Allen-Bradley 747-L532, 1747-L524, 1747-L541, 1747-L542, 1747-L543 Installation And Operation Manual

...Page 1

MANUFACTURER DATA SHEET

PLC-CPU

Manufacturer:

Allen-Bradley/Rockwell

Model Number:

SLC500

See www.geomartin.com for additional PDF datasheets

Martin Part Numbe r:

E-014624-00

VendorPartNumber:

1747-L524

PDF File: Doc_000074_Cover.pdf

Page 2

This page is intentio n allyleft blank

Page 3

Allen-Bradley

SLC 500t Modular

Hardware Style

Installation

(Cat. Nos. 1747-L511, 1747-L514,

1747-L524, 1747-L531, 1747-L532,

1747-L541, 1747-L542, 1747-L543,

1747-L551, 1747-L552, and

1747-L553)

and

Operation

Manual

Page 4

Important User

Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

death, property damage or economic loss.

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

PLC, PLC–2, PLC–3, and PLC–5 are registered trademarks of Rockwell Automation. SLC, SLC 500, SLC 5/01, SLC 5/02, SLC 5/03, SLC 5/04, SLC

5/05, PanelView, PanelView 550, PanelView 900, RediPANEL, ControlView, PBASE, DH+, DTAM, DeviceNet, and Dataliner are trademarks of

Rockwell Automation. RSLogix 500 and RSLinx are trademarks of Rockwell Software, Inc. Ethernet is a registered trademark of Digital Equipment

Corporation, Intel, and Xerox Corporation. IBM is a registered trademark of International Business Machines, Incorporated. Multimodem is a

trademark of Multi–Tech Systems, Inc. Procomm is a registered trademark of Datastorm Technologies, Inc. Tandy is a trademark of the Tandy

Corporation. Gateway 2000 is a trademark of Gateway 2000, Inc. Toshiba is a trademark of Toshiba America, Inc. Compaq is a registered trademark

of Compaq Computer Corporation. Deskpro is a trademark of Compaq Computer Corporation. Intel is a trademark of Intel Corporation.

