Page 1

ProcessLogix

Function Blocks

1757 Series

Reference Manual

Spare Allen-Bradley Parts

Page 2

Page 3

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations,

codes and standards. In no event will Allen-Bradley be responsible

or liable for indirect or consequential damage resulting from the use

or application of these products.

Any illustrations, charts, sample programs, and layout examples

shown in this publication are intended solely for purposes of

example. Since there are many variables and requirements associated

with any particular installation, Allen-Bradley does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this publication, notes may be used to make you aware

of safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequences of a

potential hazard:

WARNING

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

!

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

!

IMPORTANT

Identifies information that is critical for successful

application and understanding of the product.

Allen-Bradley is a trademark of Rockwell Automation

Spare Allen-Bradley Parts

Page 4

Rockwell Automation Support

Rockwell Automation offers support services worldwide, with over 75

sales/support offices, 512 authorized distributors, and 260 authorized

systems integrators located throughout the United States alone, plus

Rockwell Automation representatives in every major country in the

world.

Local Product Support

Contact your local Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Rockwell Automation for technical assistance,

first call your local Rockwell Automation representative, then:

• Technical Support, 440.646.5800

• Web Links, http://www.ab.com

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us of it on the

How Are We Doing? form at the back of this manual.

Page 5

Introduction to Control Builder

Components

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . iii

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . iv

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . iv

Your Questions or Comments on this Manual . . . . . . . . . iv

Chapter 1

Component Categories and Types . . . . . . . . . . . . . . . . . . . 1-1

Hardware relation category . . . . . . . . . . . . . . . . . . . . . 1-1

Functional relation category . . . . . . . . . . . . . . . . . . . . . 1-5

Component Libraries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

System (SYSTEM) Library . . . . . . . . . . . . . . . . . . . . . . . 1-7

Auxiliary (AUXILIARY) Library . . . . . . . . . . . . . . . . . . . 1-7

Device Control (DEVCTL) Library . . . . . . . . . . . . . . . . . 1-7

Data Acquisition (DATAACQ) Library . . . . . . . . . . . . . . 1-7

Input/Output Module (IO) Library . . . . . . . . . . . . . . . . 1-8

Input/Output Channel (IOCHANNEL) Library . . . . . . . . 1-9

Logic (LOGIC) Library . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Regulatory Control (REGCTL) library. . . . . . . . . . . . . . . 1-10

Sequential Control Module (SCM) library . . . . . . . . . . . 1-10

Utility (UTILITY) Library. . . . . . . . . . . . . . . . . . . . . . . . 1-10

ControlNet Interoperability (Exchange) Library . . . . . . . 1-11

Pulse Input Channel/Module (PULSEINPUT) Library . . . 1-11

1797 FLEX Ex Modules (RAIL_IO_HAZ) . . . . . . . . . . . . 1-11

Profibus Interface (PBUSIF) Library. . . . . . . . . . . . . . . . 1-11

1794 FLEX I/O Modules (RAIL_IO) . . . . . . . . . . . . . . . . 1-12

Fieldbus Interface (FBUSIF) Library . . . . . . . . . . . . . . . 1-12

Chapter 2

Physical Equipment Blocks

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Control Processor Module (CPM) . . . . . . . . . . . . . . . . . 2-1

Control Execution Environment (CEE) . . . . . . . . . . . . . 2-2

Redundancy Module (RM) . . . . . . . . . . . . . . . . . . . . . . 2-3

Input Module Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

1756-IA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

1756-IA16I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

1756-IA8D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

1756-IB16D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

1756-IB16I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

1756-IB32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

1756-IF6I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

1756-IF16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

1756-IM16I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

1756-IR6I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

1756-IT6I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Spare Allen-Bradley Parts

v Publication 1757-RM810A-EN-P - May 2002

Page 6

vi

Functional Blocks

Output Module Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

1756-OA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

1756-OA16I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

1756-OA8D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

1756-OB16D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

1756-OB16I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

1756-OB32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

1756-OF6CI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

1756-OF6VI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

1756-OF8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-19

Serial Interface Module (SIM) TC-MUX021 . . . . . . . . . . 2-19

Chapter 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

System Blocks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

CONTROLMODULE (Continuous Control). . . . . . . . . . . 3-1

SCM (Sequential Control) . . . . . . . . . . . . . . . . . . . . . . . 3-2

Auxiliary Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

AUXCALC (Auxiliary Calculation) . . . . . . . . . . . . . . . . . 3-3

DEADTIME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

GENLIN (General Linearization) . . . . . . . . . . . . . . . . . . 3-6

LEADLAG (Lead Lag) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

TOTALIZER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Device Control Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

DEVCTL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Data Acquisition Block . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

DATAACQ. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

IO Channel Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

AICHANNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

AOCHANNEL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

DICHANNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

DOCHANNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

PWMCHANNEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

SIFLAGARRCH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

SINUMARRCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

SITEXTARRCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Logic Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

2OO3 (2 out of 3 voting) . . . . . . . . . . . . . . . . . . . . . . . 3-16

AND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

CHECKBAD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

DELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

EQ (Equal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

FTRIG (Falling-edge Trigger) . . . . . . . . . . . . . . . . . . . . 3-18

GE (Greater than or Equal to). . . . . . . . . . . . . . . . . . . . 3-18

GT (Greater Than) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-19

LE (Less than or Equal to) . . . . . . . . . . . . . . . . . . . . . . 3-19

Publication 1757-RM810A-EN-P - May 2002

Page 7

vii

LIMIT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

LT (Less Than). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

MAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

MAXPULSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

MIN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

MINPULSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

MUX (Multiplexer) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-22

MUXREAL (Real Multiplexer) . . . . . . . . . . . . . . . . . . . . 3-22

MVOTE (Majority Voting). . . . . . . . . . . . . . . . . . . . . . . 3-22

NAND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

NE (Not Equal) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

nOON (n out of N voting) . . . . . . . . . . . . . . . . . . . . . . 3-24

NOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24

NOT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

OFFDELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

ONDELAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

OR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

PULSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26

QOR (Qualified OR) . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

ROL (Rotate Output Left) . . . . . . . . . . . . . . . . . . . . . . . 3-27

ROR (Rotate Output Right) . . . . . . . . . . . . . . . . . . . . . . 3-27

RS (Reset dominant SR-FLIP-FLOP) . . . . . . . . . . . . . . . . 3-28

RTRIG (Rising edge Trigger). . . . . . . . . . . . . . . . . . . . . 3-28

SEL (Binary Selection) . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

SELREAL (Real Selection) . . . . . . . . . . . . . . . . . . . . . . . 3-29

SHL (Shift Output Left). . . . . . . . . . . . . . . . . . . . . . . . . 3-29

SHR (Shift Output Right) . . . . . . . . . . . . . . . . . . . . . . . 3-29

SR (Set dominant SR-FLIP-FLOP). . . . . . . . . . . . . . . . . . 3-30

TRIG (Rising or Falling edge Trigger) . . . . . . . . . . . . . . 3-30

WATCHDOG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

XOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Regulatory Control Blocks . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

AUTOMAN (Auto Manual) . . . . . . . . . . . . . . . . . . . . . . 3-31

FANOUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

OVRDSEL(Override Selector) . . . . . . . . . . . . . . . . . . . . 3-35

PID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-37

PIDFF (PID Feedforward). . . . . . . . . . . . . . . . . . . . . . . 3-39

POSPROP (Position Proportional) . . . . . . . . . . . . . . . . . 3-42

PULSECOUNT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

PULSELENGTH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

RAMPSOAK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-47

RATIOBIAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-49

REGCALC (Regulatory Control Calculator). . . . . . . . . . . 3-52

REMCAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

SWITCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-57

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 8

viii

Sequential Control Module Blocks . . . . . . . . . . . . . . . . . . . 3-59

HANDLER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-59

STEP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-60

TRANSITION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-61

Utility Blocks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

FLAG. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

FLAGARRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-62

MESSAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

NUMERIC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-63

NUMERICARRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

PUSH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-64

TEXTARRAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-68

TIMER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-68

TYPECONVERT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-69

Exchange Blocks (ControlNet Interoperability) . . . . . . . . . . 3-70

REQFLAGARRAY (Request Flag Array) . . . . . . . . . . . . . 3-70

REQNUMARRAY (Request Number Array). . . . . . . . . . . 3-70

REQTEXTARRAY (Request Text Array) . . . . . . . . . . . . . 3-71

RSPFLAGARRAY (Response Flag Array) . . . . . . . . . . . . 3-71

RSPNUMARRAY (Response Number Array) . . . . . . . . . . 3-72

RSPTEXTARRAY (Response Text Array) . . . . . . . . . . . . 3-72

Pulse Input Channel/Module Blocks . . . . . . . . . . . . . . . . . 3-73

PICFASTCUTOFF

(Pulse Input Channel with Fast Cutoff) . . . . . . . . . . . . . 3-73

PICHANNEL (Pulse Input Channel). . . . . . . . . . . . . . . . 3-74

PITOTALIZER (Pulse Input Totalizer) . . . . . . . . . . . . . . 3-74

1757-PIM (Pulse Input Module Block). . . . . . . . . . . . . . 3-75

Publication 1757-RM810A-EN-P - May 2002

Page 9

Chapter

Introduction to Control Builder Components

1

Component Categories and Types

We divide the Control Builder components into these two major

categories:

• Hardware Relation Category (physical equipment)

• Functional Relation Category

Hardware relation category

The hardware relation category includes the physical equipment

blocks provided in Control Builder. These blocks let you quickly

integrate the related control hardware into your control strategy.

