Page 1

ControlLogix Digital I/O Modules

Catalog Numbers 1756-IA8D, 1756-IA16, 1756-IA16I, 1756-IA32, 1756-IB16, 1756-IB16D, 1756-IB16I, 1756-IB16IF, 1756-IB32,

1756-IC16, 1756-IG16, 1756-IH16I, 1756-IM16I, 1756-IN16, 1756-IV16, 1756-IV32, 1756-OA8, 1756-OA8D, 1756-OA8E,

1756-OA16, 1756-OA16I, 1756-OB8, 1756-OB8EI, 1756-OB8I, 1756-OB16D, 1756-OB16E, 1756-OB16I, 1756-OB16IEF,

1756-OB16IEFS, 1756-OB16IS, 1756-OB32, 1756-OC8, 1756-OG16, 1756-OH8I, 1756-ON8, 1756-OV16E, 1756-OV32E,

1756-OW16I, 1756-OX81

User Manual

Page 2

Important User Information

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from

your local Rockwell Automation® sales office or online at http://www.rockwellautomation.com/literature/

) describes some

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

Allen-Bradley, ControlLogix, ControlLogix-XT, DH+, Data Highway Plus, Integrated Architecture, Rockwell Software, Rockwell Automation, RS Logix, RSNetWorx, and TechConnect are trademarks of Rockwe ll

Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Page 3

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 3

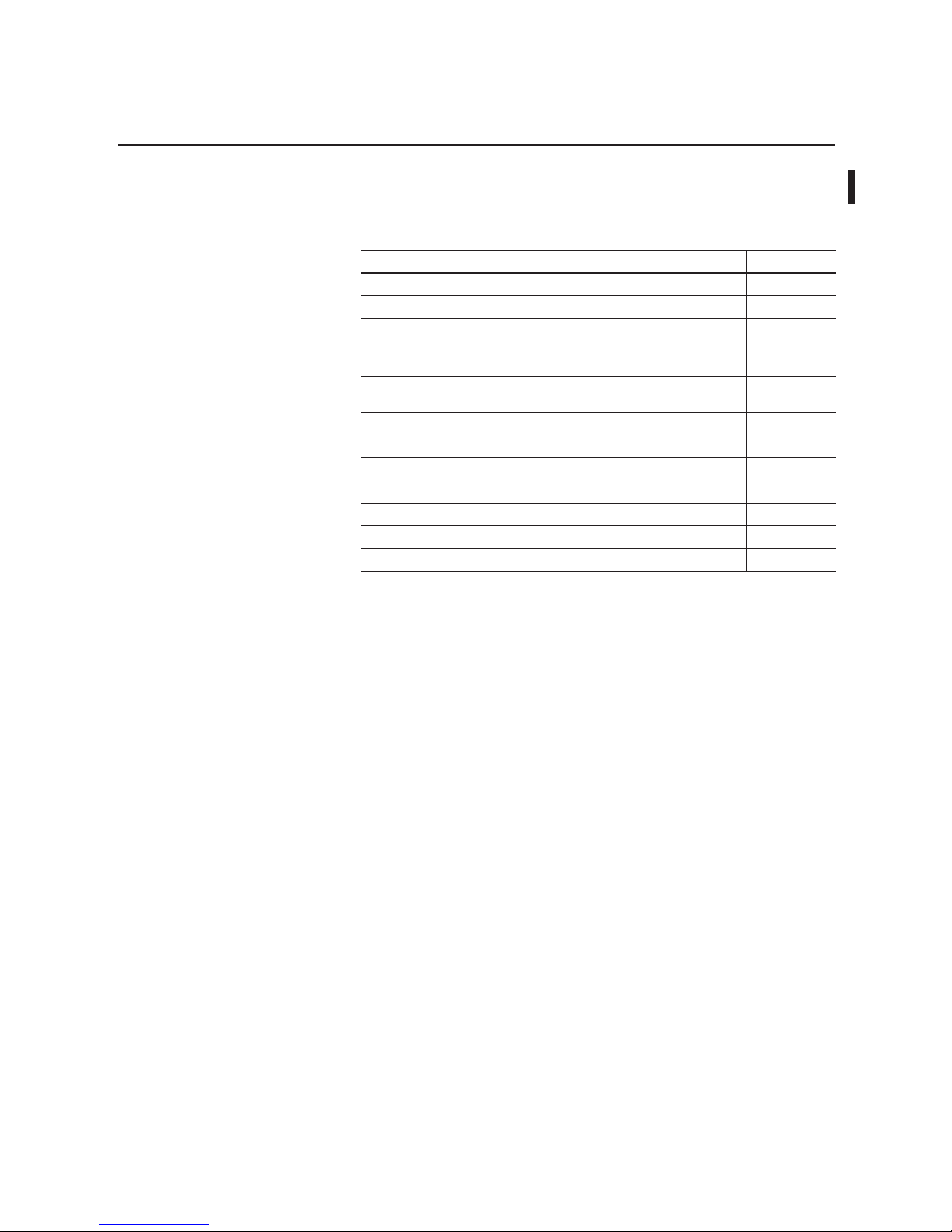

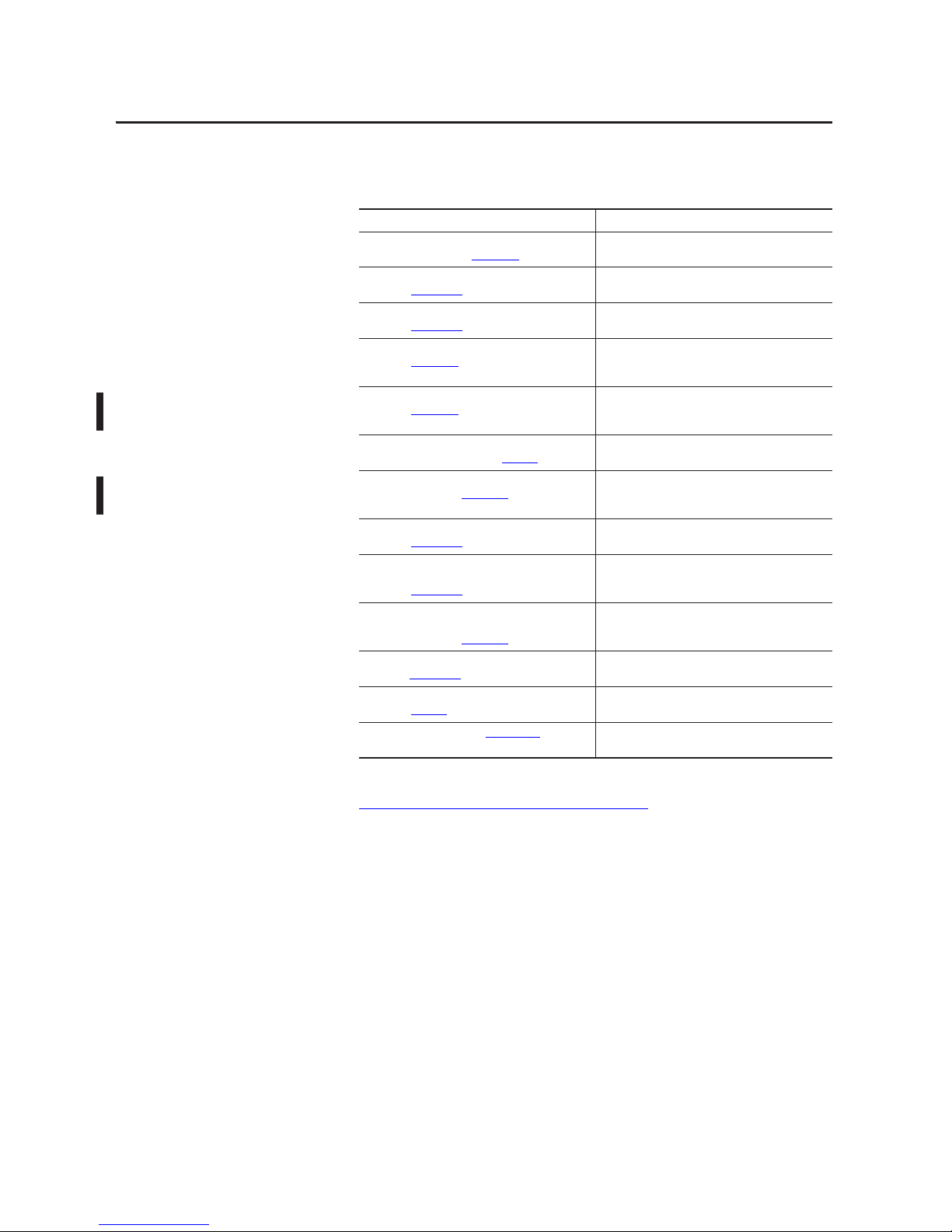

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

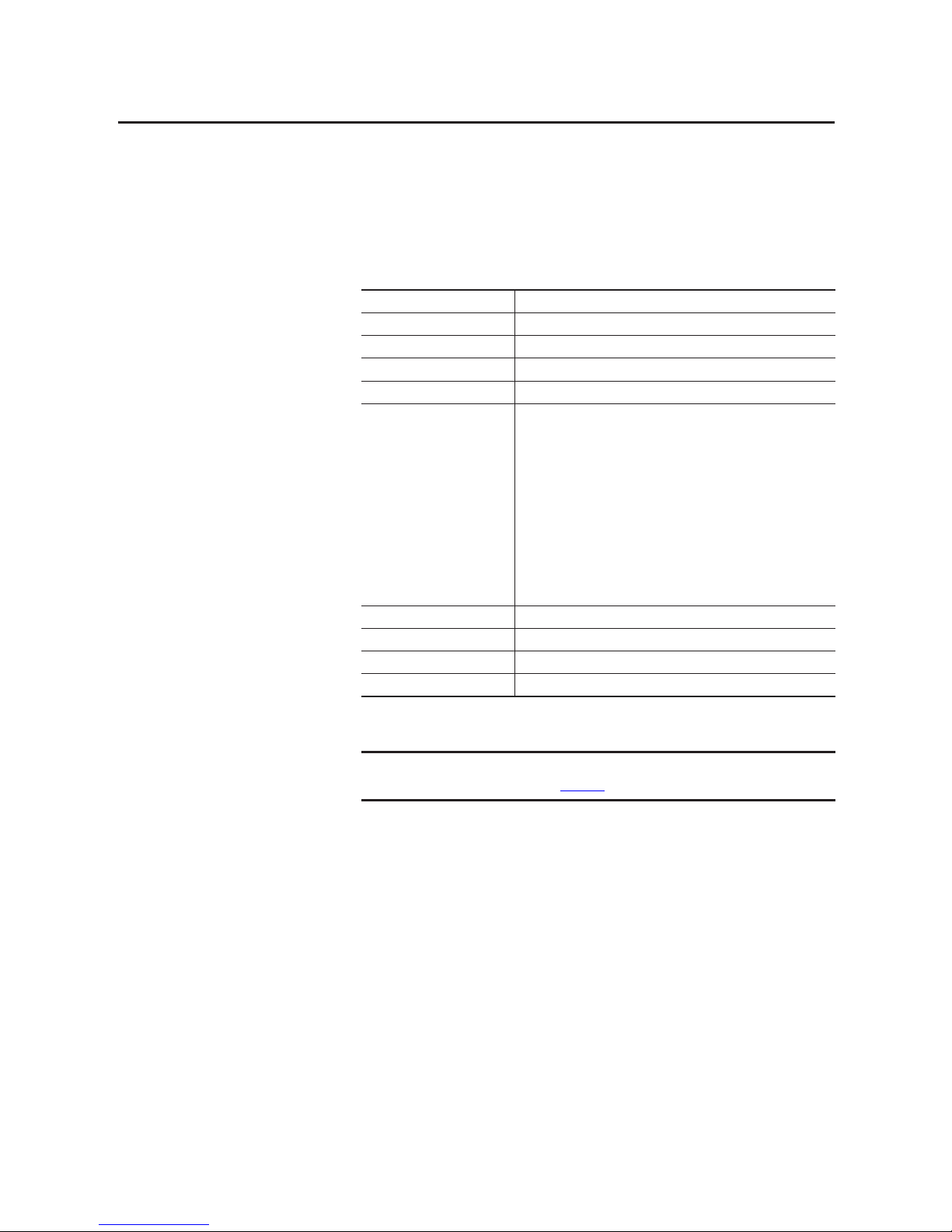

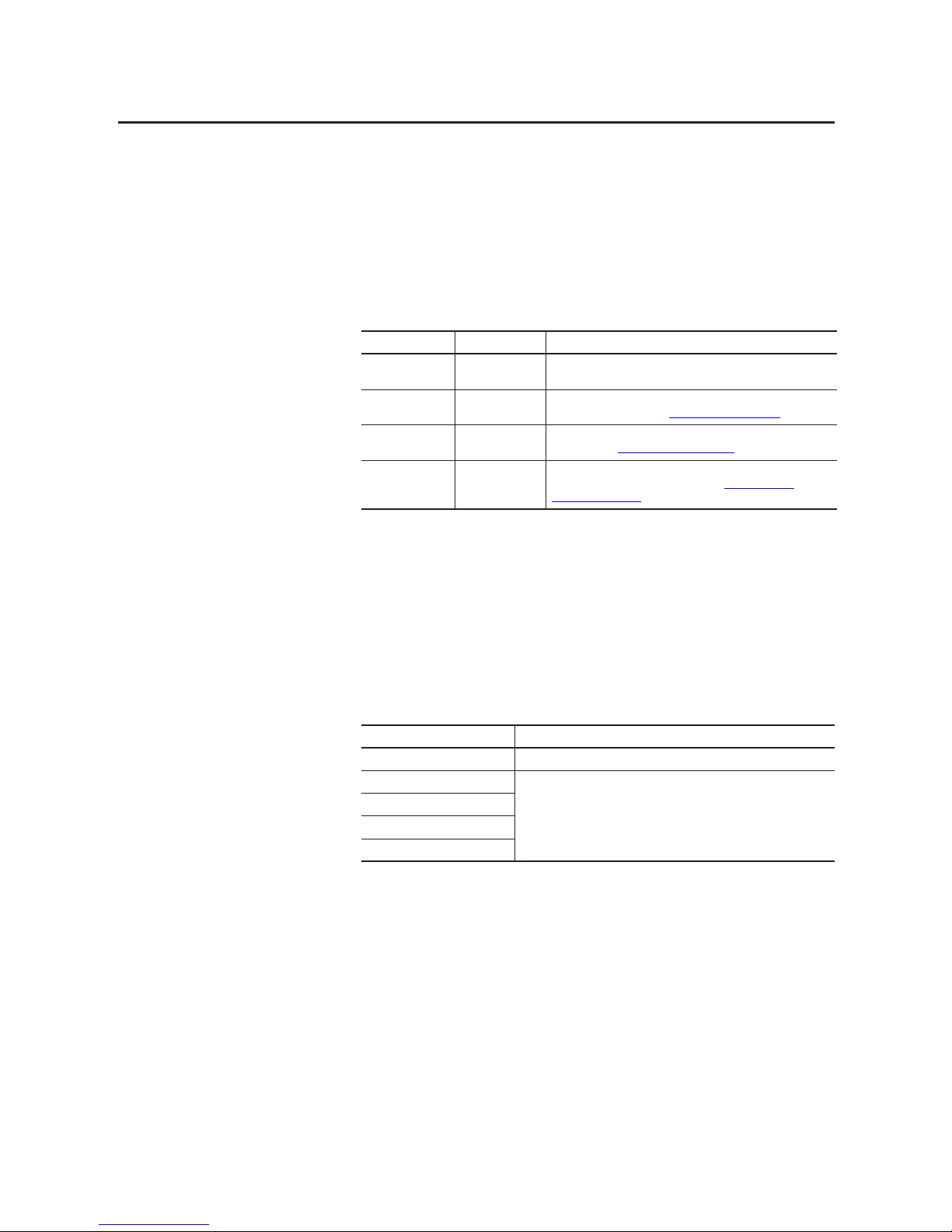

Top ic Pag e

Studio 5000™ Logix Designer application is the rebranding of RSLogix™ 5000 software 11

Added the 1756-OB16IEFS module to the list of I/O modules 15

Added content to describe when output data is sent to the 1756-OB16IEFS module in motion

applications

33

Added the 1756-OB16IEFS module to the CIP Sync time section 48

Added the 1756-OB16IEFS module to sections about electronic fusing, diagnostic latching, and

time-scheduled output control

54, 58, 63

Added the 1756-OB16IEFS module to the list of fast I/O modules 83

Added software version requirements for the 1756-OB16IEFS module 84

Added the 1756-OB16IEFS module to the table of connection formats 133

Added the wiring diagram for the 1756-OB16IEFS module 165

Added status indicators for the 1756-OB16IEFS module 179

Added tag definitions for the 1756-OB16IEFS module 202

Added the 1756-OB16IEFS module to the list of IFMs 245

Page 4

4 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Summary of Changes

Notes:

Page 5

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 5

Table of Contents

Preface

Studio 5000 Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Chapter 1

What Are ControlLogix

Digital I/O Modules?

Available Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

I/O Modules in the ControlLogix System . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Module Identification and Status Information. . . . . . . . . . . . . . . . . . . . . . 17

Chapter 2

Digital I/O Operation

in the ControlLogix System

Ownership . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Use RSNetWorx and RSLogix 5000 Software . . . . . . . . . . . . . . . . . . . . . . 20

Internal Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Direct Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rack-optimized Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Suggestions for Rack-optimized Connections . . . . . . . . . . . . . . . . . . . 26

Input Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Input Modules in a Local Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

RPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

COS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Trigger Event Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Input Modules in a Remote Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Remote Input Modules Connected via the ControlNet Network. 29

Remote Input Modules Connected via the EtherNet/IP Network 30

Output Module Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Output Modules in a Local Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Output Modules in a Remote Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Remote Output Modules Connected via the ControlNet Network. 32

Remote Output Modules Connected via the EtherNet/IP Network 33

Listen-only Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Multiple Owner-Controllers of Input Modules . . . . . . . . . . . . . . . . . . . . . 34

Configuration Changes in an Input Module with Multiple Owners . . 35

Chapter 3

Common Module Features

Input Module Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Output Module Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Common Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Removal and Insertion Under Power. . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Module Fault Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Software Configurable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Electronic Keying . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Module Inhibiting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Page 6

6 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Table of Contents

Use the System Clock to Timestamp Inputs and Schedule Outputs. 47

Producer/Consumer Communication. . . . . . . . . . . . . . . . . . . . . . . . . . 50

Status Indicator Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Common Features Specific to Input Modules. . . . . . . . . . . . . . . . . . . . . . . 50