Page 5

6–8

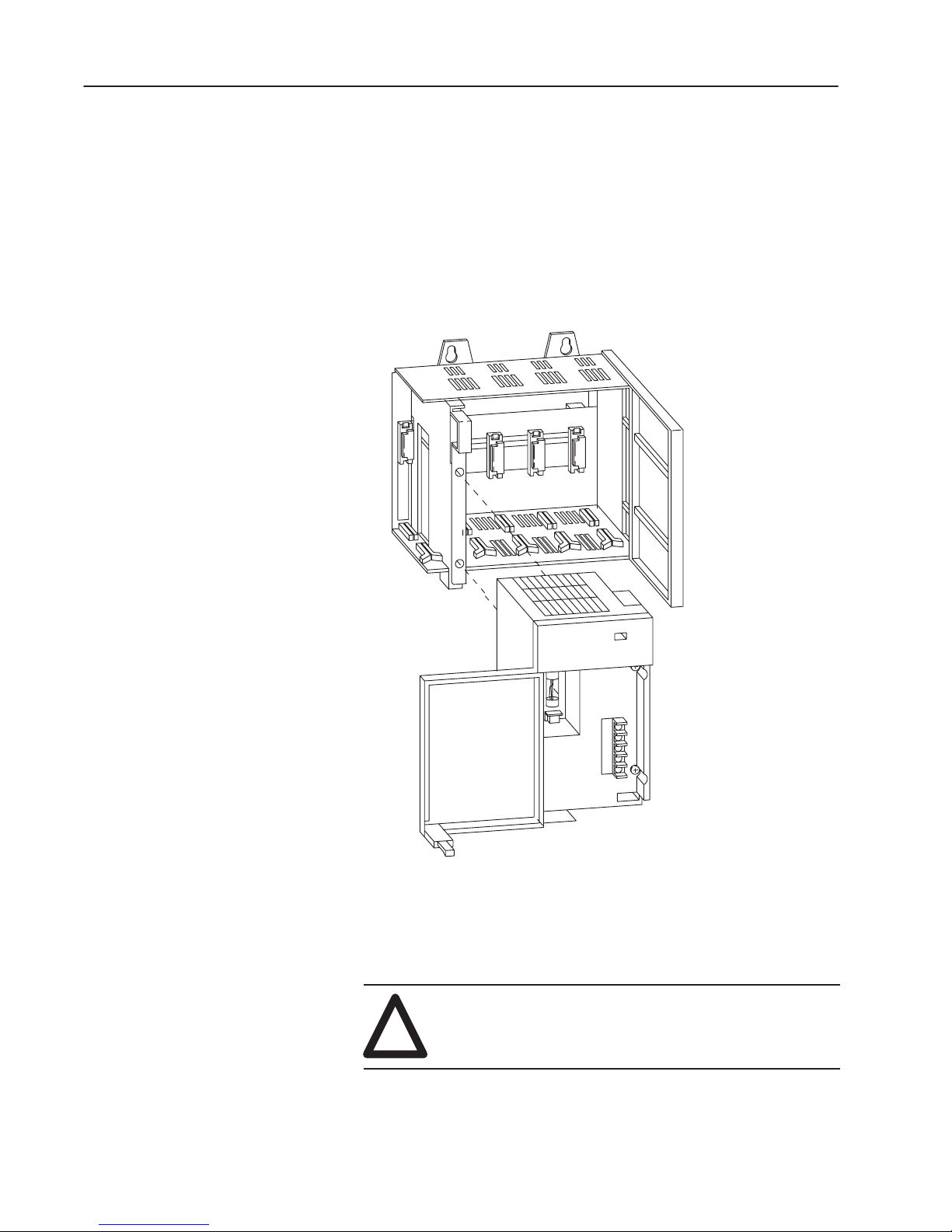

Installing Your Hardware Components

Installing Your Power

Supply

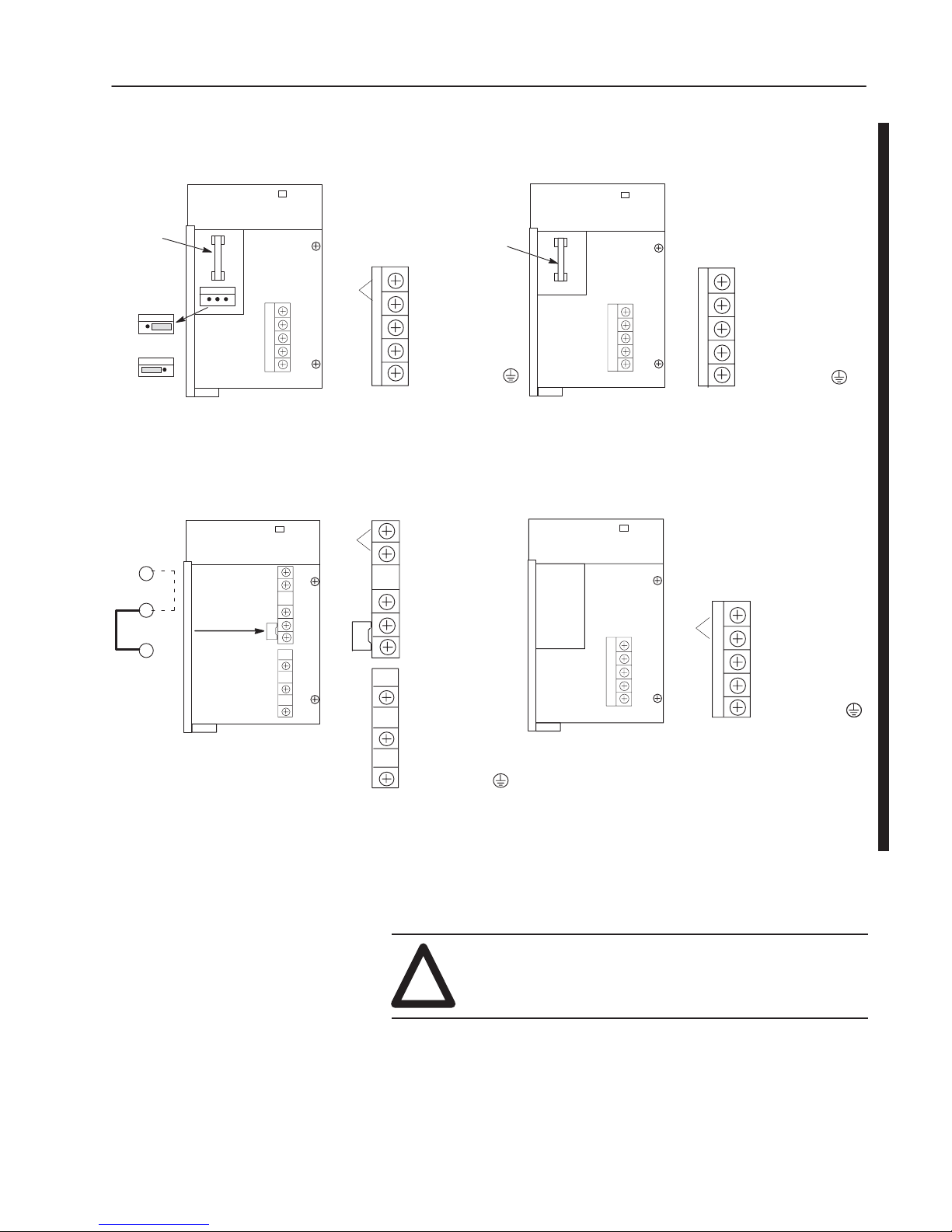

If you have multiple chassis configurations, install the chassis

interconnect cable before installing the power supply.

(See page 6–10.) Also, the power supply terminals accept two #14

AWG wires and are marked as shown in the figure on page 6–8. To

install the power supply, do the following:

1. Align the circuit board with the card guide on the left side of the

chassis. Slide the power supply in until flush with the chassis.

Publication

1747-6.2

19524

2. Fasten the power supply to the chassis with the two Phillips head

screws.

3. Place the jumper to match the input voltage. (This does not apply

to 1746-P3 or 1746-P5, which do not have a jumper.)

ATTENTION: Make jumper selection before

applying power. Hazardous voltage is present on

!

exposed pins when power is applied.

Page 6

Installing Your Hardware Components

6–9

Fuse

Jumper

Selection

100/120 Volts

200/240 V

Jumper

Selection

85–132V ac

170–265V ac

olts

1746-P1 and -P2

POWER

POWER

User

Power

User

Power

PWR OUT +24V dc

PWR OUT COM

120/240V ac

V ac NEUT

CHASSIS GROUND

PWR OUT +24V dc

PWR OUT COMMON

85–132V ac

JUMPER

170–265V ac

L185–132/170–265

Fuse

1746-P3

POWER

POWER

User

Power

NOT USED

NOT USED

+ 24V dc

dc NEUT

CHASSIS GROUND

PWR OUT +24V dc

PWR OUT COM

+125V dc

dc NEUT

CHASSIS GROUNDCHASSIS GROUND

L2

NEUTRAL

1746-P4 1746-P5

CHASSIS GROUND

4. Remove the warning label from the top of the power supply.

5. Connect line power to the power supply.

ATTENTION: If you have a 1746-P3, see page 3–5

for special grounding considerations.

!

On the 1746-P1 and -P2 power supply, use the PWR OUT + 24 VDC

and PWR OUT COM terminals to power sensors. The terminals

provide an isolated, nonfused, 200 mA, 24V dc power supply.

