Allen-Bradley 1769 Compact GuardLogix, 1756 ControlLogix, 1789 SoftLogix, 5069 CompactLogix, 5069 Compact GuardLogix Programming Manual

...Page 1

Programming Manual

Logix 5000 Controllers Messages

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix, 1769 Compact GuardLogix,

1789 SoftLogix, 5069 CompactLogix, 5069 Compact GuardLogix, Studio 5000 Logix Emulate

Page 2

Important user information

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of this equipment

before you install, configure, operate, or maintain this product. Users are required to familiarize themselves with installation and wiring instructions

in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be carried out by

suitably trained personnel in accordance with applicable code of practice. If this equipment is used in a manner not specified by the manufacturer,

the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated

with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and

diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic

loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

Important:

Labels may also be on or inside the equipment to provide specific precautions.

Identifies information that is critical for successful application and understanding of the product.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be

present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc

Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work

practices and for Personal Protective Equipment (PPE).

Allen-Bradley, Rockwell Software, Rockwell Au tomation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are prope rty of their respective companies.

Page 3

Summary of changes

This manual includes new and updated information. Use these reference tables to

locate changed information.

Grammatical and editorial style changes are not included in this summary.

Global changes

This table identifies changes that apply to all information about a subject in the

manual and the reason for the change. For example, the addition of new supported

hardware, a software design change, or additional reference material would result

in changes to all of the topics that deal with that subject.

Subject Reason

Updated screen shots throughout. The graphical user interface has been updated in release 31 of the

Logix Designer application.

Updated supported controllers. Logix Designer supports new 5069 Compact GuardLogix controllers.

New or enhanced features

This table contains a list of topics changed in this version, the reason for the

change, and a link to the topic that contains the changed information.

Topic Name Reason

Guidelines on page 15 Added tip that MSG tags can be created at the controller or Program Local

scope for some controllers in version 31 of the Logix Designer application.

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 3

Page 4

Page 5

Preface

Controller messages

Manage multiple messages

Send a message to multiple

Index

Table of contents

Studio 5000 environment.................................................................................................... 7

Additional resources ............................................................................................................. 8

Legal notices ........................................................................................................................... 8

Chapter 1

Introduction to Controller Messages ............................................................................. 11

Supported data types ......................................................................................................... 11

Message Queue ................................................................................................................... 12

Cache list .............................................................................................................................. 13

Unconnected buffers ......................................................................................................... 15

Guidelines ............................................................................................................................ 15

Get or set the number of unconnected buffers ............................................................. 16

Get the number of unconnected buffers ................................................................ 16

Set the number of unconnected buffers ................................................................. 16

Convert between INTs and DINTs............................................................................... 18

Chapter 2

Introduction ........................................................................................................................ 23

Message manager logic ....................................................................................................... 23

controllers

Chapter 3

Introduction ........................................................................................................................ 27

Configure the I/O configuration .................................................................................... 28

Define your source and destination elements ............................................................... 29

Create the MESSAGE_ CONFIGURATION data type ......................................... 30

Create the configuration array ......................................................................................... 31

Get the size of the local array ........................................................................................... 32

Load the message properties for a controller ................................................................ 33

Configure the message ....................................................................................................... 34

Step to the next controller ................................................................................................ 34

Restart the sequence .......................................................................................................... 35