Data Transfer on Either Cyclic Time or Change of State . . . . . . . . . 51

Set RPI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

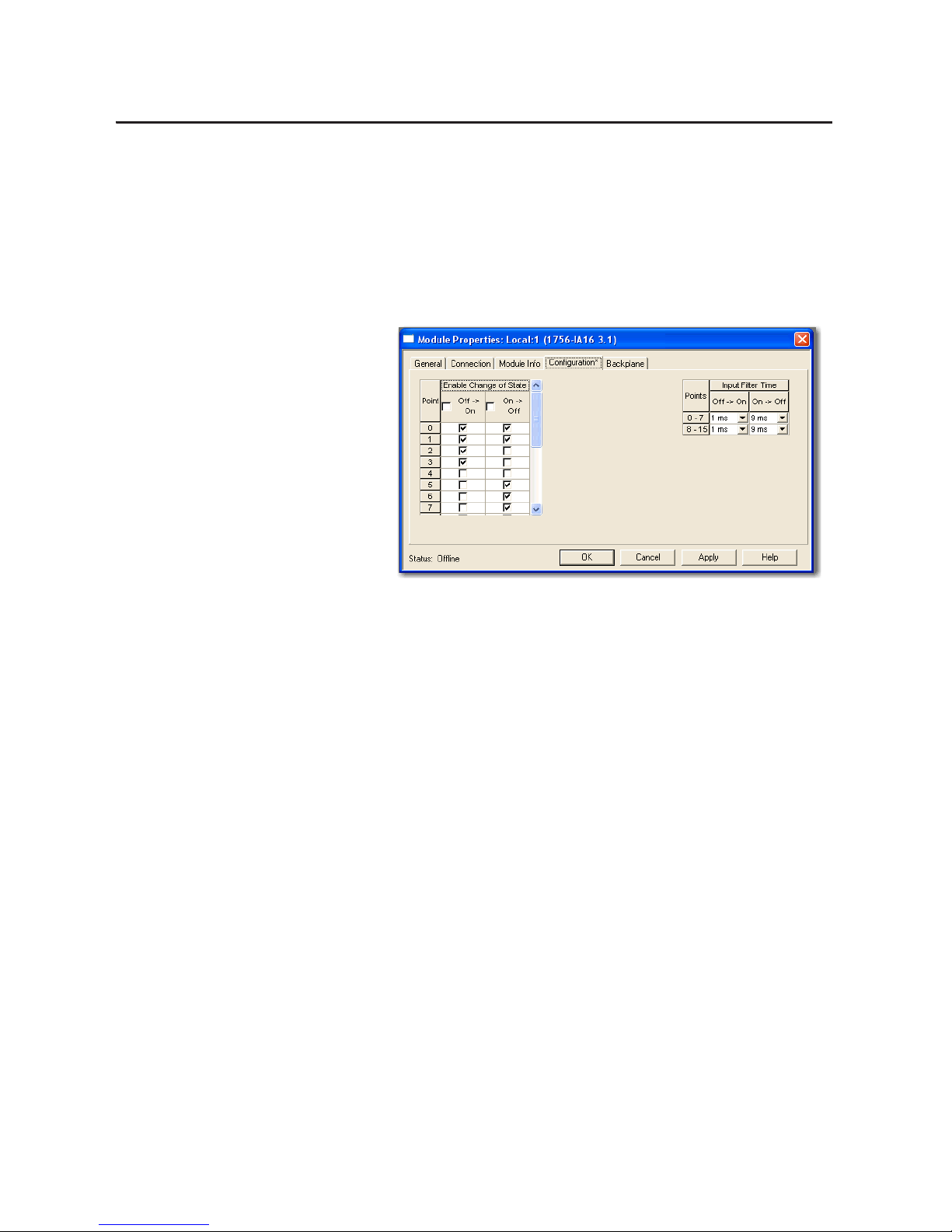

Enable Change of State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Software Configurable Filter Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Isolated and Nonisolated Varieties of Input Modules . . . . . . . . . . . . 53

Multiple Input Point Densities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Common Features Specific to Output Modules . . . . . . . . . . . . . . . . . . . . . 54

Configurable Point-level Output States. . . . . . . . . . . . . . . . . . . . . . . . . 55

Output Data Echo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Isolated and Nonisolated Varieties of Output Modules . . . . . . . . . . 56

Multiple Output Point Densities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

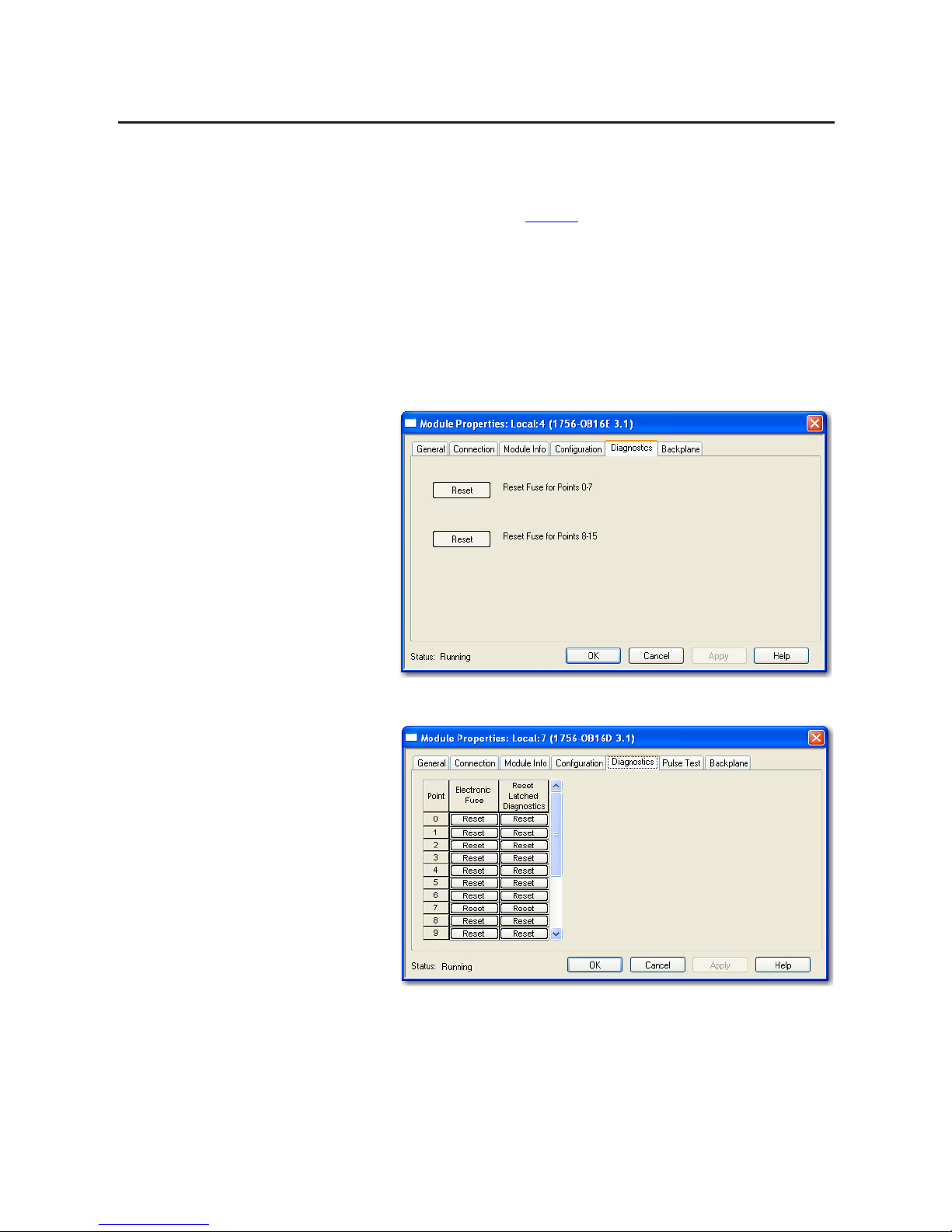

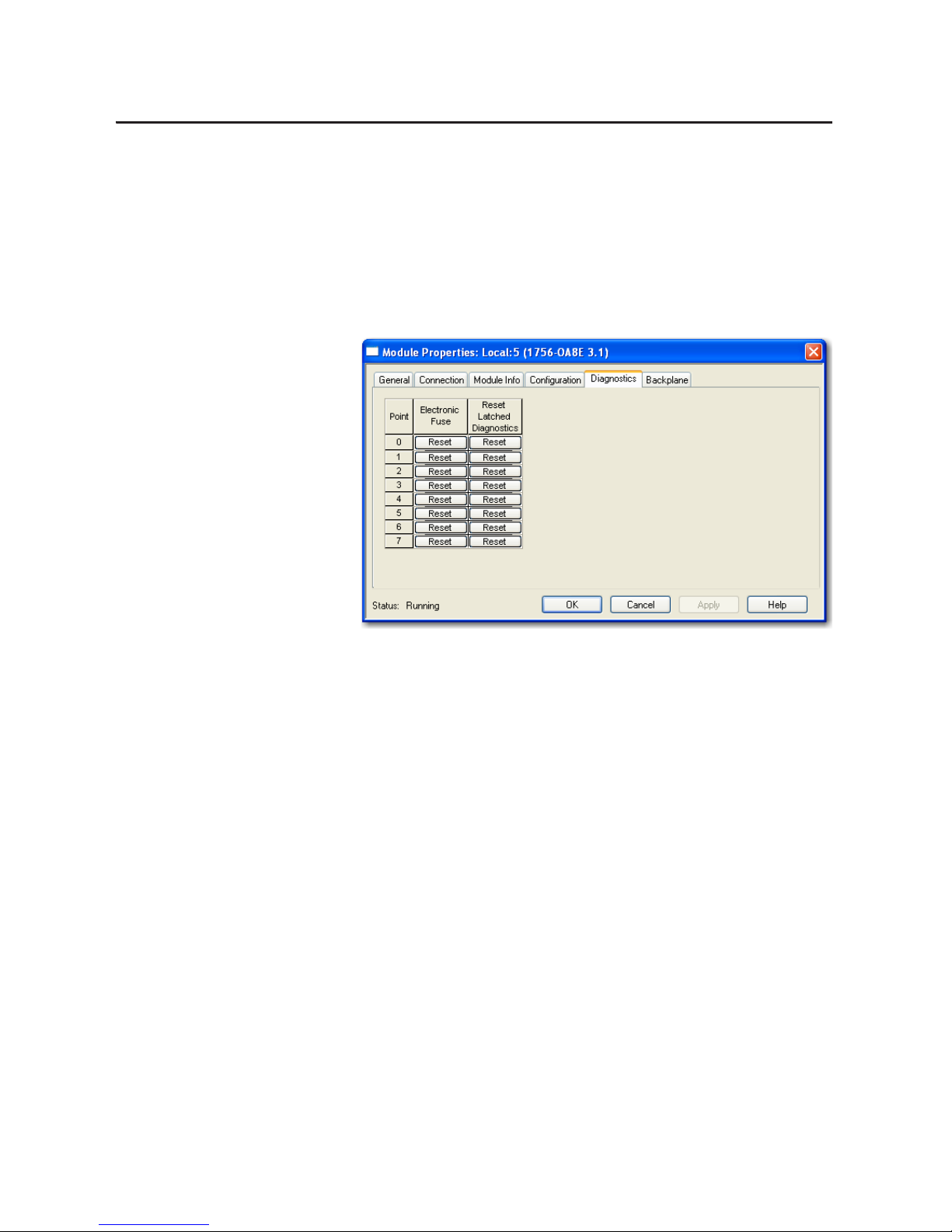

Electronic Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Field Power Loss Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Diagnostic Latch of Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Time-scheduled Output Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Fault and Status Reporting between Input Modules and Controllers. . 64

Fault and Status Reporting between Output Modules and Controllers 65

Chapter 4

Diagnostic Module Features

Diagnostic Input Module Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Diagnostic Output Module Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . 68

Diagnostic Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Diagnostic Latch of Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Diagnostic Timestamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8-Point AC/16-Point DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Point-level Fault Reporting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Features Specific to Diagnostic Input Modules. . . . . . . . . . . . . . . . . . . . . . 71

Diagnostic Change of State for Input Modules . . . . . . . . . . . . . . . . . . 71

Open Wire Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Field Power Loss Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Features Specific to Diagnostic Output Modules . . . . . . . . . . . . . . . . . . . . 75

Field Wiring Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

No Load Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Field-side Output Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Pulse Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Diagnostic Change of State for Output Modules . . . . . . . . . . . . . . . . 79

Fault and Status Reporting between Input Modules and Controllers. . 79

Fault and Status Reporting between Output Modules and Controllers 81

Page 7

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 7

Table of Contents

Chapter 5

Fast Module Features

Fast Input Module Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Fast Output Module Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Fast Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Response Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Features Specific to Fast Input Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Pulse Capture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Per Point Timestamping and Change of State. . . . . . . . . . . . . . . . . . . 87

Software Configurable Filter Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Dedicated Connection for Event Tasks. . . . . . . . . . . . . . . . . . . . . . . . . 93

Features Specific to Fast Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Programmable Fault State Delays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Pulse Width Modulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Fault and Status Reporting between Input Modules and Controllers 106

Fault and Status Reporting between Output Modules and Controllers 107

Chapter 6

Install ControlLogix I/O Modules

Install the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Key the Removable Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Connect the Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

RTB Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

RTB Wiring Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Assemble the Removable Terminal Block and Housing. . . . . . . . . . . . . 119

Choose Extended-depth Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Cabinet Size Considerations with Extended-depth Housing . . . . 121

Install the Removable Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Remove the Removable Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Remove the Module from the Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Chapter 7

Configure ControlLogix

Digital I/O Modules

Configuration Process Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

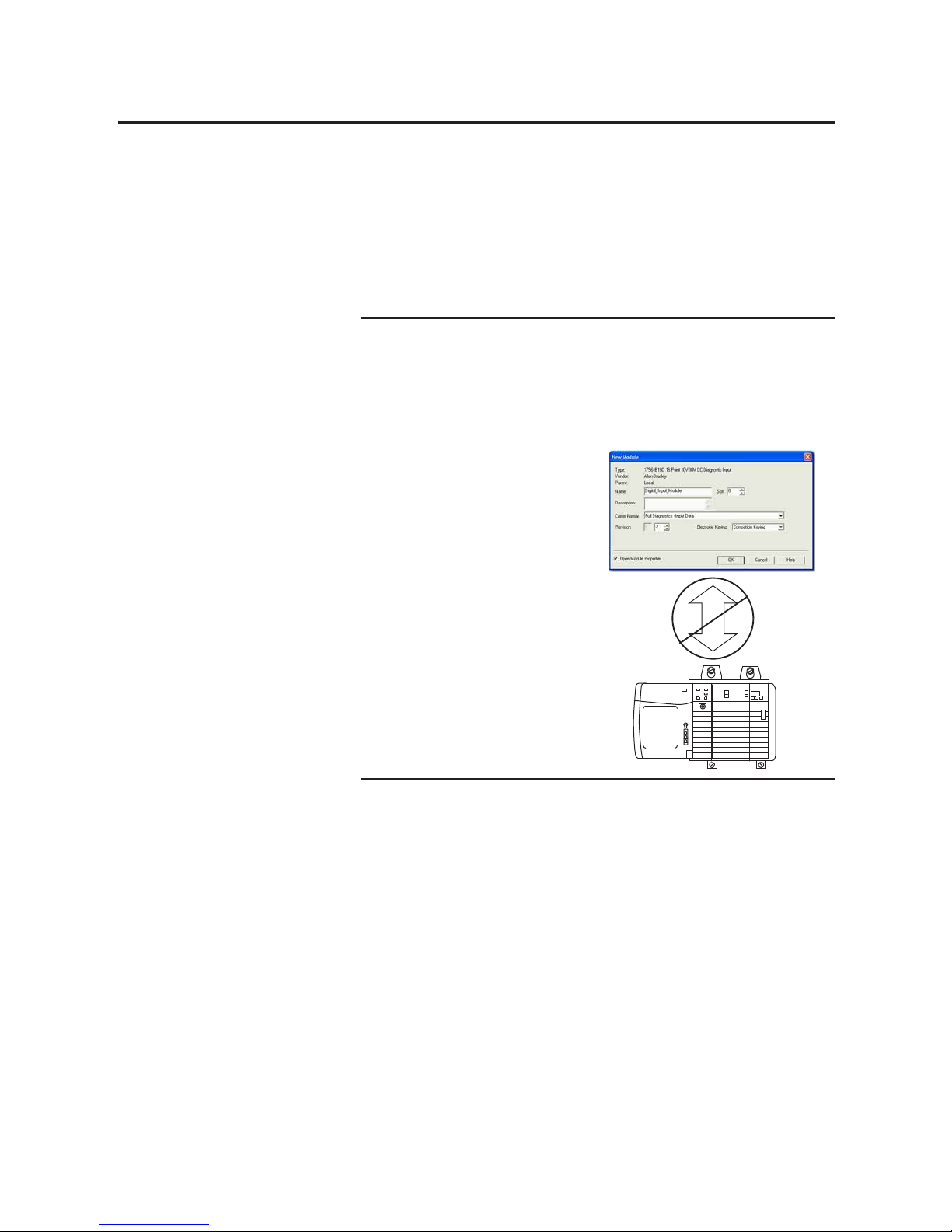

Create a New Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

Communication or Connection Formats. . . . . . . . . . . . . . . . . . . . . . 131

Edit the Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Connection Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

View and Change Module Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

Chapter 8

Wiring Diagrams

1756-IA8D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

1756-IA16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

1756-IA16I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

1756-IA32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

1756-IB16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

1756-IB16D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

1756-IB16I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1756-IB16IF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Page 8

8 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Table of Contents

1756-IB32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

1756-IC16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

1756-IG16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1756-IH16I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

1756-IM16I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

1756-IN16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

1756-IV16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

1756-IV32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

1756-OA8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

1756-OA8D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

1756-OA8E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

1756-OA16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

1756-OA16I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

1756-OB8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

1756-OB8EI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

1756-OB8I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

1756-OB16D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

1756-OB16E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

1756-OB16I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

1756-OB16IEF. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

1756-OB16IEFS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

1756-OB16IS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

1756-OB32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

1756-OC8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

1756-OG16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

1756-OH8I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

1756-ON8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

1756-OV16E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

1756-OV32E. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

1756-OW16I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

1756-OX8I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Appendix A

Troubleshoot Your Module

Status Indicators for Input Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

Status Indicators for Output Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Use RSLogix 5000 Software for Troubleshooting . . . . . . . . . . . . . . . . . . 180

Fault Type Determination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

Appendix B

Tag Definitions

Standard and Diagnostic Input Module Tags . . . . . . . . . . . . . . . . . . . . . . 183

Standard and Diagnostic Output Module Tags . . . . . . . . . . . . . . . . . . . . 186

Fast Input Module Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Fast Output Module Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

1756-OB16IEF Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

1756-OB16IEFS Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Array Data Structures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Page 9

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 9

Table of Contents

Appendix C

Use Ladder Logic To Perform

Run Time Services and

Reconfiguration

Using Message Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Processing Real-time Control and Module Services . . . . . . . . . . . . . . . . 214

One Service Performed Per Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Create a New Tag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

Enter Message Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Configuration Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

Communication Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 221

Use Timestamped Inputs and Scheduled Outputs

for Standard and Diagnostic I/O Modules. . . . . . . . . . . . . . . . . . . . . 222

Use Timestamped Inputs and Scheduled Outputs

for Fast I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 224

Reset a Fuse, Perform Pulse Test and Reset Latched Diagnostics. 227

Perform a WHO to Retrieve Module Identification and Status. . 228

Review of Tags in Ladder Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Appendix D

Choose a Correct Power Supply

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .233

Appendix E

Motor Starters for Digital I/O Modules

Determine the Maximum Number of Motor Starters. . . . . . . . . . . 236

Appendix F

Major Revision Upgrades

If Using a Compatible or Disabled Keying I/O Configuration . . . . . . 238

If Using an Exact Match Keying Configuration . . . . . . . . . . . . . . . . . . . . 238

Appendix G

1492 IFMs for Digital I/O Modules

Cable Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Appendix H

History of Changes

1756-UM058F-EN-P, April 2012 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

1756-UM058E-EN-P, August 2010 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

Glossary

Index

Page 10

10 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Table of Contents

Notes:

Page 11

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 11

Preface

This manual describes how to install, configure, and troubleshoot your

ControlLogix® digital I/O modules. There is also a complete listing of digital

input and output modules, including specifications and wiring diagrams. You

must be able to program and operate a ControlLogix controller to efficiently use

your digital I/O module.

Studio 5000 Environment

The Studio 5000™ Engineering and Design Environment combines engineering

and design elements into a common environment. The first element in the

Studio 5000 environment is the Logix Designer application. The Logix Designer

application is the rebranding of RSLogix™ 5000 software and will continue to be

the product to program Logix5000™ controllers for discrete, process, batch,

motion, safety, and drive-based solutions.

The Studio 5000 environment is the foundation for the future of Rockwell

Automation® engineering design tools and capabilities. It is the one place for

design engineers to develop all the elements of their control system.

