Allen-Bradley 1711-P05SISID050S, 1711-P05SISID100S, 1711-P05SISID050T, 1711-P05SISID100T, 1711-P05SISOD050S User Manual

...Page 1

User Manual

Original Instructions

OptiSIS® Safety Instrumented System

Catalog Numbers 1711-P05SISID050S, 1711-P05SISID050T, 1711-P05SISOD050S, 1711-P05SISOD050T, 1711-P05SISID100S,

1711-P05SISID100T, 1711-P05SISOD100S, 1711-P05SISOD100T

AB PLCs

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

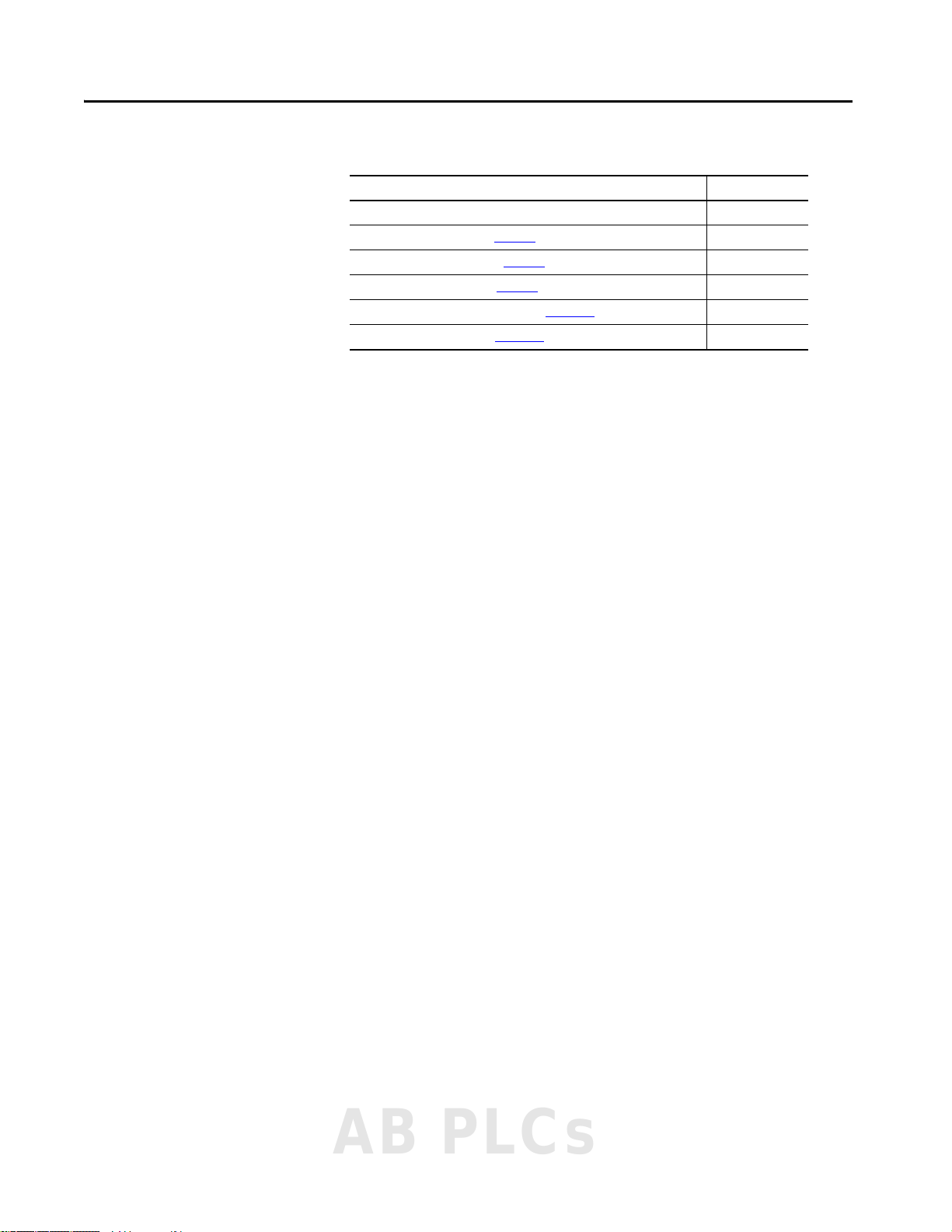

Table of Contents

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

About This Publication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

About the OptiSIS Solution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Catalog Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

I/O Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Enclosure Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 1

Safety Requirements Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fail-safe System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Fault Tolerant System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Safe State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Process Safety Lifecycle, Functional Testing, and Validation . . . . . . 15

Safety Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

PFD/PFH Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Password Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Program Enable Key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 2

Installation Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Unpack. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Storage and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Wall Mount — 50 I/O Solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Floor Mount — 100 I/O Solution . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter 3

Connect Power Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Power Distribution and Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Power Cable Types/Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cable Entry. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Bottom Entry Conduit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cable Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Lugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Power Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 3

Page 4

Table of Contents

Chapter 4

Connect Field Wiring Grounding Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Analog Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Digital and Relay Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Contact Derating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter 5

Startup First-time Powerup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Navigation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Operator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Alarm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Help. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Connect Peripherals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Application Accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Configure User Accounts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Log Out Current User . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter 6

Configure I/O Configure I/O Points. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Configure an I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configure Analog Input Characteristics . . . . . . . . . . . . . . . . . . . . . 52

Configure Digital Input Characteristics . . . . . . . . . . . . . . . . . . . . . 56

Configure Analog Output Characteristics . . . . . . . . . . . . . . . . . . . 61

Configure Digital Output Characteristics . . . . . . . . . . . . . . . . . . . 63

Validate Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Chapter 7

Configure Logic Using Cause and Effect Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Configuration Methods. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Configure Cause and Effect Charts by Using the HMI Display 68

Back up and Restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Chapter 8

Communication Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

IP Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Using Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

HART Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

HART Data Over Modbus Network. . . . . . . . . . . . . . . . . . . . . . . . 76

HART Device Management by Using an AMS . . . . . . . . . . . . . . 77

4 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 5

Table of Contents

Chapter 9

Operation Monitor System State. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

I/O Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

View Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

View Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Reset after Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Reset by Using the HMI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Reset by Using Supplied Modbus Point. . . . . . . . . . . . . . . . . . . . . . 96

Chapter 10

Maintenance Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Technical Support Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Opening the Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Repair Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Electrostatic Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Processor Module Battery Replacement . . . . . . . . . . . . . . . . . . . . . . . . . 98

Reset OptiSIS Solution Default Settings . . . . . . . . . . . . . . . . . . . . . . . 100

Change Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Preparing Your OptiSIS Solution for Upgrades . . . . . . . . . . . . . . . . . 101

Appendix A

Offline Configuration Tool Begin Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

General Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Configure Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Configure Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Configure Cause and Effect Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Save Configuration File. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Edit a Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Load or Restore Configuration File . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Appendix B

Specifications SIL Capability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Hardware Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

I/O Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

I/O Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

System Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Approximate Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Appendix C

Spare Parts List Recommended Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 5

Page 6

Table of Contents

Appendix D

Safety Checklist Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Appendix E

Modbus Communication Address Modbus RTU Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

OptiSIS Solution Modbus Map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

6 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 7

Summary of Changes

This manual contains new and updated information as indicated in the

following table.

Top ic Pag e

Updated section: Digital and Relay Output Wiring 32

Updated chapter: Configure I/O (Chapter 6

Updated chapter: Configure Logic (Chapter 7)65

Added chapter: Communication (Chapter 8)75

Added appendix: Offline Configuration Tool (Appendix A

Added appendix: Specifications (Appendix B)115

)47

)103

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 7

Page 8

Summary of Changes

Notes:

8 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 9

Preface

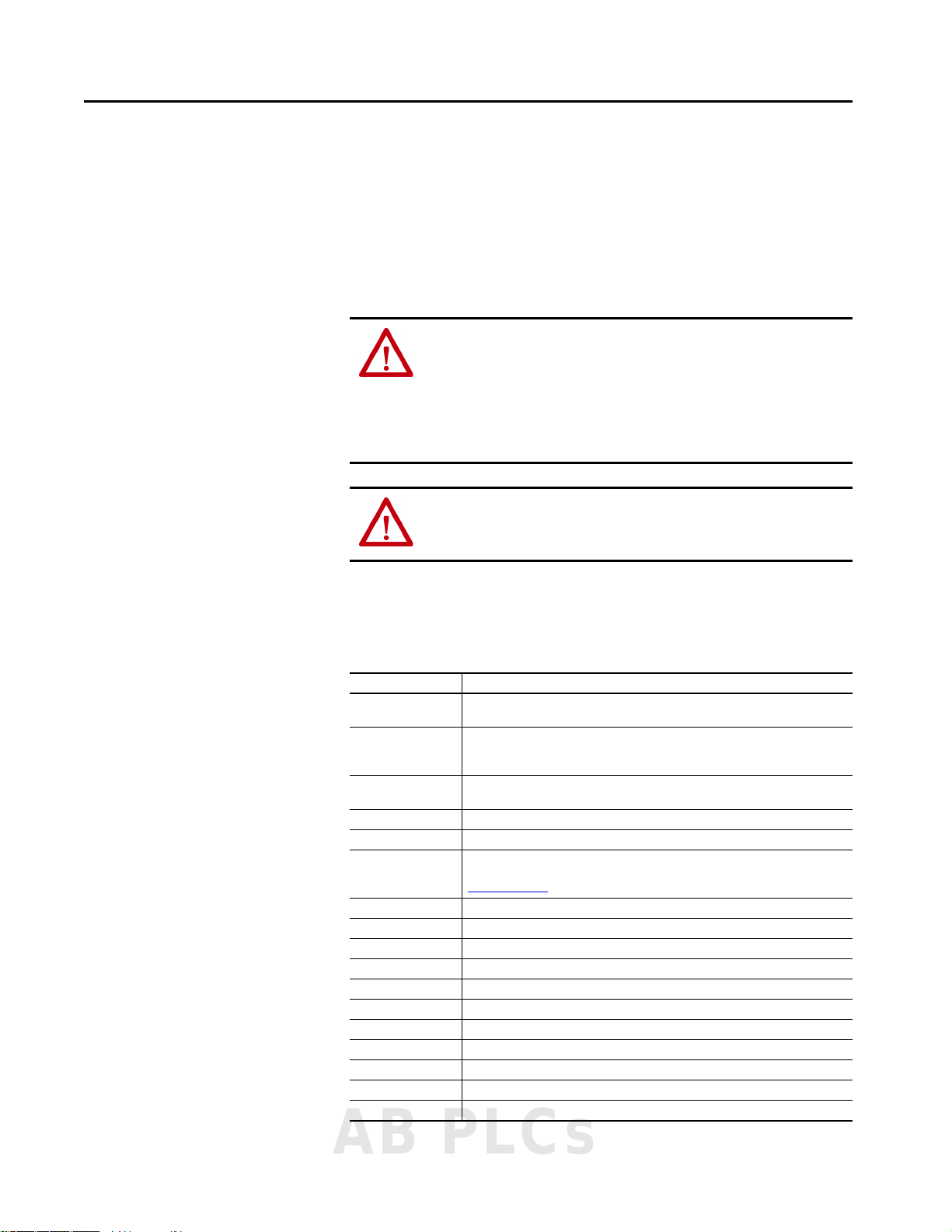

About This Publication

The OptiSIS® solution is a ready to install configurable logic solver for use in

Safety Instrumented System (SIS) applications. Once installed and wired, it

can be configured and tested to provide a complete SIS solution that can meet

application requirements up to SIL 3.

This manual is intended for engineers or technicians that are directly involved

in the installation, connection, use, and maintenance of the OptiSIS solution.

ATTENTION: To meet any claimed safety integrity level, the OptiSIS solution

must be applied by following the Process Safety Lifecycle phases that are

defined in these resources:

– IEC 61511

– Other applicable sector Functional Safety standards

– Any application sector codes

– This user manual

ATTENTION: To operate the touch screen, use a finger, gloved finger, or

plastic stylus with a minimum tip radius of 1.3 mm (0.051 in.). Use of any

other object or tool can damage the keypad or touch screen.

Terminology

This table defines the terms and abbreviations that are used in this manual.

Table 1 - Terms and Abbreviations

Term/Abbreviation Definition

AMS Asset management system: A system that is used to manage (diagnose, configure, and

maintain) smart field devices

CommDTM A communication driver that is installed as part of an AMS. This driver provides a specific

communication interface between the FDT framework and the specific automation

technology the AMS system is connected to

DeviceDTM A software driver that is installed into an AMS that is specific to a manufacturer’s device,

which provides the data interface specific to that model

DTM Device type manager. There are two types of DTM, a DeviceDTM and a CommDTM

F & G Fire and gas

FDT Field device tool: A technology for configuration a nd access of field devices. It allows field

device data to be shared between different technologies. For more information, go to

www.fd tgroup.org

HART Highway Addressable Transducer Protocol

MOC Management of change process

MTTR Mean time to restoration

PSAT Pre-startup acceptance test: A functional test of the Safety Instrumented System

PST Process safety time

PV Process variable

RTU Remote terminal unit

SIL Safety integrity level

SIS Safety Instrumented System

TCP Transmission control protocol

UTC Coordinated universal time

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 9

Page 10

Preface

1711 - P05 SIS ID 050 S

Bulletin Number

1711: OptiSIS Solution

P05 - Packaged

Solution

SIS - Safety

Instrumented System

Area

ID: Indoor

OD: Outdoor

I/O

050: 50 I/O

100: 100 I/O

Configuration

S: Fail-safe

T: Fault Tol erant

About the OptiSIS Solution

The OptiSIS solution is a packaged, pre-built, pre-programmed safety

instrumented system (SIS) logic solver that you mount, wire, and configure as

part of a complete SIS solution. The solution can meet application

requirements up to SIL 3. The solution uses a Rockwell Automation® industrial

computer, AADvance® controllers, and I/O modules.

Such applications include the following:

• Emergency Shutdown Systems/Safety Instrumented Systems

• Burner Management Systems

• High Integrity Pressure Protection Systems

• Energize to Action Systems

Catalog Numbers

I/O Configurations

The OptiSIS solution is available in two sizes:

• 50 I/O solution (see Table 15 on page 115

• 100 I/O solution (see Table 16 on page 115

for a listing of I/O types)

for a listing of I/O types)

Enclosure Options

The following enclosure options are available for the OptiSIS solution:

Location Solution Enclosure Material Enclosure Rating

Indoor (ID)

Outdoor (OD) ANSI 304 stainless steel IP66 and NEMA 4X

50 I/O and 100 I/O

Powder-coated steel IP66 and NEMA 4

10 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 11

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Integrated Display Industrial Computers for Hazardous

Locations User Manual, publication 6181X-UM001

Integrated Display Industrial Computers User Manual,

publication 6181P-UM003

Power Supply reference manual, publication 1606-RM001

Process Safebook 1 - Safety-related control systems in the

process industry reference manual, publication

SAFEBK-RM003

AADvance Safety Manual, publication ICSTT-RM446 Defines how to apply AADvance controllers for a

AADvance Troubleshooting Guide, ICSTT-RM406

PFH avg and PFD avg Data Reference Manual, publication

ICSTT-RM449

HART Protocol, www.fdtg roup.org. Provides details on HART protocol.

Field Loop Configuration application note, publication

AN-T80004

International Electrotechnical Commission

http://www.iec.ch

National Fire Protection Association (NFPA 72),

http://www.nfpa.org

International Society of Automation (ISA 84.00.01),

https://www.isa.org/

National Electric Code, http://www.necconnect.org Provides details on NEC Table 310.15(B)(16).

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website,

http://www.rockwellautomation.com/global/

certification/overview.page

Product Compatibility and Download Center (PCDC)

http://www.rockwellautomation.com/global/support/

pcdc.page?.

Contains information on how to install, configure,

operate, and troubleshoot the 6181X integrated

display industrial computers.

Contains information on how to install, configure,

operate, and troubleshoot the 6181P integrated

display industrial computers.

Provides installation, operation, and features

information for switched mode power supplies.

Provides information, guidance, and examples to

understand and apply Functional Safety and Process

Safety standards.

Safety Instrument Function.

Provides maintenance and troubleshooting

information for AADvance controllers.

Provides information on AADvance controller

reliability.

Provides information for line monitoring and includes

advice for fire detectors, which are not simple

volt-free contacts.

Provides details on IEC 61511.

Provides details on NFPA 72.

Provides details on ISA 84.00.01.

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides declarations of conformity, certificates, and

other certification details.

