Allen-Bradley 2198-H040-ERS, 2198-H003-ERS, 2198-H025-ERS, 2198-H003-ERS2, 2198-H070-ERS User Manual

...

User Manual

Original Instructions

Kinetix 5500 Servo Drives

Catalog Numbers 2198-H003-ERS, 2198-H008-ERS, 2198-H015-ERS, 2198-H025-ERS, 2198-H040-ERS, 2198-H070-ERS

2198-H003-ERS2, 2198-H008-ERS2, 2198-H015-ERS2, 2198-H025-ERS2, 2198-H040-ERS2, 2198-H070-ERS2,

2198-CAPMOD-1300

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Table of Contents

Preface

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Conventions Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Access the Attachments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

Start About the Kinetix 5500 Servo Drive System . . . . . . . . . . . . . . . . . . . . . 15

Drive Hardware and Input Power Configurations . . . . . . . . . . . . . . . 17

Standalone Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Shared AC/DC Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Shared DC Common-bus Configurations . . . . . . . . . . . . . . . . . . . 20

Shared AC/DC Hybrid Configuration. . . . . . . . . . . . . . . . . . . . . . 21

Motor Feedback and Feedback-only Configurations . . . . . . . . . . . . . 22

Typical Communication Configurations . . . . . . . . . . . . . . . . . . . . . . . . 23

Linear Topology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ring Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Star Topology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Safe Torque-off Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Hardwired Safety Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Integrated Safety Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Agency Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Plan the Kinetix 5500 Drive

System Installation

Chapter 2

System Design Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

AC Line Filter Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Transformer Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Circuit Breaker/Fuse Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

24V Control Power Evaluation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Contactor Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Passive Shunt Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Enclosure Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Minimum Clearance Requirements . . . . . . . . . . . . . . . . . . . . . . . . . 40

Electrical Noise Reduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Bonding Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Bonding Multiple Subpanels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Establishing Noise Zones. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Cable Categories for Kinetix 5500 Systems . . . . . . . . . . . . . . . . . . 45

Noise Reduction Guidelines for Drive Accessories. . . . . . . . . . . . 46

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 3

Table of Contents

Chapter 3

Mount the Kinetix 5500 Drive

System

Connector Data and Feature

Descriptions

Determine Mounting Order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Zero-stack Tab and Cutout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Shared-bus Connection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Single-axis Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Multi-axis Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Drill-hole Patterns . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Mount Your Kinetix 5500 Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Chapter 4

Kinetix 5500 Connector Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Module Status Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Safe Torque-off Connector Pinout. . . . . . . . . . . . . . . . . . . . . . . . . . 63

Input Power Connector Pinouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

DC Bus and Shunt Resistor Connector Pinouts . . . . . . . . . . . . . . 64

Digital Inputs Connector Pinouts. . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Ethernet Communication Connector Pinout . . . . . . . . . . . . . . . . 65

Motor Power, Brake, and Feedback Connector Pinouts. . . . . . . 66

Motor Feedback Connector Pinout . . . . . . . . . . . . . . . . . . . . . . . . . 66

Understand Control Signal Specifications . . . . . . . . . . . . . . . . . . . . . . . 67

Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Ethernet Communication Specifications . . . . . . . . . . . . . . . . . . . . 68

Motor Brake Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Control Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Feedback Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Absolute Position Feature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Safe Torque-off Safety Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Servo Drives with Hardwired Safety. . . . . . . . . . . . . . . . . . . . . . . . . 72

Servo Drives with Integrated Safety . . . . . . . . . . . . . . . . . . . . . . . . . 72

Chapter 5

Connect the Kinetix 5500 Drive

System

4 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Basic Wiring Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Routing the Power and Signal Cables. . . . . . . . . . . . . . . . . . . . . . . . 74

Determine the Input Power Configuration . . . . . . . . . . . . . . . . . . . . . . 75

Grounded Power Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Ungrounded Power Configurations. . . . . . . . . . . . . . . . . . . . . . . . . 77

Ground Screw Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Remove the Ground Screws in Select Power Configurations . . . . . . 79

Ground the Drive System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Ground the System Subpanel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Ground Multiple Subpanels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Wiring Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Wiring Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Wire the Power Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Wire the 24V Control Power Input Connector . . . . . . . . . . . . . . 84

Wire the Input Power Connector. . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Table of Contents

Wire the Digital Input Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Wire the Safe Torque-off Connector. . . . . . . . . . . . . . . . . . . . . . . . 86

Wire the Digital Inputs Connector . . . . . . . . . . . . . . . . . . . . . . . . . 87

Wire Kinetix VP Motors and Actuators . . . . . . . . . . . . . . . . . . . . . . . . . 87

Maximum Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Motor Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Motor Brake Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Motor Feedback Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Apply the Single Motor-cable Shield Clamp . . . . . . . . . . . . . . . . . 91

Wire Other Allen-Bradley Motors and Actuators . . . . . . . . . . . . . . . . 92

Install the Kinetix 5500 Add-On Profile. . . . . . . . . . . . . . . . . . . . . 93

Motor Power and Brake Connections . . . . . . . . . . . . . . . . . . . . . . . 94

Motor Power/Brake Cable Series Change. . . . . . . . . . . . . . . . . . . . 95

Maximum Cable Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Motor Power/Brake Cable Preparation. . . . . . . . . . . . . . . . . . . . . . 96

Apply the Motor Power/brake Shield Clamp . . . . . . . . . . . . . . . . 98

Motor Feedback Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Motor Feedback Cable Preparation . . . . . . . . . . . . . . . . . . . . . . . . 101

Capacitor Module Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

External Passive-shunt Resistor Connections . . . . . . . . . . . . . . . . . . . 105

Ethernet Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Configure and Start the

Kinetix 5500 Drive System

Chapter 6

Understand the Kinetix 5500 Display. . . . . . . . . . . . . . . . . . . . . . . . . . 108

Menu Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Setup Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Startup Sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Configure the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Set the Network Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Studio 5000 Logix Designer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Version History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Install the Kinetix 5500 Add-On Profile. . . . . . . . . . . . . . . . . . . . 114

Configure the Logix 5000 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Configure the Kinetix 5500 Drive . . . . . . . . . . . . . . . . . . . . . . . . . 118

Configure the Motion Group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Configure Feedback-only Axis Properties . . . . . . . . . . . . . . . . . . . . . . 129

Configure Induction-motor Frequency-control Axis Properties . . 130

General and Motor Categories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Basic Volts/Hertz Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Sensorless Vector Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Fan/Pump Volts/Hertz Method. . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Configure SPM Motor Closed-loop Control Axis Properties. . . . . 138

Download the Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Apply Power to the Kinetix 5500 Drive . . . . . . . . . . . . . . . . . . . . . . . . 143

Applying Power after Changing Input Voltage Range. . . . . . . . 143

Understand Bus-sharing Group Configuration . . . . . . . . . . . . . . . . . 144

Bus-sharing Group Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 5

Table of Contents

Configure Bus-sharing Groups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Test and Tune the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Test the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Tune the Axes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Chapter 7

Troubleshoot the Kinetix 5500

Drive System

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Interpret Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Display Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Fault Code Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

Kinetix 5500 Drive Status Indicators. . . . . . . . . . . . . . . . . . . . . . . 158

Kinetix 5500 Capacitor Module Status Indicators . . . . . . . . . . . 159

General Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Logix 5000 Controller and Drive Behavior . . . . . . . . . . . . . . . . . . . . . 161

Chapter 8

Remove and Replace Servo Drives Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Remove and Replace Kinetix 5500 Servo Drives . . . . . . . . . . . . . . . . 166

Remove Power and All Connections . . . . . . . . . . . . . . . . . . . . . . . 166

Remove the Servo Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Replace the Servo Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Start and Configure the Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

Kinetix 5500 Safe Torque-off Hardwired Safety

Kinetix 5500 Safe Torque-off Integrated Safety

Chapter 9

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Important Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Category 3 Requirements According to ISO 13849-1. . . . . . . . 170

Stop Category Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Performance Level (PL) and Safety Integrity Level (SIL) . . . . . 170

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Probability of Dangerous Failure Per Hour . . . . . . . . . . . . . . . . . . . . . 173

Safe Torque-off Connector Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Wire the Safe Torque-off Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Safe Torque-off Wiring Requirements. . . . . . . . . . . . . . . . . . . . . . 174

Safe Torque-off Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Safe Torque-off Feature Bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Cascade the Safe Torque-off Signal. . . . . . . . . . . . . . . . . . . . . . . . . 176

Safe Torque-off Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 176

Chapter 10

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Important Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Safety Application Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . 178

6 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Table of Contents

Category 3 Requirements According to ISO 13849. . . . . . . . . . 178

Stop Category Definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Performance Level (PL) and Safety Integrity Level (SIL) . . . . . 179

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

STO State Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Probability of Dangerous Failure Per Hour . . . . . . . . . . . . . . . . . . . . . 181

Safe Torque-off Feature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Out-of-Box State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Out-of-Box State Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Understand Integrated Safety Drive Replacement. . . . . . . . . . . . . . . 183

Replace an Integrated Safety Drive in a GuardLogix System . . . . . . 184

Configure Only When No Safety Signature Exists. . . . . . . . . . . 185

Configure Always . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Motion Direct Commands in Motion Control Systems . . . . . . . . . 186

Understand STO Bypass When Using

Motion Direct Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Logix Designer Application Warning Messages . . . . . . . . . . . . . 187

Torque Permitted in a Multi-workstation Environment . . . . . 189

Warning Icon and Text in Axis Properties . . . . . . . . . . . . . . . . . . 189

Functional Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Safe Torque-off Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Appendix A

Interconnect Diagrams Interconnect Diagram Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Power Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Single-axis Drive Wiring Examples . . . . . . . . . . . . . . . . . . . . . . . . . 194

Bus-sharing Wiring Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

Shunt Resistor Wiring Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Kinetix 5500 Servo Drive and Rotary Motor Wiring Examples. . . 199

Kinetix 5500 Drive and Linear Actuator Wiring Examples. . . . . . . 201

System Block Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 205

Appendix B

Upgrade the Drive Firmware Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

Configure Logix 5000 Controller Communication. . . . . . . . . . 209

Inhibit Feedback Only Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 210

Upgrade Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Verify the Firmware Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Appendix C

Size Multi-axis Shared-bus

Configurations

Shared-bus Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Shared AC Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Shared DC Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Shared AC/DC Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Shared AC/DC Hybrid Configurations . . . . . . . . . . . . . . . . . . . . 221

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 7

Table of Contents

Power-sharing Sizing Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Shared DC Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Shared AC/DC Hybrid Example . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Shared AC/DC Example. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Control Power Current Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Kinetix 5500 System Current Demand Example . . . . . . . . . . . . 225

Energy Calculations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

Appendix D

Motor Control Feature Support Frequency Control Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Basic Volts/Hertz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

Basic Volts/Hertz for Fan/Pump Applications . . . . . . . . . . . . . . 230

Sensorless Vector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Current Limiting for Frequency Control. . . . . . . . . . . . . . . . . . . . . . . 232

The Effects of Current Limiting . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Enable the Current Limiting Feature. . . . . . . . . . . . . . . . . . . . . . . 234

Set the CurrentVectorLimit Attribute Value. . . . . . . . . . . . . . . . 234

Stability Control for Frequency Control . . . . . . . . . . . . . . . . . . . . . . . 235

Enable the Stability Control Feature . . . . . . . . . . . . . . . . . . . . . . . 236

Skip Speeds . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Multiple Skip Speeds. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Flux Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Flux Up Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

Configure the Flux Up Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . 241

Current Regulator Loop Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Motor Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Motor Tests and Autotune Procedure . . . . . . . . . . . . . . . . . . . . . . 244

Motor Analyzer Category Troubleshooting. . . . . . . . . . . . . . . . . 245

Selection of Motor Thermal Models . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Generic Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Thermally Characterized Motors . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Speed Limited Adjustable Torque (SLAT) . . . . . . . . . . . . . . . . . . . . . 250

Motion Polarity Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

SLAT Min Speed/Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

SLAT Max Speed/Torque. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

SLAT Attributes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

Configure the Axis for SLAT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Motor Overload Retention. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

Phase Loss Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Phase-loss Detection Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Phase-loss Detection Configuration. . . . . . . . . . . . . . . . . . . . . . . . 258

Phase Loss Detection Current Example . . . . . . . . . . . . . . . . . . . . 259

Velocity Droop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Closed Loop Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Frequency Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Velocity Droop Attribute . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

Velocity Droop Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 261

8 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Table of Contents

Commutation Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Adaptive Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 9

Table of Contents

Notes:

10 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Preface

This manual provides detailed installation instructions for mounting, wiring,

and troubleshooting the Kinetix® 5500 servo drives, and system integration for

your drive and motor/actuator combination with a Logix 5000™ controller.

This manual is intended for engineers or technicians directly involved in the

installation and wiring of the Kinetix 5500 drives, and programmers directly

involved in the operation, field maintenance, and integration of these drives

with the EtherNet/IP™ communication module or controller.

If you do not have a basic understanding of Kinetix 5500 servo drives, contact

your local Rockwell Automation sales representative for information on

available training courses.

Summary of Changes

This manual contains new and updated information as indicated in the

following table.

Top ic Page

Added Access the Attachments that explains how the fault code tables (FLT Sxx, FLT Mxx, and INIT FLT for example), previously in Troubleshoot the Kinetix 5500

Drive System (chapter 7), moved to the attached spreadsheet.

Added Kinetix VP (Bulletin VPH) hygienic stainless-steel servo motors as another rotary motor compatible with Kinetix 5500 servo drives.

Added Kinetix VP (Bulletin VPAR) electric cylinders as another linear actuator compatible with Kinetix 5500 servo drives.

Added 2198-DBRxx-F AC line filters.

