Allen-Bradley 1756 ControlLogix, 1756 GuardLogix, 1769 Compact GuardLogix, 1789 SoftLogix, 5069 CompactLogix Programming Manual

...Page 1

Programming Manual

Logix 5000 Controllers Nonvo latil e Memory

Card

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix,

1769 Compact GuardLogix, 1789 SoftLogix, 5069 CompactLogix,

5069 CompactGuardLogix, Studio 5000 Logix Emulate

Page 2

Important user information

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of this

equipment before you install, configure, operate, or maintain this product. Users ar e required to familiarize themselves with installation and

wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be carried

out by suitably trained personnel in accordance with applicable code of practice. If this equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described

in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss. Attentions help you identify a hazard, avoid a

hazard, and recognize the consequence

Important:

Labels may also be on or inside the equipment to provide specific precautions.

Identifies information that is critical for successful application and understanding of the product.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to

alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that surfaces may reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control

center, to alert people to potential Arc Flash. Arc Flash will cause severe injury or death. Wear

proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work

practices and for Personal Protective Equipment (PPE).

Allen-Bradle y, Rockwell Software, Rockwell Automation, and TechConnect ar e t r ademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Auto mat ion are property of their respective companies.

Page 3

Summary of Changes

This manual includes new and updated information. Use these reference

tables to locate changed information.

Grammatical and editorial style changes are not included in this summary.

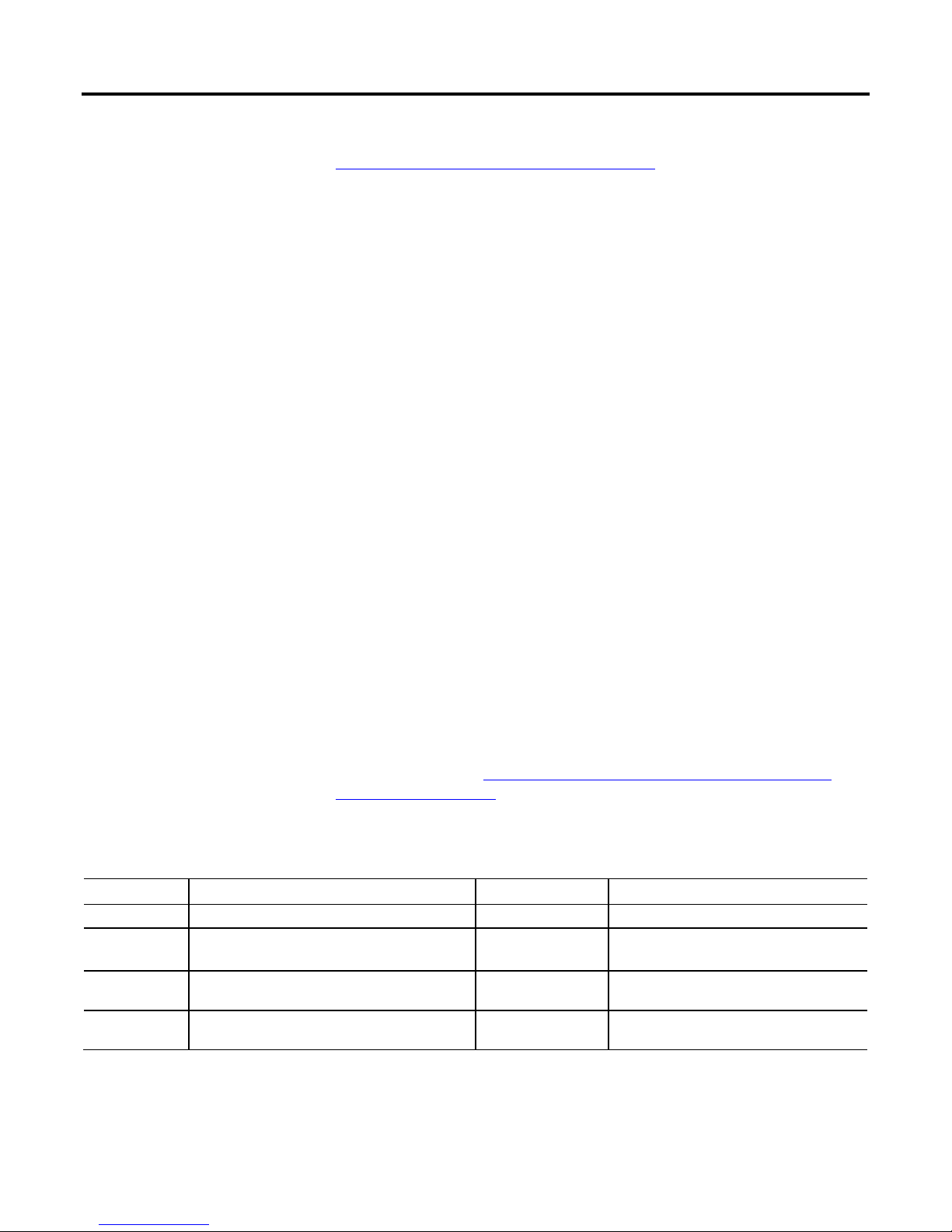

Global changes

This table identifies changes that apply to all information about a subject in

the manual and the reason for the change. For example, the addition of new

supported hardware, a software design change, or additional reference

material would result in changes to all of the topics that deal with that

subject.

Subject Reason

Updated screen shots. The Studio 5000 Logix Designer® interface has

been modified in versions 31 and later.

