Page 1

User Manual

POINT I/O Digital and Analog Modules and

POINTBlock I/O Modules

Catalog Numbers

IV2, 1734-IV4, 1734-IV8, 1734-OA2, 1734-OA4, 1734-OB2, 1734-OB2EP, 1734-IV8, 1734-OA2, 1734-OA4, 1734OB2, 1734-OB2EP, 1734-OB2E, 1734-OB4, 1734-OB4E, 1734-OB8, 1734-OB8E, 1734-OV2E, 1734-OV4E,

1734-OV8E, 1734-OW2, 1734-OW4, 1734-OX2, 1734-IE2C, 1734-IE2V, 1734-OE2C, 1734-OE2V, 1734D-IA16,

1734D-IA8XOA8, 1734D-IA8XOW8, 1734D-IB16, 1734D-IB8XOB8, 1734D-IB8XOW8

1734-IA2, 1734-IM4, 1734-IB2, 1734-IB4, 1734-IB8, 1734-IB4D, 1734-IM2, 1734-IM4, 1734-

Page 2

Important User Information

IMPORTANT

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines for

the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1 available from your local Rockwell

Automation sales office or online at http://literature.rockwellautomation.com

solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that each intended

application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

) describes some important differences between

Throughout this manual, when necessary, we use notes to make you aware of safety considerations

.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, POINT I/O, POINTBus, Rockwell Automation, RSLogi x, RSNetWorx, RSNetWorx for DeviceNet, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

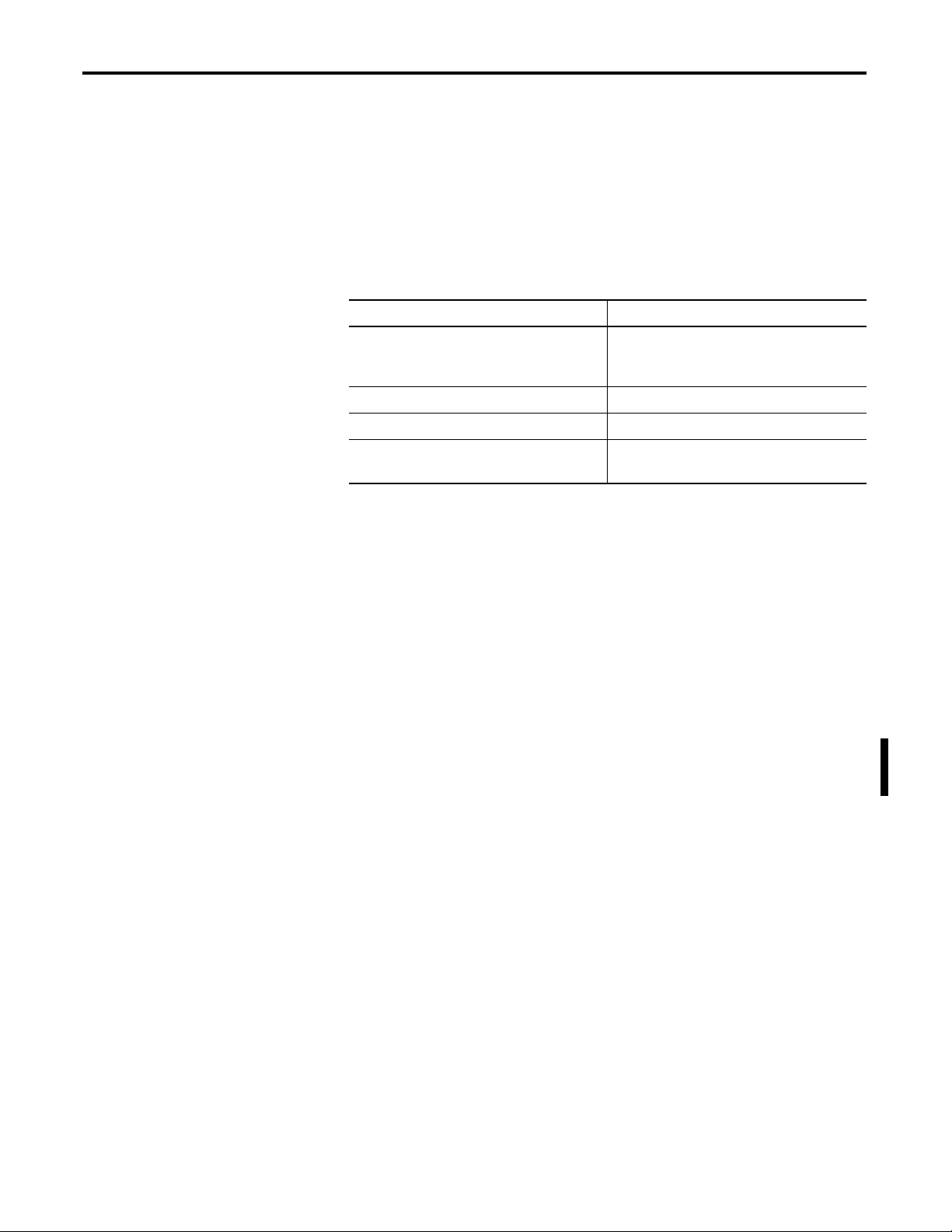

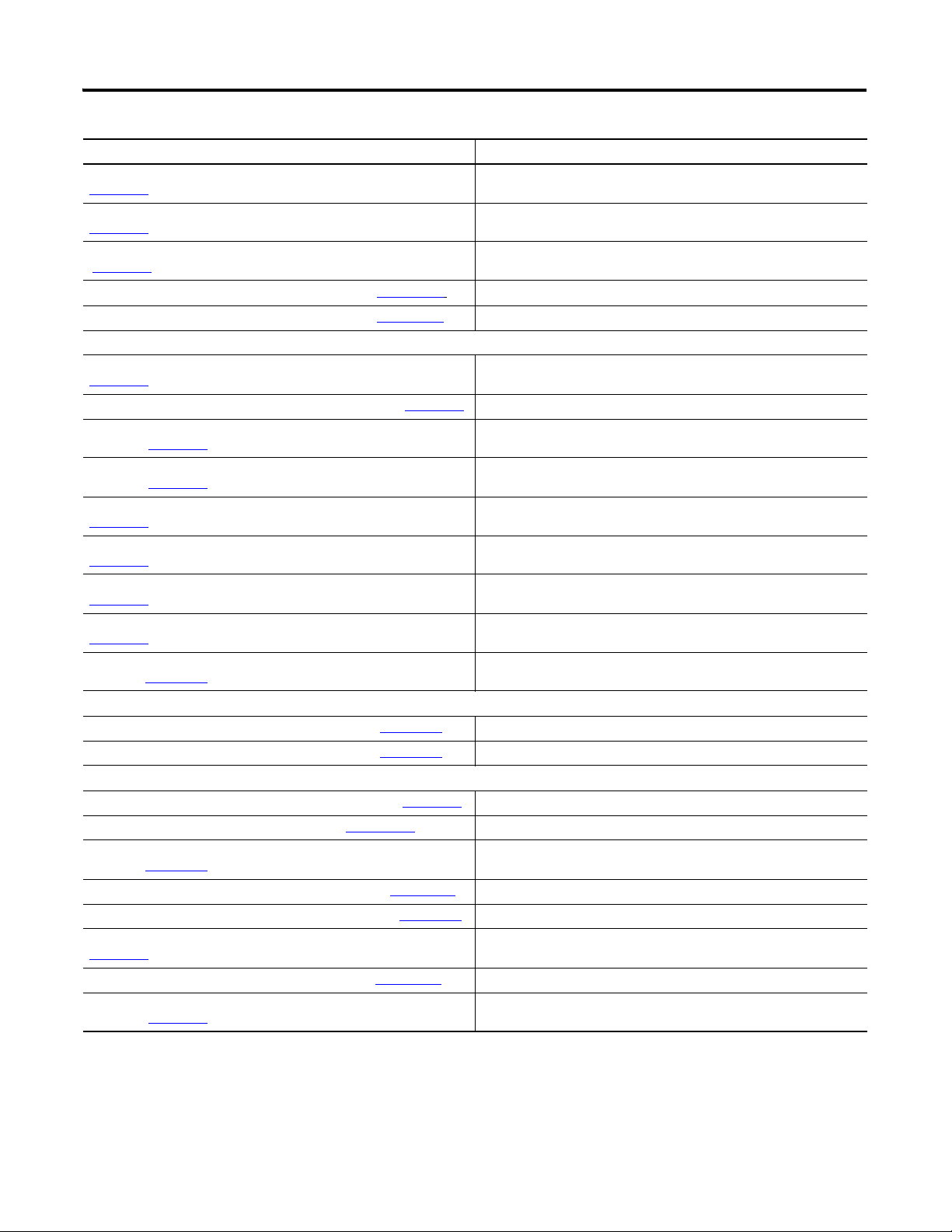

Summary of Changes

This publication contains new and revised information not in the last release.

New Information

See the table that shows what we added to this publication.

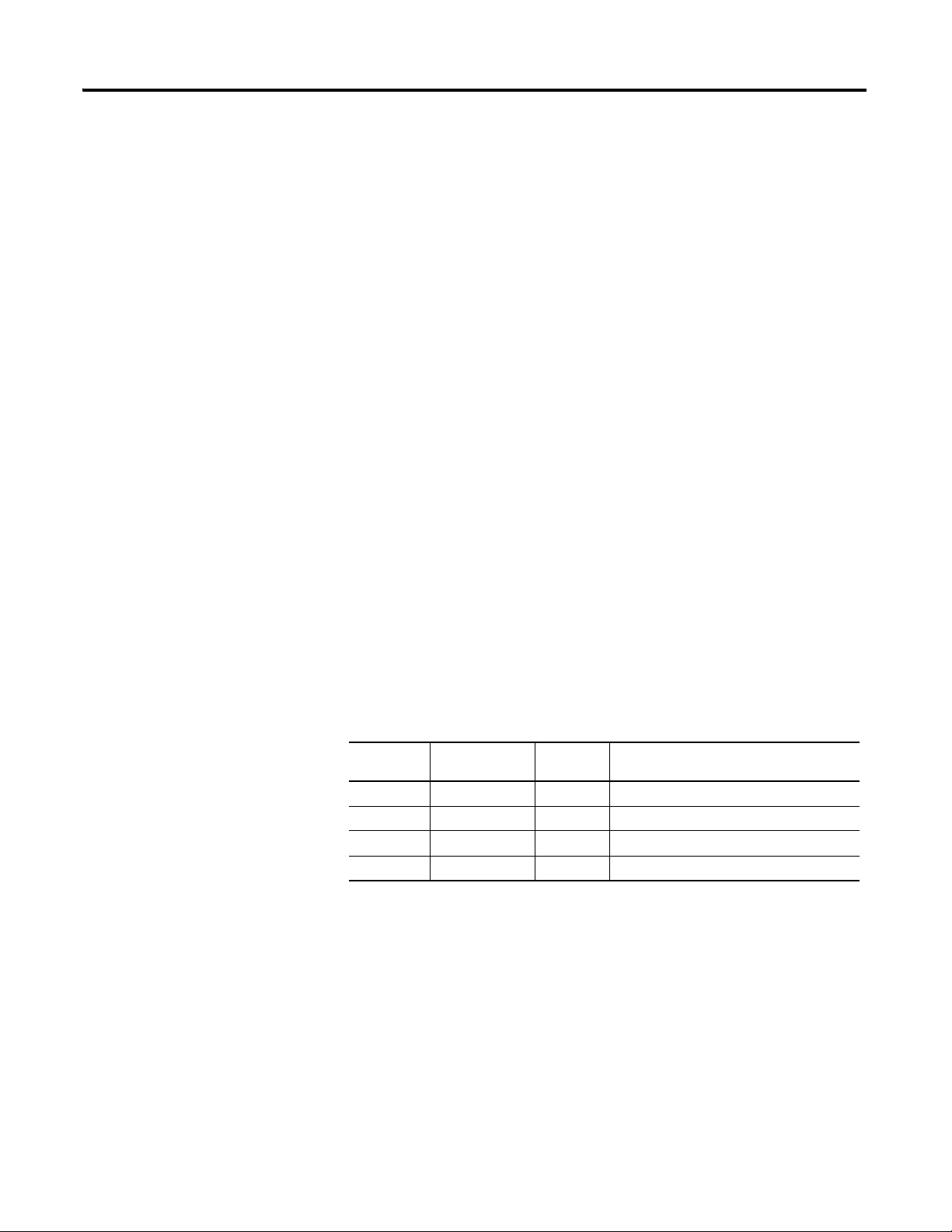

Item Added Cat. No.

Input Modules 1734-IA4

1734-IB4D

1734-IM4

Output Modules 1734-OA4

Specialty Modules 1734-IR2E

One-piece Terminal Bases 1734-TOP, 1734-TOPS

1734-TOP3, 1734-TOP3S

Revised Information

We updated additional information as necessary to more fully explain certain

procedures.

Change Bars

Change bars (as shown with this paragraph) show the areas in this manual that

are different from previous editions and indicate the addition of new or

revised information.

Publication 1734-UM001E-EN-P - July 2013

Page 4

iv Summary of Changes

Notes:

Publication 1734-UM001E-EN-P - July 2013

Page 5

Preface

Purpose of This Manual

This manual describes how to install, configure, and troubleshoot your

POINT I/O modules.

The POINT I/O modules in this manual are DeviceNet ready. Each module can

exist on the DeviceNet network as one of the following:

• As an individual node

• With an adapter (catalog number 1734-ADN or 1734-ADNX) as a single

node

When using these POINT I/O modules with an adapter, use this manual in

conjunction with the user manual for the adapter you are using as shown in the

table.

For applications using these modules in a network with a 1734-PDN DeviceNet

Communication Interface, or a 1734D-xx POINTBlock I/O module, this user

manual is the primary documentation.

