Page 1

ControlLogix

Redundancy

System

Catalog Numbers 1756-CNB/D/E,

1756-CNBR/D/E, 1756-ENBT,

1756-EWEB, 1756-L55,

1756-L55M12, 1756-L55M13,

1756-L55M14, 1756-L55M16,

1756-L55M22, 1756-L55M23,

1756-L55M24, 1756-L61, 1756-L62,

1756-L63, 1757-SRM

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

) describes some important

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware

of safety considerations.

Allen-Bradley, RSLogix, RSLogix 5000, RSView, RSLinxRSNetworx, DH+, PanelView, PanelViewPlus, Rockwell Automation,

TechConnect, and VersaView are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

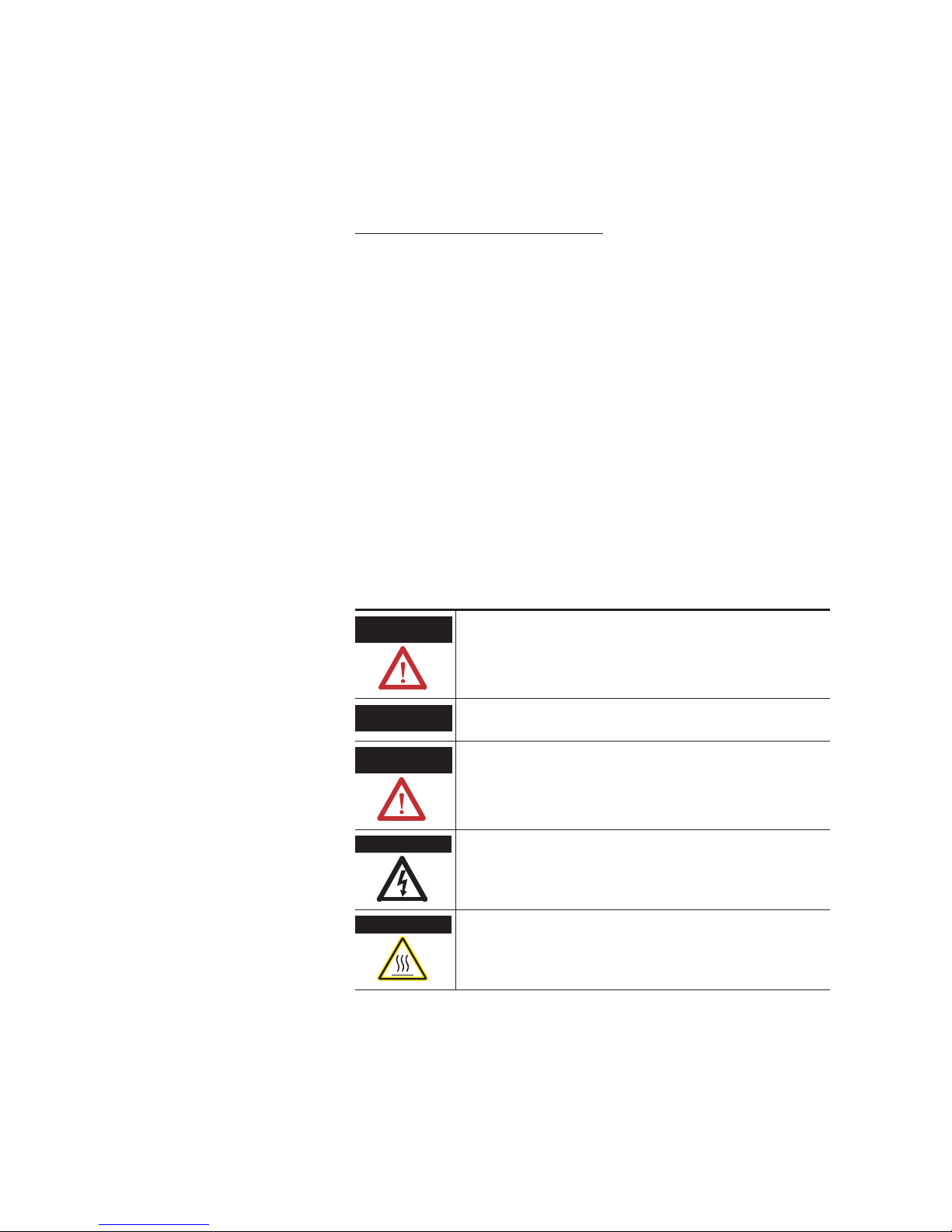

WARNING

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

IMPORTANT

Identifies information that is critical for successful application and

understanding of the product.

ATTENTION

Identifies information about practices or circumstances that can lead

to: personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence

SHOCK HAZARD

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that dangerous voltage may be present.

BURN HAZARD

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that surfaces may reach dangerous

temperatures.

Page 3

3 Publication 1756-UM523F-EN-P - December 2006

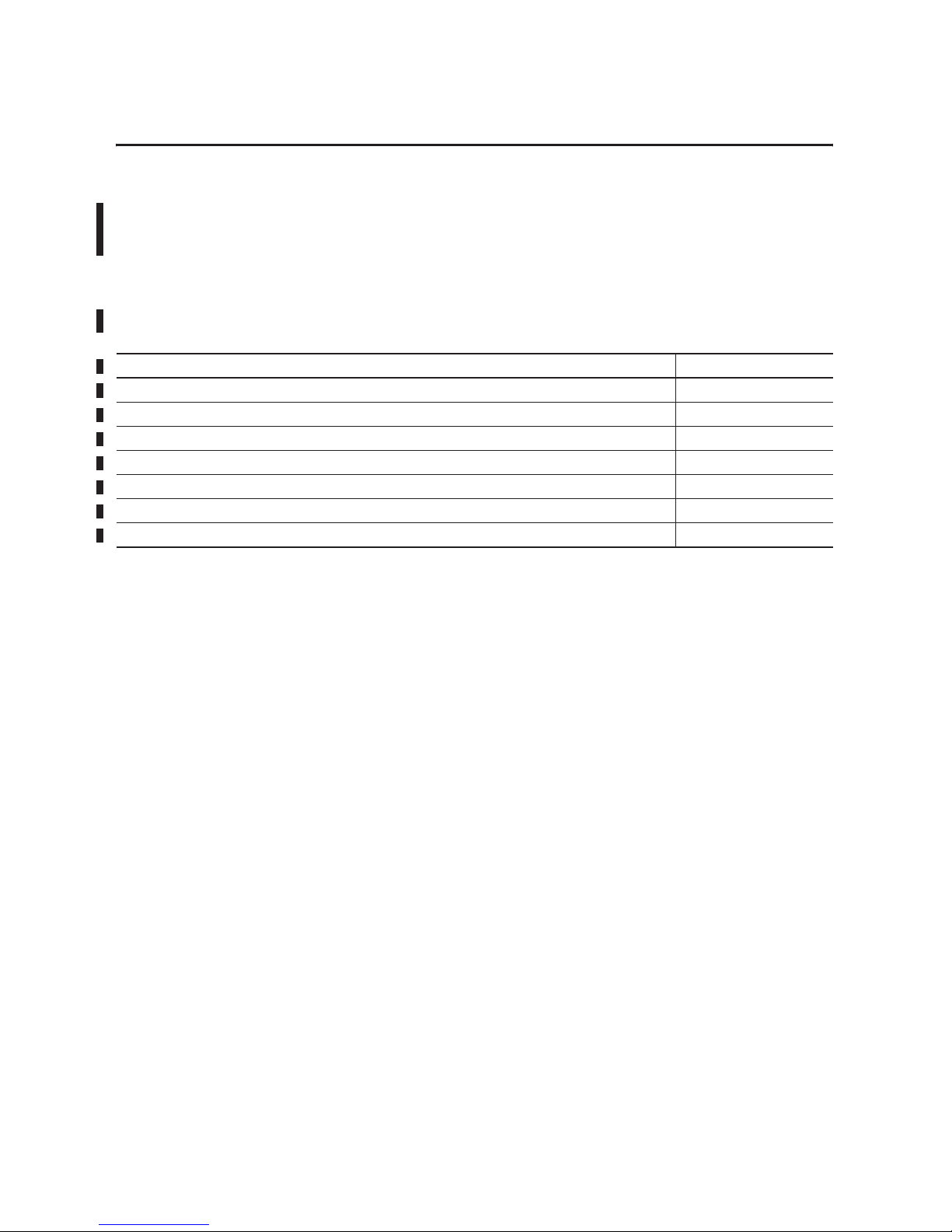

Summary of Changes

Introduction

This release of this document contains new and updated information.

To find new and updated information, look for change bars, as shown

next to this paragraph.

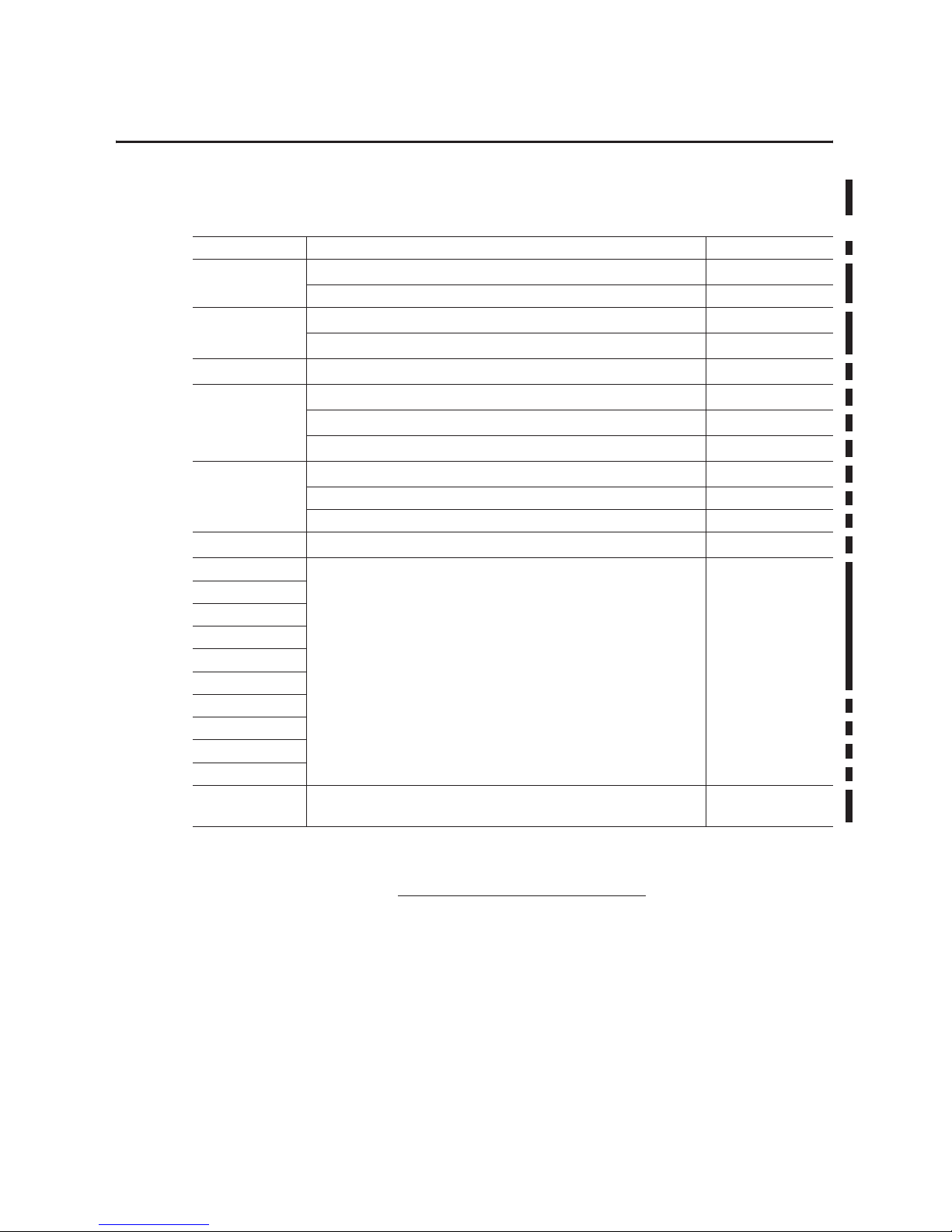

Updated Information

The document contains these changes.

Topic Page

Series E information for 1756-CNB and -CNBR modules Throughout manual

Redundant System Firmware Combinations 14

Revised Procedure for Setting the Minimum Value for the Watchdog Time 100

Restrictions and Known Anomalies Appendix E

Update an Online Redundant System 138

Store a Project to Nonvolatile Memory While Process Is Running 128

Change CNB Modules from Series D to Series E While Online 129

Page 4

Publication 1756-UM523F-EN-P - December 2006

Summary of Changes 4

Notes:

Page 5

5 Publication 1756-UM523F-EN-P - December 2006

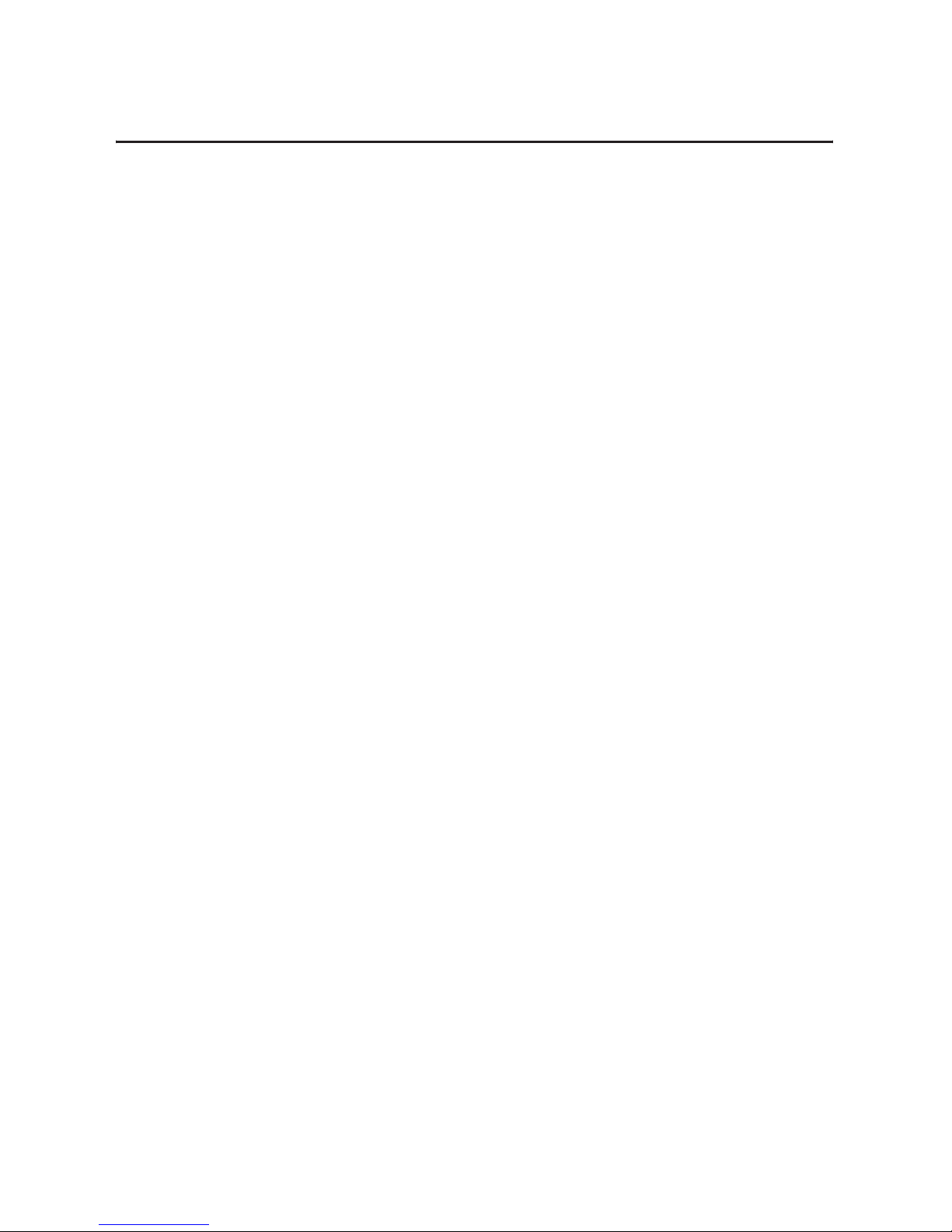

Table of Contents

Preface

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Who Should Use this Manual. . . . . . . . . . . . . . . . . . . . . . . . 11

When to Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . 11

How to Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

ControlLogix Redundancy System

Overview

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

About the Main Parts of a Redundant System . . . . . . . . . . . . 14

Firmware Combinations That Make Up a Redundant System . 14

Important Terms in a Redundant System . . . . . . . . . . . . . . . 15

Primary Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Switching from One Controller to Another . . . . . . . . . . . . . . 15

Network Access Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Bump in Outputs During a Switchover. . . . . . . . . . . . . . . . . 16

Keep the Second Controller Up to Date . . . . . . . . . . . . . . . . 16

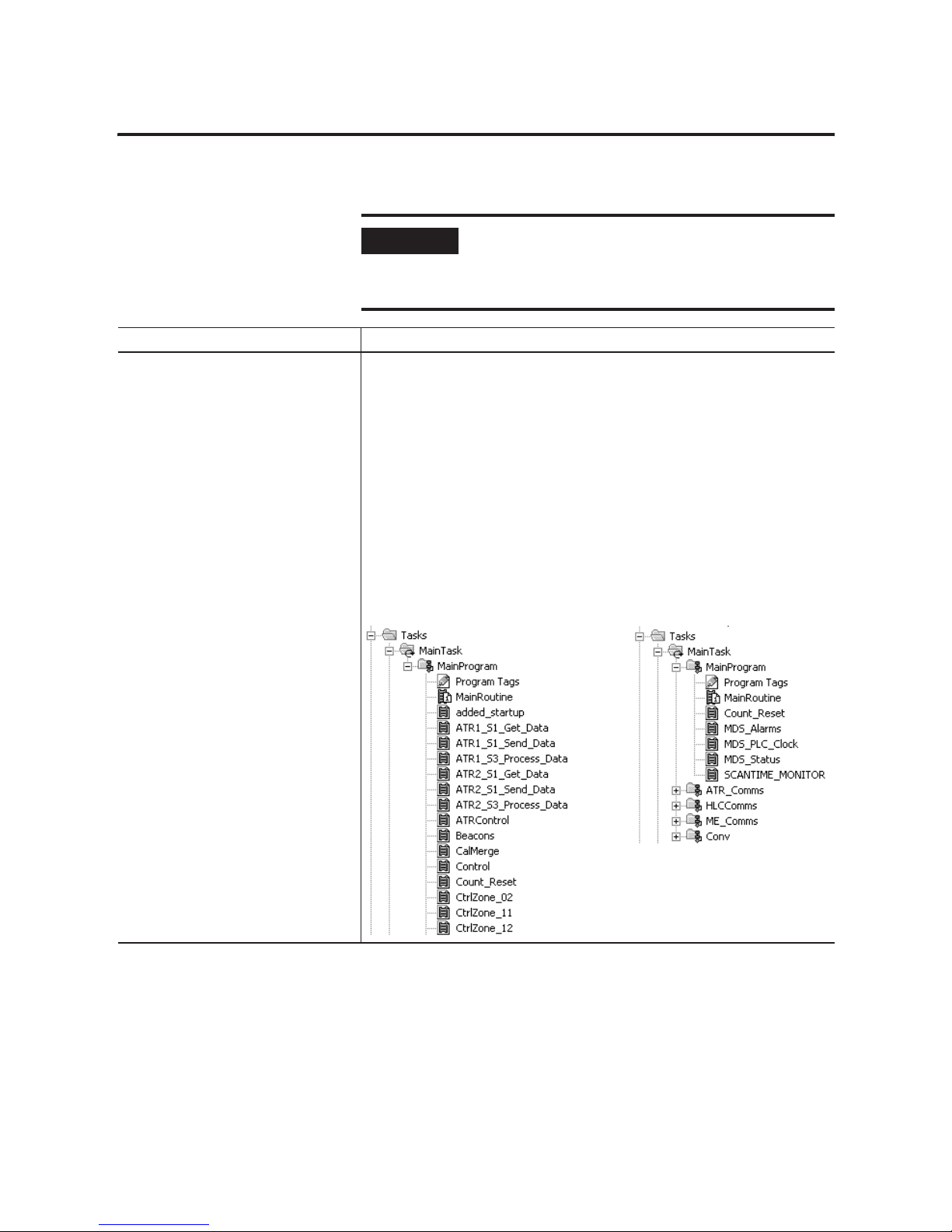

Making Online Edits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Increasing Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Network Addresses During a Switchover . . . . . . . . . . . . . . . 18

ControlNet Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Quick Start Checklists . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 2

Design the System

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Laying Out the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Placement of a Pair of Redundant Chassis . . . . . . . . . . . . . . 30

If You Need More Than 100 Meters Between Chassis . . . 30

Placement of the I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Placement of Operator Interface Terminals. . . . . . . . . . . . . . 32

Additional Redundant Components . . . . . . . . . . . . . . . . . . . 33

Redundant ControlNet Media . . . . . . . . . . . . . . . . . . . . . 33

Redundant Power Supplies. . . . . . . . . . . . . . . . . . . . . . . 34

Checking Connection Requirements. . . . . . . . . . . . . . . . . . . 35

Planning a ControlNet Network . . . . . . . . . . . . . . . . . . . . . . 35

Planning an EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . 38

Worksheet for IP Swapping . . . . . . . . . . . . . . . . . . . . . . 39

How an EtherNet/IP Module Handles a Cable Break . . . . 40

Additional Design Considerations . . . . . . . . . . . . . . . . . . . . 41

Chapter 3

Install the System

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Preliminary Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Install the Chassis for the Controllers . . . . . . . . . . . . . . . . . . 45