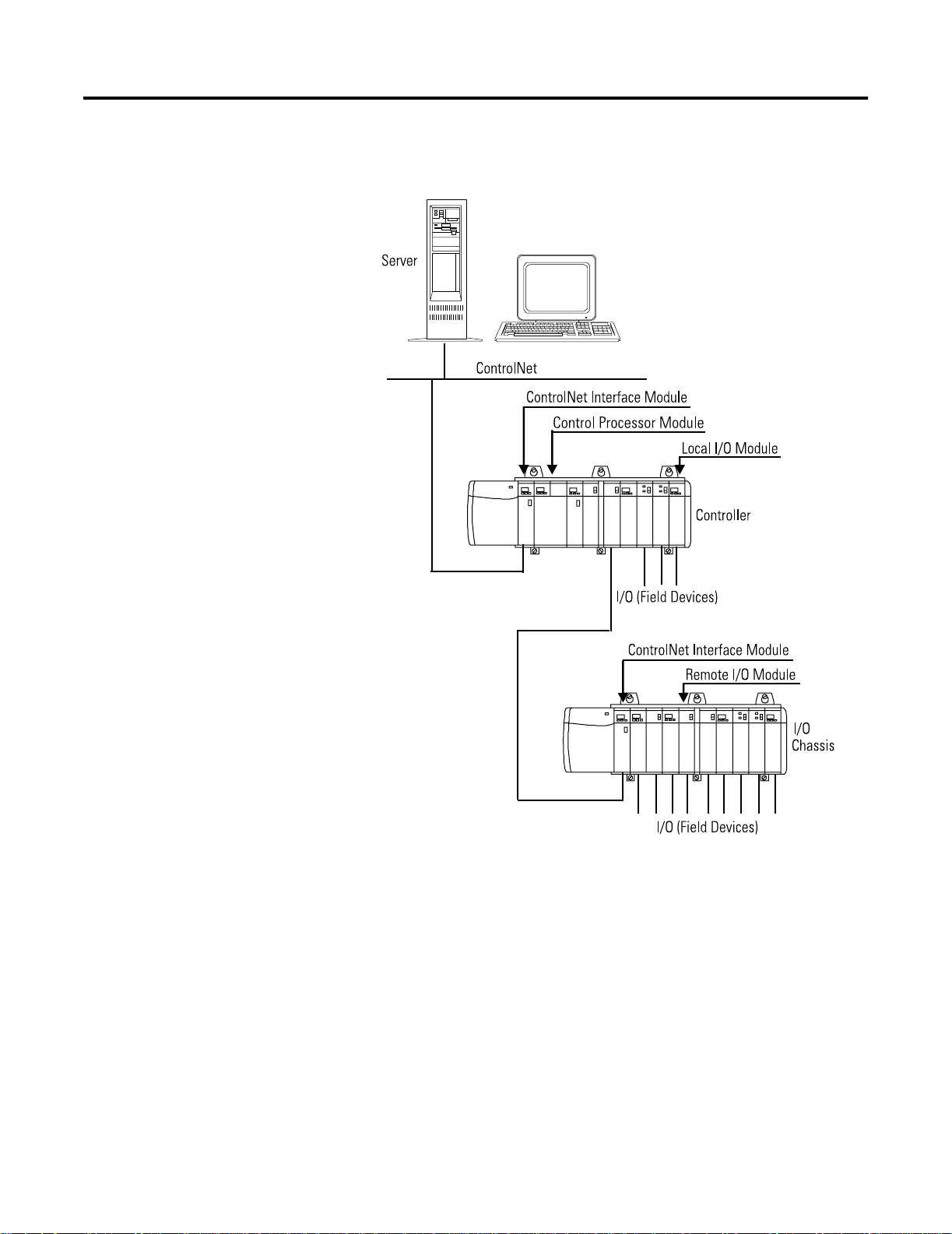

Figure 1.1 on page 1-2 shows the physical equipment that relates to

the corresponding hardware relations covered in this document for a

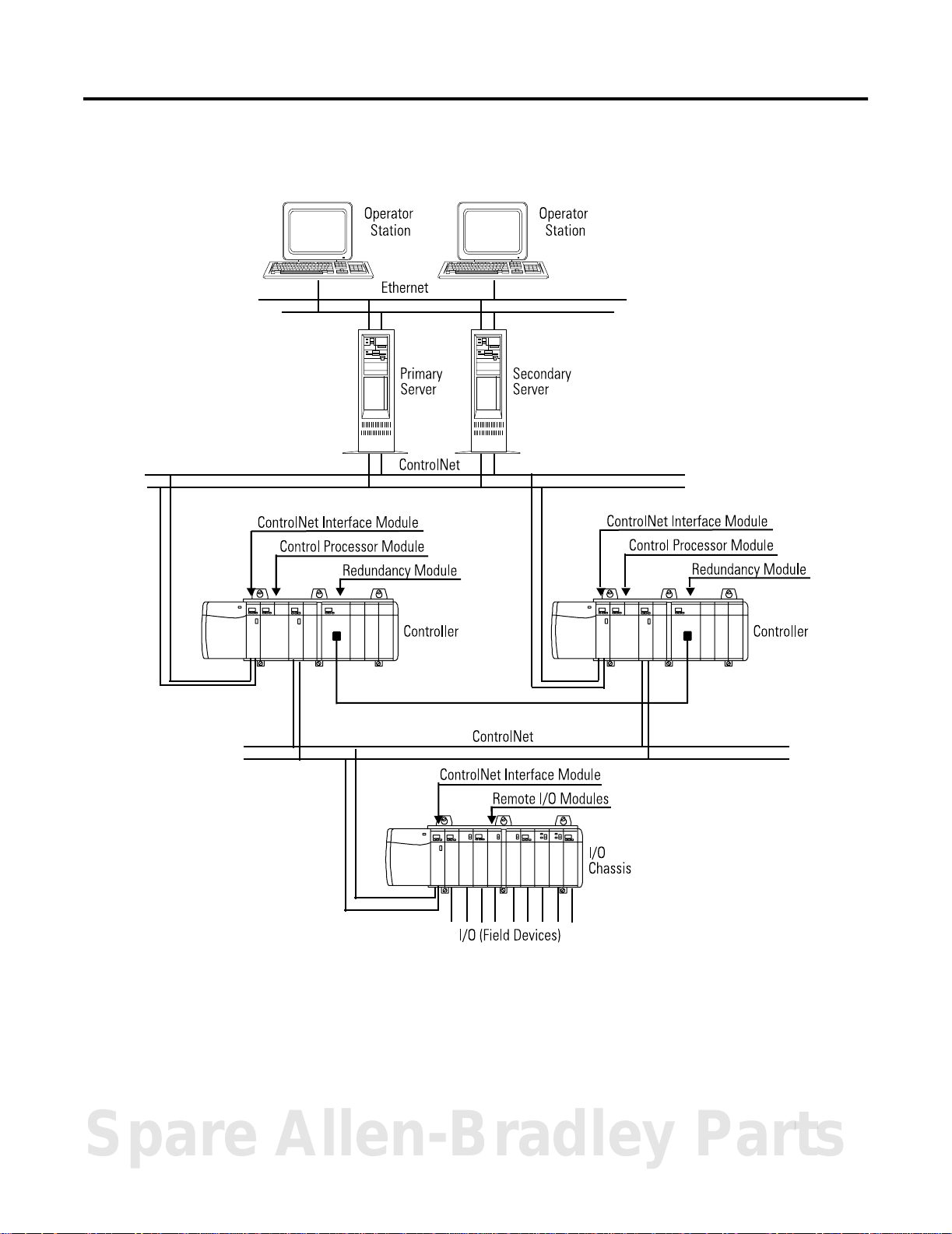

typical non-redundant system. Figure 1.2 on page 1-3 shows the

physical equipment that relates to the corresponding hardware

relations for a typical redundant system.

Spare Allen-Bradley Parts

1 Publication 1757-RM810A-EN-P - May 2002

Page 10

1-2 Introduction to Control Builder Components

Figure 1.1 Physical Equipment reference for corresponding hardware component

in typical non-redundant system architecture.

Publication 1757-RM810A-EN-P - May 2002

42778

Page 11

Introduction to Control Builder Components 1-3

Figure 1.2 Physical Equipment reference for corresponding hardware component

in typical redundant system architecture.