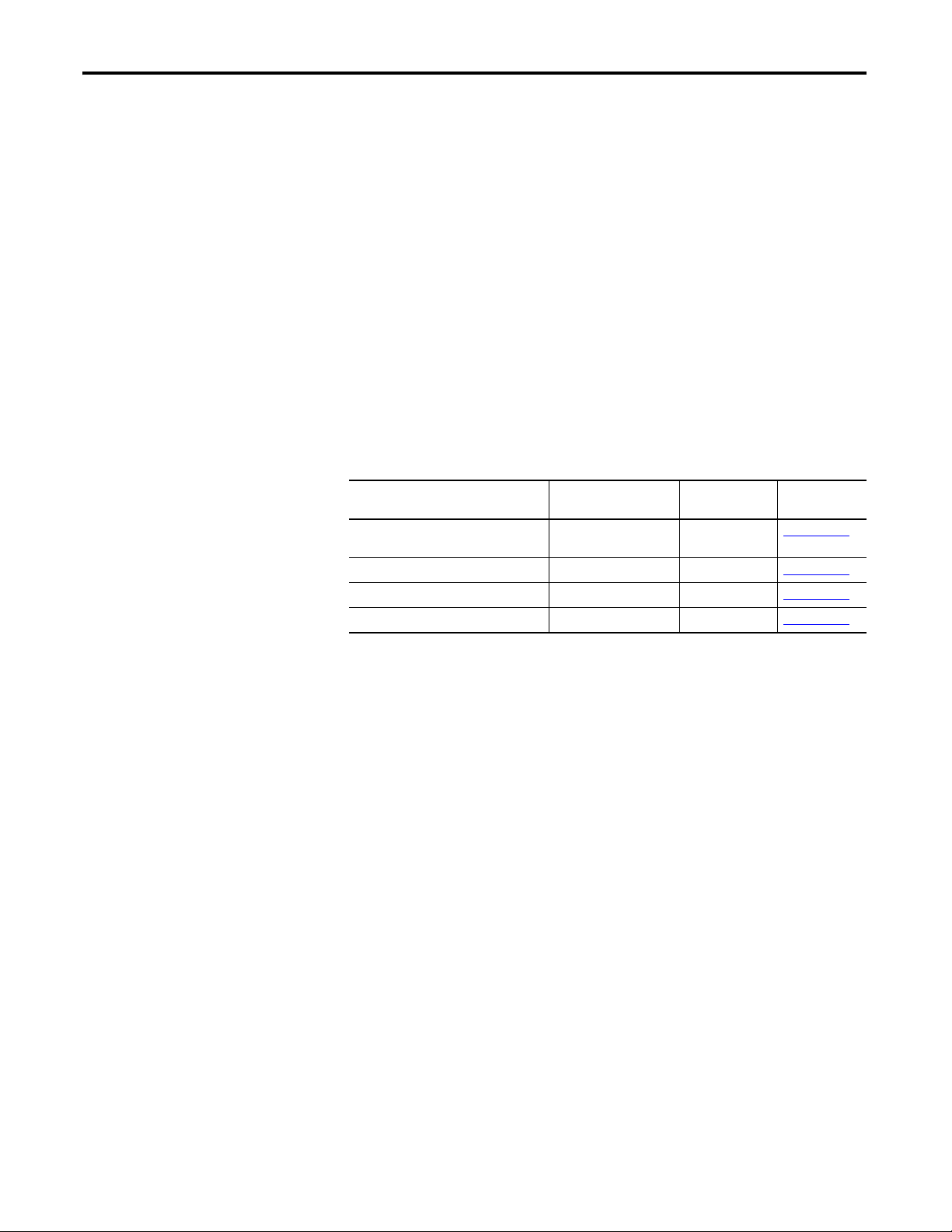

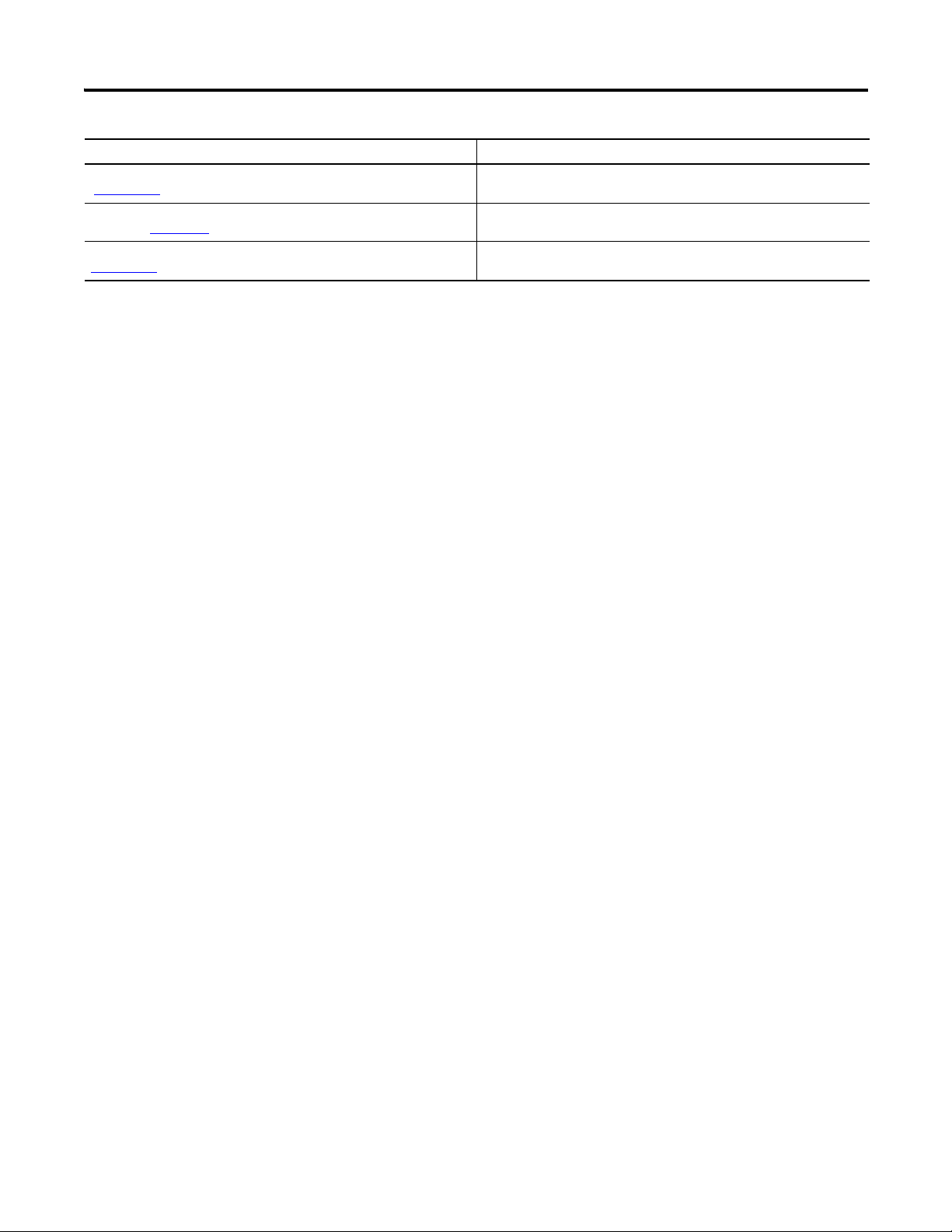

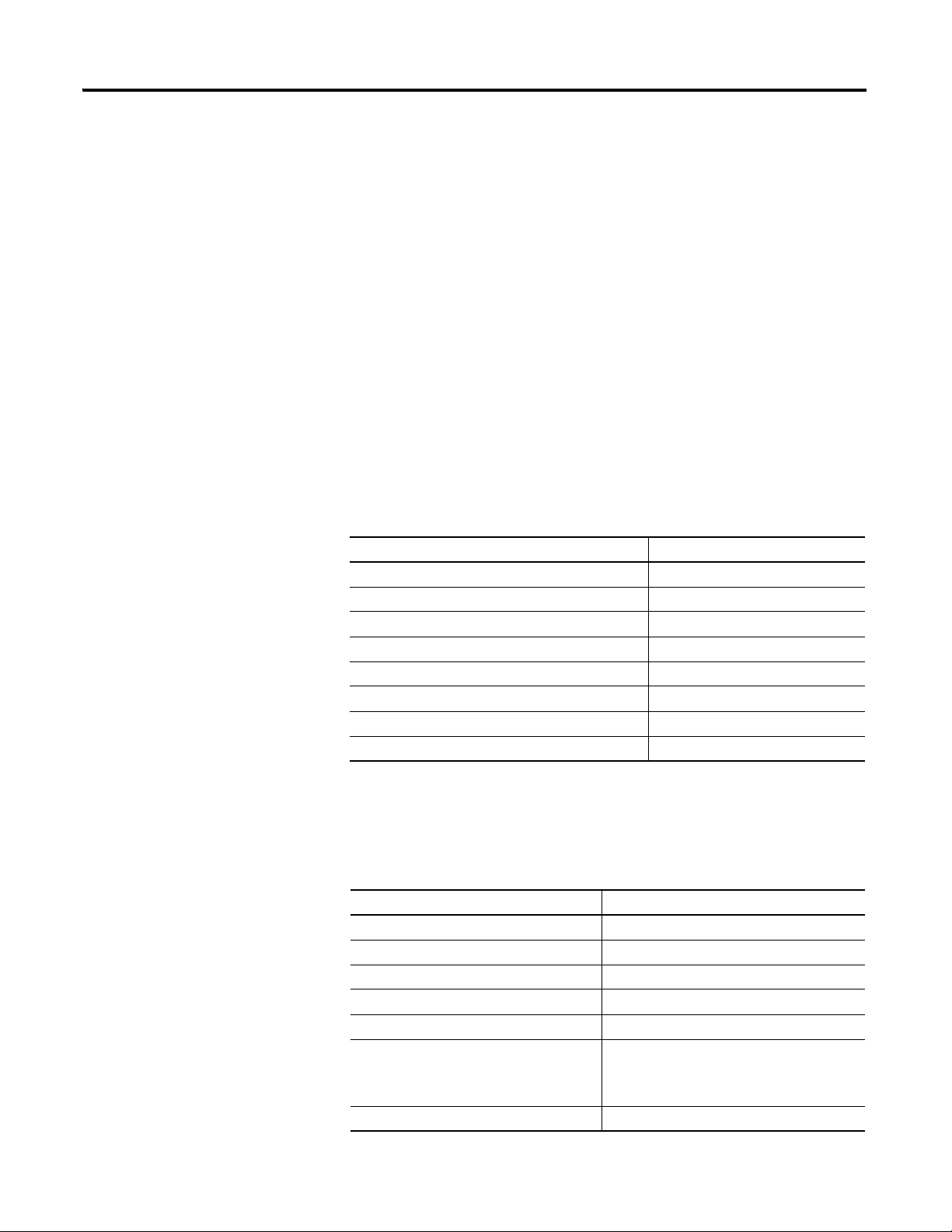

When Using POINT I/O Modules

on This Network

DeviceNet network DeviceNet adapter 1734-ADN

ControlNet network ControlNet adapter 1734-ACNR 1734-UM008

EtherNet/IP network EtherNet/IP adapter 1734-AENT 1734-UM011

PROFIBUS network PROFIBUS adapter 1734-APB 1734-UM005

Refer to User

Manual for

Cat. No. Publication

No.

1734-UM002

1734-ADNX

Who Should Use This Manual

In this manual, we assume you know how to do the following:

• Use RSNetWorx software or similar configuration software to set up and

calibrate these modules.

• Have the capability to download and use electronic data sheet (EDS) files.

If you do not, refer to your software documentation or online help before

attempting to use these modules.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 6

xiv Preface

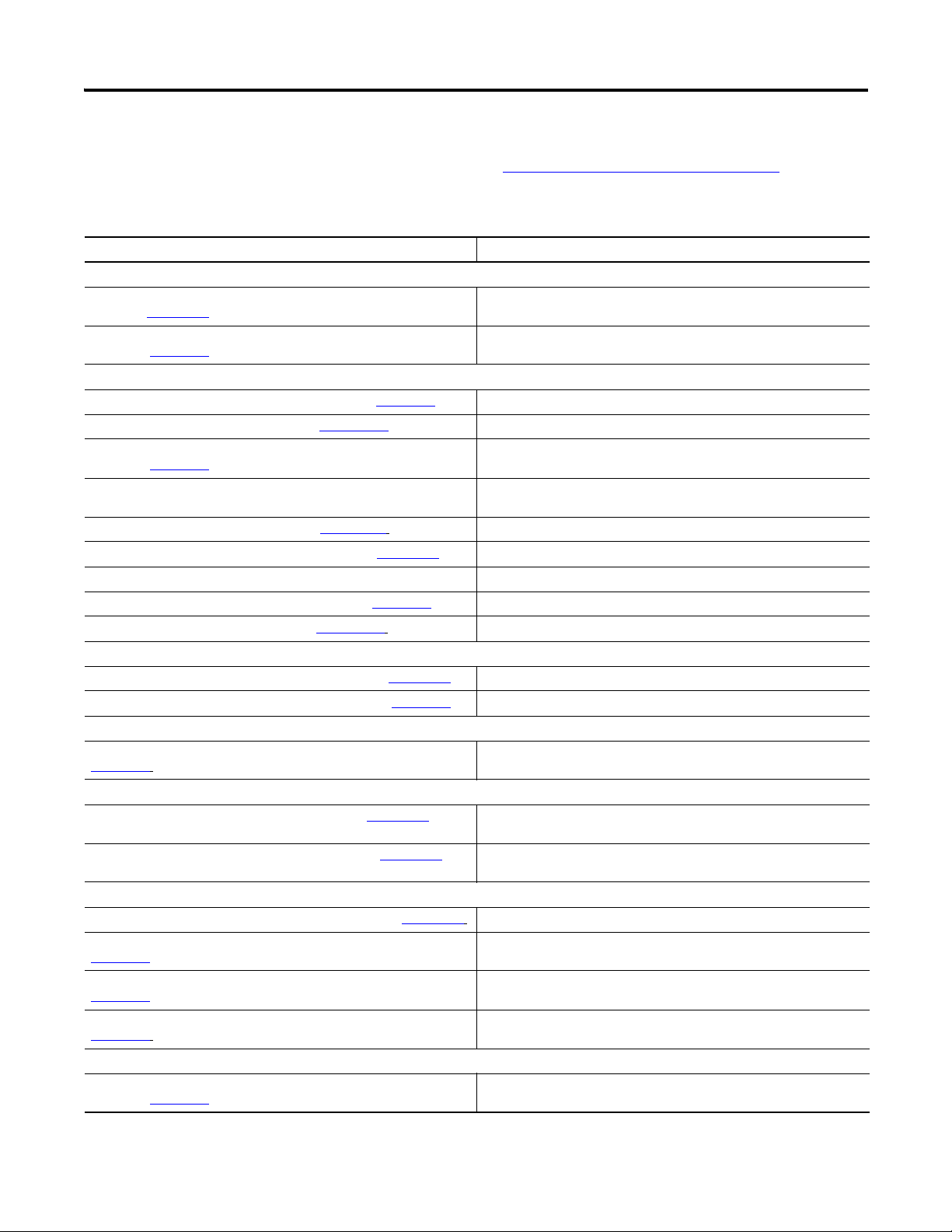

Additional Resources

Refer to this table for a list of related 1734 products and documentation. Most of

these are available from http://literature.rockwellautomation.com/

. For

specification and safety certification information, refer to the installation

instructions.

Resource Description

Analog Modules

Analog Current and Voltage Input Module Installation Instructions,

publication 1734-IN027

Analog Current and Voltage Output Module Installation Instructions,

publication 1734-IN002

Communication Devices

ControlNet Adapter Installation Instructions, publication 1734-IN582 Provides installation information about 1734-ACNR adapters

ControlNet Adapter User Manual, publication 1734-UM008

DeviceNet Communication Interface Module Installation Instructions,

publication 1734-IN057

DeviceNet Adapter Installation Instructions, publication 1734-IN026 Provides installation information about 1734-ADN and 1734-ADNX

DeviceNet Adapter User Manual, publication 1734-UM002

EtherNet/IP Adapter Installation Instructions, publication 1734-IN590 Provides installation information about 1734-AENT adapters

EtherNet/IP Adapter User Manual, publication 1734-UM011 Describes how to use 1734-AENT adapters

PROFIBUS Adapter Installation Instructions, publication 1734-IN014

PROFIBUS Adapter User Manual, publication 1734-UM005 Describes how to use 1734-APB adapters

Digital AC Input Modules

220V AC Input Module Installation Instructions, publication 1734-IN008

120V AC Input Module Installation Instructions, publication 1734-IN010 Provides installation information about 1734-IA2 and 1734-IA4 modules

Digital AC Output Modules

120/220V AC Output Module Installation Instructions, publication

1734-IN009

Digital DC Input Modules

Sink Input Module Installation Instructions, publication 1734-IN051 Provides installation information about 1734-IB2, 1734-IB4, and 1734-IB8

Source Input Module Installation Instructions, publication 1734-IN052

Digital DC Output Modules

Protected Output Module Installation Instructions, publication 1734-IN586 Provides installation information about 1734-OB2EP modules

Protected Sink Output Module Installation Instructions, publication

1734-IN585

Protected Source Output Module Installation Instructions, publication

1734-IN056

Protected Source Output Module Installation Instructions, publication

1734-IN018

POINTBlock Modules

8 AC Input/8 AC Output Module Installation Instructions,

publication 1734-IN022

Describes how to use 1734-ADN and 1734-ADNX adapters

Provides installation information about 1734-APB adapters

Provides installation information for 1734-IE2C and 1734-IE2V input

modules

Provides installation information about 1734-OE2C and 1734-OE2V modules

Describes how to use 1734-ACNR adapters

Provides installation information about 1734-PDN modules

adapters

Provides installation information about 1734-IM2 and 1734-IM4 modules

Provides installation information about 1734-OA2 and 1734-OA4 modules

modules

Provides installation information about 1734-IV2, 1734-IV4, and 1734-IV8

modules

Provides installation information about 1734-OV2E, 1734-OV4E, and

1734-OV8E modules

Provides installation information about 1734-OB2E, 1734-OB4E, and

1734-OB8E modules

Provides installation information about 1734-OB2, 1734-OB4, and 1734-OB8

modules

Provides installation information about 1734D-IA8XOA8 modules

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 7

Preface xv

Resource Description

8 AC Input/8 AC Relay Output Module Installation Instructions, publication

1734-IN023

8 DC Input/8 Output Module Installation Instructions, publication

1734-IN020

8 DC Input/8 DC Output Module Installation Instructions, publication

1734-IN021

16 AC Input Module Installation Instructions, publication 1734D-IN001 Provides installation information about 1734D-IA16 modules

16 DC Input Module Installation Instructions, publication 1734D-IN002 Provides installation information about 1734D-IB16 modules

Power Supplies, Wiring Base Assemblies, Miscellaneous

Cold Junction Wiring Base Assembly Installation Instructions, publication

1734-IN583

Field Potential Distributor Installation Instructions, publication 1734-IN059 Provides installation information about 1734-FPD distributors

POINT I/O 24V DC Expansion Power Supply Installation Instructions,

publication 1734-IN058

POINT I/O 120/240V AC Expansion Power Supply Installation Instructions,

publication 1734-IN017

POINT I/O Common Terminal Module Installation Instructions, publication

1734-IN024

POINT I/O Voltage Terminal Module Installation Instructions, publication

1734-IN024

POINT I/O Wiring Base Assembly Installation Instructions, publication

1734-IN511

POINT I/O Wiring Base Assembly Installation Instructions, publication

1734-IN013

POINT I/O One-piece Wiring Base Assembly Installation Instructions,

publication 1734-IN028

Relay Modules

Relay Output Module Installation Instructions, publication 1734-IN055 Provides installation information about 1734-OW2 and 1734-OW4 modules

Relay Output Module Installation Instructions, publication 1734-IN587

Specialty Modules

Encoder/Counter Module Installation Instructions, publication 1734-IN005 Provides installation information about 1734-IJ and 1734-IK modules

Encoder/Counter Module User Manual, publication 1734-UM006

Very High-speed Counter Module Installation Instructions,

publication 1734-IN003

Very High-speed Counter Module User Manual, publication 1734-UM003

Address Reserve Module Installation Instructions, publication 1734-IN019

ASCII RS-232 and 485 Module Installation Instructions, publication

1734-IN588

ASCII RS-232 and 485 Module User Manual, publication 1734-UM009

RTD and Isolated Thermocouple Input Module Installation Instructions,

publication 1734-IN011

Provides installation information about 1734D-IA8XOW8 modules

Provides installation information about 1734D-IB8XOB8 modules

Provides installation information about 1734D-IB8XOW8 modules

Provides installation information about 1734-TBCJC assemblies

Provides installation information about 1734-EP24DC power supplies

Provides installation information about 1734-EPAC power supplies

Provides installation information about 1734-CTM modules

Provides installation information about 1734-VTM modules

Provides installation information about 1734-TB and 1734-TBS assemblies

Provides installation information about 1734-TB3 and 1734-TB3S

assemblies

Provides installation information about 1734-TOP, 1734-TOPS, 1734-TOP3

and 1734-TOP3S assemblies

Provides installation information about 1734-OX2 modules

Describes how to use 1734-IJ and 1734-IK modules

Provides installation information about 1734-VHSC5 and 1734-VHSC24

modules

Describes how to use 1734-VHSC5 and 1734-VHSC24 modules

Provides installation information about 1734-ARM modules

Provides installation information about 1734-232ASC and 1734-485ASC

modules

Describes how to use 1734-232ASC and 1734-485ASC modules

Provides installation information about 1734-IR2, 1734-IT2I, and 1734-IR2E

modules

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 8

xvi Preface

Resource Description

RTD and Isolated Thermocouple Input User Manual, publication

1734-UM004

Synchronous Serial Interface Encoder Module Installation Instructions,

publication 1734-IN581

Synchronous Serial Interface Encoder Module User Manual, publication

1734-UM007

Describes how to use 1734-IR2, 1734-IT2I, and 1734-IR2E modules

Provides installation information about 1734-SSI modules

Describes how to use 1734-SSI modules

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 9

Table of Contents

Preface

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 1

About the Modules

Install POINT I/O Modules

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Digital Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Output Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Relay Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Analog Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Output Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Specialty Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Power Supplies, Wiring Base Assemblies, and Miscellaneous Modules. 22