Page 12

12 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

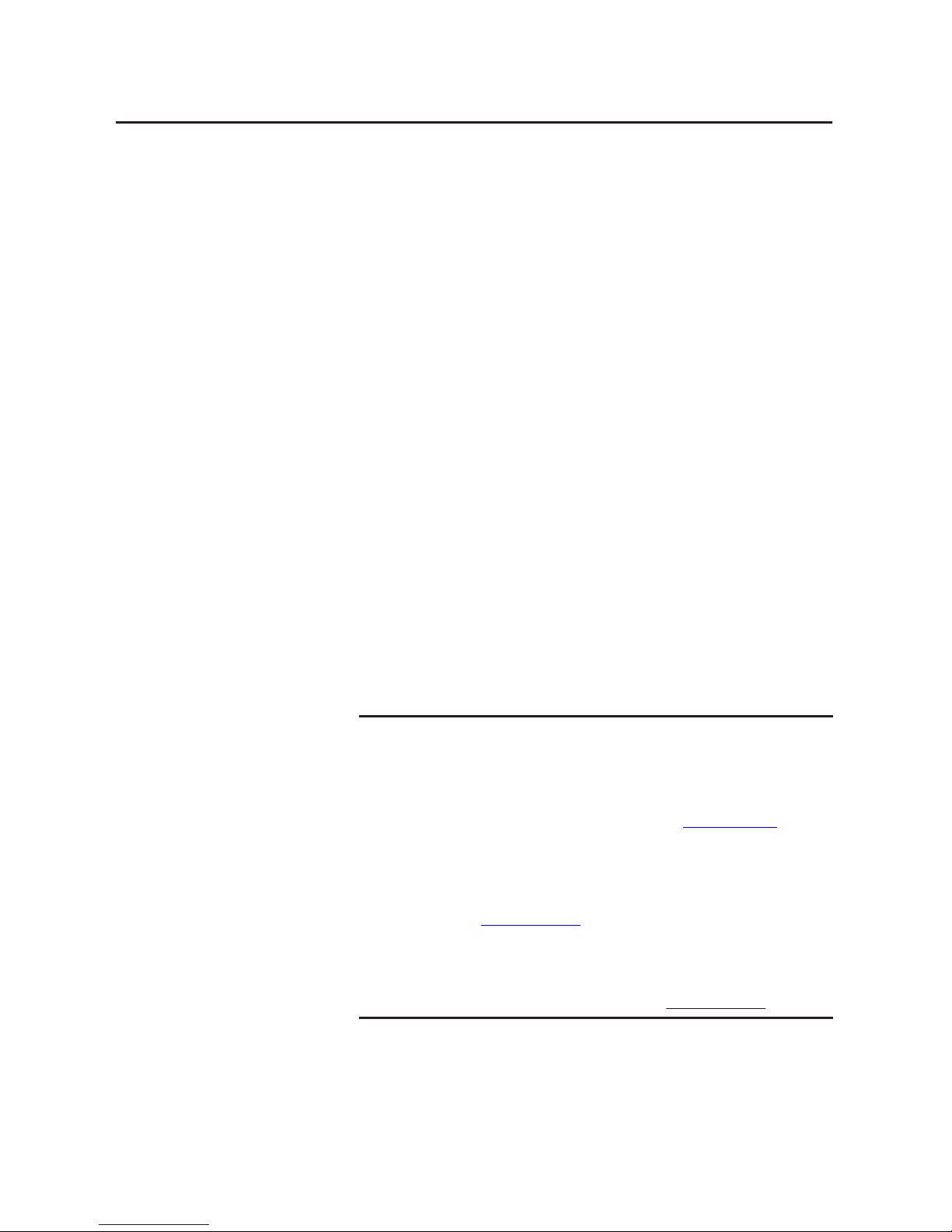

Resource Description

1756 ControlLogix I/O Modules Specifications

Technical Data, publication 1756-TD002

Provides specifications for ControlLogix I/O modules.

ControlLogix High-speed Counter Module User Manual,

publication 1756-UM007

Describes how to install, configure, and troubleshoot the

1756-HSC counter module.

ControlLogix Low-speed Counter Module User Manual,

publication 1756-UM536

Describes how to install, configure, and troubleshoot the

1756-LSC8XIB8I counter module.

ControlLo gix Peer I/O Control Appl ication Techni que,

publication 1756-AT016

Describes typical peer control applications and provides

details about how to configure I/O modules for peer

control operation.

Position-based Output Control with the MAOC Instruction,

publication 1756-AT017

Describes typical applications for using scheduled output

modules with the Motion Axis Output Cam (MAOC)

instruction.

Integrated Architecture and CIP Sync Configuration

Application Technique, publication IA-AT003

Describes how to configure CIP Sync with Integrated

Architecture™ products and applications.

ControlLogix Chassis and Power Supplies Installation

Instructions, publication 1756-IN005

Describes how to install and troubleshoot standard and

ControlLogix-XT versions of the 1756 chassis and power

supplies, including redundant power supplies.

ControlLogix Analog I/O Modules User Manual,

publication 1756-UM009

Describes how to install, configure, and troubleshoot

ControlLogix analog I/O modules.

ControlLogix Data Highway Plus-Remote I/O

Communication Interface Module User Manual,

publication 1756-UM514

Describes how to configure and operate the ControlLogix

DH+™ / Remote I/O module.

ControlLogix-XT Data Highway Plus-Remote I/O

Communication Interface Module Installation

Instructions, publication 1756-IN638

Describes how to install, configure, and troubleshoot the

ControlLogix-XT Data Highway Plus™-Remote I/O

Communication Interface module.

ControlLogix System User Manual,

publication 1756 UM001

Describes how to install, configure, program, and operate

a ControlLogix system.

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Provides general guidelines for installing a Rockwell

Automation industrial system.

Product Certifications website, http://ab.com

Provides declarations of conformity, certificates, and other

certification details.

Page 13

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 13

Chapter 1

What Are ControlLogix Digital I/O Modules?

ControlLogix® digital I/O modules are input and output modules that provide

On/Off detection and actuation. By using the producer/consumer network

model, digital I/O modules can produce information when needed while

providing additional system functions.

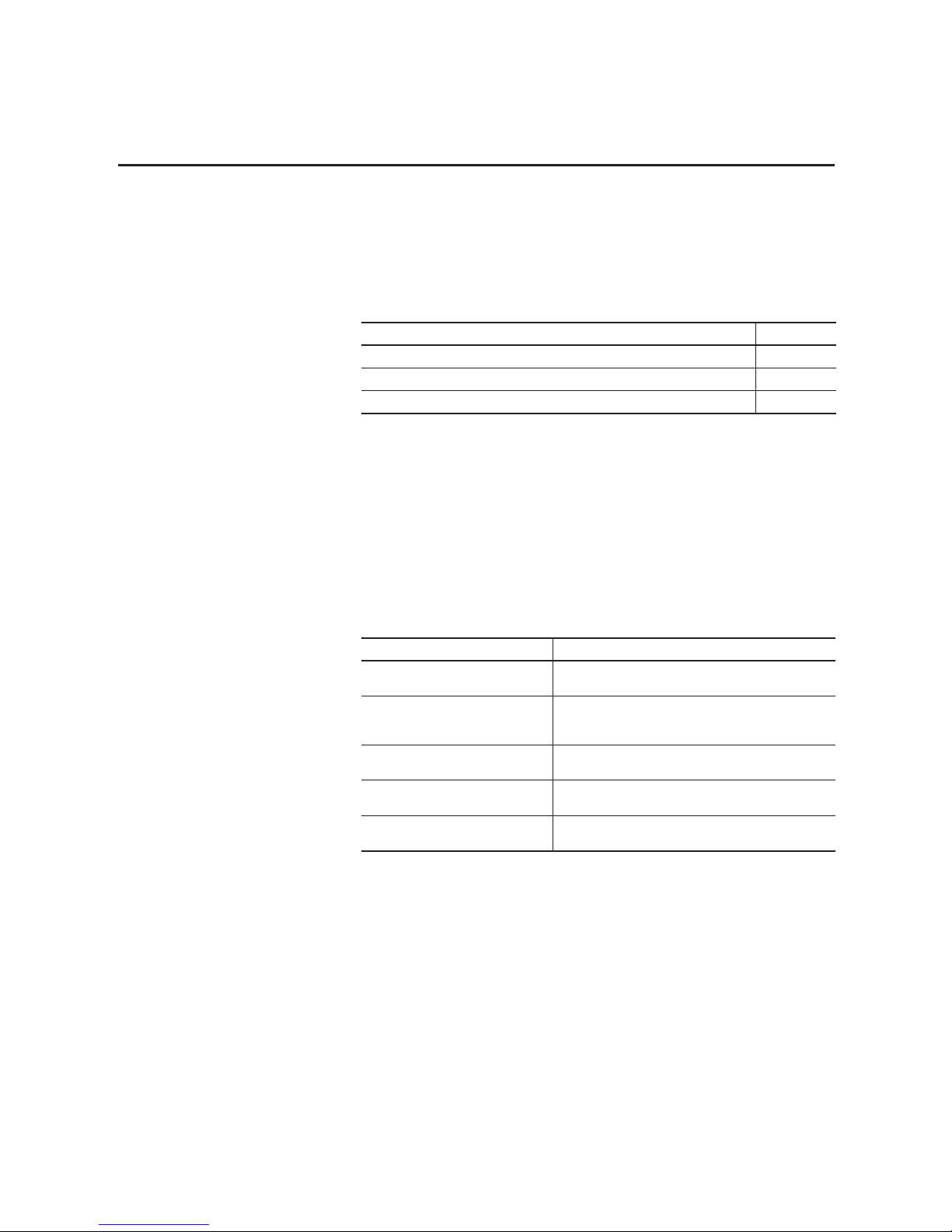

Available Features

The table lists several features available on ControlLogix digital I/O modules.

Top ic Pag e

Available Features 13

I/O Modules in the ControlLogix System 14

Module Identification and Status Info rmation 17

Feature Description

Removal and Insertion Under Power (RIUP) You can remove and insert modules and removable terminal blocks

(RTB) while power is applied.

Producer/consumer communication This communication method is an intelligent data exchange between

modules and other system devices in which each module produces

data without first being polled.

System time stamp of data A 64-bit system clock places a time stamp on the transfer of data

between the module and its owner-controller.

Module-level fault reporting and field-side

diagnostic detection

Fault and diagnostic detection capabilities to help you effec tively and

efficiently use your module and troubleshoot your application.

Agency Certification Class 1, Division 2 agency certification for any applic ation that

requires approval.

Page 14

14 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 1 What Are ControlLogix Digital I/O Modules?

I/O Modules in the

ControlLogix System

ControlLogix modules mount in a ControlLogix chassis and require either a

removable terminal block (RTB) or a Bulletin 1492 wiring interface module

(IFM)

(1)

to connect all field-side wiring.

Before you install and use your module, you must do the following:

• Install and ground a 1756 chassis and power supply. To install these

products, refer to the publications listed in Additional Resources

on

page 12.

• Order and receive an RTB or IFM and its components for your

application.

(1) The ControlLogix system has been agency certified using only the ControlLogix RTB catalog numbers 1756-TBCH, 1756-T BNH,

1756-TBSH, and 1756-TBS6H. Any application that requires agency certification of the ControlLogix system using other wiring

termination methods may require application-specific approval by the certifying agenc y.

IMPORTANT

RTBs and IFMs are not included with your module purchase. See page 116 for

RTBs and page 239

for IFMs.