42779

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 12

1-4 Introduction to Control Builder Components

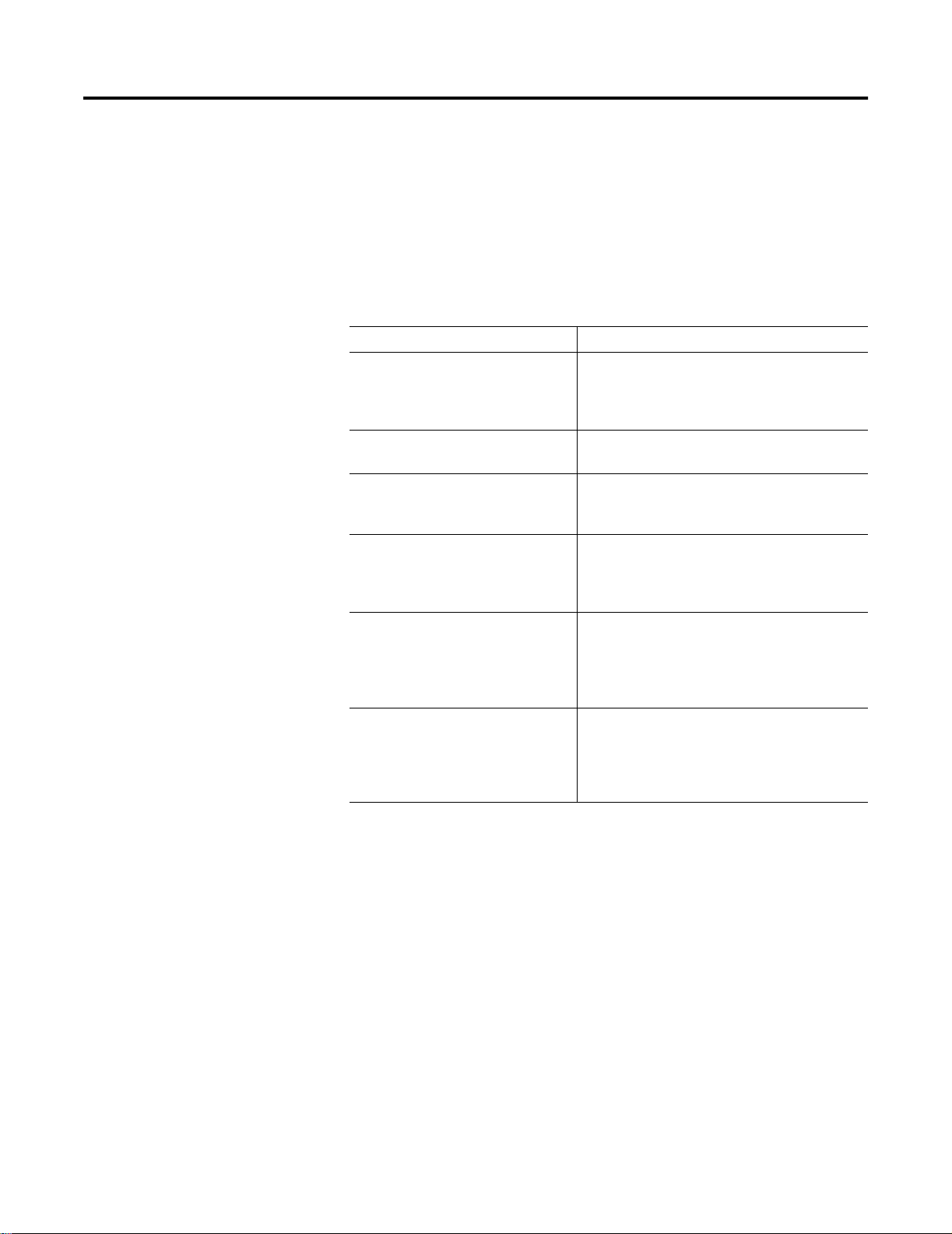

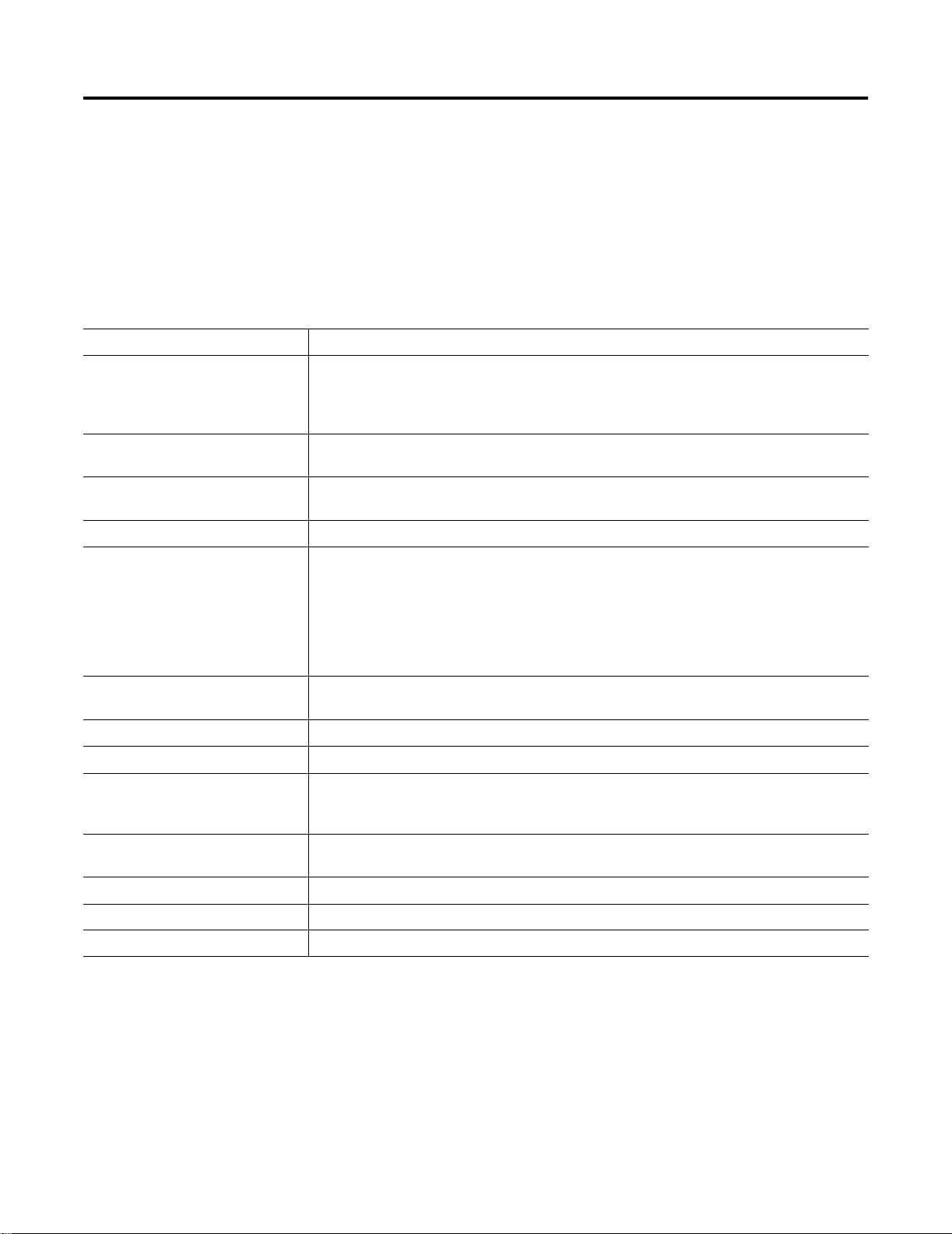

Physical equipment block types

Table identifies the physical equipment block types provided to

represent corresponding major control hardware components. The

Control Execution Environment (CEE) block is included as one of

these block types because of its relationship with the Control

Processor, although it is a functional type more than a physical one.

Physical Equipment Blocks

Type Description

Control Processor Module (CPM) Defines name/location and Control Execution

Environment (CEE) assignment for Primary and

Secondary CPMs in connected Hybrid Controllers.

This CPM is redundancy compliant.

Control Execution Environment (CEE) Supports block execution and communications in

given CPM.

Redundancy Module (RM) Defines name/location of Primary and Secondary

Redundancy Modules in Redundant Chassis Pair.

This module is redundancy compliant.

I/O Modules (IOM) Provides links for I/O channels to interface

physical I/O module to given Control Processor

Module. This includes 1756, 1757, 1797 FLEX Ex

and 1794 FLEX I/O modules.

Serial Interface Module (SIM) Provides configuration and communication

software to enable devices to communicateVia

an ASCII serial protocol to perform bi-directional

data exchange directly with the ProcessLogix

Control Processor.

Pulse Input Module Serves as the interface board between the

ProcessLogix Controller and field transducers

such as tachometers, flow meters, and magnetic

pickups. Module block descriptions are listed

under Functional Blocks, on page 3-73.

Publication 1757-RM810A-EN-P - May 2002

Page 13

Introduction to Control Builder Components 1-5

Functional relation category

Control Builder includes comprehensive libraries of function blocks

that streamline the control strategy configuration process. You simply

“drag and drop” selected blocks into a Control Module and/or

Sequential Control Module container to emulate the necessary

functional requirements of your process.

See the Control Builder Reference Manual, publication 1757-RM808,

for more information.