Publication

1747-6.2

Page 7

6–10

Installing Your Hardware Components

Installing Your Chassis

Interconnect Cable

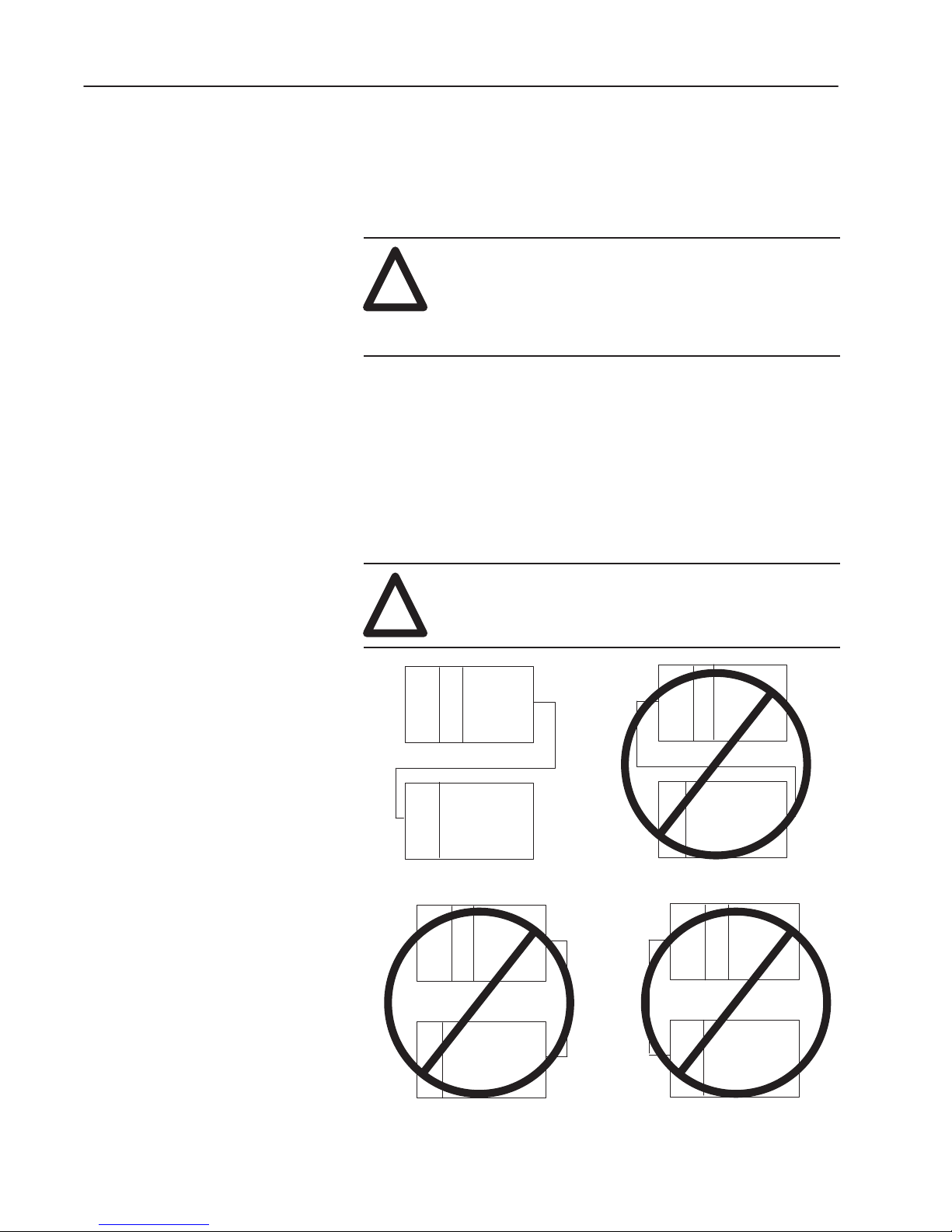

Two cables are available to link modular hardware chassis. Catalog

Number 1746-C7 cable is 152.4 mm (6 in.) in length and used when

connecting chassis side-by-side. Catalog Number 1746-C9 is

914.4 mm (36 in.) in length and used to link one chassis below the

other.

ATTENTION: Do not use any other cables than those

provided. Longer cables could affect the integrity of

!

data communications between the chassis, possibly

causing unsafe operation. Also, make sure the cable is

properly secured to protect against the effects of shock

and vibration.

Install the chassis interconnect cable before installing the power

supply in multiple chassis configurations.

The cables are “keyed” for proper installation. The end of the cable

that plugs into the right socket in the chassis has the “key” on the top

of the connector. The opposite end of the cable has the “key” on the

inside of the connector for insertion into the expansion chassis.

To remove the cable, move the tabs on the socket outward and the

connector pops out.

ATTENTION: The expansion cable must always exit

the right end of the chassis with the processor. Refer to

!

the following figures.

C

P

P

S

U

Chassis 1

P

S

Chassis 2

CORRECT INSTALLATION

C

P

P

S

U

Chassis 1

P

S

Chassis 2

INCORRECT INSTALLATION

C

P

P

S

U

Chassis 1

P

S

Chassis 2

INCORRECT INSTALLATION

C

P

P

S

U

Chassis 1

P

S

Chassis 2

INCORRECT INSTALLATION

Publication

1747-6.2

Page 8

Chapter 7

Wiring Your I/O Modules

This chapter describes how to wire your I/O modules. It covers the

following:

• defining sinking and sourcing

• preparing your wiring layout

• features of an I/O module

• recommendations for wiring I/O devices

• wiring your I/O modules

• octal label kit installation

• using removable terminal blocks

Defining Sinking and

Sourcing

Sinking and sourcing are terms used to describe a current signal flow

relationship between field input and output devices in a control

system and their power supply.

• Field devices connected to the positive side (+V) of the field

power supply are sourcing field devices.

• Field devices connected to the negative side (DC Common) of the

field power supply are called sinking field devices.

To maintain electrical compatibility between field devices and the

programmable controller system, this definition is extended to the

input/output circuits on the discrete I/O modules.

• Sourcing I/O circuits supply (source) current to sinking field

devices.

• Sinking I/O circuits receive (sink) current from sourcing field

devices.

Europe: DC sinking input and sourcing output module circuits are

the commonly used options.

Publication

1747-6.2

Page 9

Chapter 10

Troubleshooting

In this chapter, you will learn about:

• calling Allen-Bradley for assistance

• tips for troubleshooting your control system

• troubleshooting the SLC 5/01 and SLC 5/02 processors

• troubleshooting the SLC 5/03, SLC 5/04, and SLC 5/05

processors

• troubleshooting your input modules

• troubleshooting your output modules

Calling Allen-Bradley for

Assistance

If you need to contact Allen-Bradley or local distributor for

assistance, it is helpful to obtain the following (prior to calling):

• processor type, series letter, operating system (OS) number

(obtained from the status file), firmware (FRN) number (see label

on side of processor module)

• processor LED status

• processor error codes (found in S:6 of status file)

• hardware types in system (I/O modules, chassis)

• revision of programming device (on the main menu of the

Hand-Held Terminal or programming software)

Publication

1747-6.2

Page 10

10–2

Troubleshooting

Tips for Troubleshooting

Your Control System

When troubleshooting, pay careful attention to these general

warnings:

ATTENTION: Have all personnel remain clear of the

controller and equipment when power is applied. The

!

If installation and start-up procedures detailed in chapters 6, 7, and 8

were followed closely, your SLC controller will give you reliable

service. If a problem should occur, the first step in the

troubleshooting procedure is to identify the problem and its source.

problem may be intermittent and sudden unexpected

machine motion could result in injury. Have someone

ready to operate an emergency-stop switch in case it

becomes necessary to shut off power to the controller

equipment. Also, see NFPA 70E Part II for additional

guidelines for safety related work practices.

Never reach into a machine to actuate a switch since

unexpected machine motion can occur and cause

injury.

Remove all electrical power at the main power

disconnect switches before checking electrical

connections or inputs/outputs causing machine motion.

The SLC 500 controller has been designed to simplify

troubleshooting procedures. By observing the diagnostic indicators

on the front of the power supply, processor unit and I/O modules, the

majority of faults can be located and corrected. These indicators,

along with error codes identified in the programming device user

manual and programmer’s monitor, help trace the source of the fault

to the user’s input/output devices, wiring, or the controller.

Removing Power

Before working on a SLC 500 modular system, always remove the

power supply input power at the main power disconnect switch.

The power LED on the power supply indicates that DC power is

being supplied to the chassis. The LED could be off when incoming

power is present.

Publication

1747-6.2

Page 11

Troubleshooting

10–3

Replacing Fuses

When replacing a fuse, be sure to remove all power from the system.

Program Alteration

There are several causes of alteration to the user program, including

extreme environmental conditions, Electromagnetic Interference

(EMI), improper grounding, improper wiring connections, and

unauthorized tampering. If you suspect the memory has been

altered, check the program against a previously saved program on an

EEPROM, UVPROM or Flash EPROM module.

Troubleshooting the SLC

5/01 and SLC 5/02

Processors

To receive the maximum benefit of this troubleshooting section, we

recommend you follow these steps:

1. Identify the status of your processor LEDs. See chapter 5 for a

description of LEDs and their different states.

2. Using the tables on the following pages, match your processor

and power supply LEDs with the status LEDs located in the first

column.

3. Once the status LEDs are matched to the appropriate table,

simply move across the table identifying error description and

probable causes.

4. Follow the recommended action steps for each probable cause

until the error is corrected.

5. If recommended actions do not correct the error, contact your

local Allen-Bradley sales office or distributor.

