Allen-Bradley 1756 GuardLogix, 5069 CompactLogix, 1769 CompactLogix, 1769 Compact GuardLogix, 1789 SoftLogix Instruction Manual

...Page 1

Reference Manual

LOGIX 5000 Controllers Motion Instructions

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix, 1769 Compact GuardLogix, 1789

SoftLogix, 5069 CompactLogix, 5069 Compact GuardLogix, Studio 5000 Logix Emulate

Page 2

Important user information

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of this equipment

before you install, configure, operate, or maintain this product. Users are required to familiarize themselves with installation and wiring instructions

in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be carried out by

suitably trained personnel in accordance with applicable code of practice. If this equipment is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated

with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic

loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

Important:

Labels may also be on or inside the equipment to provide specific precautions.

Identifies information that is critical for successful application and understanding of the product.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be

present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc

Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work

practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their resp ective companies.

Page 3

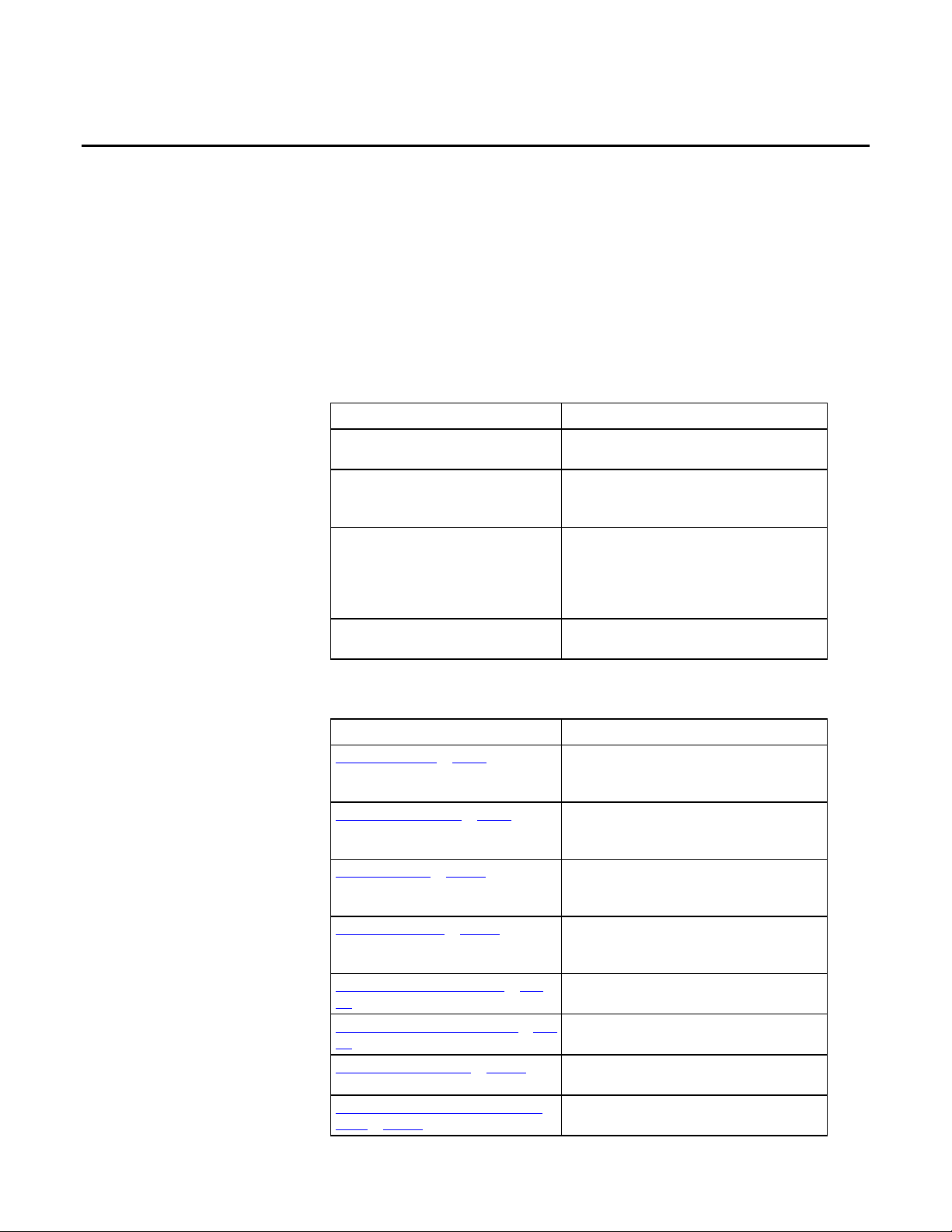

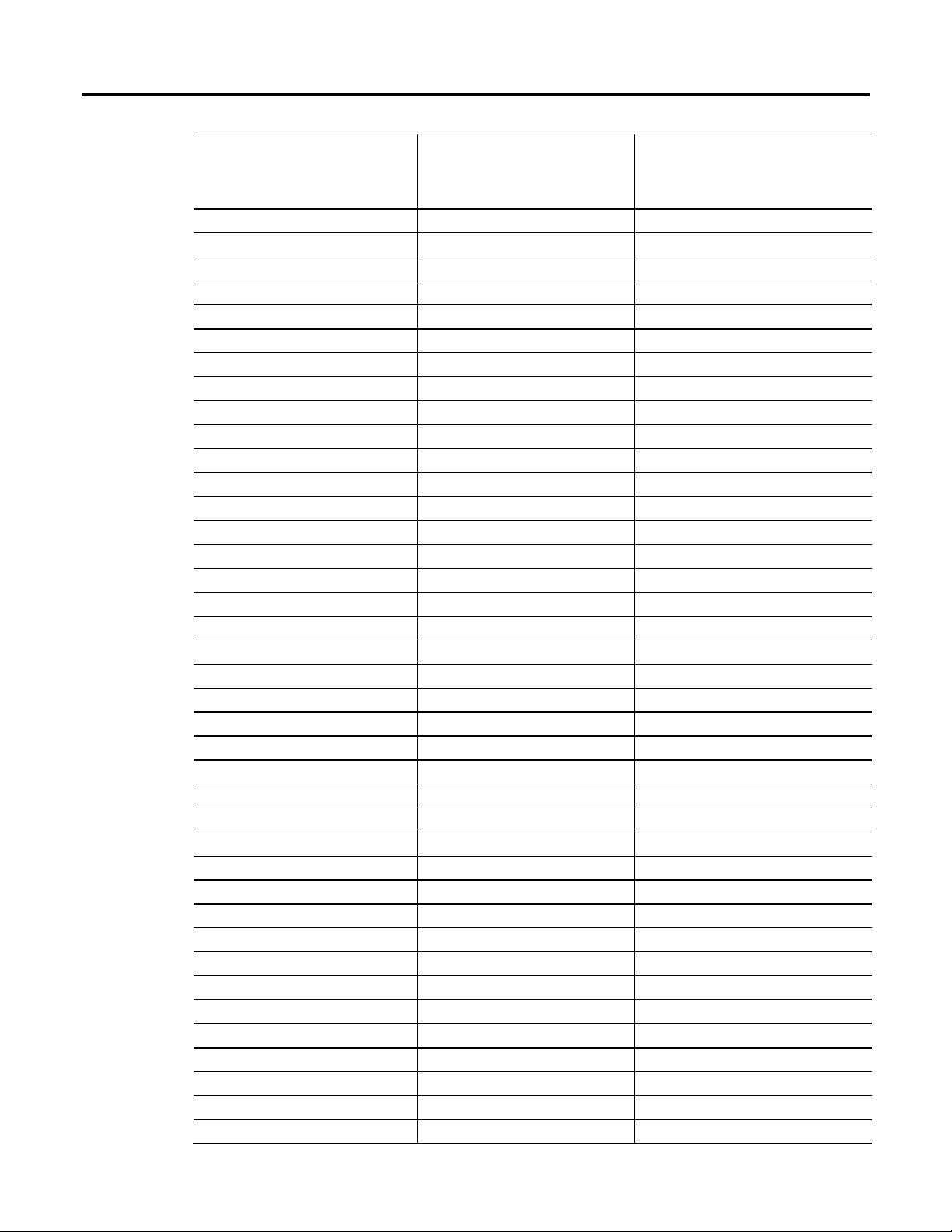

Summary of changes

This manual includes new and updated information. Use these reference tables to

locate changed information.

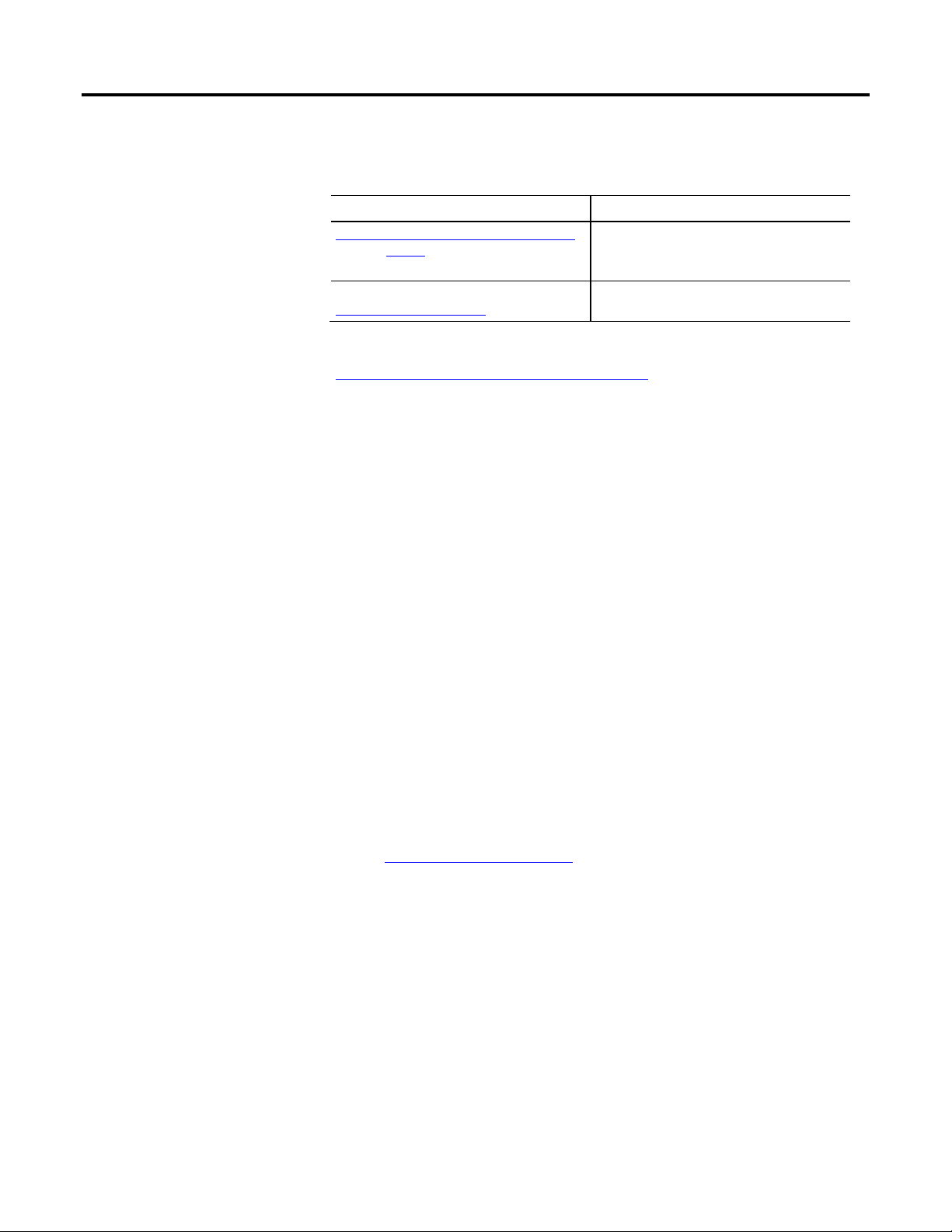

Global changes

This table identifies changes that apply to all information about a subject in the

manual and the reason for the change. For example, the addition of new supported

hardware, a software design change, or additional reference material would result

in changes to all of the topics that deal with that subject.

Subject Reason

All instruction topics. Added new safety controllers 5580 and 5380 to the list of

applicable controllers.

All instruction topics Updated the Ladder Diagram, Reset Signal, and Example

images to reflect the updated user interface.

All instruction topics In the Major/Minor Faults and See also section, replaced the

Common Attributes cross reference with a new cross

reference to the Index Through Arrays topic.

All instruction chapter title topics Added new link table with links to each instruction in the

chapter.

Topic Name Reason

Motion Axis Stop (MAS) on page 84 Updated the programming guidelines section with new

paragraph explaining using MAS on any axis associated

with a coordinate system.

Motion Direct Drive Off (MDF) on page 51 Updated the programming guidelines section with new

paragraph explaining using MAS on any axis associated

with a coordinate system.

Motion Axis Jog (MAJ) on page 101 Updated the programming guidelines section with new

paragraph explaining using MAS on any axis associated

with a coordinate system.

Motion Axis Move (MAM) on page 112 Updated the programming guidelines section with new

paragraph explaining using MAS on any axis associated

with a coordinate system.

Motion Run Hookup Diagnostic (MRHD) on page

330

Master Driven Coordinated Control (MDCC) on page

354

Motion Coordinated Stop (MCS) on page 465 Updated the descriptions for the Decel Units and Jerk Units

Motion Coordinated Transform with Orientation

(MCTO) on page 367

Updated the flow chart

Updated the description for the Nominal Master Velocity

operand.

operands.