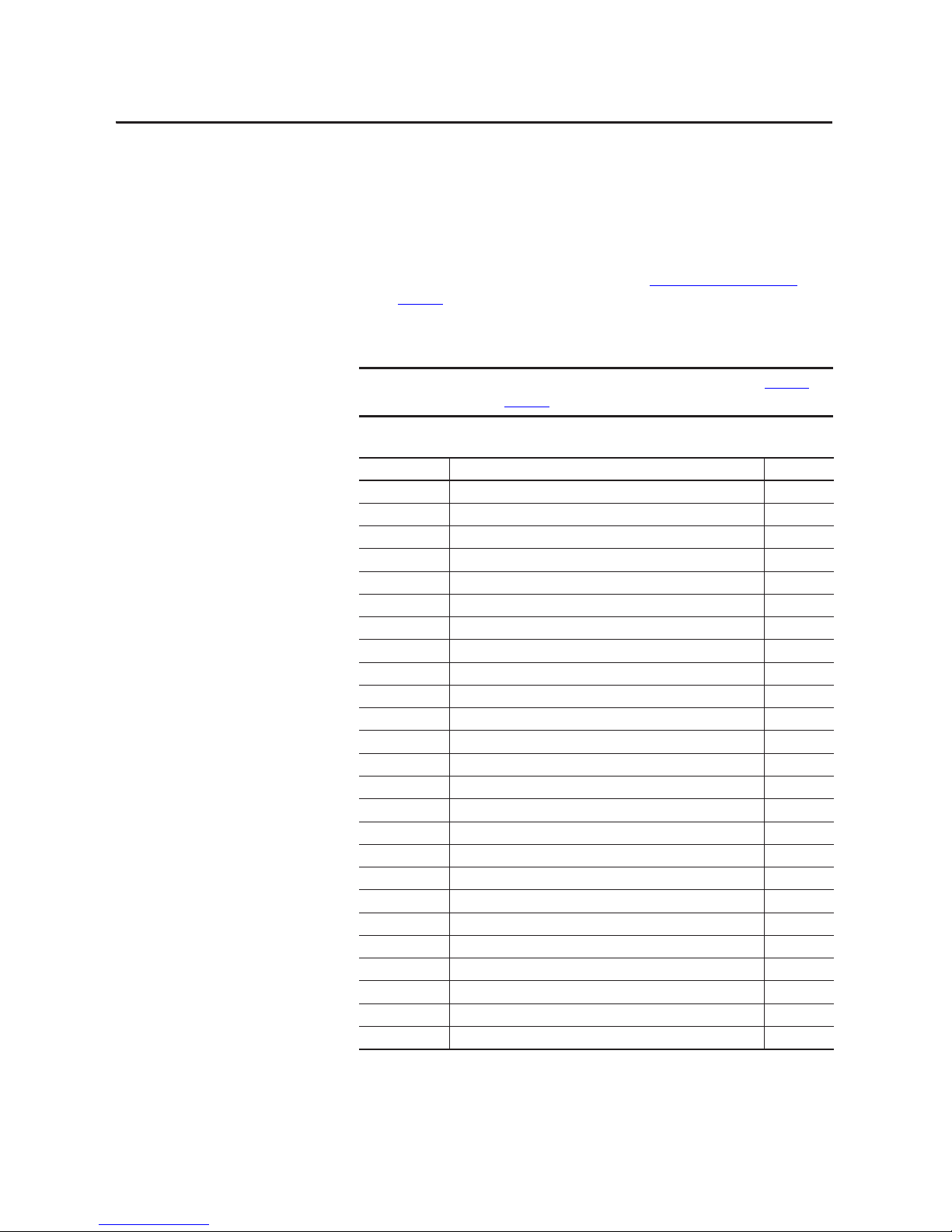

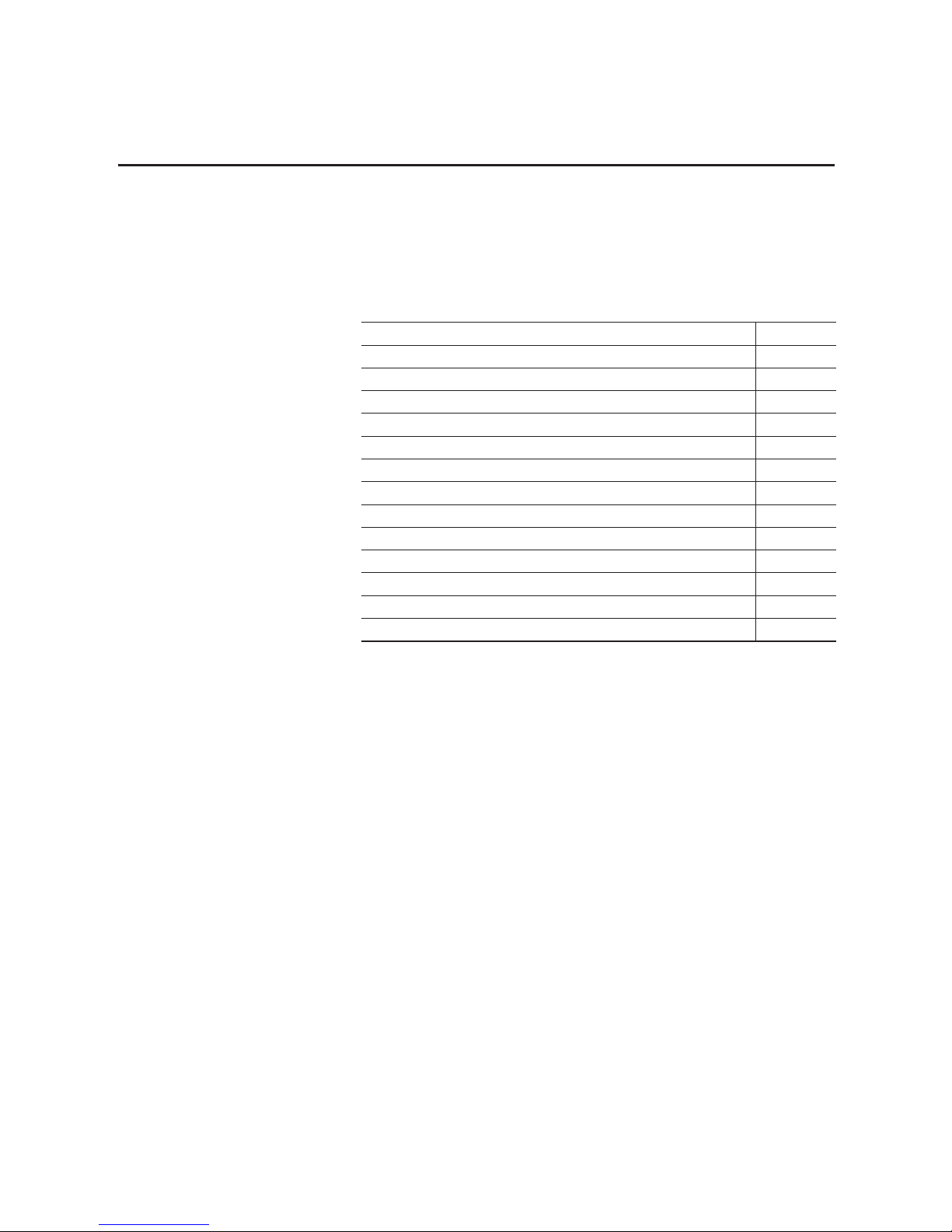

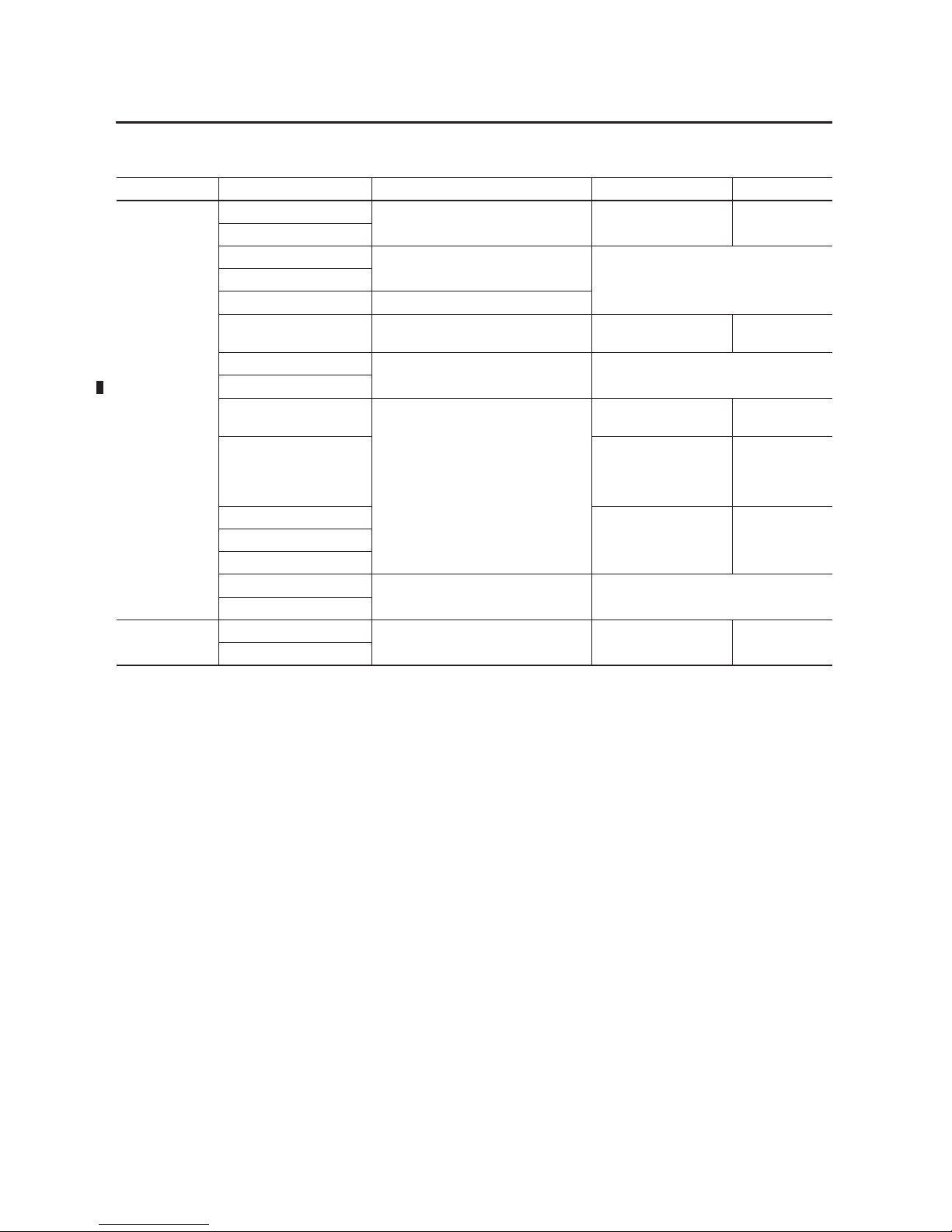

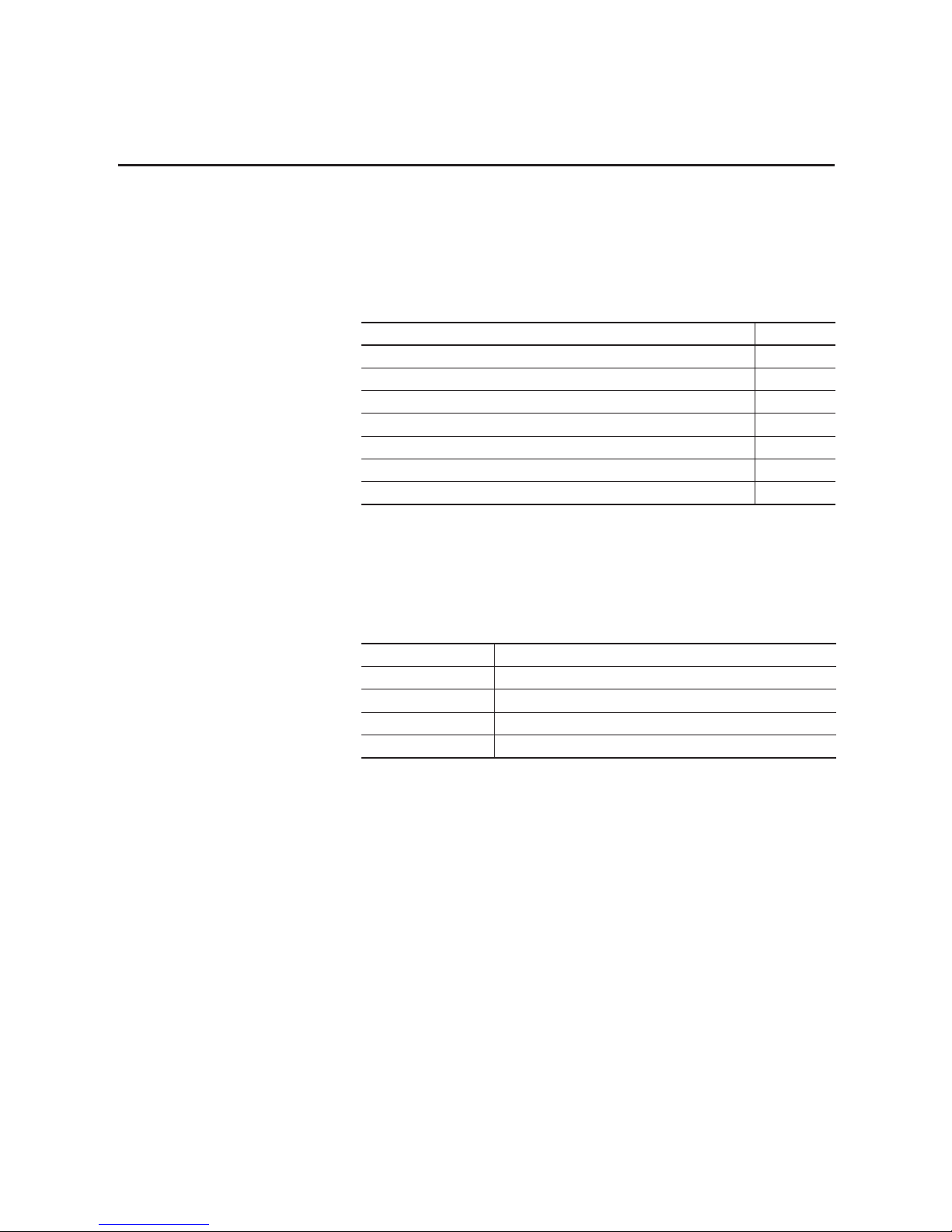

Table 1 - ControlLogix Digital I/O Modules

Cat. No. Description Page

1756-IA8D 79…132V AC 8-point diagnostic input module 139

1756-IA16 74…132V AC 16-point input module 139

1756-IA16I 79…132V AC 16-point isolated input module 140

1756-IA32 74…132V AC 32-point input module 141

1756-IB16 10…31.2V DC 16-point input module 142

1756-IB16D 10…30V DC diagnostic input module 143

1756-IB16I 10…30V DC 16-point, isolated input module 144

1756-IB16IF 10…30V DC,16-point, isolated, fast peer control input module 145

1756-IB32 10…31.2V DC 32-point input module 146

1756-IC16 30…60V DC 16-point input module 147

1756-IG16 Transitor-transitor logic (TTL) input module 148

1756-IH16I 90…146V DC 16-point isolated input module 149

1756-IM16I 159…265V AC 16-point isolated input module 150

1756-IN16 10…30V AC 16-point input module 150

1756-IV16 10…30V DC 16-point sourcing current input module 151

1756-IV32 10…30V DC 32-point sourcing current input module 152

1756-OA8 74…265V AC 8-point output module

153

1756-OA8D 74…132V AC 8-point diagnostic output module 154

1756-OA8E 74…132V AC 8-point electronically-fused output module 155

1756-OA16 74... 265V AC 16-point output module 156

1756-OA16I 74…265V AC 16-point isolated output module 157

1756-OB8 10…30V DC 8-point output module 158

1756-OB8EI 10…30V DC 8-point electronically-fused, isolated output module 159

1756-OB8I 10…30V DC 8-point isolated output module 160

1756-OB16D 19.2…30V DC 16-point diagnostic output module 161

Page 15

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 15

What Are ControlLogix Digital I/O Modules? Chapter 1

1756-OB16E 10…31.2V DC 16-point electronically-fused output module 162

1756-OB16I 10…30V DC 16-point isolated output module 163

1756-OB16IEF 10…30V DC,16-point, isolated, fast peer control output module 164

1756-OB16IEFS 10…30V DC, 16-point, isolated, fast, scheduled per point output module 165

1756-OB16IS 10…30V DC scheduled, isolated output module 166

1756-OB32 10…31.2V DC 32-point output module 167

1756-OC8 30…60V DC 8-point output module 168

1756-OG16 Transitor-transitor logic (TTL) output module 169

1756-OH81 90…146V DC 8-point isolated output module 170

1756-ON8 10…30V AC 8-point output module 171

1756-OV16E 10…30V DC 16-point electronically-fused, sinking current output module 172

1756-OV32E 10…30V DC 32-point electronically-fused, sinking current output module 173

1756-OW16I 10…265V, 5-150V DC 16-point isolated contact module 174

1756-OX8I 10…265V, 5-150V DC 8-point isolated contact module 175

Table 1 - ControlLogix Digital I/O Modules (continued)

Cat. No. Description Page

Page 16

16 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 1 What Are ControlLogix Digital I/O Modules?

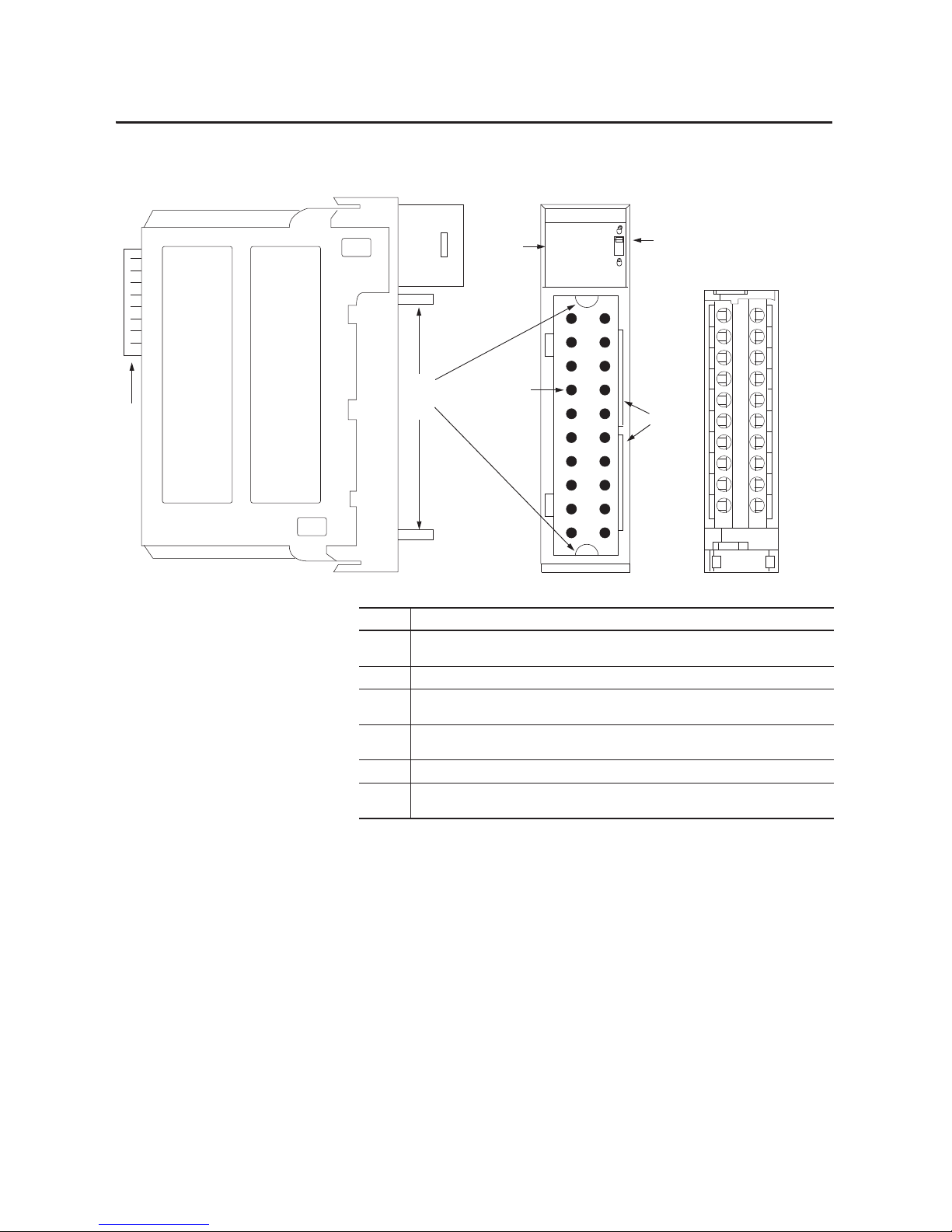

Figure 1 - Parts Illustration

40200-M

DC OUTPUT

ST

O

K

01234567

3

5

Removable Terminal Block

6

4

2

1

Item Description

1 Backplane Connector—Interface for the ControlLogix system that connects the module to the

backplane.

2 Top and bottom guides—Guides provide assistance in seating the RTB or IFM onto the module.

3 Status indicators—Indicators display the status of communication, module health, and input/output

devices. Indicators help in troubleshooting anomalies.

4 Connector pins—Input/output, power, and grounding connections are made to the module through

these pins with the use of an RTB or IFM.

5 Locking tab—The locking tab anchors the RTB or IFM on the module, maintaining wiring connections.

6 Slots for keying—Mechanically keys the RTB to prevent making the wrong wire connections to your

module.

Page 17

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 17

What Are ControlLogix Digital I/O Modules? Chapter 1

Module Identification and

Status Information

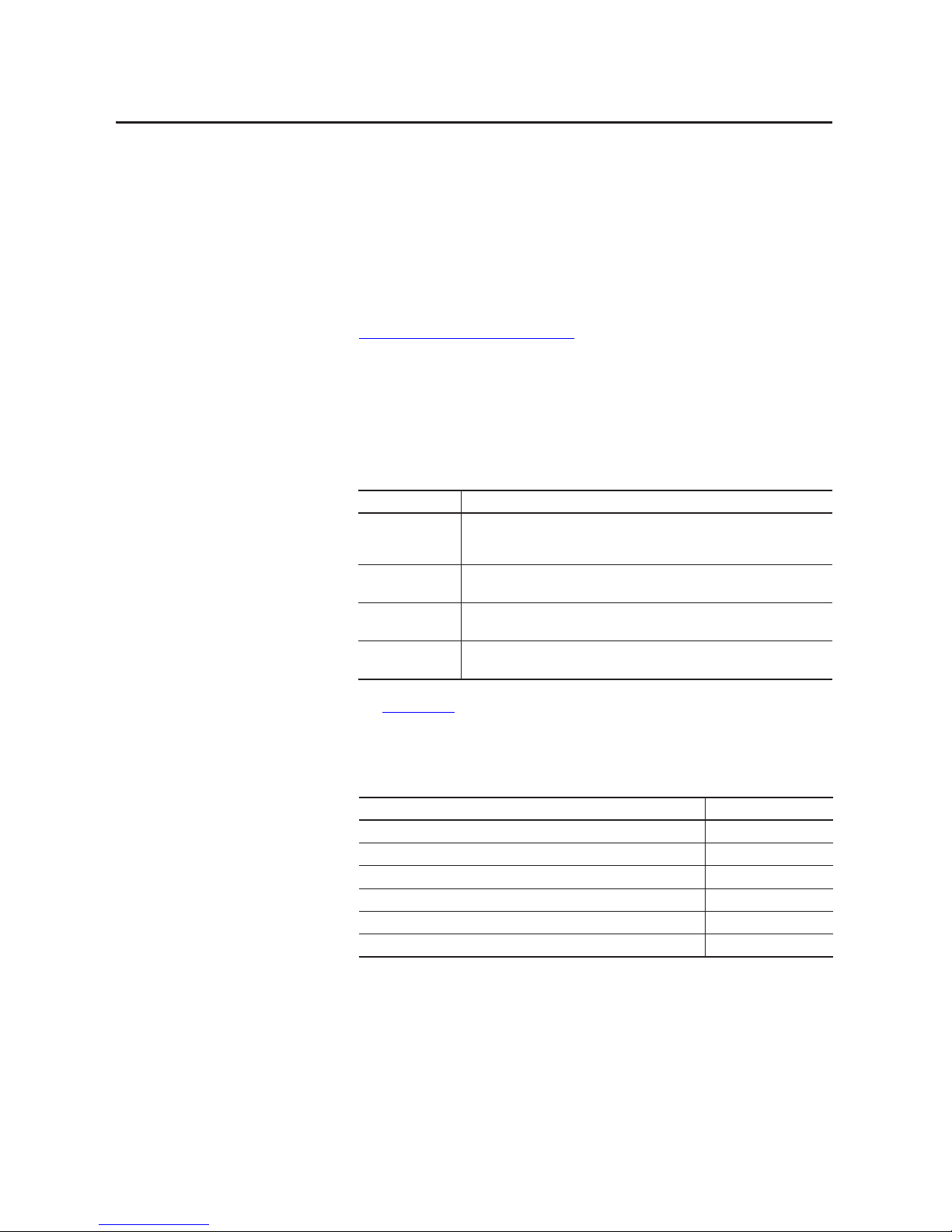

Each ControlLogix I/O module maintains specific identification information

that separates it from all other modules. This information assists you in tracking

all the components of your system.

For example, you can track module identification information to know which

modules are located in any ControlLogix chassis at any time. While retrieving

module identity, you can also retrieve module status.

Item Description

Product type Module’s product type, such as digital I/O or analog I/O

Product code Module’s catalog number

Major revision Module’s major revision number

Minor revision Module’s minor revision number

Status Module’s statu s, including these items:

• Controller ownership

• Whether the module has been configured

• Device-specific status, such as the following:

– Self-test

– Update in progress

– Communications fault

– Not owned (outputs in Program mode)

– Internal fault (needs update)

– Run mode

– Program mode (outputs only)

• Minor recoverable fault

• Minor unrecoverable fault

• Major recoverable fault

• Major unrecoverable fault

Vendor Module’s manufacturer vendor, such as Allen-Bradley

Serial number Module’s serial number

Length of ASCII text string Number of characters in module’s text string

ASCII text string Module’s ASCII text string description

IMPORTANT

You must perform a WHO service to retrieve this information. For more

information, refer to page 228

.

Page 18

18 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 1 What Are ControlLogix Digital I/O Modules?

Notes:

Page 19

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 19

Chapter 2

Digital I/O Operation in the ControlLogix System

I/O modules are the interface between controllers and field devices in a

ControlLogix system. Digital I/O modules transfer data to devices that require

just one bit to be represented (0 or 1). For example, a switch is open or closed, or

a light is on or off.

Top ic Pa ge

Ownership 20

Use RSNetWorx and RSLogix 5000 Software 20

Internal Module Operation 21

Connec tions 23

Input Module Operation 26

Input Modules in a Local Chassis 27

Input Modules in a Remote Chassis 28

Output Module Operation 31

Output Modules in a Local Chassis 31

Output Modules in a Remote Chassis 32

Listen-only Mode 34

Multiple Owner-Controllers of Input Modules 34

Configuration Changes in an Input Module with Multiple Owners 35

Page 20

20 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 2 Digital I/O Operation in the ControlLogix System

Ownership

I/O modules in a ControlLogix system can be owned by an RSLogix™ 5000

controller. An owner-controller fulfills these functions:

• Stores configuration data for every module that it owns

• Sends I/O modules configuration data to define module behavior and

begin module operation with the control system

• Resides in a local or remote chassis in regard to the I/O module’s position

Each ControlLogix I/O module must continuously maintain communication

with its owner-controller to operate normally.

Typically, each module in the system will have only one owner-controller. Input

modules can have more than one owner-controller. Output modules, however,

are limited to a single owner-controller.

For more information about using multiple owner-controllers, see Configuration

Changes in an Input Module with Multiple Owners on page 35.

Use RSNetWorx and

RSLogix 5000 Software

The I/O configuration within RSLogix 5000 software generates the

configuration data for each I/O module in the control system, including modules

in a remote chassis. A remote chassis contains the I/O module but not the

module’s owner-controller. A remote chassis can be connected to the controller

via an EtherNet/IP network or a scheduled connection on the

ControlNet network.

Configuration data from RSLogix 5000 software is transferred to the controller

during the program download and subsequently transferred to I/O modules. The

I/O modules in the local or remote chassis are ready to run as soon as the

configuration data has been downloaded. However, to enable scheduled

connections to I/O modules on the ControlNet network, you must schedule the

network by using RSNetWorx™ for ControlNet software.

RSNetWorx software transfers configuration data to I/O modules on a scheduled

ControlNet network and establishes a network update time (NUT) for the

ControlNet network that is compliant with the desired communication options

specified for each module during configuration.

Anytime a controller references a scheduled connection to I/O modules on a

scheduled ControlNet network, you must run RSNetWorx software to configure

the ControlNet network.

Page 21

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 21

Digital I/O Operation in the ControlLogix System Chapter 2

Refer to the following general steps when configuring I/O modules.