Chapter 2

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Install the Mounting Base Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Install an I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Install the Removable Terminal Block. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Remove a Mounting Base . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Wiring Digital Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

1734-IB2, 1734-IB4, and 1734-IB8 Sink Input Modules . . . . . . . . . 30

1734-IB4D Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

1734-IV2, 1734-IV4, and 1734-IV8 Source Input Modules . . . . . . 35

1734-OB2E, 1734-OB4E, 1734-OB8E, 1734-OB2,

1734-OB4, and 1734-OB8 Protected Output Modules . . . . . . . . . . 38

1734-OB2EP Protected Output Modules. . . . . . . . . . . . . . . . . . . . . . . 41

1734-OW2 and 1734-OW4 Relay Output Module s . . . . . . . . . . . . 42

1734-OW2 Modules with Load Powered by Internal Power Bus

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

1734-OW2 Modules with Load Powered by

External Power Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

1734-OW4 Modules with Load Powered by

External Power Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

1734-OV2E, 1734-OV4E, and 1734-OV8E

Sink Output Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

1734-OX2 2-relay Output Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

1734-OX2 Module with Load Powered by

Internal Power Bus Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 50

1734-OX2 Modules with Load Powered by External Power Bus

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 10

xviii

1734-IA2 and 1734-IA4 120 V AC Input Modules . . . . . . . . . . . . . 53

1734-IM2 and 1734-IM4 220V AC Input Modules . . . . . . . . . . . . . 55

1734-IM2 120V AC 2 Input Module Wiring Diagram . . . . . . . . . . 55

1734-IM4 2 Input Module Wiring Diagram . . . . . . . . . . . . . . . . . . . . 56

1734-OA2 and 1734- OA4 120/220V AC Output Modules . . . . . 57

1734-OA2 AC 2 Output Module Wiring Diagram. . . . . . . . . . . . . . 57

1734-OA4 AC 2 Output Module Wiring Diagram. . . . . . . . . . . . . . 58

Wiring Analog Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1734-IE2C Analog Current Input Module . . . . . . . . . . . . . . . . . . . . . 59

1734-IE2C Analog Current Input Module Wiring Diagram . . . . . 59

1734-IE2V Analog Voltage Input Module . . . . . . . . . . . . . . . . . . . . . . 60

1734-IE2V Analog Voltage Input Module Wiring Diagram. . . . . . 60

1734-OE2C Analog Current Output Module . . . . . . . . . . . . . . . . . . 61

1734-OE2C Analog Current Output Module

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

1734-OE2V Analog Voltage Output Module . . . . . . . . . . . . . . . . . . . 62

1734-OE2V Analog Voltage Output Module

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Wiring Power Distribution and Other Modules . . . . . . . . . . . . . . . . . . . . 63

1734-PDN Communication Interface Module. . . . . . . . . . . . . . . . . . 63

1734-PDN Module Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 63

1734-FPD Field Potential Distributor Module. . . . . . . . . . . . . . . . . . 65

1734-FPD Modules for 12/24V DC Wiring Diagram . . . . . . . . . . . 65

1734-EP24DC Expansion Power Supply . . . . . . . . . . . . . . . . . . . . . . . 68

12/24v DC Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

1734-EPAC AC Expansion Power Supply. . . . . . . . . . . . . . . . . . . . . . 71

120/240V AC Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

1734-ARM Address Reserve Module. . . . . . . . . . . . . . . . . . . . . . . . . . . 74

1734-CTM and 1734-VTM Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Sink Input Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Source Input Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Source Output Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Sink Output Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

General Purpose Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 11

Chapter 3

xix

Install POINTBlock I/O Modules

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Wiring POINTBlock Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

1734D-IB8XOB8 POINTBlock 8 DC In/8 DC Out Modules. . . 78

8 Input/8 Output Module Wiring Diagram . . . . . . . . . . . . . . . . . . . . 78

Sink Input Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Output Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

1734D-IB8XOW8 POINTBlock 8 DC In/8 Relay

Out Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8 Input/8 Relay Output Module Wiring Diagram. . . . . . . . . . . . . . . 82

Sink Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Output Wiring Diagram (Load Powered by

External Power) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

1734D-IA8XOA8 POINTBlock 8 AC In/8 AC Out Modules. . . 85

1734D-IA8XOA8 POINTBlock 8 AC In/8 AC Out Modules

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Input Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Output Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

1734D-IA8XOW8 POINTBlock 8 AC In/8 Relay

Out Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

1734D-IA8XOW8 POINTBlock 8 AC In/8 Relay

Out Modules Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Input Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Output Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

1734D-IA16 POINTBlock 16 AC Input Modules . . . . . . . . . . . . . . 91

Wire the 16 AC Input Module Wiring Diagram . . . . . . . . . . . . . . . . 91

Input Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

1734D-IB16 POINTBlock 16 DC Input Modules . . . . . . . . . . . . . . 94

16 DC Input Module Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 94

Sink Input Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 12

xx

Chapter 4

POINT I/O Module Data

About This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Digital Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Digital DC Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Digital AC Input Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Digital Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Digital DC Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Digital AC Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Relay Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Analog Input Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Communicate with Your Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Channel Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Latch Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Alarm Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Calibration Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Update Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Notch Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Range Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Channel Indicator Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Analog Output Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Operational Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Scaling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Fault and Idle/Program Mode Action . . . . . . . . . . . . . . . . . . . . . . . . . 113

Channel Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Low and High Clamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Latch Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Alarm Disable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Channel Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

POINTBlock I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 13

Chapter 5

xxi

Calibrate Your Analog Modules

Troubleshoot with the

Indicators

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Tools Required to Calibrate Your Analog Modules. . . . . . . . . . . . . . . . . 122

Calibrate the Analog Current Input Module. . . . . . . . . . . . . . . . . . . . . . . 123

Calibrate the Analog Current Output Module. . . . . . . . . . . . . . . . . . . . . 127

Calibrate the Analog Voltage Input Module . . . . . . . . . . . . . . . . . . . . . . . 132

Calibrate the Analog Voltage Output Module . . . . . . . . . . . . . . . . . . . . . 136

Chapter 6

About This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

About Module Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Network and Module Status Indications. . . . . . . . . . . . . . . . . . . . . . . 142

Troubleshoot Digital Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1734-IB2, 1734-IB4, and 1734-IB8 Sink Input Modules . . . . . . . . 144

1734-IB4D Sink Input Modules with Diagnostics . . . . . . . . . . . . . . 144

1734-OB2E, 1734-OB4E, and 1734-OB8E Source

Output Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

1734-OB2, 1734-OB4, and 1734-OB8 Source

Output Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

1734-OB2EP Protected Output Module . . . . . . . . . . . . . . . . . . . . . . 146

1734-IV2, 1734-IV4, and 1734-IV8 Source Input Modules . . . . . 146

1734-OV2E, 1734-OV4E, and 1734-OV8E

Protected Sink Output Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

1734-OW2 and 1734-OW4 Relay Output Modules. . . . . . . . . . . . 148

1734-OX2 Relay Output Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

1734-IA2 and 1734-IA4 120V AC Input Module . . . . . . . . . . . . . . 149

1734-OA2 and 1734-OA4 120/220V AC Output Module . . . . . 150

1734-IM2 and 1734-IM4 220V AC Input Module . . . . . . . . . . . . . 150

Troubleshoot Analog Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

1734-IE2C Analog Current Input Module . . . . . . . . . . . . . . . . . . . . 151

1734-OE2C Analog Current Output Module . . . . . . . . . . . . . . . . . 152

1734-IE2V Analog Voltage Input Module . . . . . . . . . . . . . . . . . . . . . 152

1734-OE2V Analog Voltage Output Module. . . . . . . . . . . . . . . . . . 153

Troubleshoot I/O Communication Modules . . . . . . . . . . . . . . . . . . . . . . 154

1734-ADN (X) DeviceNet Adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . 155

1734-ACNR ControlNet Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

1734-APB PROFIBUS Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

1734-AENT EtherNet/IP Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 14

xxii

Appendix A

Default Data Maps

About This Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 165

Digital Module Default Data Maps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

1734-IB2 Sink Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

1734-IB4 Sink Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

1734-IB8 Sink Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

1734-IB4D Sink Input Modules with Diagnostics. . . . . . . . . . . . . . 167

1734-IV2 Source Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

1734-IV4 Source Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

1734-IV8 Source Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 168

1734-IA2 Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

1734-IA4 Input Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

1734-IM2 Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

1734-IM4 Input Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

1734-OA2 Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

1734-OA4 Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

1734-OB2E, 1734-OB2 Electronically Protected

Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 170

1734-OB4E, 1734-OB4 Electronically Protected

Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

1734-OB8E, 1734-OB8 Electronically Protected

Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

1734-OB2EP Protected Output Module . . . . . . . . . . . . . . . . . . . . . . 171

1734-OV2E Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

1734-OV4E Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

1734-OV8E Output Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

1734-OW2 Relay Sink/Source Output Module. . . . . . . . . . . . . . . . 173

1734-OW4 Relay Sink/Source Output Module. . . . . . . . . . . . . . . . 173

1734-OX2 Relay Output Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

Analog Module Default Data Maps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

1734-IE2C Analog Current Input Module . . . . . . . . . . . . . . . . . . . . 174

1734-IE2V Analog Voltage Input Module . . . . . . . . . . . . . . . . . . . . . 175

1734-OE2C Analog Current Output Module . . . . . . . . . . . . . . . . . 175

1734-OE2V Analog Voltage Output Module . . . . . . . . . . . . . . . . . . 176

Appendix B

Mounting Dimensions

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

About This Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

POINT I/O Module with a 1734-ADN, 1734-ACNR,

1734-AENT, or 1734-APB Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

POINT I/O Module with a 1734-PDN Module. . . . . . . . . . . . . . . . . . . 181

POINTBlock Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Page 15

Appendix C

xxiii

Configure POINT I/O Modules in

RSLogix 5000 Software

About This Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Use the Help Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Configure Digital Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

Configure Analog Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

Appendix D

Configure POINT I/O Modules

for DeviceNet Networks

About This Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Configuring POINT I/O Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Commissioning a Node . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

Configure Digital Modules Using RSNetWorx Software . . . . . . . . . . . 213

Configure Analog Modules Using RSNetWorx Software . . . . . . . . . . . 227

About Fault/Program Action and Configuration Dialogs . . . . . . . 186

Understanding Data and Connection Formats . . . . . . . . . . . . . . . . . 186

Understanding Transition to Hard Run Behavior . . . . . . . . . . . . . . 187

Working with Dialogs for Digital Input Modules. . . . . . . . . . . . . . . 188

Working with Dialogs for Digital Output Modules. . . . . . . . . . . . . 190

Understanding Data and Connection Formats . . . . . . . . . . . . . . . . . 196

Working with Dialogs for Analog Input Modules . . . . . . . . . . . . . . 197

Working with Dialogs for Analog Output Modules . . . . . . . . . . . . 203

Using the RSNetWorx Commissioning Tool . . . . . . . . . . . . . . . . . . 211

Use Sequential Auto Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

Using Third-party Configuration Software . . . . . . . . . . . . . . . . . . . . 213

Index

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 16

xxiv

Notes:

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 17

About the Modules

Chapter

1

About This Chapter

Digital Modules

This chapter introduces POINT I/O and related modules to include the

following:

• Digital modules

• Relay output modules

• Analog modules

• Specialty modules

• Power supplies, wiring base assemblies, and miscellaneous modules

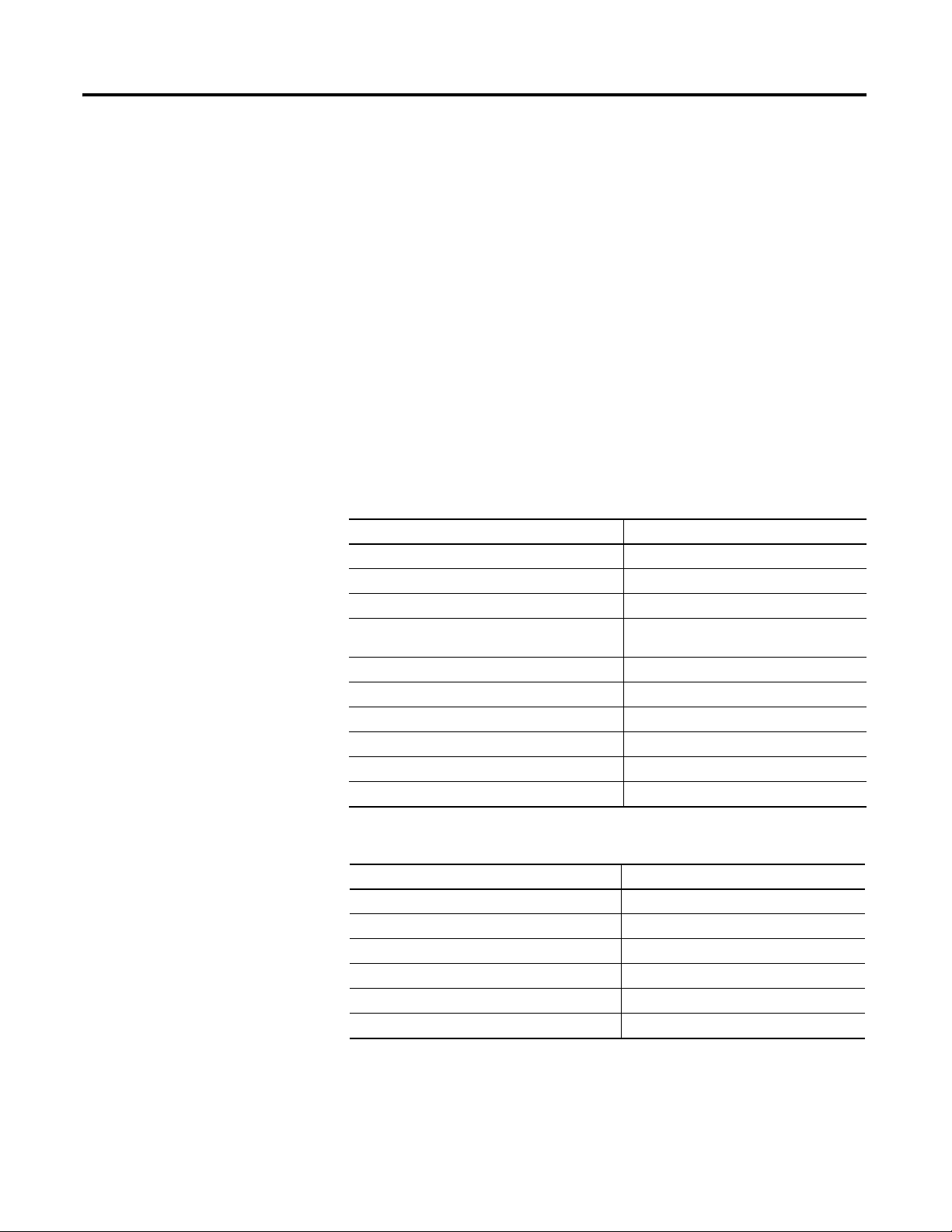

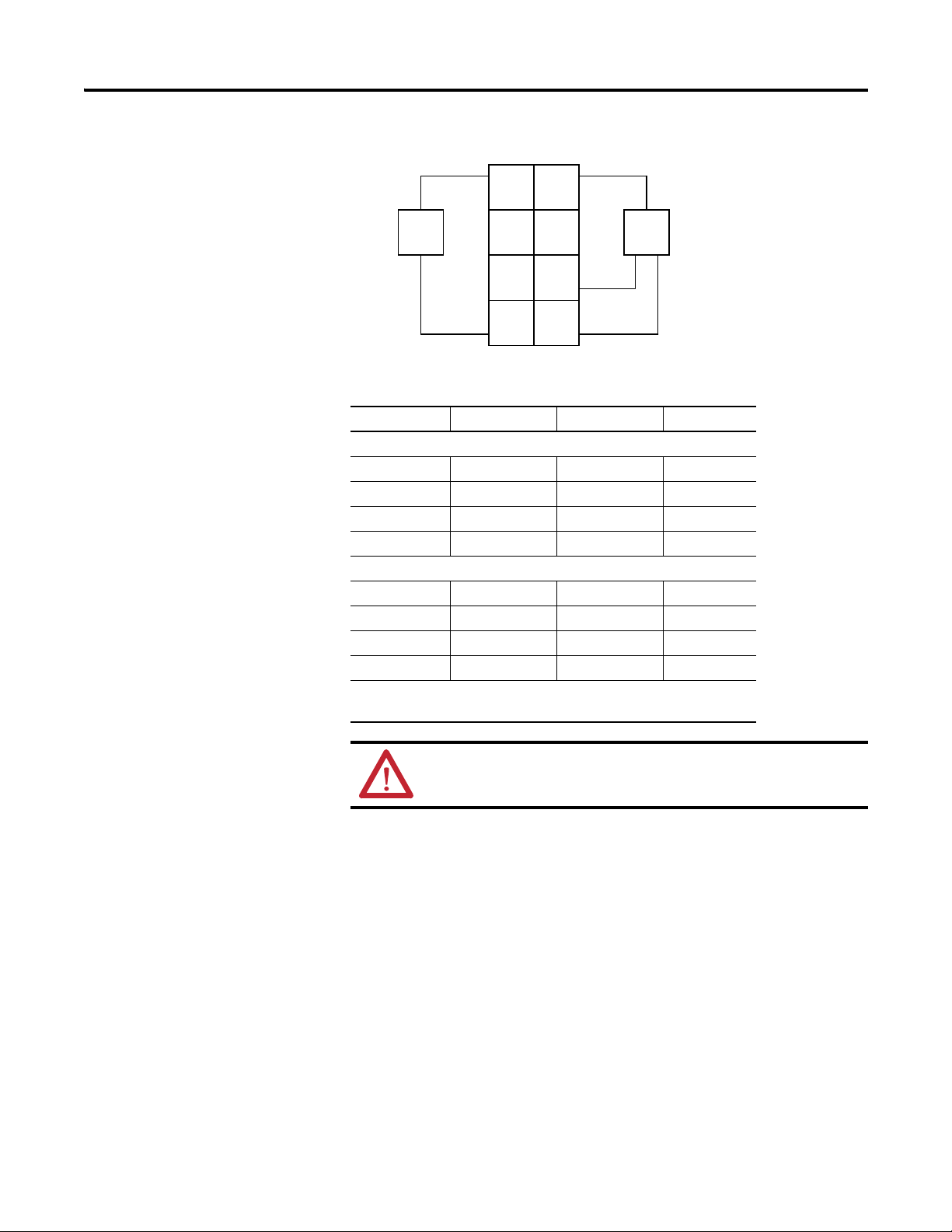

This table lists the1734 digital modules.