New or enhanced features

This table contains a list of topics changed in this version, the reason for the

change, and a link to the topic that contains the changed information.

Topic Name Reason

Cover Added 5069 Compact GuardLogix to the list of

supported controllers.

Controllers with Memory Card

Options on page 12

Updated the list of controller types.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 3

Page 4

Page 5

Preface

Store and Load a

Use a Memory Card

Index

Table of contents

Project By Using a

Memory Card

Studio 5000 environment ................................................................................ 7

Additional resources ....................................................................................... 7

Legal notices ................................................................................................... 8

Chapter 1

Introduction ................................................................................................... 11

Controllers with Memory Card Options ....................................................... 12

Prevent a Major Fault During a Load ..................................................... 13

Read/Write Card Data ............................................................................ 14

CompactFlash Card Formatting ............................................................. 14

Secure Digital Card Formatting ............................................................. 15

Perform Firmware Updates .................................................................... 15

When to Load an Image ......................................................................... 16

Store a Project ............................................................................................... 18

Load a Project ............................................................................................... 21

Check for a Load .......................................................................................... 24

Clear a Memory Card ................................................................................... 25

Change the Load Image Option ............................................................. 26

Clear the Project from the Controller ..................................................... 26

Store the Empty Image ........................................................................... 27

Reader

Chapter 2

Introduction ................................................................................................... 29

Change Which Project Loads ....................................................................... 29

Change the Load Parameters ........................................................................ 30

Other Uses for a Memory Card ..................................................................... 31

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 5

Page 6

Page 7

Studio 5000

Additional

Preface

This manual shows you how to access and use a memory card in Logix5000

controllers.This manual is one of a set of related manuals that show common

procedures for programming and operating Logix 5000™ controllers.

environment

For a complete list of common procedures manuals, refer to the

Logix 5000

Controllers Common Procedures Programming Manual, publication 1756PM001.

• The term Logix 5000 controller refers to any controller that is based on

the Logix 5000 operating system.

The Studio 5000 Automation Engineering & Design Environment®

combines engineering and design elements into a common environment. The

first element is the Studio 5000 Logix Designer® application. The Logix

Designer application is the rebranding of RSLogix 5000® software and will

continue to be the product to program Logix 5000™ controllers for discrete,

process, batch, motion, safety, and drive-based solutions.

resources

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 7

The Studio 5000® environment is the foundation for the future of

Rockwell Automation® engineering design tools and capabilities. The Studio

5000 environment is the one place for design engineers to develop all

elements of their control system.

These documents contain additional information concerning related

Rockwell Automation products.

Resource Description

Industrial Automation Wiring and

Grounding Guidelines, publication 1770-

4.1

Product Certifications webpage,

available at

http://ab.rockwellautomation.com

Provides general guidelines for

installing a Rockwell Automation

industrial system.

Provides declarations of conformity,

certificates, and other certification

details.

Page 8

Preface

Legal notices

You can view or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Rockwell Automation distributor

or sales representative.

Copyright notice

Copyright © 2018 Rockwell Automation Technologies, Inc. All Rights

Reserved. Printed in USA.

This document and any accompanying Rockwell Software products are

copyrighted by Rockwell Automation Technologies, Inc. Any reproduction

and/or distribution without prior written consent from Rockwell Automation

Technologies, Inc. is strictly prohibited. Please refer to the license agreement

for details.

End User License Agreement (EULA)

You can view the Rockwell Automation End-User License Agreement

("EULA") by opening the License.rtf file located in your product's install

folder on your hard drive.

Other Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses. Copies of those licenses are

included with the software. Corresponding Source code for open source

packages included in this product can be located at their respective web

site(s).

You may alternately obtain complete Corresponding Source code by

contacting Rockwell Automation via our Contact form on the Rockwell

Automation website:

http://www.rockwellautomation.com/global/aboutus/contact/contact.page.

Please include "Open Source" as part of the request text.

The following open source software is used in this product:

Software Copyright License Name License Text

AngularJS Copyright 2010-2017 Google, Inc. MIT License AngularJS 1.5.9 License

Bootstrap Copyright 2011-2017 Twitter, Inc.

Copyright 2011-2017 The Bootstrap Authors

jQuery Copyright 2005, 2014 JS Foundation and

other contributors

OpenSans Copyright 2017 Google, Inc. Apache License,

MIT License Bootstr ap 3.3. 7 Li cen se

MIT License jQuery 2.1.1 License

OpenSans License

Version 2.0

8 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Page 9

Preface

Trademark Notices

Allen-Bradley, ControlBus, ControlFLASH, Compact GuardLogix, Compact

I/O, ControlLogix, CompactLogix, DCM, DH+, Data Highway Plus,

DriveLogix, DPI, DriveTools, Explorer, FactoryTalk, FactoryTalk

Administration Console, FactoryTalk Alarms and Events, FactoryTalk Batch,

FactoryTalk Directory, FactoryTalk Security, FactoryTalk Services Platform,

FactoryTalk View, FactoryTalk View SE, FLEX Ex, FlexLogix, FLEX I/O,

Guard I/O, High Performance Drive, Integrated Architecture, Kinetix,

Logix5000, Logix 5000, Logix5550, MicroLogix, DeviceNet, EtherNet/IP,

PLC-2, PLC-3, PLC-5, PanelBuilder, PowerFlex, PhaseManager, POINT

I/O, PowerFlex, Rockwell Automation, RSBizWare, Rockwell Software,

RSEmulate, Historian, RSFieldbus, RSLinx, RSLogix, RSNetWorx for

DeviceNet, RSNetWorx for EtherNet/IP, RSMACC, RSView, RSView32,

Rockwell Software Studio 5000 Automation Engineering & Design

Environment, Studio 5000 View Designer, SCANport, SLC, SoftLogix,

SMC Flex, Studio 5000, Ultra 100, Ultra 200, VersaView, WINtelligent,

XM, SequenceManager are trademarks of Rockwell Automation, Inc.