1. Configure all I/O modules for a given controller by using

RSLogix 5000 software and download that information to the controller.

2. If the I/O configuration data references a scheduled connection to a

module in a remote chassis connected via the ControlNet network, run

RSNetWorx for ControlNet software to schedule the network.

3. After running RSNetWorx software, perform an online save of the

RSLogix 5000 project to make sure the configuration information that

RSNetWorx software sends to the controller is saved.

Internal Module Operation

ControlLogix I/O modules experience signal propagation delays that must be

accounted for during operation. Some of these delays are user-configurable, and

some are inherent to the module hardware.

For example, there is a small delay, typically less than 1 ms, between when a signal

is applied at the RTB of a ControlLogix input module and when a signal is sent

to the system over the backplane. This time reflects a filter time of 0 ms for a DC

input.

This section offers an explanation of the time limitations with ControlLogix I/O

modules.

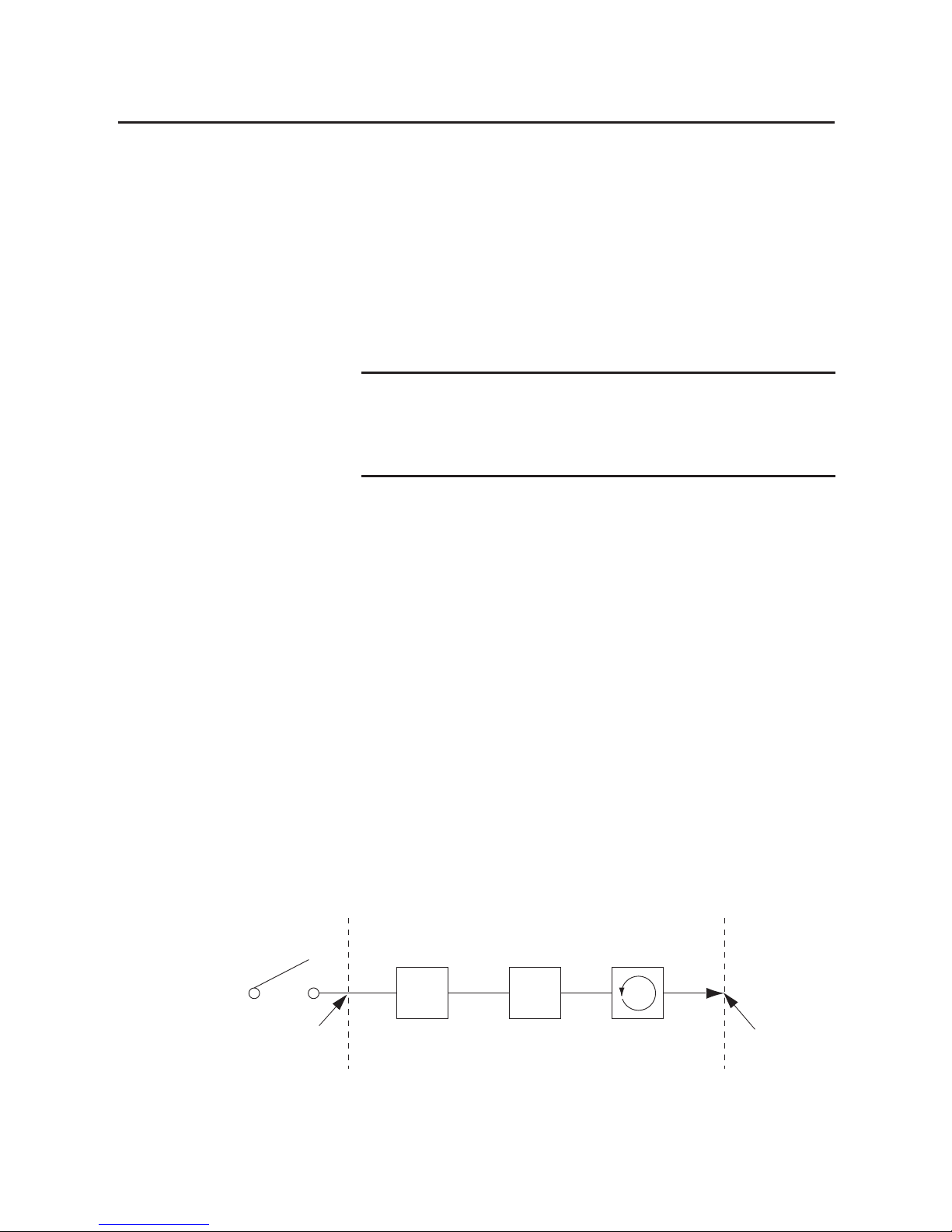

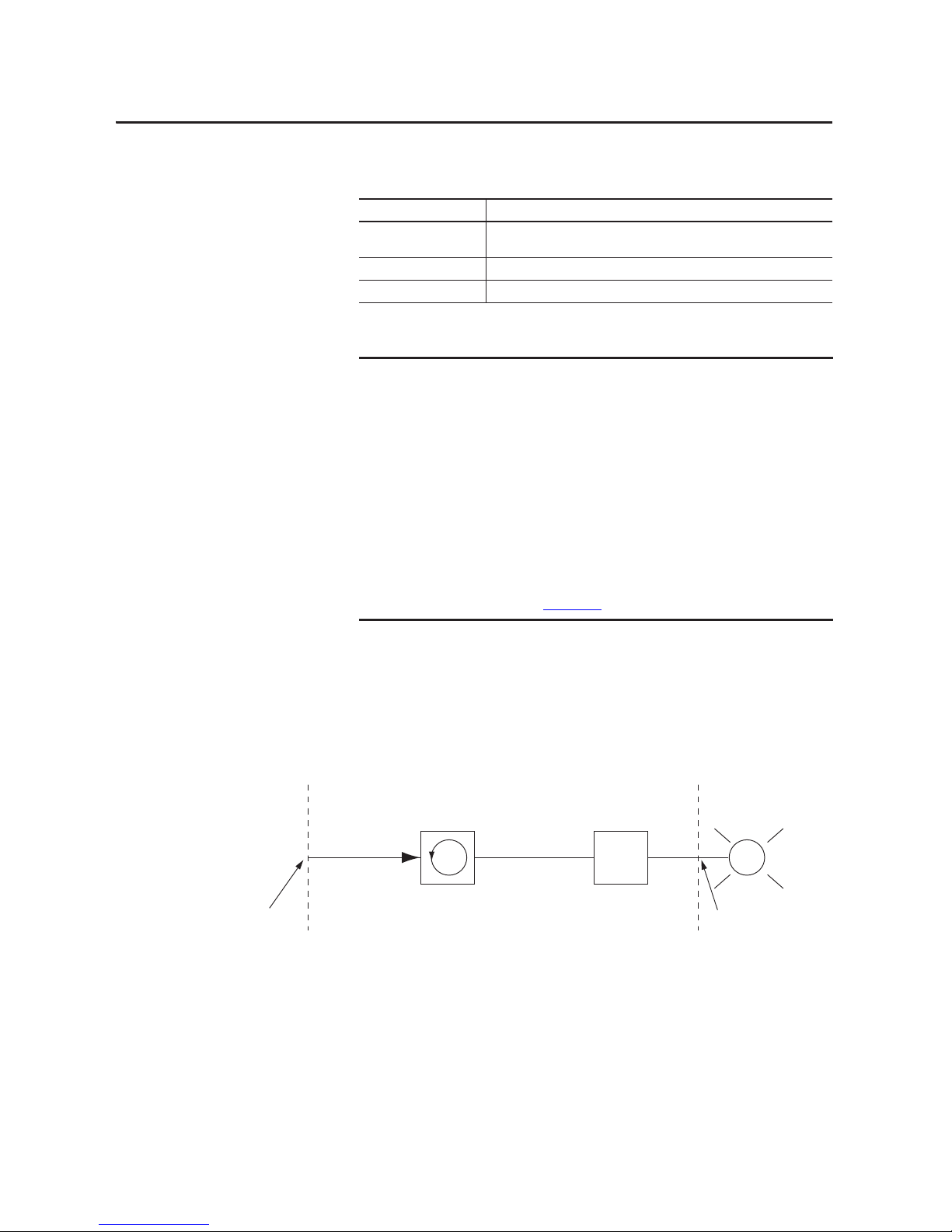

Input Modules

As shown in the illustration below, ControlLogix input modules receive a signal

at the RTB and process it internally through hardware, filters, and an ASIC scan

before sending a signal to the backplane via the requested packet interval (RPI) or

at a Change of State (COS) occurrence. The RPI is a configured interval of time

that determines when a module’s data is sent to the controller.

IMPORTANT

You must run RSNetWorx for ControlNet software whenever a new I/O module

is added to a scheduled ControlNet chassis. When a module is permanently

removed from a remote chassis, we recommend that you run RSNetWorx for

ControlNet software to reschedule the network and optimize the allocation of

network bandwidth.

42701

Hardware Delay

Filter Delay

ASIC Delay

Signal Applied

at the RTB

Signal Sent to

the Backplane

Page 22

22 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 2 Digital I/O Operation in the ControlLogix System

The table defines some of the delay factors that affect the signal propagation on

an I/O module.

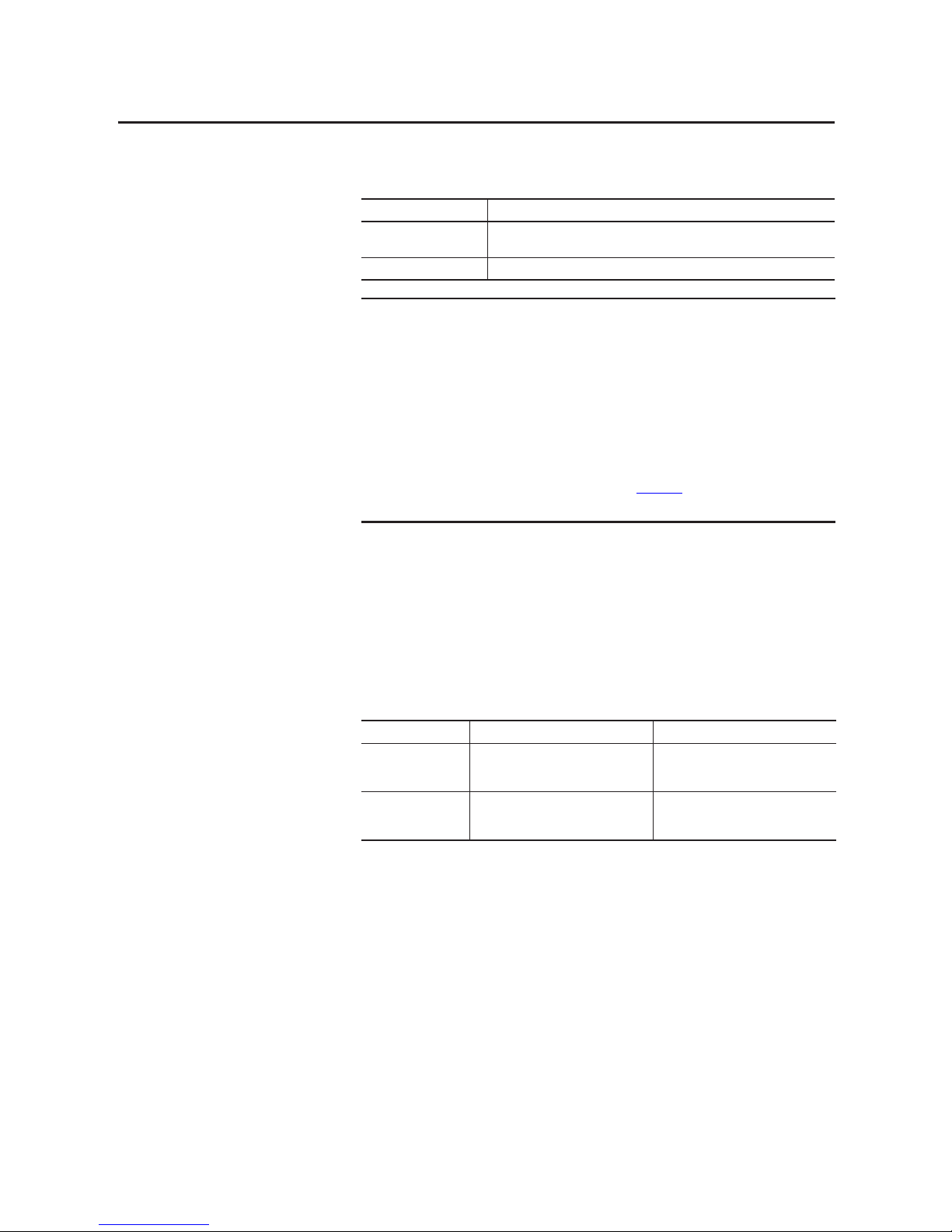

Output Modules

ControlLogix output modules receive a signal from the controller and process it

internally via hardware and an ASIC scan before sending a signal to the output

device via the RTB.

Delay Description

Hardware How the module is configured and the variance between the type of modules affects

how the signal is processed.

Filter User configuration varies between modules, thus affecting the signal propagation.

ASIC ASIC scan = 200 µs.

EXAMPLE

A typical delay time can be estimated despite the number of factors that might

contribute. For example, if you are turning on a 1756-IB16 module at 24V DC in

25 °C (77 °F) conditions, the signal propagation delay is affected by these

factors:

• Hardware delay to energize the input (typically 290 µs on the

1756-IB16 module)

• User-configurable filter time of 0, 1, or 2 ms

• ASIC scan of 200 µs

In the worst case scenario with a filter time of 0 ms, the 1756-IB16 module has

a 490 µs signal propagation delay.

These times are not guaranteed. For nominal and maximum delay times for

each module, see the 1756 ControlLogix I/O Modules Specifications Technical

Data, publication 1756-TD002

.

Hardware DelayASIC Delay

42702

Signal Sent from

RTB Output Point

Signal Received

from Controller

Page 23

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 23

Digital I/O Operation in the ControlLogix System Chapter 2

The table defines some of the delay factors that affect the signal propagation on

an I/O module.

Connections

With ControlLogix I/O modules, a connection is the data transfer link between

a controller and an I/O module. A connection can be one of these types:

• Direct

• Rack-optimized

The table lists the advantages and disadvantages of each connection type.

Delay Description

Hardware How the module is configured and the variance between the type of modules affects

how the signal is processed.

ASIC ASIC scan = 200 µs.

EXAMPLE

A typical delay time can be estimated despite the number of factors that might

contribute. For example, if you are turning on a 1756-OB16E module at 24V DC

in 25 °C (77 °F) conditions, the signal propagation delay is affected by these

factors:

• Hardware delay to energize the input (typically 70 µs on the

1756-OB16E module)

• ASIC scan of 200 µs

In the worst case scenario with a filter time of 0 ms, the 1756-OB16E module

has a 270 µs signal propagation delay.

These times are not guaranteed. See Chapter 8

for nominal and maximum

delay times for each module.

Connection Type Advantages Dis advantages

Direct All input and data echo information is

transferred, including diagnostic

information and fusing data.

With more data transferring over the

network, your system does not operate as

efficiently as with rack connections.

Rack-optimized Connection usage is economized. The

owner-controller has a single RPI value for

each connection.

Input and data echo information is limited

to general faults and data.

Page 24

24 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 2 Digital I/O Operation in the ControlLogix System

Direct Connections

A direct connection is a real-time data transfer link between the controller and

the device that occupies the slot that the configuration data references. When

module configuration data is downloaded to an owner-controller, the controller

attempts to establish a direct connection to each of the modules referenced by the

data.

If a controller has configuration data referencing a slot in the control system, the

controller periodically checks for the presence of a device there. When a device’s

presence is detected there, the controller automatically sends the configuration

data.

If the data is appropriate to the module found in the slot, a connection is made

and operation begins. If the configuration data is not appropriate, the data is

rejected and an error message appears in the software. In this case, the

configuration data can be inappropriate for any of a number of reasons. For

example, a module’s configuration data may be appropriate except for a mismatch

in electronic keying that prevents normal operation.

The controller maintains and monitors its connection with a module. Any break

in the connection causes the controller to set fault status bits in the data area

associated with the module. Breaks in the connection can be caused by a module

fault or the removal of the module from the chassis while under power.

RSLogix 5000 software monitors fault status bits to annunciate module failures.

Rack-optimized Connections

When a digital I/O module is located in a remote chassis with respect to its

owner-controller, you can choose Rack Optimization or Listen-only Rack

Optimization during module configuration. The option you choose depends on

the communication module configuration. If the communication module uses

Listen-only Rack Optimization, then the I/O module must also use Listen-only

Rack Optimization.

A rack-optimized connection economizes bandwidth between owner-controllers

and digital I/O modules in the remote chassis. Rather than having several direct

connections with individual RPI values, an owner-controller has a single rack

connection with a single RPI value. That RPI value accommodates all digital I/O

modules in the remote chassis.

Page 25

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 25

Digital I/O Operation in the ControlLogix System Chapter 2

The input, or data echo, information is limited to general faults and data. No

additional status, such as diagnostic information, is available.