Install Modules in the First Redundant Chassis . . . . . . . . . . . 46

Install Modules in the Second Redundant Chassis . . . . . . . . . 48

Page 6

Publication 1756-UM523F-EN-P - December 2006

6 Table of Contents

Install the Remote Chassis or Rails . . . . . . . . . . . . . . . . . . . . 49

Configure EtherNet/IP Modules . . . . . . . . . . . . . . . . . . . . . . 50

Flash the Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Check the Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Chapter 4

Configure the System Redundancy

Module

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

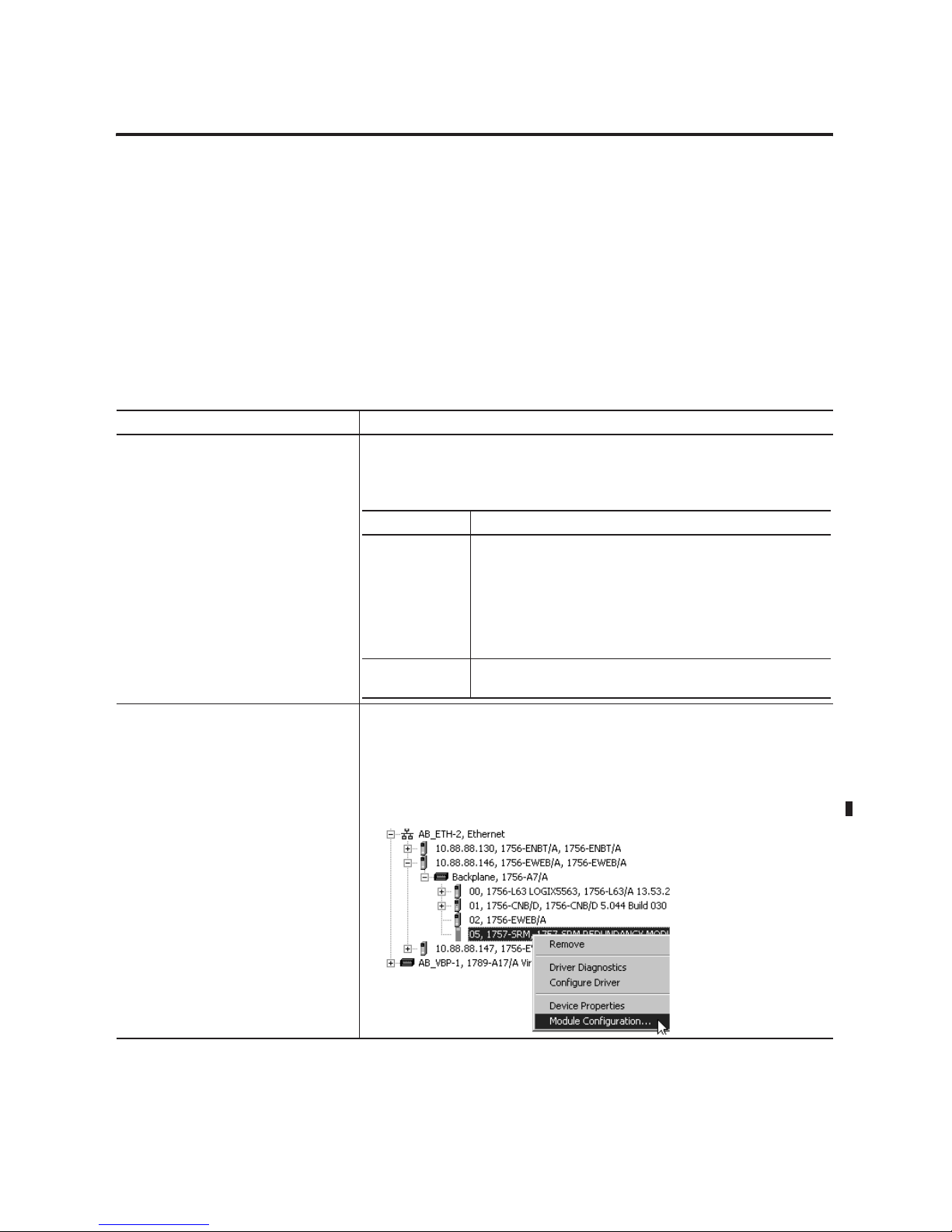

Open the SRM Configuration Tool . . . . . . . . . . . . . . . . . . . . 53

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

What to Do Next . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Check the Revision of Your SRM Configuration Tool . . . . . . 55

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Set the SRM Clock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

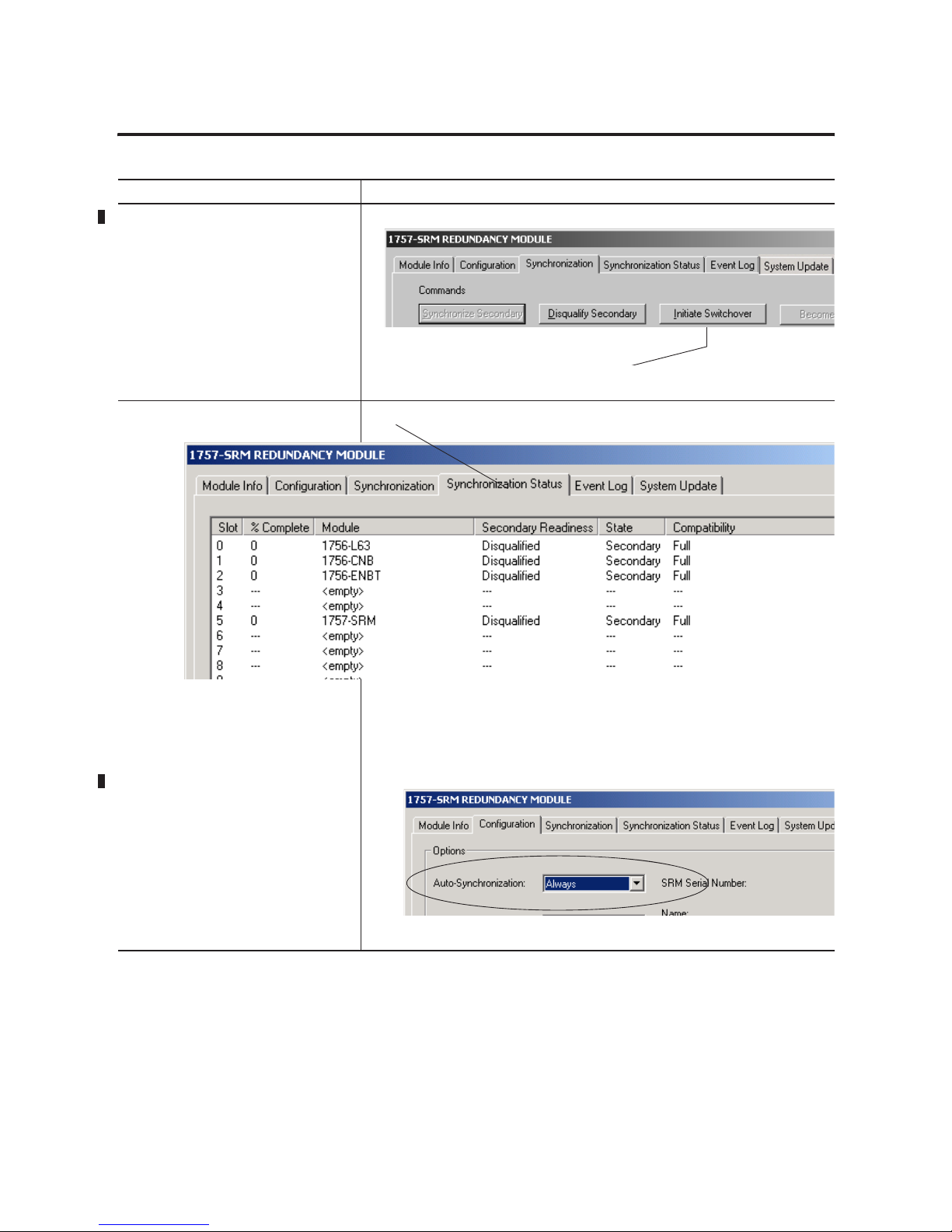

Test a Switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Change Auto-Synchronization . . . . . . . . . . . . . . . . . . . . . . . 61

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

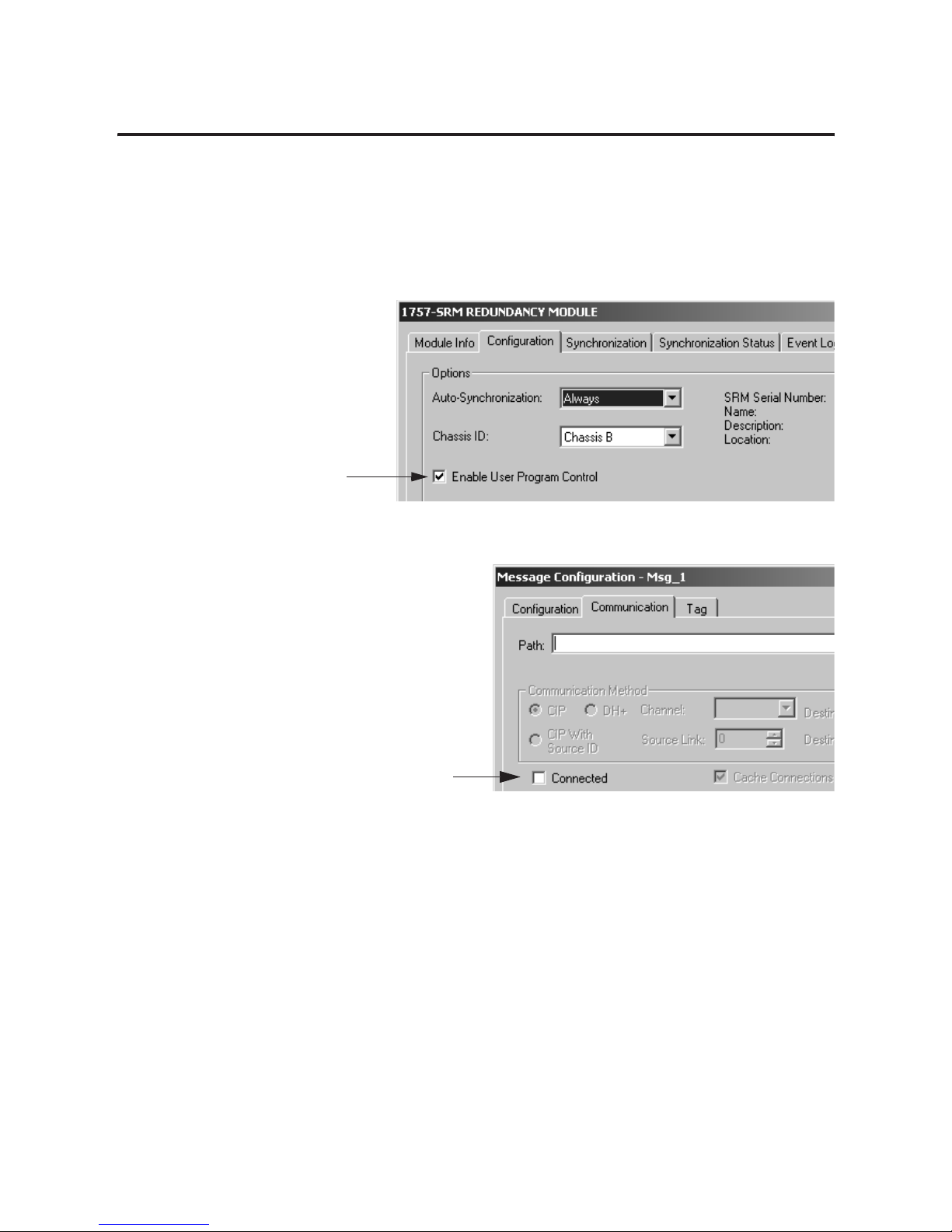

Change Program Control . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Chapter 5

Configure and Program the

Controller

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

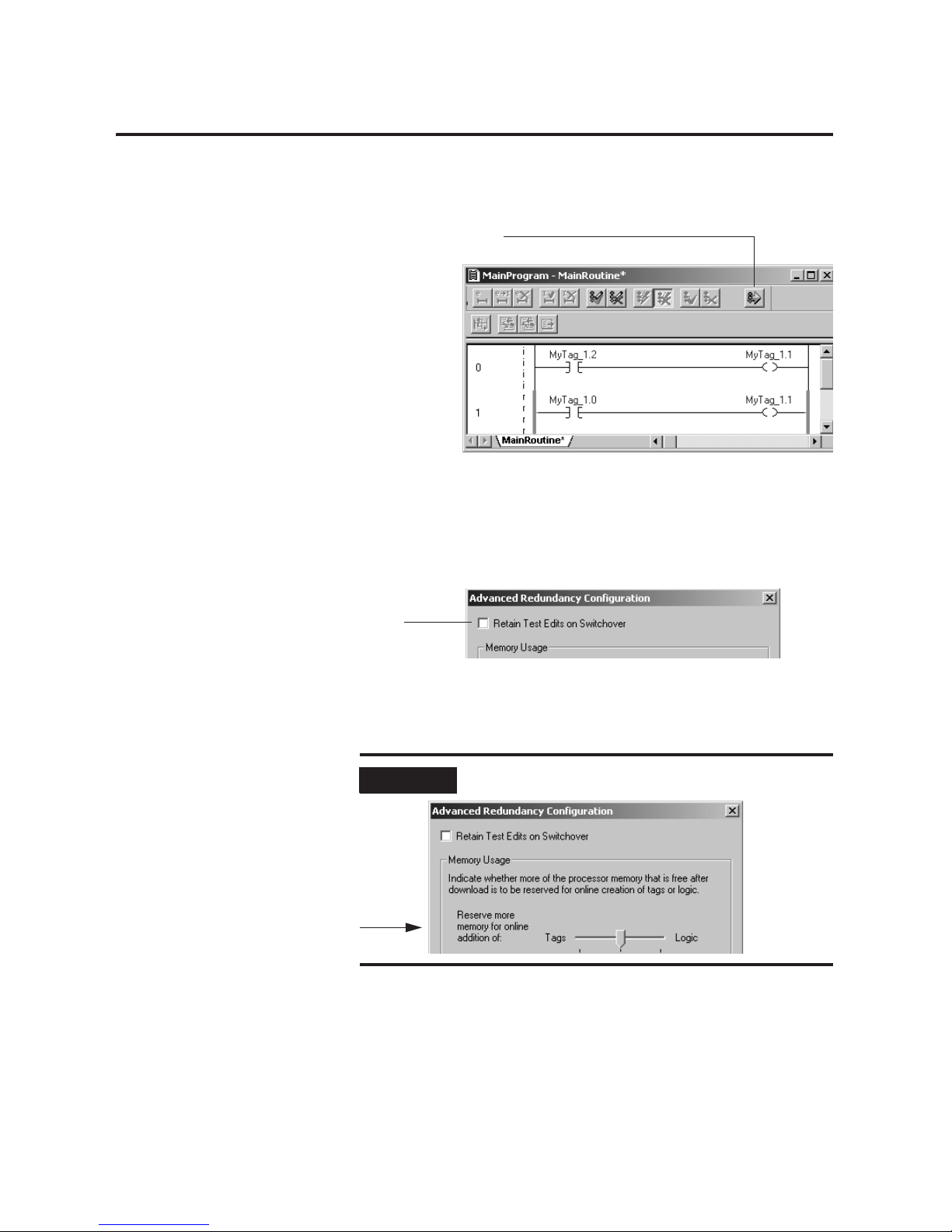

Plan for Online Edits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Decide if You Want to Keep Test Edits

after a Switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Be Aware That Finalizing Edits Removes Your

Original Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Decide How You Want to Set Aside Unused Memory . . . 67

Configure a Controller for Redundancy . . . . . . . . . . . . . . . . 68

Configure Communications . . . . . . . . . . . . . . . . . . . . . . . . . 70

Configure Produced Tags . . . . . . . . . . . . . . . . . . . . . . . 70

Configure Message (MSG) Instructions . . . . . . . . . . . . . . 72

Configure Tags for an HMI. . . . . . . . . . . . . . . . . . . . . . . 73

Estimate the Crossload Time of a Program . . . . . . . . . . . . . . 74

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Minimize Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Page 7

