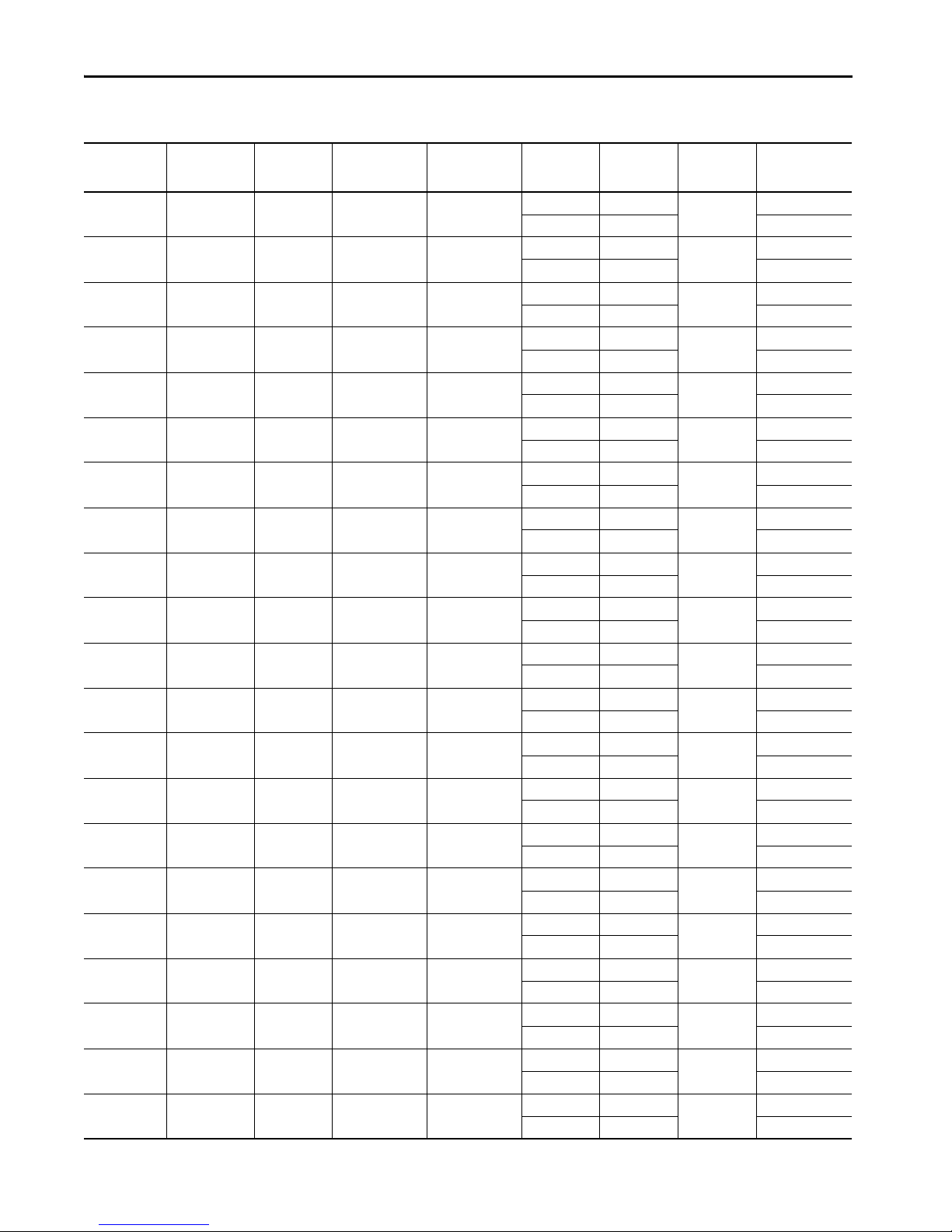

Bulletin VPL Motor Performance Specifications with Kinetix 5500 (200V-class operation) Drives

Kinetix 5500 Drive Systems

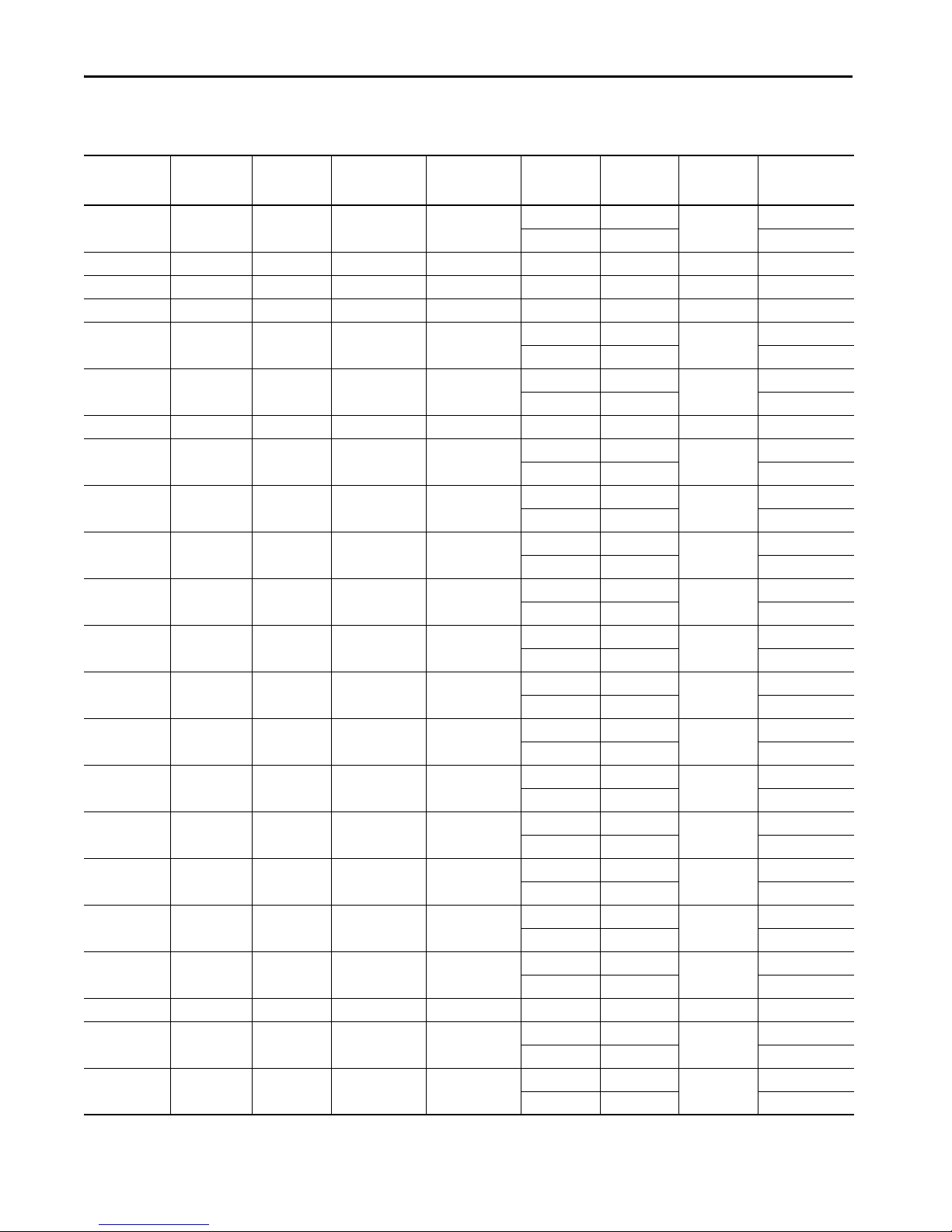

Rotary Motor

Cat. No.

VPL-A0631E 4500 4500 1.20 0.46 (4.0)

VPL-A0631M 7200 7200 1.92 0.46 (4.0) 6.48 1.33 (12.0) 0.28 (0.38) 2198-H008-ERSx

VPL-A0632F 4800 4800 2.55 0.93 (8.0) 8.75 2.69 (24.0) 0.39 (0.52) 2198-H008-ERSx

VPL-A0633C 3000 3000 2.50 1.27 (11.0) 8.75 4.09 (36.0) 0.37 (0.50) 2198-H008-ERSx

VPL-A0633F 4500 4500 3.52 1.27 (11.0)

VPL-A0751E 4800 4800 2.90 1.01 (9.0)

VPL-A0752C 3300 3300 3.80 1.61 (14.0) 13.30 4.39 (39.0) 0.49 (0.66) 2198-H015-ERSx

VPL-A0752E 4800 4800 4.90 1.61 (14.0)

VPL-A0753C 3300 3300 4.90 2.16 (19.0)

VPL-A0753E 4600 4600 6.12 2.28 (20.0)

VPL-A1001C 2800 2800 3.61 1.93 (17.0)

VPL-A1001M 6500 6500 7.15 1.95 (17.0)

VPL-A1002C 3000 3000 6.24 3.39 (30.0)

VPL-A1002F 5000 5000 10.04 3.26 (29.0)

VPL-A1003C 2250 2250 6.14 4.18 (37.0)

VPL-A1003E 3750 3750 9.58 4.18 (37.0)

VPL-A1003F 5500 5500 15.62 4.18 (37.0)

VPL-A1152B 2150 2150 6.17 5.10 (45.0)

VPL-A1152E 3300 3300 10.60 5.08 (45.0)

VPL-A1152F 5000 5000 13.56 4.70 (42.0) 45.80 13.12 (116) 2.16 (2.90) 2198-H040-ERSx

VPL-A1153C 2300 2300 8.88 6.55 (58.0)

VPL-A1303B 1950 1950 10.34 8.80 (78.0)

Rated Speed

rpm

Speed, max

rpm

System Cont inuous

Stall Current

A 0-pk

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

3.50 1.12 (9.91)

4.20 1.33 (12.0) 2198-H008-ERSx

8.80 2.87 (25.0)

12.60 4.09 (36.0) 2198-H015-ERSx

8.80 2.20 (19.0)

9.12 2.27 (20.0) 2198-H015-ERSx

17.70 4.10 (36.0)

18.90 4.39 (39.0) 2198-H025-ERSx

17.70 6.55 (58.0)

18.90 7.02 (62.0) 2198-H025-ERSx

17.70 5.13 (45.0)

25.34 7.35 (65.0) 2198-H025-ERSx

8.80 3.22 (28.0)

10.38 3.78 (33.0) 2198-H015-ERSx

17.70 3.31 (29.0)

20.20 3.78 (33.0) 2198-H025-ERSx

17.70 6.80 (60.0)

20.33 7.82 (69.0) 2198-H025-ERSx

28.30 6.77 (60.0)

34.30 7.82 (69.0) 2198-H040-ERSx

17.70 9.76 (86.0)

20.20 11.15 (99.0) 2198-H025-ERSx

28.30 9.76 (86.0)

28.80 11.15 (99.0) 2198-H040-ERSx

45.90 10.25 (90.0)

50.0 11.15 (99.0) 2198-H070-ERSx

17.70 10.95 (96.0)

21.19 13.12 (116) 2198-H025-ERSx

28.30 12.14 (107)

32.10 13.12 (116) 2198-H040-ERSx

28.30 18.30 (162)