Any Rockwell Automation logo, software or hardware product not

mentioned herein is also a trademark, registered or otherwise, of Rockwell

Automation, Inc.

Other Trademarks

CmFAS Assistant, CmDongle, CodeMeter, CodeMeter Control Center, and

WIBU are trademarks of WIBU-SYSTEMS AG in the United States and/or

other countries. Microsoft is a registered trademark of Microsoft Corporation

in the United States and/or other countries. ControlNet is a trademark of

ControlNet International. DeviceNet is a trademark of the Open DeviceNet

Vendors Association (ODVA). Ethernet/IP is a trademark of ControlNet

International under license by ODVA.

All other trademarks are the property of their respective holders and are

hereby acknowledged.

Warranty

This product is warranted in accordance with the product license. The

product’s performance may be affected by system configuration, the

application being performed, operator control, maintenance, and other related

factors. Rockwell Automation is not responsible for these intervening factors.

The instructions in this document do not cover all the details or variations in

the equipment, procedure, or process described, nor do they provide

directions for meeting every possible contingency during installation,

operation, or maintenance. This product’s implementation may vary among

users.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 9

This document is current as of the time of release of the product; however,

the accompanying software may have changed since the release. Rockwell

Automation, Inc. reserves the right to change any information contained in

Page 10

Preface

this document or the software at any time without prior notice. It is your

responsibility to obtain the most current information available from Rockwell

when installing or using this product.

Environmental compliance

Rockwell Automation maintains current product environmental information

on its website at

http://www.rockwellautomation.com/rockwellautomation/aboutus/sustainability-ethics/product-environmental-compliance.page

Contact Rockwell Automation

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support/

10 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Page 11

Introduction

Chapter 1

Store and Load a Project Using a

Memory Card

The memory card allows you to keep a copy of your project on the controller

without the need to maintain power to the controller. You can use a memory

card to store the contents of the user memory when you store the project.

Important:

Remember these guidelines with a memory card.

• Changes that you make after you store the project are not

reflected in the contents of the memory card.

• If you make changes to the project but do not store those

changes, you overwrite them when you load the project from a

memory card. If this occurs, you have to upload or download the

project to go online.

• If you want to store changes, such as online edits, tag values, or

a ControlNet network schedule, store the project after you make

the changes.

If a computer loses power and does not have enough energy capacity, it loses

the project in user memory. When this occurs, y ou can load the copy from

the memory card to the user memory of the controller:

• Whenever it powers up.

• Whenever there is no project in the controller and it powers up.

• Anytime through the Logix Designer application.