Publication 1756-UM523F-EN-P - December 2006

Table of Contents 7

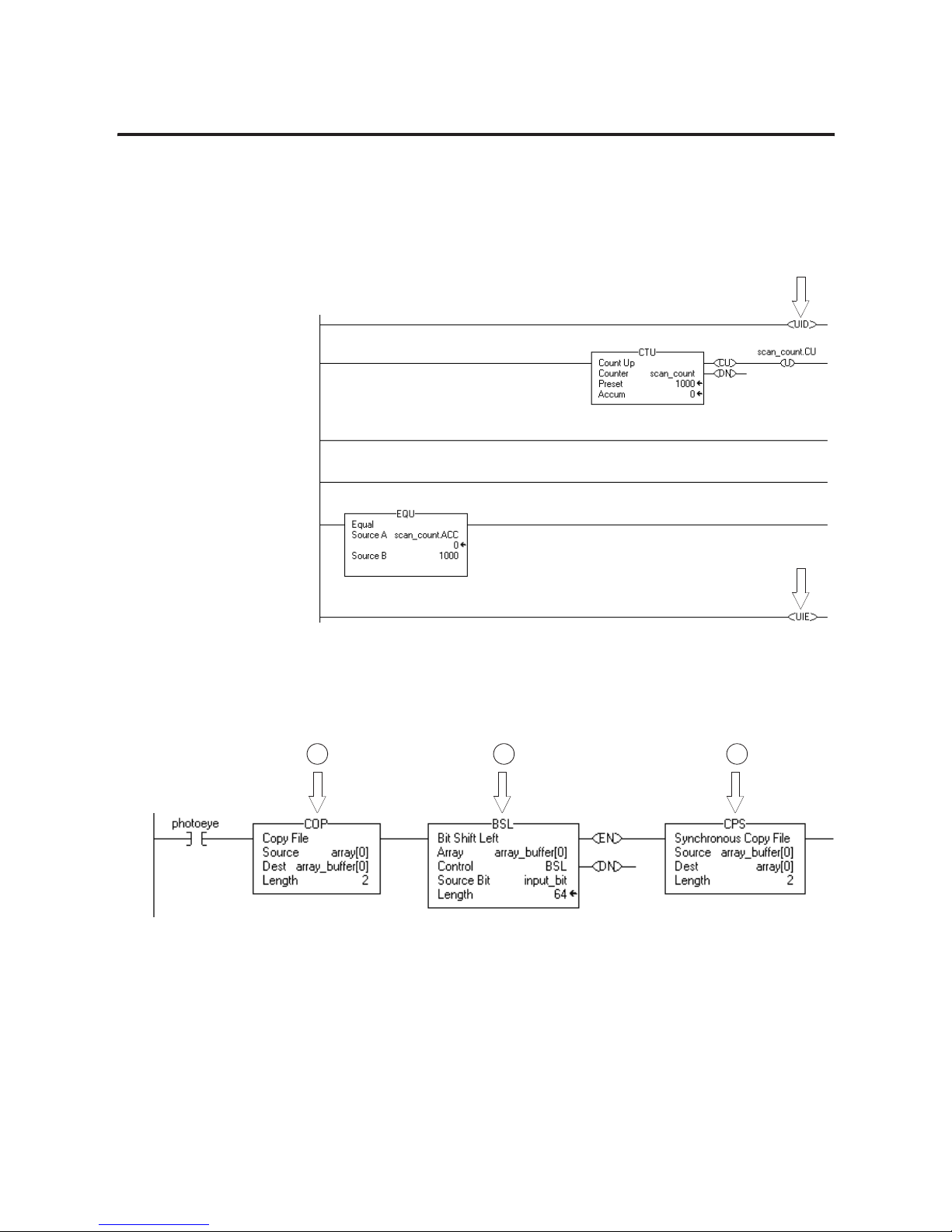

Maintain Data Integrity During a Switchover . . . . . . . . . . . . 82

Look for Array Shift Instructions . . . . . . . . . . . . . . . . . . . 84

Look for Scan-Dependent Logic . . . . . . . . . . . . . . . . . . . 84

Take Preventative Actions . . . . . . . . . . . . . . . . . . . . . . . 85

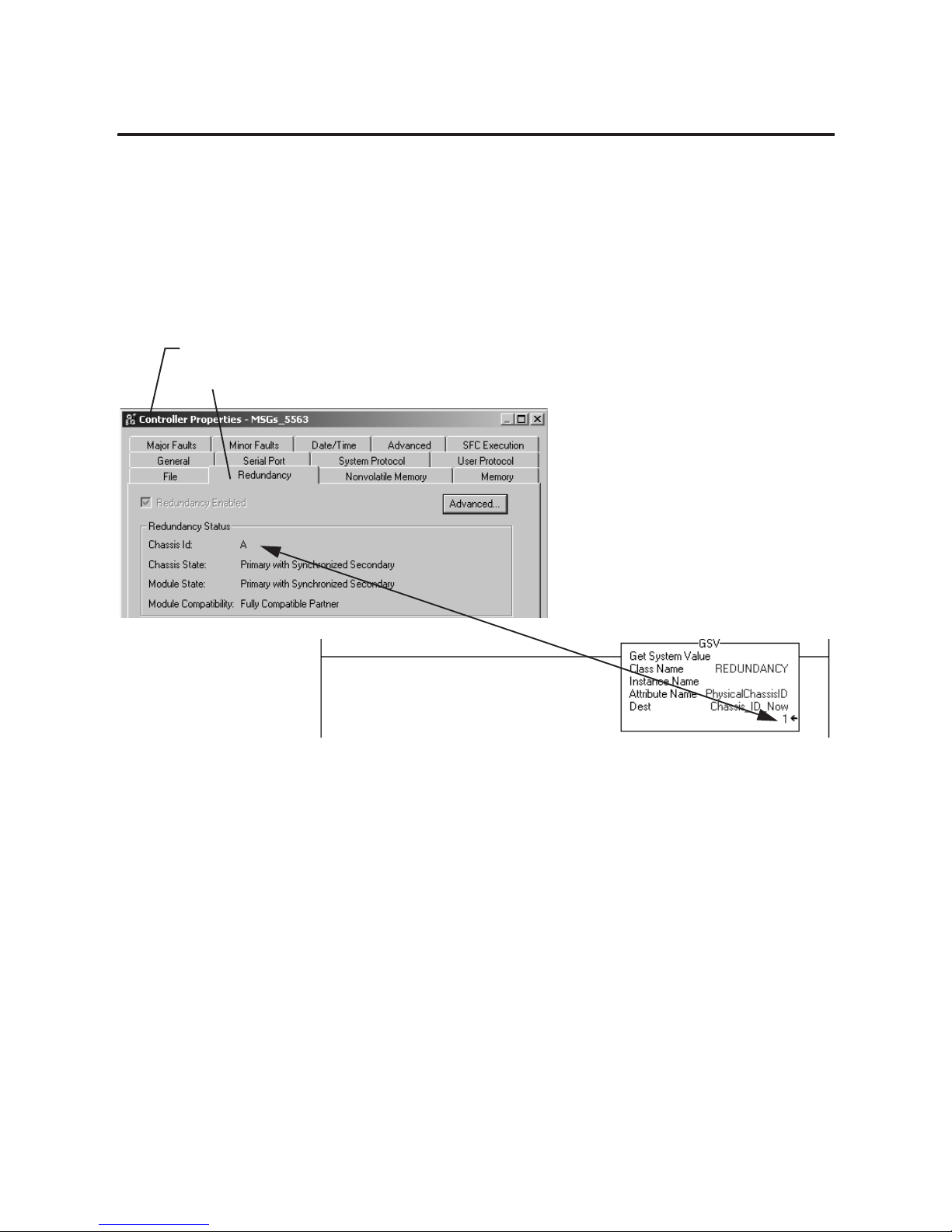

Determine the Status of Your Redundant System . . . . . . . . . 87

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

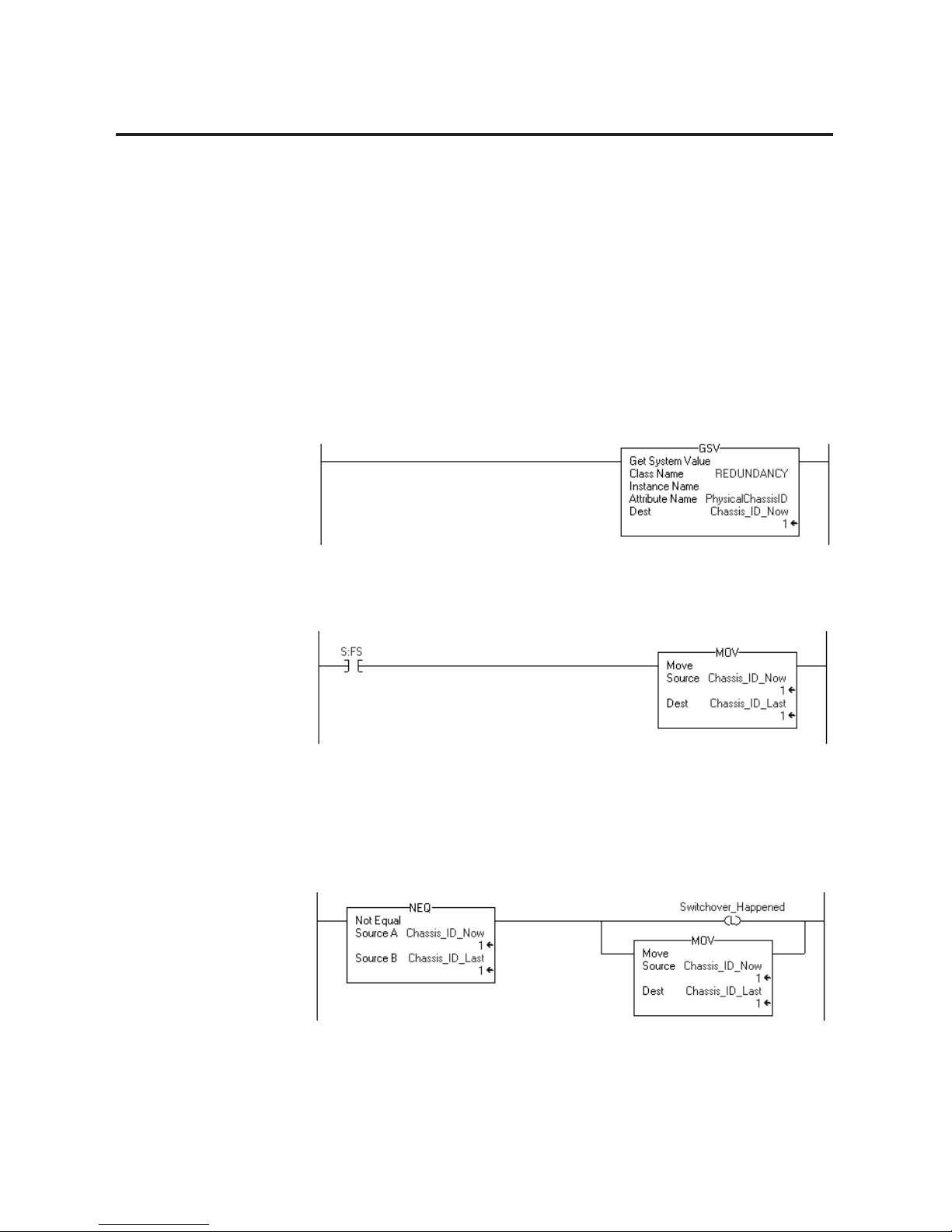

Example 1: Ladder Diagram . . . . . . . . . . . . . . . . . . . . . . 87

Example 2: Structured Text. . . . . . . . . . . . . . . . . . . . . . . 87

Check Your Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Condition Logic to Run After a Switchover . . . . . . . . . . . . . . 89

Example 1: Ladder Diagram . . . . . . . . . . . . . . . . . . . . . . 89

Example 2: Structured Text. . . . . . . . . . . . . . . . . . . . . . . 90

Send a Message to the SRM . . . . . . . . . . . . . . . . . . . . . . . . . 91

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Download the Project to the Primary Controller . . . . . . . . . . 95

Schedule a ControlNet Network. . . . . . . . . . . . . . . . . . . . . . 97

Schedule a New Network. . . . . . . . . . . . . . . . . . . . . . . . 97

Update the Schedule of an Existing Network. . . . . . . . . . 98

Check the Keepers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Save the Project for Each Controller . . . . . . . . . . . . . . . . 99

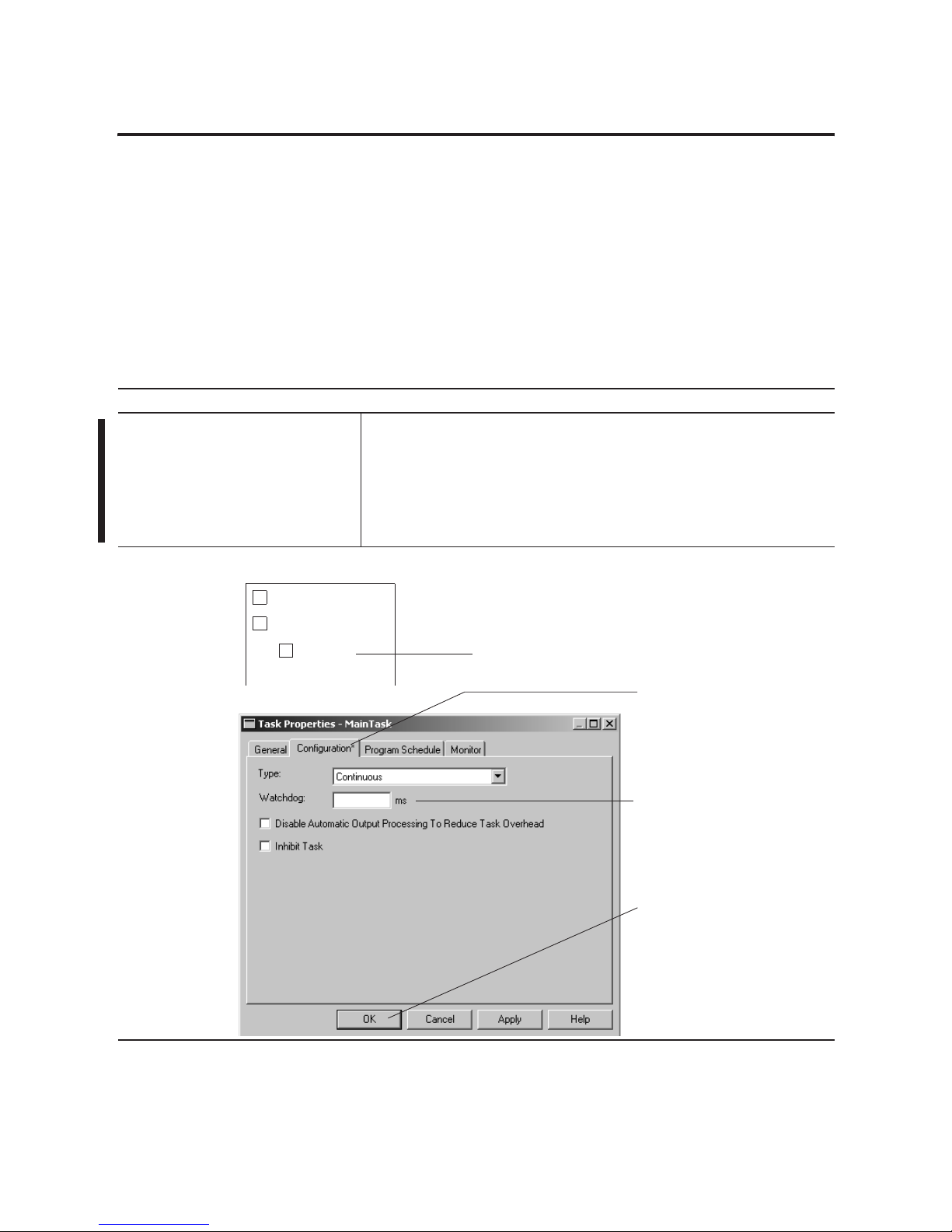

Set Task Watchdog Times . . . . . . . . . . . . . . . . . . . . . . . . . 100

Chapter 6

Maintain and Troubleshoot the

System

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Diagnose a Switchover or Disqualification . . . . . . . . . . . . . 104

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Troubleshoot a Failure to Synchronize . . . . . . . . . . . . . . . . 105

Update a Keeper Signature . . . . . . . . . . . . . . . . . . . . . . . . 107

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Edit Sessions in Progress . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Interpret the SRM Event Log . . . . . . . . . . . . . . . . . . . . . . . 109

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Interpret SRM events . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Export the SRM Event Log . . . . . . . . . . . . . . . . . . . . . . . . . 115

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Manually Synchronize the Chassis . . . . . . . . . . . . . . . . . . . 118

Optimize Communication . . . . . . . . . . . . . . . . . . . . . . . . . 119

Choose a Greater System Overhead Time Slice . . . . . . . 120

Enter a System Overhead Time Slice. . . . . . . . . . . . . . . 121

Make All Your Tasks Periodic. . . . . . . . . . . . . . . . . . . . 122

Page 8

Publication 1756-UM523F-EN-P - December 2006

8 Table of Contents

Check the Allocation of Unused Memory . . . . . . . . . . . . . . 123

Adjust CPU Usage for a CNB Module . . . . . . . . . . . . . . . . . 123

Use RSLinx Software . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Four-Character Display. . . . . . . . . . . . . . . . . . . . . . . . . 124

Send a Message to the CNB Module . . . . . . . . . . . . . . . 126

Store or Load a Project Using Nonvolatile Memory . . . . . . . 126

Store a Project to Nonvolatile Memory

While a Process Is Running . . . . . . . . . . . . . . . . . . . . . . . . 128

Chapter 7

Update Modules and Redundant

Systems

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Change CNB Modules from Series D to

Series E While Online . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Update a Redundant Control System Offline. . . . . . . . . . . . 136

Update an Online Redundant System . . . . . . . . . . . . . . . . 138

Redundant System Relationships. . . . . . . . . . . . . . . . . . 139

Appendix A

Set Up EtherNet/IP

Communication Across Subnets

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Keep an HMI Communicating with the Primary Chassis . . . 148

Install the ControlLogix Redundancy

Alias Topic Switcher Software. . . . . . . . . . . . . . . . . . . . 149

Configure a Driver to Communicate with the Primary and

Secondary EtherNet/IP Modules . . . . . . . . . . . . . . . . . . 150

Create a DDE/OPC Topic for Each Controller . . . . . . . . 151

Create an Alias Topic . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Set Up the Alias Topic Switcher . . . . . . . . . . . . . . . . . . 153

Address the Alias Topic in the HMI Project . . . . . . . . . . 154

Keep a Message Going to the Primary Chassis . . . . . . . . . . 154

Create a Periodic Trigger for the Messages . . . . . . . . . . 155

Get the Redundancy State of Chassis A . . . . . . . . . . . . 156

Get the Redundancy State of Chassis B . . . . . . . . . . . . . 157

Determine Which Chassis is Primary. . . . . . . . . . . . . . . 159

Send the Message to the Appropriate Controller . . . . . . 160

Appendix B

Convert an Existing System to

Redundancy

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Convert Local Modules to Remote Modules . . . . . . . . . . . . 163

Reconfigure the Local I/O Modules. . . . . . . . . . . . . . . . 164

Replace Local I/O Tags . . . . . . . . . . . . . . . . . . . . . . . . 164

Replace Any Aliases to Local I/O Tags . . . . . . . . . . . . . 166

Page 9

Publication 1756-UM523F-EN-P - December 2006

Table of Contents 9

Appendix C

Attributes of the Redundancy

Object

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

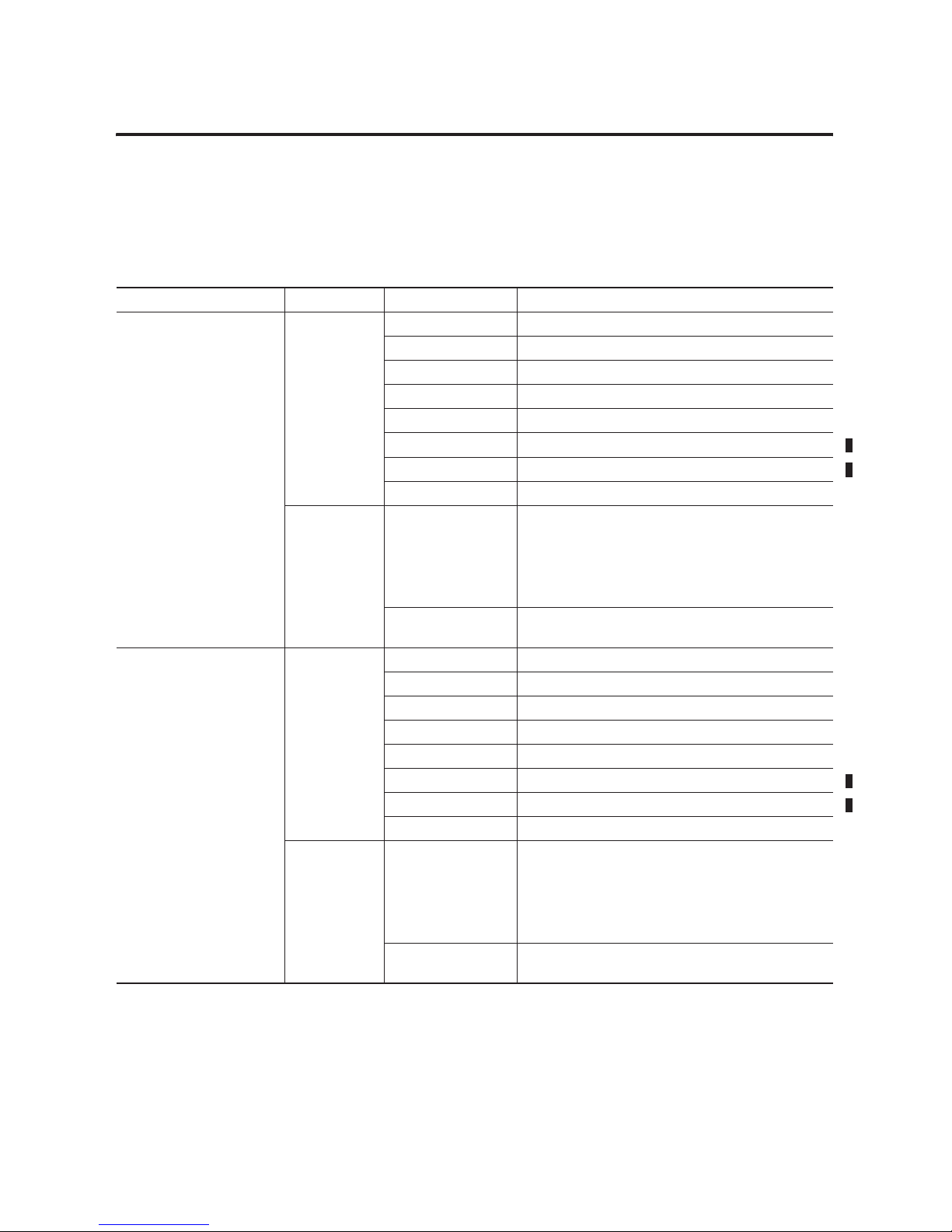

Attributes of the Redundancy Object . . . . . . . . . . . . . . . . . 169

Appendix D

Series B ControlNet Bridge

Modules

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Losing Communication while Bridging Via a

Series B ControlNet

Bridge Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Communication Stoppage While Using a Series B ControlNet

Bridge Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Appendix E

Redundant System Restrictions

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Redundant System Restrictions. . . . . . . . . . . . . . . . . . . . . . 177

Index

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . 186

Installation Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 186

New Product Satisfaction Return. . . . . . . . . . . . . . . . . . 186

Page 10

Publication 1756-UM523F-EN-P - December 2006

10 Table of Contents

Page 11

11 Publication 1756-UM523F-EN-P - December 2006

Preface

Purpose of this Manual

This manual guides the design, development, and implementation of a

redundancy system for a ControlLogix controller.

Who Should Use this

Manual

This manual is intended for those in these professions who design and

develop applications that use ControlLogix controllers:

• Software engineers

• Control engineers

• Application engineers

• Instrumentation technicians

When to Use This Manual

Use this manual throughout the lifecycle of a redundancy system. The

lifecycle consists of these stages:

• Design

• Installation

• Configuration

• Programming

• Testing

• Maintenance and troubleshooting

How to Use this Manual

This manual is divided into the basic tasks performed during the

design, development, and implementation of a ControlLogix

redundancy system.

• Each chapter covers a task.

• Tasks are organized in the sequence you will typically perform

them.

Page 12

Publication 1756-UM523F-EN-P - December 2006

Preface 12

Related Documentation

This table lists ControlLogix products and documentation that may be

valuable as in programming an application.

To view or download these publications, go to:

http://literature.rockwellautomation.com

To obtain a hard copy, contact your Rockwell Automation distributor

or sales representative.

Catalog Number Title Publication Number

1756-CNB/D and

1756-CNBR/D

ControlLogix ControlNet Bridge Module Installation Instructions 1756-IN571

ControlLogix ControlNet Interface Module Release Notes 1756-RN587

1756-CNB/E and

1756-CNBR/E

ControlLogix ControlNet Bridge Module, Series E Installation Instructions 1756-IN604

ControlLogix ControlNet Bridge Module, Series E Release Notes 1756-RN627

1756-ENBT/A 1756 10/100Mbps EtherNet/IP Bridge, Twisted Pair Media Release Notes 1756-RN602

1756-ENBT 1756-ENBT ControlLogix EtherNet/IP Product Profile 1756-PP004

ControlLogix EtherNet/IP Bridge Module Installation Instructions 1756-IN019

ControlLogix EtherNet/IP Communication Release Notes 1756-RN591

1756-EWEB 1756-EWEB EtherNet/IP Web Server Module Release Notes

1756-RN604

EtherNet/IP Web Server Module Installation Instructions 1756-IN588

EtherNet/IP Web Server Module User Manual ENET-UM527

1756-L55

ControlLogix Controller and Memory Board Installation Instructions 1756-IN101

1756-L61

ControlLogix Controller and Memory Board Installation Instructions

1756-IN101

1756-L62

1756-L63

1756-M12

1756-M13

1756-M14

1756-M16

1756-M22

1756-M23

1756-M24

1757-SRM/B ProcessLogix/ControlLogix System Redundancy Module Installation

Instructions

1757-IN092

Page 13

13 Publication 1756-UM523F-EN-P - December 2006

Chapter

1

ControlLogix Redundancy System Overview

Introduction

This chapter provides an overview of the ControlLogix redundancy

system, including commonly used terms. It also answers some

common questions about a ControlLogix redundancy system.

