Page 1

FLEX I/O System with ControlLogix for SIL 2

Catalog Number Bulletin 1794

Reference Manual

AB Drives

Page 2

Important User Information

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

http://literature.rockwellautomation.com

) describes some important differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated

with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from your local Rockwell Automation sales office or online at

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to: personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, such as a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

Allen-Bradley, Rockwell Automation, FLEX I/O, RSLinx, RSLogix 5000 and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Preface

Introduction

Manual Set-Up

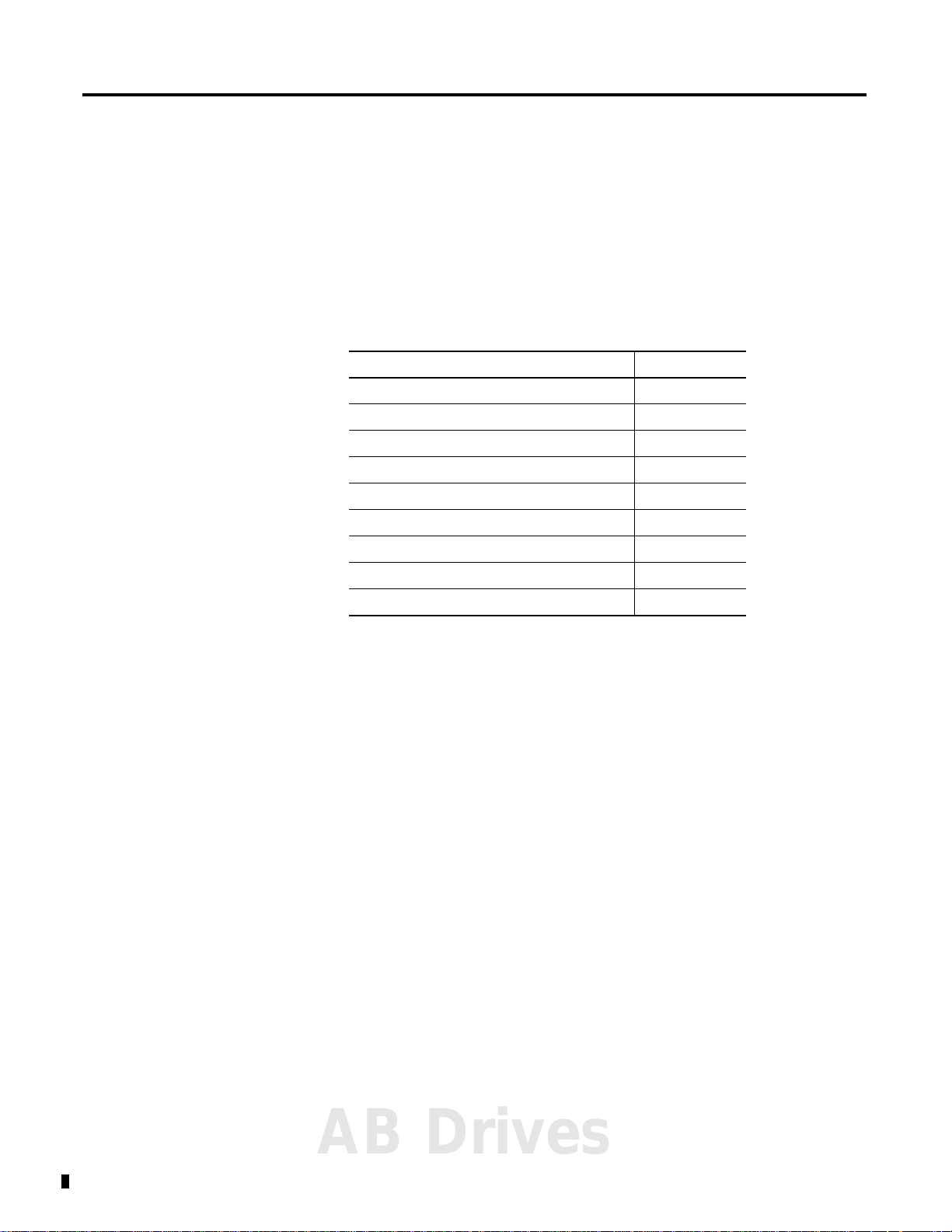

Table Preface.1

This application manual is intended to describe the FLEX I/O with ControlLogix

Control System components available from Rockwell Automation that are

suitable for use in SIL2 applications. Use this manual in conjunction with

publication 1756-RM001

Alternate architecture can be used in SIL2 applications if they are approved by

a certifying agency.

This manual is designed to make clear how the FLEX I/O with ControlLogix

Control System can be SIL2-certified. Table Preface.1 lists the information

available in each section.

Section: Title: Description:

Chapter 1 SIL Policy Introduction to the SIL policy and how that

policy relates to FLEX I/O with a ControlLogix

system.

Chapter 2 ControlLogix Communications Description of the ControlLogix communications

modules used in the SIL2-certified FLEX I/O

with ControlLogix system.

Chapter 3 FLEX I/O Modules Description of the FLEX I/O modules used in the

SIL2-certified FLEX I/O with ControlLogix

system.

Chapter 4 General Requirements for

Application Software

Application software requirements for using

ControlLogix and FLEX modules.

Chapter 5 Technical SIL2 Requirements

Appendix A Failure Estimates Failure rates based on field returns.

Understanding Terminology

for the Application Program

The following table defines acronyms used in this manual.

Table Preface.2 List of Acronyms Used Throughout the Safety Application Manual

Acronym: Full Term: Definition:

CIP Control and

Information

Protocol

DC Diagnostic

Coverage

EN European Norm. The official European Standard

GSV Get System Value A ladder logic output instruction that retrieves

Guidelines for application development in

RSLogix 5000 as they relate to SIL2.

A messaging protocol used by Logix5000™

systems. It is a native communications protocol

used on ControlNet™ communications networks,

among others.

The ratio of the detected failure rate to the total

failure rate.

specified controller status information and places

it in a destination tag.

AB Drives

1 Publication 1794-RM001G-EN-P - December 2011

Page 4

Preface 2

Table Preface.2 List of Acronyms Used Throughout the Safety Application Manual

Acronym: Full Term: Definition:

MTBF Mean Time

Average time between failure occurrences.

Between Failures

MTTR Mean Time to

Restoration

Average time needed to restore normal operation

after a failure has occurred.

PADT Programming and

Debugging Tool

RSLogix 5000 software used to program and

debug a SIL2-certified FLEX I/O with ControlLogix

application.

PC Personal

Computer

Computer used to interface with, and control, a

ControlLogix system via RSLogix 5000

programming software.

PFD Probability of

Failure on

The average probability of a system to fail to

perform its design function on demand.

Demand

PFH Probability of

Failure per Hour

The probability of a system to have a dangerous

failure occur per hour.

1oo1 One out of one A 1oo1 (one out of one) architecture consists of a

single channel where any dangerous failure leads

to a failure of the safety function.

1oo2 One out of two A 1oo2 (one out of two) architecture consists of

two channels connected in parallel such that

either channel can process the safety function.

Publication 1794-RM001G-EN-P - December 2011

Page 5

Chapter

SIL Policy

This chapter introduces you to the SIL policy and how the

ControlLogix/FLEX I/O system meets the requirements for SIL2

certification.

For information about: See page:

Introduction to SIL 1-1

SIL2 Certification 1-2

Proof Tests 1-3

SIL2-Certified FLEX I/O System Components 1-5

Hardware Designs and Firmware Functions 1-8

Hardware Designs and Firmware Functions 1-8

1

Introduction to SIL

Difference Between PFD and PFH 1-8

SIL Compliance Distribution and Weight 1-13

Response Times 1-13

Certain catalog numbers (listed in Table 1.1 on page 1-5) of the FLEX I/O with

ControlLogix system are type-approved and certified for use in SIL2

applications, according to IEC 61508. SIL requirements are based on the

standards current at the time of certification.

These requirements consist of mean time between failures (MTBF),

probability of failure, failure rates, diagnostic coverage and safe failure

fractions that fulfill SIL2 criteria. The results make the ControlLogix/FLEX

I/O system suitable up to, and including, SIL2. When the

ControlLogix/FLEX I/O system is in the maintenance or programming

mode, the user is responsible for maintaining a safe state.

For support in creation of programs, the PADT (Programming and

Debugging Tool) is required. The PADT for ControlLogix/FLEX I/O is

RSLogix 5000, per IEC 61131-3, and this Safety Reference Manual.

The TUV Rheinland has approved the ControlLogix/FLEX I/O system for

use in up to and including SIL 2 safety related applications in which the

de-energized state is considered to be the safe state. All of the examples related

to I/O included in this manual are based on achieving de-energization as the

safe state for typical Emergency Shutdown (ESD) Systems.

AB Drives

1 Publication 1794-RM001G-EN-P - December 2011

Page 6

1-2 SIL Policy

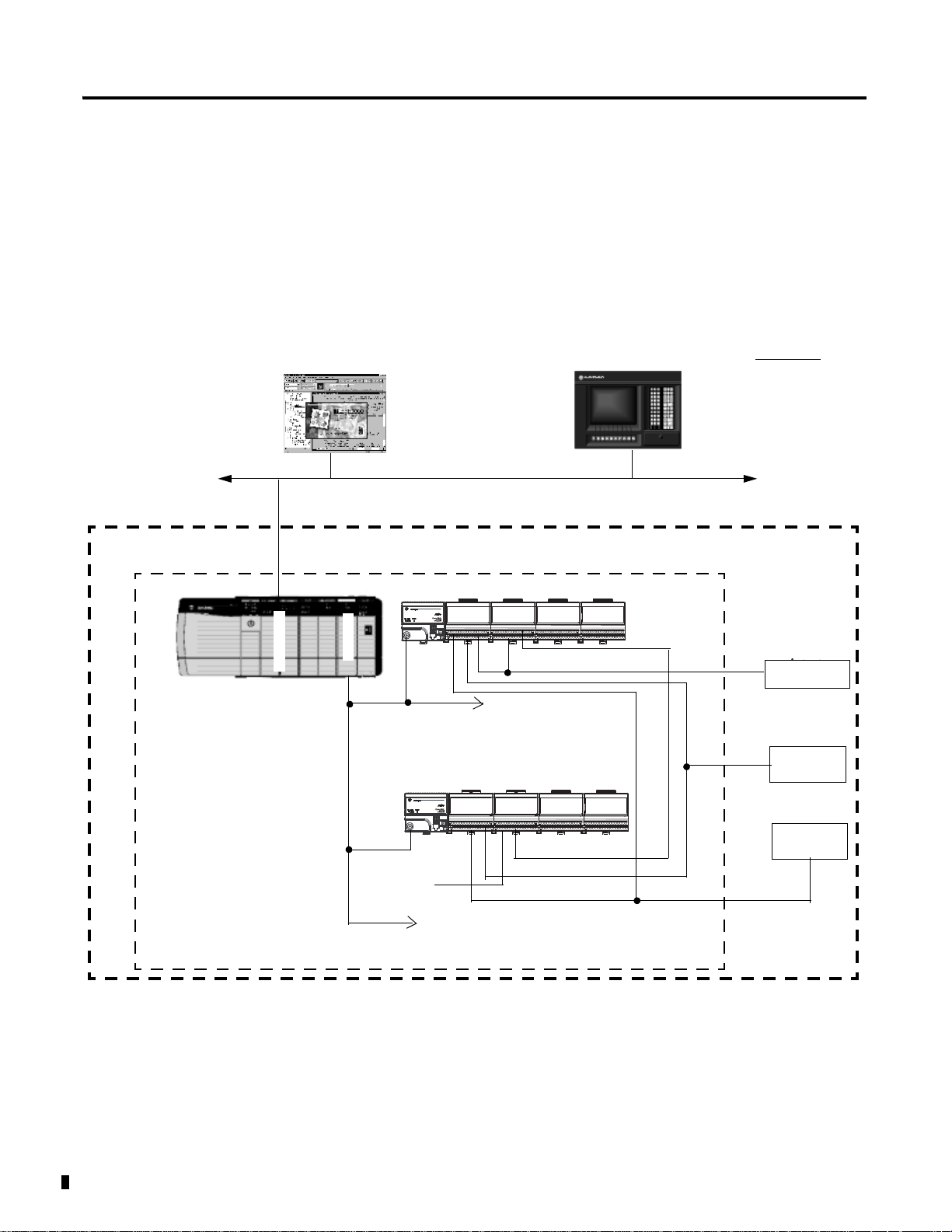

Plant-wide Ethernet/Serial

ControlNet

SIL2-certified ControlLogix components’ portion of the overall safety loop

Programming Software

For SIL applications, a programming

terminal is not normally connected.

HMI

For Diagnostics and Visualization (read-only access to controllers in the

safety loop). For more information, see publication 1756-RM001.

E

N

B

C

N

B

To other safety related

ControlLogix or FLEX I/O

remote I/O chassis

Overall Safety Loop

Actuator

Actuator

1794 FLEX I/O

Input

Device

DI1

DO2

DO1

DI2

ControlNet

Input

Device

To other safety related

ControlLogix or FLEX I/O

remote I/O chassis

See Figures 3.1 and 3.5 for details.

1

Note 1: Multiple 1756-CNB or -CNBR modules can be installed into the chassis as needed.

Other configurations are possible as long as they are SIL2 approved.