Provides help to find product-related downloads

including firmware, release notes, associated

software, drivers, tools, and utilities.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 11

Page 12

Preface

Notes:

12 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 13

Safety Requirements

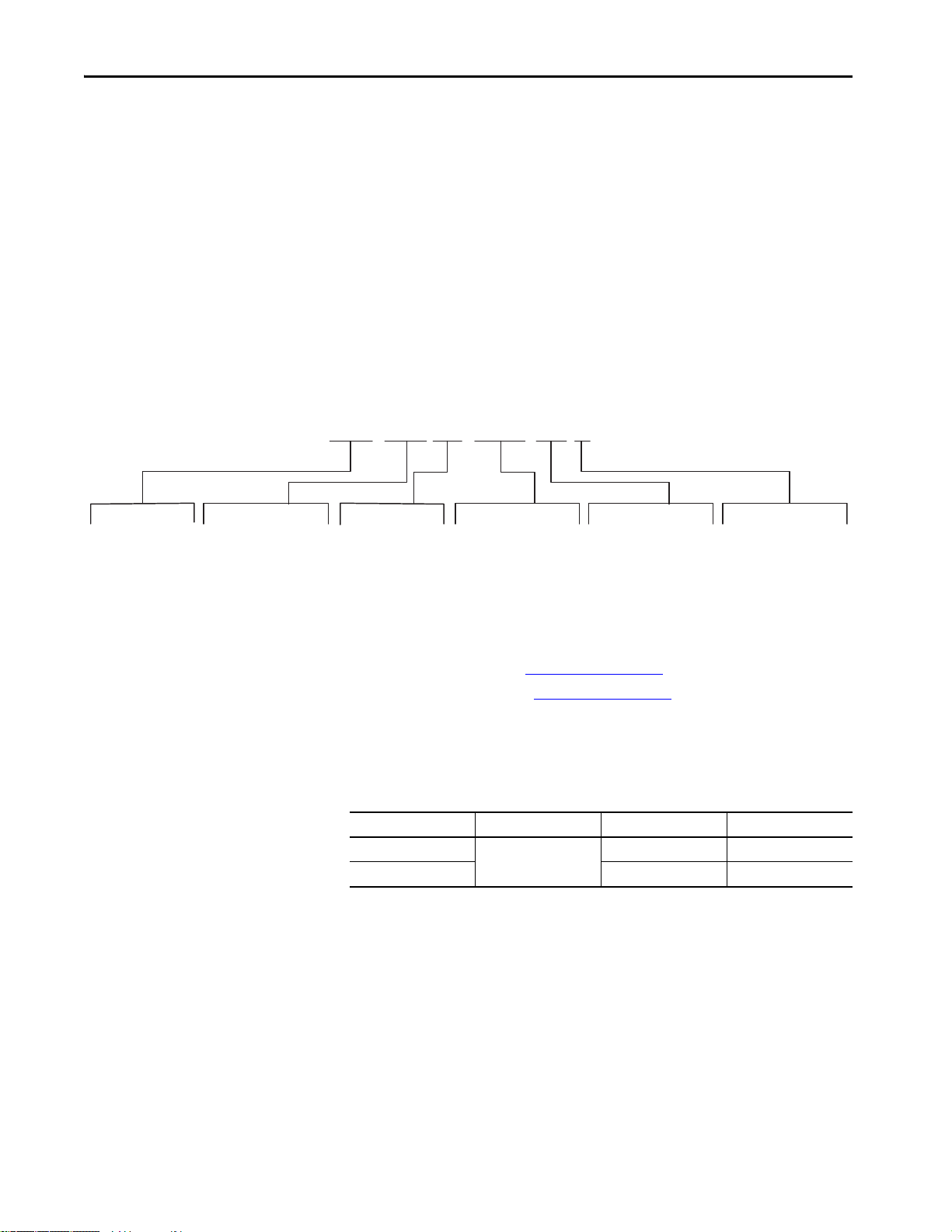

Sensors

I/P

A

CPU

A

CPU

B

V

V

O/P

A

Final

Elements

I/P = Input Module

CPU = Processor Modules

O/P = Output Modules

V = Vote

Chapter 1

Introduction

Safety Architecture

The certification authority Technischer Überwachungs-Verein (TÜV)

independently certifies that the AADvance control system meets the

requirements of IEC 61508 SIL 3.

The OptiSIS solution is designed and implemented in accordance with the

requirements of the AADvance Controller Safety Manual, publication

ICSTT-RM446

certifications.

The OptiSIS solution is available in both Fail-safe and Fault Tolerant

configurations.

. See the AADvance Controllers Safety Manual for

ATTENTION: Personnel responsible for deploying a Process Safety solution

must verify that the SIS is tested against the Safety Requirements

Specification (SRS) before the introduction of Hazardous materials into the

Process.

ATTENTION: The Safety Architecture defines how the system behaves under

fault conditions. The correct architecture must be selected based on the

requirements that are defined in the SRS.

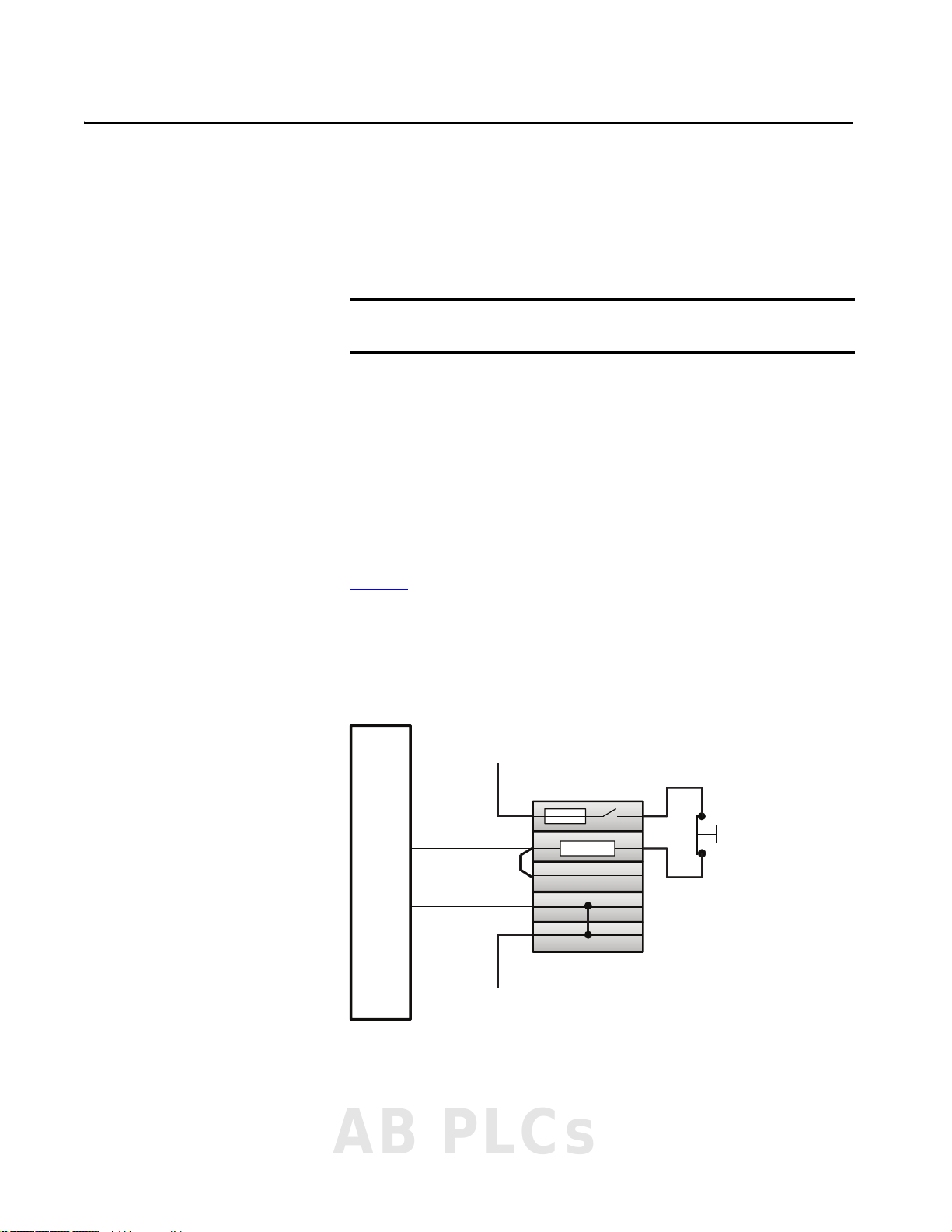

Fail-safe System

The Fail-safe architecture option means that the failure of a channel or module

can degrade the applied safety integrity level, or can result in the loss of

function where the Fail-safe system brings the process to the safe state.

The actual behavior under fault conditions is also dependent on configuration

options.