Added 24V Control Power Evaluation with information to help evaluate 24V control power current requirements. 37

Added Contactor Selection with information to help evaluate AC input power system requirements. 37

Added Passive Shunt Considerations with information to help evaluate when an external shunt resistor is required. 38

Added the 2198-CAPMOD-1300 capacitor module power dissipation specifications to the table. 40

Added Capacitor Module Features and Indicators (previously in Chapter 5) and Module Status Connector Pinout. 63

Added new information regarding the use of 2198-DBRxx-F AC line filters and servo drive ground screw settings. 75…79

Updated the maximum input current rating (40 A) for the 24V input power shared-bus connection system. 84

Updated Install the Kinetix 5500 Add-On Profile with instructions for accessing downloads on the Product Compatibility Download Center (PCDC). 114

Added step 5

Updated Motor Analyzer Category Troubleshooting with rated slip-speed information. 245

The Certifications appendix was removed with links to the Product Certifications website added to Chapter 9 and Chapter 10. 169 and 177

to the Tune the Axes procedure. 152

12

16 and

throughout

16 and

throughout

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 11

Preface

Conventions Used in This Manual

Access the Attachments

These conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Catalog number string 2198-Hxxx-ERSx is used when there’s no need

to distinguish between -ERS or -ERS2 servo drives.

Kinetix 5500 Drive Cat. No. Description

2198-Hxxx-ERS Kinetix 5500 drive with hardwired safe torque-off functionality

2198-Hxxx-ERS2 Kinetix 5500 drive with integrated safe torque-off functionality

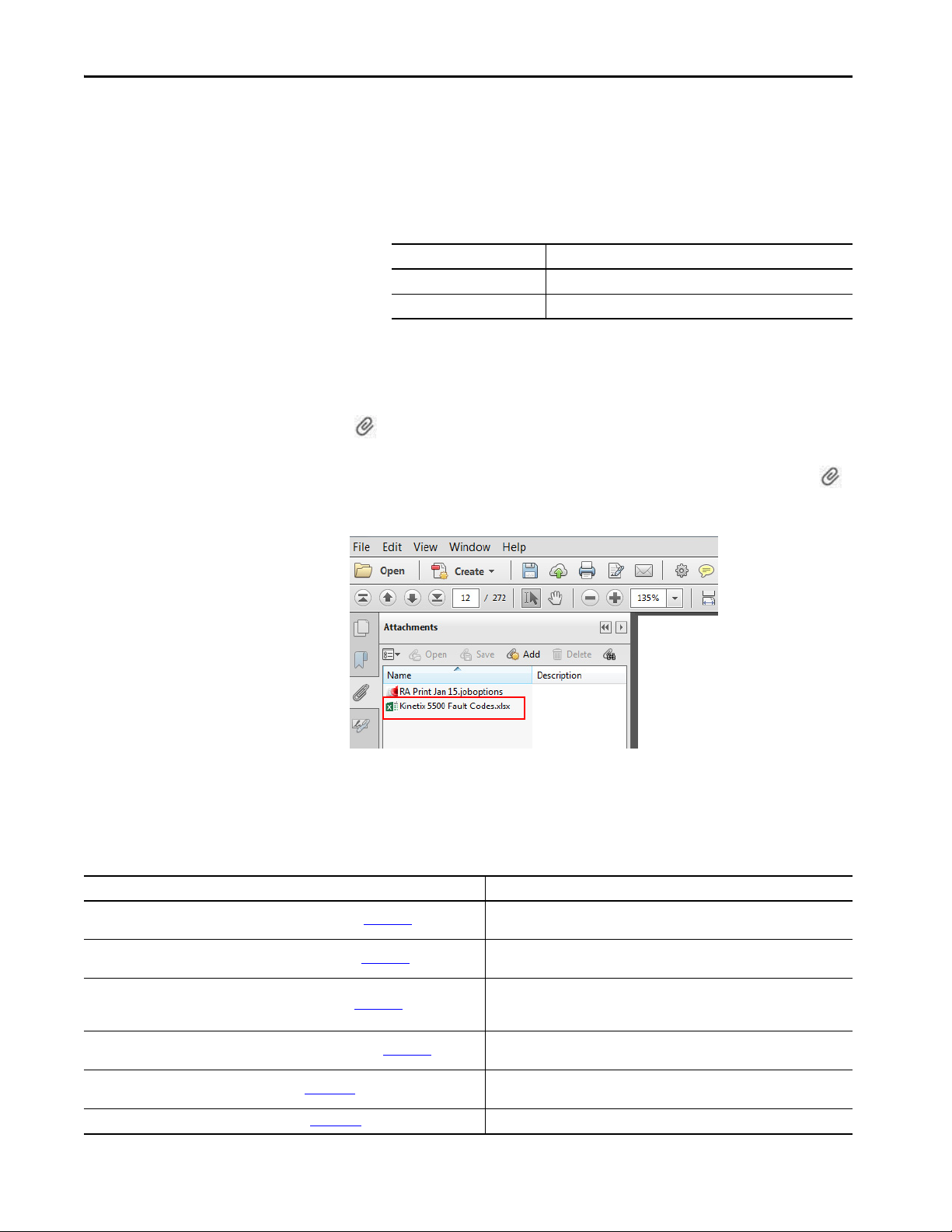

The Microsoft Excel spreadsheet that is attached to this publication contains

fault code descriptions. To use the spreadsheet file, click the Attachments link

, right-click the spreadsheet file, and save the file to your computer.

If the PDF file opens in a browser and you don't see the Attachments link ,

download the PDF file and reopen the file with the Adobe Acrobat Reader

application.

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Table 1 - Additional Resources

Resource Description

Kinetix Rotary Motion Specifications Technical Data, publication KNX-TD001

Kinetix Linear Motion Specifications Technical Data, publication KNX-TD002

Kinetix Servo Drives Specifications Technical Data, publication KNX-TD003

Kinetix Motion Accessories Specifications Technical Data, publication KNX-TD004

AC Line Filter Installation Instructions, publication 2198-IN003

Shunt Resistor Installation Instructions, publication 2097-IN002 Provides information on how to install and wire Bulletin 2097 shunt resistors.

12 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Product specifications for Kinetix VP (Bulletin VPL, VPF, VPH, and VPS), MP-Series™

(Bulletin MPL, MPM, MPF, and MPS), TL-Series™, and HPK-Series™ rotary motors.

Product specifications for MP-Series (Bulletin MPAS ballscrew, MPAR, and MPAI)

and LDAT-Series linear actuators.

Product specifications for Kinetix Integrated Motion over the EtherNet/IP network,

Integrated Motion over sercos interface, EtherNet/IP networking, and component

servo drive families.

Product specifications for Bulletin 2090 motor and interface cables, low-profile

connector kits, drive power components, and other servo drive accessory items.

Provides information on how to install AC line filters designed for Kinetix 5500 and

Kinetix 5700 servo drive systems.

Table 1 - Additional Resources (continued)

Resource Description

System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

Kinetix Motion Control Selection Guide, publication KNX-SG001

Kinetix 5500 Drive Systems Design Guide, publication KNX-RM009

Rockwell Automation Product Selection

website http://www.rockwellautomation.com/global/support/selection.page

Motion Analyzer System Sizing and Selection Tool

website https://motionanalyzer.rockwellautomation.com/

Product Certifications website, rok.auto/certifications

Motor Nameplate Datasheet Entry for Custom Motor Applications Application Technique,

publication 2198-AT002

Vertical Load and Holding Brake Management Application Technique,

publication MOTION-AT003

Integrated Motion on the EtherNet/IP Network Reference Manual,

publication MOTION-RM003

Integrated Motion on the EtherNet/IP Network Configuration and Startup User Manual,

publication MOTION-UM003

GuardLogix 5570 Controllers User Manual, publication 1756-UM022

GuardLogix 5580 Controllers User Manual, publication 1756-UM543

Compact GuardLogix 5370 Controllers User Manual, publication 1769-UM022

Compact GuardLogix 5380 Controllers User Manual, publication 5069-UM001

GuardLogix 5570 and Compact GuardLogix 5370 Controller Systems Safety Reference

Manual, publication 1756-RM099

GuardLogix 5580 and Compact GuardLogix 5380 Controller Systems Safety Reference

Manual, publication 1756-RM012

ControlFLASH Firmware Upgrade Kit User Manual, publication 1756-UM105

Rockwell Automatio n Industrial Automation Glossary, publication AG-7 .1

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Information, examples, and techniques designed to minimize system failures

caused by electrical noise.

Overview of Kinetix servo drives, motors, actuators, and motion accessories

designed to help make initial decisions for the motion control products best suited

for your system requirements.

System design guide to select the required (drive specific) drive module, power

accessory, feedback connector kit, and motor cable catalog numbers for your

Kinetix 5500 drive and Kinetix VP motor motion control system.

Online product selection and system configuration tools, including AutoCAD (DXF)

drawings.

Comprehensive motion application sizing tool used for analysis, optimization,

selection, and validation of your Kinetix Motion Control system.

Provides declarations of conformity, certificates, and other certification details.

Provides information on the use of nameplate data entry for custom induction

motors and permanent-magnet motors that are used in applications with

Kinetix 5700 servo drives.

Provides information on vertical loads and how the servo motor holding-brake

option can be used to help keep a load from falling.

Information on the AXIS_CIP_DRIVE attributes and the configuration software

control modes and methods.

Information on how to configure and troubleshoot your ControlLogix® and

CompactLogix™ EtherNet/IP network modules.

Provides information on how to install, configure, program, and use ControlLogix

controllers and GuardLogix® controllers in Studio 5000 Logix Designer® projects.

Provides information on how to install, configure, program, and use CompactLogix

and Compact GuardLogix controllers.

Provides information on how to achieve and maintain Safety Integrity Level (SIL)

and Performance Level (PL) safety application requirements for GuardLogix and

Compact GuardLogix controllers.

Provides information on how to upgrade your drive firmware by using

ControlFLASH ™ software.

A glossary of industrial automation terms and abbreviations.

Provides general guidelines for installing a Rockwell Automation industrial system.

Preface

You can view or download publications at

http://www.rockwellautomation.com/global/literature-library/overview.page

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 13

.

Preface

Notes:

14 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Chapter 1

Start

Use this chapter to become familiar with the Kinetix® 5500 drive system and

obtain an overview of the installation configurations.

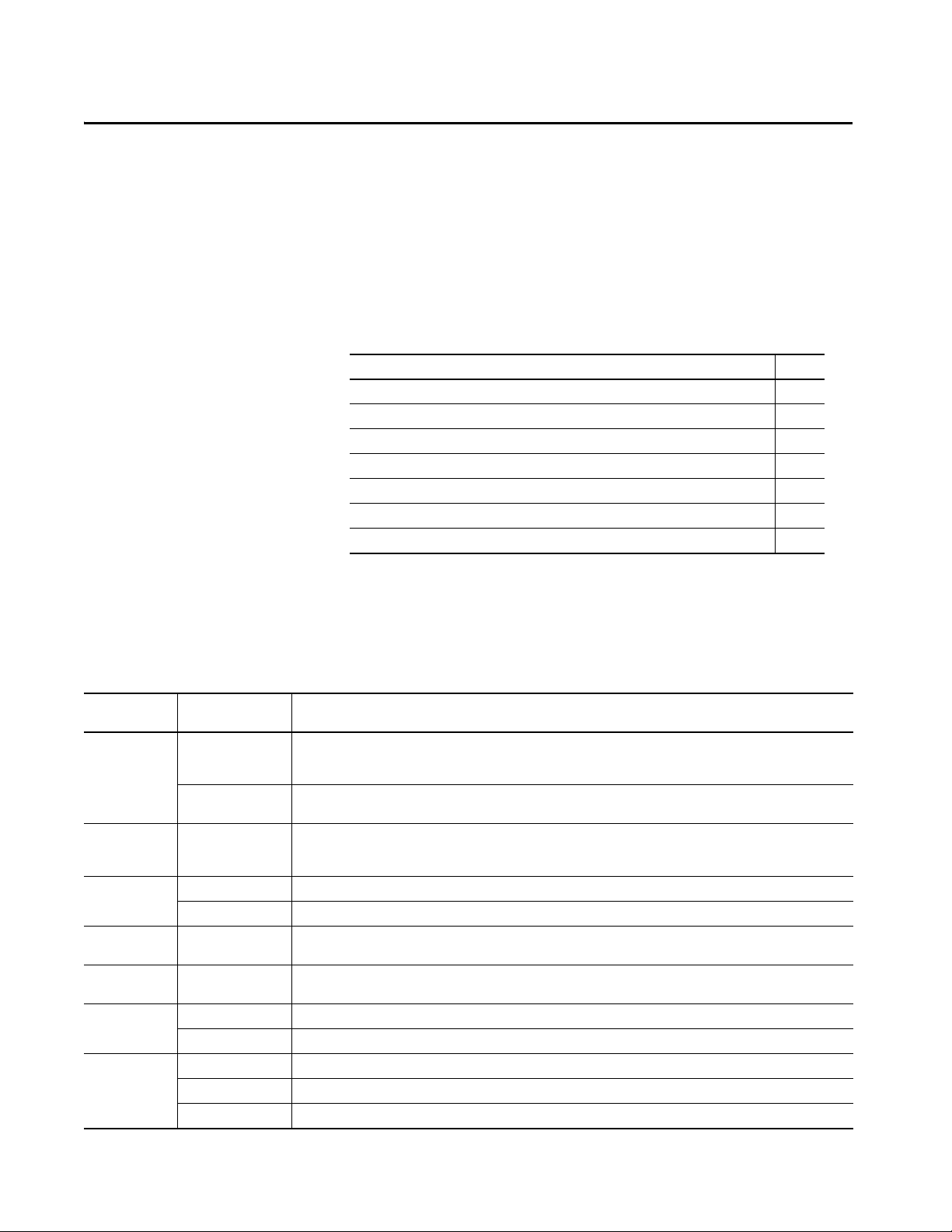

Top ic Pa ge

About the Kinetix 5500 Servo Drive System 15

Drive Hardware and Input Power Configurations 17

Motor Feedback and Feedback-only Configurations 22

Typical Communication Configurations 23

Safe Torque-off Configurations 26

Catalog Number Explanation 29

Agenc y Compliance 30

About the Kinetix 5500 Servo Drive System

Table 2 - Kinetix 5500 Drive System Overview

Drive System

Component

Kinetix 5500

Servo Drives

Kinetix 5500

Capacitor Module

Shared-bus

Connector Kits

Feedba ck

Connector Kit

Hiperface to DSL

Converter Kit

I/O Connector Kits

Connector Sets

Cat. No. Description

2198-Hxxx-ERS

2198-Hxxx-ERS2

2198-CAPMOD-1300

2198-H040-x-x Input wiring connectors and DC bus T-connector for frame 1 and 2 servo drives.