Digital Module Description Cat. No.

2, 4, and 8 sink input modules 1734-IB2, 1734-IB4, 1734-IB8, 1734-IB4D

2, 4, and 8 source input modules 1734-IV2, 1734-IV4, 1734-IV8

2, 4, and 8 sink output modules 1734-OV2E, 1734-OV4E, 1734-OV8E

2, 4, and 8 protected

source output modules

2 protected source output modules 1734-OB2EP

2 and 4 relay output modules 1734-OW2, 1734-OW4

2 relay output modules 1734-OX2

2 120/220V AC output modules 1734-OA2, 1734-OA4

2 120V AC input modules 1734-IA2, 1734-IA4

2 240V AC input modules 1734-IM2, 1734-IM4

1734-OB2, 1734-OB4, 1734-OB8,

1734-OB2E, 1734-OB4E, 1734-OB8E

This table lists the 1734D POINTBlock modules.

POINTBlock Module Description Cat. No.

8 AC input and 8 AC output 1734D-IA8XOA8 and 1734-IA8XOA8S

8 AC input and 8 relay output 1734D-IA8XOW8 and 1734-IA8XOW8S

8 DC input and 8 DC output 1734D-IB8XOB8 and 1734-IB8XOB8S

8 DC input and 8 relay output 1734D-IB8XOW8 and 1734-IB8XOW8S

16 AC input 1734D-IA16 and 1734-IA16S

16 DC input 1734D-IB16 and 1734-IB16S

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 18

2 About the Modules

Input Modules

For input modules, DC inputs are 24V DC nominal, with an input range of

10…28.8V dc, and are offered with 2, 4,or 8 sinking style inputs, or 2, 4, or 8

sourcing style inputs. The 1734-IB2, 1734-IB4, 1734-IB4D, and 1734-IB8 input

modules are sinking modules. The 1734-IV2, 1734-IV4, and 1734-IV8 modules

are sourcing input modules.

For input modules, AC inputs are 120V AC nominal with an input range of

85…132V ac, or 220V AC nominal with an input range of 159…264V ac, with

sinking inputs.

Features of the all input modules include the following:

• Autobaud (will match baud of existing devices on the network)

• Selectable input filter times (0…65 ms with 1 ms default)

• Sequential auto addressing

Output Modules

The 1734-OB2, 1734-OB4, 1734-OB8, 1734-OB2E, 1734-OB4E, and 1734-

OB8E DC output modules have current limited sourcing outputs, which source a

positive voltage of up to 1 A with respect to their DC return per channel. The

1734-OB2EP sources a positive voltage of up to 2 A with respect to its DC

return per channel. The outputs are not isolated from each other. For these

modules, DC outputs are 24V DC nominal, with a range of 10…28.8V dc. A

number of output diagnostic features are incorporated to assist in

troubleshooting. The 1734-OB2E, 1734-OB2EP, 1734-OB4E, and 1734-OB8E

modules feature the following:

• Output diagnostics (short circuit and wire-off indication and reporting

bits per channel)

• Current limited outputs

• Autobaud (will match baud of existing devices on the network)

• Sequential auto addressing

The 1734-OV2E, 1734-OV4E, and 1734-OV8E modules are protected sink

output modules protected to 1 A. The outputs are not isolated from each other.

For these modules, DC outputs are 24V DC nominal, with a range of 10…28.8V

dc. A number of output diagnostic features are incorporated to assist in

troubleshooting. The 1734-OV2E, 1734-OV4E, and 1734-OV8E modules

feature the following (note that 1734-OV2E, 1734-OV4E, and 1734-OV8E

modules have no wire-off indication):

• Output diagnostics (short circuit and reporting bits per channel)

• Current limited outputs

• Autobaud (will match baud of existing devices on the network)

• Sequential auto addressing

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 19

About the Modules 3

The 1734-OA2 and 1734-OA4 AC output modules have sourcing outputs,

which source a voltage of up to 0.75 A per channel. The outputs are not isolated

from each other. For this module, AC outputs are 120/220V AC nominal, with a

range of 74…264V dc. The 1734-OA2 and 1734-OA4 modules feature the

following:

• Autobaud (will match baud of existing devices on the network)

• Sequential auto addressing

Relay Output Modules

Two versions of relay modules are:

• 1734-OW2, 1734-OW4 relay module.

• 1734-OX2 relay module.

The 1734-OW2 and 1734-OW4 relay outputs are Type A (Normally Open),

the 1734-OX2 relay outputs are Type 2 Form C. Both modules’ outputs sink or

source a current with respect to power or return. Contact outputs are isolated

from each other. Each output is rated 5…240V rms at 2 A (current is load

dependant). Features include:

• Autobaud (will match baud of existing devices on the network).

• Sequential auto addressing.

Analog Modules

The 1734 analog modules consist of input modules (1734-IE2C and 1734IE2V) and output modules (1734-OE2C and 1734-OE2V). Each module has

two single-ended, non-isolated channels.

Cat. No. Module Type Number of

Channels

1734-IE2C Analog Input 2 16 bits across 0…21 mA

1734-IE2V Analog Input 2 15 bits plus sign across -10…10V

1734-OE2C Analog Output 2 13 bits across 0…21 mA

1734-OE2V Analog Output 2 14 bits across -10…10V

Resolution

The features of the analog modules depend on the type of analog module: input

or output. These are features common to both input and output modules.

• Data - The current input and output modules operate in unipolar mode

only. Voltage input and output modules operate in unipolar or bipolar

modes. Data returned from the module is scaled by the user to any 16 bit

signed integer

(–32,768...+32,767).

• Input modules produce 6 bytes of data.

– Channel 0 Data (2 bytes)

– Channel 1 Data (2 bytes)

– Channel 0 Status (1 byte)

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 20

4 About the Modules

– Channel 1 Status (1 byte)

• Output modules consume 4 bytes of data.

– Channel 0 Data (2 bytes)

– Channel 1 Data (2 bytes)

• Output modules produce 2 bytes of data.

– Channel 0 Status (1 byte)

– Channel 1 Status (1 byte)

• Operational modes

– Current - two modes

• 0 to 20 mA

• 4 to 20 mA (default mode)

– Vol ta ge - t wo m ode s

• 0 to 10V (default mode)

• -10 to +10V

• Individually set channel mode

• Scaling - conversion to engineering units

Input Modules

These features are available on input modules.

• Latching alarms, when set, latch low- and high-alarm status information.

Available alarms include:

– Low.

– Low Low.

– High.

– High High.

• Disable alarms - disables all channel alarms and faults so they are not

reported in the channel status field. Four different alarms are available.

• Settable update rate update rate determines how often an input channel is

scanned.

• Notch filter is selectable for both inputs (50, 60, 250, and

500 Hz).

• Digital filter sets a time constant.

Output Modules

These are features available on output modules.

• Latching alarms, when set, latch low and high clamp alarm status

information.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 21

About the Modules 5

• Low and high clamps can be set individually or on a channel basis. When

the output value reaches clamp value, a status bit is set, indicating the

output is clamped.

• Disable alarms - disables all channel alarms and faults so they are not

reported in the channel status field.

• Fault and Idle mode action let you select what happens to the output if

a fault occurs or if the module is in idle mode. The choices are the

following:

– Hold Last State

– Low Clamp

– High Clamp

– User-defined va lue

Specialty Modules

Power Supplies, Wiring Base Assemblies, and Miscellaneous Modules

For more information about the following 1734 specialty modules, refer to the

installation instructions and user manuals listed in the Related Products and

Documentation section of this manual.

Module Description Cat. No.

5V Encoder/Counter Module 1734-IJ

24V Encoder/Counter Module 1734-IK

24V Very High-speed Counter Module 1734-VHSC24

5V Very High-speed Counter Module 1734-VHSC5

ASCII RS-232 and RS-485 Module 1734-232ASC, 1734-485ASC

Isolated Thermocouple Input Module 1734-IT2I

RTD Input Module 1734-IR2, 1734-IR2E

Synchronous Serial-interface Encoder Module 1734-SSI

For more information about the following, refer to the installation instructions

and user manuals listed in the Related Products and Documentation section of

this manual.

Module Description Cat. No.

Cold-junction Wiring Base Assembly 1734-TBCJC

Field Potential Distributor 1734-FPD

POINT I/O 24V DC Expansion Power Supply 1734-EP24DC

POINT I/O Common Terminal Module 1734-CTM

POINT I/O Voltage Terminal Module 1734-VTM

Wiring Base Assembly 1734-TB, 1734-TBS,

1734-TB3, 1734-TB3S,

1734-TOP, 1734-TOPS,

1734-TOP3, 1734-TOP3S

Address Reserve Module 1734-ARM

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 22

6 About the Modules

Notes:

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 23

Install POINT I/O Modules

Chapter

2

About This Chapter

Read this chapter for installation and wiring information including how to

complete the following:

• Install the mounting base assembly.

• Install an I/O module.

• Install the removable terminal block.

• Remove a mounting base.

• Wire digital modules.

• Wire analog modules.

• Wire power distribution and other modules, such as communication

interface modules, field potential distributor modules, expansion power

supplies, and addressable reserve modules.

Environment and Enclosure

ATTENTION:

This equipment is intended for use in a Pollution Degree 2 industrial

environment, in overvoltage Category II applications (as defined in IEC

publication 60664-1), at altitudes up to 2000 m (6561 ft) without derating.

This equipment is considered Group 1, Class A industrial equipment

according to IEC/CISPR Publication 11. Without appropriate precautions,

there may be potential difficulties ensuring electromagnetic compatibility

in other environments due to conducted as well as radiated disturbance.

This equipment is supplied as open-type equipment. It must be mounted

within an enclosure that is suitably designed for those specific

environmental conditions that will be present and appropriately designed

to prevent personal injury resulting from accessibility to live parts. The

interior of the enclosure must be accessible only by the use of a tool.

Subsequent sections of this publication may contain additional information

regarding specific enclosure type ratings that are required to comply with

certain product safety certifications.

See NEMA Standards publication 250 and IEC publication 60529, as

applicable, for explanations of the degrees of protection provided by

different types of enclosure. Also, see the appropriate sections in this

publication, as well as the Allen-Bradley publication 1770-4.1 (Industrial

Automation Wiring and Grounding Guidelines), for additional installation

requirements pertaining to this equipment.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 24

8 Install POINT I/O Modules

ATTENTION: POINT I/O is grounded through the DIN rail to chassis

ground. Use zinc-plated, yellow-chromated steel DIN rail to assure

proper grounding. The use of DIN rail materials (for example, aluminum

or plastic) that can corrode, oxidize, or are poor conductors, can result in

improper or intermittent grounding.

Secure DIN rail to mounting surface approximately every 200 mm

(7.8 in.).

Explosion Hazard

WARNING:

• Do not disconnect equipment unless power has been removed or the

area is known to be nonhazardous.

• Do not disconnect connections to this equipment unless power has been

removed or the area is known to be nonhazardous. Secure any external

connections that mate to this equipment by using screws, sliding

latches, threaded connectors, or other means provided with this product.

• Substitution of components may impair suitability for Class I, Division 2.

• If this product contains batteries, they must only be changed in an area

known to be nonhazardous.

Prevent Electrostatic Discharge

ATTENTION: This equipment is sensitive to electrostatic discharge,

which can cause internal damage and affect normal operation. Follow

these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe packaging when not in

use.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 25

Install POINT I/O Modules 9

24VDC

Source

Output

Module

Status

Network

Status

1734

OB4E

NO

DE:

0

1

2

3

5

9

1

1

10

3

4

8

2

46145

6

7

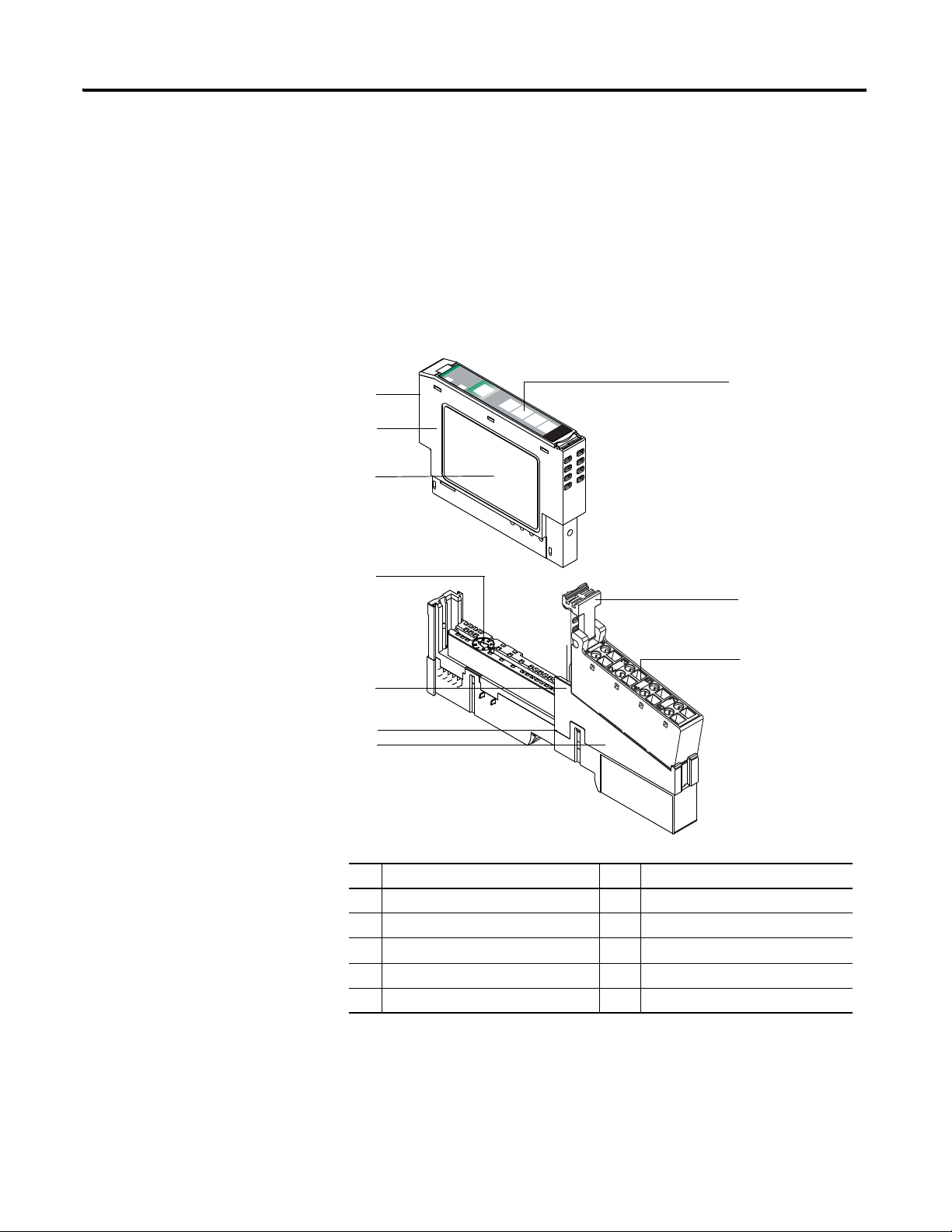

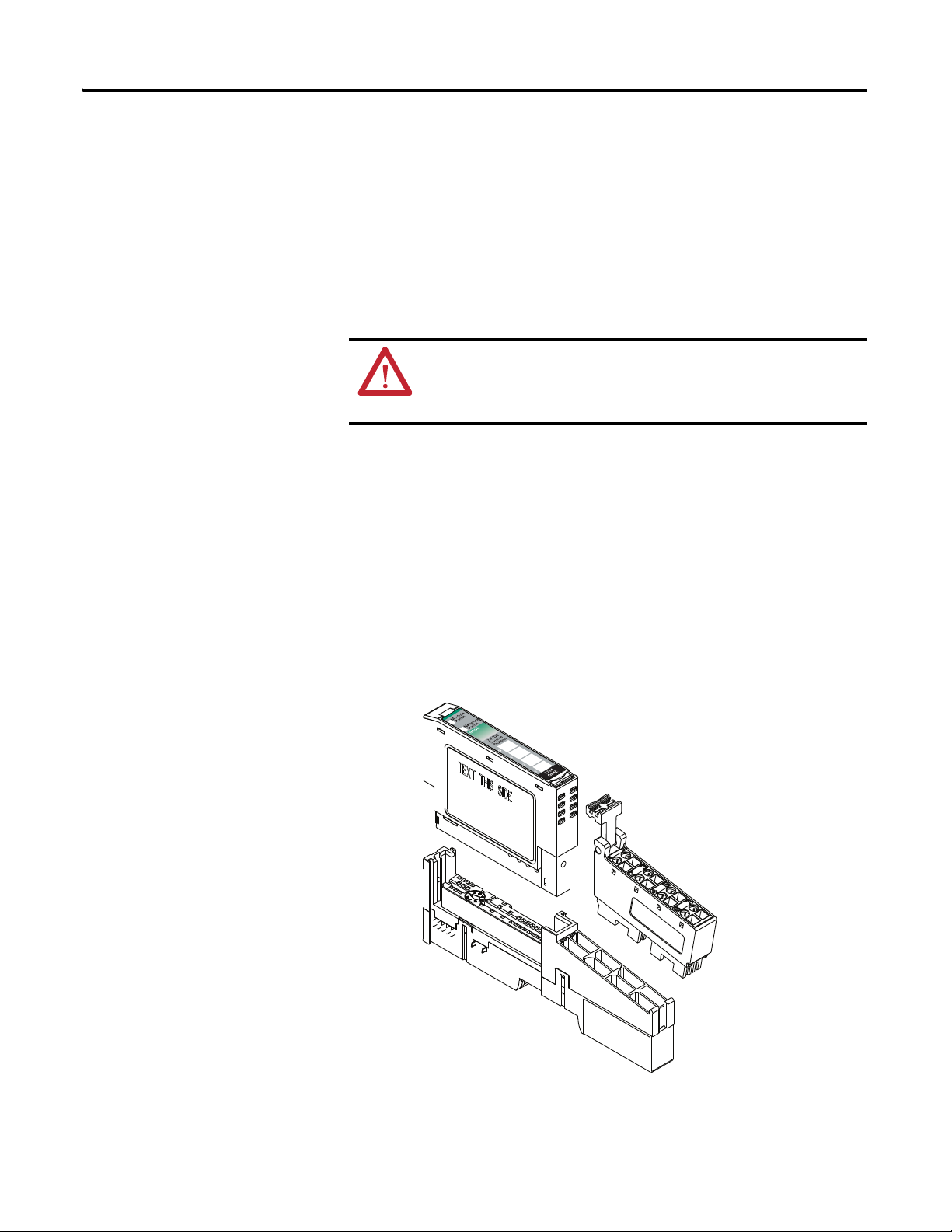

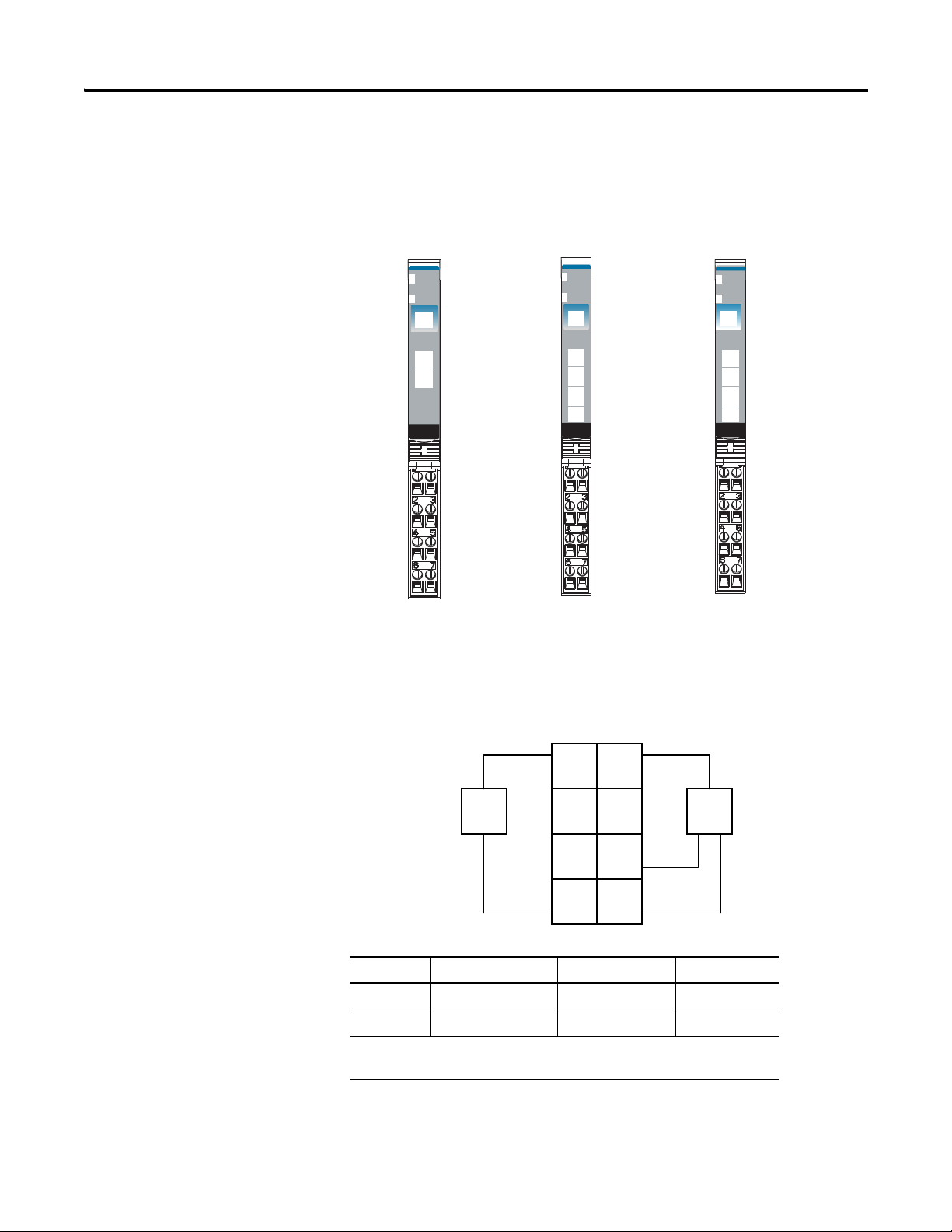

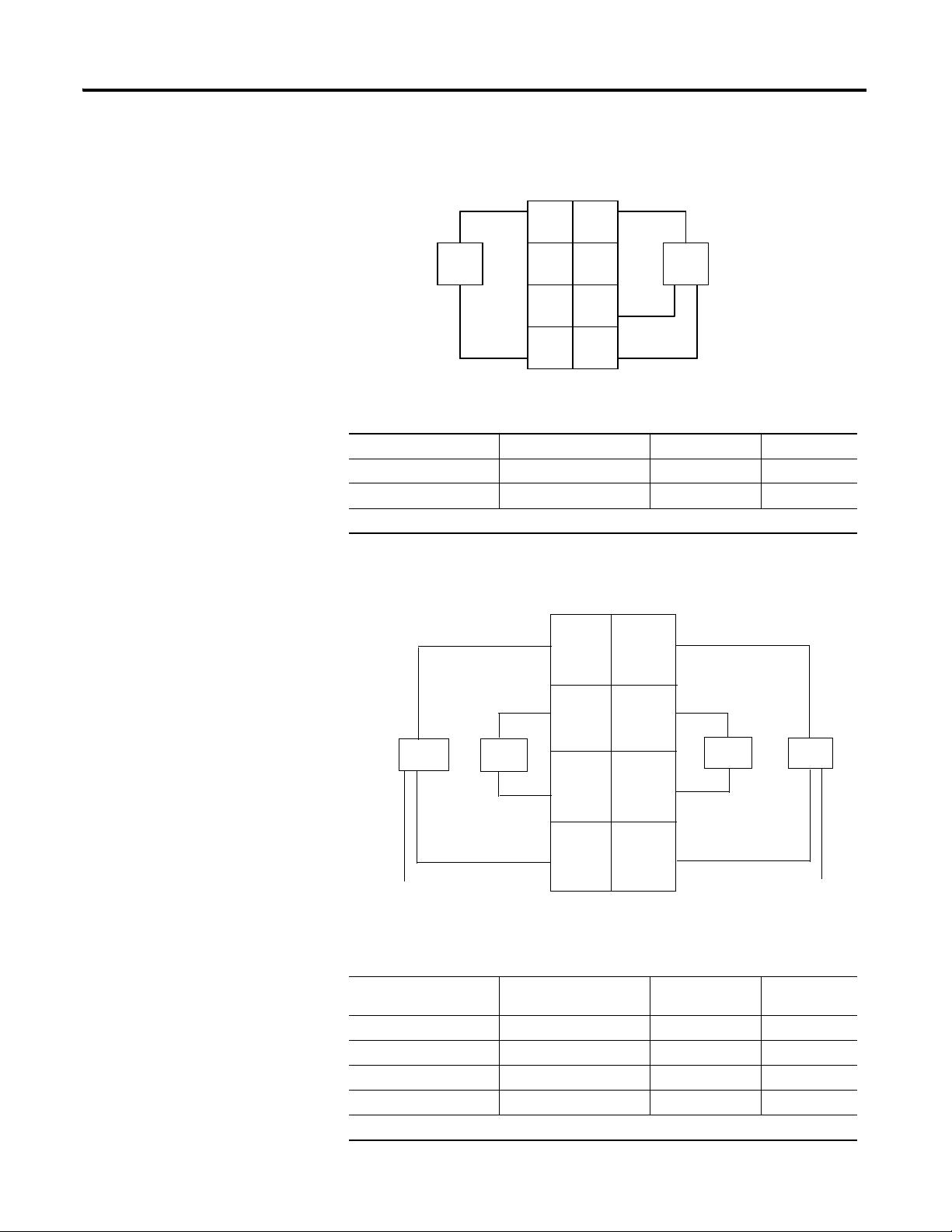

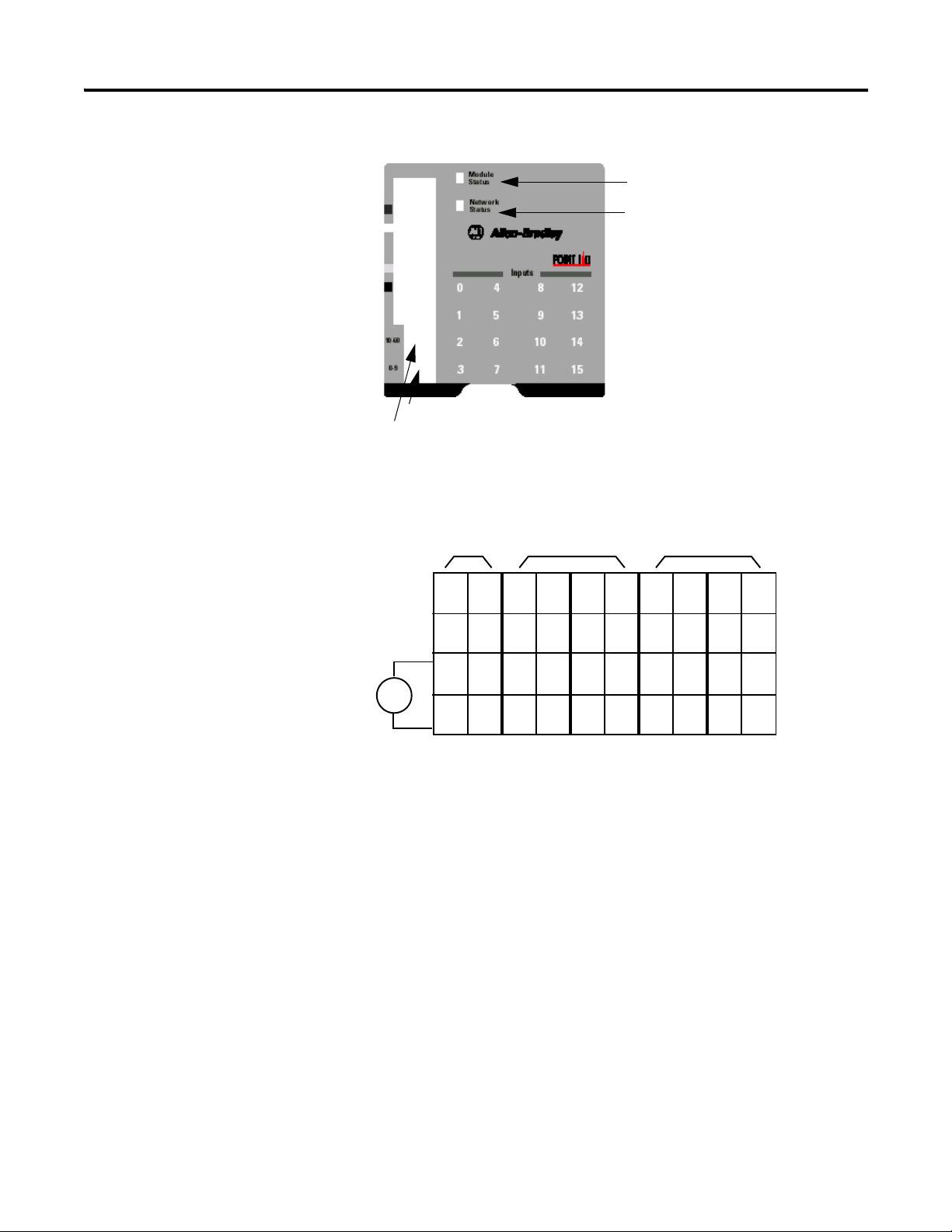

Install the Mounting Base Assembly

The 1734-TB, 1734-TBS, 1734-TB3, or 1734-TB3S wiring base assembly

consists of a 1734-MB mounting base and a 1734-RTB or 1734-RTBS removable

terminal block.

An alternative is the 1734-TOP, 1734-TOPS, 1734-TOP3, or 1734-TOP3S

POINT I/O one-piece terminal base.

Refer to the figures that show these wiring bases.

To install the mounting base assembly on the DIN rail, proceed as follows.