The functional relation category conveniently groups function blocks

according to a related functional block type or component library. The

component libraries provide a convenient way to group related

function blocks for easy access and reference.

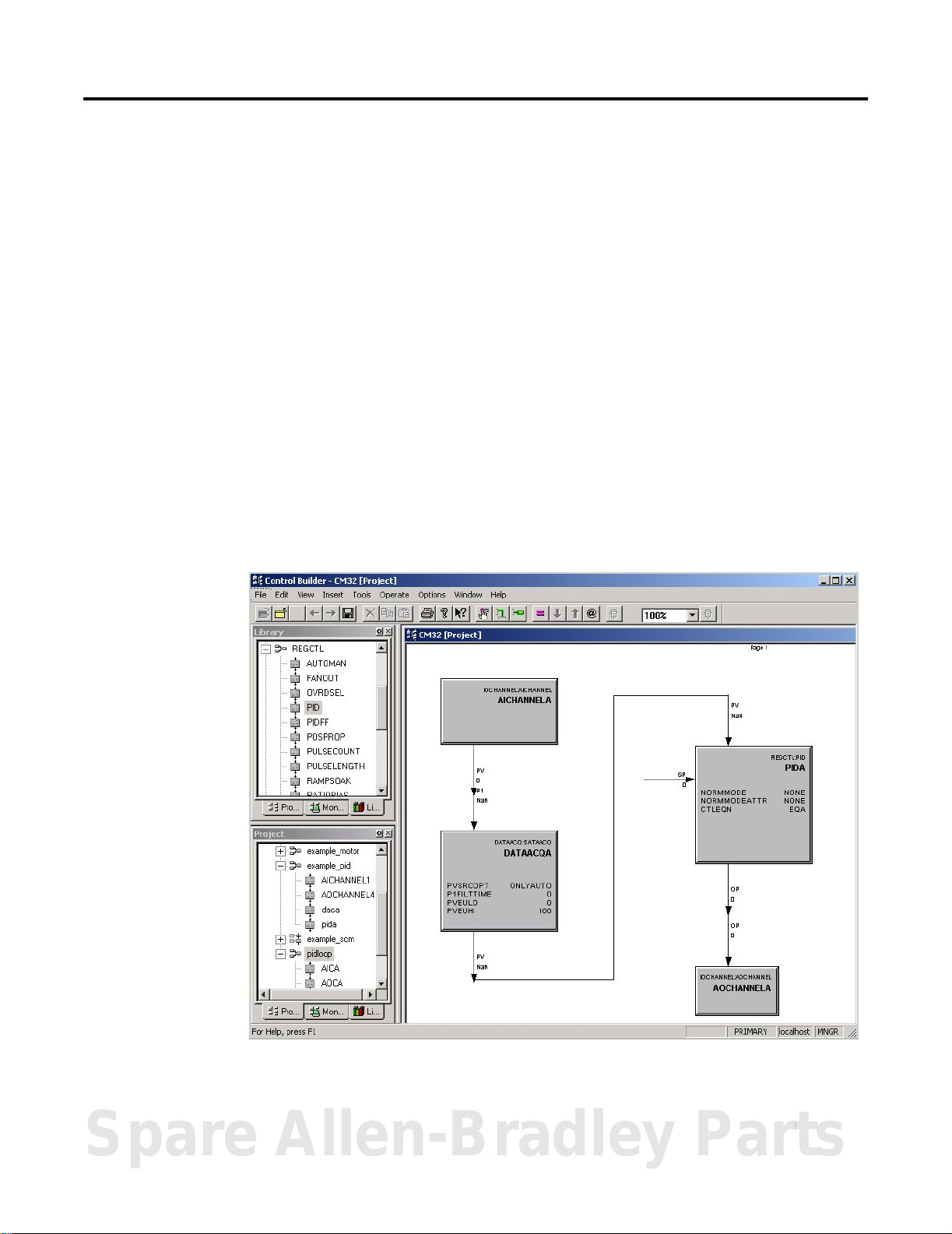

Figure 1.3 on page 1-5 shows the general graphic orientation and

Windows look-and-feel of Control Builder.

Figure 1.3 TypicalView of control module configuration in Control Builder.

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 14

1-6 Introduction to Control Builder Components

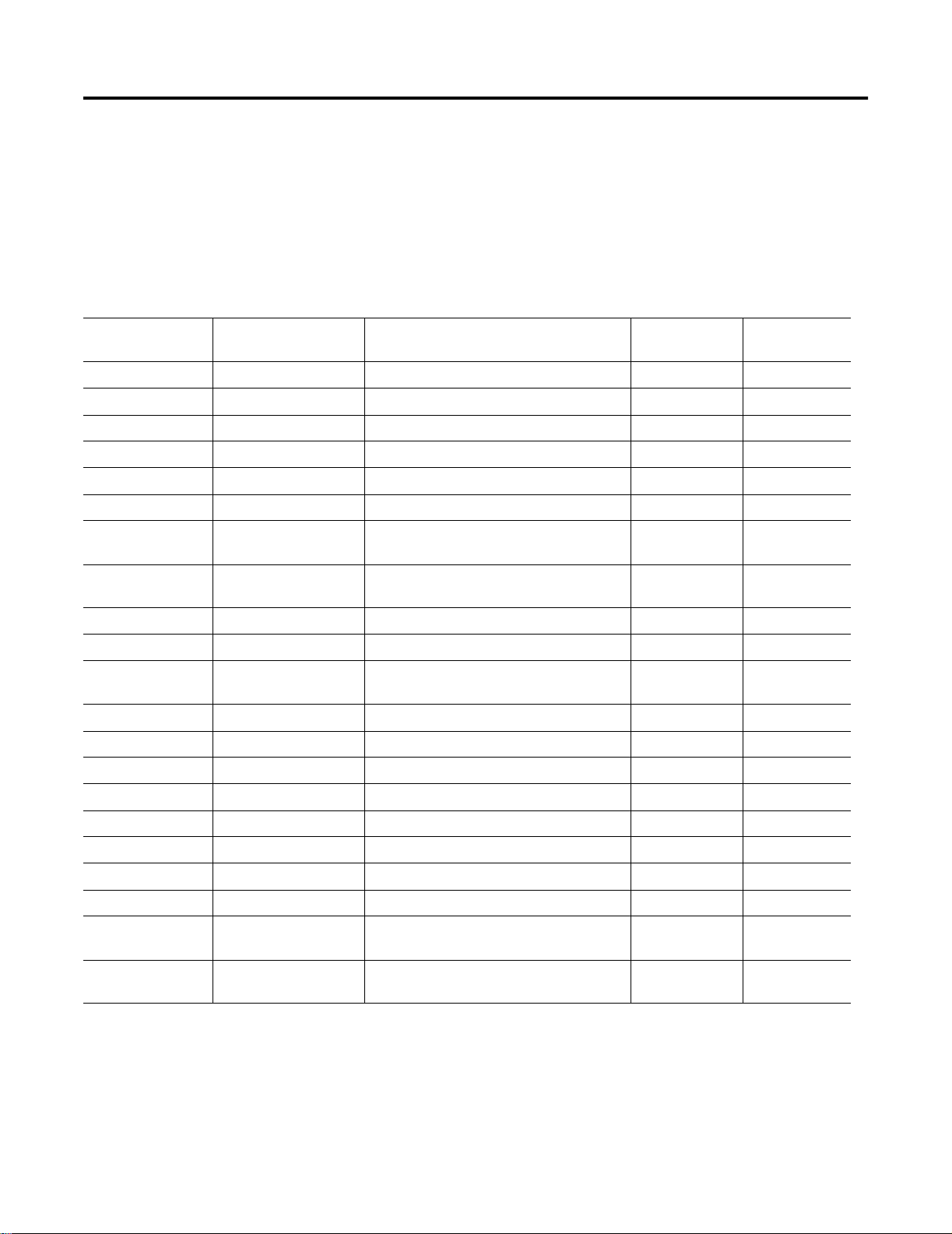

Functional block types

Table identifies the functional block types used to represent a group

of corresponding function blocks provided in Control Builder. These

block types are used as a way to simplify information retrieval for a

given function block, and do not necessarily correspond to an actual

Control Builder function.

Functional Blocks

Type Description

System/

Continuous Control/

Sequential Control

Auxiliary Includes block types for performing auxiliary control functions, such as: calculation, general

Device Control Provides a multi-input/multi-output function that provides an interface to discrete devices such as

Data Acquisition Provides signal conditioning for a process inputValue from another function block.

I/O Channel (IOC) Includes channel block types (analog input, analog output, digital input, digital output, pulse width

Logic Provides a set of Boolean, selection and comparison functions to be used as a basis for integrated

Regulatory Control Includes block types for building internal control loops.

Sequential Control Module Includes block types for building a sequential control function.

Utility Includes block types for performing utility control functions, such as: status flag, numeric storage

ControlNet Interoperability

(Exchange) Blocks

Control Module (CM) is a Control Builder “container” that uses predefined continuous (discrete)

control function blocks to define a given process control strategy.

