Allen-Bradley 1769-L24ERQBFC1B, 1769-L18ER-BB1B, 1769-L27ERM-QBFC1B, 1769-L30ER, 1769-L30ERM User Manual

...Page 1

User Manual

CompactLogix 5370 Controllers

Catalog Numbers 1769-L16ER-BB1B, 1769-L18ER-BB1B, 1769-L18ERM-BB1B, 1769-L19ER-BB1B, 1769-L24ER-QB1B, 1769-L24ERQBFC1B, 1769-L27ERM-QBFC1B, 1769-L30ER, 1769-L30ER-NSE, 1769-L30ERM, 1769-L33ER, 1769-L33ERM, 1769-L36ERM

Для уменьшения размера файла удалены фотографии обложки и пустые страницы между разделами

Page 2

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

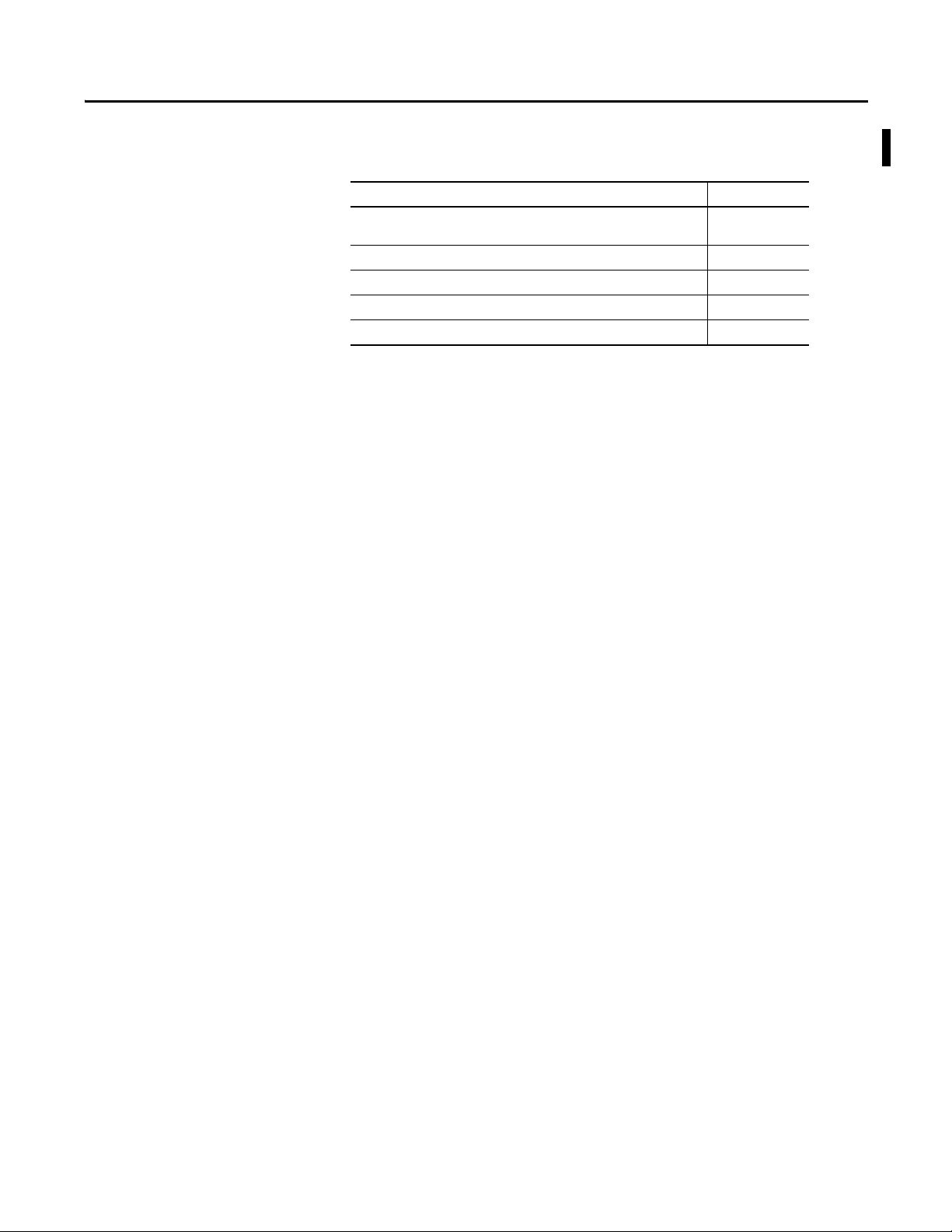

Top ic Pag e

Added 1769-L19ER-BB1B information Throughout

Added section Install the Removable Terminal Block 25

Added section Install the Removable Terminal Block 49

Added section Install the Removable Terminal Block 64

Updated the information on depleting stored energy from the 1769-L30ER-NSE 118

document

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 3

Page 3

Table of Contents

Preface

Install the CompactLogix 5370 L1

Controller

Install the CompactLogix 5370 L2

Controller

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

CompactLogix 5370 L1 Controller Parts. . . . . . . . . . . . . . . . . . . . . . . 18

Installation Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Install the Secure Digital Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Install the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Mount the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Ground the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Install the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Install the Removable Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connect Power to the Controller (Series B) . . . . . . . . . . . . . . . . . . . . 26

Connect to the Controller via a USB Cable . . . . . . . . . . . . . . . . . . . . . . . . 31

Connect the Controller to an EtherNet/IP Network. . . . . . . . . . . . . . . . 32

Connecting to Different EtherNet/IP Network Topologies. . . . . . 32

Chapter 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

CompactLogix 5370 L2 Controller Parts. . . . . . . . . . . . . . . . . . . . . . . 37

Installation Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Install the Secure Digital Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Install the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Mount the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Ground the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Install the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Install the Removable Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . 49

Wire the Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Wire Size and Terminal Screw Torque . . . . . . . . . . . . . . . . . . . . . . . . . 50

Connect Power to the Control System . . . . . . . . . . . . . . . . . . . . . . . . . 50

Connect to the Controller via a USB Cable . . . . . . . . . . . . . . . . . . . . . . . . 53

Connect the Controller to an EtherNet/IP Network. . . . . . . . . . . . . . . . 54

Connecting to Different EtherNet/IP Network Topologies. . . . . . 54

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 5

Page 4

Table of Contents

Chapter 3

Install the CompactLogix 5370 L3

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Controller

Installation Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Install the Secure Digital Card. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Install the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Connect to the Controller via a USB Cable. . . . . . . . . . . . . . . . . . . . . . . . . 72

Connect the Controller to an EtherNet/IP Network . . . . . . . . . . . . . . . . 73

Chapter 4

Complete Software Tasks Required at

Set the IP Address of a Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

CompactLogix 5370 Controller

Installation

Change the IP Address of a Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Load the Controller Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Select the Operating Mode of the Controller . . . . . . . . . . . . . . . . . . . . . . 112

CompactLogix 5370 L3 Controller Parts . . . . . . . . . . . . . . . . . . . . . . . 59

Assemble the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Install the Removable Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Wire the Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Wire Size and Terminal Screw Torque . . . . . . . . . . . . . . . . . . . . . . . . . 65

Mount the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Ground the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Connect Power to the Control System . . . . . . . . . . . . . . . . . . . . . . . . . 71

Connecting to Different EtherNet/IP Network Topologies . . . . . . 74

Use the BOOTP Server to Set the IP Address of the Controller . . 79

Use the DHCP Server to Set the IP Address of the Controller. . . . 86

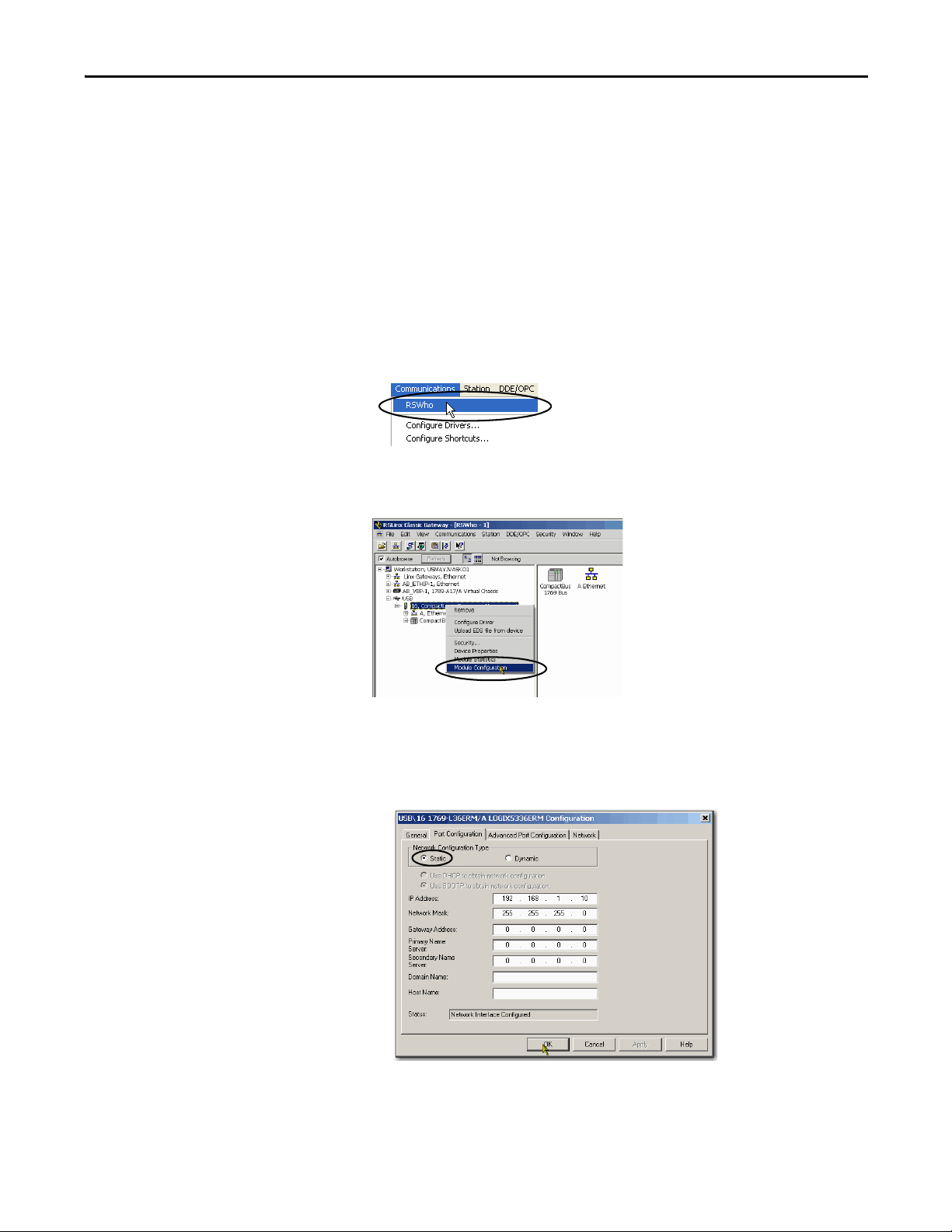

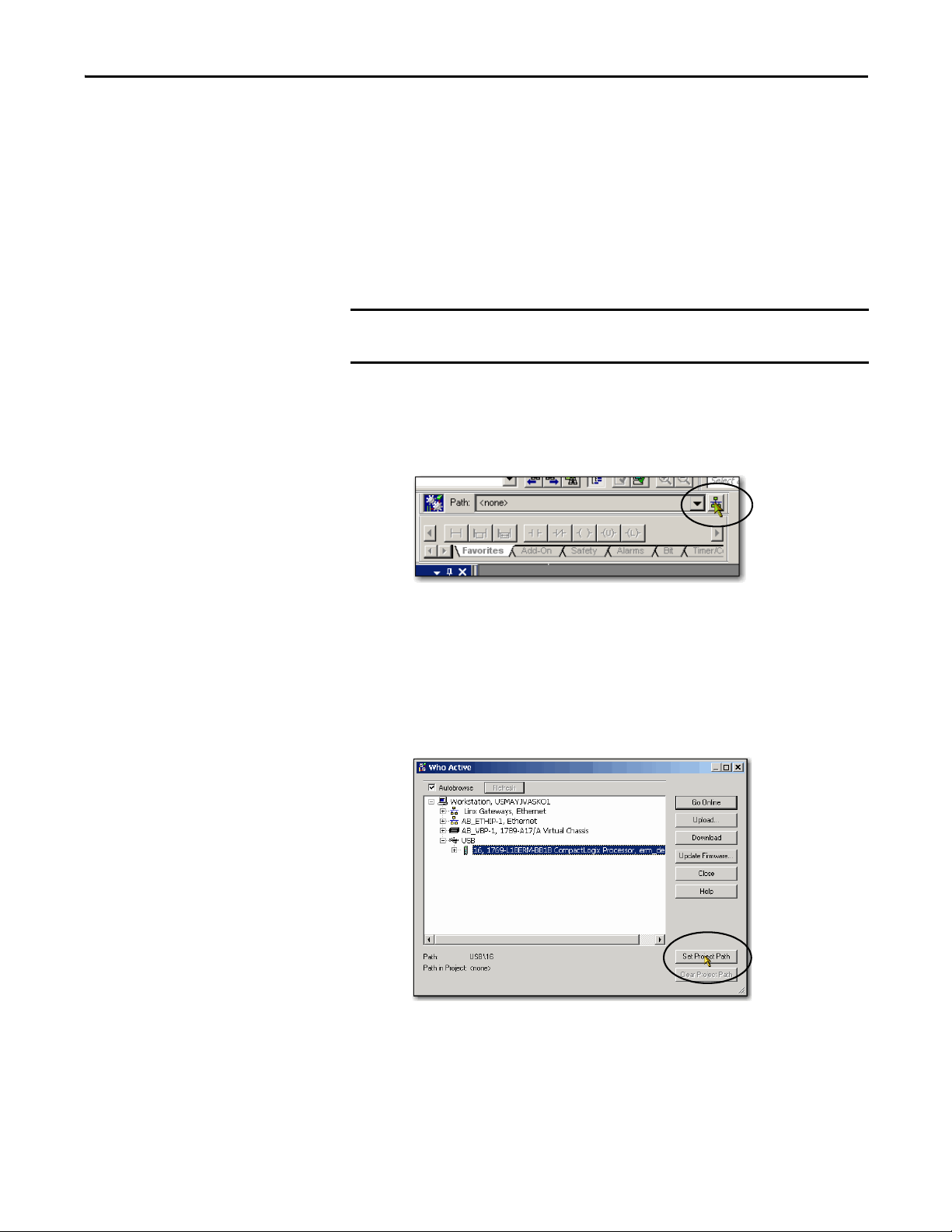

Use RSLinx Software to Set the IP Address of the Controller. . . . . 87

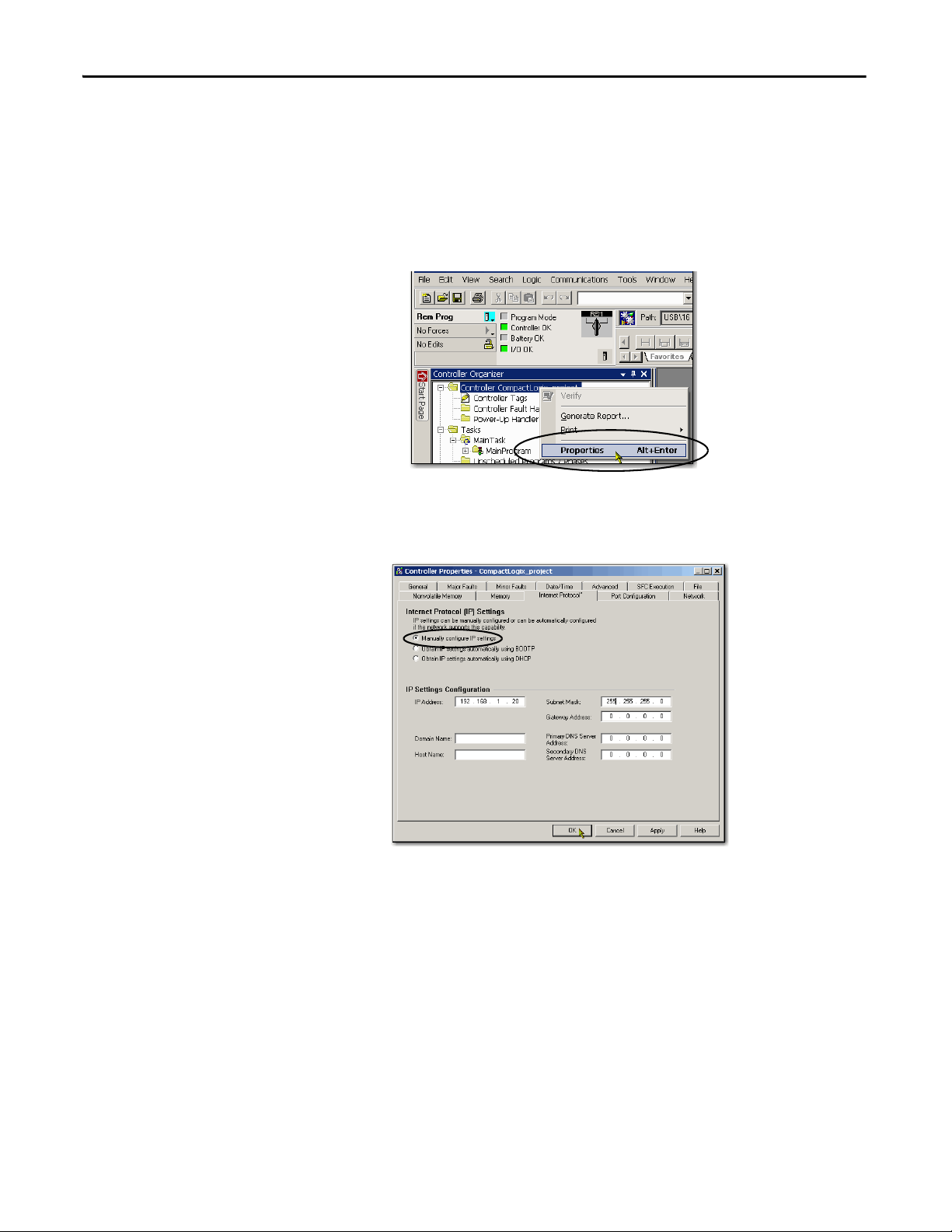

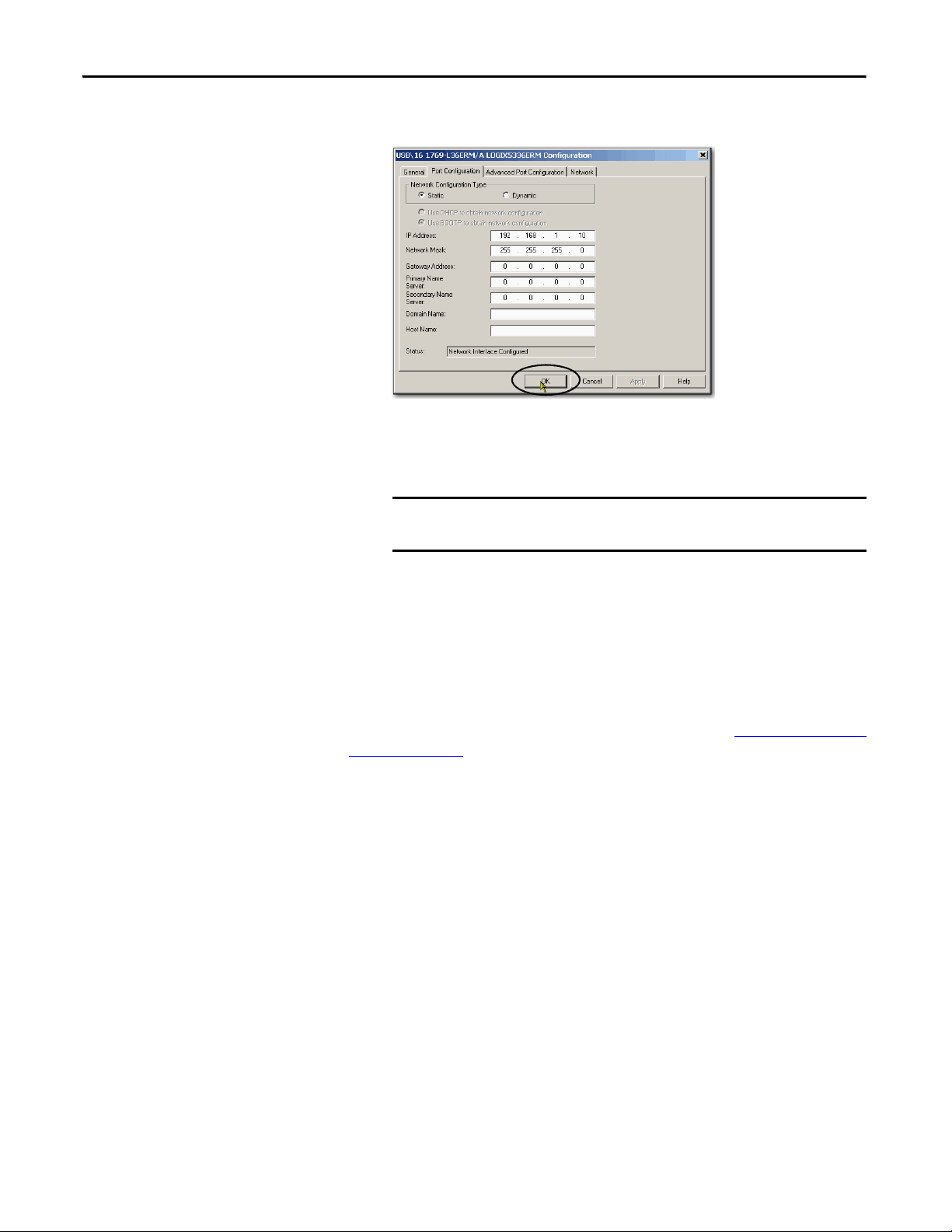

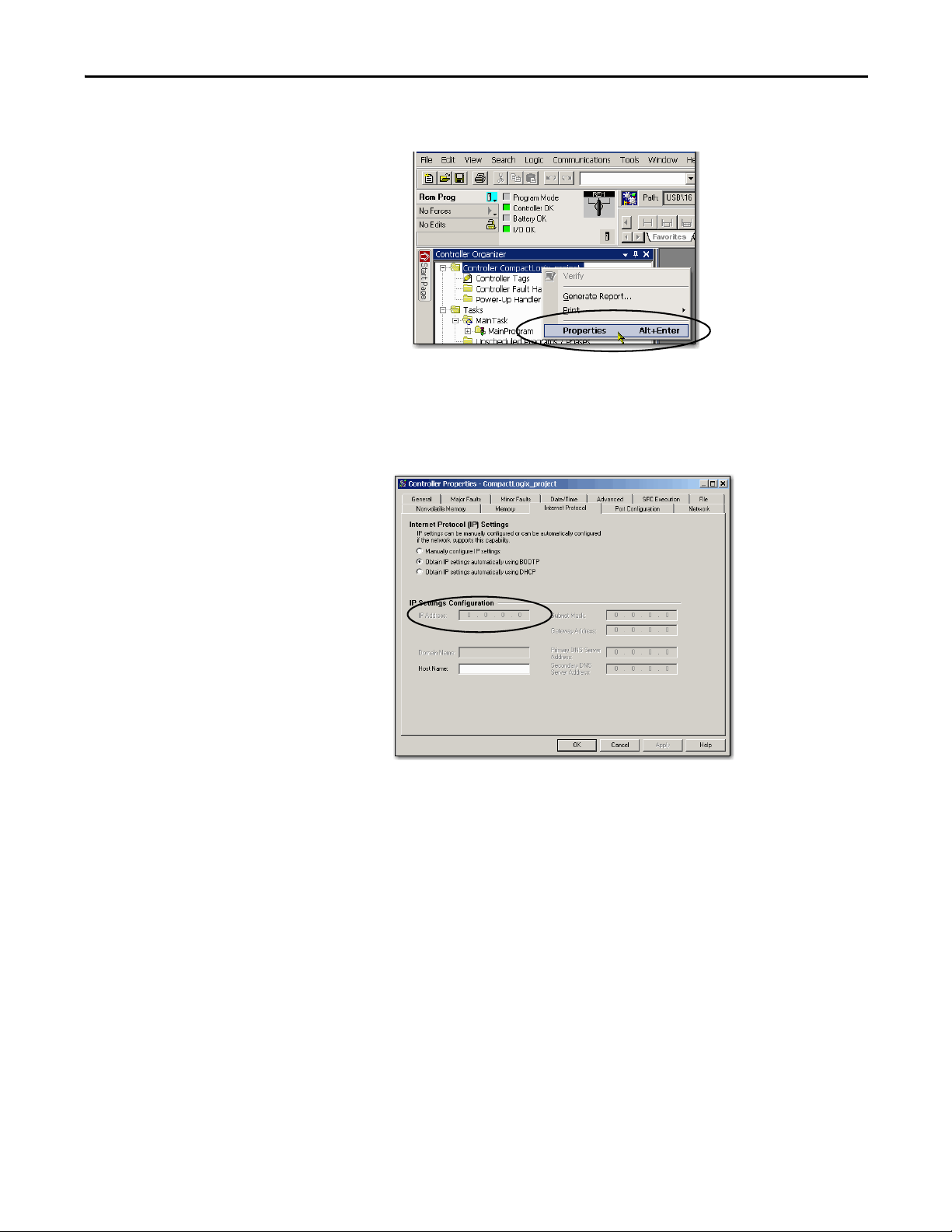

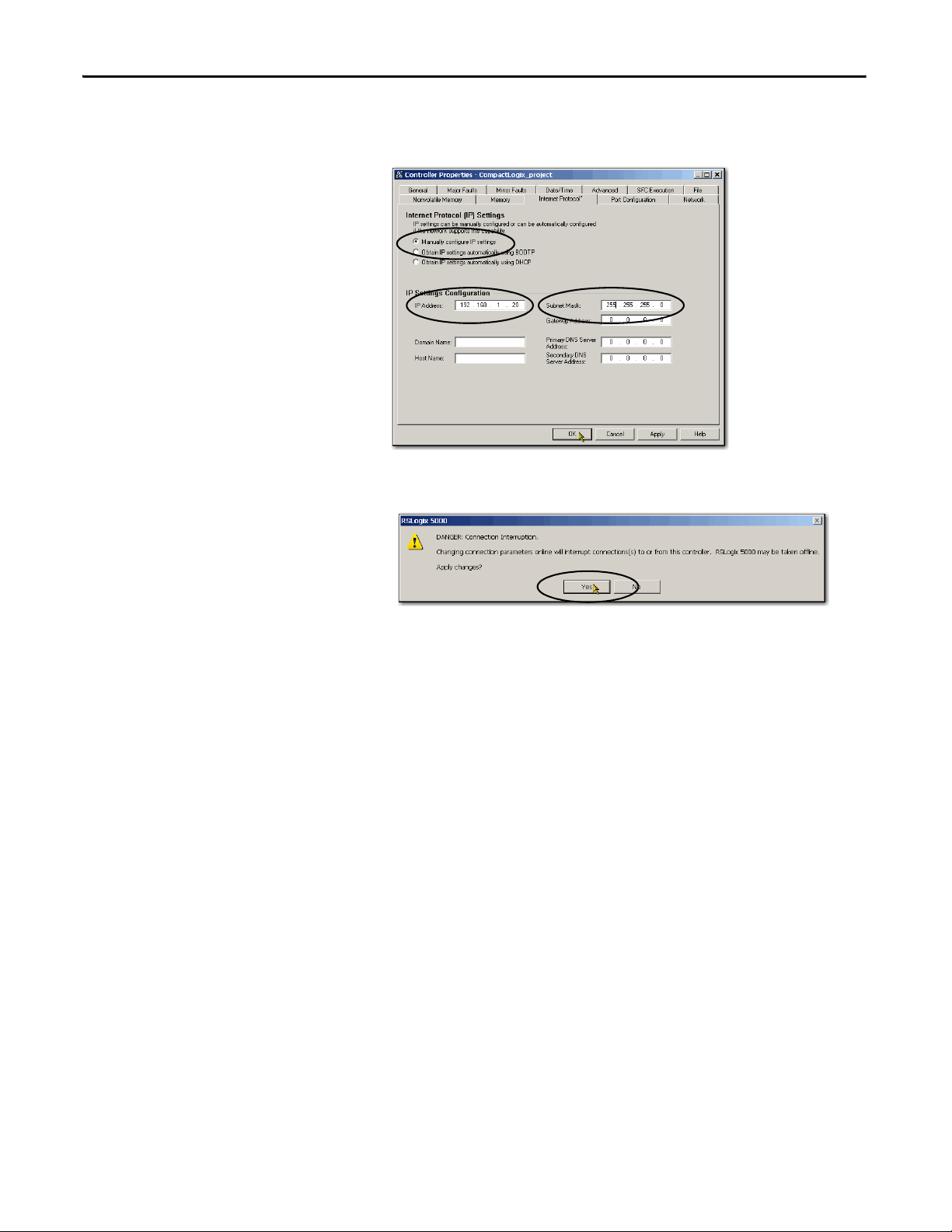

Use the Studio 5000 Environment to Set the IP Address of the

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Use the SD Card to Set the IP Address of the Controller. . . . . . . . . 93

