Page 1

Enhanced and

Ethernet PLC-5

Programmable

Controllers

1785-L11B, -L20B, -L30B, -L40B,

-L40L, -L60B, -L60L, -L80B, -L20E,

-L40E, -L80E, -L26B, -L46B, -L86B

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manua l , in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injur y or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may

be present.

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfa ces may be

dangerous temperatures.

Page 3

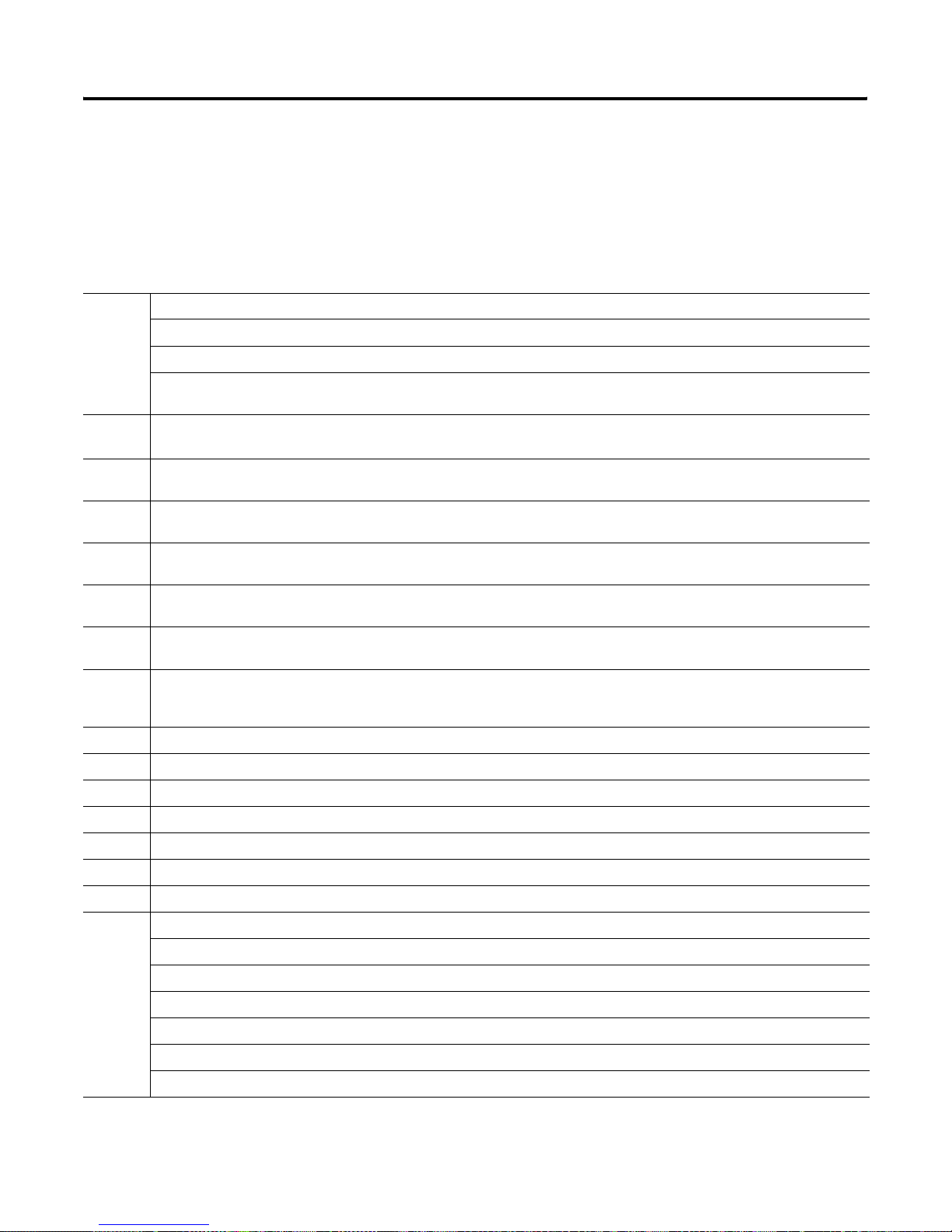

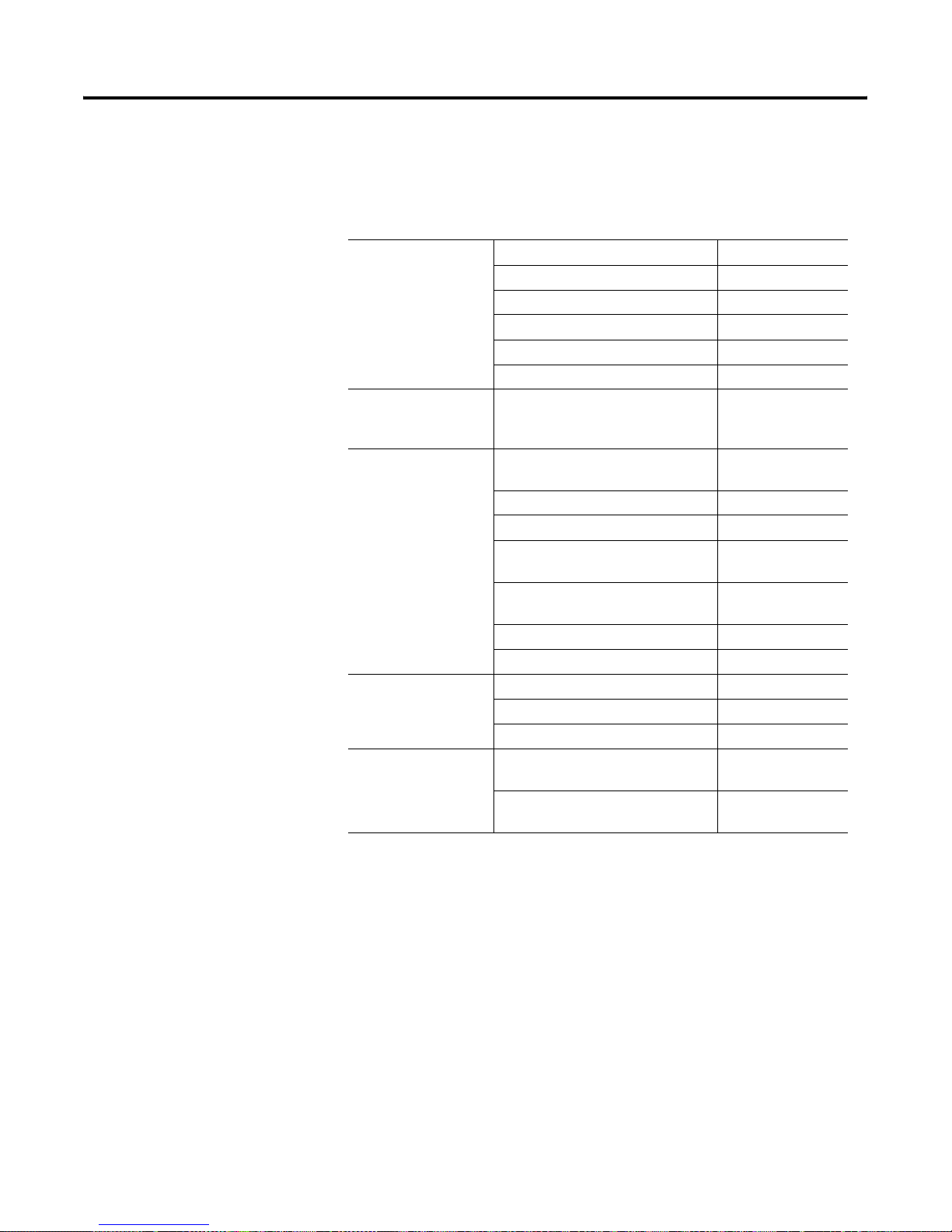

Summary of Changes

Summary of Changes

Changes to this Manual

Find the New Information

This user manual contains new and updated information.

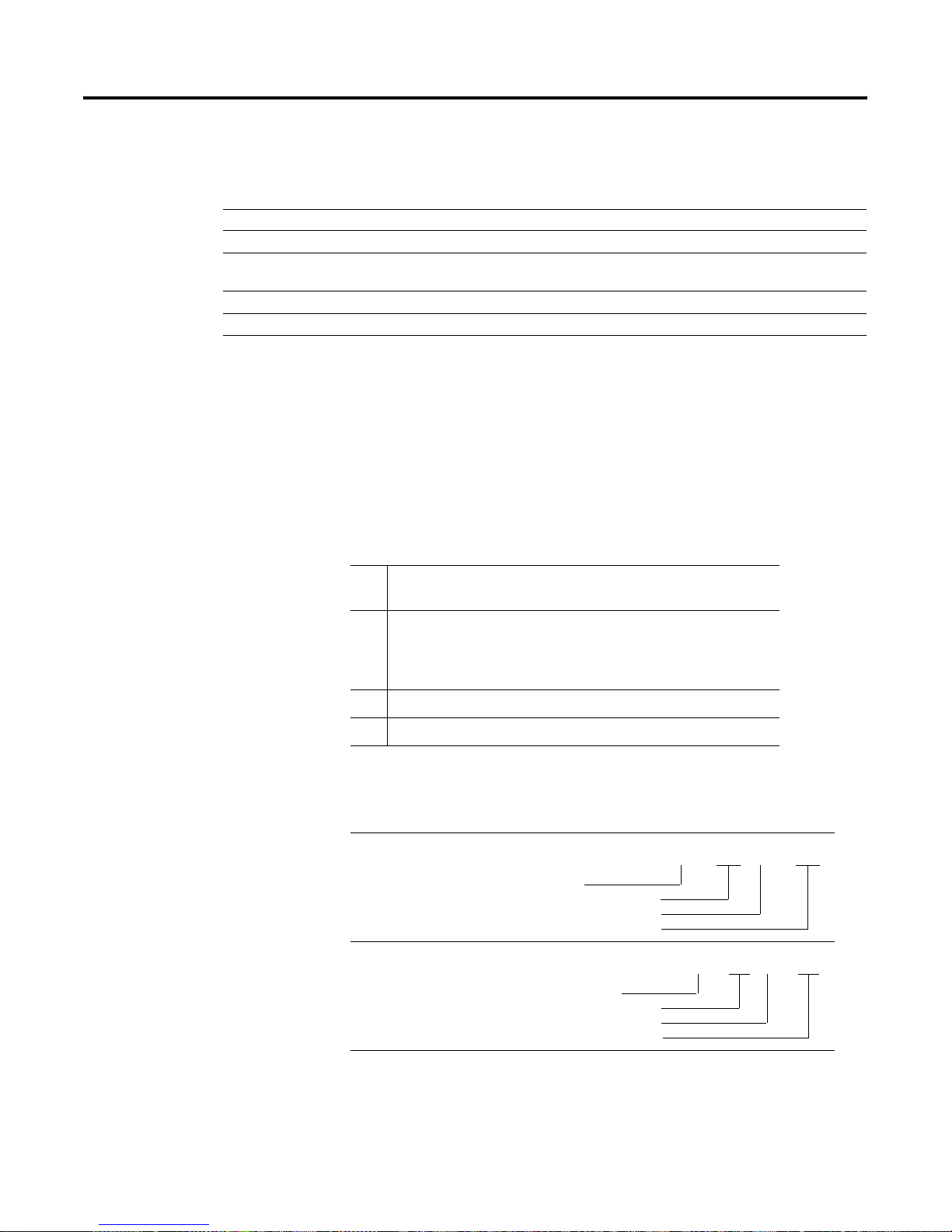

The black revision bars, as shown on the left, indicate the changes.

For specific locations of the new information, refer to the table below.

This New and Updated Information Is on Page

Domain Name Service 11-15

User Provided Web Pages 11-16

Multihop Messaging over Ethernet 11-29

TCP/IP Communications 11-32

Additional Ethernet Diagnostics 11-35

Memory Card Diagnostics B-12

Troubleshooting and Diagnostics F-2

Additional Ethernet PLC-5 Controller Enhan ce ment

Ethernet PLC-5 controllers support use of the 1785-RC Relay Cartridge.

The relay cartridge serves as an interface from the controller to a user-supplied

external device such as an Allen-Bradley 700P relay. When the controller is in

run mode, it monitors online ladder program edits and I/O forcing activity.

When either of these is detected, the controller opens the relay on the relay

cartridge for one second.

1 Publication 1785-UM012D - EN-P - July 2005

Page 4

Summary of Changes 2

Notes

Publication 1785-UM012D-EN-P - July 2005

Page 5

Table of Contents

Preface

Understanding Your

Programmable Controller

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Related PLC-5 Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Terms Used in This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Manual Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Chapter 1

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Lay Out the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Identifying Controller Components . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

PLC-5/11, -5/20, and -5/26 Controller Front Panels. . . . . . . . . 1-3

PLC-5/40, -5/46, -5/60, -5/80, and -5/86

Controller Front Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

PLC-5/20E Controller Front Panel . . . . . . . . . . . . . . . . . . . . . . 1-6

PLC-5/40E and -5/80E Controller Front Panels . . . . . . . . . . . 1-7

PLC-5/40L and -5/60L Controller Front Panels . . . . . . . . . . . 1-8

Programming Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Using a Controller Channel as a Remote I/O Scanner . . . . . . . . . . 1-11

Using a Controller Channel as a Remote I/O Adapter . . . . . . . . . . 1-12

Using a PLC-5/40L, -5/60L Programmable Controller as an

Extended-Local I/O Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Selecting and Placing I/ O

Placing Syste m Hardware

Chapter 2

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Selecting I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Guidelines for Selecting I/O Modules . . . . . . . . . . . . . . . . . . . . 2-2

Selecting I/O Module Density . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Placing I/O Modules in a Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Chapter 3

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Determining the Proper Environment . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Protecting Your Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Preventing Electrostatic Discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Laying Out Your Cable Raceway. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Categorize Conductors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Route Conductors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Laying Out Your Backpanel Spacing . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Chassis Dimensions (Series B) . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

I/O Chassis and External Power Supply Dimensions . . . . . . . 3-6

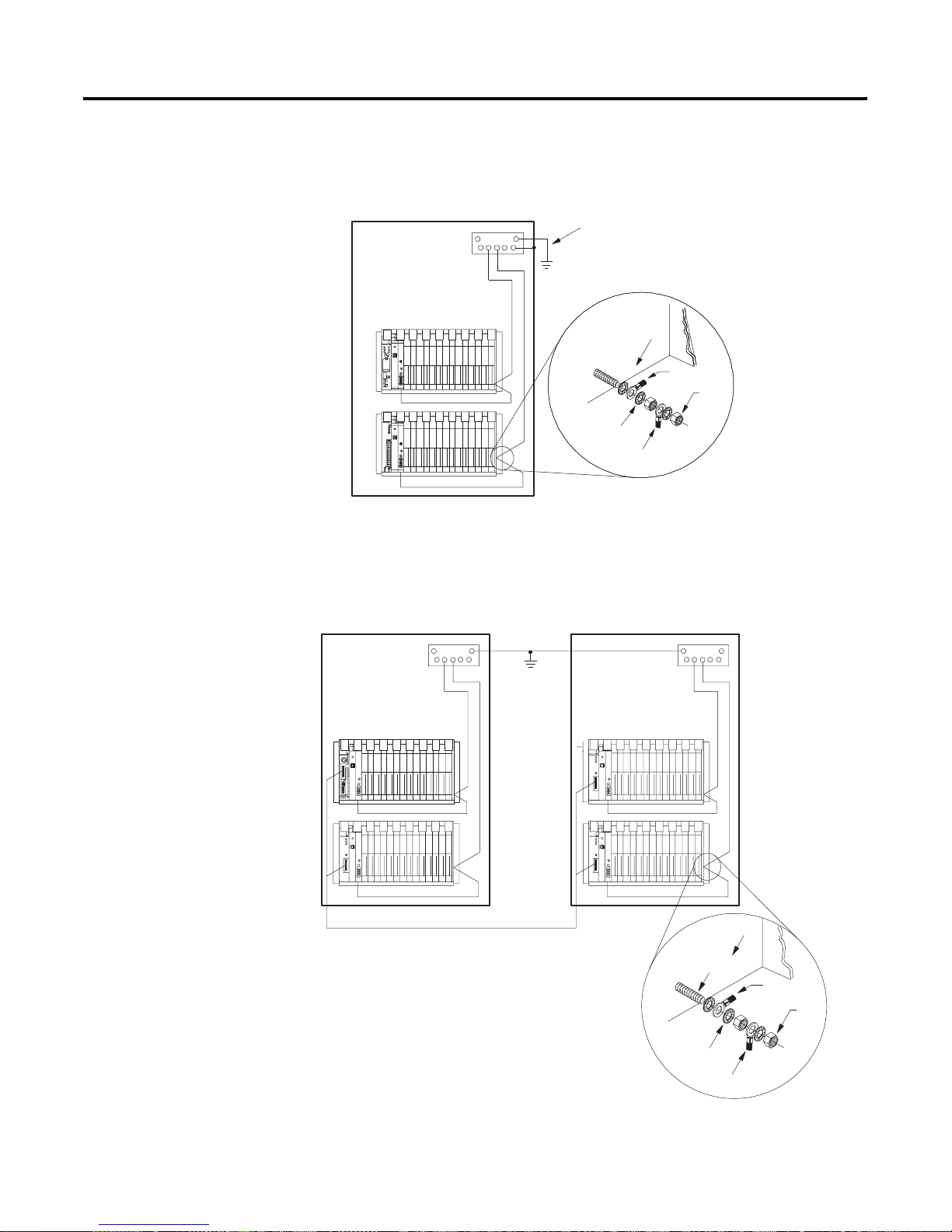

Grounding Your System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

1 Publication 1785-UM012D - EN-P - July 2005

Page 6

T able of Contents 2

Addressing I/ O and Controller

Memory

Chapter 4

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

I/O Addressing Concept. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Choosing an Addressing Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Addressing Block-Transfer Modules. . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Addressing Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Assigning Racks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Understanding PLC-5 Controller Memory. . . . . . . . . . . . . . . . . . . . 4-10

Understanding Data Storage (Data-Table Files) . . . . . . . . . . . . 4-11

Addressing File Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

Understanding Program-File Storage . . . . . . . . . . . . . . . . . . . . . 4-15

Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Specifying I/O Image Addresses . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Specifying Logical Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Specifying Indirect Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-18

Specifying Indexed Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-20

Specifying Symbolic Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Optimizing Instruction Execution Time

and Controller Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

Effectively Using I/O Memory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Communicating with