2198-H070-x-x Input wiring connectors and DC bus T-connector for frame 3 servo drives.

2198-KITCON-DSL Replacement feedback connector kit with 2-pin connector plug and grounding plate inside the connector housing.

2198-H2DCK

(series B or later)

2198-KITCON-IOSP Replacement I/O connector kit (spring clamp) for I/O (IOD) connector.

2198-KITCON-IOSC Replacement I/O connector kit (screw terminal) for I/O (IOD) connector.

2198-KITCON-PWR40 Replacement connector set, 40 A, for frame 1 and frame 2 drives.

2198-KITCON-PWR70 Replacement connector set, 70 A, for frame 3 drives.

2198-KITCON-CAP1300 Replacement connector set, 40 A, for capacitor module.

200V-class (single-phase or three-phase) and 400V-class (three-phase) drives operate in standalone and multi-axis shared AC,

shared DC, shared AC/DC, and shared AC/DC hybrid configurations. Modules are zero-stacked from drive-to-drive and use the

shared-bus connection system to extend power in multi-axis configuration s. Safe torque-off via hardwired (STO) connector.

Same power structures as 2198-Hxxx-ERS servo drives with standalone and multi-axis bus-sharing capability. Safe torque-off via

the EtherNet/IP™ network.

Use for energy storage and/or to improve performance in applications producing regenerative energy and requiring shorter duty

cycles (1360 μf). Modules are zero-stacked side-by-side with servo drives and use the shared-bus connection system to extend

power.

Use the 2198-H2DCK Hiperface-to-DSL feedback converter kit with MP-Series™ (Bulletin MPL, MPM, MPF, and MPS) rotary

motors, MP-Series (Bulletin MPAS ballscrew, MPAR, MPAI) linear actuators, and LDAT-Series linear thrusters.

The Kinetix 5500 servo drives are designed to provide a Kinetix Integrated

Motion solution for your drive and motor/actuator application.

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 15

Chapter 1 Start

Table 2 - Kinetix 5500 Drive System Overview (continued)

Drive System

Component

Encoder Output

Module

Logix 5000™

Controller Platform

Studio 5000®

Environment

Rotary Servo

Motors

Linear Actuators

Induction Motors N/A Induction motors with open loop frequency control are also supported.

Cables

AC Line Filters

24V DC Power

Supply

External Shunt

Resistors

Cat. No. Description

2198-ABQE

Bulletin 1769

Bulletin 5069

1756-EN2T module

1756-EN2TR module

1756-EN3TR module

N/A

VPL-Axxxx, VPL-Bxxxx

VPF-Axxxx, VPF-Bxxxx

VPH-Axxxx, VPH-Bxxxx

VPS-Bxxxx

MP-Series

Kinetix VP

MP-Series

LDAT-Series

2090-CSxM1DF-xxAxxx

2090-CSxM1DG-xxAxxx

2090-CFBM7DF-CEAxxx Bulletin 2090 motor feedback cables for MP-Series motors and actuators.

2090-CPxM7DF-xxAxxx Bulletin 2090 motor power/brake cables for MP-Series motors and actuators.

1585J-M8CBJM-x Ethernet cables are available in standard lengths. Shielded cable is recommended.

2198-DB08-F

2198-DB20-F

2198-DB42-F

2198-DBR20-F

2198-DBR40-F

2198-DBR90-F

1606-XLxxx Bulletin 1606 24V DC power supply for control circuitry, digital inputs, safety, and motor brake.

2097-R6 and 2097-R7 Bulletin 2097 external passive shunt resistors for when the internal shunt capability of the drive is exceeded.

The Allen-Bradley® encoder output module is a DIN-rail mounted EtherNet/IP network-based standalone module capable of

outputting encoder pulses to a customer-supplied peripheral device (cameras, for example, used in line-scan vision systems).

Integrated Motion on the EtherNet/IP network in CompactLogix™ 5370, CompactLogix 5380, and CompactLogix 5480 controllers

and Integrated Safety in Compact GuardLogix® 5370 controllers. Linear, device-level ring (DLR), and star topology is supported.

EtherNet/IP network communication modules for use with ControlLogix® 5570, ControlLogix 5580, and GuardLogix 5570

controllers. Linear, device-level ring (DLR), and star topology is supported.

Studio 5000 Logix Designer® application, version 21.00 or later, provides support for programming, commissioning, and

maintaining the CompactLogix and ControlLogix controller families. Version 24.00 or later is required for 2198-Hxxx-ERS2 servo

drives.

Compatible rotary motors include 200V and 400V-class Kinetix VP (Bulletin VPL, VPF, VPH, and VPS).

Compatible rotary motors include 200V and 400V-class MP-Series (Bulletin MPL, MPM, MPF, and MPS) when used with the

Hiperface-to-DSL feedback converter kit.

Compatible linear actuators include 200V and 400V-class Kinetix VP (Bulletin VPAR), MP-Series (Bulletin MPAS ballscrew, MPAR,

and MPAI) and LDAT-Series when used with the Hiperface-to-DSL feedback converter kit.

Bulletin 2090 flying-lead single-cable for motor power, feedback, and 24V DC brake power with Kinetix VP motors. Designed

specifically for Kinetix 5500 servo drives.

Bulletin 2090 flying-lead single cable for motor power, feedback, and 24V DC brake power with Kinetix VP motors and actuators.

Designed with longer leads than 2090-CSxM1DF cables to accommodate Kinetix 5500 or Kinetix 5700 drive families.

Bulletin 2198 three-phase AC line filters are required to meet CE and available for use in all Kinetix 5500 drive systems. Use

2198-DBxx-F filters as field replacements in existing installations. Select 2198-DBRxx-F filters for all new systems and do not

remove the servo drive ground screws.

Bulletin 2198 three-phase AC line filters are required to meet CE and available for use with all Kinetix 5500 drive systems. Select

2198-DBRxx-F filters for all new systems and do not remove the servo drive ground screws.

16 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Start Chapter 1

Single-phase or

Three- phase

Input Power

Line

Disconnect

Device

Input

Fusin g

2198-Hxxx-ERSx Drive

(front view)

2097-Rx

Shunt Resistor

(optional component)

2198-Hxxx-ERSx Drive

(top view)

AC Input Power

Bonded Cabinet

Ground Bus

Mains AC and 24V input

wired to standard input

connectors.

2198-DBRxx-F

AC Lin e Filter

(can be required

for CE)

Shared DC (DC common bus)

Shared 24V (control power input)

2198-Hxxx-ERSx Drive (top view)

with 2198-CAPMOD-1300

Capacitor Module

2198-H0x0-x-x shared-bus

connection system for bussharing configurations.

Mains AC input wired to

standard input connector.

Digital Inputs

to Sensors and Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

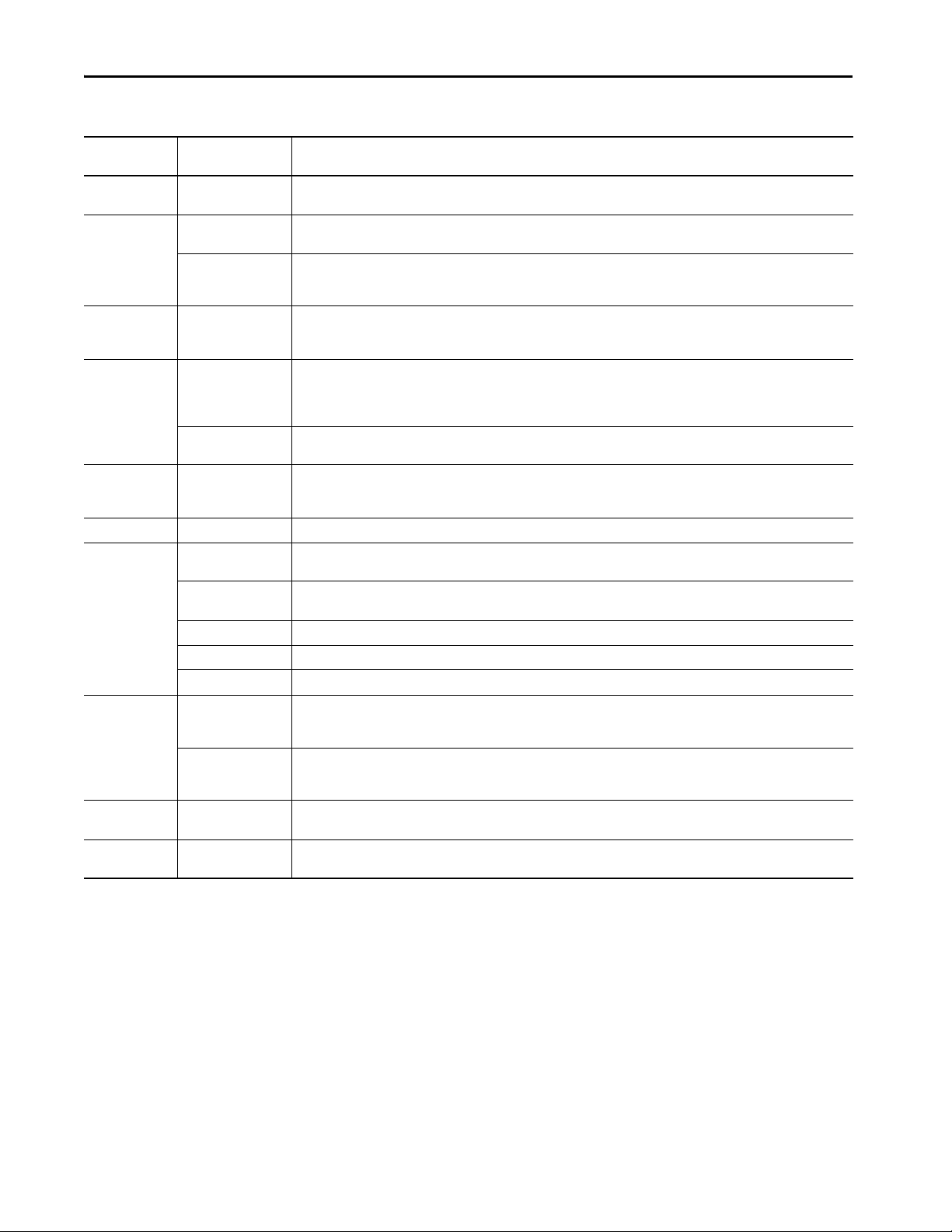

Drive Hardware and Input Power Configurations

Typical Kinetix 5500 systems include single-phase and three-phase standalone

configurations, three-phase shared AC, shared AC/DC, shared DC, and

shared AC/DC hybrid configurations.

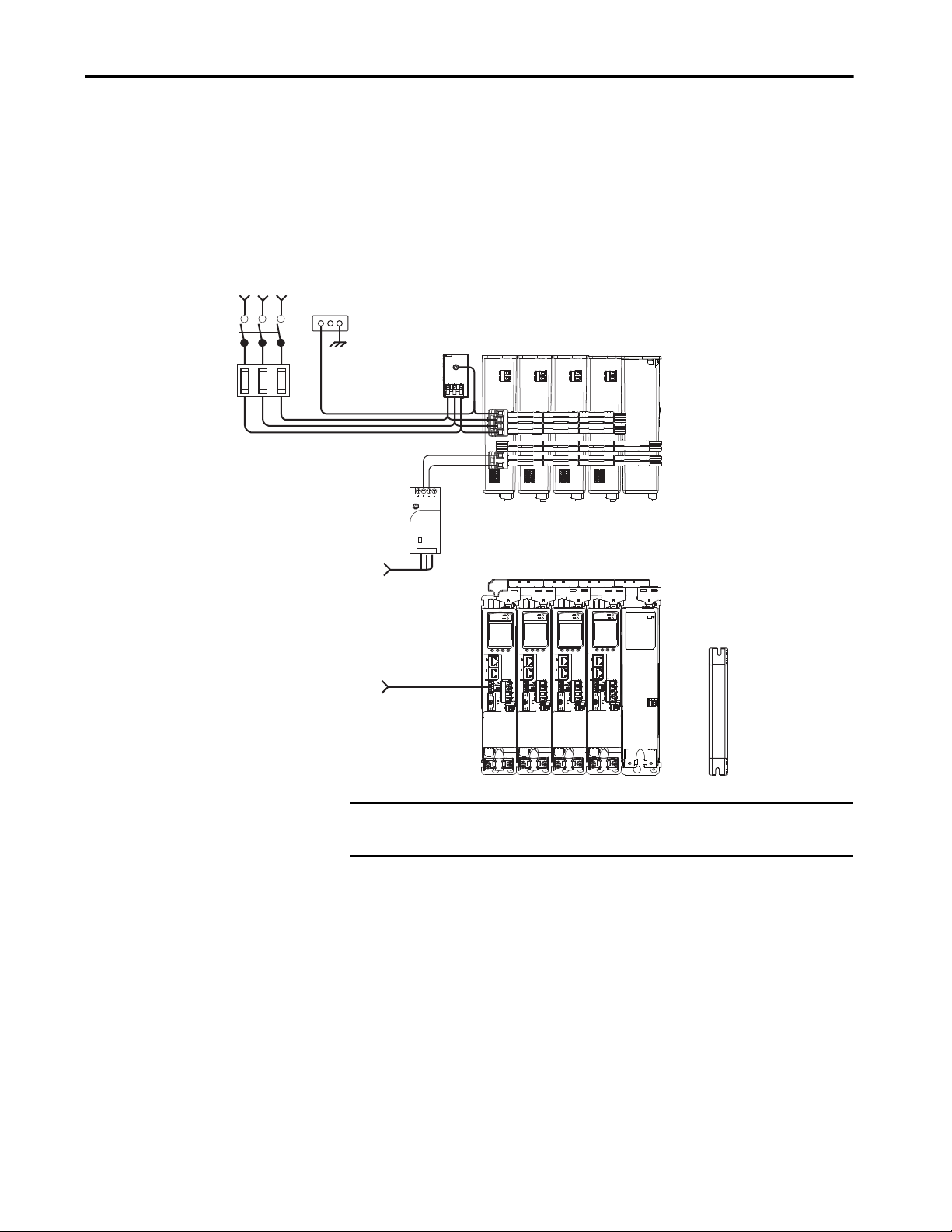

Standalone Configurations

In these examples, a single standalone drive is shown with and without the

Bulletin 2198 capacitor module.