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 5

Page 6

Page 7

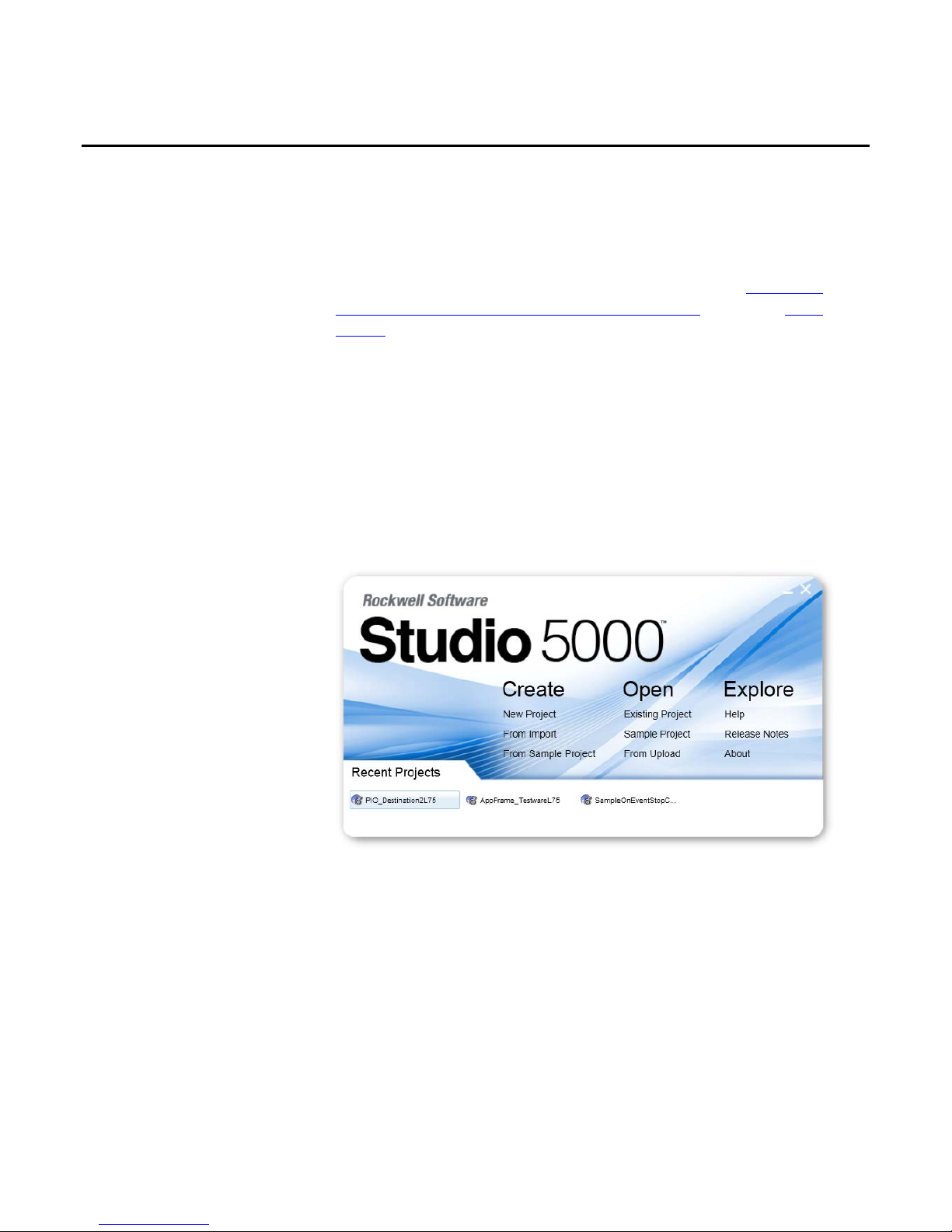

Studio 5000 environment

Preface

This manual shows how to program message (MSG) instructions to and from

Logix 5000™ controllers. This manual is one of a set of related manuals that show

common procedures for programming and operating Logix 5000™ controllers.

For a complete list of common procedures manuals, refer to the

Controllers Common Procedures Programming Manual, publication 1756PM001.

• The term Logix 5000 controller refers to any controller that is based on the

Logix 5000 operating system.

The Studio 5000 Automation Engineering & Design Environment® combines

engineering and design elements into a common environment. The first element is

the Studio 5000 Logix Designer® application. The Logix Designer application is

the rebranding of RSLogix 5000® software and will continue to be the product to

program Logix 5000™ controllers for discrete, process, batch, motion, safety, and

drive-based solutions.

Logix 5000

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 7

The Studio 5000® environment is the foundation for the future of

Rockwell Automation® engineering design tools and capabilities. The Studio 5000

environment is the one place for design engineers to develop all elements of their

control system.

Page 8

Preface

Provides declarations of conformity, certificates, and other

Additional resources

Legal notices

These documents contain additional information concerning related Rockwell

Automation products.

Resource Description

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications webpage, available at

http://ab.rockwellautomation.com

Provides general guidelines for installing a Rockwell

Automation industrial system.

certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature. To order paper copies of

technical documentation, contact your local Rockwell Automation distributor or

sales representative.

Copyright notice

Copyright © 2018 Rockwell Automation Technologies, Inc. All Rights Reserved.

Printed in USA.

This document and any accompanying Rockwell Software products are

copyrighted by Rockwell Automation Technologies, Inc. Any reproduction

and/or distribution without prior written consent from Rockwell Automation

Technologies, Inc. is strictly prohibited. Please refer to the license agreement for

details.

End User License Agreement (EULA)

You can view the Rockwell Automation End-User License Agreement ("EULA")

by opening the License.rtf file located in your product's install folder on your hard

drive.

Other Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses. Copies of those licenses are

included with the software. Corresponding Source code for open source packages

included in this product can be located at their respective web site(s).

You may alternately obtain complete Corresponding Source code by contacting

Rockwell Automation via our Contact form on the Rockwell Automation

website:

http://www.rockwellautomation.com/global/aboutus/contact/contact.page.

Please include "Open Source" as part of the request text.

8 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Page 9

Preface

A full list of all open source software used in this product and their corresponding

licenses can be found in the OPENSOURCE folder included with the Release

Notes. The default installed location of these licenses is C:\Program Files

(x86)\Common

Files\Rockwell\Help\<Product>\ReleaseNotes\OPENSOURCE\index.htm.

Trademark Notices

Allen-Bradley, ControlBus, ControlFLASH, Compact GuardLogix, Compact

I/O, ControlLogix, CompactLogix, DCM, DH+, Data Highway Plus,

DriveLogix, DPI, DriveTools, Explorer, FactoryTalk, FactoryTalk Administration

Console, FactoryTalk Alarms and Events, FactoryTalk Batch, FactoryTalk

Directory, FactoryTalk Security, FactoryTalk Services Platform, FactoryTalk

View, FactoryTalk View SE, FLEX Ex, FlexLogix, FLEX I/O, Guard I/O, High

Performance Drive, Integrated Architecture, Kinetix, Logix5000, Logix 5000,

Logix5550, MicroLogix, DeviceNet, EtherNet/IP, PLC-2, PLC-3, PLC-5,

PanelBuilder, PowerFlex, PhaseManager, POINT I/O, PowerFlex, Rockwell

Automation, RSBizWare, Rockwell Software, RSEmulate, Historian, RSFieldbus,

RSLinx, RSLogix, RSNetWorx for DeviceNet, RSNetWorx for EtherNet/IP,

RSMACC, RSView, RSView32, Rockwell Software Studio 5000 Automation

Engineering & Design Environment, Studio 5000 View Designer, SCANport,

SLC, SoftLogix, SMC Flex, Studio 5000, Ultra 100, Ultra 200, VersaView,

WINtelligent, XM, SequenceManager are trademarks of Rockwell Automation,

Inc.

Any Rockwell Automation logo, software or hardware product not mentioned

herein is also a trademark, registered or otherwise, of Rockwell Automation, Inc.

Other Trademarks

CmFAS Assistant, CmDongle, CodeMeter, CodeMeter Control Center, and

WIBU are trademarks of WIBU-SYSTEMS AG in the United States and/or

other countries. Microsoft is a registered trademark of Microsoft Corporation in

the United States and/or other countries. ControlNet is a trademark of

ControlNet International. DeviceNet is a trademark of the Open DeviceNet

Vendors Association (ODVA). Ethernet/IP is a trademark of ControlNet

International under license by ODVA.

All other trademarks are the property of their respective holders and are hereby

acknowledged.

Warranty

This product is warranted in accordance with the product license. The product’s

performance may be affected by system configuration, the application being

performed, operator control, maintenance, and other related factors. Rockwell

Automation is not responsible for these intervening factors. The instructions in

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 9

Page 10

Preface

this document do not cover all the details or variations in the equipment,

procedure, or process described, nor do they provide directions for meeting every

possible contingency during installation, operation, or maintenance. This

product’s implementation may vary among users.