Sequential Control Module (SCM) is a Control Builder “container” that uses predefined sequential

control function blocks to define the sequential operation for a given process control strategy.

linearization and totalization.

motors, pumps, solenoidValves, and motor-operatedValves.

modulator) to represent I/O points that are device independent; each I/O channel type has a

standard interface with control function blocks.

This category also includes array channel blocks to support communications with the associated

Serial Interface Module and the connected Field Terminal Assembly (FTA) device. You assign an

array channel block to one of the SIM block’s 32 channels as well as designating which of the two

FTAs it is associated with. The array channel block types are flag, numeric, and text.

logic control.

and timer capabilities. Blocks have been added for message, data array, and parameter type

convert support.

Includes block types for performing ControlNet Interoperability functions, such as: Flag, Numeric

and Text storage.

Pulse Input Channel/ Module Blocks Provides a standard interface to the Pulse Input Module, 1757-PIM.

PROFIBUS Interface Provides a standard interface to the PROFIBUS Interface Module, SST-PFBCLX.

Fieldbus Interface Provides a standard interface to the Fieldbus Interface Module, 1757-FIM.

Publication 1757-RM810A-EN-P - May 2002

Page 15

Introduction to Control Builder Components 1-7

Component Libraries

System (SYSTEM) Library

The System Library includes the function blocks listed below. Detailed

descriptions are given in the following chapter titled Functional

Blocks.

• CONTROL MODULE

• SEQUENTIAL CONTROL MODULE

Auxiliary (AUXILIARY) Library

The Auxiliary Library includes the function blocks listed below.

Detailed descriptions are given in the following chapter titled

Functional Blocks.

• AUXCALC

• DEADTIME

• GENLIN

• LEADLAG

• TOTALIZER

Device Control (DEVCTL) Library

The Device Control Library includes the DEVCTL function block. A

detailed description is given in the following chapter titled Functional

Blocks.

Data Acquisition (DATAACQ) Library

The Data Acquisition Library includes the DATAACQ function block. A

detailed description is given in the following chapter titled Functional

Blocks.

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 16

1-8 Introduction to Control Builder Components

I/O Module Library

Input/Output Module (IO) Library

The Input/Output Module Library includes the Input/Output Module

(IOM) function blocks listed in the following table. Blocks are

identified by model number. Detailed descriptions are presented in

the following chapter titled Functional Blocks.

IOM Function

Blocks

1756-IA8D 8 Diagnostic Input 120V ac Yes

1756-IA16 16 Digital Input 120V ac No

1756-IA16I 16 Digital Input 120V ac Yes

1756-IB32 32 Digital Input 24V dc No

1756-IB16D 16 Diagnostic Input 24V dc Yes

1756-IB16I 16 Digital Input 24V dc Yes

1756-IF6I 6 Analog Input 10V and

1756-IF16 16 Analog Input 10V and

1756-IM16I 16 Digital Input 220V ac Yes

1756-IT6I 6 Resistance Temperature Detector (RTD) Input Resistance Yes

1756-IR6I 6 Thermocouple Input Low level mV No

1756-OA8D 8 Diagnostic Output 120V ac Yes

1756-OA16 16 Digital Output 120/220V ac No

1756-OA16I 16 Digital Output 120/220V ac Yes

Number of Channels Type Rating Isolated

Yes

4 to 20 mA

No

4 to 20 mA

1756-OB16D 16 Diagnostic Output 24V dc Yes

1756-OB32 32 Digital Output 24V dc No

1756-OB16I 16 Digital Output 24V dc Yes

1756-OF6CI 6 Analog Output 4 to 20 mA Yes

TC-OAV061 6 Analog Output 10V Yes

1756-OF8 8 Analog Output 10V and

4 to 20 mA

TC-MUX021 Up to 32 FTA Array

Points

Publication 1757-RM810A-EN-P - May 2002

Bi-directional data exchange with devices

using ASCII serial protocol communications

Modbus FTA or

A-B FTA

No

Page 17

Introduction to Control Builder Components 1-9

Input/Output Channel (IOCHANNEL) Library

The Input/Output Channel Library includes the function blocks listed

below. Detailed descriptions are given in the following chapter titled

Functional Blocks.

• AICHANNEL

• DOCHANNEL

• AOCHANNEL

• PWMCHANNEL

• DICHANNEL

• SIFLAGARRCH

• SINUMARRCH

• SITEXTARRCH

Logic (LOGIC) Library

The Logic Library includes the function blocks listed below. Detailed

descriptions are given in the following chapter titled Functional

Blocks.

• AND

• CHECKBAD

• DELAY

• EQ

• FTRIG

• GE

• GT

• LE

• LIMIT

• LT

• MAX

• MAXPULSE

• MIN

• MINPULSE

• MUX

• MUXREAL

• MVOTE

• NAND

• NE

• nOON

• NOR

• NOT

• OFFDELAY

• ONDELAY

• OR

• PULSE

• QOR

• ROL

• ROR

• RS

• RTRIG

• SEL

• SELREAL

• SHL

• SHR

• SR

• TRIG

• WATCHDOG

• XOR

• 2OO3

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 18

1-10 Introduction to Control Builder Components

Regulatory Control (REGCTL) library

The Regulatory Control Library includes the function blocks listed

below. Detailed descriptions are given in the following chapter titled

Functional Blocks.

• AUTOMAN

• FANOUT

• OVRDSEL

• PID

• PIDEXTRESET

• PIDFF

• POSPROP

• PULSECOUNT

• PULSELENGTH

• RAMPSOAK

• RATIOBIAS

• REGCALC

• REMCAS

• SWITCH

Sequential Control Module (SCM) library

The Sequential Control Module Library includes the function blocks

listed below. Detailed descriptions are given in the following chapter

titled Functional Blocks.

• HANDLER

• STEP

• TRANSITION

Publication 1757-RM810A-EN-P - May 2002

Utility (UTILITY) Library

The Utility Library includes the function blocks listed below. Detailed

descriptions are given in the following chapter titled Functional

Blocks.

• FLAG

• FLAGARRAY

• MESSAGE

• NUMERIC

• NUMERICARRAY

• PUSH

• TEXTARRAY

• TIMER

• TYPECONVERT

Page 19

Introduction to Control Builder Components 1-11

ControlNet Interoperability (Exchange) Library

The Exchange Library includes the function blocks listed below.

Detailed descriptions are given in the following chapter titled

Functional Blocks.

• REQFLAGARRAY

• RSPFLAGARRAY

• REQNUMARRAY

• RSPNUMARRAY

• REQTEXTARRAY

• RSPTEXTARRAY

Pulse Input Channel/Module (PULSEINPUT) Library

The Pulse Input Channel/Module Library includes the function blocks

listed below. Detailed descriptions are given in the following chapter

titled Functional Blocks.

• Pulse Input Channel with Fast Cutoff

• Pulse Input Channel

• Pulse Input Module

• Pulse Input Totalizer

1797 FLEX Ex Modules (RAIL_IO_HAZ)

The 1797 FLEX Ex I/O Library includes the IOM blocks associated

with the 1797 FLEX EX components designed for use in locations with

potentially explosive atmospheres. Please refer to the 1797 FLEX Ex

Implementation Guide in Knowledge Builder for complete details

about the 1797 FLEX Ex I/O Modules.

Profibus Interface (PBUSIF) Library

The Profibus Interface Library includes the blocks associated with

linking Profibus devices with the ProcessLogix system. Please refer to

the Profibus Interface Implementation Guide in Knowledge Builder

for complete details about Profibus components.

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 20

1-12 Introduction to Control Builder Components

1794 FLEX I/O Modules (RAIL_IO)

The 1794 FLEX I/O Module library includes the IOM blocks associated

with the 1794 FLEX I/O components designed for use in general

purpose locations. Please refer to the 1794 FLEX I/O Implementation

Guide in Knowledge Builder for complete details about the 1794 FLEX

I/O Modules.

Fieldbus Interface (FBUSIF) Library

The Fieldbus Interface Library includes the IOM and IOC blocks

associated with linking F

ProcessLogix system through the Linking Device. Please refer to the

Linking Device Implementation Guide in Knowledge Builder for

complete details about the Fieldbus Interface components.

OUNDATION Fieldbus devices with the

Publication 1757-RM810A-EN-P - May 2002

Page 21

Physical Equipment Blocks

Chapter

2

Overview

This section provides detailed reference data for each physical

equipment block type that is part of the hardware relation category for

Control Builder.

See the ProcessLogix Function Block Parameter Reference Manual,

publication 1757-RM811A-EN-P, for definitions of each parameter.

Control Processor Module (CPM)

Description Identifies the primary and secondary Control Processor Modules (CPM) and associated CEE to implement the control

strategy built in the Control Builder application. This block’s parameters characterize the redundant CPM as a whole.

This block always runs at an execution period of 2 seconds. It is redundancy compliant.

Function • Supports Hybrid Controller Redundant Chassis Pair hardware configurations.

• Publishes parameters describing the status and configuration of the CPM.

• Processes the computation of statistical parameters and notification reporting.

• Serves as a faceplate for any parameters whose scope corresponds to that of the entire CPM.

