Allen-Bradley 20-750-APS, 20-750-ENETR, 20-750-DENC-1, 20-750-DNET, 20-750-PBUS Installation Instructions Manual

...Page 1

Installation Instructions

PowerFlex 750-Series AC Drives

Catalog Numbers 20F, 20G, 21G

Page 2

Important User Information

IMPORTANT

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required

to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Preface

Introduction

Read the General Precautions

Prepare for Installation

Lift and Mount the Drive

Instructions in Other Languages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Commonly Used Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Qualified Personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Personal Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Product Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Class 1 LED Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 2

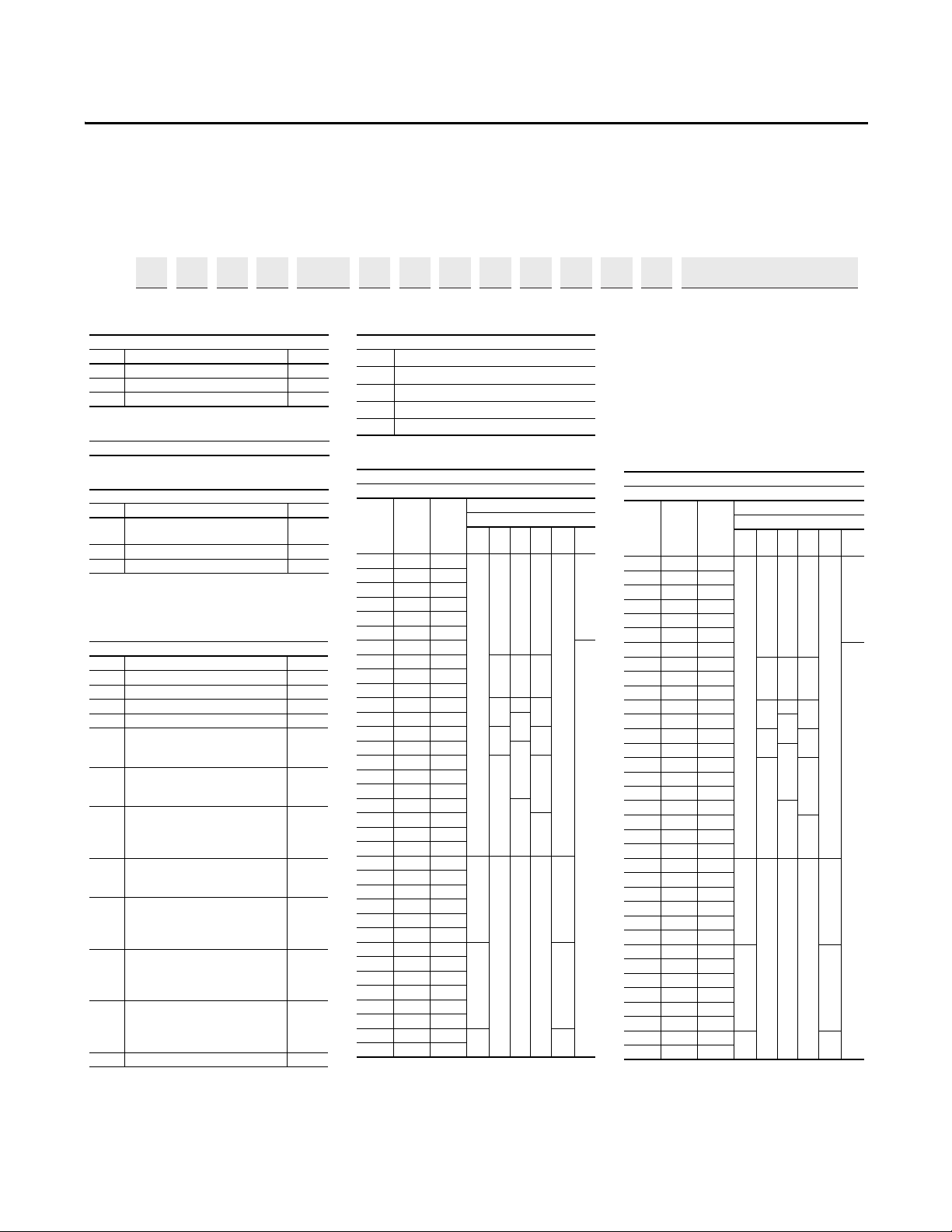

Wall Mount Frames 1…7 Drive Rating Cross-References . . . . . . . . . . . . 15

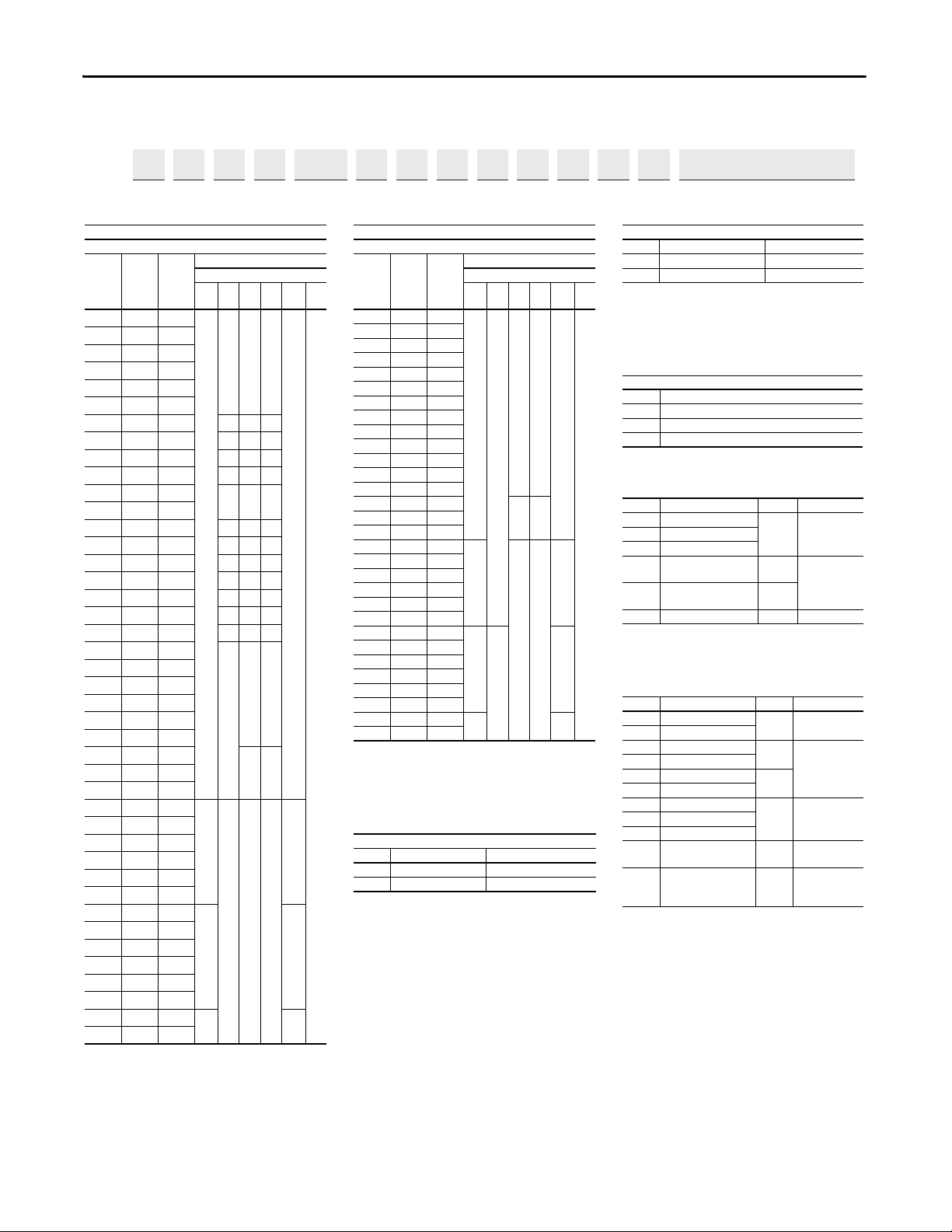

Floor Mount Frames 8…10 Drive Rating Cross-References . . . . . . . . . . 17

CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Access Panels, Covers, and Doors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Minimum Clearances. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Mounting Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Environmental Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 3

Drive Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Recommended Mounting Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Attach Lifting Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Release Floor Mount Drive Cabinet From Shipping Skid . . . . . . . . . . . . 41

Remove Drive Cabinet Lifting Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Install IP20, NEMA/UL Type 1 Debris Screen or

Optional Exhaust Hood . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Install IP54, NEMA 12 Cabinet Blower Assembly and Exhaust Hood 43

Install Floor Mount Drive with Cabinet Options Bay and Wiring Bay 44

Approximate Dimensions - Wall Mount Frames 1…7 and

Floor Mount Frames 8…10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Approximate Dimensions - Floor Mount Drives

with Cabinet Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Release Drive Assembly From Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Fiber-Optic Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Disconnect Drive Control Pod Wiring Connections . . . . . . . . . . . . . . . 121

Disconnect Wire Connections - No Drive Control Pod . . . . . . . . . . . . 123

Disconnect Control and Power Wire Harnesses . . . . . . . . . . . . . . . . . . . 125

Disconnect DC Bus Fuse Wire Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Release Cabinet Options Assembly From Cabinet . . . . . . . . . . . . . . . . . 127

Prepare the Roll-Out Cart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Remove Drive Assembly or Cabinet Options Assembly. . . . . . . . . . . . . 138

Remove DC Back Bus Guard - Common DC Input Drives . . . . . . . . . 143

Reinstall Drive Assembly or Cabinet Options Assembly . . . . . . . . . . . . 144

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 3

Page 4

Chapter 4

Power Wiring

Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Power Cable Types Acceptable for 200…600 Volt Installations. . . . . . 147

Motor Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Terminal Block Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Three-Phase Terminal Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Wall Mount Frames 1…7 AC Input Power Terminals . . . . . . . . . . . . . . 151

Wall Mount Frames 5…7 Common DC Input Terminal Locations. . 153

Wall Mount Frames 5…7 Common DC Input Power Terminals . . . . 155

Floor Mount Frames 8…10 Bus Bar Locations . . . . . . . . . . . . . . . . . . . . . 156

Floor Mount Cabinet Options Bay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Floor Mount Frames 8…10 Power Wiring Options . . . . . . . . . . . . . . . . 161

Floor Mount Frames 8…10 Power Terminal L-Brackets . . . . . . . . . . . . 162

Recommended Motor Cable Spacing -

Floor Mount Frames 8 and Larger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Fuse and Circuit Breaker Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Motor Overload Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Short Circuit Current Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Short Circuit Current Ratings -

Floor Mount Drives with Cabinet Options. . . . . . . . . . . . . . . . . . . . . . . . 185

Input Contactor Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Output Contactor Precaution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Bypass Contactor Precaution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Applying and Removing Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Drives with Cabinet Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

Input Power Circuit Breakers and Disconnect Switches . . . . . . . . . . . . 194

Cabinet Options Bay Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Drive Power Jumper Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

Chapter 5

I/O Wiring

4 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

I/O Terminal Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Access Drive Control Pod. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

PowerFlex 753 Main Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

PowerFlex 755 Main Control Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 228

Hardware Enable Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Safety Enable Circuitry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

PowerFlex 755 Fiber Optic Interface Board . . . . . . . . . . . . . . . . . . . . . . . 233

AC Input Drive Control and Power Terminal Block . . . . . . . . . . . . . . . 234

Common DC Input Drive Control and Power Terminal Blocks . . . . 235

Control Transformer Connections - Common DC Input Drives. . . . 238

Uninterruptible Power Supply Connections -

Common DC Input Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

120/240V AC Power Supply Connections -

Common DC Input Drives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 240

753 Main Control Board I/O Wiring Examples . . . . . . . . . . . . . . . . . . . 241

Page 5

Drive Device Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 244

Option Module Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

11-Series I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 246

11-Series I/O Wiring Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

22-Series I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

22-Series I/O Wiring Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

Safe Torque Off Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Safe Speed Monitor Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Auxiliary Power Supply Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . 266

DeviceNet Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

ControlNet Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Dual-Port EtherNet/IP Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . 269

Profibus Option Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

BACnet/IP Option Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

20-COMM Carrier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Single Incremental Encoder Option Module. . . . . . . . . . . . . . . . . . . . . . . 273

Dual Incremental Encoder Option Module. . . . . . . . . . . . . . . . . . . . . . . . 275

Universal Feedback Option Module - 755 Drives Only . . . . . . . . . . . . . 279

Motor Power Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Feedback Device Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Motor Feedback Wiring Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Control Pod Cable Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 292

Control Wiring - Early Frame 8 Drives with Cabinet Options . . . . . . 293

Control Wiring - Current Frame 8 Drives with Cabinet Options . . . 295

Control Wiring - Frame 9 and 10 Drives with Cabinet Options. . . . . 296

Enclosure Options - Floor Mount Frames 8…10 . . . . . . . . . . . . . . . . . . . 298

Integrated Motion Drives

Configuring Option Modules for Integrated Motion . . . . . . . . . . . . . . . 299

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 5

Page 6

Notes:

6 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 7

Preface

Introduction

This document explains the BASIC STEPS for mechanical installation and for

connecting incoming power, the motor, and basic I/O to the PowerFlex 750Series Adjustable Frequency AC drive.

The information that is provided is intended for qualified installers only.

The Additional Resources section is a directory of Rockwell Automation

publications that provide detailed drive information from wiring and grounding

recommendations to troubleshooting and repair.

Instructions in Other Languages

English This instruction sheet is available in multiple languages at

German Diese Anleitung steht in mehreren Sprachen unter

French Ces instructions sont disponibles dans différentes langues à l’adresse suivante:

Italian La presente scheda d’istruzione è disponibile in varie lingue sul sito

Spanish Puede encontrar esta hoja de instrucciones en varios idiomas en

Portuguese Esta folha de instruções está disponível em várias línguas em

Chinese

(Simplified)

Japanese 本説明書シートの多言語版は Web サイト

Korean

Russian

Chinese

(Complex)

Czech Tato stránka s pokyny je k dispozici ve více jazykových verzích na adrese

http://rockwellautomation.com/literature. Select publication language and type “750-IN001“ in the

search field.

http://rockwellautomation.com/literature zur Verfügung. Wählen Sie Ihre Sprache aus, und geben Sie

„750-IN001“ in das Suchfeld ein.

http://rockwellautomation.com/literature

champ de recherche.

http://rockwellautomation.com/literature

nel campo di ricerca.

http://rockwellautomation.com/literature. Selecione el idioma de publicación y escriba “750-IN001“

en el campo de búsqueda.

http://rockwellautomation.com/literature

IN001“ no espaço de busca.

从以下网页可以获得本说明书的多种语言的版本 :

http://rockwellautomation.com/literature

请选择出版物的语言 , 并在搜索栏输入 “750-IN001” 印。

http://rockwellautomation.com/literature

にて入手できます。出版言語を選択し、検索フィールドに 「750-

IN001

」とタイプしてください。

㢨 ⮹⥭ ⺴ http://rockwellautomation.com/literature㜄㉐ 㜠⤠ 㛬㛨⦐ ㇠㟝䚔 ㍌㢼㏩⏼␘.

㻐䑄 㛬㛨㝴 㡔䝉㡸 ㉔䈑䚌㐡㐐㝘 "750 - IN001"ᶴㇽ 䙸☐㜄㢼␘.

. Sélectionner la langue puis taper « 750-IN001 » dans le

. Selezionare la lingua desiderata e digitare “750-IN001“

. Seleccione a língua de publicação e entre com “750-

。

Данное руководство на других языках можно найти по адресу

http://rockwellautomation.com/literature. Выберите язык и введите в окно поиска «750-IN001».