33.0 20.33 (180) 2198-H040-ERSx

28.30 19.85 (175)

31.0 20.72 (183) 2198-H040-ERSx

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW (Hp)

0.19 (0.25)

0.44 (0.59)

0.50 (0.67)

0.66 (0.88)

0.59 (0.79)

0.80 (1.07)

0.56 (0.75)

1.29 (1.73)

1.03 (1.38)

1.60 (2.14)

0.87 (1.17)

1.31 (1.76)

1.90 (2.55)

1.02 (1.37)

1.47 (1.97)

1.35 (1.81)

1.61 (2.16)

Kinetix 5500 Drives

(240V AC Input)

2198-H003-ERSx

2198-H008-ERSx

2198-H008-ERSx

2198-H015-ERSx

2198-H015-ERSx

2198-H015-ERSx

2198-H008-ERSx

2198-H015-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H040-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H025-ERSx

2198-H025-ERSx

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 17

Page 18

Kinetix 5500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H008-ERSx and VPL-A0631M

2.0

1.5

1.0

0.5

0

0

4000

8000

60002000

17.7

13.3

8.85

4.42

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H008-ERS

x and VPL-A0631E

17.7

13.3

8.85

4.42

0

2.0

1.5

1.0

0.5

0

0

3000

5000

40001000

2000

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H008-ERS

x and VPL-A0633C

Speed (rpm)

0

2000

30001000

Torque

(N•m)

Torque

(lb•in)

2198-H008-ERS

x and VPL-A0632F

3.0

2.5

2.0

1.5

1.0

0.5

0

Speed (rpm)