Controller-Resident I/O

Communicating with Remote I/O

Chapter 5

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Introduction to PLC-5 Controller Scanning. . . . . . . . . . . . . . . . . . . . 5-1

Program Scanning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Transferring Data to Controller-Resident I/O. . . . . . . . . . . . . . . . . . 5-3

Transferring Discrete Data to Controller-Resident I/O . . . . . . . 5-3

Transferring Immediate I/O Requests. . . . . . . . . . . . . . . . . . . . . 5-3

Transferring Block-Transfer Data to Controller-Resident I/O . 5-4

Configuring the System for Controller-Resident I/O . . . . . . . . . . . . 5-4

Chapter 6

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Selecting Devices That You Can Connect . . . . . . . . . . . . . . . . . . . . . 6-2

Introduction to Remote I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Designing a Remote I/O Link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

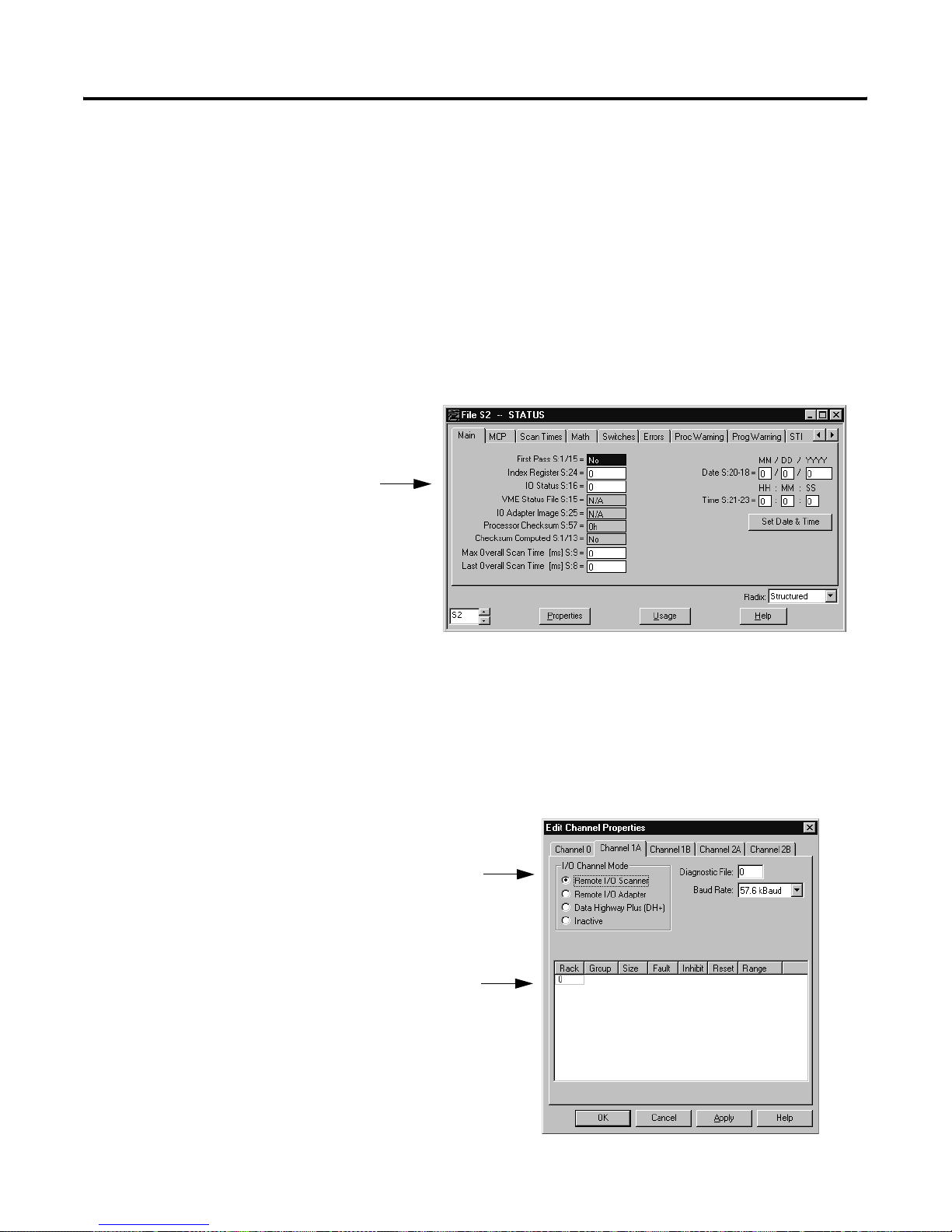

Configuring a Controller Channel as a Scanner . . . . . . . . . . . . . . . . . 6-6

Define an I/O Status File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Specify Channel Configuration Information . . . . . . . . . . . . . . . . 6-7

Specify the Scan List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Communicating to a Remote I/O Node Adapter . . . . . . . . . . . . . . 6-11

Troubleshooting Remote I/O Communication Difficulties. . . 6-12

Transferring Block Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13

Block-Transfers of Remote I/O Data . . . . . . . . . . . . . . . . . . . . . . . 6-15

Block-Transfer Sequence with Status Bits . . . . . . . . . . . . . . . . . . . . 6-17

Publication 1785-UM012D-EN-P - July 2005

Page 7

Communicating with a PLC-5

Adapter Channel

Table of Contents 3

Block-Transfer Programming Considerations . . . . . . . . . . . . . . . . . 6-19

General Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-19

For Controller-Resident Local Racks . . . . . . . . . . . . . . . . . . . . . 6-20

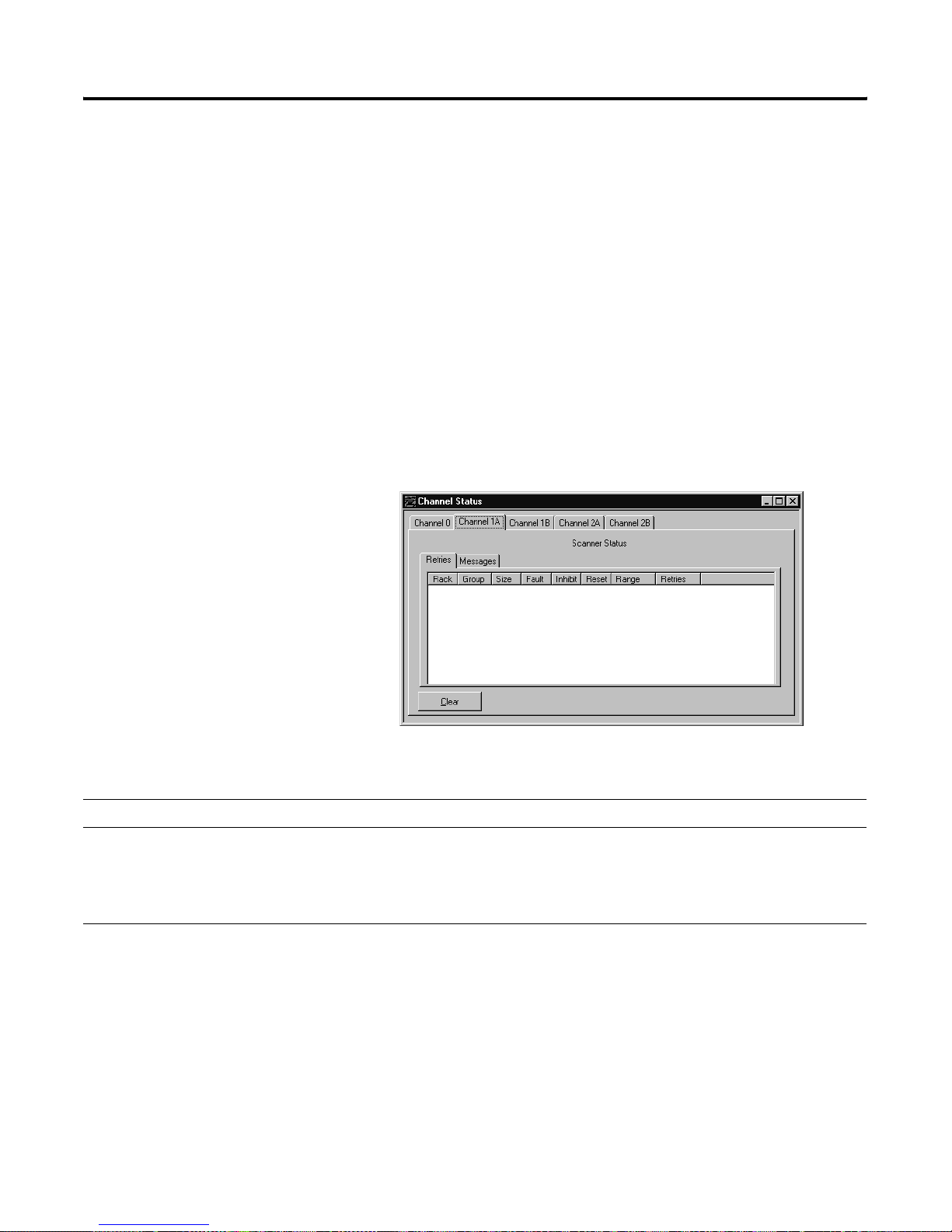

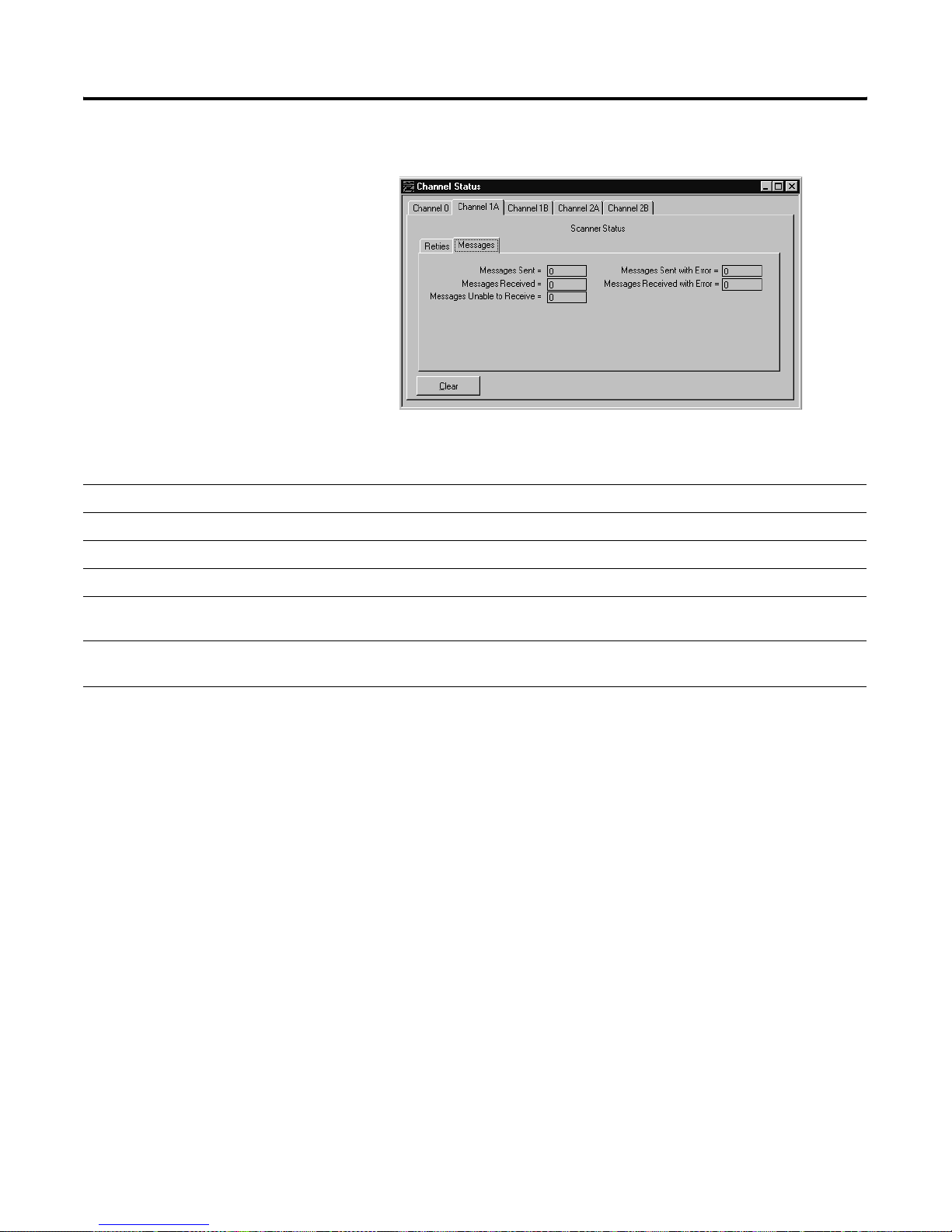

Monitoring Remote I/O Scanner Channels. . . . . . . . . . . . . . . . . . . 6-21

Monitoring transmission retries . . . . . . . . . . . . . . . . . . . . . . . . . 6-21

Addressing the I/O Status File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-24

Chapter 7

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Configuring Communication to a PLC-5 Adapter Channel . . . . . . . 7-2

Specify an Adapter Channel’s Communication Rate,

Address, and Rack Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Specify the Discrete Transfer Configuration Files. . . . . . . . . . . . 7-5

Programming Discrete Transfers in Adapter Mode. . . . . . . . . . . . . 7-10

Programming Block-Transfers of Data to an Adapter Channel . . . 7-10

Configure Block-Transfer Requests . . . . . . . . . . . . . . . . . . . . . . 7-11

Examples of Block-Transfer Ladder Logic

Effects of Programming Block-Transfers to an Adapter-Mode

Controller Channel on Discrete Data Transfer . . . . . . . . . . . . . 7-15

Monitoring the Status of the Adapter Channel . . . . . . . . . . . . . 7-17

Monitoring the Status of the Supervisory Controller. . . . . . . . . 7-18

Monitoring Remote I/O Adapter Channels. . . . . . . . . . . . . . . . . . . 7-19

Communicating with

Extended-Local I/O

Communicating with Devices on a

DH+ Link

Chapter 8

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Selecting Devices That You Can Connect . . . . . . . . . . . . . . . . . . . . . 8-1

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Addressing and Placing I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Transferring Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Discrete Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-5

Transferring Block Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Calculating Block-Transfer Completion Time . . . . . . . . . . . . . . . 8-7

Considerations for Extended-local Racks. . . . . . . . . . . . . . . . . . . 8-8

Configuring the Controller as an Extended-Local I/O Scanner. . . . 8-9

Monitoring Extended-Local I/O Status. . . . . . . . . . . . . . . . . . . . . . 8-12

Chapter 9

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Selecting Devices That You Can Connect . . . . . . . . . . . . . . . . . . . . . 9-1

Link Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Configuring the Channel for DH+ Communication . . . . . . . . . . . . . 9-3

Using the Global Status Flag File . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Monitoring DH+ Communication Channels. . . . . . . . . . . . . . . . . . . 9-7

Monitoring Data Sent with Acknowledgment . . . . . . . . . . . . . . . 9-8

Monitoring Data Sent without Acknowledgment . . . . . . . . . . . 9-10

Publication 1785-UM012D - EN-P - July 2005

Page 8

T able of Contents 4

Communicating with Devices on a

Serial Link

Monitoring General Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Estimating DH+ Link Performance. . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Size and Number of Messages . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Message Destination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Internal Processing Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-15

Average DH+ Link Response Time Test Results . . . . . . . . . . . 9-16

Application Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Chapter 10

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Choosing Between RS-232C, RS-422A, and RS-423 . . . . . . . . . . . . 10-1

Configuring the Controller

Serial Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Using Channel 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

User Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

System Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Master Station to Remote Station Communication Methods . . 10-4

Polling Inactive Priority Stations. . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Changing Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-5

Configuring Channel 0. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-6

Configure Channel 0 for DF1 Point-to-Point . . . . . . . . . . . . . . 10-6

Configure Channel 0 as a Slave Station . . . . . . . . . . . . . . . . . . . 10-9

Configure Channel 0 as a Master Station . . . . . . . . . . . . . . . . . 10-12

Configure Channel 0 for User Mode (ASCII Protocol). . . . . . 10-18

Configure Channel 0 for a Communication Mode Change. . . 10-21

Monitoring Channel 0 Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-22

Using the System Mode Status Display . . . . . . . . . . . . . . . . . . 10-22

Using the User Mode (ASCII) Status Display . . . . . . . . . . . . . 10-24

Communicating with Devices on

an Ethernet Networ k

Publication 1785-UM012D-EN-P - July 2005

Chapter 11

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Media and Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Assigning Your IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Network Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Configuring Channel 2 for Ethernet Communication. . . . . . . . . . . 11-2

Manually Configuring Channel 2 . . . . . . . . . . . . . . . . . . . . . . . . 11-2

Using BOOTP to Enter Configuration Information. . . . . . . . . 11-5

Editing the BOOTPTAB Configuration File. . . . . . . . . . . . . . . 11-7

Using Advanced Ethernet Functions . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Using Broadcast Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-9

Using Subnet Masks and Gateways . . . . . . . . . . . . . . . . . . . . . 11-11

Manually Configuring Channel 2 for Controllers on Subnets. 11-12

Page 9

Table of Contents 5

Using BOOTP to Configure Channel 2

for Controllers on Subnets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-13

Using Domain Name Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-15

Using the Embedded Web Server. . . . . . . . . . . . . . . . . . . . . . . . . . 11-16

Generating User Provided Web Pages . . . . . . . . . . . . . . . . . . . 11-22

Importing User Page Files to the PLC-5 Controller . . . . . . . . 11-26

Using Multihop Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-29

Multihop Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-30

Comparing Multihop and Non-Multihop Messages

Over Ethernet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-32

Communicating with ControlLogix Devices . . . . . . . . . . . . . . . . . 11-32

TCP/IP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-32

Interpreting Error Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-33

Interpreting Ethernet Status Data. . . . . . . . . . . . . . . . . . . . . . . . . . 11-34

Monitoring general Ethernet status . . . . . . . . . . . . . . . . . . . . . 11-35

Monitoring Ethernet commands. . . . . . . . . . . . . . . . . . . . . . . . 11-36

Monitoring Ethernet replies . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-36

Ethernet PLC-5 Performance Considerations . . . . . . . . . . . . . . . . 11-37

Performance: Host to Ethernet PLC-5 Controller. . . . . . . . . . 11-37

Performance: Ethernet PLC-5 Controller to Ethernet

PLC-5 Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-38

Protecti ng Your Programs

Programming Considerations

Chapter 12

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

About Passwords and Privileges . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-2