以下網頁提供本說明書的多國語言版本:

http://rockwellautomation.com/literature

“750-IN001” 即可。

http://rockwellautomation.com/literature. Zvolte jazyk publikace a do vstupního pole pro

. 請選擇出版語言,並於搜尋欄鍵入

vyhledávání zadejte „750-IN001“.

Polis h Niniejsza instrukcja dostępna jest w wielu językach na stronie

http://rockwellautomation.com/literature. Wybrać język publikacji, w polu wyszukiwania wpisać

“750-IN001”.

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 7

Page 8

Preface

Additional Resources

The following table lists publications that provide general drive-related

information.

Resource Description

PowerFlex 750-Series AC Drives Programming Manual,

publication 750-PM001

PowerFlex 750-Series AC Drives Technical Data,

publication 750-TD001

PowerFlex 20-HIM-A6 / -C6S HIM (Human Interface

Module) User Manual, publication 20HIM-UM001

PowerFlex 750-Series AC Drives Hardware Service Manual

- Frame 8 and Larger, publication 750-TG001

PowerFlex 755 Drive Embedded EtherNet/IP Adapter User

Manual, publication 750COM-UM001

PowerFlex 750-Series Drive DeviceNet Option Module User

Manual, publication 750COM-UM002

PowerFlex 7-Class Network Communication Adapter User

Manuals, publications 750COM-UMxxx

PowerFlex 750-Series Safe Torque Off User Manual,

publication 750-UM002

Safe Speed Monitor Option Module for PowerFlex

750-Series AC Drives Safety Reference Manual, publication

750-RM001

Wiring and Grounding Guidelines for Pulse Width

Modulated (PWM) AC Drives, publication DRIVES-IN001

PowerFlex AC Drives in Common Bus Configurations,

publication DRIVES-AT002

Safety Guidelines for the Application, Installation, and

Maintenance of Solid-State Control, publication SGI-1.1

Guarding Against Electrostatic Damage, publication 8000-

4.5.2

Product Certifications website, http://ab.com

Provides detailed information on:

• I/O, control, and feedback options

• Parameters and programming

• Faults, alarms, and troubleshooting

Provides detailed information on:

• Drive specifications

• Option specifications

• Fuse and circuit breaker ratings

Provides detailed information on HIM components,

operation, features.

Provides detailed information on:

• Preventive maintenance

• Component testing

• Hardware replacement procedures

These publications provide detailed information on to

configure, use, and troubleshoot PowerFlex 750-Series

communication option modules and adapters.

These publications provide detailed information on to

install, configure, and operate the 750-Series safety

option modules.

Provides basic information to properly wire and ground

PWM AC drives.

Provides basic information to properly wire and ground

PWM AC drives with a common bus.

Provides general guidelines for the application,

installation, and maintenance of solid-state control.

Provides practices for guarding against Electrostatic

damage (ESD)

Provides declarations of conformity, certific ates, and other

certification details.

8 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 9

Preface

IMPORTANT

Commonly Used Tools

Installation and Service Tools

Care must be taken to be sure that tools and/or hardware components do not

fall into open drive assemblies. Do not energize the drive unless all loose tools

and/or hardware components have been removed from the drive assemblies

and enclosure.

This list covers the tools that are needed for drive installation.

Tool Description Details

ESD-protected place of work Work surface, Floor cover, seat, and ground connections

ESD-protective clothing Wrist wrap, shoes, overall clothing (coat)

Multimeter Digital multimeter, capable of AC and DC voltage, continuity, resistance,

Allen socket wrench 4 mm, 5 mm

Allen-socket wrench extension 254 mm (10 in.)

Flat-nose screw driver 5 mm (0.19 in.), 6.4 mm (0.25 in.), 9.5 mm (0.375 in.), #1, #2

Hexalobular screw driver/bit #15, #20, #25, #40, #45

Hexagonal socket wrench 7 mm, 8 mm, 10 mm, 12 mm, 13 mm, 17 mm, 18 mm

Combination wrench 10 mm, 17 mm

Phillips® screw driver/bit

(1)

Pozid riv®

Torque wrench 1...12 N•m (8.8…106 lb•in)

Torque wrench 6...50 N•m (53…443 lb•in)

Roll-out cart 20-750-CART1-F8

(1)

capacitance measurements, and fo rward diode bias tests. Fluke model 87 III or

equivalent.

#2, 492-C

#2, M3 x 7

Note: The roll-out car t is required to remove the Frame 8 and larger drive

assembly from the enclosure.

(1) Phillips and Pozidriv are registered trademarks of the Phillips Screw Company.

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 9

Page 10

Preface

Notes:

10 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 11

Qualified Personnel

Personal Safety

Read the General Precautions

ATTENTION: Only qualified personnel familiar with adjustable frequency AC

drives and associated machinery should plan or implement the installation,

start-up and subsequent maintenance of the system. Failure to comply may

result in personal injury and/or equipment damage.

ATTENTION: To avoid an electric shock hazard, verify that the voltage on the

bus capacitors has discharged completely before servicing.

Frames 1…7: Measure the DC bus voltage at the power terminal block by

measuring between the +DC and -DC terminals (see Figure 88

location) or between the +DC and -DC test point sockets if equipped. Also measure

between the +DC terminal or test point and the chassis, and between the -DC

terminal or testpoint and the chassis. The voltage must be zero for all three

measurements.

Frames 8…10: Measure the DC bus voltage at the DC+ and DC- TESTPOINT

sockets on the front of the power module (see Figure 92

Chapter 1

and Figure 89 for

for location).

ATTENTION: Hazard of personal injury or equipment damage exists when using

bipolar input sources. Noise and drift in sensitive input circuits can cause

unpredictable changes in motor speed and direction. Use speed command

parameters to help reduce input source sensitivity.

ATTENTION: Risk of injury or equipment damage exists. DPI or SCANport host

products must not be directly connected together via 1202 cables.

Unpredictable behavior can result if two or more devices are connected in this

manner.

ATTENTION: The drive start/stop/enable control circuitry includes solid state

components. If hazards due to accidental contact with moving machinery or

unintentional flow of liquid, gas or solids exists, an additional hardwired stop

circuit may be required to remove the AC line to the drive. An auxiliary braking

method may be required.

ATTENTION: Hazard of personal injury or equipment damage due to

unexpected machine operation exists if the drive is configured to automatically

issue a Start or Run command. Do not use these functions without considering

applicable local, national and international codes, standards, regulations or

industry guidelines.

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 11

Page 12

Chapter 1 Read the General Precautions

Product Safety

ATTENTION: An incorrectly applied or installed drive can result in component

damage or a reduction in product life. Wiring or application errors such as under

sizing the motor, incorrect or inadequate AC supply, a corrosive environment, or

excessive surrounding air temperatures may result in malfunction of the

system.

ATTENTION: This drive contains ESD (Electrostatic Discharge) sensitive parts

and assemblies. Static control precautions are required when installing, testing,

servicing or repairing this assembly. Component damage may result if ESD

control procedures are not followed. If you are not familiar with static control

procedures, reference Guarding Against Electrostatic Damage, publication

8000-4.5.2 or any other applicable ESD protection handbook.

ATTENTION: Configuring an analog input for 0…20 mA operation and driving

it from a voltage source could cause component damage. Verify proper

configuration prior to applying input signals.

Class 1 LED Product

ATTENTION: Hazard of permanent eye damage exists when using optical

transmission equipment. This product emits intense light and invisible

radiation. Do not look into module ports or fiber optic cable connectors.

12 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 13

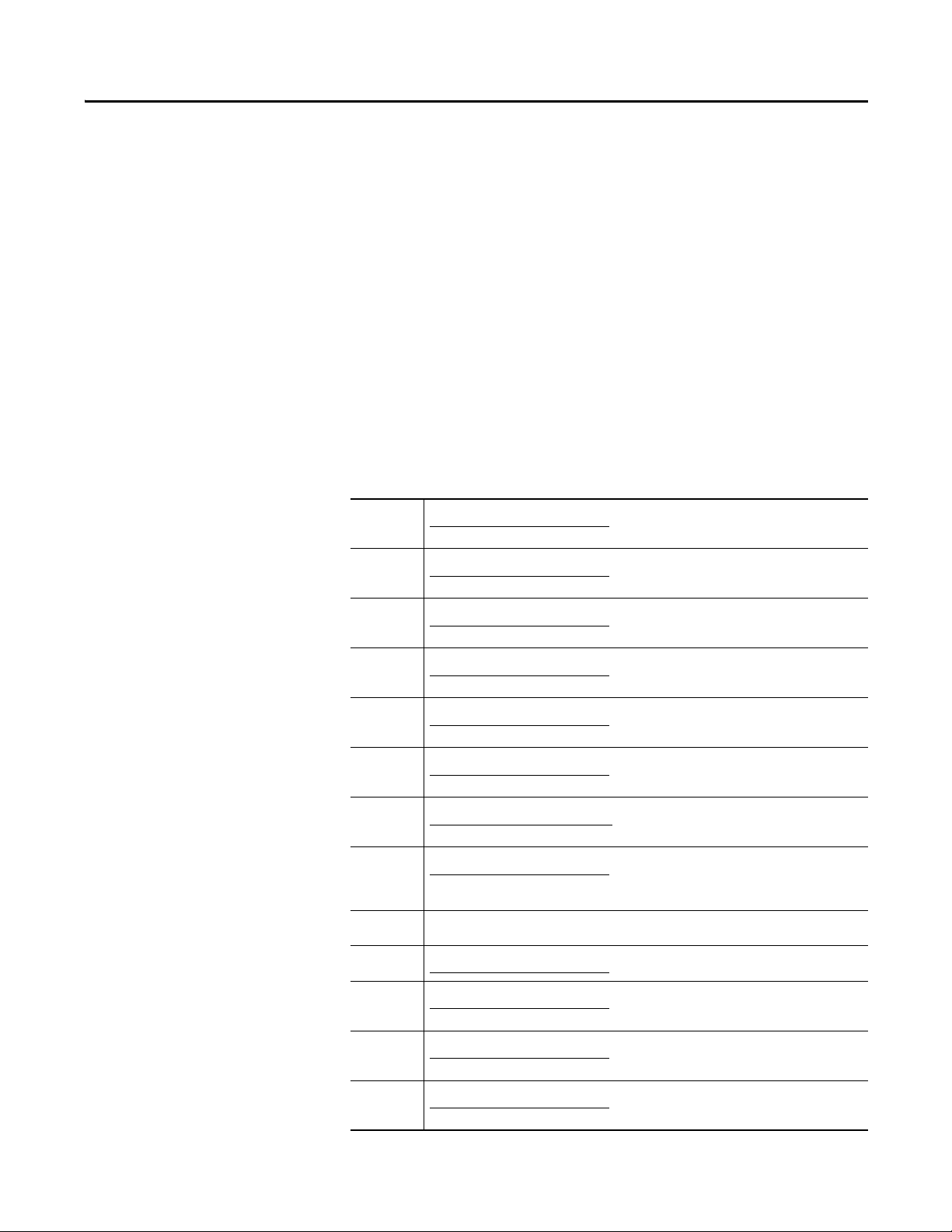

Chapter 2

a

b

c

d

e

f1

f2

Drive

Code Type Frames

20F PowerFlex 753 1…7

20G PowerFlex 755 1…10

21G PowerFlex 755 Drive with Options 8…10

Future Use

Input

Ty p e

Code Descrip tion Frames

1

AC Input with Precharge,

includes DC Terminals

1…5

8…10

4 DC Input with

Precharge

5…10

A AC Input with Precharge, no DC

Ter mi na l s

6…8

(1)

(1) The DC Bus B ar kit

(20-750-DCBB1-Fx)

is available for Frames

6…7

AC input drives th at require DC bus

terminals.

Enclosure

Code Description Frames

R IP20, NEMA/UL Type Open, Frame 1 1

F

(1)

(1) For Frames 6…7 a user installed Flange kit (20-750-FLNG4-Fx) is

available to convert a Code N drive that provides a NEMA/UL Type

4X/12 back.

Flange (NEMA/UL Type 4X/12 back) 2…5

G IP54, NEMA/UL Type 12 2…7

N

(2)

(2) Frames 2…5 are IP20, Frames 6…7 are IP00.

IP20/IP00, NEMA/UL Type Open 2…7

B

(3)

(3) Available as a drive with options (21G).

IP20, NEMA/UL Type 1,

600 mm (23.6 in.) Deep,

Standard Cabinet Color (RAL 7032)

8…10

J

(3)

IP54, UL Type 12,

800 mm (31.5 in.) Deep,

Standard Cabinet Color (RAL 7032)

8…10

K

(3)

IP54, NEMA 12,

2500 MCC Style Cabinet and Options w/MCC

Power Bus, 800 mm (31.5 in.) Deep,

Standard Cabinet Color (RAL 7032)

8…10

L

(3)

IP20, NEMA/UL Type 1,

800 mm (31.5 in.) Deep,

Standard Cabinet Color (RAL 7032)

8…10

P

(3)

IP20, NEMA/UL Type 1,

2500 MCC Style Cabinet and Options w/MCC

Power Bus, 800 mm (31.5 in.) Deep,

Standard Cabinet Color (RAL 7032)

8…10

W

(3)

IP20, NEMA/UL Type 1,

2500 MCC Style Cabinet and Options w/MCC

Power Bus, 800 mm (31.5 in.) Deep,

CenterLine 2100 Gray (ASA49)

8…10

Y

(3)

IP54, NEMA 12,

2500 MCC Style Cabinet and Options w/MCC

Power Bus, 800 mm (31.5 in.) Deep,

CenterLine 2100 Gray (ASA49)

8…10

T IP00, UL Open Type without Control POD 8…10

Voltage Rating

Code Voltage

C 400V AC/540V

DC

D 480V AC/650V

DC

E 600V AC/810V

DC

F 690V AC/932V DC (not UL

listed)

ND Rating

400V, 50 Hz Input

Code Amps kW

Frame

Enclosure Code

B, J,

L, T

FGN

K, P,

W, Y

R

2P1 2.1 0.75

–

222

–

1

3P5 3.5 1.5

5P0 5.0 2.2

8P7 8.7 4

011 11.5 5.5

015 15.4 7.5

022 22 11

–

030 30 15

333037 37 18.5

043 43 22

060 60 30

4

4

4

072 72 37

5

085 85 45

55

104 104 55

6

140 140 75

(1)

(1) For Frames 6…7 a user installed Flange kit (20-750-FLNG4-Fx) is

available to convert a Code N drive that provides a NEMA/UL Type

4X/12 back.

6

170 170 90

205 205 110

260 260 132

7

302 302 160

7367 367 200

456 456 250

460 460 250

8

–––

8

(2)

(2) Available as a drive with options (21G ).

540 540 315

567 567 315

650 650 355

750 750 400

770 770 400

910 910 500

99

(2)

1K0 1040 560

1K1 1090 630

1K2 1175 710

1K4 1465 800

1K5 1480 850

1K6 1590 900

10 10

(2)

2K1 2150 1250

ND Rating

480V, 60 Hz Input

Code Amps Hp

Frame

Enclosure Code

B, J,

L, T

FGN

K, P,

W, Y

R

2P1 2.1 1

–

222

–

1

3P4 3.4 2

5P0 5.0 3

8P0 8.0 5

011 11 7.5

014 14 10

022 22 15

–

027 27 20

333034 34 25

040 40 30

052 52 40

4

4

4

065 65 50

5

077 77 60

55

096 96 75

6

125 125 100

(1)

(1) For Frames 6…7 a user installed Flange kit (20-750-FLNG4-Fx) is

available to convert a Code N drive that provides a NEMA/UL Type

4X/12 back.

6

156 156 125

186 186 150

248 248 200

7

302 302 250

7361 361 300

415 415 350

430 430 350

8

–––

8

(2)

(2) Available as a drive with options (21G).