Change the Network IP Address with RSLinx Classic Software. . . 95

Change the Network IP Address with an SD Card . . . . . . . . . . . . . . 97

Use the ControlFLASH Software to Load Firmware . . . . . . . . . . . 104

Use AutoFlash to Load Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Use the Secure Digital Card to Load Firmware . . . . . . . . . . . . . . . . . 111

Chapter 5

CompactLogix 5370 Controllers

Overview

6 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

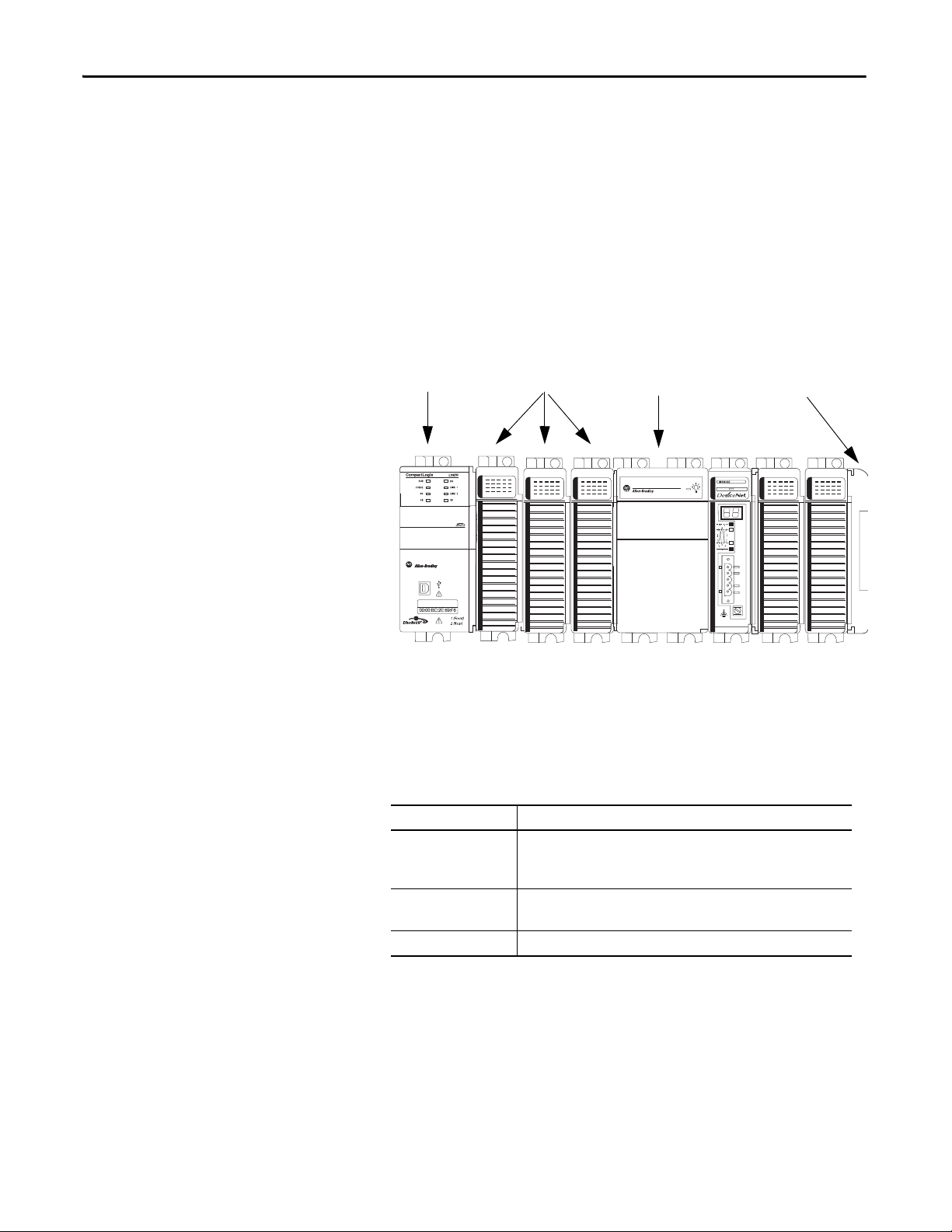

CompactLogix 5370 Control System Components. . . . . . . . . . . . . . . . . 116

Controller Functionality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Support for Integrated Motion over an EtherNet/IP Network. . . 118

Electronic Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Example System Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

DeviceNet Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Page 5

Chapter 6

Table of Contents

Communicate over Networks

Use I/O Modules with CompactLogix

5370 L1 Controllers

EtherNet/IP Network Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Available Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

EtherNet/IP Network Functionality on CompactLogix 5370

Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Nodes on an EtherNet/IP Network. . . . . . . . . . . . . . . . . . . . . . . . . . . 125

EtherNet/IP Network Topologies . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Socket Interface with CompactLogix 5370 Controllers . . . . . . . . . 133

Quality of Service (QoS) and I/O Module Connections . . . . . . . . 133

EtherNet/IP Network Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 134

DeviceNet Network Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Available Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Compact I/O 1769-SDN DeviceNet Scanner. . . . . . . . . . . . . . . . . . 137

Power Supply Distance Rating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

Current Capacity in CompactLogix 5370 L3 Control Systems . . 142

Chapter 7

Select I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Connect Field Power to I/O Devices Connected to a CompactLogix

5730 L1 Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Embedded I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Local Expansion Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Distributed I/O Modules over an EtherNet/IP Network . . . . . . . 162

Validate I/O Layout. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Set the Number of Local Expansion Modules . . . . . . . . . . . . . . . . . . 164

Empty Slots and Removal and Insertion Under Power Situations 165

Estimate Requested Packet Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

Module Faults Related to RPI Estimates. . . . . . . . . . . . . . . . . . . . . . . 168

Calculate System Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . 168

Physical Placement of I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Use the Event Task. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

Configure I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Common Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 175

I/O Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Configure Distributed I/O Modules on an EtherNet/IP Network . . 176

Monitor I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

Bus Off Detection and Recovery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 7

Page 6

Table of Contents

Chapter 8

Use I/O Modules with CompactLogix

5370 L2 Controllers

Select I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Embedded I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Determine Embedded Module Update Time . . . . . . . . . . . . . . . . . . . . . . 198

Channel Update Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Embedded Analog I/O Modules Data Arrays . . . . . . . . . . . . . . . . . . . . . . 204

Input Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Output Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Configuration Array . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Local Expansion Modules - Optional . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Distributed I/O Modules over an EtherNet/IP Network. . . . . . . . 216

Distributed I/O Modules over a DeviceNet Network . . . . . . . . . . . 217

Validate I/O Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Estimate Requested Packet Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Module Fault Related to RPI Estimates. . . . . . . . . . . . . . . . . . . . . . . . 220

System Power Availability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

Power Supply Distance Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Configure Local I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Configure Embedded I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Configure Local Expansion Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Common Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 226

I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

Configure Distributed I/O Modules on an EtherNet/IP Network. . . 227

Configure Distributed I/O Modules on a DeviceNet Network . . . . . . 231

Monitor I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

End Cap Detection and Module Faults . . . . . . . . . . . . . . . . . . . . . . . . 235

Use I/O Modules with CompactLogix

5370 L3 Controllers

Chapter 9

Select I/O Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Local Expansion Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 238

Distributed I/O Modules over an EtherNet/IP Network. . . . . . . . 240

Distributed I/O Modules over a DeviceNet Network . . . . . . . . . . . 241

Validate I/O Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Estimate Requested Packet Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

Module Fault Related to RPI Estimates. . . . . . . . . . . . . . . . . . . . . . . . 244

Calculate System Power Consumption . . . . . . . . . . . . . . . . . . . . . . . . 245

Physical Placement of I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

Power Supply Distance Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

Configure I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253

Common Configuration Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 254

I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Configure Distributed I/O Modules on an EtherNet/IP Network. . . 255

Configure Distributed I/O Modules on a DeviceNet Network . . . . . . 258

Monitor I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

End Cap Detection and Module Faults . . . . . . . . . . . . . . . . . . . . . . . . 262

8 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 7

Chapter 10

Table of Contents

Develop Applications

Elements of a Control Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

Tasks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 264

Task Priority. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267

Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 268

Scheduled and Unscheduled Programs . . . . . . . . . . . . . . . . . . . . . . . . 269

Routines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 271

Extended Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 272

Access Extended Properties in Logic . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Programming Languages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 274

Add-On Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Access the Module Object . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Create the Add-On Instruction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 276

Monitoring Controller Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 278

Monitoring I/O Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 279

Determine if I/O Communication has Timed Out. . . . . . . . . . . . . 280

Determine if I/O Communication to a Specific I/O Module has

Timed Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Interrupt the Execution of Logic and Execute the Fault Handler 281

System Overhead Time Slice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 282

Configure the System Overhead Time Slice. . . . . . . . . . . . . . . . . . . . 283

Sample Controller Projects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 284

Develop Integrated Motion over an

EtherNet/IP Network Application

Chapter 11

Motion Axes Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

AXIS_VIRTUAL Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

AXIS_CIP_DRIVE Axis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 286

Maximum Number of Position Loop-configured Drives. . . . . . . . . . . . 287

Position Loop-configured Drive Limits. . . . . . . . . . . . . . . . . . . . . . . . 287

Time Synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

Configure Integrated Motion on the EtherNet/IP Network . . . . . . . . 289

Enable Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

Add a Drive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 290

Scalability in Applications Using Integrated Motion on EtherNet/IP

Networks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 293

1769-L30ERM, 1769-L33ERM, and 1769-L36ERM Controllers 293

1769-L18ERM-BB1B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 295

1769-L27ERM-QBFC1B Controller . . . . . . . . . . . . . . . . . . . . . . . . . 296

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 9

Page 8

Table of Contents

Chapter 12

Use a Secure Digital Card

Troubleshoot the Module

Replacement Considerations

Connect Power to the Series A L1

CompactLogix 5370 Controllers

Store or Load a Project with the Secure Digital Card . . . . . . . . . . . . . . . 299

Store a Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

Load a Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 302

Appendix A

Use Logix Designer Application for Troubleshooting. . . . . . . . . . . . . . . 305

Fault Type Determination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Use the CompactLogix 5370 Controllers Status Indicators . . . . . . . . . 308

Appendix B

Product Comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 311

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 314

Appendix C

CompactLogix 5370 L1, Series A, Controller Power Connection. . . . 315

CompactLogix 5370 L1, Series A, Controller Field Power to I/O Devices

Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 321

History of Changes

Index

Appendix D

Changes to the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 325

10 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 9

Preface

This manual describes the necessary tasks to install, configure, program, and

operate a CompactLogix™ 5370 controller. This manual is intended for

automation engineers and control system developers.

CompactLogix 5370 controllers are designed to provide solution for small and

medium-sized applications.

Additional Resources

These resources contain information about related products from Rockwell

Automation.

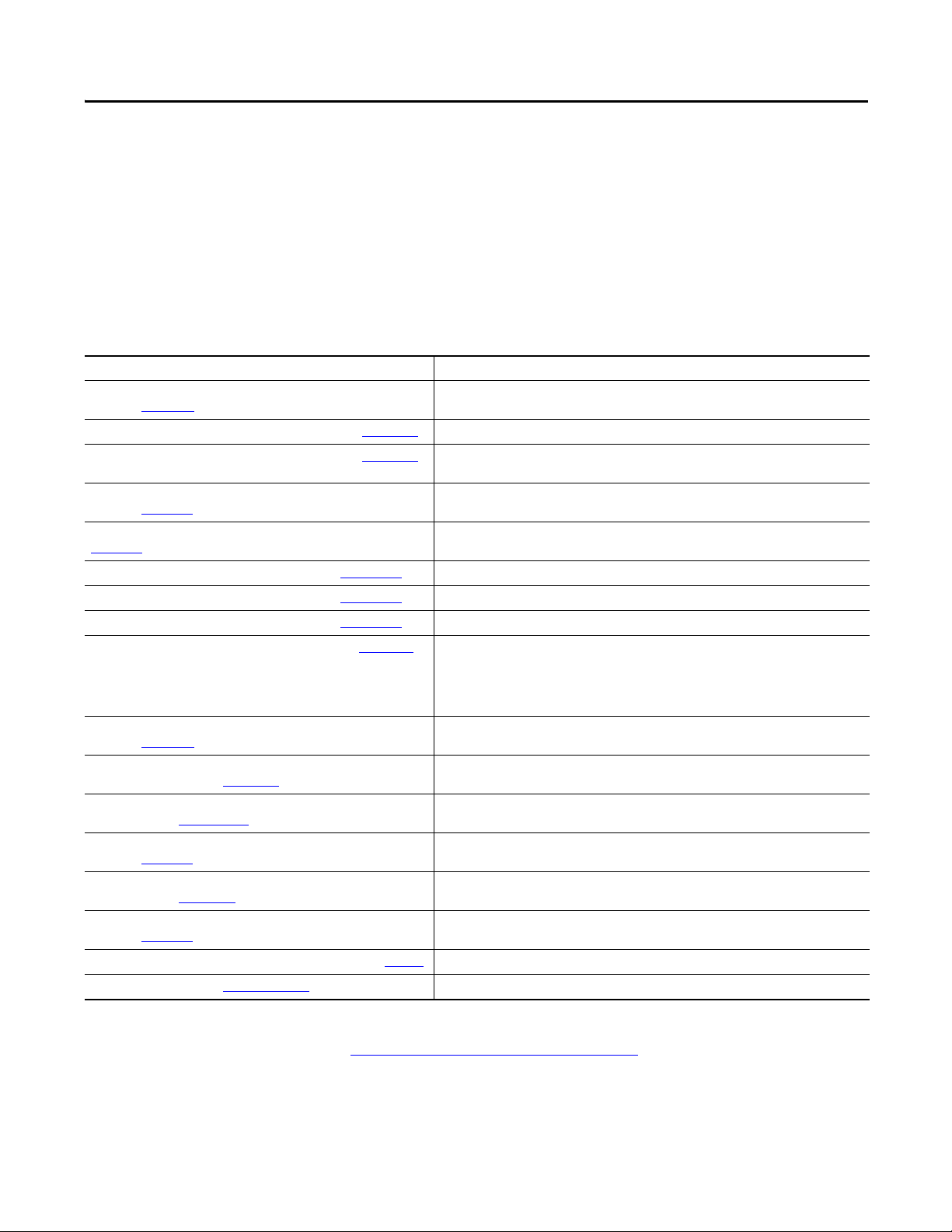

Resource Description

CompactLogix Controllers Specifications Technical Data,

publication 1769-TD005

1769-SDN DeviceNet Scanner Module User Manual, publication 1769-UM009

Compact High-speed Counter Module User Manual, publication 1769-UM006

Compact I/O DeviceNet Scanner Module Installation Instructions,

publication 1769-IN060

Compact I/O Expansion Power Supplies Installation Instructions, publication

1769-IN028

CompactLogix 5370 L1 Controllers Quick Start, publication IASIMP-QS024

CompactLogix 5370 L2 Controllers Quick Start, publication IASIMP-QS025 Describes basic tasks to design, install and start a CompactLogix 5370 L2 control system.

CompactLogix 5370 L3 Controllers Quick Start, publication IASIMP-QS023 Describes basic tasks to design, install and start a CompactLogix 5370 L3 control system.

Ethernet Design Considerations Reference Manual, publication ENET-RM002

EtherNet/IP Embedded Switch Technology Application Guide,

publication ENET-AP005

Execution Time and Memory Use for Logix5000 Controller Instructions

Reference Manual, publication 1756-RM087

Integrated Motion on the EtherNet/IP Network Configuration and Startup User

Manual, publication MOTION-UM003

POINT I/O 24V dc Expansion Power Supply Installation Instruc tions,

publication 1734-IN058

POINT I/O Digital and Analog Modules and POINTBlock I/O Modules User

Manual, publication 1734-UM001

POINT I/O Field Potential Distributor Modules Installation Instructions,

publication 1734-IN059

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Product Certifications website, http://w ww.ab.com Provides declarations of conformity, certificates, and other certification details.

Provides CompactLogix controller specifications for all CompactLogix controllers.

Describes how to use the 1769-SDN to back up your CompactLogix 5370 L2 or L3 controller.

Describes high-speed counter operation for standalone 1769-HSC when used with L2 and L3

Compact controllers as well as embedded high-speed counters in L2 embedded controllers.

Describes how to install the Compact I/O™ modules.

Describes how to wire the 1769 Compact I/O power supply.

Describes basic tasks to design, install and start a CompactLogix 5370 L1 control system.

Describes the following concepts that you must consider when designing a control system that

includes an EtherNet/IP network:

• EtherNet/IP overview

• Ethernet infrastructure

• EtherNet/IP protocol

Describes how to use a DLR network topology.

Assists in estimating the memory use and execution time of programmed logic and in selecting

among different programming options.

Describes how to configure an Integrated Motion over

EtherNet/IP motion application and to star t up that motion solution in a Logix5000 control system.

Describes the 1734-EP24DC expansion power supply.

Describes how to return a 1734 POINT I/O module to Autobaud.

Describes the 1734-FPD POINT I/O Field Power Distributor module.

Provides general guidelines for installing a Rockwell Automation industrial system.

You can view or download publications at

http://www.rockwellautomation.com/literature/. To order paper copies of technical

documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 11

Page 10

Chapter 1

Install the CompactLogix 5370 L1 Controller

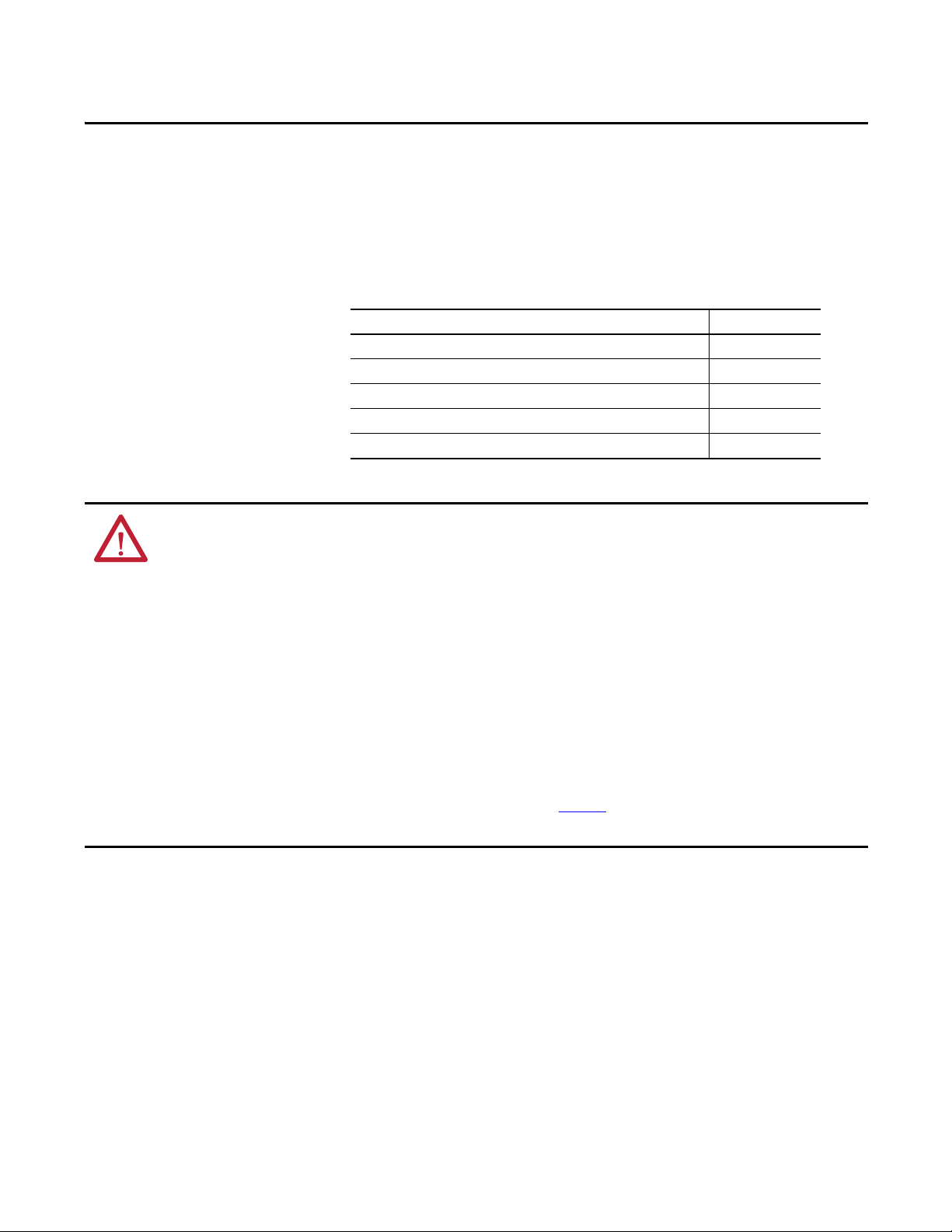

Top ic Pag e

Before You Begin 16

Install the Secure Digital Card 19

Install the System 21

Connec t to the Controller via a USB Cab le 31

Connect the Controller to an EtherNet/IP Network 32

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as defined

in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according to IEC/CISPR 11. Without appropriate precautions,

there may be difficulties with electromagnetic compatibility in residential and other environments due to conducted and radiated

disturbances.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA, V2, V1, V0 (or equivalent) if nonmetallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures

, for additional installation requirements

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 13

Page 11

Chapter 1 Install the CompactLogix 5370 L1 Controller

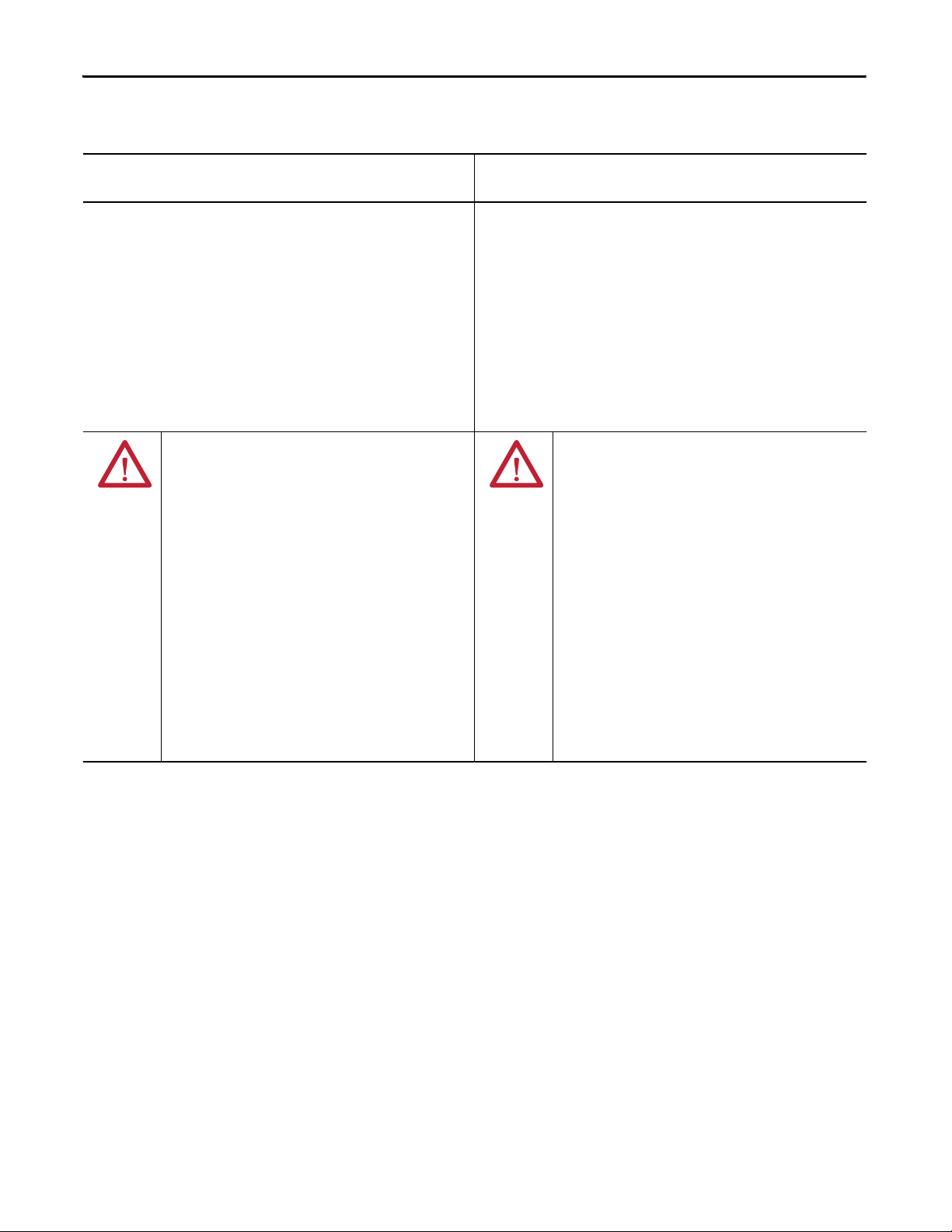

North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations.