Description Description

1 Module Locking Mechanism 2 Slide-in Writable Label

3 RTB Removing Handle 4 Removable Terminal Block (RTB)

5 Mounting Base 6 Interlocking Side Pieces

7 DIN Rail Locking Screw (orange) 8 Mechanical Keying (orange)

9 Module Wiring Diagram 10 Insertable I/O Module

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 26

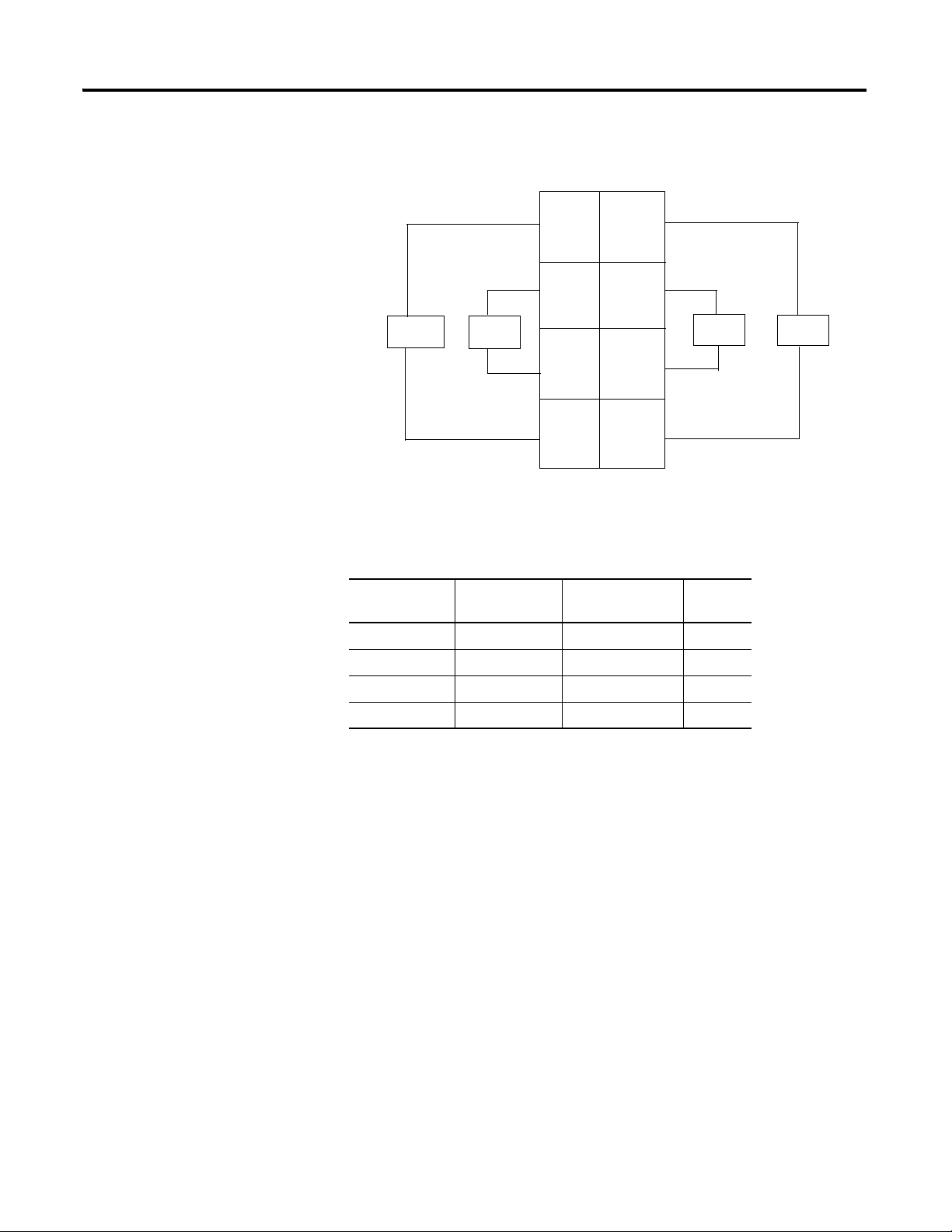

10 Install POINT I/O Modules

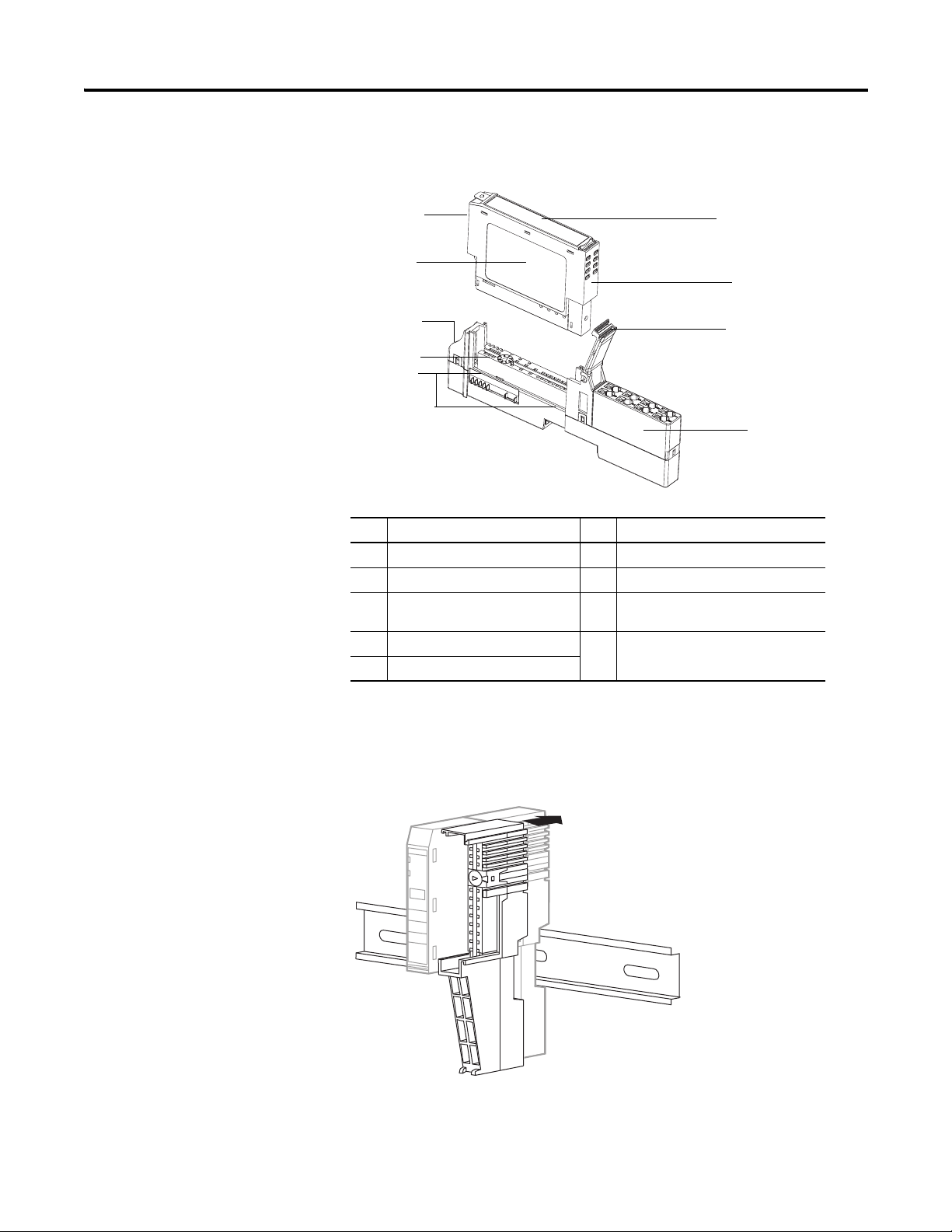

46116

5

3

1

2

8

9

7

4

6

46117

Description Description

1 Module Locking Mechanism 2 Slide-in Writable Label

3 Insertable I/O Module 4 Handle

5 One-piece Terminal Base with

Screw or Spring Clamp

7 Mechanical Keying (orange) 8 DIN Rail Locking Screw (orange)

9 Module Wiring Diagram

6 Interlocking Side Pieces

1. Position the mounting base (wiring base assembly) vertically above the

installed units (adapter, power supply, or existing module).

2. Slide the mounting base down, allowing the interlocking side pieces to

engage the adjacent module, power supply, or adapter.

3. Press firmly to seat the mounting base on the DIN rail.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 27

Install POINT I/O Modules 11

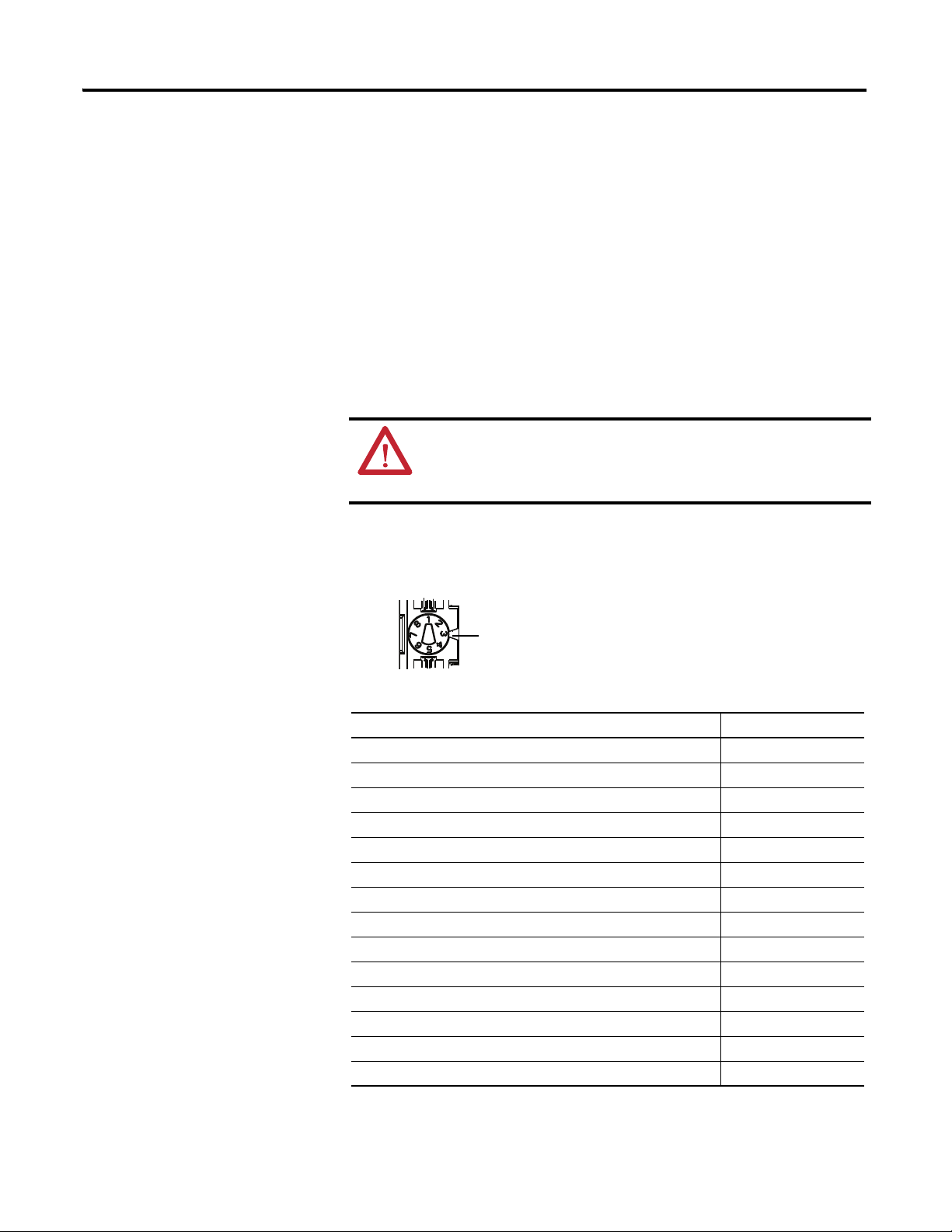

Notch Position 3 is shown

46148

The mounting base snaps into place.

4. To remove the mounting base from the DIN rail, remove any installed

module (and any module immediately to the right), and use a small-bladed

screwdriver to rotate the DIN-rail locking screw to a vertical position and

release the locking mechanism.

5. Lift straight up to remove the mounting base.

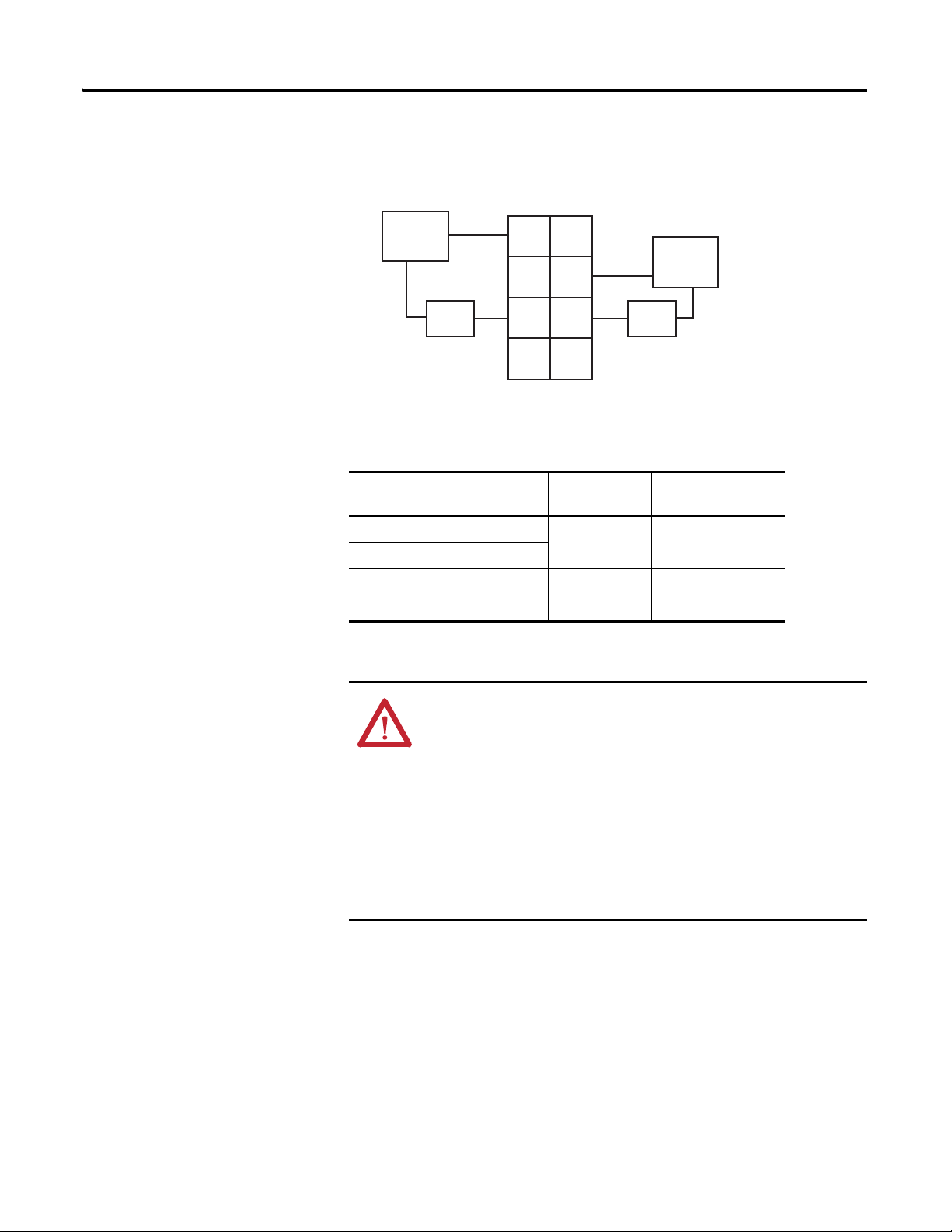

Install an I/O Module

Install the module before or after base installation. Make sure that the mounting

base is correctly keyed before installing the module into the mounting base. In

addition, make sure the mounting base locking screw is positioned horizontal

referenced to the base.

WARNING: When you insert or remove the module while

backplane power is on, an electrical arc can occur. This could cause

an explosion in hazardous location installations. Be sure that power

is removed or the area is nonhazardous before proceeding.

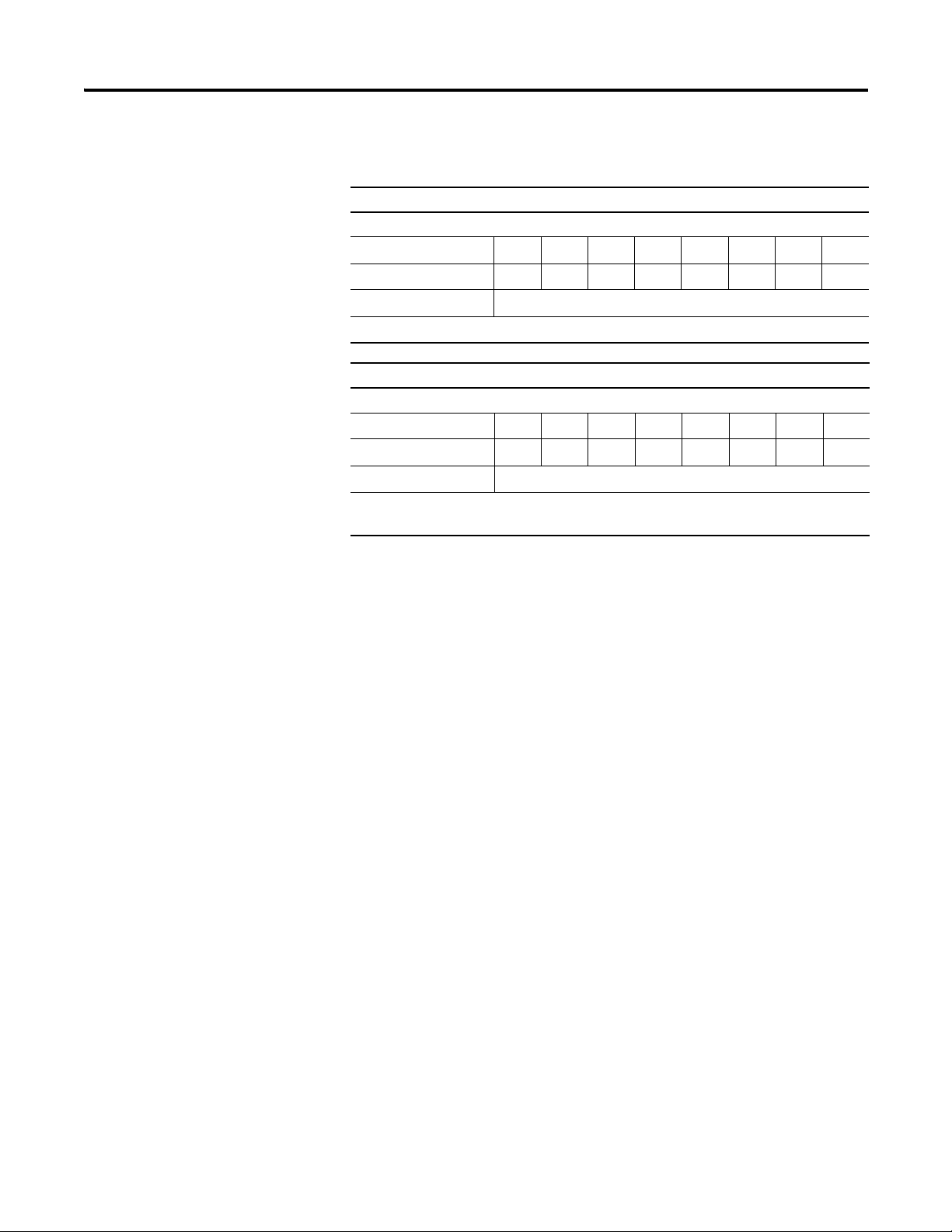

1. Using a bladed screwdriver, rotate the keyswitch on the mounting base

clockwise until the number required for the type of module aligns with the

notch in the base.