Publication

1747-6.2

Page 12

10–4

Troubleshooting

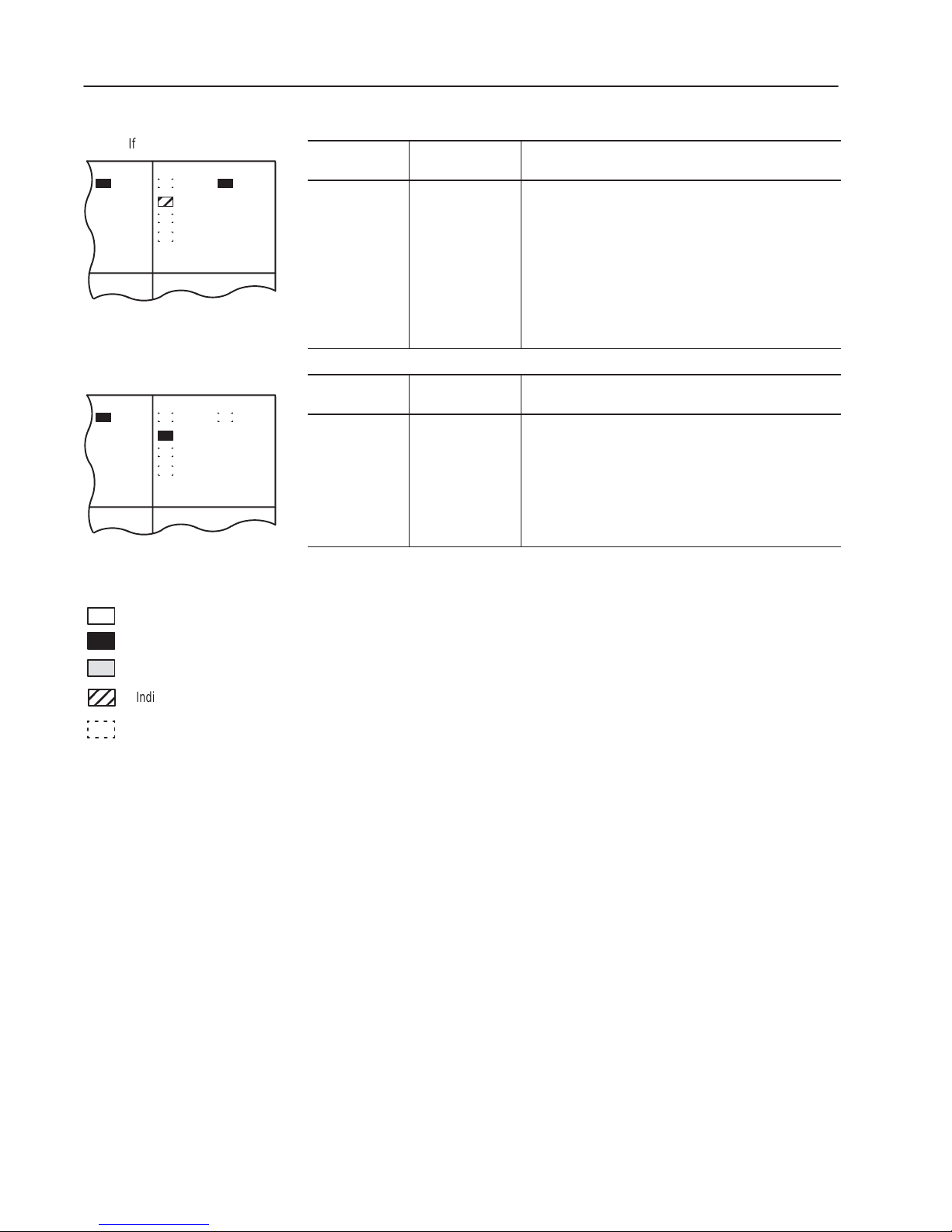

Identifying SLC 5/01 and SLC 5/02 Processor Errors

The following LEDs and tables provide you with information

regarding error messages, possible cause(s) for the error, and

recommended action to take to resolve the error.

If the LEDs indicate:

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

➀

COMM

The Following

Error Exists

Inadequate

System Power

Probable Cause Recommended Action

1. Verify proper line voltage and connections on the

No Line Power

power terminals.

2. Verify proper 120/240V power supply jumper

selection. See page 6–8.

1. Check the incoming power fuse, check for proper

Power Supply

Fuse Blown

incoming power connections. Replace fuse.

2. If fuse blows again, replace the power supply. See

page 9–8 on fuse replacement.

1. Remove line power to power supply. Remove

several output modules from the chassis. Wait five

minutes. Reapply power.

Power Supply

Overloaded

2. If condition reoccurs, re-calculate module

configuration power required and verify proper power

supply selection. See page 2–11.

This problem can occur intermittently if power supply is

slightly overloaded when output loading and

temperature varies.

1. Recheck other probable causes.

Defective Power

Supply

2. Monitor the line power to chassis power supply for

possible transient or shorting.

3. Replace the power supply.

If the LEDs indicate:

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

➀

COMM

Inadequate

System Power

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Status of LED does not matter.

➀

The RUN LED on the SLC 5/01 processor is actually

labeled “PC RUN.” Also, the SLC 5/01 processor does

not have a COMM LED.

Publication

1747-6.2

The Following

Error Exists

Probable Cause Recommended Action

Improper Line

Power Voltage

Selection

Verify proper 120/240V power supply jumper selection.

See page 6–8.

Page 13

Troubleshooting

10–5

If the LEDs indicate:

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

➀

COMM

The Following

Error Exists

Processor Not in

Run Mode

Probable Cause Recommended Action

1. Verify selected processor mode.

Either Improper

Mode Selected or

User Program

Logic Error

2. If in program/test modes attempt Run mode entry.

3. If in suspend mode, check user program logic for

suspend instructions.

Refer to either the Hand-Held Terminal User Manual

(Catalog Number 1747-NP002) or your programming

software user manual.

1. Check proper 120/240V power supply jumper

Line Power Out of

Operating Range

selection and incoming power connections.

2. Monitor for proper line voltage at the incoming

power connections.

See page 6–8 for power supply installation.

1. Remove power and inspect the power supply

Improper Seating

of Power Supply,

and/or Processor

in the Chassis

chassis connections and the processor chassis

connections.

2. Re-install the devices and re-apply power.

Important: The processor only operates in slot 0 of

chassis #1.

1. Attempt Run mode selection of Processor in

existing chassis.

2. Place processor in another chassis not in the

Defective

Processor, Power

Supply or Chassis

existing system. Apply power, reconfigure and attempt

Run mode selection. If unsuccessful, replace

processor.

3. Try existing power supply in test chassis. If

unsuccessful, replace power supply. If entry into the

Run mode is allowed, replace the existing chassis.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Status of LED does not matter.

➀

The RUN LED on the SLC 5/01 processor is

actually labeled “PC RUN.” Also, the

SLC 5/01 processor does not have a COMM

LED.

Publication

1747-6.2

Page 14

10–6

ault

ault

Troubleshooting

If the LEDs indicate:

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

If the LEDs indicate:

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

➀

➀

COMM

COMM

The Following

Error Exists

System

Inoperable,

No Major CPU

F

sDetected

The Following

Error Exists

Probable Cause Recommended Action

1. Monitor logic in Run mode and verify desired I/O

status.