485 485 400

545 545 450

617 617 500

710 710 600

740 740 650

800 800 700

99

(2)

960 960 800

1K0 1045 900

1K2 1135 1000

1K3 1365 1100

1K4 1420 1250

1K5 1525 1350

10 10

(2)

2K0 2070 1750

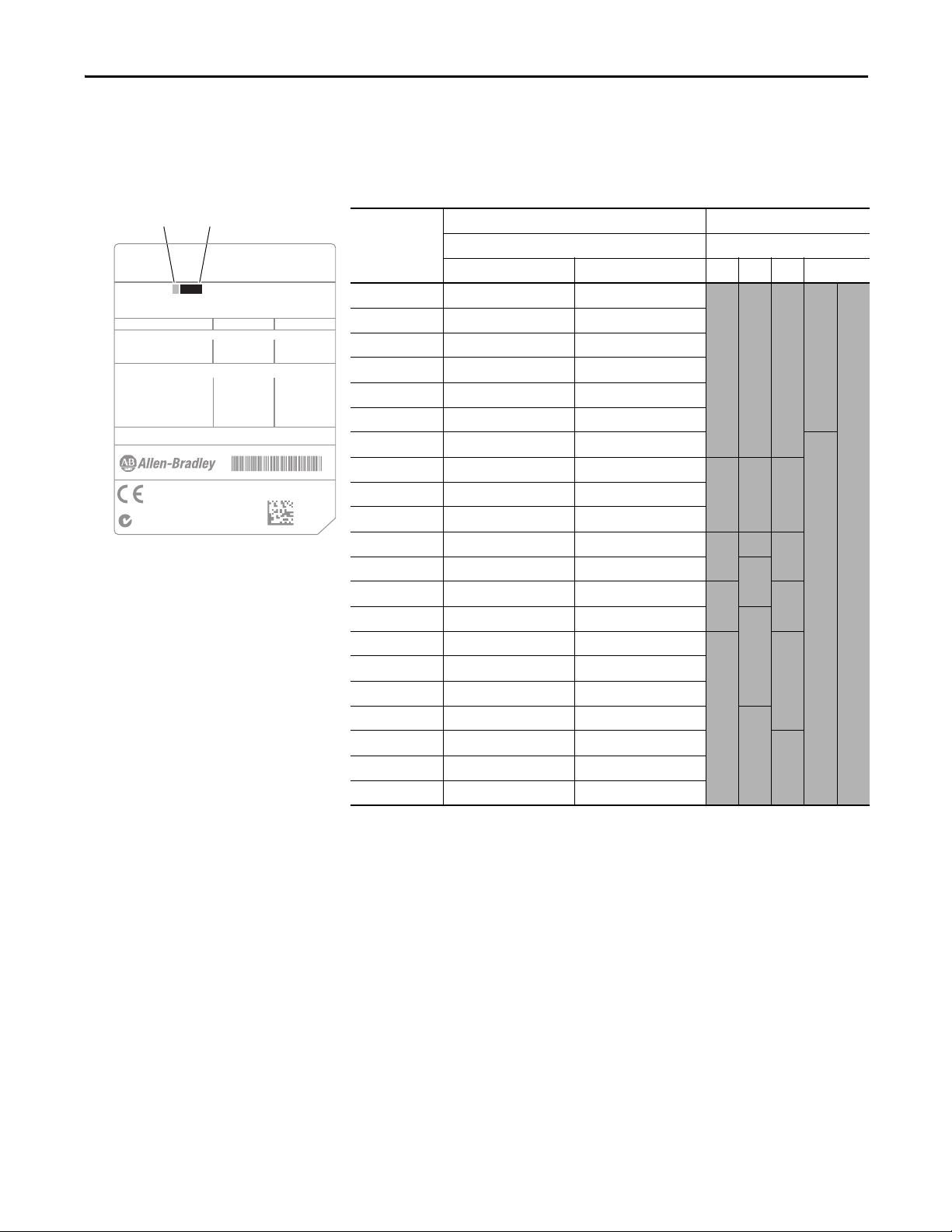

Prepare for Installation

Catalog Number Explanation

1…3 4 5 6 7 8…10 11 12 13 14 15 16 17 18

20G 1 A N D 248 A A 0 N N N N N -LD-P3-P11…

abcde ghif1…f4 Cabinet Options (21G)

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 13

Page 14

Chapter 2 Prepare for Installation

f3 f4

g

h

i

PowerFlex 755 w/Options (21G)

Required Selections

PowerFlex 755 w/Options (21G)

Additional Selections

ND Rating

600V, 60 Hz Input

Code Amps Hp

Frame

Enclosure Code

B, J,

L, T

FGN

K, P,

W, Y

R

1P7 1.7 1

–

333

–

–

2P7 2.7 2

3P9 3.9 3

6P1 6.1 5

9P0 9 7.5

011 11 1 0

012

(1)

(1) Required for uncontrolled common DC bus appl ications. Optional

for all AC applications.

12 10

–66

017 17 1 5

333

018

(1)

18 15

–66

022 22 2 0

333

023

(1)

23 20

–66

024

(1)

24 20

027 27 2 5

444

028

(1)

28 25

–66

032 32 3 0

444

033

(1)

33 30

–66

041 41 4 0

555

042

(1)

42 40

–66

052 52 5 0

5–5

053

(1)

53 50

(2)

(2) For Frames 6…7 a user installed Flange kit (20-750-FLNG4-Fx) is

available to convert a Code N drive that provides a NEMA/UL Type

4X/12 back.

66

063 63 6 0

077 77 7 5

09999100

125 125 125

144 144 150

192 192 200

77

242 242 250

289 289 300

295 295 300

8

–––

8

(3)

(3) Available as a drive with options (21G).

355 355 350

395 395 400

435 435 450

460 460 500

510 510 500

595 595 600

99

(3)

630 630 700

760 760 800

825 825 900

900 900 950

980 980 1000

1K1 1110 1100

10 10

(3)

1K4 1430 1400

ND Rating

690V, 50 Hz Input (not UL listed)

Code Amps kW

Frame

Enclosure Code

B, J,

L, T

FGN

K, P,

W, Y

R

012 12 7.5

–

(1)

(1) For Frames 6…7 a user installed Flange kit (20-750-FLNG4-Fx) is

available to convert a Code N drive that provides a NEMA/UL Type

4X/12 back.

66

–

–

015 15 11

020 20 15

023 23 18.5

030 30 22

034 34 30

046 46 37

050 50 45

061 61 55

082 82 75

098 98 90

119 119 110

142 142 132

171 171 160

77212 212 200

263 263 250

265 265 250

8

––

8

(2)

(2) Available as a drive with options (21G ).

330 330 315

370 370 355

415 415 400

460 460 450

500 500 500

590 590 560

9

–

9

(2)

650 650 630

710 710 710

765 765 750

795 795 800

960 960 900

1K0 1040 1000

10 10

(2)

1K4 1400 1400

Filtering and CM Cap Configuration

(1)

(1) 480V drives must select code “A.” Jumpers are included for field

reconfiguration as desired.

Code Filtering Default CM Cap

Conne cti on

AYes Jumper

Removed

J Yes Jumper

Installed

Dynamic Braking

(1)

(1) Not available on Frames 8…10, specify Code “N.”

Code Internal Resistor

(2)

(2) Frames 1…2 only. Internal Resistor kits (20-750-DB1-Dx) sold

separately.

Internal Transistor

(3)

(3) Standard on Frames 1…5, optional on 6…7.

ANo Yes

NNo No

Door Mounted HIM (Frames

8…10)

Code Opera tor

Interface

0 No Door Mounted

HIM

2 Enhanced LCD, Full Nume ric,

IP20

4 Enhanced LCD, Full Numeric, IP66 NEMA Type

4X/12

Code Option Frames Type

LD Light

Duty

8…10

System Overload

Duty Cycle

(1)

(1) Only one option of this type ma y be selected.

ND Normal

Duty

HD Heavy

Duty

P3

Input Thermal

Magnetic

Circuit

Breaker

8…10

Power

Disconnect

(1)

P5

Input Non-Fused

Molded

Case Disconnect

Switch

8 Only

P14 Wiring Only

Bay

8…10 Wiring Only Bay

Code Option Frames Type

P11 Input

Contactor

8 Only Contactors

(1)(2)

(1) Only one option of this type ma y be selected.

(2) Contactor options are not available for systems with MCC power

bus.

P12 Output

Contacto r

L1 3% Input

Reactor

8…9

Reactors

(1)

L2 3% Output

Reactor

L3 5% Input

Reactor

8 Only

L4 5% Output

Reactor

P20 1200 Amp

Bus

8…10

MCC Power

Bus

Capacity

(1)

P22 2000 Amp

Bus

P24 3000 Amp

Bus

P30

UPS Control Bus, DC Input

w/Precharge only

8…10 UPS Control

Bus

X1

Auxiliary

Tra nsf o rme r

(500VA available),

IP20

Cabinet

Only

8 Only

(3)

(3) Standard on all other cabinet configurations.

Auxiliary

Power

Catalog Number Explanation (continued)

1…3 4 5 6 7 8…10 11 12 13 14 15 16 17 18

20G 1 A N D 248 A A 0 N N N N N -LD-P3-P11…

abcde ghif1…f4 Cabinet Options (21G)

14 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

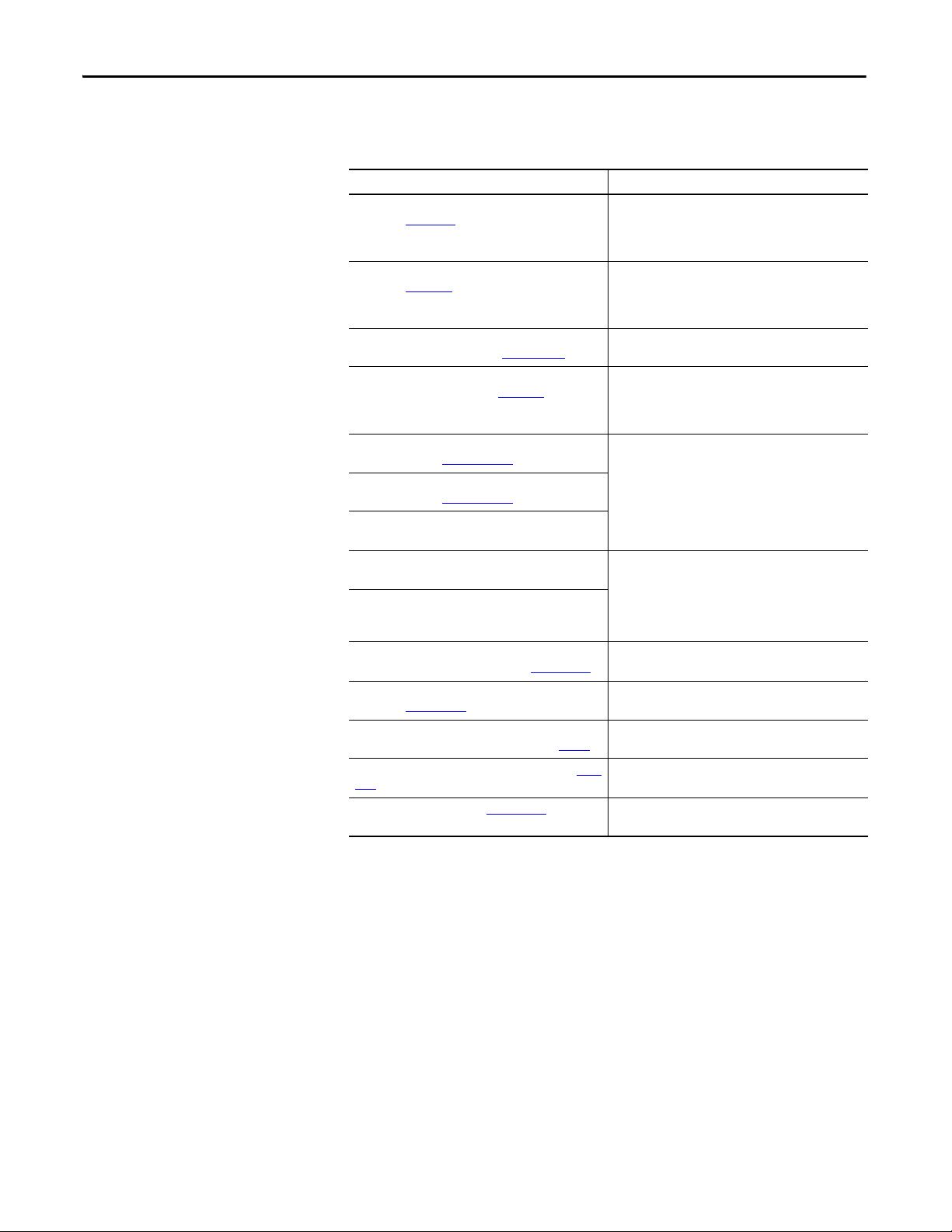

Page 15

Wall Mount Frames 1…7

Cat No. 20G11 N D 011 AA0NNNNN

UL Type 1 - only with Debris Hood and Conduit Plate

UL Open Type/IP20 - without Debris Hood and Conduit Plate

Specifications and Custom Catalog Number

representing options installed at factory.

See Nameplate 2 (Located behind HIM)

for equivalent base catalog number and separate options

Nameplate 1:

Mfd. in 2009 on Jan. 19

Series: A

Input: 3 Phase, 47-63Hz

AC Voltage Range

Amps ND (HD)

Power ND (HD)

Output: 3 Phase, 0-400 Hz

AC Voltage Range

Base Frequency (default)

Continuous Amps ND (HD)

60Sec Ovld Amps ND (HD)