Defining Privilege Classes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-3

Assigning a Privilege Class to a Channel or Offline File . . . . . . . . . 12-4

Assigning a Privilege Class to a Node. . . . . . . . . . . . . . . . . . . . . . . . 12-4

Assigning Read/Write Privileges to a Program File. . . . . . . . . . . . . 12-5

Assigning Read/Write Privileges to a Data File . . . . . . . . . . . . . . . . 12-5

Chapter 13

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Forcing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Forcing Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

Forcing SFC Transitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

Extended Forcing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

Increased Program Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

I/O Force Privileges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-4

Using Protected Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-5

Using Selectable Timed Interrupts (STIs)

and Controller Input Interrupts (PIIs) . . . . . . . . . . . . . . . . . . . . 13-5

Setting Up and Using Extended Forcing . . . . . . . . . . . . . . . . . . . . . 13-5

Step 1 - Select Which Group of Data You Want to Force . . . . 13-6

Publication 1785-UM012D - EN-P - July 2005

Page 10

T able of Contents 6

Preparing Power-U p Routi nes

Step 2 - Use the Programming Software to Enter

or Edit the Data You Want to Force in the Extended Force

Configuration Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-7

Step 3 - Use the Programming Software to Enter

Force Values for the Specified Data Table Files . . . . . . . . . . . . 13-8

Step 4 - Enable or Disable the Forces . . . . . . . . . . . . . . . . . . . . 13-8

Using Extended Forcing with Time-Critical Applications. . . . . 13-8

Using Special Programming Routines. . . . . . . . . . . . . . . . . . . . . . . 13-10

Priority Scheduling for Interrupts and MCPs. . . . . . . . . . . . . . . . . 13-11

Program Execution States. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-12

Influencing Priority Scheduling. . . . . . . . . . . . . . . . . . . . . . . . . 13-14

Defining and Programming Interrupt Routines. . . . . . . . . . . . . . . 13-15

Chapter 14

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Setting Power-Up Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

Allowing or Inhibiting Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

Defining a Controller Power-Up Procedure. . . . . . . . . . . . . . . . . . . 14-2

Preparing Fault Routi nes

Chapter 15

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

Understanding the Fault Routine Concept. . . . . . . . . . . . . . . . . . . . 15-1

Responses to a Major Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-1

Understanding Controller-Detected Major Faults . . . . . . . . . . . . . . 15-2

Fault in a Controller-Resident or Extended-Local I/O Rack . . 15-3

Fault in a Remote I/O Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . 15-3

Defining a Fault Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-4

Defining a Watchdog Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-5

Avoiding Multiple Watchdog Faults. . . . . . . . . . . . . . . . . . . . . . 15-6

Programming a Fault Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-6

Setting an Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-7

Clearing a Major Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-7

Changing the Fault Routine from Ladder Logic . . . . . . . . . . . . 15-9

Using Ladder Logic to Recover from a Fault. . . . . . . . . . . . . . 15-10

Block-Transfers in Fault Routines . . . . . . . . . . . . . . . . . . . . . . 15-11

Testing a Fault Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-11

Monitoring Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-11

Monitoring Major/Minor Faults and Fault Codes. . . . . . . . . . 15-12

Interpreting Major Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-12

Interpreting Minor Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-12

Monitoring Status Bits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-13

Publication 1785-UM012D-EN-P - July 2005

Page 11

Using Main Control Programs

Using Selectable Timed Interrupts

Using Processor Input Interrupts

Table of Contents 7

Chapter 16

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

Selecting Main Control Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-1

Understanding How the

Controller Interprets MCPs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-2

Configuring MCPs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-3

Monitoring MCPs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-5

Chapter 17

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

Using a Selectable Timed Interrupt. . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

Writing STI Ladder Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-1

STI Application Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-2

Block-Transfers in Selectable Timed Interrupts (STIs) . . . . . . . 17-2

Defining a Selectable Timed Interrupt . . . . . . . . . . . . . . . . . . . . . . . 17-3

Monitoring Selectable Timed Interrupts. . . . . . . . . . . . . . . . . . . . . . 17-4

Chapter 18

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

Using a Processor Input Interrupt. . . . . . . . . . . . . . . . . . . . . . . . . . . 18-1

Writing PII Ladder Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2

PII Application Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-2

Block-Transfers in Processor Input Interrupts (PIIs) . . . . . . . . 18-3

Design Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18-4

Defining a Controller Input Interrupt. . . . . . . . . . . . . . . . . . . . . . . . 18-5

Monitoring Controller Input Interrupts . . . . . . . . . . . . . . . . . . . . . . 18-6

System Specifications

Processor Status File

Appendix A

Controller Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Memory and Channel Specifications. . . . . . . . . . . . . . . . . . . . . . A-2

Memory Backup Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

EEPROM Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

S:0 - S:2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

S:3-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

S:11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

S:12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

S:13-S:24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

S:26-S:35 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

S:36-S:78 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-11

S:79-S:127 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Publication 1785-UM012D - EN-P - July 2005

Page 12

T able of Contents 8

Maximizing System Performance

Appendix C

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Program Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Effects of False Logic versus True Logic on Logic Scan Time. . C-2

Effects of Different Input States on Logic Scan Time . . . . . . . . C-2

Effects of Different Instructions on Logic Scan Time . . . . . . . . C-3

Effects of Using Interrupts on Logic Scan Time. . . . . . . . . . . . . C-3

Effects of Housekeeping Time. . . . . . . . . . . . . . . . . . . . . . . . . . . C-4

Editing While in Remote Run Mode . . . . . . . . . . . . . . . . . . . . . . C-4

Putting Block-Transfer Modules in Controller-Resident Chassis C-5

Using Global Status Flag Files . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Calculating Throughput. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5

Input and Output Modules Delay. . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

I/O Backplane Transfer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Remote I/O Scan Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6

Communication Rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Number of Rack Entries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7

Block-Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-8

Calculating Worst-Case Remote I/O Scan Time. . . . . . . . . . . . . C-9

Optimizing Remote I/O Scan Time. . . . . . . . . . . . . . . . . . . . . . . C-9

Controller Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-11

Example Calculation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-12

Performance Effects of Online Operations . . . . . . . . . . . . . . . . . . . C-12

Effect of Inserting Ladder Rungs at the 56K-word Limit. . . . . . . . C-13

Using Program Control Instructions. . . . . . . . . . . . . . . . . . . . . . . . . C-14

Using JMP/LBL Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

Using FOR/NXT Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . C-14

Instruction Set Quick Reference

Publication 1785-UM012D-EN-P - July 2005

Appendix D

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Relay Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

Timer Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

Counter Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Compare Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Compute Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-7

Logical Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-14

Conversion Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-15

Bit Modify and Move Instructions . . . . . . . . . . . . . . . . . . . . . . D-16

File Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-17

Diagnostic Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-19

Shift Register Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-20

Sequencer Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-21

Program Control Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . D-22

Process Control, Message Instructions. . . . . . . . . . . . . . . . . . . D-25

Block Transfer Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . D-25

Page 13

Switch Setting Reference

Table of Contents 9

ASCII Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-27

Bit and Word Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-30

File, Program Control, and ASCII Instructions. . . . . . . . . . . . D-32

Appendix E

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-1

Controller Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Switch 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-2

Switch 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-3

I/O Chassis Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-4

PLC-5 Controller in the I/O Chassis . . . . . . . . . . . . . . . . . . . . . . E-4

1771-ASB Remote I/O Adapter or 1771-ALX

Extended-Local I/O Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . E-5

I/O Chassis Configuration Plug. . . . . . . . . . . . . . . . . . . . . . . . . . E-6

Remote I/O Adapter Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-7

(1771-ASB Series C and D) without Complementary I/O . . . . . E-7

(1771-ASB Series C and D) I/O Rack Number -

without Complementary I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-8

Extended-Local I/O Adapter Module . . . . . . . . . . . . . . . . . . . . . . . . E-9

(1771-ALX) Switch SW1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E-9

(1771-ALX) Configuration Plug . . . . . . . . . . . . . . . . . . . . . . . . . E-10

Troubleshooting

Appendix F

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1

PLC-5 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

General Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-2

Controller Communication Channel Troubleshooting . . . . . . . . F-4

Extended-Local I/O Troubleshooting. . . . . . . . . . . . . . . . . . . . . F-5

Ethernet Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-5

Ethernet Transmit LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

Remote I/O System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

Troubleshooting Guide for the 1771-ASB Series C and D

Adapter Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-6

Troubleshooting Guide for the 1771-ASB Series C and D

Adapter Module (continued). . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-8

Extended-Local I/O System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-9

Troubleshooting Guide for the 1771-ALX Adapter Module . . . F-9

Unexpected Operation when Entering Run Mode. . . . . . . . . . . . . . . F-9

Instructions with Unique Prescan Operations. . . . . . . . . . . . . . F-10

Suggested Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-11

Publication 1785-UM012D - EN-P - July 2005

Page 14

T able of Contents 10

Cable Reference

Index

Appendix G

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

Channel 0 Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-1

Serial Cable Pin Assignments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-2

Connecting Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-3

Programming Cable Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . G-5

Ethernet Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G-9

Publication 1785-UM012D-EN-P - July 2005

Page 15

Using This Manual

Preface

Purpose of This Manual

Related PLC-5

Documentation

The purpose of this manual is to help you design, operate and maintain an

Enhanced and Ethernet PLC-5 programmable controller system. Use this

manual to:

• determine the features of the controllers and how you use them

• design your PLC-5 system

• operate and maintain your PLC-5 system

The following docume nts contain additional i nformation rela ted to the

procedures described in this document..

Publication Title Publication Number

Industrial Automation Wiring and Grounding Guidelines 1770-4.1

PLC-5 Programmable Controller Instruction Set Reference 1785-6.1

Configuring Complementary I/O for PLC-5 Controllers 1785-6.8.3

Data Highway Cable Installation Manual 1770-6.2.2

SCADA System Selection Guide, AG-SG001

PLC-5 Protected Controllers Product Data 1785-2.28

PLC-5 Protected Controller Supplement 1785-6.5.13

1 Publication 1785-UM012D - EN-P - July 2005

1771 Remote I/O Adapter Module User Manual 1771-UM001

ControlNet PLC-5 Programmable Controllers User Manual 1785-UM022

To get this documentation, you can either:

• view or download an electronic version from the internet at

www.rockwellautomation.com/literature

• contact y our local di stri but or or Rockwell Auto mation representative to

place an order

Page 16

Preface 2

Terms Used in This Manual

Term Definition

Block-transfer data data transferred, in blocks of data up to 64 words, to/from a block-

Discrete-transfer data data (words) transferred to/from a discrete I/O module

Enhanced PLC-5 controllers references PLC-5/11, -5/20, -5/26, -5/30, -5/40, -5/46, -5/40L,

Ethernet a local area network with a baseband communication rate of 10M

Ethernet PLC-5 controllers references PLC-5/20E, -5/40E, and -5/80E controllers

Become familiar with the following terms and definitions which are used

throughout this manual.

transfer I/O module (for example, an analog module)

-5/46L, -5/60, -5/60L, -5/80, and -5/86 controllers

PLC-5/26, -5/46, and -5/86 controllers are protected

controllers. See the PLC-5 Protected Controllers Supplement,

publication 1785-6.5.13

This term also refers to the PLC-5/V30B, -5/V40B, -5/V40L, and

-5/V80B controllers when applicable. See the PLC-5/VME VMEbus

Programmable Controllers User Manual, publication 1785-6.5.9,

for more information

bps designed for the high-speed exchange of information between

computers and related devices

Extended-local I/O I/O connected to a controller across a parallel link to achieve

higher throughput, thus limiting its distance from the controller

Extended local I/O link a parallel link for carrying I/O data between a PLC-5/40L or -5/60L

controller and extended-local I/O adapters

PLC-5 controller used to generically reference Enhanced PLC-5 and Ethernet PLC-5

controllers in this manual only

Controller-resident local I/O

chassis

Remote I/O link a serial communication link between a PLC-5 controller port in

Remote I/O chassis the hardware enclosure that contains an adapter and I/O modules

the I/O chassis in which the PLC-5 controller is installed

scanner mode and an adapter as well as I/O modules that are

located remotely from the PLC-5 controller

that are located remotely on a serial communication link to a PLC-5

controller in scanner mode

Publication 1785-UM012D-EN-P - July 2005

Page 17

Preface 3

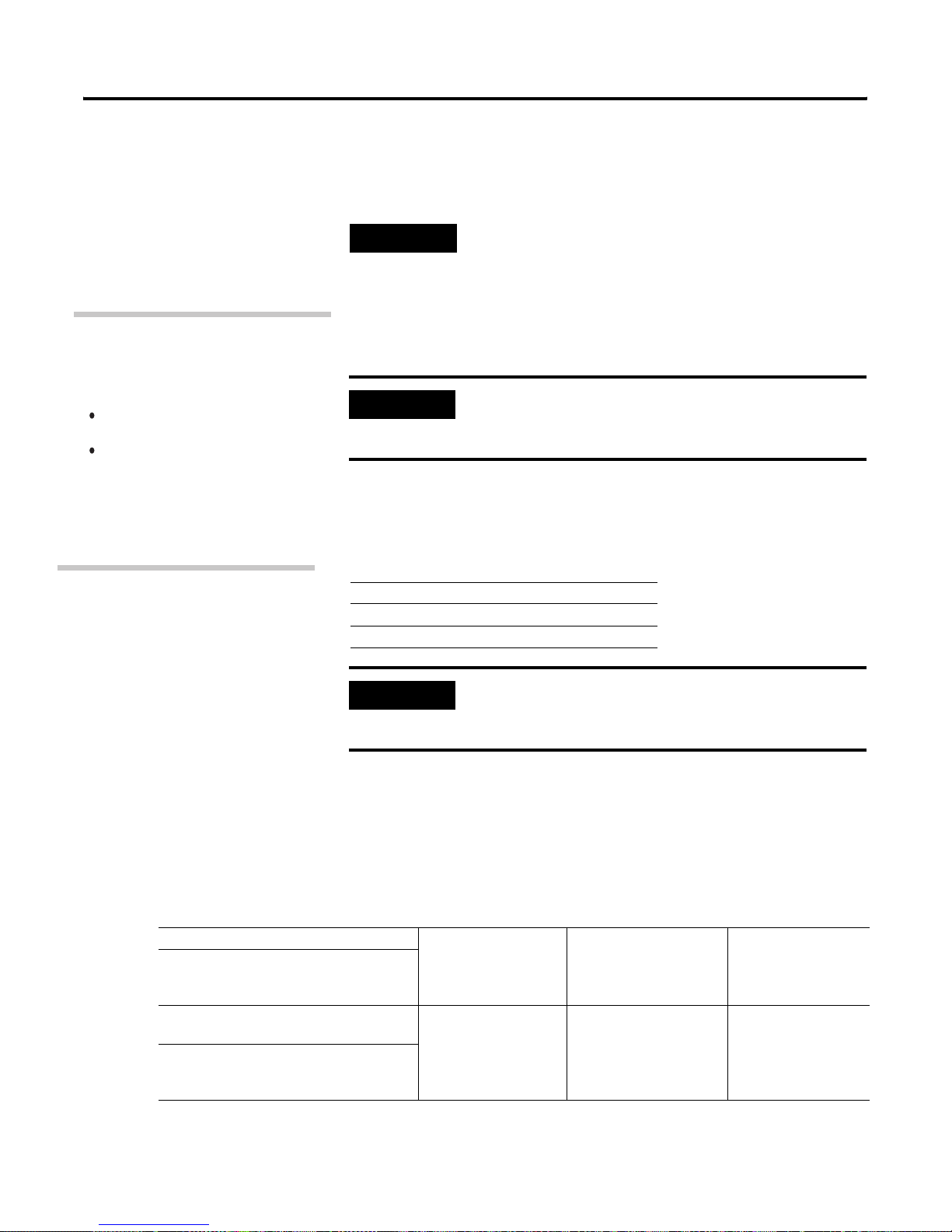

Manual Overview

This manual has three main sections:

• Design

• Operate

• Maintain

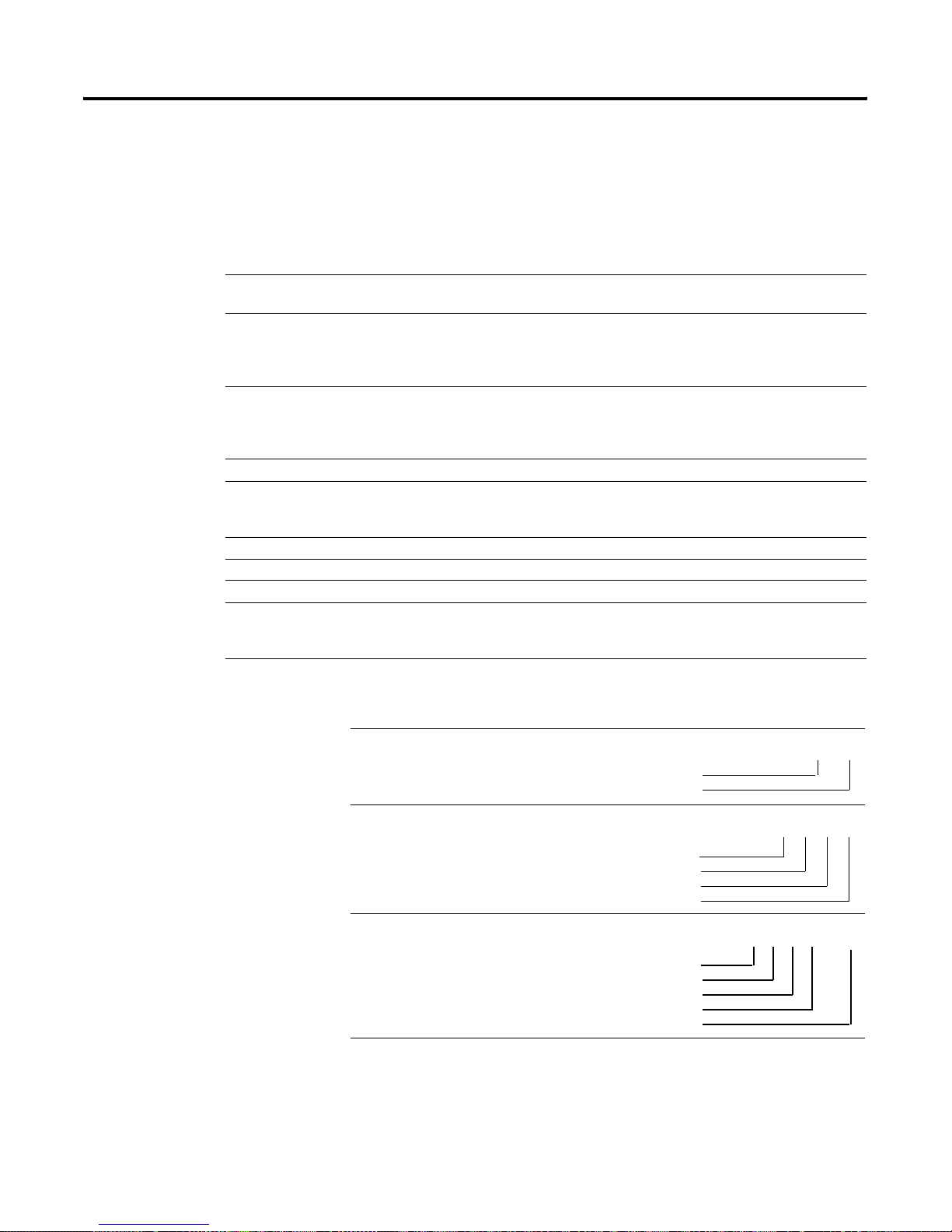

Section: For information about: See Title:

Design An overview of the PLC-5 controllers’ capabilities and keyswitch Chapter 1 Understanding Your Controller

Guidelines for selecting and placing I/O modules Chapter 2 Selecting and Placing I/O

The proper environment for your PLC-5 system Chapter 3 Placing System Hardware

Choosing addressing mode, assigning rack numbers, and understanding

PLC-5 memory

Operate Configuring the controller for controller-resident I/O, transferring data, and

monitoring status

Configuring a system for remote I/O communication, designing a remote

I/O link, transferring data, and monitoring status

Configuring a PLC-5 adapter channel, transferring data, and

monitoring status

For PLC-5/40L, -5/46L, and -5/60L Controllers only: Configuring an

extended-local I/O system, transferring data, and monitoring status

Configuring a system for Data Highway Plus™ and monitoring

channel status

Configuring a system for serial communications and monitoring

channel status

Chapter 4 Addressing I/O and Controller Memory

Chapter 5 Communicating with Controller-Resident I/O

Chapter 6 Communicating with Remote I/O

Chapter 7 Communicating with a PLC-5

Adapter Channel

Chapter 8 Communicating with Extended-Local I/O

Chapter 9 Communicating with Devices on a DH+ Link

Chapter 10 Communicating with Devices on a

Serial Link

For PLC-5/20E, -5/40E, and -5/80E Controllers only:

Configuring a system for Ethernet communications and monitoring

channel status

Assigning passwords and privileges Chapter 12 Protecting Your Programs

PLC-5 programming feature overview Chapter 13 Programming Considerations

Defining power-up procedure Chapter 14 Preparing Power-Up Routines

Defining, programming, and monitoring fault routines Chapter 15 Preparing Fault Routines

Configuring and monitoring main control programs Chapter 16 Using Main Control Programs

Using, defining, and monitoring selectable timed interrupts Chapter 17 Using Selectable Timed Interrupts

Using, defining, and monitoring Controller input interrupts Chapter 18 Using Controller Input Interrupts

Maintain System specifications Appendix A System Specifications

Listing of the controller status file words and meaning Appendix B Controller Status File

General and specific performance considerations Appendix C Maximizing System Performance

Guide to ladder instructions and execution times Appendix D Instruction Set Quick Reference

How to set system switches Appendix E Switch Setting Reference

Potential problems and recommended solutions Appendix F Troubleshooting

Guidelines for choosing and making cables Appendix G Cable Reference

Chapter 11 Communicating with Devices on an

Ethernet Network

Publication 1785-UM012D - EN-P - July 2005

Page 18

Preface 4

Notes

Publication 1785-UM012D-EN-P - July 2005

Page 19

Using This Chapter

Chapter

1

Understanding Your Programmable Controller

For Information About Go to Page

Lay Out the System 1-1

Identifying controller components 1-2

Programming features 1-10

Using a controller channel as a remote I/O scanner 1-11

Using a controller channel as a remote I/O adapter 1-12

Using a PLC-5/40L, -5/60L programmable controller as an

extended-local I/O scanner

1-14

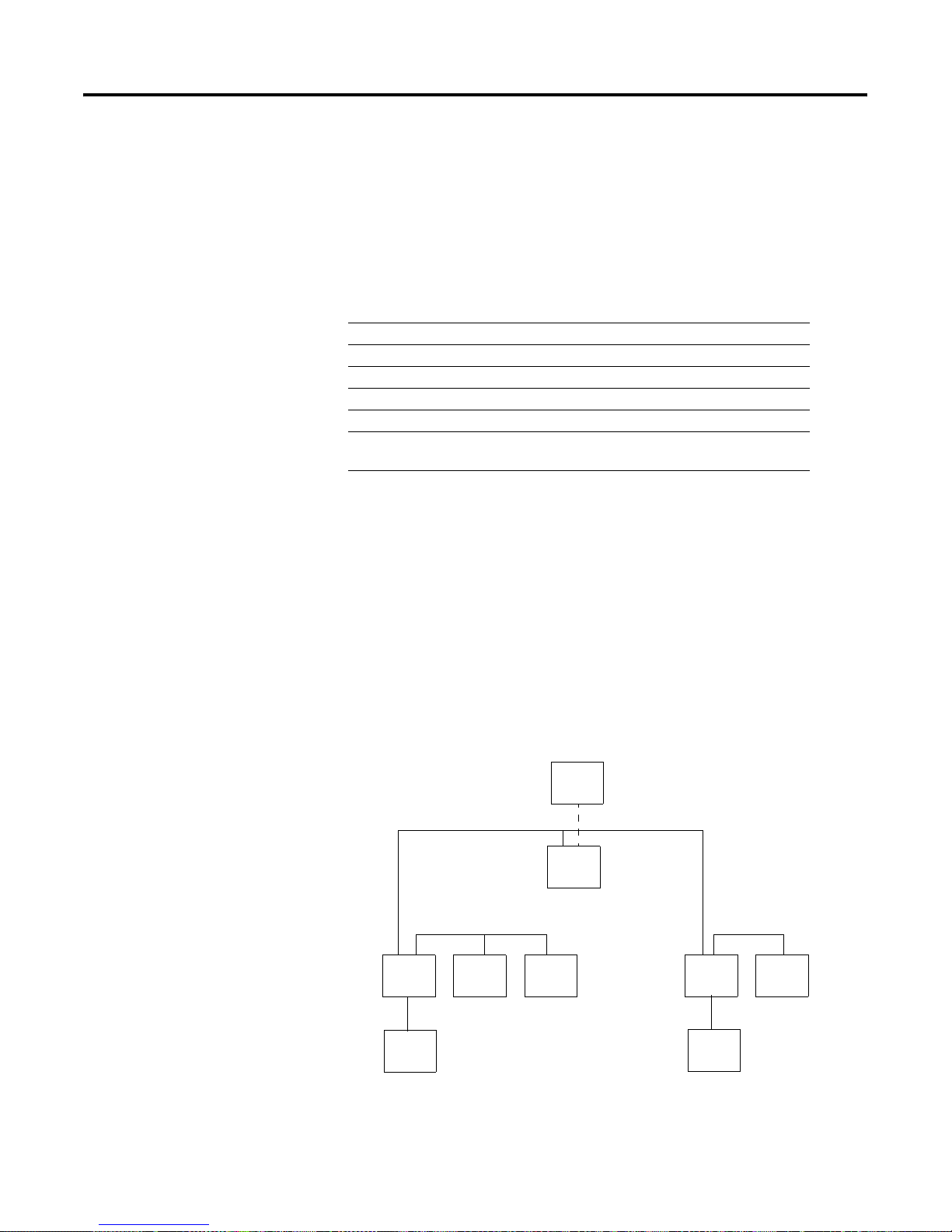

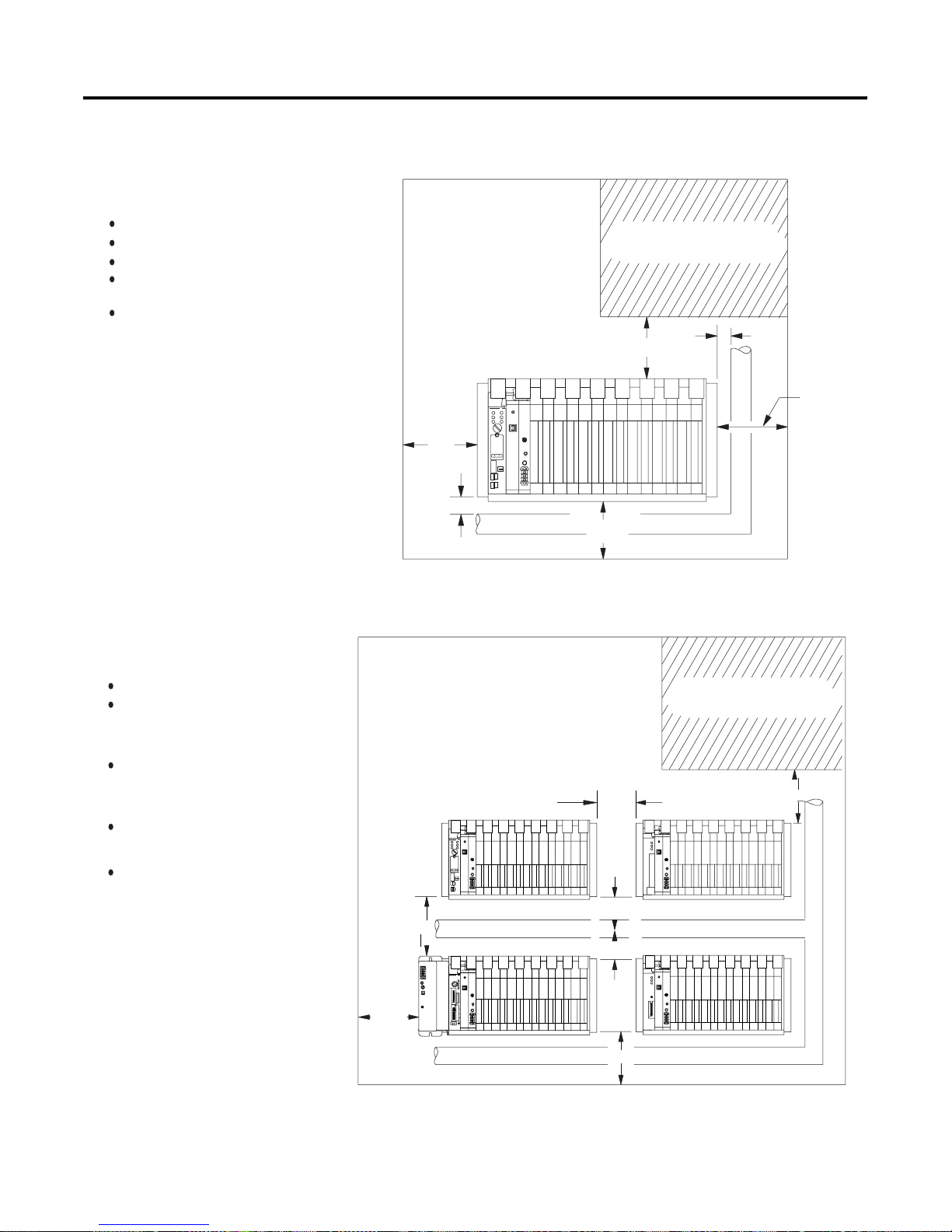

Lay Out the System

Lay out the system by determining the network configuration and the

placement of components in each location. Decide at this time whether each

location will have its own controller.

Place each controller’s I/O on an isolated network to maximize the

performance and to more ea sily accommodate future network or system

configuration changes. If you plan to share I/O, make sure the I/O is on a

network that each controller can access.

Assume that Network A and Netw or k B both re quir e a c ontr oller and its I/O.

Both controllers interact with time critical information.

RSView

Network C

Panel C

Network B

Panel B

chassis 1

Panel B

chassis 2

Panel A

chassis 1

Network A

Panel A

chassis 2

Panel A

chassis 3

1 Publication 1785-UM012D - EN-P - July 2005

Panel

View

Panel

View

Page 20

1-2 Understanding Your Programmable Controller

For a PLC-5 controller to control I/O modules, both the contro ller and the

I/O modules must be directly attached to the same network.

Identifying Controller

Components

I/O Location Controller in

Panel A, chassis 1

Panel A, chassis 1 yes yes

Panel A, chassis 2 yes no

Panel A, chassis 3 yes no

Panel B, chassis 1 yes yes

Panel B, chassis 2 no yes

Panel C, chassis 1 yes yes

Controller in

Panel B, chassis 1

Evaluate what communications need to occur between controllers. If there is

sporadic information that is not time-critical, use a message-based network

such as an EtherNet/IP (the information portion) or Data Highway Plus

TM

.

To become familiar with the controller’s front panels, use these figures:

For the Front Panels Of Page

PLC-5/11, -5/20 and -5/26 controllers 1-3

PLC-5/30 controllers 1-4

PLC-5/40, -5/46, -5/60, -5/80 and -5/86 controllers 1-5

PLC-5/20E controllers 1-6

PLC-5/40E and -5/80E controllers 1-7

PLC-5/40L and -5/60L controllers 1-8

Publication 1785-UM012D-EN-P - July 2005

Page 21

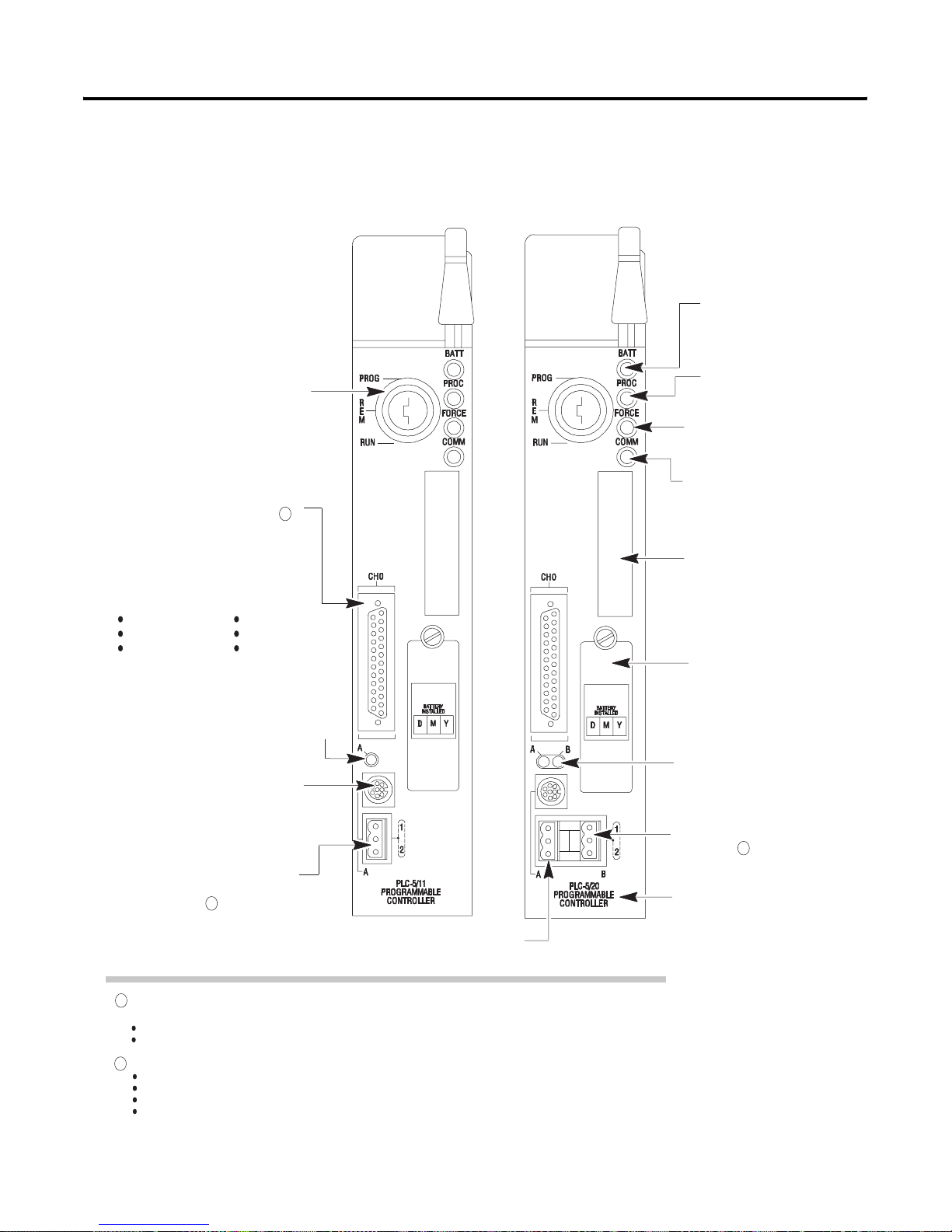

Understanding Your Programmable Controller 1-3

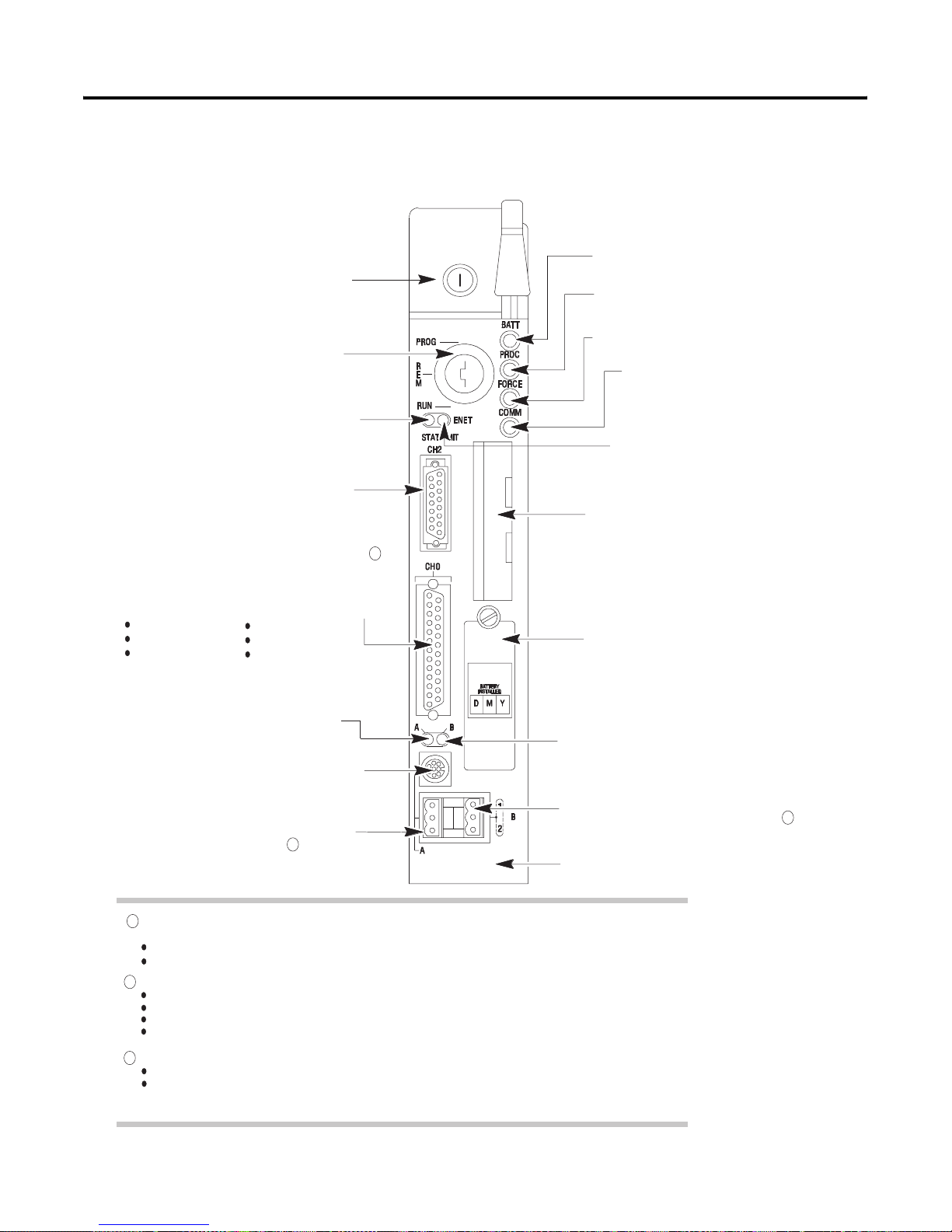

PLC-5/11, -5/20, and -5/26 Controll er Front Panels

keyswitch; selects controller mode

channel 0-25-pin D-shell serial port;

supports standard EIA RS-232C and

RS-423 and is RS-422A compatible

1

Use this port with ASCII or DF1

full-duplex, half-duplex master, and

half-duplex slave protocols. The port's

default configuration supports controller

programming:

DF1 point-to-point

2400 bps

no parity

one stop-bit

BCC error check

no handshaking

PLC-5/11 Controller

PLC-5/20 or -5/26 Controller

battery indicator (red when

the battery is low)

controller RUN/FAULT

indicator (green when

running; red when faulted)

force indicator (amber when

I/O forces are enabled)

channel 0 communication

status indicator (green when

the channel is communicating)

Install memory module here.

Install battery here

channel 1A status indicator

(lights green and red)

8-pin mini-DIN, DH+ programming

terminal connection parallel to

channel 1A

channel 1A communication port; for

the PLC-5/11 controller, the default

configuration is DH+

2

channel 1A communication port;

this 3-pin port is a dedicated DH+ port

1

Channel 0 is optically-coupled (provides high electrical noise immunity) and can be used with most RS-422A

equipment as long as:

termination resistors are not used

the distance and transmission rate are reduced to comply with RS-423 requirements

Configure these 3-pin ports for:

2

remote I/O scanner

remote I/O adapter,

DH+ communication

unused

channel 1B status indicator

(lights green and red)

channel 1B communication port;

its default configuration is remote

I/O scanner

2

PLC-5 family member designation

Publication 1785-UM012D - EN-P - July 2005

Page 22

1-4 Understanding Your Programmable Controller

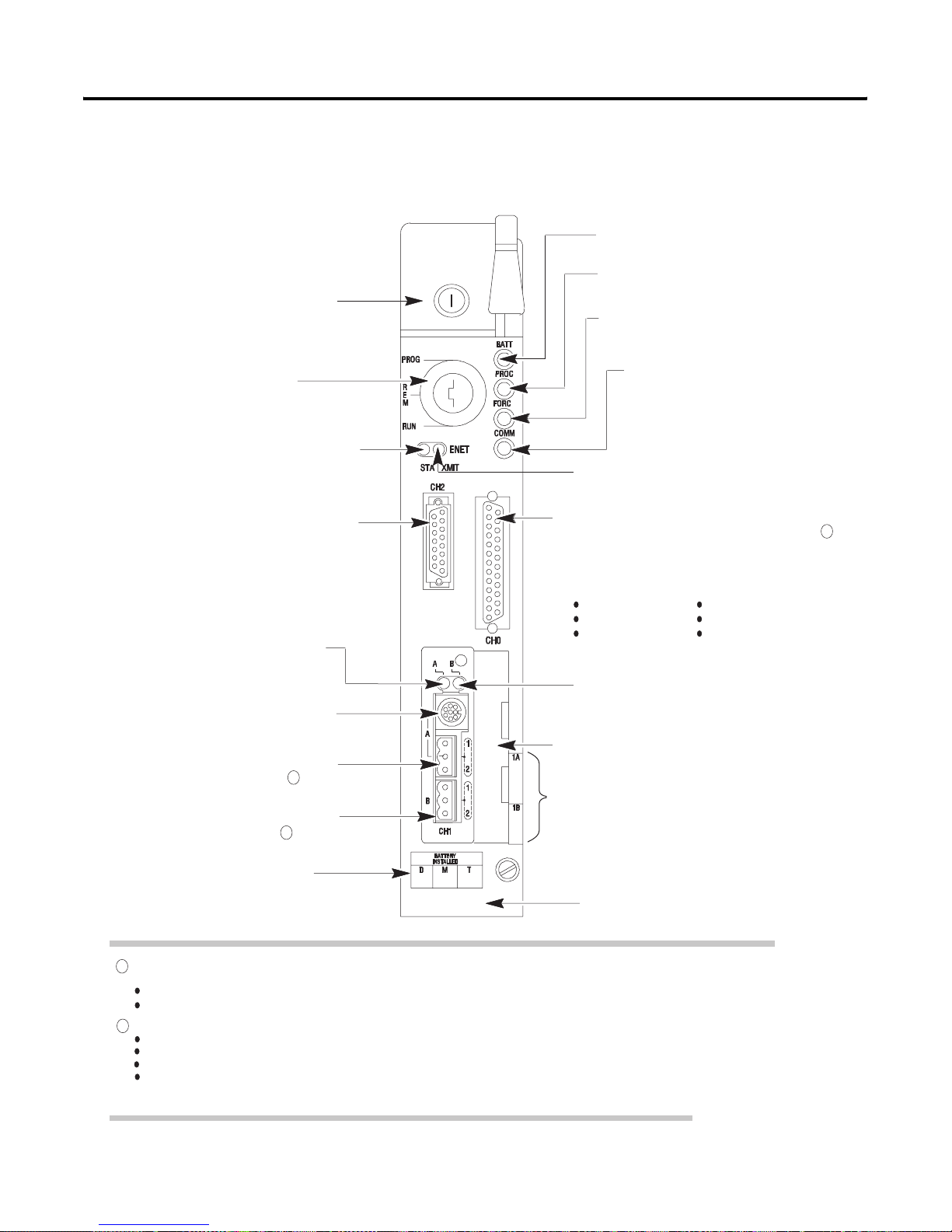

keyswitch; selects controler mode

channel 1A status indicator

(lights green and red)

PLC-5/30 Controller Front Panell

battery indicator (lights red when the

battery is low)

controller RUN/FAULT indicator (green

when running; red when faulted)

force indicator (amber when

I/O forces are enabled)

channel 0 communication status indicator

(green when the channel is communicating)

channel 0-25-pin D-shell serial port; supports standard

EIA RS-232C and RS-423 and is RS-422A compatible

Use this port with ASCII or DF1 full-duplex, half-duplex

master, and half-duplex slave protocols. The port's

default configuration supports processor programming:

DF1 point-to-point

2400 bps

no parity

one stop-bit

BCC error check

no handshaking

1

8-pin mini-DIN, DH+ programming terminal

connection parallel to channel 1A

channel 1A communication port;

its default configuration is DH+

channel 1B communication port;

its default configuration is remote I/O scanner

2

2

Install battery here

Channel 0 is optically-coupled (provides high electrical noise immunity) and can be used with most RS-422

1

equipment as long as:

termination resistors are not used

the distance and transmission rate are reduced to comply with RS-423 requirements

2

Configure these 3-pin ports for:

remote I/O scanner,

remote I/O adapter,

DH+ communication

unused

channel 1B status indicator (lights green and red)

Install memory module here

Use these labels to write information about the

channel: communication mode, station addresses, etc.

PLC-5 family member designation

Publication 1785-UM012D-EN-P - July 2005

Page 23

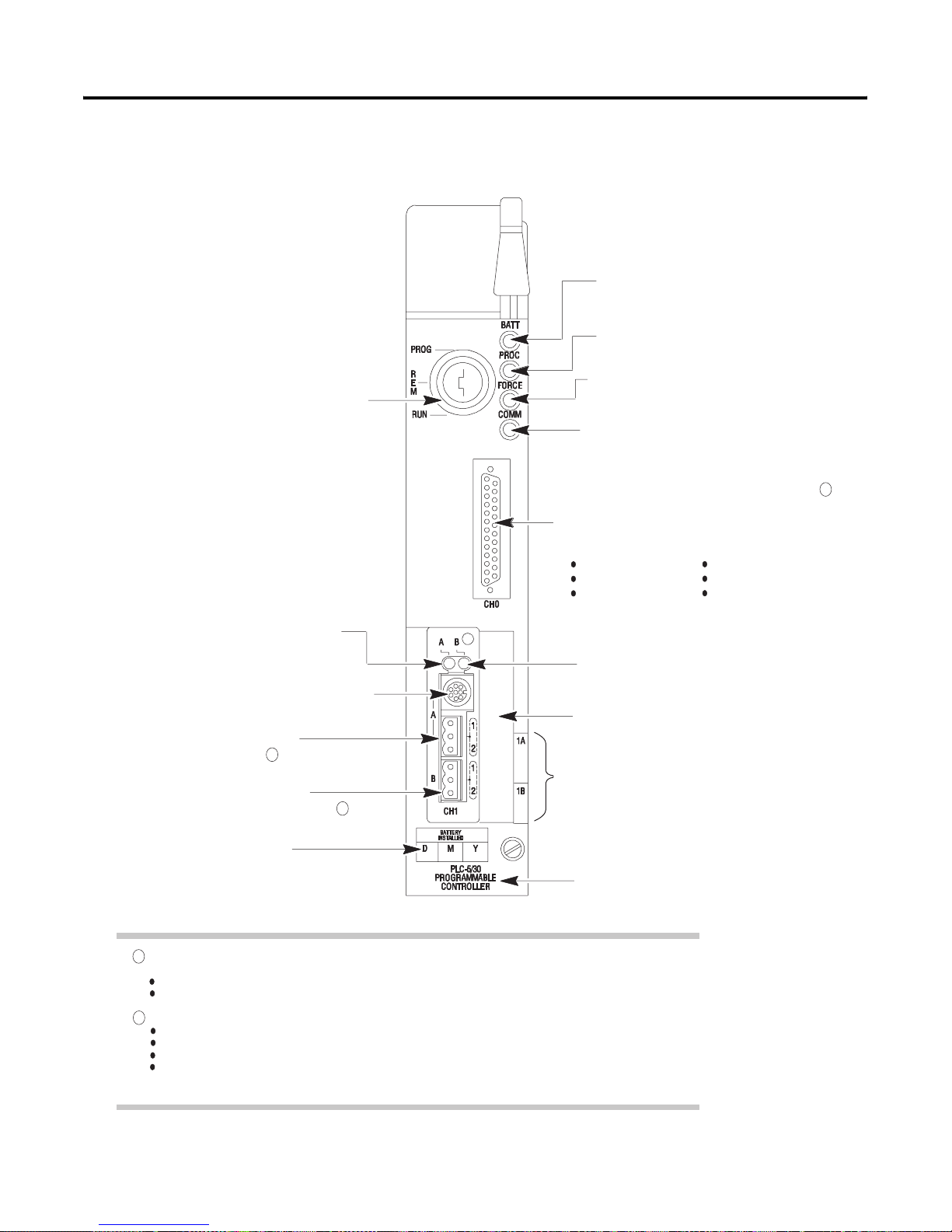

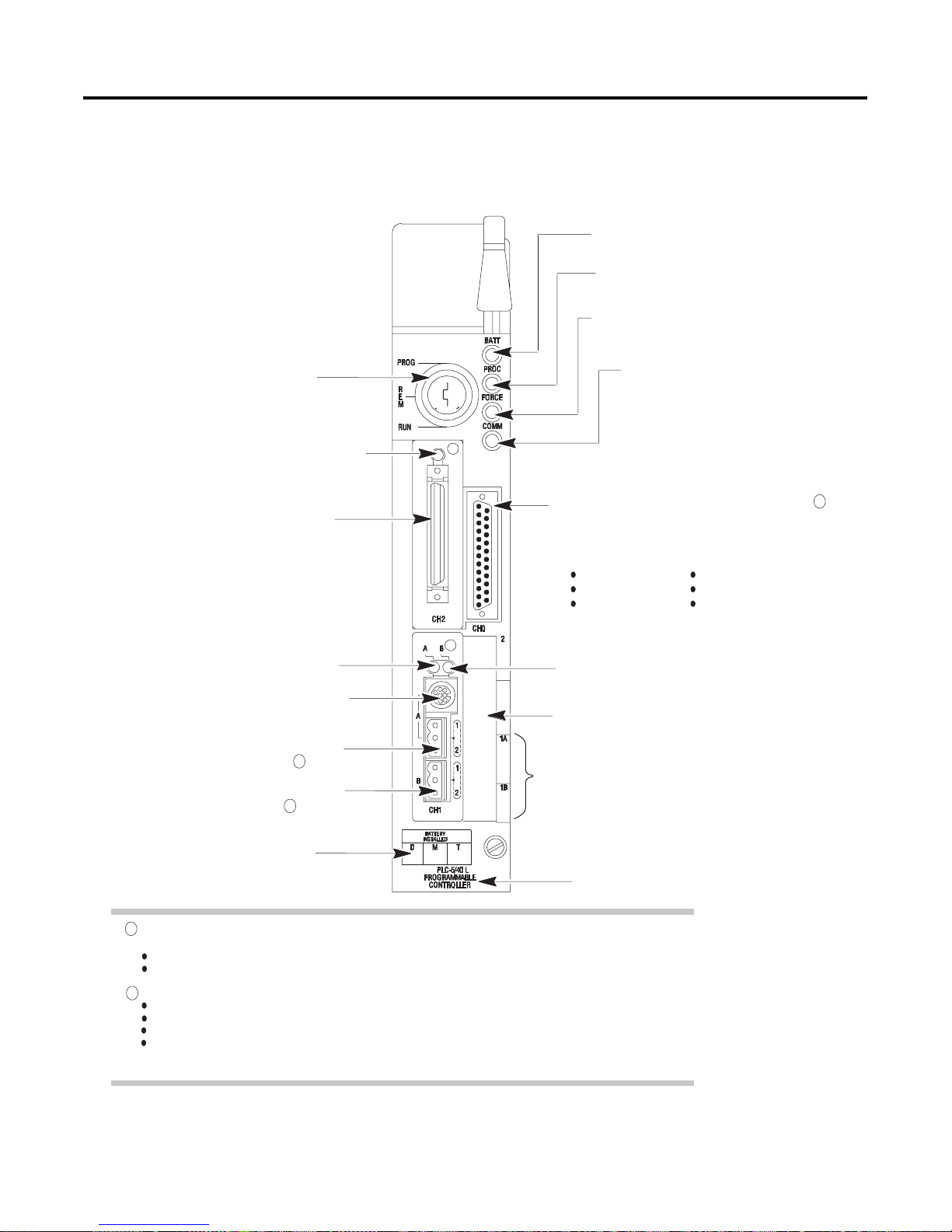

keyswitch; selects controller mode

channel 2A status indicator

(lights green and red)

Understanding Your Programmable Controller 1-5

PLC-5/40, -5/46, -5/60, -5/80, and -5/86 Controller Front Panel

battery indicator (red when the battery is low)

controler RUN/FAULT indicator (green when

running; red when faulted)

force indicator (amber when I/O forces are enabled)

channel 0 communication status indicator

(green when the channel is communicating)

8-pin mini-DIN, DH+ programming

terminal connection parallel to channel

2A when channel 2A is configured for

DH+ communications

channel 2A communication port;

its default configuration is unused

2

channel 2B communication port;

its default configuration is unused

2

channel 1A status indicator

(lights green and red)

8-pin mini-DIN, DH+ programming terminal

connection parallel to channel 1A

channel 1A communication port;

its default configuration is DH+

at 57.6 kbps

2

channel 1B communication port;

its default configuration is remote I/O scanner

channel 2B status indicator (lights green and red)

channel 0-25-pin D-shell serial port; supports standard

EIA RS-232C and RS-423 and is RS-422A compatible

1

Use this port with ASCII or DF1 full-duplex, half-duplex

master, and half-duplex slave protocols. The port's

default configuration supports processor programming:

DF1 point-to-point

2400 bps

no parity

one stop-bit

BCC error check

no handshaking

channel 1B status indicator (lights green and red)

Use these labels to write information about the

channel: communication mode, station addresses etc.