+V

SIL2 Certification

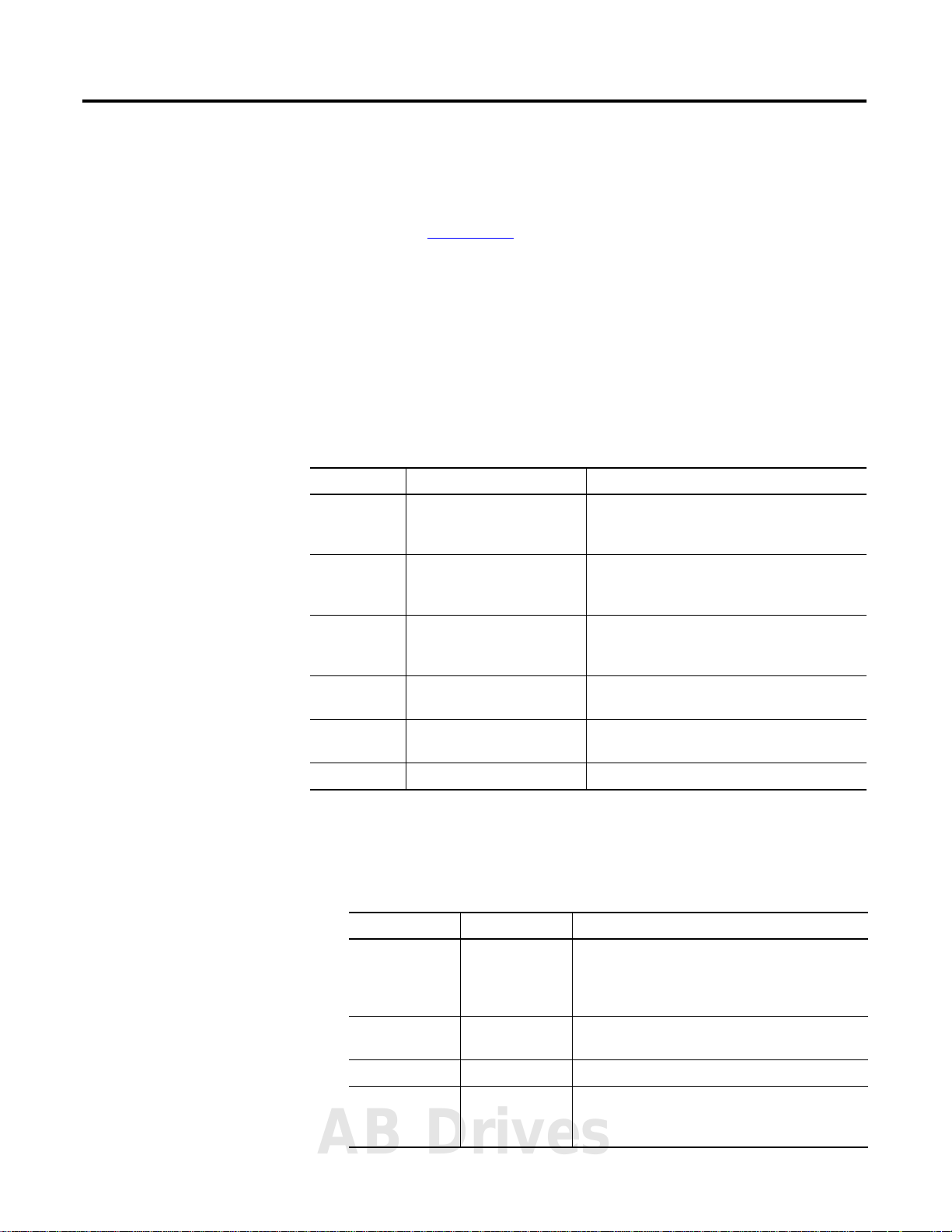

Figure 1.1 shows a typical SIL loop, including:

• the overall safety loop

• the ControlLogix/FLEX I/O portion of the overall safety loop

• how other devices (for example, HMI) connect to the loop, while

operating outside the loop

Figure 1.1

Note 2: Two adapters are required for meeting SIL2 as shown in the figure.

The adapters can be either ControlNet or Ethernet and must be from the list of approved products.

Publication 1794-RM001G-EN-P - December 2011

Page 7

SIL Policy 1-3

IMPORTANT

IMPORTANT

Important Note related to published PFDs.

• The user must choose the appropriate PFD depending

on combinations and the appropriate 1oo1 or 1oo2

configuration.

• Descrete and analog inputs must be used in a 1oo2

configuration for SIL 2.

• Adapters must be used in a 1oo2.

• Outputs may be 1oo2 in series or 1oo1 monitored by

an input with an external relay as a secondary device to

remove power.

• Some specialized inputs can only be wired to a single

sensor such as thermocuples and two 1oo1 PFDs must

be used for each.

• The total PFD for two 1oo1s is the sum of both.

The system user is responsible for:

Proof Tests

• the set-up, SIL rating and validation of any sensors or

actuators connected to the ControlLogix/FLEX I/O

control system.

• project management and functional testing.

programming the application software and the module

configuration according to the description in the

following chapters.

The SIL2 portion of the certified system excludes the

development tools and display/human machine interface

(HMI) devices; these tools and devices are not part of the

run time control loop.

IEC 61508 requires the user to perform various proof tests of the equipment

used in the system. Proof tests are performed at user-defined times (for

example, proof test intervals can be once a year, once every two years or

whatever timeframe is appropriate) and include some of the following tests:

• Testing of all fault routines to verify that process parameters are

monitored properly and the system reacts properly when a fault

condition arises.

• Testing of digital input or output channels to verify that they are not

stuck in the ON or OFF state.

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 8

1-4 SIL Policy

IMPORTANT

• Calibration of analog input and output modules to verify that accurate

data is obtained from and used on the modules.

Users’ specific applications will determine the timeframe

for the proof test interval.

However, keep in mind that the Probability of Failure on

Demand (PFD) calculations listed in Table 1.2 on page 1-8

use a proof test interval of once per year. If the proof test

interval is changed, the information must be recalculated.

For more information on system proof tests, see Publication 1756-RM001

more information on the necessary I/O module, see Table 1.1.

. For

Publication 1794-RM001G-EN-P - December 2011

Page 9

SIL Policy 1-5

SIL2-Certified FLEX I/O

Table 1.1 lists the components available for use in a SIL2-certified FLEX I/O

system. For a list of ControlLogix SIL2 certified products, see publication

System Components

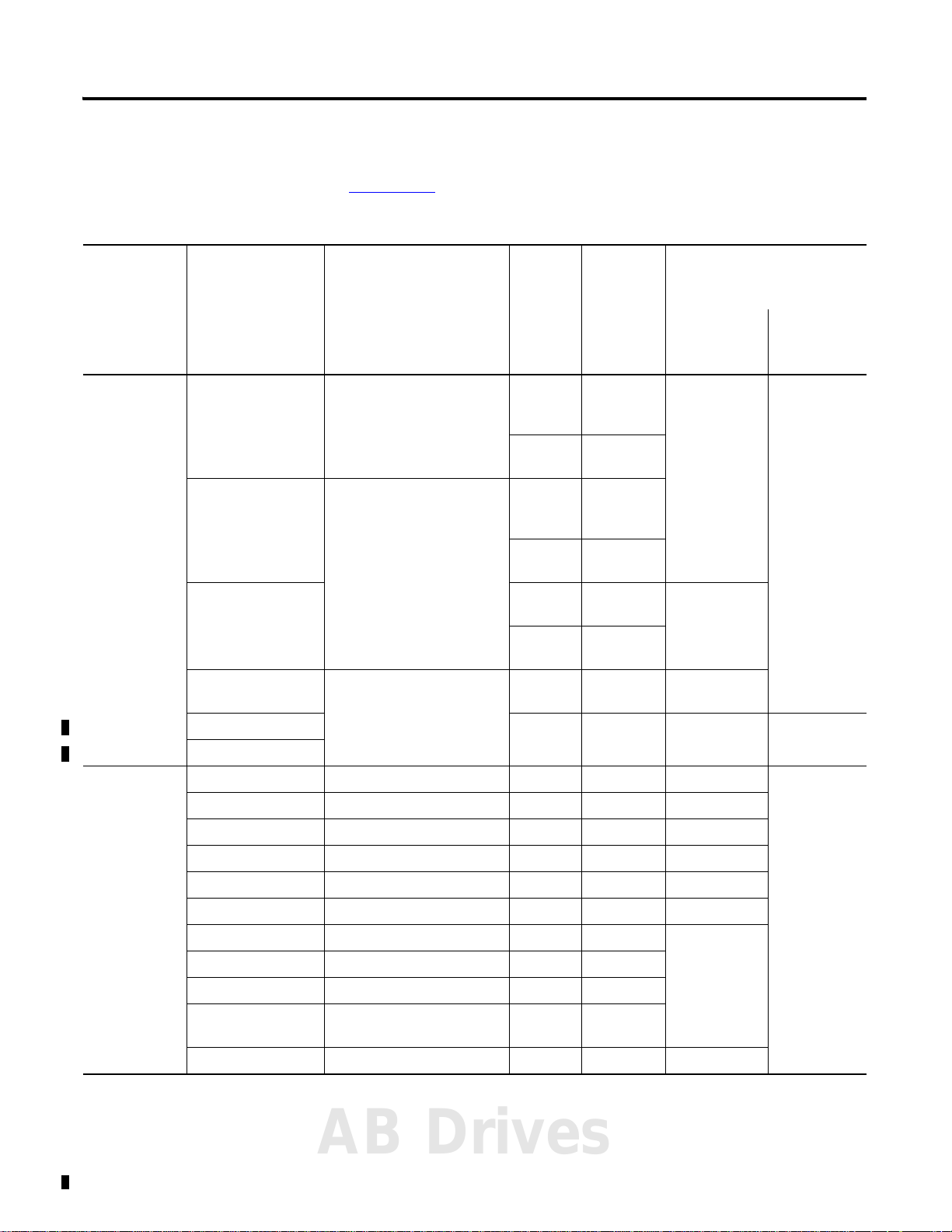

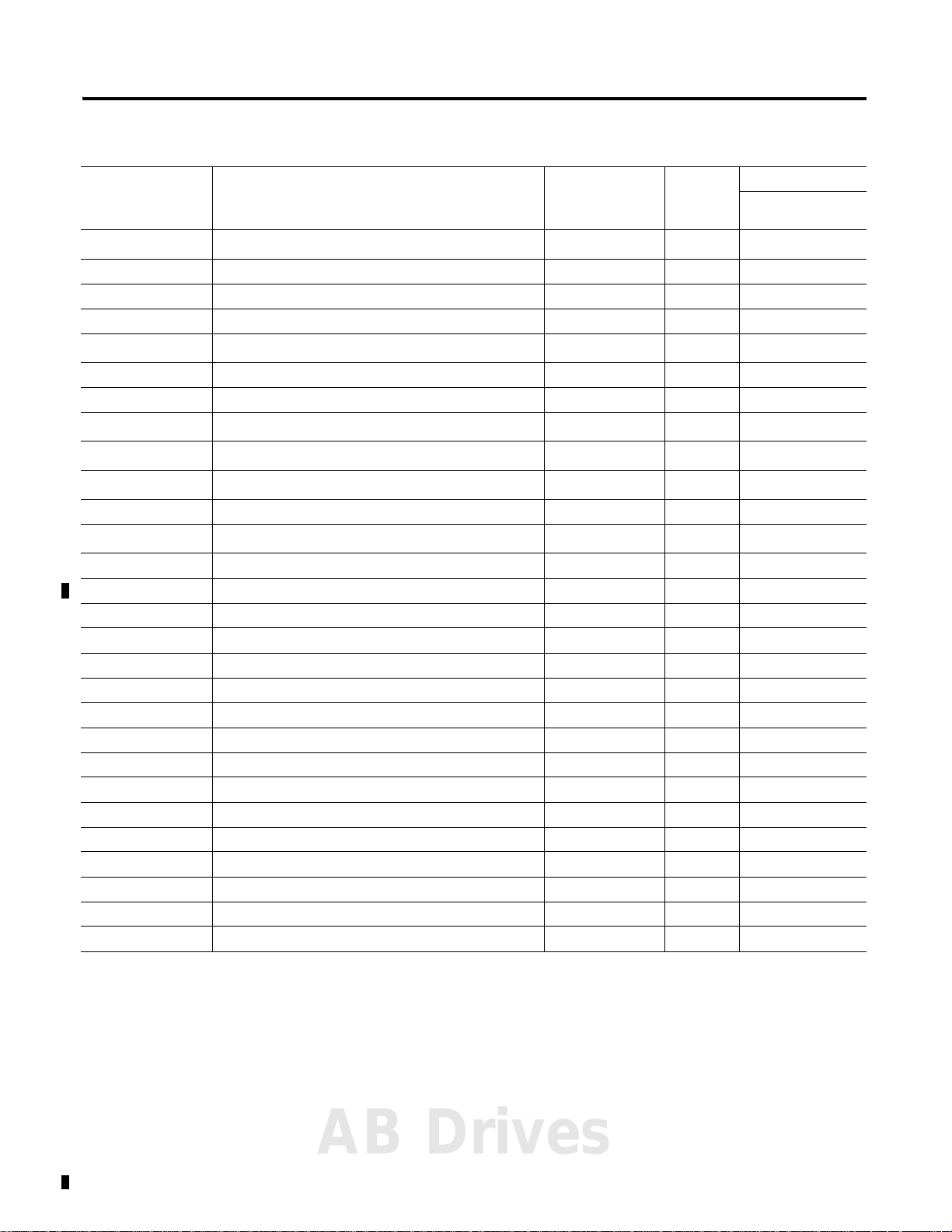

Table 1.1 FLEX I/O Components For Use in the SIL 2 System

Device Type: Catalog Number:

Adapter 1794-ACN15 ControlNet Single Media

1794-ACNR15 ControlNet Redundant Media

1794-ACNR15XT C 5.1, 5.2, 5.3,

(1)

Adapter

Adapter

1756-RM001

Description:

.