This document is current as of the time of release of the product; however, the

accompanying software may have changed since the release. Rockwell Automation,

Inc. reserves the right to change any information contained in this document or

the software at any time without prior notice. It is your responsibility to obtain the

most current information available from Rockwell when installing or using this

product.

Environmental compliance

Rockwell Automation maintains current product environmental information on

its website at

http://www.rockwellautomation.com/rockwellautomation/about-

us/sustainability-ethics/product-environmental-compliance.page

Contact Rockwell Automation

Customer Support Telephone — 1.440.646.3434

Online Support — http://www.rockwellautomation.com/support/

10 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Page 11

Introduction to Controller

Supported data types

Messages

Chapter 1

Controller messages

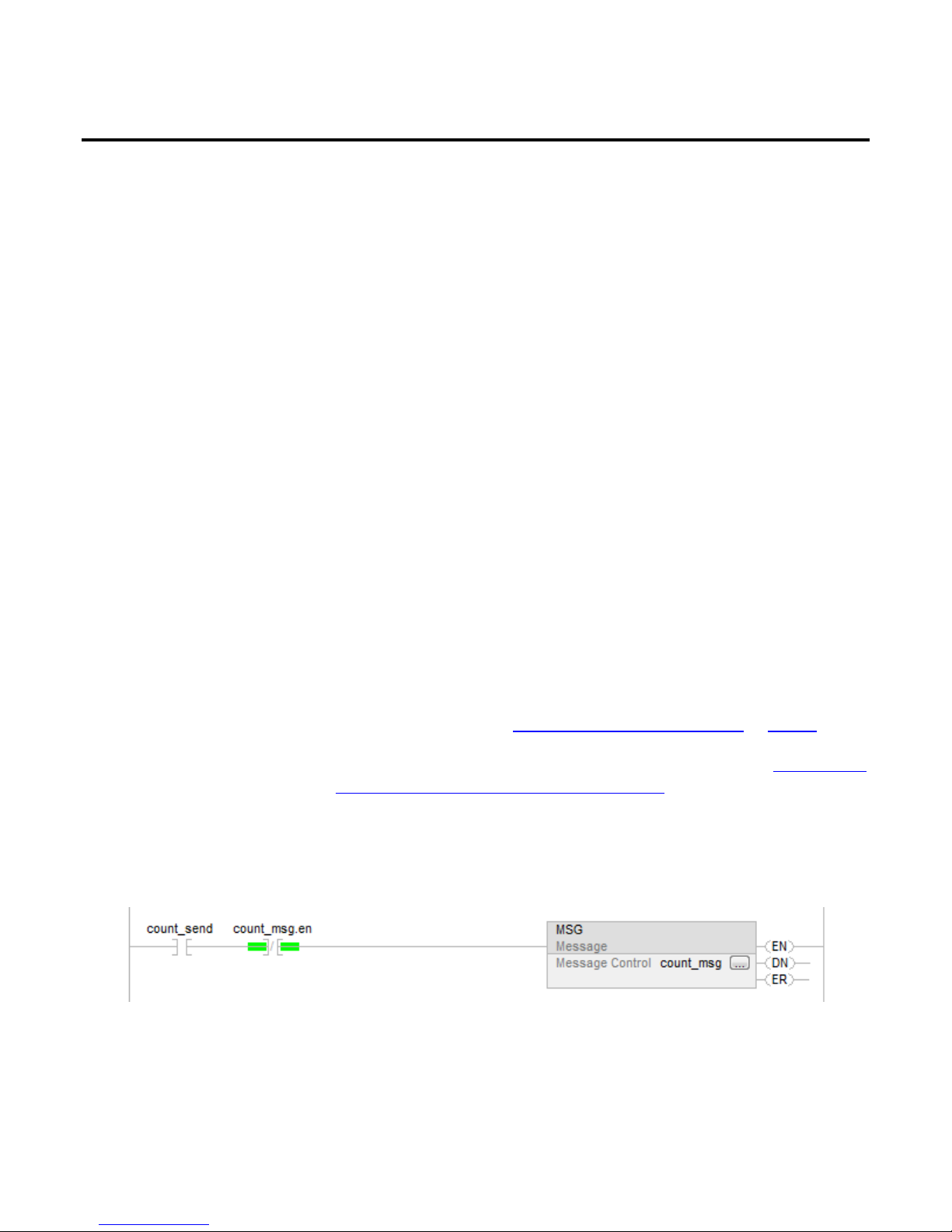

This section describes how to transfer (send or receive) data between controllers

by executing a message (MSG) instruction. It explains cache connections and

buffers so you can correctly program the controller.

The following data types are supported when sending CIP messages.

• SINT

• INT

Example: Execute a message (MSG) instruction

If count_send = 1

and count_msg.EN = 0 (MSG instruction is not enabled)

then execute a MSG instruction that sends data to another controller.

• DINT

• LINT

• REAL

In addition, you can send a message with any structure type that is predefined,

module-defined, or user-defined.

For more information, see "Convert between INTs and DINTs on page 18

For complete details on programming a message instruction, see the LOGIX 5000

Controllers General Instruction Reference Manual, publication 1756-RM003.

".