Install memory module here

2

Install battery here

1

Channel 0 is optically-coupled (provides high electrical noise immunity) and can be used with most RS-422A

equipment as long as:

termination resistors are not used

the distance and transmission rate are reduced to comply with RS-423 requirements

2

Configure these 3-pin ports for:

remote I/O scanner,

remote I/O adapter,

DH+ communication

unused

PLC-5 family member designation

Publication 1785-UM012D - EN-P - July 2005

Page 24

1-6 Understanding Your Programmable Controller

external transceiver fuse

keyswitch; selects controller mode

channel 2 Ethernet status indicator (green when

functioning normally; red when not functioning)

channel 2 communication port;

a 15-pin Ethernet port

channel 0*25-pin D-shell serial port; supports standard

EIA RS-232C and RS-423 and is RS-422A compatible

Use this port with ASCII or DF1 full-duplex, half-duplex

master, and half-duplex slave protocols. The port's

default configuration supports controller programming:

DF1 point-to-point

2400 bps

no parity

one stop-bit

BCC error check

no handshaking

PLC-5/20E Controller Front Pa ne l

1

battery indicator (red when the battery is low)

controller RUN/FAULT indicator (green when

running; red when faulted)

force indicator (amber when I/O forces

are enabled)

channel 0 communication status indicator

(green when the channel is communicating)

channel 2, Ethernet transmit indicator

(green when the channel is communicating)

Install memory module here

Install battery here

channel 1A status indicator

(lights green and red)

8-pin mini-DIN, DH+ programming terminal

connection parallel to channel 1A

channel 1A communication port; its default

configuration is DH+ communication

1

Channel 0 is optically-coupled (provides high electrical noise immunity) and can be used with most RS-422A

equipment as long as:

termination resistors are not used

the distance and transmission rate are reduced to comply with RS-423 requirements

2

Configure these 3-pin ports for:

remote I/O scanner

remote I/O adapter

DH+ communication

unused

Configure this 3-pin port for:

3

remote I/O adapter

DH+ communication

3

PLC-5/20E

Programmable

Controller

channel 1B status indicator

(lights green and red)

channel 1B communication port;

its default configuration is remote I/O scanner

PLC-5 family member designation

2

Publication 1785-UM012D-EN-P - July 2005

Page 25

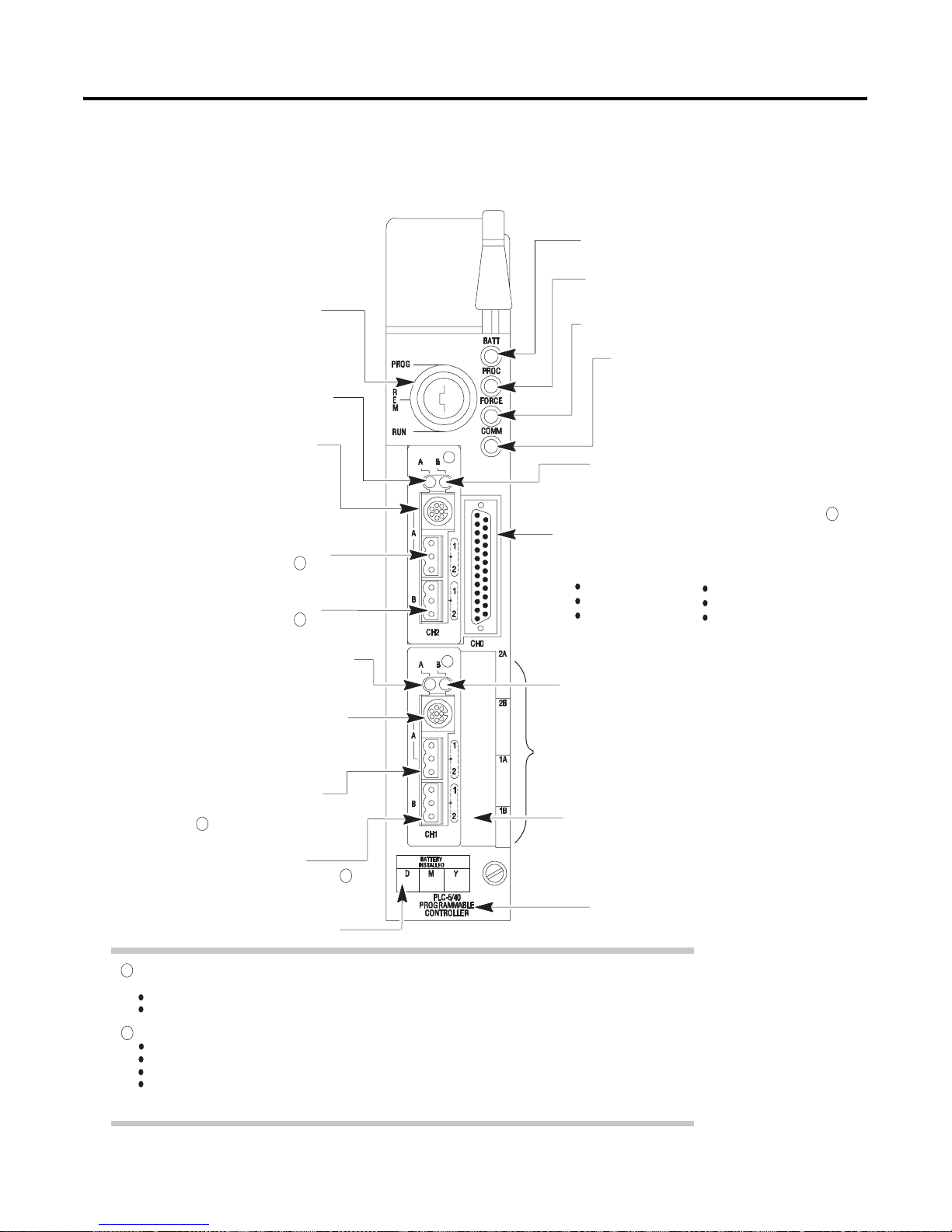

external transceiver fuse

keyswitch; selects controller mode

channel 2 Ethernet status indicator (green when

functioning normally; red when not functioning)

PLC-5/40E and -5/80E Con troller Front Panels

Understanding Your Programmable Controller 1-7

battery indicator (red when the battery is low)

controller RUN/FAULT indicator (green when

running; red when faulted)

force indicator (amber when I/O forces

are enabled)

channel 0 communication status indicator

(green when the channel is communicating)

channel 2, Ethernet transmit indicator (green when

the channel is communicating)

channel 2 communication port;

a 15-pin Ethernet port

channel 1A status indicator

(lights green and red)

8-pin mini-DIN, DH+ programming terminal

connection parallel to channel 1A

channel 1A communication port; its default

configuration is DH+ communication

2

channel 1B communication port; its default

configuration is remote I/O scanner

2

Install battery here

PLC-5/40E

Programmable

Controller

Channel 0 is optically-coupled (provides high electrical noise immunity) and can be used with most RS-422A

1

equipment as long as:

termination resistors are not used

the distance and transmission rate are reduced to comply with RS-423 requirements

2

Configure these 3-pin ports for:

remote I/O scanner

remote I/O adapter

DH+ communication

unused

channel 0-25-pin D-shell serial port; supports standard

EIA RS-232C and RS-423 and is RS-422A compatible

Use this port with ASCII or DF1 full-duplex, half-duplex

master, and half-duplex slave protocols. The port's

default configuration supports controller programming:

DF1 point-to-point

2400 bps

no parity

one stop-bit

BCC error check

no handshaking

channel 1B status indicator (lights green and red)

Install memory module here

Use these labels to write information about the

channel: communication mode, station addresses etc.

PLC-5 family member designation

1

Publication 1785-UM012D - EN-P - July 2005

Page 26

1-8 Understanding Your Programmable Controller

PLC-5/40L and -5/6 0L Controller Front Panels

battery indicator (red when the battery is low)

controller RUN/FAULT indicator (green when

running; red when faulted)

force indicator (amber when I/O forces

are enabled)

keyswitch; selects controller mode

channel 2 extended-local I/O status indicator

(green when functioning normally; red when

not functioning)

channel 2 communication port; a 50-pin,

dedicated extended-local I/O port

channel 1A status indicator

(lights green and red)

8-pin mini-DIN, DH+ programming terminal

connection parallel to channel 1A

channel 1A communication port; its default

2

configuration is DH+ communication

channel 1B communication port; its default

configuration is remote I/O scanner

2

channel 0 communication status indicator

(green when the channel is communicating)

channel 0*25-pin D-shell serial port; supports standard

EIA RS-232C and RS-423 and is RS-422A compatible

Use this port with ASCII or DF1 full-duplex, half-duplex

master, and half-duplex slave protocols. The port's

default configuration supports controler programming:

DF1 point-to-point

2400 bps

no parity

one stop-bit

BCC error check

no handshaking

channel 1B status indicator (lights green and red)

Install memory module here

Use these labels to write information about the

channel: communication mode, station addresses etc.

1

Install battery here

1

Channel 0 is optically-coupled (provides high electrical noise immunity) and can be used with most RS-422A

equipment as long as:

termination resistors are not used

the distance and transmission rate are reduced to comply with RS-423 requirements

Configure these 3-pin ports for:

2

remote I/O scanner,

remote I/O adapter,

DH+ communication

unused

Publication 1785-UM012D-EN-P - July 2005

PLC-5 family member designation

Page 27

Understanding Your Programmable Controller 1-9

Use the keyswitch to change the mode in which a controller is operating.

If You Want to Turn the Keyswitch to

• Run your program.

Outputs are enabled. (Equipment being controlled by the I/O

addressed in the ladder program begins operation.)

• Force I/O.

• Save your programs to a disk drive (during operation).

• Enable outputs.

• Edit data table values.

Notes:

• You cannot create or delete a program file, create or delete

data files, edit online, or change the modes of operation

through the programming software while in run mode.

• You can prevent forcing and data table changes by

usingRSLogix5 programming software to set user control bit

S:26/6.

• Disable outputs (outputs are turned off).

• Create, modify, and delete ladder files, SFC files, or data

files.

• Download to/from a memory module.

• Save/restore programs.

Notes:

• The controller does not scan the program.

• You cannot change the mode of operation through the

programming software while in program mode.

Change between remote program, remote test, and remote run

modes through the programming software.

RUN

PROG

R

E

M

RUN

PROG (program)

PROG

R

E

M

RUN

REM (remote)

Remote run

• Enable outputs.

• Save/restore programs.

• Edit while operating.

Remote program

See the program-mode description above.

Remote test

• Execute ladder programs with outputs disabled.

• Cannot create or delete ladder programs or data files.

• Save/restore programs.

• Edit while operating.

PROG

R

E

M

RUN

Publication 1785-UM012D - EN-P - July 2005

Page 28

1-10 Understanding Your Programmable Controller

Programming Features

This Capability Lets You

Ladder logic program using a language that is representative of relay logic.

Subroutines store recurring sections of program logic that can be accessed from multiple program

Sequential Function Charts

(SFCs)

This table highlights the programming features of a PLC-5 programmable

controller.

Choose this language

• if you are more familiar with ladder logic than with programming languages such

as BASIC

Your plant personnel may be more familiar with ladder logic; consider their needs

as well.

• performing diagnostics

• programming discrete control

files.

A subroutine saves memory because you program repetitive logic only once. The JSR

instruction directs the controller to go to a separate subroutine file within the logic

controller , scan that subroutine file once, and return to the point of departure.

use sequence-control language to control and display the state of a sequential process.

Instead of using one long ladder program for your application, divide the logic into steps

and transitions. A step corresponds to a control task; a transition corresponds to a

condition that must occur before the programmable controller can perform the next

control task. The display of these steps and transitions lets you see what state the

machine process is in at a given time via a flowchart form.

SFCs offer constructs that enable execution of multiple paths of logic, or a single

selected path of logic, as well as the ability to jump forwards and backwards.

Troubleshooting can be reduced to a small routine of logic instead of an entire ladder

file.

SFCs are best for defining the order of events in a sequential process.

Structured text program using a language similar to BASIC.

Choose structured text if you are:

• more familiar with programming languages such as BASIC than with ladder logic

• using complex mathematical algorithms

• using program constructs that repeat or “loop”

• creating custom data-table monitoring screens

Main Control Programs

(MCPs)

separate sequential logic from ladder logic and structured text as a way of modularized

your process and making troubleshooting easier.

Use several main control programs (MCPs) to define one main control program for each

particular machine or function of your process. MCPs accommodate independent or

non-sequential activities.

A main control program can be an SFC file numbered 1-999 or a ladder-logic file or

structured-text program numbered 2-999.

One data table is used by all MCPs (i.e., you do not have a separate data table for each

MCP).

Publication 1785-UM012D-EN-P - July 2005

Page 29

Understanding Your Programmable Controll er 1-11

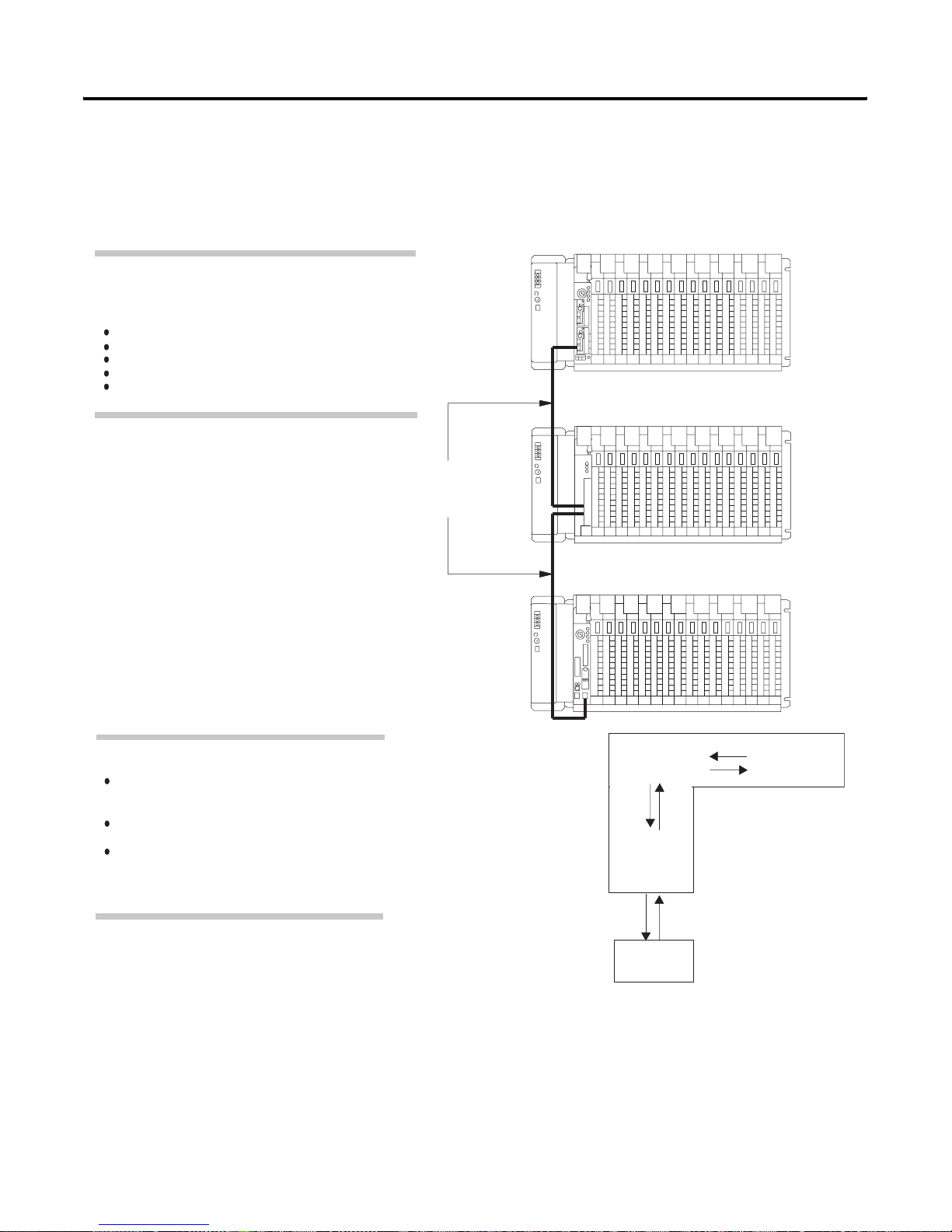

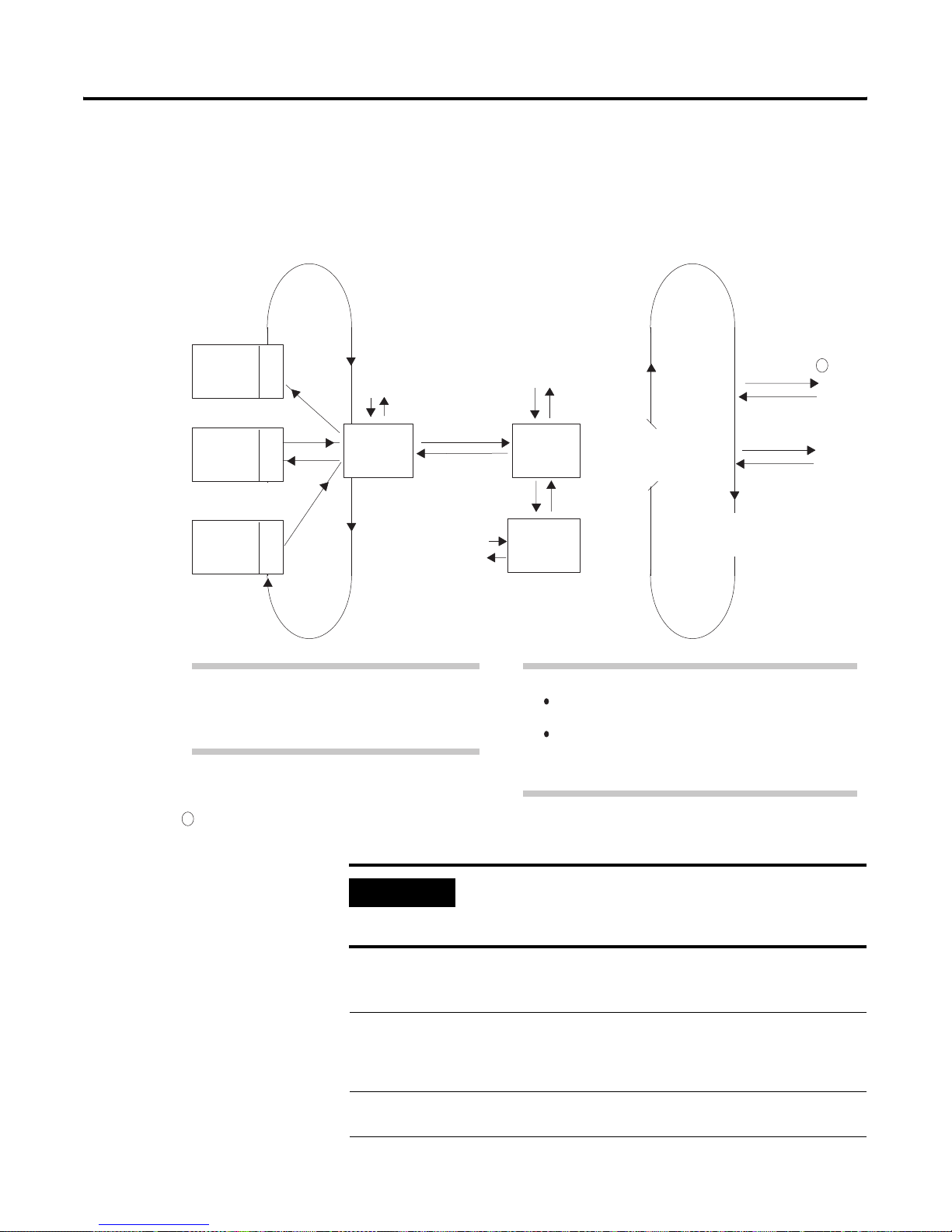

Using a Controller Channel

Configure a remote I/O channel for scanner mode to read and write I/O

information between a controller and an I/O device remotely located from the

as a Remote I/O Scanner

A controller with a channel configured for scanner mode

acts as a supervisory controller for other controllers that

are in adapter mode as well as remote I/O adapter modules.