Firmware

Revision:

(2)

Series

C4.3

D 10.1, 10.2,

C4.3

D 10.1, 10.2,

(2) (3)

5.1, 5.2, 5.3,

5.x

10.3, 10.x

5.1, 5.2, 5.3,

5.x

10.3, 10.x

5.x

Related Documentation

with More Information on

Catalog Number:

Installation

Instructions:

1794-IN101 NA

1794-IN128

User Manual:

(4)

I/O Modules Digital

D 10.1, 10.2,

10.3, 10.x

1794-AENT 10/100Mb Ethernet

Communication Adapter

1794-AENTR A 1.011, 1.x 1794-IN131 1794-UM066

1794-AENTRXT

1794-IB16 16 Sink Input Module A NA 1794-IN093 NA

1794-IB10XOB6 10 Input/6 Output Module A NA 1794-IN083

1794-OB16 16 Source Output Module A NA 1794-IN094

1794-OB16P 16 Protected Output Module A NA 1794-IN094

1794-OB8EP 8 Protected Output Module A NA 1794-IN094

1794-OW8 Isolated Relay Output Module A NA 1794-IN019

1794-OB8EPXT 8 Protected Output Module A NA 1794-IN124

1794-IB16XT 16 Sink Input Module A NA

1794-OB16PXT 16 Protected Output Module A NA

1794-IB10XOB6XT 10 Input/6 Output Combo

Module

1794-OW8XT 8 Relay Output Module A NA 1794-IN019

B4.1

4.2, 4.x

ANA

1794-IN082

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 10

1-6 SIL Policy

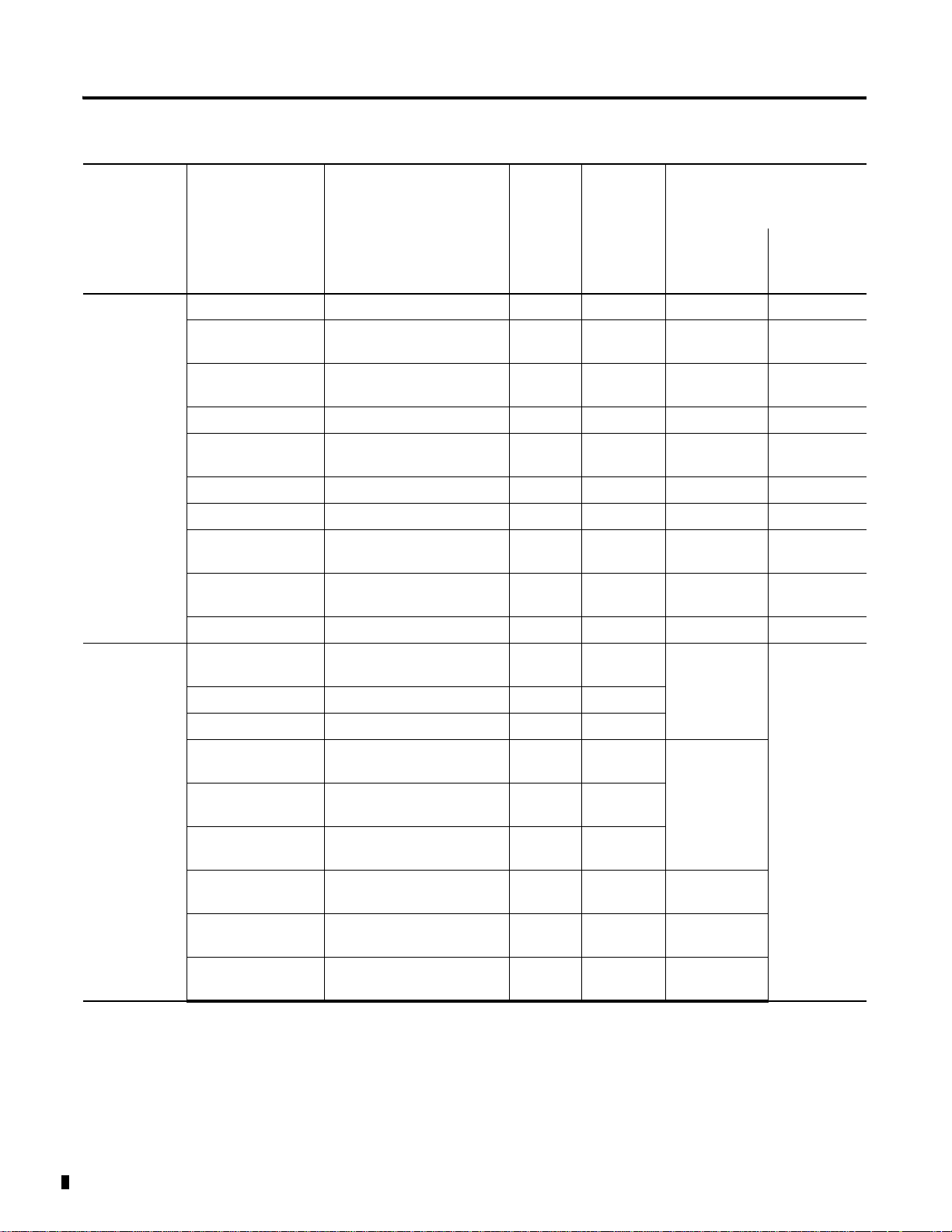

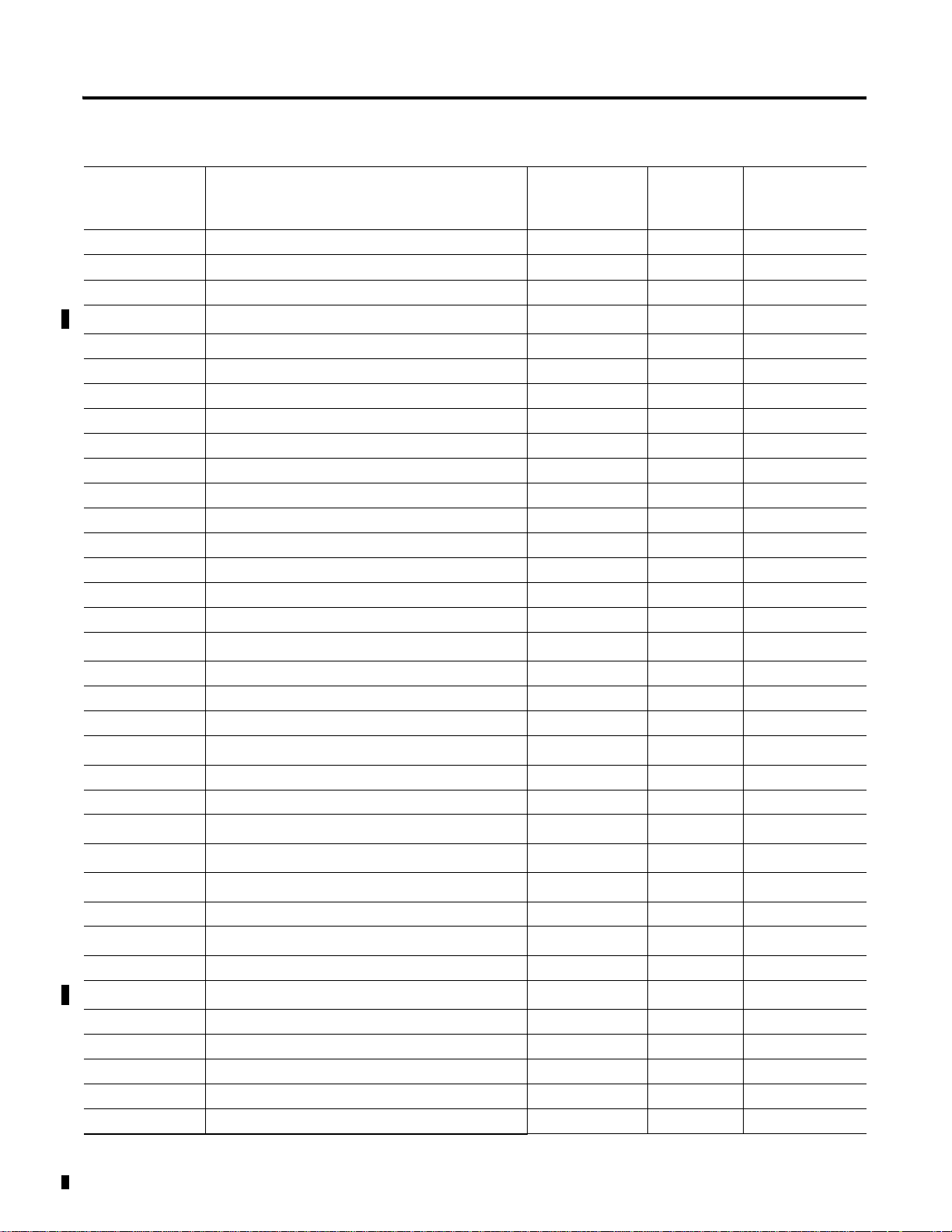

Table 1.1 FLEX I/O Components For Use in the SIL 2 System

Device Type: Catalog Number:

I/O Modules Analog

1794-IE8 8 Input Analog Module B NA 1794-IN100 1794-UM002

1794-IF4I 4 Isolated Input Analog

1794-IF2XOF2I 2 In/2 Out Isolated Combo

1794-OE4 4 Output Analog Module B NA 1794-IN100 1794-UM002

1794-OF4I 4 Isolated Output Analog

1794-IT8 Thermocouple Input Module A K, K.x 1794-IN021 1794-UM007

1794-IR8 RTD Input Module A K, K.x 1794-IN021 1794-UM004

1794-IRT8 TC/RTD Input Module B B, D, E, E.1,

1794-IJ2 2 Ch. Frequency Counter

(1)

Module

Module

Module

Module

Description:

Related Documentation

(4)

with More Information on

Catalog Number:

Series

(2)

Firmware

Revision:

(2) (3)

Installation

Instructions:

User Manual:

A F, G, H, I, I.x 1794-IN038 1794-UM008

A F, G, H, I, I.x 1794-IN039 1794-UM008

A F, G, H, I, I.x 1794-IN037 1794-UM008

1794-IN050 1794-UM012

E.x

A D 1794-IN049 1794-UM011

I/O Modules Analog

1794-IP4 4 Ch. Pulse Counter Module B 4, 4.x 1794-IN064 1794-UM016

1794-IE4XOE2XT 4 Input/2 Output Analog

B NA 1794-IN125 NA

Combo Module

1794-IE8XT 8 Input analog Module B NA

1794-OE4XT 4 Output Analog Module B NA

1794-IF2XOF2IXT 2 Input/2 Output Isolated

A I, I.x 1794-IN129

Analog Combo Module

1794-IF4IXT 4 Isolated Input Analog

A I, I.x

Module

1794-OF4IXT 4 Isolated Output Analog

A I, I.x

Module

1794-IF4ICFXT 4 Isolated Input Analog

A I, I.x 1794-IN130

Module

1794-IJ2XT 2 Ch. Frequency Counter

A E, E.x 1794-IN049

Module

1794-IRT8XT 8 TC/RTD Input Analog

B D, E, E.1, E.x 1794-IN050

Module

Publication 1794-RM001G-EN-P - December 2011

Page 11

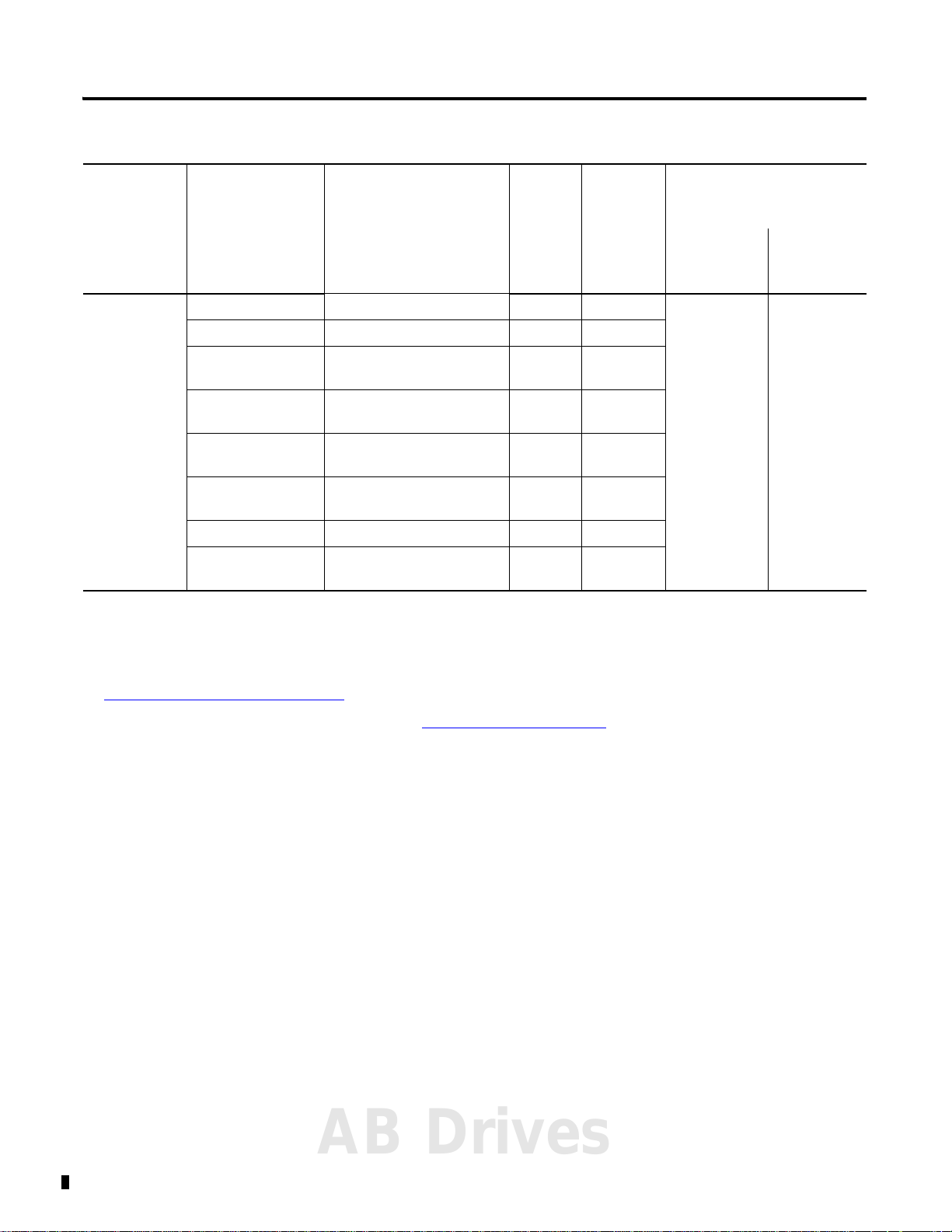

Table 1.1 FLEX I/O Components For Use in the SIL 2 System

SIL Policy 1-7

Related Documentation

with More Information on

Catalog Number:

Device Type: Catalog Number:

Terminal Base

Units

1794-TB3 3-Wire Terminal Base Unit A NA 1794-IN092 NA

1794-TB3S 3-Wire Terminal Base Unit A NA

1794-TB3T Temperature Terminal Base

Firmware

Revision:

(1)

Description:

Series

(2)

(2) (3)

ANA

Installation

Instructions:

User Manual:

Unit

1794-TB3TS Spring-clamp Temperature

ANA

Base Unit

1794-TB3G Cage-clamp Gen. Terminal

ANA

Base Unit

1794-TB3GS Spring-clamp Gen. Terminal

ANA

Base Unit

1794-TBN NEMA Terminal Base Unit A NA

1794-TBNF Fused NEMA Terminal Base

ANA

Unit

(1)

Certain catalog numbers have a K suffix. This indicates a conformally coated version of the product. These K versions have the same SIL2 certification as the non-K

versions.