Topic Page

About the Main Parts of a Redundant System 14

Firmware Combinations That Make Up a Redundant System 14

Primary Chassis 15

Switching from One Controller to Another 15

Network Access Port 16

Bump in Outputs During a Switchover 16

Keep the Second Controller Up to Date 16

Making Online Edits 18

Increasing Scan Time 18

Network Addresses During a Switchover 18

Quick Start Checklists 21

Page 14

Publication 1756-UM523F-EN-P - December 2006

14 ControlLogix Redundancy System Overview

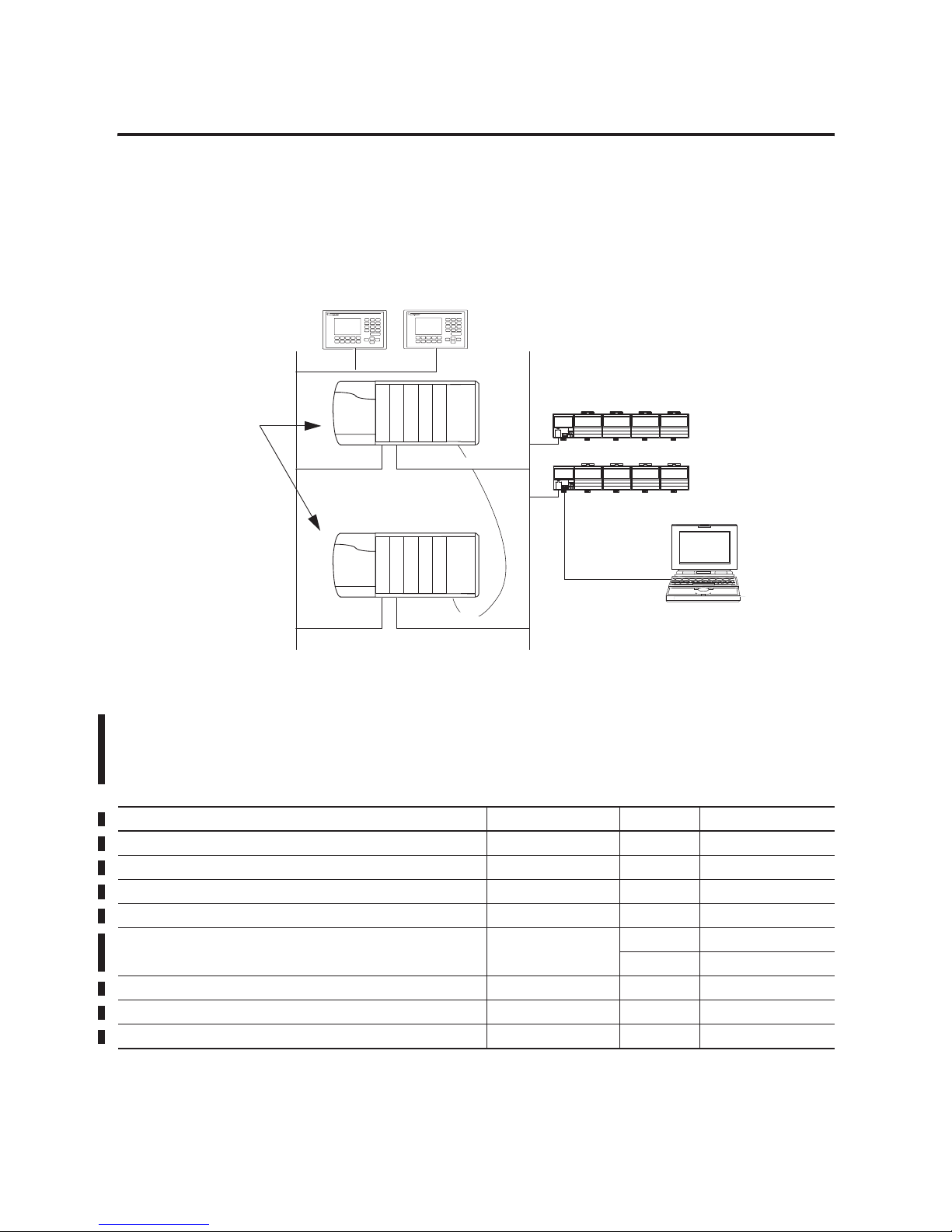

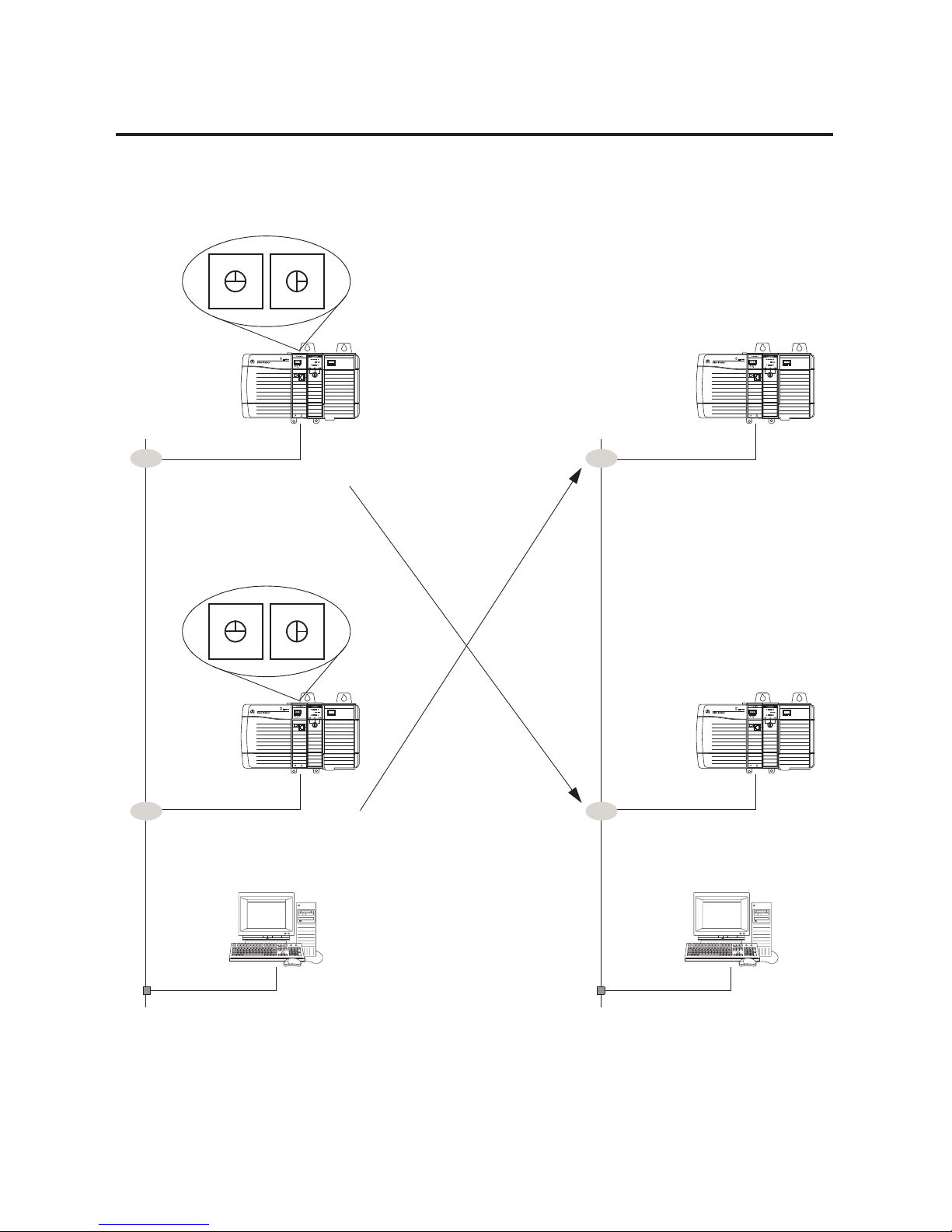

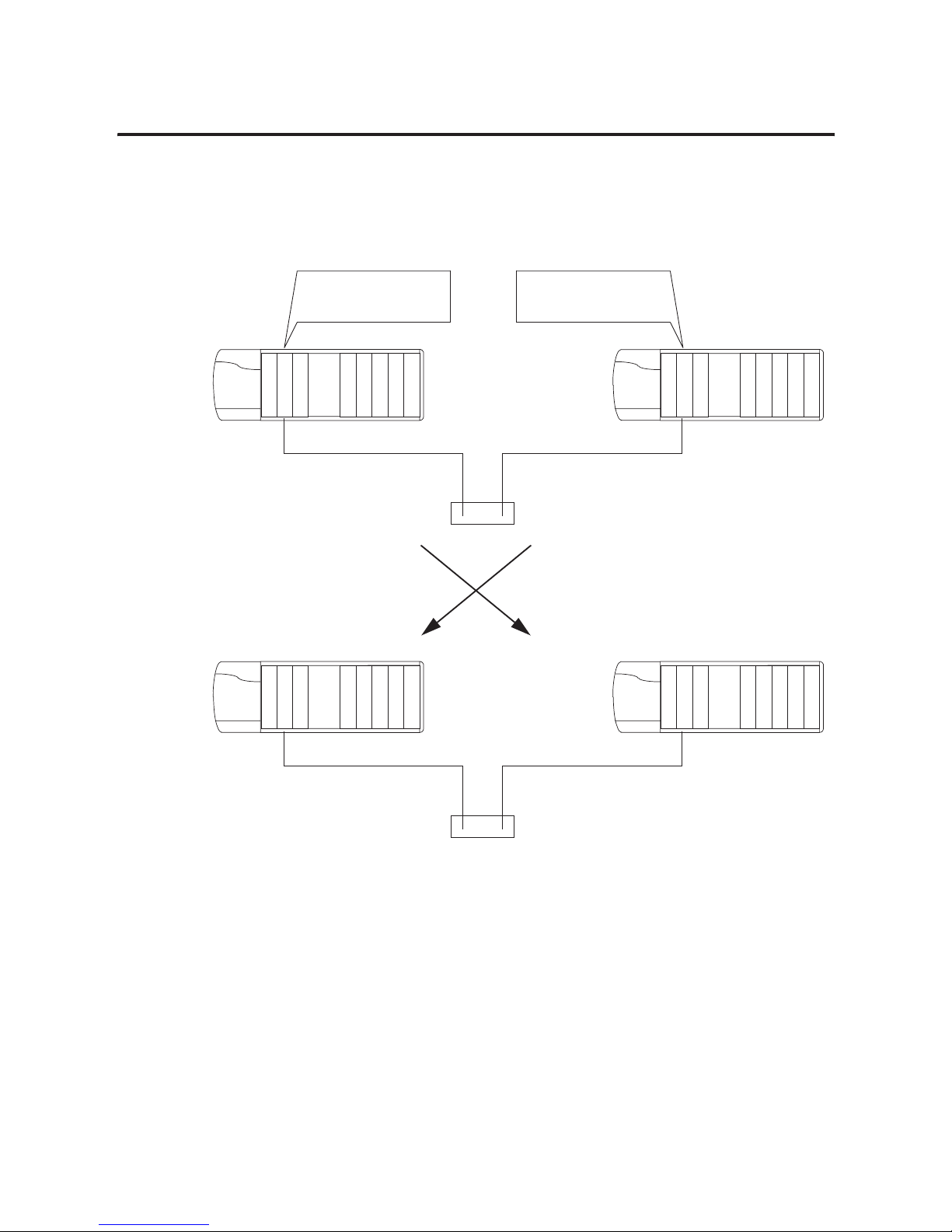

About the Main Parts of a

Redundant System

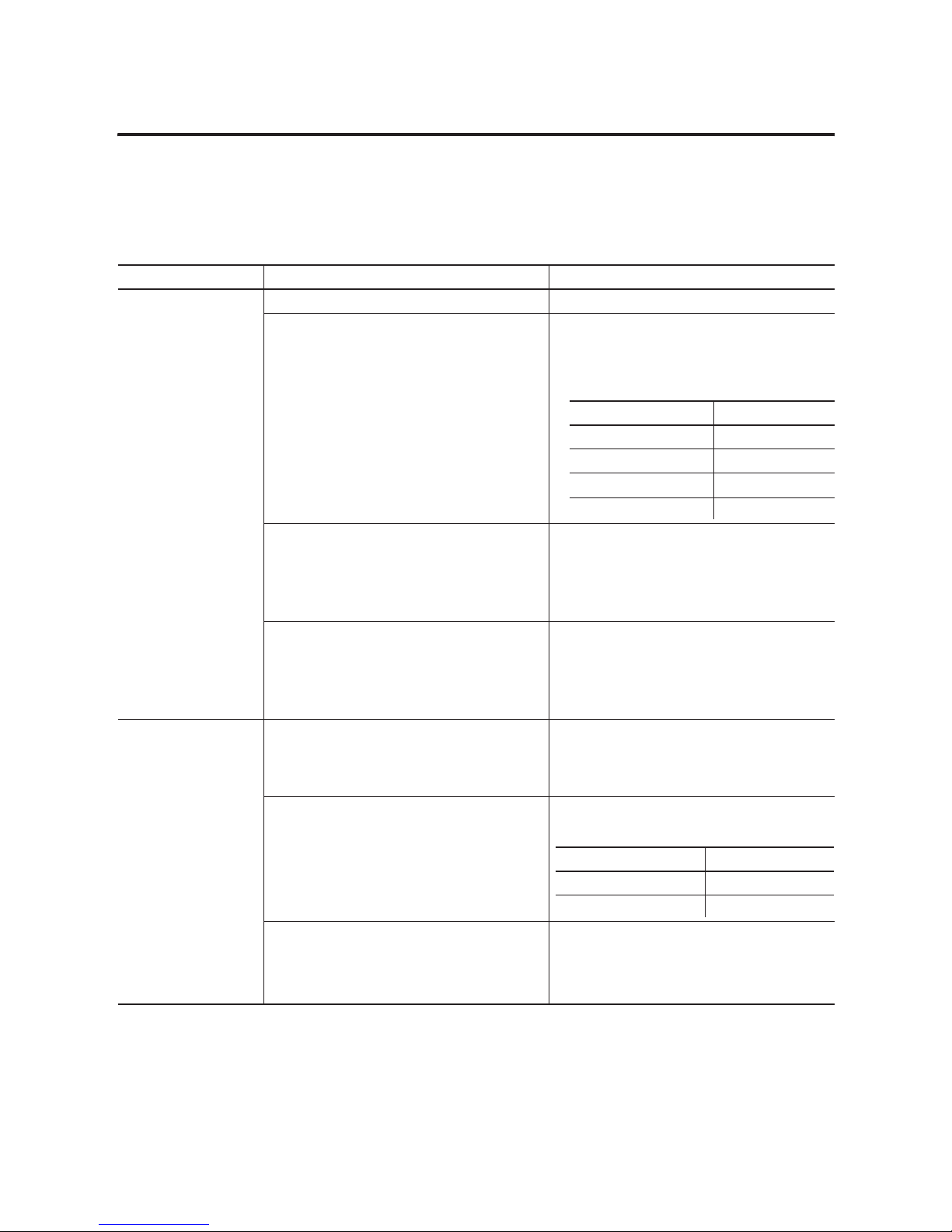

The ControlLogix redundancy system uses an identical pair of

ControlLogix chassis to keep a machine or process running if a

problem occurs with any hardware in one of the chassis.

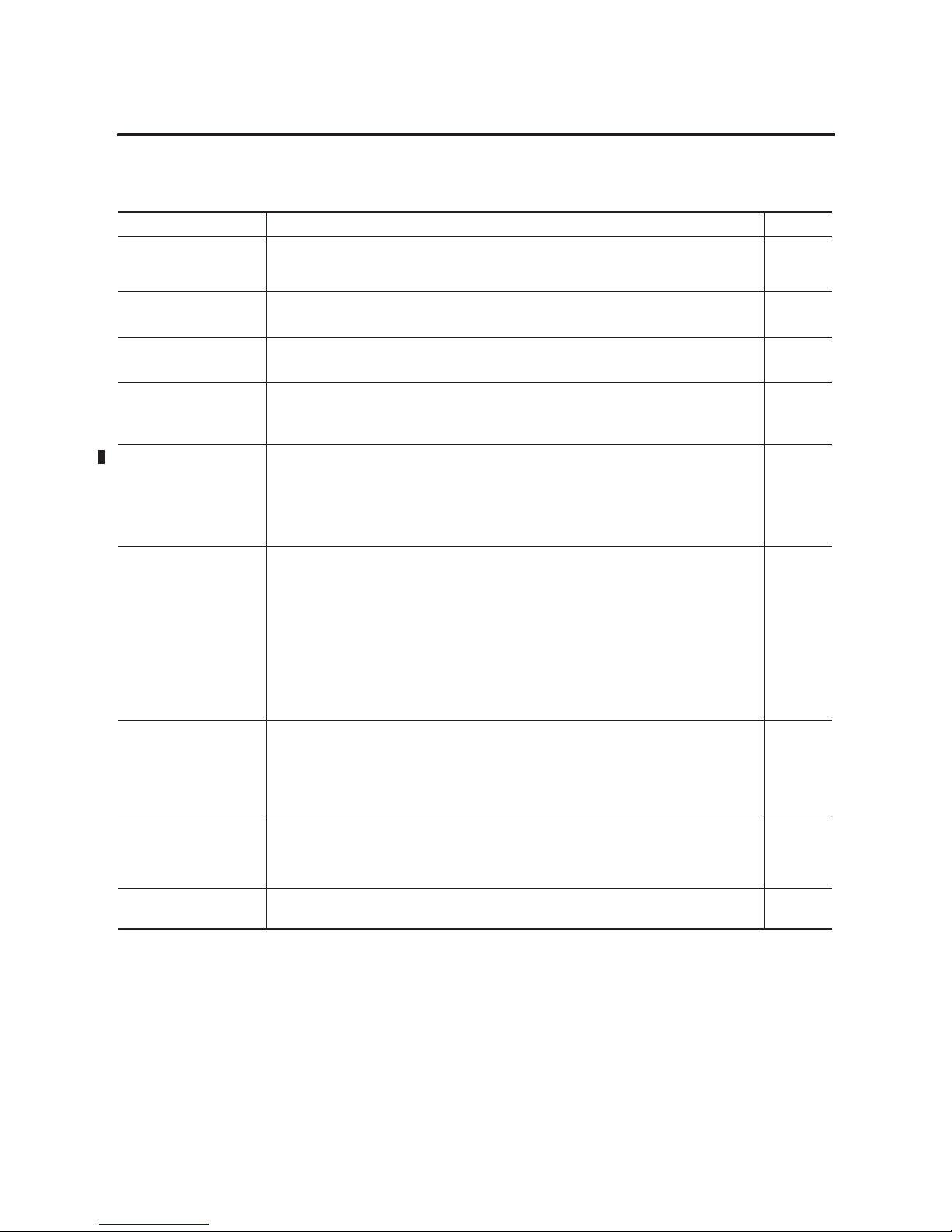

This diagram illustrates the layout of a simple redundant setup.

ControlLogix Redundant System

Firmware Combinations

That Make Up a Redundant

System

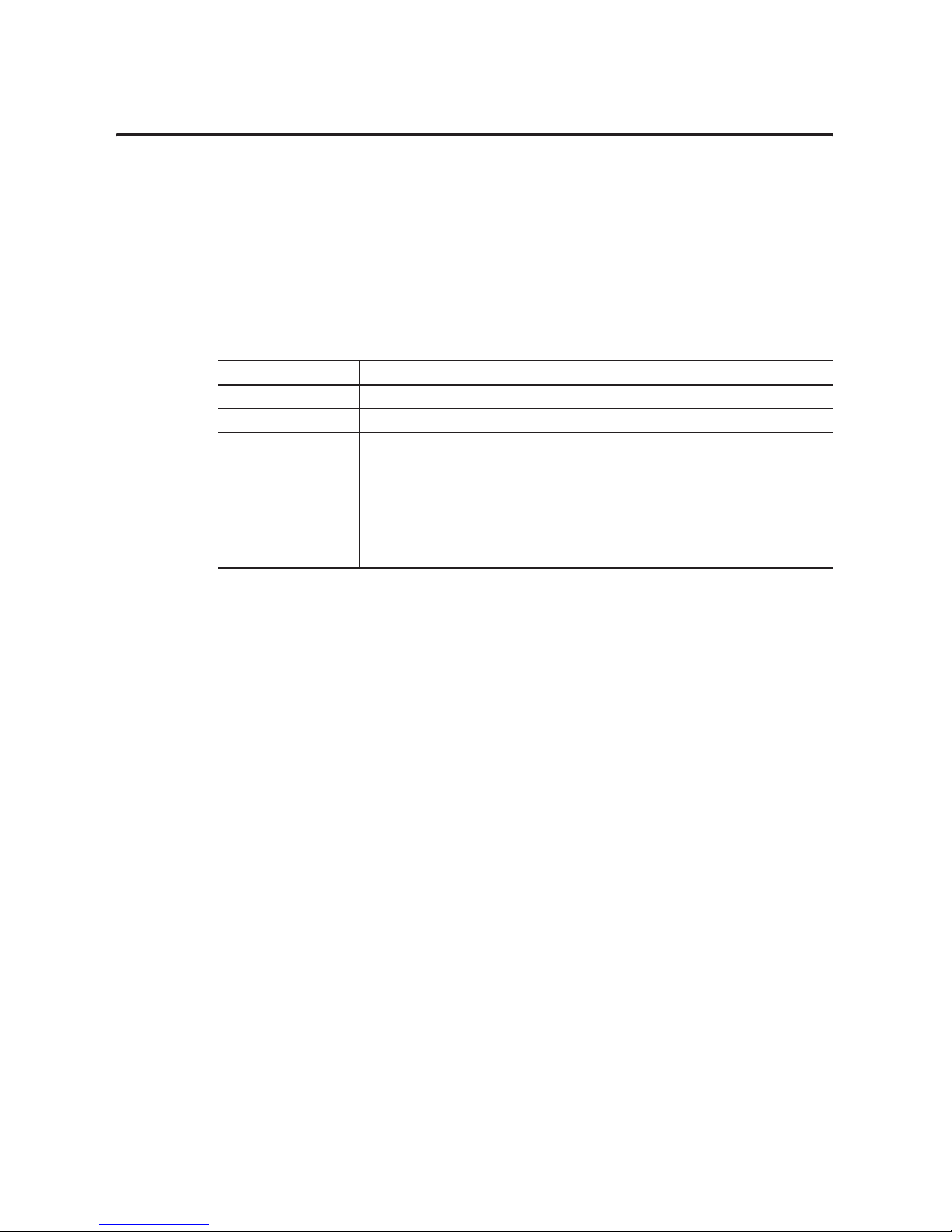

These firmware combinations make up revisions 15.56 and 15.57 of

the ControlLogix redundancy system.