Figure 1 - Typical Kinetix 5500 Standalone Installation

Allen-Bradley

1606-XL

Power Supply

Input

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 17

Chapter 1 Start

1606-XL

Power Supply

Input

Allen-Bradley

Kinetix 5500 Servo Drives (top view)

(2198-H008-ERS drives shown)

2097-Rx

Shunt Resistor

(optional component)

Line

Disconnect

Device

Input

Fusing

Three-phase

Input Power

AC Input Power

Bonded Cabinet

Ground Bus

Kinetix 5500 Servo Drives (front view)

(2198-H008-ERS drives shown)

2198-DBRxx-F

AC Line Filter

(can be required for CE)

Share d AC (mains AC input)

Shared 24V (control power input)

Shared-bus connection system

for bus-sharing configurations.

Digital Inputs

to Sensors and Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

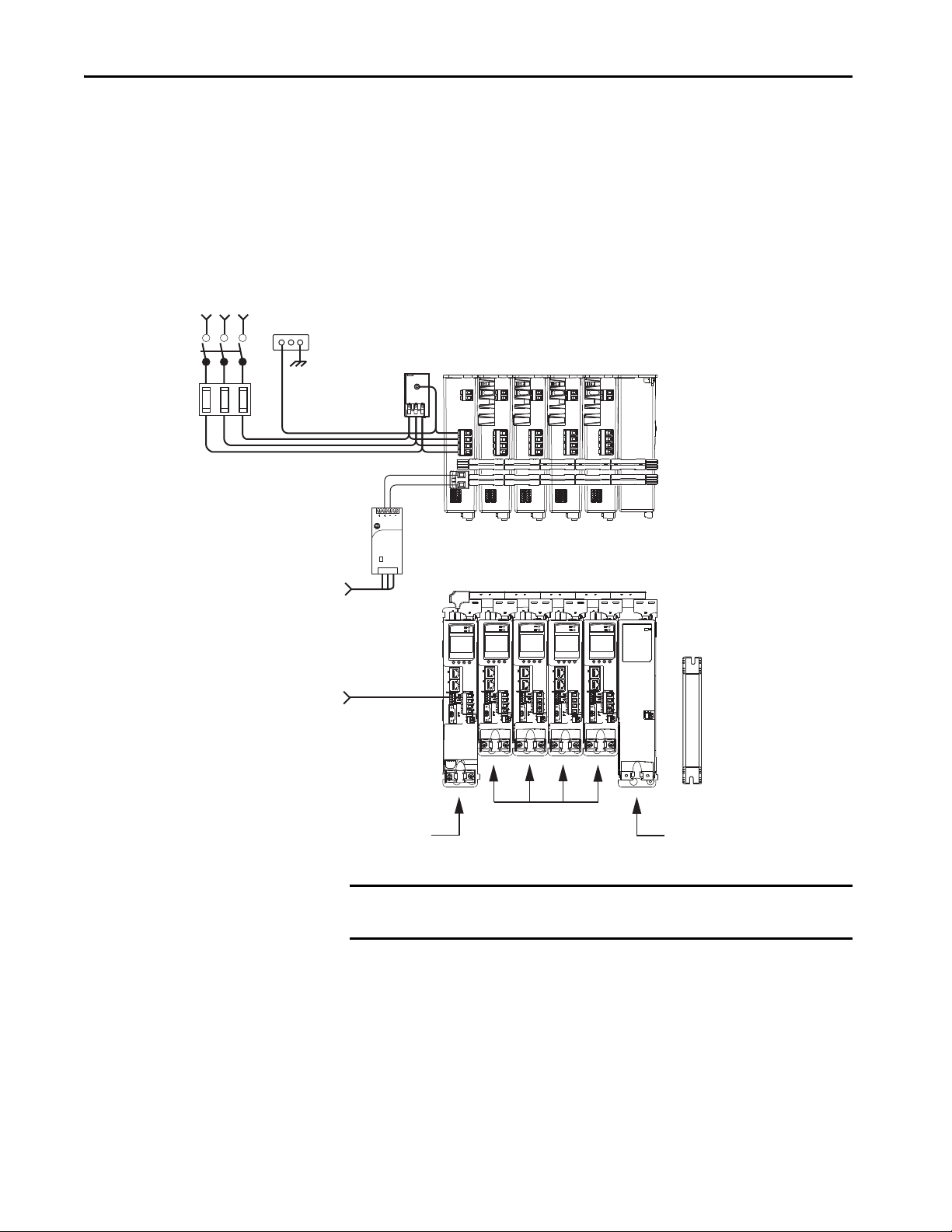

In this example, three-phase AC power and 24V control power is shared in a

multi-axis configuration. All drives must have the same power rating (catalog

number).

Figure 2 - Typical Shared AC Installations

IMPORTANT In shared AC configurations, all drives must have the same power rating.

Shared AC configurations do not support Bulletin 2198 capacitor modules.

18 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Start Chapter 1

1606-XL

Power Supply

Input

Allen-Bradley

2097-Rx

Shunt Resistor

(optional component)

Line

Disconnect

Device

Input

Fusing

Three-phase

Input Power

AC Input Power

Bonded Cabinet

Ground Bus

2198-DBRxx-F

AC Line Filter

(can be required for CE)

Kinetix 5500 Servo Drives (top view)

(2198-H015-ERS drives shown)

Kinetix 5500 Servo Drives (front view)

(2198-H015-ERS drives shown)

Share d AC (mains AC input)

Shared DC (DC common bus)

Shared 24V (control power input)

2198-CAPMOD-1300 Capacitor Module

(optional component)

Shared-bus connection system for

bus-sharing configurations.

Digital Inputs

to Sensors and Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

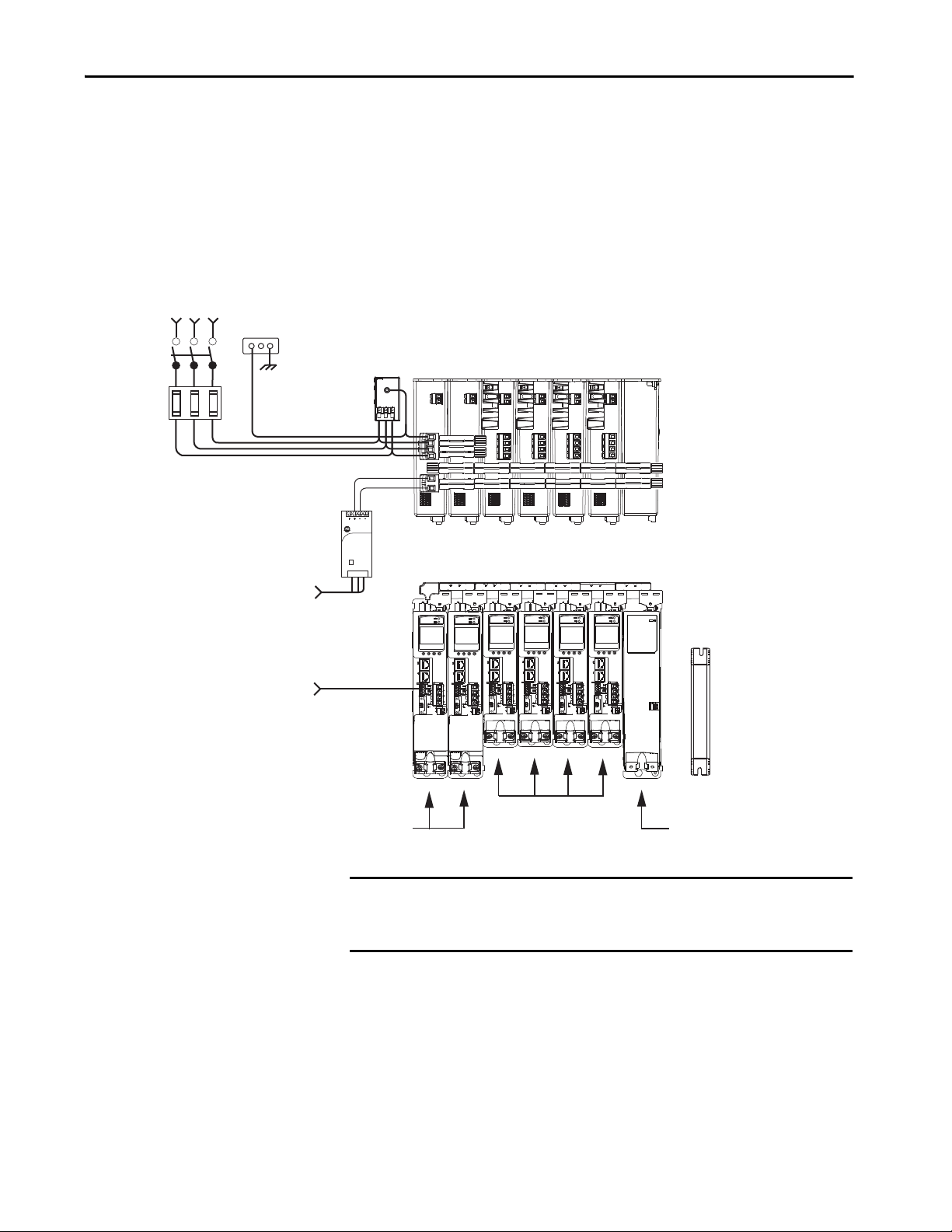

Shared AC/DC Configurations

In this example, three-phase AC input power, 24V control power, and DC-bus

power are shared in a multi-axis configuration. All drives must be the same

power rating (catalog number).

Figure 3 - Typical Shared AC/DC Installations

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 19

IMPORTANT In shared AC/DC configurations, all drives must have the same power rating

(catalog number).

Chapter 1 Start

Kinetix 5500 Servo Drive System (top view)

2097-Rx

Shunt Resistor

(optional component)

Line

Disconnect

Device

Input

Fusing

Three-phase

Input Power

2198-H040-ERS

Common-bus Leader Drive

AC Inp ut Power

Bonded Cabinet

Ground Bus

Kinetix 5500 Servo Drive System (front view)

2198-H008-ERS

Common-bus

Follower Drives

2198-DBRxx-F

AC Line Filt er

(can be required for CE)

Shared DC (DC common bus)

Shared 24V (control power input)

2198-CAPMOD-1300 Capacitor Module

(optional component)

Shared-bus connection system

for bus-sharing configurations.

Digital Inputs

to Sensors and Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

Shared DC Common-bus Configurations

In this multi-axis example, the common-bus leader (sourcing) drive receives

three-phase AC input power and supplies DC power to common-bus follower

(sinking) drives. The common-bus leader-drive power rating is greater than or

equal to the power rating of each follower drive.

Figure 4 - Typical Shared DC Common-bus Installations

Allen-Bradley

1606-XL

Power Supply

Input

(

IMPORTANT In shared DC common-bus configurations, the leader drive power rating

must be greater than or equal to the power rating of the follower drives.

20 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Start Chapter 1

1606-XL

Power Supply

Input

Allen-Bradley

Kinetix 5500 Servo Drive System (top view)

2097-Rx

Shunt Resistor

(optional component)

Line

Disconnect

Device

Input

Fusing

Three-phase

Input Power

Digital Inputs

to Sensors and Control String

2198-H040-ERS

Common-bus (converter)

Leader Drives

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

AC Input Po wer

Bonded Cabinet

Ground Bus

Kinetix 5500 Servo Drive System (front view)

2198-H008-ERS

Common-bus (inverter)

Follower Drives

2198-DBRxx-F

AC Line Filter

(can be required for CE)

Share d AC (mains AC input)

Shared DC (DC common bus)

Shared 24V (control power input)

Shared-bus connection system for

bus-sharing configurations.

2198-CAPMOD-1300 Capacitor Module

(optional component)

Shared AC/DC Hybrid Configuration

In this multi-axis example, three-phase AC input power is supplied to two

converter drives. The converter drive ratings must be the same, and greater

than or equal to the power ratings of the inverter drives. This parallel converter

configuration increases the DC-bus power supplied to the inverter drives.

Figure 5 - Typical Shared AC/DC Bus Hybrid Installations

IMPORTANT In shared AC/DC hybrid configuration, the converter drives must have the

same power rating and must be greater than or equal to the power ratings

of the inverter drives.