0

3000

5000

4000

1000

2000

26.5

22.1

17.7

13.3

8.85

4.42

0

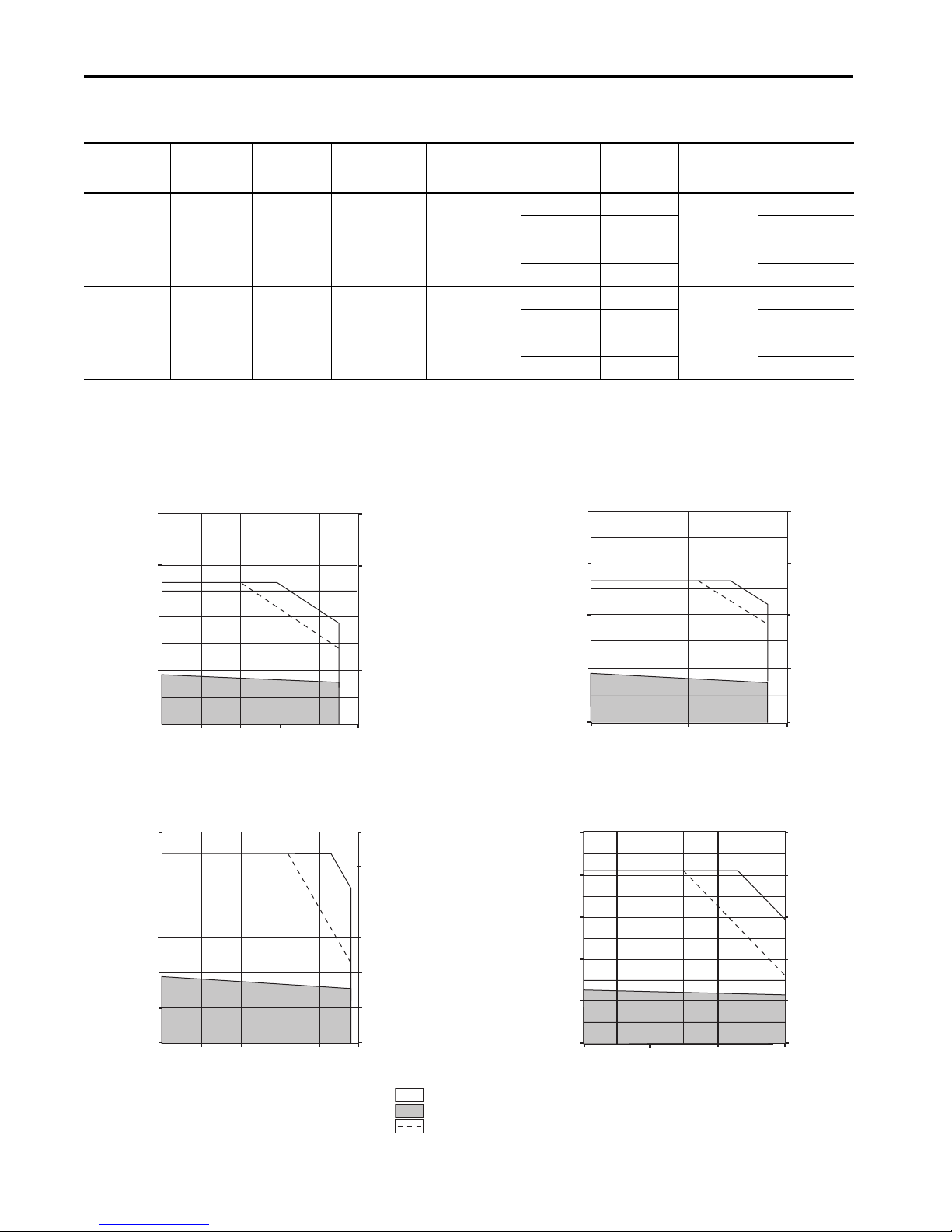

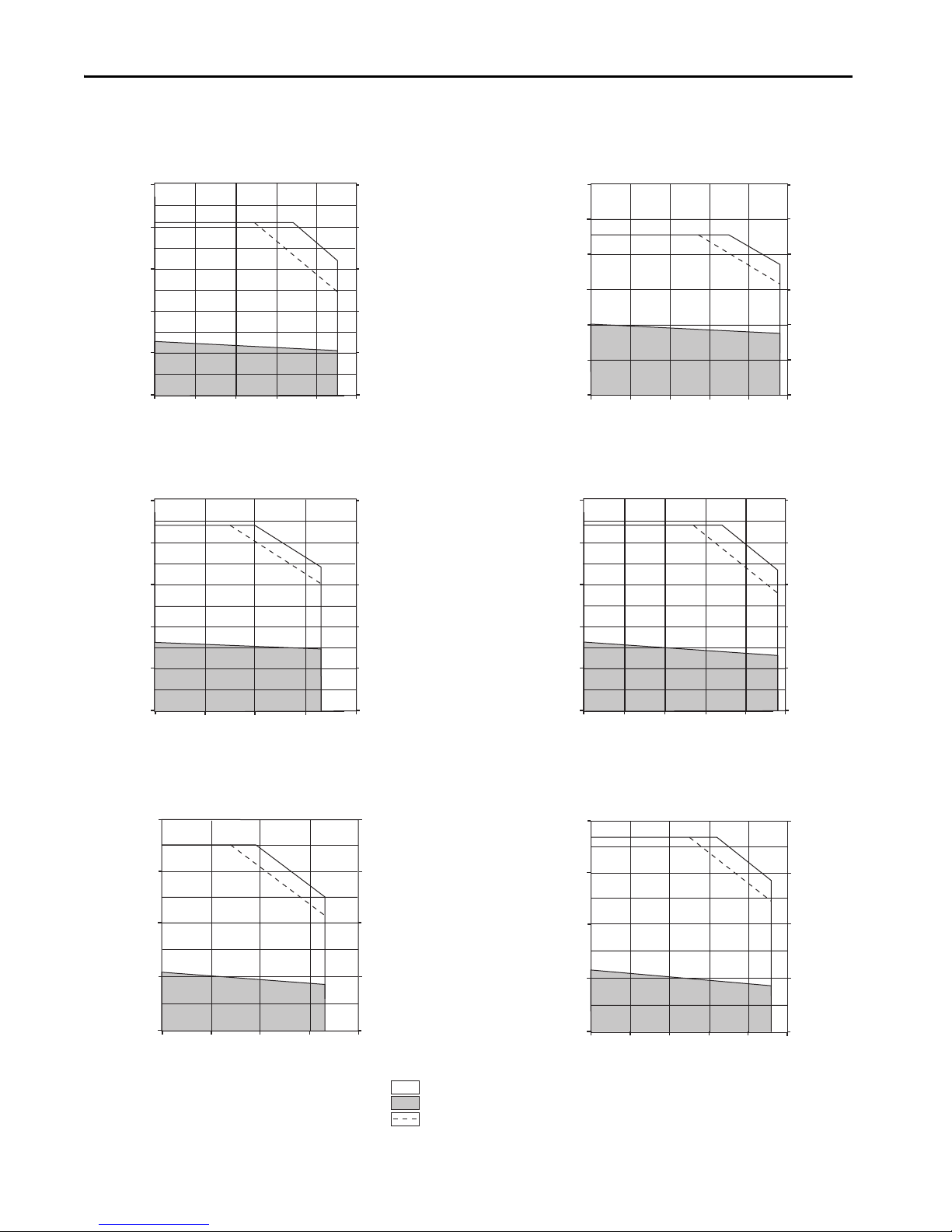

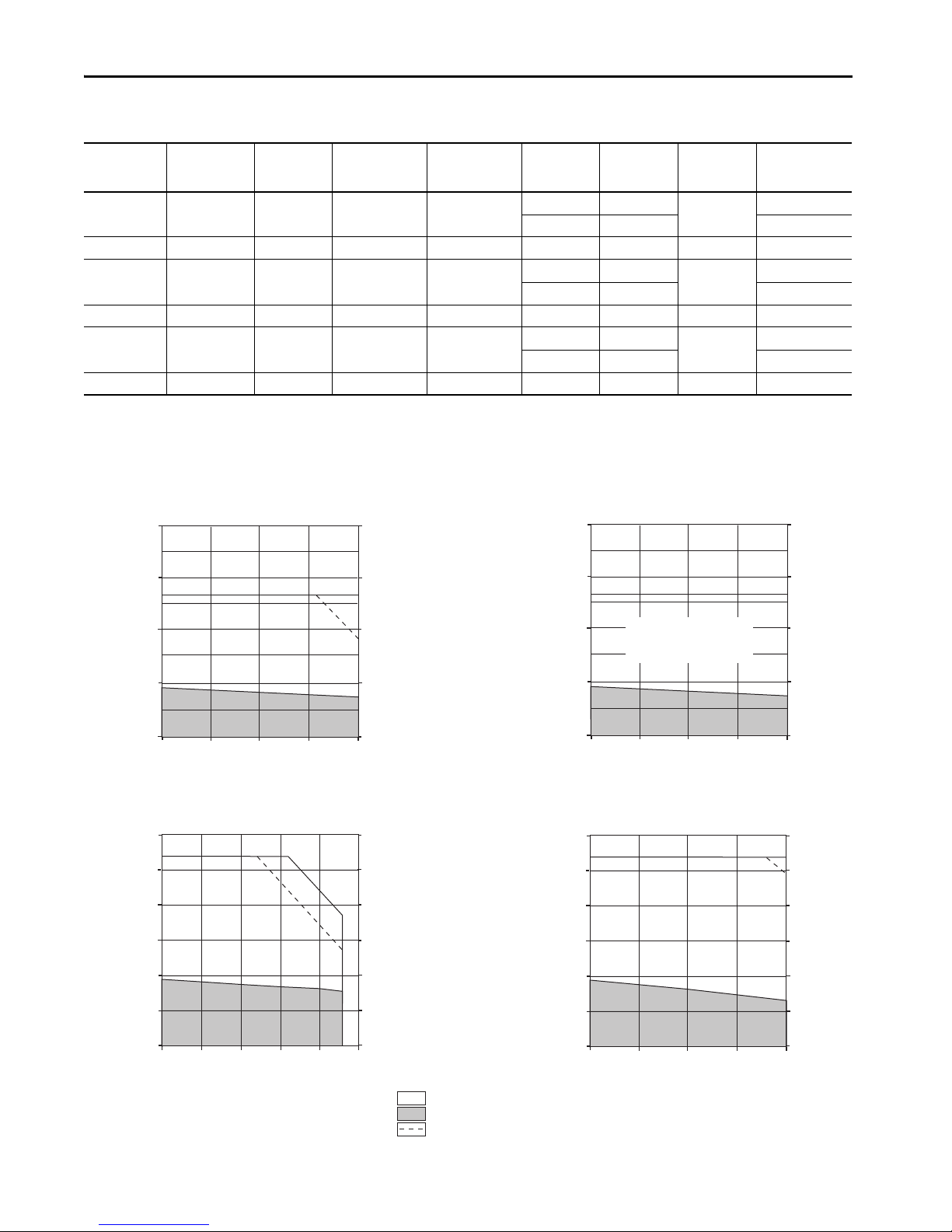

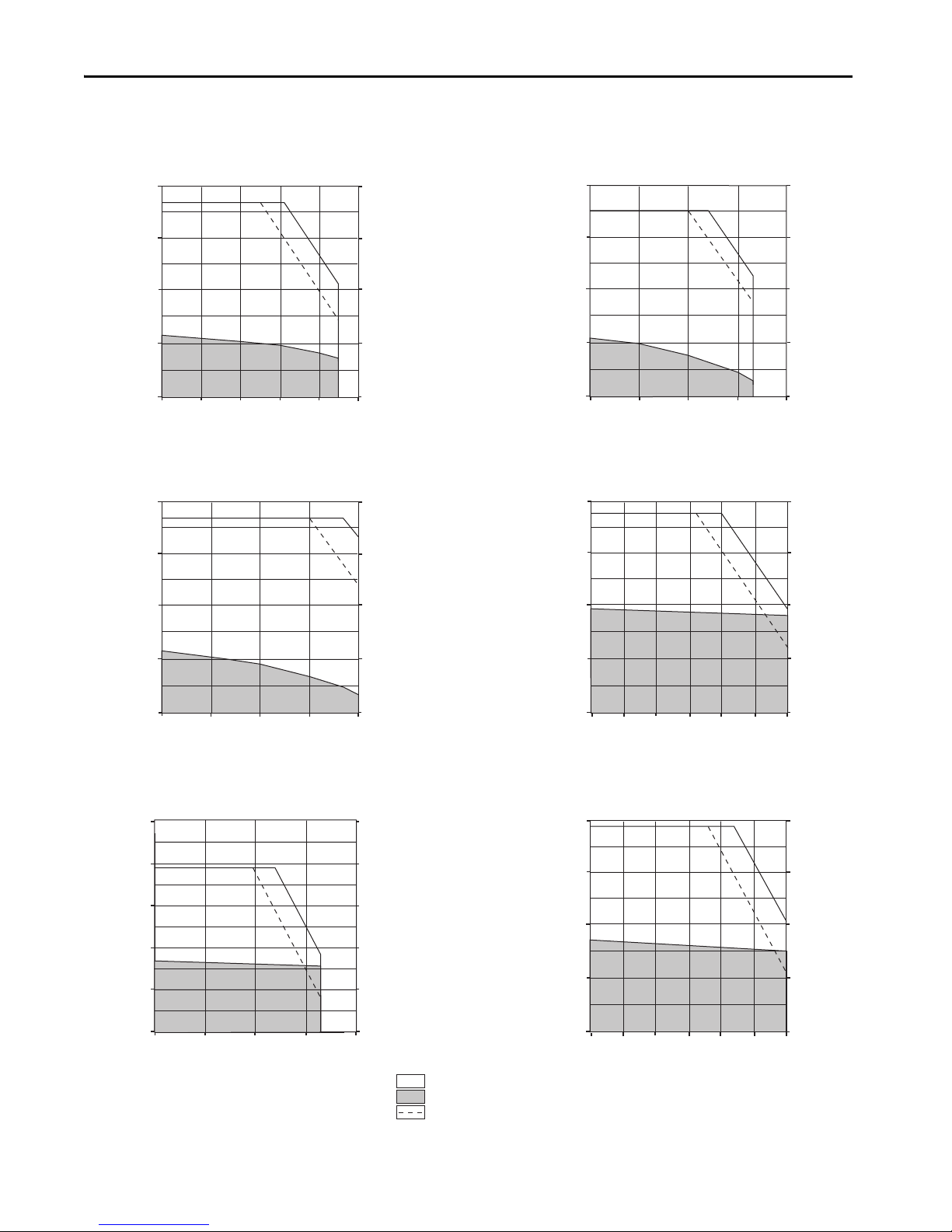

= Intermittent operating region

= Continuous operating region

= Drive operation with 200V AC rms input voltage

Bulletin VPL Motor Performance Specifications with Kinetix 5500 (200V-class operation) Drives (cont.)

Rotary Motor

Cat. No.

VPL-A1303F 4000 4000 18.60 7.75 (69.0)

VPL-A1304A 1600 1600 9.43 10.29 (91.0)

VPL-A1304D 3000 3000 18.40 10.20 (90.0)

VPL-A1306C 2000 2000 14.78 13.38 (118)

Performance specification data and curves reflect nominal sys tem performance of a typical system with the motor at 40 °C (104 °F) and the drive at 50 °C (122 °F) ambient, and rated line voltage. For

additional information on ambient and line conditions, refer to Motion Analyzer software.

Rated Speed

rpm

Speed, max

rpm

System Cont inuous

Stall Current

A 0-pk

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

45.90 15.36 (136)

62.0 20.72 (183) 2198-H070-ERSx

28.30 25.03 (221)

33.76 28.45 (252) 2198-H040-ERSx

45.90 21.48 (190)

58.0 27.10 (240) 2198-H070-ERSx

45.90 28.50 (252)

55.83 34.62 (306) 2198-H070-ERSx

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW (Hp)

2.50 (3.35)

1.55 (2.08)

2.60 (3.50)

2.13 (2.86)

Kinetix 5500 Drives

(240V AC Input)

2198-H040-ERSx

2198-H025-ERSx

2198-H040-ERSx

2198-H040-ERSx

Kinetix 5500 (200V-class operation) Drives/Kinetix VP Low Inertia Motor Curves

18 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 19

Kinetix 5500 (200V-class operation) Drives/Kinetix VP Low Inertia Motor Curves (continued)

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H015-ERSx and VPL-A0633F

Speed (rpm)

0

3000

5000

4000

1000

2000

Torque

(N•m)

Torque

(lb•in)

2198-H015-ERSx and VPL-A0751E

3.0

2.5

2.0

1.5

1.0

0.5

0

Speed (rpm)

0

3000

5000

4000

1000

2000

26.5

22.1

17.7

13.3

8.85

4.42

0

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H015-ERSx and VPL-A0752C

Speed (rpm)

0

2000

4000

30001000

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H025-ERS

x and VPL-A0752E

Speed (rpm)

0

3000

5000

4000

1000

2000

= Intermittent operating region

= Continuous operating region

= Drive operation with 200V AC rms input voltage

Torque

(N•m)

Torque

(lb•in)

2198-H025-ERSx and VPL-A0753C

70.8

53.1

35.4

1.77

0

8.0

6.0

4.0

2.0

0

Speed (rpm)

0

2000

4000

30001000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H025-ERS

x and VPL-A0753E

70.8

53.1

35.4

17.7

0

8.0

6.0

4.0

2.0

0

0

3000

5000

40001000

2000

Kinetix 5500 Drive Systems

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 19

Page 20

Kinetix 5500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H025-ERSx and VPL-A1001M

35.4

26.5

17.7

8.85

0

4.0

3.0

2.0

1.0

0

0

4000

8000

60002000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H015-ERSx and VPL-A1001C

35.4

26.5

17.7

8.85

0

0

2000

4.0

3.0

2.0

1.0

0

30001000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H040-ERS

x and VPL-A1002F

70.8

53.1

35.4

17.7

0

8.0

6.0

4.0

2.0

0

0

3000

5000

40001000

2000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H025-ERS

x and VPL-A1002C

70.8

53.1

35.4

1.77

0

0

2000

8.0

6.0

4.0

2.0

0

30001000

Torque

(N•m)

Torque

(lb•in)

2198-H040-ERSx and VPL-A1003E

12.0

10.0

8.0

6.0

4.0

2.0

0

Speed (rpm)

106

88.5

70.8

53.1

35.4

17.7

0

0

2000

4000

30001000

Torque

(N•m)

Torque

(lb•in)

2198-H025-ERSx and VPL-A1003C

12.0

10.0

8.0

6.0

4.0

2.0

0

Speed (rpm)

0

1500

2500

2000

500

1000

106

88.5

70.8

53.1

35.4

17.7

0

= Intermittent operating region

= Continuous operating region

= Drive operation with 200V AC rms input voltage

Kinetix 5500 (200V-class operation) Drives/Kinetix VP Low Inertia Motor Curves (continued)

20 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 21

Kinetix 5500 (200V-class operation) Drives/Kinetix VP Low Inertia Motor Curves (continued)

Torque

(N•m)

Torque

(lb•in)

0

0

3.0

6.0

9.0

15.0

12.0

26.5

53.1

79.6

106

133

2198-H025-ERSx and VPL-A1152B

Speed (rpm)

0

1500

2500

2000

500

1000

Torque

(N•m)

Torque

(lb•in)

2198-H070-ERSx and VPL-A1003F

12.0

10.0

8.0

6.0

4.0

2.0

0

Speed (rpm)

106

88.5

70.8

53.1

35.4

17.7

0

0

4000

60002000

Torque

(N•m)

Torque

(lb•in)

0

0

3.0

6.0

9.0

15.0

12.0

26.5

53.1

79.6

106

133

2198-H040-ERSx and VPL-A1152E

Speed (rpm)

0

2000

4000

30001000

Torque

(N•m)

Torque

(lb•in)

0

0

3.0

6.0

9.0

15.0

12.0

26.5

53.1

79.6

106

133

2198-H040-ERSx and VPL-A1152F

Speed (rpm)

0

3000

5000

4000

1000

2000

Torque

(N•m)

Torque

(lb•in)

2198-H040-ERSx and VPL-A1153C

24.0

20.0

16.0

12.0

8.0

4.0

0

Speed (rpm)