(2)

The FW versions marked with extension .x (x can be 0 ... 99) are constitute to minor changes for enhancements. The test institute will be informed on any change.

(3)

Users must use these series and firmware revisions for their application to be SIL2 certified. Firmware revisions are available by visiting

http://support.rockwellautomation.com/ControlFlash/

(4)

These publications are available from Rockwell Automation by visiting http://literature.rockwellautomation.com.

(4)

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 12

1-8 SIL Policy

Hardware Designs and Firmware Functions

Difference Between PFD and PFH

Diagnostic hardware designs and firmware functions designed into the

ControlLogix/FLEX I/O platform allow it to achieve at least SIL2

certification in a single-controller configuration. These diagnostic features are

incorporated into specific FLEX I/O components, such as the:

• adapter

• power supply

• I/O modules

• terminal base units

and are covered in subsequent sections. The ControlLogix/FLEX I/O

platform’s designs, features and characteristics make it one of the most

intelligent platforms.

Table 1.2 and Table 1.3 present values of the PFDs and PFHs for the specific

FLEX I/O products evaluated by TUV.

FLEX I/O uses the same PFD and PFH assumptions as stated in publication

1756-RM001

.

Table 1.2 FLEX I/O Product Probability of Failure on Demand (PFD) Calculations (T1 = 1 yr)

Catalog Number Description Mean Time

Between Failure

(1)

(MTBF)

1794-ACN15 ControlNet Single Media Adapter 8,223,684 1.22E-07 2.15E-06

1794-ACNR15 ControlNet Redundant Media Adapter 8,223,684 1.22E-07 2.15E-06

1794-AENT 10/100Mb Ethernet Communication Adapter 691,134 1.45E-06 2.76E-05

1794-AENTR 10/100Mb Ethernet Redundant Communication Adapter 1,268,070 7.89E-07 1.45E-05

1794-IB10XOB6 10 Input/6 Output Module 4,943,442 2.02E-07 3.60E-06

1794-IB16 16 Sink Input Module 4,105,090 2.44E-07 4.34E-06

1794-IE8 Analog Input Module 37,952,679 2.63E-08 4.64E-07

1794-IF2XOF2I Isolated Analog Input/Output Module 25,296,960 3.95E-08 6.97E-07

1794-IF4I Isolated Analog Input Module 11,746,343 8.51E-08 1.50E-06

1794-IJ2 Frequency Counter Module 2,418,321 4.14E-07 7.45E-06

1794-IP4 Pulse Counter Module 2,375,360 4.21E-07 7.58E-06

1794-IR8 RTD Input Module 6,191,655 1.62E-07 2.87E-06

1794-IRT8 TC/RTD/mV Input Module 1,182,438 8.46E-07 1.56E-05

1794-IT8 Thermocouple Input Module 1,564,324 6.39E-07 1.17E-05

1794-OB16 16 Source Output Module 1,883,594 5.31E-07 9.62E-06

1794-OB16P Protected Output Module 2,135,280 4.68E-07 8.46E-06

(3)

λ

Calculated PFD

1oo2 architecture

Publication 1794-RM001G-EN-P - December 2011

Page 13

Table 1.2 FLEX I/O Product Probability of Failure on Demand (PFD) Calculations (T1 = 1 yr)

SIL Policy 1-9

Catalog Number Description Mean Time

Between Failure

(1)

(MTBF)

1794-OB8EP Protected Output Module

2,389,669

(2)

(3)

λ

4.18E-07 7.54E-06

Calculated PFD

1oo2 architecture

1794-OE4 Analog Output Module 23,807,086 4.20E-08 7.41E-07

1794-OF4I Isolated Analog Output Module 7,191,128 1.39E-07 2.47E-06

1794-OW8 Relay Output Module 14,766,876 6.77E-08 1.20E-06

1794-TB3 Terminal Base Units

21,128,346

(2)

4.73E-08 8.35E-07

1794-TB3G Generic Terminal Base Units 27,320,800 3.66E-08 6.45E-07

1794-TB3GS Generic Terminal Base Units 46,425,600 2.15E-08 3.79E-07

1794-TB3S Terminal Base Unit

1794-TB3T Temperature Terminal Base Units

1794-TB3TS Temperature Terminal Base Units

71,433,747

73,096,226

75,763,399

(2)

(2)

(2)

1.40E-08 2.46E-07

1.37E-08 2.41E-07

1.32E-08 2.32E-07

1794-TBN Terminal Base Units 75,716,615 1.32E-08 2.32E-07

1794-TBNF Fused Terminal Base Units

4,812,320

(2)

2.08E-07 3.70E-06

1794-ACNR15XT ControlNet Redundant Media Adapter 8,223,684 1.22E-07 2.15E-06

1794-AENTRXT 10/100Mb Ethernet Redundant Communication Adapter 1,268,070 7.89E-07 1.45E-05

1794-OB8EPXT 8 Protected Output Module 14,771,049 6.77E-08 1.20E-06

1794-IB16XT 16 Sink Input Module 35,587,189 2.81E-08 4.95E-07

1794-OB16PXT 16 Protected Output Module 26,709,401 3.74E-08 6.60E-07

1794-IB10XOB6XT 10 Input/6 Output Combo Module 22,202,487 4.50E-08 7.94E-07

1794-OW8XT 8 Relay Output Module 18,518,519 5.40E-08 9.53E-07

1794-IE4XOE2XT 4 Input/2 Output Analog Combo Module 11,800,802 8.47E-08 1.50E-06

1794-IE8XT 8 Input analog Module 14,041,000 7.12E-08 1.26E-06

1794-OE4XT 4 Output Analog Module 11,381,744 8.79E-08 1.55E-06

1794-IF2XOF2IXT 2 Input/2 Output Isolated Analog Combo Module 6,317,918 1.58E-07 2.81E-06

1794-IF4IXT 4 Isolated Input Analog Module 7,297,140 1.37E-07 2.43E-06

1794-IF4ICFXT 4 Isolated Input Analog Module 7,297,140 1.37E-07 2.43E-06

1794-OF4IXT 4 Isolated Output Analog Module 5,493,902 1.82E-07 3.24E-06

1794-IJ2XT 2 Ch. Frequency Counter Module 11,714,128 8.54E-08 1.51E-06

1794-IRT8XT 8 TC/RTD Input Analog Module 8,204,792 1.22E-07 2.16E-06

(1)

MTBF measured in hours.

(2)

Calculated using field-based values for components

(3)

λ = Failure Rate = 1/MTBF

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 14

1-10 SIL Policy

Table 1.3 FLEX I/O Product Probability of Undetected Dangerous Failure per Hour (PFH) Calculations (T1 = 1 yr)

Catalog Number Description Mean Time

Between Failure

(1)

(MTBF)

(3)

λ

Calculated PFH

1oo2 architecture

1794-ACN15 ControlNet Single Media Adapter 8,223,684 1.22E-07 8.64E-10

1794-ACNR15 ControlNet Redundant Media Adapter 8,223,684 1.22E-07 8.64E-10

1794-AENT 10/100Mb Ethernet Communication Adapter 691,134 1.45E-06 1.19E-08

1794-AENTR 10/100Mb Ethernet Redundant Communication Adapter

1,268,070

(2)

7.89E-07 6.05E-09

1794-IB10XOB6 10 Input/6 Output Module 4,943,442 2.02E-07 1.45E-09

1794-IB16 16 Sink Input Module 4,105,090 2.44E-07 1.76E-09

1794-IE8 Analog Input Module 37,952,679 2.63E-08 1.85E-10

1794-IF2XOF2I Isolated Analog Input/Output Module 25,296,960 3.95E-08 2.78E-10

1794-IF4I Isolated Analog Input Module 11,746,343 8.51E-08 6.02E-10

1794-IJ2 Frequency Counter Module 2,418,321 4.14E-07 3.04E-09

1794-IP4 Pulse Counter Module 2,375,360 4.21E-07 3.10E-09

1794-IR8 RTD Input Module 6,191,655 1.62E-07 1.15E-09

1794-IRT8 TC/RTD/mV Input Module 1,182,438 8.46E-07 6.53E-09

1794-IT8 Thermocouple Input Module 1,564,324 6.39E-07 4.82E-09

1794-OB16 16 Source Output Module 1,883,594 5.31E-07 3.96E-09

1794-OB16P Protected Output Module 2,135,280 4.68E-07 3.47E-09

1794-OB8EP Protected Output Module

2,389,669

(2)

4.18E-07 3.08E-09

1794-OE4 Analog Output Module 23,807,086 4.20E-08 2.96E-10

1794-OF4I Isolated Analog Output Module 7,191,128 1.39E-07 9.90E-10

1794-OW8 Relay Output Module 14,766,876 6.77E-08 4.78E-10

1794-TB3 Terminal Base Units

21,128,346

(2)

4.73E-08 3.33E-10

1794-TB3G Generic Terminal Base Units 27,320,800 3.66E-08 2.57E-10

1794-TB3GS Generic Terminal Base Units 46,425,600 2.15E-08 1.51E-10

1794-TB3S Terminal Base Unit

1794-TB3T Temperature Terminal Base Units

1794-TB3TS Temperature Terminal Base Units

71,433,747

73,096,226

75,763,399

(2)

(2)

(2)

1.40E-08 9.82E-11

1.37E-08 9.59E11

1.32E-08 9.25E-11

1794-TBN Terminal Base Units 75,716,615 1.32E-08 9.26E-11

1794-TBNF Fused Terminal Base Units

4,812,320

(2)

2.08E-07 1.49E-09

1794-ACNR15XT ControlNet Redundant Media Adapte 8,223,684 1.22E-07 8.64E-10

1794-AENTRXT 10/100Mb Ethernet Redundant Communication Adapter

1,268,070

(2)

7.89E-07 6.05E-09

1794-OB8EPXT 8 Protected Output Module 14,771,049 6.77E-08 4.78E-10

1794-IB16XT 16 Sink Input Module 35,587,189 2.81E-08 1.97E-10

1794-OB16PXT 16 Protected Output Module 26,709,401 3.74E-08 2.63E-10

1794-IB10XOB6XT 10 Input/6 Output Combo Module 22,202,487 4.50E-08 3.17E-10

1794-OW8XT 8 Relay Output Module 18,518,519 5.40E-08 3.80E-10

Publication 1794-RM001G-EN-P - December 2011

Page 15

Table 1.3 FLEX I/O Product Probability of Undetected Dangerous Failure per Hour (PFH) Calculations (T1 = 1 yr)

SIL Policy 1-11

Catalog Number Description Mean Time

Between Failure

(1)

(MTBF)

1794-IE4XOE2XT 4 Input/2 Output Analog Combo Module 11,800,802 8.47E-08 5.99E-10

1794-IE8XT 8 Input analog Module 14,041,000 7.12E-08 5.03E-10

1794-OE4XT 4 Output Analog Module 11,381,744 8.79E-08 6.22E-10

1794-IF2XOF2IXT 2 Input/2 Output Isolated Analog Combo Module 6,317,918 1.58E-07 1.13E-09

1794-IF4IXT 4 Isolated Input Analog Module 7,297,140 1.37E-07 9.75E-10

1794-IF4ICFXT 4 Isolated Input Analog Module 7,297,140 1.37E-07 9.75E-10

1794-OF4IXT 4 Isolated Output Analog Module 5,493,902 1.82E-07 1.30E-09

1794-IJ2XT 2 Ch. Frequency Counter Module 11,714,128 8.54E-08 6.04E-10

1794-IRT8XT 8 TC/RTD Input Analog Module 8,204,792 1.22E-07 8.66E-10

(1)

MTBF measured in hours.

(2)

Calculated using field-based values for components

(3)

λ = Failure Rate = 1/MTBF

(3)