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 11

Page 12

Chapter 1

Controller messages

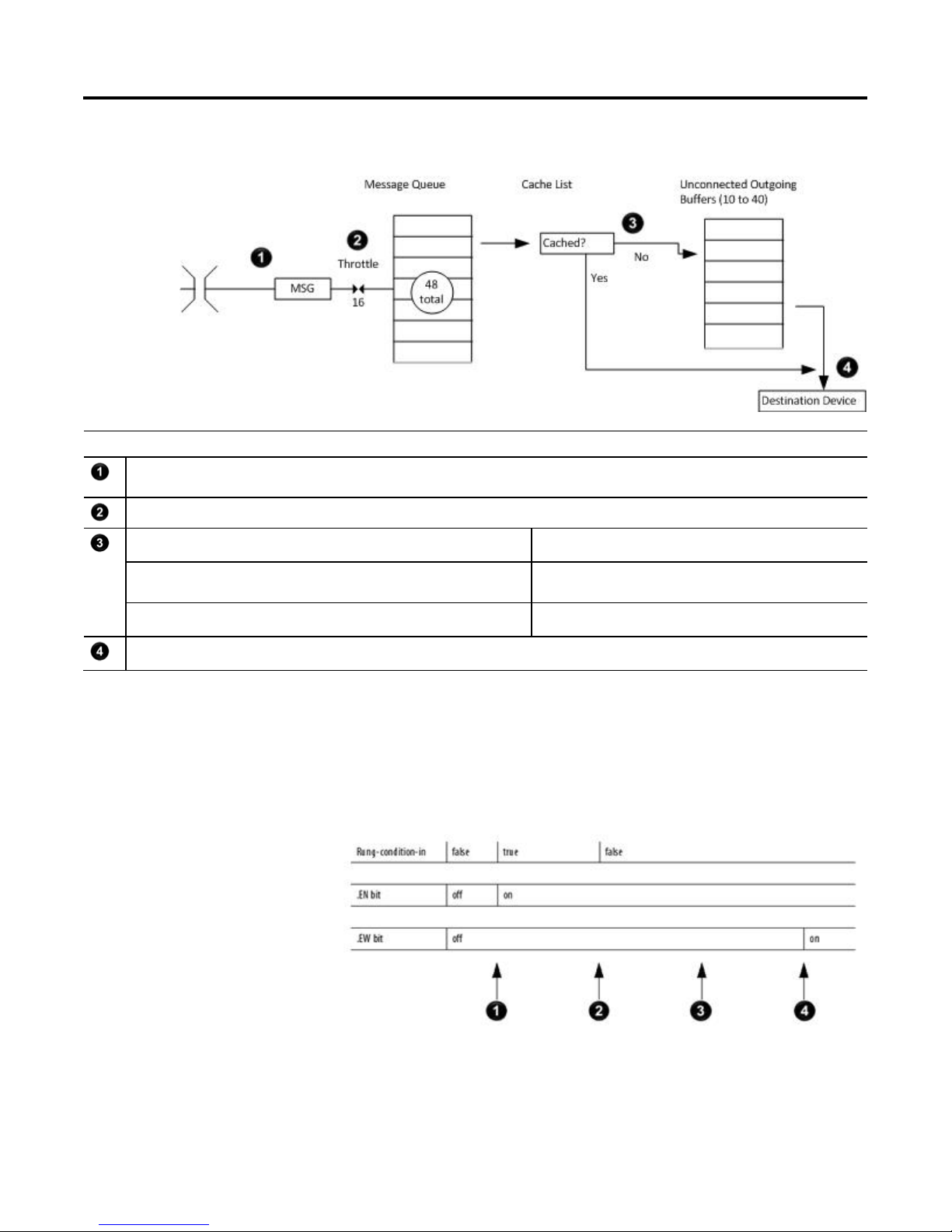

Message Queue

This diagram shows how the controller processes MSG instructions.

Description

The controller scans the MSG instruction and its rung-condition-in goes true. The message passes to a throttle that has 16 positions. If the throttle is full, the message

remains enabled but is held until another controller scan.

The System-overhead time slice executes and the message is pulled from the throttle to the message queue.

If the MSG instruction Then the MSG instruction

Does not use a connection or the connection was not previously cached Uses an unconnected buffer to establish communication with the

destination device.

Uses a connection and the connection is cached Does not use an unconnected buffer.

Communication occurs with the destination device.

The message queue holds up to 48 MSG instructions, including those that you

configure as a block-transfer read or block-transfer write. When the queue is full,

an instruction tries to enter the queue on each subsequent scan of the instruction,

as shown in the following illustration.

12 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Page 13

Controller messages

Chapter 1

(1) CIP data table read or write messages can be connected o r unconnected. However for most applications, it is recommended you leave CIP data table read or write

Cache list

Description

&

The controller scans the MSG instruction.

The rung-condition-in for the MSG instruction is true.

The EN bit is set.

The MSG instruction attempts to enter the queue but 16 throttle positions exist. If all 16 are filled and a 17th message is executed, the message is enabled.

The EW bit remains cleared.

The controller scans the MSG instruction.

The rung-condition-in for the MSG instruction is false.

The EN bit remains set.

The MSG instruction attempts to pass through the throttle, but no open positions exist yet.

The EW bit remains cleared.

The controller scans the MSG instruction.

The MSG instruction attempts to enter the queue. This time the throttle position is open and the message can pass to the message queue.

The EW bit is set.

Depending on how you configure a MSG instruction, it may use a connection to

send or receive data.

This type of message And this communication method Uses a connection

CIP data table read or write — Your option

PLC-2, PLC-3, PLC-5, or SLC (all types)

CIP generic — Your option

Block-transfer read or write — Yes

messages connected.

(2) CIP generic messages can be connected or unco nnected. However for most application s, it is recommended you leave CIP generic messages u nconnected, unless you

want to use the Large Connection option.

CIP

CIP with Source ID

DH+ Yes

No

(1)

(2)

If a MSG instruction uses a connection, you have the option to leave the

connection open (cache) or close the connection when the message is done

transmitting.

If you Then

Cache the connection The connection stays open after the MSG instruction is done. This optimizes

execution time. Opening a connection each time the message executes increases

execution time.

Do not cache the connection The connection closes after the MSG instruction is done. This frees up that

connection for other uses.

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 13

Page 14

Chapter 1

Controller messages

•

The controller has the following limits on the number of connections that you can

cache.

If you have this software version and firmware

revision

11.x or earlier

12.x or later Up to 32 connections.

Then you can cache

Block transfer messages for up to 16 connections.

• Other types of messages for up to 16 connections.

If several messages go to the same device, the messages may be able to share a

connection.

If the MSG instructions are to And they are Then

Different devices — Each MSG instruction uses 1 connection.