Produc ts marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class

I Division 2 Groups A, B, C, D, Hazardous Locations and nonhazardous

locations only. Each product is supplied with markings on the rating

nameplate indicating the hazardous location temperature code.

When combining products within a system, the most adverse

temperature code (lowest "T" number) may be used to help

determine the overall temperature code of the system. Combinations

of equipment in your system are subject to investigation by the local

Authority Having Jurisdiction at the time of installation.

WARNING: EXPLOSION HAZARD -

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this equipment

unless power has been removed or the area is

known to be nonhazardous. Secure any external

connections that mate to this equipment by using

screws, sliding latches, threaded connectors, or

other means provided with this product.

• Substitution of components may impair suitability

for Class I, Division 2.

• If this product contains batteries, they must only

be changed in an area known to be nonhazardous.

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à

une utilisation en environnements de Classe I Division 2 Groupes A, B,

C, D dangereux et non dangereux. Chaque produit est livré avec des

marquages sur sa plaque d'identification qui indiquent le code de

température pour les environnements dangereux. Lorsque plusieurs

produits sont combinés dans un système, le code de température le

plus défavorable (code de température le plus faible) peut être utilisé

pour déterminer le code de température global du système. Les

combinaisons d'équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de

l'installation.

AVERTISSEMENT: RISQUE D’EXPLOSION –

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher l'équipement.

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher les connecteurs. Fixer tous les

connecteurs externes reliés à cet équipement à

l'aide de vis, loquets coulissants, connecteurs

filetés ou autres moyens fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

14 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 12

Install the CompactLogix 5370 L1 Controller Chapter 1

European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has been found to

comply with the Essential Health and Safety Requirements relating to the design and construction of Category 3 equipment intended for use in

Zone 2 potentially explosive atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN 60079-15 and EN 60079-0.

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

WARNING:

• This equipment must be installed in an enclosure providing at least IP54 protection when applied in Zone 2 environments.

• This equipment shall be used within its specified ratings defined by Rockwell Automation.

• Provision shall be made to prevent the rated voltage from being exceeded by transient disturbances of more than 40% when

applied in Zone 2 environments.

• Secure any external connections that mate to this equipment by using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

• Enclosure must be marked with the following: "Warning - Do not open when energized." After installation of equipment into

the enclosure, access to termination compartments shall be dimensioned so that conductors can be readily connected.

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 15

Page 13

Chapter 1 Install the CompactLogix 5370 L1 Controller

Removable Connector for

Embedded Power Supply

Embedded I/O Module

Before You Begin

The CompactLogix™ 5370 L1, series B, controller redesign occurred to provide

an option to use one external power supply for system power and field side power.

There are differences between the CompactLogix 5370 L1, series A and B,

controllers, which are detailed throughout the sections of this manual.

Consider the following before installing a CompactLogix 5370 L1 controller:

ATT EN TI ON : If this equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment can be impaired.

• The control system includes the controller, an embedded power supply,

and embedded I/O points.

• The embedded power supply for the series A L16ER, L18ER or L18ERM

controller is a 24V DC nominal, non-isolated power supply with an input

range of 10…28.8V DC. You wire the embedded power supply via a

removable connector.

• The embedded power supply for the series B L16ER, L18ER, L18ERM

and series A L19ER controller is a 24V DC nominal, isolated

power supply with an input range of 10…28.8V DC. You wire the

embedded power supply via a removable connector.

16 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 14

Install the CompactLogix 5370 L1 Controller Chapter 1

IMPORTANT

IMPORTANT

You must use a dedicated external Class 2/SELV-approved power

supply to provide power to the system, according to needs of the

application, and within the operating voltage range of the controller

for only series A L16ER, L18ER, and L18ERM controllers.

The external power supply that provides power to the embedded

power supply of the controller cannot be used to provide power to any

other components or devices in the application for only series A L16ER,

L18ER, and L18ERM controllers.

• A second, fused external power supply must be used to provide power to

other components for only series A L16ER, L18ER, and L18ERM

controllers (see Appendix

C).

• Power for other components can be provided from the external power

supply that is used to provide power to the system for only series B L16ER,

L18ER, L18ERM Controllers, and series A L19ER Controllers.

• The controller has 16 embedded digital input points and 16 embedded

digital output points. You wire the input and output points via a removable

connector.

• The controller supports the use of a limited number of

1734 POINT I/O

modules on the POINTBus backplane as local

expansion modules.

You must use the latest series and firmware revision for all 1734

POINT I/O™ modules in the local expansion slots to make sure that your

application operates as expected. Use of an older firmware revision

renders the entire 1734 bus inoperable.

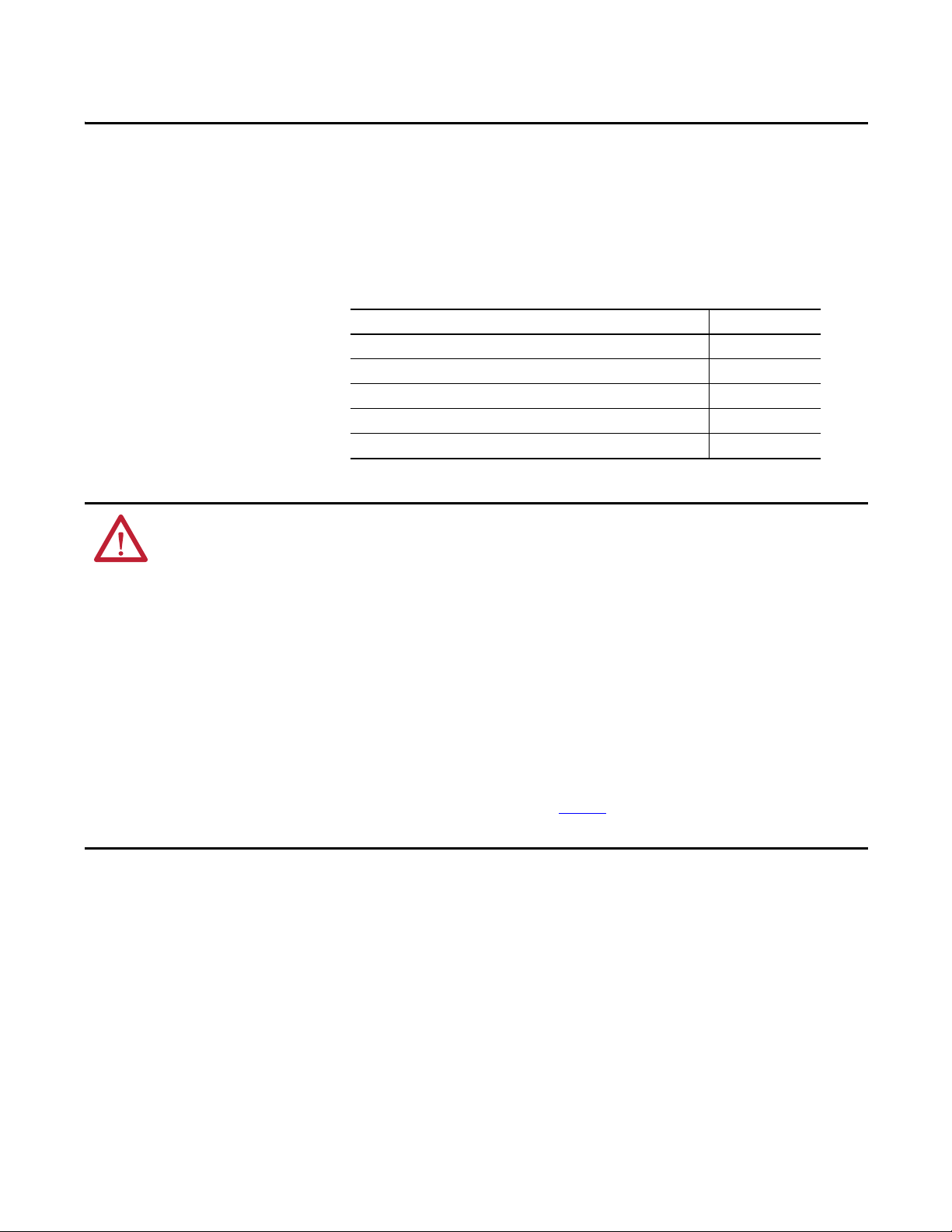

The following table lists local expansion module support by controller

catalog number.

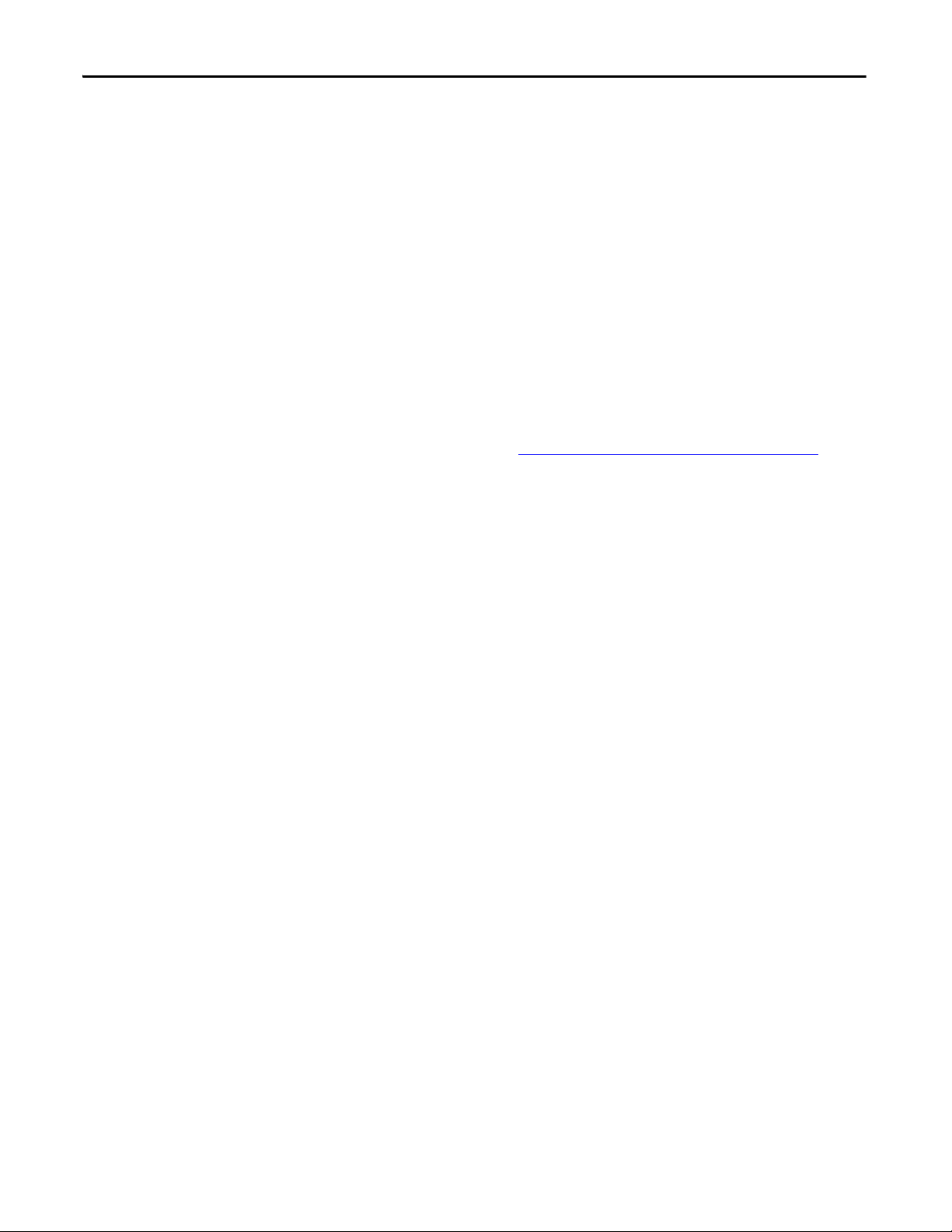

Table 1 - Local Expansion Module Support for CompactLogix 5370 L1 Controllers

Cat. No. 1734 POINT I/O Modules Supported, max

1769-L16ER-BB1B 6

1769-L18ER-BB1B 8

1769-L18ERM-BB1B

1769-L19ER-BB1B

See Chapter 7

for further information about the I/O modules.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 17

Page 15

Chapter 1 Install the CompactLogix 5370 L1 Controller

IMPORTANT

ATT EN TI ON : Do not discard the end cap. Use this end cap to cover the

exposed interconnections on the last mounting base on the DIN rail.

Failure to do so could result in equipment damage or injury from

electric shock.

For more information on how to terminate the end of your system, see

page 25

.

1734 POINT I/O modules support removal and insertion under power.

CompactLogix 5370 L1 Controller Parts

These parts are included in the box when you order your controller:

• Controller - Specific catalog number varies by order

• 1784-SD1 Secure Digital (SD) card with 1 GB of memory storage

Installation Summary

A 1784-SD2 SD card with 2 GB of memory storage, or more 1784-SD1

SD cards, are also available if you need extra memory.

The life expectancy of nonvolatile media is dependent on the number

of write cycles that are performed. Nonvolatile media use a wear

leveling technique or technology for prolonging the service life, but

avoid frequent writes.

Avoid frequent writes when logging data. We recommend that you log

data to a buffer in the memory of your controller and limit the number

of times data is written to removable media.

• An end cap protective cover that slides onto the right side of the

CompactLogix 5370 L1 control system.

To install a CompactLogix 5370 L1 controller, follow these steps.

1. Install the Secure Digital Card

2. Install the System

3. Connect to the Controller via a USB Cable

.

.

.

4. Connect the Controller to an EtherNet/IP Network

18 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

.

Page 16

Install the CompactLogix 5370 L1 Controller Chapter 1

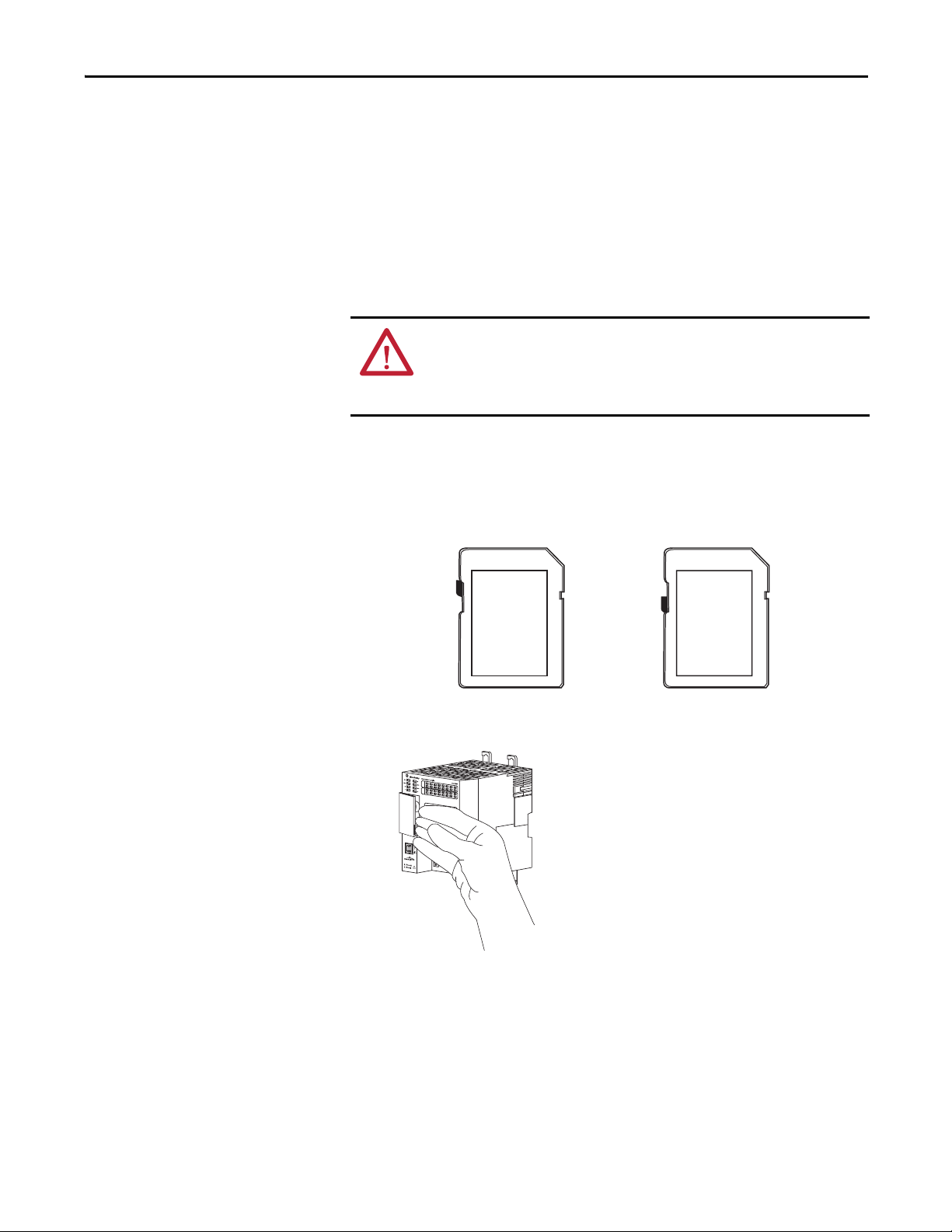

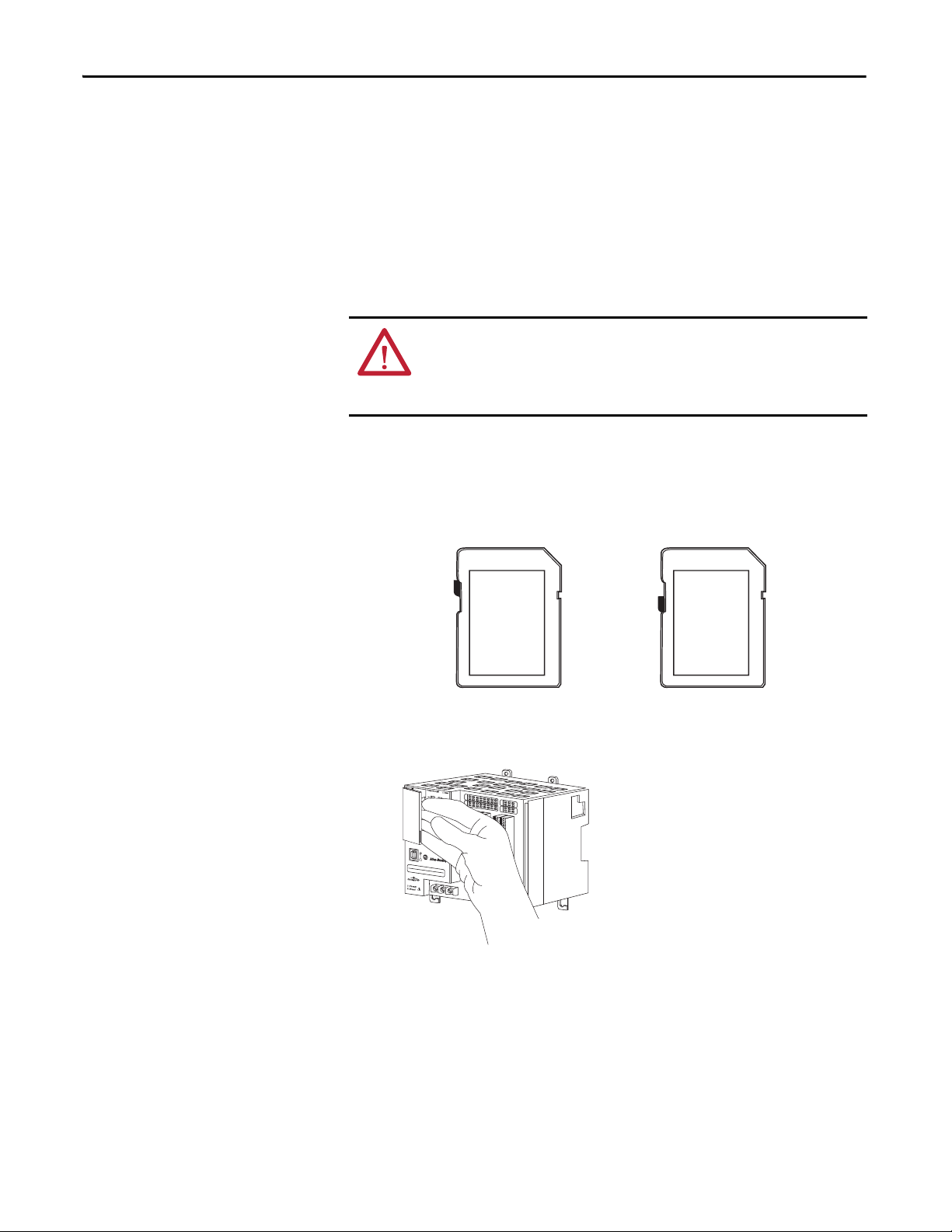

Unlocked Locked

Install the Secure

Digital Card

The CompactLogix 5370 L1 controller is shipped from the factory with the

1784-SD1 SD card installed.

Complete these steps to reinstall an SD card that has been removed from the

controller back into the controller or to install a new SD card into the controller.

We recommend that you leave the SD card in the controller, even when it is not

used. If the controller experiences a major non-recoverable fault, extended fault

information is saved to the card.

WARNING: When you insert or remove the SD card while power is on, an

electrical arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

1. Verify that the SD card is locked or unlocked according to your preference.

Consider the following when deciding to lock the card before installation:

– If the card is unlocked, the controller can write data to it or read data

from it.