212

177

142

106

70.8

35.4

0

0

1500

2500

2000

500

1000

Torque

(N•m)

Torque

(lb•in)

2198-H040-ERSx and VPL-A1303B

24.0

20.0

16.0

12.0

8.0

4.0

0

Speed (rpm)

212

177

142

106

70.8

35.4

0

0

1000

2000

1500500

= Intermittent operating region

= Continuous operating region

= Drive operation with 200V AC rms input voltage

Kinetix 5500 Drive Systems

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 21

Page 22

Kinetix 5500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

0

0

6.0

12.0

18.0

30.0

24.0

53.1

106

159

212

265

2198-H040-ERSx and VPL-A1304A

Speed (rpm)

0

1000

2000

1500500

Torque

(N•m)

Torque

(lb•in)

2198-H070-ERSx and VPL-A1303F

24.0

20.0

16.0

12.0

8.0

4.0

0

Speed (rpm)

212

177

142

106

70.8

35.4

0

0

2000

4000

30001000

Torque

(N•m)

Torque

(lb•in)

0

0

6.0

12.0

18.0

30.0

24.0

53.1

106

159

212

265

2198-H070-ERSx and VPL-A1304D

Speed (rpm)

0

2000

30001000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

500 1000 1500 20000

2198-H070-ERSx and VPL-A1306C

40.0

35.0

30.0

25.0

20.0

15.0

10.0

5.0

0

354

310

265

221

177

133

88.5

44.2

0

= Intermittent operating region

= Continuous operating region

= Drive operation with 200V AC rms input voltage

Kinetix 5500 (200V-class operation) Drives/Kinetix VP Low Inertia Motor Curves (continued)

22 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 23

Kinetix 5500 Drive Systems

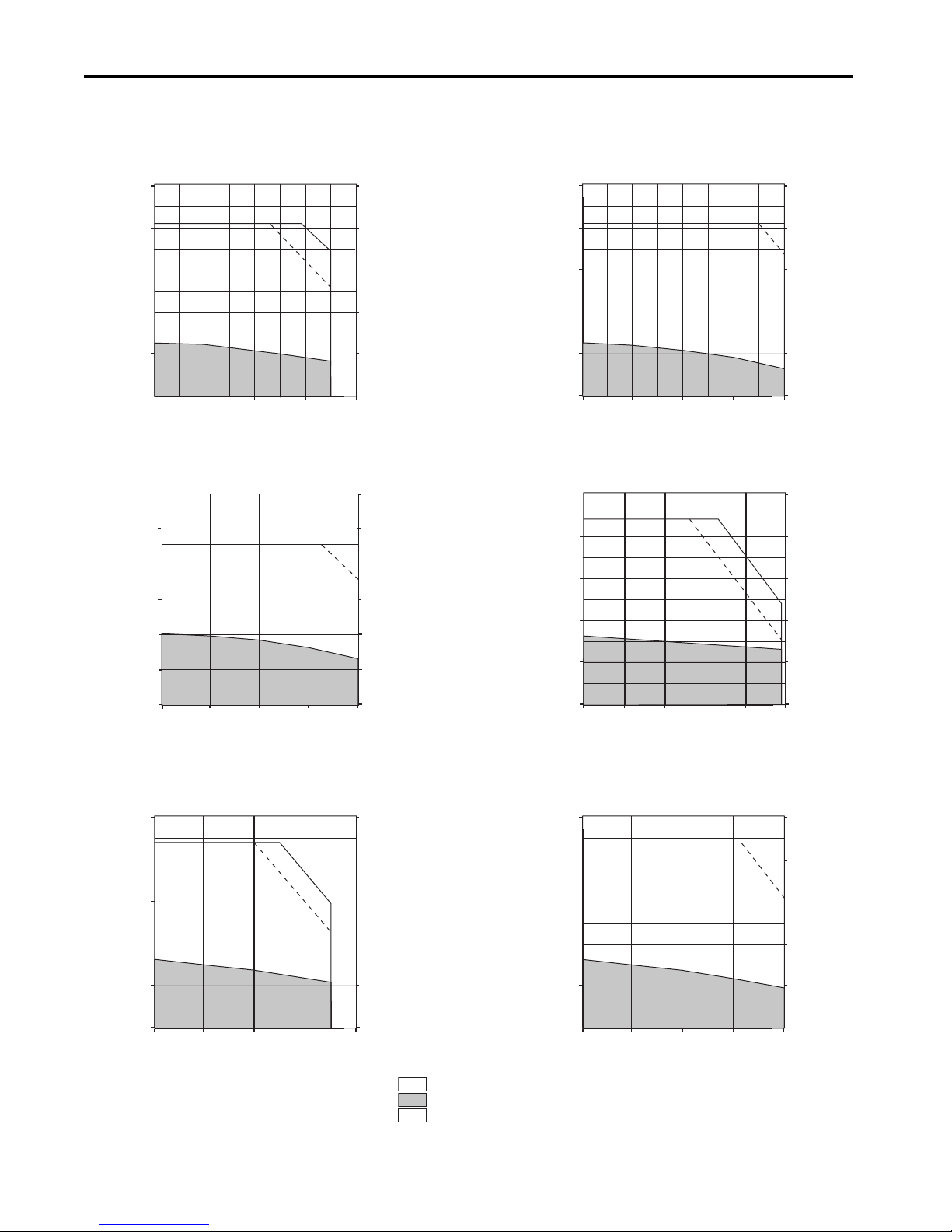

Kinetix 5500 (400V-class operation) Drives with Kinetix VP Low Inertia Motors

This section provides system combination information for the Kinetix 5500 drives (with 400 and 480V, nominal input)

when matched with Kinetix VP (400V-class) low-inertia motors. Single cable catalog numbers, system performance

specifications, and the optimum torque/speed curves are included.

Bulletin VPL Motor Cable Combinations

Rotary Motor (400V-class)

Cat. No.

Single Cable Cat. No.

(1)

Feedback Type

VPL-B063xx

VPL-B0751M, VPL-B0752E, VPL-B0752F, VPL-B0753E, VPL-B0753F

VPL-B1001M, VPL-B1002E,

2090-CSBM1Dx-18AAxx or

2090-CSWM1Dx-18AAxx (standard, non-flex)

2090-CSBM1Dx-18AFxx (continuous-flex)

VPL-B1003C

VPL-B0752M, VPL-B0753M 2090-CSBM1Dx-14AAxx or

VPL-B1002M, VPL-B1003F, VPL-B1003T

VPL-B1152C

2090-CSWM1Dx-14AAxx (standard, non-flex)

2090-CSBM1Dx-14AFxx (continuous-flex)

2090-CSBM1Dx-18AAxx or

2090-CSWM1Dx-18AAxx (standard, non-flex)

Multi-turn or Single-turn

Digital Encoder Feedback

2090-CSBM1Dx-18AFxx (continuous-flex)

VPL-B1152F, VPL-B1152T, VPL-B1153E, VPL-B1153F

VPL-B1303x, VPL-B1304x, VPL-B1306x

VPL-B1651C, VPL-B1651F, VPL-B1652C, VPL-B1652F, VPL-B1653C, VPL-B1653D, VPL-B1654B

2090-CSBM1Dx-14AAxx or

2090-CSWM1Dx-14AAxx (standard, non-flex)

2090-CSBM1Dx-14AFxx (continuous-flex)

VPL-B1654D 2090-CSBM1Dx-10AFxx (continuous-flex)

(1) Use 2090-CSxM1DF or 2090-CSxM1DG cables. Cable length xx is in meters, 01 (3.3)…50 (164) in 1.0 m (3.3 f t) increments. Refer to the Kinetix Motion Accessories Technical Data, publication

KNX-TD004

, for cable specifications. For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Single Motor Cable Overview beginning on page 13.

Bulletin VPL Motor Performance Specifications with Kinetix 5500 (400V-class operation) Drives

Motor Cat. No.

VPL-B0631T 8000 8000 1.20 0.46 (4.0)

VPL-B0631U 8000 8000 1.92 0.46 (4.0) 6.48 1.33 (12.0) 0.31 (0.42) 2198-H008-ERSx

VPL-B0632F 4600 4600 1.20 0.93 (8.0)

VPL-B0632T 8000 8000 2.55 0.93 (8.0) 8.75 2.69 (24.0) 0.54 (0.72) 2198-H008-ERSx

VPL-B0633M 6500 6700 2.50 1.27 (11.0) 8.75 4.09 (36.0) 0.57 (0.76) 2198-H008-ERSx

VPL-B0633T 6500 8000 3.52 1.27 (11.0)

VPL-B0751M 8000 8000 2.90 1.01 (9.0)

VPL-B0752E 4900 4900 2.70 1.61 (14.0)

VPL-B0752F 7000 7000 3.80 1.61 (14.0) 13.30 4.39 (39.0) 0.80 (1.07) 219 8-H015-ERSx

VPL-B0752M 8000 8000 4.90 1.61 (14.0)

VPL-B0753E 4500 4500 3.80 2.28 (20.0) 13.30 7.35 (65.0) 0.81 (1.09) 2198-H015-ERSx

Rated Speed

rpm

Speed, max

rpm

System Continuous

Stall Current

A (0-pk)

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

3.50 1.12 (10.0)

4.20 1.33 (12.0) 2198-H008-ERSx

3.50 2.26 (20.0)

4.20 2.69 (24.0) 2198-H008-ERSx

8.80 2.87 (25.0)

12.60 4.09 (36.0) 2198-H015-ERSx

8.80 2.20 (19.0)

9.12 2.27 (20.0) 2198-H015-ERSx

8.80 4.10 (36.0)

9.45 4.39 (39.0) 2198-H015-ERSx

17.70 4.10 (36.0)

18.90 4.39 (39.0) 2198-H025-ERSx

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW (Hp)

0.31 (0.42)

0.37 (0.50)

0.57 (0.76)

0.54 (0.72)

0.67 (0.90)

0.81 (1.09)

Kinetix 5500 Drives

(480V AC input)

2198-H003-ERSx

2198-H003-ERSx

2198-H008-ERSx

2198-H008-ERSx

2198-H008-ERSx

2198-H015-ERSx

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 23

Page 24

Kinetix 5500 Drive Systems

Bulletin VPL Motor Performance Specifications with Kinetix 5500 (400V-class operation) Drives (cont.)

Motor Cat. No.