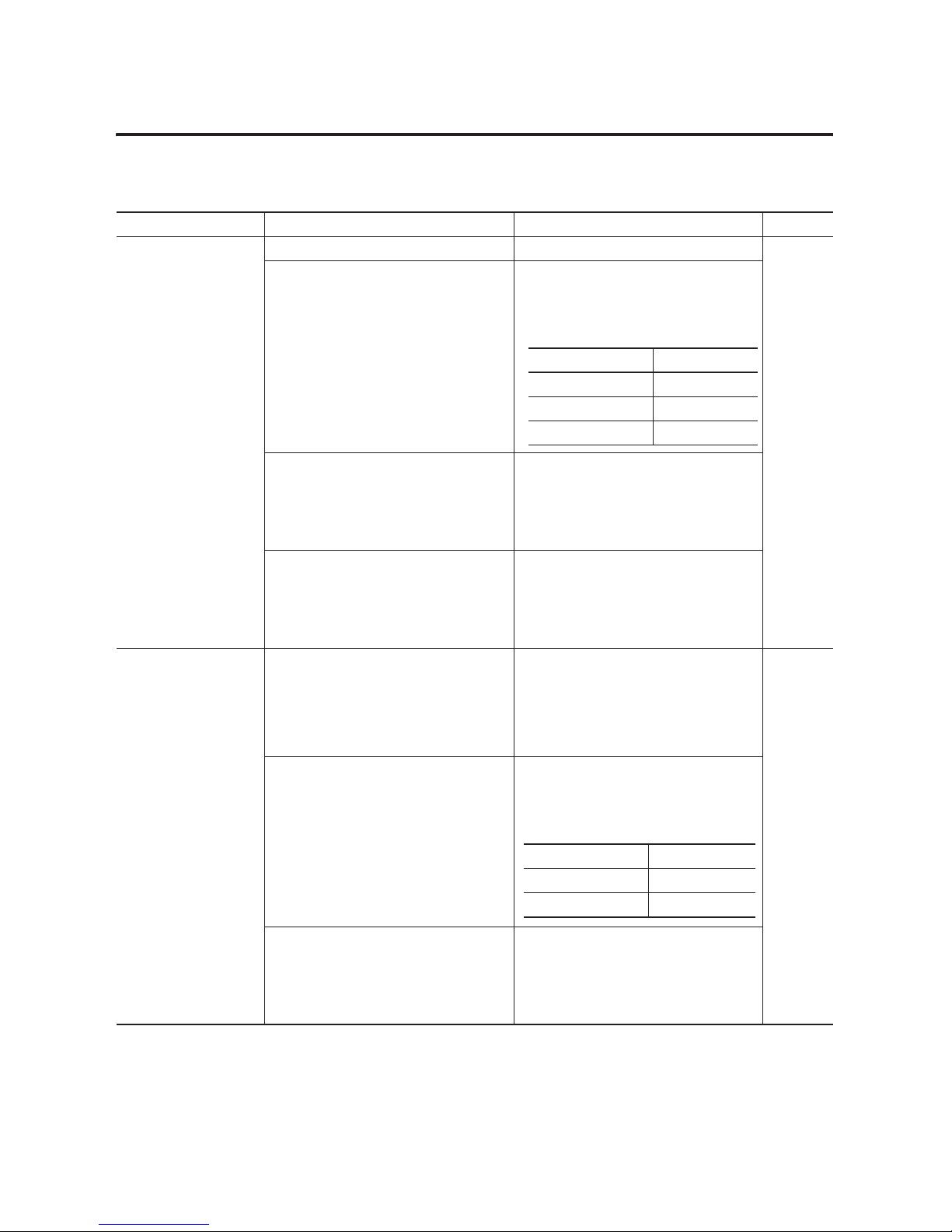

ControlLogix Redundancy Firmware Combinations

Identical Pair of

ControlLogix Chassis that

Controls a Machine or

Process

At Least 2 Other

ControlNet Nodes,

with Node Numbers

That are Lower Than

Those of the Two

1756-CNB Modules in

the Redundant Chassis

Network 2 - ControlNet Network for

I/O Communications

43128

Computer That is Connected to the

Network Access Port of a Remote Node

Network 1 -

EtherNet/IP Network or

ControlNet Network for HMI

Module Catalog Number Series Firmware Revision

ControlLogix5555 controller 1756-L55Mxx Any 15.57

ControlLogix5561 controller 1756-L61 Any 15.56

ControlLogix5562 controller 1756-L62 Any 15.56

ControlLogix5563 controller 1756-L63 Any 15.56

ControlNet bridge module 1756-CNB

1756-CNBR

D7.12

E 11.002

1756 10/100 Mbps EtherNet/IP Bridge, Twisted Pair Media 1756-ENBT Any 4.3

1756 10/100 Mbps EtherNet/IP Bridge w/ Enhanced Web Services 1756-EWEB Any 4.3

Redundancy module 1757-SRM Any 4.3

Page 15

Publication 1756-UM523F-EN-P - December 2006

ControlLogix Redundancy System Overview 15

Important Terms in a

Redundant System

Redundancy requires no additional programming and is transparent to

any devices connected over an EtherNet/IP or ControlNet network.

Redundancy uses 1757-SRM modules to maintain communication

between the pair of redundant chassis.

In a redundant system, these terms describe the relationship between

the two redundant chassis.

Redundancy Terms

Primary Chassis

In a pair of redundant chassis, the first chassis turned on becomes the

primary chassis. When the secondary chassis receives power, it

synchronizes itself with the primary chassis.

Switching from One

Controller to Another

When primary chassis components fail, control switches to the

secondary controller. A switchover occurs for any of these reasons:

• any of these situations in the primary chassis:

– loss of power

– major fault of the controller

– removal, insertion, or failure of any module in the primary

chassis

– break or disconnection of a ControlNet tap or ethernet cable

• command from the primary controller

• command from RSLinx software

Term Description

Primary Controller The controller that is currently controlling the machine or process.

Primary Chassis The chassis that contains the primary controller or controllers.

Secondary Controller The controller that is standing by to take control of the machine or process. A secondary

controller always resides in a different chassis than the primary controller.

Secondary Chassis The chassis that contains the secondary controller or controllers.

Switchover Transfer of control from the primary controller to the secondary controller. After a

switchover, the controller that takes control becomes the primary controller. Its partner

controller (the controller that was previously the primary controller) becomes the

secondary controller.

Page 16

Publication 1756-UM523F-EN-P - December 2006

16 ControlLogix Redundancy System Overview

Network Access Port

To connect a device to the network access port (NAP) of a

1756-CNB/D/E or 1756-CNBR/D/E module, use an NAP that is outside

of a redundant chassis.

Bump in Outputs During a

Switchover

Depending on how you organize your RSLogix 5000 project, outputs

may or may not experience a change in state (bump) during a

switchover.

• During the switchover, outputs controlled by the highest priority

task experience a bump-free switchover. For example, outputs

do not revert to a previous state.

• Outputs in lower priority tasks may experience a change of

state.

The switchover time of a redundant system depends on the type of

failure and the network update time (NUT) of the ControlNet network.

For a NUT of 10 ms, the switchover time is approximately 80...220 ms.

Keep the Second Controller

Up to Date

To take over control, the secondary controller requires the same

project as the primary controller. It also requires up-to-date tag values.

These terms describe the process of communication between the two

controllers.

IMPORTANT

Use of the Network Access Port (NAP)

Do not connect any device to the network access port (NAP) of

a 1756-CNB/D/E or -CNBR/D/E module in a redundant chassis.

• If you connect a device to the NAP of a CNB module in a

redundant chassis, a switchover will fail to occur if the

CNB module is disconnected from the network. While

the CNB module is disconnected from the network, the

controller will be unable to control any I/O devices

through that CNB module.

• If you connect a workstation to the NAP of a CNB

module in a redundant chassis, the workstation will be

unable to go online after a switchover.

To connect a device to a ControlNet network via a NAP, use a

NAP that is outside of a redundant chassis.

Page 17

Publication 1756-UM523F-EN-P - December 2006

ControlLogix Redundancy System Overview 17

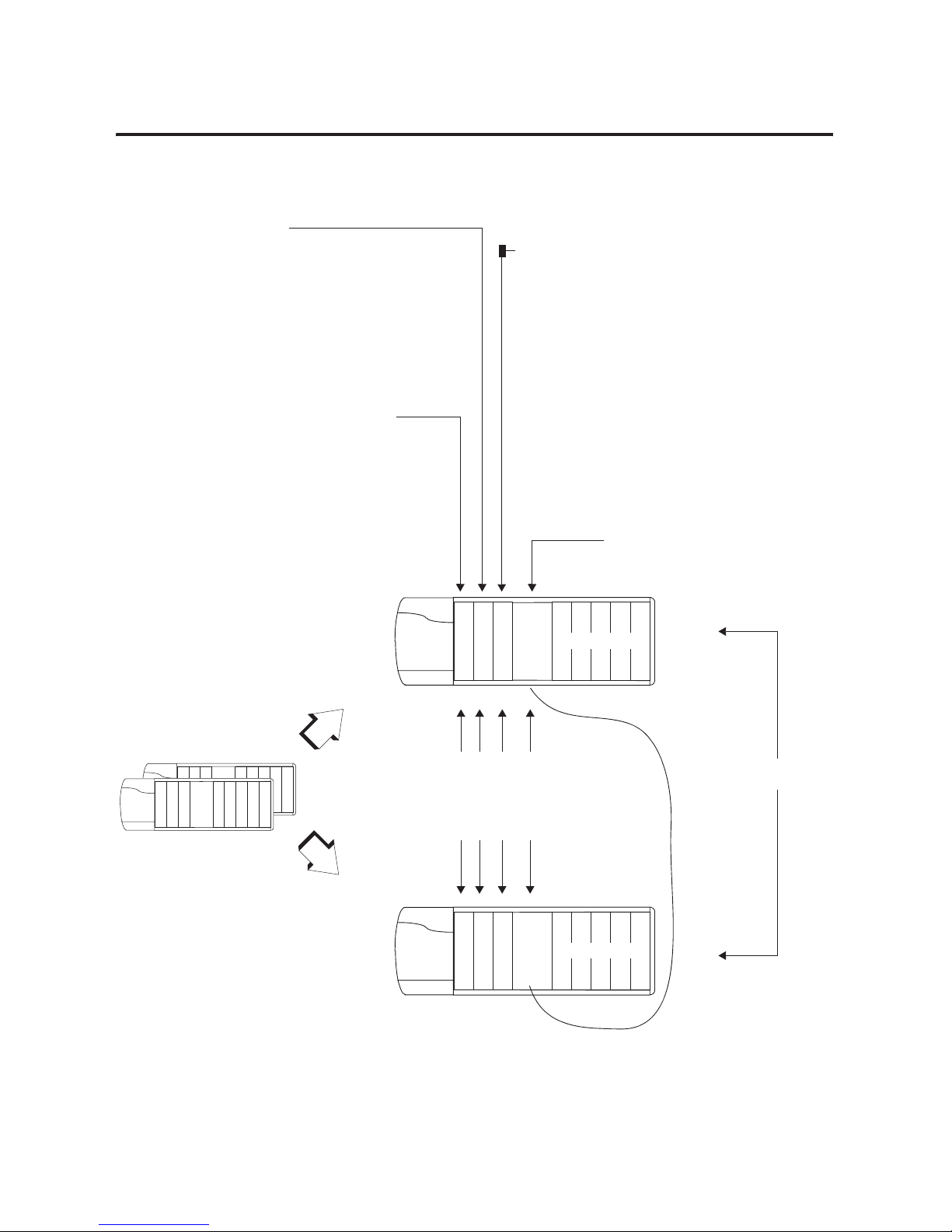

Controller Communication Terms

The 1757-SRM modules keep communication between the primary

and secondary chassis.

• Unless you are updating controller revisions, do not download

the project to the secondary controller. While the secondary

controller is synchronizing with the primary controller, the

1757-SRM modules automatically let the primary controller

transfer the project to the secondary controller.

• Once the secondary controller is synchronized, the 1757-SRM

modules keep the controller synchronized by providing the path

for crossloading any changes that occur in the primary

controller. These changes include:

– online edits.

– force values.

– changes to properties.

– changes to data.

– results of logic execution.

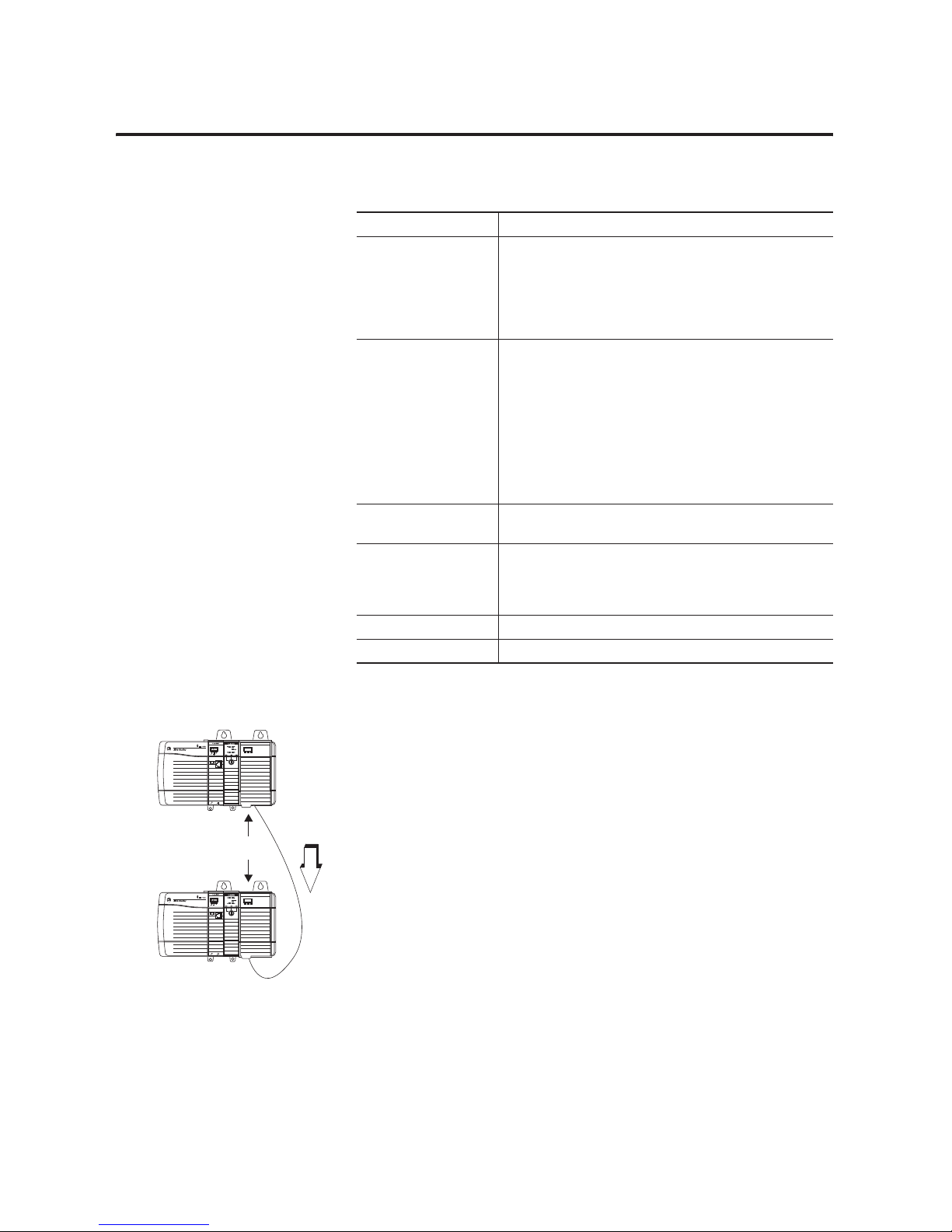

Term Description

Crossload The transfer of any or all of the contents of the primary

controller to the secondary controller. This could be updated

tag values, force values, online edits, or any other information

about the project. A crossload happens initially when the

chassis synchronize and then repeatedly as the primary

controller executes its logic.

Synchronize The process that readies a secondary chassis to take over

control if a failure occurs in the primary chassis. During

synchronization, the 1757-SRM modules check that the partner

modules in the redundant chassis pair are compatible with

each other. The SRM modules also provide the path for

crossloading (transferring) the content of the primary controller

to the secondary controller.

Synchronization occurs when power is applied to the secondary

chassis and after a switchover is diagnosed and fixed.

Synchronized The secondary chassis is ready to assume control if the primary

chassis fails.

Disqualified The secondary chassis is not synchronized with the primary

chassis. If a secondary chassis is disqualified, it cannot take

over control of the machine or process. A secondary chassis

can be manually disqualified.

Qualify Same as synchronize.

Qualified Same as synchronized.

1757-SRM Modules

Primary Chassis

43129

Secondary Chassis

Crossload

Page 18

Publication 1756-UM523F-EN-P - December 2006

18 ControlLogix Redundancy System Overview

Making Online Edits

Online edits automatically crossload to the secondary controller. They

become inactive if a switchover happens before you assemble them

into the project. This stops a mistake from faulting both the old and

new primary controllers.

Suppose you test an online edit and it causes the controller to fault. In

that case, a switchover happens. The new primary controller

automatically untests the edits and goes back to the original code.

You have the option to keep the edits active after a switchover (at the

risk of faulting both controllers).