2. Open the door for the SD card.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 19

Page 17

Chapter 1 Install the CompactLogix 5370 L1 Controller

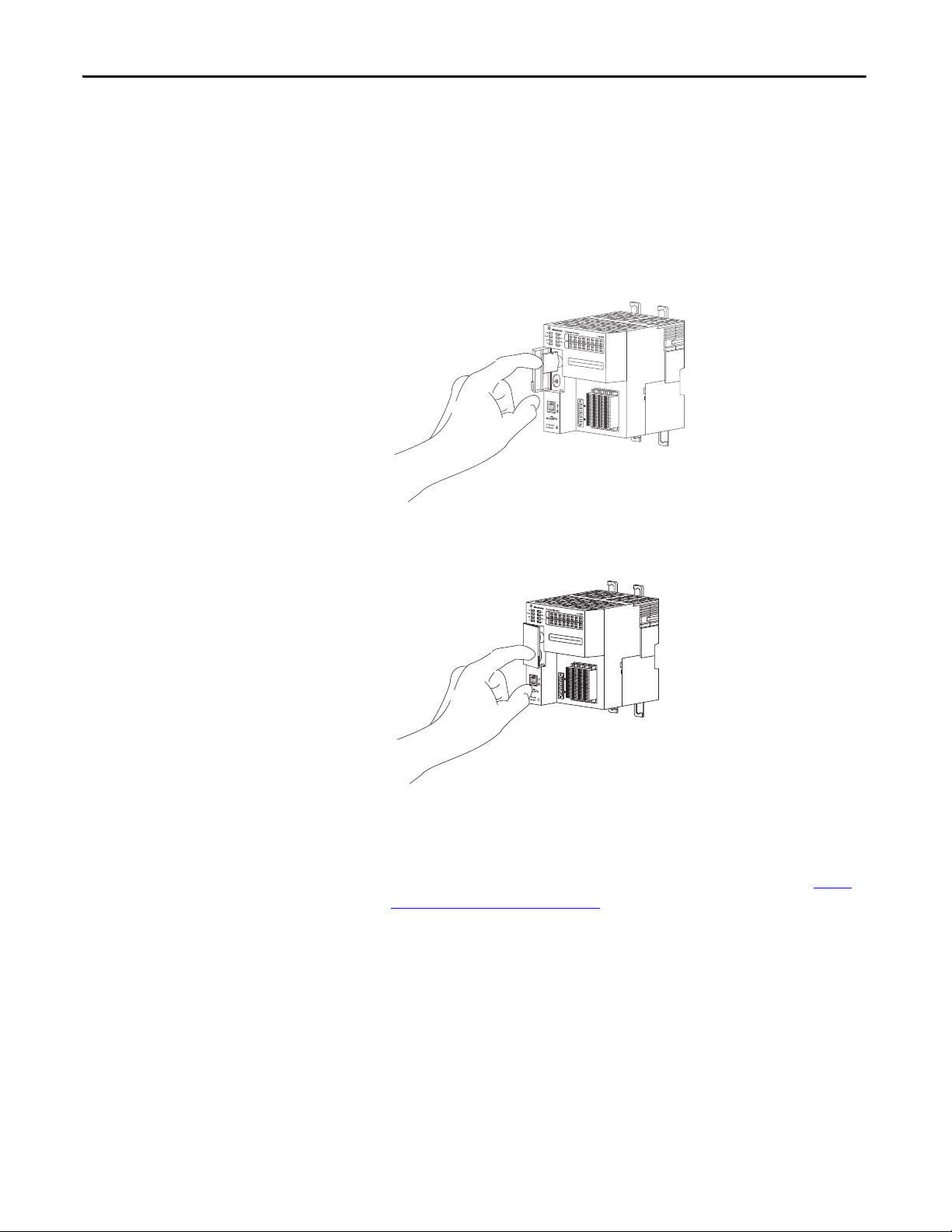

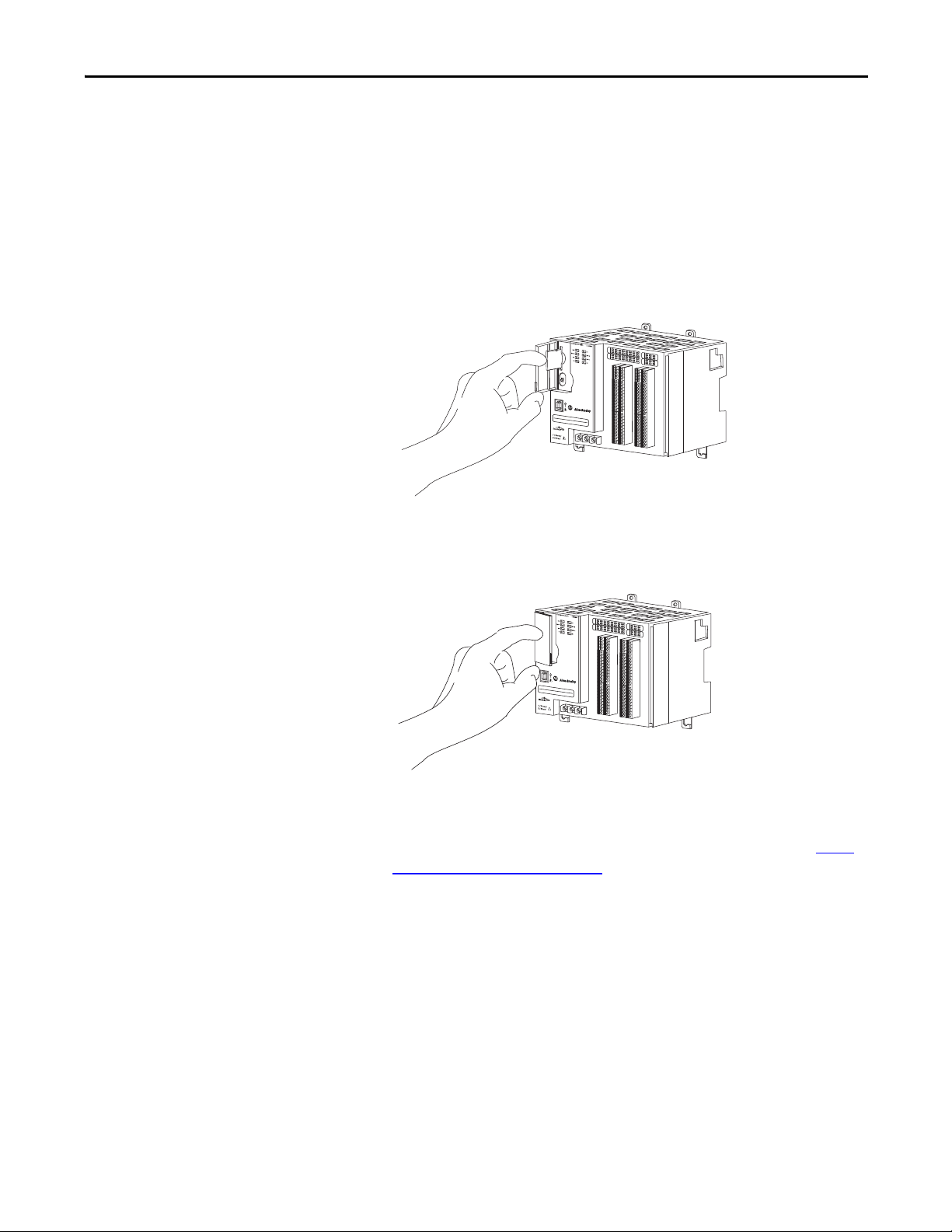

3. Insert the SD card into the SD card slot.

You can install the SD card in only one orientation. The beveled corner is

at the top.

If you feel resistance when inserting the SD card, pull it out and change the

orientation.

4. Gently press the card until it clicks into place.

5. Close the SD card door.

We recommend that you keep the SD card door closed during normal

system operation. For more information on using the SD card, see Use a

Secure Digital Card on page 297.

20 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 18

Install the CompactLogix 5370 L1 Controller Chapter 1

Install the System

Complete the following steps to install the CompactLogix 5370 L1

control system.

• Mount the System

• Ground the System

• Install the Controller

• Connect Power to the Controller (Series B) L16 ER, L18ER, L18ERM

series B controllers, and series A L19ER

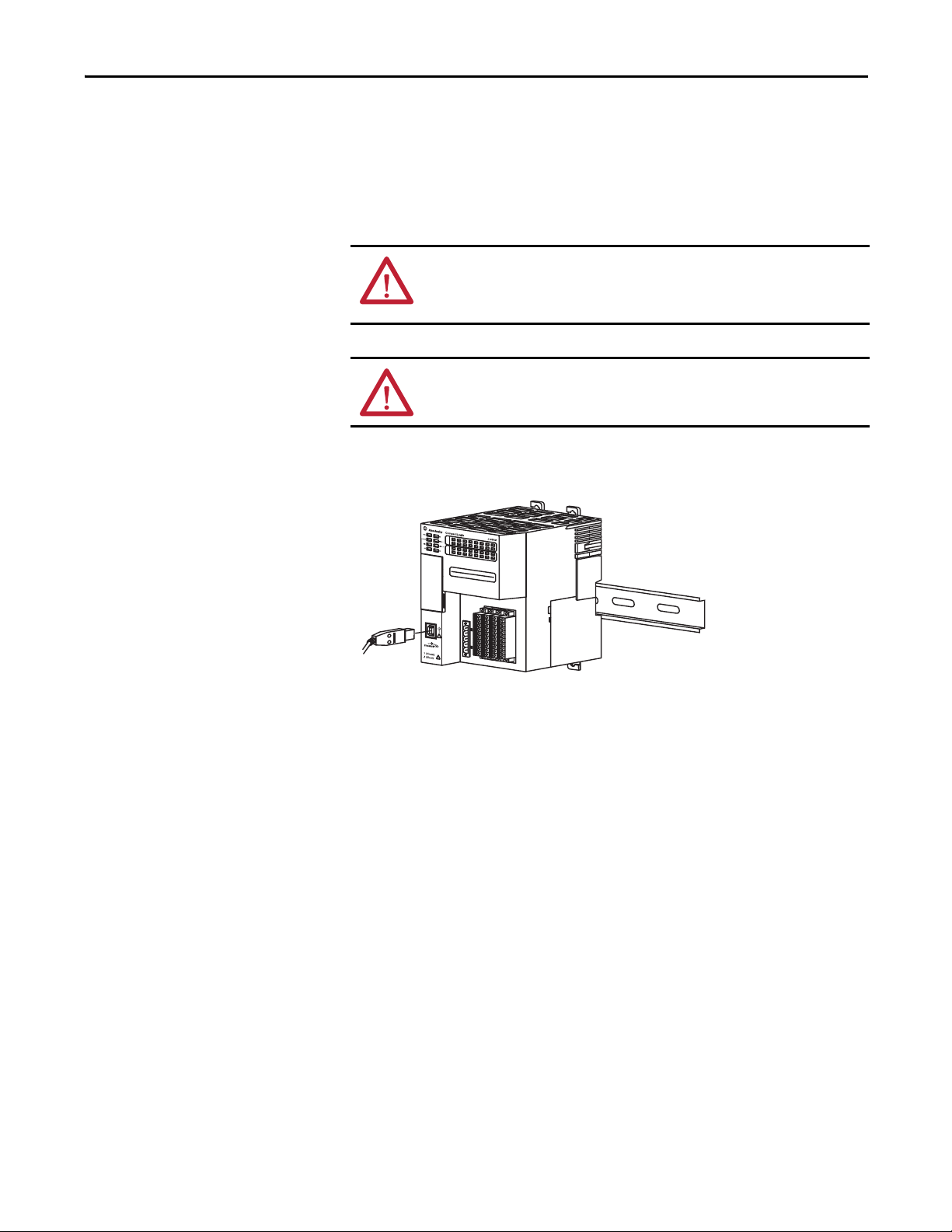

Mount the System

You mount a CompactLogix 5370 L1 control system on a DIN rail. Before you

complete the steps that are required to install the system, install a DIN rail.

WARNING: When used in a Class I, Division 2, hazardous location, this

equipment must be mounted in a suitable enclosure with proper wiring

method that complies with the governing electrical codes.

Before you mount a CompactLogix 5370 L1 control system, consider

the following requirements:

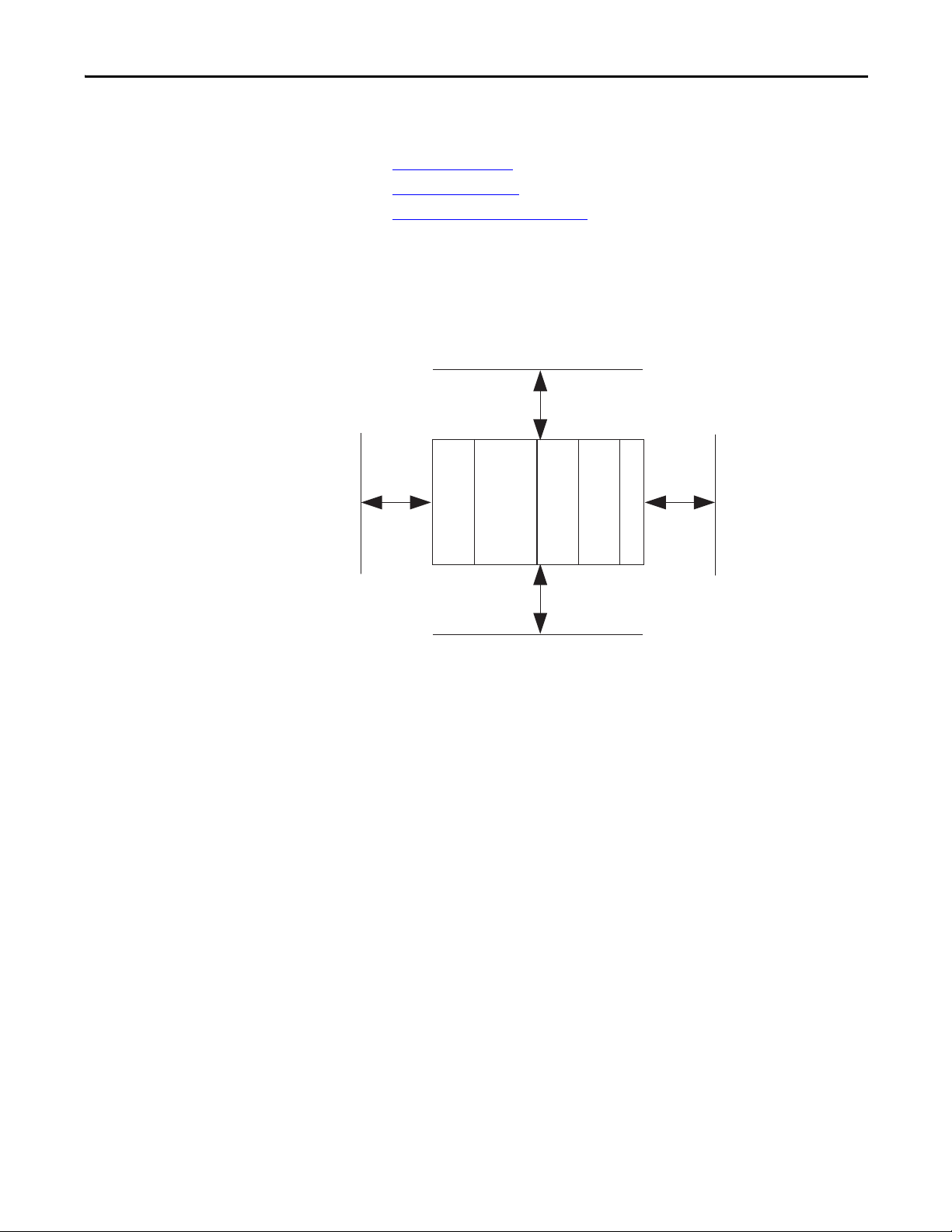

• Available DIN Rails

• Minimum Spacing

• System Dimensions

Available DIN Rails

ATTENTION: This product is grounded through the DIN rail to chassis ground.

Use zinc-plated yellow-chromate steel DIN rail to assure proper grounding.

The use of other DIN rail materials (for example, aluminum or plastic) that

can corrode, oxidize, or are poor conductors, can result in improper or

intermittent grounding. Secure DIN rail to mounting surface approximately

every 200 mm (7.8 in.) and use end-anchors appropriately.

You can mount the CompactLogix 5370 L1 controller on the following

DIN rails:

• EN 50 022 - 35 x 7.5 mm (1.38 x 0.30 in.)

• EN 50 022 - 35 x 15 mm (1.38 x 0.59 in.)

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 21

Page 19

Chapter 1 Install the CompactLogix 5370 L1 Controller

IMPORTANT

Bottom

Top

CompactLogix 5370 L1

Controller with

Embedded Power

Supply and I/O Module

End Cap

50 mm

(2 in.)

50 mm

(2 in.)

50 mm

(2 in.)

50 mm

(2 in.)

Side Side

1734 POINT I/O Module

1734 POINT I/O Module

1734 POINT I/O Module

You must install bumpers on the back of your CompactLogix 5370 L1

controller before mounting it on the EN 50022 - 35 x 15 mm

(1.38 x 0.59 in.) DIN rail.

Bumper Selection:

• For more information on Bumper Selection, see Rockwell

Automation® Knowledgebase article #591565. You can access the

article at: (Login required)

https://rockwellautomation.custhelp.com/

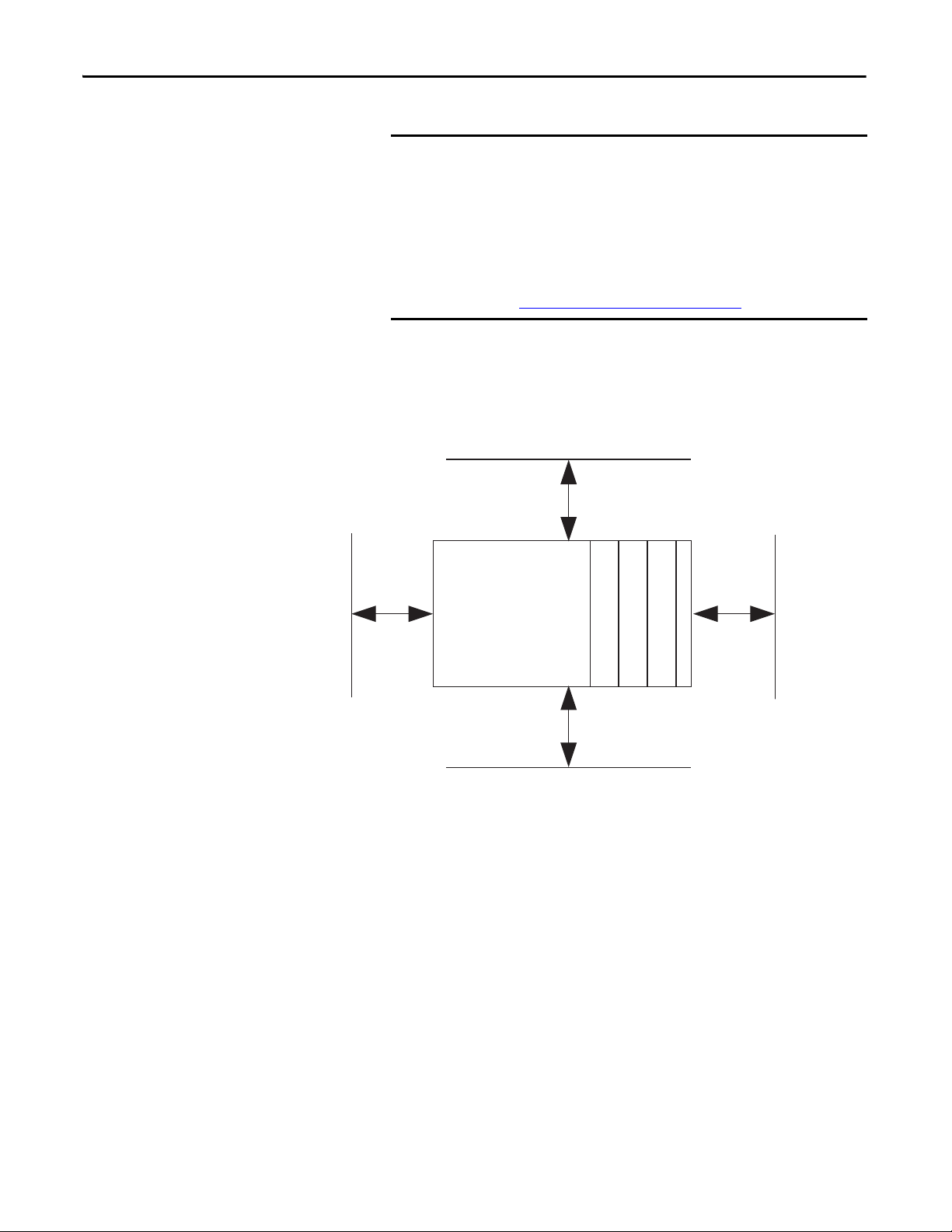

Minimum Spacing

Maintain spacing from enclosure walls, wireways, and adjacent equipment. Allow

50 mm (2 in.) of space on all sides, as shown. This spacing provides ventilation

and electrical isolation.