New instruction

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 3

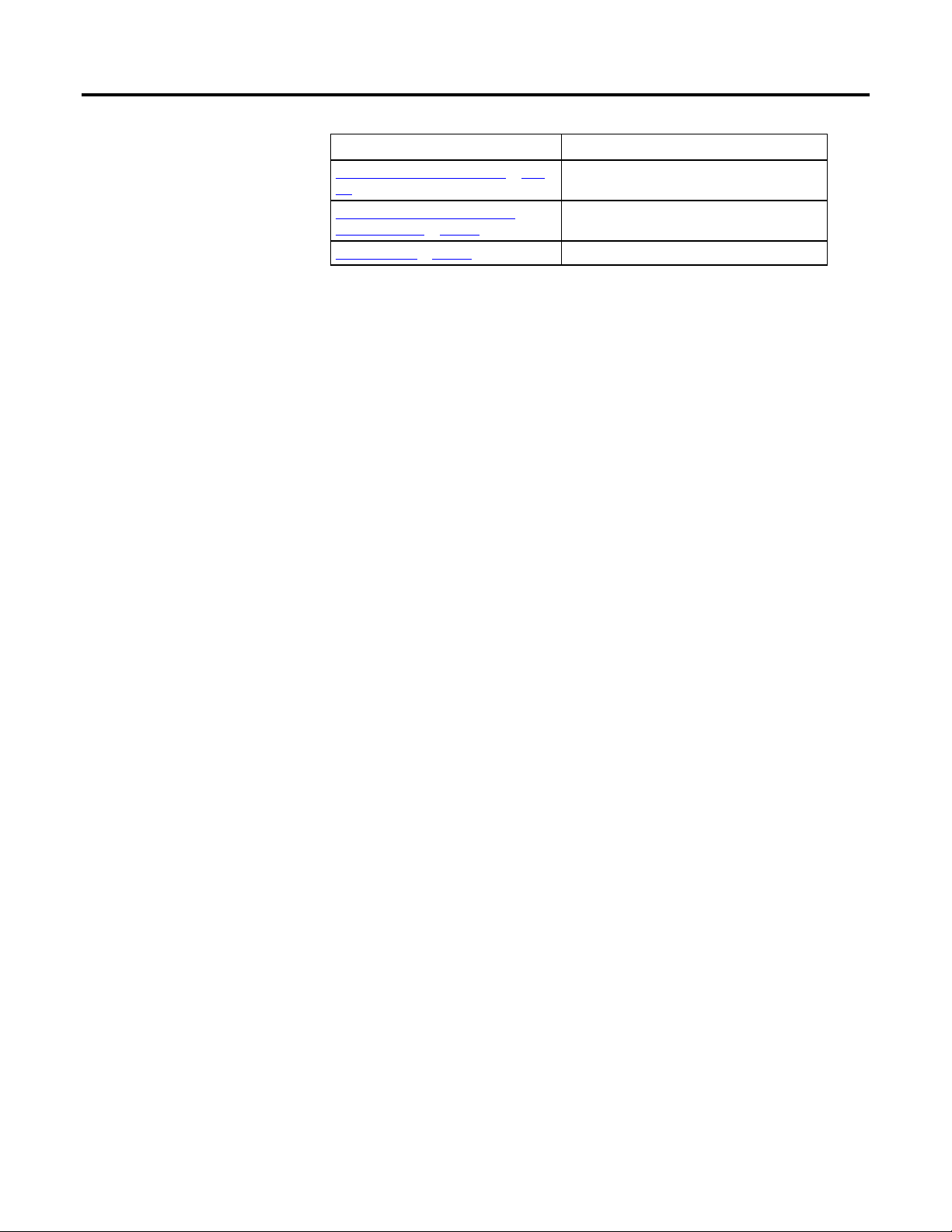

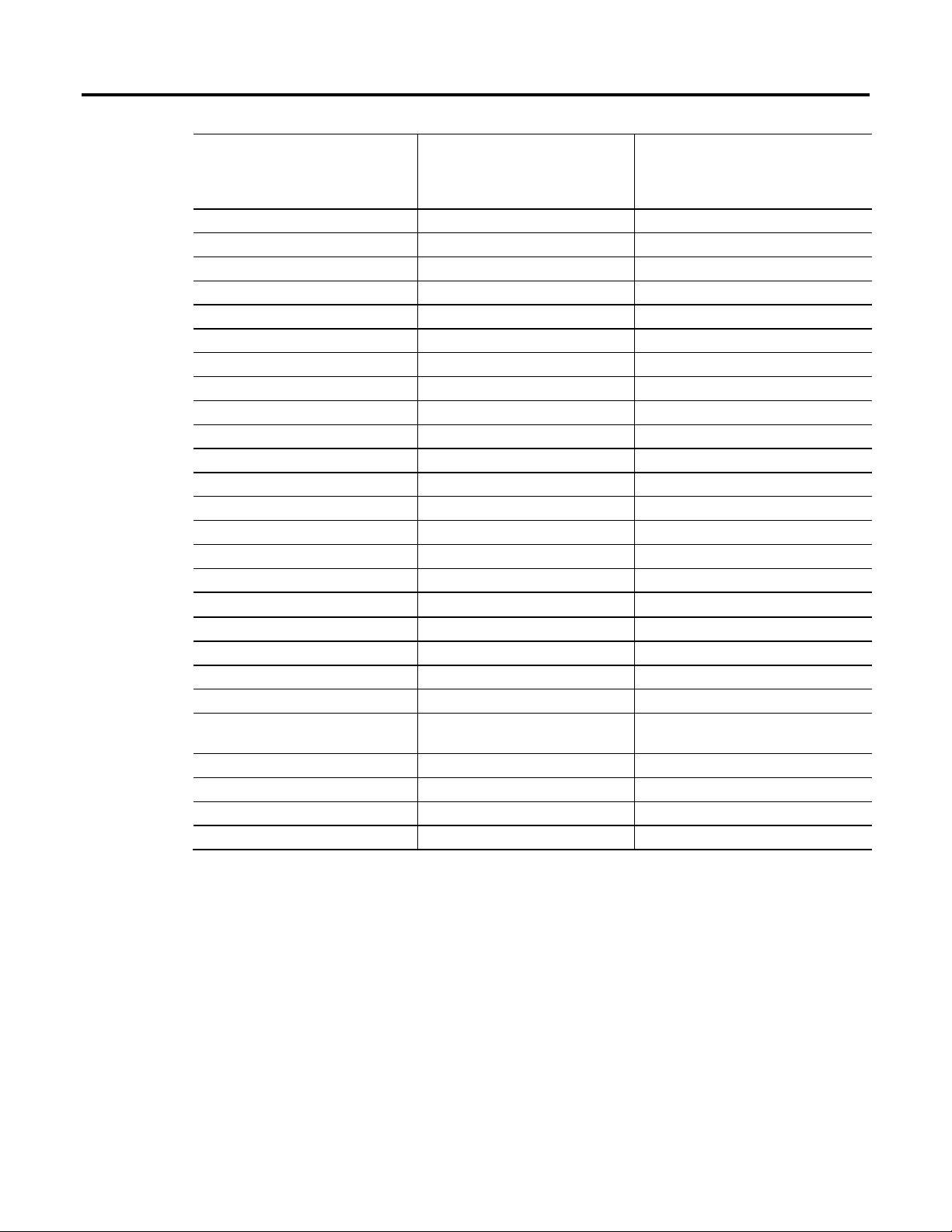

Page 4

Summary of changes

Topic Name Reason

Motion Coordinated Path Move (MCPM) on page

377

Motion Calculate Transform Position with

Orientation (MCTPO) on page 406

Motion Error Codes on page 557 Added new error codes

New instruction

New instruction

4 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 5

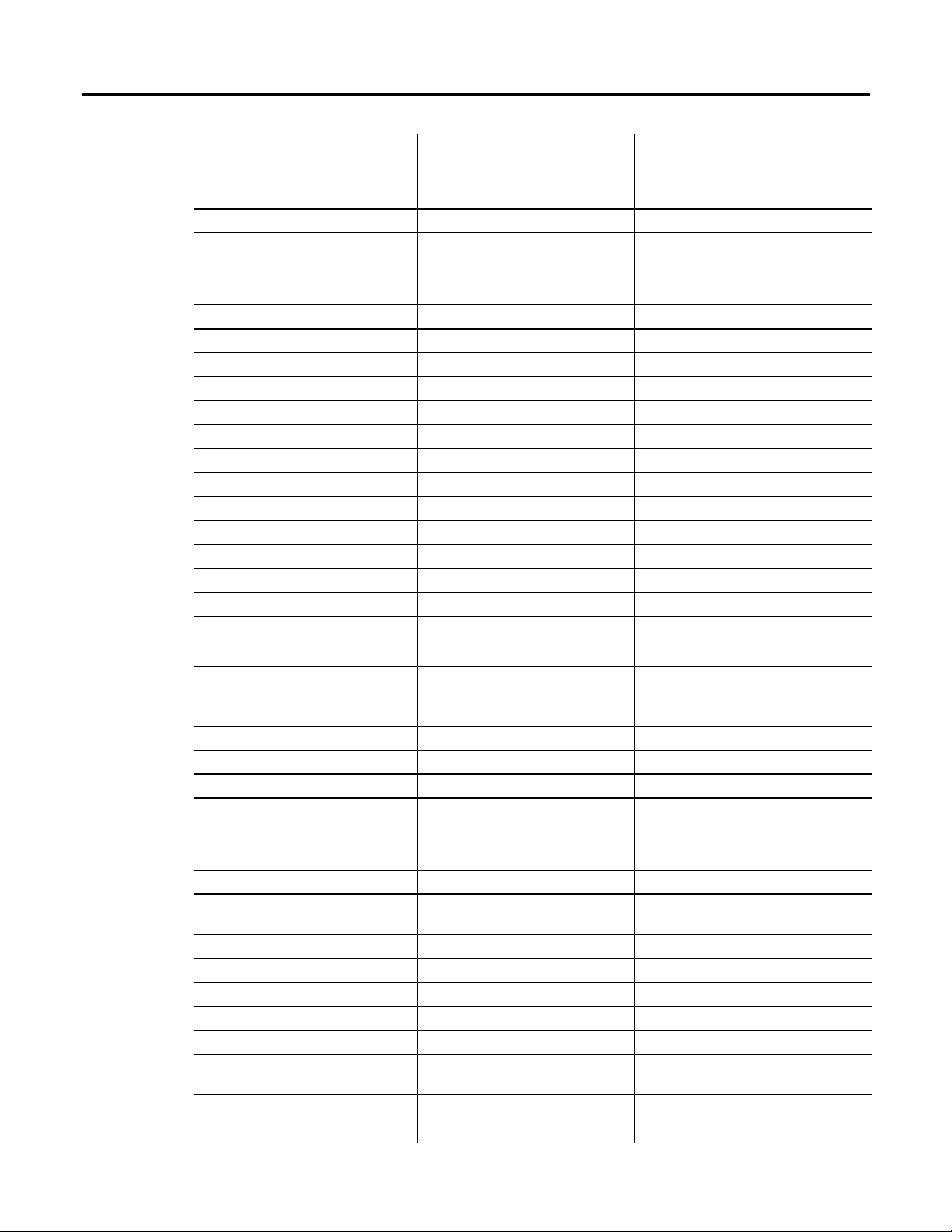

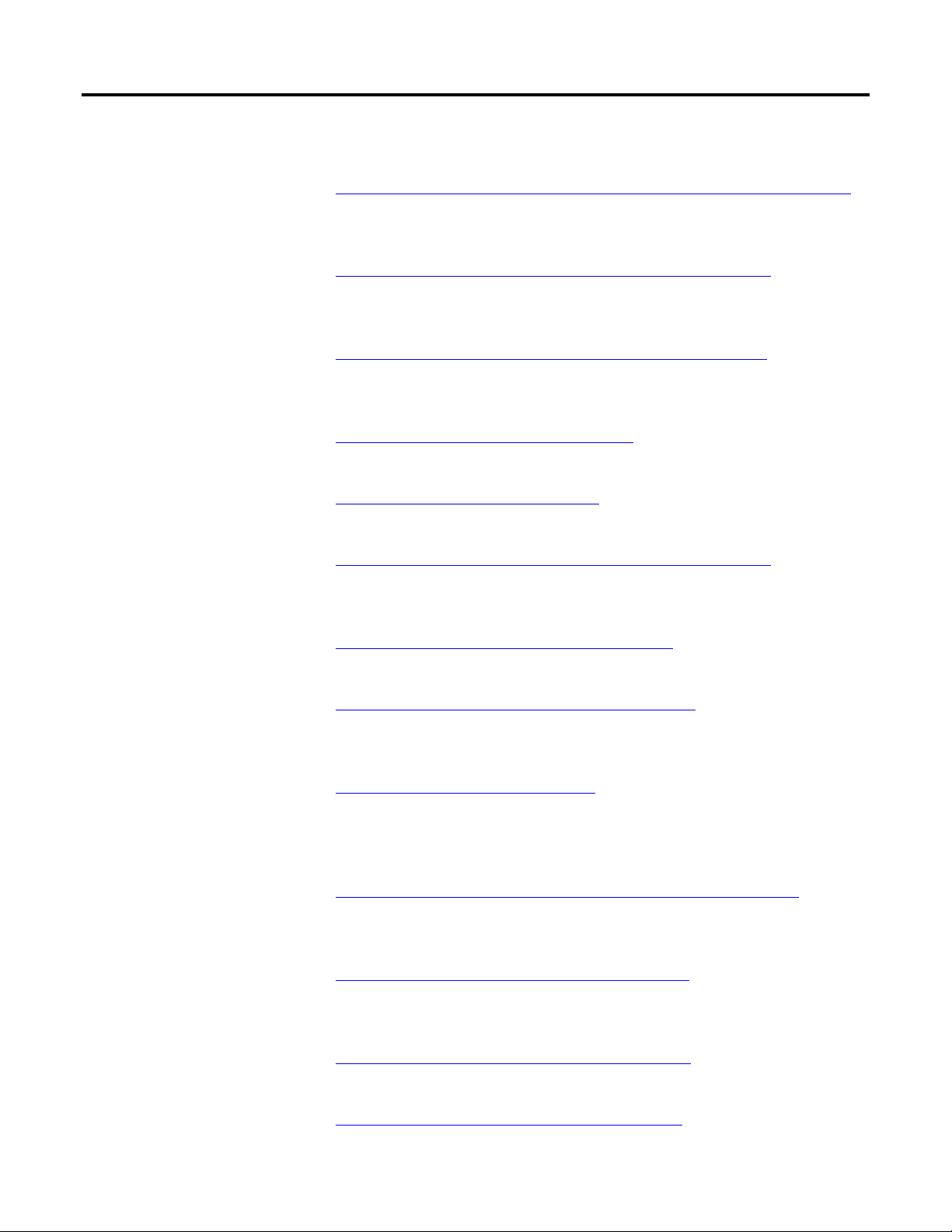

Instruction Locator

Use this locator to find the applicable Logix5000 controllers instruction manual

for each instruction.