VPL-B0753F 4500 6600 4.09 2.16 (19.0)

VPL-B0753M 6000 8000 6.12 2.28 (20.0)

VPL-B1001M 6000 6000 3.61 1.93 (17.0)

VPL-B1002E 3300 3300 3.44 3.39 (30.0)

VPL-B1002M 6000 6000 6.24 3.39 (30.0)

VPL-B1003C 2500 2500 3.41 4.18 (37.0)

VPL-B1003F 4750 4750 6.14 4.18 (37.0)

VPL-B1003T 7000 7000 9.58 4.18 (37.0)

VPL-B1152C 2250 2250 3.13 5.10 (45.0)

VPL-B1152F 4000 4500 6.17 5.10 (45.0)

VPL-B1152T 6500 6500 10 .81 5.08 (45.0)

VPL-B1153E 3200 3200 6.13 6.55 (58.0)

VPL-B1153F 5000 5000 8.88 6.55 (58.0)

VPL-B1303C 2250 2250 6.30 8.80 (78.0)

VPL-B1303F 4000 4000 10.10 8.80 (78.0)

VPL-B1304C 2150 2150 7.0 10.29 (91.0)

VPL-B1304E 3500 3500 9.44 10.29 (91.0)

VPL-B1306C 2500 250 0 10.80 13.38 (118)

VPL-B1306F 4250 4250 14.78 13.38 (118)

VPL-B1651C 2750 275 0 10.21 11.50 (102)

VPL-B1651F 4750 4750 17.60 11.43 (101)

Rated Speed

rpm

Speed, max

rpm

System Continuous

Stall Current

A (0-pk)

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

17.70 6.55 (58.0)

18.90 7.02 (62.0) 2198-H025-ERSx

17.70 5.13 (45.0)

25.34 7.35 (65.0) 2198-H025-ERSx

8.80 3.22 (28.0)

10.38 3.78 (33.0) 2198-H015-ERSx

8.80 6.47 (57.0)

10.69 7.82 (69.0) 2198-H015-ERSx

17.70 6.80 (60.0)

20.33 7.82 (69.0) 2198-H025-ERSx

8.80 9.29 (82.0)

10.61 11.15 (99.0) 2198-H015-ERSx

17.70 9.76 (86.0)

20.20 11.15 (99.0) 2198-H025-ERSx

28.30 9.76 (86.0)

28.80 11.15 (99.0) 2198-H040-ERSx

8.80 10.80 (95.0)

10.74 13.12 (116) 2198-H015-ERSx

17.70 10.95 (97.0)

21.19 13.12 (116) 2198-H025-ERSx

28.30 12.14 (107)

32.10 13.12 (116) 2198-H040-ERSx

17.70 16.85 (149)

21.33 20.33 (180) 2198-H025-ERSx

28.30 18.30 (162)

33.0 20.33 (180) 2198-H040-ERSx

17.70 19.83 (175)

18.47 20.72 (183) 2198-H025-ER Sx

28.30 19.85 (175)

31.0 20.72 (183) 2198-H040-ERSx

17.70 22.55 (199)

22.3 28.45 (252) 2198-H025-ERSx

28.30 25.03 (221)

33.76 28.45 (252) 2198-H040-ER Sx

28.30 31.21 (276)

32.94 34.62 (306) 2198-H040-ER Sx

45.90 28.50 (252)

55.83 34.62 (306) 2198-H070-ER Sx

28.30 21.68 (192)

29.29 22.45 (199) 2198-H040-ER Sx

45.90 18.02 (159)

57.27 22.45 (199) 2198-H070-ER Sx

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW (Hp)

0.65 (0.87)

0.82 (1.10)

1.14 (1.53)

1.12 (1.50)

1.86 (2.49)

0.96 (1.29)

1.65 (2.21)

1.77 (2.37)

1.06 (1.42)

1.40 (1.88)

2.29 (3.07)

1.75 (2.35)

2.30 (3.08)

1.83 (2.45)

2.82 (3.78)

1.75 (2.35)

2.82 (3.78)

2.46 (3.30)

2.95 (3.95)

2.32 (3.11)

4.38 (5.87)

Kinetix 5500 Drives

(480V AC input)

2198-H015-ERSx

2198-H015-ERSx

2198-H008-ERSx

2198-H008-ERSx

2198-H015-ERSx

2198-H008-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H008-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H025-ERSx

2198-H040-ERSx

2198-H025-ERSx

2198-H040-ERSx

24 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 25

Kinetix 5500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H008-ERSx and VPL-B0631T

2.0

1.5

1.0

0.5

0

0

4000

8000

60002000

17.7

13.3

8.85

4.42

0

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H008-ERSx and VPL-B0631U

2.0

1.5

1.0

0.5

0

0

4000

8000

60002000

17.7

13.3

8.85

4.42

0

Peak curve represents

480V and 400V inputs

Torque

(N•m)

Torque

(lb•in)

2198-H008-ERSx and VPL-B0632F

3.0

2.5

2.0

1.5

1.0

0.5

0

Speed (rpm)

0

3000

5000

4000

1000

2000

26.5

22.1

17.7

13.3

8.85

4.42

0

Torque

(N•m)

Torque

(lb•in)

2198-H008-ERSx and VPL-B0632T

3.0

2.5

2.0

1.5

1.0

0.5

0

26.5

22.1

17.7

13.3

8.85

4.42

0

Speed (rpm)

0

4000

8000

60002000

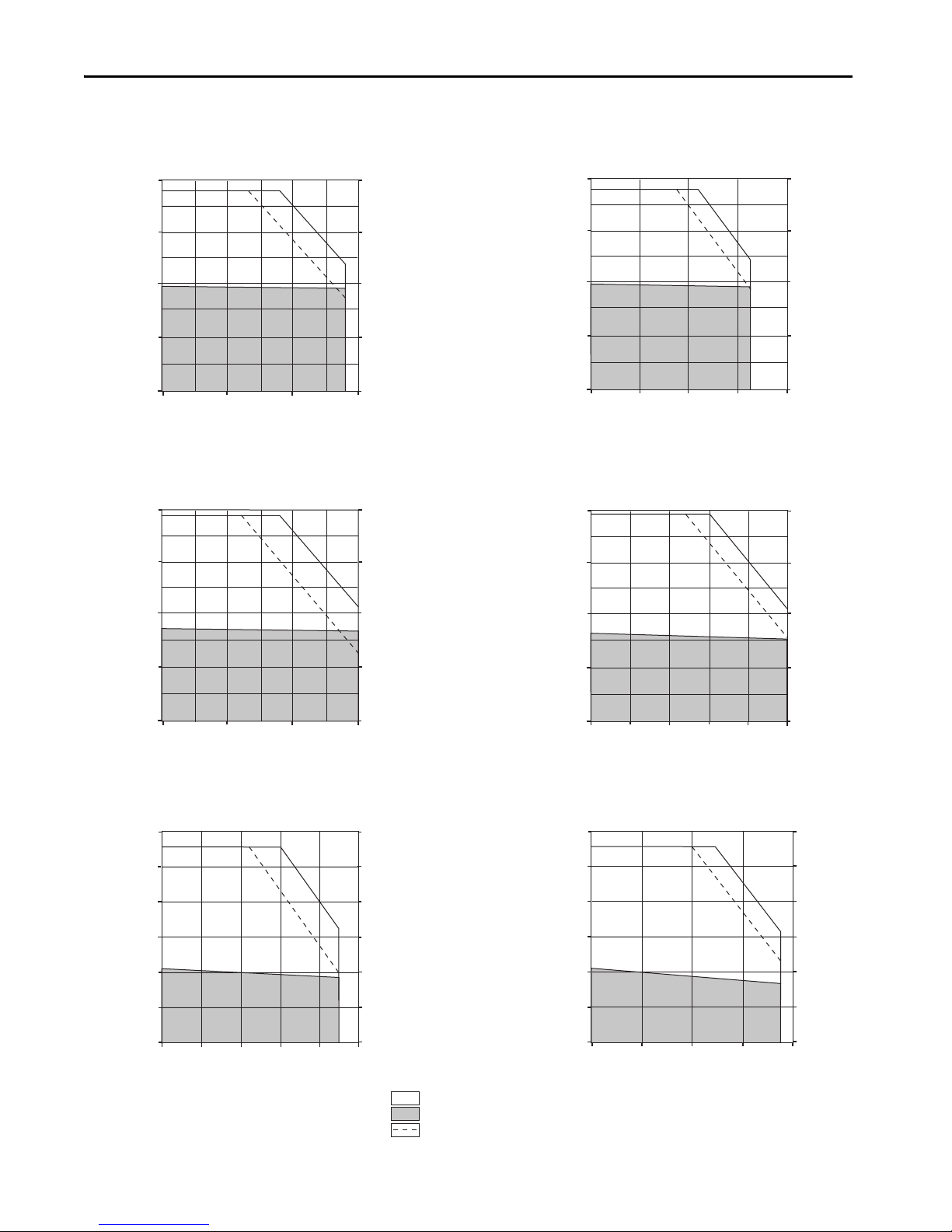

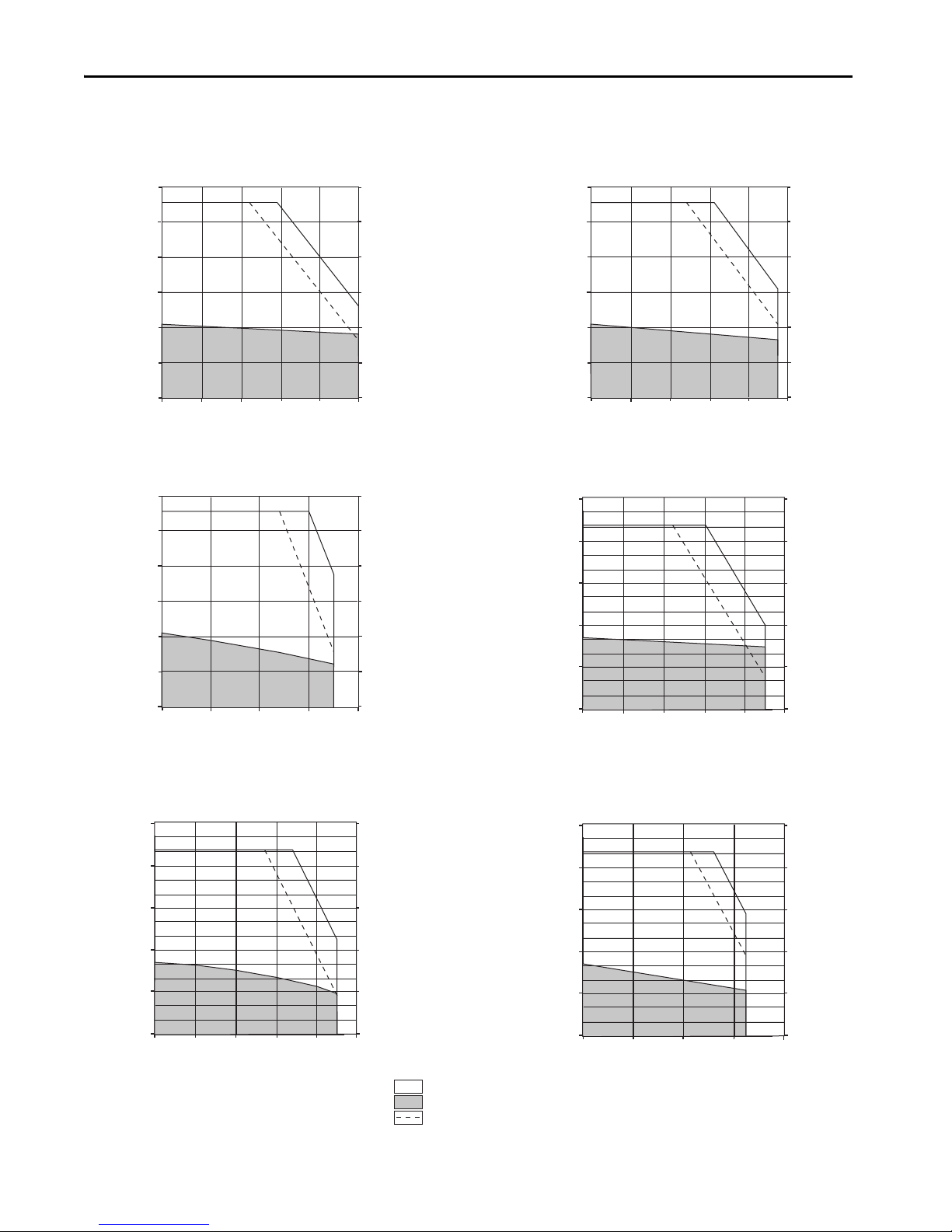

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

Bulletin VPL Motor Performance Specifications with Kinetix 5500 (400V-class operation) Drives (cont.)