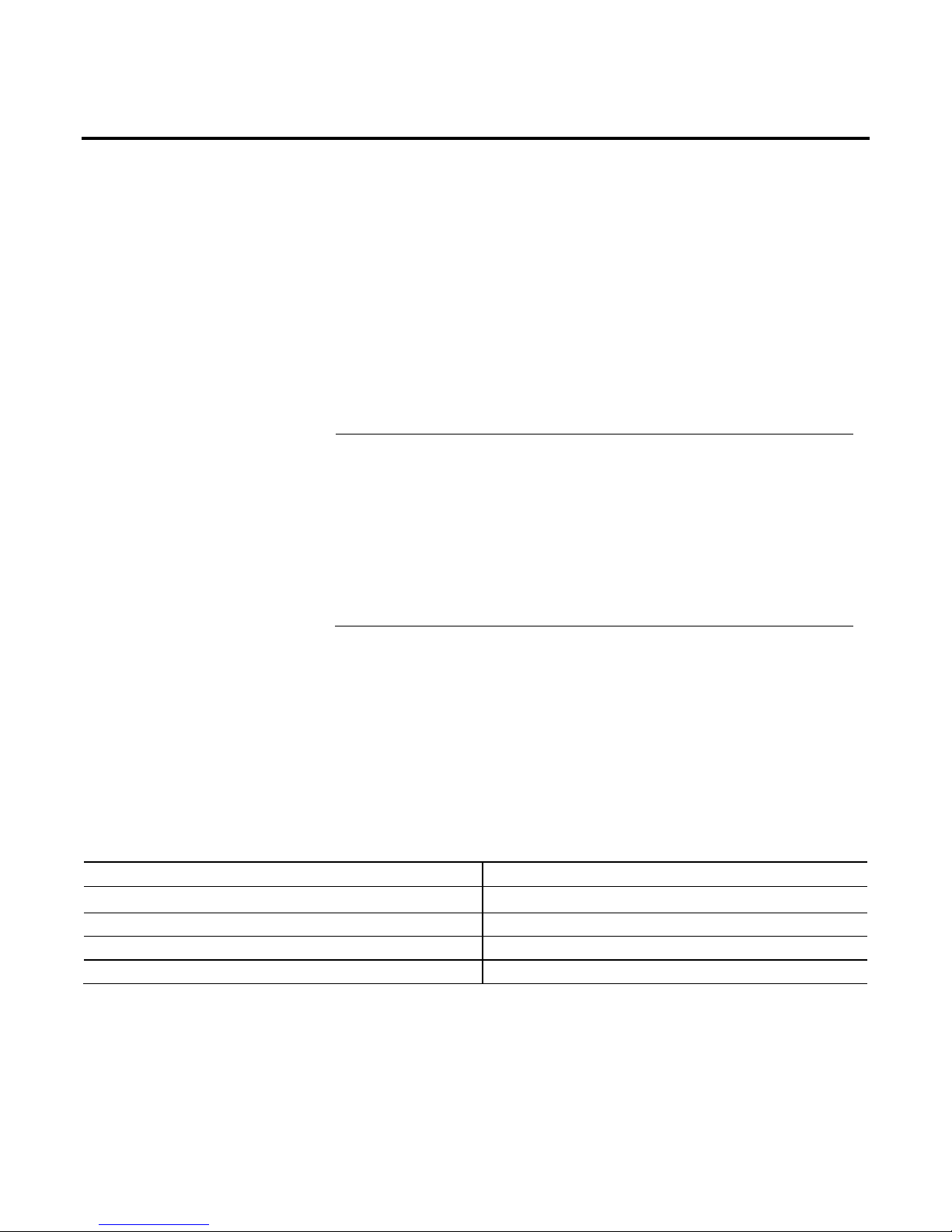

A store or load operation from a memory card has these parameters.

Parameter Store and Load

How much time does a store or load operation take? Less than three minutes

What controller mode do I use to store or load a project? Program mode

Can I go online with the controller during a store or load? No

What is the state of the I/O during a store or load? I/O remains in its configured state for Program mode

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 11

Page 12

Chapter 1

Store and Load a Project Using a Memory Card

Controllers with

Memory Card

Options

These Logix 5000 controllers support a memory card for project storage.

Controller

Type

CompactLogix

5370

Compact

GuardLogix

5370

CompactLogix

5380

Catalog Number Firmware

Revision

1769-L16ER-BB1B 20.x or later Yes

1769-L18ER-BB1B

1769-L18ERM-BB1B

1769-L24ER-QB1B 21.x or later

1769-L24ER-QBFC1B

1769-L26ER-BB1B

1769-L27ERM-QBFC1B

1769-L30ER 20.x or later

1769-L30ER-NSE

1769-L30ERM

1769-L33ER

1769-L36ERM

1769-L30ERMS

1769-L33ERMS

1769-L36ERMS

1769-L37ERMOS 30.x or later

5069-L306ER

5069-L306ERM

5069-L3100ERM

5069-L310ER

5069-L310ERM

5069-L310ER-NSE

5069-L320ER

5069-L320ERM

5069-L330ER

5069-L330ERM

5069-L340ER

5069-L340ERM

5069-L350ERM

5069-L380ERM

28.x or later Yes

29.x or later Yes

Supports a 1784-SD1 or 1784SD2 Secure Digital (SD) Card

12 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Page 13

Store and Load a Project Using a Memory Card

Chapter 1

Prevent a Major Fault

Controller

Type

Compact

GuardLogix

5380

CompactLogix

5480

ControlLogix

5570

Catalog Number Firmware

Revision

5069-L306ERMS2

5069-L306ERS2

5069-L3100ERMS2

5069-L3100ERS2

5069-L310ERMS2

5069-L310ERS2

5069-L320ERMS2

5069-L320ERS2

5069-L330ERMS2

5069-L330ERS2

5069-L340ERMS2

5069-L340ERS2

5069-L350ERMS2

5069-L350ERS2

5069-L380ERMS2

5069-L380ERS2

5069-L45ERMW 31.x or later Yes

1756-L72

1756-L73

1756-L74

1756-L75

1756-L71 20.x or later

31.x or later Yes

19.x or later Yes

Supports a 1784-SD1 or 1784SD2 Secure Digital (SD) Card

During a Load

GuardLogix

5570

ControlLogix

5580

GuardLogix

5580

If the major and minor revisions of the project on the memory card do not

match the major and minor revision of the controller, a major fault may

occur during a load.

The memory card stores the firmware for projects for revision 12.0 or later.

Depending on the current revision of the controller, you may be able to use

the memory card to update the firmware of the controller and load the

project.

1756-L71S

1756-L72S

1756-L73S

1756-L81E

1756-L82E

1756-L83E

1756-L84E

1756-L85E

1756-L81ES

1756-L82ES

1756-L83ES

1756-L84ES

31.x or later Yes

29.x or later Yes

31.x or later Yes

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 13

Page 14

Chapter 1

Store and Load a Project Using a Memory Card

• Leaves existing data.

Read/Write Card Data

CompactFlash Card

Formatting

Sample ladder logic code for the Logix Designer applications are available

for using your file system on a Logix5000 controller to read and write data

on a memory card. These are the files you need:

• CF_Read_Write.ACD

• CF_Read_Write_Example.ACD

• Logix-AP007B-EN-P.pdf

To access these files, see

http://samplecode.rockwellautomation.com/idc/groups/public/documents/we

bassets/sc_home_page.hcst.

The Logix Designer 1784-CF128 CompactFlash card does not have to be

formatted to store controller information.

If the revision of

your project is

11.x

≥ 12.0

Then

The CompactFlash card uses a special format.