Logix5000 Controllers General Instructions

Reference Manual 1756-RM003

Absolute Value (ABS) Alarm (ALM) Master Driven Coordinated Control (MDCC)

Add (ADD) Attach to Equipment Phase (PATT) Motion Apply Axis Tuning (MAAT)

Analog Alarm (ALMA) Attach to Equipment Sequence (SATT) Motion Apply Hookup Diagnostics (MAHD)

Always False (AFI) Coordinated Control (CC) Motion Arm Output Cam (MAOC)

Arc Cosine (ACS, ACOS) D Flip-Flop (DFF) Motion Arm Registration (MAR)

Arc Sine (ASN, ASIN) Deadtime (DEDT) Motion Arm Watch (MAW)

Arc Tangent (ATN, ATAN) Derivative (DERV) Motion Axis Fault Reset (MAFR)

ASCII Chars in Buffer (ACB) Detach from Equipment Phase (PDET) Motion Axis Gear (MAG)

ASCII Clear Buffer (ACL) Detach from Equipment Sequence (SDET) Motion Axis Home (MAH)

ASCII Handshake Lines (AHL) Discrete 3-State Device (D3SD) Motion Axis Jog (MAJ)

ASCII Read (ARD) Discrete 2-State Device (D2SD) Motion Axis Move (MAM)

ASCII Read Line (ARL) Enhanced PID (PIDE) Motion Axis Position Cam (MAPC)

ASCII Test for Buffer Line (ABL) Enhanced Select (ESEL) Motion Axis Stop (MAS)

ASCII Write (AWT) Equipment Phase Clear Failure (PCLF) Motion Axis Time Cam (MATC)

ASCII Write Append (AWA) Equipment Phase Command (PCMD) Motion Axis Shutdown (MASD)

Bit Field Distribute (BTD) Equipment Phase External Request (PXRQ) Motion Axis Shutdown Reset (MASR)

Bit Field Distribute with Target (BTDT) Equipment Phase Failure (PFL) Motion Calculate Cam Profile (MCCP)

Bit Shift Left (BSL) Equipment Phase New Parameters (PRNP) Motion Coordinated Path Move (MCPM)

Logix5000 Controllers Advanced Process

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Reference Manual MOTION-RM002

Bit Shift Right (BSR) Equipment Phase Override Command (POVR) Motion Calculate Slave Values (MCSV)

Bitwise And (AND) Equipment Phase Paused (PPD) Motion Coordinated Transform with Orientation

(MCTO)

Bitwise (NOT) Equipment Sequence Assign Sequence Identifier

(SASI)

Bitwise (OR) Equipment Sequence Clear Failure (SCLF) Motion Calculate Transform Position with

Boolean AND (BAND) Equipment Sequence command (SCMD) Motion Change Dynamics (MCD)

Boolean Exclusive OR (BXOR) Equipment Sequence Override (SOVR) Motion Coordinated Change Dynamics (MCCD)

Boolean NOT (BNOT) Function Generator (FGEN) Motion Coordinated Circular Move (MCCM)

Boolean OR (BOR) High Pass Filter (HPF) Motion Coordinated Linear Move (MCLM)

Break (BRK) High/Low Limit (HLL) Motion Coordinated Shutdown (MCSD)

Breakpoints (BPT) Integrator (INTG) Motion Coordinated Shutdown Reset (MCSR)

Clear (CLR) Internal Model Control (IMC) Motion Coordinated Stop (MCS)

Compare (CMP) JK Flip-Flop (JKFF) Motion Coordinated Transform (MCT)

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 5

Motion Calculate Transform Position (MCTP)

Orientation (MCTPO)

Page 6

Instruction Locator

Logix5000 Controllers General Instructions

Reference Manual 1756-RM003

Convert to BCD (TOD) Lead-Lag (LDLG) Motion Direct Drive Off (MDF)

Convert to Integer (FRD) Low Pass Filter (LPF) Motion Direct Drive On (MDO)

Copy File (COP), Synchronous Copy File (CPS) Maximum Capture (MAXC) Motion Direct Start (MDS)

Cosine (COS) Minimum Capture (MINC) Motion Disarm Output Cam (MDOC)

Compute (CPT) Modular Multivariable Control (MMC) Motion Disarm Registration (MDR)

Count down (CTD) Moving Average (MAVE) Motion Disarm Watch (MDW)

Count up (CTU) Moving Standard Deviation (MSTD) Motion Group Shutdown (MGSD)

Count up/down CTUD Multiplexer (MUX) Motion Group Shutdown Reset (MGSR)

Data Transition (DTR) Notch Filter (NTCH) Motion Group Stop (MGS)

Degrees (DEG) Phase State Complete (PSC) Motion Group Strobe Position (MGSP)

Diagnostic Detect (DDT) Position Proportional (POSP) Motion Redefine Position (MRP)

Digital Alarm (ALMD) Proportional + Integral (PI) Motion Run Axis Tuning (MRAT)

DINT To String (DTOS) Pulse Multiplier (PMUL) Motion Run Hookup Diagnostics (MRHD)

Divide (DIV) Ramp/Soak (RMPS) Motion Servo Off (MSF)

End of Transition (EOT) Rate Limiter (RLIM) Motion Servo On (MSO)

Equal to (EQU) Reset Dominant (RESD)

File Arithmetic (FAL) Scale (SCL)

File Bit Comparison (FBC) S-Curve (SCRV)

FIFO Load (FFL) Second-Order Controller (SOC)

FIFO Unload (FFU) Second-Order Lead Lag (LDL2)

Logix5000 Controllers Advanced Process

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Reference Manual MOTION-RM002

File Average (AVE) Select (SEL)

File Standard Deviation (STD) Selected Negate (SNEG)

File Fill (FLL) Selected Summer (SSUM)

File Sort (SRT) Set Dominant (SETD)

Find String (FIND) Split Range Time Proportional (SRTP)

For (FOR) Totalizer (TOT)

File Search and Compare (FSC) Up/Down Accumulator (UPDN)

Get System Value (GSV) and Set System Value

(SST)

Greater Than or Equal to (GEQ)

Greater than (GRT)

Insert String (INSERT)

Immediate Output (IOT)

Jump to Label (JMP) and Label (LBL)

Jump to Subroutine (JSR), Subroutine (SBR), and

Return (RET)

Jump to External Routine (JXR)

Less Than (LES)

6 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 7

Instruction Locator

Logix5000 Controllers General Instructions

Reference Manual 1756-RM003

Less Than or Equal to (LEQ)

LIFO Load (LFL)

LIFO Unload (LFU)

License Validation (LV)

Limit (LIM)

Log Base (LOG)

Lower to Case (LOWER)

Masked Move (MVM)

Masked Move with Target (MVMT)

Master Control Reset (MCR)

Masked Equal to (MEQ)

Message (MSG)

Middle String (MID)

Modulo (MOD)

Move (MOV)

Multiply (MUL)

Natural Log (LN)

Negate (NEG)

Not Equal to (NEQ)

No Operation (NOP)

One Shot (ONS)

One Shot Falling (OSF)

One Shot Falling with Input (OSFI)

One Shot Rising (OSR)

One Shot Rising with Input (OSRI)

Output Energize (OTE)

Output Latch (OTL)

Output Unlatch (OTU)

Proportional Integral Derivative (PID)

Radian (RAD)

Real to String (RTOS)

Reset (RES)

Reset SFC (SFR)

Return (RET)

Retentive Timer On (RTO)

Retentive Timer On with Reset (RTOR)

Pause SFC (SFP)

Size In Elements (SIZE)

Sequencer Input (SQI)

Logix5000 Controllers Advanced Process

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Reference Manual MOTION-RM002

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 7

Page 8

Instruction Locator

Logix5000 Controllers General Instructions

Reference Manual 1756-RM003

Sequencer Load (SQL)

Sequencer Output (SQO)

Sine (SIN)

Square Roost (SQR/SQRT)

String Concatenate (CONCAT)

String Delete (DELETE)

String to DINT (STOD)

String to REAL (STOR)

Swap Byte (SWPB)

Subtract (SUB)

Tangent (TAN)

Timer Off Delay (TOF)

Timer Off Delay with Reset (TOFR)

Timer On Delay (TON)

Timer On Delay with Reset (TONR)

Temporary End (TND)

Tracepoints (TPT)

Trigger Event Task (EVENT)

Truncate (TRN)

Unknown Instruction (UNK)

Upper Case (UPPER)

User Interrupt Disable (UID)/User Interrupt Enable

(UIE)

X to the Power of Y (XPY)

Examine if Closed (XIC)

Examine If Open (XIO)

Bitwise Exclusive (XOR)

Logix5000 Controllers Advanced Process

Control and Drives and Equipment Phase

and Sequence Instructions Reference

Manual 1756-RM006

Logix5000 Controllers Motion Instructions

Reference Manual MOTION-RM002

8 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 9

Preface

Motion State Instructions

Motion Move Instructions

Table of contents

Studio 5000 environment................................................................................................. 15

Additional resources .......................................................................................................... 16

Legal Notices ....................................................................................................................... 16

Understand Instruction Timing ..................................................................................... 23

Immediate Type Instructions .......................................................................................... 23

Message Type Instructions ............................................................................................... 24

Process Type Instructions ................................................................................................. 25

Write a Motion Application Program ........................................................................... 27

Chapter 1

Motion State Instructions ................................................................................................ 29

Motion Axis Fault Reset (MAFR) .......................................................................... 35

MAFR Flow Chart (True) ....................................................................................... 39

Motion Axis Shutdown (MASD) ........................................................................... 40

MASD Flow Chart (True) ....................................................................................... 45

Motion Axis Shutdown Reset (MASR)................................................................. 45

MASR Flow Chart (True) ....................................................................................... 50

Motion Direct Drive Off (MDF) ........................................................................... 51

MDF Flow Chart (True) .......................................................................................... 55

Motion Direct Drive On (MDO) .......................................................................... 56

MDO Flow Chart (True) ......................................................................................... 62

Motion Drive Start (MDS) ...................................................................................... 63

Motion Servo Off (MSF) .......................................................................................... 71

MSF Flow Chart (True) ........................................................................................... 76

Motion Servo On (MSO) ......................................................................................... 77

MSO Flow Chart (True) .......................................................................................... 81

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 9

Chapter 2

Motion Move Instructions ............................................................................................... 83

Motion Axis Stop (MAS) ......................................................................................... 84

Motion Axis Home (MAH) .................................................................................... 93

MAH Flow Chart (True) ....................................................................................... 100

Motion Axis Jog (MAJ) .......................................................................................... 101

Motion Axis Move (MAM) ................................................................................... 112

Motion Axis Gear (MAG) ..................................................................................... 125

MAG Flow Chart (True) ....................................................................................... 137

Motion Change Dynamics (MCD) ..................................................................... 138

MCD Flow Chart (True) ....................................................................................... 148

Motion Redefine Position (MRP) ........................................................................ 149

MRP Flow Chart (True) ........................................................................................ 155

Motion Calculate Cam Profile (MCCP) ............................................................ 156

Page 10

Table of contents

Motion Group Instructions

Motion Event Instructions

Motion Configuration

Motion Calculate Slave Values (MCSV) ............................................................. 163

Motion Axis Position Cam (MAPC) .................................................................. 166

MAPC Flow Chart (True) ..................................................................................... 190

Motion Axis Time Cam (MATC) ....................................................................... 191

MATC Flow Chart (True) .................................................................................... 209

Chapter 3

Motion Group Instructions ........................................................................................... 211

Motion Group Stop (MGS) ................................................................................... 212

MGS Flow Chart (True) ........................................................................................ 219

Motion Group Shutdown (MGSD) .................................................................... 220

MGSD Flow Chart (True) ..................................................................................... 225

Motion Group Shutdown Reset (MGSR) .......................................................... 226

MGSR Flow Chart (True) ..................................................................................... 229

Motion Group Strobe Position (MGSP) ............................................................ 230

MGSP Flow Chart (True) ...................................................................................... 233

Chapter 4

Motion Event Instructions ............................................................................................. 235

Motion Arm Watch (MAW) ................................................................................ 236

MAW Flow Chart (True) ...................................................................................... 242

Understand a Programming example ................................................................... 243

Motion Disarm Watch (MDW) ........................................................................... 243

MDW Flow Chart (True) ...................................................................................... 248

Motion Arm Registration (MAR) ........................................................................ 249

MAR Flow Chart (True) ........................................................................................ 257

Motion Disarm Registration (MDR) .................................................................. 258

Motion Arm Output Cam (MAOC) .................................................................. 262

Scheduled Output Module ..................................................................................... 282

Specifying the Output Cam ................................................................................... 289

Specifying Output Compensation ........................................................................ 293

MAOC Flow Chart (True) .................................................................................... 297

Motion Disarm Output Cam (MDOC) ............................................................. 298

MDOC Flow Chart (True) ................................................................................... 303

Instructions

10 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Chapter 5

Motion Configuration Instructions ............................................................................. 305

Motion Apply Axis Tuning (MAAT) ................................................................. 306

MAAT Flow Chart (True) .................................................................................... 313

Motion Run Axis Tuning (MRAT) ..................................................................... 313

MRAT Flow Chart (True)..................................................................................... 323

Motion Apply Hookup Diagnostics (MAHD) ................................................. 324

MAHD Flow Chart (True) ................................................................................... 329

Page 11

Multi-Axis Coordinated

MDSC Functionality

Motion Instructions

Table of contents

Motion Run Hookup Diagnostics (MRHD) ..................................................... 330

MRHD Flow Chart (True) ................................................................................... 343

Modify Motion Configuration Parameters ................................................................ 344

Chapter 6

Multi-Axis Coordinated Motion Instructions ........................................................... 345

Master Driven Coordinated Control (MDCC) ............................................... 354

Motion Calculate Transform Position (MCTP) .............................................. 361

Motion Coordinated Transform with Orientation (MCTO) ....................... 367

Motion Coordinated Path Move (MCPM) ....................................................... 377

Motion Coordinated Change Dynamics (MCCD) ......................................... 392

Motion Calculate Transform Position with Orientation (MCTPO) .......... 406

Motion Coordinated Circular Move (MCCM) ............................................... 414