Figure 1 - Fail-safe System

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 13

Page 14

Chapter 1 Safety Requirements

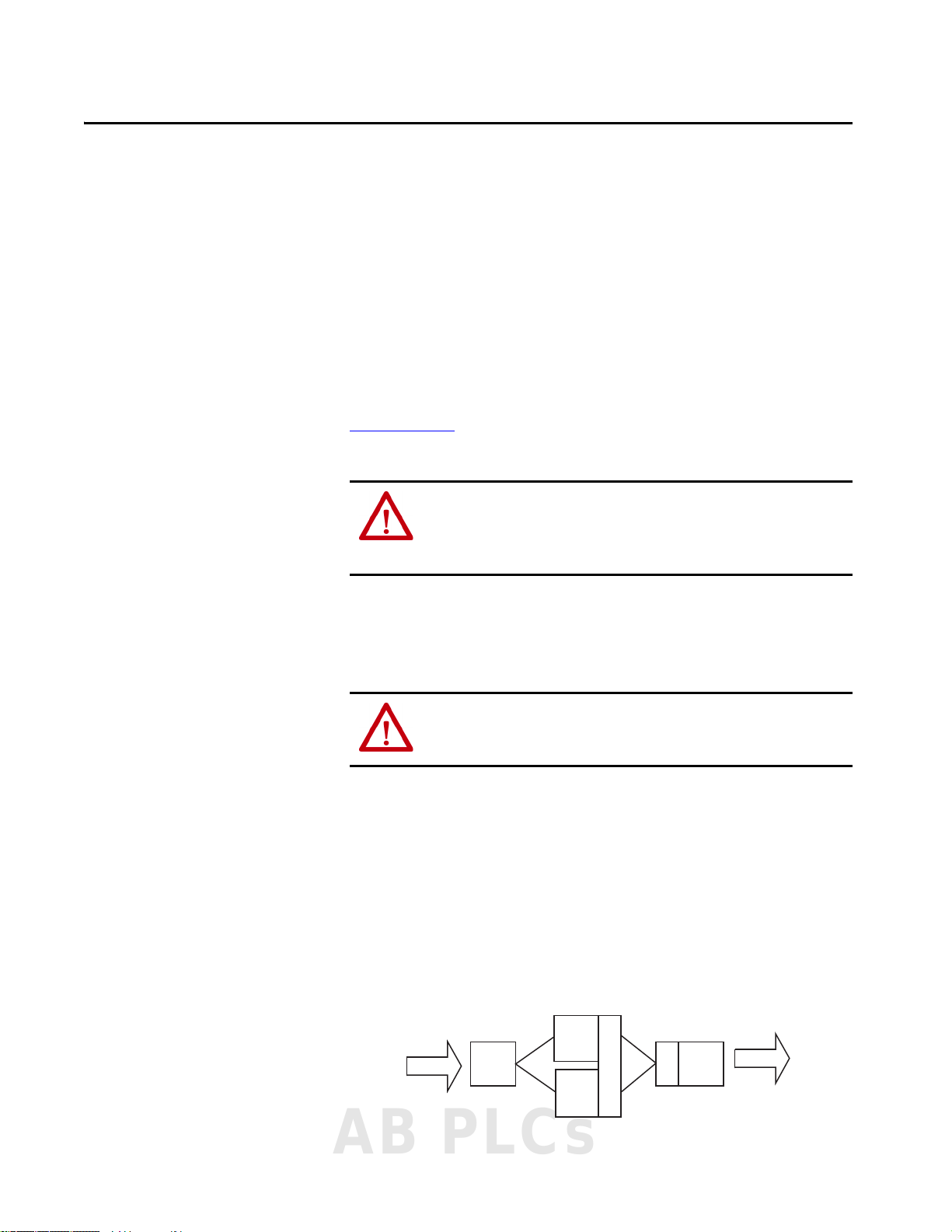

Sensors

Final

Elements

I/P

A

I/P

B

CPU

A

CPU

B

CPU

C

V

V

V

V

V

V

V

O/P

A

O/P

B

I/P = Input Module

CPU = Processor Modules

O/P = Output Modules

V = Vote

Fault Tolerant System

The Fault Tolerant architecture option means that the failure of a channel or

module does not degrade the applied safety integrity level, or result in the loss

of function and the resulting taking the process to the safe state.

The actual behavior under fault conditions is also dependent on configuration

options.

Figure 2 - Fault Tolerant System

Safe State

The internal configuration of the AADvance system that is used in the

OptiSIS solution is that the safe-state is OFF (de-energize-to-action).

De-energize-to-action is the state that an input or output assumes during a

channel or module failure. The OptiSIS solution does however, let you

configure digital inputs and digital outputs to operate in either a normally

energized (de-energize-to-action) or a normally de-energized (energize-toaction).

See Configure I/O on page 47

state.

ATTENTION: Use Energize-to-action configurations only if the following

conditions apply:

• At least two independent power sources to the OptiSIS solution panel must

be used.

• At least one of the power feeds to the panel must be a secure power source

(for example, a UPS or a battery). The power supply hold-up time must

provide power for long enough to bring the process to a safe state.

• OptiSIS solution power supplies generate an alarm when power is lost

(either due to power feed failure or PSU failure). Any power failure alarm

must be responded to and rectified within the mean time to restoration

(MTTR).

• For SIL 3 and high demand energize-to-action applications, the Fault

Tolerant option must be used.

for the configuration of the normal operating

14 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 15

Safety Requirements Chapter 1

Process Safety Lifecycle, Functional Testing, and Validation

Safety Data

ATTENTION: Follow the Process Safety Lifecycle as described in the

AADvance Controller Safety Manual, publication ICSTT-RM446

Before putting the system into operation, perform a pre-startup acceptance

test (PSAT) which is a functional test of the safety instrumented system (SIS).

The PSAT must be a documented and recorded test procedure that includes

(but is not limited to) the following:

• All power, signal, and ground wiring is checked and secure.

• All input/output loops are functionally exercised through their entire

operating range (including field device calibration).

• All safety functions are tested, including timing properties.

• All functions such as bypasses, alarms, and communication interfaces

(where appropriate) are tested and recorded.

It is recommended to evaluate your PSAT with the checklist in Appendix D

This evaluation helps you to meet safety requirements for the OptiSIS

solution.

The OptiSIS solution has a process safety time (PST) of 1.5 seconds. The PST

brings the system to its safe state (off ) in the event a dangerous fault is

detected. The PST of the safety functions the SIS performs should be equal to,

or less than, the OptiSIS PST of 1.5 seconds. This value is not configurable in

the standard system.

.

.

Mean time to restoration (MTTR) is the maximum allowed time between the

occurrence of a failure and the completion of the repair of that failure, to

maintain the assigned safety integrity level. The allowed time includes the time

to detect the failure, initiate the repair, and fully complete the repair. This

configurable parameter has a range of 0…168 hours (no decimals).

ATTENTION:

• Faulty output modules in a dual configuration that is used in energize to trip

applications must be replaced within the MTTR to maintain SIL 3

performance.

• Faulty processors in a dual configuration must be replaced within the MTTR

to maintain SIL 3 performance.

• The MTTR timer is provided in the human machine interface (HMI). You can

configure the MTTR time according to your SIL level from the System Status

display when you are logged in as the Engineer user in the HMI. If you want

to maintain SIL 3 performance, act on the timer alarm. For more information

on Maintenance displays, see Chapter 8

.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 15

Page 16

Chapter 1 Safety Requirements

PFD/PFH Data

Reliability, PFD, and PFH data is published in the PFHavg and PFDavg Data

for AADvance Controllers, publication ICSTT-RM449

.

Password Protection

The HMI has a security model that is built in to restrict access to specific

functions. The model relies on user roles as defined in this table. The password

is case-sensitive.

ATTENTION: For security reasons, we recommend that you change the

default passwords.

Table 2 - HMI User Roles and Passwords

User Role Default

Default (not logged in)

Operator operator X

Supervisor supervisor X X

Maintenance maintenance X X X

Engineer engineer X X X X

Administrator administrator

RA Administrator raadmin X X X X X X

(1) For HMI version B10 and earlier, the password for Administrator is pass word.

Passwor d

Force I/O

Apply Configurations

Acknowledge/Reset Alarms

Remove Suppress and Force

(1)

XX X XX

Access Diagnostic Functions

Suppress I/O

Shutdown System

Table 3 - Windows User Passwords

User Password

Administrator 1ADMINISTRATOR

Operator 1OPERATOR

The Windows Administrator has complete control over the industrial personal

computer. They can change settings and access the files and programs that are

stored in the personal computer.

Operator has limited control over the industrial personal computer and its

intended purpose is to execute the OptiSIS solution application.

See Application Accounts on page 42

16 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

for login and password information.