• Use only a Logix5000 controller to store a project on a CompactFlash card.

• Store only a single project and no other data on a CompactFlash card.

• When you store a project on a C ompa ctFl ash card, you overwrite the entire contents of the card. In

other words, you lose everything that is currently on the card.

The CompactFlash card uses the FAT16 file system.

If the card Then the controller

Is already formatted for the

FAT16 file system.

The CompactFlash card using the FAT16 file system:

• Stores multiple projects and associated firmware.

• If a card already contains a project with same name, a store overwrites the project on the

CompactFlash card.

• Loads the most recently stored project.

With a revision ≥ 12.0, you can also use a card reader to read and manipulate the files on a memory

card.

See "Use a Memory Card Reader on page 29

• Creates folders and files for the project and firmware.

."

14 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Page 15

Store and Load a Project Using a Memory Card

Chapter 1

• Leaves existing data.

• Does not allow writing to the card.

Remove the card from the controller. This prevents the controller from setting the

Secure Digital Card

Perform Firmware

Formatting

A Secure Digital (SD) memory card (catalog numbers 1784-SD1 (1 GB),

1784-SD2 (2 GB) that uses the FAT 16 file system does not have to be

formatted when storing a project to a controller.

If the revision of your

project is

≥ 18.0

Then

The SD card uses the FAT16 file system.

If the card: Then the controller:

Is unlocked.

Is locked.

The SD card using the FAT16 file system:

• Stores multiple projects and associated firmware.

• Overwrites the project on the card if it contains a project with the same name

• Loads the most recently stored project.

You also can use a card reader to read and manipulate the files on a memory card.

See "Use a Memory Card Reader on page 29."

See "Store a Project on page 18" for loading an SD card in the controller.

This table outlines the options and precautions for updating the firmware of a

Updates

If Then

controller that has a memory card.

• Creates folders and files for the project and firmware.

You meet all of these conditions.

• The controller has a memory card.

• The project on the memory card has

a revision ≥ 12.0.

• The project on the memory card has

a Load Image option = On Power

Up or On Corrupt Memory.

• A controller in service has a

revision ≥ 12.0.

Update the firmware by using one of these options.

• Memory card

• Logix Designer application

• ControlFLASH™ software (See the Important: note on the next page)

Follow this procedure to update the firmware and load the project by using the

memory card.

1. Install the card in the controller.

2. If the Load Image option = On Corrupt Memory and the controller contains a

project, before powering down, disconnect the battery or disengage the Energy

Storage Module (ESM) from the controller.

3. Turn on or cycle power to the controller.

Follow this procedure if you use the Logix Designer application or ControlFLASH

software to update the firmware.

1.

Load Image option of the memory card to User Initiated during the update.

2. After the firmware update is completed, store the project to the memory card.

This ensures that the revision of the project on the memory card matches the

revision of the controller.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 15

Page 16

Chapter 1

Store and Load a Project Using a Memory Card

to ensure the

If you want to load an image

Then choose

Notes

• During a power cycle, online changes, tag values,

When to Load an

If Then

You do not meet all of the preceding

conditions.

Update the firmware by using either:

• Logix Designer application.

• ControlFLASH software. See the Important: note on the next page.

Take these precautions.

• Before you update the firmware either:

• After you update the firmware, store the project to the memory card

revision of the project on the memory card matches the revision of the controller.

Important: Make sure the SD card is unlocked if set to load On Power Up

• Remove the memory card from the controller.

• Check the Load Image option of the memory card. I f it is set to On

Power Up or On Corrupt Memory, store the project with the Load

Image option set to User Initiated.

Otherwise, a major fault may occur when you update the controller firmware.

This occurs because the On Power Up or On Corrupt Memory options cause

the controller to load the project from the memory card. The firmware

mismatch after the load causes a major fault.

before using the ControlFLASH software. Otherwise, the updated

data may be overwritten by firmware on the SD card. An error

message appears. Refer to the ControlLogix System User Manual,

publication 1756-UM 001 avail able at

http://literature.rockwellautomation.com/idc/groups/literature/docum

ents/um/1756-um001_-en-p.pdf, before updating.

Also, while it’s not required for operation, leave the SD card

installed in the controller. The SD card saves extended diagnostic

information that you can send to Rockwell Automation that

provides enhanced diagnostics of your controller application and

firmware should circumstances require this data.

Image

Whenever you turn on or cycle the chassis

power

16 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

You have several options for when (under what conditions) to load the

project into the user memory (RAM) of the controller.

On Power Up

and network schedules that you have not stored

on the memory card are lost.

• Loading from a memory card may also change

the firmware of the controller. For more

information, see "Perform Firmware Updates

page 15."

• You can use the Logix Designer application to

load the project.

on

Page 17

Store and Load a Project Using a Memory Card

Chapter 1

• For example, if the battery becomes discharged

or the ESM is disengaged and the controller loses

If you want to load an image Then choose Notes

Whenever there is no project in the

controller and you turn on or cycle the

chassis power

Only through the Logix Designer

application

On Corrupt Memory

power, the project is cleared from memory. When

power is restored, this load option loads the

project back into the controller.

• Loading from a memory card may also change

the firmware of the controller. For more

information, see "Perform Firmware Updates

page 15."

• You can use the Logix Designer application to

load the project.

User Initiated

The following table provides load option examples.