The same device, cached, and not a large connection Enabled simultaneously (same scan) Each MSG instruction uses 1 connection and 1 cached

buffer.

Not enabled simultaneously All MSG instructions use 1 connection and 1 cached buffer.

They share the connection and the buffer.

The same device, cached, and a large connection Enabled simultaneously (same scan) Each MSG instruction uses 1 connection and 1 cached

buffer.

Not enabled simultaneously All MSG instructions use 1 connection and 1 cached buffer.

They share the connection and the buffer.

Example: Share a connection

• If the controller alternates between sending a block-transfer read message and a block-transfer write message to the same module, then together the

messages count as one connection. Caching both messages counts as one on the cached buffer.

• If the controller sends 10 cached connected messages to the same bridge module (for example, 1756-EN2T) where 7 utilize a standard connection (large

connection unchecked) and 3 utilize a large connection, then the 7 standard connection messages all utilize one cached connection. The 3 large connection

messages all utilize another cached connection. In total, the 10 messages use 2 cached connections.

14 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Page 15

Controller messages

Chapter 1

•

ControlLogix 5580, Compact GuardLogix 5380, and GuardLogix 5580 controllers, enter an MSG tag as either

5 or SLC 500 controller, and it transfers integers (not REALs),

Unconnected buffers

Guidelines

To establish a connection or process unconnected messages, the controller uses an

unconnected buffer.

Term Definition

Unconnected buffer An allocation of memory that the controller uses to process unconnected communication. The controller performs unconnected communication

when it:

• Establishes a connection with a device, including an I/O module.

• Executes a MSG instruction that does not use a connection.

The controller can have 10 to 40 unconnected buffers.

• The default number is 10.

• To increase the number of unconnected buffers, execute a MSG instruction that reconfigures the number of unconnected buffers.

• Each unconnected buffer uses 1.2 KB of memory.

• If all unconnected buffers are in use when an instruction leaves the message queue, an error occurs and data does not transfer.

If a MSG instruction uses a connection, the instruction uses an unconnected

buffer when it first executes to establish a connection. If you configure the

instruction to cache the connection, it no longer requires an unconnected buffer

once the connection is established.

As you plan and program your MSG instructions, follow these guidelines.

Guideline Details

For each MSG instruction, create a control tag.

Keep the source and destination data at the controller scope.

If your message is to a device that uses 16-bit integers, such as a

PLCuse a buffer of INTs in the message and DINTs throughout the

project.

Cache the connection for those MSG instructions that execute

most frequently, up to the maximum number permissible for

your controller revision.

If you want to enable more than 16 MSGs at one time, use a

management strategy to ensure some MSG instructions are not

delayed entering the queue.

Data type = MESSAGE

• Scope = controller

• The tag cannot be part of an array or a user-defined data type.

A MSG instruction can access only tags that are in the Controller Tags folder (controller scope).

Tip: On CompactLogix 5370, ControlLogix 5570, Compact GuardLogix 5370, and GuardLogix 5570

controllers, enter an MSG tag only as a controller scope tag.

In versions 31 and later of the Logix Designer application, on CompactLogix 5380, CompactLogix 5480,

a controller scope or a Program Local scope tag.

Logix 5000 controllers execute more efficiently and use less memory when working with 32-bit integers

(DINTs).

See Convert Between INTs and DINTs on page 18.

Execution time is optimized when the contr oller does not open a connection each time the message

executes.

To guarantee the execution of each message, use one of these options:

• Enable each message in sequence.

• Enable the messages in groups.

• Program a message to communicate with multiple devices.

• Program logic to coordinate the execution of messages.

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 15

Page 16

Chapter 1

Controller messages

Get or set the number of

Get the number of unconnected

Set the number of unconnected

Keep the number of unconnected and uncached MSGs less than

the number of unconnected buffers.

The controller can have 10 to 40 unconnected buffers. The default number is 10.

• If all unconnected buffers are in use when an instruction leaves the message queue, an error occurs, the

data is not transferred.

• You can increase the number of unconnected buffers (up to 40), provided you continue to adhere to the

previous guideline.

• To increase the number of unconnected buffers, see "Get or Set the Number of Unconnected Buffers

page 16".

To determine or change the number of unconnected buffers, use a MSG

unconnected buffers

instruction.

• The range is 10 to 40 unconnected buffers.

• The default number is 10.

• Each unconnected buffers uses 1.1 KB of memory.

To determine the number of unconnected buffers that are currently available,

buffers

On this tab For this item Type or choose

Configuration Message Type CIP Generic

Service Type Custom

Service Code 3

Class 304

Instance 1

Attribute 0

Source Element so urce_array where data type = SINT[4]

Source Length (bytes) 4 (Write 4 SINTs.)

Destination Element destinatio n_array where data type = SINT[10] (Leave all values = 0.)

Communication Path 1, slot_number_o f_controller

configure a Message (MSG) instruction as follows.

In this element Enter

source_array[0] 1

source_array[1] 0

source_array[2] 17

source_array[3] 0

destination_a rray[6] = current number of unconnected buffers

on

buffers

16 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

As a starting value, set the number of unconnected buffers equal to the number of

unconnected and uncached messages enabled at one time plus 5. The additional 5

buffers provide a cushion in case you underestimate the number of messages that

are enabled at once.

Page 17

Controller messages

Chapter 1

To change the number of unconnected buffers of the controller, configure a

Message (MSG) instruction as follows.

On this tab For this item Type or select

Configuration Message Type CIP Generic

Service Type Custom

Service Code 4

Class 304

Instance 1

Attribute 0

Source Element so urce_array where data type = SINT[8]

In this element Enter

source_array[0] 1

source_array[1] 0

source_array[2] 17

source_array[3] 0

source_array[4] Number of unconnected buffers

that you want.

source_array[5] 0

source_array[6] 0

source_array[7] 0

Source Length (bytes) 8 (Write 8 SINTs.)

Destination Element destinatio n_array where data type = SINT[6] (Leave all the values = 0.)

Communication Path THIS

or for earlier Logix 5000 controllers: 1, slot_number_of_controller

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 17

Page 18

Chapter 1

Controller messages

Convert between INTs and

Example: Set the number of unconnected b uffers

If S:FS = 1 (first scan)

then set the number of unconnected buffers for the controller.