• Secondary waits to take control if the “Primary” fails.

• The address of the Secondary chassis equals the address of the Primary chassis plus one.

Inputs Integrated Control Protocol (ICP) communications

Outputs See above.

Parameters ALMENBSTATE

BATTERYNOTOK

CCLCNT

CCLINFO

CCLLOADSTAT

CCLNAME

CEECOMMAND

CEESTATE

CPMCOMMAND

[0..numChans-1]

CPMSTATE

CPUFREEAVG

CPUFREEMIN

DESC

DRIVERNAME

EUDESC

FREEMEM

FREEMEMINK

HIALM

INALM

IPADDRESS

MAXFREEBLKSZ

MAXFREEINK

MODISREDUN

MULREDUNSTAT

NETWORKTYPE

PCMSTATE

RAMSCRUBERRS

RAMSWEEPERR

RDNCAPABILITY

RDNCHASSISID

RDNDELAYAVG

RDNDELAYMAX

RDNSYNCSTATE

RDNXFERAVG

RDNXFERMAX

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SECMODNAME

SECNAMESTRING

SECTMPNAME

SLOTNUMBER

STATSRESET

TOTALMEM

TOTALMEMINK

ULCNBMAC

USEDMEM

USEDMEMINK

USESIM

Spare Allen-Bradley Parts

1 Publication 1757-RM810A-EN-P - May 2002

Page 22

2-2 Physical Equipment Blocks

Control Execution Environment (CEE)

Description Provides control functionality for associated Control Processor Module block. This block’s parameters characterize the

CEE within the CPM. In the future, multiple CEEs may be assigned to a single CPM.

This block always runs at an execution period of 2 seconds.

There are two versions of the CEE available, the standard version CEE-50ms, and the fast version CEE-5ms.

Function • Publishes parameters describing the status and configuration of the CEE.

• Processes the computation of statistical parameters and notification reporting.

• Runs on the CPM hardware platform. In the future, CEE will run on other platforms as well.

• Serves as a faceplate for any parameters whose scope corresponds to that of the CEE rather than the CPM as a

whole.

• Supports configurable subscription rate for peer-to-peer communications.

• Supports peer-to-peer communications among CEEs assigned to CPMs located in the same management domain.

• Sequential Control Module function blocks are supported. Special care should be taken in configuring the SCMs in

5 msec CEE.

Inputs Integrated Control Protocol (ICP) communications

Outputs See above.

Parameters ALMENBSTATE

BASEPERIOD

CEECOMMAND

CEESTATE

CPUCYCLEAVG [0..39]

CPUCYCLEMAX [0..39]

CPUFREEAVG

CRCYCLEOVRN [0..40]

DESC

EUDESC

HIALM

INALM

LSCYCLEOVRN [0..40]

NUMACCRQUAVG

NUMACCRQUMAXNUMCC

LRQU

NUMNTFRQUAVG

NUMNTFRQUMAX

NUMPARRSPAVG

NUMPARRSPMAX

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

STATSRESET

SUBSCPERIOD

Publication 1757-RM810A-EN-P - May 2002

Page 23

Physical Equipment Blocks 2-3

Redundancy Module (RM)

Description Identifies the Primary and Secondary Redundancy Modules connected by a dedicated redundancy cable in a

Redundant Chassis Pair (RCP). It associates the Primary RM with its “partner” Secondary RM block.

This block always runs at an execution period of 2 seconds. It is redundancy compliant.

Function • Provides parameters describing the status and configuration of the RM.

• Handles notification reporting.

• Serves as a faceplate for any parameters whose scope corresponds to that of the RM as a whole.

Inputs Integrated Control Protocol (ICP) communications

Redundancy communications through the redundancy cable.

Outputs See above.

Parameters ALMENBSTATE

AREVISION

AUTOSYNCCMD

AUTOSYNCOPT

AUTOSYNCSTAT

AVERSION

BECMPRICMD

BREVISION

BVERSION

CHANINUSE [0..31]

CJDISABLE

CLKADJUST

CLKTIME

CLKZONE

CONFIGURED

DISPPOS

DISQSECCMD

DRIVERNAME

ENTERSBYCMD

ERRFL

ERRORCODE

ERRORMSGIDX

EUDESC

GENSTATE

GENSTATEA

HIALM

INTISWCMD

IPADDRESS

KEYWORD

LASTSYNCABRT

LASTSYNCARES

MAJRECFAULT

MAJURECFAULT

MINRECFAULT

MINURECFAULT

MODCOMPATA

MODTYPEA

MULREDUNSTAT

NETWORKTYPE

NUMSLOTS

PREVISION

PRODCODE

PRODTYPE

PRODTYPEA

PROGCMD

PROGCMDRECOG

QUALPROGA

READINESS

READINESSA

RECOVMSGIDX

REDUNSTATE

REDUNSTATEA

REFRESHMS

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SECMODNAME

SECNAMESTRING

SECTMPNAME

SERIALNUM

SLOTNUMBER

STDTIME

SWAPCTRLCMD

SWAPPOSCMD

SWAPSBYCMD

SYNCSECCMD

ULCNBMAC

VENDORID

WCTCLKTIME

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 24

2-4 Physical Equipment Blocks

Input Module Blocks

1756-IA16

1756-IA16 (16-Channel - 120Vac Non-Isolated - Digital Input)

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 16 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device.

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

COS [0..numChans-1]

DESC

DLCNBSLOT

ELOF [0..numChans-1]

ESTWEIGHT

EUDESC

EWIREOFF [0..numChans-1]

EXECSTATE

FILTERHDR

[0..numChans-1]

FILTEROFF [0..numChans/8]

FILTERON [0..numChans/8]

HIALM

HWFAULT [0..numChans-1]

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NOFIELDPWR

[0..numChans-1]

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

PVVAL [0..numChans-1]

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

WIREOFF [0..numChans-1]

Publication 1757-RM810A-EN-P - May 2002

Page 25

Physical Equipment Blocks 2-5

1756-IA16I

16-Channel - 120Vac Isolated - Digital Input

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 16 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device.

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

COS [0..numChans-1]

DESC

DLCNBSLOT

ELOF [0..numChans-1]

ESTWEIGHT

EUDESC

EWIREOFF [0..numChans-1]

EXECSTATE

FILTERHDR

[0..numChans-1]

FILTEROFF [0..numChans/8]

FILTERON [0..numChans/8]

HIALM

HWFAULT [0..numChans-1]

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NOFIELDPWR

[0..numChans-1]

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

PVVA L [0..numChans-1]

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

WIREOFF [0..numChans-1]

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 26

2-6 Physical Equipment Blocks

1756-IA8D

8-Channel - 120Vac Diagnostic Input

Description Identifies the physical IOM for the CPM to provide links to associated IOC and provides selected diagnostic

information for associated channels.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Supports the following diagnostics, which are user configurable for each channel:

– Open Wire Detection: Senses when current input for a given channel falls below a certain value. When an

input uses dry contacts, you must include a bleed resistor in the input. You may not need a bleed resistor for

solid state contacts.

– Loss of Field Power: Senses when field power of a group of channels is lost.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 8 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device.

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ESTWEIGHT

EUDESC

EXECSTATE

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

Publication 1757-RM810A-EN-P - May 2002

Page 27

Physical Equipment Blocks 2-7

1756-IB16D

116-Channel - 24Vdc Diagnostic Input

Description Identifies the physical IOM for the CPM to provide links to associated IOC and provides selected diagnostic

information for associated channels.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Supports the following diagnostic, which is user configurable for each channel:

– Open Wire Detection: Senses when current input for a given channel falls below a certain value. When an

input uses dry contacts, you must include a bleed resistor in the input. You may not need a bleed resistor for

solid state contacts.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 16 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device.

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ESTWEIGHT

EUDESC

EXECSTATE

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 28

2-8 Physical Equipment Blocks

1756-IB16I

116 Channel - 24Vdc Isolated - Digital Input

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 16 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device. Data is “triggered”, or is current digital (Boolean) value.)

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

COS [0..numChans-1]

DESC

DLCNBSLOT

ELOF [0..numChans-1]

ESTWEIGHT

EUDESC

EWIREOFF

[0..numChans-1]

EXECSTATE

FILTERHDR

[0..numChans-1]

FILTEROFF

[0..numChans/8]

FILTERON [0..numChans/8]

HIALM

HWFAULT [0..numChans-1]

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NOFIELDPWR

[0..numChans-1]

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

PVVAL [0..numChans-1]

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

WIREOFF [0..numChans-1]

1756-IB32

32 Channel - 24Vdc Non-Isolated - Digital Input

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 32 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device. Data is “triggered”, or is current digital (Boolean) value.)

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

COS [0..numChans-1]

DESC

DLCNBSLOT

ELOF [0..numChans-1]

ESTWEIGHT

EUDESC

Publication 1757-RM810A-EN-P - May 2002

EWIREOFF

[0..numChans-1]

EXECSTATE

FILTERHDR

[0..numChans-1]

FILTEROFF

[0..numChans/8]

FILTERON [0..numChans/8]

HIALM

HWFAULT [0..numChans-1]

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NOFIELDPWR

[0..numChans-1]

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

PVVAL [0..numChans-1]

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

WIREOFF [0..numChans-1]

Page 29

Physical Equipment Blocks 2-9

1756-IF6I

6-Channel, 10V, 4–20mA, Isolated Analog Input

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 6 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device.