λ

Calculated PFH

1oo2 architecture

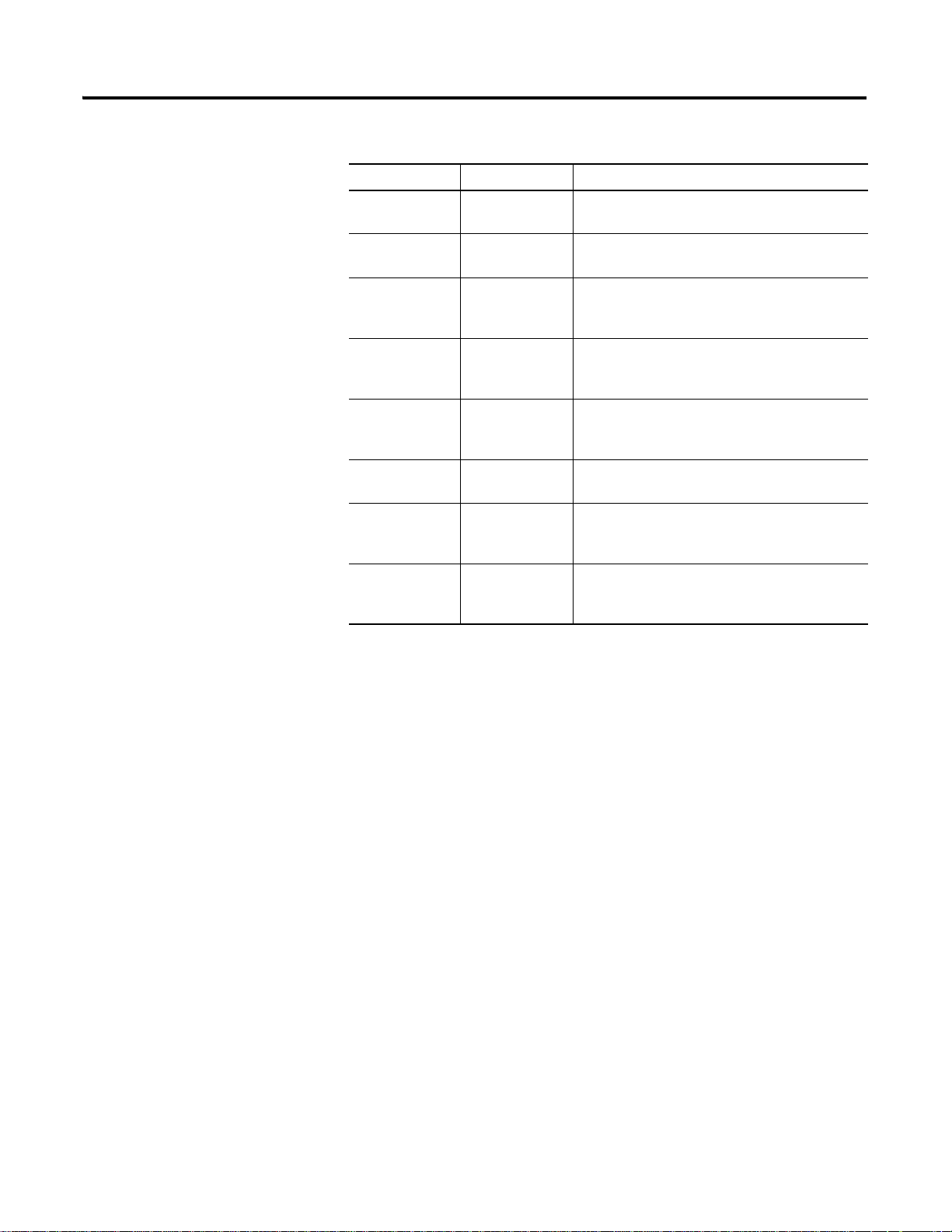

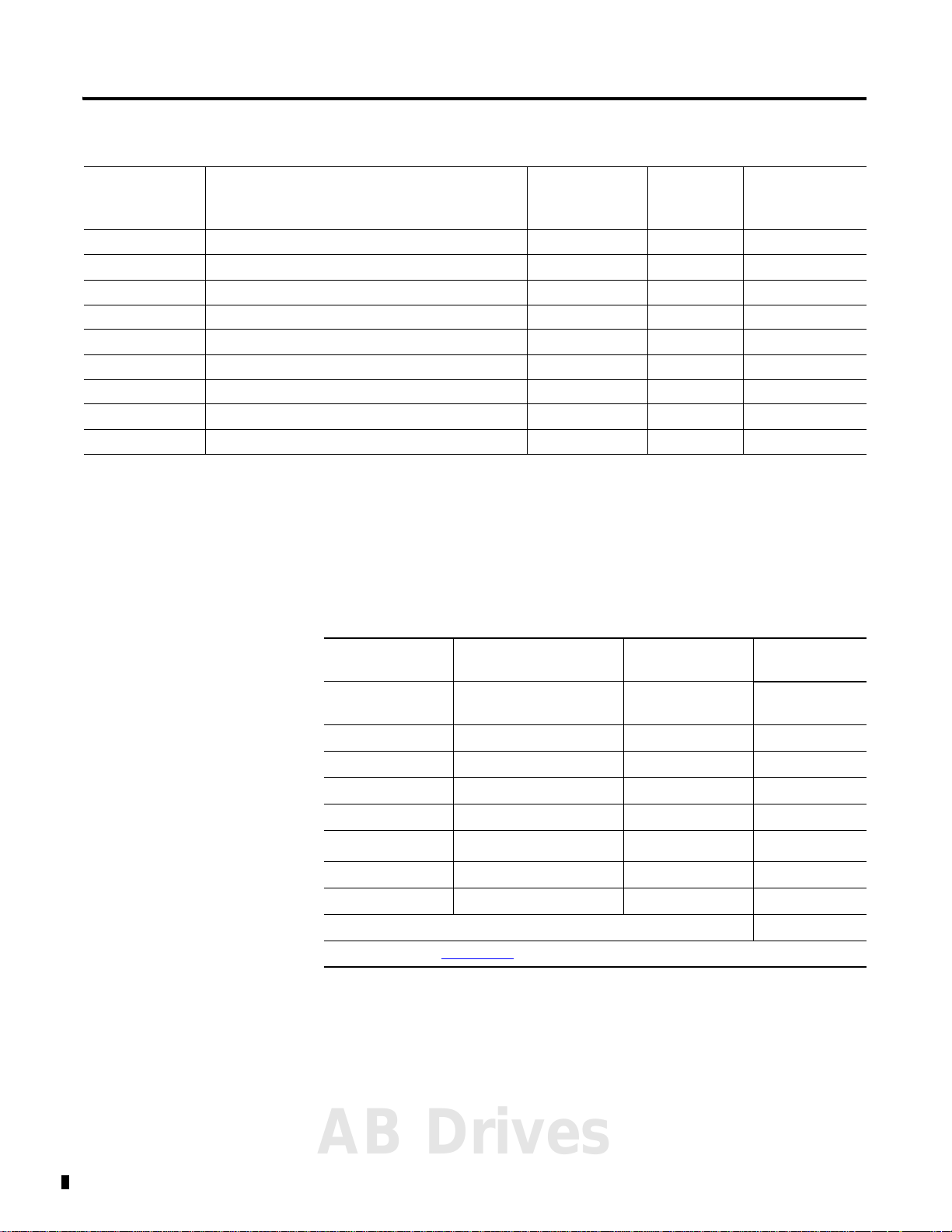

Table 1.4 shows an example of a PFD calculation for a safety loop involving

two DC input modules used in a 1oo2 configuration and a DC output module.

Table 1.4

Catalog Number: Description: MTBF: Calculated

1oo2 PFD:

1794-ACNR15 ControlNet Dual Media

Adapter 1.5

1794-IB16 24V DC Input Module 6,409,846 4.34E-06

1794-IB16 24V DC Input Module 6,409,846 4.34E-06

1794-OB16 24V DC Output Module 4,284,857 9.62E-06

1794-OW8 Relay Output Module 1,312,973 1.20E-06

1756-L63B

1756-CNB ControlNet Bridge Module 3,596,087 1.15E-04

1756-CNB ControlNet Bridge Module 3,596,087 1.15E-04

Total PFD calculation for a safety loop consisting of these products: 3.70E-04

1 See Publication 1756-RM001

1

ControlLogix Controller 2,460,065 2.33E-04

for more information.

3,259,605 1.56E-06

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 16

1-12 SIL Policy

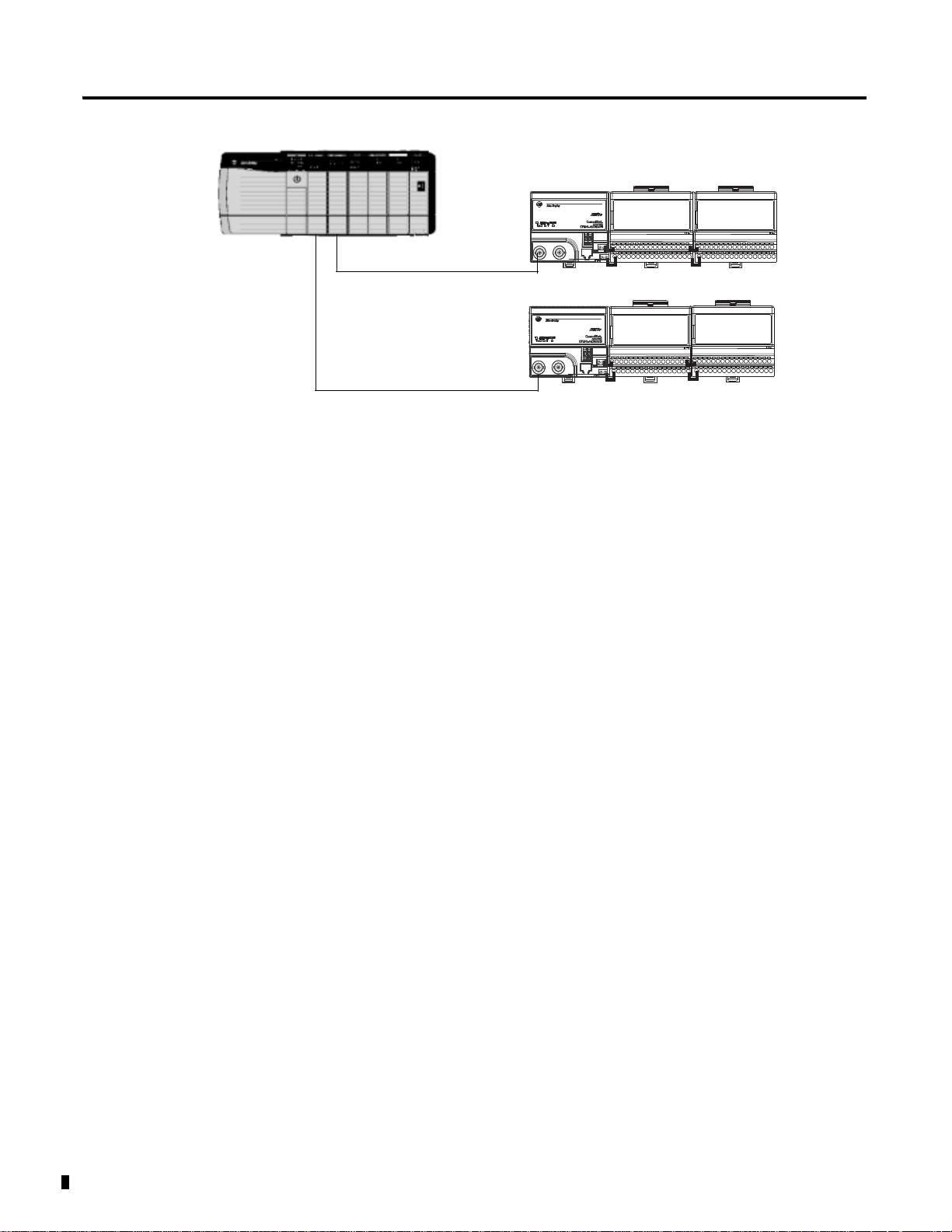

B

B

1794-OB16

1794-IB16

1794-TB3 (1)

1794-TB3 (2)

1794-ACNR15 (1)

1794-ACNR15 (2)

1794-IB16

1794-OW8

1756-CNB

1756-L63B

ControlNet

ControlNet

1756-CNB

Publication 1794-RM001G-EN-P - December 2011

Page 17

SIL Policy 1-13

SIL Compliance Distribution and Weight

Response Times

The programmable controller may conservatively be assumed to contribute

10% of the reliability burden. A SIL 2 system may need to incorporate multiple

inputs for critical sensors and input devices, as well as dual outputs connected

in series to dual actuators dependent on SIL assessments for the safety related

system.

The response time of the system is defined as the amount of time it takes for a

change in an input condition to be recognized and processed by the

controller’s ladder logic program, and then to initiate the appropriate output

signal to an actuator. The system response time is the sum of the following:

• input hardware delays

• input filtering

• I/O and communication module RPI settings

• controller program scan times

• output module propagation delays

See Table 1.1 for associated module information.

Each of the times listed above is variably dependent on factors such as the type

of I/O module and instructions used in the ladder program. For examples of

how to perform these calculations, see publication 1756-RM001

.

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 18

1-14 SIL Policy

Notes:

Publication 1794-RM001G-EN-P - December 2011

Page 19

Chapter

2

ControlLogix Communications

This chapter discusses the communication modules used in a ControlLogix

SIL2 system.

For information about: See page:

ControlNet Bridge Module 2-1

EtherNet/IP Bridge Module 2-1

ControlNet Bridge Module

Related Communications Modules

Documentation

The ControlNet bridge modules (1756-CNB & 1756-CNBR) provide for the

communications between ControlLogix and FLEX I/O system.

2-3

ControlNet Cabling

For remote racks, 802.3 compliant shielded or unshielded twisted pair cable is

required for EtherNet/IP. Although it is not a requirement to use redundant

media with the 1756-CNBR, it does provide higher system availability.

Redundant media is not required for SIL2 operation.

ControlNet Module Diagnostic Coverage

All communications over the passive ControlNet media occur via CIP, which

guarantees delivery of the data. All modules independently verify proper

transmission of the data.

EtherNet/IP Bridge Module

The EtherNet/IP bridge modules (1756-ENBT, 1756-EN2T, 1756-EN2TR,

and 1756-EN2TXT) provide for the communications between ControlLogix

and FLEX I/O system.

AB Drives

1 Publication 1794-RM001G-EN-P - December 2011

Page 20

2-2 ControlLogix Communications

EtherNet/IP Cabling

802.3 compliant shielded or unshielded twisted pair cable is required for

EtherNet/IP.

EtherNet/IP Module Diagnostic Coverage

Communications over 10/100 MbpsNet media occur via CIP, which

guarantees delivery of the data. All modules independently verify proper

transmission of the data.

Module Fault Reporting for any FLEX I/O Module

To monitor the connection status for this type of connection, use a Get

System Value (GSV) and an examination of MODULE objects’ "Entry Status"

attribute for a running connection.

An example of how this might be done is shown in Figure 2.1. This method,

or something similiar, must be used to interrogate the health of each I/O

module in the system.

Figure 2.1 Example of Checking a Module’s Health in Ladder Logic

GSV

Obtain MODULE

Object’s Entry Status

NEQ

Check Entry Status to

make sure module is

running

AND

Mask Off Lower 12

Bits of Value

Fault

For more information on the GSV instruction, monitor the SlotStatusBits for

the Input tag of the associated adapter. The lower 8 bits of this tag correspond

to the associated slot. For example, the tag "Node3:I.SlotlStatusBits" is defined

as follows:

Publication 1794-RM001G-EN-P - December 2011

NODE3 - This is the name given to the associated 1794-AVNR15.

I = This indicates the Input file.

Page 21

ControlLogix Communications 2-3

Module

0

Module

1

Module

2

Module

3

Module

4

Module

5

Module

6

Module

7

SlotStatusBits - This is a 32 bit value. The lower 8 bits of this value are defined

as follows for FLEX I/O:

Related Communications Modules Documentation

For more information on ControlLogix communications modules, see the

following Rockwell Automation publications listed in Table 2.1:

Table 2.1

Catalog

Number: Description:

1756-CNB ControlNet Communication

Module

1756-CNBR Redundant ControlNet

Communication Module

Installation

Instructions:

1756-IN571

User Manual:

CNET-UM001

These publications are available from Rockwell Automation at:

http://literature.rockwellautomation.com

.

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 22

2-4 ControlLogix Communications

Publication 1794-RM001G-EN-P - December 2011

Page 23

Chapter

FLEX I/O Modules

This chapter discusses the FLEX I/O modules that are SIL2 certified.

For information about: See page:

Overview of FLEX I/O Modules 3-1

Using Digital Input Modules 3-2

Wiring FLEX I/O Digital Input Modules 3-3

General Considerations when using Any FLEX

I/O Digital Output Module

Wiring FLEX I/O Digital Output Modules 3-5

Using Analog Input Modules 3-7

3-4

3

Overview of FLEX I/O Modules

Wiring FLEX I/O Analog Input Modules 3-9

Checklist for SIL Inputs 3-18

Checklist for SIL Outputs 3-19

In the most basic description, there are two types of SIL2-certified FLEX I/O

modules:

• Digital I/O modules

• Analog I/O modules

With each type, however, there are differences between specific modules.