Module Keyswitch Position

1734-ARM

1734-CTM, 1734-VTM 5

1734-IA2, 1734-IA4 8

1734-IB2,1734-IB4, 1734-IB8 1

1734-IE2C, 1734-IE2V 3

1734-IM2, 1734-IM4 8

1734-IV2, 1734-IV4, 1734-IV8 1

1734-OA2, 1734-OA4 8

1734-OB2, 1734-OB4, 1734-OB8, 1734-OB2E, 1734-OB4E, 1734-OB8E 1

1734-OB2EP 1

1734-OE2C, 1734-OE2V 4

1734-OV2E, 1734-OV4E, 1734-OV8E 1

1734-OW2, 1734-OW4 7

1734-OX2 7

(1)

–

(1) Use the same keyswitch position as the removed module.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 28

12 Install POINT I/O Modules

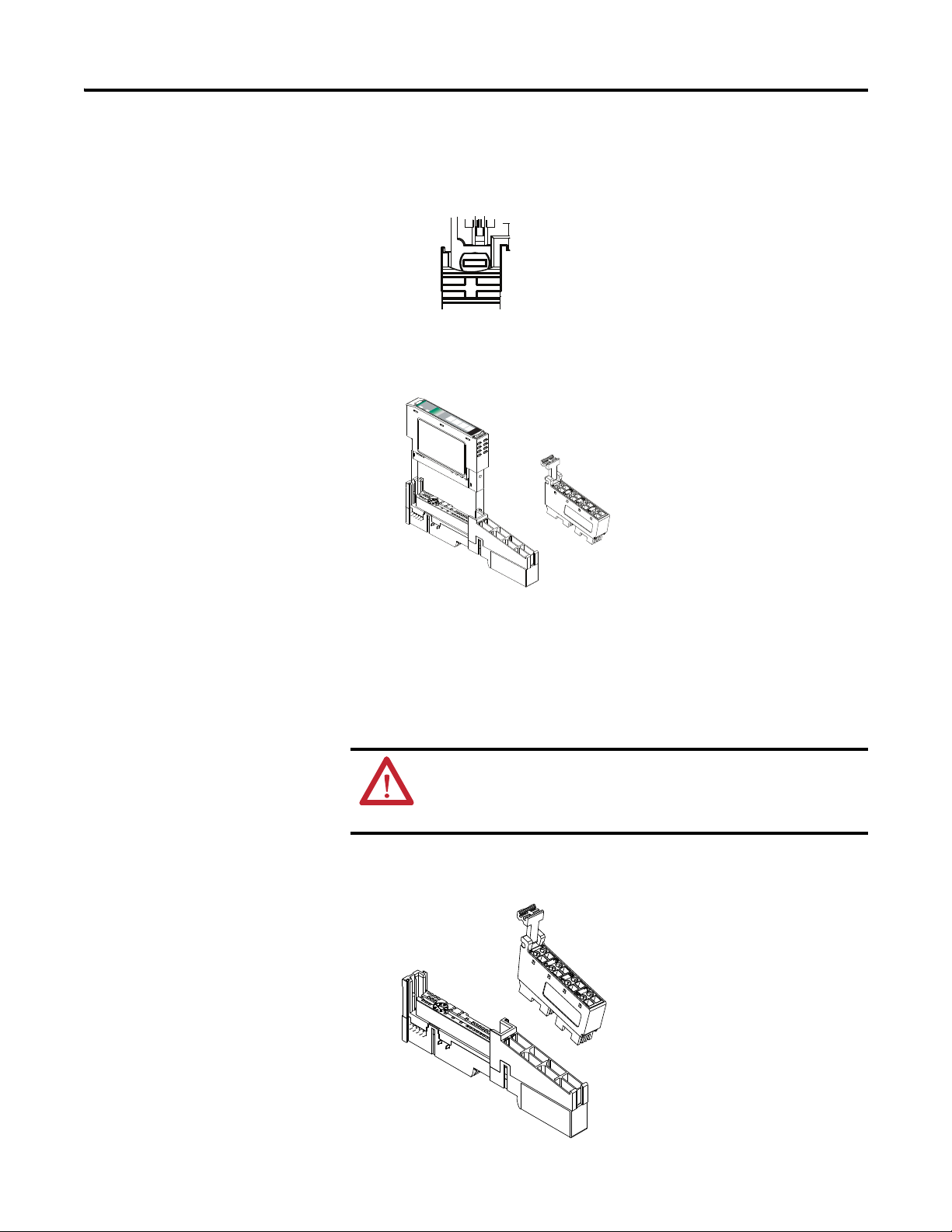

46149

46150

2. Make certain the DIN-rail locking screw is in the horizontal position,

noting that you cannot insert the module if the locking mechanism is

unlocked.

3. Insert the module straight down into the mounting base and press to

secure, locking the module into place.

dule

Mo

k

Status

or

Netw

Status

NODE:

C

D

t

rce

u

u

24V

So

Outp

0

1

2

4

3

3

17

OB4E

Install the Removable Terminal Block

A removable terminal block is supplied with your mounting base assembly. To

remove, pull up on the removable terminal block (RTB) handle. This lets you

remove and replace the base as necessary without removing any of the wiring. To

reinsert the removable terminal block, proceed as follows.

WARNING: When you connect or disconnect the RTB with field-side

power applied, an electrical arc can occur. This could cause an explosion

in hazardous location installations. Be sure to remove power or that the

area is nonhazardous before proceeding.

1. Insert the RTB end opposite the handle into the base unit.

This end has a curved section that engages with the mounting base.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 29

Install POINT I/O Modules 13

30880

2. Rotate the terminal block into the mounting base until it locks itself in

place.

3. If an I/O module is installed, snap the RTB handle into place on the

module.

Remove a Mounting Base

To remove a mounting base, you must remove any installed module, and remove

the removable terminal block (RTB), if wired.

WARNING: When you insert or remove the module while backplane

power is on, an electrical arc can occur. This could cause an explosion in

hazardous location installations. Be sure to remove power or that the

area is nonhazardous before proceeding.

1. Unlatch the RTB handle on the I/O module.

2. Pull on the RTB handle to remove the RTB.

3. Press in on the module lock on the top of the module, and pull up on the

I/O module to remove it from the base.

4. Remove the module to the right of the base you are removing, noting that

the interlocking portion of the base sits under the adjacent module.

5. Use a small-bladed screwdriver to rotate the orange DIN-rail locking screw

on the mounting base to a vertical position, noting that this releases the

locking mechanism.

6. Lift the mounting base straight up to remove.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 30

14 Install POINT I/O Modules

24VDC

Sink

Input

Module

Status

Network

Status

1734

IB2

NODE:

0

1

24VDC

Sink

Input

Module

Status

Network

Status

1734

IB4

NODE:

0

1

2

3

Status of Input 0

Status of Input 1

Input 0

NC

C

V

Input 1

NC

C

V

Input = 0 and 1

NC = No Connection (2 and 3)

C = Common (4 and 5)

V = Supply (6 and 7)

Input 0

C

V

Input 1

C

V

Input 2 Input 3

Status of Input 2

Status of Input 3

Input = 0, 1, 2 and 3

C = Common (4 and 5)

V = Supply (6 and 7)

1734-IB2

1734-IB4 1734-IB8

Input 0

Input 1

Input 2 Input 3

Input 4

Input 5

Input 6 Input 7

Input = 0, 1, 2, 3, 4, 5, 6 and 7

V and C are daisychained from either the adapter,

1734-FPD module, 1734-EP24DC power supply, or a

user-supplied auxiliary terminal block.

Status of Input 0

Status of Input 1

Status - Input 0 & 4

Status - Input 1 & 5

Status - Input 2 & 6

Status - Input 3 & 7

Prox

In 0 In 1

NC

C

VV

C

NC

Prox

V = 12/24V DC

C = Common

3-wire

Sink Input

2-wire

3

5

7

01

2

4

6

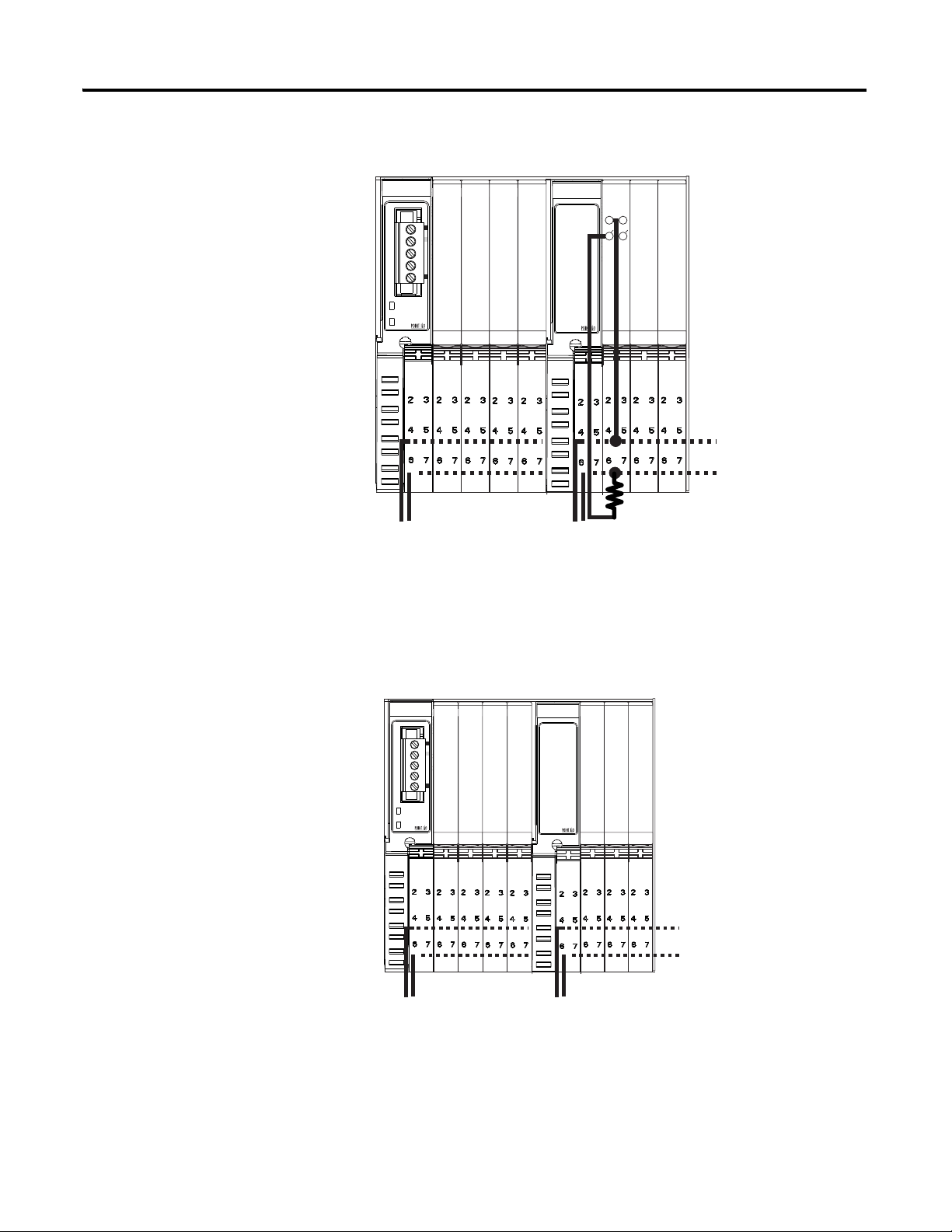

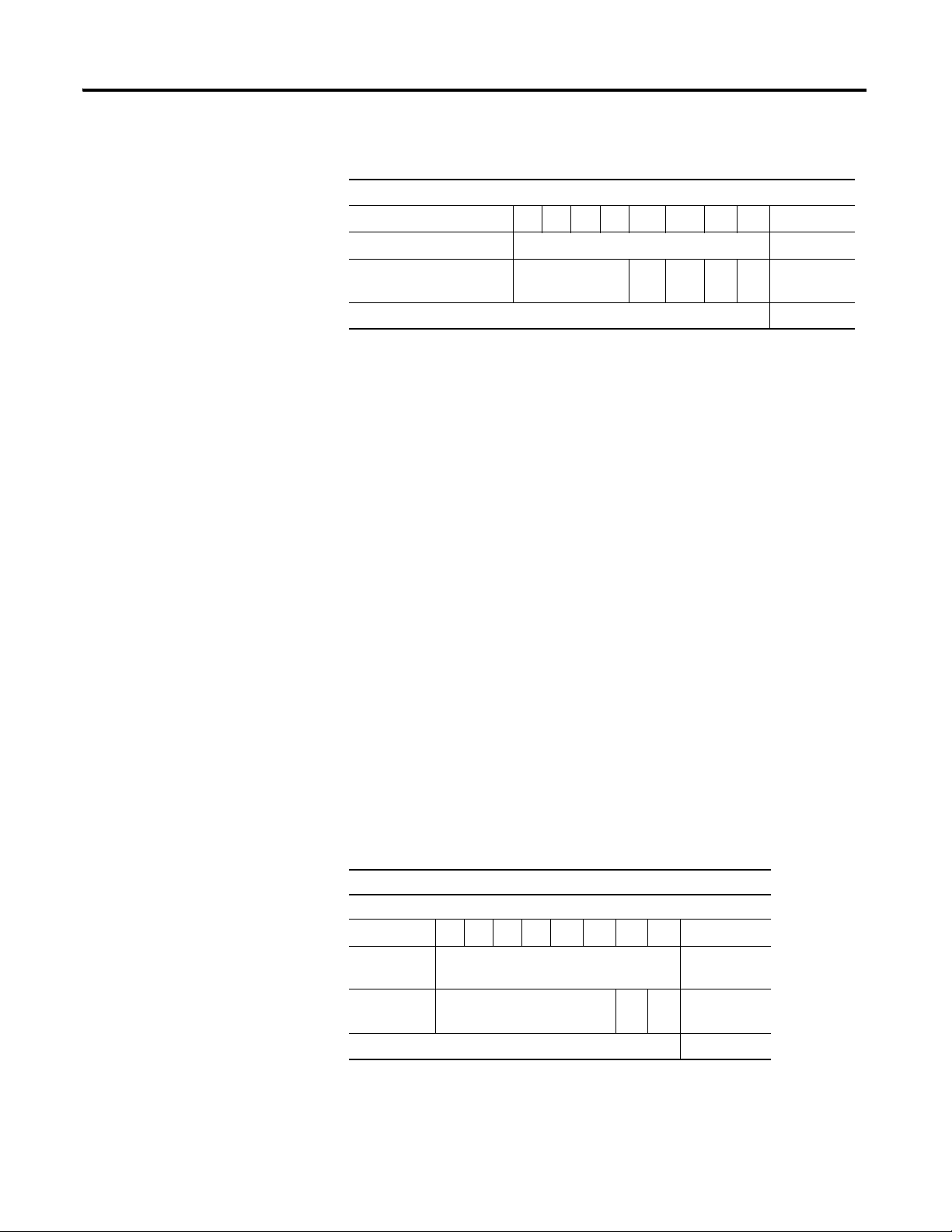

Wiring Digital Modules

Refer to this section to wire digital modules.

1734-IB2, 1734-IB4, and 1734-IB8 Sink Input Modules

Module

Status

Network

Status

NODE:

24VDC

Sink

Input

0

4

1

5

2

6

3

7

1734

IB8

1734-IB2 Module Wiring Diagram

Channel Input Common Voltage

00 4 6

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

11 5 7

Connect common on 3-wire proximity switches. 12/24V DC is supplied

through the internal power bus.

Page 31

Install POINT I/O Modules 15

Prox

In 0 In 1

In 2

C

VV

C

In 3

Prox ProxProx

V = 12/24V DC

C = Common

Sink Input

3

5

7

01

2

4

6

3-wire2-wire

Prox

In 0

In 1

In 2

In 4

In 6

In 7

In 5

In 3

Prox

Prox

Prox

Sink Input

3

5

7

01

2

4

6

C

V

Prox

Prox

Prox

C

V

V = 12/24V DC

C = Common

3-wire

3-wire

3-wire 3-wire

2-wire

2-wire

2-wire 2-wire

Prox

1734-IB4 Module Wiring Diagram

Channel Input Common Voltage

00 4 6

11 5 7

22 4 6

33 5 7

Connect common on 3- proximity switches. 12/24V DC is supplied

through the internal power bus.

1734-IB8 Module Wiring Diagram

Channel Input Channel Input

0044

1155

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 32

16 Install POINT I/O Modules

Terminal Block with Bus Connector Strip

Channel Input Channel Input

2266

3377

Daisychain common and power connections from 1734 adapter,

1734-FPD module, 1734-EP24DC power supply, or from a usersupplied external auxiliary terminal block.

ATTENTION: When connecting more than one wire in a termination

point, make sure that both wires are the same gauge and type.

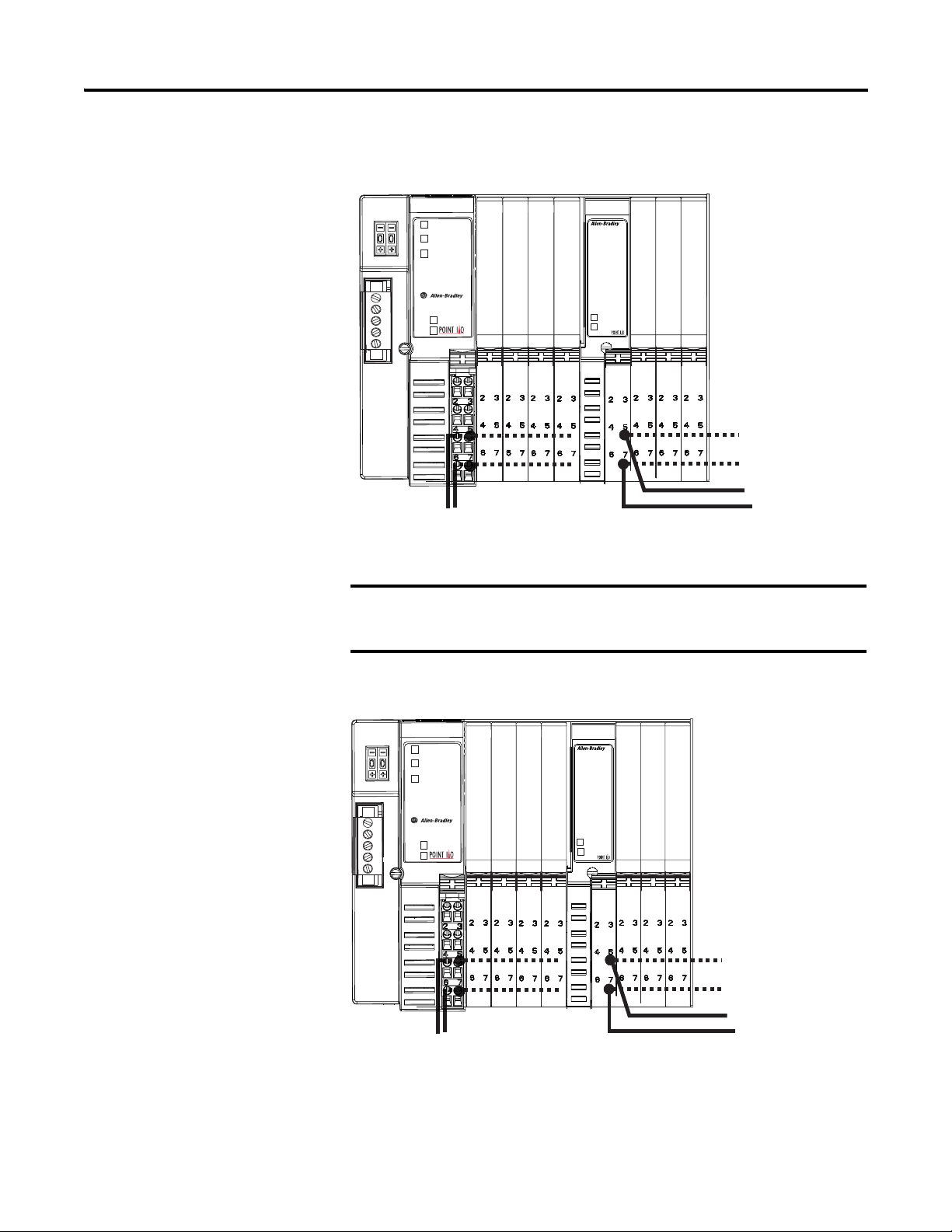

Example of Wiring - 1734-IB8 Module Using 2-Wire Proximity Switches

Module

Module

Status

Status

Network

Network

Status

DeviceNet

Status

24V dc Return

24V dc

System

Power

DeviceNet

Power

0

4

0

4

1

5

1

5

2

6

2

6

3

7

3

7

1734

1734

IB8

OB8E

Prox

Terminal Block with Bus connector strip

Prox

Prox

Prox

Prox

Prox

Prox

Prox

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 33

Install POINT I/O Modules 17

In 0

In 1

In 2

In 3

In 4

In 5

In 6 In 7

0

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

V

V

V

V

V

VV

V

C

C

C

C

C

C

CC

1734-IB8

1734-VTM

1734-CTM

Prox

Prox

1

1734-IB8

V = Voltage Out

C = Common

Terminal Block with Bus Connector Strip

Example of Wiring - 1734-IB8 Module Using 3-wire Proximity Switches

Example of Wiring - 1734-IB8 Module Using 3-wire Proximity Switches

Module

Module

Status

Status

Network

Network

Status

DeviceNet

Status

0

4

4

1

5

5

2

6

6

3

7

7

1734

IB8

Prox

Prox

Prox

Prox

Prox

Prox

Prox

Prox

System

Power

DeviceNet

Power

0

1

2

3

1734

OB8E

24V dc Return

24V dc

Terminal Block with bus connector strip

Terminal Block with bus connector strip

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 34

18 Install POINT I/O Modules

46118

Input 0 SSV 0

Input 1 SSV 1

Input 2 SSV 2

Input 3 SSV 3

Note that voltage and current are

daisychained from either the

adapter, 1734-FPD module, or

1734-EP24DC module.