Table 2 - Load Option Examples

Example Description

Load Image = On Power Up

Load Mode = Program

Load Image = On Corrupt Memory

Load = Run

Load Image = On Power Up

Load Mode = Program

Revision ≥ 12.0

1. You update the firmware of the controller to the desired revision.

2. You store the project for the controller on the memory card.

3. When you turn on power to the controller after installation, the project

loads into the controller.

4. The controller remains in Program mode.

1. You store the project for the controller on the memory card (the major

and minor revisions of the firmware in the controller match the major

and minor revisions of the project on the memory card.)

2. If the battery discharges or the ESM is disengaged and power to the

controller is interrupted, the project is cleared from the controller

memory.

3. When power is restored, the project automatically loads into the

controller and the controller returns to Run mode.

1. The controller fails.

2. You remove the memory card.

3. You replace the failed controller with a new controller.

4. You replace the memory card.

5. When you turn on the power, the firmware and project load into the

controller. The controller remains in Program mode.

on

Load Image = On Power Up

Load Image = Not applicable

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 17

1. You want to load a different project into your controller.

2. A memory card contains the desired project.

3. With the memory card installed in the controller, you use the Logix

Designer application to load the project into the controller.

Page 18

Chapter 1

Store and Load a Project Using a Memory Card

ATTENTION:

Store a Project

This section explains how to store a project on the memory card of the

controller.

During a store operation, all active servo axes are turned

off. Before you store a project, make sure that this does not cause any

unexpected movement of an axis.

Before you store the project:

• Make all the required edits to the logic.

• Download the project to the controller.

• Schedule your ControlNet networks.

Follow these steps to store a project.

1. Go online with the controller.

2. Put the controller in Program Mode (Rem Program or Program).

3. On the Online toolbar, click the Contro ller Pro per tie s icon.

Tip:

For 1756-L7x controllers only , Energy Storage instead of Battery

OK appears beside the Controller Properties icon. Refer to the

ControlLogix System User Manual, publication 1756-UM001

available at

http://literature.rockwellautomation.com/idc/groups/literature/docu

ments/um/1756-um001_-en-p.pdf, for information on the Energy

Storage Module.

4. On the Controller Properties dialog box, click the Nonvolatile

Memory tab and then click Load/Store.

18 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Page 19

Store and Load a Project Using a Memory Card

Chapter 1

Important: At the bottom of the Nonvolatile Memory tab, a message

appears if the CompactFlash card or SD card is empty.

A message also appears if the SD card is locked.

5. At the bottom of the Nonvolatile Memory tab, select Inhibit

Automatic Firm war e Up d a te checkbox if you do not want to

automatically store an image during a Save or Load operation.

6. Choose when (under what conditions) to load the project back into the

user memory (RAM) of the controller.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 19

Description

The project that is currently on the memory card of the controller (if

any project is there).

The project that is currently in the user memory (RAM) of the

controller.

Store operation.

In the Load Image field, if you choose On Power Up or On Corrupt

Memory, you must also choose the Load Mode you want to controller

to go to after the load.

Page 20

Chapter 1

Store and Load a Project Using a Memory Card

• On the front of the controller, the OK status

• On the front of the controller, the SD and OK

• Remote Program

• Remote Run

7. In the Automatic Firmware Update list, use the default (disable) or

choose the appropriate firmware supervisor.

For details on the firmware supervisor options, see the ControlLogix

System User Manual, publication 1756-UM001 available at

http://literature.rockwellautomation.com/idc/groups/literature/documen

ts/um/1756-um001_-en-p.pdf .

8. Click <-- Store.

Important:

Store is not active i f the SD card i s locked.

A dialog box asks you to confirm the store operation.

9. To store the project, click Yes.

The table describes the events that occur for the memory card being

used.

If using This happens during the store

CompactFlash Card

SD Card

indicator shows the following sequence: flashing

green > solid red > solid green.

• Logix Designer application goes offline.

• A dialog box indicates the store operation is in

progress.

status indicators flash green.

• The Status Display shows SAVE. See the

illustration.

• A dialog box tells you that the store is in

progress.

20 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

10. Click OK.

Page 21

Store and Load a Project Using a Memory Card

Chapter 1

Load a Project

When the store operation is finished, you remain offline.

For procedures on loading and removing the SD card in the card slot,

refer to the ControlLogix System User Manual, publication 1756-

UM001 available at

http://literature.rockwellautomation.com/idc/groups/literature/documen

ts/um/1756-um001_-en-p.pdf.

Follow these steps to use the Logix Designer application to load the project

from a memory card.

ATTENTION: During a load operation, all active servo axes are turned

off. Before you load a project, make sure that this does not cause any

unexpected movement of an axis.

Important: Make sure the SD card is unlocked if set to load On Power Up

before using the ControlFLASH software. Otherwise, the updated

data may be overwritten by firmware on the SD card. An error

message appears. Refer to the ControlLogix System User Manual,

publication 1756-UM 001 avail able at

http://literature.rockwellautomation.com/idc/groups/literature/docum

ents/um/1756-um001_-en-p.pdf, before updating.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 21

1. Go online with the controller.

Page 22

Chapter 1

Store and Load a Project Using a Memory Card

2. Did the Connected To Go Online dialog box open?

If Then

No

Yes

a. Put the controller in Program mode (Rem Program or Program).

b. On the Online toolbar, clic k the Controller Properties icon.

Put the controller in Program mode (Rem Program or Program).

You can either:

• Click the General tab on the Connected To Go Online dialog

box.