The scanner-mode PLC-5 controller can:

gather data from node adapter devices in remote I/O racks

process I/O data from 8-, 16-, or 32-point I/O modules

address I/O in 2-, 1-, or 1/2-slot I/O groups

support a complementary I/O configuration

support block-transfer in any I/O chassis

controller.

PLC-5/40

1771-ASB

Remote I/O

Link Cable:

Belden 9463

PLC-5/20

The scanner-mode PLC-5 controller:

transfers discrete data and block-transfer data

to/from modules in remote I/O racks as well as

to/from controllers in adapter mode.

scans remote I/O buffers asynchronously to the

program scan.

updates the input/output image data table from

the remote I/O buffer(s) synchronously to the

program scan

PLC-5 data table

is updated

synchronously to

program scan

(at housekeeping).

Remote I/O buffers

are updated

asynchronously to

the program scan.

PLC-5

Data Table

Output

Remote I/O

Buffer

Output Input

Input

Remote I/O

Link

Controller

-resident

I/O

Publication 1785-UM012D - EN-P - July 2005

Page 30

1-12 Understanding Your Programmable Controller

A controller transfers I/O data and status data using:

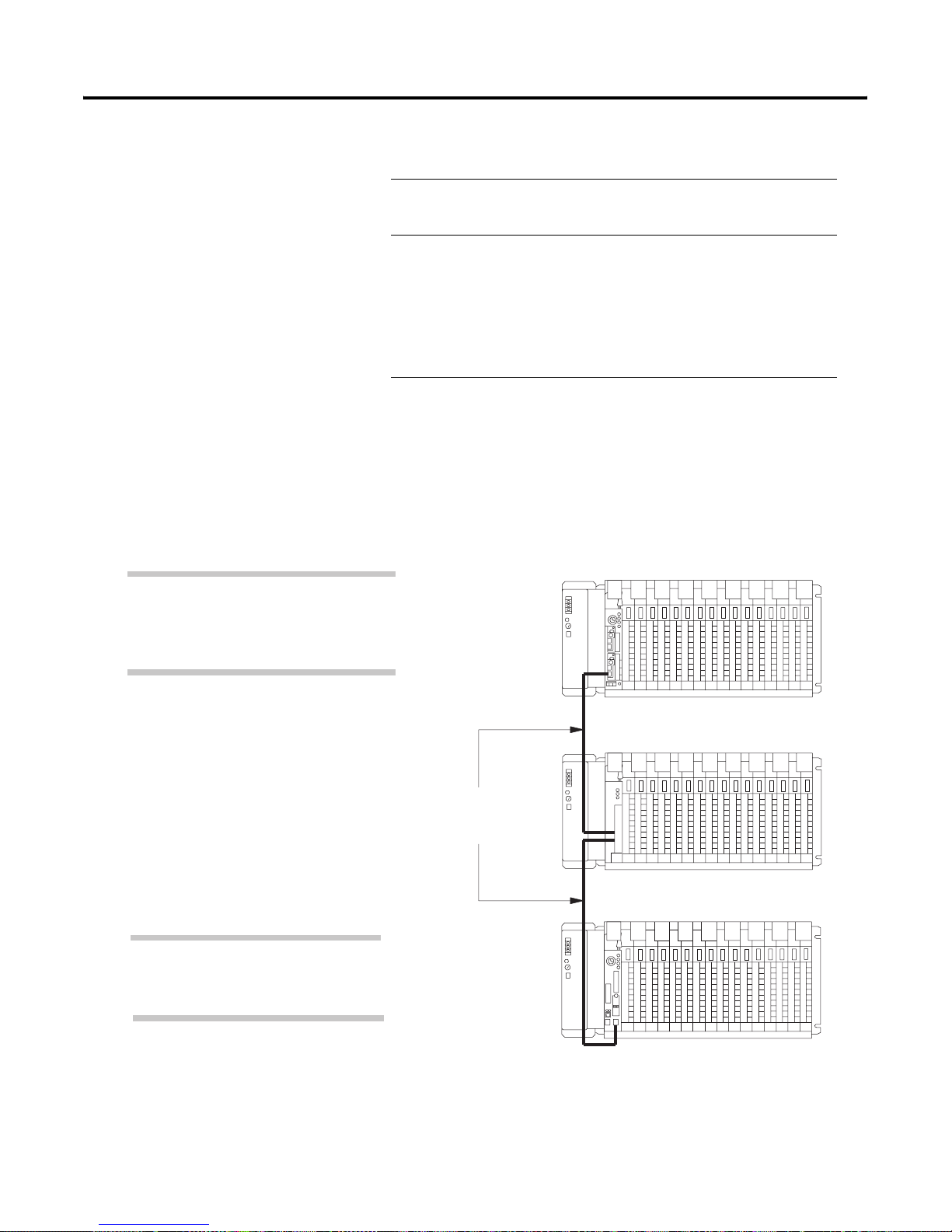

Using a Controller Channel

as a Remote I/O Adapter

In this example, a PLC-5/40 controller channel is

the supervisory (scanner-mode) controller of the

1771-ASB module and the PLC-5/20 controller.

• discrete

data transfers of 8 words per rack

transfers

occur automatically on the remote I/O network

• block-transfers special data transfers that require ladder logic

instructions to achieve the transfer

allow a transfer of a maximum of 64 words of data

also used to communicate information between a

scanner channel and an adapter-mode controller

channel

Configure a controller channel for adapter mode when you need predictable,

real-time exchange of data between a distributed control adapter-mode

controller channel and a supervisory controller. The remote I/O adapter

channel exchanges data with a supervisory controller.

PLC-5/40

Connect the controllers via the remote I/O link.

You can monitor status between the

supervisory controller and the adapter-mode

PLC-5 controller channel at a consistent rate

(i.e., the transmission rate of the remote I/O link

is unaffected by programming terminals and

other non-control-related communications).

The adapter-mode PLC-5 controller can monitor

and control its controller-resident local I/O while

communicating with the supervisory controller via

a remote I/O link.

1771-ASB

Remote I/O

Link Cable:

Belden 9463

PLC-5/20

Publication 1785-UM012D-EN-P - July 2005

Page 31

Understanding Your Programmable Controll er 1-13

For Enhanced and Ethernet programmable controller channels in adapter

mode, you do n ot ne ed ladder logic i n the a dapter c ontroll er for block- tran sfer

instructions. You define the block-transfers via an adapter configuration

screen and by defining block-transfer files.

Supervisory

Controller

1

The following programmable controllers can operate as supervisory controllers:

PLC-2/20 and PLC-2/30 controllers

PLC-3 and PLC-3/10 controllers

PLC-5/15 and PLC-5/25E controllers

All Enhanced and Ethernet PLC-5 controllers; separate channels can be configured for a remote I/O scanner and an adapter

PLC-5/V30, PLC-5/V40, PLC-5/V40L, and PLC-5/V80 controllers

PLC-5/250 controllers

All PLC-5 family controllers, except the PLC-5/10, can operate as remote I/O adapter modules

2

1

Remote I/O Link

PLC-5 controller

channel in

adapter mode

1771 I/O

2

Remote I/O Link

PanelView

Publication 1785-UM012D - EN-P - July 2005

Page 32

1-14 Understanding Your Programmable Controller

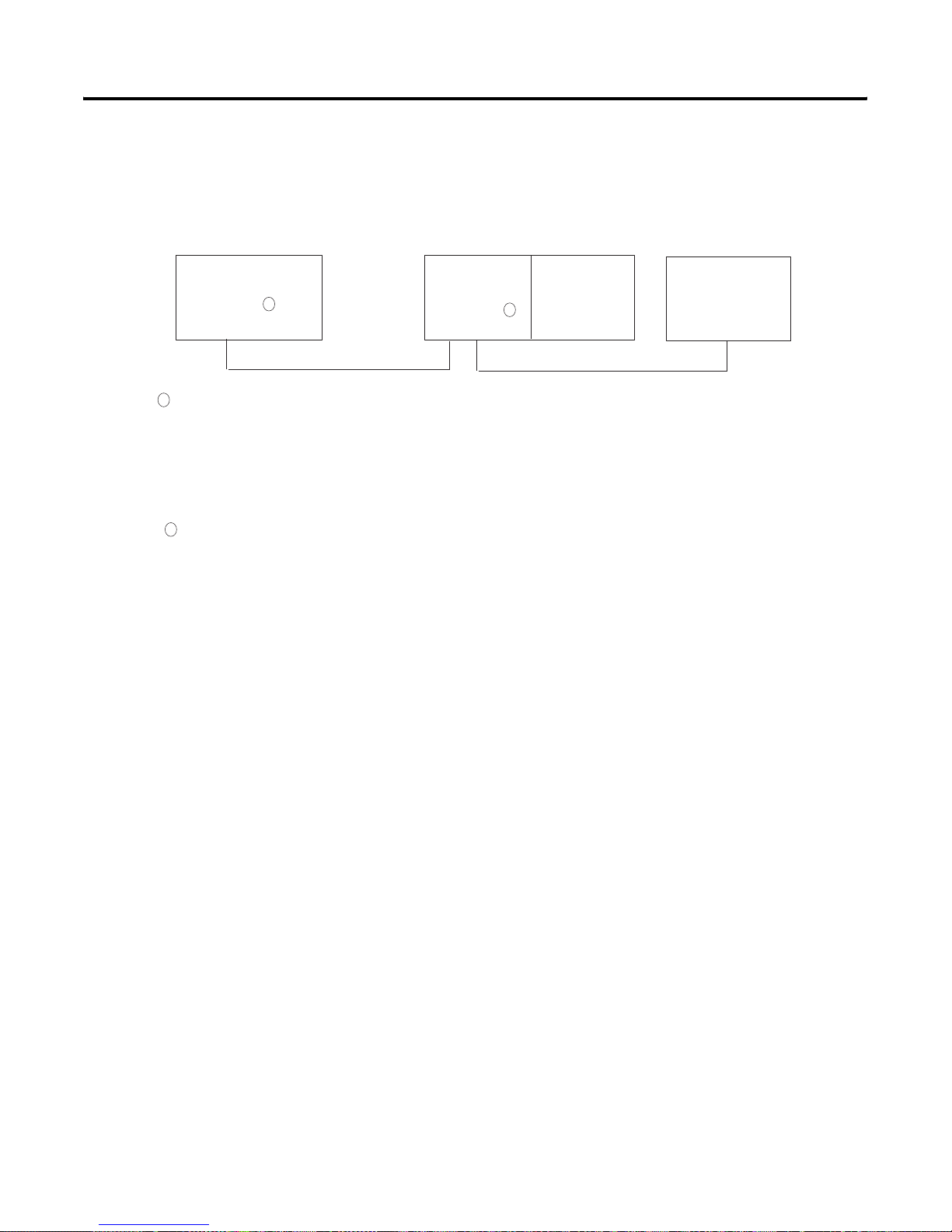

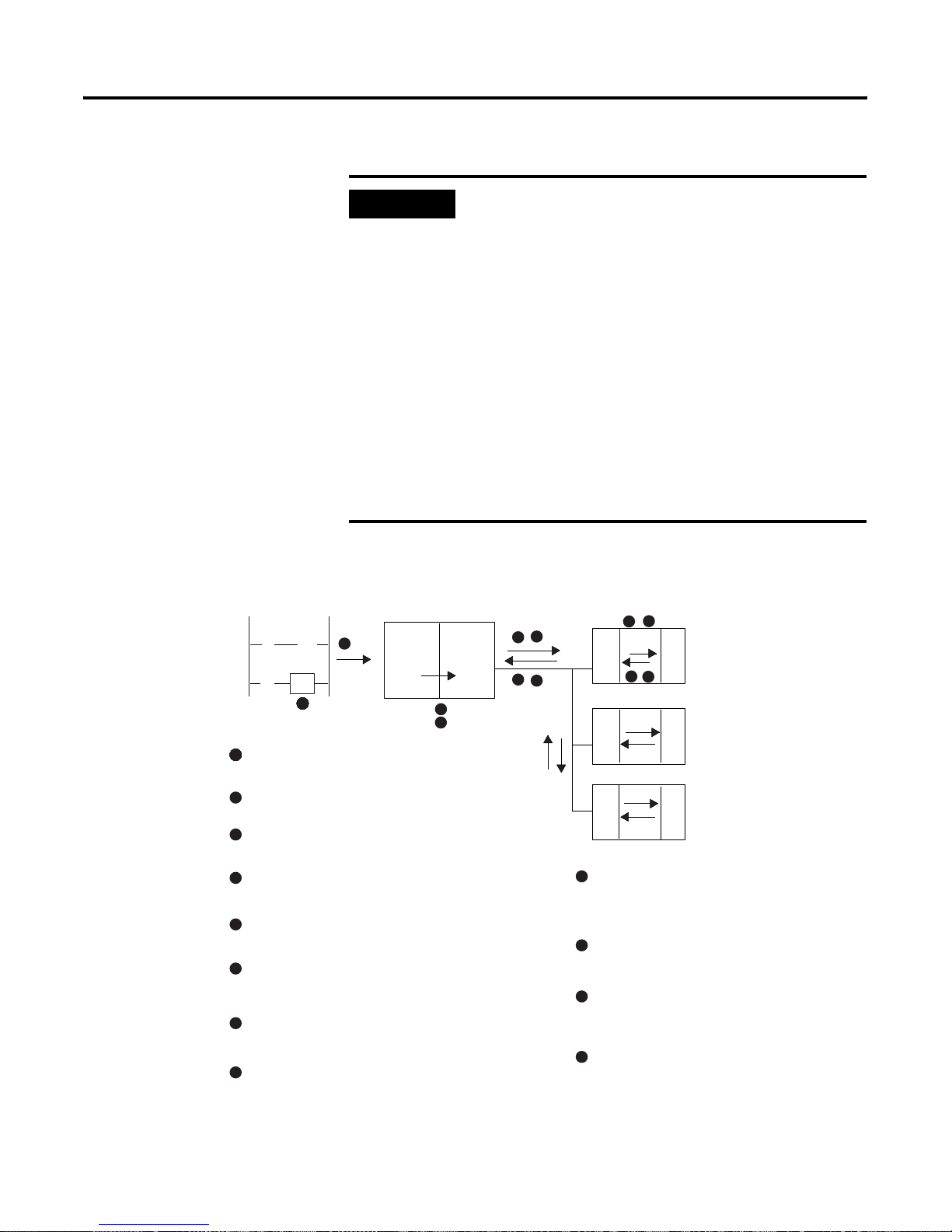

Using a PLC-5/40L, -5/60L

Programmable Controller

as an Extended-Local I/O

Scanner

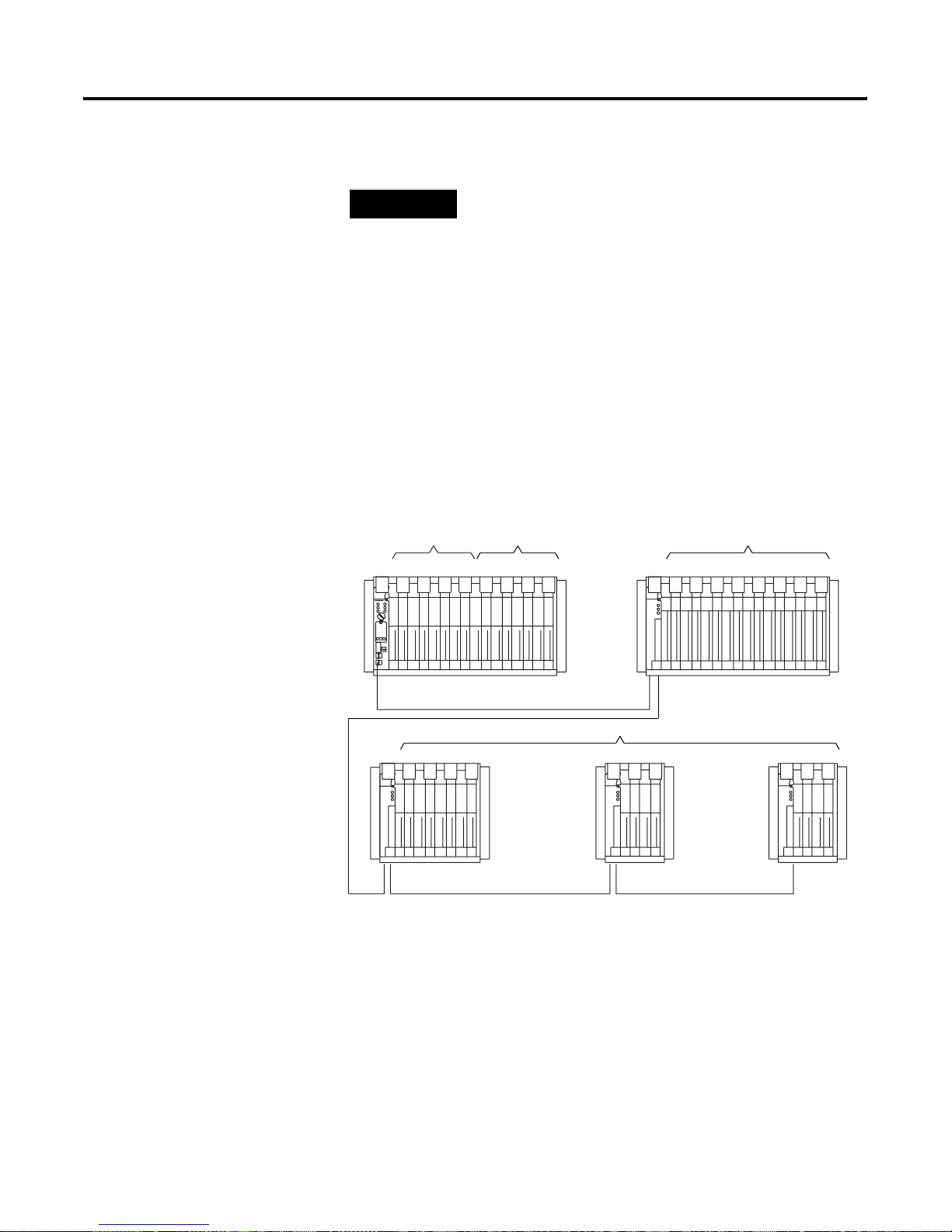

A PLC-5/40L or -5/60L controller (channel 2) and an

extended-local I/O adapter module (1771-ALX) form an

extended-local I/O link.