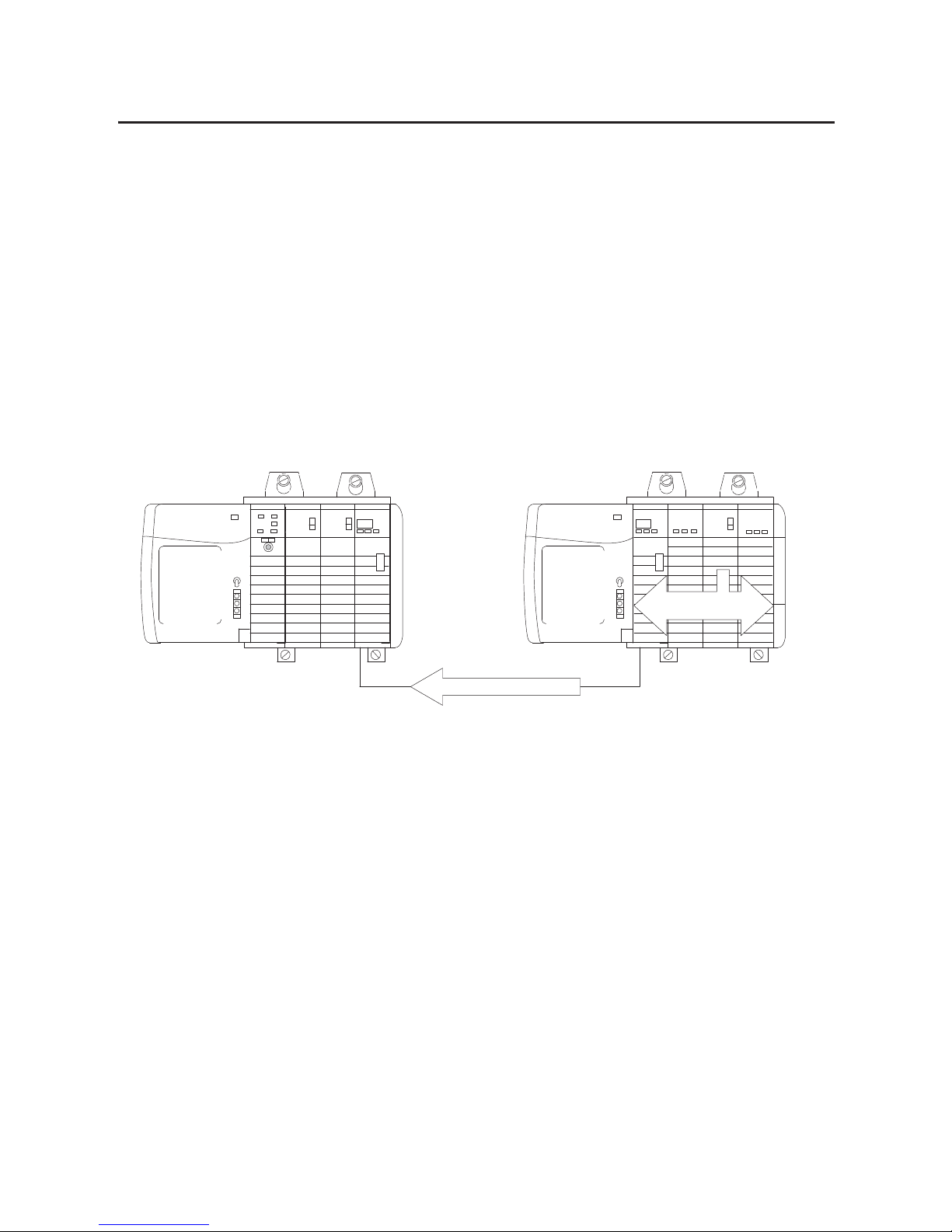

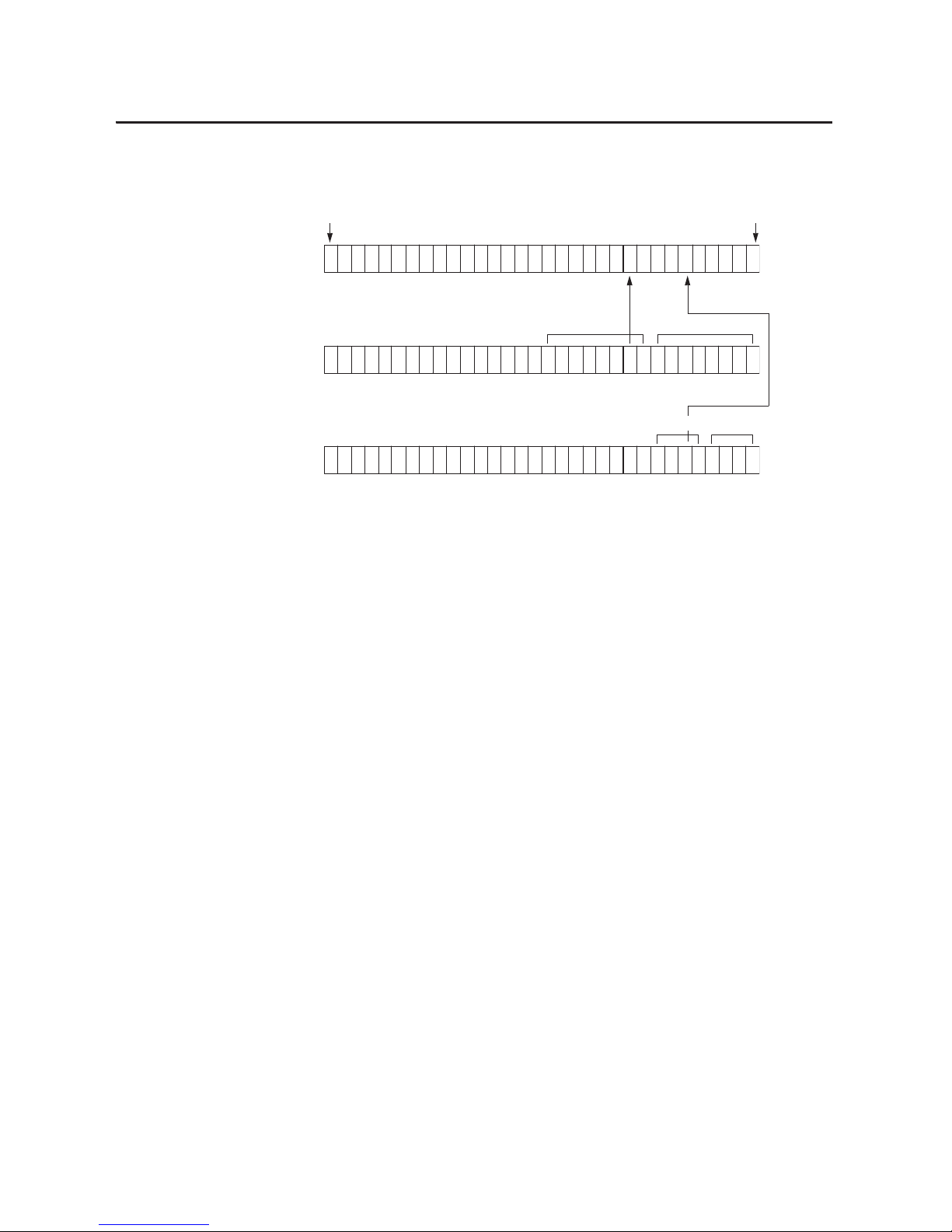

The illustration below shows how a rack-optimized connection eliminates the

need for three separate connections. The owner-controller in the local chassis

communicates with all the I/O modules in the remote chassis but uses only one

connection. The ControlNet communication module sends data from the

modules simultaneously at the RPI.

Figure 2 - Rack-optimized Connection

IMPORTANT

Because rack-optimized connections are applicable only in applications that

use a remote chassis, you must configure the communication format , as

described in Chapter 7

, for both the remote I/O module and the remote

1756-CNB module or EtherNet/IP module.

Make sure you configure both modules for rack optimization. If you choose a

different communication format for each module, the controller makes two

connections to the same chassis (one for each format) and the same data

travels across the ControlNet network.

If you use rack optimization for both modules, you preserve bandwidth and

configure your system to operate more efficiently.

IMPORTANT

Each controller can establish connections, in any combination of direct or rackoptimized. In other words, you can use a rack-optimized connection between

an owner-controller and multiple remote I/O modules while simultaneously

using a direct connection between that same controller and any other I/O

modules in the same remote chassis.

Local Chassis

Remote Chassis

ControlNet Network

41021

One Connection for

All Remote I/O

Page 26

26 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 2 Digital I/O Operation in the ControlLogix System

Suggestions for Rack-optimized Connections

We recommend that you use a rack-optimized connection for these applications:

• Standard digital I/O modules

• Non-fused digital output modules

• Owner-controllers running low on connections

Input Module Operation

In traditional I/O systems, controllers poll input modules to obtain their input

status. In the ControlLogix system, a controller does not poll digital input

modules. Instead, the modules multicast their data either upon change of state

(COS) or requested packet interval (RPI). The frequency depends on the

options chosen during configuration and whether the input module is local or

remote. This method of communication uses the Producer/Consumer model.

The input module is the producer of input data and the controller is the

consumer of the data.

All ControlLogix inputs are updated asynchronously in relation to the

controller’s task execution. In other words, an input may be updated in the

controller at any time during the controller’s execution of the tasks it is

configured to run. The input device determines when the input is sent based on

its configuration.

An input module’s behavior also varies depending upon whether it operates in the

local chassis or in a remote chassis. The following sections detail the differences in

data transfers between local and remote installations.

IMPORTANT

Rack-optimized connections are available only to digital I/O modules.

However, do not use a rack-optimized connection for diagnostic I/O modules or

fused output modules. Diagnostic and fused output data will not be

transferred over a rack-optimized connection. This defeats the purpose of using

those modules.

Page 27

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 27

Digital I/O Operation in the ControlLogix System Chapter 2

Input Modules in a

Local Chassis

When a module resides in the same chassis as the owner-controller, the following

two configuration parameters affect how and when an input module multicasts

data:

• Requested packet interval (RPI)

• Change of state (COS)

RPI

The RPI defines the slowest rate at which a module multicasts its data to the

owner-controller. The time ranges from 200 µs…750 ms and is sent to the module

with all other configuration parameters. When the specified time frame elapses,

the module will multicast data. This is also called a cyclic update.

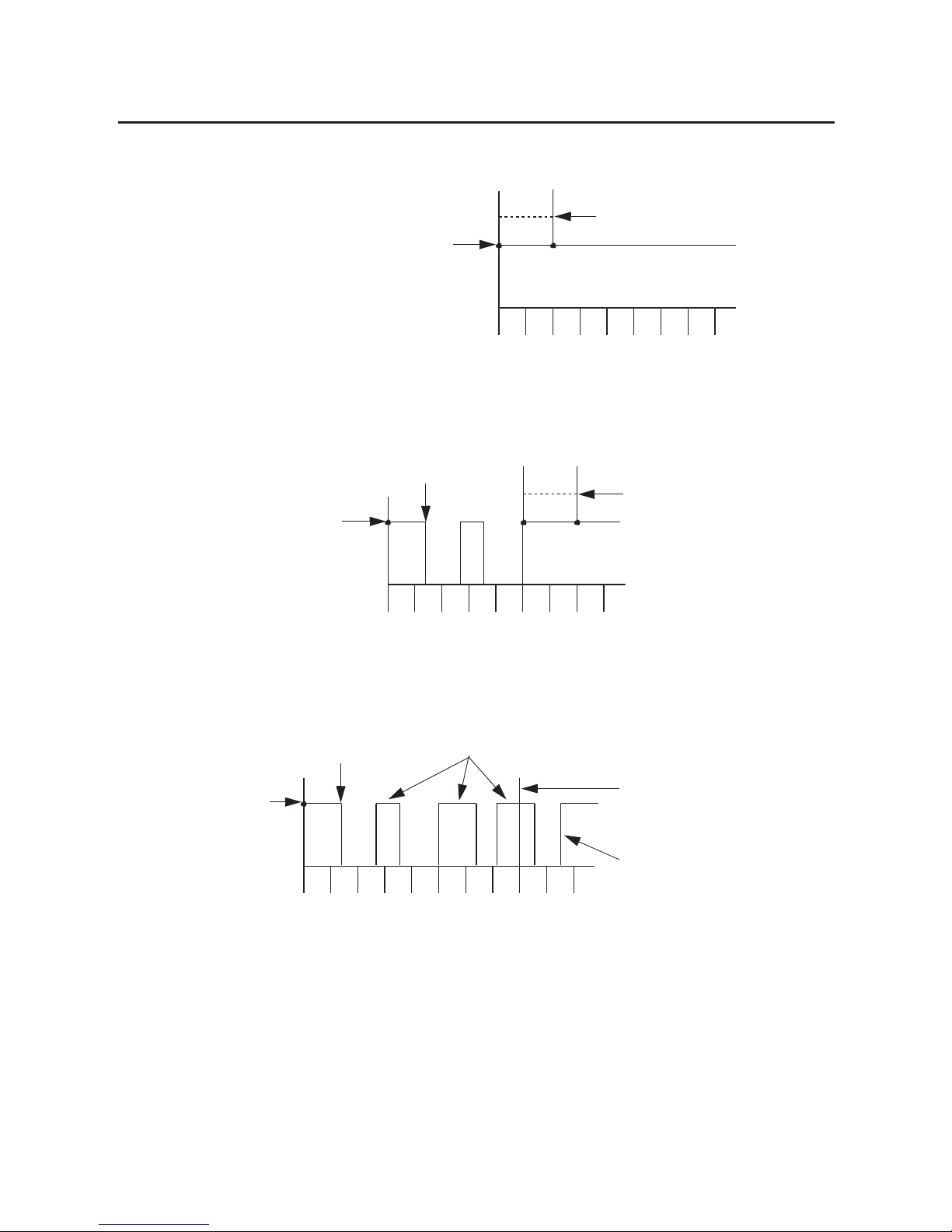

COS

COS instructs the module to transfer data whenever a specified input point

transitions from On to Off or Off to On. The transition is referred to as a change

of state.

COS configuration occurs on a per-point basis, but all module data is multicast

when any point enabled for COS changes state. COS is more efficient than RPI

because it multicasts data only when a change occurs.

For example, if an input is changing state consistently every two seconds and the

RPI is set at 750 ms, the data transfer will look like the illustration.

IMPORTANT

The module’s COS feature defaults to Enabled for both On to Off and Off to On.

IMPORTANT

You must specify an RPI regardless of whether you enable COS. If a change does

not occur within the RPI timeframe, the module still will multicast data at the

rate specified by the RPI.

41381

= COS Multicast

= RPI Multicast

250 500 750

1 Second

1250 1500 1750

2 Seconds 3 Seconds

2250 2500 2750 3250

Page 28

28 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 2 Digital I/O Operation in the ControlLogix System

Because the RPI and COS functions are asynchronous to the program scan, it is

possible for an input to change state during program scan execution. The point

must be buffered to prevent this from occurring. To buffer the point, you can

copy the input data from your input tags to another structure and use the data

from there.

Trigger Event Tasks

When configured, ControlLogix digital input modules can trigger an event task.

The event task lets you execute a section of logic immediately when an event, or

receipt of new data, occurs.

Your ControlLogix digital I/O module can trigger event tasks whenever module

input data changes state. Refer to these considerations when using a digital input

module to trigger an event task:

• Only one input module can trigger a specific event task.

• Input modules trigger the event task based on the module’s COS

configuration. The COS configuration defines which points prompt the

module to produce data if they turn On or Off. This production of data

triggers the event task.

• Typically, enable COS for only one point on the module. If you enable

COS for multiple points, a task overlap of the event task may occur.

For more information on event tasks, refer to the Logix5000 Controllers Tasks,

Programs, and Routines Programming Manual, publication 1756-PM005

.

Input Modules in a

Remote Chassis

If an input module physically resides in a chassis other than where the

owner-controller resides, the role of the RPI and the module’s COS behavior

changes slightly with respect to getting data to the owner.

The RPI and COS behavior still define when the module will multicast data

within its own chassis, as described in the previous section. But, only the value of

the RPI determines when the owner-controller will receive it over the network.

TIP

To minimize traffic and conserve bandwidth, use a larger RPI value if COS is

enabled and the module is in the same chassis as its owner-controller.

Page 29

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 29

Digital I/O Operation in the ControlLogix System Chapter 2

Remote Input Modules Connected via the ControlNet Network

When an RPI value is specified for an input module in a remote chassis

connected by a scheduled ControlNet network, in addition to instructing the

module to multicast data within its own chassis, the RPI also reserves a spot in

the stream of data flowing across the ControlNet network.

The timing of this reserved spot may or may not coincide with the exact value of

the RPI. But, the control system will guarantee that the owner-controller will

receive data at least as often as the specified RPI.

As shown in the illustration below, the input data within the remote chassis is

multicast at the configured RPI. The ControlNet communication module sends

input data back to the owner-controller at least as often as the RPI.

Figure 3 - Remote Input Modules on ControlNet Network

The module’s RPI and reserved spot on the network are asynchronous to each

other. This means there are best and worst case scenarios as to when the

owner-controller will receive updated data from the module in a remote chassis.

Best Case RPI Multicast Scenario

In the best case scenario, the module performs an RPI multicast with updated

channel data just before the reserved network slot is made available. In this case,

the remotely-located owner receives the data almost immediately.

40947

ControlNet Network

Local Chassis Remote Chassis

Multicast Data

Page 30

30 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 2 Digital I/O Operation in the ControlLogix System

Worst Case RPI Multicast Scenario

In the worst case scenario, the module performs an RPI multicast just after the

reserved network slot has passed. In this case, the owner-controller will not

receive data until the next available network slot.

When selecting values for the remotely located module’s RPI, system throughput

is optimized when its RPI value is a power of two times the current NUT

running on the ControlNet network.

For example, the following table shows recommended RPI values for a system by

using a NUT of 5 ms.

Remote Input Modules Connected via the EtherNet/IP Network

When remote digital input modules are connected to the owner-controller via an

EtherNet/IP network, data is transferred to the owner-controller at these times:

• At the RPI, the module produces data within its own chassis.

• At the COS (if enabled), the 1756 EtherNet/IP communication module

in the remote chassis immediately sends the module’s data over the

network to the owner-controller as long as it has not sent data within a

timeframe that is one-quarter the value of the digital input module’s RPI.

This prevents flooding the network with data.

For example, if a digital input module uses an RPI = 100 ms, the

EtherNet/IP module sends module data immediately on receiving it if

another data packet was not sent within the last 25 ms.

For more information about specifying an RPI rate, see the Logix5000

Controllers Design Considerations Reference Manual,

publication 1756-RM094

.

IMPORTANT

Enabling the COS feature on an input module in a remote chassis allows the

module to multicast data at both the RPI rate and when the input changes

state. This helps to reduce the worst case time.