User Program

Logic Error

2. Check for minor CPU faults.

Refer to either the Hand-Held Terminal User Manual

(Catalog Number 1747-NP002) or your programming

software user manual

Defective I/O

Devices or I/O

Wiring

Test inputs and outputs according to I/O troubleshooting

procedures starting on page 10–26.

Probable Cause Recommended Action

CPU Memory

Error

Cycle power.

1. Remove power and then remove the memory module

from the processor.

2. Re-install the processor and re-apply power to the

Faulty Memory

Module

power supply

If steady CPU FAULT LED changes to flashing, replace the

existing memory module with a replacement module.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Status of LED does not matter.

➀

The RUN LED on the SLC 5/01 processor is

actually labeled “PC RUN.” Also, the

SLC 5/01 processor does not have a COMM

LED.

CPUF

Faulty CPU/Power

Supply

Processor

Firmware Installed

Incorrectly

Refer to chapter 6 for removing and installing memory

modules.

1. Place the processor in another chassis not in the

existing system and cycle power.

If steady CPU FAULT LED reappears, replace the

processor.

2. If CPU FAULT LED clears, monitor the line power

going to the power supply in existing system.

3. Replace existing system power supply if line power

checks OK.

If upgrading the processor to a different firmware level,

verify firmware chip orientation matches the upgrade kit

directions.

Publication

1747-6.2

Page 15

Troubleshooting

10–7

If the LEDs indicate:

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

If the LEDs indicate:

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

➀

➀

COMM

COMM

The Following

Error Exists

CPU Major

Fault

The Following

Error Exists

System does

not operate per

ladder logic.

Probable Cause Recommended Action

Initial CPU Factory

Power-up

Condition

1. Refer to chapter 8 and follow the start-up procedures.

2. Clear processor memory to get rid of the flashing CPU

FAULT LED.

1. Monitor Status File Word S:6 for major error code.

Hardware/Software

Major Fault

Detected

2. Refer to either the Hand-Held Terminal User Manual

(Catalog Number 1747-NP002) or the Instruction Set

Reference Manual for error codes and additional

troubleshooting information.

Erratic repetitive

power cycling can

cause a processor

major hardware

fault.

3. Remove hardware/software condition causing fault.

4. Clear Status File S:1/13 major error bits, if set.

5. Clear Status File S:5 minor error bits, if set.

6. Clear Status File S:6 major error code (optional).

7. Attempt a processor Run mode entry.

If unsuccessful, repeat recommended action steps above.

Probable Cause Recommended Action

1. Monitor program file online and identify forced I/O.

User Forced I/O

Disabling

Operation

2. Disable appropriate forces and test system conditions

again.

Refer to either the Hand-Held Terminal User Manual

(Catalog Number 1747-NP002) or your programming

software user manual.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Status of LED does not matter.

➀

The RUN LED on the SLC 5/01 processor is

actually labeled “PC RUN.” Also, the

SLC 5/01 processor does not have a COMM

LED.

Publication

1747-6.2

Page 16

10–8

Troubleshooting

If the LEDs indicate:

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

If the LEDs indicate:

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

➀

➀

COMM

COMM

The Following

Error Exists

System does

not operate per

programmed

forces.

The Following

Error Exists

CPU Major

Error with Low

or No Battery

Back-up

Probable Cause Recommended Action

1. Monitor program file online and identify programmed

forces.

User Programmed

Forces are Not

Enabled

2. Enable appropriate forces and test system conditions

again. Once forces are enabled, the FORCED I/O LED

goes on steady.

Refer to either the Hand-Held Terminal User Manual

(Catalog Number 1747-NP002) or your programming

software user manual.

Probable Cause Recommended Action

1. Verify battery is connected. See pages 6–1 and 9–4.

2. Replace the battery if you want RAM battery backup.

See page 9–4. If you want to back up RAM with the

Loss of RAM

during Power

Down Period

capacitor in a SLC 5/01 (1747-L511), add or replace the

BATTERY LOW LED jumper.

3. Refer to processor major fault recommended action

steps.

Refer to either the Hand-Held Terminal User Manual

(Catalog Number 1747-NP002) or your programming

software user manual.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Status of LED does not matter.

➀

The RUN LED on the SLC 5/01 processor is

actually labeled “PC RUN.” Also, the

SLC 5/01 processor does not have a COMM

LED.

Publication

1747-6.2

Page 17

Troubleshooting

ceivingdata.

ata.

Identifying SLC 5/02 Processor Communication Errors

10–9

If the LEDs indicate:

➀

The Following

Error Exists

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

COMM

The SLC 5/02

processor is not

receivingd

re

No

communication

to the

programmer.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Probable Cause Recommended Action

1. Check communication parameters of programmer.

Programmer and processor baud rate must match.

DH-485

communication

parameters are

improperly set up.

Programmer and processor node addresses must be

different.

2. Try different combinations of:

a. baud rate (Processor default is 19200.)

b. node address (Processor default is 1.)

3. Try to increase the maximum node address. (Default

is 31.)

1. Check cable continuity.

Bad Connection of

Communication

Device

2. Check cable connections between programmer and

processor.

3. Check communication device (for example, the

1747-PIC). Replace if necessary.

1. Verify proper power supply selection and backplane

Low or No Power

to Communication

Device

loading. (1747-PIC and 1747-AIC draw power off the

backplane.)

2. Verify proper 120/240V power supply jumper selection.

See page 6–8.

Indicates the LED is FLASHING.

Indicates the LED is FLASHING or OFF.

Status of LED does not matter.

➀

The RUN LED on the SLC 5/01 processor is

actually labeled “PC RUN.” Also, the

SLC 5/01 processor does not have a COMM

LED.

Publication

1747-6.2

Page 18

10–10

Troubleshooting

If the LEDs indicate:

➀

The Following

Error Exists

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

COMM

The SLC 5/02

processor is

receiving data,

but is not

communicating

with the

programmer.

If the LEDs indicate:

➀

The Following

Error Exists

POWER

RUN

CPU FAULT

FORCED I/O

BATTERY LOW

COMM

A fatal error has

occurred.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Probable Cause Recommended Action

1. Check communication parameters of programmer.

Programmer and processor baud rate must match.

DH-485

communication

parameters are

improperly set up.

Programmer and processor node addresses must be

different.

2. Try different combinations of:

a. baud rate (Processor default is 19200.)

b. node address (Processor default is 1.)

3. Try to increase the maximum node address. (Default

is 31.)

Probable Cause Recommended Action

1. Cycle power to obtain flashing CPU FAULT LED and

default program.

Excessive noise or

a faulty SLC 5/02

processor.

2. Examine the error code following the power cycle.

Take appropriate action.

3. Reload your program.

4. Contact your local Allen-Bradley representative if the

error persists.

Indicates the LED is FLASHING.

Indicates the LED is FLASHING or OFF.

Status of LED does not matter.

➀

The RUN LED on the SLC 5/01 processor is

actually labeled “PC RUN.” Also, the

SLC 5/01 processor does not have a COMM

LED.