3 Sec Ovld Amps ND (HD)

0-400

50 Hz

342-440 432-528

0-460

60 Hz

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx xxx xxx xxx

5.5 HP (4 HP) 7.5 HP (5 HP)

N223

Serial Number: xxxxxxxx

Original Firmware: x.xxx

Made in the U.S.A. Fac1C

400V Class 480V Class

➊ ➋

Drive Nameplate 1, Wall Mount Frames 1…7

Drive Rating Cross-references

Prepare for Installation Chapter 2

➋➊

Drive Code

Input Voltage and ND Amp Rating Enclosure Code

400V AC 480V AC F G N R

20F or 20G C2P1 D2P1

2 2 2 1

20F or 20G C3P5 D3P4

20F or 20G C5P0 D5P0

20F or 20G C8P7 D8P0

20F or 20G C011 D011

20F or 20G C015 D014

20F or 20G C022 D022

20F or 20G C030 D027 3 3 3

20F or 20G C037 D034

20F or 20G C043 D040

20F or 20G C060 D052

20F or 20G C072 D065

4 4 4

5

20F or 20G C085 D077 5 5

20F or 20G C104 D096 6

20F or 20G C140 D125

N/A 6

20F or 20G C170 D156

20F or 20G C205 D186

20F or 20G C260 D248

7

20F or 20G C302 D302 7

20F or 20G C367 D361

20F or 20G C456 D415

–

Wall Mo unt Frame

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 15

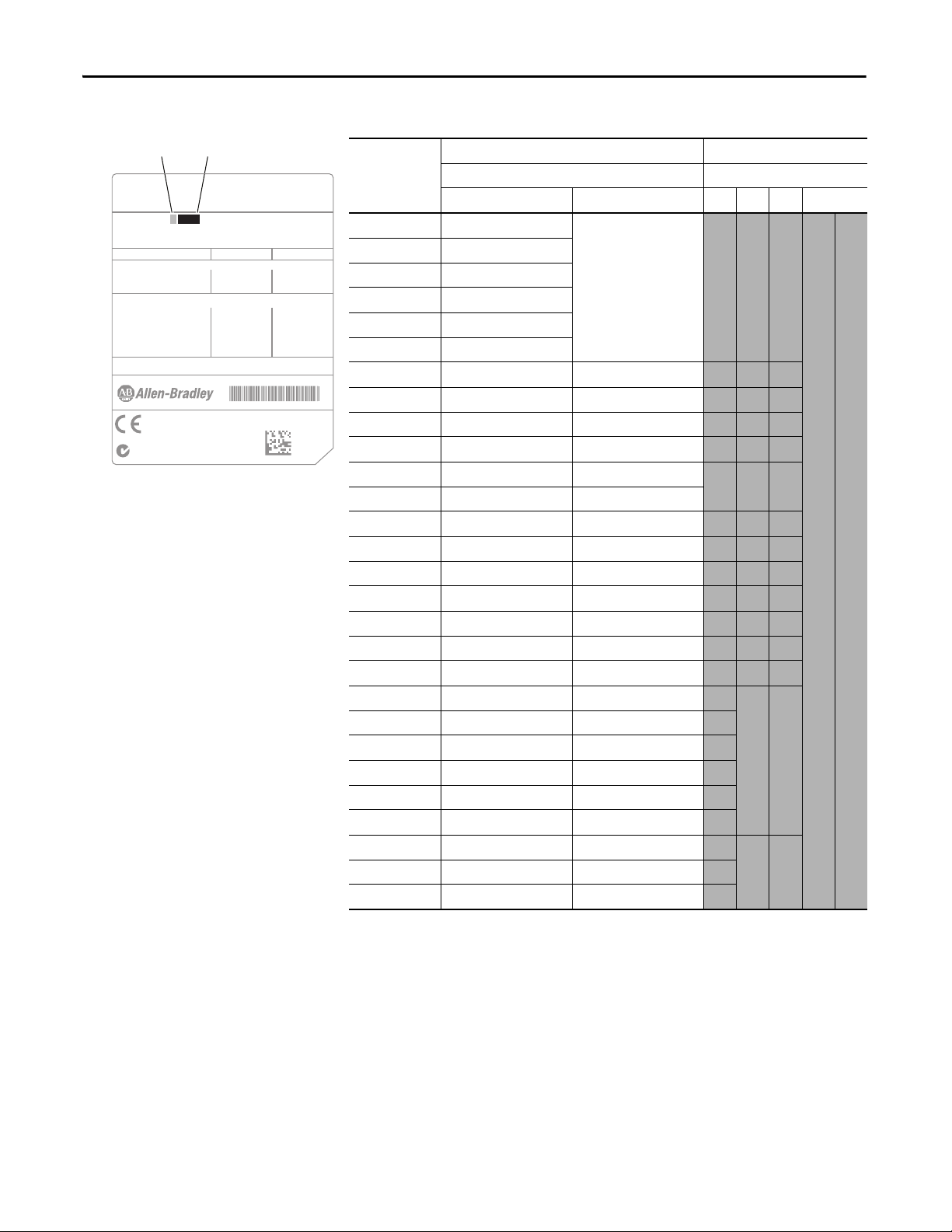

Page 16

Chapter 2 Prepare for Installation

Cat No. 20G11 N D 011 AA0NNNNN

UL Type 1 - only with Debris Hood and Conduit Plate

UL Open Type/IP20 - without Debris Hood and Conduit Plate

Specifications and Custom Catalog Number

representing options installed at factory.

See Nameplate 2 (Located behind HIM)

for equivalent base catalog number and separate options

Nameplate 1:

Mfd. in 2009 on Jan. 19

Series: A

Input: 3 Phase, 47-63Hz

AC Voltage Range

Amps ND (HD)

Power ND (HD)

Output: 3 Phase, 0-400 Hz

AC Voltage Range

Base Frequency (default)

Continuous Amps ND (HD)

60Sec Ovld Amps ND (HD)

3 Sec Ovld Amps ND (HD)

0-400

50 Hz

342-440 432-528

0-460

60 Hz

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx xxx xxx xxx

5.5 HP (4 HP) 7.5 HP (5 HP)

N223

Serial Number: xxxxxxxx

Original Firmware: x.xxx

Made in the U.S.A. Fac1C

400V Class 480V Class

➊ ➋

Drive Nameplate 1, Wall Mount Frames 1…7

➋➊

Drive Code

Input Voltage and ND Amp Rating Enclosure Code

600V AC 690V AC F G N R

20F or 20G E1P7 –

3 3 3 –

20F or 20G E2P7

20F or 20G E3P9

20F or 20G E6P1

20F or 20G E9P0

20F or 20G E011

20F or 20G E012 F012

– 6 6

20F or 20G E017 – 3 3 3

20F or 20G E018 F015

– 6 6

20F or 20G E022 – 3 3 3

20F or 20G E023 F020 – 6 6

20F or 20G E024 F023

20F or 20G E027 –

4 4 4

20F or 20G E028 F030 – 6 6

20F or 20G E032 –

4 4 4

20F or 20G E033 F034 – 6 6

20F or 20G E041 – 5 5 5

20F or 20G E042 F046

– 6 6

20F or 20G E052 – 5 – 5

20F or 20G E053 F050 6 6

20F or 20G E063 F061

20F or 20G E077 F082

20F or 20G E099 F098

20F or 20G E125 F119

20F or 20G E144 F142

20F or 20G E192 F171 7 7

20F or 20G E242 F212

20F or 20G E289 F263

Wall Moun t Frame

16 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

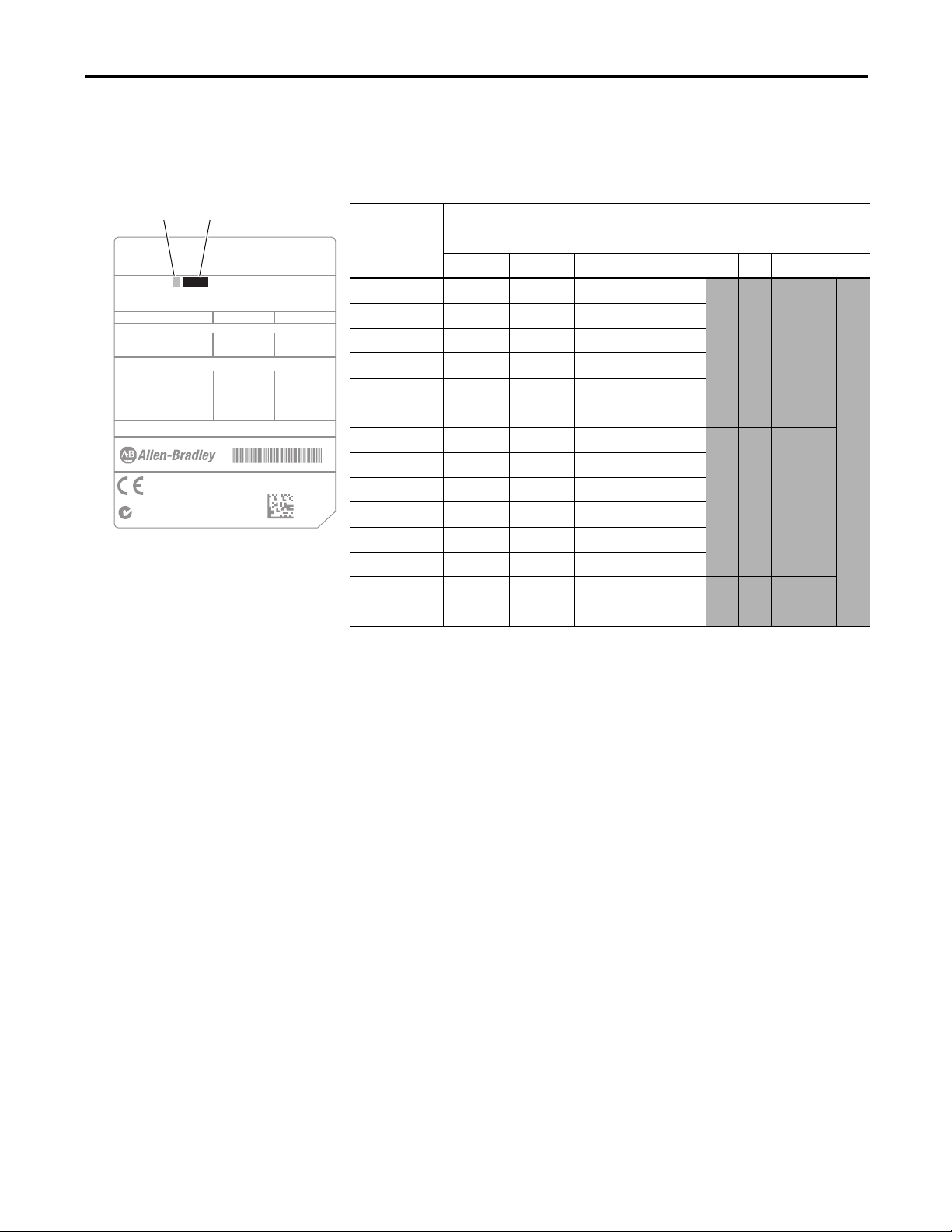

Page 17

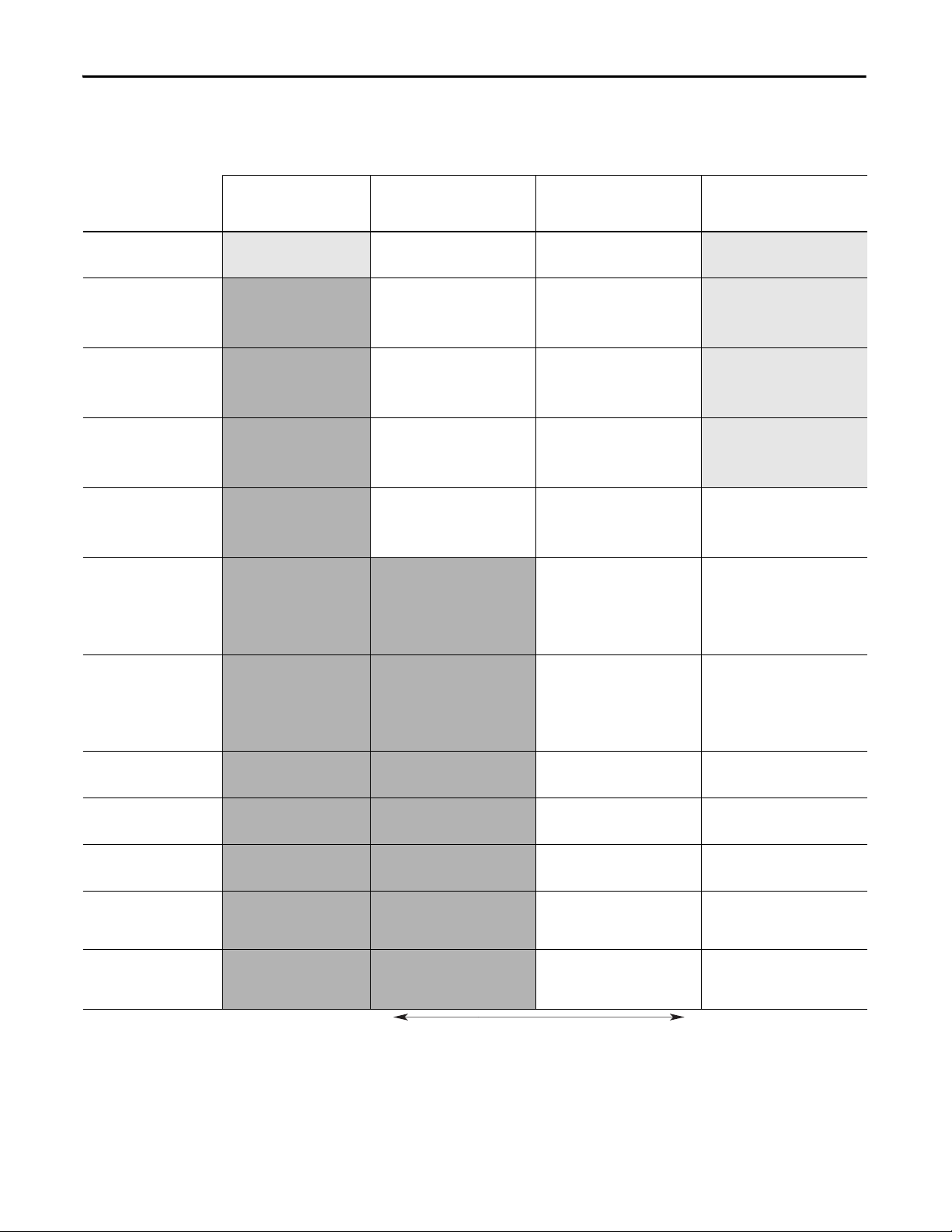

Floor Mount Frames 8…10

Cat No: 20G1A B D 430 JN0NNNNN

CM Cap Jumpers Installed

UL Type 1 / IP20 in 600 mm deep cabinet

Specifications and Custom Catalog Number

representing options installed at factory.

See Nameplate 2 (Located behind HIM)

for equivalent base catalog number and separate options

Nameplate 1:

MFD DATE: 2010/08/20

Series: B

Input: 3-Phase, 47-63 Hz

AC Voltage Range

Amps LD/ND/HD

Power LD/ND/HD

Auxillary Input Power: 120V//240V AC, 50/60Hz, 8.3A/4.2A, 1kVA

Output: 3-Phase, 0-400 Hz

AC Voltage Range

Base Freq. (default)

Cont. Amps LD/ND/HD

60S OL Amps LD/ND/HD

3S OL Amps LD/ND/HD

0-400

50 Hz

360-440 432-528

0-460

60 Hz

xxx/xxx/xxx

xxx/xxx/xxx

/xxx/xxx

xxx/xxx/xxx

xxx/xxx/xxx

/xxx/xxx

xxxx/xxxx/xxxx xxxx/xxxx/xxxx

315/250/200 (kW) 400/350/300 (HP)

N223

Serial Number: xxxxxxxx

Original Firmware: x.xxx

Product of U.S.A. FAC 1100

400V Class 480V Class

➊ ➋

Drive Nameplate 1, Floor Mount Frames 8…10

Drive Rating Cross-references

➋➊

Drive Code

Input Voltage and ND Amp Rating Enclosure Code

400V AC 480V AC 600V AC 690V AC B L, J P, K W, Y

20G or 21G C460 D430 E295 F265

20G or 21G C540 D485 E355 F330

20G or 21G C567 D545 E395 F370

20G or 21G C650 D617 E435 F415

20G or 21G C750 D710 E460 F460

20G or 21G C770 D740 E510 F500

20G or 21G C910 D800 E595 F590

20G or 21G C1K0 D960 E630 F650

20G or 21G C1K1 D1K0 E760 F710

20G or 21G C1K2 D1K2 E825 F765

20G or 21G C1K4 D1K3 E900 F795

20G or 21G C1K5 D1K4 E980 F960

20G or 21G C1K6 D1K5 E1K1 F1K0

20G or 21G C2K1 D2K0 E1K4 F1K4

Prepare for Installation Chapter 2

8 8 8 8

9 9 9 9

Floor Mount Frame

10 10 10 10

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 17

Page 18

Chapter 2 Prepare for Installation

CE Conformity

Compliance with the Low Voltage Directive and Electromagnetic Compatibility

Directive has been demonstrated using harmonized European Norm (EN)

standards, referenced by the Official Journal of the European Union. PowerFlex

750-Series drives comply with the EN standards listed in this section when

installed according to these installation instructions.

EU Declarations of Conformity are available online at:

www.rockwellautomation.com/products/certification/

Low Voltage Directive

• EN 61800-5-1 Adjustable speed electrical power drive systems – Part 5-1:

Safety requirements – Electrical, thermal and energy.

EMC Directive

• EN 61800-3 Adjustable speed electrical power drive systems – Part 3:

EMC product standard including specific test methods.

General Considerations

• For EU compliance, drives must satisfy installation requirements that are

related to both EN 61800-5-1 and EN 61800-3 provided in this

document.