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 21

Chapter 1 Start

2090-CSBM1DF or 2090-CSBM1DG

Single Motor Cables

2198-KITCON-DSL Connector Kit

• Accepts DSL motor feedback from Kinetix VP

(Bulletin VPL, VPF, VPH, VPS) rotary motors

and Kinetix VP electric cylinders.

• Feedback-only (DSL)

Bulletin 2090 Motor Power and Feedback Cables

MP-Series Linear Actuators

(MPAR-B3xxxx electric cylinder is shown)

MP-Series Rotary Motors

(MPL-Bxxxx motor is shown)

LDAT-Sxxxxxx-xDx

Linear Thrusters

2198-H2DCK Converter Kit

Converts 15-pin Hiperface feedback into 2-pin DSL feedback for:

• MP-Series rotary motors and linear actuators

• LDAT-Series linear thrusters

• Feedback-only (absolute single-turn/multi-turn Hiperface)

2-pin Motor Feedback

(MF) Connector

2198-Hxxx-ERSx Drive

(front view)

MP-Series Linear Actuators

(MPAS-B9xxx ballscrew linear stage is shown)

Kinetix VP Rotary Motors

(VPL-Bxxxx motor is shown)

MP-Series Linear Actuators

(MPAI-B3xxxx heavy-duty electric c ylinder is shown)

Induction Rotary Motors

(no feedback, V/Hz)

Kinetix VP Electric Cylinders

(Bulletin VPAR)

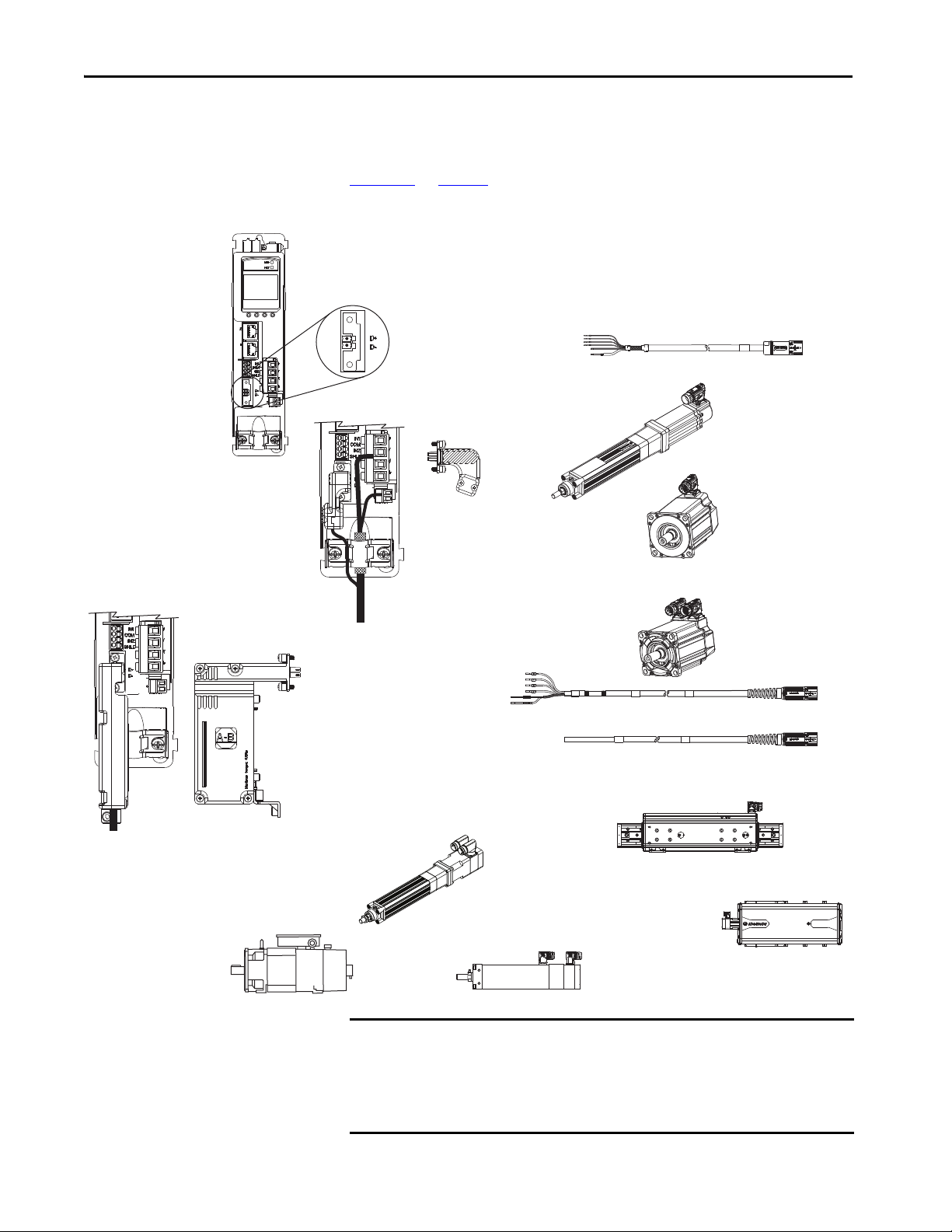

Motor Feedback and Feedback-only Configurations

Feedback connections are made at the 2-pin motor feedback (MF) connector.

These examples illustrate how you can use the Bulletin 2198 connector kits for

making these connections. To see motor power and brake connections, refer to

Chapter 5

Figure 6 - Feedback Configuration Examples

on page 73.

IMPORTANT In 2198-H2DCK converter kit applications, you can replace the 2090-

CPxM7DF power/brake cable with a 2090-CSBM1DF single motor cable, and

reuse the 2090-CFBM7DF feedback cable. This increases the maximum cable

length for 18 and 14 AWG single cables to 50 m (164 ft). 2090-CSxM1DF-

10Axxx (10 AWG) cables do not support this 50 m (164 ft) option.

22 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Start Chapter 1

2198-ABQE

Encoder Output Module

Compac tLogix 5370 Controller

Studio 5000 Logix Designer

Application

1585J-M8CBJM-x

Ethernet (shielded) Cable

1734-AENTR POINT I/O™

EtherNet/IP Adapter

CompactLogix Controller Programming Network

PanelView™ Plus

Display Terminal

1585J-M8CBJM-OM15

0.15 m (6 in.) Ethernet cable

for drive-to-drive connections.