Motor Cat. No.

VPL-B1652C 2700 270 0 16.0 19.40 (172)

VPL-B1652F 4000 4000 18.60 17.60 (156) 60.00 48.60 (430) 4.77 (6.40) 2198-H070-ERSx

VPL-B1653C 2300 230 0 17.75 25.76 (228)

VPL-B1653D 3000 3000 18.60 24.20 (214) 68.00 67.80 (600) 5.50 (7.30) 2198-H070-ERSx

VPL-B1654B 1850 1850 15.54 32.97 (292)

VPL-B1654D 3000 3000 24.47 32.0 (283) 81.30 75.30 (666) 7.16 (9.60) 2198-H070-ERSx

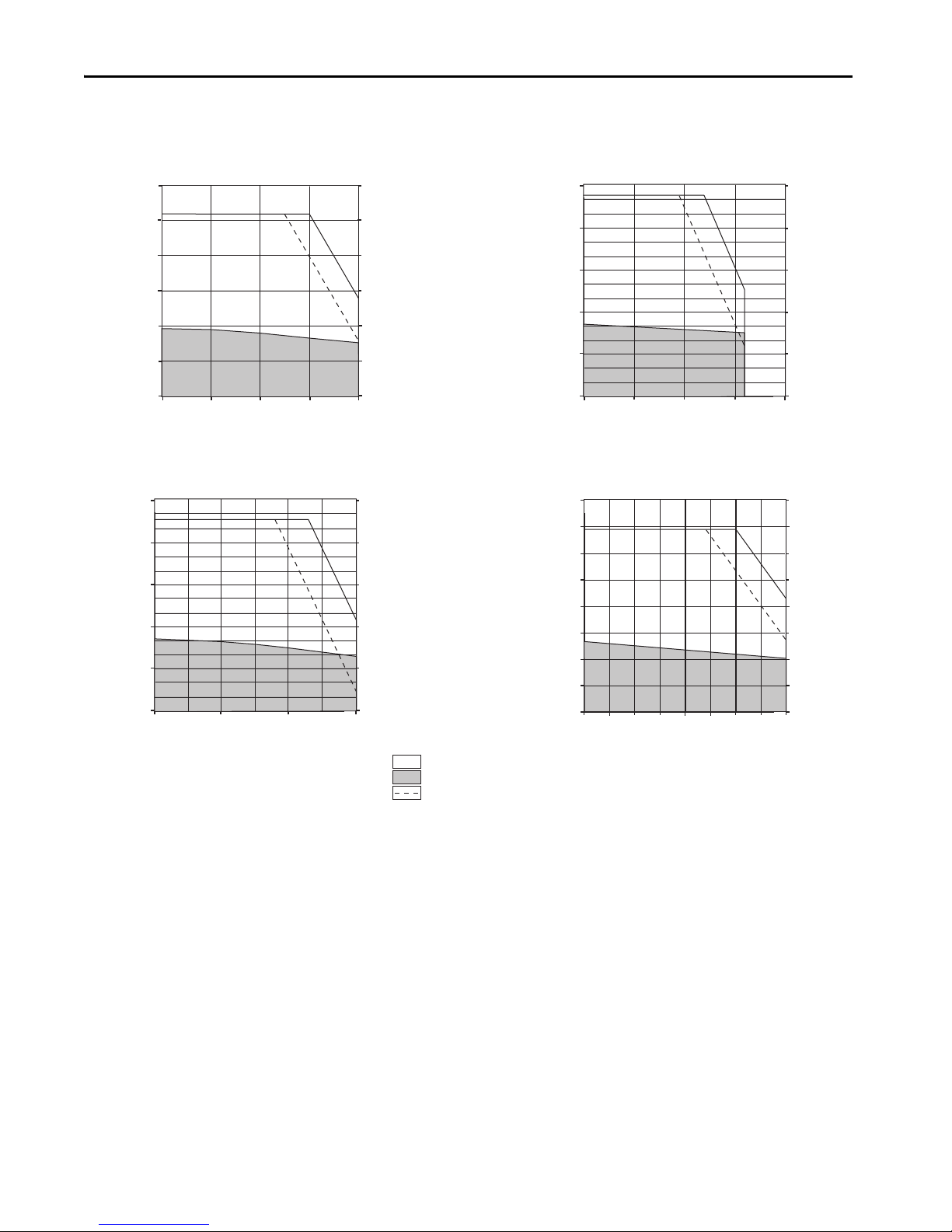

Performance specification data and curves reflect nominal sys tem performance of a typical system with the motor at 40 °C (104 °F) and the drive at 50 °C (122 °F) ambient, and rated line voltage. For

additional information on ambient and line conditions, refer to Motion Analyzer software.

Rated Speed

rpm

Speed, max

rpm

System Continuous

Stall Current

A (0-pk)

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

45.90 44.78 (396)

49.88 48.60 (430) 2198-H070-ER Sx

45.90 55.14 (488)

55.60 66.70 (590) 2198-H070-ER Sx

45.90 65.38 (578)

55.75 79.30 (702) 2198-H070-ER Sx

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW (Hp)

4.18 (5.60)

4.38 (5.87)

5.55 (7.44)

Kinetix 5500 Drives

(480V AC input)

2198-H040-ERSx

2198-H040-ERSx

2198-H040-ERSx

Kinetix 5500 (400V-class operation) Drives/Kinetix VP Low Inertia Motor Curves

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 25

Page 26

Kinetix 5500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H008-ERSx and VPL-B0633M

Speed (rpm)

0

4000

8000

60002000

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H015-ERSx and VPL-B0633T

Speed (rpm)

0

4000

8000

60002000

Torque

(N•m)

Torque

(lb•in)

2198-H015-ERS

x and VPL-B0751M

3.0

2.5

2.0

1.5

1.0

0.5

0

26.5

22.1

17.7

13.3

8.85

4.42

0

Speed (rpm)

0

4000

8000

60002000

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H015-ERS

x and VPL-B0752E

Speed (rpm)

0

3000

5000

4000

1000

2000

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H015-ERSx and VPL-B0752F

Speed (rpm)

0

4000

8000

60002000

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H025-ERSx and VPL-B0752M

Speed (rpm)

0

4000

8000

60002000

Kinetix 5500 (400V-class operation) Drives/Kinetix VP Low Inertia Motor Curves (continued)

26 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 27

Kinetix 5500 (400V-class operation) Drives/Kinetix VP Low Inertia Motor Curves (continued)

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H015-ERSx and VPL-B0753E

70.8

53.1

35.4

17.7

0

8.0

6.0

4.0

2.0

0

0

3000

5000

40001000

2000

Torque

(N•m)

Torque

(lb•in)

2198-H025-ERS

x and VPL-B0753F

70.8

53.1

35.4

1.77

0

8.0

6.0

4.0

2.0

0

Speed (rpm)

0

4000

8000

60002000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H015-ERSx and VPL-B1001M

35.4

26.5

17.7

8.85

0

0

2000

4.0

3.0

2.0

1.0

0

30001000 6000

5000

4000

Torque

(N•m)

Torque

(lb•in)

2198-H025-ERSx and VPL-B0753M

70.8

53.1

35.4

17.7

0

8.0

6.0

4.0

2.0

0

Speed (rpm)

0

4000

8000

60002000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H025-ERSx and VPL-B1002M

70.8

53.1

35.4

17.7

0

0

2000

8.0

6.0

4.0

2.0

0

30001000 6000

5000

4000

Torque

(N•m)

Torque

(lb•in)

0

0

2.0

4.0

6.0

10.0

8.0

17.7

35.4

53.1

70.8

88.5

2198-H015-ERSx and VPL-B1002E

Speed (rpm)

0

2000

4000

30001000

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

Kinetix 5500 Drive Systems

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 27

Page 28

Kinetix 5500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

2198-H015-ERSx and VPL-B1003C

12.0

10.0

8.0

6.0

4.0

2.0

0

Speed (rpm)

106

88.5

70.8

53.1

35.4

17.7

0

0

1500

2500

2000

500

1000

Torque

(N•m)

Torque

(lb•in)

2198-H025-ERSx and VPL-B1003F

12.0

10.0

8.0

6.0

4.0

2.0

0

Speed (rpm)

106

88.5

70.8

53.1

35.4

17.7

0

0

3000

5000

4000

1000

2000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H040-ERSx and VPL-B1003T

0

4000

8000

60002000

12.0

10.0

8.0

6.0

4.0

2.0

0

106

88.5

70.8

53.1

35.4

17.7

0

Torque

(N•m)

Torque

(lb•in)

0

0

3.0

6.0

9.0

15.0

12.0

26.5

53.1

79.6

106

133

2198-H015-ERSx and VPL-B1152C

Speed (rpm)

0

1500

2500

2000

500

1000

Torque

(N•m)

Torque

(lb•in)

0

0

3.0

6.0

9.0

15.0

12.0

26.5

53.1

79.6

106

133

2198-H025-ERSx and VPL-B1152F

Speed (rpm)

0

3000

5000

4000

1000

2000

Torque

(N•m)

Torque

(lb•in)

0

0

3.0

6.0

9.0

15.0

12.0

26.5

53.1

79.6

106

133

2198-H040-ERSx and VPL-B1152T

Speed (rpm)