• PowerFlex 750-Series AC Drives comply with the EMC requirements of

EN 61800-3 when installed according to good EMC practices and the

instructions that are provided in this document. However, many factors

can influence the EMC compliance of an entire machine or installation,

and compliance of the drive itself does not ensure compliance of all

applications.

• PowerFlex 750-Series drives are not intended to be used on public lowvoltage networks that supply domestic premises. Without additional

mitigation, radio frequency interference is expected if used on such a

network. The installer is responsible to take measures such as

supplementary line filters and enclosures to prevent interference, in

addition to the installation requirements of this document.

ATTENTION: NEMA/UL Open Type and Flange Mount drives must either

be installed in a supplementary enclosure or equipped with a “NEMA

Type 1 Kit” to be CE-compliant with respect to protection against

electrical shock.

• Requirements for supplementary mitigation that is related to specific highfrequency emission limits are provided in Tabl e 1

.

18 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 19

Prepare for Installation Chapter 2

• PowerFlex 750-Series drives generate harmonic current emissions on the

AC supply system. When operated on a public low-voltage network it is

the responsibility of the installer or user to ensure that applicable

requirements of the distribution network operator have been met.

Consultation with the network operator and Rockwell Automation can be

necessary.

ATTENTION: PowerFlex 750-Series drives produce DC current in the

protective earthing conductor which can reduce the ability of RCDs

(residual current-operated protective devices) or RCMs (residual

current-operated monitoring devices) of type A or AC to provide

protection for other equipment in the installation. Where an RCD or

RCM is used for protection in case of direct or indirect contact, only an

RCD or RCM of Type B is allowed on the supply side of this product.

Installation Requirements Related to EN 61800-5-1 and the Low Voltage Directive

Frame 1 Drives

• Voltage classes up to 480V PowerFlex 750-Series Frame 1 drives can only

be used on a “center grounded” supply system for altitudes up to and

including 2000 m (6562 ft).

Frame 2 and Larger Drives

• Voltage classes up to 690V PowerFlex 750-Series Frame 2 and larger drives

are compliant with the CE LV Directive when used on a “corner-earthed”

supply system and all other common supply systems for altitudes up to and

including 2000 m (6562 ft).

• When used at altitudes above 2000 m (6562 ft) up to a maximum of

4800 m (15,748 ft), PowerFlex 750-Series drives of voltage classes up to

480V cannot be powered from a “corner-earthed” supply system to

maintain compliance with the CE LV Directive. Altitude derating curves

are provided in the PowerFlex 750-Series AC Drives Technical Data,

publication 750-TD001

.

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 19

Page 20

Chapter 2 Prepare for Installation

All Drive Frames

• Drives that are provided in the IP54, NEMA/UL Type 12 enclosure are

compliant with the CE LV Directive when installed in pollution degree

1…4 environments. All other enclosure types must be installed in a

pollution degree 1 or 2 environment to be compliant with the CE LV

Directive. Characteristics of the different pollution degree ratings are

provided in the PowerFlex 750-Series AC Drives Technical Data,

publication 750-TD001

• PowerFlex 750-Series drives produce leakage current in the protective

earthing conductor that exceeds 3.5 mA AC and/or 10 mA DC. The

minimum size of the protective earthing (grounding) conductor that is

used in the application must comply with local safety regulations for highprotective earthing conductor current equipment.

ATTENTION: PowerFlex 750-Series drives produce DC current in the

protective earthing conductor which can reduce the ability of RCDs

(residual current-operated protective devices) or RCMs (residual

current-operated monitoring devices) of type A or AC to provide

protection for other equipment in the installation. Where an RCD or

RCM is used for protection in case of direct or indirect contact, only an

RCD or RCM of Type B is allowed on the supply side of this product.

.

20 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 21

Prepare for Installation Chapter 2

Installation Requirements Related to EN 61800-3 and the EMC Directive

• The drive must be earthed (grounded) as described in Power Wiring on

page 145.

• Output power wiring to the motor must employ cable with a braided

shield providing 75% or greater coverage, or the cables must be housed in

metal conduit, or equivalent shielding must be provided. Continuous

shielding must be provided from the drive enclosure to the motor

enclosure. Both ends of the motor cable shield (or conduit) must terminate

with a low-impedance connection to earth.

Wall Mount Drive Frames 1…7: At the drive end of the motor cable, either

a. The cable shield must be clamped to a properly installed “EMC plate”

for the drive. Kit number 20-750-EMC1-Fx.

or

b. The cable shield or conduit must terminate in a shielded connector that

is installed in a conduit plate or conduit box that is provided in the

“NEMA Type 1 Kit” for the drive (kit number 20-750-NEMA1-Fx).

Floor Mount Drive Frames 8 and larger: At the drive end of the motor

cable, terminate the shield at the PE Grounding Bar (See page 156

• At the motor end, the motor cable shield or conduit must terminate in a

shielded connector which must be properly installed in an earthed motor

wiring box that is attached to the motor. The motor-wiring box cover must

be installed and earthed.

• All control (I/O) and signal wiring to the drive must use cable with a

braided shield providing 75% or greater coverage, or the cables must be

housed in metal conduit, or equivalent shielding must be provided. When

shielded cable is used, the cable shield is terminated with a low-impedance

connection to earth at only one end of the cable, preferably the end where

the receiver is located. When the cable shield is terminated at the drive

end, it can be terminated either by using a shielded connector with a

conduit plate or conduit box, or the shield can be clamped to an “EMC

plate.”

• Motor cables must be separated from control and signal wiring wherever

possible.

• Maximum motor-cable length must not exceed the maximum length that

is indicated in Ta ble 1

limits for the specific standard and installation environment.

• EMC cores must be applied to input power and motor cables for some

models of the PowerFlex 750-Series drives as indicated in Tab le 1

• The drive must be powered from an earthed supply system such as a TN or

TT system and the PE-A and PE-B jumpers in the drive must be installed

(see Drive Power Jumper Configuration

• IP00 and NEMA/UL Open Type Frame 8 and higher frames must be

installed in suitable supplementary EMC enclosures to achieve compliance

with EN 61800-3.

for compliance with radio-frequency emission

on page 209).

).

.

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 21

Page 22

Chapter 2 Prepare for Installation

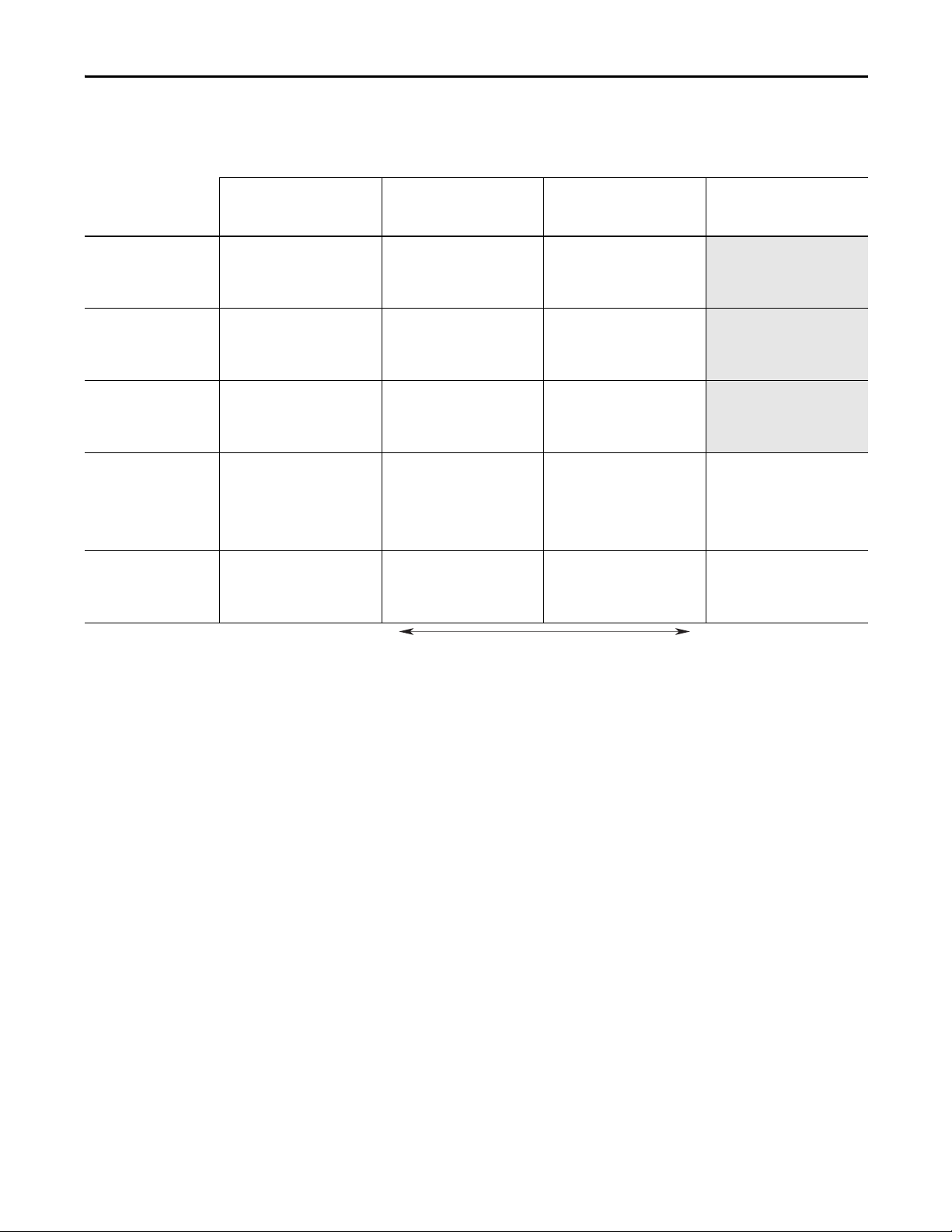

Table 1 - PowerFlex 750-Series 400/480V Input Drives RF Emission Compliance and Installation

Requirements

Standard / Limits

Drive Frame

Catalog Number

Wall Mount Frame 1

20F11xx2P1…20F11xx015

EN61800-3 Category C1

EN61000-6-3

CISPR11 Group 1 Class B

EN61800-3 Category C2

EN61000-6-4

CISPR11 Group 1 Class A

(Input Power

≤ 20 kVA)

N/A 30 m motor cable limit with each wire

looped once around an input core.

EN61800-3 Category C3

(I

≤ 100 A)

CISPR11 Group 1 Class A

(Input Power > 20 kVA)

30 m motor cable limit with each wire

(1) (2)

looped once around an input core.

20G11xx2P1…20G11xx015

Wall Mount Frame 2

20F11xx2P1…20F11xx022

20G11xx2P1…20G11xx022

Wall Mount Frame 3

20F11xx030…20F11xx043

20G11xx030…20G11xx043

Wall Mount Frame 4

20F11xx060…20F11xx072

20G11xx060…20G11xx072

Wall Mount Frame 5

20F11xx085…20F11xx104

20G11xx085…20G11xx104

150 m cable limit with Schaffner

FN3258-30-nn filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

150 m cable limit with Schaffner

FN3258-55-nn filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

150 m cable limit with Schaffner

FN3258-75-nn filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

150 m cable limit with Schaffner

FN3258-130-nn filter.

Supplementary EMC enclosure is

required to provide attenuation of

30 m motor cable limit with input core.

(1)

150 m motor cable limit with Schaffner

FN3258-30-nn filter.

30 m motor cable limit with input core.

(1)

150 m motor cable limit with Schaffner

FN3258-55-nn filter.

30 m motor cable limit with input and

output cores.

150 m motor cable limit with Schaffner

FN3258-75-nn filter.

30 m motor cable limit with input and

output cores.

150 m motor cable limit with Schaffner

FN3258-130-nn filter.

(1)

(1)

30 m motor cable limit with input core.

(1)

150 m motor cable limit with Schaffner

FN3258-30-nn filter.

30 m motor cable limit with input core.

(1)

150 m motor cable limit with Schaffner

FN3258-55-nn filter.

30 m motor cable limit with input and

output cores.

150 m motor cable limit with Schaffner

FN3258-75-nn filter.

30 m motor cable limit with input and

output cores.

150 m motor cable limit with Schaffner

FN3258-130-nn filter.

(1)

(1)

radiated emissions.

Wall Mount Frame 6

20F11xx140…20F11xx260

20G11xx140…20G11xx260

Wall Mount Frame 7

20F11xx302…20F11xx456

20G11xx302…20G11xx456

Floor Mount Frame 8 - AC Input

20G1Axx460…20G1Axx770

21G1Axx460…21G1Axx770

Floor Mount Frame 9 - AC Input

20G11xx910…20G11xx1K5

21G11xx910…21G11xx1K5

Floor Mount Frame 10 - AC Input

20G11xx1K6…20G11xx2K1

21G11xx1K6…21G11xx2K1

Floor Mount Frames 8…9 Common DC Input

20G14xx460…20G14xx1K5

150 m cable limit with 22-RFD323

filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

150 m cable limit with 22-RFD480

filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

Compliance possible with

supplementary mitigation

(Consult factory)

Compliance possible with

supplementary mitigation

(Consult factory)

Compliance possible with

supplementary mitigation

(Consult factory)

Compliance possible with

supplementary mitigation

(Consult factory)

100 m motor cable limit with Schaffner

FN3359-320-nn filter.

150 m motor cable limit with 22RFD323 filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

150 m motor cable limit with Schaffner

FN3359-600-nn filter.

150 m motor cable limit with 22RFD480 filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

Compliance possible with

supplementary mitigation

(Consult factory)

Compliance possible with

supplementary mitigation

(Consult factory)

Compliance possible with

supplementary mitigation

(Consult factory)

Compliance possible with

supplementary mitigation

(Consult factory)

30 m motor cable limit with no filter.

100 m motor cable limit with Schaffner

FN3359-320-nn filter.

150 m motor cable limit with 22-

RFD323 filter.

30 m motor cable limit with no filter.

150 m motor cable limit with Schaffner

FN3359-600-nn filter.

150 m motor cable limit with 22RFD480 filter.

(3)

30 m motor cable limit

(4)

core.

30 m motor cable limit

(4)

and input core.

core

30 m motor cable limit

(4)

and input core. With door

core

shielding kit installed.

30 m motor cable limit

(4)

and input core.

core

with output

(3)

with output

(3)

with output

(5)

(3)

with output

(6)

21G14xx460…21G14xx1K5

Floor Mount Frame 10 - Common

DC Input

20G14xx1K6…20G14xx2K1

Compliance possible with

supplementary mitigation

(Consult factory)

Compliance possible with

supplementary mitigation

(Consult factory)

30 m motor cable limit

(4)

core

and input core.

shielding kit installed.

(3)

with output

(6)

With door

(5)

21G14xx1K6…21G14xx2K1

More Stringent Limits Less Stringent Limits

(1) Rating-specific EMC cores are part of EMC kit numbers 20-750-EMC1-nn and 20-750-EMC2-nn.

(2) To meet the C2 rating with a Dual Encoder module installed, Frame 1 drives must be installed in a supplementary EMC enclosure to attenuate radiated emissions.

(3) Intended to be powered from an industrial power network that is supplied by a dedicated power transformer or generator and not from LV power lines that supply other customers.

(4) EMC kit number 20-750-EMCCM1-F8. Kit contains one core. Each drive assembly requires one EMC kit. Order one kit for a Frame 8 drive, two kits for a Frame 9 drive, three kits for a Frame 10 drive.

(5) Door-shielding kit number 20-750-EMCDK1-F10. Kit contains shield brackets for three doors.

(6) EMC kit number 20-750-CBPEMCCM1-F8. Kit contains one core. Each drive assembly requires one EMC kit. Order one kit for a Frame 8 drive, two kits for a Frame 9 drive, three kits for a Frame 10 drive.