Page 17

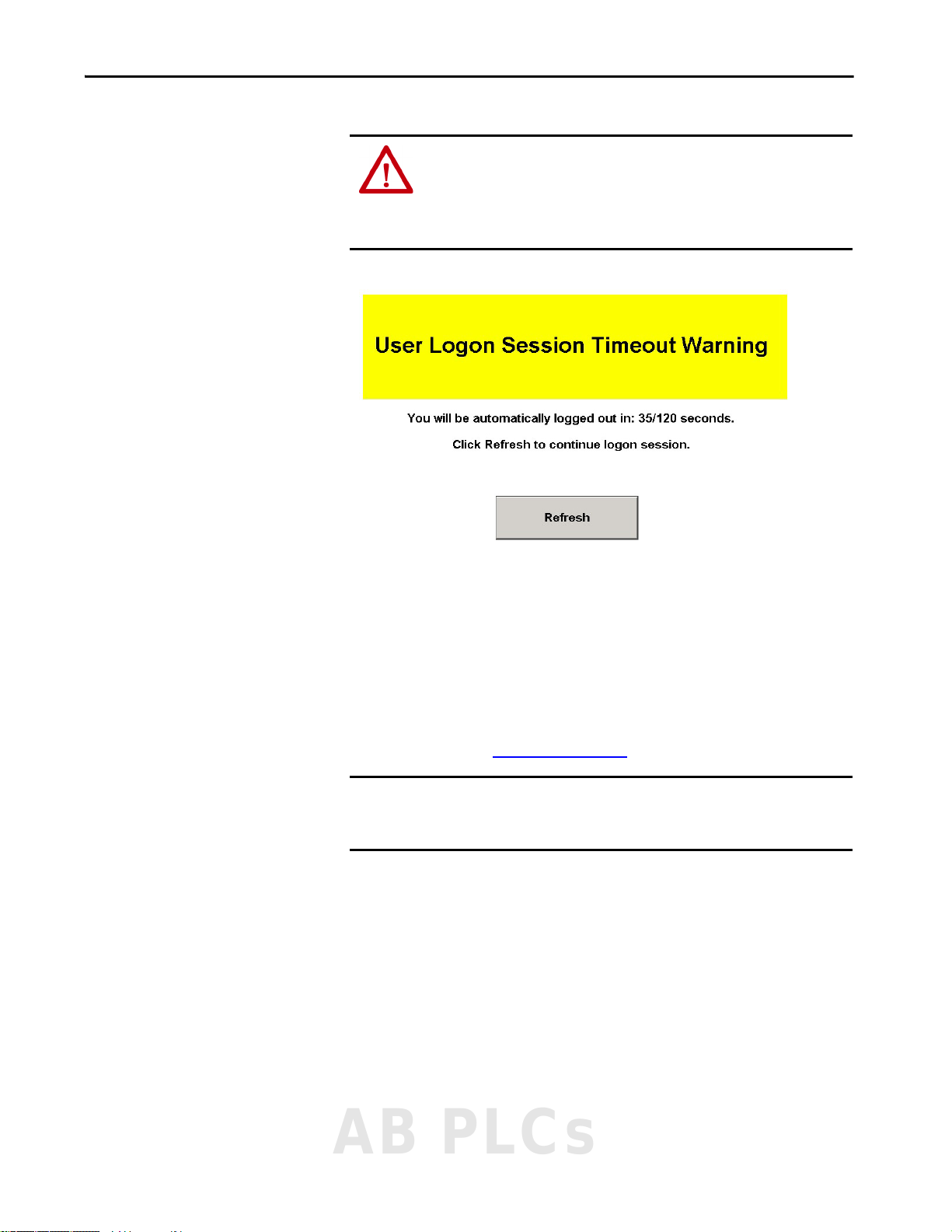

ATTENTION: The OptiSIS has an auto-logout feature. The User Logon Session

Timeout Warning display automatically appears after 20 minutes of

inactivity and lets you refresh the application before completing the

automatic log-off process. All users are automatically logged off after 20

minutes of inactivity to Default.

Figure 3 - User Session Timeout Warning

Safety Requirements Chapter 1

Program Enable Key

The Program Enable Key is a security device that is required to be present in an

OptiSIS solution when applying Rockwell Automation supplied application

and firmware updates. The key is a 9-way 'D' type plug and is supplied with the

processor base unit.

The key must be plugged into the processor base unit to allow upgrades to be

performed. The key is installed if the controller appears in yellow on the

Overview display (see Figure 43 on page 80

IMPORTANT The Program Enable Key is shipped in the base unit. Do not leave the

Program Enable Key in place. Store the key in a safe place with controlled

access.

).

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 17

Page 18

Chapter 1 Safety Requirements

Diagnostics

Certification

The AADvance controller embodies sophisticated internal diagnostic systems

to identify faults that develop during operation and raise appropriate alarm and

status indications. The diagnostic systems run automatically and check for

system faults that are associated with the controller (processor and I/O

modules) and field faults that are associated with field I/O circuits. The

internal diagnostics detect and reveal both safe and dangerous failures.

ATTENTION: When the OptiSIS solution is located in a normally unmanned

area, a method for reporting diagnostic alarms into a normally manned area

must be provided to make sure that the defined MTTR is met.

The OptiSIS solution does not carry a specific ‘Product’ certification as it is a

Solution, which is composed of standard products. Each product that is used in

the solution carries specific certifications. To find more information, go to the

Rockwell Automation Product Certification website:

http://www.rockwellautomation.com/global/certification/

Each of the products that are used to create the solution have been installed,

wired, and programmed in accordance with the appropriate user manuals.

Specifically, the AADvance equipment has been designed, installed,

programmed, and tested according to both the AADvance Controller Safety

Manual, publication ICSTT-RM446

phases of IEC61511.

, and following the appropriate lifecycle

18 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 19

Chapter 2

Installation

This chapter provides basic background information about the solution and

instructions for installation.

ATTENTION: You must use installation and commissioning procedures that

comply with applicable standards of the country of installation. The

applicable standards can include, for example, IEC 61511, NFPA72, and ISA

84.00.01, depending on the location.

ATTENTION: Radio Frequency Interference can influence most electronic

equipment. Exercise caution regarding the use of portable communication

equipment around such equipment. Post signs in the vicinity of the

equipment to provide caution against the use of portable communications

equipment.

Introduction

IMPORTANT These guidelines are not intended to supersede local electrical codes.

Figure 4, Figure 5, and Figure 6 show the solution and its components:

• AADvance controller CPU

• Flexible inputs (analog/digital)

•Analog outputs

• Digital outputs

•Industrial computer (HMI)

• Enclosure and accessories

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 19

Page 20

Chapter 2 Installation

AADvance Controller CPU

and I/O Modules

Industrial Computer

(Mounted on Door)

Power Distribution

Logic Write Keyswitch

(Mounted on Door)