• Use the keyswitch on the front of the controller.

3. On the Controller Properties dialog box, click the Nonvolatile

Memory tab.

4. Click Load/Store.

22 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Page 23

Store and Load a Project Using a Memory Card

Chapter 1

OK status indicator is solid green; SD

5. At the bottom of the Image in Nonvolatile Memory area, click Load -

->.

A dialog box asks you to confirm the load.

6. To load the project from the memory card, click Yes.

The table describes the events that occur for these m emory cards.

Logix Designer application goes offline.

When the load is finished, you remain offline.

If using And the load Then the OK status indicators

display

CompactFlash

Card

SD Card Does not

Does not

include

firmware

Includ

es

firmw

are

include

firmware

Includ

es

firmw

are

Solid red> solid green

Flashing red> solid red> solid green

status indicator flashes green.

Status Display shows LOAD. See the

illustration.

OK status indicator flashes red; SD

status indicator flashes green.

Status Display shows UPDT. See the

illustration.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 23

Page 24

Chapter 1

Store and Load a Project Using a Memory Card

Check for a Load

Figure 1: Load and Update Examples on the Status Display

When the controller loads a project from a memory card, it:

• Logs a minor fault (type 7, code 49).

• Sets the FaultLog object, MinorFaultBits attribute, bit 7.

If you want your project to flag that it loaded from a memory card, use this

logic.

On the first scan of the project (S:FS is on), the GSV instruction gets the

FaultLog object, MinorFaultBits attribute, and stores the value in

minor_fault_bits. If bit 7 is on, the controller loaded the project from its

memory card.

24 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Page 25

Store and Load a Project Using a Memory Card

Chapter 1

Clear a Memory

Where Is

Minor_fault_bits Tag that stores the FaultLog object, MinorFaultBits

attribute. Data type is DINT.

NVM_load Tag that indicates that the controller loaded the

project from its memory card.

Follow these steps to remove a project from a memory card.

Card

1. Go online with the controller.

2. On the Online toolbar, click the Contro ller Pro per tie s icon.

Tip:

For 1756-L7x controllers only, Energy Storage instead of Battery OK

appears adjacent to the controller properties icon. Refer to the

ControlLogix System User Manual, publication 1756-UM001 available at

http://literature.rockwellautomation.com/idc/groups/literature/documents/u

m/1756-um001_-en-p.pdf, for information on the Energy Storage Module.

3. On the Control Properties dialog box, click the Nonvolatile Memory

tab.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 25

4. Is Load Image set to User Initiated?

If Then

No Go to "Change the Load Image Option on page 26."

Yes Go to "Clear the Project from the Controller on page 26."

Page 26

Chapter 1

Store and Load a Project Using a Memory Card

Change the Load

Clear the Project from

1. On the Nonvolatile Memo ry tab, click Load/Store.

Image Option

2. From the Load Image list, choose User Initiated.

3. Click <- Store.

Important: Store is not active if a card is locked.

A dialog box asks you to confirm the store operation.

4. To store the project, click Yes.

A dialog box indicates the store operation is in progress.

5. Click OK.

Wait until the OK status indicator on the front of the controller is

steady green.

This indicates the store operation is finish ed.

If your application allows you to clear a project, follow these steps.

the Controller

1. With power still applied to the controller, disconnect the battery or

other energy storage module from the controller.

2. Cycle the power to the chassis.

3. Reconnect the battery or other energy storage module to the controller.

For more information, see these publications.

• ControlLogix Energy Storage Modules Installation Instructions,

publication 1756-IN616 available at

http://literature.rockwellautomation.com/idc/groups/literature/docu

ments/um/1756-in616_-en-p.pdf.

• ControlLogix System User Manual, publication 1756-UM001

available at

http://literature.rockwellautomation.com/idc/groups/literature/docu

ments/um/1756-um001_-en-p.pdf.

26 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Page 27

Store and Load a Project Using a Memory Card

Chapter 1

Important:

Store the Empty Image

1. Go online with the controller.

The Connected To Go Online dialog box opens.

2. On the Controller Properties dialog box, click the Nonvolatile

Memory tab.

3. Click Load/Store.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 27

4. At the bottom of the Controller area, click <--Store.

Store is not active if a SD card is locked.

A dialog box asks you to confirm the store operation.

5. Click Yes to store the project.

The table describes the events that occur for the memory card being

used.

Page 28

Chapter 1

Store and Load a Project Using a Memory Card

• On the front of the controller, the OK status indicator

• On the front of the controller, the SD and OK status

If using This happens during the store operation

CompactFlashCard

displays the following sequence: flashing green> solid

red> solid green.

• Logix Designer application goes offline.

• A dialog box indicates the stor e is in progre ss.

SD Card

indicators flash green.

• The Status Display shows SAVE. See "Store a Project

on page 18."

• Logix Designer application goes offline.

• A dialog box tells you that the store operation is in

progress.

6. Click OK.

When the store operation is finished, you remain offline.

28 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Page 29

Description

Introduction

Change Which

Project Loads

Chapter 2

Use a Memory Card Reader

A sample controller project that reads and writes a memory card is available

with the Logix Designer application. In the application, from the Help menu,

choose Vendor Sample Projects to display a list of available sample

projects.

A memory card can store multiple projects. By default, the controller loads

the project that you most recently stored, according to the load options of

that project.

To assign a project to load from the memory card, edit the Load.xml file on

the card by following the steps that match the numbers in the illustration.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 29

To change the project that loads from the card, use a text editor to open

the Load.xml file.