Kinetix 5500 Servo Drive System

842E-CM Integrated

Motion Encoder

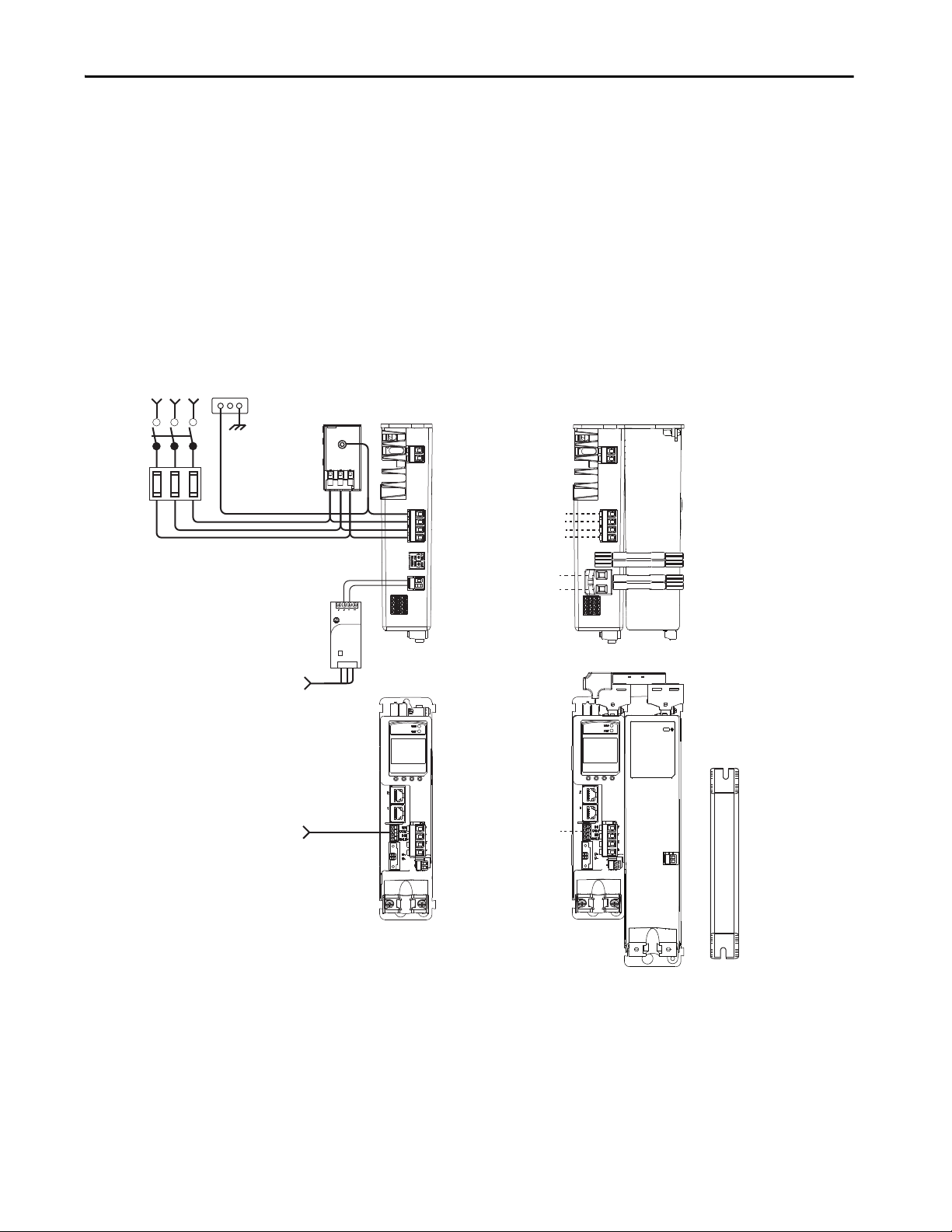

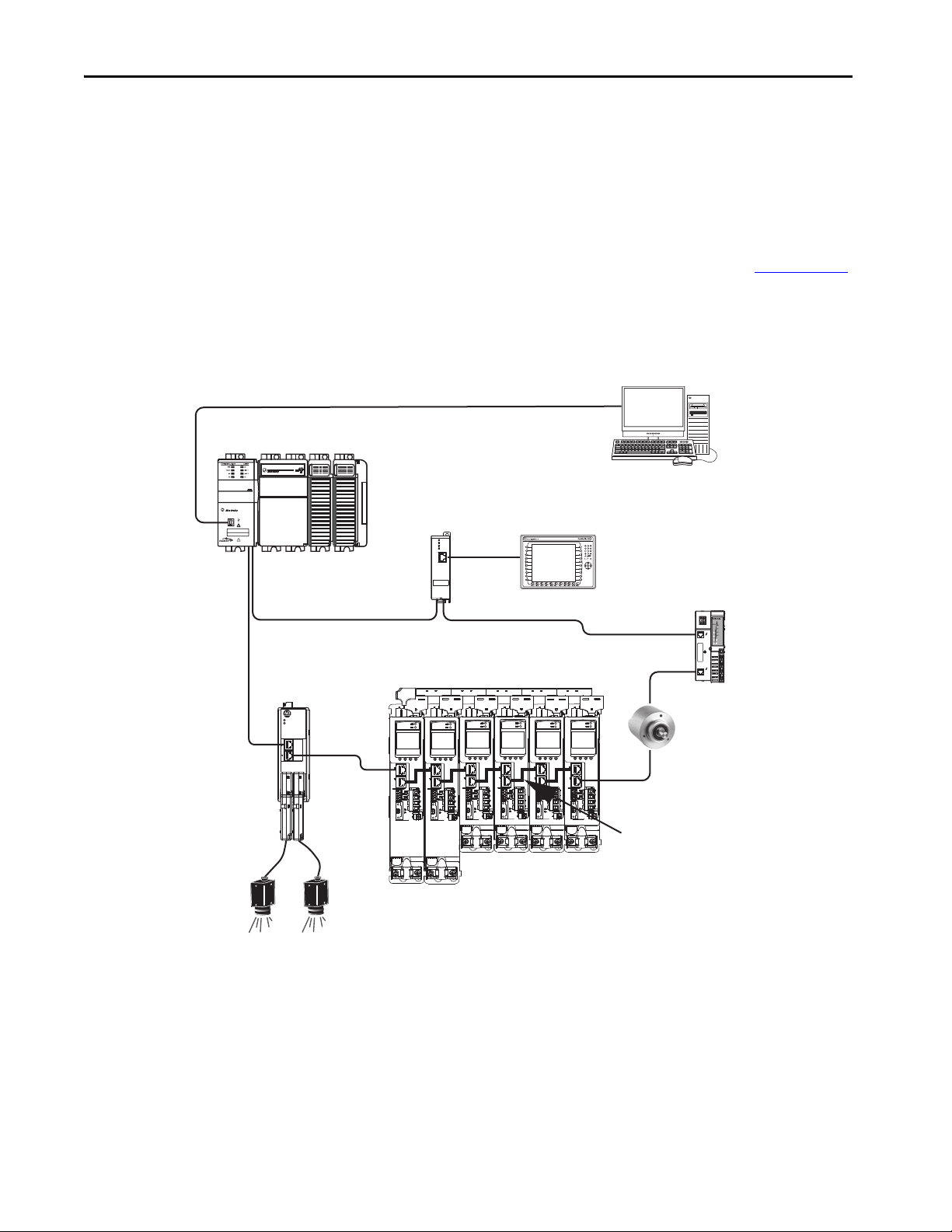

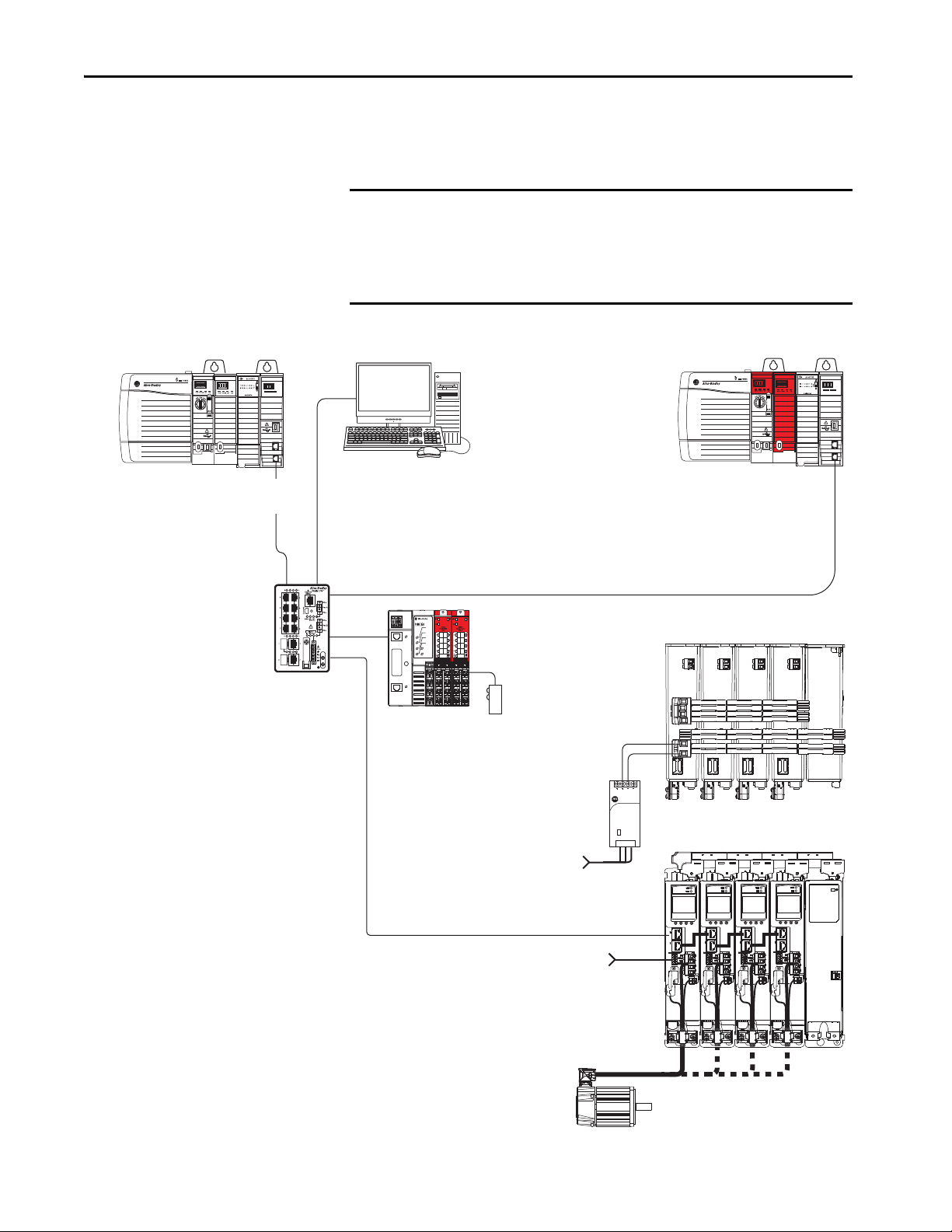

Typical Communication Configurations

The Kinetix 5500 drives support any Ethernet topology including linear, ring,

and star by using ControlLogix, GuardLogix, or CompactLogix controllers.

These examples feature the CompactLogix 5370 programmable automation

controllers (Bulletin 1769) with support for Integrated Motion over the

EtherNet/IP network.

Refer to CompactLogix Controllers Specifications Technical Data, publication

1769-TD005

, for more information on CompactLogix 5370 L1, L2, and L3

controllers.

Linear Topology

In this example, all devices are connected in linear topology. The Kinetix 5500

drives include dual-port connectivity, however, if any device becomes

disconnected, all devices downstream of that device lose communication.

Devices without dual ports must include the 1783-ETAP module or be

connected at the end of the line.

Figure 7 - Kinetix 5500 Linear Communication Installation

00:00:BC:2E:69:F6

1 (Front)

2 (Rear)

MOD

NET

OUTPUT-A OUTPUT-B

1734-AENTR

02

0

POINT I O

Module

Status

Network

Activity

Network

Status

Point Bus

Status

Link 1

Activity/

System

Status

Power

Field

Power

Link 2

Activity/

Status

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 23

Chapter 1 Start

1 (Front)

2 (Rear)

00:00:BC:2E:69:F6

02

0

1734-AENTR

Module

Status

Network

Activity

Network

Status

Point Bus

Status

System

Power

Field

Power

POINT I O

Link 1

Activity/

Status

Link 2

Activity/

Status

MOD

NET

OUTPUT-A OUTPUT-B

2198-ABQE

Encoder Output Module

1734-AENTR POINT I/O

EtherNet/IP Adapter

CompactLogix Controller Programming Network

1783-ETAP

Module

1585J-M8CBJM-OM15

0.15 m (6 in.) Ethernet cable

for drive-to-drive connections.

Panel View Plus

Display Terminal

Kinetix 5500 Servo Drive System

Compac tLogix 5370 Controller

Studio 5000 Logix Designer

Application

1585J-M8CBJM-x Ethernet

(shielded) Cable

842E-CM Integrated

Motion Encoder

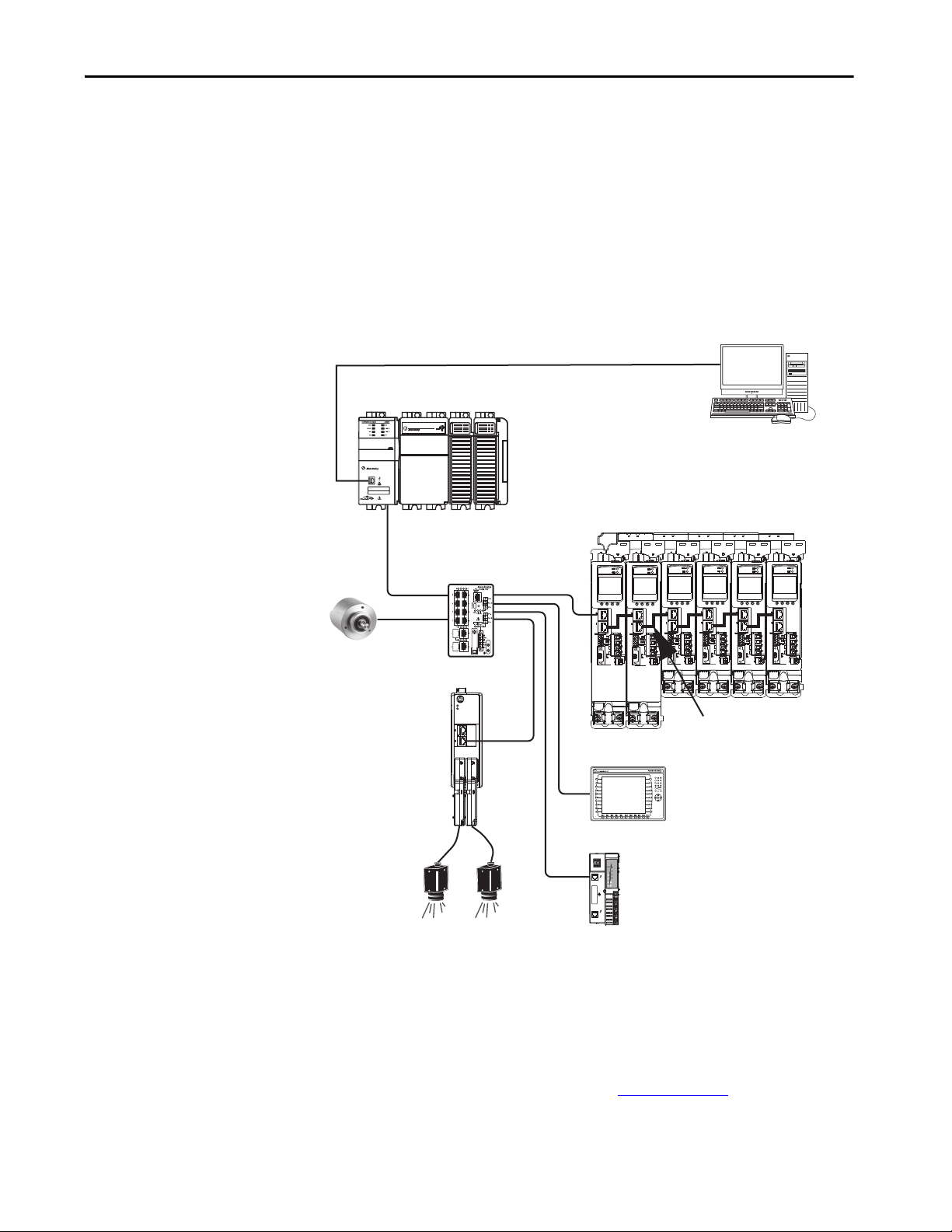

Ring Topology

In this example, the devices are connected by using ring topology. If only one

device in the ring is disconnected, the rest of the devices continue to

communicate. For ring topology to work correctly, a device level ring (DLR)

supervisor is required (for example, the Bulletin 1783 ETAP device). DLR is

an ODVA standard. For more information, refer to the EtherNet/IP

Embedded Switch Technology Application Guide, publication ENET-AP005

Devices without dual ports, for example the display terminal, require a

1783-ETAP module to complete the network ring.

Figure 8 - Kinetix 5500 Ring Communication Installation

.

24 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Start Chapter 1

2198-ABQE

Encoder Output Module

1585J-M8CBJM-x

Ethernet (shielded) Cable

1734-AENTR POINT I/O

EtherNet/IP Adap ter

CompactLogix Controller Programming Network

PanelView Plus

Display Terminal

1783-BMS

Stratix® 5700

Switch

1585J-M8CBJM-OM15

0.15 m (6 in.) Ethernet cable

for drive-to-drive connections.

Kinetix 5500 Servo Drive System

CompactLogix 53 70 Controller

Studio 5000 Logix Designer

Application

842E-CM Integrated

Motion Encoder

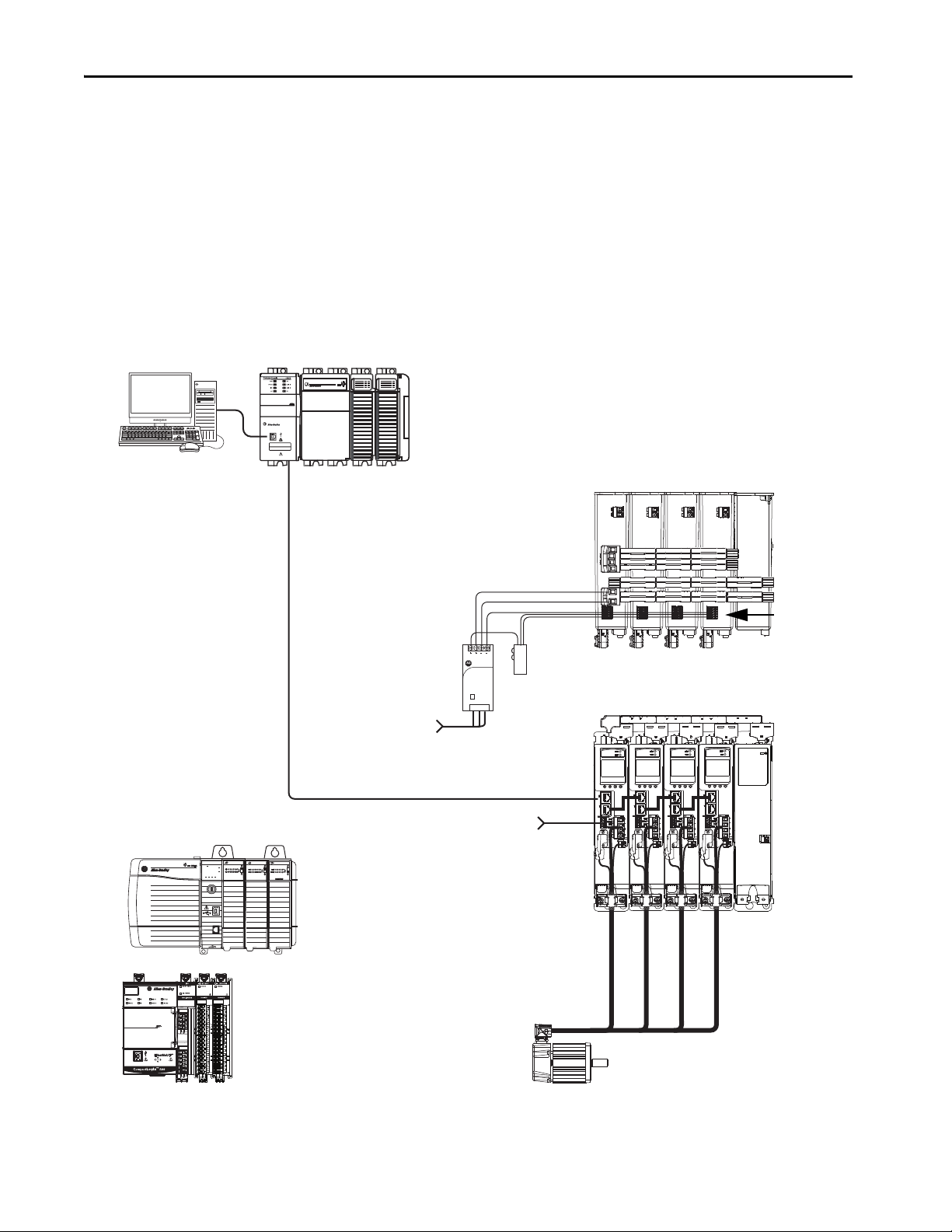

Star Topology

In this example, the devices are connected by using star topology. Each device is

connected directly to the switch.