EN61800-3 Category C3

I > 100 A

N/A

(1)

N/A

N/A

N/A

30 m motor cable limit with input and

output cores.

150 m motor cable limit with Schaffner

FN3258-130-nn filter.

(3)

30 m motor cable limit with no filter.

100 m motor cable limit with Schaffner

FN3359-320-nn filter.

150 m motor cable limit with 22-

RFD323 filter.

(3)

30 m motor cable limit with no filter.

150 m motor cable limit with Schaffner

FN3359-600-nn filter.

(1)

150 m motor cable limit with 22RFD480 filter.

30 m motor cable limit

(4)

core.

30 m motor cable limit

(4)

and input core.

core

30 m motor cable limit

(4)

and input core. With door

core

shielding kit installed.

30 m motor cable limit

(4)

and input core.

core

30 m motor cable limit

(4)

core

and input core. With door

shielding kit installed.

(3)

with output

(3)

with output

(3)

with output

(5)

(3)

with output

(6)

(3)

with output

(5)

(3)

(3)

22 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 23

Table 2 - PowerFlex 750-Series 600/690V Input Drives RF Emission Compliance and Installation

Requirements

Drive Frame

Catalog Number

Wall Mount Frame 3: 600V (3

Hp and higher.)

20F11xE3P9…20F11xE022

20G11xE3P9…20G11xE022

Wall Mount Frame 4: 600V

20F11xE027…20F11xE032

20G11xE027…20G11xE032

Wall Mount Frame 5: 600V

20F11xE041…20F11xE052

20G11xE041…20G11xE052

Wall Mount Frame 6: 600/690V

20F11xx012…20F11xx144

20G11xx012…20G11xx144

Frame 7: 600/690

20F11xx192…20F11xx289

20G11xx192…20G11xx289

(1) Rating-specific EMC cores are part of EMC kit numbers 20-750-EMC3-nn and 20 -750-EMC4-nn.

EN61800-3 Category C1

EN61000-6-3

CISPR11 Group 1 Class B

50 m cable limit with Schaffner

FN258HV-42-33 filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

50 m cable limit with Schaffner

FN258HV-55-34 filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

50 m cable limit with Schaffner

FN258HV-100-35 filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

50 m cable limit with Schaffner

FN258HV-100-35 filter (up to 90 kW

drives) or FN3359HV-250-28 filter

(110 kW and larger drives).

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

50 m cable limit with Schaffner

FN3359HV-400-99 filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

More Stringent Limits Less Stringent Limits

EN61800-3 Category C2

EN61000-6-4

CISPR11 Group 1 Class A

(Input Power

30 m motor cable limit with one input

and one output core.

30 m motor cable limit with one input

and one output core.

30 m motor cable limit with one input

and one output core.

50 m cable limit with Schaffner

FN258HV-100-35 filter (up to 90 kW

drives) or FN3359HV-250-28 filter

≤ 20 kVA)

(110 kW and larger drives).

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

50 m cable limit with Schaffner

FN3359HV-400-99 filter.

Supplementary EMC enclosure is

required to provide attenuation of

radiated emissions.

(1)

(1)

(1)

Standard / Limits

EN61800-3 Category C3

(I

≤ 100 A)

CISPR11 Group 1 Class A

(Input Power > 20 kVA)

30 m motor cable limit with one input

and one output core.

30 m motor cable limit with one input

and one output core.

30 m motor cable limit with one input

and one output core.

30 m motor cable limit with one input

and one output core.

30 m motor cable limit with one input

and one output core.

Prepare for Installation Chapter 2

EN61800-3 Category C3

I > 100 A

(1)

(1)

(1)

(1)

(1)

N/A

N/A

N/A

30 m motor cable limit with one input

and one output core.

30 m motor cable limit with one input

and one output core.

(1)

(1)

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 23

Page 24

Chapter 2 Prepare for Installation

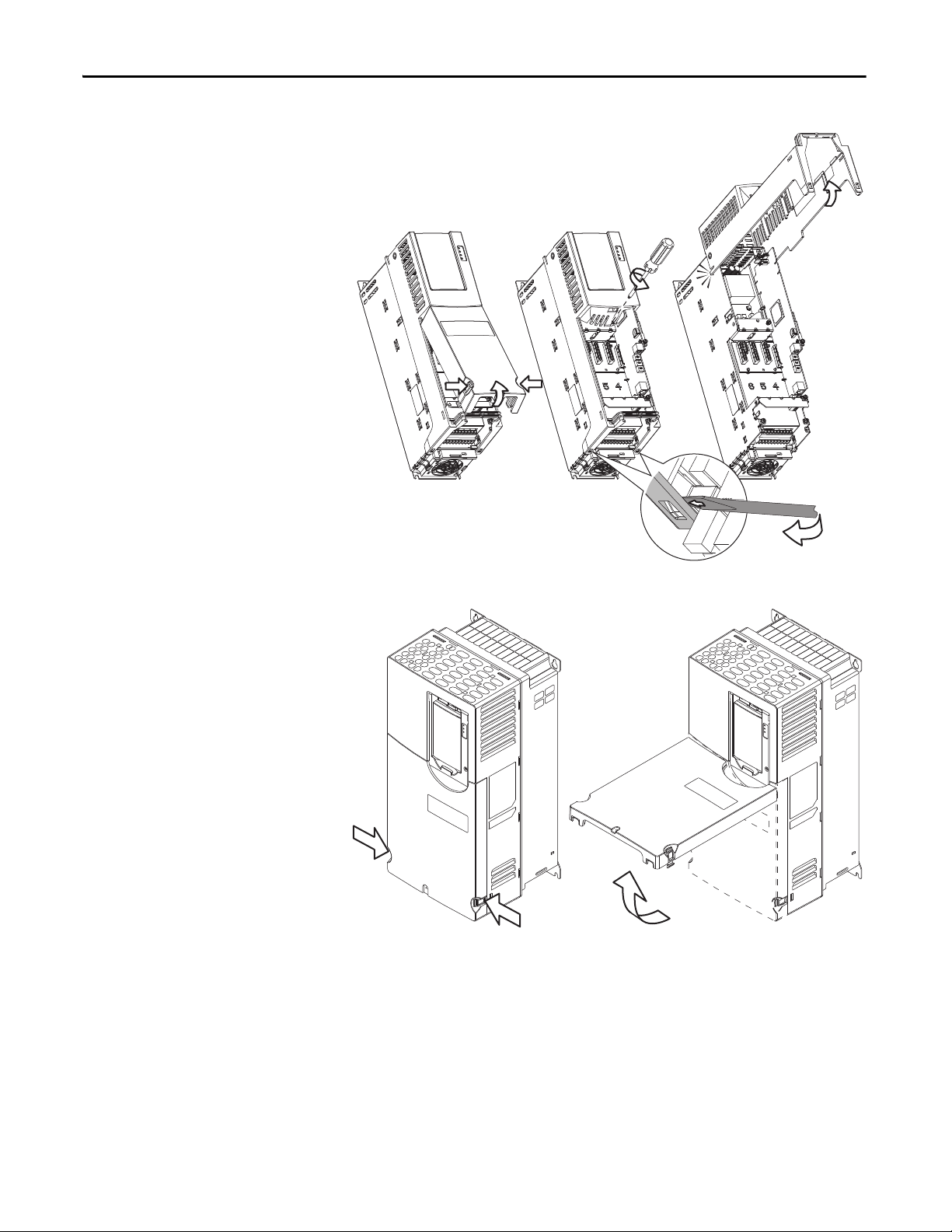

Access Panels, Covers, and Doors

Figure 1 - Enclosure Code R (IP20, NEMA/UL Open Type) Wall Mount Frame 1

Figure 2 - Enclosure Code N (IP20, NEMA/UL Open Type) Wall Mount Frames 2…5

24 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 25

Prepare for Installation Chapter 2

Figure 3 - Enclosure Code G (IP54, NEMA/UL Type 12) Wall Mount Frames 2…5

2x:

M4 X 0.7

When cover is replaced:

• Recommended torque (screws and nuts) = 0.68 N•m (6.0 lb•in)

• Recommended screwdriver = 6.4 mm (0.25 in.) flat or T20 Hexalobular

• Recommended hex socket = 7 mm

Figure 4 - Enclosure Code N (IP00, NEMA/UL Open Type) Wall Mount Frames 6 and 7

90°

When cover is replaced:

• Recommended screwdriver = 9.5 mm (0.375 in.) flat

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 25

Page 26

Chapter 2 Prepare for Installation

Figure 5 - Enclosure Code N (IP00, NEMA/UL Open Type) Wall Mount Frames 6 and 7 Access Door

When door is replaced:

• Recommended screwdriver = 6.4 mm (0.25 in.) flat or T20 Hexalobular

26 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 27

Prepare for Installation Chapter 2

90°

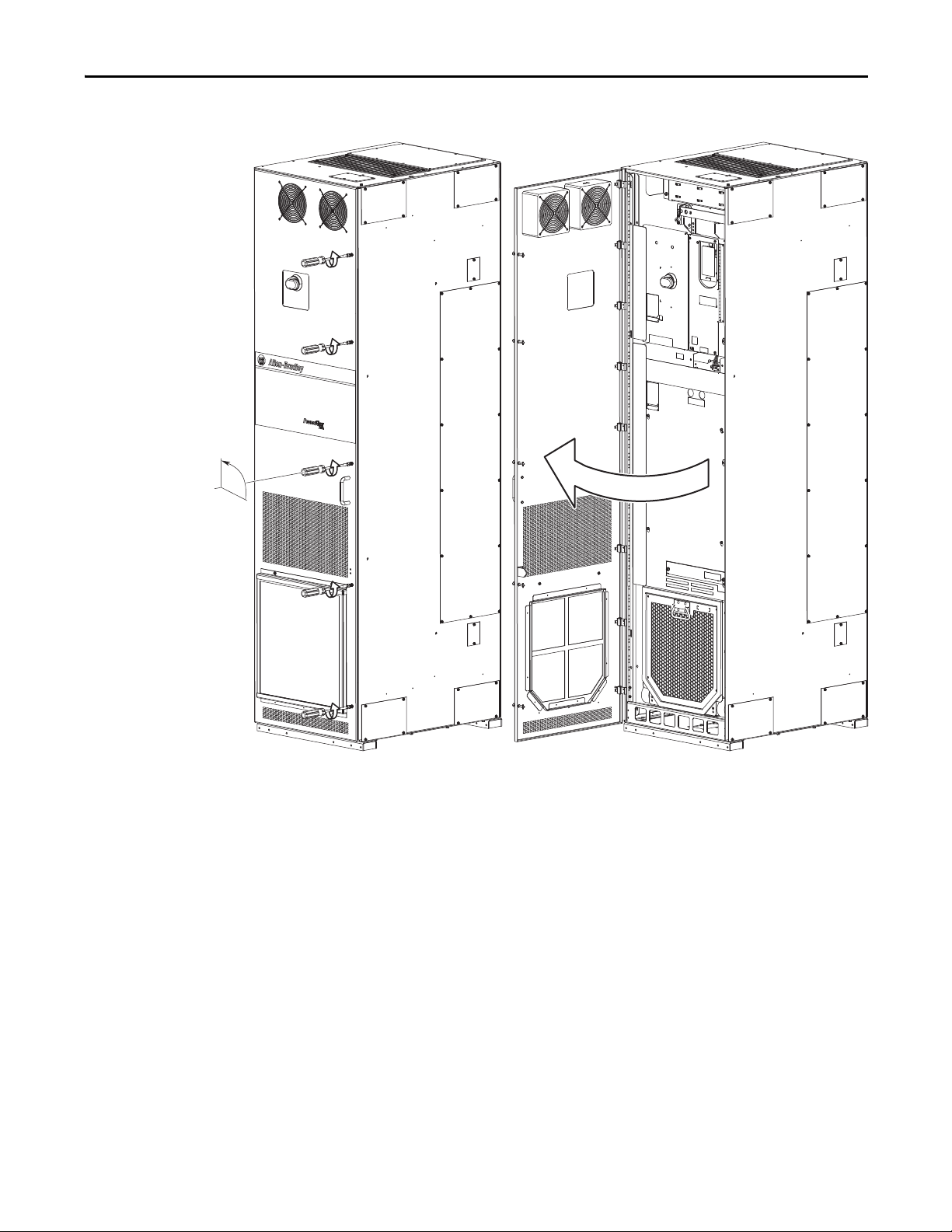

Figure 6 - Floor Mount Frames 8 and Larger Cabinet Access Door (All Enclosure Types)

To release or secure door:

• Recommended screwdriver = 9.5 mm (0.375 in.) flat

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 27

Page 28

Chapter 2 Prepare for Installation

➊

➋

➌

➎

➍

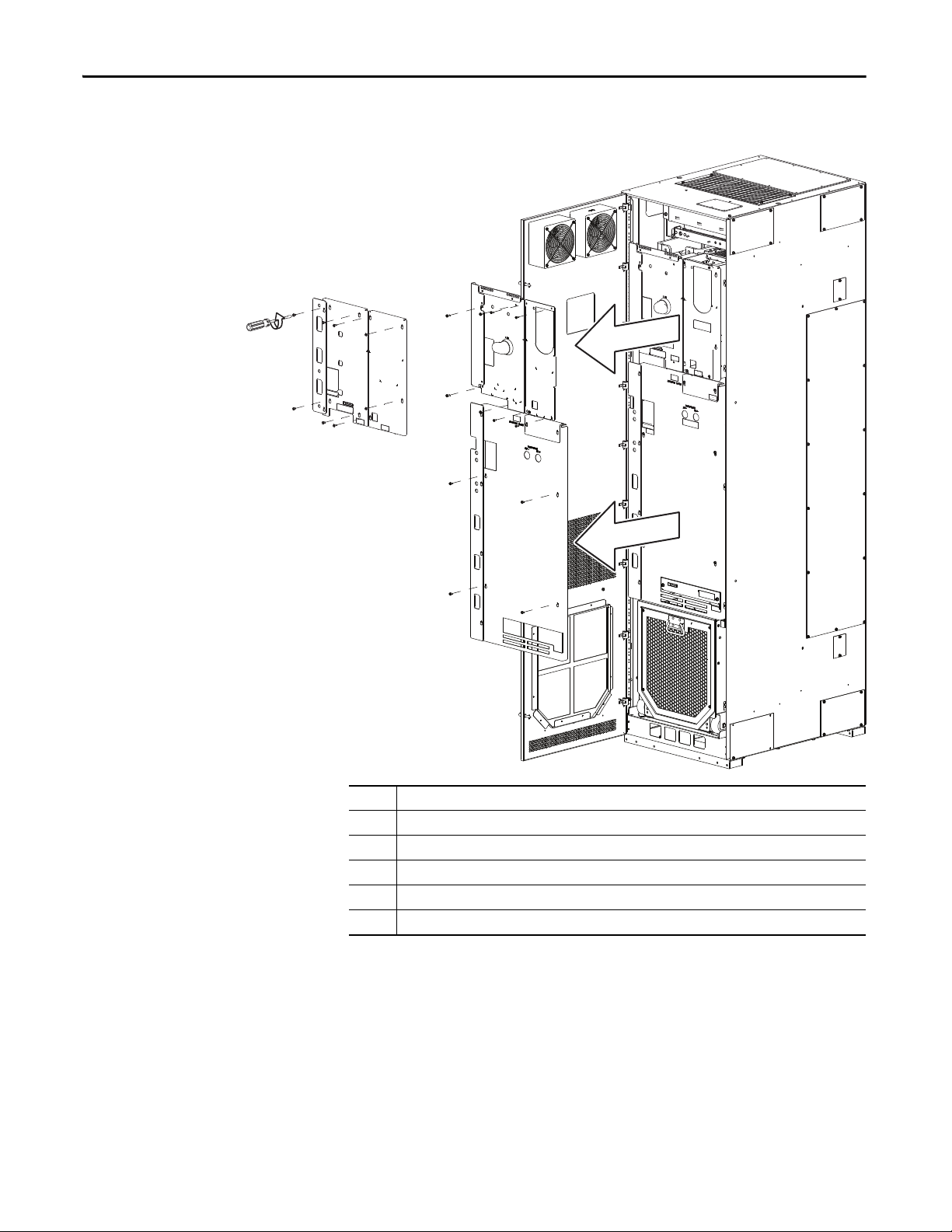

Figure 7 - Floor Mount Drive-assembly Access Panels - All Enclosure Types (IP20, NEMA/UL Type 1