Because the differences propagate to varying levels in each module type, a

graphical representation can best provide an overview of the many

SIL2-certified FLEX I/O modules.

FLEX I/O modules are designed with inherent features that assist them in

complying with the requirements of the 61508 Standard. For example, the

modules all have a common backplane interface, execute power-up and

runtime diagnostics, and offer electronic keying.

Table 1.1 lists the FLEX I/O modules initially submitted for SIL2

certification.

AB Drives

1 Publication 1794-RM001G-EN-P - December 2011

Page 24

3-2 FLEX I/O Modules

Using Digital Input Modules

General Considerations when using Any FLEX I/O Digital Input Module

Regardless of the type of FLEX I/O input module used, there are a number of

general application considerations that users must follow when applying these

modules in a SIL2 application:

• Proof Tests - Periodically (for example, once every several years) a

System Validation test must be performed. Manually, or automatically,

test inputs to make sure that all inputs are operational and not stuck in

the ON or OFF state. Inputs must be cycled from ON to OFF or OFF

to ON. .

• Wire sensors to separate input points on two separate modules that are

on different ControlNet nodes.

• Configuration parameters (for example, RPI, filter values) must be

identical between the two modules.

• The same controller must own both modules.

• Monitor the ControlNet status bits for the associated module and

ensure that appropriate action is invoked via the application logic by

these status bits.

Publication 1794-RM001G-EN-P - December 2011

Page 25

FLEX I/O Modules 3-3

Input 1 Input 2

Input

COM

+24V

12 3 45 67 891011121314150

24VDC SINK INPUT

1794-IB16

12 3 45 67 891011121314150

24VDC SINK INPUT

1794-IB16

12 3 45 67 891011121314150

24VDC SINK INPUT

1794-IB16

12 3 45 67 891011121314150

24VDC SINK INPUT

1794-IB16

Input

COM

+24V

Input 1 Input 2

SIL2 SENSOR

SENSOR

SENSOR

+24V dc

Optional relay contact

to switch line voltage

for periodic automated

testing

43366

One-Sensor Wiring Example

Two-Sensor Wiring Example

43366

Note 1: Both sensors are monitoring the same safety application.

1

1

Input BInput A

Actuator

Input BInput A

Input BInput A

Tim er

Timer preset in milliseconds to

compensate for filter time and

hardware delay differences.

Fault

Timer Done

Alarm to Operator

Fault

Wiring FLEX I/O Digital Input Modules

The wiring diagrams in Figure 3.1 show two methods of wiring the digital

input Module. In either case, users must determine whether the use of 1 or 2

sensors is appropriate to fulfill SIL2 requirements.

Figure 3.1 ControlLogix Digital Input Module Wiring

Application logic can compare input values or states for concurrence.

Figure 3.2

The user program must also contain rungs to annunciate a fault in the event of

a sustained miscompare between two points.

Figure 3.3

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 26

3-4 FLEX I/O Modules

The control, diagnostics and alarming functions must be performed in

sequence. For more information on faults, see publication 1756-RM001

.

General Considerations when using Any FLEX I/O Digital Output Module

Regardless of the type of FLEX I/O output module used, there are a number

of general application considerations that you must follow when applying

these modules in a SIL2 application:

• Proof Tests - Periodically (for example, once every several years) a

System Validation test must be performed. Manually, or automatically,

test outputs to make sure that all outputs are operational and not stuck

in the ON or OFF state. Outputs must be cycled from ON to OFF or

OFF to ON. For additional information, refer to publication

1756-RM001

.

Figure 3.4

Application Logic

Output Bit

Output Bit

Timer done

Fault

Monitoring Input

Monitoring Input

Output Fault

Actuator

Tim er

Fault

Alarm to Operator

The control, diagnostics and alarming functions must be performed in

sequence..

• Use of external Relays to disconnect Module Power if Output

De-energization is Critical: To make sure outputs will de-energize,

users must wire an external method that can remove power from the

actuator if a short or other fault is detected.

Publication 1794-RM001G-EN-P - December 2011

• Test outputs at specific times to make sure they are operating

properly. The method and frequency of testing is determined by the

type of module.

Page 27

FLEX I/O Modules 3-5

12 345 67 891011121314150

24VDC SOURCE OUTPUT

1794-OB16

1 2 3 4 5 6 7 8 91011121314150

24VDC SINK INPUT

1794-IB16

Standard Digital

Output Module

43363

Standard Digital

Input Module

+24V

COM

Output

Actuator

Install a relay in position A or B. This relay is controlled by another

output in the ControlLogix/FLEX I/O system. If a short circuit or fault

occurs on output modules, the relay can disconnect power to the

modules. An isolated relay output module (1794-OW8) can be used for

this purpose when it is connected to a different 1794-ACN15 or

-ACNR15 ControlNet Adapter module.

Wire output point

to input point to

verify the correct

state of the output

COM

24V dc

A

B

Note: Other configurations are possible as long they are

SIL2 approved.

• Monitor the ControlNet status bits for the associated module and

ensure that appropriate action is invoked via the application logic by

these status bits.

Wiring FLEX I/O Digital Output Modules

Standard Digital Output Modules

When using standard output modules, users must wire an output to an

actuator and then back to an input to monitor the output’s performance.

In addition to following the General Considerations when using Any FLEX

I/O Digital Output Module on page 3-4, the user must wire each standard

output to a corresponding input to validate that the output is following its

commanded state.

Figure 3.5 ControlLogix/FLEX I/O Standard Output Module Wiring

Application logic must be written to generate a fault in the event of a

miscompare between the requested state of an output (echo) and the actual

output state monitored by an input channel (see Figure 3.4).

The control, diagnostics and alarming functions must be performed in

sequence.

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 28

3-6 FLEX I/O Modules

1 2 3 4 5 67 8910 11121314150

24VDC SINK INPUT

1794-IB16

1 2 3 4 5 67 8910 11121314150

24VDC SOURCE OUTPUT

1794-OB16

1 2 3 4 5 67 8910 11121314150

24VDC SOURCE OUTPUT

1794-OB16

Isolated Relay

Output Module

43364

Standard Digital

Input Module

Standard Digital

Output Module

+24V

COM

Wire output point

to input point to

verify the correct

state of the output

Output

Output

Actuator

+24V

COM

Note 1: An external relay can be replaced with an isolated

relay module which is mounted in another FLEX I/O rail.

Users can also wire a standard digital output module in series with an isolated

relay output module in series with a critical actuator. In the event that a failure

is detected, the output from both output modules must be set to OFF to

guarantee the Output Loads de-energize. This is shown in Figure 3.6.

Figure 3.6 ControlLogix/FLEX I/O Standard Output Module Wiring With an Isolated

Relay Module

Publication 1794-RM001G-EN-P - December 2011

Page 29

FLEX I/O Modules 3-7

Using Analog Input Modules

General Considerations when using Any FLEX I/O Analog Input Module

There are a number of general application considerations that you must follow

when applying these modules in a SIL2 application:

• Proof Tests - Periodically (for example, once every several years) a

System Validation test must be performed. Manually, or automatically,

test inputs to make sure that all inputs are operational. Field signal levels

should be varied over the full operating range to make sure that the

corresponding channel data varies accordingly. For additional

information, refer to publication 1756-RM001

• Calibrate Inputs Periodically, As Necessary: FLEX I/O modules

ship from the factory with a highly accurate level of calibration.

However, because each application is different, users are responsible for

making sure their FLEX I/O modules are properly calibrated for their

specific application.

Users can employ tests in application program logic to determine when

a module requires recalibration. For example, to determine whether an

input module needs to be recalibrated, a user can determine a tolerance

band of accuracy for a specific application. The user can then measure

input values on multiple channels and compare those values to

acceptable values within the tolerance band. Based on the differences in

the comparison, the user could then determine whether recalibration is

necessary.

.

Calibration (and subsequent recalibration) is not a safety issue.

However, we recommend that each analog input be calibrated at least

every 3 years to verify the accuracy of the input signal and avoid

nuisance application shutdowns.

• Compare Analog Input Data and Annunciate Miscompares: When

wiring sensors to two inputs channels, the values from those channels

must be compared to each other for concurrence within an acceptable

range for the application before actuating an output. Any miscompare

between the two inputs outside the programmed acceptable range must

be annunciated as a fault.

In Figure 3.7, a user-defined percentage of acceptable deviation (that is,

tolerance) is applied to the configured input range of the analog inputs

(that is, range) and the result is stored (that is, delta). This delta value is

then added to and subtracted from one of the input channels; the results

define an acceptable High and Low limit of deviation. The second input

channel is then compared to these limits to determine if the input are

working properly.

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 30

3-8 FLEX I/O Modules

Timer done

Tim er

Inputs Faulted

Alarm to Operator

Inputs OK

SUB

Delta

Input 1

Low Limit

ADD

Delta

Input 1

High Limit

MULT

Range

Tole rance %

Delta

Inputs Faulted

LIM

Low Limit

Input 2

High Limit

Inputs OK

The input’s OK bit preconditions a Timer run that is preset to

accommodate an acceptable fault response time and any communication

filtering lags in the system. If the inputs miscompare for longer than the

preset value, a fault is registered with a corresponding alarm.

Figure 3.7

The control, diagnostics and alarming functions must be performed in

sequence.

• Configuration parameters (for example, RPI, filter values) must be

identical between the two modules.

• The same controller must own both modules.

• Monitor the ControlNet status bits for the associated module and

ensure that appropriate action is invoked via the application logic by

these status bits.

• Wire sensors to separate input channels on two separate modules that

are on different ControlNet nodes.

Publication 1794-RM001G-EN-P - December 2011

Page 31

FLEX I/O Modules 3-9

Input 1 Input 2

Input

COM

+24V

Input

COM

+24V

Input 1 Input 2

SIL2 SENSOR

SENSOR

43366A

One-Sensor Wiring Example

Two-Sensor Wiring Example

SENSOR

Note 1: Both sensors are monitoring the same safety application.

1

1

Voltage

Transmitter A

1794-TB3

1794-TB3

1794-TB3

1794-TB3

Analog Input

1794-IE8

Analog Input

1794-IE8

Analog Input

1794-IF4I

Analog Input

1794-IF4I

Voltage

Transmitter A

Voltage

Transmitter B

Voltage

Transmitter B

+

-

+

-

+

-

+

-

Wiring FLEX I/O Analog Input Modules

The wiring diagrams in show two methods of wiring the analog input

Module. In either case, users must determine whether the use of 1 or 2

sensors is appropriate to fulfill SIL2 requirements.

Figure 3.8 ControlLogix Analog Input Module Wiring

Wiring the Single-Ended Input Module in Voltage Mode

In addition to following the General Considerations when using Any FLEX

I/O Analog Input Module on page 3-7, make sure you use the correct

documentation (listed in Table 1.1 on page 1-5) to wire the module.

Figure 3.9 FLEX I/O Analog Input Module Wiring in Voltage Mode

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 32

3-10 FLEX I/O Modules

RET

RET

RET

RET

Current

Source B

Current

Source B

Current

Source A

Current

Source A

1794-TB3

1794-TB3

1794-TB3

1794-TB3

1794-IE8

Analog Input

1794-IE8

Analog Input

1794-IE8

Analog Input

1794-IF4I

Analog Input

1794-IF4I

Wiring the Single-Ended Input Module in Current Mode

In addition to following the General Considerations when using Any FLEX

I/O Analog Input Module on page 3-7, before wiring the module, consider

the following application guideline:

• Placement of Other Devices in Current Loop: you can locate other

devices in an input channel’s current loop anywhere as long as the

current source can provide sufficient voltage to accommodate all of the

voltage drops (each module input is 250 ohms)

Publication 1794-RM001G-EN-P - December 2011

Page 33

FLEX I/O Modules 3-11

+

-

+

-

+

-

+

-

Thermocouple

Input Module

Thermocouple

Input Module

Thermocouple/

RTD/mV

Input Module

Thermocouple/

RTD/mV

Input Module

1794-TB3T

1794-TB3T

1794-TB3G

1794-TB3G

1794-IT8

1794-IT8

1794-IRT8

1794-IRT8

Wiring the Thermocouple Input Module

In addition to following the General Considerations when using Any FLEX

I/O Analog Input Module on page 3-7, before wiring the module, consider

the following application guideline:

• Wire to Same Input Channel on Both Modules: When wiring

thermocouples, wire two in parallel to two modules. Use the same

channel on each module to make sure of consistent temperature

readings.

Figure 3.10 FLEX I/O Analog Thermocouple Module Wiring

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 34

3-12 FLEX I/O Modules

RTD

Input Module

RTD

Input Module

Thermocouple/

RTD/mV

Input Module

Thermocouple/

RTD/mV

Input Module

1794-TB3T

1794-TB3T

1794-TB3G

1794-TB3G

1794-IR8

1794-IR8

1794-IRT8

1794-IRT8

4-Wire RTD

3-Wire RTD

Note: 2, 3, or 4-wire RTDs can be used as applicable to the associated RTD input module.

Wiring the RTD Input Module

In addition to following the General Considerations when using Any FLEX

I/O Analog Input Module on page 3-7, before wiring the module, consider

the following application guideline:

• RTDs cannot be wired in parallel without severely affecting their

accuracy. Two sensors must be used.

Figure 3.11 FLEX I/O Analog RTD Module Wiring

Publication 1794-RM001G-EN-P - December 2011

Page 35

FLEX I/O Modules 3-13

Using Analog Output Modules

General Considerations when using Any FLEX I/O Analog Output Module

There are a number of general application considerations that you must follow

when applying the analog output modules in a SIL2 application:

• Proof Tests - Periodically (for example, once every several years) a

System Validation test must be performed. Manually, or automatically,

test outputs to make sure that all outputs are operational. Channel data

should be varied over the full operating range to make sure that the

corresponding field signal levels vary accordingly. For additional

information on , see Publication 1756-RM001

• Calibrate Outputs Periodically, As Necessary: FLEX I/O modules

ship from the factory with a highly accurate level of calibration.

However, because each application is different, users are responsible for

making sure their FLEX I/O modules are properly calibrated for their

specific application.