Publication

1747-6.2

Page 19

10–1

1Troubleshooting

Troubleshooting the

SLC 5/03, SLC 5/04, and

SLC 5/05 Processors

Between the time you apply power to an SLC 5/03, SLC 5/04, or

SLC 5/05 processor and the communications are established via a

connected programming device, the only form of communication

between you and the processor is through the LED display.

When power is applied, all of the LEDs flash on and then off while

the processor conducts hardware tests. This is part of the normal

powerup sequence. Following the selftest by the processor, all the

LEDs again flash on momentarily. If a user program is in a running

state, the RUN LED will be on. If a fault exists within the processor,

the FLT LED is on.

To receive the maximum benefit of this troubleshooting section, we

recommend you follow these steps:

1. Identify the status of your processor LEDs. See chapter 5 for

description of LEDs and their different states.

2. Using the tables on the following pages, match your processor

and power supply LEDs with the status LEDs located in the first

column.

3. Once the status LEDs are matched to the appropriate table,

simply move across the table identifying error description and

probable causes.

4. Then follow the recommended action steps for each probable

cause until the cause is identified.

5. If recommended actions do not identify the trouble cause, contact

your local Allen-Bradley sales office or distributor.

Clearing SLC 5/03, SLC 5/04, and SLC 5/05 Processor Faults

Using the Keyswitch

Toggle the keyswitch from RUN to PROG and then back to RUN;

this clears the fault. If the keyswitch is left in the RUN position, the

processor mode cannot be changed from a programmer/operator

interface device. If you return the keyswitch to the REM position,

you can then use a programmer/operator interface device to change

the processor mode.

ATTENTION: If you clear a processor fault using the

keyswitch, the processor immediately enters the Run

!

mode.

Publication

1747-6.2

Page 20

10–12

Troubleshooting

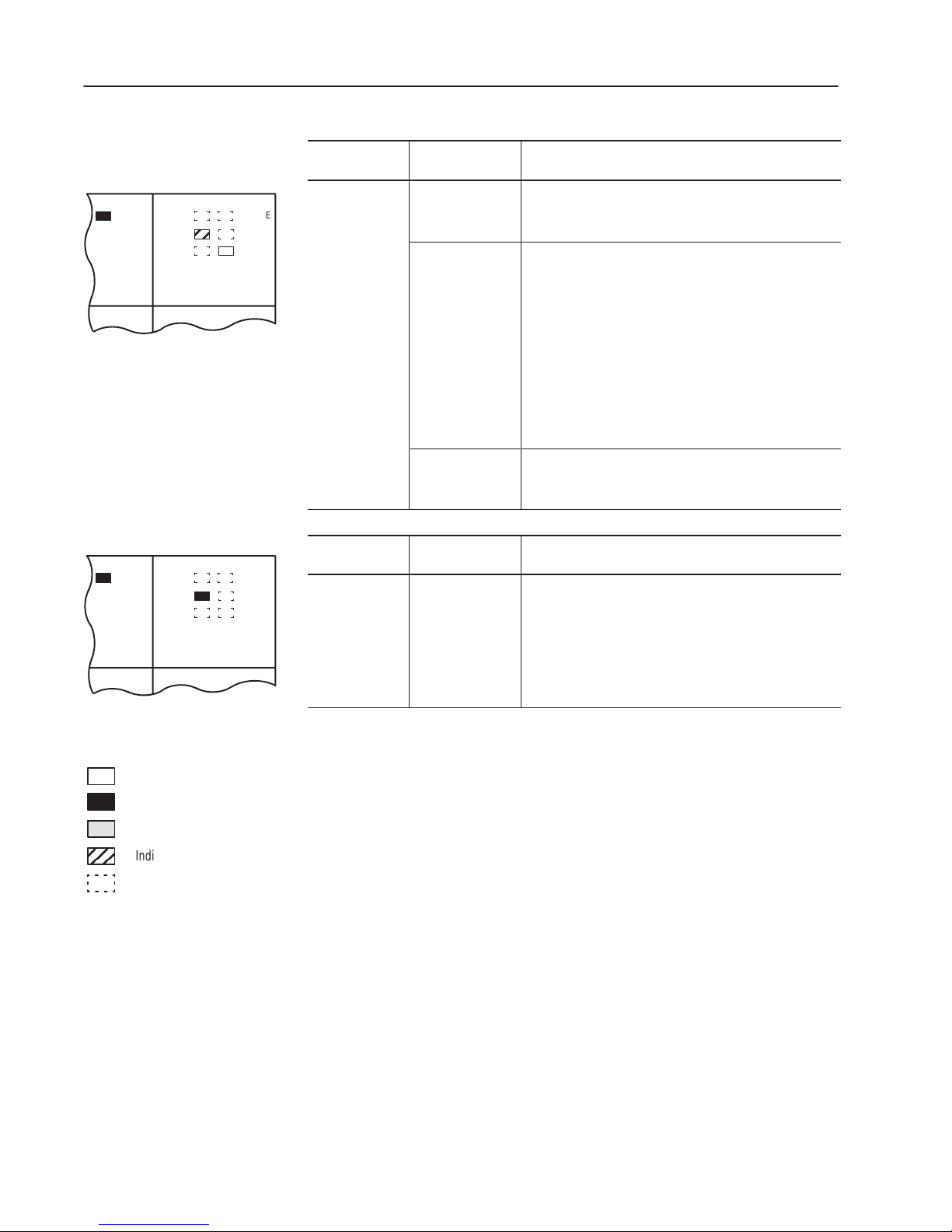

Identifying SLC 5/03, SLC 5/04, and SLC 5/05 Processor Errors

The following LEDs and tables provide you with information

regarding error messages, possible cause(s) for the error, and

recommended action to take to resolve the error.

If the LEDs indicate:

POWER

RUN

FLT

BATT

➀

FORCE

DH485

RS232

The Following

Error Exists

Inadequate

System Power

Probable Cause Recommended Action

1. Verify proper line voltage and connections on the

No Line Power

power terminals.

2. Verify proper 120/240V power supply jumper

selection. See page 6–8.

1. Check the incoming power fuse, check for proper

Power Supply

Fuse Blown

incoming power connections. Replace fuse.

2. If fuse blows again, replace the power supply. See

page 9–8 on fuse replacement.

1. Remove line power to power supply. Remove

several output modules from the chassis. Wait five

minutes. Reapply power.

Power Supply

Overloaded

2. If condition reoccurs, re-calculate module

configuration power required and verify proper power

supply selection. See page 2–11.

This problem can occur intermittently if power supply is

overloaded when output loading and temperature

varies.

1. Recheck other probable causes.

Defective Power

Supply

2. Monitor the line power to chassis power supply for

possible transient or shorting.

3. Replace the power supply.

If the LEDs indicate:

POWER

RUN

FLT

BATT

➀

FORCE

DH485

RS232

Inadequate

System Power

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Status of LED does not matter.

➀

The DH485 LED on the SLC 5/03 processor is labeled DH+ on

the SLC 5/04 processor, and ENET on the SLC 5/05 processor.