22 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 20

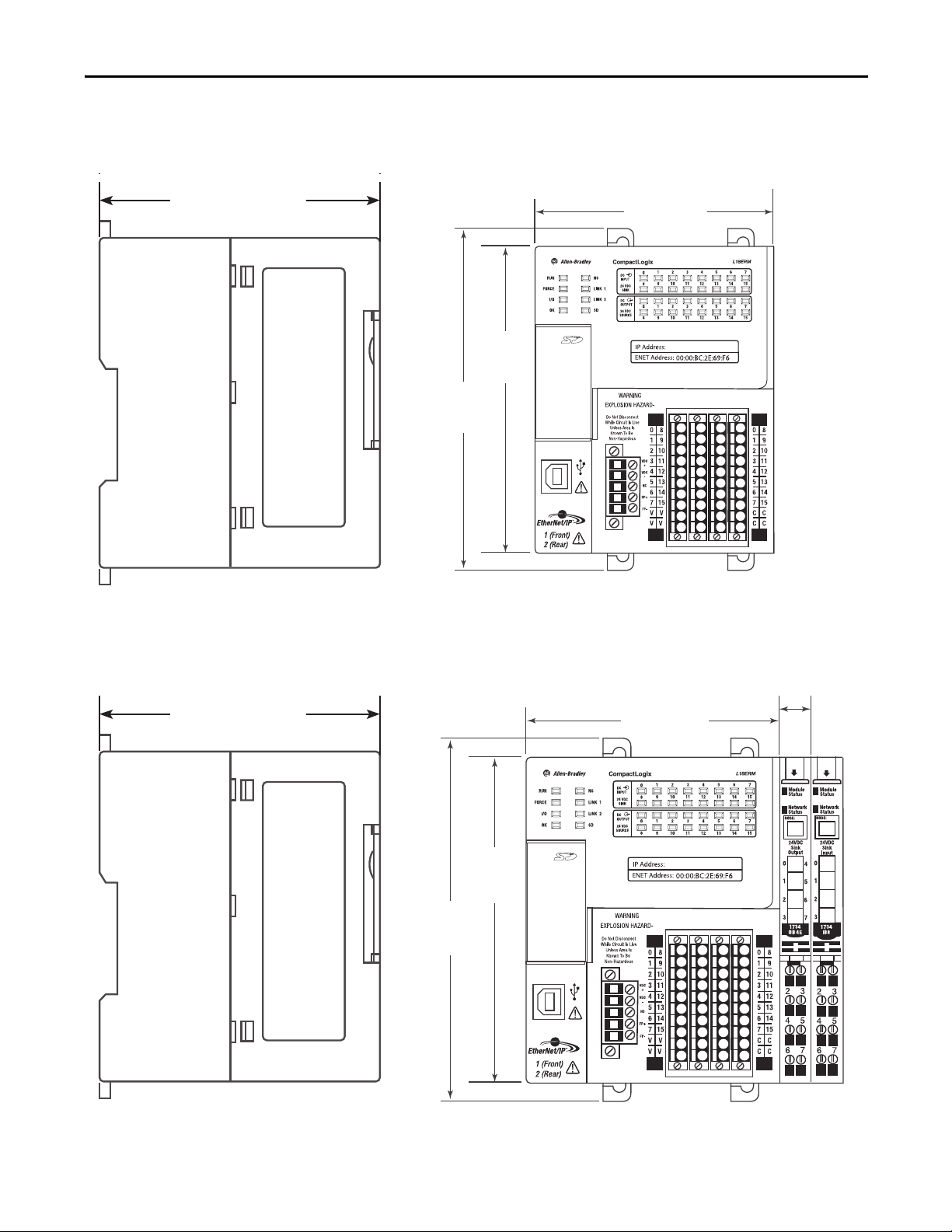

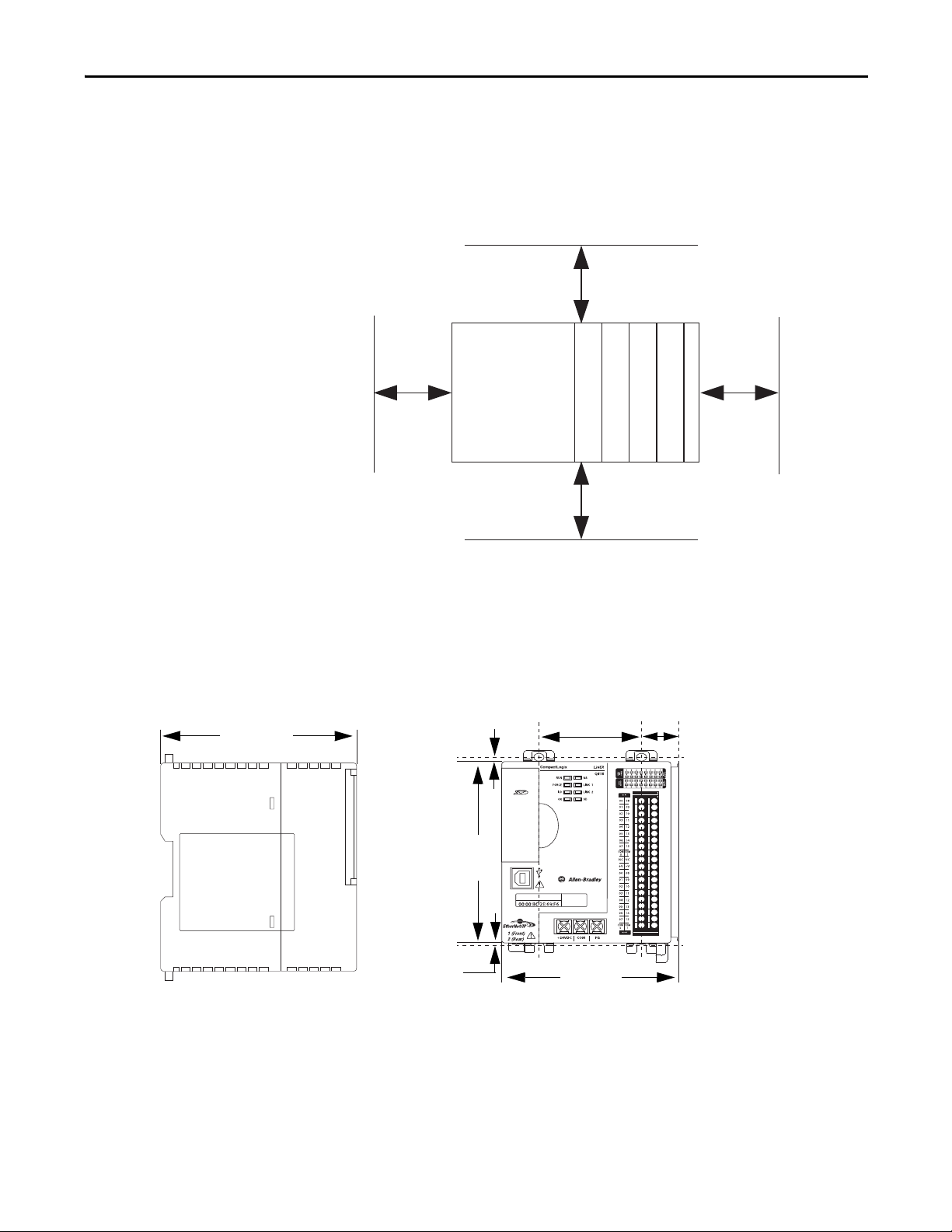

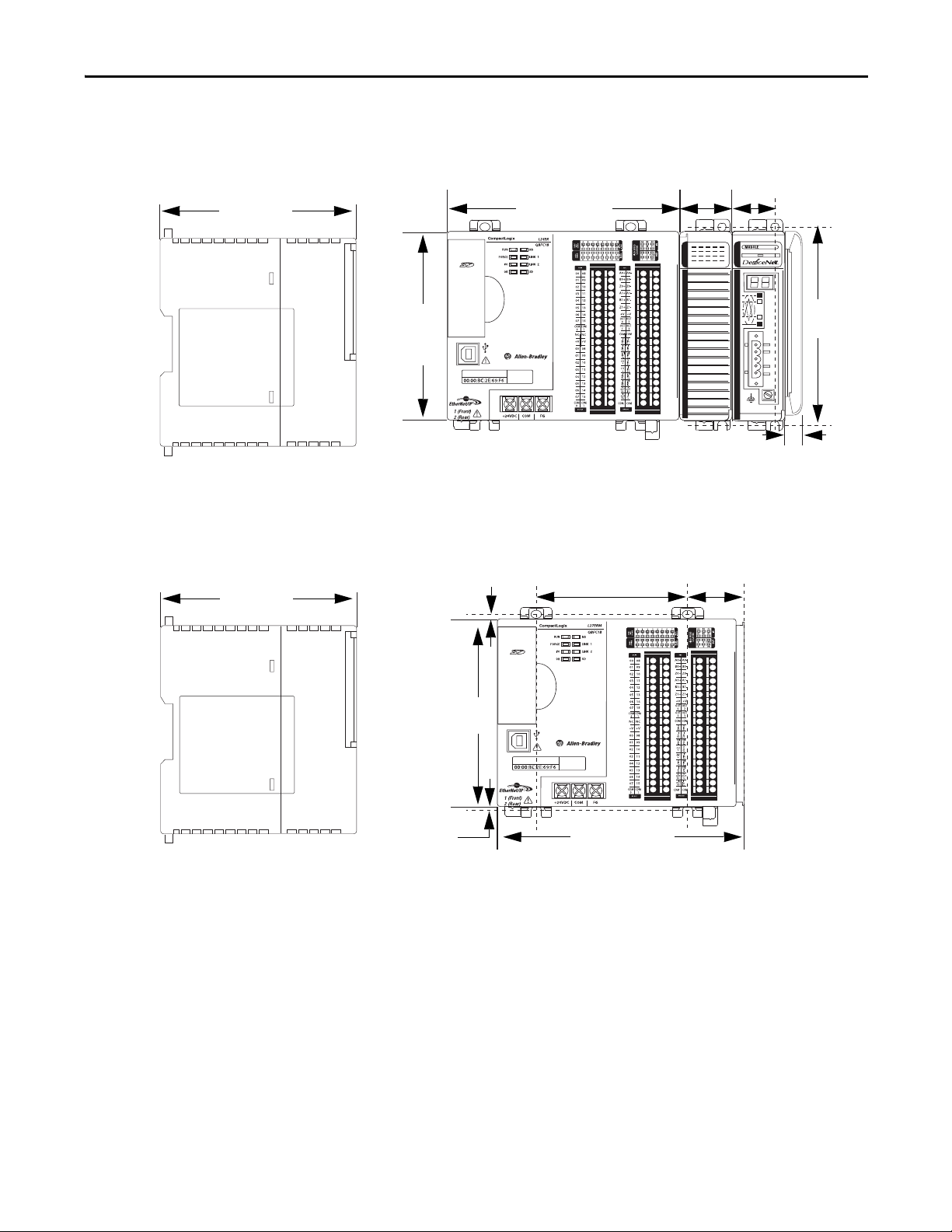

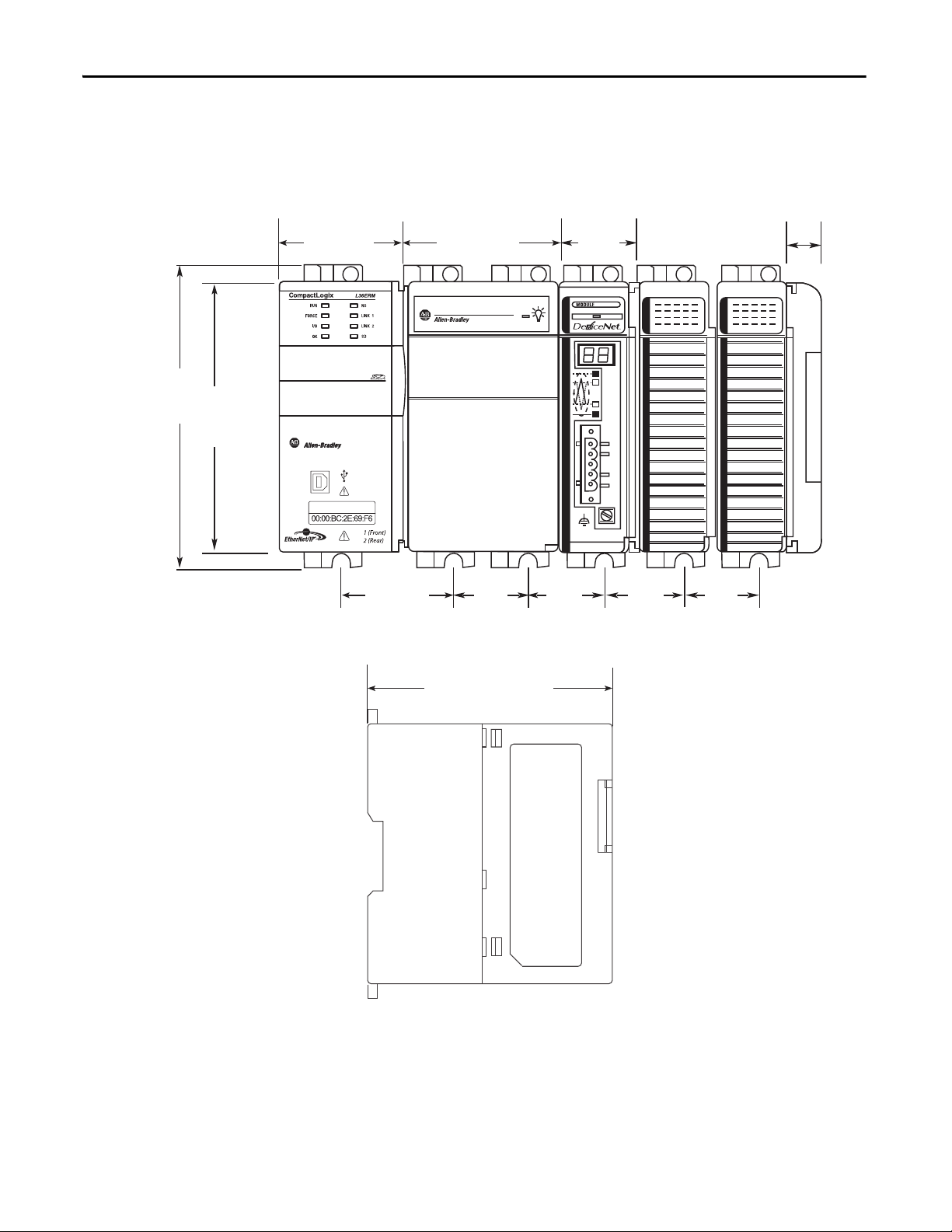

System Dimensions

144.00 mm

(5.67 in.)

130.00 mm

(5.11 in.)

100.00 mm

(3.94 in.)

105 mm

(4.13 in.)

144.00 mm

(5.67 in.)

130.00 mm

(5.11 in.)

100.00 mm

(3.94 in.)

12.00 mm

(0.47 in.)

105 mm

(4.13 in.)

This graphic shows the system dimensions.

Install the CompactLogix 5370 L1 Controller Chapter 1

This graphic shows the system dimensions with Expansion I/O modules

installed.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 23

Page 21

Chapter 1 Install the CompactLogix 5370 L1 Controller

Ground the System

ATTENTION: This product is intended to be mounted to a well-grounded

mounting surface such as a metal panel. Additional grounding connections

from the power supply's mounting tabs or DIN rail (if used) are not required

unless the mounting surface cannot be grounded.

See Industrial Automation Wiring and Grounding Guidelines, Rockwell

Automation publication 1770-4.1

, for additional information.

Install the Controller

Complete these steps to install the controller.

1. Pull out the locking tabs.

2. Slide the controller into position on the DIN rail and push the locking

tabs in.

24 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 22

Install the CompactLogix 5370 L1 Controller Chapter 1

Thermocouple

Input

Module

Status

Network

Status

1734

IT2I

NODE:

0

1

Insert the module straight

down into the mounting base.

Hook the RTB end into

the mounting base

end and rotate until it

locks into place.

44012

3. If you are not using local expansion modules, use the tongue-and-groove

slots on the right side of the controller to slide a protective covering onto

the controller. The protective cover ships with the controller.

The covering covers the exposed interconnections on the right side of the

controller. Failure to use a protective covering can result in equipment

damage or injury from electric shock.

If you are using local expansion modules, see Local Expansion Modules

on

page 158 for more information on how to install them in a

CompactLogix 5370 L1 control system.

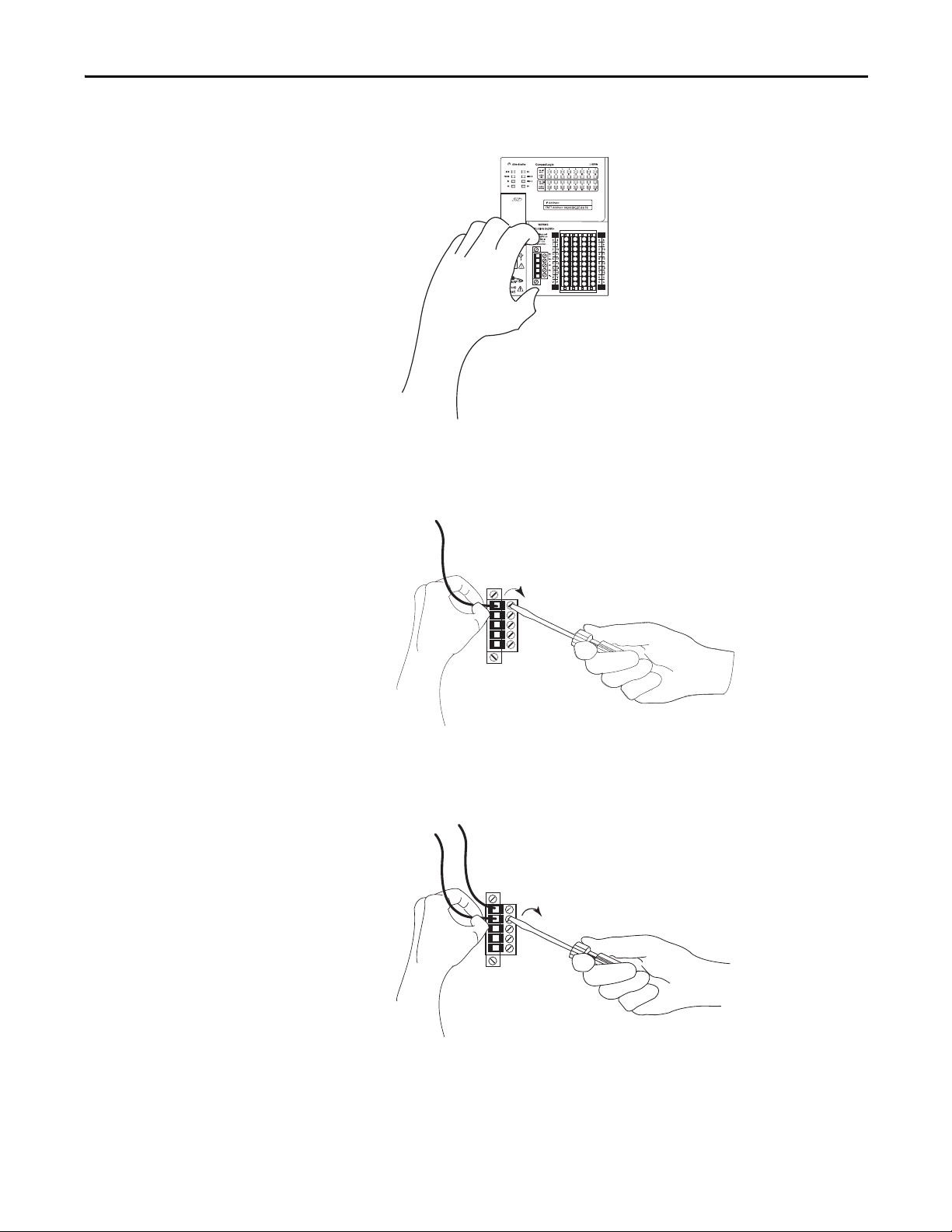

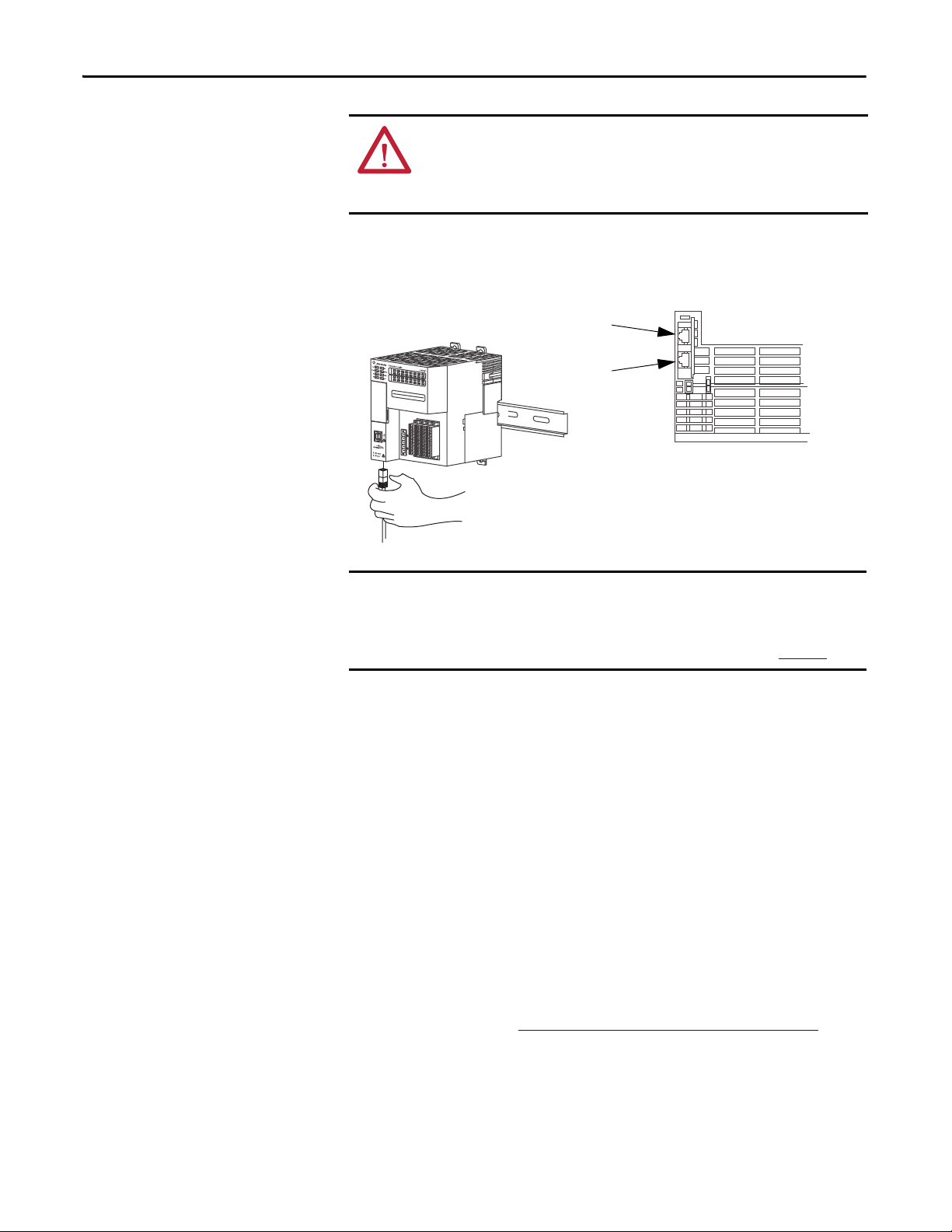

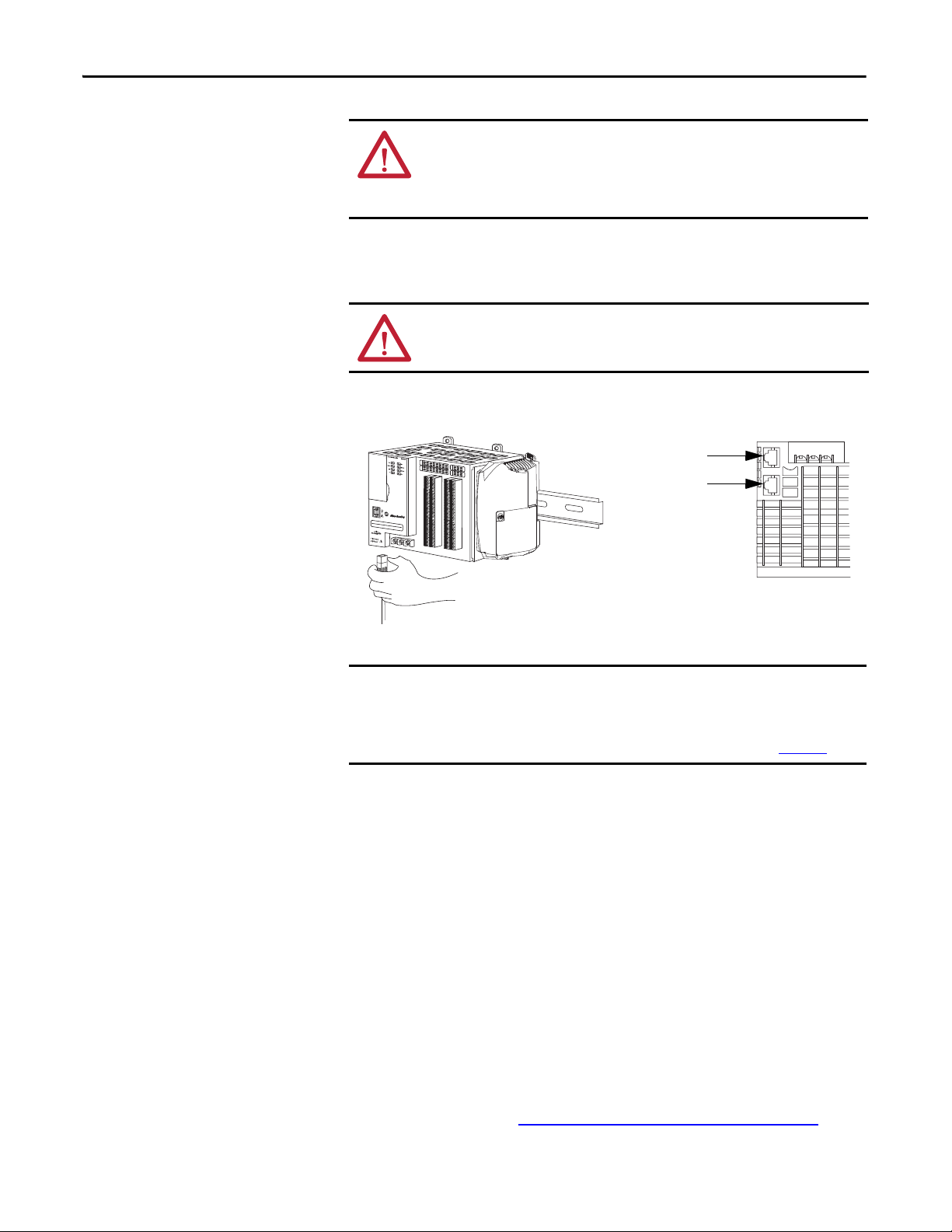

Install the Removable Terminal Block

A removable terminal block (RTB) is supplied with your wiring base assembly. To

remove, pull up on the RTB handle. This allows the mounting base to be

removed and replaced as necessary without removing any of the wirings. To

reinsert the removable terminal block, proceed as follows:

1. Insert the end opposite the handle into the base unit. This end has a curved

section that engages with the wiring base.

2. Rotate the RTB into the wiring base until it locks itself in place.

3. If an I/O module is installed, snap the RTB handle into place on the

module.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 25

Page 23

Chapter 1 Install the CompactLogix 5370 L1 Controller

IMPORTANT

WARNING: When you connect or disconnect the RTB with field-side power

applied, an electrical arc can occur. This can cause an explosion in hazardous

location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

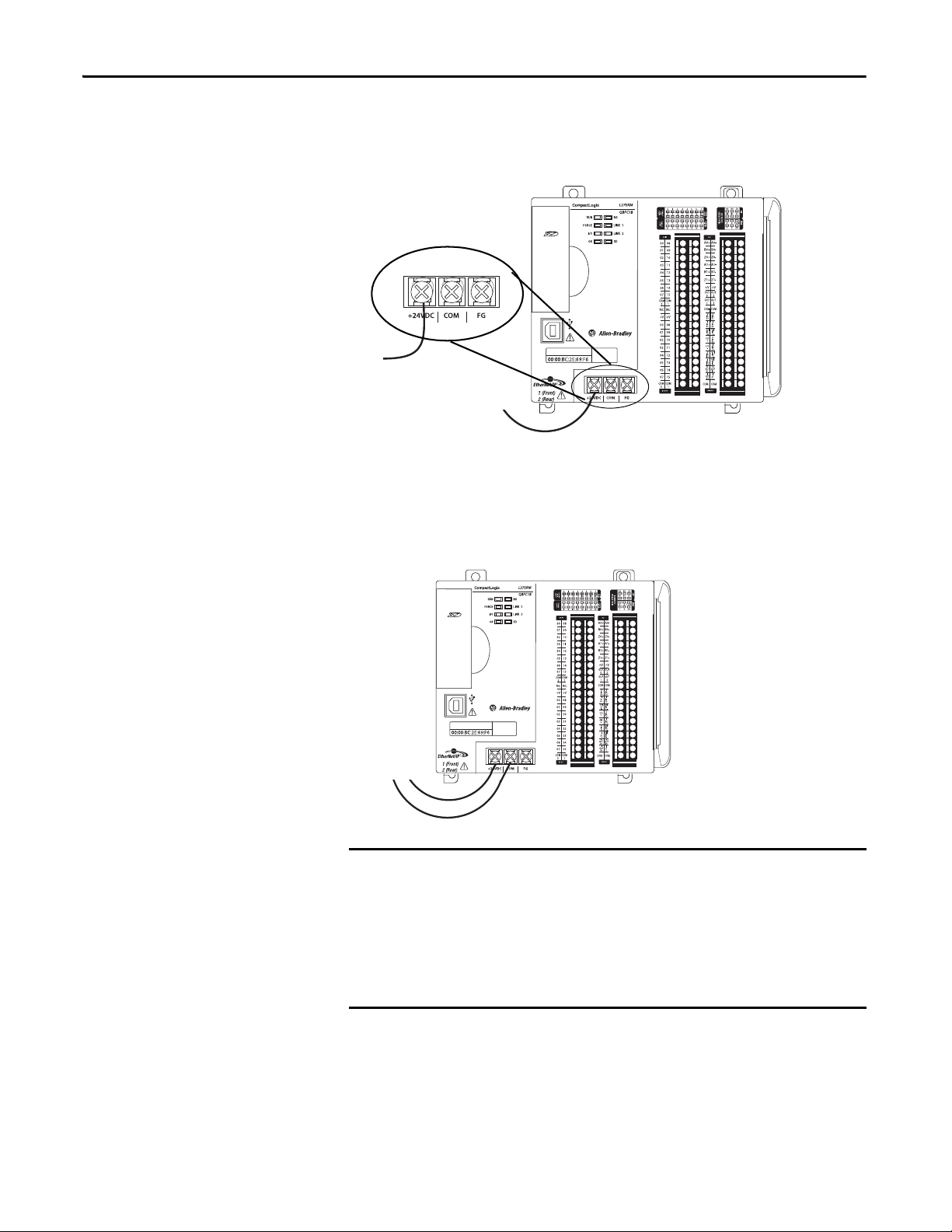

Connect Power to the Controller (Series B)

For information to connect power to a series A L1 controller, see Appendix C.