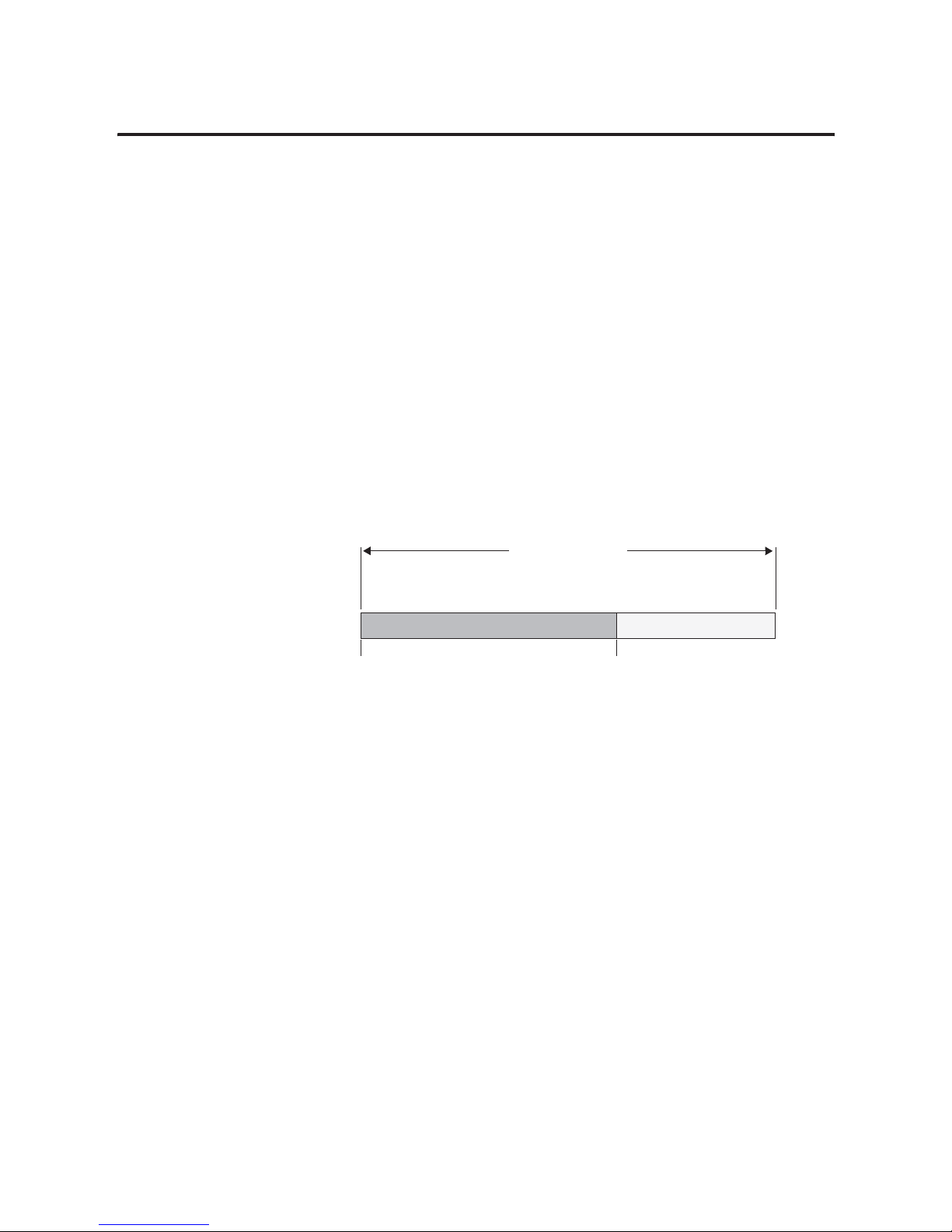

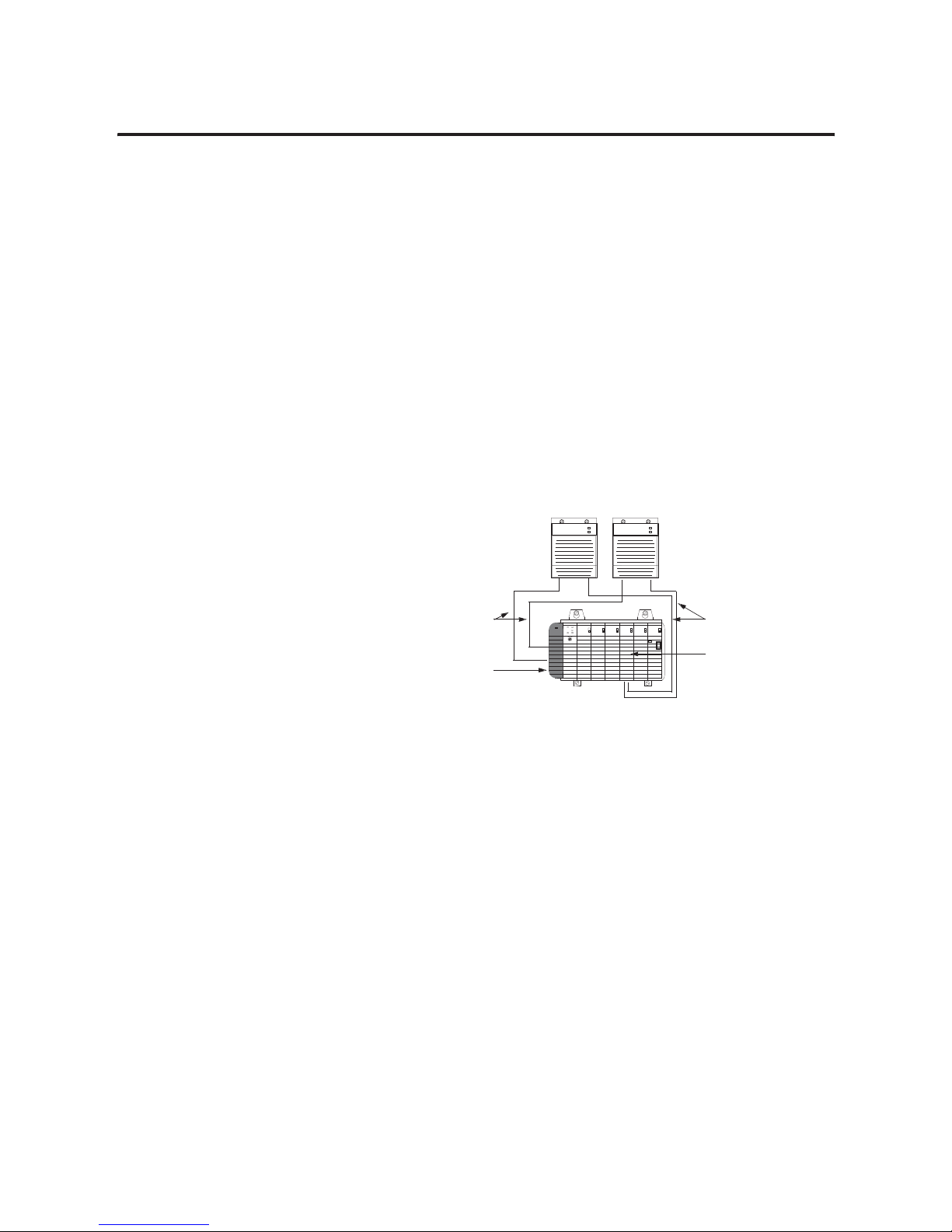

Increasing Scan Time

At the end of each program, the primary controller pauses its

execution to crossload the result of any output instruction that

executed in the program. This results in an increased program scan

time for a synchronized redundancy system.

Scan Time

Network Addresses During

a Switchover

Each CNB, ENBT, or EWEB module in a redundant chassis shares a

pair of network addresses with its partner in the other chassis.

Execute Program in

Primary Controller

Start of Program End of Program

Crossload Results to

Secondary Controller

Program Scan Time

Page 19

Publication 1756-UM523F-EN-P - December 2006

ControlLogix Redundancy System Overview 19

ControlNet Network

24

4

2

3

5

6

7

0

1

4

2

3

5

6

7

0

1

Workstations and HMIs continue to connect

to the same node number.

Secondary

Chassis

CNB modules in the primary chassis

use the node number to which they

are set.

4

2

3

5

6

7

0

1

4

2

3

5

6

7

0

1

CNB modules in the secondary chassis use the

node number to which they are set plus

1.

Primary

Chassis

25

Set each pair of CNB modules to

the same node number.

25

Primary

Chassis

CNB modules swap node numbers.

CNB modules swap node numbers.

Secondary

Chassis

24

Switchover

Workstations and HMIs continue to connect

to the same node number.

Page 20

Publication 1756-UM523F-EN-P - December 2006

20 ControlLogix Redundancy System Overview

EtherNet/IP Network

E

N

B

T

An EtherNet/IP module in the primary

chassis uses the IP address to which

it is set.

An EtherNet/IP module in the

secondary chassis uses the IP address

to which it is set + 1 in the last address

segment.

Port Configuration

Switchover

EtherNet/IP Modules

Primary

Chassis

Secondary

Chassis

E

N

B

T

Port Configuration

Set both EtherNet/IP modules to the

SAME IP address.

10.10.10.10 10.10.10.11

Secondary

Chassis

E

N

B

T

Primary

Chassis

E

N

B

T

10.10.10.

11 10.10.10.10

Page 21

Publication 1756-UM523F-EN-P - December 2006

ControlLogix Redundancy System Overview 21

Quick Start Checklists

These checklists provide a summary of the criteria for a successful

ControlLogix redundancy system. See the remaining chapters for more

information on each parameter.

System Layout

Parameter Criteria Page

ControlNet Networks • ControlNet networks are the primary networks for the system.

• OK to bridge to devices on other networks, such as DeviceNet, Universal Remote I/O,

and DH+ networks.

• Networks follow the guidelines in Logix5000 Controllers Design Considerations,

publication 1756-RM094.

28, 31

I/O Placement • All I/O modules in remote chassis or DIN rails (no I/O in the local chassis)

• All I/O in only these locations:

• Same ControlNet network as the redundant controllers (no bridging)

• DeviceNet network (via a 1756-DNB module in a remote chassis)

• Universal remote I/O network (via a 1756-DHRIO module in a remote chassis)

28, 31

ControlNet Network Update

Tim es

• NUTs ≤ 90 ms

• NUTs ≤ specified relationship to each other

35

Number of ControlNet Nodes At least 2 nodes on each network in addition to the CNBs in the redundant chassis. For

example, each ControlNet network has at least 4 nodes.

35

ControlNet Node Assignments • Nonredundant nodes use the lowest node numbers.

• CNB modules in the redundant chassis set close to the scheduled network maximum

(SMAX).

• 2 consecutive node addresses for each set of partner CNB modules (one in each

chassis).

• Switches of each partner CNB module set to the same node address.

18, 35

Network Access Ports No devices connected to the network access ports of CNB modules in the redundant

chassis.

28

EtherNet/IP Networks EtherNet/IP networks are only for HMIs, workstations, and messaging (no control of I/O).

No EtherNet/IP network for:

• control of I/O.

• peer interlocking (produced and consumed tags).

28, 38

Page 22

Publication 1756-UM523F-EN-P - December 2006

22 ControlLogix Redundancy System Overview

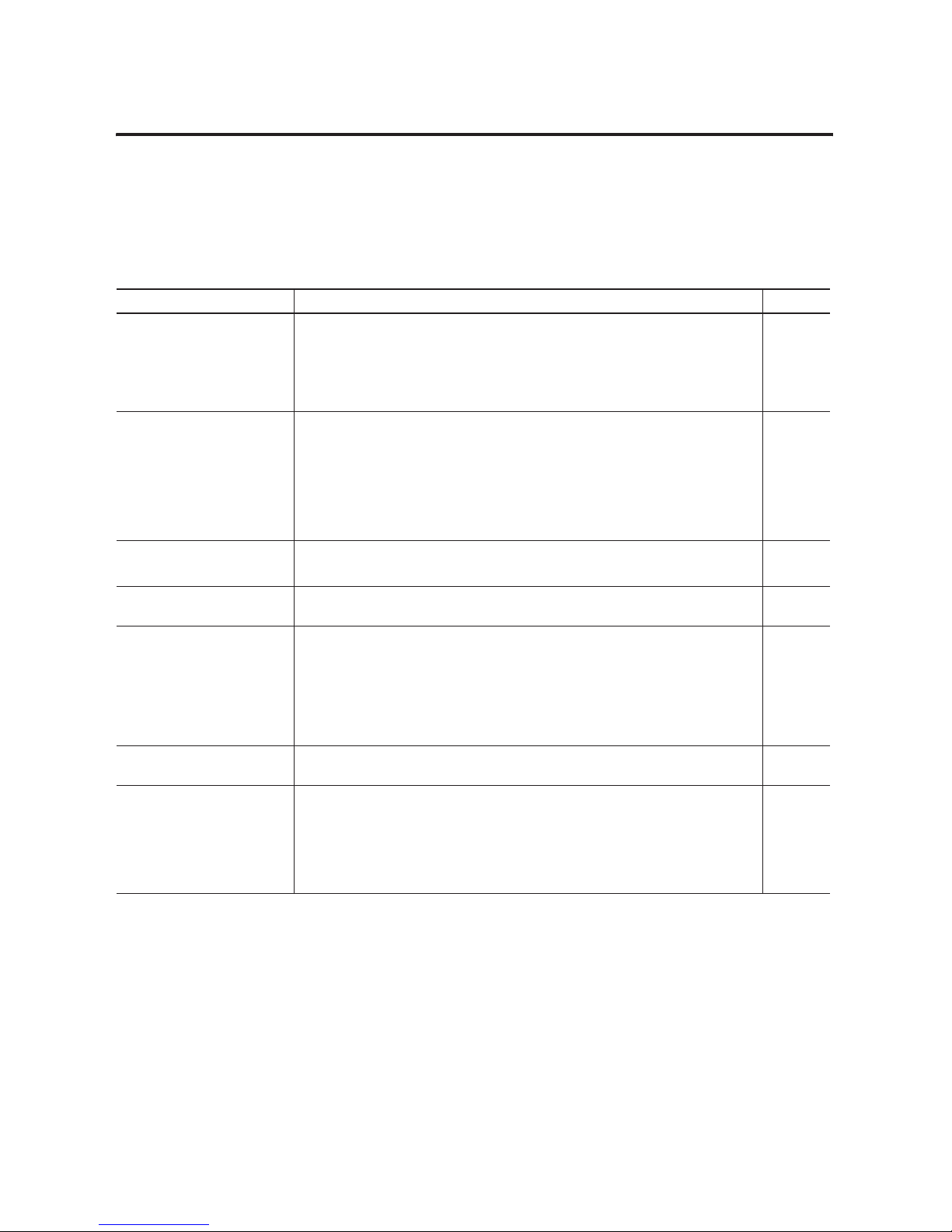

Redundant Chassis Configuration

Parameter Criteria Page

Chassis Size Same size chassis for each pair of redundant chassis. 29

Chassis Layout • Only these modules in each redundant chassis:

• Controllers

• ControlNet modules

• EtherNet/IP modules

• System redundancy module (needs 2 slots)

• Each chassis within a redundant pair looks the same.

• Identical modules (same catalog number, series, revision, and memory size)

• Same slot assignments

29

System Redundancy

Modules

1757-SRM module:

• 1 in each redundant chassis

• Needs 2 slots

• Needs 1757-SRCx cable [1 m (3 ft), 3 m (9 ft), 10 m (30 ft), 50 m (150 ft), and 100 m (300 ft)]

29, 30

Controllers ControlLogix5555, ControlLogix5561, ControlLogix5562, or ControlLogix5563 controllers

• Which type of controller do you want to use?

• If ControlLogix5555, then 1 or 2 controllers in each redundant chassis.

• If ControlLogix5561, ControlLogix5562, or ControlLogix5563, then only 1 controller in

each redundant chassis.

• Same type of controller throughout the chassis.

• Enough memory for 2 copies of all data.

• 7 connections for redundancy.

29

ControlNet Modules 1756-CNB/D/E or 1756-CNBR/D/E module or modules:

• CPU usage ≤ 75%.

• CNB modules have the same keeper information.

•≤ 5 CNB modules. See also parameter .

29, 107,

123

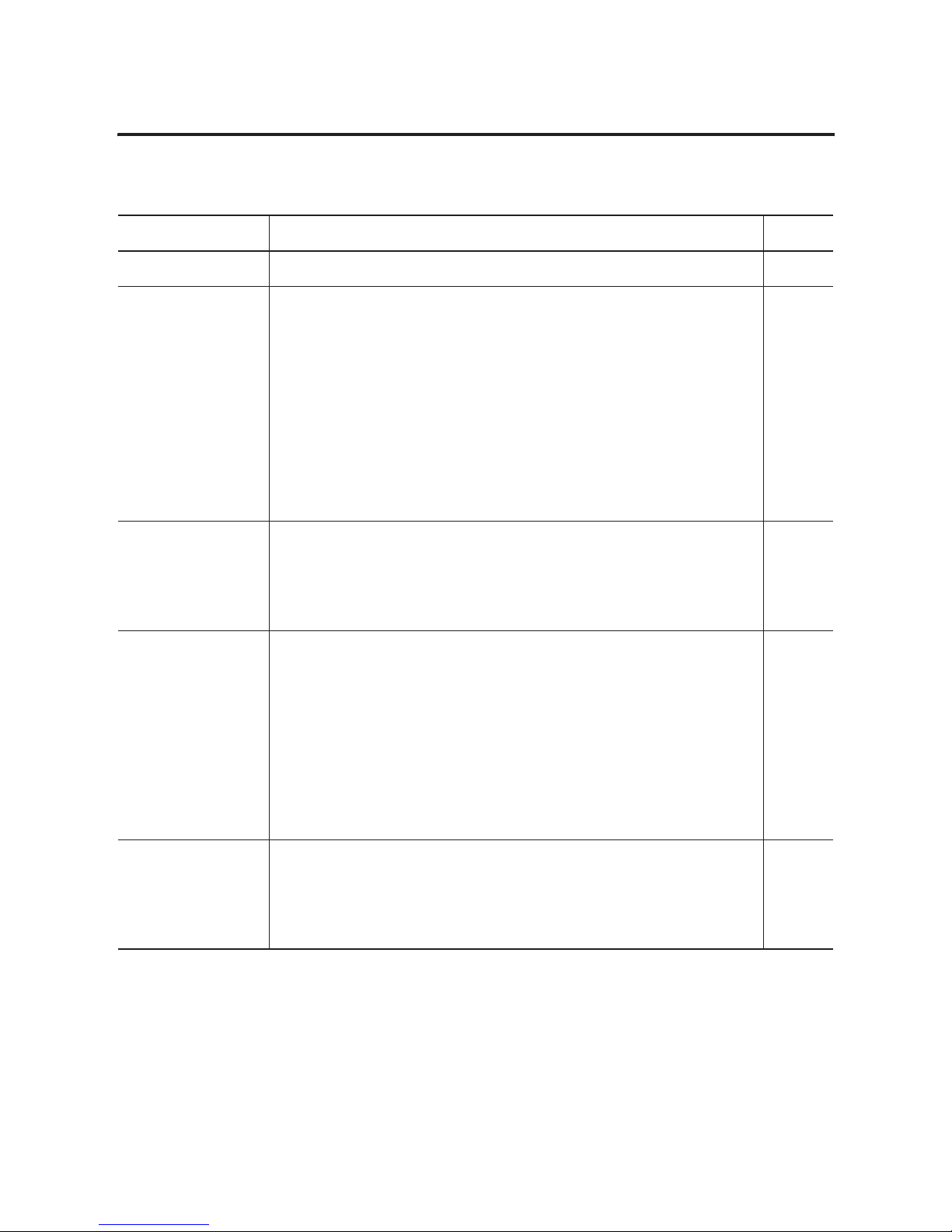

Page 23

Publication 1756-UM523F-EN-P - December 2006

ControlLogix Redundancy System Overview 23

EtherNet/IP Modules 1756-ENBT or 1756-EWEB modules:

• Which modules do you want to use?

• If 1756-ENBT, catalog revision greater than or equal to E01 (E01, E02, …, F01). See the

label on the side of the module or its box.

• If 1756-EWEB, any catalog revision.

• Up to 2 EtherNet/IP modules in each redundant chassis, within these limits.

29, 38

Redundant Chassis Configuration (Continued)

Parameter Criteria Page

If you have Use up to

1 ControlNet module 2 EtherNet/IP modules

2 ControlNet modules 2 EtherNet/IP modules

3 ControlNet modules 2 EtherNet/IP modules

4 ControlNet modules 1 EtherNet/IP module

5 ControlNet modules No EtherNet/IP modules

Do not use more than 5 ControlNet

modules.

Page 24

Publication 1756-UM523F-EN-P - December 2006

24 ControlLogix Redundancy System Overview

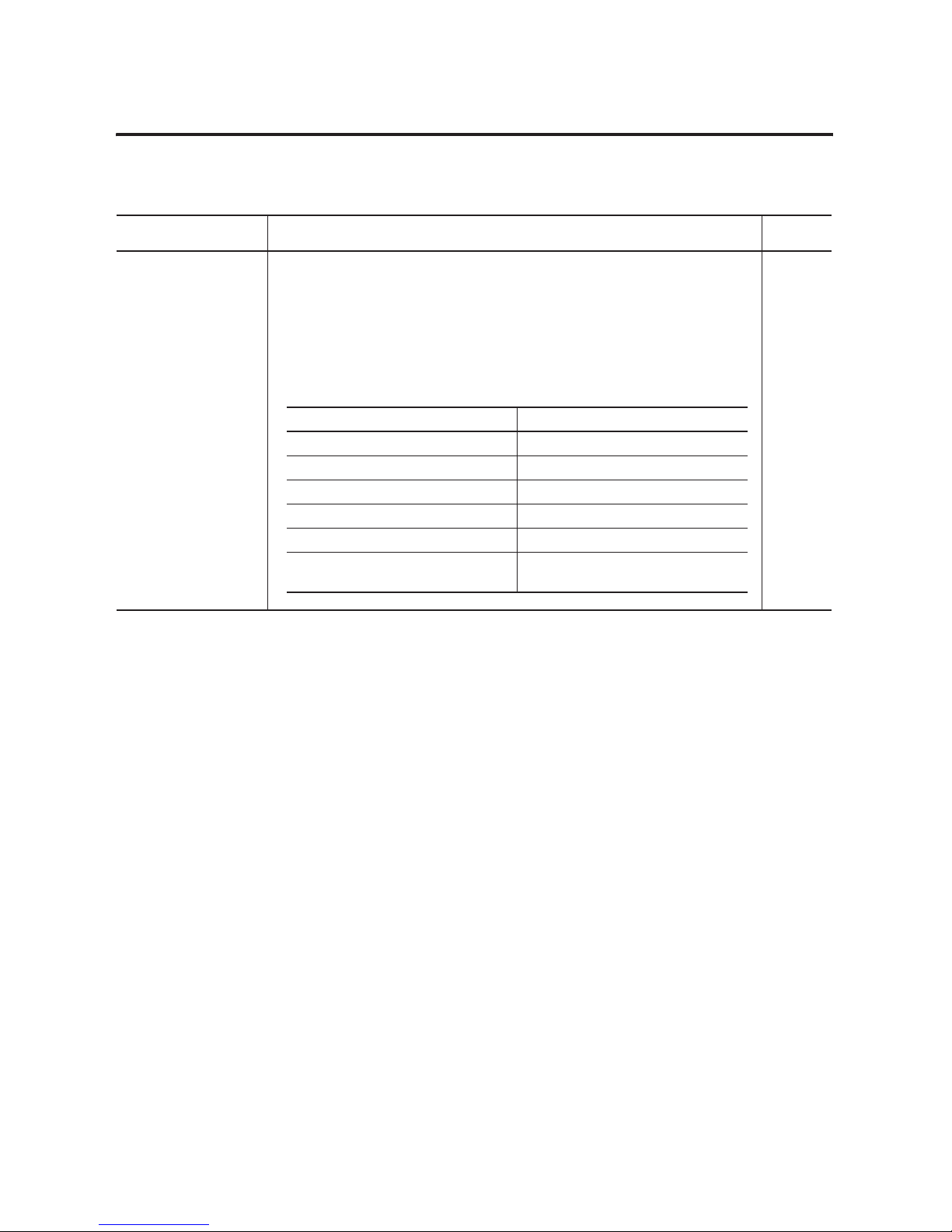

RSLogix5000 Project

Parameter Criteria Page

Number of Projects Only one RSLogix 5000 project for the pair of redundant controllers. The project automatically

crossloads to the secondary controller when the secondary controller synchronizes with the

primary controller.