Source_Array[0] = 1

Source_Array[0] = 1

Source_Array[1] = 0

Source_Array[2] = 17

Source_Array[3] = 0

Source_Array[4] = 12 (The number of unconnected buffers that you want. In this example, we want 12 buffers.)

If UCB_Set.EN = 0 (MSG instruction is not already enabled)

then MSG instruction sets the number of unconnected buffers = Source_Array[4].

DINTs

Tag Name Type Description

UCB_Set MESSAGE Control tag for the MSG instruction.

Source_Array SINT[8] Source values for the MSG instruction, including the number of unconnected buffers

that you want.

In the Logix 5000 controller, use the DINT data type for integers whenever

possible. Logix 5000 controllers execute more efficiently and use less memory

when working with 32-bit integers (DINTs).

If your message is to a device that uses 16-bit integers, such as a PLC-5 or SLC 500

controller, and it transfers integers (not REALs), use a buffer of INTs in the

message and DINTs throughout the project. This increases the efficiency of your

project.

18 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Page 19

Controller messages

Chapter 1

Read 16-bit integers

Data from the

device

Word 1

Word 2

Word 3

Buffer of INTs

INT_Buffer[0]

INT_Buffer[1]

INT_Buffer[2]

Description

The Message (MSG) instruction reads 16-bit integers (INTs) from the device and stores them in a temporary array of INTs.

A File Arith/Logical (FAL) instruction converts the INTs to DINTs for use by other instructions in your project.

Write 16-bit integers

DINTs for use in the

project

DINT_Array[0]

DINT_Array[1]

DINT_Array[2]

DINTs from the project

DINT_Array[0]

DINT_Array[1]

DINT_Array[2]

Description

An FAL instruction converts the DINTs from the Logix 5000 controller to INTs.

The MSG instruction writes the INTs from the temporary array to the device.

Buffer of INTs

INT_Buffer[0]

INT_Buffer[1]

INT_Buffer[2]

Data for the

device

Word 1

Word 2

Word 3

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 19

Page 20

Chapter 1

Controller messages

Example:

Read integer values from a PLC-5 controller

If Condition_1 = 1

and Msg_1.EN = 0 (MSG instruction is not enabled)

then read 3 integers from the PLC-5 controller and store them in INT_Buffer (3 INTs).

If Msg_1.DN =1 (MSG instruction has read the data)

then reset the FAL instruction.

The FAL instruction sets DINT_Array = INT_Buffer. This converts the values to 32-bit integers (DINTs).

Example:

If Control_2.DN = 1 (FAL instruction has converted the DINTs to INTs)

Write integer values to a PLC-5 controller

If Condition_2 = 1

then reset the FAL instruction.

The FAL instruction sets INT_Buffer = DINT_Array. This converts the values to 16-bit integers (INTs).

and Msg_2.EN = 0 (MSG instruction is not enabled)

then write the integers in INT_Buffer (3 INTs) to the PLC-5 controller.

20 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Page 21

Controller messages

Chapter 1

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 21

Page 22

Page 23

Introduction

Message manager logic

Chapter 2

Manage multiple messages

You can use ladder logic to send groups of message (MSG) instructions in

sequence.

• To be processed, each MSG instruction must enter the message queue.

• The queue holds 48 MSGs.

• If more than 16 MSGs are enabled at one time, the message throttle

prevents some of the messages from entering the message queue. If this

occurs, the MSG is held until room exists on the queue for the controller to

process the MSG. On each subsequent scan of the MSG, it checks the queue

to see if room exists.

Example:

The message manager logic lets you control the number of MSGs that are enabled

at one time and enable subsequent MSGs in sequence. In this way, MSGs enter

and exit the queue in order and do not need to wait for room on the queue to

become available.

The message manager logic sends three groups of MSGs. Use as many groups as

needed to include all your MSGs.

The Msg_Group tag controls the enabling of each MSG.

• The tag uses the DINT data type.

• Each bit of the tag corresponds to a group of MSGs. For example,

Msg_Group.0 enables and disables the first group of MSGs (group 0).

Message manner logic

To make the example easier to follow, each group contains only two MSGs. In your project, use more MSGs in each group, such as five.

Initialize the logic

If S:FS = 1 (first scan)

then initialize the MSGs:

Msg_Group = 0, which disables all MSGs.

Msg_Group.0 =1, which enables the first group of MSGs.

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 23

Page 24

Chapter 2

Manage multiple messages

Restart the sequence

If the MSGs in group 2 (last group) are currently enabled (Msg_Group.2 = 1)

and Msg_4 is in the state of done or error

and Msg_5 is in the state of done or error

then restart the sequence of MSGs with the first group:

Msg_Group.2 = 0. This disables the last group of MSGs.

Msg_Group.0 = 1. This enables the first group of MSGs.

Send the first group of MSGs

If Msg_Group.0 changes from 0 -> 1 then

send Msg_0.

send Msg_1.

Because a MSG instruction is a transitional instruction, it executes only when its rung-condition-in changes from false to true.

Enable the second group of MSGs

If the MSGs in group 0 are currently enabled (Msg_Group.0 = 1)

and Msg_0 is in the state of done or error

and Msg_1 is in the state of done or error

then:

Msg_Group.0 = 0. This disables the current group of MSGs.

Msg_Group.1 = 1. This enables the next group of MSGs.

24 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Page 25

Manage multiple messages

Chapter 2

Send the second group of MSGs

If Msg_Group.1 changes from 0 -> 1 then

send Msg_2.

send Msg_3.

Enable the next group of MSGs

If the MSGs in group 1 are currently enabled (Msg_Group.1 = 1)

and Msg_2 is in the state of done or error

and Msg_3 is in the state of done or error

then:

Msg_Group.1 = 0. This disables the current group of MSGs.

Msg_Group.2 = 1. This enables the next group of MSGs.

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 25

Page 26

Chapter 2

Manage multiple messages

Send the next group of MSGs

If Msg_Group.1 changes from 0 -> 1 then

send Msg_2.

send Msg_3.