Users can employ tests in application program logic to determine when

a module requires recalibration. For example, to determine whether an

output module needs to be recalibrated, a user can determine a tolerance

band of accuracy for a specific application. The user can then measure

output values on multiple channels and compare those values to

acceptable values within the tolerance band. Based on the differences in

the comparison, the user could then determine whether recalibration is

necessary.

.

Calibration (and subsequent recalibration) is not a safety issue.

However, we recommend that each analog output be calibrated at least

every 3 years to verify the accuracy of the input signal and avoid

nuisance application shutdowns.

• For typical emergency shutdown (ESD) applications outputs must

be configured to De-energize: When configuring any FLEX I/O

output module, each output must be configured to de-energize in the

event of a fault and in the event of the controller going into program

mode. For exceptions to the typical ESD applications, see publication

1756-RM001

.

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 36

3-14 FLEX I/O Modules

Timer done

Tim er

Outputs Faulted

Alarm to Operator

Outputs OK

ADD

Delta

Monitoring input

High Limit

MULT

Range

Tole rance %

Delta

Outputs Faulted

LIM

Low Limit

Output Echo

High Limit

Outputs OK

SUB

Delta

Monitoring input

Low Limit

• Wire Output Back to Input and Examination of Output Data

Feedback signal: Users must wire an analog output to an actuator and

then back to an analog input to monitor the output’s performance. (The

use of feedback transmitters to verify an output’s performance is

acceptable.) The application logic must examine the Data Feedback

value associated with each output point to make sure that the requested

output command from the controller was received by the module. The

value must be compared to the analog input that is monitoring the

output to make sure the value is in an acceptable range for the

application.

In the ladder diagram in Figure 3.12, a user-defined percentage of

acceptable deviation (that is, tolerance) is applied to the configured

range of the analog input and output (that is, range) and the result is

stored (that is, delta). This delta value is then added to and subtracted

from the monitoring analog input channel; the results define an

acceptable High and Low limit of deviation. The analog Output

Feedback is then compared to these limits to determine if the output are

working properly.

The output’s OK bit preconditions a Timer run that is preset to

accommodate an acceptable fault response time and any communication

filtering, or output, lags in the system. If the monitoring input value and

the Output Feedback miscompare for longer than the preset value, a

fault is registered with a corresponding alarm.

Figure 3.12 Monitoring an Analog Output with an Analog Input

Publication 1794-RM001G-EN-P - December 2011

The control, diagnostics and alarming functions must be performed in

sequence.

Page 37

FLEX I/O Modules 3-15

• When wiring two analog output modules in the same application, make

sure:

– Both modules use identical configuration.

– The same controller owns both modules.

• Monitor the ControlNet status bits for the associated module and

ensure that appropriate action is invoked via the application logic by

these status bits.

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 38

3-16 FLEX I/O Modules

+

_

V RET

+

_

V RET

1794-TB3

1794-IF4I

Analog Output

Module

1794-TB3

1794-IE8

Analog Input

Module

Isolated Analog

Output Module

Isolated Analog

Input Module

1794-OF4I

1794-TB3

1794-TB3

Actuator

Actuator

1794-OE4

Wiring FLEX I/O Analog Output Modules

In general, good design practice dictates that each analog output must be wired

to a separate input terminal to make sure that the output is functioning

properly.

Wiring the Analog Output Module in Voltage Mode

Users must wire analog outputs to an actuator and then back to an analog

input to monitor the output performance.

Publication 1794-RM001G-EN-P - December 2011

Page 39

FLEX I/O Modules 3-17

1794-TB3

1794-IF4I

Analog Output

Module

1794-TB3

1794-IE8

Analog Input

Module

Isolated Analog

Output Module

Isolated Analog

Input Module

1794-OF4I

1794-TB3

1794-TB3

Actuator

Actuator

1794-OE4

Wiring the Analog Output Module in Current Mode

In addition to following the General Considerations when using Any FLEX

I/O Analog Output Module on page 3-13, consider the following application

guideline before wiring the module in current mode:

• Placement of Other Devices in Current Loop: you can locate other

devices in an output channel’s current loop anywhere as long as the

current source can provide sufficient voltage to accommodate all of the

voltage drops.

+

+

_

_

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 40

3-18 FLEX I/O Modules

Checklist for SIL Inputs

The following checklist is required for planning, programming and start up of

SIL inputs. It may be used as a planning guide as well as during proof testing. If

used as a planning guide, the checklist can be saved as a record of the plan.

For programming or start-up, an individual checklist can be filled in for every

single SIL input channel in a system. This is the only way to make sure that the

requirements were fully and clearly implemented. This checklist can also be

used as documentation on the connection of external wiring to the application

program.

Input Check List for ControlLogix/FLEX I/O System

Company:

Site:

Loop definition:

SIL input channels in the:

No. All Input Module Requirements (apply to both digital and analog input modules) Yes No Comment

1 Is the RPI value set to an appropriate value for your application?

2 Are all modules owned by the same controller?

3 Have you performed proof tests on the system and modules?

4 Have you set up the fault routines?

5 Are control, diagnostics and alarming functions performed in sequence in application logic?

Note: The user must ensure that the hardware series and the firmware series and revision of the FLEX I/O

modules in their system are SIL2 certified.

6 Is the application logic monitoring one ControlNet status bit for the associated module and is appropriate

action invoked via the application logic by these bits?

No. Additional Digital Input Module-Only Requirements Yes No Comment

1 When two digital input modules are wired in the same application, do the following conditions exist:

• Both modules are owned by the same controller.

• Sensors are wired to separate input points.

• The operational state is ON.

• The non-operational state is. OFF.

• Configuration parameters (for example, RPI, filter values) are identical.

• Both input modules are on different ControlNet nodes.

2 For the standard input modules, is the Communication Format set to one of the Input Data choices?

No. Additional Analog Input Module-Only Requirements Yes No Comment

1 Have you calibrated the modules as often as required by your application?

2 Are you using ladder logic to compare the analog input data on two channels to make sure there is

concurrence within an acceptable range and that redundant data is used properly?

3 Have you written application logic to examine bits for any condition that may cause a fault and appropriate

fault routines to handle the fault condition?

4 When wiring the FLEX I/O analog module in voltage mode, are transmitter connections wired correctly?

5 When wiring the FLEX I/O analog module in current mode, are loop devices placed properly?

6 When wiring FLEX I/O thermocouple modules in parallel, have you wired to the same channel on each

module?

7 When wiring two FLEX I/O RTD modules, are two sensors used?

8 When two analog inputs are wired in the same application, are both modules on different ControlNet Nodes?

Publication 1794-RM001G-EN-P - December 2011

Page 41

FLEX I/O Modules 3-19

Checklist for SIL Outputs

The following checklist is required for planning, programming and start up of

SIL outputs. It may be used as a planning guide as well as during proof testing.

If used as a planning guide, the checklist can be saved as a record of the plan.

For programming or start-up, an individual requirement checklist must be

filled in for every single SIL output channel in a system. This is the only way to

make sure that the requirements are fully and clearly implemented. This

checklist can also be used as documentation on the connection of external

wiring to the application program.

Output Check List for ControlLogix/FLEX I/O System

Company:

Site:

Loop definition:

SIL output channels in the:

No. All Output Module Requirements (apply to both digital and analog output modules) Yes No Comment:

1 Have you performed proof tests on the modules?

2 Is the RPI value set to an appropriate value for your application?

3 Have you set up fault routines, including comparing output data with a corresponding input point?

4 If required, have you used external relays in your application to disconnect module power if a short or

other fault is detected on the module or isolated output in series?

5 Is the control of the external relay implemented in ladder logic?

6 Have you examined the Output Data feedback signal in application logic?

7 Are all outputs configured to deenergize in the event of a fault or the controller entering program

mode?

8 Do two modules of the same type, used in the same application, use identical configurations?

9 Does one controller own both modules if two of the same type are used in an application?

10 Are control, diagnostics and alarming functions performed in sequence in application logic?

11 Is the application logic monitoring one ControlNet status bit for the associated module and is

appropriate action invoked via the application logic by these bits?

No. Digital Output Module-Only Requirements Yes No Comment

1 For the standard output modules, is the Communication Format set to Output Data?

2 For standard output modules, have you wired the outputs to a corresponding input to validate that the

output is following its commanded state?

No. Analog Output Module-Only Requirements Yes No Comment

1 Have you calibrated the modules as often as required by your application?

2 When wiring the FLEX I/O analog output module in current mode, are loop devices placed properly?

3 Have you written application logic to examine bits for any condition that may cause a fault and

appropriate fault routines to handle the fault condition?

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 42

3-20 FLEX I/O Modules

Notes:

Publication 1794-RM001G-EN-P - December 2011

Page 43

Chapter

General Requirements for

Application Software

Refer to publication 1756-RM001, Using ControlLogix in SIL2 Applications.

4

AB Drives

1 Publication 1794-RM001G-EN-P - December 2011

Page 44

4-2 General Requirements for Application Software

Notes:

Publication 1794-RM001G-EN-P - December 2011

Page 45

Chapter

Technical SIL2 Requirements for the

Application Program

Refer to publication 1756-RM001 for Technical SIL2 Requirements for the

application program.

5

AB Drives

1 Publication 1794-RM001G-EN-P - December 2011

Page 46

5-2 Technical SIL2 Requirements for the Application Program

Notes:

Publication 1794-RM001G-EN-P - December 2011

Page 47

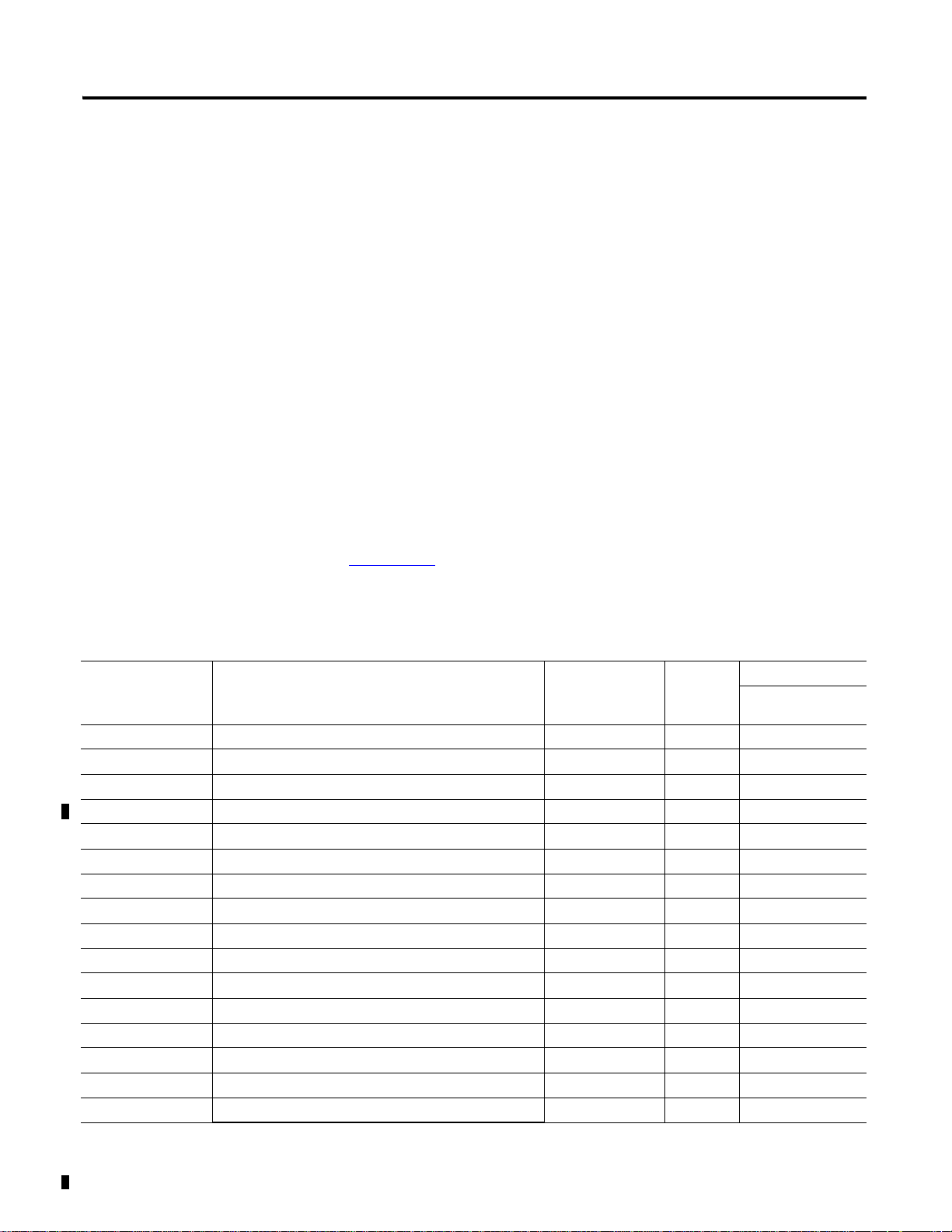

Failure Estimates

The following tables list the failure estimates for the FLEX I/O products

included in this manual for different proof test intervals.