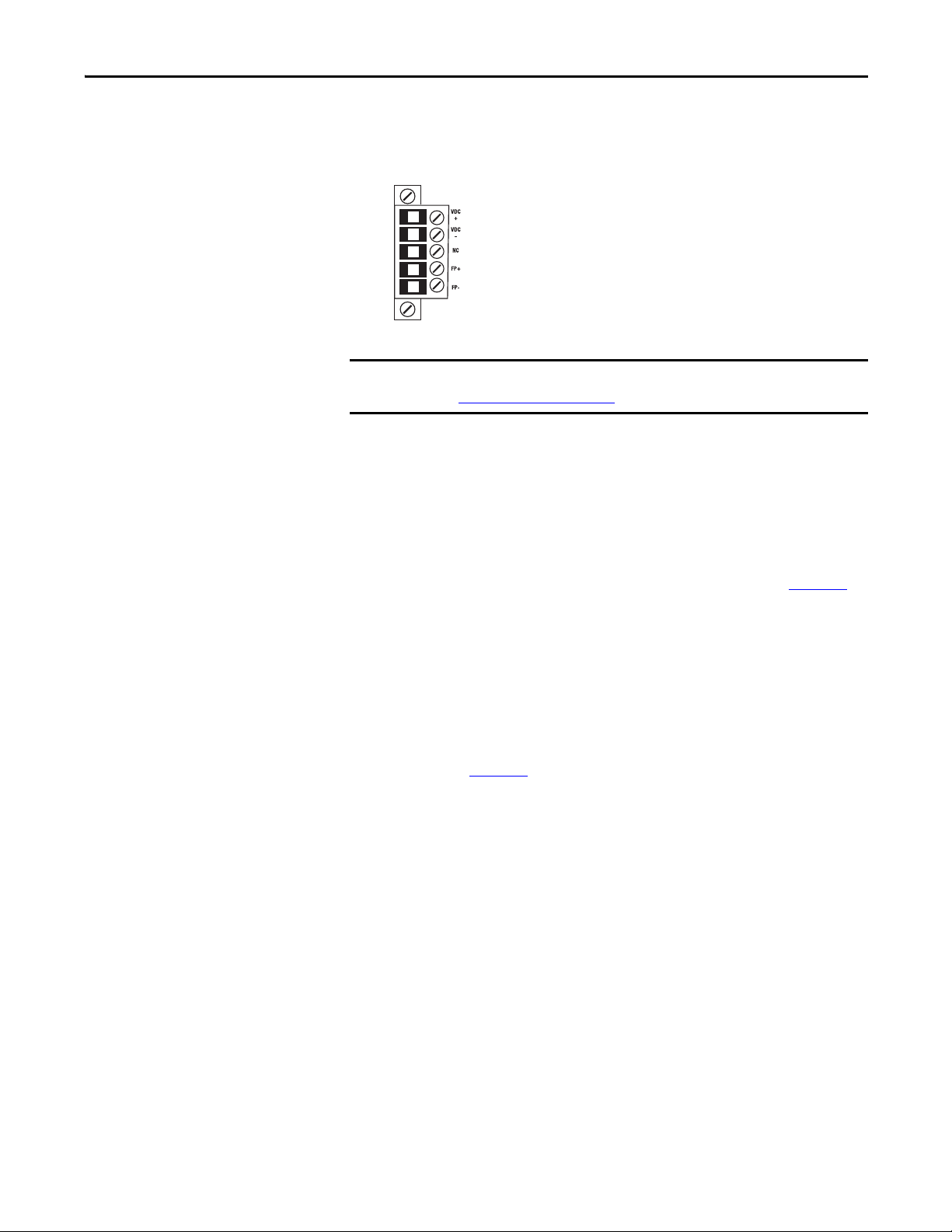

This section describes how to power the controller via the VDC+ and VDCterminals.

Connections to the VDC+ and VDC- terminals do not provide power to input or

output devices that are connected to the embedded I/O modules of the

controller or local expansion modules. Power must be connected to the FP+

and FP- terminals to provide power to input or output devices that are

connected to the embedded I/O modules of the controller or local expansion

modules.

The external power supply can be used to power both the VDC+/- and FP+/terminals on the series B L1 controller, see page 144

For more information on how to provide power to input or output devices that

are connected to the embedded I/O modules of the controller and local

expansion modules, see page 144

.

.

WARNING: Do not connect directly to line voltage. Line voltage must be

supplied by a suitable, approved isolating transformer or power supply having

short circuit capacity not exceeding 100VA maximum or equivalent. The

controller power requirement is 30VA.

26 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 24

Install the CompactLogix 5370 L1 Controller Chapter 1

IMPORTANT

Power is connected to the controller via a removable connector that is connected

to the front of the controller. The following graphic shows the connector.

The controller is grounded once it is installed on a DIN rail as described in

Mount the System

on page 21.

Consider these points before completing the steps in this section:

• This section describes how to connect an external 24V DC power source

to the CompactLogix 5370 L1 controller.

For information on how to provide field power to input and output

devices that are connected to the embedded I/O modules of the controller

and local expansion modules via the removable connector, see page 144

• Use a power source that most effectively meets your application needs.

That is, calculate The power requirements for your application before

choosing a power source to avoid using a power source that far exceeds

your application requirements.

• This section assumes that any DIN rail you use has been grounded

following Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

.

• The embedded power supply of the CompactLogix 5370 L1 controller

provides power to the controller and POINTBus backplane.

.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 27

Page 25

Chapter 1 Install the CompactLogix 5370 L1 Controller

• Not all Class 2/SELV-listed power supplies are certified for use in all

applications, for example, use in nonhazardous and hazardous

environments.

Before installing an external power supply, consult all specification and

certification information to verify that you are using an acceptable external

power supply.

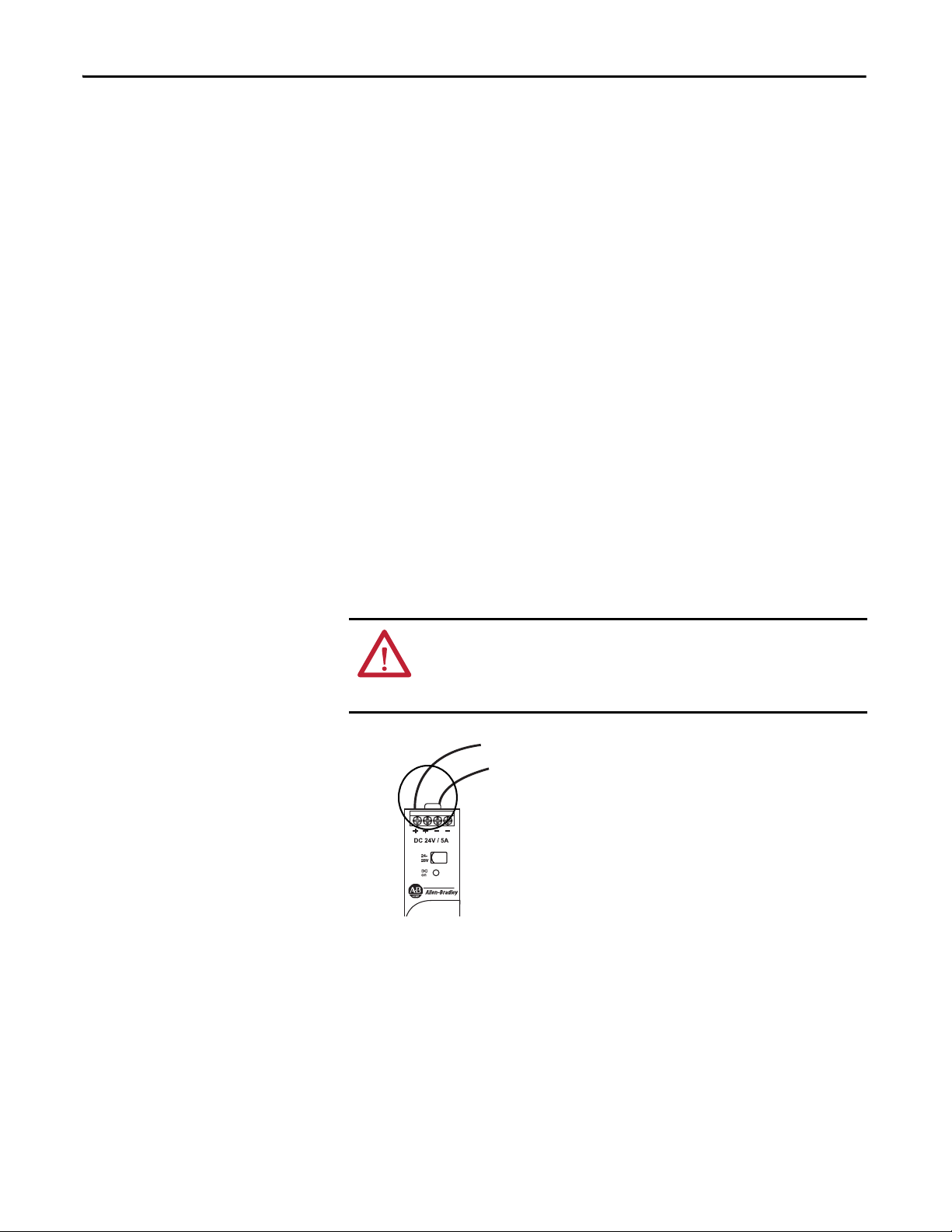

• Only for example purposes, this section describes how to use a 1606XLE120E, NEC Class 2 switched-mode power supply. The exact steps for

other external power supplies can vary from the steps that are described

here.

Complete these steps to connect power to the CompactLogix series B L16ER,

L18ER, L18ERM and series A L19ER controllers.

1. Verify that the external 24V DC power source is not powered.

2. Mount the external 24V DC power source on a DIN rail.

The external 24V DC power source can be installed on the same DIN rail

as the controller or a separate DIN rail.

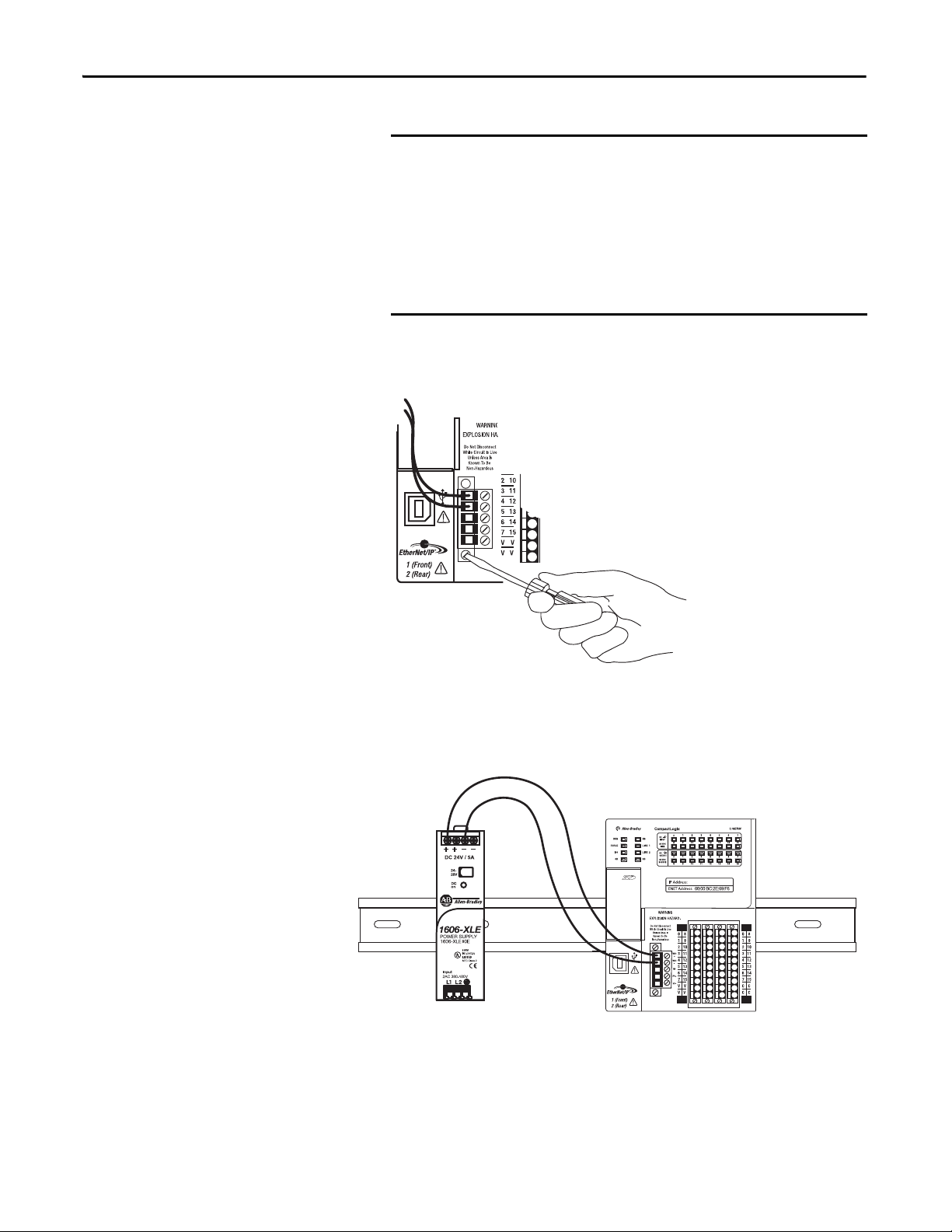

3. Connect wires to the 24V DC+ and 24V DC- connections on the external

24V DC power source.

WARNING: If you connect or disconnect wiring while the field-side power is on,

an electrical arc can occur. This could cause an explosion in hazardous location

installations. Be sure that power is removed or the area is nonhazardous before

proceeding.

28 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 26

Install the CompactLogix 5370 L1 Controller Chapter 1

4. Pull the removable connector off the CompactLogix 5370 L1 controller.

5. Connect the wire that is connected to the 24V DC+ terminal on the

external 24V DC power source to the VDC+ terminal, that is, the top

terminal, on the removable connector.

6. Connect the wire that is connected to the 24V DC- terminal on the

external 24V DC power source to the VDC- terminal, that is, the terminal

that is second from the top, on the removable connector.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 29

Page 27

Chapter 1 Install the CompactLogix 5370 L1 Controller

IMPORTANT

If your application requires a power control device, for example, a

switch or relay, between the external 24V DC power source and the

CompactLogix 5370 L1 controller to control when the controller is

powered, you must install the power control device at the VDC+

terminal on the removable connector.

If you install the power control device at the VDC- terminal, the

CompactLogix 5370 L1 controller can have problems powering up or

powering down properly.

7. Plug the removable connector back into the controller.

8. Secure the removable connector in place.

9. Turn on power to the external 24V DC power source.

The following graphic shows an external 24V DC power source that is connected

to a CompactLogix 5370 L1 controller.

30 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 28

Install the CompactLogix 5370 L1 Controller Chapter 1

Connect to the Controller via

a USB Cable

The controller has a USB port that uses a Type B receptacle. The port is USB

2.0-compatible and operates at 12 Mbps.

Use a USB cable to connect your computer to the USB port. With this

connection, you can upgrade firmware and download programs to the controller

directly from your computer.

ATTENTION: The USB port is intended only for temporary local

programming purposes and not intended for permanent connection.

The USB cable is not to exceed 3.0 m (9.84 ft) and must not contain hubs.

WARNING: Do not use the USB port in hazardous locations.

Plug the USB cable into the CompactLogix 5370 L1 controller.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 31

Page 29

Chapter 1 Install the CompactLogix 5370 L1 Controller

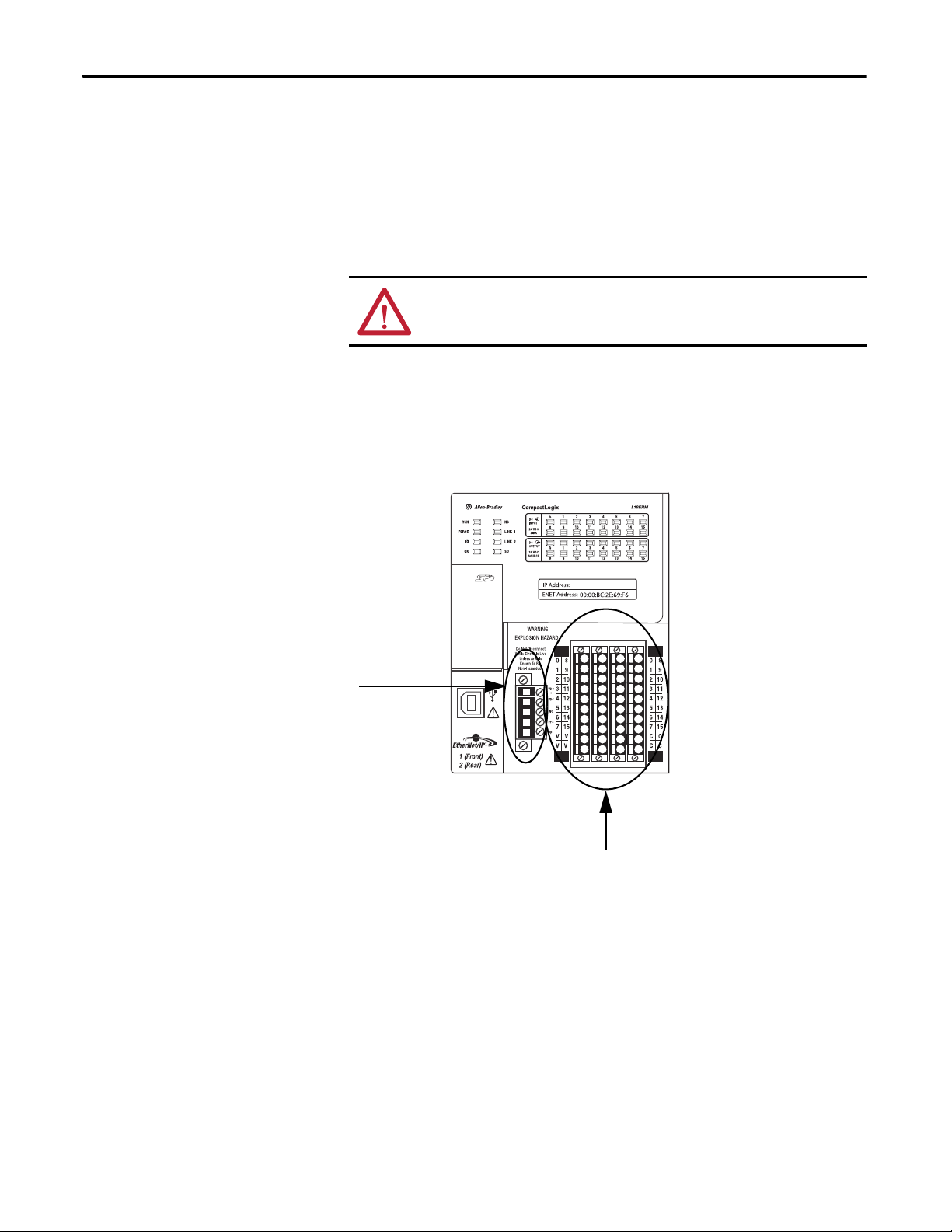

IMPORTANT

Port 1 - Fron t

Port 2 - Bac k

Bottom of Controller

Connect the Controller to an

EtherNet/IP Network

WARNING: If you connect or disconnect the communication cable with

power applied to this module or any device on the network, an electrical arc

can occur. This could cause an explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

Connect the RJ45 connector of the Ethernet cable to one of the Ethernet ports

on the controller. The ports are on the bottom of the controller.

This example shows how to connect the controller to the network through one

port. Depending on the network topology of your application, you can connect

both ports of the controller to the EtherNet/IP network.

For more information on EtherNet/IP network topologies, see page 127

.

Connecting to Different EtherNet/IP Network Topologies

CompactLogix 5370 L1 controllers have embedded switch technology and two

EtherNet/IP ports that let you use it in various EtherNet/IP network topologies:

• Device-level ring network topology - Both ports on the controller are

connected to the network.

• Linear network topology - Both ports on the controller are connected to

the network.

• Star network topology - One port on the controller is connected to

the network.

There are connection and configuration requirements for each EtherNet/IP

network topology.

For more information, see EtherNet/IP Network Topologies

on page 127.

32 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 30

Chapter 2

Install the CompactLogix 5370 L2 Controller

Top ic Pag e

Before You Begin 36

Install the Secure Digital Card 38

Install the System 40

Connec t to the Controller via a USB Cab le 53

Connect the Controller to an EtherNet/IP Network 54

ATTENTION: Environment and Enclosure

This equipment is intended for use in a Pollution Degree 2 industrial environment, in overvoltage Category II applications (as defined

in IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment according to IEC/CISPR 11. Without appropriate precautions,

there may be difficulties with electromagnetic compatibility in residential and other environments due to conducted and radiated

disturbances.

This equipment is supplied as open-type equipment. It must be mounted within an enclosure that is suitably designed for those

specific environmental conditions that will be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The enclosure must have suitable flame-retardant properties to prevent or minimize the spread of flame,

complying with a flame spread rating of 5VA, V2, V1, V0 (or equivalent) if nonmetallic. The interior of the enclosure must be

accessible only by the use of a tool. Subsequent sections of this publication may contain additional information regarding specific

enclosure type ratings that are required to comply with certain product safety certifications.

In addition to this publication, see the following:

• Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

• NEMA 250 and IEC 60529, as applicable, for explanations of the degrees of protection provided by enclosures

, for additional installation requirements

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 33

Page 31

Chapter 2 Install the CompactLogix 5370 L2 Controller

North American Hazardous Location Approval

The following information applies when operating this equipment in

hazardous locations.

Produc ts marked "CL I, DIV 2, GP A, B, C, D" are suitable for use in Class

I Division 2 Groups A, B, C, D, Hazardous Locations and nonhazardous

locations only. Each product is supplied with markings on the rating

nameplate indicating the hazardous location temperature code.

When combining products within a system, the most adverse

temperature code (lowest "T" number) may be used to help

determine the overall temperature code of the system. Combinations

of equipment in your system are subject to investigation by the local

Authority Having Jurisdiction at the time of installation.

WARNING: EXPLOSION HAZARD -

• Do not disconnect equipment unless power has

been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this equipment

unless power has been removed or the area is

known to be nonhazardous. Secure any external

connections that mate to this equipment by using

screws, sliding latches, threaded connectors, or

other means provided with this product.

• Substitution of components may impair suitability

for Class I, Division 2.

• If this product contains batteries, they must only

be changed in an area known to be nonhazardous.

Informations sur l’utilisation de cet équipement en environnements

dangereux.

Les produits marqués "CL I, DIV 2, GP A, B, C, D" ne conviennent qu'à

une utilisation en environnements de Classe I Division 2 Groupes A, B,

C, D dangereux et non dangereux. Chaque produit est livré avec des

marquages sur sa plaque d'identification qui indiquent le code de

température pour les environnements dangereux. Lorsque plusieurs

produits sont combinés dans un système, le code de température le

plus défavorable (code de température le plus faible) peut être utilisé

pour déterminer le code de température global du système. Les

combinaisons d'équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de

l'installation.

AVERTISSEMENT: RISQUE D’EXPLOSION –

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher l'équipement.

• Couper le courant ou s'assurer que

l'environnement est classé non dangereux avant

de débrancher les connecteurs. Fixer tous les

connecteurs externes reliés à cet équipement à

l'aide de vis, loquets coulissants, connecteurs

filetés ou autres moyens fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S'assurer que l'environnement est classé non

dangereux avant de changer les piles.

34 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 32

Install the CompactLogix 5370 L2 Controller Chapter 2

European Hazardous Location Approval

The following applies when the product bears the Ex Marking.

This equipment is intended for use in potentially explosive atmospheres as defined by European Union Directive 94/9/EC and has been found to

comply with the Essential Health and Safety Requirements relating to the design and construction of Category 3 equipment intended for use in

Zone 2 potentially explosive atmospheres, given in Annex II to this Directive.

Compliance with the Essential Health and Safety Requirements has been assured by compliance with EN 60079-15 and EN 60079-0.

ATTENTION: This equipment is not resistant to sunlight or other sources of UV radiation.

WARNING:

• This equipment must be installed in an enclosure providing at least IP54 protection when applied in Zone 2 environments.

• This equipment shall be used within its specified ratings defined by Rockwell Automation.

• Provision shall be made to prevent the rated voltage from being exceeded by transient disturbances of more than 40% when

applied in Zone 2 environments.

• Secure any external connections that mate to this equipment by using screws, sliding latches, threaded connectors, or other

means provided with this product.

• Do not disconnect equipment unless power has been removed or the area is known to be nonhazardous.

• Enclosure must be marked with the following: "Warning - Do not open when energized." After installation of equipment into

the enclosure, access to termination compartments shall be dimensioned so that conductors can be readily connected.

ATTENTION: Prevent Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which can cause internal damage and affect normal operation. Follow these

guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in use.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 35

Page 33

Chapter 2 Install the CompactLogix 5370 L2 Controller

Embedded Power

Supply Terminals

Embedded I/O Modules

1769-L24ER-QBFC1B Control

End Cap

Before You Begin

Consider the following before installing a CompactLogix™ 5370 L2 controller:

• The control system includes a controller, an embedded power supply,

embedded I/O points, and a 1769-ECR right end cap.

• The embedded power supply is a 24V DC input, isolated power supply

The following graphic shows an example CompactLogix 5370 L2

controller.

ATTENTION: You must use an external power supply that is Class 2 or

SELV-listed for series A L1 controllers.

For example, you can use a 1606-XLSDNET4, standard switched-mode

power supply, as shown in this chapter.

• The controllers have embedded I/O points. You wire the input and output

points via a removable connector.

• The controller supports the use of up to four Compact I/O™ modules on

the local 1769 CompactBus backplane as local expansion modules.

For more information on using embedded I/O points and local

expansion modules, see Chapter 8, Use I/O Modules with

CompactLogix 5370 L2 Controllers on page 183.

• You must terminate the end of the CompactBus via a 1769-ECR right end

cap as shown in step 6 on page 47

.