Shown)

No. Description

➊ Lef t Front Conve rter Cover with Side Shiel d (AC Input Drives)

➋ Right Front Converter Cover (No Control Pod)

➌ Lef t Front Conver ter Cover with Side Shie ld (Common DC Input Drives)

➍ Right Front Converter Cover (With Control Pod)

➎ Inverter Front Cover with Side Shield (Common DC Input Drives)

When covers are replaced:

• Recommended torque = 2.8 N•m (25.0 lb•in)

• Recommended screwdriver = 6.4 mm (0.25 in.) flat or T25 Hexalobular

28 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 29

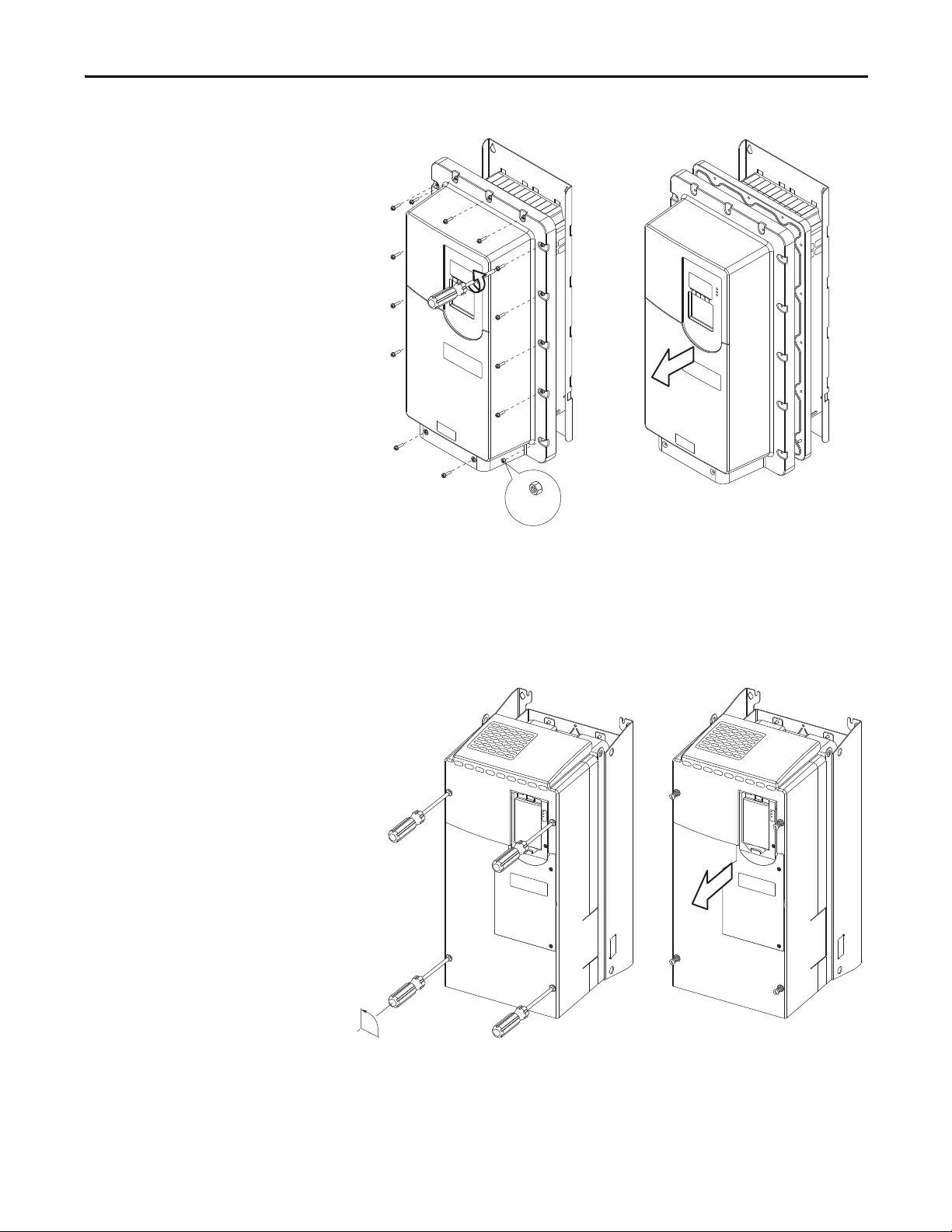

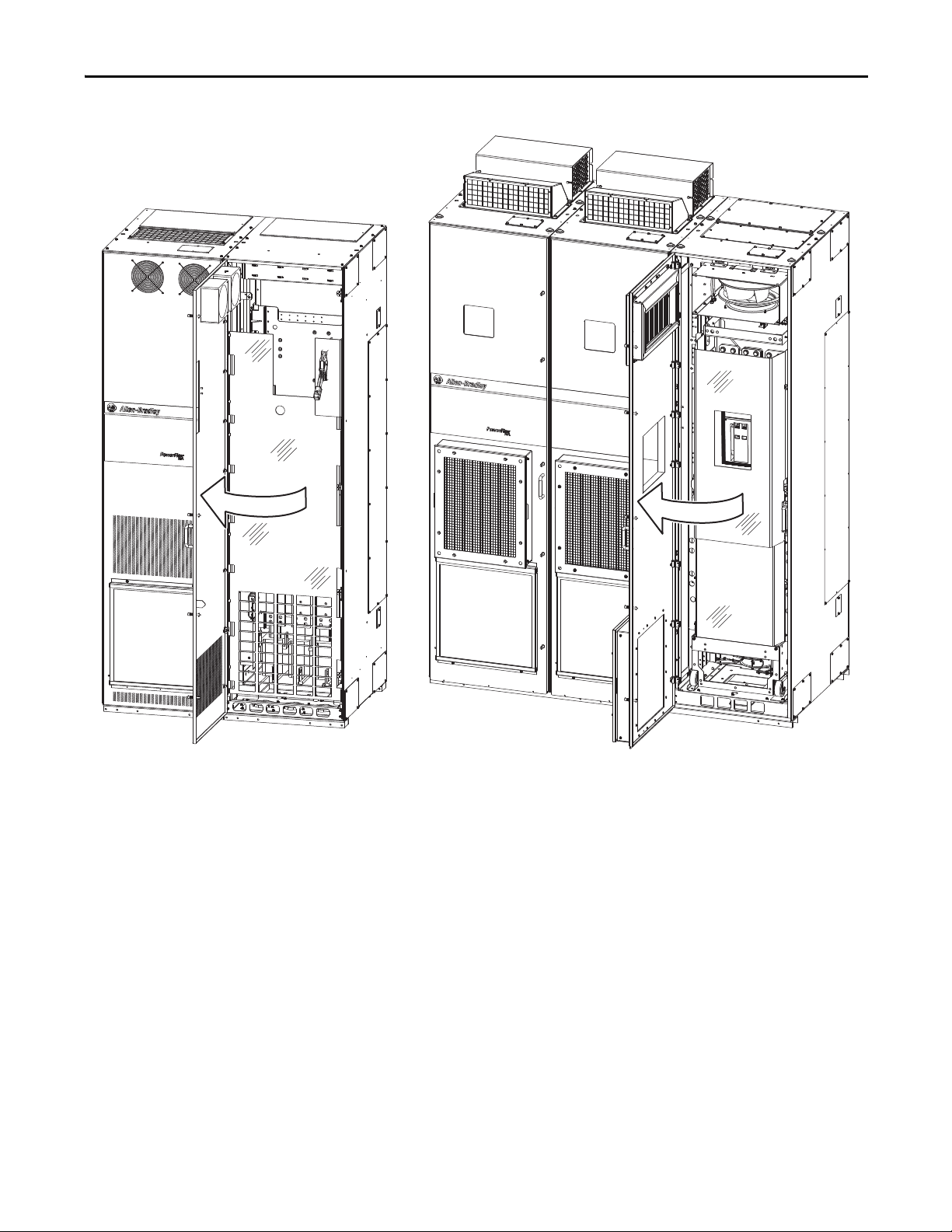

Figure 8 - Floor Mount Cabinet Options Bay Access Door

Floor Mount Frame 8 - IP20, NEMA/UL Type 1 Floor Mount Frame 9 - IP54, NEMA 12

Prepare for Installation Chapter 2

To release or secure door:

• Recommended screwdriver = 9.5 mm (0.375 in.) flat

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 29

Page 30

Chapter 2 Prepare for Installation

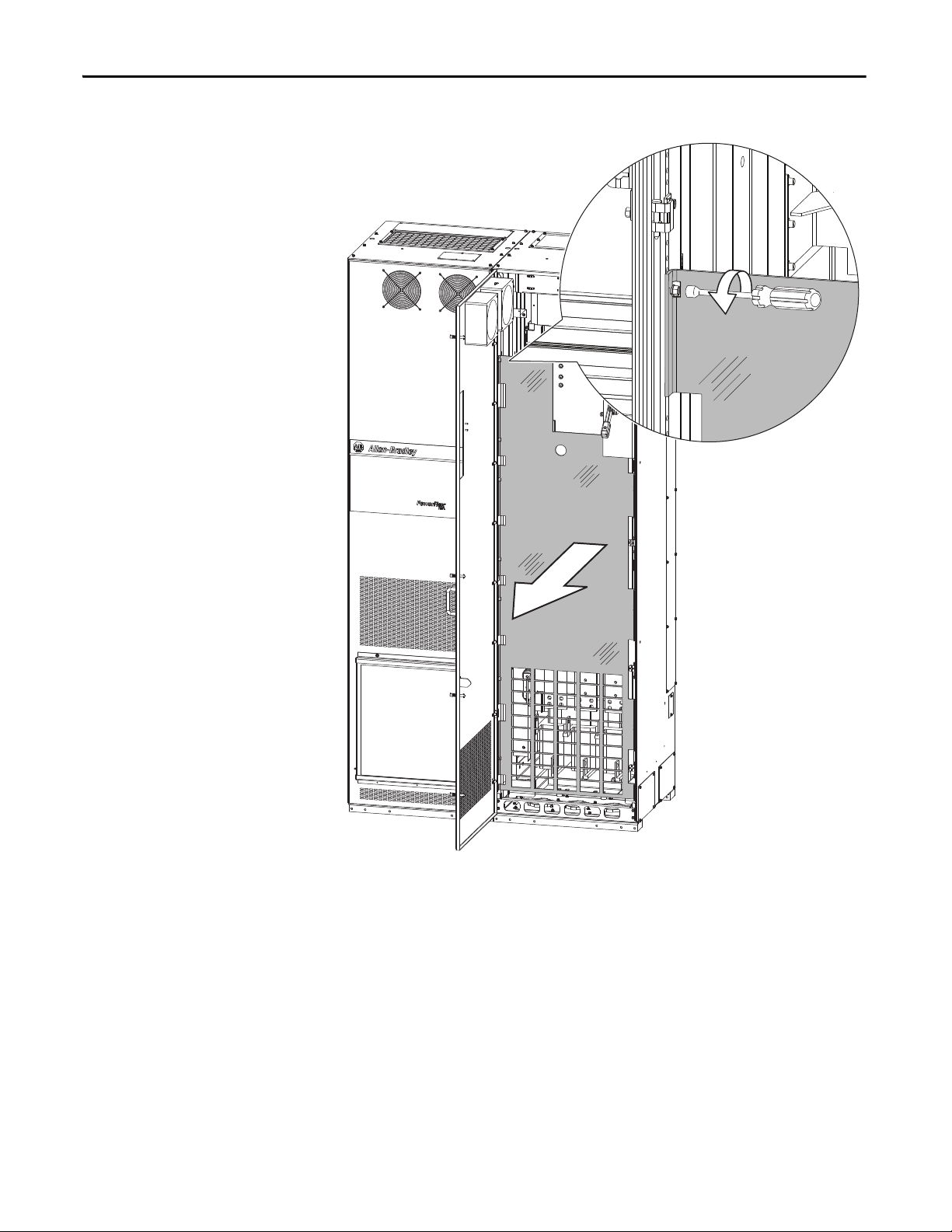

Figure 9 - Full Cabinet Options Bay Guard - Floor Mount Frame 8

To remove the full bay guard, loosen the ten M5 screws. It is not necessary to

remove these screws.

When the full bay guard is replaced:

• Recommended torque = 2.8 N•m (25.0 lb•in)

• Recommended driver = 8 mm Hexagonal socket

30 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 31

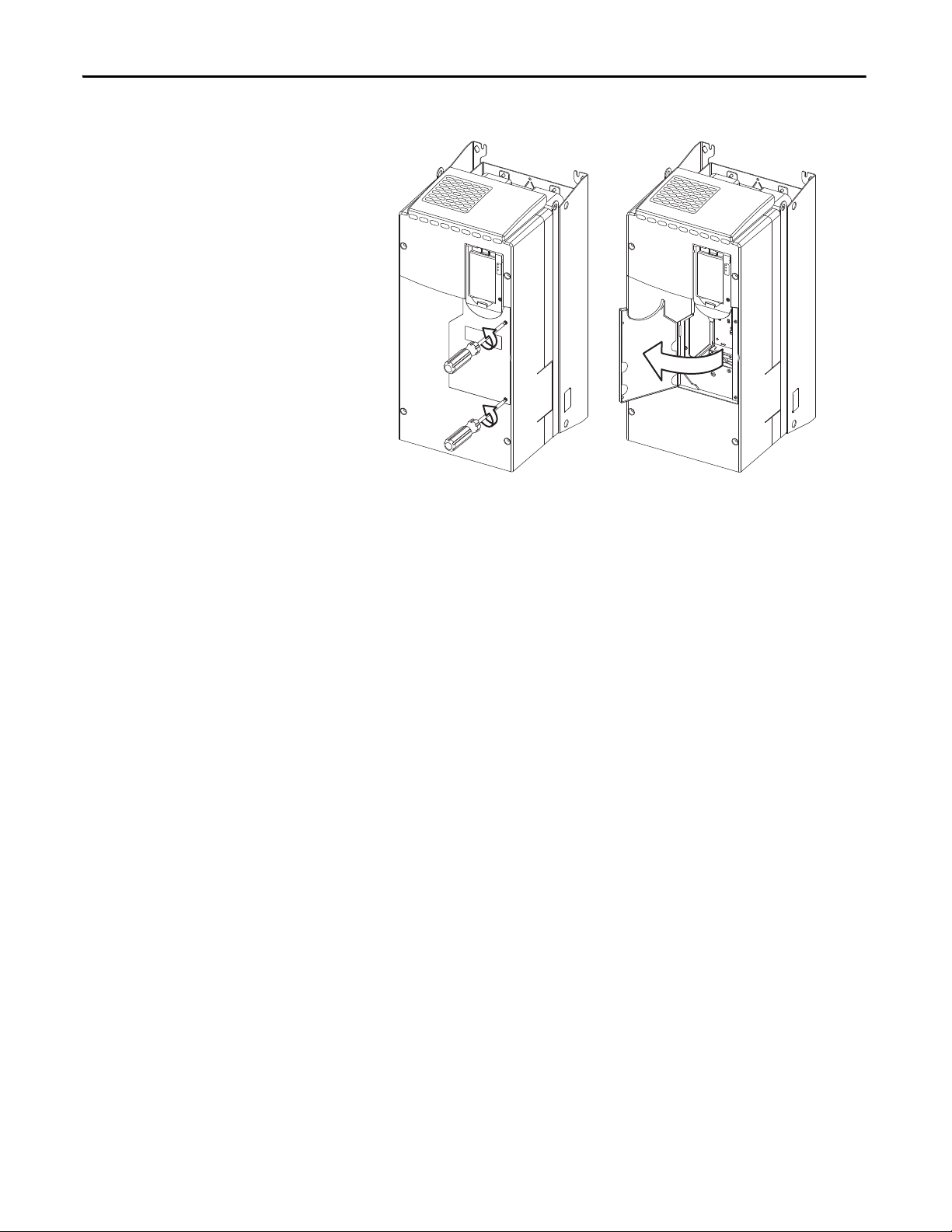

Figure 10 - Full Cabinet Options Bay Guard Floor Mount Frame 9

Prepare for Installation Chapter 2

To remove the full bay guard, loosen the ten M5 screws. It is not necessary to

remove these screws.