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

BADCAL [0..numChans-1]

CALBIAS [0..numChans-1]

CATNUMBER

CEESTATE

CHANTEXT

CJDISABLE

CJOFFSET

CJOFFSET

[0..numChans-1]

DESC

DIGFILTER

[0..numChans-1]

DLCNBSLOT

ESTWEIGHT

EUDESC

EXECSTATE

HIALM

HIGHENG [0..numChans-1]

HIGHSIGNAL

[0..numChans-1]

IFTRANS

INALM

INPUTRANGE

[0..numChans-1]

IOMSLOT

IOMTYPE

KEYWORD

LOWENG [0..numChans-1]

LOWSIGNAL

[0..numChans-1]

MAJORREV

MINORREV

NOTCHFILTER

[0..numChans-1]

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

OHMOFFSET

[0..numChans-1]

ORDERINCEE

ORDERINCM

OVERRANGE

[0..numChans-1]

PERIOD

PHASE

PRODTYPE

PVRAW [0..numChans-1]

RTPPRESENT

SAMPLERATE

1756-IF16

16-Channel,10V, 4 –20mA, Non-Isolated Analog Input

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SENSORTYPE

[0..numChans-1]

SIPTYPE [0..numChans-1]

TEMPMODE

ULCNBMAC

UNDERRANGE

[0..numChans-1]

UPDATOPT

VENDOR

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 16 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device.

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ESTWEIGHT

EUDESC

EXECSTATE

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 30

2-10 Physical Equipment Blocks

1756-IM16I

6-Channel - 220Vac Isolated - Digital Input

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 16 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device.

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

COS [0..numChans-1]

DESC

DLCNBSLOT

ELOF [0..numChans-1]

ESTWEIGHT

EUDESC

EWIREOFF [0..numChans-1]

EXECSTATE

FILTERHDR

[0..numChans-1]

FILTEROFF [0..numChans/8]

FILTERON [0..numChans/8]

HIALM

HWFAULT [0..numChans-1]

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NOFIELDPWR

[0..numChans-1]

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

PVVAL [0..numChans-1]

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

WIREOFF [0..numChans-1]

1756-IR6I

6-Channel - RTD Input

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 6 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device.

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ESTWEIGHT

Publication 1757-RM810A-EN-P - May 2002

EUDESC

EXECSTATE

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

Page 31

Physical Equipment Blocks 2-11

1756-IT6I

6-Channel - Thermocouple Input

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 6 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from physical device.

Outputs Real-time data transmission to configured IOC.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ESTWEIGHT

EUDESC

EXECSTATE

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 32

2-12 Physical Equipment Blocks

Output Module Blocks

1756-OA16

116-Channel - 120/220Vac Non-Isolated - Digital Output

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 16 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from configured IOC.

Outputs Real-time data transmission to physical device.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ENOLOAD

[0..numChans-1]

ESTWEIGHT

ETRANS

EUDESC

EVERIFY [0..numChans-1]

EXECSTATE

EZCROSS [0..numChans-1]

FAILSTATE

[0..numChans-1]

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NOFIELDPWR

[0..numChans-1]

NOLOAD [0..numChans-1]

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

PVSTS

PVVAL [0..numChans-1]

PWMPERIOD

[0..numChans-1]

SAFESTATE

[0..numChans-1]

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SHORT [0..numChans-1]

ULCNBMAC

UPDATOPT

VENDOR

VERIFYLOST

[0..numChans-1]

Publication 1757-RM810A-EN-P - May 2002

Page 33

Physical Equipment Blocks 2-13

1756-OA16I

16-Channel - 120/220Vac Isolated - Digital Output

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 16 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from configured IOC.

Outputs Real-time data transmission to physical device.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ENOLOAD

[0..numChans-1]

ESTWEIGHT

ETRANS

EUDESC

EVERIFY [0..numChans-1]

EXECSTATE

EZCROSS [0..numChans-1]

FAILSTATE

[0..numChans-1]

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NOFIELDPWR

[0..numChans-1]

NOLOAD [0..numChans-1]

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

PVSTS

PVVAL [0..numChans-1]

PWMPERIOD

[0..numChans-1]

SAFESTATE

[0..numChans-1]

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SHORT [0..numChans-1]

ULCNBMAC

UPDATOPT

VENDOR

VERIFYLOST

[0..numChans-1]

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 34

2-14 Physical Equipment Blocks

1756-OA8D

8-Channel - 120Vac- Diagnostic Output

Description Identifies the physical IOM for the CPM to provide links to associated IOC and provides selected diagnostic

information for associated channels.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Supports the following diagnostics, which are user configurable for each channel with the exception of the Short

Circuit Protection/Overload diagnostic which is always enabled:

– Short Circuit Protection/Overload: Senses when current draw for a given channel is above the limit and

protects the device from damage.

– Loss of Field Power: Senses lack of power for a channel, if zero-crossing on the ac-line power is not detected

which causes the output state to change.

– No Load/Hardware Point Fault: Senses when the output current draw falls below the threshold or a hardware

output failure occurs. It only works when the output is in the OFF state.

– Output Verification: Verifies if the actual output state matches the commanded output state for field side

verification. It only works when the output is in the ON state.

– Pulse Test: Periodically checks the output to verify that it still has the ability to change states without causing

the load to transition. (This function only operates in systems with software version R120 or greater.)

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 8 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from configured IOC. Data is “triggered”, or is current digital (Boolean) value or pulsed

(real) value.

Outputs Real-time data transmission to physical device.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ESTWEIGHT

EUDESC

EXECSTATE

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

Publication 1757-RM810A-EN-P - May 2002

Page 35

Physical Equipment Blocks 2-15

1756-OB16D

116-Channel - 24Vdc- Diagnostic Output

Description Identifies the physical IOM for the CPM to provide links to associated IOC and provides selected diagnostic

information for associated channels.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Supports the following diagnostics, which are user configurable for each channel with the exception of the Short

Circuit Protection/Overload diagnostic, which is always enabled.

– Short Circuit Protection/Overload: Senses when current draw for a given channel is above the limit and

protects the device from damage.

– No Load/Hardware Point Fault: Senses when the output current draw falls below the threshold or a hardware

output failure occurs. It only works when the output is in the OFF state.

– Output Verification: Verifies if the actual output state matches the commanded output state for field side

verification. It only works when the output is in the ON state.

– Pulse Test: Periodically checks the output to verify that it still has the ability to change states without causing

the load to transition. (This function only operates in systems with software version R120 or greater.)

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 16 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from configured IOC. Data is “triggered”, or is current digital (Boolean) value or pulsed

(real) value.

Outputs Real-time data transmission to physical device.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ESTWEIGHT

EUDESC

EXECSTATE

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

UPDATOPT

VENDOR

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 36

2-16 Physical Equipment Blocks

1756-OB16I

16-Channel - 24Vdc Isolated Digital Output

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 16 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from configured IOC. Data is “triggered”, or is current digital (Boolean) value or pulsed

(real) value.

Outputs Real-time data transmission to physical device.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ENOLOAD

[0..numChans-1]

ESTWEIGHT

ETRANS

EUDESC

EVERIFY [0..numChans-1]

EXECSTATE

EZCROSS [0..numChans-1]

FAILSTATE

[0..numChans-1]

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NOFIELDPWR

[0..numChans-1]

NOLOAD [0..numChans-1]

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

PVSTS

PVVAL [0..numChans-1]

PWMPERIOD

[0..numChans-1]

SAFESTATE

[0..numChans-1]

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SHORT [0..numChans-1]

ULCNBMAC

UPDATOPT

VENDOR

VERIFYLOST

[0..numChans-1]

Publication 1757-RM810A-EN-P - May 2002

Page 37

Physical Equipment Blocks 2-17

1756-OB32

2-Channel - 24Vdc Non-Isolated Digital Output

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 32 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from configured IOC. Data is “triggered”, or is current digital (Boolean) value or pulsed

(real) value.

Outputs Real-time data transmission to physical device.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ENOLOAD

[0..numChans-1]

ESTWEIGHT

ETRANS

EUDESC

EVERIFY [0..numChans-1]

EXECSTATE

EZCROSS [0..numChans-1]

FAILSTATE

[0..numChans-1]

HIALM

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NOFIELDPWR

[0..numChans-1]

NOLOAD [0..numChans-1]

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

PVSTS

PVVAL [0..numChans-1]

PWMPERIOD

[0..numChans-1]

SAFESTATE

[0..numChans-1]

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SHORT [0..numChans-1]

ULCNBMAC

UPDATOPT

VENDOR

VERIFYLOST

[0..numChans-1]

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 38

2-18 Physical Equipment Blocks

1756-OF6CI

6-Channel - 4 to 20mA - Analog Output

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 6 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from configured IOC.