Power Suppli es

Power Feeds

Customer Field Terminals

•Analog Output

•Modbus RTU

• Modbus TCP/IP

• Digital Output

Customer Field Terminals

Flexible Inputs

Figure 4 - OptiSIS Solution – External View

Figure 5 - OptiSIS Solution – Internal View

20 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 21

Installation Chapter 2

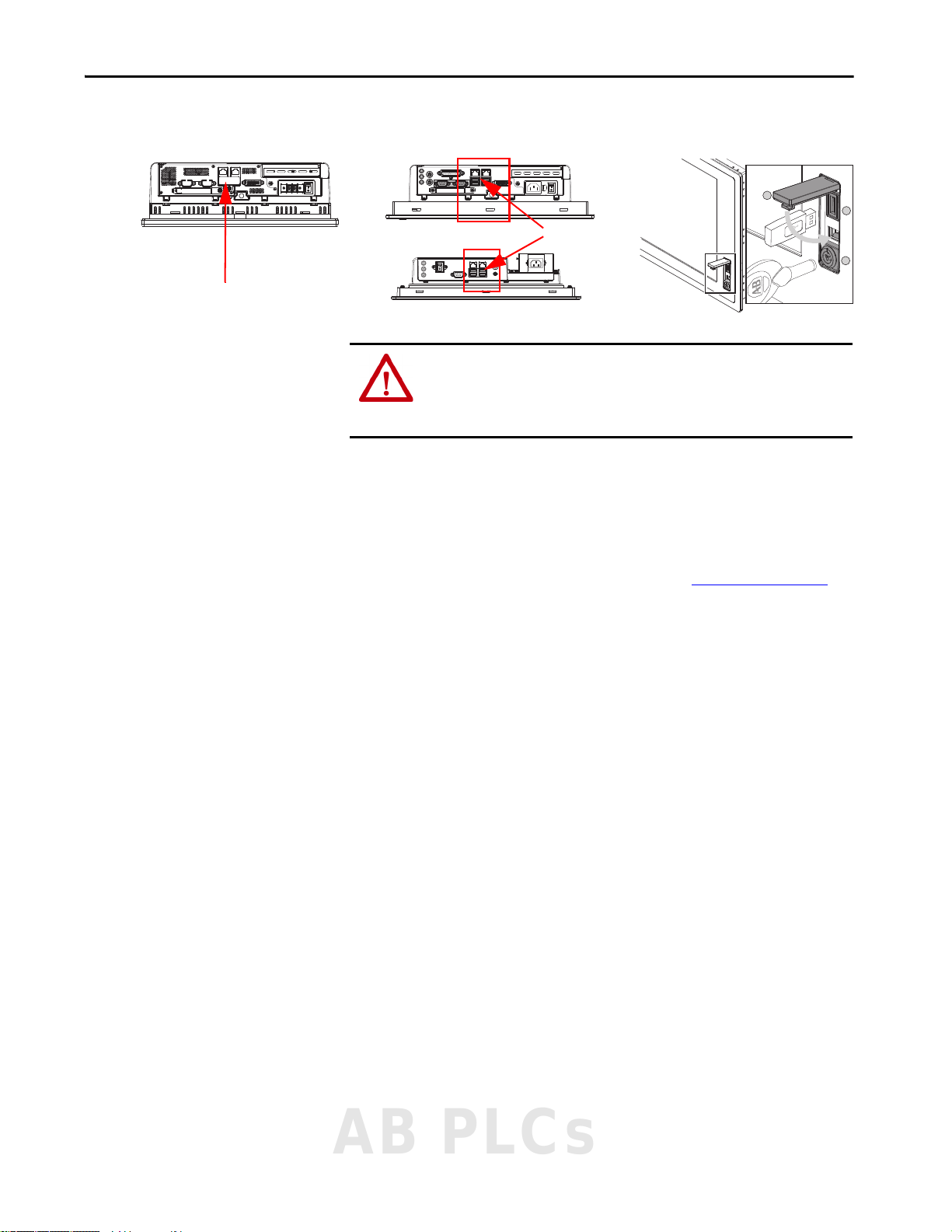

Hinged Door Covering

the USB Ports

6181X Bottom View 6181P Front View6181P Bottom View

USB Ports

Figure 6 - HMI- USB Port Location

ATTENTION: The bottom side USB ports on the 6181X HMI are functionally

hot-pluggable in an environment that is known to be nonhazardous. For

European Zone 2 applications, do not use the USB ports unless the area is

known to be nonhazardous.

All required components are mounted, wired, and installed inside the solution

enclosure.

Installation

The 50 I/O system is contained within a wall-mounted cabinet. The 100 I/O

system is contained within a floor-standing panel. See Table 23 on page 117

enclosure dimensions.

for

Unpack

Before unpacking any items, the packaging must be inspected for damage that

can occur during shipment.

If any packaging is damaged, the package identification marks (such as box

number or crate number) must be noted and communicated to

Rockwell Automation. The package must be stored in a suitable storage area in

the condition it was received. Rockwell Automation then contacts the shipping

agent who can request to inspect the damage. The package must not be opened

without the express written permission of Rockwell Automation.

If packaging is not damaged, the OptiSIS solution must be removed from the

packaging. Verify that all items on packing list are included. If any items are

missing, contact Rockwell Automation.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 21

Page 22

Chapter 2 Installation

Inspection

• Visually inspect the cabinets for mechanical damage. Check the

paintwork for scratches and abrasions.

• Verify that the cabinet door opens and closes and that all latches operate

smoothly.

• Verify that cable assemblies were not damaged during shipment and that

they are appropriately dressed with cable ties and/or spiral wrap.

• Verify that all wire ducts are fitted with covers.

Storage and Operation

Consider the environmental characteristics that are listed in Table 20 on

page 117 when you select the device and the mounting location.

IMPORTANT The standard unit is meant to be installed in a nonhazardous environment.

For additional environmental needs for your SIS, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

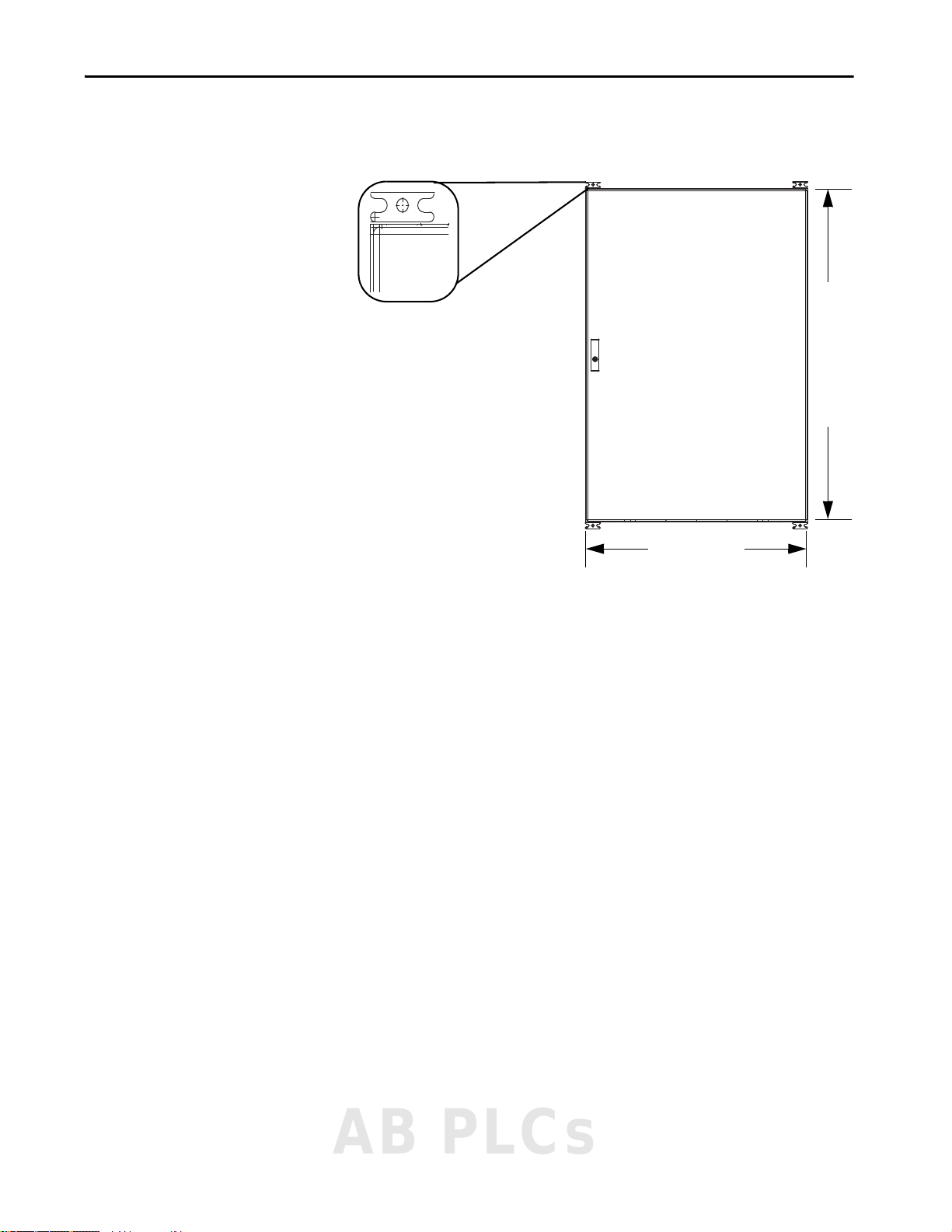

Wall Mount — 50 I/O Solution

ATTENTION: Crush hazard!

Dropping of the unit can lead to personal injury and/or component damage.

Always support the unit fully during installation; use an assistant.

To mount the 50 I/O OptiSIS solution to the wall, follow these steps.

1. Determine the mounting location and verify that the location is suitable

for the solution by checking the following :

• The site is free from excessive dirt and moisture.

• Sufficient room on all sides of the enclosure is available for the cable

to exit the enclosure and to open the door.

The door swing radius is 800 mm (32 in.) and extends to 110°

without forcing.

22 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 23

Installation Chapter 2

800 mm (32 in.)

1199 mm (47 in.)

Wal l Mou nt Br acke t

2. Place the enclosure on the wall in the desired location and verify that it is

level.

3. Secure the wall mount bracket.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 23

Page 24

Chapter 2 Installation

800 mm (32 in.)

2006 mm

(79 in.)