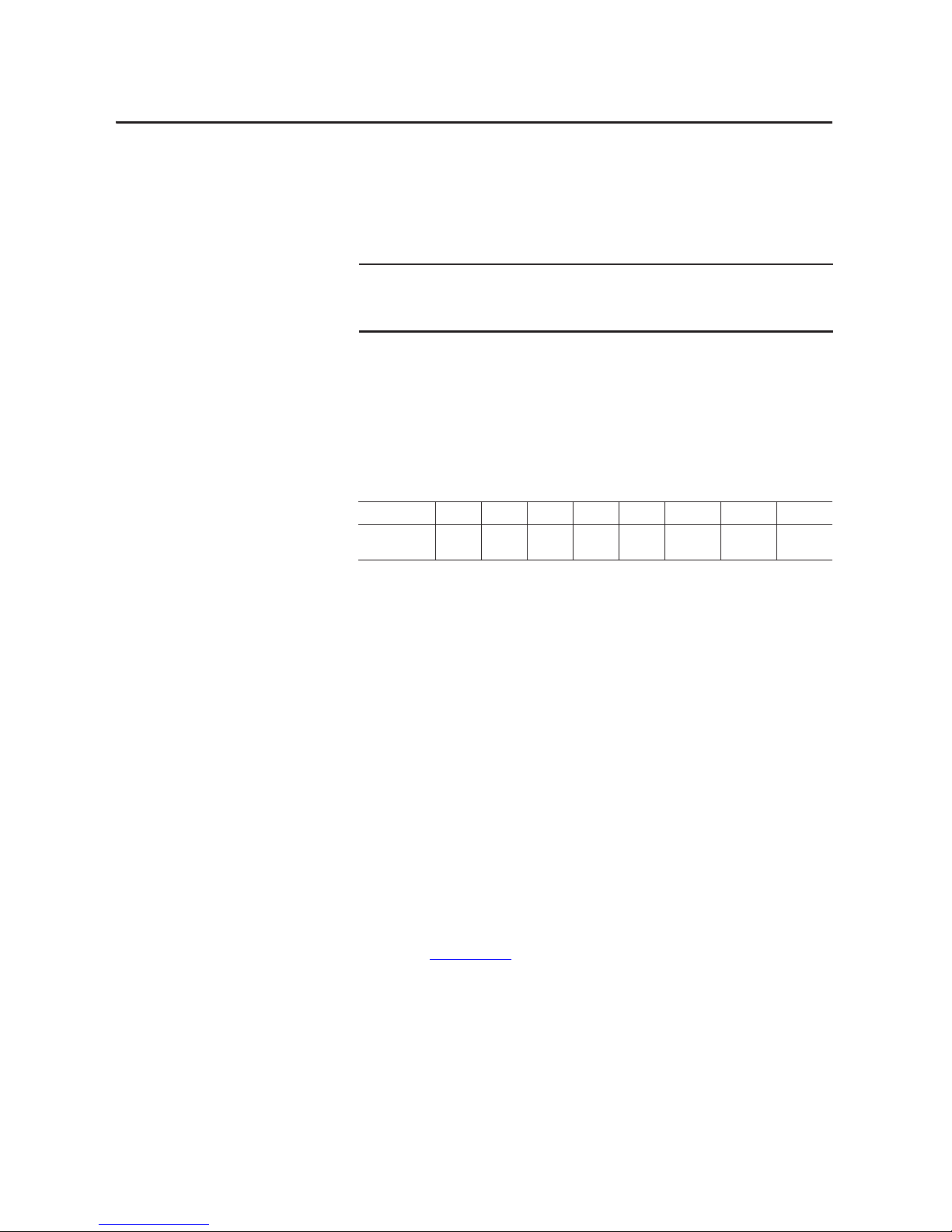

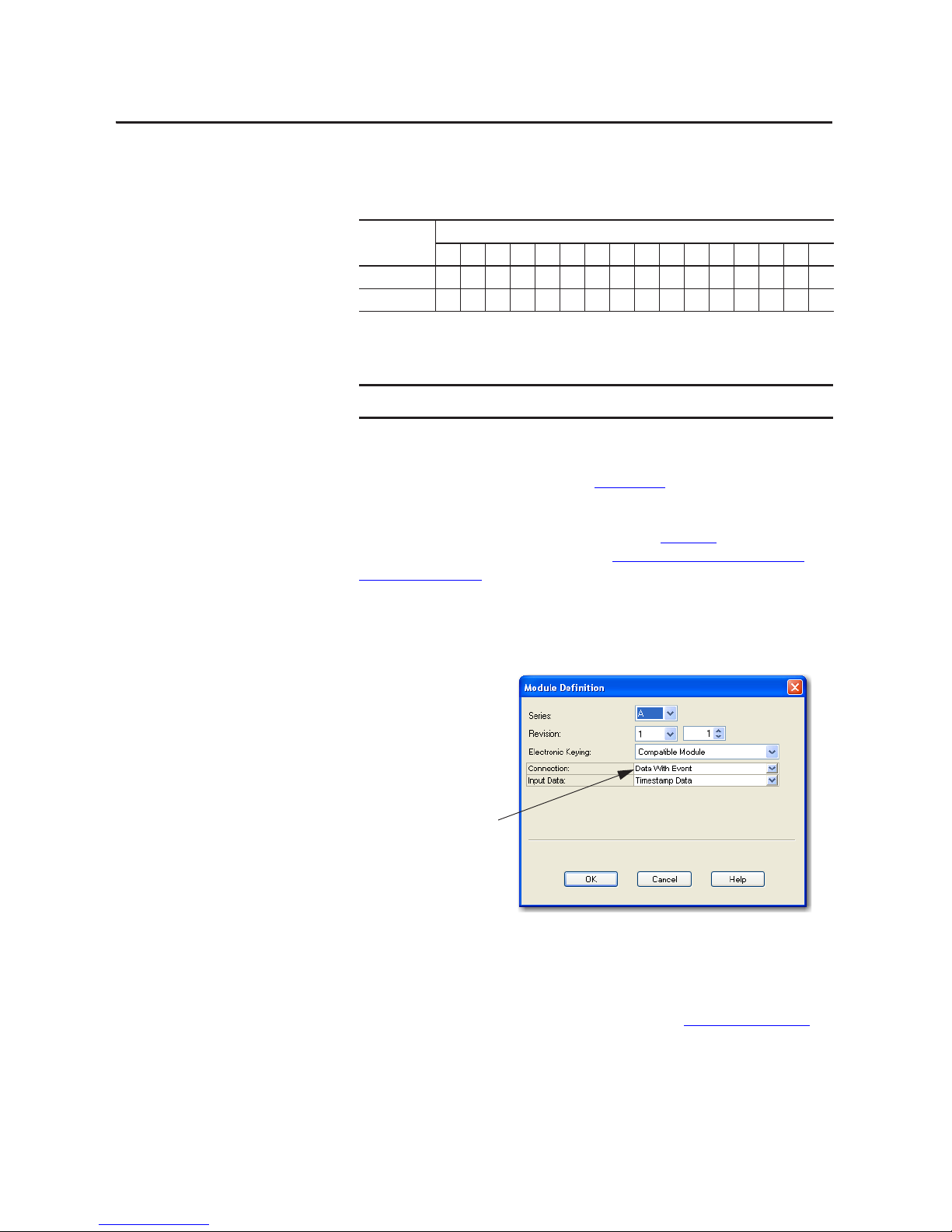

Table 2 - Recommended RPI Values for System by Using NUT of 5 ms

NUT=5 ms x2

0

x2

1

x2

2

x2

3

x2

4

x2

5

x2

6

x2

7

Optimal RPI

Valu es ( ms)

5 ms 10 ms 20 ms 40 ms 80 ms 160 ms 320 ms 640 ms

Page 31

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 31

Digital I/O Operation in the ControlLogix System Chapter 2

Output Module Operation

An owner-controller sends output data to an output module when either one of

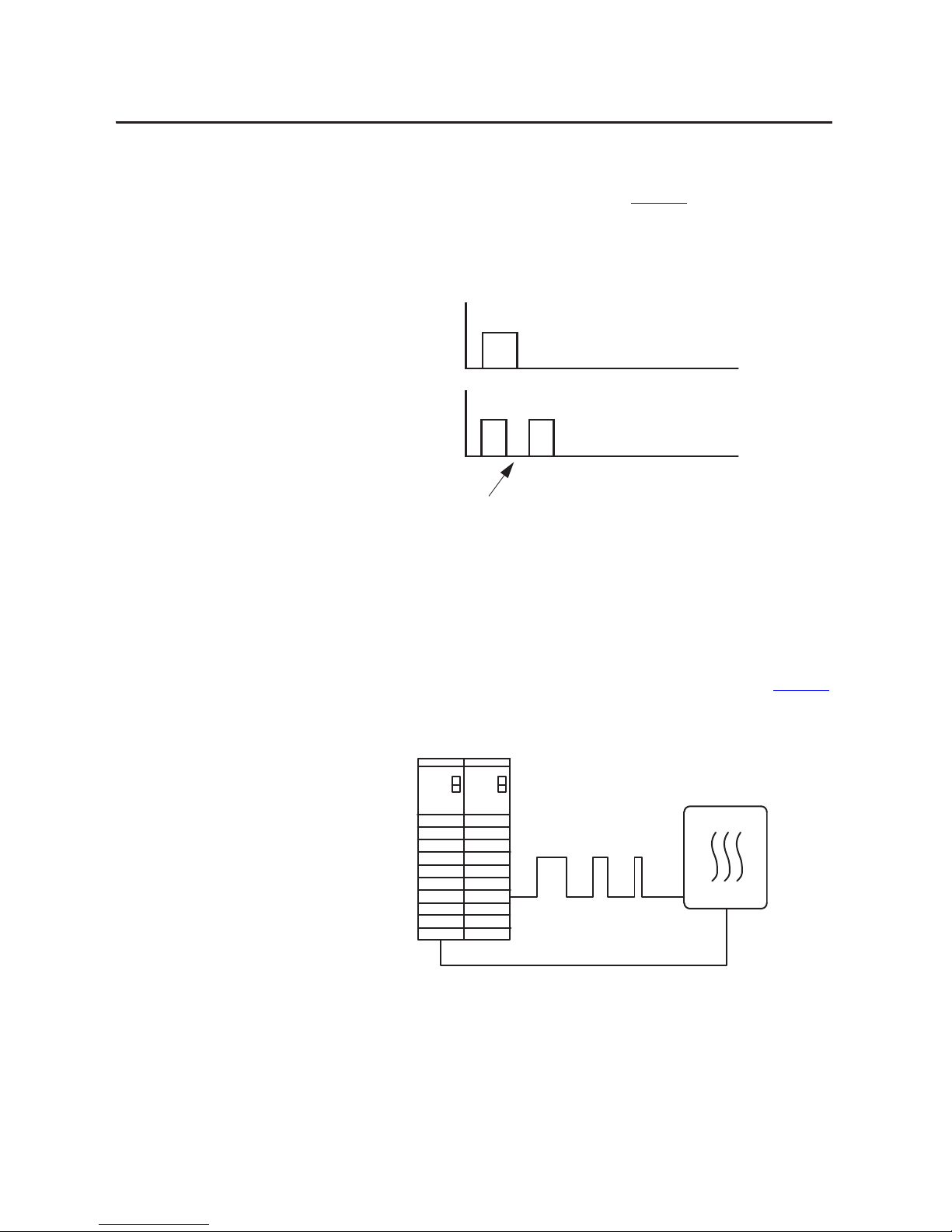

two things occur:

• At the end of every one of its tasks (local chassis only)

• At the rate specified in the module’s RPI

When an output module physically resides in a remote chassis with respect to the

owner-controller, the owner-controller sends data to the output module only at

the RPI rate specified for the module. Updates are not performed at the end of

the owner-controller’s tasks.

Whenever the module receives data from the controller, it immediately

multicasts the output commands it received to the rest of the system. The actual

output data is echoed by the output module as input data and multicast back out

onto the network. This is called output data echo.

Output Modules in a

Local Chassis

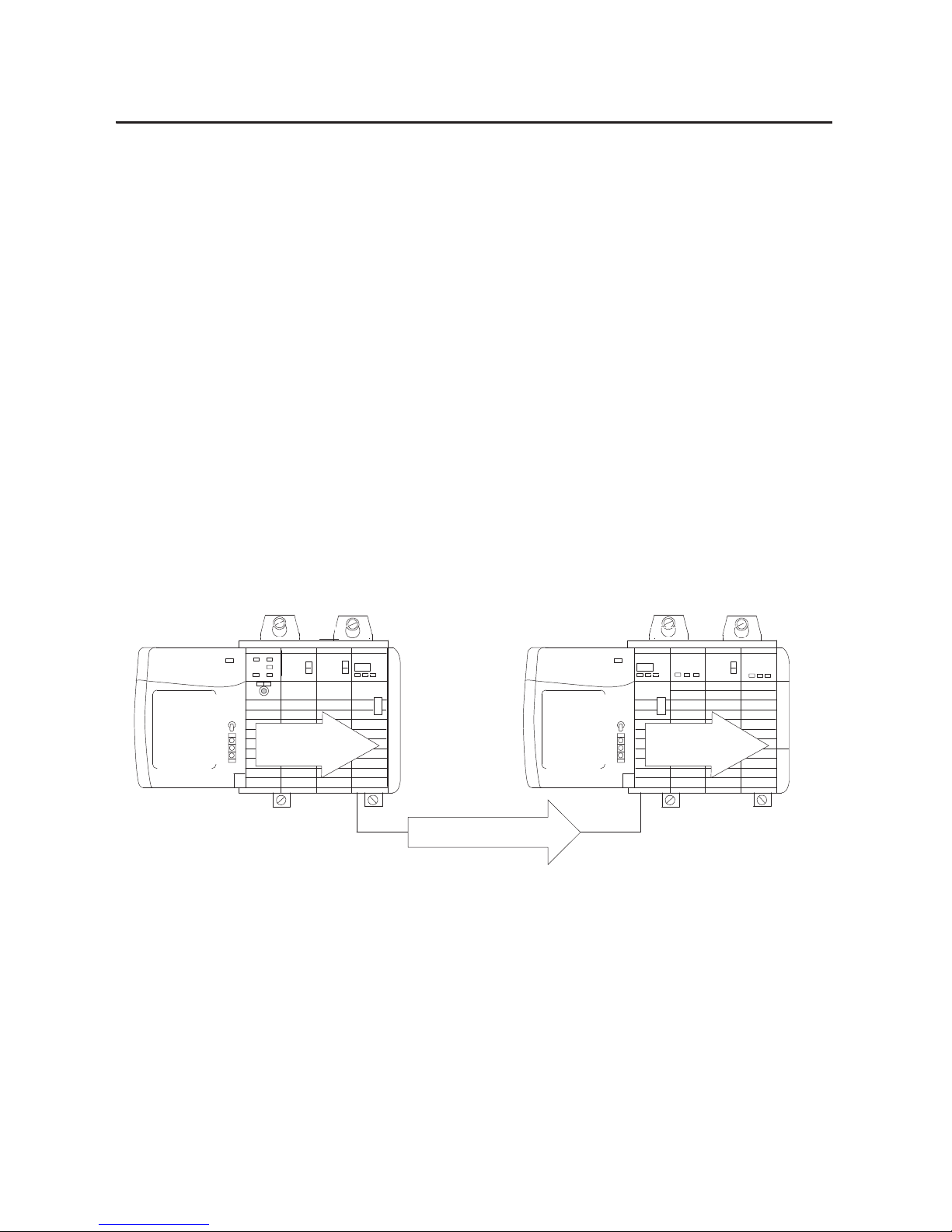

The owner-controller updates ControlLogix digital output modules in the local

chassis at the end of every task and at the RPI.

When you specify an RPI value for a digital output module, you instruct the

owner-controller when to broadcast the output data to the module. If the module

resides in the same chassis as the owner-controller, as shown in the illustration

below, the module receives the data almost immediately after the ownercontroller sends it. Backplane transfer times are small.

Figure 4 - Local Output Modules

Depending on the value of the RPI with respect to the length of the program

scan, the output module can receive and echo data multiple times during one

program scan.

IMPORTANT

In this Producer/Consumer model, the output module is the consumer of the

controller’s output data and the producer of the data echo.

40949

Data is sent at the end of

every task and at the RPI.

Page 32

32 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 2 Digital I/O Operation in the ControlLogix System

Output Modules in a

Remote Chassis

If an output module physically resides in a chassis other than that of the

owner-controller, the owner-controller normally sends data to the output module

at the RPI rate specified. Updates are not performed at the end of the controller’s

tasks.

In addition, the role of the RPI for a remote output module changes slightly with

respect to getting data from the owner-controller.

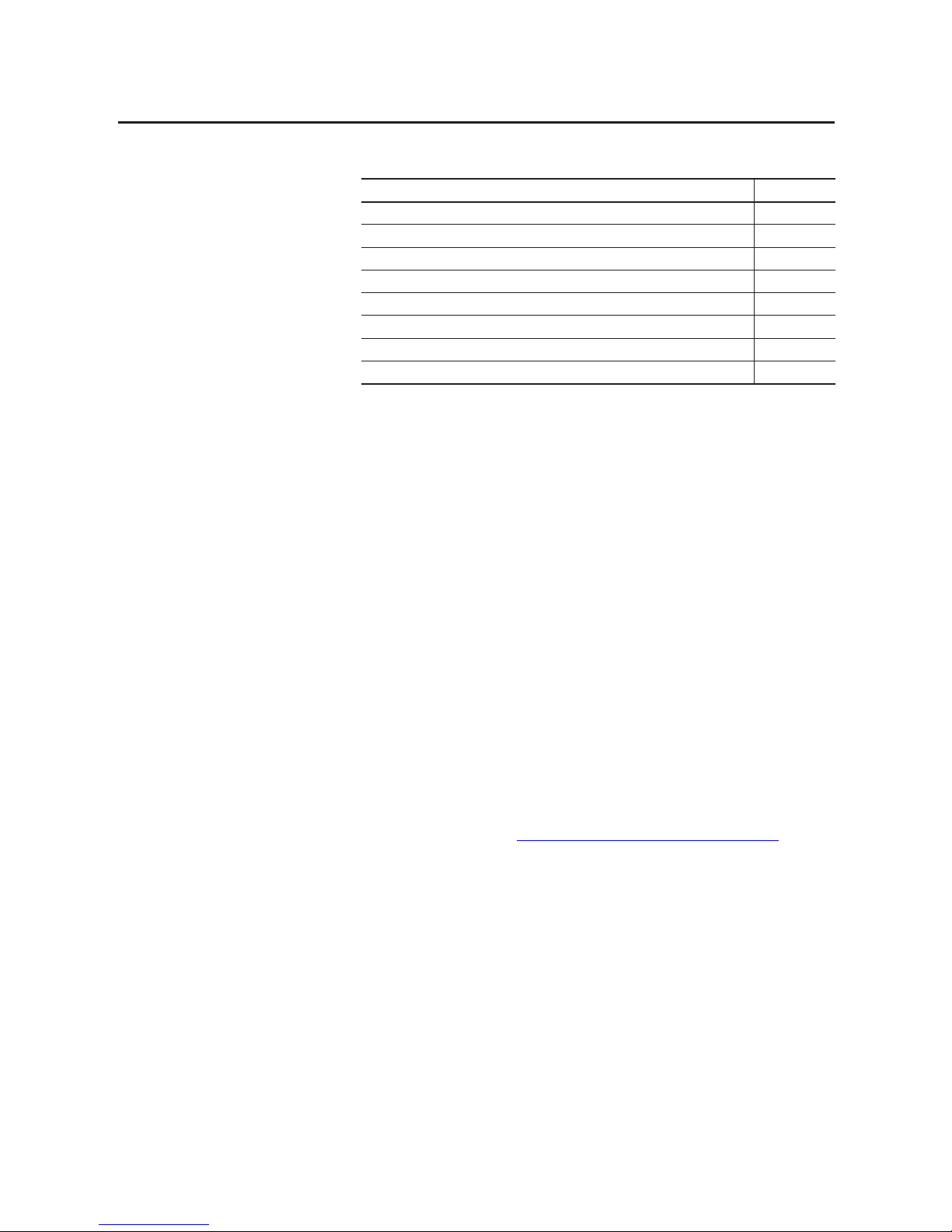

Remote Output Modules Connected via the ControlNet Network

When an RPI value is specified for an output module in a remote chassis

connected to the owner-controller by a scheduled ControlNet network, in

addition to instructing the owner-controller to multicast the output data within

its own chassis, the RPI also reserves a spot in the stream of data flowing across

the ControlNet network.

The timing of this reserved spot may or may not coincide with the exact value of

the RPI. But, the control system will guarantee that the output module will

receive data at least as often as the specified RPI, as shown in the illustration

below.

Figure 5 - Remote Output Modules on ControlNet Network

The reserved spot on the network and the output data sent by the controller are

asynchronous to each other. This means there are best and worst case scenarios as

to when the owner-controller will receive updated data from the module in a

remote chassis.

Best Case RPI Multicast Scenario

In the best case scenario, the owner-controller sends the output data just before

the reserved network slot is made available. In this case, the remote output

module receives the data almost immediately.

42675

ControlNet Network

Local Chassis Remote Chassis

Data is sent from t he

owner-co ntroller.

Output data is sent at

least as often as RPI.

Page 33

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 33

Digital I/O Operation in the ControlLogix System Chapter 2

Worst Case RPI Multicast Scenario

In the worst case scenario, the owner-controller sends the output data just after

the reserved network slot has passed. In this case, the output module does not

receive data until the next available network slot.

Remote Output Modules Connected via the EtherNet/IP Network

When remote digital output modules are connected to the owner-controller via

an EtherNet/IP network, the controller sends output data at these times:

• When the RPI timer expires

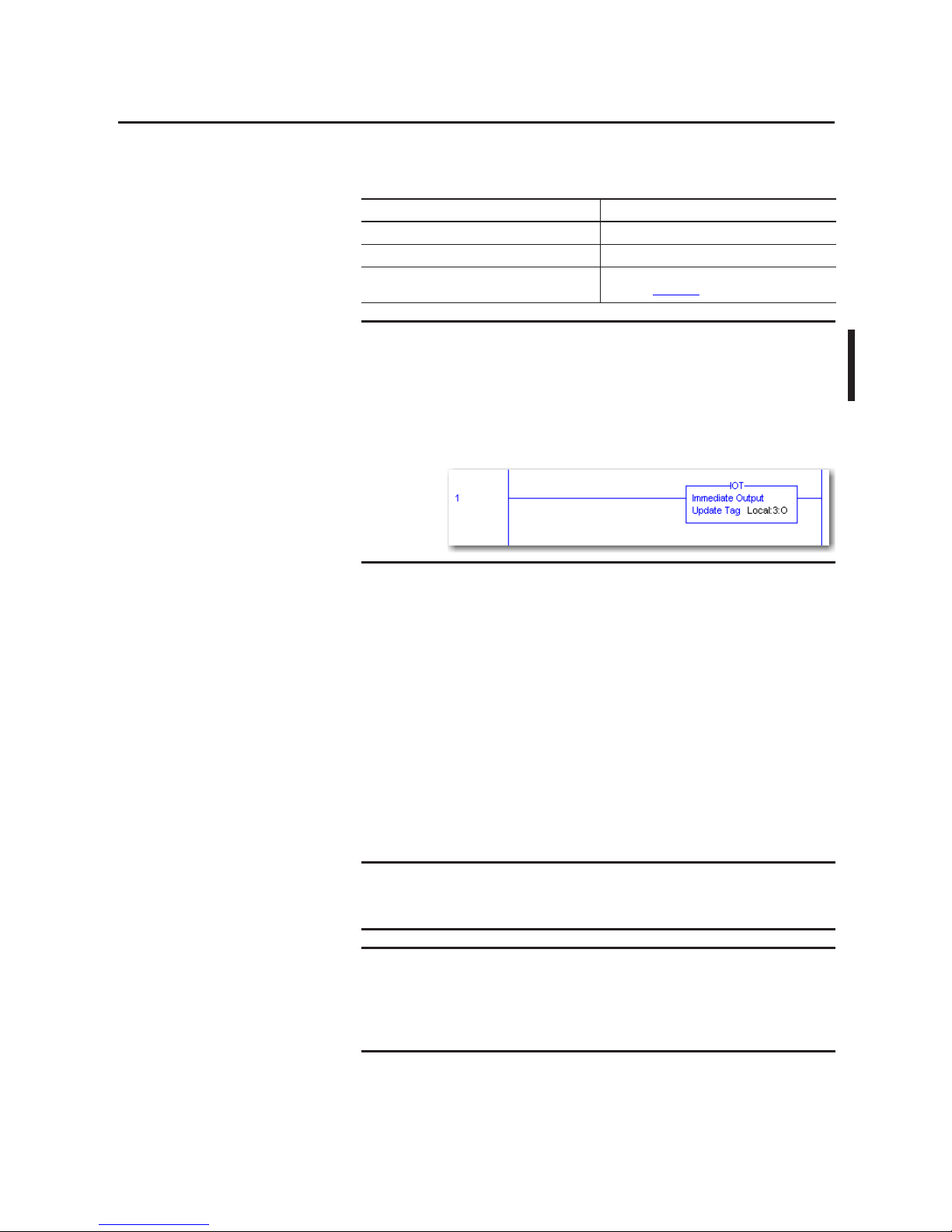

• When an Immediate Output (IOT) instruction, if programmed, is

executed

An IOT sends data immediately and resets the RPI timer.