65

Controller Properties • ControlLogix5555, ControlLogix5561, ControlLogix5562, or ControlLogix5563 controller.

• Redundancy enabled.

68

Task Structure • Only one task at the highest priority.

• If more than one task, all tasks periodic.

70, 76,

119

I/O • Outputs that require a bumpless switchover are in the highest priority task.

• Requested packet interval (RPI) less than or equal to 375 milliseconds. (Larger RPIs may

produce a bump at switchover.).

70

Task Watchdog Time Watchdog time ≥ (2 * maximum_scan_time) + 150 ms

where:

Maximum_scan_time is the maximum scan time for the entire task when the secondary

controller is synchronized.

100

Minimizing Scan Time • A few large programs instead of a lot of small programs.

• No unused tags.

• Arrays and user-defined data types instead of individual tags.

• User-defined data types as compact as possible.

• Code as compact as possible.

• Code runs only when you need it.

• Data grouped by how often you need it.

• DINT tags instead of SINT or INT tags.

76

Data Integrity Special treatment for:

• Bit Shift Left (BSL) and Bit Shift Right (BSR) instructions.

• FIFO Unload (FFU) instructions.

• logic that is scan dependent.

82

Produced and Consumed

Tags

If you want a controller in another chassis to consume a tag from the redundant controller, use

a comm format of None. In the I/O configuration of the consuming controller, select a comm

format of None for the remote CNB module (the CNB that is physically in the redundant

chassis). This comm format of None is only available over a ControlNet network.

70

Message (MSG)

Instructions

For any MSG instruction from a controller in another chassis to a redundant controller, cache

the connection.

70

Page 25

Publication 1756-UM523F-EN-P - December 2006

ControlLogix Redundancy System Overview 25

Operator Interface Terminals

Parameter Operator Interfaces Criteria Page

EtherNet/IP Network PanelView Standard terminal Same as a nonredundant system 28, 32, 38

• PanelView Plus terminal

• VersaView industrial computer running a

Windows CE operating system

• Use RSLinx Enterprise software revision

3.0 or later.

• Set aside connections for each PanelView

Plus or VersaView CE terminal:

RSView Supervisory Edition software with

RSLinx Enterprise software

• Use RSLinx Enterprise software revision

3.0 or later.

• Use IP swapping.

• Keep the HMI and both redundant chassis

on the same subnet.

• RSView Supervisory Edition software with

RSLinx 2.x software

• RSView 32 software

• Any other HMI client software that uses

RSLinx 2.x software

Limit the number of RSLinx servers that a

controller uses to 1 (ideal) to 3 (maximum).

ControlNet Network • PanelView Standard terminal

• PanelView 1000e/1400e terminal

Do terminals use unscheduled

communication?

• Yes — U se ≤ 4 terminals per controller.

• No — Use the number of terminals that

you need.

28, 32, 35

• PanelView Plus terminal

• VersaView industrial computer running a

Windows CE operating system

• Use RSLinx Enterprise software revision

3.0 or later.

• Set aside connections for each PanelView

Plus or VersaView CE terminal.

• RSView Supervisory Edition software with

RSLinx 2.x software

• RSView 32 software

• Any other HMI client software that uses

RSLinx 2.x software

Limit the number of RSLinx servers that a

controller uses to 1 (ideal) to 3 (maximum).

In this module Set aside

controller 5 connections

ENBT 5 connections

EWEB 5 connections

In this module Set aside

Controller 5 connections

CNB 5 connections

Page 26

Publication 1756-UM523F-EN-P - December 2006

26 ControlLogix Redundancy System Overview

Notes:

Page 27

27 Publication 1756-UM523F-EN-P - December 2006

Chapter

2

Design the System

Introduction

This chapter explains how to design a redundancy system for a

ControlLogix controller.

Topic Page

Laying Out the System 28

Placement of a Pair of Redundant Chassis 30

Placement of the I/O 31

Placement of Operator Interface Terminals 32

Additional Redundant Components 33

Checking Connection Requirements 35

Planning a ControlNet Network 35

Planning an EtherNet/IP Network 38

Additional Design Considerations 41

Page 28

Publication 1756-UM523F-EN-P - December 2006

28 Design the System

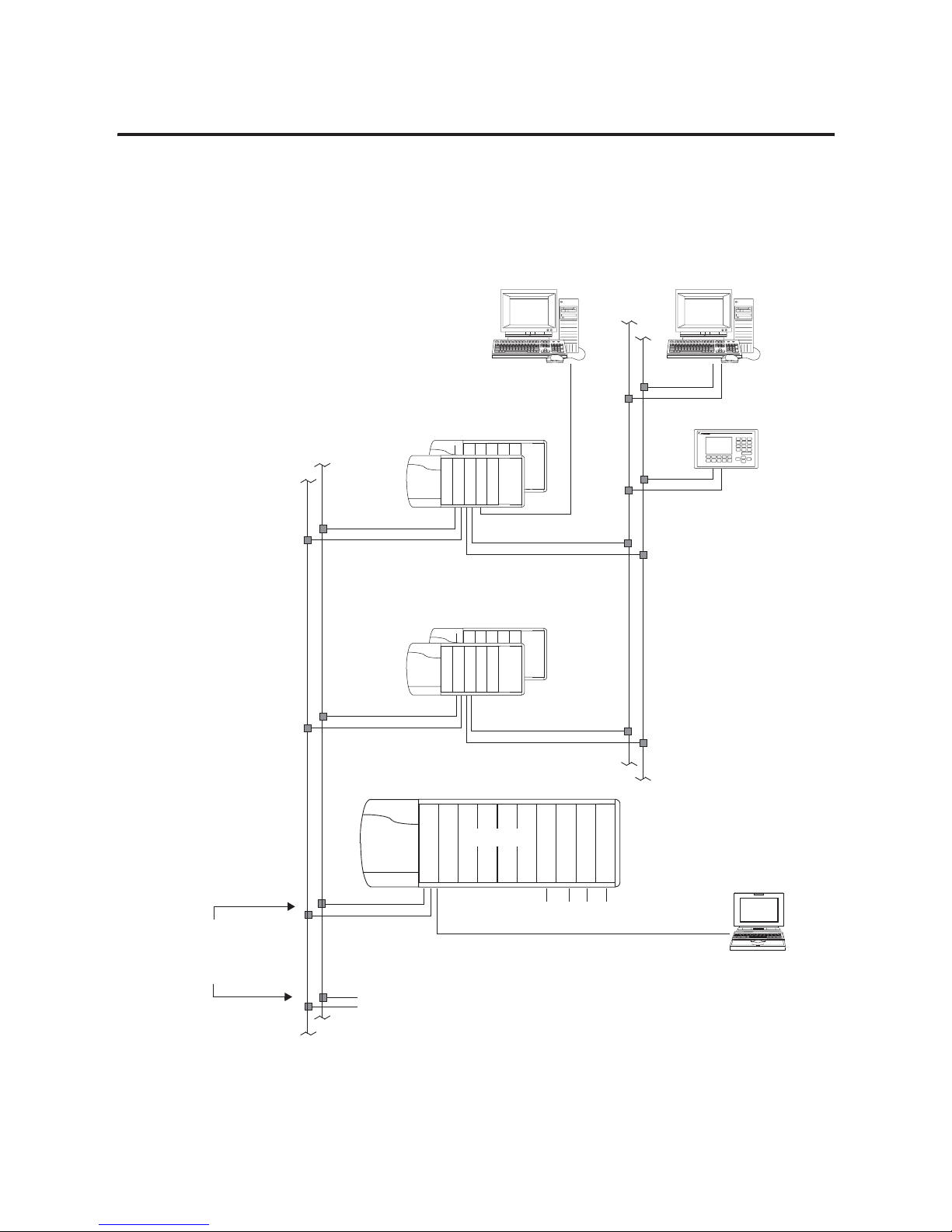

Laying Out the System

ControlLogix Redundancy Requirements and Recommendations

C

N

B

E

N

B

I/O Modules

D

N

B

D

H

R

I

O

M

V

I

Other Networks

Remote location for all:

• I/O

• DNB, DHRIO, & MVI

communication modules

Assign the lowest node numbers

to nonredundant nodes.

An additional node can be:

• a second CNB module in the same remote chassis or in a different remote chassis.

• any other ControlNet device (not required to be keeper capable).

ControlNet network:

• Set NUT ≤ 90 ms

• Set RPIs ≤ 375 ms

• If multiple ControlNet

networks, set NUTs

≤ specified values.

For unscheduled communication,

use ≤ 4 PanelView terminals per

controller.

At least 2 nodes in

addition to the CNBs in

the redundant chassis

Multiple redundant chassis

pairs are OK.

Use separate networks for unscheduled and scheduled

communication.

• For unscheduled communication (HMI, workstations,

message instructions), use either an EtherNet/IP or a

ControlNet network.

• For scheduled communications (I/O, produced/consumed

tags), use a ControlNet network.

To connect a computer to the

network via an NAP, use a remote

node.

EtherNet/IP ControlNet

ControlNet

or

Unscheduled Communication

Scheduled Communication

Page 29

Publication 1756-UM523F-EN-P - December 2006

Design the System 29

ControlLogix Redundancy Requirements and Recommendations (Continued)

1757-SRCx cable is available in

1 m (3 ft), 3 m (9 ft), 10 m (30 ft), 50 m

(150 ft), and 100 m (300 ft) lengths.

L

•

•

•

E

N

B

T

S

R

M

Redundant

Chassis A

Redundant

Chassis B

No Other Modules

1756-CNB/D/E or 1756-CNBR/D/E module or modules:

• 1-5 in each redundant chassis.

•≤ 5 total communication modules (CNBs, ENBTs, and

EWEBs) in each redundant chassis.

• Keep CPU usage ≤ 75%.

• Allocate 2 consecutive node addresses for each set of

partner CNB modules (one in each chassis).

• Assign each partner CNB module to the same node

address.

• Assign the higher node addresses in the system to the

CNB modules in the redundant chassis.

1757-SRM module:

• Only 1 in each redundant chassis

• Uses 2 slots

ControlLogix5555, ControlLogix5561, ControlLogix5562, or

ControlLogix5563 controllers:

• Same type of controller throughout the chassis.

• If ControlLogix5555, then 1 or 2 controllers in each

redundant chassis.

• If ControlLogix5561, ControlLogix5562, or

ControlLogix5563, then only 1 controller in each

redundant chassis.

• Enough memory for 2 copies of all data.

• 7 connections for redundancy.

C

N

B

L

•

•

•

E

N

B

T

S

R

M

No Other Modules

C

N

B

Same Size of Chassis

Identical Modules:

• Same Slot Number

• Same Catalog Number, Series, and Revision

• Same Memory Size (controller)

1756-ENBT or 1756-EWEB modules:

• 1- 2 in each redundant chassis.

•≤ 5 total communication modules (CNBs and ENBTs) in each

redundant chassis.

• For 1756-ENBT modules, catalog revision must be greater than

or equal to E01 (E01, E02, …, F01). See the side of the module

or its box.

• Requires RSLinx software, version 2.50.

Page 30

Publication 1756-UM523F-EN-P - December 2006

30 Design the System

Placement of a Pair of

Redundant Chassis

With the standard redundancy module cables, a pair of redundant

chassis (primary and secondary) can function up to 100 m (300 ft)

apart.

Redundant Chassis Placement

If You Need More Than 100 Meters Between Chassis

To place the primary and secondary controller chassis more than 100

meters apart, use a custom fiber optic cable. For a custom cable,

follow these rules:

• Keep total light loss through the cable less than or equal to 7dB.

• Keep total length less than or equal to 4 km.

• Use high quality 62.5/125 micron multi-mode fiber-optic cable.

• Use professionally installed SC-style connectors to connect to

the 1757-SRM modules.

Redundancy Module Cable:

• 1757-SRC1 cable - 1 m (3 ft)

• 1757-SRC3 cable - 3 m (9 ft)

• 1757-SRC10 cable - 10 m (30 ft)

• 1757-SRC50 cable - 50 m (150 ft)

• 1757-SRC100 cable - 100 m (300 ft)

L

•

•

•

E

N

B

T

S

R

M

Redundant

Chassis A

Redundant

Chassis B

No Other Modules

C

N

B

L

•

•

•

E

N

B

T

S

R

M

No Other Modules

C

N

B

Page 31

Publication 1756-UM523F-EN-P - December 2006

Design the System 31

Placement of the I/O

In a ControlLogix redundancy system, place all I/O in only these

locations:

• Same ControlNet network as the redundant controllers (no

bridging to I/O modules on another ControlNet network)

• DeviceNet network

• Universal remote I/O network

IO Placement

HMI – Yes

Universal Remote I/O Network

I/O – Yes

HMI – Yes

DeviceNet Network

I/O – Yes

C

N

B

D

N

B

I/O Modules

C

N

B

E

N

B

D

H

R

I

HMI – Yes

EtherNet/IP Network

I/O – No

HMI – Yes

I/O – No

ControlNet Network

Redundant Chassis Pair

Remote Chassis

ControlNet Network

Page 32

Publication 1756-UM523F-EN-P - December 2006

32 Design the System

Placement of Operator

Interface Terminals

For operator interface terminals, stay within these limitations.

Operator Interface Terminal Limitations

Network Operator Interfaces Guidelines

EtherNet/IP network PanelView Standard terminal Same as a nonredundant system

• PanelView Plus terminal

• VersaView industrial computer running a

Windows CE operating system

• Use RSLinx Enterprise software revision 3.0 or

later.

• Set aside connections for each PanelView Plus or

VersaView CE terminal.

RSView Supervisory Edition software with RSLinx

Enterprise software

• Use RSLinx Enterprise software revision 3.0 or

later.

• Use IP swapping.

• Keep the HMI and both redundant chassis on the

same subnet.

• RSView Supervisory Edition software with

RSLinx 2.x software

• RSView 32 software

• Any other HMI client software that uses

RSLinx 2.x software

Limit the number of RSLinx servers that a controller

uses to 1 (ideal) to 3 (maximum).

ControlNet network • PanelView Standard terminal

• PanelView 1000e/1400e terminal

Do your terminals use unscheduled communication?

• Yes — Use ≤ 4 terminals per controller.

• No — Use the number of terminals that you need.

• PanelView Plus terminal

• VersaView industrial computer running a

Windows CE operating system

Set aside connections for each PanelView Plus or

VersaView CE terminal.

• RSView Supervisory Edition software

• RSView 32 software

• Any other HMI client software that uses

RSLinx 2.x software

Limit the number of RSLinx servers that a controller

uses to 1 (ideal) to 3 (maximum).

In this module Set aside

Controller 5 connections

CNB 5 connections

ENBT 5 connections

EWEB 5 connections

In this module Set aside

Controller 5 connections

CNB 5 connections

Page 33

Publication 1756-UM523F-EN-P - December 2006

Design the System 33

Additional Redundant

Components

In addition to using redundant pairs of controllers, you may also add

these redundant components to your system:

• Redundant ControlNet Media

• Redundant Power Supplies

Redundant ControlNet Media

Redundant ControlNet media prevents a loss of communication if a

trunkline or tap is severed or disconnected. It uses these components:

• 1756-CNBR ControlNet modules

• Two identical ControlNet links

Redundant ControlNet Media Components

ControlLogix Chassis with

1756-CNBR Module

Redundant Media

ControlNet Node

ControlNet Node

Page 34

Publication 1756-UM523F-EN-P - December 2006

34 Design the System

Redundant Power Supplies

Redundant power supplies let you maintain power to a ControlLogix

chassis if a power supply fails. Redundant power supplies use these

supplies:

• Two redundant power supplies, any combination of 1756-PA75R

and 1756-PB75R.

• 1756-PSCA chassis adapter module, in place of the standard

power supply.

• Two 1756-CPR cables to connect the power supplies to the

1756-PSCA adapter.

• User-supplied annunciator wiring to connect the power supplies

to the input modules if needed.

Redundant Power Supplies

1756-PA75R or

1756-PB75R

Power Supply

ControlLogix Chassis

with 1756-PSCA Module

1756-CPR Cable

1756-PA75R or

1756-PB75R

Power Supply

Annunciator Wiring

1756 Digital

Input Module

Page 35

Publication 1756-UM523F-EN-P - December 2006

Design the System 35

Checking Connection

Requirements

Set aside seven connections in each redundant controller for

redundancy communication.

• Two connections for the SRM

• Five connections for the partner controller

Planning a ControlNet

Network

Follow these guidelines to plan a ControlNet network.

ControlNet Network Guidelines

Guideline Details

Make sure the network has at least 2 nodes plus the

redundant chassis pair.

An additional node can be:

• a second CNB module in the same remote chassis or in a different remote

chassis.

• any other ControlNet device.

• a workstation that is running RSLinx software.

If your ControlNet network contains only one node other than the redundant

chassis pair, that node will drop its connections during a switchover. This may

cause the outputs of that node to change state during the switchover.

Give the lowest ControlNet addresses to I/O chassis and

other remote chassis.

Do not give the lowest addresses to the redundant chassis pair.

If you give the lowest address to a CNB module in the redundant chassis pair:

• on a switchover, you may temporarily lose communication with I/O

modules, produced tags, and consumed tags.

• If you remove the CNB module from the primary chassis while chassis

power is on, you may temporarily lose communication with I/O modules,

produced tags, and consumed tags.

• If every ControlNet node powers down at the same time (for example, a

plant-wide power loss), you may have to cycle the power to the primary

chassis to restore communication.

Page 36

Publication 1756-UM523F-EN-P - December 2006

36 Design the System

Set aside 2 consecutive ControlNet addresses for each

pair of redundant chassis (for example, nodes 3 and 4).

• If each redundant chassis has multiple CNB modules, set aside a pair of

node numbers for each pair of CNB modules (one in each chassis).

• Do not configure any other device on the ControlNet network for either of

these addresses. For example, if you allocated nodes 3 and 4 for the

redundant chassis, then no other device should use those node numbers.

Know that the switchover time depends on the NUT of

the ControlNet network.

Use the network update time (NUT) of the ControlNet network to estimate

how long it takes your system to switchover.

Example 1

The chassis loses power and the NUT = 4 ms. In that case, the switchover

time is approximately 60 ms.

Example 2

The chassis loses power and the NUT = 10 ms. In that case, the switchover

time is approximately 80 ms.

Example 3

You unplug the CNB from the network and the NUT = 10 ms. In that case, the

switchover time is approximately 220 ms.

Use a NUT that is less than or equal to 90 ms. If you use a larger network update time (NUT), the controller could lose its

connection with a module during a switchover. This could cause outputs to

change state.

Guideline Details

Pair of CNB modules (one in each

redundant chassis)

Slot and node numbers

Slot # Primary node # Secondary node #

(primary node # + 1)

1st pair of CNB modules

2nd pair of CNB modules

3rd pair of CNB modules

4th pair of CNB modules

5th pair of CNB modules

If And the NUT is Then the switchover time is

The chassis loses power or

a module fails

6 ms or less 60 ms

7 ms or more 5 (NUT ) + MAX (2 (NUT ), 30)

A CNB module cannot

communicate with any

other node

⇒ 14 (NUT ) + MAX (2 (NUT ), 30) + 50

Page 37

Publication 1756-UM523F-EN-P - December 2006

Design the System 37

Do the redundant chassis use more than 1 ControlNet

network?

• Yes — See page 29.

• No — Skip this guideline.

The NUT of each network must be within the values indicated on page 29. If

you use a larger network update time (NUT), the controller could lose its

connection with a module during a switchover. This could cause outputs to

change state.

Example

Guideline Details

If the NUT of this network is 5 ms…

ControlNet

Network 1

Then the NUT of this network must be

21 ms or less.

ControlNet

Network 2

If the smallest

NUT on a network

is (ms)

Then the largest NUT on any other

network must be less than or equal

to (ms)

215

317

419

521

623

725

827

929

10 31

11 33

12 35

13 37

14 39

15 41

16 43

17 46

18 48

19 50

20 52

21 55

22 57

23 59

24 62

25 64

26 66

27 68

28 71

29 73

30 75

31 78

32 80

33 82

34 84

35 87

36 89

37...90 90

If the smallest

NUT on a network

is (ms)

Then the largest NUT on any other

network must be less than or equal

to (ms)

Page 38

Publication 1756-UM523F-EN-P - December 2006

38 Design the System

Planning an EtherNet/IP

Network

Follow these guidelines as you plan your EtherNet/IP network.

EtherNet/IP Network Guidelines

Guideline Details

Use EtherNet/IP only for HMIs, workstations, and

messaging.

In a redundant system, use an EtherNet/IP network only for HMI, workstation,

and message communication. Do not use an EtherNet/IP network for:

• control of I/O modules.

• peer interlocking (produced and consumed tags).

Important: RSLogix 5000 software lets you set up and download a project

that tries to use an EtherNet/IP network for I/O, produced tags, or consumed

tags. Those communications do not work however.

Are communication delays OK during a switchover?

If Yes, then continue with EtherNet/IP.

If No, then use ControlNet.

Communication stops over an EtherNet/IP network with your controllers and

HMIs during a switchover.