Publication

1747-6.2

The Following

Error Exists

Probable Cause Recommended Action

Improper Line

Power Voltage

Selection

Verify proper 120/240V power supply jumper selection.

See page 6–8.

Page 21

Troubleshooting

10–13

If the LEDs indicate:

POWER

RUN

FLT

BATT

➀

FORCE

DH485

RS232

The Following

Error Exists

Processor Not in

Run Mode

Probable Cause Recommended Action

1. Verify selected processor mode.

2. If the processor is in the Program/Test modes,

attempt Run mode entry:

Either Improper

Mode Selected or

User Program

Logic

• If keyswitch is in the REM position and

there is no key, use the programmer.

• If keyswitch is in REM or PROG position,

and you have the key,

toggle to the RUN

position.

3. If in the suspend mode, check user program logic

for suspend instructions.

Refer to your programming software user manual.

1. Check proper 120/240V power supply jumper

Line Power Out of

Operating Range

selection and incoming power connections.

2. Monitor for proper line voltage at the incoming

power connections.

See page 6–8 for power supply installation.

1. Remove power and inspect the power supply

Improper Seating

of Power Supply,

and/or Processor

in the Chassis

chassis connections and the processor chassis

connections.

2. Re-install the devices and re-apply power.

Important: The processor only operates in slot 0 of

chassis #1.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Status of LED does not matter.

➀

The DH485 LED on the SLC 5/03 processor is labeled DH+ on

the SLC 5/04 processor, and ENET on the SLC 5/05 processor.

Defective

Processor, Power

Supply, or Chassis

1. Attempt Run mode selection of Processor in

existing chassis:

• If keyswitch is in the REM position and there is

no key, use the programmer.

• If keyswitch is in REM or PROG position, and you

have the key, toggle to the RUN position.

2. Place processor in another chassis not in the

existing system. Apply power, reconfigure and attempt

Run mode selection. If unsuccessful, replace

processor.

3. Try existing power supply in test chassis. If

unsuccessful, replace power supply. If entry into the

Run mode is allowed, replace the existing chassis.

Publication

1747-6.2

Page 22

10–14

NoMajorCPU

ault

Troubleshooting

If the LEDs indicate:

POWER

RUN

FLT

BATT

If the LEDs indicate:

POWER

RUN

FLT

BATT

➀

FORCE

DH485

RS232

➀

FORCE

DH485

RS232

The Following

Error Exists

System

Inoperable,

Faults Detected

The Following

Error Exists

CPU Fault

CPUF

Probable Cause Recommended Action

1. Monitor logic in Run mode and verify desired I/O

User Program

Logic Error

status.

2. Check for minor CPU faults.

Refer to your programming software user manual.

Defective I/O

Devices or I/O

Wiring

Test inputs and outputs according to I/O troubleshooting

procedures starting on page 10–26.

Probable Cause Recommended Action

CPU Memory

Error

Cycle power.

1. Remove power and then remove the memory module

from the processor.

2. Re-install the processor and re-apply power to the

Faulty Memory

Module

power supply.

If steady FLT LED changes to flashing, replace the existing

memory module with a replacement module.

Refer to chapter 6 for removing and installing memory

modules.

1. Place the processor in another chassis not in the

existing system and cycle power. If steady FLT LED

Faulty CPU/Power

Supply

reappears, replace the processor.

2. If FLT LED clears, monitor the line power going to the

power supply in existing system.

3. Replace existing system power supply if line power

checks OK.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Status of LED does not matter.

➀

The DH485 LED on the SLC 5/03 processor is labeled DH+ on

the SLC 5/04 processor, and ENET on the SLC 5/05 processor.

Publication

1747-6.2

Processor

Firmware Installed

Incorrectly

If upgrading the processor to a different firmware level,

verify firmware chip orientation matches the upgrade kit

directions.

Page 23

Troubleshooting

10–15

If the LEDs indicate:

POWER

RUN

FLT

BATT

If the LEDs indicate:

POWER

RUN

FLT

BATT

➀

FORCE

DH485

RS232

➀

FORCE

DH485

RS232

The Following

Error Exists

CPU Major

Fault

The Following

Error Exists

System does

not operate per

ladder logic.

Probable Cause Recommended Action

Initial CPU Factory

Power-up

Condition in Effect

1. Refer to chapter 8 and follow the start-up procedures.

2. Clear processor memory to get rid of the flashing FLT

LED.

1. Use programmer to monitor and clear the fault (or if

keyswitch in REM):

a. Monitor Status File Word S:6 for major error code.

Hardware/

Software Major

Fault Detected

b. Refer to your programming software user manual for

error codes and additional troubleshooting information.

c. Remove hardware/software condition causing fault.

d. Clear Status File S:1/13 major error bits, if set.

Erratic repetitive

power cycling can

cause a CPU

major hardware

fault.

e. Clear Status File S:5 minor error bits, if set.

f. Clear Status File S:6 major error code (optional).

g. Attempt a processor Run mode entry.

If unsuccessful, repeat recommended action steps above.

2. Use the keyswitch to clear the fault. Toggle the

keyswitch to PROG and back to RUN. (See page 10–11.)

If FAULT occurs again, use programmer to get error code

and determine the source of problem.

Probable Cause Recommended Action

User Forced I/O

Disabling

Operation

1. Monitor program file online and identify forced I/O.

2. Disable appropriate forces and test system conditions

again.

Refer to your programming software user manual.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Status of LED does not matter.

➀

The DH485 LED on the SLC 5/03 processor is labeled DH+ on

the SLC 5/04 processor, and ENET on the SLC 5/05 processor.

Publication

1747-6.2

Page 24

10–16

Troubleshooting

If the LEDs indicate:

➀

The Following

Error Exists

POWER

RUN

FLT

BATT

FORCE

DH485

RS232

System does

not operate per

programmed

forces.

If the LEDs indicate:

➀

The Following

Error Exists

POWER

RUN

FLT

BATT

FORCE

DH485

RS232

CPU Major

Error with Low

or No Battery

Back-up

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Probable Cause Recommended Action

1. Monitor program file online and identify programmed

User programmed

forces are not

enabled.

forces.

2. Enable appropriate forces and test system conditions

again. Once forces are enabled, the FORCE LED goes on

steady.

Refer to your programming software user manual.

Probable Cause Recommended Action

1. Verify battery is connected. See pages 6–1 and 9–5.

Loss of RAM

during Power

Down Period

2. Replace the battery if you want RAM battery backup.

See page 9–5.

3. Refer to processor major fault recommended action

steps.

Refer to your programming software user manual.

Indicates the LED is FLASHING.

Status of LED does not matter.

➀

The DH485 LED on the SLC 5/03 processor is labeled DH+ on

the SLC 5/04 processor, and ENET on the SLC 5/05 processor.

Publication

1747-6.2

Page 25

Troubleshooting

Identifying SLC 5/03, SLC 5/04, and SLC 5/05 Processor

Communication Errors

10–17

If the LEDs indicate:

➀

The Following

Error Exists

POWER

RUN

FLT

BATT

FORCE

DH485

RS232

Fatal Error and

No

Communication

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Indicates the LED is FLASHING or OFF.