Motion Coordinated Linear Move (MCLM) .................................................... 437

Motion Coordinated Shutdown (MCSD) ......................................................... 458

Motion Coordinated Shutdown Reset (MCSR) ............................................... 462

Motion Coordinated Stop (MCS) ....................................................................... 465

Motion Coordinated Transform (MCT) ........................................................... 476

Speed, acceleration, deceleration, and jerk enumerations for coordinated

motion ........................................................................................................................ 489

Returned Calculated Data Parameter for Coordinated System Motion

Instruction ................................................................................................................. 494

Status Bits for Motion Instructions (MCLM, MCCM) when MDCC Is

Active .......................................................................................................................... 496

Change between master driven and time driven modes for Coordinated

Motion instructions ................................................................................................. 499

Choose a Termination Type .................................................................................. 500

Common Action Table for Slave Coordinate System and Master Axis ....... 509

Input and Output Parameters Structure for Coordinate System Motion

Instructions ................................................................................................................ 511

Returned Calculated Data Parameter for Coordinated System Motion

Instruction ................................................................................................................. 519

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 11

Chapter 7

Master Driven Axis Control (MDAC) ....................................................................... 521

Changing Between Master Driven and Time Driven Modes for Single Axis

Motion Instructions ........................................................................................................ 529

Common Action Table for Slave and Master Axis ................................................... 531

Input and Output Parameters Structure for Single Axis Motion Instructions ... 533

Speed, Acceleration, Deceleration, and Jerk Enumerations .................................... 538

Time Based Planning ....................................................................................................... 546

Status Bits for Motion Instructions (MAM, MATC, MAJ) When MDAC Is

Active .................................................................................................................................. 550

Page 12

Table of contents

Program a velocity profile

Motion Error Codes, faults,

Overview of motion-related

Overview of Structured Text

and jerk rate and tune an

S-Curve Profile

and attributes

Chapter 8

Definition of Jerk ............................................................................................................. 551

Choose a Profile ................................................................................................................ 551

Velocity Profile Effects .................................................................................................... 553

Tune an S-Curve Profile ................................................................................................. 553

Chapter 9

Motion Error Codes (.ERR) .......................................................................................... 557

Handle Motion Faults ..................................................................................................... 568

Motion Attributes ............................................................................................................ 569

Understand Motion Status and Configuration Parameters .................................... 608

Troubleshoot Axis Motion ............................................................................................ 608

Chapter 10

data types

Programming

CAM Structure ................................................................................................................. 627

CAM_PROFILE Structure ........................................................................................... 627

MOTION_GROUP Structure .................................................................................... 628

MOTION_INSTRUCTION Data Type ................................................................. 630

OUTPUT_CAM Structure .......................................................................................... 632

OUTPUT_COMPENSATION Structure............................................................... 633

Chapter 11

Structured Text Syntax ................................................................................................... 635

Structured Text Components: Assignments .............................................................. 636

Structured Text Components: Expressions ................................................................ 638

Use arithmetic operators and functions ...................................................................... 640

Use relational operators .................................................................................................. 641

Use logical operators ........................................................................................................ 642

Use bitwise operators ....................................................................................................... 643

Determine the order of execution ................................................................................. 644

Structured Text Components: Instructions ............................................................... 644

Structured Text Components: Constructs ................................................................. 645

Character string literals ................................................................................................... 646

IF_THEN .......................................................................................................................... 648

CASE_OF ......................................................................................................................... 651

FOR_DO ........................................................................................................................... 653

WHILE_DO .................................................................................................................... 655

REPEAT_UNTIL ........................................................................................................... 658

Structured Text Components: Comments ................................................................ 660

12 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 13

Common attributes for

Index

Motion instructions

Table of contents

Chapter 12

Common Attributes ........................................................................................................ 663

Index Through Arrays ..................................................................................................... 663

Immediate values .............................................................................................................. 664

Floating Point Values ...................................................................................................... 664

LINT data types ............................................................................................................... 666

Data Types ......................................................................................................................... 667

Data Conversions ............................................................................................................. 669

Math Status Flags ............................................................................................................. 673

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 13

Page 14

Page 15

Studio 5000 environment

Preface

This manual provides a programmer with details about the available General,

Motion, Process, and Drives instruction set for a Logix-based controller.

If you design, program, or troubleshoot safety applications that use GuardLogix

controllers, refer to the

Reference Manual , publication 1756-RM095 .

This manual is one of a set of related manuals that show common procedures for

programming and operating Logix 5000™ controllers.

GuardLogix Safety Application Instruction Set Safety

For a complete list of common procedures manuals, refer to the

Controllers Common Procedures Programming Manual , publication

1756-PM001 .

The term Logix 5000 controller refers to any controller that is based on the Logix

5000 operating system.

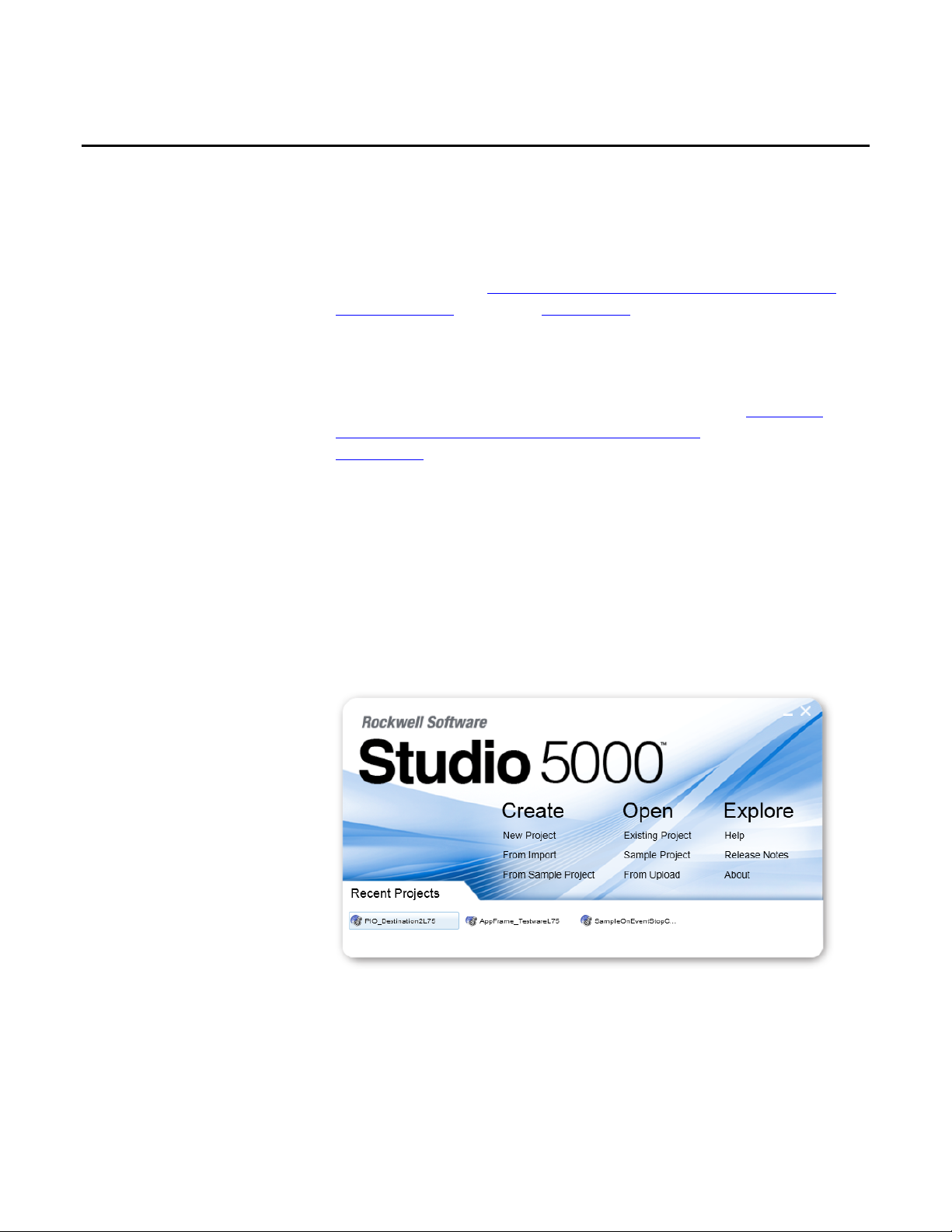

The Studio 5000 Automation Engineering & Design Environment® combines

engineering and design elements into a common environment. The first element is

the Studio 5000 Logix Designer® application. The Logix Designer application is

the rebranding of RSLogix 5000® software and will continue to be the product to

program Logix 5000™ controllers for discrete, process, batch, motion, safety, and

drive-based solutions.

Logix 5000

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 15

The Studio 5000® environment is the foundation for the future of

Rockwell Automation® engineering design tools and capabilities. The Studio 5000

environment is the one place for design engineers to develop all elements of their

control system.

Page 16

Preface

Additional resources

Legal Notices

These documents contain additional information concerning related Rockwell

Automation products.

Resource Description

Industrial Automation Wiring and Grounding Guidelines ,

publication 1770-4.1

Provides general guidelines for installing a Rockwell

Automation industrial system.

Product Certifications webpage, available at

http://ab.rockwellautomation.com

Provides declarations of conformity, certificates, and other

certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Rockwell Automation distributor or

sales representative.

Copyright Notice

Copyright © 2018 Rockwell Automation Technologies, Inc. All Rights Reserved.

Printed in USA.

This document and any accompanying Rockwell Software products are

copyrighted by Rockwell Automation Technologies, Inc. Any reproduction

and/or distribution without prior written consent from Rockwell Automation

Technologies, Inc. is strictly prohibited. Please refer to the license agreement for

details.

End User License Agreement (EULA)

You can view the Rockwell Automation End-User License Agreement ("EULA")

by opening the License.rtf file located in your product's install folder on your hard

drive.

16 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Other Licenses

Botan (http://botan.randombit.net/

) is distributed under these terms:

Copyright (C) 1999-2013, 2014 Jack Lloyd

2001 Peter J Jones

2004-2007 Justin Karneges

2004 Vaclav Ovsik

2005 Matthew Gregan

2005-2006 Matt Johnston

2006 Luca Piccarreta

2007 Yves Jerschow

2007-2008 FlexSecure GmbH

2007-2008 Technische Universitat Darmstadt

2007-2008 Falko Strenzke

Page 17

Preface

2007-2008 Martin Doering

2007 Manuel Hartl

2007 Christoph Ludwig

2007 Patrick Sona

2010 Olivier de Gaalon

2012 Vojtech Kral

2012 Markus Wanner

2013 Joel Low

All rights reserved.

Redistribution and use in source and binary forms, with or without modification,

are permitted provided that the following conditions are met:

1. Redistributions of source code must retain the above copyright notice, this

list of conditions, and the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice,

this list of conditions, and the following disclaimer in the documentation

and/or other materials provided with the distribution.

THIS SOFTWARE IS PROVIDED BY THE COPYRIGHT HOLDERS AND

CONTRIBUTORS "AS IS" AND ANY EXPRESS OR IMPLIED

WARRANTIES, INCLUDING, BUT NOT LIMITED TO, THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE ARE DISCLAIMED. IN NO EVENT SHALL

THE COPYRIGHT HOLDER OR CONTRIBUTORS BE LIABLE FOR

ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY, OR

CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED TO,

PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS OF

USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION) HOWEVER

CAUSED AND ON ANY THEORY OF LIABILITY, WHETHER IN

CONTRACT, STRICT LIABILITY, OR TORT (INCLUDING

NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY OUT OF THE

USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE POSSIBILITY OF

SUCH DAMAGE.

The package GNU Compiler Collection (GCC) is licensed under the following

licenses:

GNU General Public License v3.0, the text of which is available at

http://www.gnu.org/licenses/gpl-3.0-standalone.html

. Copyright © 2007 Free

Software Foundation, Inc.

MIT License, the text of which is available at

http://www.opensource.org/licenses/MIT

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 17

.

Page 18

Preface

GNU General Public License v3.0 with GCC Runtime Library exception (v3.1),

the text of which is available at

https://olex-secure.openlogic.com/licenses/base_license/gpl-gcc-v3-license-base

Copyright (C) 2009 Free Software Foundation, Inc.

GNU Lesser General Public License v2.1, the text of which is available at

http://www.gnu.org/licenses/old-licenses/lgpl-2.1-standalone.html

. Copyright

(C) 1991, 1999 Free Software Foundation, Inc.

GNU General Public License v2.0, the text of which is available at

http://www.gnu.org/licenses/old-licenses/gpl-2.0-standalone.html

. Copyright

(C) 1989, 1991 Free Software Foundation, Inc.

Mozilla Public License 1.1, the text of which is available at

http://www.mozilla.org/MPL/MPL-1.1.html

.

Unicode, Inc. License Agreement, the text of which is available at

http://www.unicode.org/copyright.html

. Copyright © 1991-2009 Unicode, Inc.

.

GNU Library General Public License v2.0, the text of which is available at

http://www.gnu.org/licenses/old-licenses/lgpl-2.0-standalone.html

. Copyright

(C) 1991 Free Software Foundation, Inc.

BSD 3-clause New or Revised License, the text of which is available at

http://www.opensource.org/licenses/BSD-3-Clause

.

BSD 2-clause (FreeBSD License), the text of which is available at

http://www.freebsd.org/copyright/freebsd-license.html

. Copyright 1992-2012

The FreeBSD Project.

GNU Free Documentation License v1.3, the text of which is available at

http://www.gnu.org/licenses/fdl-1.3.txt

. Copyright © 2000, 2001, 2002, 2007,

2008 Free Software Foundation, Inc.

GNU General Public License v2.0 w/ServerHandler library exception, the text of

which is available at

https://olex-secure.openlogic.com/licenses/gpl-serverhandler-exception

.

Copyright (C) 1989, 1991 Free Software Foundation, Inc.

GNU Lesser General Public License v3.0, the text of which is available at

http://www.gnu.org/licenses/lgpl-3.0-standalone.html

. Copyright © 2007 Free

Software Foundation, Inc.

Creative Commons Attribution 3.0, the text of which is available at

http://creativecommons.org/licenses/by/3.0/legalcode

Independent JPEG Group License, the text of which is available at

https://olex-secure.openlogic.com/licenses/ijg-license

18 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

.