• You will not be able to communicate with them for up to a minute.

• The actual delay depends on your network topology.

If you need bumpless communication, use a ControlNet network.

If you need a redundant network, use ControlNet. 2 EtherNet/IP modules in same chassis does not give you redundant

EtherNet/IP communication. A switchover still happens if one of the modules

fails or a cable breaks.

See How an EtherNet/IP Module Handles a Cable Break on page 40.

Make sure that your ENBT modules are catalog revision

E01 or later.

To use a 1756-ENBT module in a redundant controller chassis, make sure the

catalog revision of the module is greater than or equal to E01 (E01, E02, …,

F01).

• To find the catalog revision, look at the label on the side of the module or

box.

• If you use an older ENBT module, your secondary chassis will not

synchronize.

ControlLog

1756-ENBT

CAT. NO./SERIES

E01

CAT. REV.

Ethernet/IP 10/100

Catalog Revision

Page 39

Publication 1756-UM523F-EN-P - December 2006

Design the System 39

Worksheet for IP Swapping

Decide how to handle IP addresses. If both redundant chassis are on Then

Same subnet

Use IP swapping.

During a switchover the primary and

secondary modules swap IP

addresses. This lets you use the same

IP address regardless of which

chassis is primary.

See the next guideline for details.

Different subnets

Do not use IP swapping.

You must change to the new primary

address after a switchover. Use

ControlLogix Redundancy Alias Topic

Switcher software to do this. See

Appendix A.

If you are using IP swapping, give the same IP address to

the primary module and its partner.

A. Give the same IP address, subnet mask, and gateway address to both

modules in the redundant pair.

B. Leave the next highest IP address open for the secondary module.

The module in the secondary chassis automatically uses the IP address of the

primary + 1.

Guideline Details

Switch

Primary

Chassis

Secondary

Chassis

Switch

Router

Switch

Primary

Chassis

Secondary

Chassis

For example

Set the primary and secondary

modules to:

10.10.10.10

Leave this open for the secondary: 10.10.10.11

Pair of ENBT or EWEB Modules

(one in each redundant chassis)

Slot # Configuration

Primary

IP Address

Secondary IP Address

(primary address + 1)

Subnet Mask Gateway

Address

1st pair of ENBT or EWEB modules

2nd pair of ENBT or EWEB modules

Page 40

Publication 1756-UM523F-EN-P - December 2006

40 Design the System

How an EtherNet/IP Module Handles a Cable Break

An EtherNet/IP module looks for a carrier signal only from the closest

switch. It does not know the health of the network beyond that point.

Data does not have to be flowing.

If the EtherNet/IP module:

• gets the carrier signal, it considers the network as OK.

• does not get the carrier signal, it shows Link lost.

/LQNORVW/LQNORVW

VZLWFK

SULPDU\FKDVVLV

VHFRQGDU\FKDVVLV

ZLOOGLVTXDOLI\

ZRQ¶WV\QFKURQL]H

(WKHU1HW,3PRGXOH

VKRZV

/LQNORVW

ZLOOVZLWFKRYHU

ZRQ¶WV\QFKURQL]H

(WKHU1HW,3PRGXOH

VKRZV

/LQNORVW

URXWHU

VZLWFK

VZLWFK

ZRQ¶WVZLWFKRYHU

ZLOOV\QFKURQL]H

+0,FDQ¶WFRPPXQLFDWHZLWK

SULPDU\FKDVVLV

ZRQ¶WVZLWFKRYHURUGLVTXDOLI\WKH

VHFRQGDU\FKDVVLV

ZLOOV\QFKURQL]H

+0,ZRQ¶WEHDEOHWRFRPPXQLFDWH

ZLWKWKLVFKDVVLVLILWEHFRPHVSULPDU\

6XEQHW$ 6XEQHW%

C

One switch

One subnet

Several switches

Several subnets

Page 41

Publication 1756-UM523F-EN-P - December 2006

Design the System 41

Additional Design

Considerations

Keep these things in mind as you design your system.

Additional Design Considerations

Switchover always triggers an event

task in a remote, nonredundant

controller.

A switchover triggers an event task under this combination of circumstances:

• The event task is in a nonredundant controller. An event task is not permitted in a redundant

controller.

• A redundant controller triggers the event task via a produced tag.

This occurs regardless of how you configure the produced tag.

Simultaneous branch delays the

execution of a higher priority task.

Both configurations always trigger an

event task during a switchover.

In an SFC, each path of a simultaneous branch delays

the execution of a higher priority task by up to 25 μs.

Page 42

Publication 1756-UM523F-EN-P - December 2006

42 Design the System

Notes:

Page 43

43 Publication 1756-UM523F-EN-P - December 2006

Chapter

3

Install the System

Introduction

This chapter explains how to install the hardware of a ControlLogix

redundancy system.

Preliminary Information

Topic Page

Preliminary Information 43

Install the Chassis for the Controllers 45

Install Modules in the First Redundant Chassis 46

Install Modules in the Second Redundant Chassis 48

Install the Remote Chassis or Rails 49

Configure EtherNet/IP Modules 50

Flash the Modules 51

Check the Installation 51

IMPORTANT

Use of the Network Access Port (NAP)

Do not connect any device to the network access port (NAP) of

a 1756-CNB/D/E or 1756-CNBR/D/E module in a redundant

chassis.

• If you connect a device to the NAP of a CNB module in a

redundant chassis, a switchover will fail to occur if the CNB

module is disconnected from the network. While the CNB

module is disconnected from the network, the controller

will be unable to control any I/O devices through that CNB

module.

• If you connect a workstation to the NAP of a CNB module in

a redundant chassis, the workstation will be unable to go

online after a switchover.

To connect a device to a ControlNet network via a NAP, use a

NAP that is outside of a redundant chassis.

Page 44

Publication 1756-UM523F-EN-P - December 2006

44 Install the System

This chapter provides the sequence of tasks and the critical actions for

the successful installation of a ControlLogix redundancy system. It

does not replace the installation instructions for the components of

the system. During installation, refer to these publications.

Installation Publications

Installation instructions provide important information, such as

detailed installation steps, safety considerations, enclosure

requirements, and hazardous location information.

Before installing the system, review these guidelines for safe handling

of ControlLogix components.

Install this component According to this publication

1756-A4, -A7, -A10, -A13, or -A17 chassis ControlLogix Chassis Installation Instructions, publication 1756-IN080

1756-PA72 or -PB72 power supply ControlLogix Power Supplies Installation Instructions, publication 1756-5.67

1756-PA75 or -PB75 power supply ControlLogix Power Supplies Installation Instructions, publication 1756-5.78

ControlLogix controller ControlLogix Controller and Memory Board Installation Instructions, publication

1756-IN101

1756-CNB/D/E or -CNBR/D/E module ControlLogix ControlNet Bridge Installation Instructions, publication 1756-IN571

1756-ENBT module ControlLogix EtherNet/IP Bridge Module Installation Instructions, publication

1756-IN019

1756-EWEB module EtherNet/IP Web Server Module Installation Instructions, publication 1756-IN588

1757-SRM module ProcessLogix/ControlLogix System Redundancy Module Installation Instructions,

publication 1757-IN092

WARNING

When you insert or remove a module while backplane power is

on, an electrical arc can occur. This could cause an explosion in

hazardous location installations. Be sure that power is removed

or the area is nonhazardous before proceeding.

Page 45

Publication 1756-UM523F-EN-P - December 2006

Install the System 45

Repeated electrical arcing causes excessive wear to contacts on both a

module and its mating connector. Worn contacts may create electrical

resistance that can affect module operation.

Install the Chassis for the

Controllers

1. Install the two ControlLogix chassis (redundant) that will contain

the controllers.

• Place the chassis within the length of a 1757-SRCx cable.

• Install each chassis according to the ControlLogix Chassis

Installation Instructions, publication 1756-IN080.

• If you are converting an existing system that contains local

I/O modules, you still need two additional chassis. In a

redundant system, you must place all I/O modules outside

the redundant chassis pair.

ATTENTION

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic discharge, which

can cause internal damage and affect normal operation. Follow

these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in appropriate

static-safe packaging.

1.

42798

2.

Page 46

Publication 1756-UM523F-EN-P - December 2006

46 Install the System

2. For each chassis, install a ControlLogix power supply according

to the corresponding installation instructions.

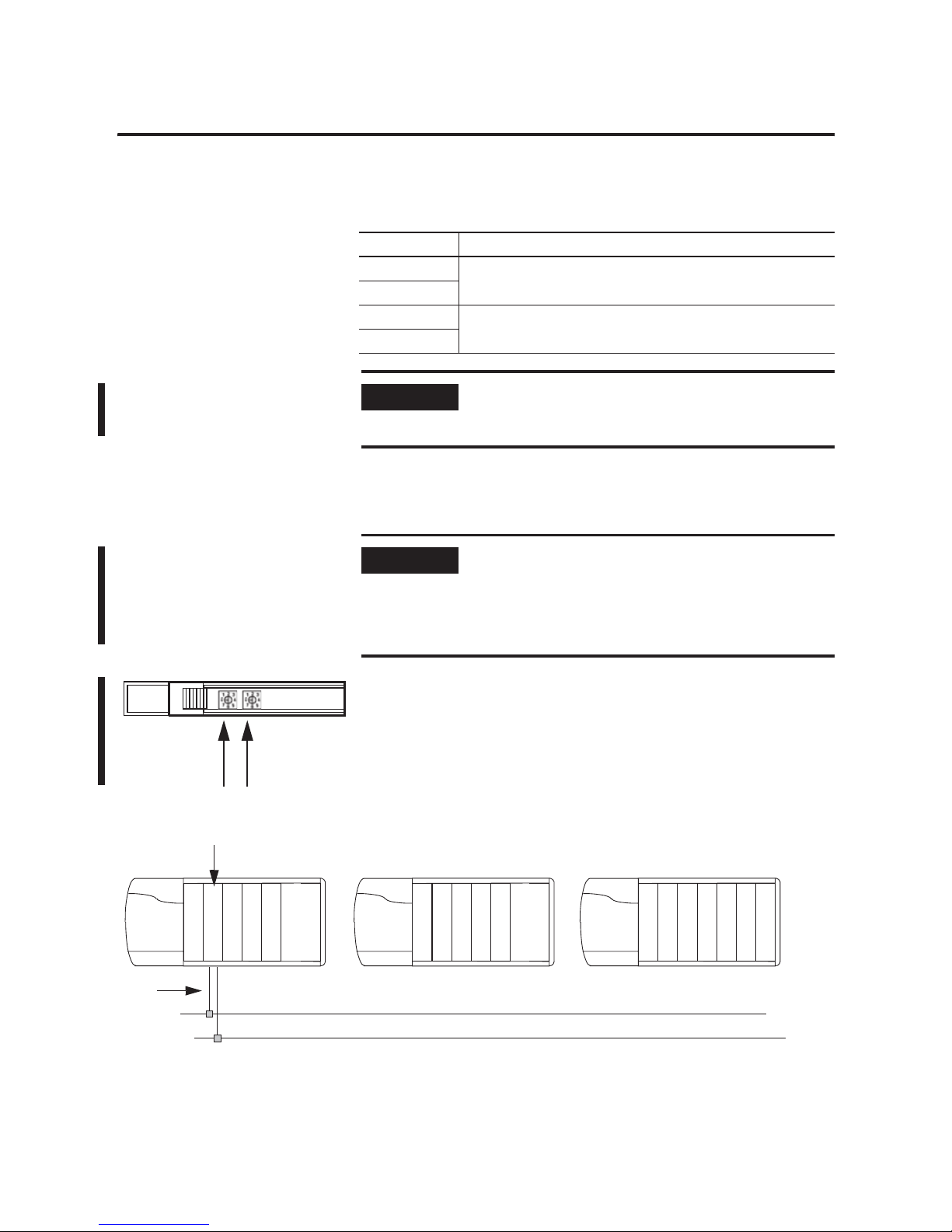

Install Modules in the First

Redundant Chassis

1. Set the rotary switches of each of the 1756-CNB/D/E or

1756-CNBR/D/E modules to the primary node number plus one.

For example, modules 3 and 4 have a primary node number of

2. If you allocate nodes 3 and 4 for the redundant chassis, set

both CNB modules to node 3.

Power Supply Publication

1756-PA72 ControlLogix Power Supplies Installation Instructions, publication

1756-IN078B

1756-PB72

1756-PA75R ControlLogix Redundant Power Supply Installation Instructions,

publication 1756-IN573C

1756-PB75R

IMPORTANT

We recommend constant power supply to one of the redundant

chassis to maintain uninterrupted operation of the redundant

controller parts.

IMPORTANT

Set the rotary switches of the 1756-CNB/D/E or

1756-CNBR/D/E modules for both redundant chassis to the

same node address.

The primary node number is the node number of the primary

chassis.

42796

Nodes 3 and 4

2.

3.

C

N

B

This is only an example. You can install the

module in any slot.

Page 47

Publication 1756-UM523F-EN-P - December 2006

Install the System 47

2. Install a 1756-CNB/D/E or 1756-CNBR/D/E module. See

ControlLogix ControlNet Bridge Installation Instructions,

publication 1756-IN571.

3. Connect the CNB module to the ControlNet network.

4. Install the controller or controllers. See ControlLogix Controller

and Memory Board Installation Instructions, publication

1756-IN101.

5. Install the 1756-ENBT or 1756-EWEB module or modules (2

maximum), if required. Connect each module to an ethernet

switch.

6. Install the 1757-SRM module. See ProcessLogix/ControlLogix

System Redundancy Module Installation Instructions, publication

1757-IN092.

WARNING

If you connect or disconnect the communications cable with

power applied to this module or any device on the network, an

electrical arc can occur. This could cause an explosion in

hazardous location installations.

Be sure that power is removed or the area is nonhazardous

before proceeding.

4.

42799

L

5

5

S

R

M

C

N

B

6.

This is only an example. You can install the

modules in any slot.

E

N

B

T

5.

Page 48

Publication 1756-UM523F-EN-P - December 2006

48 Install the System

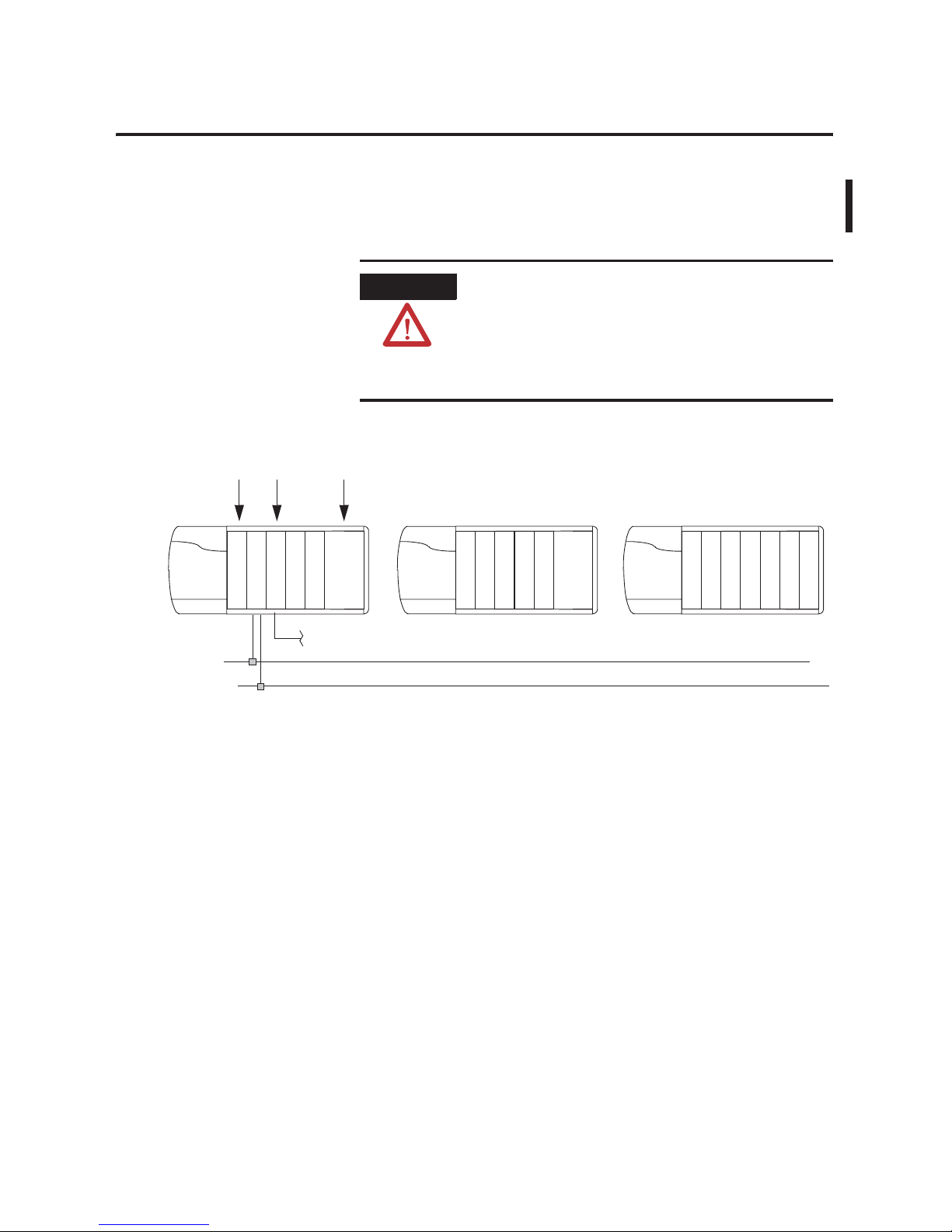

Install Modules in the

Second Redundant Chassis

1. For each module in the first redundant chassis, install an

identical module into the same slot of the second redundant

chassis.

2. Connect the CNB, ENBT, and EWEB modules to their respective

networks.

3. Connect one of these fiber optic cables to the 1757-SRM

modules:

• 1757-SRC1

• 1757-SRC3

• 1757-SRC10

• 1757-SRC50

• 1757-SRC100

2.

42800

L

5

5

S

R

M

C

N

B

1.

L

5

5

S

R

M

C

N

B

3.

E

N

B

T

E

N

B

T

IMPORTANT

• The modules in each redundant chassis must match each other

slot-by-slot.

• Set the rotary switches of the 1756-CNB/D/E or 1756-CNBR/D/E

modules for both redundant chassis to the same node address.

Page 49

Publication 1756-UM523F-EN-P - December 2006

Install the System 49

Install the Remote Chassis

or Rails

You must install all I/O modules and additional types of

communication modules in remote chassis or on DIN rails. This

example shows a remote 1756 chassis. You can use any type of

chassis or device that you can connect to the ControlNet network.

As you install the chassis, follow these guidelines:

• Do not assign any device to the address of the CNB modules in

the redundant chassis plus one.

For example, if you set the rotary switches of the CNB modules

in the redundant chassis to node 11, no other device should use

node 12.

• Use a remote chassis for communication modules such as:

– 1756-ENET

– 1756-DHRIO

– 1756-MVI

– 1756-DNB

42197

L

5

5

S

R

M

C

N

B

C

N

B

D

N

B

L

5

5

S

R

M

C

N

B

DeviceNet Network

I/O Modules

Other ControlNet Node(s)

You must have at least 2 other nodes in addition to the redundant

chassis pair. See Lay Out the System on page 2.

E

N

B

T

E

N

B

T

IMPORTANT

If you connect the workstation to the network via a network

access port on a CNB module, use a CNB module in a remote

chassis. This lets a switchover occur after the failure of a

ControlNet tap of a primary chassis.

Page 50

Publication 1756-UM523F-EN-P - December 2006

50 Install the System

Configure EtherNet/IP

Modules

To use an EtherNet/IP module, give it an IP address, subnet mask, and

gateway address.

Action Details

Before you begin. A. Perform these steps if you have not already:

• installed and connected both 1757-SRM modules.

• obtained the IP address, subnet mask, and gateway address for each EtherNet/IP

module. See Plan the EtherNet/IP Networks on page 12.

• Do you know how to configure an EtherNet/IP module in a nonredundant system?

• If no, then continue with step B.

• If yes, then go to step B.

B. Get this publication:

EtherNet/IP Modules in Logix5000 Control Systems, publication ENET-UM001

You will use that publication when you configure each module.

Configure the EtherNet/IP modules in the

first chassis.

A. Turn on the power to only one of the redundant chassis.

For example, if both chassis are on, turn off one of them.

B. Configure the EtherNet/IP module in the chassis that is on.

• Do you see the IP address on the front of the module?

• If no, then return to step B.

• If yes, then continue with step C.

C. Repeat step B for each EtherNet/IP module in this chassis.

Configure the EtherNet/IP modules in the

second chassis.

A. Turn off the chassis that you just configured.

B. Turn on the other chassis.

C. Configure the EtherNet/IP module in the chassis that is on.

• Do you see the IP address on the front of the module?

• If no, then return to step C.

• If yes, then continue with step C.

D. Repeat step C for each EtherNet/IP module in this chassis.

Page 51

Publication 1756-UM523F-EN-P - December 2006

Install the System 51

Flash the Modules

To flash the modules, perform this procedure.

1. Turn on the power to one of the redundant chassis.

2. Wait for the 1757-SRM module to display PRIM.

3. Flash upgrade each module in the chassis with a compatible

revision of firmware.

• See the ControlFLASH Firmware Upgrade Kit User Manual,

publication 1756-6.5.6.

• To find the chassis in RSLinx software, locate the node

number or IP address on the front of the communication

module.

4. Turn off the power to the chassis.