• You cannot remove nor install Compact I/O modules while the controller

is powered.

36 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 34

Install the CompactLogix 5370 L2 Controller Chapter 2

IMPORTANT

ATTENTION: CompactLogix 5370 L2 control systems do not support

removal and insertion under power (RIUP). Removing a 1769 Compact

I/O module or end cap generates a controller fault and may also result in

damage to system components.

CompactLogix 5370 L2 Controller Parts

These parts are included in the box when you order your controller:

• Controller - Specific catalog number varies by order

• 1769-ECR Compact I/O end cap/terminator

• 1784-SD1 Secure Digital (SD) card with 1 GB of memory storage

A 1784-SD2 SD card with 2 GB of memory storage, or more1784-SD1

SD cards, are also available if you need extra memory.

Installation Summary

The life expectancy of nonvolatile media is dependent on the number

of write cycles that are performed. Nonvolatile media use a wear

leveling technique or technology for prolonging the service life, but

avoid frequent writes.

Avoid frequent writes when logging data. We recommend that you log

data to a buffer in the memory of your controller and limit the number

of times data is written to removable media.

To install a CompactLogix 5370 L2 controller, follow these steps.

1. Install the Secure Digital Card

2. Install the System

3. Connect to the Controller via a USB Cable

4. Connect the Controller to an EtherNet/IP Network

.

.

.

.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 37

Page 35

Chapter 2 Install the CompactLogix 5370 L2 Controller

Unlocked Locked

Install the Secure

Digital Card

The CompactLogix 5370 L2 controller is shipped from the factory with the

1784-SD1 SD card installed.

Complete these steps to reinstall an SD card that has been removed from the

controller back into the controller or to install a new SD card into the controller.

We recommend that you leave the SD card in the controller, even when it is not

used. If the controller experiences a Major Non-recoverable Fault, extended fault

information is saved to the card.

WARNING: When you insert or remove the SD card while power is on, an

electrical arc can occur. This could cause an explosion in hazardous location

installations.

Be sure that power is removed or the area is nonhazardous before proceeding.

1. Verify that the SD card is locked or unlocked according to your preference.

Consider the following when deciding to lock the card before installation:

– If the card is unlocked, the controller can write data to it or read data

from it.

38 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

2. Open the door for the SD card.

Page 36

Install the CompactLogix 5370 L2 Controller Chapter 2

3. Insert the SD card into the SD card slot.

You can install the SD card in one orientation only. The beveled corner is

at the bottom.

If you feel resistance when inserting the SD card, pull it out and change the

orientation.

4. Gently press the card until it clicks into place.

5. Close the SD card door.

We recommend that you keep the SD card door closed during normal

system operation. For more information on using the SD card, see Use a

Secure Digital Card on page 297.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 39

Page 37

Chapter 2 Install the CompactLogix 5370 L2 Controller

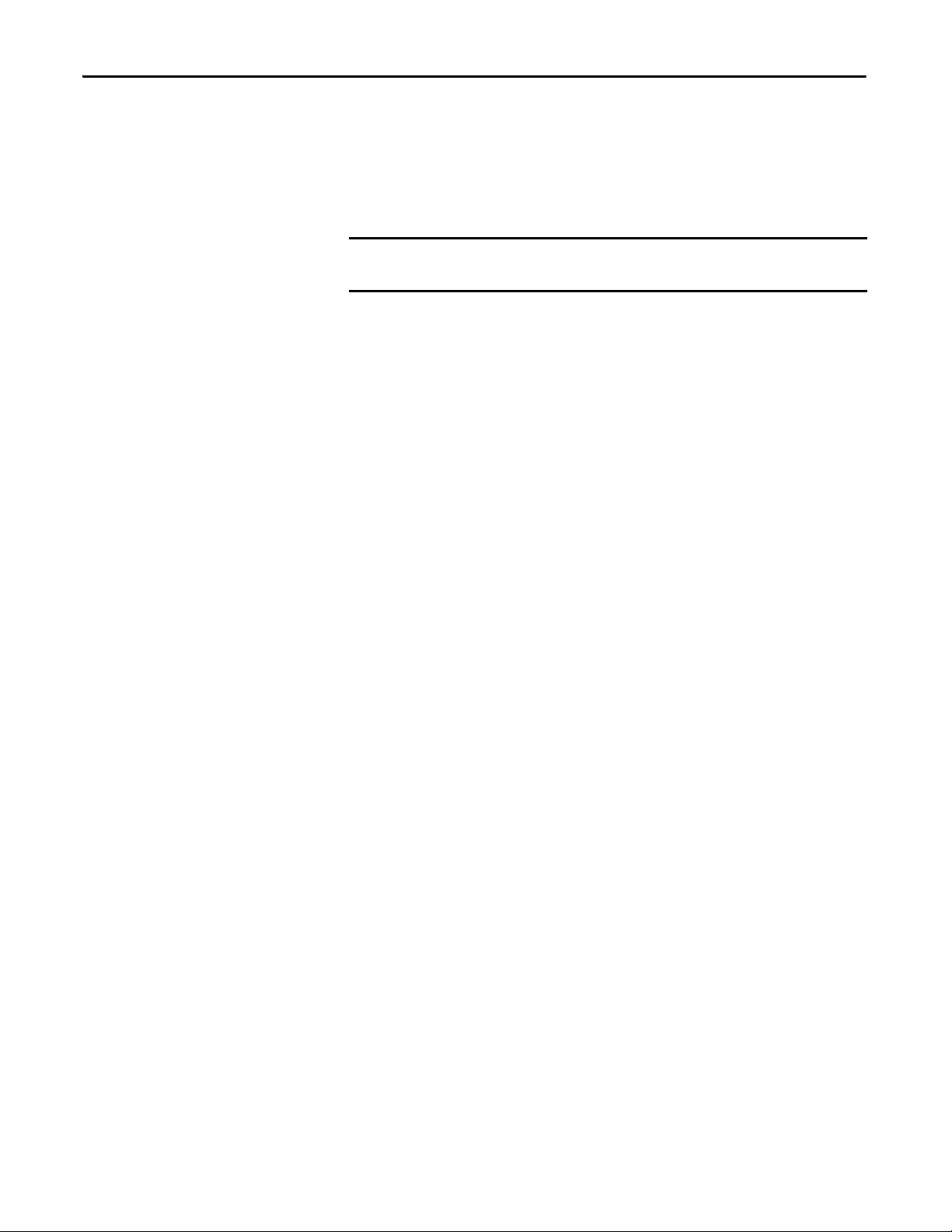

Install the System

Complete the following tasks to install the CompactLogix 5370 L2

control system:

• Mount the System

• Ground the System

• Install the Controller

• Connect Power to the Control System

Mount the System

You can mount a CompactLogix 5370 L2 control system on a DIN rail or

apanel.

WARNING: When used in a Class I, Division 2, hazardous location, this

equipment must be mounted in a suitable enclosure with proper wiring

method that complies with the governing electrical codes.

Before you mount a CompactLogix 5370 L2 control system, consider

the following requirements:

• Available DIN Rails

• Minimum Spacing

• System Dimensions

Available DIN Rails

ATTENTION: This product is grounded through the DIN rail to chassis ground.

Use zinc-plated yellow-chromate steel DIN rail to assure proper grounding.

The use of other DIN rail materials (for example, aluminum or plastic) that

can corrode, oxidize, or are poor conductors, can result in improper or

intermittent grounding. Secure DIN rail to mounting surface approximately

every 200 mm (7.8 in.) and use end-anchors appropriately.

You can mount the CompactLogix 5370 L2 controller on the following

DIN rails:

• EN 50 022 - 35 x 7.5 mm (1.38 x 0.30 in.)

• EN 50 022 - 35 x 15 mm (1.38 x 0.59 in.)

40 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 38

Install the CompactLogix 5370 L2 Controller Chapter 2

Bottom

Top

CompactLogix 5370 L2

Controller wi th

Embedded Power

Supply and I/O Points

End Cap

50 mm

(2 in.)

50 mm

(2 in.)

50 mm

(2 in.)

50 mm

(2 in.)

Side Side

Compact I/O Module

Compact I/O Module

Compact I/O Module

Compact I/O Module

118.00 mm

(4.65 in.)

105 mm

(4.13 in.)

115.00 mm

(4.53 in.)

27.65 mm

(1.09 in.)

59.70 mm

(2.35 in.)

3.06 mm

(0.12 in.)

2.8 mm

(0.12 in.)

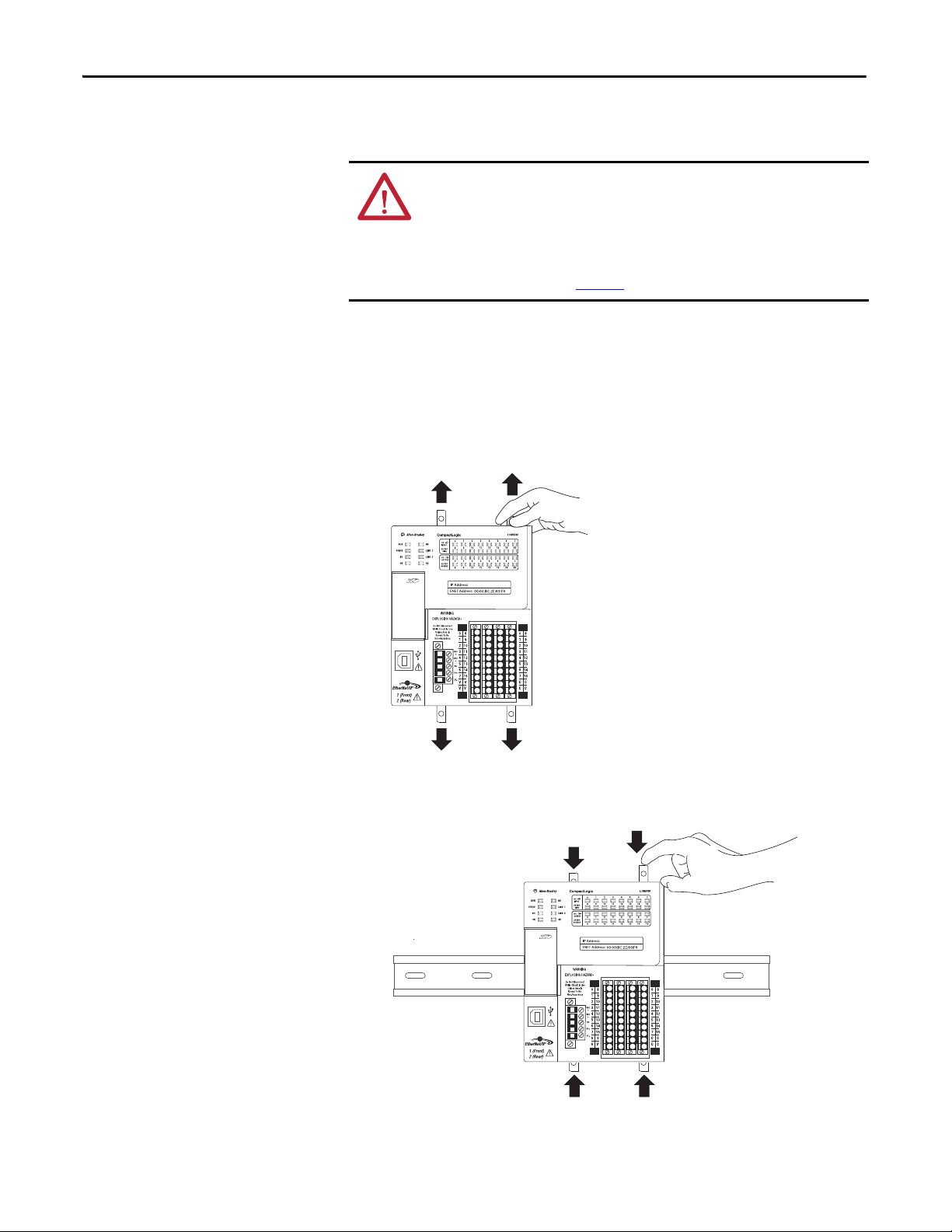

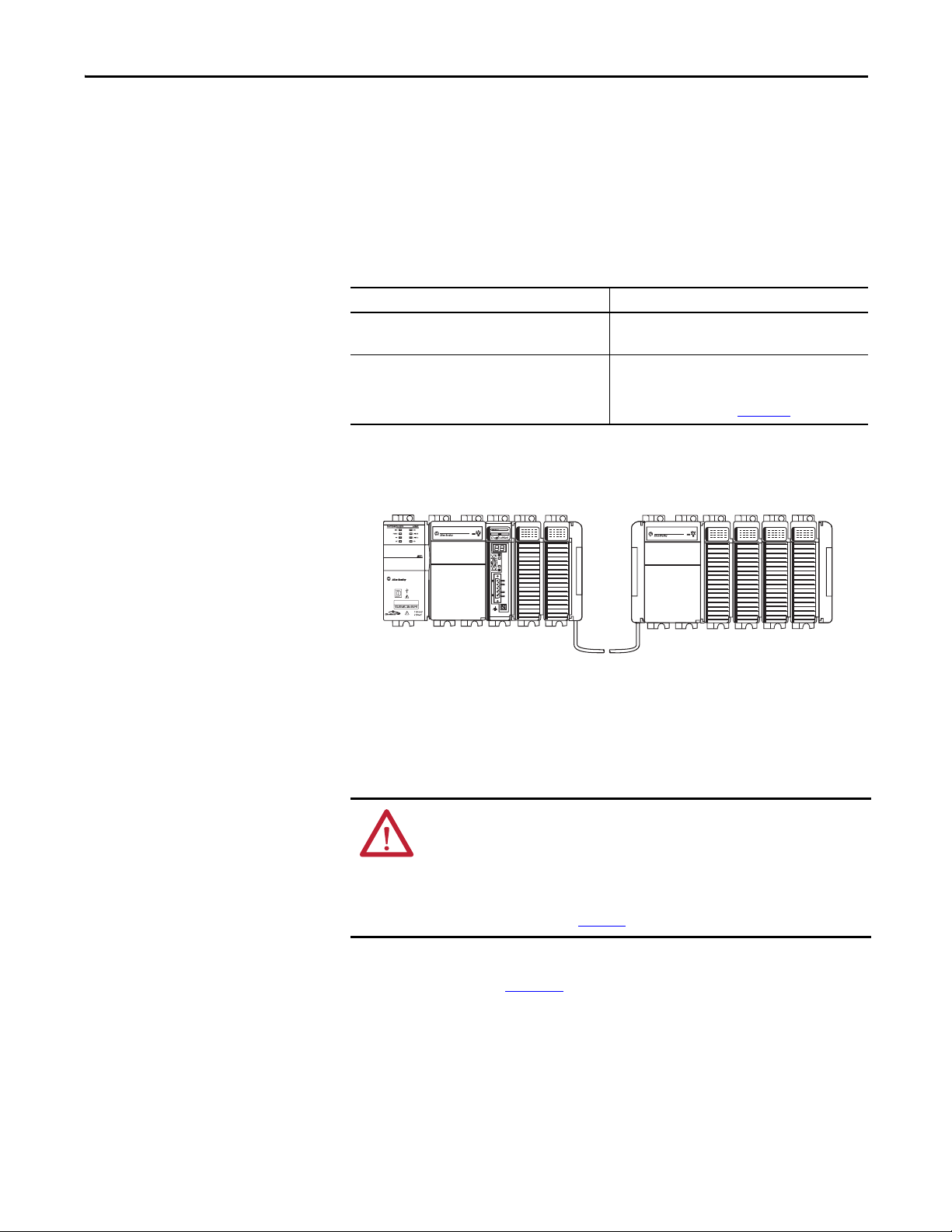

Minimum Spacing

Maintain spacing from enclosure walls, wireways, and adjacent equipment. Allow

50 mm (2 in.) of space on all sides, as shown. This spacing provides ventilation

and electrical isolation.

System Dimensions

This graphic shows the system dimensions for the

1769-L24ER-QB1B controller.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 41

Page 39

Chapter 2 Install the CompactLogix 5370 L2 Controller

118.00 mm

(4.65 in.)

115.00 mm

(4.53 in.)

35.00 mm

(1.38 in.)

105 mm

(4.13 in.)

18.00 mm

(0.71 in.)

25.00 mm

(0.98 in.)

126.6 mm

(4.98 in.)

118.00 mm

(4.65 in.)

105 mm

(4.13 in.)

140.00 mm

(5.51 in.)

27.65 mm

(1.09 in.)

84.70 mm

(3.33 in.)

3.06 mm

(0.12 in.)

2.8 mm

(0.12 in.)

This graphic shows the system dimensions for the 1769-L24ER-QB1B controller

with expansion modules installed.

This graphic shows the system dimensions for the

1769-L24ER-QBFC1B controller.

42 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 40

Install the CompactLogix 5370 L2 Controller Chapter 2

118.00 mm

(4.65 in.)

35.00 mm

(1.38 in.)

105 mm

(4.13 in.)

140.00 mm

(5.51 in.)

18.00 mm

(0.71 in.)

25.00 mm

(0.98 in.)

126.6 mm

(4.98 in.)

118.00 mm

(4.65 in.)

105 mm

(4.13 in.)

140.00 mm

(5.51 in.)

84.70 mm

(3.33 in.)

27.65 mm

(1.09 in.)

3.06 mm

(0.12 in.)

2.8 mm

(0.12 in.)

This graphic shows the system dimensions for the 1769-L24ER-QBFC1B

controller with expansion modules installed.

This graphic shows the system dimensions for the

1769-L27ERM-QBFC1B controller.

This graphic shows the system dimensions for the

1769-L27ERM-QBFC1B controller with expansion modules installed.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 43

Page 41

Chapter 2 Install the CompactLogix 5370 L2 Controller

118.00 mm

(4.65 in.)

35.00 mm

(1.38 in.)

105 mm

(4.13 in.)

140.00 mm

(5.51 in.)

18.00 mm

(0.71 in.)

126.6 mm

(4.98 in.)

25.00 mm

(0.98 in.)

44 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 42

Install the CompactLogix 5370 L2 Controller Chapter 2

IMPORTANT

TIP

TIP

Mount the Controller on a Panel

Use two M4 or #8 pan head screws to mount the controller. Mounting screws are

required on every module. Use this procedure to use the assembled modules as a

template for drilling holes in the panel.

Due to module mounting hole tolerance, it is important to follow these

procedures.

1. On a clean work surface, assemble no more than three modules.

2. Using the assembled modules as a template, carefully mark the center of all

module-mounting holes on the panel.

3. Return the assembled modules to the clean work surface, including any

previously mounted modules.

4. Drill and tap the mounting holes for the recommended M4 or #8 screw.

5. Place the modules back on the panel and check for proper hole alignment.

The grounding plate, that is, where you install the mounting screws,

grounds the module when it is panel-mounted.

6. Use the mounting screws to attach the modules to the panel.

If you are mounting more modules, mount only the last one of this group

and put the others aside. This reduces remounting time when you are

drilling and tapping the next group of modules.

7. Repeat steps 1

…6 for any remaining modules.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 45

Page 43

Chapter 2 Install the CompactLogix 5370 L2 Controller

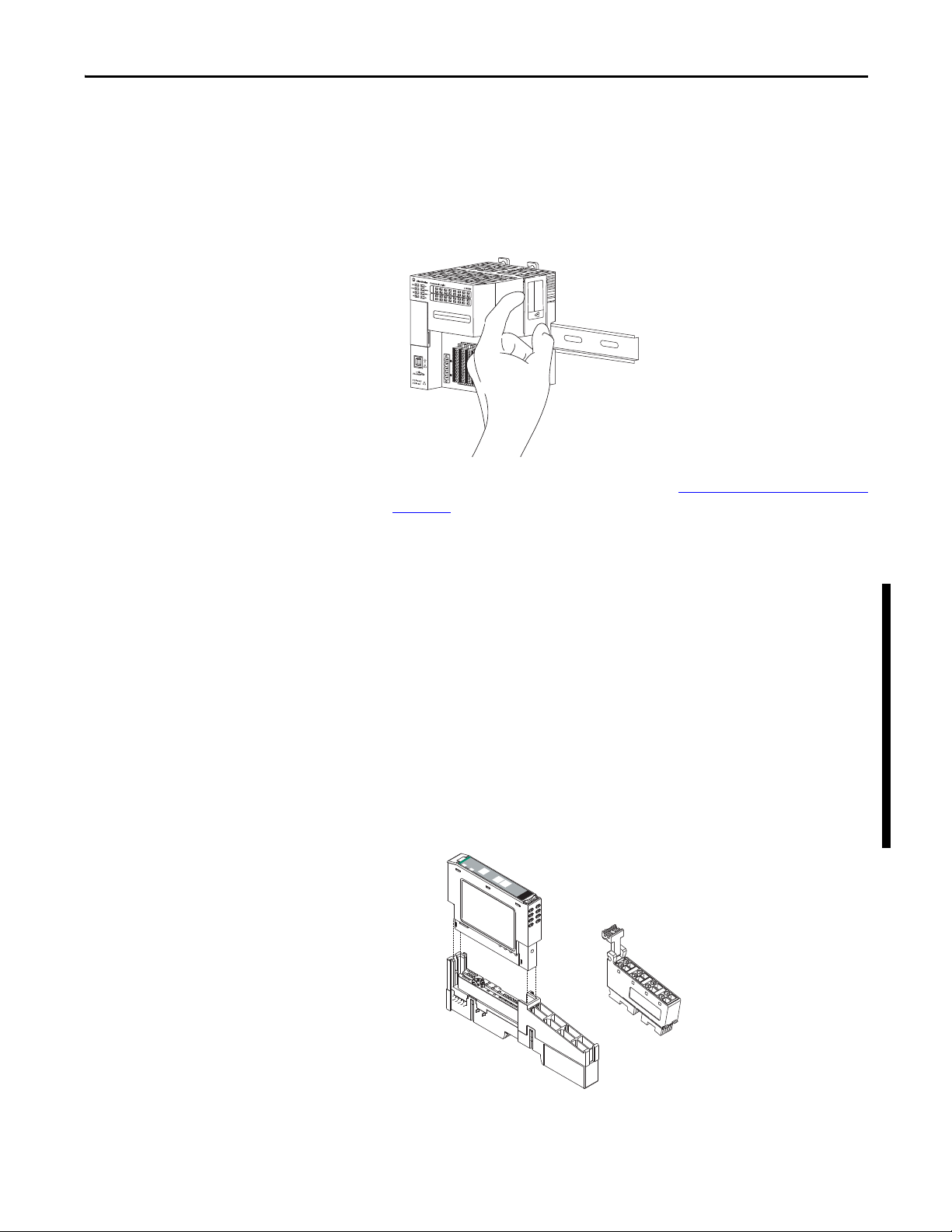

Mount the Controller on the DIN Rail

You can mount the controller on the following DIN rails:

• EN 50 022 - 35 x 7.5 mm (1.38 x 0.30 in.)

• EN 50 022 - 35 x 15 mm (1.38 x 0.59 in.)

ATTENTION: This product is grounded through the DIN rail to chassis ground.

Use zinc-plated yellow-chromate steel DIN rail to assure proper grounding.

The use of other DIN rail materials (for example, aluminum or plastic) that

can corrode, oxidize, or are poor conductors, can result in improper or

intermittent grounding. Secure DIN rail to mounting surface approximately

every 200 mm (7.8 in.) and use end-anchors appropriately.