.

Page 19

Preface

Boost Software License 1.0, and BSD 3-clause (University of California Regents),

the text of which is available at http://www.boost.org/LICENSE_1_0.txt

.

The package Newlib is licensed under the following licenses:

GNU General Public License v2.0 w/Autoconf exception, the text of which is

available at http://spdx.org/licenses/GPL-2.0-with-autoconf-exception

.

Copyright (C) 1989, 1991 Free Software Foundation, Inc.

GNU General Public License v3.0 w/Autoconf exception, the text of which is

available at http://spdx.org/licenses/GPL-3.0-with-autoconf-exception

.

Copyright © 2009 Free Software Foundation, Inc.

OpenSSL distributed under these terms:

Copyright (c) 1998-2017 The OpenSSL Project. All rights reserved.

Redistribution and use in source and binary forms, with or without modification,

are permitted provided that the following conditions are met:

1. Redistributions of source code must retain the above copyright notice, this

list of conditions and the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice,

this list of conditions and the following disclaimer in the documentation

and/or other materials provided with the distribution.

3. All advertising materials mentioning features or use of this software must

display the following acknowledgment: "This product includes software

developed by the OpenSSL Project for use in the OpenSSL Toolkit.

(http://www.openssl.org/)"

4. The names "OpenSSL Toolkit" and "OpenSSL Project" must not be used to

endorse or promote products derived from this software without prior

written permission. For written permission, please contact

openssl-core@openssl.org.

5. Products derived from this software may not be called "OpenSSL" nor may

"OpenSSL" appear in their names without prior written permission of the

OpenSSL Project.

6. Redistributions of any form whatsoever must retain the following

acknowledgment: "This product includes software developed by the

OpenSSL Project for use in the OpenSSL Toolkit

(http://www.openssl.org/)"

THIS SOFTWARE IS PROVIDED BY THE OpenSSL PROJECT "AS IS''

AND ANY EXPRESSED OR IMPLIED WARRANTIES, INCLUDING, BUT

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 19

Page 20

Preface

NOT LIMITED TO, THE IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE

ARE DISCLAIMED. IN NO EVENT SHALL THE OpenSSL PROJECT OR

ITS CONTRIBUTORS BE LIABLE FOR ANY DIRECT, INDIRECT,

INCIDENTAL, SPECIAL, EXEMPLARY, OR CONSEQUENTIAL

DAMAGES (INCLUDING, BUT NOT LIMITED TO, PROCUREMENT

OF SUBSTITUTE GOODS OR SERVICES; LOSS OF USE, DATA, OR

PROFITS; OR BUSINESS INTERRUPTION) HOWEVER CAUSED AND

ON ANY THEORY OF LIABILITY, WHETHER IN CONTRACT, STRICT

LIABILITY, OR TORT (INCLUDING NEGLIGENCE OR OTHERWISE)

ARISING IN ANY WAY OUT OF THE USE OF THIS SOFTWARE, EVEN

IF ADVISED OF THE POSSIBILITY OF SUCH DAMAGE.

=================================================

===================

This product includes cryptographic software written by Eric Young

(eay@cryptsoft.com). This product includes software written by Tim Hudson

(tjh@cryptsoft.com).

/

Original SSLeay License

-----------------------

/Copyright (C) 1995-1998 Eric Young (eay@cryptsoft.com)

All rights reserved.

This package is an SSL implementation written by Eric Young

(eay@cryptsoft.com).

The implementation was written so as to conform with Netscapes SSL.

This library is free for commercial and non-commercial use as long as the

following conditions are adhered to. The following conditions apply to all code

found in this distribution, be it the RC4, RSA, lhash, DES, etc., code; not just the

SSL code. The SSL documentation included with this distribution is covered by

the same copyright terms except that the holder is Tim Hudson

(tjh@cryptsoft.com).

Copyright remains Eric Young's, and as such any Copyright notices in the code are

not to be removed.

If this package is used in a product, Eric Young should be given attribution as the

author of the parts of the library used. This can be in the form of a textual message

at program startup or in documentation (online or textual) provided with the

package.

20 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 21

Preface

Redistribution and use in source and binary forms, with or without modification,

are permitted provided that the following conditions are met:

1. Redistributions of source code must retain the copyright notice, this list of

conditions and the following disclaimer.

2. Redistributions in binary form must reproduce the above copyright notice,

this list of conditions and the following disclaimer in the documentation

and/or other materials provided with the distribution.

3. All advertising materials mentioning features or use of this software must

display the following acknowledgment: "This product includes

cryptographic software written by Eric Young (eay@cryptsoft.com)" The

word 'cryptographic' can be left out if the routines from the library being

used are not cryptographic related :-).

4. If you include any Windows specific code (or a derivative thereof) from the

apps directory (application code) you must include an acknowledgment:

"This product includes software written by Tim Hudson

(tjh@cryptsoft.com)"

THIS SOFTWARE IS PROVIDED BY ERIC YOUNG "AS IS'' AND ANY

EXPRESS OR IMPLIED WARRANTIES, INCLUDING, BUT NOT

LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY

AND FITNESS FOR A PARTICULAR PURPOSE ARE DISCLAIMED. IN

NO EVENT SHALL THE AUTHOR OR CONTRIBUTORS BE LIABLE

FOR ANY DIRECT, INDIRECT, INCIDENTAL, SPECIAL, EXEMPLARY,

OR CONSEQUENTIAL DAMAGES (INCLUDING, BUT NOT LIMITED

TO, PROCUREMENT OF SUBSTITUTE GOODS OR SERVICES; LOSS

OF USE, DATA, OR PROFITS; OR BUSINESS INTERRUPTION)

HOWEVER CAUSED AND ON ANY THEORY OF LIABILITY,

WHETHER IN CONTRACT, STRICT LIABILITY, OR TORT

(INCLUDING NEGLIGENCE OR OTHERWISE) ARISING IN ANY WAY

OUT OF THE USE OF THIS SOFTWARE, EVEN IF ADVISED OF THE

POSSIBILITY OF SUCH DAMAGE.

The licence and distribution terms for any publicly available version or derivative

of this code cannot be changed. [i.e., this code cannot simply be copied and put

under another distribution licence (including the GNU Public Licence.)]

Trademark Notices

Allen-Bradley, ControlBus, ControlFLASH, Compact GuardLogix, Compact

I/O, ControlLogix, CompactLogix, DCM, DH+, Data Highway Plus,

DriveLogix, DPI, DriveTools, Explorer, FactoryTalk, FactoryTalk Administration

Console, FactoryTalk Alarms and Events, FactoryTalk Batch, FactoryTalk

Directory, FactoryTalk Security, FactoryTalk Services Platform, FactoryTalk

View, FactoryTalk View SE, FLEX Ex, FlexLogix, FLEX I/O, Guard I/O, High

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 21

Page 22

Preface

Performance Drive, Integrated Architecture, Kinetix, Logix5000, Logix 5000,

Logix5550, MicroLogix, DeviceNet, EtherNet/IP, PLC-2, PLC-3, PLC-5,

PanelBuilder, PowerFlex, PhaseManager, POINT I/O, PowerFlex, Rockwell

Automation, RSBizWare, Rockwell Software, RSEmulate, Historian,

RSFieldbus, RSLinx, RSLogix, RSNetWorx for DeviceNet, RSNetWorx for

EtherNet/IP, RSMACC, RSView, RSView32, Rockwell Software Studio 5000

Automation Engineering & Design Environment, Studio 5000 View Designer,

SCANport, SLC, SoftLogix, SMC Flex, Studio 5000, Ultra 100, Ultra 200,

VersaView, WINtelligent, XM, SequenceManager are trademarks of Rockwell

Automation, Inc.

Any Rockwell Automation logo, software or hardware product not mentioned

herein is also a trademark, registered or otherwise, of Rockwell Automation, Inc.

Other Trademarks

CmFAS Assistant, CmDongle, CodeMeter, CodeMeter Control Center, and

WIBU are trademarks of WIBU-SYSTEMS AG in the United States and/or

other countries. Microsoft is a registered trademark of Microsoft Corporation in

the United States and/or other countries. ControlNet is a trademark of

ControlNet International. DeviceNet is a trademark of the Open DeviceNet

Vendors Association (ODVA). Ethernet/IP is a trademark of ControlNet

International under license by ODVA.

All other trademarks are the property of their respective holders and are hereby

acknowledged.

Warranty

This product is warranted in accordance with the product license. The product’s

performance may be affected by system configuration, the application being

performed, operator control, maintenance, and other related factors. Rockwell

Automation is not responsible for these intervening factors. The instructions in

this document do not cover all the details or variations in the equipment,

procedure, or process described, nor do they provide directions for meeting every

possible contingency during installation, operation, or maintenance. This

product’s implementation may vary among users.

This document is current as of the time of release of the product; however, the

accompanying software may have changed since the release. Rockwell Automation,

Inc. reserves the right to change any information contained in this document or

the software at any time without prior notice. It is your responsibility to obtain the

most current information available from Rockwell when installing or using this

product.