26 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Page 27

Introduction

Chapter 3

Send a message to multiple controllers

Program a single message instruction to communicate with multiple controllers.

To reconfigure a MSG instruction during runtime, write new values to the

members of the MESSAGE data type.

Important:

In the MESSAGE data type, the RemoteElement member stores the tag name or address of the data in the controller that receives the message.

If the message Then the RemoteElement is the

Reads data Source element

Writes data Destination element

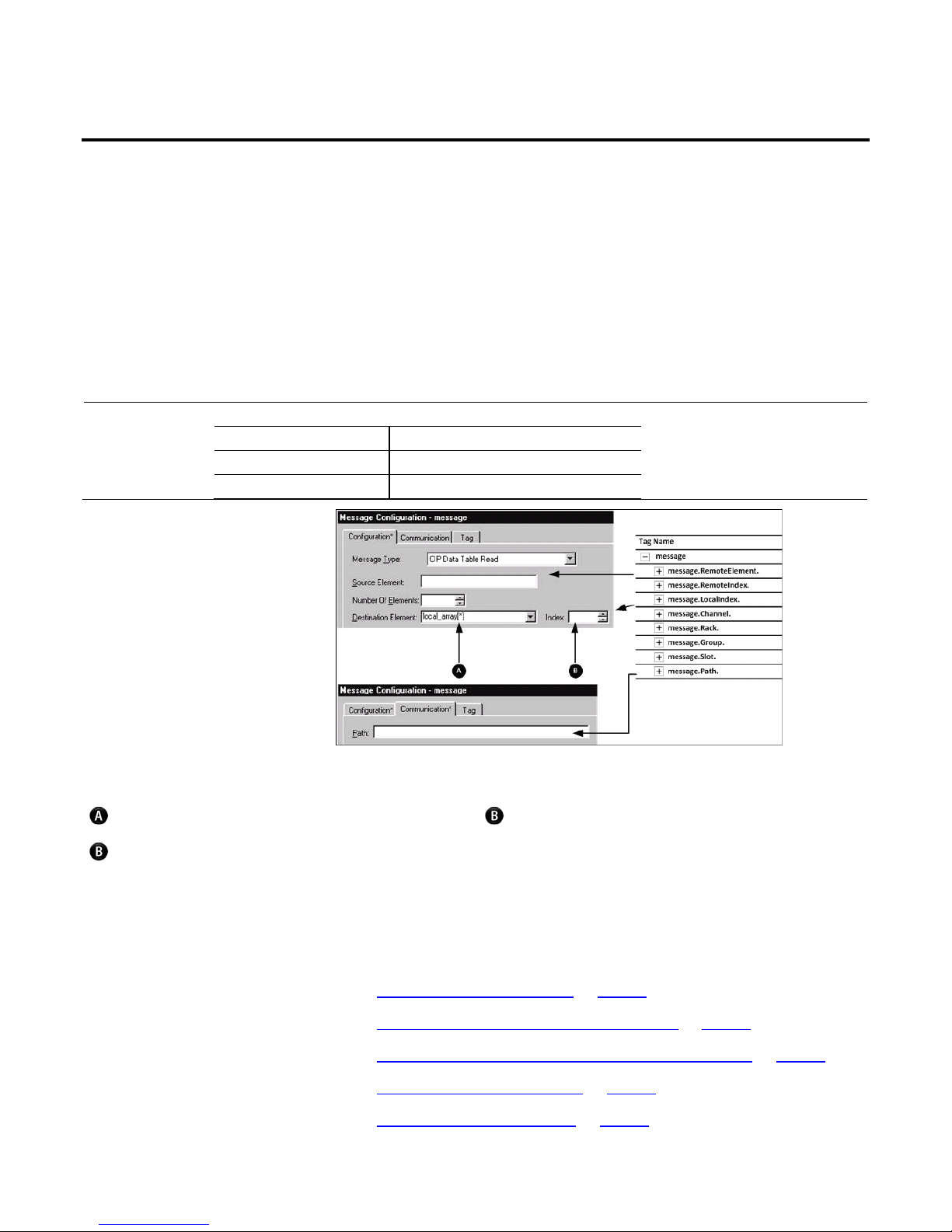

If using an asterisk [*] to designate the element number of the array, the value in provides the element number.

The Index box is available only when using an asterisk [*] in Source Element or Destination Element. The instruction substitutes the value of Index for the asterisk

[*].

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 27

Complete the following to send a message to multiple controllers:

• Set Up the I/O Configuration on page 28

• Define Your Source and Destination Elements on page 29

• Create the MESSAGE_ CONFIGURATION Data Type on page 30

• Create the Configuration Array on page 31

• Get the Size of the Local Array on page 32

Page 28

Chapter 3

Send a message to multiple controllers

Configure the I/O

• Load the Message Properties for a Controller on page 33

• Configure the Message on page 34

• Step to the Next Controller on page 34

• Restart the Sequence on page 35

Tip:

To copy the above components from a sample project, open the C:\Users\Public\Public Documents\Studio 5000\Samples\ENU\v<current_project>\Rockwell

Automation folder.

configuration

Although not required, it is recommended that you add the communication

modules and remote controllers to the I/O configuration of the controller. This

makes it easier to define the path to each remote controller.

For example, once you add the local communication module, the remote

communication module, and the destination controller, clicking Browse lets you

select the destination.

Message Path Browser

Path: peer_controller

peer_controller

I/O Configuration

[0] 1756-CNB/x Local_CNB

2 [0] 1756-CNB/x chassis_b

[1] 1756-L55/x

peer_controller

28 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Page 29

Send a message to multiple controllers

Chapter 3

Define your source and

destination elements

An array stores the data that is read from or written to each remote controller.

Each element in the array corresponds to another remote controller.

1. Use the following worksheet to organize the tag names in the local and

remote controllers.