Kinetix 5500 drives have dual ports, so linear topology is maintained from

drive-to-drive, but Kinetix 5500 drives and other devices operate

independently. The loss of one device does not impact the operation of other

devices.

Figure 9 - Kinetix 5500 Star Communication Installation

00:00:BC:2E:69:F6

1 (Front)

2 (Rear)

MOD

NET

OUTPUT-A OUTPUT-B

You can use the 842E-CM integrated motion encoder for applications

requiring an external encoder for gearing or camming to the Kineitx 5700

drive. By providing auxiliary feedback directly through the EtherNet/IP

network, the 842E-CM encoder helps eliminate the need for point-to-point

wiring while letting customers use the encoder in a variety of network

topologies. For more information, see the 842E-CM Integrated Motion on

EtherNet/IP Product Profile, publication 842ECM-PP001

.

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 25

Chapter 1 Start

1 (Front)

2 (Rear)

00:00:BC:2E:69:F6

1606-XL

Power Supply

Input

Allen-Bradley

OKFORCESDRUN

Logix5585

LINK

NET

TM

SAFETY ON

0000

DC INPUT

AC OUTPUT

DC INPUT

1585J-M8CBJM-x

Ethernet (shielded) Cable

Studio 5000 Logix Designer

Application

(version 21.0 or later)

AC Inp ut Power

Safety

Device

2198-Hxxx-ERS Servo Drives

(front view)

Digital Inputs to Sensors and Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

Kinetix VP

Servo Motors

Module Definition

Configured with

Motion-only

Connection

Safe Torque-off

(STO) Connectors

Any Logix 5000 Controller

(CompactLogix 5370 controller is shown)

2198-Hxxx-ERS Servo Drives

(top view)

ControlLogix 5570 Controllers or

GuardLogix 5570 Safety Controllers

ControlLogix 5580 Controllers or

GuardLogix 5580 Safety Controllers

CompactLogix 53 70 Controllers or

Compact GuardLogix 5370 Safety Controllers

CompactLogix 5380 or 5480 Controllers or

Compact GuardLogix 5380 Safety Controllers

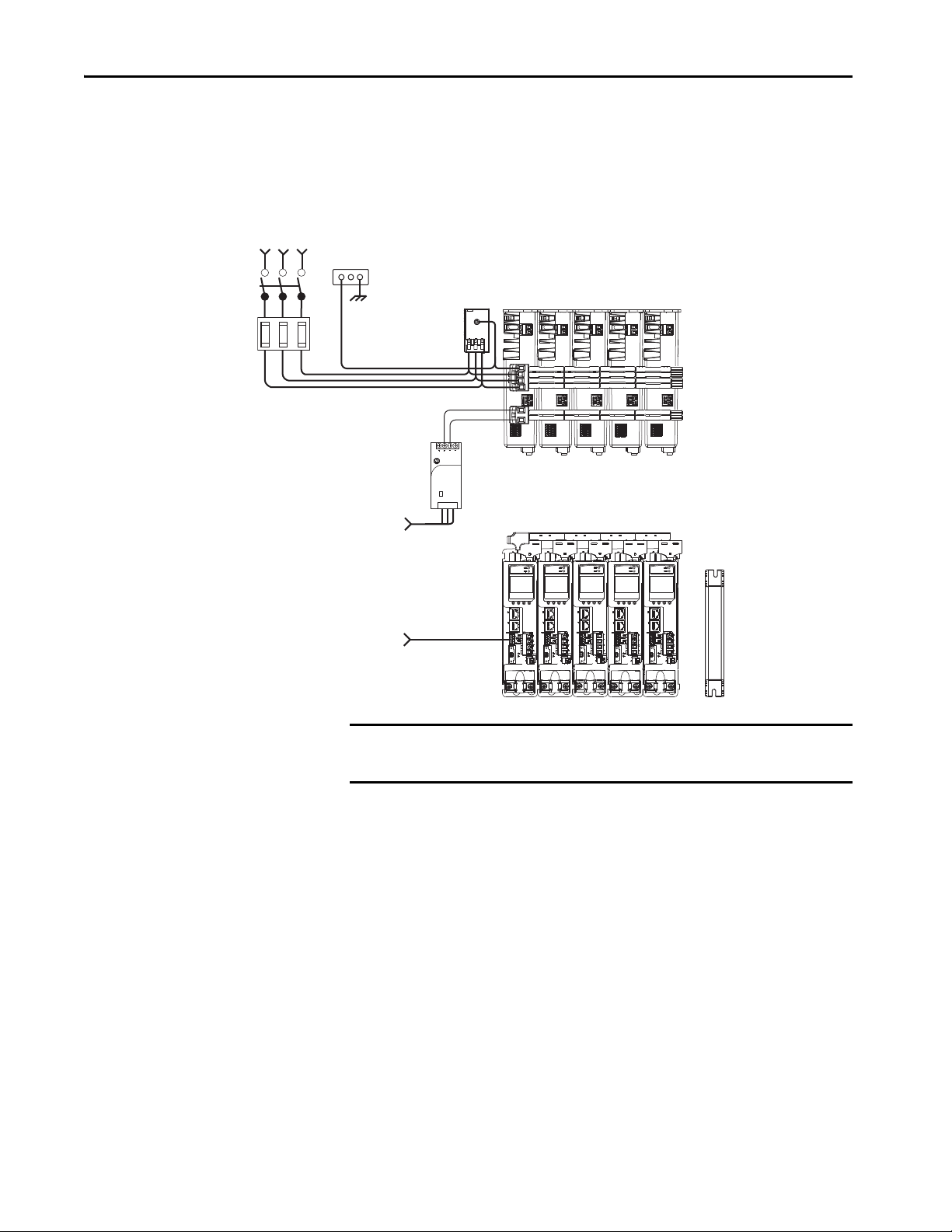

Safe Torque-off Configurations

Kinetix 5500 servo drives are available with safe torque-off via hardwired

connections or integrated over the EtherNet/IP network. These examples

illustrate the safe torque-off configuration options.

Hardwired Safety Configuration

The 2198-Hxxx-ERS drives use the safe torque-off (STO) connector for

wiring external safety devices and cascading hardwired safety connections from

one drive to another.

Figure 10 - Safe Torque-off (hardwired) Configuration

26 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Start Chapter 1

1606-XL

Power Supply

Input

Allen-Bradley

LNK1LNK2NET OK

EtherNet/IP

1

2

1585J-M8CBJM-x

Ethernet (shielded) Cable

Studio 5000 Logix Designer

Application

(version 24.0 or later)

AC Input Po wer

2198-Hxxx-ERS2 Servo Drives

(top view)

2198-Hxxx-ERS2 Servo Drives

(front view)

Digital Inputs to Sensors and Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

Kinetix VP

Servo Motors

1783-BMS

Stratix 5700

Switch

Module Definition

Configured with

Motion and Safety

Connections

1734-AENTR

POINT Guard I/O™

EtherNet/IP Adapter

Safety

Device

Motion and Safety Connections to the Drive

Compact GuardLogix 5370 Controller,

Compact GuardLogix 5380 Safety Controller or

GuardLogix 5570 Controller,

GuardLogix 5580 Safety Controller

(GuardLogix 5570 Safety Controller is shown)

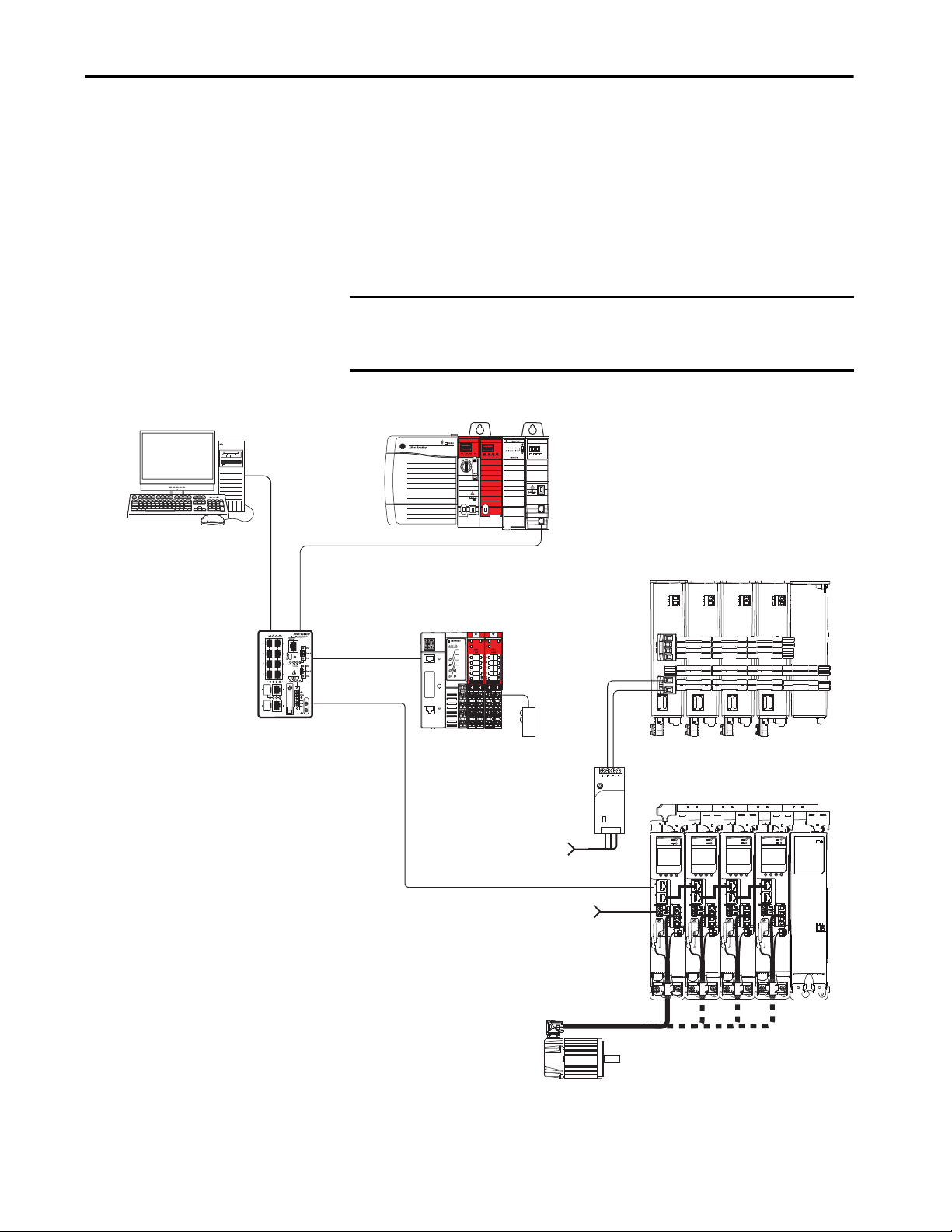

Integrated Safety Configurations

The GuardLogix 5570 or Compact GuardLogix 5370 safety controller issues

the safe torque-off (STO) command over the EtherNet/IP network and the

2198-Hxxx-ERS2 integrated safety drive executes the command.

In this example, a single GuardLogix safety controller makes a Motion and

Safety connection with the 2198-Hxxx-ERS2 integrated safety drives.

IMPORTANT If only one controller is used in an application with Motion and Safety

connections, the controller must be a GuardLogix 5570 or Compact

GuardLogix 5370 safety controller.

Figure 11 - Motion and Safety Configuration (single controller)

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 27

Chapter 1 Start

1585J-M8CBJM-x

Ethernet (shielded) Cable

Studio 5000 Logix Designer

Application

(version 24.0 or later)

AC Input Po wer

2198-Hxxx-ERS2 Servo Drives

(top view)

2198-Hxxx-ERS2 Servo Drives

(front view)

Digital Inputs to Sensors and Control String

1606-XLxxx

24V DC Control, Digital Inputs,

and Motor Brake Power

(customer-supplied)

Kinetix VP

Servo Motors

1734-AENTR

POINT Guard I/O

EtherNet/IP Adapter

1783-BMS

Stratix 5700

Switch

Motion Program

Module Definition

Configured with

Motion only

Connection

Safety Program

Module Definition

Config ured with S afety

only Connection

Safety

Device

Motion and Safety Connections to the Drive

Any Logix 5000 Controller

(ControlLogix 5570 controller is shown)

Compact GuardLogix 5370 Controller,

Compact GuardLogix 5380 Safety Controller or

GuardLogix 5570 Controller,

GuardLogix 5580 Safety Controller

(GuardLogix 5570 Safety Controller is shown)

In this example, a non-safety controller makes the Motion-only connection

and a separate GuardLogix safety controller makes the Safety-only connection

with 2198-Hxxx-ERS2 integrated safety drives.

IMPORTANT If two controllers are used in an application with Motion-only and

Safety-only connections, the Safety-only connection must be a

GuardLogix 5570 or Compact GuardLogix 5370 safety controller and the

Motion-only connection must be a ControlLogix 5570 or

CompactLogix 5370 controller.