When the full bay guard is replaced:

• Recommended torque = 2.8 N•m (25.0 lb•in)

• Recommended driver = 8 mm Hexagonal socket

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 31

Page 32

Chapter 2 Prepare for Installation

Airflow through the drive

must not be impeded.

860 mm

(33.9 in.)

860 mm

(33.9 in.)

20-750-CART1-F8

182 mm (7.2 in.)

Airflow through the drive must not be impeded.

IP20, NEMA/UL Type 1

IP54, NEMA 12

IP20, NEMA/UL Type 1

with Optional Exhaust Hood

Minimum Clearances

Specified vertical clearance requirements (indicated in Figure 11) are intended to

be from the drive to the closest object that can restrict airflow through the drive

heat sink and chassis. The drive must be mounted in a vertical orientation as

shown and must make full contact with the mounting surface. Do not use

standoffs or spacers. In addition, inlet air temperature must not exceed the

product specification.

Figure 11 - Minimum Mounting Clearances – Wall Mount Frames 1…7

76.2 mm (3.0 in.)

76.2 mm (3.0 in.)

Figure 12 - Minimum Mounting Clearances – Floor Mount Drive Cabinets

32 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 33

Prepare for Installation Chapter 2

Mounting Considerations

Environmental Specifications

Wall Mount Frames 1…7

• Mount the drive upright on a flat, vertical, and level surface.

• Verify that the drive is in full contact with the mounting surface as

depicted in Figure 11

.

Floor Mount Frames 8…10

• Install the drive upright on a flat and level surface.

• Verify that the drive cabinet is square, vertical, and stable.

• Verify that the filter and debris screens are installed.

All Mounting Styles and Frames

• Protect the cooling fan by avoiding dust or metallic particles.

• Do not expose to a corrosive atmosphere.

• Protect from moisture and direct sunlight (unless rated for outdoor use).

Maximum Surrounding Air Temperature

IP20, NEMA/UL Open Type:

IP00, NEMA/UL Open Type:

IP20, NEMA/UL Type 1 (w/Hood):

IP20, NEMA/UL Type 1 (w/Label):

IP20, NEMA/UL Type 1 (MCC Cabinet):

IP54, NEMA 12 (MCC Cabinet):

Flange Mount –

Front:

IP20, NEMA/UL Open Type:

IP00, NEMA/UL Open Type:

Back/Heat Sink:

IP66, NEMA/UL Type 4X

Stand-alone/Wall Mount –

IP54, NEMA/UL Type 12

Storage Temperature (all const.): -40…70 °C (-40…158 °F)

Atmosphere: Important: Drive must

0…50 °C (32…122 °F)

0…50 °C (32…122 °F)

0…40 °C (32…104 °F)

0…40 °C (32…104 °F)

0…40 °C (32…104 °F)

0…40 °C (32…104 °F)

0…50 °C (32…122 °F)

0…50 °C (32…122 °F)

0…40 °C (32…104 °F)

0…40 °C (32…104 °F)

atmosphere contains volatile or corrosive gas, vapors, or dust. If the drive

is not going to be immediately installed, it must be stored in an area

where it is not exposed to a corrosive atmosphere.

Wall Mount Frames 1…5, All Ratings

Wall Mount Frames 6…7, All Ratings

Wall Mount Frames 1…5, All Ratings

Wall Mount Frames 6…7, All Ratings

Floor Mount Frames 8…10, All Ratings

Floor Mount Frames 8…10, All Ratings

Wall Mount Frames 2…5, All Ratings

Wall Mount Frames 6…7, All Ratings

Wall Mount Frames 2…7, All Ratings

Wall Mount Frames 2…7, All Ratings

not be installed in an area where the ambient

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 33

Page 34

Chapter 2 Prepare for Installation

Notes:

34 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 35

Lift and Mount the Drive

Chapter 3

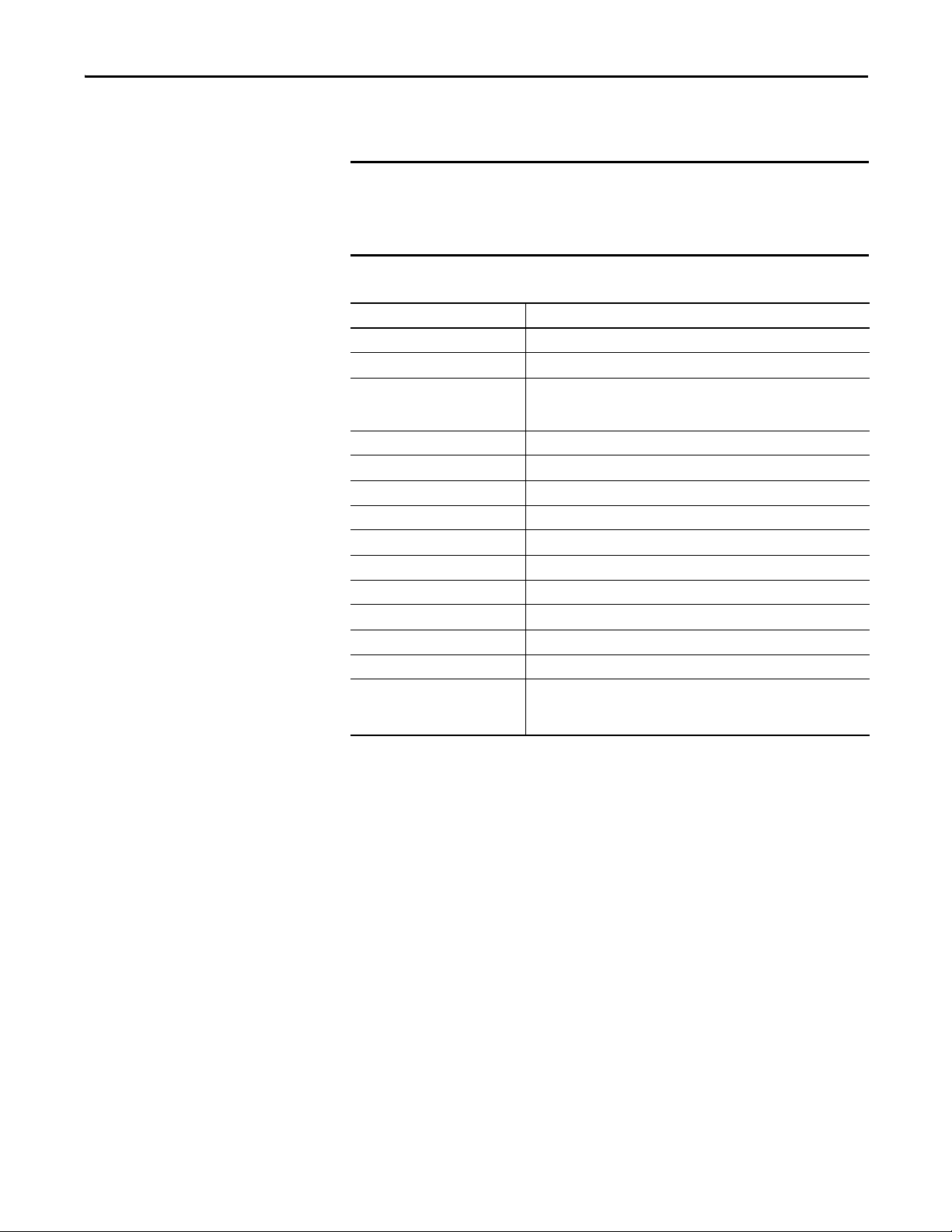

Drive Weights

Drive Frame

Standard

(20F, 20G)

Standard

(20G)

with

Options

(21G)

AC Input

and Common

DC Input

AC Input 8 250…400 350…650 623 (1374) 1145 (2525) 644 (1419) 1166 (2570)

Common DC

Input

AC Input 8 250…400 350…650 1145 (2525) 1675 (3694) 1166 (2570) 1696 (3739)

Size

1 0.75…7.5 1…10

2 0.75…11 1…15 8 (17) 8 (17) 8 (17)

3 15…22 0.5…30 12 (26) 12 (26) 12 (26)

4 30…37 20…50 14 (30) 14 (30) 14 (30)

5 45…55 30…70 20 (45) 20 (45) 20 (45)

6 5.5…75 75…100 37 (82) 89 (197) 37 (82)

7 132…200 150…300 69 (152) 135 (297) 79 (174)

9 500…850 700…1250 1246 (2748) 2290 (5051) 1287 (2838) 2332 (5141)

10 900…1250 1350…1750 1869 (4122) 3435 (7576) 1931 (4257) 3498 (7711)

8 250…400 350…650 566 (1248) 1088 (2400) 586 (1293) 1109 (2445)

9 500…850 700…1250 1132 (2497) 2176 (4799) 1173 (2587) 2218 (4889)

10 900…1250 1350…1750 1698 (3745) 3264 (7199) 1760 (3880) 3327 (7334)

9 500…850 700…1250 1730 (3815) 2820 (6219) 1771 (3905) 2862 (6309)

10 900…1250 1350…1750 2315 (5106) 3965 (8745) 2377 (5241) 4028 (8880)

All lifting equipment and lifting components (hooks, bolts, lifts, slings, chains,

and so forth) must be properly sized and rated to safely lift and hold the weight of

the drive while mounting.

ATTENTION: To guard against possible personal injury and/or equipment

damage…

• Inspect all lifting hardware for proper attachment before lifting drive.

• Do not allow any part of the drive or lifting mechanism to make contact with

electrically charged conductors or components.

• Do not subject the drive to high rates of acceleration or deceleration while

transporting to the mounting location or when lifting.

• Do not allow personnel or their limbs directly underneath the drive when it is

being lifted and mounted.

Table 3 - Approximate Drive Weights - Wall Mount Frames 1…7 and Floor Mount Frames 8…10

Drive Rating Enclosure Code/Weight kg (lb)

kW (400V, 690V) Hp (480V, 600V) FGNR

6 (13)

45…132 50…200 38 (84) 91 (200) 39 (85)

200…250 300…350 96 (212) 162 (357) 106 (234)

B, L P, W J K, Y

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 35

Page 36

Chapter 3 Lift and Mount the Drive

IMPORTANT

Recommended Mounting Hardware

Table 4 - Maximum Component Weights - Floor Mount Frames 8…10

Component Weight kg (lb)

AC Input Common DC Input

Converter/DC Input w/Precharge 64 (140) 64 (140)

Inverter 222 (490) 165 (363)

Drive Assembly (Open, IP00) 286 (630) 229 (504)

Cabinet Options Assembly with Circuit Breaker and Reactor 296 (653) –

Frame Size Fastener Size Notes

1

2

M6 (#10 or #12)

M12 (1/2 in.) Property Class 8.8 (Minimum)9

Wall Mount

Floor Mou nt

3

4

5

6 M6 (#12)

7M8 (5/16 in.)

8

10

Mounting hardware is provided with enclosure type F (Flange mount) drives.

The hardware supplied must be used to meet the enclosure rating.

36 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 37

Lift and Mount the Drive Chapter 3

>

1

/

2 A

A

<45°

>

1

/

2 A

A

<45°

Attach Lifting Hardware

Figure 13 - Rigging Geometry

Enclosure Code F

Wall Mount Frame 6 Lifting Points – 2 Places

Wall Mount Frame 7 Lifting Points – 4 Places

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 37

Page 38

Chapter 3 Lift and Mount the Drive

Enclosure Code N

Wall Mount Frame 6 Lifting Points – 6 Places

Wall Mount Frame 7 Lifting Points – 8 Places

Enclosure Code G

Wall Mount Frames 6 and 7 Lifting Points – 4 Places

38 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 39

Lift and Mount the Drive Chapter 3

Open Type Drive (Removed From Cabinet)

Floor Mount Drive Assembly – IP00, NEMA/UL Type Open Drive Lifting Points – 2 Places

Enclosure Codes B and L

Floor Mount Frame 8 Lifting Points – 2 Places

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 39

Page 40

Chapter 3 Lift and Mount the Drive

Floor Mount Frames 9 and 10 Lifting Points – 2 Places

Enclosure Codes J, K, and Y

Floor Mount Frame 9 with Cabinet Options Bay Lifting Points – 2 Places

40 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 41

Lift and Mount the Drive Chapter 3

IMPORTANT

Release Floor Mount Drive Cabinet From Shipping Skid

Remove the bolts fastening a vertically oriented drive cabinet to the shipping skid

and lift.

<45°

1

/

>

2 A

A

<45°

1

/

>

2 A

A

M10 x 25

17 mm

Remove the shipping crate that encloses a horizontally oriented drive cabinet on

the shipping skid and lift.

Drives equipped with the MCC bus option, with codes P20, P22, and P24 in the

catalog string, are not to be shipped horizontally.

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 41

Page 42

Chapter 3 Lift and Mount the Drive

Floor Mou nt Frame 8

Floor Mou nt Frame 9

Floor Mou nt Frame 10

Remove Drive Cabinet Lifting Angle

After the drive cabinet is in its final position, remove the lifting angle.

M12

67.8 N•m (600 lb•in)

18 mm

42 Rockwell Automation Publication 750-IN001O-EN-P - October 2014

Page 43

Lift and Mount the Drive Chapter 3

Debris Screen (Supplied) Exhaust Hood (Optional Kit)

Install IP20, NEMA/UL Type 1 Debris Screen or Optional Exhaust Hood

IP20, NEMA/UL Type 1 drives are equipped with a top mounted debris screen.

An optional exhaust hood is also available as a kit (20-750-HOOD1-F8).

1. Install the supplied debris screen over the exhaust vent.

or

Install the optional exhaust hood with the grill facing the front of the drive.

2. Secure with the four screws provided.

T25

4.0 N•m (35 lb•in)

Install IP54, NEMA 12 Cabinet Blower Assembly and Exhaust Hood

IP54, NEMA 12 drives are equipped with top a mounted blower assembly and

exhaust hood.

1. Install the cabinet blower assembly. Note the required power connection.

2. Secure with the ten screws provided.

3. Install the exhaust hood with the grill facing the front of the drive.

4. Secure with the four screws provided.

T25

4.0 N•m (35 lb•in)

Rockwell Automation Publication 750-IN001O-EN-P - October 2014 43

Page 44

Chapter 3 Lift and Mount the Drive

Drive Cabinets

Cabinet Options Bay

IP54, NEMA 12 Enclosure Rating Shown

Install Floor Mount Drive with Cabinet Options Bay and Wiring Bay

Frame 9 drives configured with both the cabinet options bay and wiring bay ship

in two sections. The following procedure describes how to join the wiring bay to

the cabinet options bay.