Name of Remote

Controller

Tag or Address of Data in Remo te

Controller

Tag in This Controller

local_array[0]

local_array[1]

local_array[2]

local_array[3]

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 29

2. Create the local_array tag, which stores the data in this controller.

Tag Name Type

local_array data_type [length]

where:

data_type is the data type of the data that the message sends or receives, such as

DINT, REAL, or STRING.

length is the number of elements in the local array.

Page 30

Chapter 3

Send a message to multiple controllers

Create the MESSAGE_

CONFIGURATION data type

Create a user-defined data type to store the configuration variables for the message

to each controller.

• Some of the required members of the data type use a string data type.

• The default STRING data type stores 82 characters.

• If your paths or remote tag names or addresses use less than 82 characters,

you have the option of creating a new string type that stores fewer

characters. This lets you conserve memory.

• To create a string type, click File > New Component > String Type.

• If you create a string type, use it in place of the STRING data type.

To store the configuration variables for the message to each controller, expand the

Assets > Data Types folder, right-click User Defined, and select New Data Type

to create the following user-defined data type.

30 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Data Type: MESSAGE_CONFIGURATION

Name: MESSAGE_CONFIGURATION

Description: Configuration properties for a message to another controller

Members

Name Data Type Style Description

Path

RemoteElement

STRING

STRING

Page 31

Send a message to multiple controllers

Chapter 3

(1) Number indicates the number of controll ers to send the message

Create the configuration

array

Store the configuration properties for each controller in an array. Before each

execution of the MSG instruction, your logic loads new properties into the

instruction. This sends the message to another controller.

1. To store the configuration properties for the message, create the following

array.

Tag Name Type Scope

message_config MESSAGE_CONFIGURATION[number]

(1)

Any

2. In the message_config array, enter the path to the first controller that

receives the message.

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 31

Page 32

Chapter 3

Send a message to multiple controllers

Get the size of the local

3. In the message_config array, enter the tag name or address of the data in the

first controller to receive the message.

4. Enter the path and remote element for each additional controller.

Tag Name Value

message_config {…}

message_config[0] {…}

message_config[0].Path

message_config[0].RemoteElement

message_config[1] {…}

message_config[1].Path

message_config[1].RemoteElement

array

32 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

The SIZE instruction:

• Counts the number of elements in local_array.

• Counts the number of elements in Dimension 0 of the array. In this case,

that is the only dimension.

Local_array_length (DINT) stores the size (number of elements) of local_array.

This value tells a subsequent rung when the message is sent to all controllers and to

start with the first controller again.

Page 33

Send a message to multiple controllers

Chapter 3

Load the message

1. The XIO instruction conditions the rung to continuously send the message.

properties for a controller

2. The first COP instruction loads the path for the message. The value of

index determines which element the instruction loads from message_config.

The instruction loads one element from message_config.

3. The second COP instruction loads the tag name or address of the data in

the controller that receives the message. The value of index determines

which element the instruction loads from message_config. The instruction

loads one element from message_config.

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 33

Page 34

Chapter 3

Send a message to multiple controllers

Configure the message

Step to the next controller

The following table explains how to configure the message.

On this tab If you want to For this item Type or select

Configuration Read (receive) data from the other

controllers

Write (send) data to the other

controllers

Communication — Path Path to the first controller

Message Type The read-type that corresponds to the other controllers

Source Element Tag or address that contains the data in the first controller

Number Of Elements 1

Destination Element local_array[*]

Index 0

Message Type The write-type that corresponds to other controllers

Source Element local_array[*]

Index 0

Number Of Elements 1

Destination Element Tag or address that contains the data in the first controller

Cache Connections

Clear the Cache Connections check box (more efficient since this procedure

continuously changes the path of the message)

After the MSG instruction sends the message, the following actions occur.

1. The first ADD instruction increments the index. This lets the logic load the

configuration properties for the next controller into the MSG instruction.

2. The second ADD instruction increments the LocalIndex member of the

MSG instruction. This lets the logic load the value from the next controller

into the next element of local_array.

34 Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Page 35

Send a message to multiple controllers

Chapter 3

Restart the sequence

When the index equals the local_array_length, the controller sends the message to

all other controllers.

1. The first CLR instruction sets the index equal to 0. This lets the logic load

the configuration properties for the first controller into the MSG

instruction and start the sequence of messages again.

2. The second CLR instruction sets the LocalIndex member of the MSG

instruction equal to 0. This lets the logic load the value from the first

controller into the first element of local_array.

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 35

Page 36

Page 37

A

Index

array

controller configuration 28

B

block transfer

guidelines 15

buffer

for unconnected messages 14, 16

convert between 16 and 32-bit data 18

example illustration 11

limits 12

manage multiple messages 21

processing 11

queue 12

to a single controller 11

to multiple controllers 25

unconnected buffer 14, 16

P

C

cache

connection 13

communicate

message instruction 11

other controllers 11

connection

cache 13

controller

message properties 30

messages 11

D

data type

convert data 18

message configuration 27

G

guidelines

messages 15

processing

message 11

Q

queue

message 12

T

tag

guidelines for messages 15

organize for message 11

L

ladder logic

manage messages 21

M

message

cache connection 13

controller 11

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018 37

Page 38

Rockwell Automation support

Rockwell Automation provides technical information on the web to assist you in using its products. At

http://www.rockwellautomation.com/support

can also visit our Support Center at https://rockwellautomation.custhelp.com for software updates, support chats and forums, technical

information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more information, contact your local

distributor or Rockwell Automation representative, or visit http://www.rockwellautomation.com/services/online-phone

Installation assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual. You can contact

Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or Canada Use the Worldwide Locator available at http: //www.rockwellautomation.com/locations, or contact your local Rockwell

New product satisfaction return

you can find technical and application notes, sample code, and links to software service packs. You

.

Automation representative.

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility. However, if

your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain one) to

your distributor to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Documentation feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document, complete the

feedback form, publication RA-DU002

.

Rockwell Automation Publication 1756-PM012H-EN-P - February 2018

Supersedes Publicat ion 1756-PM012G-EN-P - June 2016 Copyright © 2018 Rockwell Automation Technologies, Inc. All Right s Reserved. Printed in the U.S.A.

Loading...

Loading...