Outputs Real-time data transmission to physical device.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

BADCAL [0..numChans-1]

CALBIAS

[0..numChans-1]

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ESTWEIGHT

EUDESC

EXECSTATE

FAULTVALUE

[0..numChans-1]

HIALM

HIGHENG [0..numChans-1]

HIGHSIGNAL

[0..numChans-1]

INALM

IOMSLOT

IOMTYPE

KEYWORD

LOWENG [0..numChans-1]

LOWSIGNAL

[0..numChans-1]

MAJORREV

MINORREV

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

OPFINAL [0..numChans-1]

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SAMPLERATE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SIPTYPE [0..numChans-1]

ULCNBMAC

UPDATOPT

VENDOR

1756-OF6VI

6-Channel - 10V - Analog Output

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 6 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from configured IOC.

Outputs Real-time data transmission to physical device.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

BADCAL [0..numChans-1]

CALBIAS [0..numChans-1]

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ESTWEIGHT

EUDESC

EXECSTATE

Publication 1757-RM810A-EN-P - May 2002

FAULTVALUE

[0..numChans-1]

HIALM

HIGHENG [0..numChans-1]

HIGHSIGNAL

[0..numChans-1]

INALM

IOMSLOT

IOMTYPE

KEYWORD

LOWENG [0..numChans-1]

LOWSIGNAL

[0..numChans-1]

MAJORREV

MINORREV

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

OPFINAL [0..numChans-1]

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SAMPLERATE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SIPTYPE [0..numChans-1]

ULCNBMAC

UPDATOPT

VENDOR

Page 39

Physical Equipment Blocks 2-19

1756-OF8

8-Channel - 10V & 4 to 20mA Non-Isolated - Analog Output

Description Identifies the physical IOM for the CPM to provide links to associated IOC.

Function • Defines type of IOM, number of channels, execution state, and communications path for data.

• Provides link to IOC through IO manager software resident in the CPM.

• Executes once every cycle.

• Includes IOC assignment to one of 8 channels (points), as part of IOM configuration.

Inputs Real-time data transmission from configured IOC.

Outputs Real-time data transmission to physical device.

Parameters ALMENBSTATE

ASACONNSTS

ASAERRCODE

ASAERRINFO

BADCAL [0..numChans-1]

CALBIAS [0..numChans-1]

CATNUMBER

CEESTATE

CHANTEXT

DESC

DLCNBSLOT

ESTWEIGHT

EUDESC

EXECSTATE

FAULTVALUE

[0..numChans-1]

HIALM

HIGHENG [0..numChans-1]

HIGHSIGNAL

[0..numChans-1]

INALM

IOMSLOT

IOMTYPE

KEYWORD

LOWENG [0..numChans-1]

LOWSIGNAL [0..numChans-1]

MAJORREV

MINORREV

NUMCHANS

NUMCONN

NUMDISCONN

NUMSHUTDOWN

OPFINAL [0..numChans-1]

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SAMPLERATE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SIPTYPE

[0..numChans-1]

ULCNBMAC

UPDATOPT

VENDOR

Serial Interface Module (SIM) TC-MUX021

Up to 32 Array Channel Function Blocks

Description Identifies the physical Serial Interface Module (SIM) for the CPM to provide links to associated Array Channel blocks

and provides selected diagnostic events for associated channels.

Function • Provides configuration and communication software to enable devices to communicate via an ASCII serial protocol

to perform bi-directional data exchange directly with the ProcessLogix Control Processor.

• Stores are not guaranteed during a failover. That is, the store attempt may occur in the primary, but not reach the

IO Module before the failover occurs. The secondary will not attempt to re-send the information.

Inputs Real-time data transmission from configured FTAs.

Outputs Real-time data transmission to physical device.

Parameters ALMENBSTATE

ASACONNSTS [0..7]

ASAERRCODE [0..7]

ASAERRINFO [0..7]

CATNUMBER

CEESTATE

CHANINUSE [0..31]

CHANSTS [0..31]

DESC

DLCNBSLOT

ERRCODE [0..31]

ERRFL [0..31]

ESTWEIGHT

EUDESC

EXECSTATE

FTAAOVRNFL

FTAASTS

FTABOVRNFL

FTA BS TS

INALM

IOMSLOT

IOMTYPE

KEYWORD

MAJORREV

MINORREV

NUMCHANS

NUMCONN [0..7]

NUMDISCONN [0..7]

NUMSHUTDOWN [0..7]

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PRODTYPE

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

ULCNBMAC

VENDOR

Spare Allen-Bradley Parts

Publication 1757-RM810A-EN-P - May 2002

Page 40

2-20 Physical Equipment Blocks

Publication 1757-RM810A-EN-P - May 2002

Page 41

Functional Blocks

Chapter

3

Overview

This section provides detailed reference data for each functional block

type that is part of the functional relation category for the Control

Builder. It presents the block types associated with a given

component library. The reference data is organized alphabetically by

component library/block type, and then alphabetically within each

type by the function block name.

See the ProcessLogix Function Block Parameter Reference Manual,

publication 1757-RM811, for definitions of each parameter.

System Blocks

CONTROLMODULE (Continuous Control)

Description One of two system container blocks supported by CEE. It holds continuous and discrete function blocks.

Function Configurable building block for defining control strategies. Lets you encapsulate strategies according to function.

It provides these basic services for configured blocks:

• Serves as the unit of load for continuous and discrete control strategies.

• Transfers data between passive parameters that have no associated active connector.

• Executes component function blocks in an established order, which is configurable or arbitrarily determined by the

CM.

• Provides independent tag names component blocks their parameters.

• Serves the execution master for continuous and discrete control strategies.

Inputs Input parameters for component blocks that connect to other CMs and SCMs.

Outputs Output parameters for component blocks that connect to other CMs and SCMs.

Parameters ALMENBSTATE

CEESTATE

CONNLISTSIZE

DESC

ESTWEIGHT

EUDESC

EXECSTATE

HIALM

INALM

INSERTINDEX

KEYWORD

LOADSTATE

ORDERINCEE

ORDERINCM

PERIOD

PHASE

PREVLOADSTAT

SCANAREA

SCANASSOCDSP

SCANCTRLLVL

SCANEUHI

SCANEULO

SCANGRPDTL

SCANPNTDTL

SCMASTEP [1..10]

SCMID

SCMMODE

SCMNAME

SCMOPT

SCMSTATE

TBREF [0..2]

UNITTEXT

VERSION

Spare Allen-Bradley Parts

1 Publication 1757-RM810A-EN-P - May 2002

Page 42

3-2 Functional Blocks

SCM (Sequential Control)

Description A system container block that consists of sequences of STEP and TRANSITION blocks grouped by specific HANDLER

blocks.

• The SCM block may only contain its own components (that is, HANDLER, STEP and TRANSITION blocks); it cannot

contain other basic blocks such as PID or logic blocks.

Function Used to organize normal- and exception-based sequential control logic.

Parameters ABORTALM.FL

ABORTALM.PR

ABORTALM.SV

ABORTLOCK

ACTIVEHANDLR [1..8]

ACTIVELOC.HANDLER

ACTIVELOC.HANDLERN

ACTIVELOC.HNDTYPE

ACTIVELOC.STEP [1..10]

ACTIVELOC.STEPN [1..10]

ACTIVELOC.TIME [1..10]

ALIASBLKTYP [ ]

ALIASOPT

ALIASPRMTYP [ ]

ALMENBSTATE

AUXCMD

AUXOPT

AUXREQ

AUXREQDATA [1..5]

AUXSTS

AUXUNIT

CEESTATE

CMDEXEC

COMMAND

CONFIGCODE

CONFIGDESC

CONFIGSTS

CONTROLLOCK

DESC

ENBHANDLER [1..8]

ESTWEIGHT

EUDESC

EVALTRANS [1..10] [1..10]

EVALTRANSN [1..10]

[1..10]

EXCMODEOPT

EXECCODE

EXECDESC

EXECSTATE

EXECSTS

FAILALM.FL

FAILALM.PR

FAILALM.SV

HIALM

HIALM.PR

HIALM.SV

HIALM.TYPE

HISTDESC

HOLDALM.FL

HOLDALM.PR

HOLDALM.SV

INALM

INSERTINDEX

INSTSELECT

INVCOND [1..8]

INVFRMHNDLER [1..8]

INVFRMHNDLERN [1..8]

INVFRMHNDTYP [1..8]

INVFROMSTEP [1..8] [1..10]

INVFROMSTEPN [1..8]

[1..10]

INVREASON [1..8]

INVTHREAD [1..8]

INVTIME [1..8]

KEYWORD

LOADSTATE

MODE

MODEATTR

NORMMODE

NORMMODEATTR

NUMALIASES

NUMHISTPARMS

NUMINSTANCES

NUMRECPARMS

NUMTHREADS

NUMTRANS

ORDERINCEE

ORDERINCM

PAUSEFL

PERIOD

PHASE

PREVLOADSTAT

RECDESC [1..50]

RECMATCODE [1..50]

RECSCALE [1..50]

RECTARGET [1..50]

RECTARGETMAX [1..50]

RECTARGETMIN [1..50]