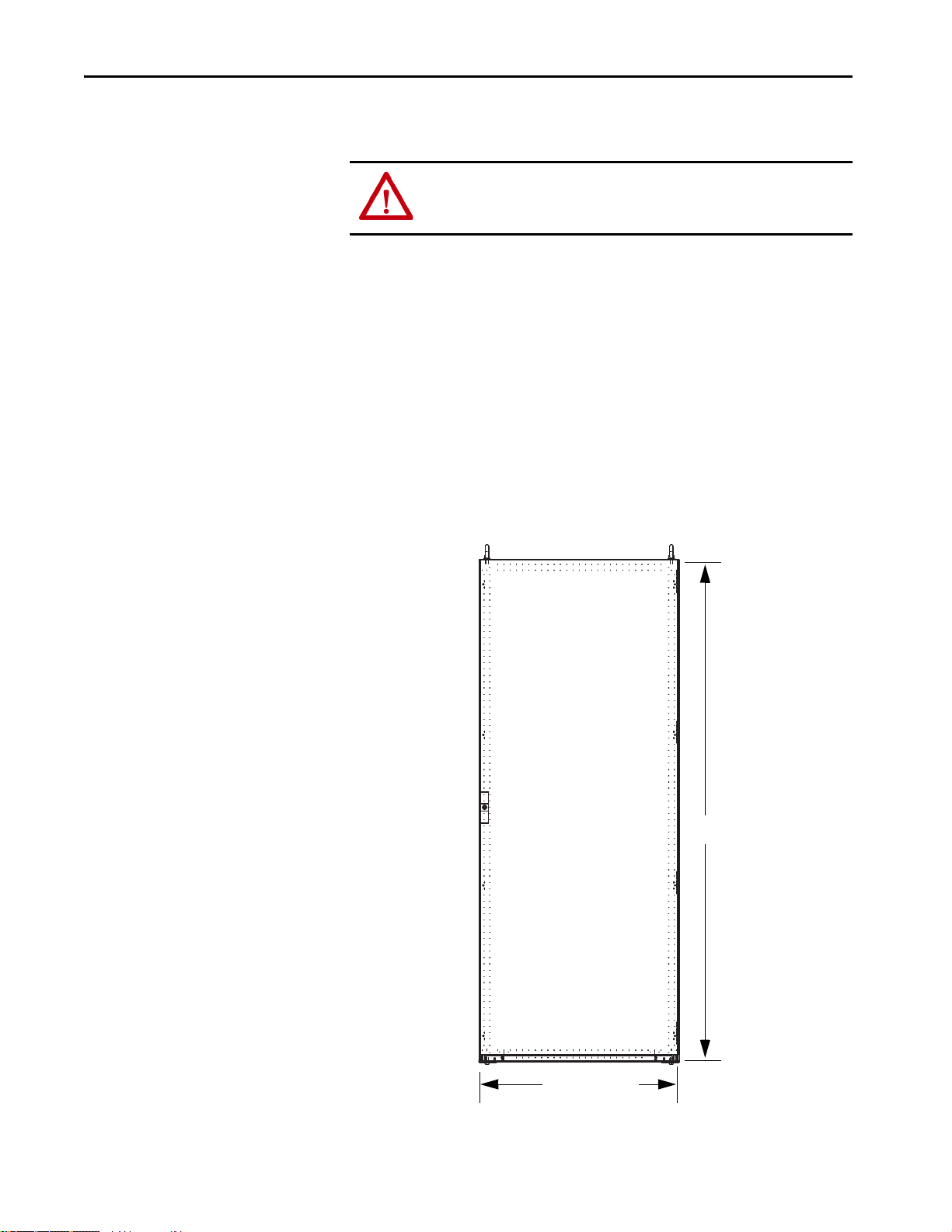

Floor Mount — 100 I/O Solution

ATTENTION: Crush hazard!

Dropping of the unit can lead to personal injury and/or component damage.

Always support the unit fully during installation; use an assistant.

1. Determine the mounting location and verify that the location is suitable

for the solution by checking the following :

• The site is free from excessive dirt and moisture.

• The enclosure stands level after installation.

• Sufficient room on all sides of the enclosure is available for the cable

to exit the enclosure and to open the door.

The door swing radius is 800 mm (32 in.) and extends to 110°

without forcing.

2. Place the enclosure in the position where it is to operate and verify that

the enclosure is level.

Leveling feet allow you to fine-tune the level of the enclosure due to

unevenness at the installation site.

24 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 25

Connect Power

Chapter 3

Introduction

Power Distribution and Grounding

The OptiSIS solution uses standard Allen-Bradley® power supplies and

redundancy modules. The OptiSIS solution accepts dual power feeds of the

same, or different, voltages. See detailed power distribution drawings for power

details.

IMPORTANT The A and B power feeds do not have to be the same.

IMPORTANT These guidelines are not intended to supersede local electrical codes.

Connect power to terminals shown in the supplied wiring drawings. Terminal

locations are shown in Figure 7

Figure 7 - Terminal Locations

.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 25

Page 26

Chapter 3 Connect Power

There are two ground connections that must be connected before power is

applied to the system.

• The AC safety ground is provided to help protect personnel from

electric shock under fault conditions. Internally, all exposed metal

surfaces, for example, cabinets, racks, and chassis ground connections,

are connected to this termination point.

ATTENTION: The AC Safety Ground must be terminated to a suitable ground.

The recommended/minimum wire size to use for the Protective (Safety)

Earth is 6 mm² (10 AWG).

• The instrument ground is provided to minimize electrical noise for all

DC analog/digital signals. The shields/screens for incoming and

outgoing cables can be connected to the supplied ground termination,

which are internally connected to this point.

Power Cable Types/ Recommendations

Connect to a clean (low noise) ground by using a minimum of 6 mm

2

(10 AWG) conductor.

ATTENTION: Good ground connections must be verified before any work is

conducted. Failure to comply can cause serious injury.

This section includes information about the major issues for proper selection

of cable, and provides recommendations to address these issues. Consider these

conditions and requirements when you choose cable material and construction

for your installation:

• Environment: moisture, temperature, and harsh or corrosive chemicals.

• Mechanical needs: geometry, shielding, flexibility, and crush resistance.

• Electrical characteristics: cable capacitance/charging current, resistance/

voltage drop, current rating, and insulation.

• Safety issues: electrical code requirements, grounding needs, and others.

Choosing incorrect cabling can be costly and can adversely affect the

performance of your installation.

In general, follow these temperature ratings for installations:

Surrounding Air Temperature Recommended Wire

50 °C (122 °F) 90 °C (194 °F)

40 °C (104 °F) 75 °C (167 °F)

The OptiSIS solution is rated for use with 75 °C (167 °F) cable. Cable must be

sized by using the 75 °C (167 °F) column in NEC Table 310.15(B)(16)

(formerly Table 310.16). The temperature rating of the lugs is not relevant.

IMPORTANT The temperature rating of the wire affects the required gauge. Verify that

your installation meets all applicable national, state, and local codes.

26 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 27

Connect Power Chapter 3

Cable Entry

Verify that cable sizes, wires, and cabinet penetrations for incoming cables are

to local regulations, specifications, and requirements.

Bottom Entry Conduit

Cable entry is through the bottom gland plate (NEMA 4 models only) for

both the 50 I/O and 100 I/O solutions. To route your cable through the

bottom gland plate, follow these steps.

1. Prepare the installation site so the foundation is level.

2. Remove gland plate, drill holes.

IMPORTANT The outdoor NEMA 4X model does not come with a gland plate. Cable entry

locations are placed at the time of installation.

3. Before the OptiSIS solution is installed, place and stub up conduit

approximately 2 in. (51 mm) above floor level and confirm that all

incoming conduit is clear of any internal components.

For approximate section base dimensions and ground bus locations, see

Installation on page 21

shipped with the solution.

, or elevation and floor plan drawings that are

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 27

Page 28

Chapter 3 Connect Power

Cable Installation

Verify that cabinet penetrations for incoming cables are to local regulations,

specifications, and requirements. Size cables and wires per local codes,

specifications, and requirements.

The OptiSIS solution is rated for use with 75 °C (167 °F) cable. Cable must be

sized by using the 75 °C (167 °F) column in NEC Table 310.15(B)(16)

(formerly Table 310.16). The temperature rating of the lugs is not relevant.

ATTENTION: Properly connect all line and load cables to avoid a bolted fault

and equipment damage.

Lugs

Follow this procedure to install the lugs. The lug accepts a wire size from

2…50 mm

2

(14…2/0 AWG).

1. Verify the compatibility of wire size, type, and stranding versus the

power lugs furnished.