Table A.1 MTBF Field Data and Per Module PFD Estimates - T1 = 1 year

Appendix

A

Catalog Number: Description:

1794-ACN15 ControlNet Single Media Adapter 8,223,684 1.22E-07 2.15E-06

1794-ACNR15 ControlNet Redundant Media Adapter 8,223,684 1.22E-07 2.15E-06

1794-AENT 10/100Mb Ethernet Communication Adapter 691,134 1.45E-06 2.76E-05

1794-AENTR 10/100Mb Ethernet Redundant Communication Adapter 1,268,070 7.89E-07 1.45E-05

1794-IB10XOB6 10 Input/6 Output Module 4,943,442 2.02E-07 3.60E-06

1794-IB16 16 Sink Input Module 4,105,090 2.44E-07 4.34E-06

1794-IE8 Analog Input Module 37,952,679 2.63E-08 4.64E-07

1794-IF2XOF2I Isolated Analog Input/Output Module 25,296,960 3.95E-08 6.97E-07

1794-IF4I Isolated Analog Input Module 11,746,343 8.51E-08 1.50E-06

1794-IJ2 Frequency Counter Module 2,418,321 4.14E-07 7.45E-06

1794-IP4 Pulse Counter Module 2,375,360 4.21E-07 7.58E-06

1794-IR8 RTD Input Module 6,191,655 1.62E-07 2.87E-06

1794-IRT8 TC/RTD/mV Input Module 1,182,438 8.46E-07 1.56E-05

1794-IT8 Thermocouple Input Module 1,564,324 6.39E-07 1.17E-05

1794-OB16 16 Source Output Module 1,883,594 5.31E-07 9.62E-06

1794-OB16P Protected Output Module 2,135,280 4.68E-07 8.46E-06

1794-OB8EP Protected Output Module

(MTBF)

2,389,669

(1)

(2)

(3)

λ

4.18E-07 7.54E-06

Estimated PFD

1oo2

1794-OE4 Analog Output Module 23,807,086 4.20E-08 7.41E-07

1794-OF4I Isolated Analog Output Module 7,191,128 1.39E-07 2.47E-06

1794-OW8 Relay Output Module 14,766,876 6.77E-08 1.20E-06

1794-TB3 Terminal Base Units

1794-TB3G Generic Terminal Base Units 27,320,800 3.66E-08 6.45E-07

1794-TB3GS Generic Terminal Base Units 46,425,600 2.15E-08 3.79E-07

1794-TB3S Terminal Base Unit

1794-TB3T Temperature Terminal Base Units

1794-TB3TS Temperature Terminal Base Units

1794-TBN Terminal Base Units 75,716,615 1.32E-08 2.32E-07

1794-TBNF Fused Terminal Base Units

1794-ACNR15XT ControlNet Redundant Media Adapter 8,223,684 1.22E-07 2.15E-06

21,128,346

71,433,747

73,096,226

75,763,399

4,812,320

(2)

(2)

(2)

(2)

(2)

4.73E-08 8.35E-07

1.40E-08 2.46E-07

1.37E-08 2.41E-07

1.32E-08 2.32E-07

2.08E-07 3.70E-06

AB Drives

1 Publication 1794-RM001G-EN-P - December 2011

Page 48

A-2 Failure Estimates

Table A.1 MTBF Field Data and Per Module PFD Estimates - T1 = 1 year

Catalog Number: Description:

(MTBF)

(1)

(3)

λ

Estimated PFD

1oo2

1794-AENTRXT 10/100Mb Ethernet Redundant Communication Adapter 1,268,070 7.89E-07 1.45E-05

1794-OB8EPXT 8 Protected Output Module 14,771,049 6.77E-08 1.20E-06

1794-IB16XT 16 Sink Input Module 35,587,189 2.81E-08 4.95E-07

1794-OB16PXT 16 Protected Output Module 26,709,401 3.74E-08 6.60E-07

1794-IB10XOB6XT 10 Input/6 Output Combo Module 22,202,487 4.50E-08 7.94E-07

1794-OW8XT 8 Relay Output Module 18,518,519 5.40E-08 9.53E-07

1794-IE4XOE2XT 4 Input/2 Output Analog Combo Module 11,800,802 8.47E-08 1.50E-06

1794-IE8XT 8 Input analog Module 14,041,000 7.12E-08 1.26E-06

1794-OE4XT 4 Output Analog Module 11,381,744 8.79E-08 1.55E-06

1794-IF2XOF2IXT 2 Input/2 Output Isolated Analog Combo Module 6,317,918 1.58E-07 2.81E-06

1794-IF4IXT 4 Isolated Input Analog Module 7,297,140 1.37E-07 2.43E-06

1794-IF4ICFXT 4 Isolated Input Analog Module 7,297,140 1.37E-07 2.43E-06

1794-OF4IXT 4 Isolated Output Analog Module 5,493,902 1.82E-07 3.24E-06

1794-IJ2XT 2 Ch. Frequency Counter Module 11,714,128 8.54E-08 1.51E-06

1794-IRT8XT 8 TC/RTD Input Analog Module 8,204,792 1.22E-07 2.16E-06

(1)

MTBF measured in hours.

(2)

Calculated using field-based values for components

(3)

λ = Failure Rate = 1 / MTBF

Table A.2 MTBF Field Data and Per Module PFD Estimates - T1 = 2 years

Catalog Number: Description:

(MTBF)

(1)

λ

(3)

Estimated

PFD 1oo2

1794-ACN15 ControlNet Single Media Adapter 8,223,684 1.22E-07 4.33E-06

1794-ACNR15 ControlNet Redundant Media Adapter 8,223,684 1.22E-07 4.33E-06

1794-AENT 10/100Mb Ethernet Communication Adapter 691,134 1.45E-06 5.92E-05

1794-AENTR 10/100Mb Ethernet Redundant Communication Adapter 1,268,070 7.89E-07 3.02E-05

1794-IB10XOB6 10 Input/6 Output Module 4,943,442 2.02E-07 7.27E-06

1794-IB16 16 Sink Input Module 4,105,090 2.44E-07 8.79E-06

1794-IE8 Analog Input Module 37,952,679 2.63E-08 9.28E-07

1794-IF2XOF2I Isolated Analog Input/Output Module 25,296,960 3.95E-08 1.39E-06

1794-IF4I Isolated Analog Input Module 11,746,343 8.51E-08 3.02E-06

1794-IJ2 Frequency Counter Module 2,418,321 4.14E-07 1.52E-05

1794-IP4 Pulse Counter Module 2,375,360 4.21E-07 1.55E-05

1794-IR8 RTD Input Module 6,191,655 1.62E-07 5.77E-06

1794-IRT8 TC/RTD/mV Input Module 1,182,438 8.46E-07 3.26E-05

Publication 1794-RM001G-EN-P - December 2011

Page 49

Table A.2 MTBF Field Data and Per Module PFD Estimates - T1 = 2 years

Failure Estimates A-3

Catalog Number: Description:

(MTBF)

(1)

λ

(3)

Estimated

PFD 1oo2

1794-IT8 Thermocouple Input Module 1,564,324 6.39E-07 2.41E-05

1794-OB16 16 Source Output Module 1,883,594 5.31E-07 1.98E-05

1794-OB16P Protected Output Module 2,135,280 4.68E-07 1.73E-05

1794-OB8EP Protected Output Module

2,389,669

(2)

4.18E-07 1.54E-05

1794-OE4 Analog Output Module 23,807,086 4.20E-08 1.48E-06

1794-OF4I Isolated Analog Output Module 7,191,128 1.39E-07 4.96E-06

1794-OW8 Relay Output Module 14,766,876 6.77E-08 2.40E-06

1794-TB3 Terminal Base Units

21,128,346

(2)

4.73E-08 1.67E-06

1794-TB3G Generic Terminal Base Units 27,320,800 3.66E-08 1.29E-06

1794-TB3GS Generic Terminal Base Units 46,425,600 2.15E-08 7.58E-07

1794-TB3S Terminal Base Unit

1794-TB3T Temperature Terminal Base Units

1794-TB3TS Temperature Terminal Base Units

71,433,747

73,096,226

75,763,399

(2)

1.40E-08 4.92E-07

(2)

1.37E-08 4.81E-07

(2)

1.32E-08 4.64E-07

1794-TBN Terminal Base Units 75,716,615 1.32E-08 4.64E-07

1794-TBNF Fused Terminal Base Units

4,812,320

(2)

2.08E-07 7.47E-06

1794-ACNR15XT ControlNet Redundant Media Adapter 8,223,684 1.22E-07 4.33E-06

1794-AENTRXT 10/100Mb Ethernet Redundant Communication Adapter 1,268,070 7.89E-07 3.02E-05

1794-OB8EPXT 8 Protected Output Module 14,771,049 6.77E-08 2.40E-06

1794-IB16XT 16 Sink Input Module 35,587,189 2.81E-08 9.90E-07

1794-OB16PXT 16 Protected Output Module 26,709,401 3.74E-08 1.32E-06

1794-IB10XOB6XT 10 Input/6 Output Combo Module 22,202,487 4.50E-08 1.59E-06

1794-OW8XT 8 Relay Output Module 18,518,519 5.40E-08 1.91E-06

1794-IE4XOE2XT 4 Input/2 Output Analog Combo Module 11,800,802 8.47E-08 3.00E-06

1794-IE8XT 8 Input analog Module 14,041,000 7.12E-08 2.52E-06

1794-OE4XT 4 Output Analog Module 11,381,744 8.79E-08 3.12E-06

1794-IF2XOF2IXT 2 Input/2 Output Isolated Analog Combo Module 6,317,918 1.58E-07 5.66E-06

1794-IF4IXT 4 Isolated Input Analog Module 7,297,140 1.37E-07 4.89E-06

1794-IF4ICFXT 4 Isolated Input Analog Module 7,297,140 1.37E-07 4.89E-06

1794-OF4IXT 4 Isolated Output Analog Module 5,493,902 1.82E-07 6.52E-06

1794-IJ2XT 2 Ch. Frequency Counter Module 11,714,128 8.54E-08 3.03E-06

1794-IRT8XT 8 TC/RTD Input Analog Module 8,204,792 1.22E-07 4.34E-06

(1)

MTBF measured in hours.

(2)

Calculated using field-based values for components

(3)

λ = Failure Rate = 1 / MTB

AB Drives

Publication 1794-RM001G-EN-P - December 2011

Page 50

A-4 Failure Estimates

Table A.3 MTBF Field Data and Per Module PFD Estimates - T1 = 5 years

Catalog Number: Description:

(MTBF)

(1)

(3)

λ

Estimated

PFD 1oo2

1794-ACN15 ControlNet Single Media Adapter 8,223,684 1.22E-07 1.10E-05

1794-ACNR15 ControlNet Redundant Media Adapter 8,223,684 1.22E-07 1.10E-05

1794-AENT 10/100Mb Ethernet Communication Adapter 691,134 1.45E-06 1.79E-04

1794-AENTR 10/100Mb Ethernet Redundant Communication Adapter 1,268,070 7.89E-07 8.47E-05

1794-IB10XOB6 10 Input/6 Output Module 4,943,442 2.02E-07 1.88E-05

1794-IB16 16 Sink Input Module 4,105,090 2.44E-07 2.28E-05

1794-IE8 Analog Input Module 37,952,679 2.63E-08 2.33E-06

1794-IF2XOF2I Isolated Analog Input/Output Module 25,296,960 3.95E-08 3.50E-06

1794-IF4I Isolated Analog Input Module 11,746,343 8.51E-08 7.64E-06

1794-IJ2 Frequency Counter Module 2,418,321 4.14E-07 4.05E-05

1794-IP4 Pulse Counter Module 2,375,360 4.21E-07 4.13E-05

1794-IR8 RTD Input Module 6,191,655 1.62E-07 1.48E-05

1794-IRT8 TC/RTD/mV Input Module 1,182,438 8.46E-07 9.19E-05

1794-IT8 Thermocouple Input Module 1,564,324 6.39E-07 6.62E-05

1794-OB16 16 Source Output Module 1,883,594 5.31E-07 5.36E-05

1794-OB16P Protected Output Module 2,135,280 4.68E-07 4.65E-05

1794-OB8EP Protected Output Module

2,389,669

(2)

4.18E-07 4.10E-05

1794-OE4 Analog Output Module 23,807,086 4.20E-08 3.73E-06

1794-OF4I Isolated Analog Output Module 7,191,128 1.39E-07 1.27E-05

1794-OW8 Relay Output Module 14,766,876 6.77E-08 6.05E-06

1794-TB3 Terminal Base Units

21,128,346

(2)

4.73E-08 4.21E-06

1794-TB3G Generic Terminal Base Units 27,320,800 3.66E-08 3.24E-06

1794-TB3GS Generic Terminal Base Units 46,425,600 2.15E-08 1.90E-06

1794-TB3S Terminal Base Unit

1794-TB3T Temperature Terminal Base Units

1794-TB3TS Temperature Terminal Base Units

71,433,747

73,096,226

75,763,399

(2)

(2)

(2)

1.40E-08 1.23E-06

1.37E-08 1.20E-06

1.32E-08 1.16E-06

1794-TBN Terminal Base Units 75,716,615 1.32E-08 1.16E-06

1794-TBNF Fused Terminal Base Units

4,812,320

(2)

2.08E-07 1.93E-05

1794-ACNR15XT ControlNet Redundant Media Adapter 8,223,684 1.22E-07 1.10E-05

1794-AENTRXT 10/100Mb Ethernet Redundant Communication Adapter 1,268,070 7.89E-07 8.47E-05

1794-OB8EPXT 8 Protected Output Module 14,771,049 6.77E-08 6.05E-06

1794-IB16XT 16 Sink Input Module 35,587,189 2.81E-08 2.48E-06

1794-OB16PXT 16 Protected Output Module 26,709,401 3.74E-08 3.32E-06

Publication 1794-RM001G-EN-P - December 2011

Page 51

Table A.3 MTBF Field Data and Per Module PFD Estimates - T1 = 5 years

Failure Estimates A-5

Catalog Number: Description:

(MTBF)

(1)

(3)

λ

Estimated

PFD 1oo2

1794-IB10XOB6XT 10 Input/6 Output Combo Module 22,202,487 4.50E-08 4.00E-06

1794-OW8XT 8 Relay Output Module 18,518,519 5.40E-08 4.81E-06

1794-IE4XOE2XT 4 Input/2 Output Analog Combo Module 11,800,802 8.47E-08 7.61E-06

1794-IE8XT 8 Input analog Module 14,041,000 7.12E-08 6.37E-06

1794-OE4XT 4 Output Analog Module 11,381,744 8.79E-08 7.89E-06

1794-IF2XOF2IXT 2 Input/2 Output Isolated Analog Combo Module 6,317,918 1.58E-07 1.45E-05

1794-IF4IXT 4 Isolated Input Analog Module 7,297,140 1.37E-07 1.25E-05

1794-IF4ICFXT 4 Isolated Input Analog Module 7,297,140 1.37E-07 1.25E-05

1794-OF4IXT 4 Isolated Output Analog Module 5,493,902 1.82E-07 1.68E-05

1794-IJ2XT 2 Ch. Frequency Counter Module 11,714,128 8.54E-08 7.67E-06

1794-IRT8XT 8 TC/RTD Input Analog Module 8,204,792 1.22E-07 1.11E-05

(1)

MTBF measured in hours.

(2)

Calculated using field-based values for components

(3)

λ = Failure Rate = 1 / MTBF

Table A.4 MTBF Field Data and Per Module PFH Estimates - T1 = 1 year

Catalog Number: Description:

(MTBF)

(1)

λ

(3)

Estimated

PFH 1oo2

1794-ACN15 ControlNet Single Media Adapter 8,223,684 1.22E-07 8.64E-10

1794-ACNR15 ControlNet Redundant Media Adapter 8,223,684 1.22E-07 8.64E-10