0

4000

8000

60002000

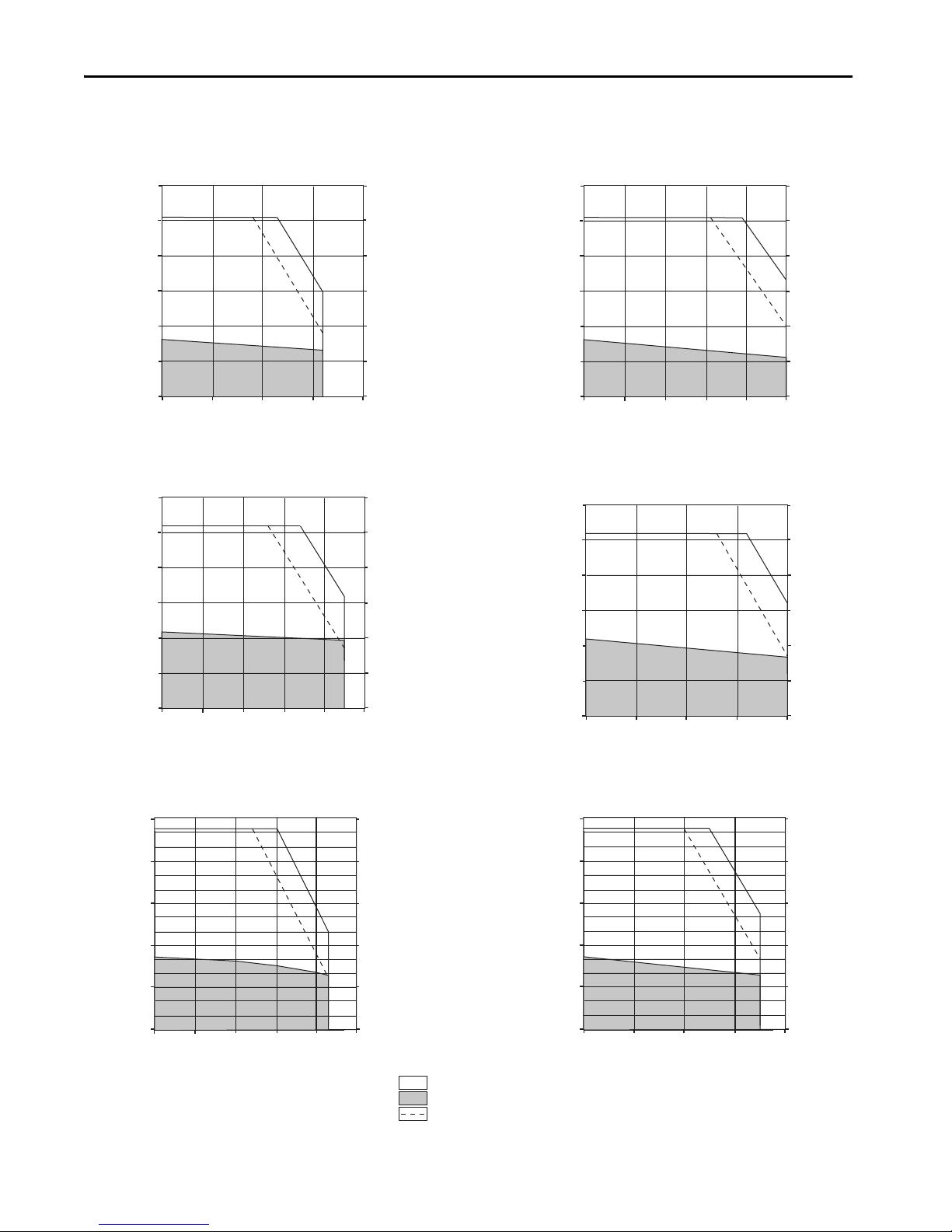

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

Kinetix 5500 (400V-class operation) Drives/Kinetix VP Low Inertia Motor Curves (continued)

28 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 29

Kinetix 5500 (400V-class operation) Drives/Kinetix VP Low Inertia Motor Curves (continued)

Torque

(N•m)

Torque

(lb•in)

2198-H025-ERSx and VPL-B1153E

24.0

20.0

16.0

12.0

8.0

4.0

0

Speed (rpm)

212

177

142

106

70.8

35.4

0

0

2000

4000

30001000

Torque

(N•m)

Torque

(lb•in)

2198-H040-ERSx and VPL-B1153F

24.0

20.0

16.0

12.0

8.0

4.0

0

Speed (rpm)

212

177

142

106

70.8

35.4

0

0

3000

5000

4000

1000

2000

Torque

(N•m)

Torque

(lb•in)

2198-H025-ERSx and VPL-B1303C

24.0

20.0

16.0

12.0

8.0

4.0

0

Speed (rpm)

212

177

142

106

70.8

35.4

0

0

1500

2500

2000

500

1000

Torque

(N•m)

Torque

(lb•in)

2198-H040-ERS

x and VPL-B1303F

24.0

20.0

16.0

12.0

8.0

4.0

0

Speed (rpm)

212

177

142

106

70.8

35.4

0

0

2000

4000

30001000

Torque

(N•m)

Torque

(lb•in)

0

0

6.0

12.0

18.0

30.0

24.0

53.1

106

159

212

265

2198-H025-ERS

x and VPL-B1304C

Speed (rpm)

0

1500

2500

2000

500

1000

Torque

(N•m)

Torque

(lb•in)

0

0

6.0

12.0

18.0

30.0

24.0

53.1

106

159

212

265

2198-H040-ERSx and VPL-B1304E

0

2000

4000

30001000

Speed (rpm)

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

Kinetix 5500 Drive Systems

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 29

Page 30

Kinetix 5500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H040-ERSx and VPL-B1306C

354

265

177

88.5

0

40.0

30.0

20.0

10.0

0

0

1500

2500

2000

500

1000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H070-ERSx and VPL-B1306F

354

265

177

88.5

0

40.0

30.0

20.0

10.0

0

0

3000

5000

4000

1000

2000

Torque

(N•m)

Torque

(lb•in)

2198-H040-ERSx and VPL-B1651C

24.0

20.0

16.0

12.0

8.0

4.0

0

Speed (rpm)

212

177

142

106

70.8

35.4

0

0

2000

30001000

Torque

(N•m)

Torque

(lb•in)

2198-H070-ERSx and VPL-B1651F

24.0

20.0

16.0

12.0

8.0

4.0

0

Speed (rpm)

212

177

142

106

70.8

35.4

0

0

3000

5000

4000

1000

2000

Torque

(N•m)

Torque

(lb•in)

0

0

10.0

20.0

30.0

50.0

40.0

88.5

177

265

354

442

2198-H070-ERSx and VPL-B1652C

Speed (rpm)

0

2000

30001000

Torque

(N•m)

Torque

(lb•in)

0

0

10.0

20.0

30.0

50.0

40.0

88.5

177

265

354

442

2198-H070-ERSx and VPL-B1652F

Speed (rpm)

0

2000

4000

30001000

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

Kinetix 5500 (400V-class operation) Drives/Kinetix VP Low Inertia Motor Curves (continued)

30 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 31

Kinetix 5500 (400V-class operation) Drives/Kinetix VP Low Inertia Motor Curves (continued)

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H070-ERSx and VPL-B1653C

708

531

354

177

0

80.0

60.0

40.0

20.0

0

0

1500

2500

2000

500

1000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H070-ERSx and VPL-B1653D

708

531

354

177

0

0

1000

80.0

60.0

40.0

20.0

0

1500500 3000

2500

2000

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H070-ERSx and VPL-B1654B

708

531

354

177

0

80.0

60.0

40.0

20.0

0

0

1000

2000

1500500

Torque

(N•m)

Torque

(lb•in)

Speed (rpm)

2198-H070-ERSx and VPL-B1654D

708

531

354

177

0

0

1000

80.0

60.0

40.0

20.0

0

1500500 3000

2500

2000

= Intermittent operating region

= Continuous operating region

= Drive operation with 400V AC rms input voltage

Kinetix 5500 Drive Systems

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 31

Page 32

Kinetix 5500 Drive Systems

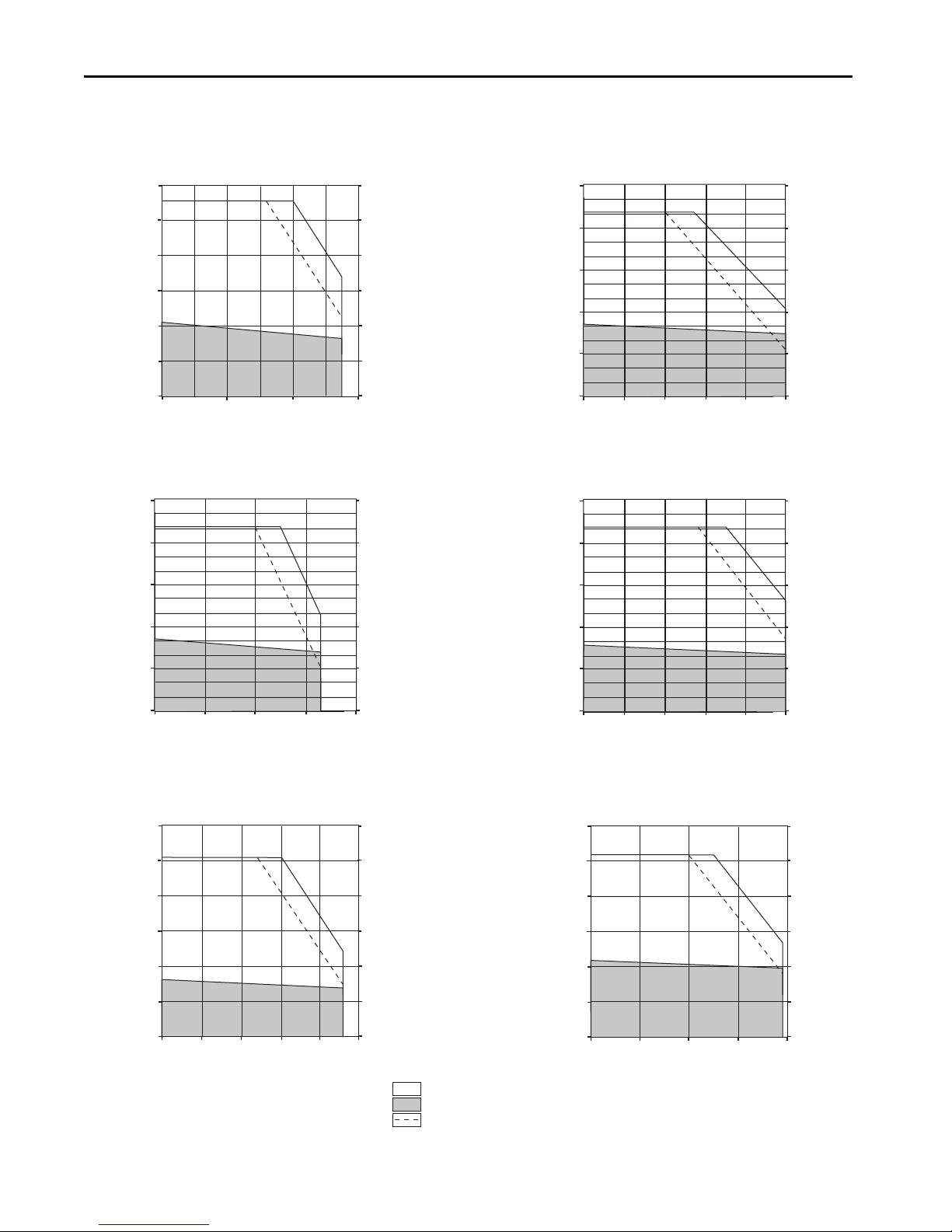

Kinetix 5500 (200V-class operation) Drives with Kinetix VP Food Grade Motors

This section provides system combination information for the Kinetix 5500 drives (with 200 and 240V, nominal input)

when matched with Kinetix VP (200V-class) food-grade motors. Single cable catalog numbers, system performance

specifications, and the optimum torque/speed curves are included.