Common connections for threewire devices require an external

wiring connection. A 1734-CTM

module can provide the common

connection.

Module Status

Network Status

Status of Input 0

Status of Input 1

Status of Input 2

Status of Input 3

In 0

V 0

Sink Input

3

5

7

0

1

2

4

6

Prox

Prox

Prox

Prox

In 2

In 3

In 1 V 1

V 2

V 3

V=10/28.8V DC

If a common connection is required (three-wire devices), then a 1734-CTM common terminal module

can be required.

1734-IB4D Modules

1734-IB4D Module Wiring Diagram

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Channel Terminal Number

0 0 External

12

24

36

Connect common on three-wire proximity switches. 10/28.8V DC is supplied through the internal

power bus.

(1) Common connections require an external connection, such as a 1734-CTM module.

Input Common

(1)

Page 35

Install POINT I/O Modules 19

24VDC

Source

Input

Module

Status

Network

Status

1734

IV2

NODE:

0

1

24VDC

Source

Input

Module

Status

Network

Status

1734

IV4

NODE:

0

1

2

3

NC

C

V

Input 1

NC

C

V

Input = 0 and 1

NC = No Connection (2 and 3)

C = Common (4 and 5)

V = Supply (6 and 7)

Input = 0, 1, 2 and 3

C = Common (4 and 5)

V = Supply (6 and 7)

1734-IV2

1734-IV4

24VDC

Source

Input

Module

Status

Network

Status

1734

IV8

NODE:

0

1

2

3

4

5

6

7

Input 0

Input 2

C

V

Input 1

Input 3

C

V

Input 0

Input 2

Input 1

Input 3

Input 0

Input 6

Input 5

Input 7

Input 4

Input = 0, 1, 2, 3, 4, 5, 6 and 7

V and C are daisychained from either the

adapter, 1734-FPD module, 1734-EP24DC

power supply, or from a user-supplied auxiliary

terminal block.

1734-IV8

Module Status

Network Status

Status of Input 0

Status of Input 1

Module Status

Network Status

Status of Input 0

Status of Input 1

Status of Input 2

Status of Input 3

Module Status

Network Status

Status of Input 0 and 4

Status of Input 1 and 5

Status of Input 2 and 6

Status of Input 3 and 7

41974

Prox

In 0 In 1

NC

C

VV

C

NC

Prox

Source Input

V = 12/24V DC,

C = Common

2-wire

3-wire

3

5

7

01

2

4

6

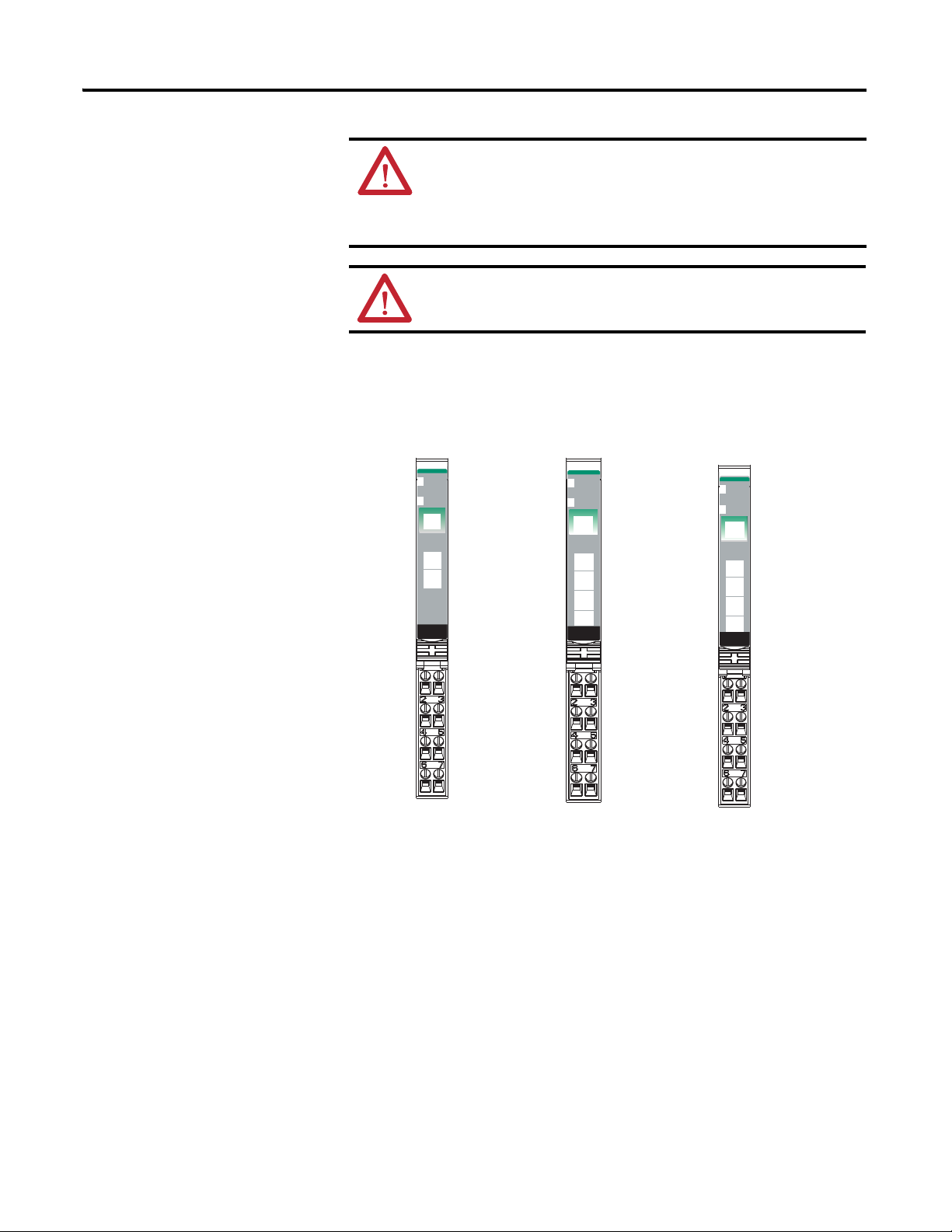

1734-IV2, 1734-IV4, and 1734-IV8 Source Input Modules

1734-IV2 Module Wiring Diagram

Channel Input Terminal Common

Channel 0 0 4 6

Channel 1 1 5 7

Connect power on 3-wire proximity switches. 12/24V DC is supplied through the

internal power bus.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Terminal

Power

Page 36

20 Install POINT I/O Modules

Prox

In 0 In 1

In 2

C

VV

C

In 3

Prox

Source Input

ProxProx

V = 12/24V DC

C = Common

3

5

7

0

1

2

4

6

2-wire3-wire

Source Input Wiring

In 0

In 1

In 2

In 3

In 4

In 5

In 6 In 7

0

2

3

4

5

6

7

0

1

2

3

4

5

6

7

0

1

2

3

4

5

6

7

C

C

C

C

C

CC

C

V

V

V

V

V

V

VV

1734-IB8

1734-CTM

1734-VTM

Prox

Prox

1

1734-IB8

V = Voltage Out

C = Common

3-wire

2-wire

1734-IV4 Module Wiring Diagram

Channel Input Terminal Common Terminal Power

Channel 0 0 4 6

Channel 1 1 5 7

Channel 2 2 4 6

Channel 3 3 5 7

Connect power on 3-wire proximity switches. 12/24V DC is supplied through the internal

power bus.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

1734-IV8 Module Wiring Diagram

Channel Input Terminal Channel Input Terminal

Channel 0 0 Channel 4 4

Channel 1 1 Channel 5 5

Channel 2 2 Channel 6 6

Channel 3 3 Channel 7 7

Daisychain common and power connections from 1734 Adapter, 1734-FPD, 1734-EP24DC

or from user supplied external auxiliary terminal block.

Page 37

Install POINT I/O Modules 21

24VDC

Source

Output

Module

Status

Network

Status

1734

OB8E

0

1

2

3

NODE:

4

5

6

7

42016

Module Status

Network Status

Status of Output 0

Status of Output 1

Status of Output 3

Output 0

Output 0

C

C

Output 1

Output 1

C

C

24VDC

Source

Output

Module

Status

Network

Status

1734

OB2E

NODE:

0

1

Output 0

Output 2

Output 1

Output 3

C

C

V

V

C = Common

V = Supply

1734-OB2E

1734-OB4E

Output 0

Output 2

Output 1

Output 3

Output 4

Output 6

Output 5

Output 7

1734-OB8E

Status of Output 0 & 4

Status of Output 1 & 5

Status of Output 2 & 6

Status of Output 3 & 7

Status of Output 2

Status of Output 0

Status of Output 1

WARNING: When you connect or disconnect wiring while field side

power is on, an electrical arc can occur. This could cause an explosion in

hazardous location installations.

Be sure that power is removed or the area is nonhazardous before

proceeding.

ATT ENTI ON: When connecting more than one wire in a termination

point, make sure that both wires are the same gauge and type.

1734-OB2E, 1734-OB4E, 1734-OB8E, 1734-OB2, 1734-OB4, and 1734-OB8 Protected Output Modules

Module

Status

Network

Status

NODE:

24VDC

Source

Output

0

1

2

3

1734

OB4E

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 38

22 Install POINT I/O Modules

24VDC

Source

Output

Module

Status

Network

Status

1734

OB8

0

1

2

3

NODE:

4

5

6

7

42016

Status of Output 0

Status of Output 1

Status of Output 2

Status of Output 3

Output 0

Output 0

C

C

Output 1

Output 1

C

C

Output 0

Output 2

Output 1

Output 3

C

C

V

V

C = Common

V = Supply

1734-OB2

1734-OB4

Output 0

Output 2

Output 1

Output 3

Output 4

Output 6

Output 5

Output 7

1734-OB8

Status of Output 0 & 4

Status of Output 1 & 5

Status of Output 2 & 6

Status of Output 3 & 7

Module Status

Network Status

Status of Output 0

Status of Output 1

Out 0

Out 1

Out 1

Out 0

CC

V

V

44338

0

2

6

4

3

5

7

1

V = 12/24V DC, C = Common

Field power is supplied from internal power bus

Load

Load

Module

Status

Network

Status

NODE:

24VDC

Source

Output

0

1

1734

OB2

Module

Status

Network

Status

NODE:

24VDC

Source

Output

0

1

2

3

1734

OB4

1734-OB2 and 1734-OB2E Module Wiring Diagram

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Channel Output

Channel 0 0, 2 4 6

Terminal

Common

Terminal

Channel 1 1, 3 5 7

Module power is supplied from the internal power bus.

Power

Page 39

Install POINT I/O Modules 23

44339

V = 12/24V DC,

C = Common

Field power is supplied from internal power bus

Out 0

Out 1

Out 3

Out 2

CC

C

C

0

2

6

4

3

5

7

1

Load

Load

Load

Load

1734-OB4 and 1734-OB4E Module Wiring Diagram

Channel Output

Terminal

Common

Terminal

Channel 0 0 6

Channel 1 1 7

Channel 2 2 4

Channel 3 3 5

Module power is supplied from internal power bus.

Power

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 40

24 Install POINT I/O Modules

Out 0

Out 1

Out 3

Out 2

Load

Load

Common must be daisychained from a 1734 adapter, 1734-FPD module, 1734-EP24DC

power supply, or from a user-supplied auxiliary terminal block. The 24V DC power to the

module is supplied by the internal power bus and comes from the same 1734 adapter,

1734-FPD module, or 1734-EP24DC power supply as common.

2

6

3

7

4

5

Load

Out 4

Out 5

C

Load

Load

Load

C

Load

Load

Out 6

Out 7

0

1

1734-CTM

1734-OB8, 1734-OB8E

Load

Load

Load

Load

Out 7

Out 0

Out 1

Out 2

Out 3

Out 4

Out 5

Out 6

C

CC

C

C

C

C

C

5

1

3

7

0

4

5

6

2

1

3

7

0

4

6

2

1734-OB8 and 1734-OB8E Module Wiring Diagram

Channel

Output Terminal Common Terminal Power

Number

Channel 0 0 Common is

Channel 1 1

Channel 2 2

Channel 3 3

Channel 4 4

Channel 5 5

Channel 6 6

Channel 7 7

Module power is supplied from the internal power bus.

daisychained from

either a 1734 adapter,

1734-FPD module,

1734-EP24DC power

supply, or from a usersupplied external

terminal block.

The 24V DC power for

the module is supplied

by the internal power

bus and originates

from the same adapter,

1734-FPD module, or

1734-EP24DC power

supply as common.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 41

1734-OB2EP Protected Output Module

Protected

Sourcing

Output

Module

Status

Network

Status

1734

OB2EP

NODE:

0

1

42016

Module Status

Network Status

Status of Output 0

Status of Output 1

Output 0

Connection

Output 0

Connection

Output 1

Connection

Output 1

Connection

C

C

V

V

C = Common

V = Supply

V = 12/24V DC, C = Common

Field power is supplied from internal power

bus

Out 0

Out 1

Out 1

Out 0

CC

V

V

0

2

6

4

3

5

7

1

Load

Load

Install POINT I/O Modules 25

1734-OB2EP DC Protected Output Module Wiring Diagram

Channel Output

Term in al

Channel 0 0, 2 4 6

Channel 1 1, 3 5 7

Module power is supplied from the internal power bus.

Common

Terminal

Power

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 42

26 Install POINT I/O Modules

Relay

Output

Module

Status

Network

Status

1734

OW2

NODE:

0

1

41974

Module Status

Network Status

Status of Output 0

Status of Output 1

C

V

C

V

C = Common

V = Supply

Output 0A

Output 0B

Output 1A

Output 1B

Output 0A

Output 0B

Output 1A

Output 1B

Output 2A

Output 2B

Output 3A

Output 3B

1734-OW41734-OW2

Status of Output 0

Status of Output 1

Status of Output 2

Status of Output 3

Module Status

Network Status

C

C

V

V

Out = Output channel relay contacts

V = Supply (can range from +5V DC…240V AC)

C = Common

Out 0A

Out 0B

Out 1A

Out 1B

Load

Load

0

2

4

6

3

5

7

1

1734-OW2 and 1734-OW4 Relay Output Modules

Module

Status

Network

Status

NODE:

Relay

Output

0

1

2

3

1734

OW4

ATTENTION: Relay contacts are not powered by the internal power bus.

Load power can be provided by the internal power bus or an external

power source.

1734-OW2 Modules with Load Powered by Internal Power Bus Wiring Diagram

Channel Output Common Supply

0A 0 4 6

0B 2 4 6

1A 1 5 7

1B 3 5 7

Supply voltage can range from +5V DC…240V AC, depending on relay load.

Power for the module can be provided by the internal power bus.

Rockwell Automation Publication 1734-UM001E-EN-P - July 2013

Page 43

Install POINT I/O Modules 27

C

C

V

V

Out 0A

Out 0B

Out 1A

Out 1B

Load

Power

Supply

Out = Output channel relay contacts

Power Supply = can range from +5V DC…240V AC

C = Common

0

2

4

6

3

5

7

1

Power

Supply

Load

Out 2A

Out 3A

Out 3B

Out 2B

Out 0A

Out 0B

Out 1A

Out 1B

Load

Power

Supply

Out = Output channel relay contacts

0

2

4

6

3

5

7

1

Power

Supply

Load

Power

Supply

Load