• When a new schedule is created for a 1756-OB16IEFS module from the

motion planner for a cam that has been armed by an MAOC instruction

Because the 1756-OB16IEFS module is the only 1756 module that can be

used in a remote chassis with the MAOC instruction, it is the only module

that receives output data in this scenario

.

IMPORTANT

These best and worst case scenarios indicate the time required for output data

to transfer from the owner-controller to the module once the owner-controller

has produced it. They do not take into account the user program time in the

owner-controller.

The receipt of new data is a function of the length of the user program and its

asynchronous relationship with the RPI.

The owner-controller updates remote output modules at the end of each task

as well as at the RPI, as described earlier in this section, if your application uses

these components:

• 1756-CNB/D or 1756-CNBR/D modules

• RSLogix 5000 software, version 8.02.00 or later

Page 34

34 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 2 Digital I/O Operation in the ControlLogix System

Listen-only Mode

Any controller in the system can listen to the data from any I/O module, such as

input data, echoed output data, or echoed diagnostic information. Even if a

controller does not own a module, or hold the module’s configuration data, the

controller can still listen to the module.

During the module configuration process, you can specify one of several Listen

modes. For more information, see Communication or Connection Formats

on

page 131.

Choosing a Listen mode allows the controller and module to establish

communication without the controller sending any configuration data. In this

instance, another controller owns the module being listened to.

Multiple Owner-Controllers

of Input Modules

If a connection is lost between an owner-controller and a module, the connection

is also lost between any controllers listening to that module. As a result, the

ControlLogix system lets you define more than one owner-controller for input

modules.

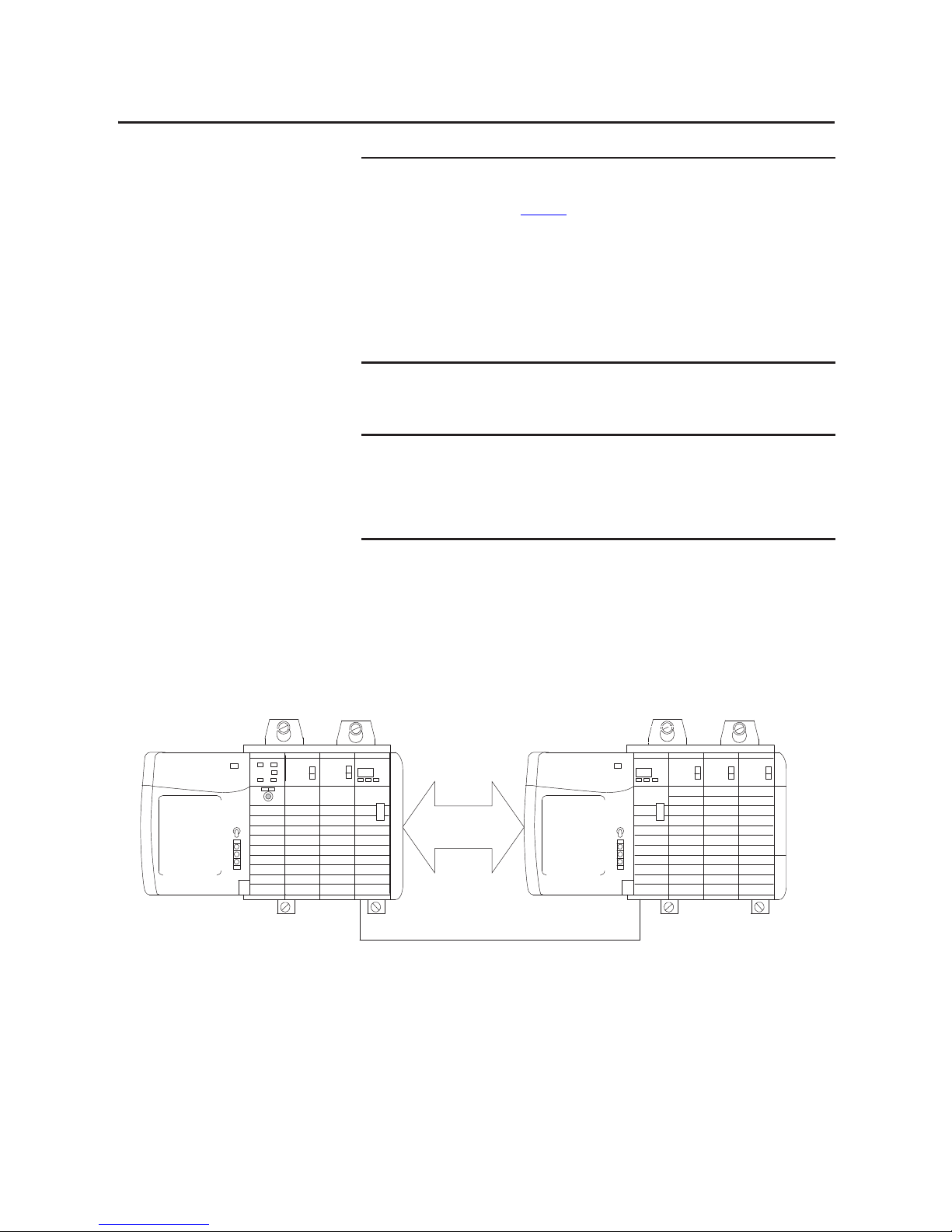

In the illustration below, controller A and controller B both have been config ured

to be owner-controllers of the same input module.

Figure 6 - Identical Owner-Controller Configurations for Input Module

IMPORTANT

In Listen-only mode, controllers continue to receive data multicast from the I/O

module as long as the connection between the owner-controller and I/O

module is maintained.

If the connection between the owner-controller and module is broken, the

module stops multicasting data and connections to all listening controllers are

also broken.

IMPORTANT

Only input modules can have multiple owner-controllers. If multiple ownercontrollers are connected to the same input module, they must maintain

identical configurations for that module.

Input Module

Configuration

Data

Xxxxx

Xxxxx

Xxxxx

Input Module

Configuration

Data

Xxxxx

Xxxxx

Xxxxx

41056

Initial Configuration Initial Configuration

A

B

Input

A B

Page 35

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 35

Digital I/O Operation in the ControlLogix System Chapter 2

As soon as a controller receives its user program, it will try to establish a

connection with the input module. A connection is established with the

controller whose configuration data arrives first. When the second controller’s

configuration data arrives, the module compares it to its current configuration

data, which was received and accepted from the first controller.

If the configuration data sent by the second controller matches the data sent by

the first controller, that connection is also accepted. If any parameter of the

second configuration data is different from the first, the module rejects the

connection and the user is informed by an error in the software or via program

logic.

The advantage of multiple owners over a Listen-only connection is that either of

the controllers can break the connection to the module, and the module will

continue to operate and multicast data to the system through the connection

maintained by the other controller.

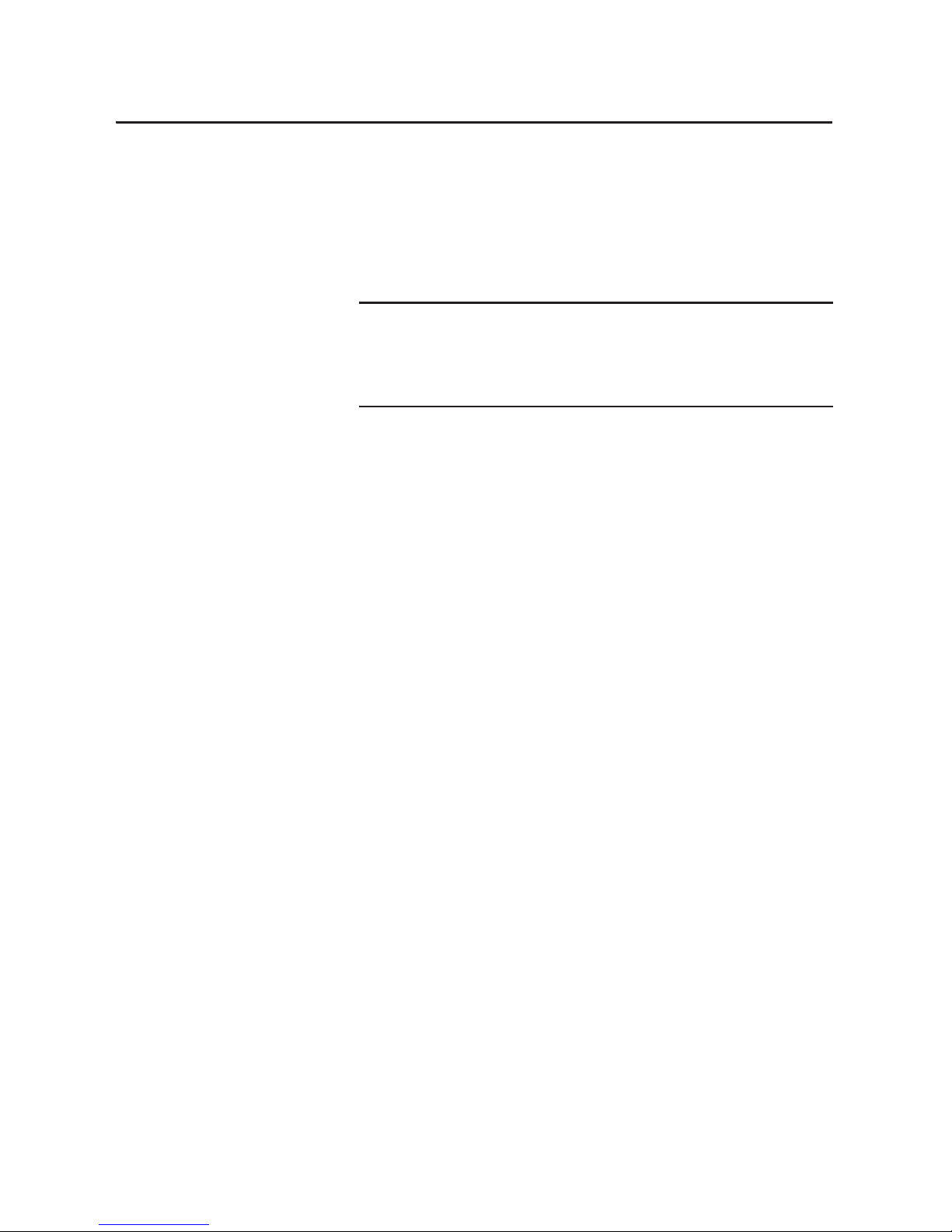

Configuration Changes in an

Input Module with Multiple

Owners

You must be careful when changing an input module’s configuration data in a

multiple owner scenario. If the configuration data is changed in owner A and sent

to the module, that configuration data is accepted as the new configuration for

the module. Owner B will continue to listen unaware that any changes have been

made in the module’s behavior, as illustrated below.

Figure 7 - Module Configuration Changes with Multiple Owners

41057

Input Module

Configuration

Data

Xxxxx

Zzzzz

Xxxxx

Input Module

Configuration

Data

Xxxxx

Xxxxx

Xxxxx

Initial Configuration Initial Configuration

A BInput

AB

IMPORTANT

A message in RSLogix 5000 software alerts you to the possibility of a multiple

owner-controller situation and lets you inhibit the connection before changing

the module’s configuration. When changing the configuration for a module

with multiple owners, we recommend the connection be inhibited.

Page 36

36 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 2 Digital I/O Operation in the ControlLogix System

To prevent other owner-controllers from receiving potentially erroneous data, use

these steps when changing a module’s configuration in a multiple owner scenario

while online.

1. For each owner-controller, inhibit the connection to the module either in

the software on the Connection tab or the message dialog box warning you

of the multiple owner condition.

2. Make the appropriate configuration data changes in the software. For more

information about using RSLogix 5000 software to change the

configuration, see Chapter

7.

3. Repeat step 1

and step 2 for all owner-controllers, making the exact same

changes in each.

4. Clear the Inhibit checkbox in each owner-controller configuration.

Page 37

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 37

Chapter 3

Common Module Features

Input Module Compatibility

ControlLogix digital input modules interface to sensing devices and detect

whether they are On or Off.

ControlLogix input modules convert AC or DC On/Off signals from user

devices to appropriate logic level for use within the processor. Typical input

devices include the following:

• Proximity switches

• Limit switches

• Selector switches

• Float switches

• Push button switches

When designing systems with ControlLogix input modules, consider these

factors:

• Voltage necessary for your application

• Current leakage

• Whether you need a solid state device

• Whether your application should use sinking or sourcing wiring

Top ic P age

Input Module Compatibility 37

Output Module Compatibility 38

Common Features 39

Common Features Specific to Input Modules 50

Common Features Specific to Output Modules 54

Fault and Status Reporting between Input Modules and Controllers 64

Fault and Status Reporting between Output Modules and Controllers 65

Page 38

38 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 3 Common Module Features

Output Module Compatibility

ControlLogix output modules can be used to drive a variety of output devices.

Typical output devices compatible with ControlLogix outputs include these

items:

• Motor starters

• Solenoids

• Indicators

Follow these guidelines when designing a system:

• Make sure that the ControlLogix outputs can supply the necessary surge

and continuous current for proper operation.

• Make sure that the surge and continuous current are not exceeded.

Damage to the module could result.

When sizing output loads, refer to the documentation supplied with the output

device for the surge and continuous current needed to operate the device.

The ControlLogix standard digital outputs are capable of directly driving the

ControlLogix standard digital inputs. The exceptions are the AC and DC

diagnostic input modules. When diagnostics are used, a shunt resistor is required

for leakage current.

For information on the compatibility of motor starters with ControlLogix

output modules, see Appendix

E.

Page 39

Rockwell Automation Publication 1756-UM058G-EN-P - November 2012 39

Common Module Features Chapter 3

Common Features

The table below lists features common to all ControlLogix digital I/O modules.

Removal and Insertion Under Power

All ControlLogix I/O modules may be inserted and removed from the chassis

while power is applied. This feature allows greater availability of the overall

control system. While the module is being removed or inserted, there is no

additional disruption to the rest of the control process. This helps prevent an

entire production line from having to be shut down.

Module Fault Reporting

ControlLogix digital I/O modules provide both hardware and software

indication when a module fault has occurred. Each module’s fault status indicator

and RSLogix 5000 software will graphically display this fault and include a fault

message describing the nature of the fault.

This feature lets you determine how your module has been affected and what

action should be taken to resume normal operation.

The 1756-OB16IEF module extends this feature by enabling you to define the

duration of time before the module transitions to On or Off after a fault occurs.

For more information, see Programmable Fault State Delays

on page 95.

Top ic Pag e

Removal and Insertion Under Power 39

Module Fault Reporting 39

Software Configurable 40

Electronic Keying 40

Module Inhibiting 46

Use the System Clock to Timestamp Inputs and Schedule Outputs 47

Producer/Consumer Communication 50

Status Indicator Information 50

Page 40

40 Rockwell Automation Publication 1756-UM058G-EN-P - November 2012

Chapter 3 Common Module Features

Software Configurable

RSLogix 5000 software provides an interface to configure each module. All

module features are enabled or disabled through the I/O configuration within

the software.

You can also use the software to retrieve the following information from any

module in the system:

• Serial number

• Firmware revision information

• Product code

• Ve n d o r

• Error and fault information

• Diagnostic counters

By eliminating tasks, such as setting hardware switches and jumpers, the software

makes module configuration easier and more reliable.

Electronic Keying

The electronic keying feature automatically compares the expected module, as

exists in the RSLogix 5000 I/O Configuration tree, to the physical module in the

chassis before I/O communication begins. You can use electronic keying to help

prevent communication to a module that does not match the type and revision

expected.

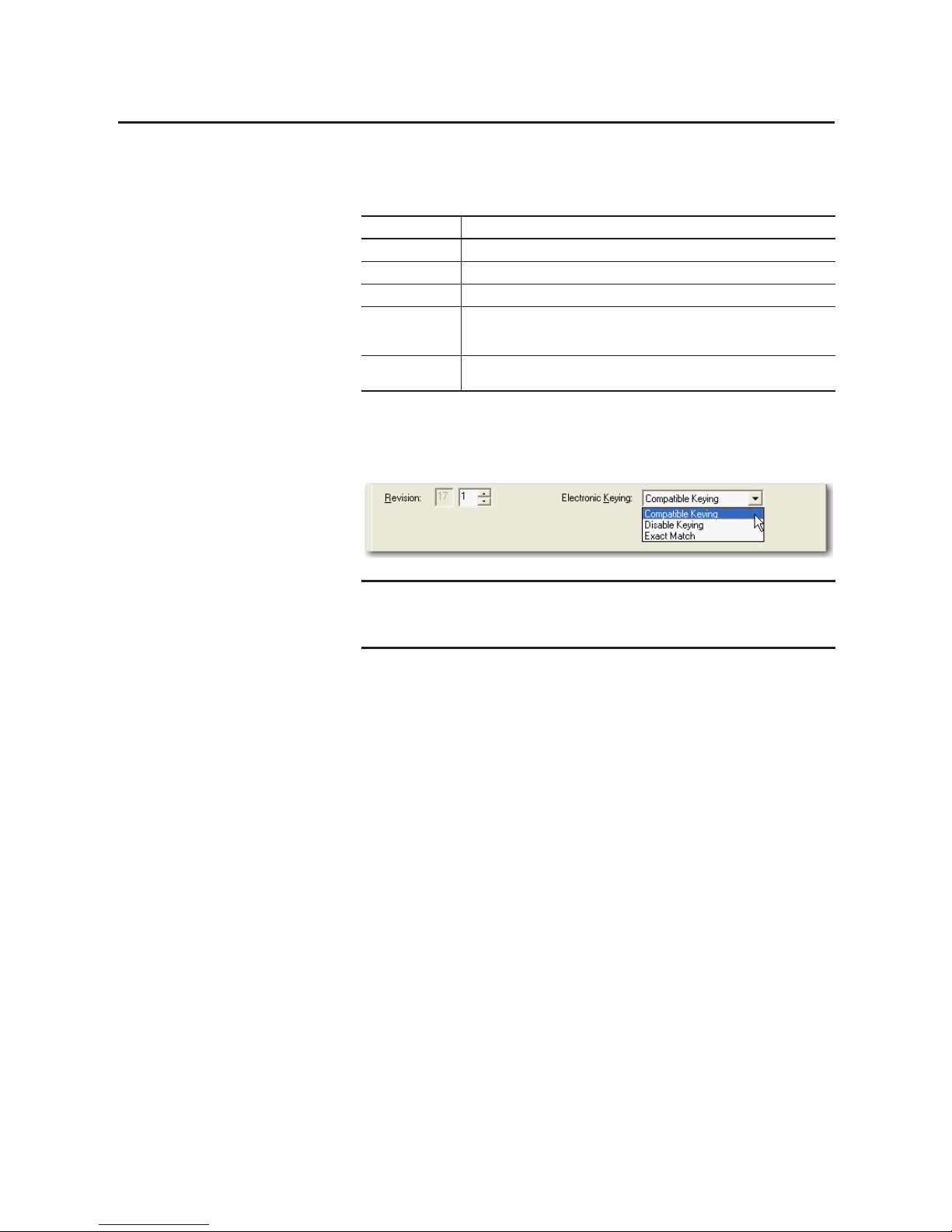

For each module in the I/O Configuration tree, the user-selected keying option