22 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 23

Preface

Understand

Immediate Type

Environmental Compliance

Rockwell Automation maintains current product environmental information on

its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainabili

ty-ethics/product-environmental-compliance.page

Contact Rockwell

Customer Support Telephone — 1.440.646.3434

Instruction Timing

Instructions

Online Support — http://www.rockwellautomation.com/support/

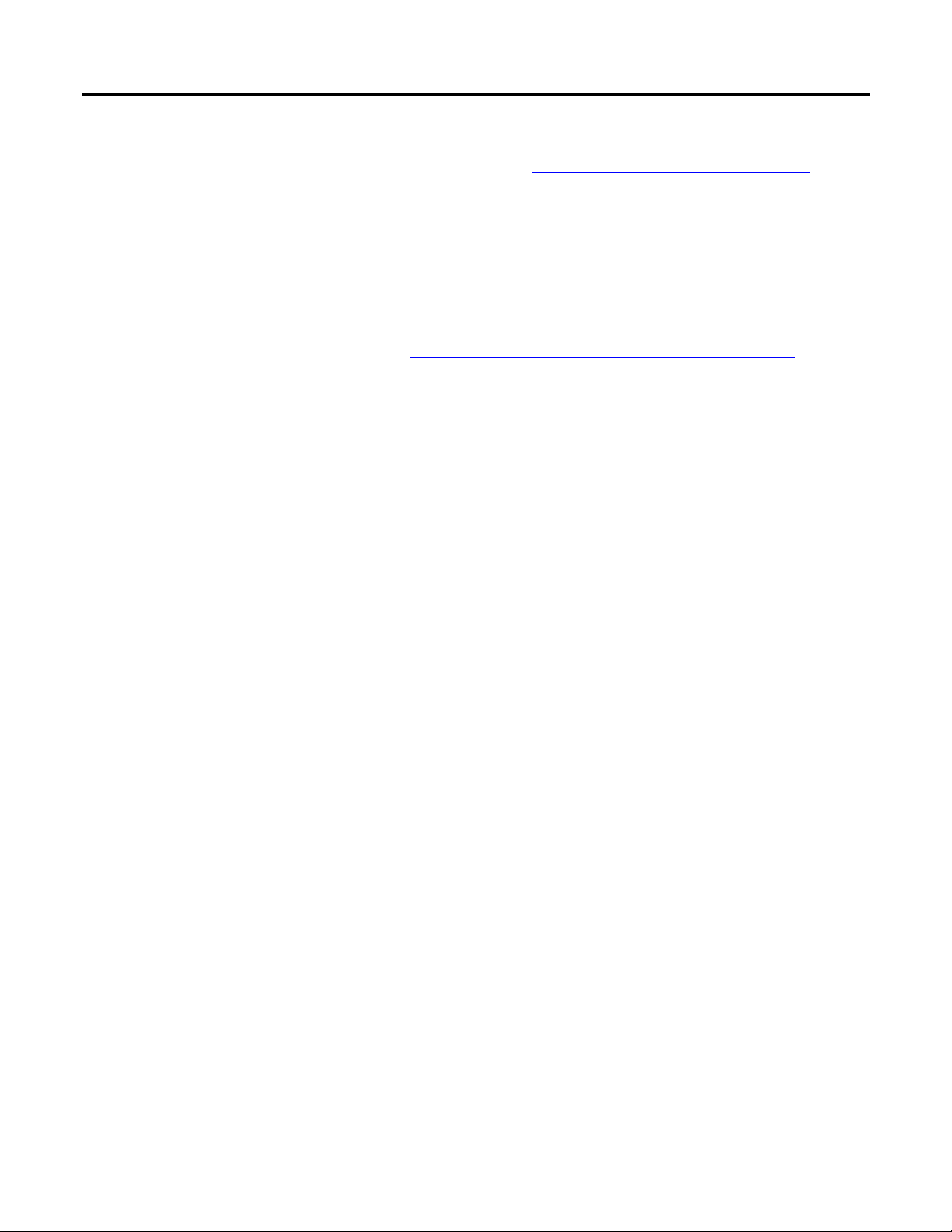

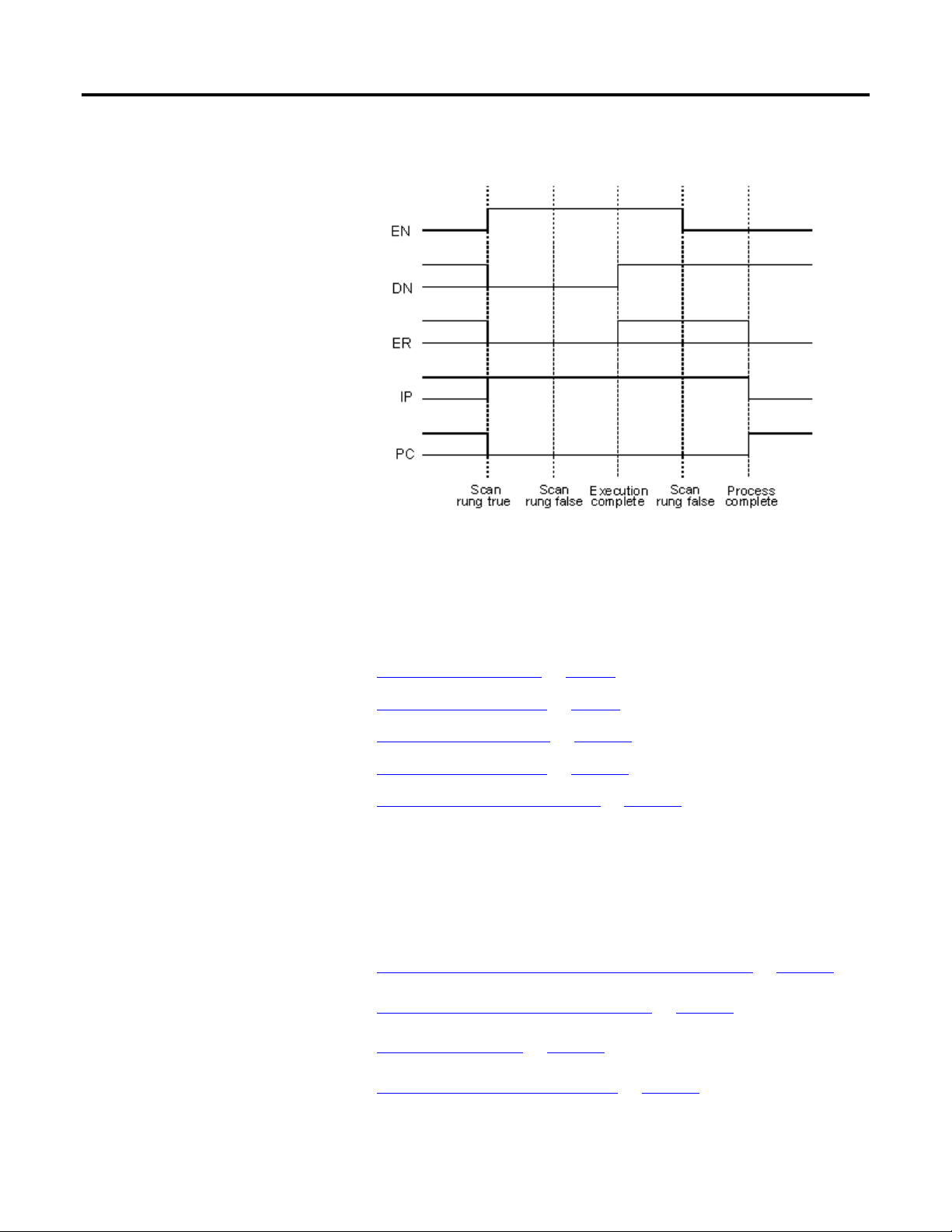

Motion instructions use three types of timing sequences:

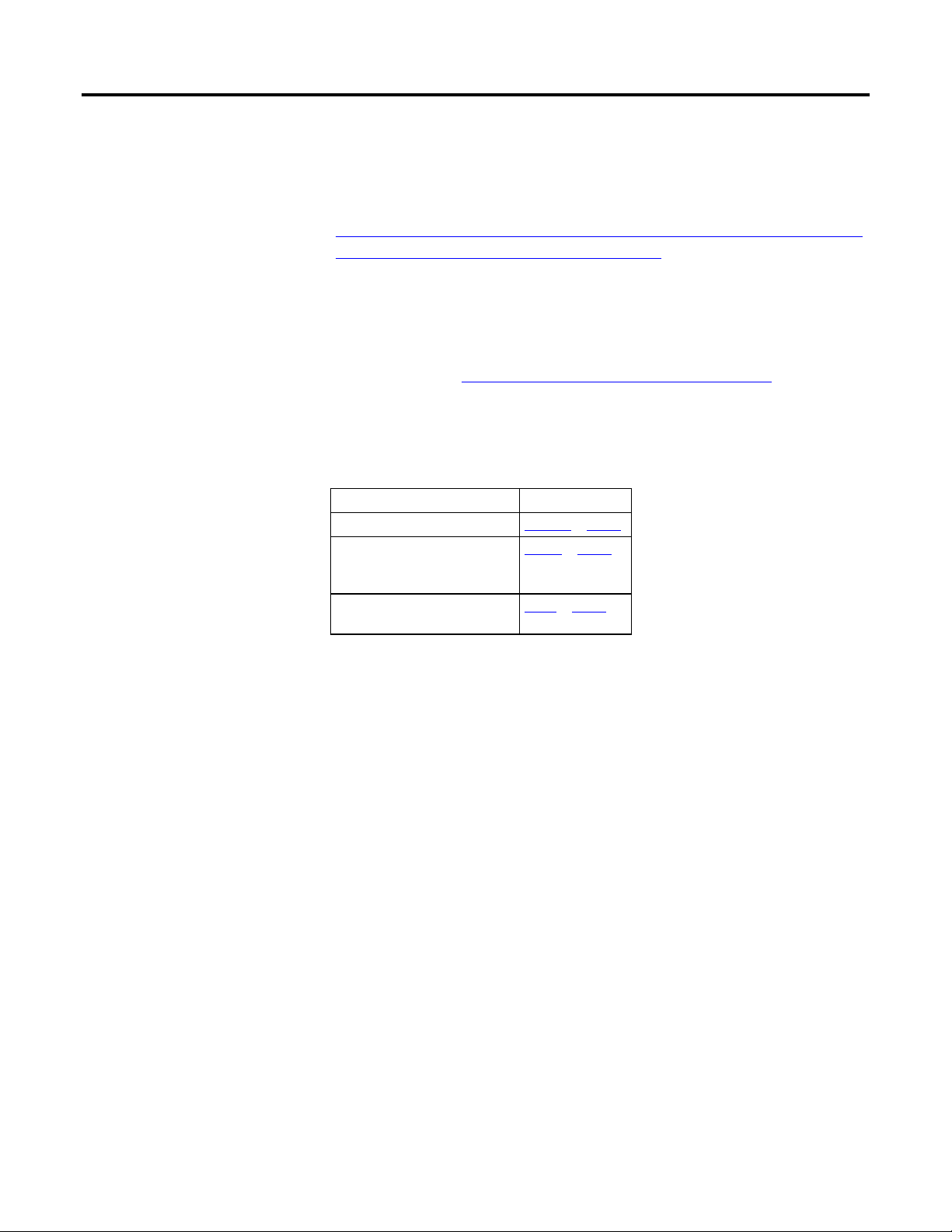

Description Timing Type

The instruction completes in one scan. immediate on page 23

The instruction completes over several

scans because the instruction sends

messages to the servo module.

The instruction could take an indefinite

amount of time to complete.

message on page 24

process on page 25

Immediate type motion instructions execute to completion in one scan. If the

controller detects an error during the execution of these instructions, the error

status bit sets and the operation ends.

Examples of immediate type instructions include the:

• Motion Change Dynamics (MCD) instruction

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 23

• Motion Group Strobe Position (MGSP) instruction

Immediate instructions work as follows:

1. When the rung that contains the motion instruction becomes true, the

controller:

• Sets the enable (EN) bit.

• Clears the done (DN) bit.

• Clears the error (ER) bit.

2. The controller executes the instruction completely.

Page 24

Preface

Message Type

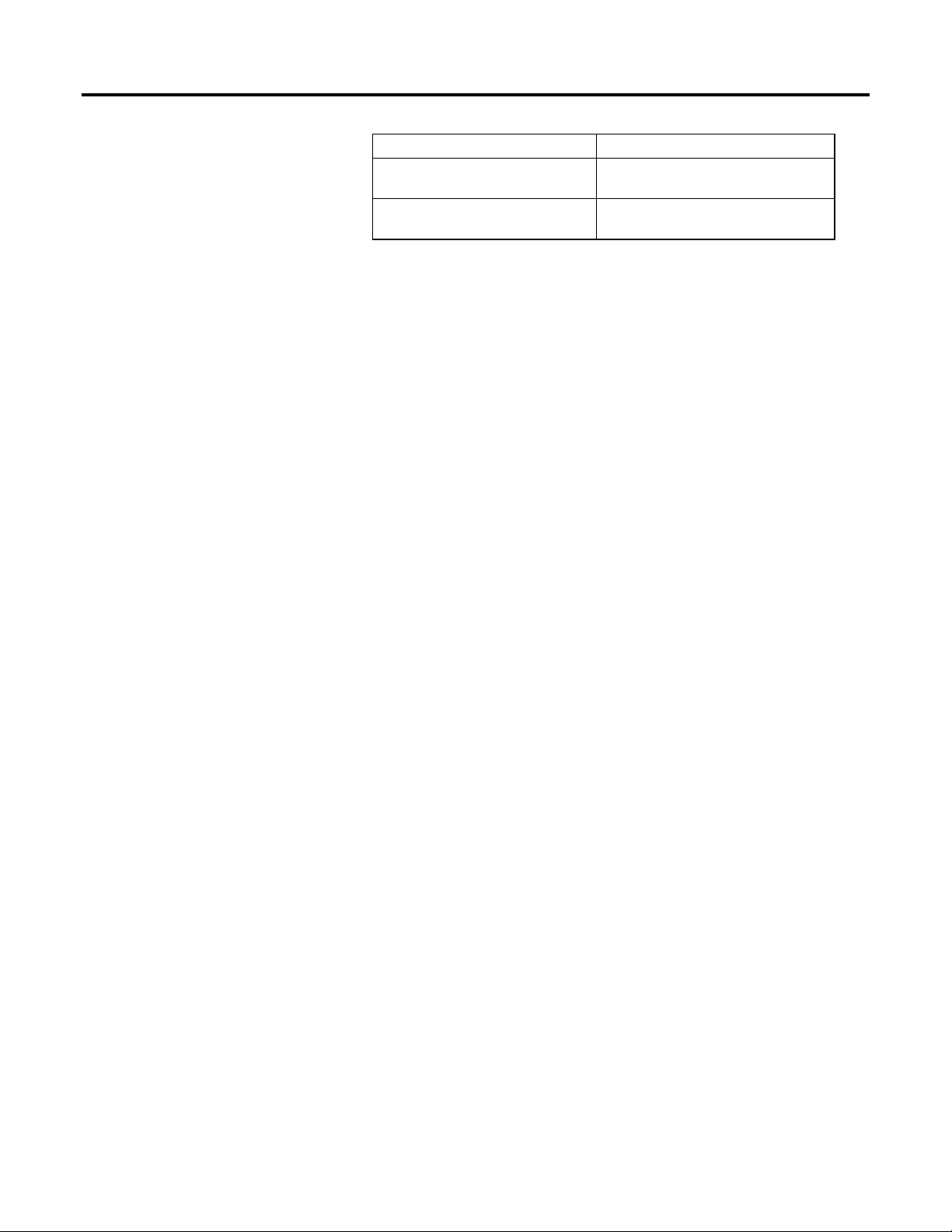

If the controller: Then:

Does not detect an error when the instruction

executes

Detects an error when the instruction executes

The controller sets the .DN bit.

The controller sets the .ER bit and stores an error

code in the control structure.

3. The next time the rung becomes false after either the .DN or .ER bit sets,

the controller clears the .EN bit.

4. The controller can execute the instruction again when the rung becomes

true.

Message type motion instructions send one or more messages to the servo module.

Instructions

Examples of message type instructions include the:

• Motion Direct Drive On (MDO) instruction

• Motion Redefine Position (MRP) instruction

Message type instruction work as follows:

1. When the rung that contains the motion instruction becomes true, the

controller:

• Sets the enable (EN) bit.

• Clears the done (DN) bit.

• Clears the error (ER) bit.

2. The controller begins to execute the instruction by setting up a message

request to the servo module.

Tip:

The remainder of the instruction executes in parallel to the program scan.

3. The controller checks if the servo module is ready to receive a new message.

24 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

4. The controller places the results of the check in the message status word of

the control structure.

5. When the module is ready, the controller constructs and transmits the

message to the module.

Tip:

This process may repeat several times if the instruction requires multiple

messages.

6. The instruction executes.

Page 25

Preface

Process Type

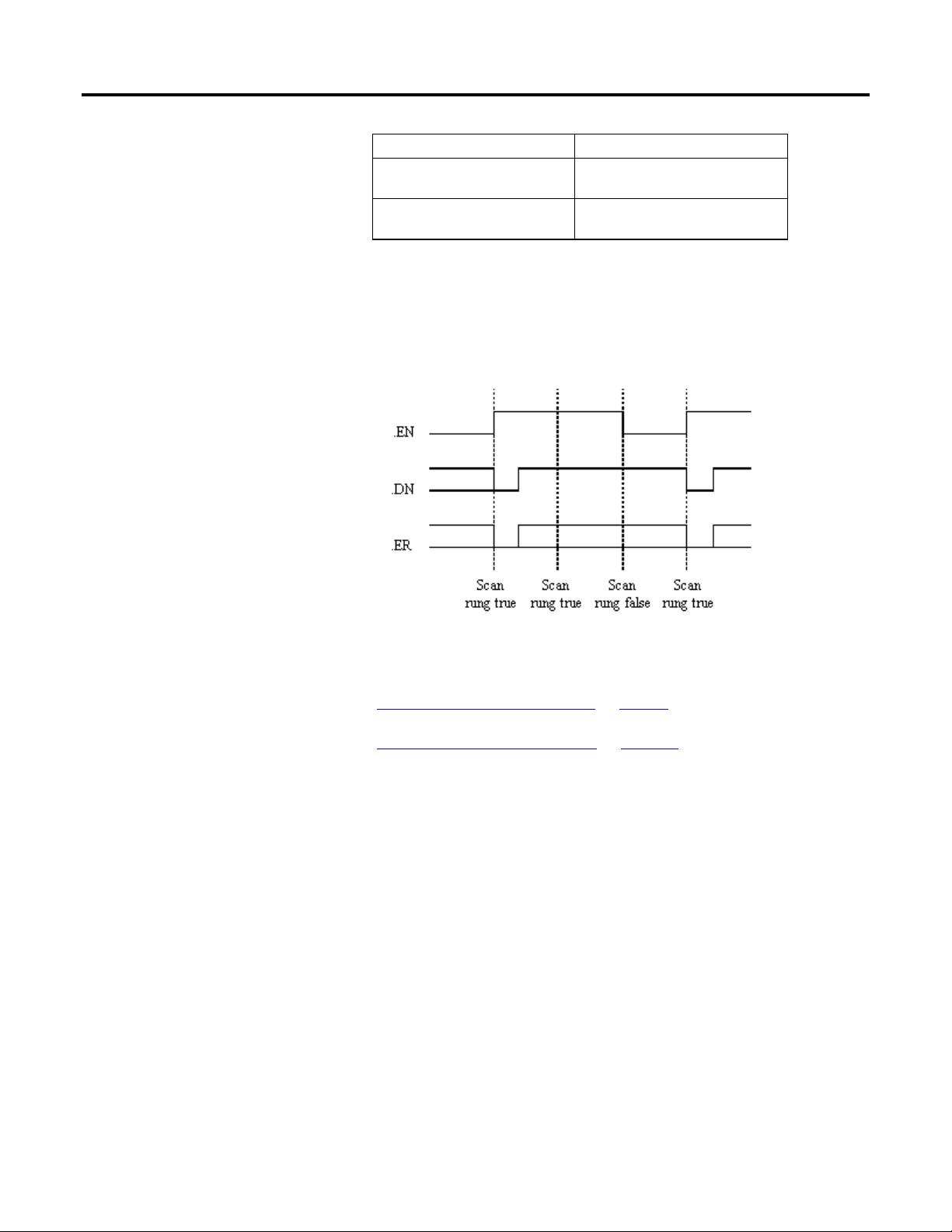

If the controller: Then:

Does not detect an error when the

instruction executes

Detects an error when the instruction

executes

The controller sets the .DN bit.