The extended-local I/O link is a parallel link that enables a

PLC-5/40L or -5/60L controller to scan a maximum of 16

extended-local I/O chassis.

Due to the cabling design, you can remove an adapter module

from a chassis on the extended-local I/O link without disrupting

communication to other chassis on the extended-local I/O link.

Important: The PLC-5/40L and -5/60L controllers cannot be

used as extended-local I/O adapters.

Use the extended-local I/O link when you need I/O updates more quickly

than is possible from remote I/O link. An extended-local I/O link provides

faster scan and update time than a remote I/O lin k. The extended-local I/O

link is limited to 30.5 cable-m (100 cable-ft). If an I/O chassis is located more

than 30.5m from the controller, you must use a remote I/O link.

PLC-5/60L

Extended-local

I/O Link Cable:

1771-CXx

1771-ALX

ExtendedLocal

I/O Link

Input

Output

PLC-5 data table

is updated

synchronously to

program scan

(at housekeeping).

Remote I/O buffers

are updated

asynchronously to

the program scan.

PLC-5 data table

OutputInput

Remote

I/O

Buffer

OutputInput

Remote I/O

Link

Input

Output

ControllerResident

Local I/O

Publication 1785-UM012D-EN-P - July 2005

Page 33

Using This Chapter

Selecting and Placing I/O

For Information About Go to Page

Selecting I/O modules 2-1

Selecting I/O module density 2-2

Placing I/O modules in a chassis 2-3

Chapter

2

Selecting I/O Modules

Select I/O modules to interface your PLC-5 controller with machines or

processes that you determine while analyzing your plant operation.

Use the following list and table as guidelines for selecting I/O modules and

operator control interface(s).

• How much I/O is required to control your process(es)?

• Where will you concentrate I/O points for portions of an entire process

when the entire process is distributed over a large physical area?

• What type of I/O is required to control your process(es)?

• What is the required voltage range for each I/O mod ule?

• What is the backplane current required for each I/O module?

• What are the noise and distance limitations for each I/O module?

• What isolation is required for each I/O module?

1 Publication 1785-UM012D - EN-P - July 2005

Page 34

2-2 Selecting and Placing I/O

Guidelines for Selecting I/O Modules

Choose this Type of

I/O Module

Discrete input module

and block I/O module

Discrete output module

and block I/O module

Analog input module Temperature transducers, pressure transducers, load cell

Analog output module Analog valves, actuators, chart recorders, electric motor

Specialty I/O modules Encoders, flow meters, I/O communication, ASCII, RF type

Selecting I/O Module

For these Types of Field Devices or Operati ons

(examples)

Selector switches, pushbuttons, photoelectric eyes, limit

switches, circuit breakers, proximity switches, level

switches, motor starter contacts, relay contacts,

thumbwheel switches

Alarms, control relays, fans, lights, horns, valves, motor

starter , or solenoids

transducers, humidity transducers, flow transducers, and

potentiometers

drives, analog meters

devices, weigh scales, bar-code readers, tag readers,

display devices

The density of an I/O module is the number of controller input or output

image-table bits to which it corresponds. A bidirectional module with 8 input

Density

bits and 8 output bits has a density of 8. I/O module density helps determine

your I/O addressing scheme. See chapter 4 for more information about I/O

addressing.

Explanation

Input modules sense on/off or opened/closed

signals. Discrete signals can be either ac or dc.

Output module signals interface with on/off or

opened/closed devices. Discrete signals can be

either ac or dc.

Convert continuous analog signals into input values

for the PLC controller.

Interpret PLC controller output to analog signals

(generally through transducers) for field devices.

Are generally used for specific applications such as

position control, PID, and external device

communication.

Publication 1785-UM012D-EN-P - July 2005

Use these guidelines for selecting I/O module density:

Choose this I/O Density If You

8-point I/O module • currently use 8-point modules

• need integral, separately-fused outputs

• want to minimize cost per module

16-point I/O module • currently use 16-point modules

• need separately-fused outputs with a special

wiring arm

32-point I/O module • currently use 32-point modules

• want to minimize number of modules

• want to minimize the space required for I/O

chassis

• want to minimize cost per I/O point

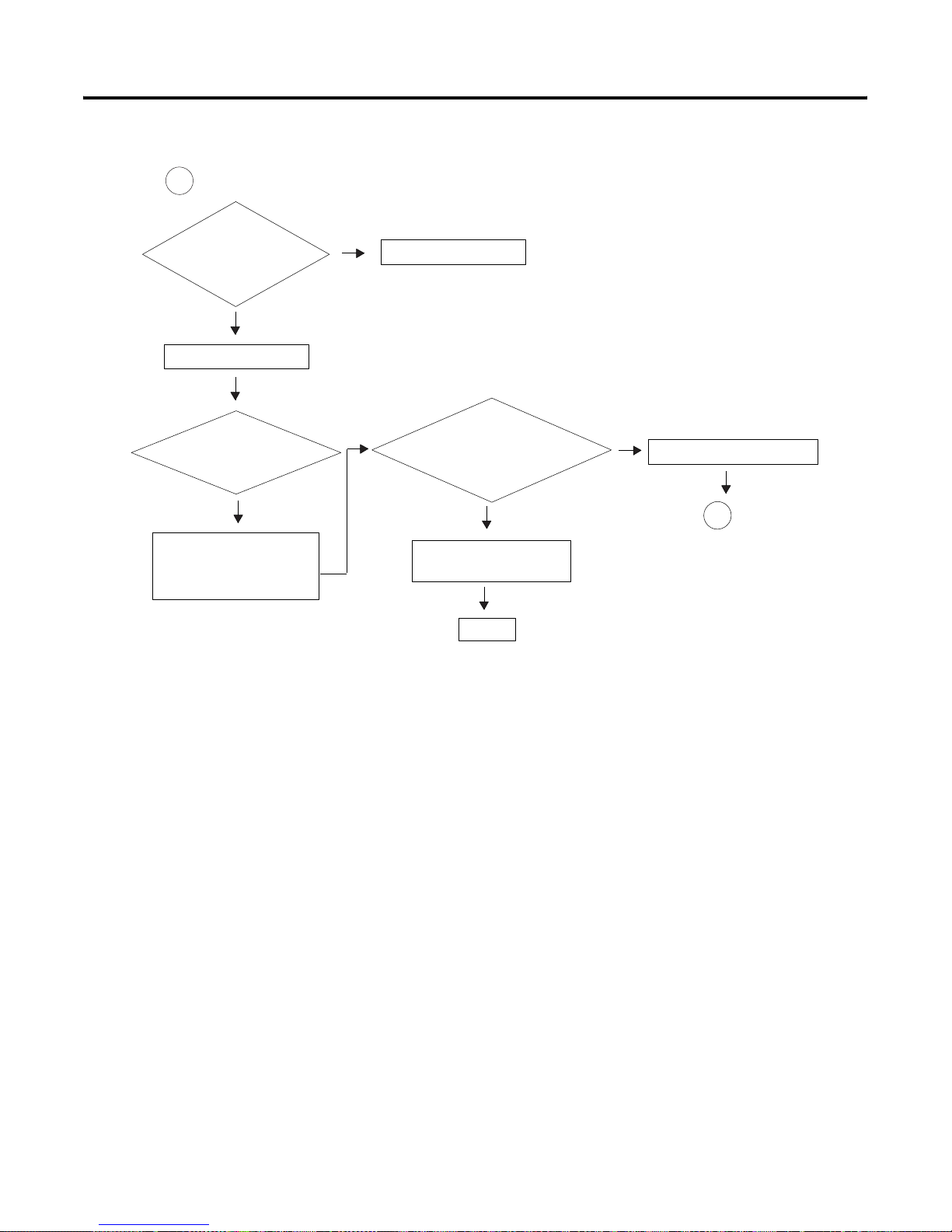

Page 35

Selecting and Placing I/ O 2-3

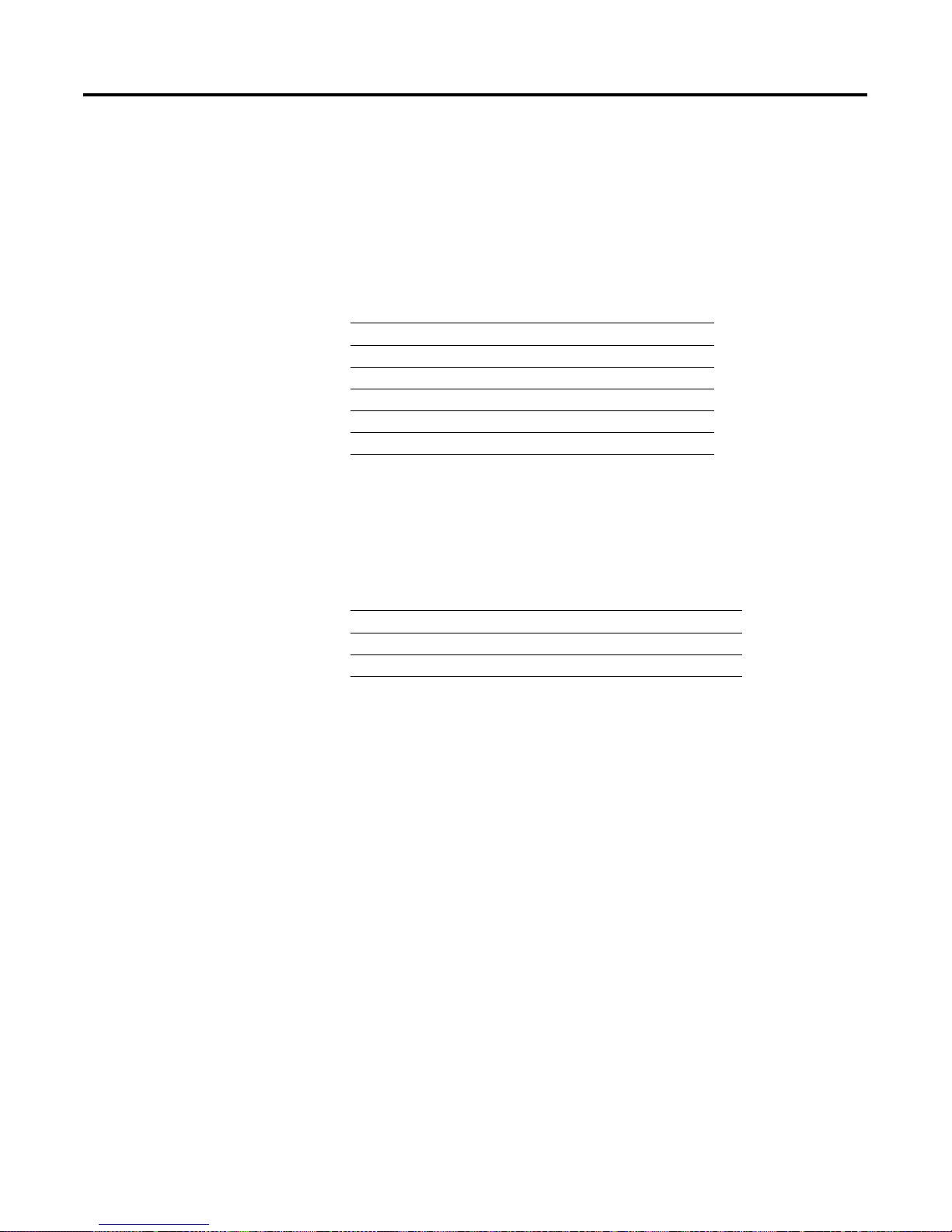

Placing I/O Modules in a

Chassis

Module placement priority:

1. block-transfer modules (all types)

2. dc input modules

3. dc output modules

4. ac input modules

5. ac output modules

Place block-transfer modules according to these guidelines:

Place as many modules as possible for which you need

fast block-transfer times in your controller-resident local

I/O chassis.

Place modules in which block-transfer timing is not as

critical in remote I/O chassis.

Ac output modules should always be the furthest I/O

modules away from any block-transfer modules in the

same chassis.

Place I/O modules in a chassis depending on the electrical characteristics of

the module. The placement is made left to right, with the left-most position

being closest in the chassis to the PLC-5 controller or the I/ O adapter module.

The placement order is as follows:

Priority:

P

L

C

/

A

S

B

1

Block

Transfer

212334455

Block

Transfer

dc

inputdcinputdcoutputdcoutputacinputacinputacoutputacoutput

lowV highV

Place input and output modules according to

these guidelines:

left to right

lowest voltage to highest voltage

For optimal speed using discrete I/O, use the

following module-placement priority scheme:

1. controller chassis

2. extended-local I/O chassis

3. remote I/O chassis

empty

Publication 1785-UM012D - EN-P - July 2005

Page 36

2-4 Selecting and Placing I/O

Notes

Publication 1785-UM012D-EN-P - July 2005

Page 37

Using This Chapter

Placing System Hardware

For Information About Go to Page

Determining the proper environment 3-1

Protecting your controller 3-3

Avoiding electrostatic damage 3-3

Laying out your cable raceway 3-4

Laying out your backpanel spacing 3-5

Grounding your system 3-6

Chapter

3

Determining the Proper

Environment

Place the controller in an environment with conditions that fall within these

guidelines:

Environmental Condition Acceptable Range

Operating temperature 0 to 60° C (32 to 140° F)

Storage temperature -40 to 85° C (-40 to 185° F)

Relative humidity 5 to 95% (without condensation)

Separate your programmable controller system from other equipment and

plant walls to allow for convection cooling. Convection cooling draws a

vertical column of air upward over the controller. This cooling air must not

exceed 60° C (140° F) at any point immediately below the controller . If the air

temperature exceeds 60° C, install fans that bring in filtered air or recirculate

internal air inside the enclosure, or install air-conditioning/heat-exchanger

units.

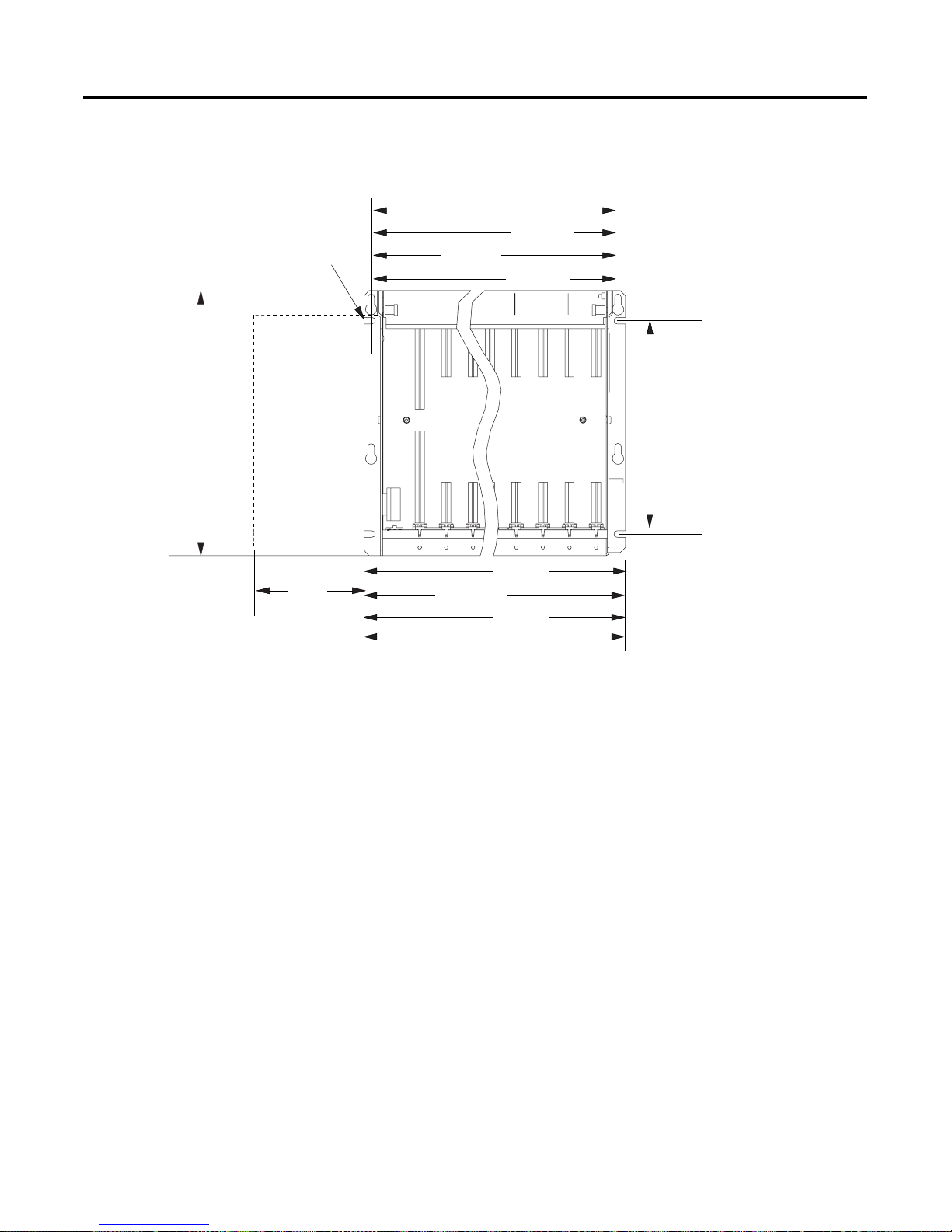

To allow for proper convection cooling in enclosures containing a