Edit the name of the project that you want to load.

• Use the name of an XML file that is in the CurrentApp folder.

• In the CurrentApp folder, a project is comprised of an XML file and a

P5K file.

Page 30

Chapter 2

Use a Memory Card Reader

Change the Load

When you store a project to a memory card, you define:

Parameters

• When to load the project (On Power Up, On Corrupt Memory, User

Initiated).

• What mode to set the controller (if the keyswitch is in REM and the

Load mode is not User Initiated).

To assign a project to load from the memory card, edit the Load.xml file on

the card by following the steps that match the numbers in the illustration.

30 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Description

To change the load parameters for a project, use a text editor to open the

XML file with the same name as the project.

Edit the Load Image option of the project.

To set the Load Image option to: Then enter:

On Power Up ALWAYS

On Corrupt Memory CORRUPT_RAM

User Initiated USER_INITIATED

Edit the Load Mode option of the project (does not apply if the Load Image

option is User Initiated).

To set the Load Mode option to: Then enter:

Program (Remote Only) PROGRAM

Run (Remote Only) RUN

Page 31

Use a Memory Card Reader

Chapter 2

Other Uses for a

Memory Card

For these controllers, you can use the memory card to store data and

controller projects.

• 1756 ControlLogix controllers, revision 13 and later

• 1756-L7x ControlLogix controllers, firmware revision 18 and later

• 1756 GuardLogix controllers, revision 18 and later

• 1769-L32E CompactLogix controllers, serial number SS0QZ000 and

later

• 1769-L35E CompactLogix controllers, serial number SS0OR9GE

and later

• CompactLogix 5370 controllers, revision 20 and later

Observe these examples:

• A PanelView terminal changes tag values in a controller project. If a

controller loses power, and is not battery backed up, it loses the

program running in the controller and the values changed by the

PanelView terminal. Use the memory card and logic in the project to

store tag values as they change. When the project reloads from the

memory card, it can check the memory card for any saved tag values

and reload those into the project.

• Store a collection of recipes on the memory card. To change a recipe,

program the controller to read data for the new recipe from a memory

card.

• Program the controller to write data logs at specific time intervals.

You can also use a memory card reader to read and write memory cards. This

method writes tag values in binary. You can read the data with any text

editor, but the data displays as the ASCII equivalent of the binary data.

For more information, see the sample projects available with the Logix

Designer application. In the application, from the Help menu, choose

Vendor Sample Projects to display a list of sample projects.

You can also see the 28539 Technical Note "W orking w ith the CompactFlash

File System on Logix5000 Controllers" from the MySupport Knowledgebase.

Access this database by clicking the Knowledgebase link from

http://www.rockwellautomation.com

.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 31

Page 32

Page 33

1

Index

1756-L7x controller

SD card 17

1784-CF64 Industrial CompactFlash card

format 14

storage of firmware 15

1784-SD1 Secure Digital card

format 14

storage of firmware 15

A

automatic firmware update

inhibit 17

options 17

C

clear

nonvolatile memory 25

project 25

configure

load from nonvolatile memory 16, 21

ControlFlash

Secure Digital unlock precaution 15

controller

nonvolatile memory 11, 29

update firmware

during load from nonvolatile memory 15

L

L7x controller

status display 21

load

change image 26

change projects 29

controller check 24

controller mode 17

example options 16

image 16

prevent major fault 13

project 21

SD card 17

set parameters 30

status display 21

M

memory cards

additional uses 31

firmware update 15

guidelines 11

load status indicators 21

Logix5000 controllers 11

parameters 11

sample code 14

save status indicators 17

use of reader 29

F

fault

during load from nonvolatile memory 13

GSV instruction 24

firmware

update load from nonvolatile memory 15

format

CompactFlash card 14

Secure Digital card 14

I

inhibit

automatic firmware update 17

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018 33

N

nonvolatile memory

check for a load 24

clear 25

fault during load 13

load a project 21

load image options 16

overview 11, 29

supported controllers 29

P

parameters

memory card 11

project

load 21

Page 34

Index

load from nonvolatile memory 16, 21

nonvolatile memory 11, 29

store 17

R

remove

SD card 17

S

SD card

load 17

slot 17

Secure Digital card

format 14

status display

ControlLogix 1756-L7x controller 21

Secure Digital 17

status indicators

load project 21

save project 17

store

project 17

U

update

firmware with memory card 15

status display 21

34 Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Page 35

Rockwell Automation support

Rockwell Automation provides technical information on the web to assist you in using its products. At

http://www.rockwellautomation.com/support you can find technical and application notes, sample code, and links to software servi ce

packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com for software updates, support chats and forums,

technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more information, contact your

local distributor or Rockwell Automation representative, or visit http://www.rockwellautomation.com/services/online-phone.

Installation assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual. You can

contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Worldwide Locator available at http://www.rockwellautomation.com/locations,

or contact your local Rockwell Automation representative.

New product satisfaction return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the

phone number above to obtain one) to your distributor to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Documentation feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete the feedback form, publication RA-DU002

.

Rockwell Automation Publication 1756-PM017H-EN-P - February 2018

Supersedes Publication 1756-PM017G-EN-P - June 2016 Copyright © 2018 Rockwell Automation Technologies, Inc. All Rights Reserved. Printed in the U.S.A.

Loading...

Loading...