The controller sets the .ER bit and stores an

error code in the control structure.

7. The next time the rung becomes false after either the .DN or .ER bit sets,

the controller clears the .EN bit.

8. When the rung becomes true, the controller can execute the instruction

again.

Instructions

See also

Motion Direct Drive On (MDO) on page 56

Motion Redefine Position (MRP) on page 149

Process type motion instructions initiate motion processes that can take an

indefinite amount of time to complete.

Examples of process type instructions include the:

• Motion Arm Watch Position (MAW) instruction

• Motion Axis Move (MAM) instruction

Process type instructions work as follows:

1. When the rung that contains the motion instruction becomes true, the

controller:

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 25

Page 26

Preface

•

• Sets the .ER bit.

•

• Sets the enable (.EN) bit.

• Clears the done (.DN) bit.

• Clears the error (.ER) bit.

• Clears the process complete (.PC) bit.

2. The controller initiates the motion process.

If: Then the controller:

The controller does not detect an error when the

instruction executes

Sets the .DN bit.

• Sets the in process (.IP) bit.

The controller detects an error when the instruction

executes

The controller detects another instance of the motion

instruction

The motion process reaches the point where the

instruction can be executed again

One of the following occurs during the motion

process:

• The motion process completes

• Another instance of the instruction executes

• Another instruction stops the motion process

• A motion fault stops the motion process

3. Once the initiation of the motion process completes, the program scan can

continue.

The remainder of the instruction and the control process continue in parallel with the program scan.

Tip:

4. The next time the rung becomes false after either the .DN bit or the .ER bit

sets, the controller clears the .EN bit.

• Stores an error code in the control structure.

• Does not change the .IP and .PC bits.

Clears the .IP bit for that instance.

Sets the .DN bit.

Tip: For some process type instructions, like MAM, this will occur on the first

scan. For others, like MAH, the .DN bit will not be set until the entire homing

process is complete.

Sets the .DN bit.

• Sets the .PC bit.

• Clears the .IP bit.

26 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 27

Preface

Write a Motion

5. When the rung becomes true, the instruction can execute again.

Application Program

To write a motion application program, you can insert motion instructions

directly into the ladder diagram application program. The motion instruction set

consists of five groups of motion instructions:

• Motion state instructions on page 29

• Motion move instructions on page 83

• Motion group instructions on page 211

• Motion event instructions on page 235

• Motion configuration instructions on page 305

These instructions operate on one or more axes. You must identify and configure

axes before you can use them. For more information about configuring axes, see

the ControlLogix Motion Module User Manual, publication 1756-6.5.16.

See also

Understand Motion Status and Configuration Parameters on page 608

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 27

Modify Motion Configuration Parameters on page 344

Handle Motion Faults on page 568

Understand a Programming Example on page 243

Page 28

Preface

28 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 29

Motion State Instructions

Chapter 1

Motion State Instructions

Motion state control instructions directly control or change the operating states

of an axis. These are the motion state instructions.

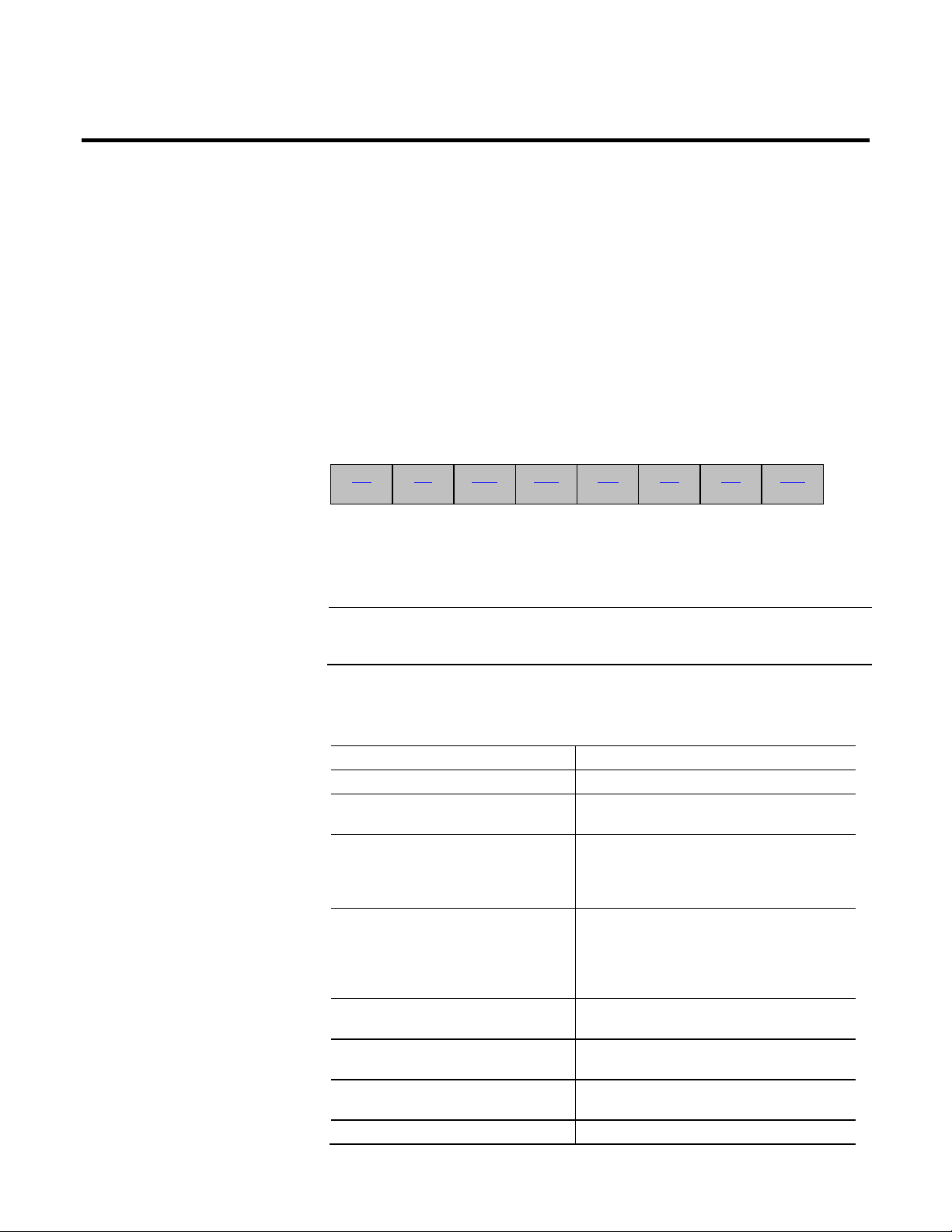

Available Instructions

Ladder Diagram and Structured Text

MSO MSF MASD MASR MDO MDF MDS MAFR

Function Block

Not available

Important:

Tags used for the motion control attribute of instructions should only be used once. Re-use of the motion

control tag in other instructions can cause unintended operation. This may result in damage to equipment

or personal injury.

Motion state control instructions directly control or change the operating states of

an axis. The motion state instructions are:

If you want to: Use this instruction:

Enable the servo drive and activate the axis servo loop. MSO

Disable the servo drive and deactivate the axis servo

loop.

Force an axis into the shutdown operating state. Once

the axis is in the shutdown operating state, the

controller will block any instructions that initiate axis

motion.

Change an axis from an existing shutdown operating

state to an axis ready operating state. If all of the axes

of a servo module are removed from the shutdown

state as a result of this instruction, the OK relay

contacts for the module will close.

Enable the servo drive and set the servo output voltage

of an axis.

Deactivate the servo drive and set the servo output

voltage to the output offset voltage.

Activate the drive control loops for the specified axis

and run the motor at the specified speed.

Clear all motion faults for an axis. MAFR

MSF

MASD

MASR

MDO

MDF

MDS

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 29

Page 30

Chapter 1

Motion State Instructions

The five operating states of a non-CIP axis are:

Operating State Description

Axis Ready This is the normal power-up state of the axis. In this state:

• The servo module drive enable output is inactive.

• Servo action is disabled.

• No servo faults are present.

Direct Drive Control This operating state allows the servo module DAC to directly

control an external drive. In this state:

• The servo module drive enable output is active.

• Position servo action is disabled.

Servo Control This operating state allows the servo module to perform closed

loop motion. In this state:

• The servo module drive enable output is active.

• Servo action is enabled.

• The axis is forced to maintain the commanded servo position.

Axis Faulted In this operating state, a servo fault is present, and the status of

the drive enable output, the action of the servo, and the

condition of the OK contact depend on the faults and fault

actions that are present.

Shutdown This operating state allows the OK relay contacts to open a set of

contacts in the E- string of the drive power supply. In this state:

• The servo module drive enable output is inactive.

• Servo action is disabled.

• The OK contact is open.

The 16 operating states of a CIP axis are:

As Shown in the Logix Designer

Operating State

Initializing 0 During the Initializing State, the drive first initializes

Programming Application Description

all attributes to their factory default values, that is,

resets all active faults. The drive then waits for the

controller to establish connections to it. Once

connections are established, the controller sets

configuration attributes in the drive to values stored

in the controller. If the drive supports synchronous

operation, the controller then synchronizes with the

drive. Once this process has been completed

successfully, the drive and all its associated axis

instances transition to the Pre-charge state. If a

problem is found during the initializing process, an

Initialization Fault is generated. An Initialization

Fault is an unrecoverable fault. You can only clear the

fault can via a power cycle or a drive reset. If the

connection to the drive closes for any reason during

operation, the drive returns to the Initializing State

30 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 31

Motion State Instructions

Chapter 1

Pre-Charge 1 The drive is waiting for the DC Bus to fully charge,

that is, the DC Bus Up status bit is cleared. Once the

DC Bus reaches an operational voltage level, that is,

DC Bus Up status bit is set, the axis transitions to the

Stopped state.

The drive's power structure is always disabled in this

state, that is, the Power Structure Enabled status bit

is cleared. Any attempt to enable the drive via the

Axis Control mechanism while in this state is

reported back to the controller as an error in the

Response Status and the axis remains in the

Pre-charge state.

Stopped 2 In the Stopped state, the drive's inverter power

structure should either be disabled and free of

torque, that is, the Power Structure Enabled status

bit is cleared, or held in a static condition via an

active control loop, that is, Power Structure Enabled

status bit is set. The drive cannot initiate motion in

the Stopped state nor can the drive respond to a

planner generated command reference, that is, the

Tracking Command status bit is cleared.

In general, the axis should be at rest. However, if you

apply an external force or torque to the load, a brake

may be needed to maintain the rest condition. In the

Stopped state, main power is applied to the drive

and the DC Bus are at an operational voltage level. If

there are any Start Inhibited conditions detected

while in this state, the axis transitions to the Start

Inhibited state. If an Enable request or one of the Run

Test service requests is applied to an axis in the

Stopped state, the motion axis transitions to the

Starting state.

Starting 3 When an Enable request is given to an axis in the

Stopped or Stopping state while it is performing a

Flying Start, the axis immediately transitions to the

Starting state. In this state, the drive checks the

following conditions before transitioning to the

Running state.

• Brake Release delay time

• Induction Motor flux level

The drive control and power structures are activated

during the Starting state, that is, the Power Structure

Enabled status bit is set. But the command reference

is set to a local static value and does not track the

command reference derived from the motion

planner, that is, the Tracking Command status bit is

cleared. If all the starting conditions are met, the axis

state transitions to either the Running state or the

Testing state.

Running 4 The drive's power structure is active, that is, the

Power Structure Enabled status bit is set.

Additionally, the selected Control Mode is enabled

and actively tracking command data from the

controller-based or drive-based motion planner

output to affect axis motion, that is, the Tracking

Command status bit is set.

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 31

Page 32

Chapter 1

Motion State Instructions

Testing 5 When any one of the Run Test request services is sent

to the motion axis while in the Stopped state, that is,

services that require an active power structure to

execute, the axis immediately transitions to the

Starting state, that is, the Power Structure Enabled

status bit is set. Then once the Starting state

conditions are met, the axis transitions to the Testing

state. Like the Running state, in the Testing state,

the drive's power structure is active.

The motion axis remains in this state for the duration

of the requested test procedure and then returns to

the Stopped state. The motion axis can also exit the

Testing state by either a fault or an explicit Axis

Control request.

Stopping 6 When a Disable request is issued to an axis in the

Running or Testing state, the axis immediately

transitions to the Stopping state. In this state, the

axis is in the process of stopping and no longer tracks

command data from the motion planner, that is, the

Tracking Command status bit is cleared.

Once the selected Stopping Mode procedure has

completed, the axis transitions to the Stopped state.

Aborting 7 When a Major Fault occurs in the drive while the axis

is in either the Running or Testing states, the motion

axis immediately transitions to the Aborting state. In

this state, the axis is in the process of stopping and

no longer tracks command data from the motion

planner, that is, the Tracking Command status bit is

cleared. The Aborting state executes the appropriate

stopping action as specified by the drive. As with the

Stopping state, in the Aborting state the power

structure remains active, that is, the Power Structure

Enabled status bit is set, for as long as the stopping

action takes to complete. Once the stopping

procedure is complete the axis transitions to the

Faulted state.