Status of LED does not matter.

➀

The DH485 LED on the SLC 5/03 processor is labeled DH+ on

the SLC 5/04 processor, and ENET on the SLC 5/05 processor.

Probable Cause Recommended Action

1. Check line power.

Inadequate

System Power

2. Check 120/240V power supply jumper selection. See

page 6–8. Also, see the recommended actions for

inadequate system power on page 10–12.

Communication

channel is “shut

down.”

Check communication channel configuration with your

programming software. Also, see “Returning the SLC 5/03,

SLC 5/04, and SLC 5/05 Processors to ‘Initial Factory

Conditions’” on page 10–25.

Communication

channel is

Replace processor.

damaged.

Publication

1747-6.2

Page 26

10–18

4.)

4.)

Troubleshooting

If the LEDs indicate:

POWER

RUN

FLT

BATT

➀

FORCE

DH485

RS232

The Following

Error Exists

The SLC 5/03

and SLC 5/04

processors are

trying to

establish

communication,

but cannot find

other active

nodes. (The

LED is flashing

green on the

SLC 5/03 and

SLC 5/0

SLC

5/0

Probable Cause Recommended Action

1. Check communication parameters of programmer.

Programmer and processor baud rate must match.

Programmer and processor node addresses must be

different.

DH-485 or DH+

communication

parameters are

improperly set up.

2. Try different combinations of:

a. baud rate (Processor default is 19.2K for DH-485 on

the SLC 5/03, and 57.6K for DH+ on the SLC 5/04.)

b. node address (Processor default is 1.)

3. Try to increase the maximum node address. (Default

is 31 for the SLC 5/03 processor only.)

See your programming software user manual for channel

configuration information.

1. Check cable continuity.

Bad Connection of

Communication

Device

2. Check cable connections between programmer and

processor.

3. Check communication device (for example, the

1747-PIC). Replace if necessary.

1. Verify proper power supply selection and backplane

Low or No Power

to Communication

Device

loading. (The 1747-PIC and 1747-AIC draw power off the

backplane.)

2. Verify proper 120/240V power supply jumper selection.

See page 6–8.

Duplicate drop

is detected.

(The LED is

flashing red on

the SLC 5/04.)

An ENET fault is

being reported

via a code.

(The LED is

flashing red on

the SLC 5/05.)

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Indicates the LED is FLASHING or OFF.

Status of LED does not matter.

➀

The DH485 LED on the SLC 5/03 processor is labeled DH+ on

the SLC 5/04 processor, and ENET on the SLC 5/05 processor.

Another DH+

device is already

on the DH+

network at the

node address of

this same device.

A hardware or

software fault has

occured.

1. Remove this device from the DH+ network.

2. Cycle power.

3. Reset the node address to an unused node before

reconnecting device to the DH+ network. (Can perform

reset if on-line via channel 0 RS-232 port without

disconnecting from DH+.)

Contact Allen-Bradley Global Technical Services for

assistance.

Publication

1747-6.2

Page 27

Troubleshooting

unication

no

.

no

.

10–19

If the RS232 Channel

is in DH485 Mode

and the LEDs

➀

indicate:

POWER

RUN

FLT

BATT

If the RS232 Channel

is in DH485 Mode

and the LEDs

➀

indicate:

POWER

RUN

FLT

BATT

FORCE

DH485

RS232

FORCE

DH485

RS232

The Following

Error Exists

Fatal Error and

No

Comm

The Following

Error Exists

The SLC 5/03,

SLC 5/04, or

SLC 5/05

processor is

trying to

establish

communication,

but cannot find

other active

des

des

Probable Cause Recommended Action

1. Check line power.

Inadequate

System Power

2. Check 120/240V power supply jumper selection. See

page 6–8. Also, see the recommended action for

Inadequate System Power on page 10–12.

Communication

channel is “shut

down.”

Check communication channel configuration with your

programming software. Also, see “Returning the SLC 5/03,

SLC 5/04, and SLC 5/05 Processors to ‘Initial Factory

Conditions’” on page 10–25.

Communication

channel is

Replace processor.

damaged.

Channel

configured for

DF1.

See your programming software user manual for channel

configuration information.

Probable Cause Recommended Action

1. Check communication parameters of programmer.

Programmer and processor baud rate must match.

Programmer and processor node addresses must be

DH-485

communication

parameters are

improperly set up.

different.

2. Try different combinations of:

a. baud rate (Processor default is 19200.)

b. node address (Processor default is 1.)

3. Try to increase the maximum node address. (Default

is 31.)

See your programming software user manual for channel

configuration information.

1. Check cable continuity.

Bad Connection

2. Check cable connections between programmer and

processor.

1. Verify proper power supply selection and backplane

Low or No Power

to Communication

Device

loading. (The 1747-PIC and 1747-AIC draw power off the

backplane.)

2. Verify proper 120/240V power supply jumper selection.

See page 6–8.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Indicates the LED is FLASHING or OFF.

Status of LED does not matter.

➀

The DH485 LED on the SLC 5/03 processor is labeled DH+ on

the SLC 5/04 processor, and ENET on the SLC 5/05 processor.

Publication

1747-6.2

Page 28

10–20

aramet

c.

ckin

Troubleshooting

If the RS232 Channel

is in DH485 Mode

and the LEDs

➀

indicate:

POWER

RUN

FLT

BATT

If the LEDs indicate:

POWER

RUN

FLT

BATT

FORCE

DH485

RS232

➀

FORCE

DH485

RS232

The Following

Error Exists

Probable Cause Recommended Action

Channel is

configured for

DH485 mode.

The SLC 5/03,

SLC 5/04, or RS232/DF1

SLC 5/05

processor is not

p

ers

improperly set up.

transmitting.

Hardware Problem

The Following

Error Exists

Probable Cause Recommended Action

Excessive noise or

A fatal error has

occurred.

a faulty SLC 5/03,

SLC 5/04, or

SLC 5/05

processor.

Check communication parameters of channel

configuration. Also, see your programming software user

manual.

Check communication parameters of programmer and

channel configuration:

a. baud rate

b. DF1 node addresses (Processor default is 1 for DF1

half-duplex, and 9 for DF1 full-duplex.)

error che

g

d. number of data bits

Programmer and processor baud rate must match.

Programmer and processor addresses must be different.

See your programming software user manual.

1. Check cable connections.

2. Check cable pinouts. Also, see appendix B for

RS-232 pinouts.

1. Cycle power to obtain flashing FLT LED and default

program.

2. Examine the error code following the power cycle.

Take appropriate action.

3. Reload your program.

4. Contact your local Allen-Bradley representative if the

error persists.

Refer to the following key to determine the status of

the LED indicators:

Indicates the LED is OFF.

Indicates the LED is ON.

Indicates the LED is FLASHING.

Indicates the LED is FLASHING or OFF.

Status of LED does not matter.

➀

The DH485 LED on the SLC 5/03 processor is labeled DH+ on

the SLC 5/04 processor, and ENET on the SLC 5/05 processor.

Publication

1747-6.2

Loading...

Loading...