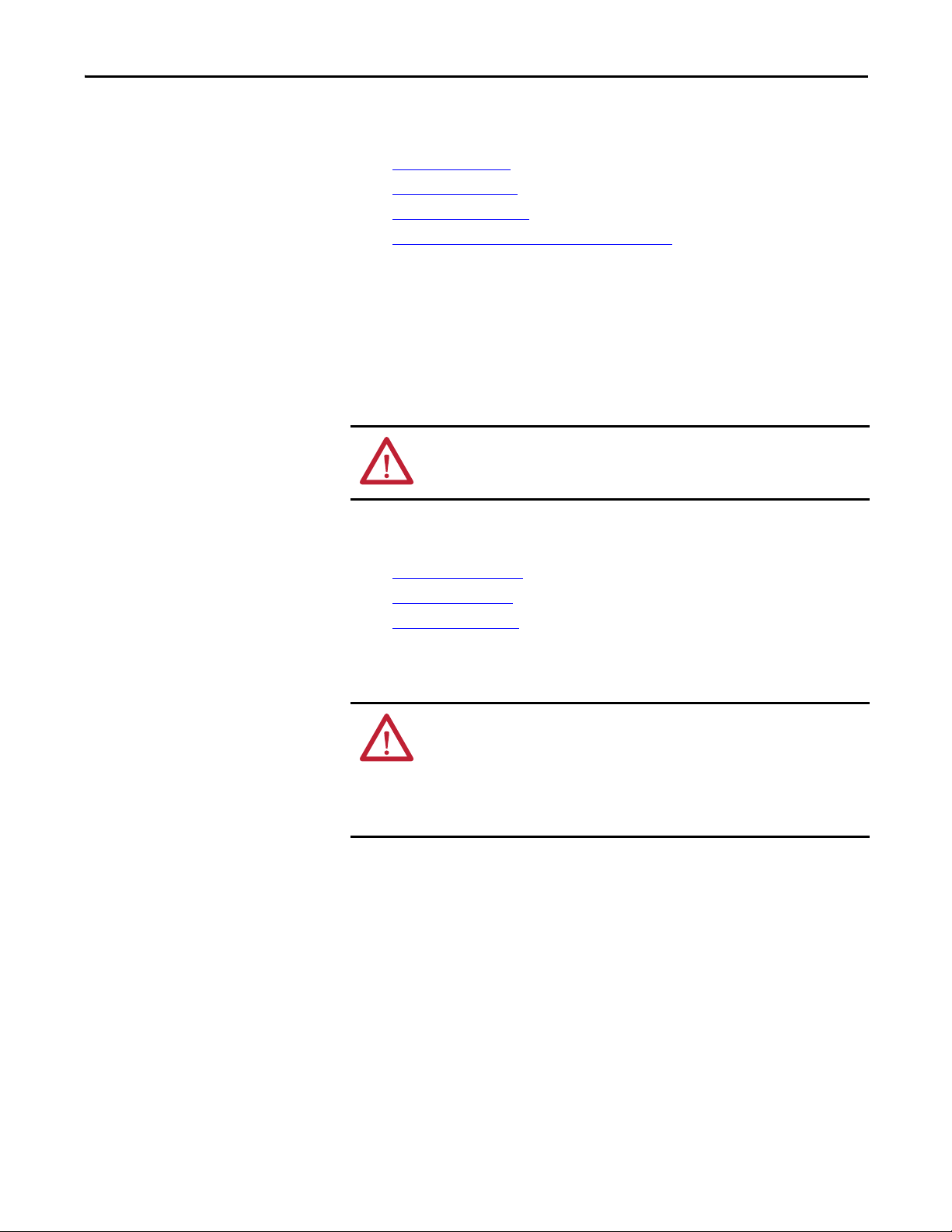

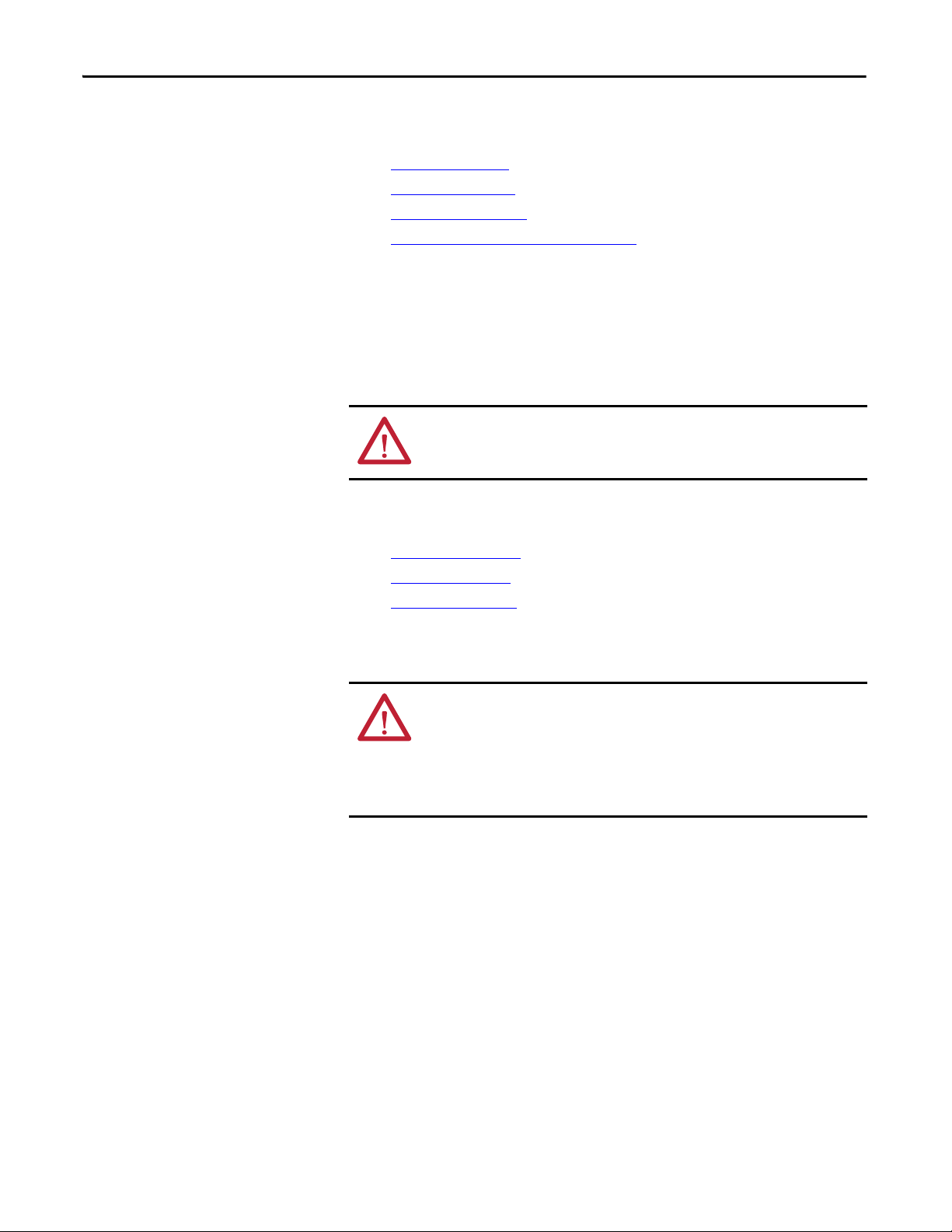

1. Hook the DIN rail latch at the top of the back of the controller on the

DIN rail.

2. Swing the controller downward until it touches the DIN rail and press the

controller against the DIN rail until it clicks in place.

Ground the System

ATTENTION: This product is intended to be mounted to a well-grounded

mounting surface such as a metal panel. Additional grounding connections

from the power supply's mounting tabs or DIN rail (if used) are not required

unless the mounting surface cannot be grounded.

See Industrial Automation Wiring and Grounding Guidelines, Rockwell

Automation® publication 1770-4.1

, for additional information.

46 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 44

Install the CompactLogix 5370 L2 Controller Chapter 2

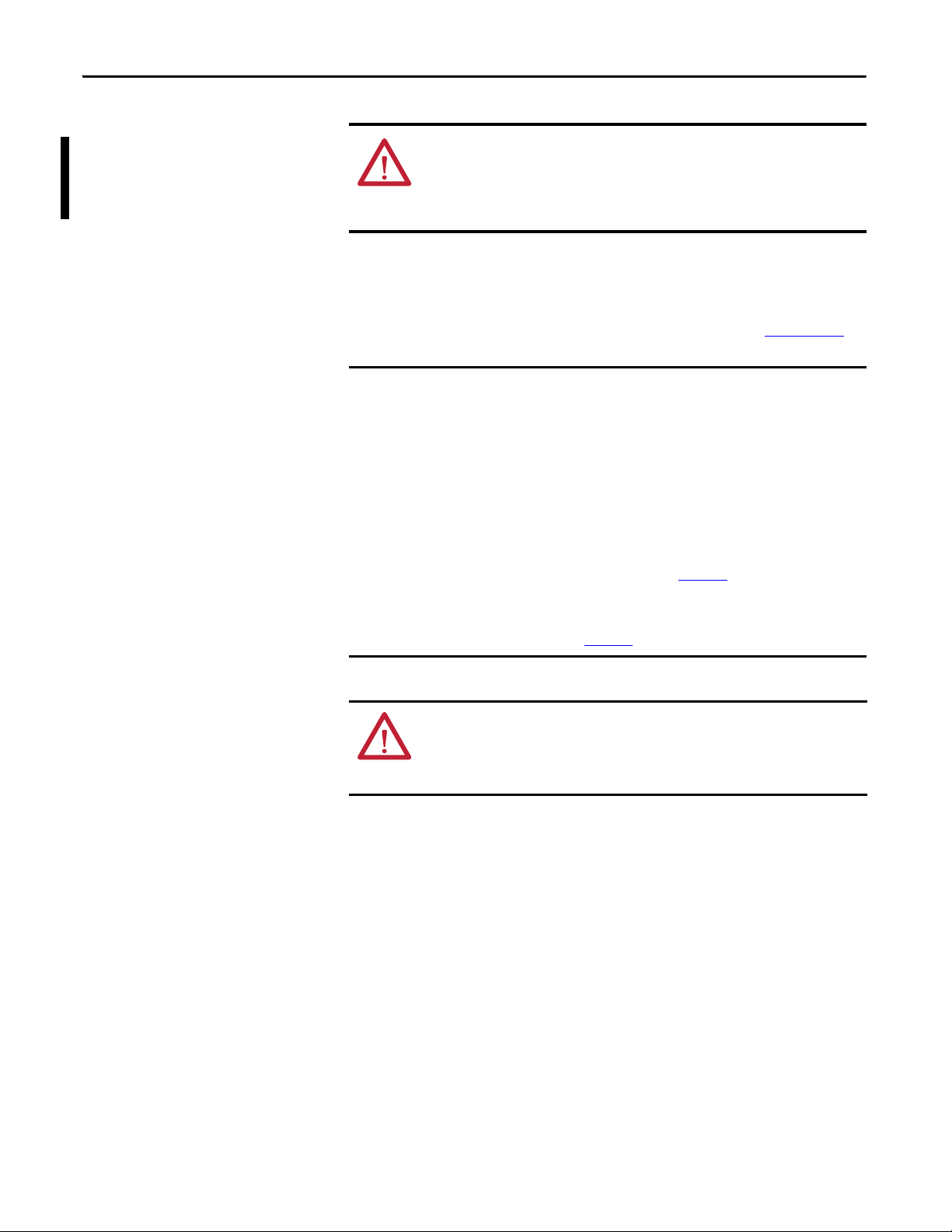

Install the Controller

Complete these steps to install the controller.

1. Pull out the bottom locking tabs.

2. Hook the top of the controller on the DIN rail.

3. Swing it downward until the controller is flush against the DIN rail and

push it down against the DIN rail.

4. Push the controller against the DIN rail.

5. Push the locking tabs in.

6. If you are not using local expansion modules, slide the 1769-ECR end cap

onto the right side of the controller.

Rockwell Automation Publication 1769-UM021G-EN-P - October 2015 47

Page 45

Chapter 2 Install the CompactLogix 5370 L2 Controller

IMPORTANT

You must install an end cap onto the right side of the

CompactLogix 5370 L2 controller system either at the end of the

controller or at the end of any local expansion modules that can be

installed onto the controller.

7. Push the end cap locking mechanism to the right to lock it onto

the controller.

If you are using local expansion modules, see Local Expansion Modules -

Optional on page 214 for more information on how to install them in a

CompactLogix 5370 L2 control system.

48 Rockwell Automation Publication 1769-UM021G-EN-P - October 2015

Page 46

Install the CompactLogix 5370 L2 Controller Chapter 2

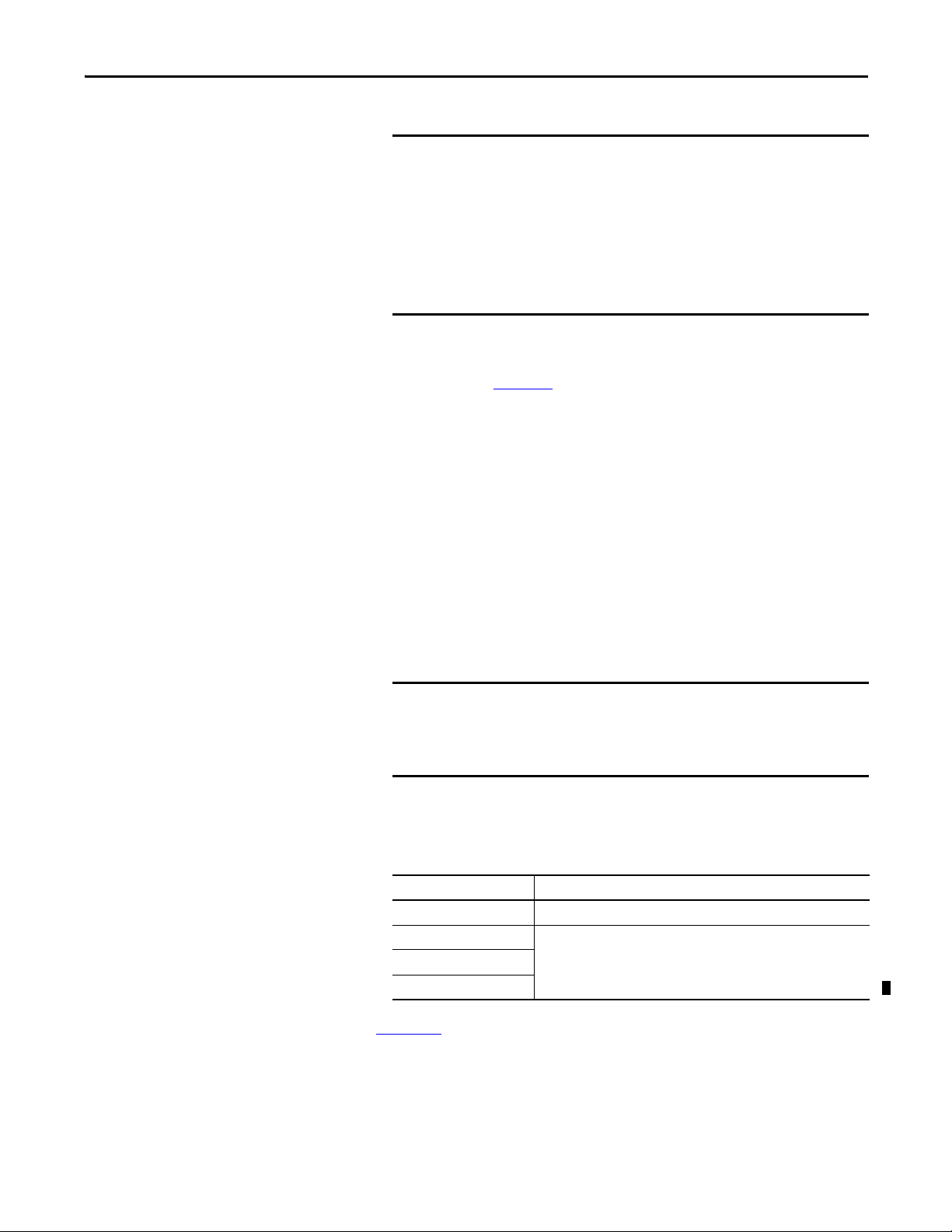

TIP

TIP

1

3

2

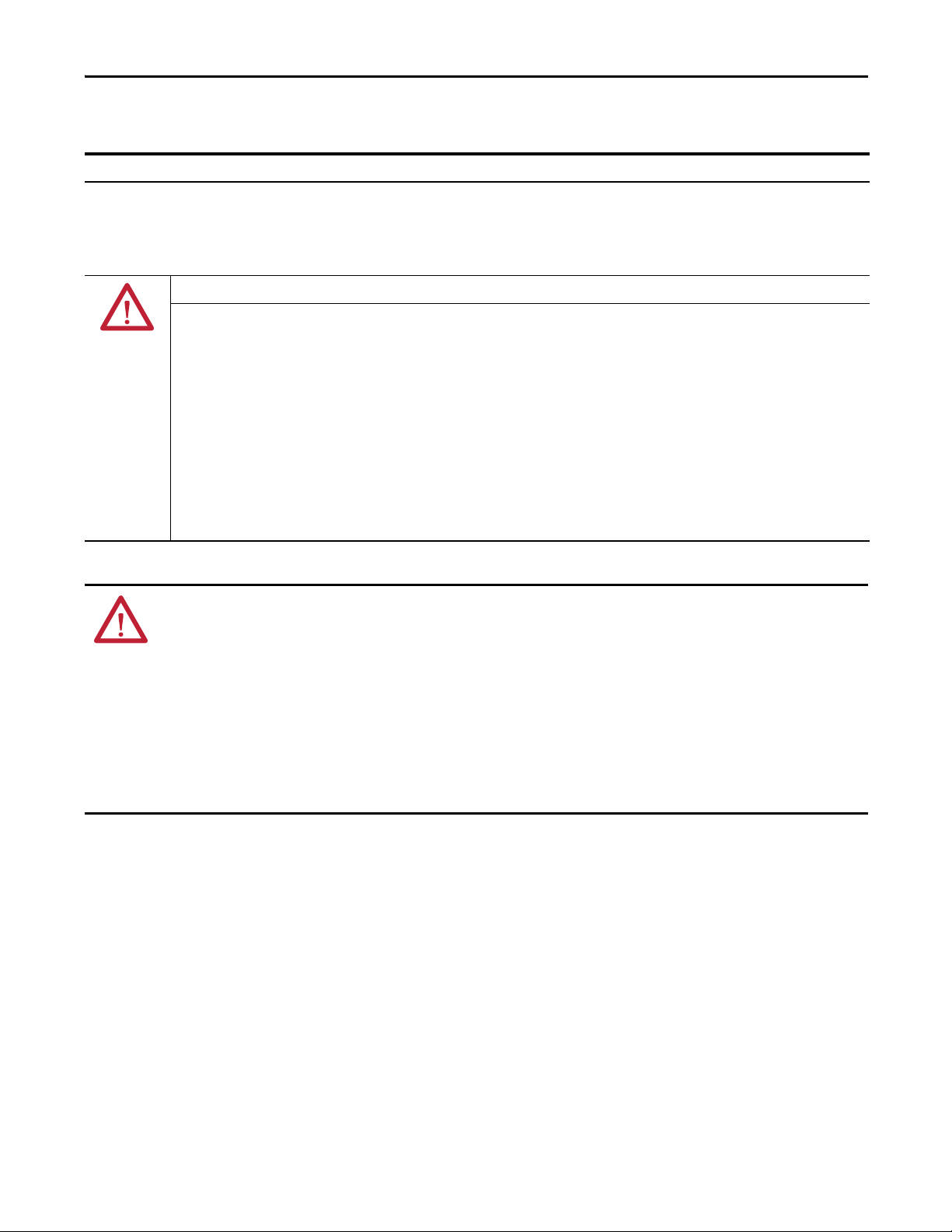

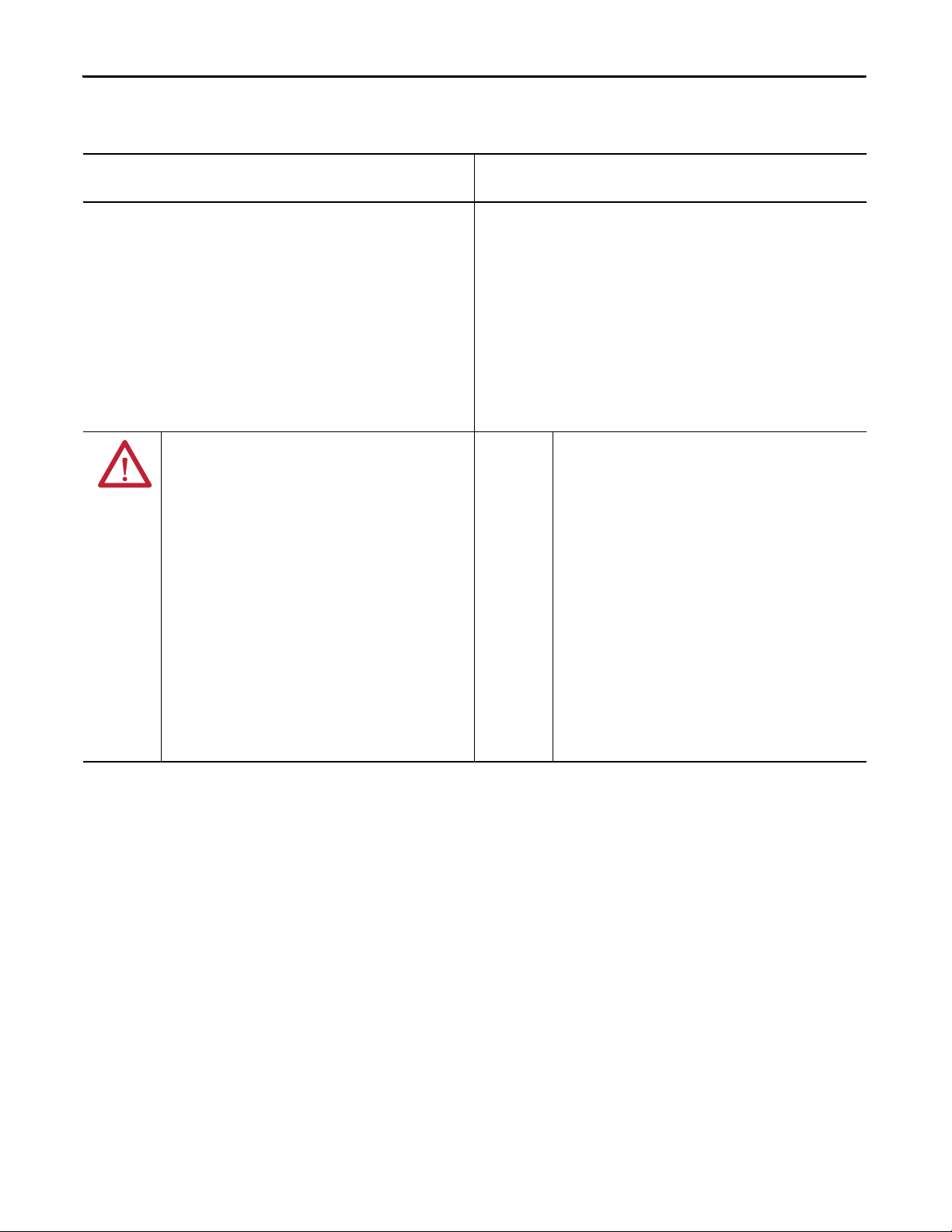

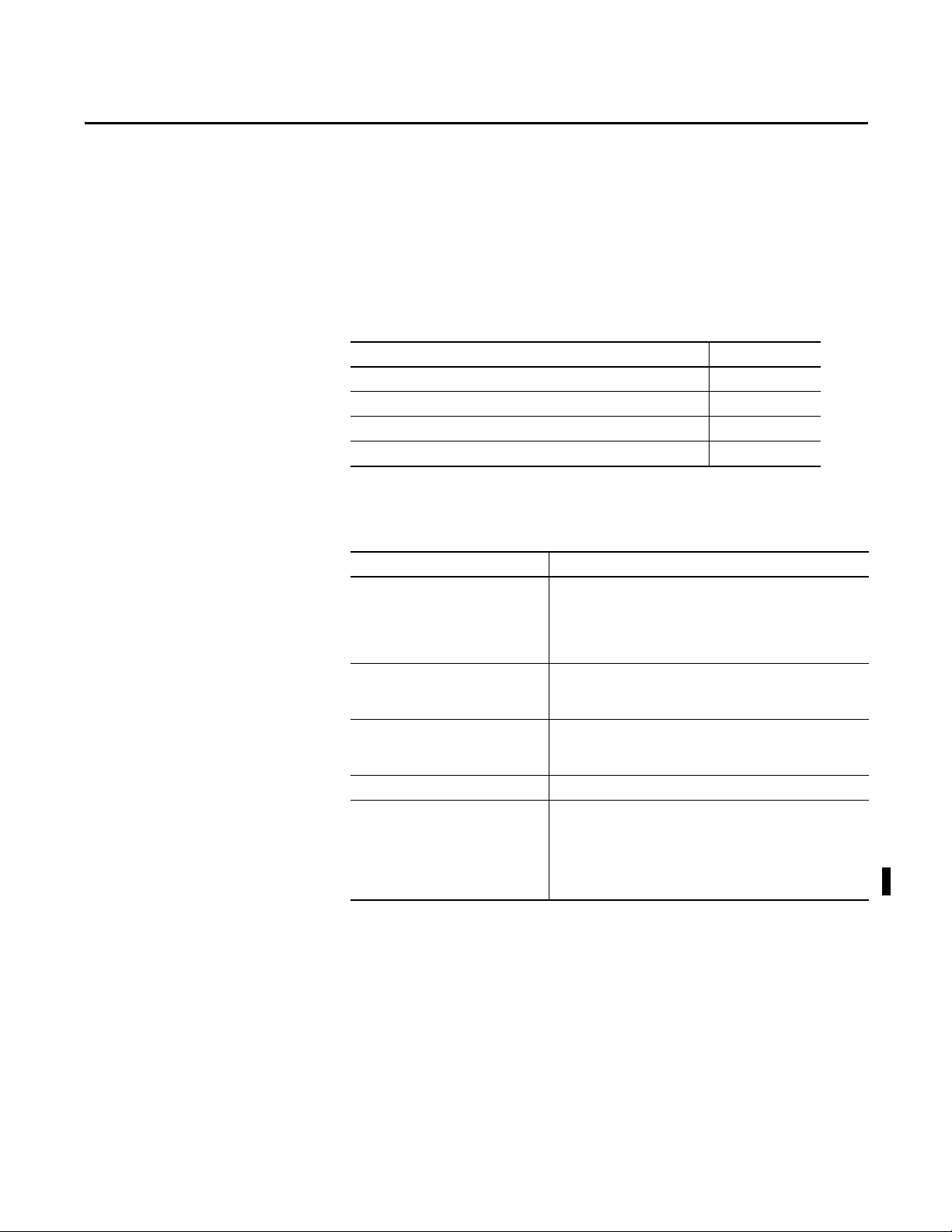

Install the Removable Terminal Block

To remove the RTB, loosen the upper and lower retaining screws. The terminal

block backs away from the module as you remove the screws. When replacing the

terminal block, torque the retaining screws to 0.46 N

Item Description

1 Wiring the finger-safe cover

2 Lower retaining screws

3 Uppe r retaining s crews

•m (4.1 lb•in).

Wire the Terminal Block

When wiring the terminal block, keep the finger-safe cover in place.

1. Loosen the retaining screws to be wired.

2. Route the wire under the terminal pressure plate.

You can use the bare wire or a spade lug. The terminals accept a 6.35 mm

(0.25 in.) spade lug.

The retaining screws are non-captive. You can use a ring lug [maximum 6.35

mm (0.25 in.) o.d. with a 3.53 mm (0.139 in.) minimum i.d. (M3.5)] with the

module.

3. Tighten the retaining screw making sure the pressure plate secures the wire.

Recommended torque when tightening retaining screws is 0.68 N•m

(6 lb•in).

If you need to remove the finger-safe cover, insert a screwdriver into one of the

square wiring holes and gently pry the cover off. If you wire the terminal block