When faults conditions are detected in the controller

that are not visible to the drive, or when the drive

reports a Minor Fault condition, the controller brings

the axis to a stop, either directly via an Axis Control

state change request or motion planner stop, or

indirectly via a fault handler in the user program. If

the Axis State reported by the driv e is Stopping, the

controller sets the CIP Axis State to Aborting based

on the presence of the fault condition.

32 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 33

Motion State Instructions

Chapter 1

Faulted 8 The faulted state is identical to the Stopped state or

the Shutdown state with the exception that there are

one or more faults active. Faults are latched

conditions. Therefore, a Fault Reset is required to

clear the faults and, assuming the original fault

condition has been removed, the axis transitions to

the Axis State of the drive.

There are many different sources of faults:

• CIP Initialization Faults - Faults that occur when

the drive transitions out of the Initializing state.

These faults can apply to a specific axis or the

entire drive.

• CIP Axis Faults - Faults that apply to a specific axis

and are the direct result of Axis Exceptions

configured to generate a Fault response. Axis

exceptions are run-time conditions that are

related to Motor, Inverter, Converter, Bus

Regulator, and Feedback components.

• Safety Fault: Faults that apply to a specific axis

and are generated by a fault condition detected

in the drive’s safety monitor functionality. A

Safety Fault always results in the axis

transitioning to the Stopped state.

• Motion Fault: Faults generally associated with

fault conditions generated by the motion planner

function. These faults can include conditions

related to the input, for example, actual position,

or output, for example, command position,

signals.

• Module Fault: Faults that apply to the entire drive

and affect all axes associated with that drive.

Module faults include all node faults reported by

the drive and also communication fault

conditions detected on the controller side of the

motion connection.

• Group Fault: Faults related to the motion group

object function and affect all axes associated with

the motion group. Group Fault conditions are

detected by controller and are associated with

the time synchronization function common to all

axes in the motion group.

• Configuration Fault: Fault generated anytime

there is an error when sending configuration data

to the drive.

Start Inhibited 9 This state is the same as the Stopped state with the

exception that the axis has one or more 'start inhibit'

conditions that prevent it from successfully

transitioning to the Starting state. Once corrected,

the axis state automatically transitions back to the

Stopped state.

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 33

Page 34

Chapter 1

Motion State Instructions

Shutdown 10 When a Shutdown request is issued to the drive or a

Shutdown fault action is executed by the drive, the

targeted axis immediately transitions to the

Shutdown state. The Shutdown state has the same

basic characteristics of the Stopped state except that

it can be configured via the Shutdown Action

attribute to drop the DC Bus power to the drive's

power structure.

Regardless of whether DC Bus power is disconnected,

this state requires an explicit Shutdown Reset

request from the controller to transition to the

Pre-charge state. If the drive is configured to keep DC

Bus power active while in the Shutdown state, then

the motion axis transitions through the Pre-charge

state to the Stopped state.

In the case where a Shutdown fault action is initiated

by the drive in response to an exception condition

that is configured to be a major fault, the drive

executes the Shutdown action. However, the axis

goes to the Faulted state, not the Shutdown state.

Similarly, when the axis is in the Shutdown state and

a major fault condition occurs, the axis transitions to

the Faulted state. A Fault Reset request from the

controller clears the fault and, assuming the original

fault condition has been removed, the axis

transitions to the Shutdown state. A Shutdown Reset

request from the controller, however, both clears the

fault and performs a shutdown reset so, assuming

the original fault condition has been removed, the

axis transitions to the Pre-charge state.

Axis Inhibited 11 If you inhibit the axis, the associated instance in the

CIP Motion connection is eliminated and the axis

state transitions to the Axis Inhibited state. If this is

the only instance supported by the CIP Motion

connection, the connection itself is closed. The Axis

Inhibited state is a controller-only sub state of the

Self-test state

(1)

. The Axis Inhibited condition is

checked during the controller Self-test state as

qualification for transition to the Initializing state. If

currently Axis Inhibited, you must execute an

Un-Inhibit operation to transition to the Initializing

state and restore axis function.

Not Grouped 12 If a CIP Motion axis is created and not associated with

a Motion Group, the axis state is set to the Not

Grouped state. A CIP Motion axis must be assigned to

a Motion Group for the axis to be updated by the

periodic Motion Task and carry out its function. This

condition is checked during the controller Self-test

state as qualification for transition to the Initializing

state. For this reason, the Not Grouped state is

considered a controller-only sub state of the Self-test

state.

34 Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018

Page 35

Motion State Instructions

Chapter 1

Motion Axis Fault Reset (MAFR)

No Device 13 If the CIP Motion axis in the controller is created, but

not currently associated with a drive, the axis state

indicates the No Device state. A CIP Motion axis must

be associated with a physical drive to function. This

condition is checked during the controller Self-test

state as qualification for transition to the Initializing

state. For this reason, the No Device state is

considered a controller-only sub state of the Self Test

state.

(1) The Self-test state is a drive state. This state does not appear in the Logix

Designer programming application as an operating state of a CIP axis. Instead,

self-test is represented as the Initializing state for a CIP axis.

See also

Motion Configuration Instructions on page 305

Motion Move Instructions on page 83

Multi-Axis Coordinated Motion Instructions on page 345

Motion Event Instructions on page 235

Motion Group Instructions on page 211

This information applies to the CompactLogix 5370, ControlLogix 5570,

Compact GuardLogix 5370, GuardLogix 5570, Compact GuardLogix 5380,

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and GuardLogix

5580 controllers. Controller differences are noted where applicable.

Use the Motion Axis Fault Reset (MAFR) instruction to clear all motion faults for

an axis. This is the only method for clearing axis motion faults.

Important:

The MAFR instruction removes the fault status, but does not perform any other recovery, such as enabling

servo action. In addition, when the controller removes the fault status, the condition that generated the

fault(s) may still exist. If the condition is not corrected before using the MAFR instruction, the axis immediately

faults again.

Rockwell Automation Publication MOTION-RM002H-EN-P-February 2018 35

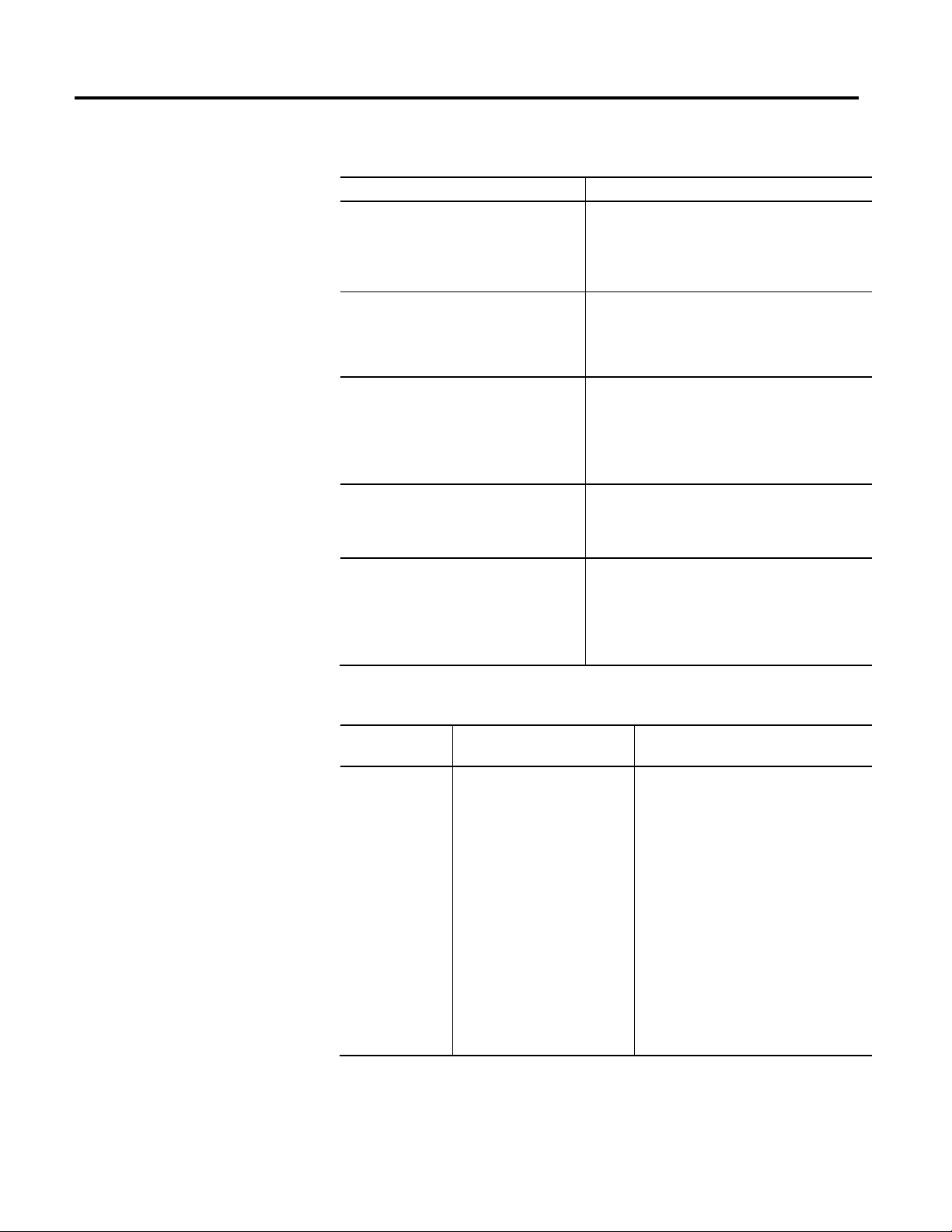

Available Languages

Ladder Diagram

Page 36

Chapter 1

Motion State Instructions

Function Block

This instruction is not available in function block.

Structured Text

MAFR(Axis,MotionControl);

Operands

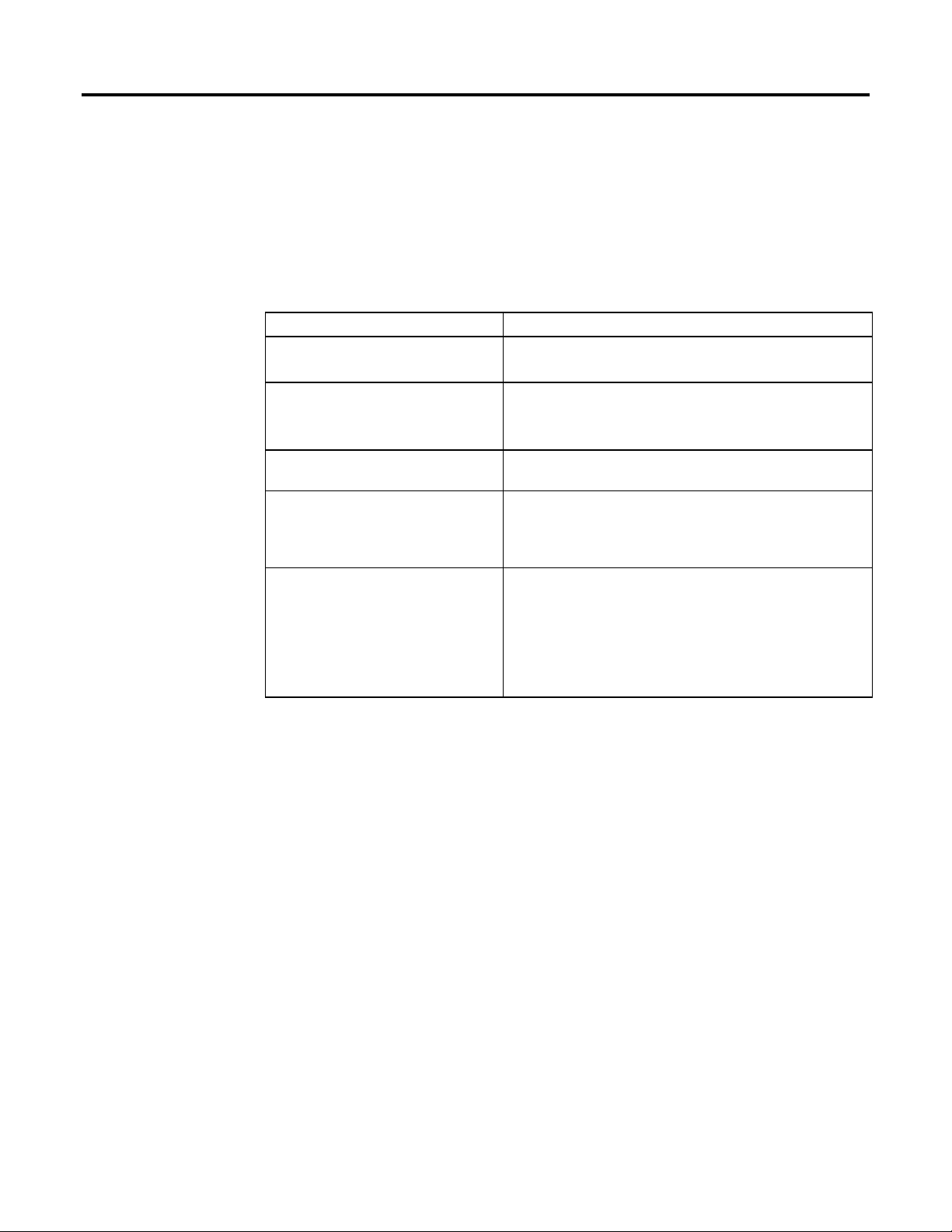

Ladder Diagram and Structured Text

Operand Type

CompactLogix 5380,

CompactLogix 5480,

ControlLogix 5580, Compact

GuardLogix 5380, and

GuardLogix 5580 controllers

Axis AXIS_CIP_DRIVE

AXIS_VIRTUAL

Motion Control MOTION_INSTRUCTION MOTION_INSTRUCTION Tag Structure used to access

Type

CompactLogix 5370, ControlLogix

5570, Compact GuardLogix 5370,

and GuardLogix 5570 controllers

AXIS_CIP_DRIVE

AXIS_VIRTUAL

AXIS_GENERIC

AXIS_GENERIC_DRIVE

AXIS_SERVO

AXIS_SERVO_DRIVE

Format Description

Tag Name of the axis to perform

operation on

instruction status parameters.