Figure 12 - Motion and Safety Configuration (multi-controller)

EtherNet/IP

LNK1LNK2NET OK

2

1

Allen-Bradley

1606-XL

Power Supply

Input

LNK1LNK2NET OK

EtherNet/IP

2

1

28 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Start Chapter 1

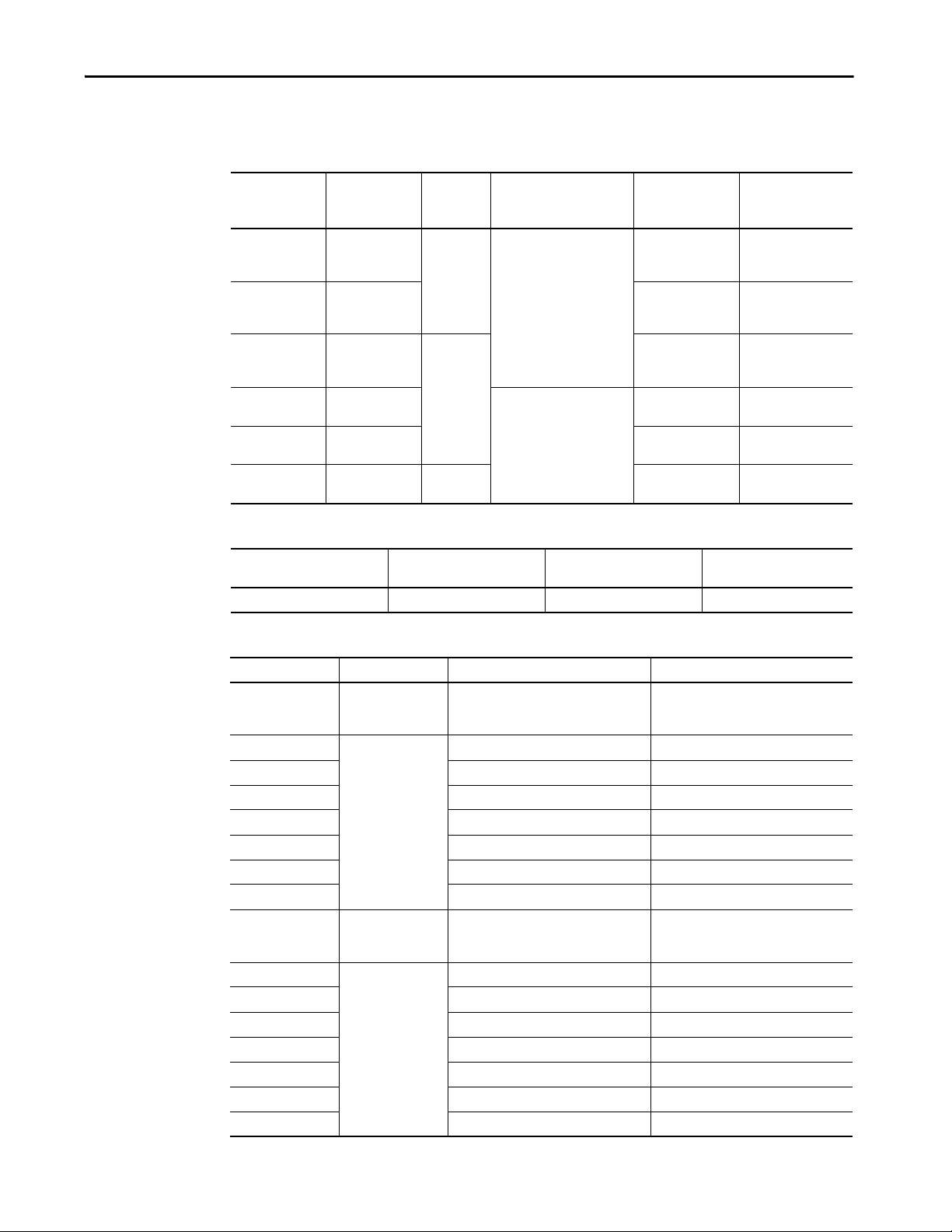

Catalog Number Explanation

Drive Cat. No.

(hardwired STO)

2198-H003-ERS 2198-H003-ERS2

2198-H008-ERS 2198-H008-ERS2

2198-H015-ERS 2198-H015-ERS2

2198-H025-ERS 2198-H025-ERS2

2198-H040-ERS 2198-H040-ERS2

2198-H070-ERS 2198-H070-ERS2 3

Capacitor Module

Cat. No.

2198-CAPMOD-1300 2 650V DC, nom 1360 μF, min

Kinetix 5500 drive catalog numbers and performance descriptions.

Table 3 - Kinetix 5500 Servo Drive Catalog Numbers

Drive Cat. No.

(integrated STO)

Frame Size Input Voltage

1

2

195…264V rms, single-phase

195…264V rms, three-phase

324…528V rms, three-phase

195…264V rms, three-phase

324…528V rms, three-phase

Table 4 - Capacitor Module Catalog Number

Frame Size Rated Voltage Capacitance

Continuous Output

Power

kW

0.2 kW

0.3 kW

0.6 kW

0.5 kW

0.8 kW

1.6 kW

1.0 kW

1.5 KW

3.2 kW

2.4 kW

5.1 kW

4.0 kW

8.3 kW

7.0 kW

14.6 kW

Continuous Output

Current

A 0-pk

1.4

3.5

7.1

11.3

18.4

32.5

Table 5 - Shared-bus Connector Kit Catalog Numbers

Kit Cat. No. Frame Size Application Description

2198-H040-ADP-IN Frame 1 or 2 First drive

2198-H040-A-T

2198-H040-D-T DC sharing only DC bus T-connector

2198-H040-P-T Control power sharing only Control power T-connector

2198-H040-AD-T AC and DC-bus sharing AC and DC bus T-connectors

2198-H040-AP-T AC and control power sharing AC and control power T-connectors

2198-H040-DP-T DC and control power sharing DC and control power T-connectors

2198-H040-ADP-T AC, DC, and control power sharing AC, DC, and control power T-connectors

2198-H070-ADP-IN

2198-H070-A-T

2198-H070-D-T DC sharing only DC bus T-connector

2198-H070-P-T Control power sharing only Control power T-connector

2198-H070-AD-T AC and DC-bus sharing AC and DC bus T-connectors

2198-H070-AP-T AC and control power sharing AC and control power T-connectors

2198-H070-DP-T DC and control power sharing DC and control power T-connectors

2198-H070-ADP-T AC, DC, and control power sharing AC, DC, and control power T-connectors

Next drive is…

Frame 1 drives:

2198-H003-ERSx

2198-H008-ERSx

Frame 2 drives:

2198-H015-ERSx

2198-H025-ERSx

2198-H040-ERSx

Frame 3 drive:

2198-H070-ERSx

Next drive is…

Frame 3 drives:

2198-H070-ERSx

AC sharing only AC bus T-connector

First drive

AC sharing only AC bus T-connector

• Mains AC input wiring connector

• 24V DC input wiring connector

•DC bus T-connector

• Mains AC input wiring connector

• 24V DC input wiring connector

•DC bus T-connector

Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 29

Chapter 1 Start

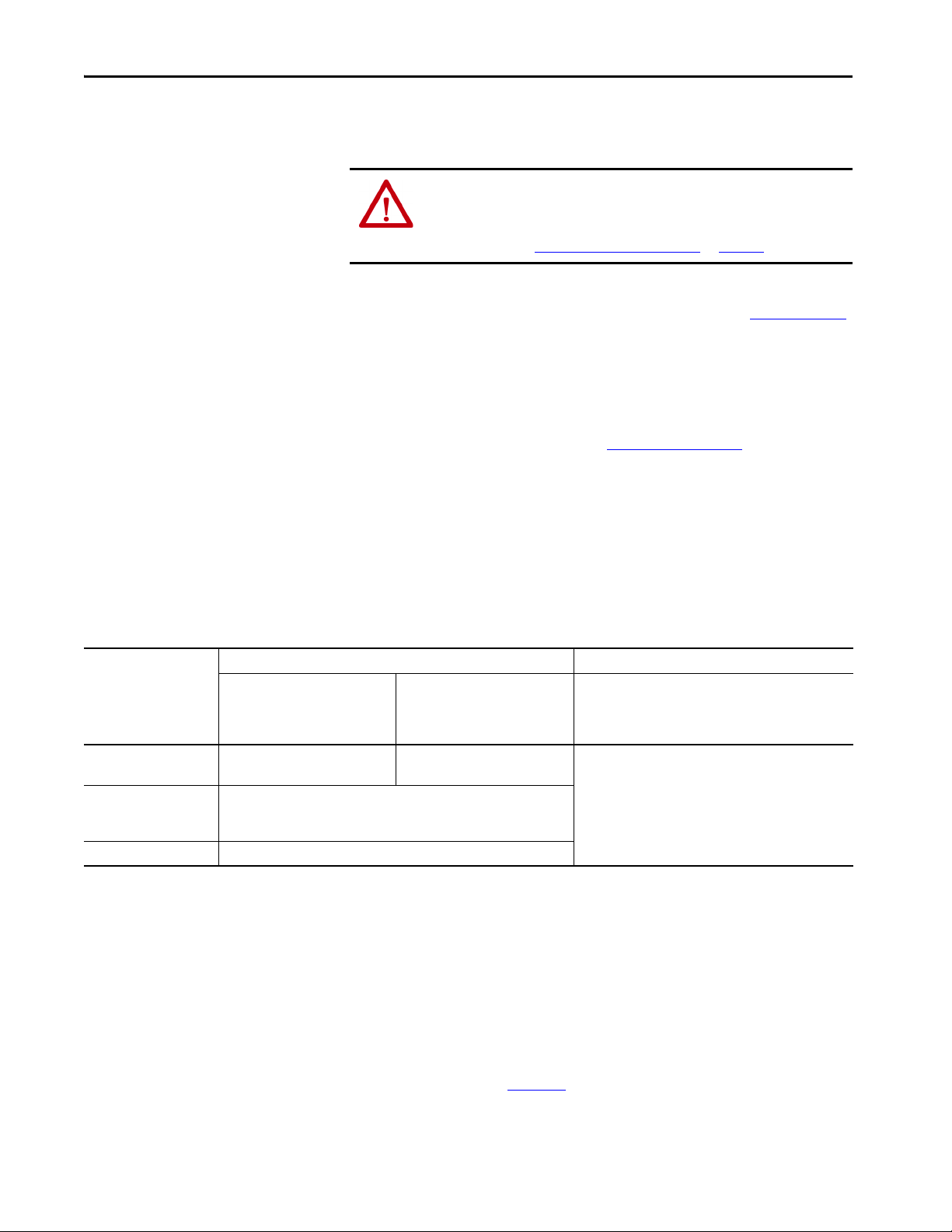

Agency Compliance

If this product is installed within the European Union and has the CE mark,

the following regulations apply.

ATT EN TI ON : Meeting CE requires a grounded system, and the method of

grounding the AC line filter and drive must match. Failure to do this renders

the filter ineffective and can cause damage to the filter. For grounding

examples, refer to Grounded Power Configurations

on page 75.

For more information on electrical noise reduction, refer to the System Design

for Control of Electrical Noise Reference Manual, publication GMC-RM001

To meet CE requirements, these requirements apply:

• Install an AC line filter (catalog number 2198-DBRxx-F) for input

power as close to the Kinetix 5500 drive as possible.

• Bond drive, capacitor module, and line filter grounding screws by using a

braided ground strap as shown in Figure 43 on page 80

.

• Use Bulletin 2090 single motor cables with Kinetix VP servo motors

and actuators. Use Bulletin 2090 motor power/brake and feedback

cables for other compatible Allen-Bradley motors and actuators.

• Combined motor cable length for all axes on the same DC bus must not

exceed 250 m (820 ft). Drive-to-motor cables must not exceed 50 m

(164 ft); however, use of continuous-flex cable and 2198-H2DCK

converter kit limits the maximum length.

.

Table 6 - Drive-to-Motor Maximum Cable Length

Kinetix VP Servo Motors Other Compatible Rotary Motors/Linear Actuators

Kinetix 5500 Servo Drive

Cat. No.

2198-H003-ERSx

2198-H008-ERSx

2198-H015-ERSx

2198-H025-ERSx

2198-H040-ERSx

2198-H070-ERSx 50 (164)

(1) When using 2090-CSBM1E1 cable in your continuous-flex application, the maximum cable length including the standard (non-flex) cable back to the drive, is 30 m (98.4 ft)

(2) Requires use of the 2198-H2DCK Hiperface-to-DSL (series B or later) feedback converter kit.

(3) The 20 m (65.6 ft) limitation is attributed to the 2090-CPxM7DF power/brake cable. In 2198-H2DCK converter kit applications, you can replace the 2090-CPxM7DF power/brake cable with a

2090-CSBM1DF or 2090-CSBM1DG single motor cable (and reuse the 2090-CFBM7DF feedback cable) to increase the maximum cable length t o 50 m (164 f t). This app lies to only 1 8 and 14 AWG sing le

cables. 2090-CSxM1Dx-10Axxx (10 AWG/M40 connector) single cables are not compatible with 2090-CPBM7DF-10Axxx (10 AWG/M40 connector) power/brake cables.

Standard (non-flex) Cables

Cat. No. 2090-CSxM1DF/DG-xxAAxx

m (ft)

50 (164) 30 (98.4)

50 (164)

Continuous-flex Cables

Cat. No. 2090-CSBM1DF/DG-xxAFxx

Cat. No. 2090-CSBM1E1-xxAFxx

m (ft)

(1)

Bulletin 2090 Motor/Actuator Cables

Cat. No. 2090-CxxM7DF

m (ft)

20 (65.6)

(3)

• Install the Kinetix 5500 system inside an approved enclosure. Run input

power wiring in conduit (grounded to the enclosure) outside of the

enclosure. Separate signal and power cables.

• Segregate input power wiring from control wiring and motor cables.

(2)

Refer to Appendix A on page 193

for input power wiring and drive/motor

interconnect diagrams.

30 Rockwell Automation Publication 2198-UM001I-EN-P - May 2019

Loading...

Loading...