Kinetix 5500 servo drives are capable of 200V or 400V-class operation. These system performance tables and torque/

speed curves reflect single-phase and three-phase drive operation with 200V-class motors; however, only

2198-H003-ERSx, 2198-H008-ERSx, and 2198-H015-ERSx drives are capable of single-phase operation.

Bulletin VPF Motor Cable Combinations

Rotary Motor (200V-class)

Cat. No.

VPF-A0632F, VPF-A0633C, VPF-A0633F

VPF-A0752C, VPF-A0753C

VPF-A1001C

VPF-A0752E, VPF-A0753E

VPF-A1001M, VPF-A1002C, VPF-A1002F

VPF-A1003C, VPF-A1003E, VPF-A1003F

VPF-A1153C

VPF-A1303B, VPF-A1303F

VPF-A1304A, VPF-A1304D

(1) Use 2090-CSxM1DF or 2090-CSxM1DG cables. Cable length xx is in meters, 01 (3.3)…50 (164) in 1.0 m (3.3 f t) increments. Refer to the Kinetix Motion Accessories Technical Data, publication

KNX-TD004

, for cable specifications. For cable configuration illustrations and feature descriptions, by catalog number, refer to 2090-Series Single Motor Cable Overview beginning on page 13.

Single Cable Cat. No.

2090-CSBM1Dx-18AAxx or

2090-CSWM1Dx-18AAxx (standard, non-flex)

2090-CSBM1Dx-18AFxx (continuous-flex)

2090-CSBM1Dx-14AAxx or

2090-CSWM1Dx-14AAxx (standard, non-flex)

2090-CSBM1Dx-14AFxx (continuous-flex)

(1)

Feedback Type

Multi-turn or Single-turn

Digital Encoder Feedback

32 Rockwell Automation Publication KNX-RM009C-EN-P - May 2019

Page 33

Bulletin VPF Motor Performance Specifications with Kinetix 5500 (200V-class operation) Drives

Kinetix 5500 Drive Systems

Rotary Motor

Cat. No.

VPF-A0632F 4800 4800 2.55 0.93 (8.0) 8.75 2.69 (24.0) 0.36 (0.48 ) 2198-H0 08-ERSx

VPF-A0633C 3000 3000 2.50 1.27 (11.0) 8.75 4.09 (36.0) 0.37 (0.50) 2198-H008-ERSx

VPF-A0633F 4500 4500 3.52 1.27 (11.0)

VPF-A0752C 3300 3300 3.80 1.61 (14.0) 13.30 4.39 (39.0) 0.49 (0.66) 2198-H015-ERSx

VPF-A0752E 4800 4800 4.90 1.61 (14.0)

VPF-A0753C 3300 3300 4.09 2.16 (19.0)

VPF-A0753E 4600 4600 6.12 2.28 (20.0)

VPF-A1001C 2800 2800 3.61 1.93 (17.0)

VPF-A1001M 6500 6500 7.15 1.95 (17.0)

VPF-A1002C 3000 3000 6.24 3.39 (30.0)

VPF-A1002F 5000 5000 10.04 3.26 (29.0)

VPF-A1003C 2250 2250 6.14 4.18 (37.0)

VPF-A1003E 3750 3750 9.58 4.18 (37.0)

VPF-A1003F 5500 5500 15.62 4.18 (37.0)

VPF-A1153C 2300 2300 8.88 6.50 (58.0)

VPF-A1303B 1950 1950 10.34 8.80 (78.0)

VPF-A1303F 4000 4000 18.60 7.75 (69.0)

VPF-A1304A 1600 1600 9.43 10 .29 (91.0)

VPF-A1304D 3000 3000 18.40 10.20 (90.0)

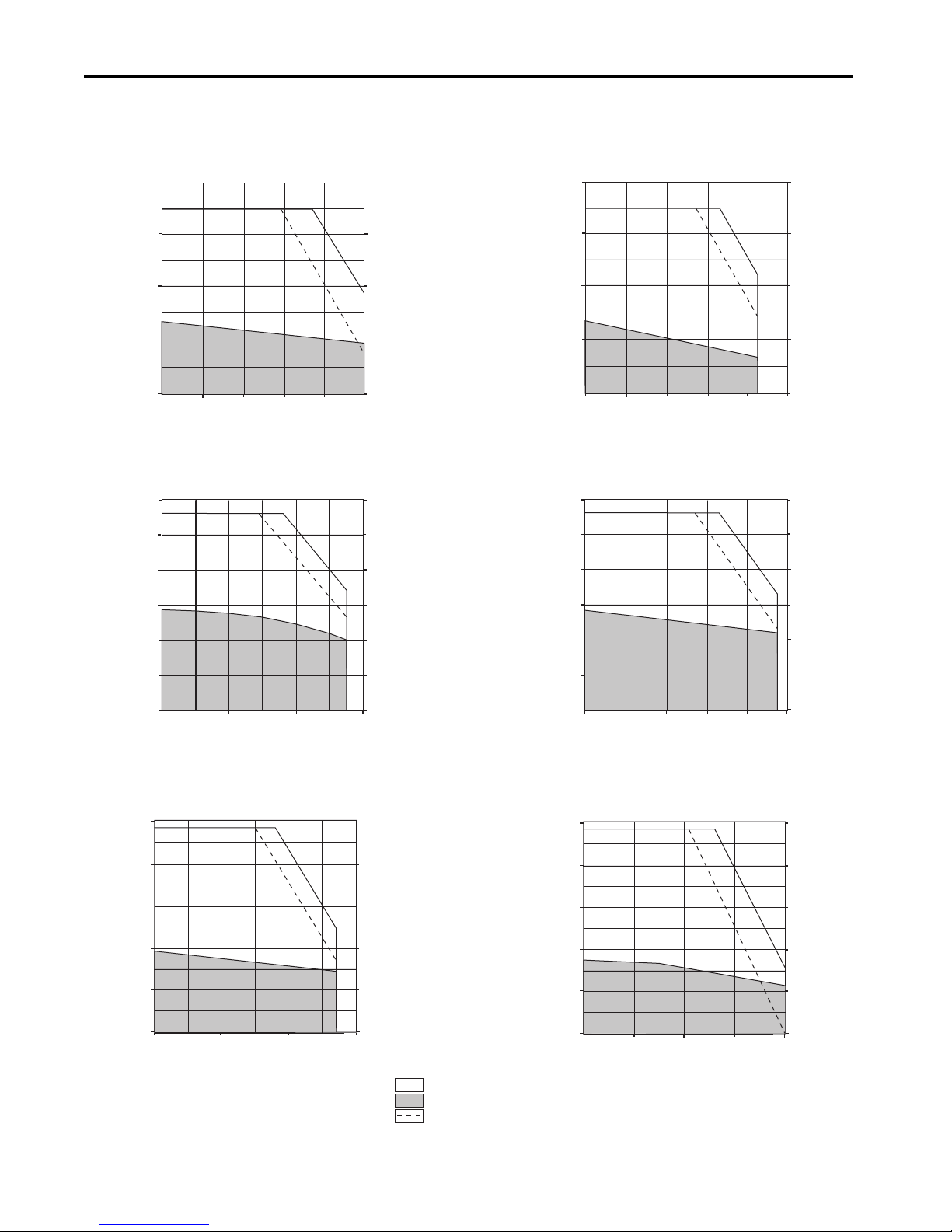

Performance specification data and curves reflect nominal sys tem performance of a typical system with the motor at 40 °C (104 °F) and the drive at 50 °C (122 °F) ambient, and rated line voltage. For

additional information on ambient and line conditions, refer to Motion Analyzer software.

Rated Speed

rpm

Speed, max

rpm

System Continuous

Stall Current

A 0-pk

System Continuous

Stall Torque

N•m (lb•in)

System Peak

Stall Current

A 0-pk

8.80 2.87 (25.0)

12.60 4.09 (36.0) 2198-H015-ERSx

17.70 4.10 (36.0)

18.90 4.39 (39.0) 2198-H025-ERSx

17.70 6.55 (58.0)

18.90 7.02 (62.0) 2198-H025-ERSx

17.70 5.13 (45.0)

25.34 7.35 (65.0) 2198-H025-ERSx

8.80 3.22 (28.0)

10.38 3.78 (33.0) 2198-H015-ERSx

17.70 3.31 (29.0)

20.20 3.78 (33.0) 2198-H025-ERSx

17.70 6.80 (60.0)

20.33 7.82 (69.0) 2198-H025-ERSx

28.30 6.77 (60.0)

34.30 7.82 (69.0) 2198-H040-ERSx

17.70 9.76 (86.0)

20.20 11.15 (99.0) 2198-H025-ERSx

28.30 9.76 (86.0)

28.80 11.15 (99.0) 2198-H040-ERSx

45.90 10.25 (90.0)

50.0 11.15 (99.0) 2198-H070-ERSx

28.30 18.30 (162)

33.0 20.33 (180) 2198-H040-ERSx

28.30 19.85 (175)

31.0 20.72 (183) 2198-H040-ERSx

45.90 15.36 (136)

62.0 20.72 (183) 2198-H070-ERSx

28.30 25.03 (221)

33.76 28.45 (252) 2198-H040-ERSx

45.90 21.48 (190)

58.0 27.10 (240) 2198-H070-ERSx

System Peak

Stall Torque

N•m (lb•in)

Motor Rated

Output

kW (Hp)

0.47 (0.63)

0.63 (0.84)

0.59 (0.79)

0.76 (1.02)

0.56 (0.75)

1.29 (1.73)

1.03 (1.38)

1.60 (2.14)

0.83 (1.11)

1.25 (1.67)

1.81 (2.42)

1.16 (1.56)

1.53 (2.05)

2.25 (3.02)

1.47 (1.98)

1.98 (2.65)

Kinetix 5500 Drives

(240V AC Input)

2198-H008-ERSx

2198-H015-ERSx

2198-H015-ERSx

2198-H015-ERSx

2198-H008-ERSx

2198-H015-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H040-ERSx

2198-H025-ERSx

2198-H025-ERSx

2198-H040-ERSx

2198-H025-ERSx

2198-H040-ERSx

Rockwell Automation Publication KNX-RM009C-EN-P - May 2019 33

Page 34

Kinetix 5500 Drive Systems

Torque

(N•m)

Torque

(lb•in)

2198-H008-ERSx and VPF-A0632F

3.0

2.5

2.0

1.5

1.0

0.5

0

Speed (rpm)

0

3000

5000

4000

1000

2000

26.5

22.1

17.7

13.3

8.85

4.42

0

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H008-ERS

x and VPF-A0633C

Speed (rpm)

0

2000

30001000

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H015-ERS

x and VPF-A0633F

Speed (rpm)

0

3000

5000

4000

1000

2000

Torque

(N•m)

Torque

(lb•in)

0

0

1.0

2.0

3.0

5.0

4.0

8.85

17.7

26.5

35.4

44.2

2198-H015-ERS

x and VPF-A0752C

Speed (rpm)

0

2000

4000

30001000

Torque

(N•m)

Torque