Use correct lugs in all applications.

Power Layout

2. Crimp compression lugs with manufacturer recommended tools.

3. To verify field wire connection points, use the electrical schematics.

The OptiSIS solution uses standard Allen-Bradley power supplies and

redundancy modules. The system design accommodates dual inputs of

24V DC, 110…240V AC, and/or 110…300V DC.

28 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 29

Connect Field Wiring

Chapter 4

Grounding Requirements

Input Wiring

IMPORTANT Analog and digital inputs support a signal ground (default) and also provide

a place to terminate a shield/screen to maintain signal quality.

When external field device power is used, it must be kept separate from the

signal wiring to minimize signal noise.

Field input signals are individually referenced to the instrument ground

(OptiSIS Field Power common, 0V), each has a removable link to allow them

to float regarding instrument ground. The recommended/minimum wire size

to use for the instrument ground (on the instrument ground bus bar) is 6 mm2

(10 AWG).

See the Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1

The device type and where the field wire lands determine whether the flexible

inputs can be wired as analog or digital.

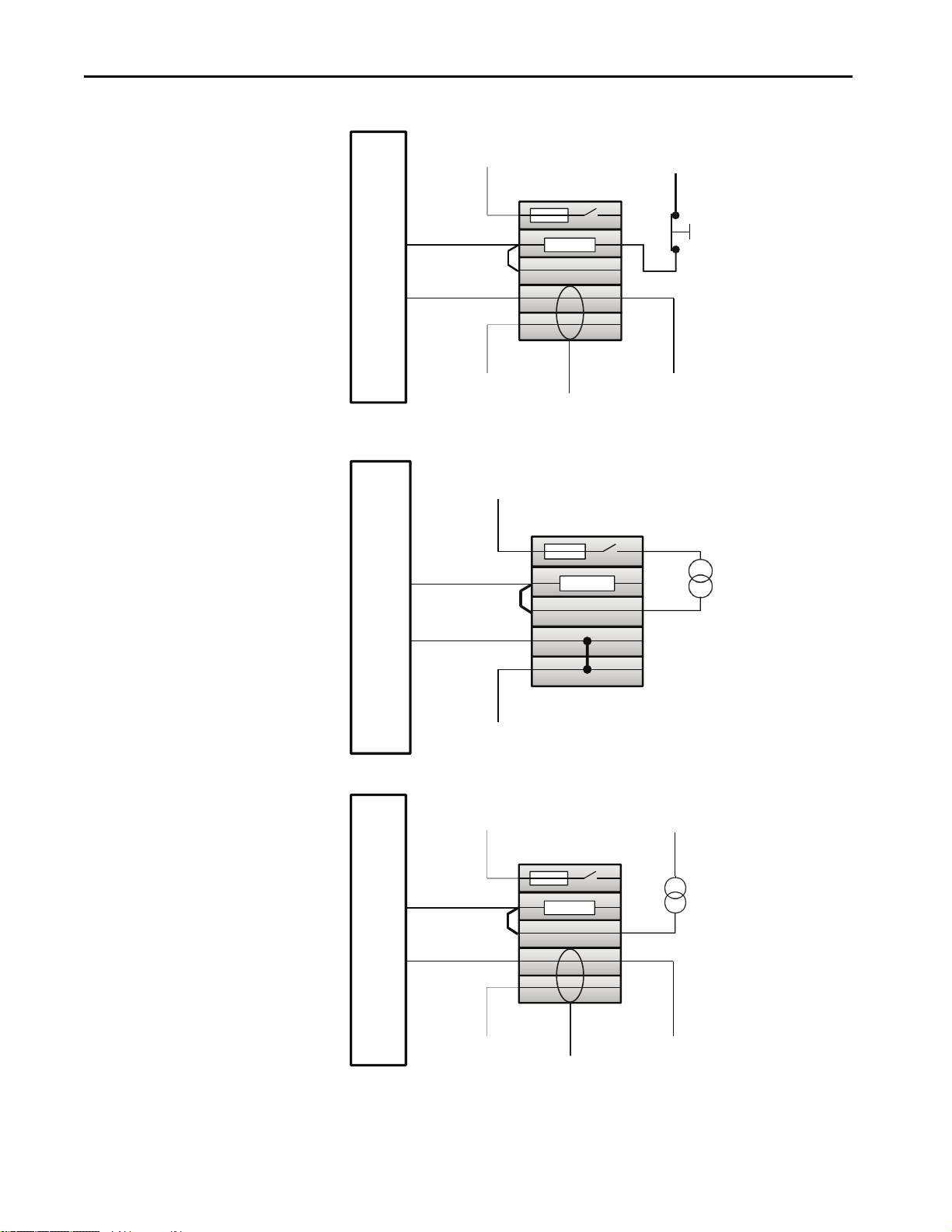

Figure 8 - Digital Input (OptiSIS Solution Powered)

Channel

, for additional information.

Input

24V DC

+

–

0V DC

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 29

Page 30

Chapter 4 Connect Field Wiring

24V DC

0V DC

Input

Channel

+

–

24V DC

0V DC

24V DC

0V DC

End-user to remove jumper

Input

Channel

+

–

Figure 9 - Digital Input (Field Powered)

Input

24V DC

Channel

+

–

24V DC

0V DC

End-user to remove jumper

Figure 10 - Analog Input (OptiSIS Solution Powered)

Figure 11 - Analog Input (Field Powered)

0V DC

30 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 31

Connect Field Wir ing Chapter 4

Device Power

Device Signal

Device Signal/

Power Return

Device Power

Device Signal +

Device Signal –

Device Power Return

Figure 12 - Analog Input (OptiSIS Solution Powered, 3-wire Transmitter)

Input

24V DC

Channel

+

–

0V DC

Figure 13 - Analog Input (OptiSIS Solution Powered, 4-wire Transmitter)

Input

24V DC

Channel

+

–

0V DC

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 31

Page 32

Chapter 4 Connect Field Wiring

Device Signal +

Device Signal –

1

0

111223244344

33

34

12

1

DO Power Line

Terminal Block

DO Return Line

Terminal Block

Relay 3 N.O./1 N.C.

Contact s

Diode Block

End Barrier

DO Power Line

DO Return Line

System-consumed

N.C. Contact

System-consumed

N.O. Contact

Customer

N.O. Contact

Customer

N.O. Contact

Analog Output Wiring

Digital and Relay Output Wiring

Figure 14 - Analog Output Wiring

Analog

24V DC

Output

Channel

+

–

0V DC

Figure 15 - Relay Wiring Legend

Load

ATT EN TI ON : System contacts are used to detect failures in the relay output

circuit. Wiring that is associated with these contacts, if modified, results in

32 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

output fault alarms and reduce safety integrity of the output circuit.

Page 33

Connect Field Wir ing Chapter 4

1

0

111223244344

33

34

Link

Link

Custom er Power

Customer Return

Load

Link

Custom er Power

Customer Return

LoadLoad

1

0

111223244344

33

34

Customer Power

Customer Return

Load

Figure 16 - N.O. Contact for a Normally De-energized Output (Parallel Contacts, Energize to

Trip )

Figure 17 - N.C. Contact for a Normally Energized Output (Series Contacts, De-energize to Trip)

34

33

Figure 18 - 24V DC Powered Digital Output

ATT EN TI ON : External power source must have circuit protection to avoid

exceeding the current rating of the output relay contacts.

0

1

111223244344

Contact Derating

Contact rating is 6 A at 250V AC/30V DC. Derate the maximum continuous

current by 0.1 A for each 1 °C (1.8 °F) above 55 °C (131 °F).

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 33

Page 34

Chapter 4 Connect Field Wiring

Notes:

34 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 35

Startup

Chapter 5

First-time Powerup

Navigation

Follow these steps the first time you apply power to the OptiSIS solution.

1. Switch all circuit breakers to the Off position and open all fuses.

2. Energize the power feed and verify voltage at main incoming terminals.

3. Close each 120V AC circuit breaker one at a time and verify that the

corresponding power supply is energized.

4. Measure the output voltage of the power supply and verify that it is

delivering 24V DC.

5. Close each 24V DC fuse one at a time and verify that the corresponding

equipment receives 24V DC by measuring at the power terminals of the

receiving equipment.

6. Close all 24V DC fuses and check that the system powers up as

expected.

The HMI application facilitates user navigation through a centralized icon

toolbar. The following are the main displays:

• Operator

•Maintenance

• Alarm

•Warning

•Help

Each main display contains at least one page, where pages are equivalent to

displays. To access a particular display, press the corresponding icon.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 35

Page 36

Chapter 5 Startup

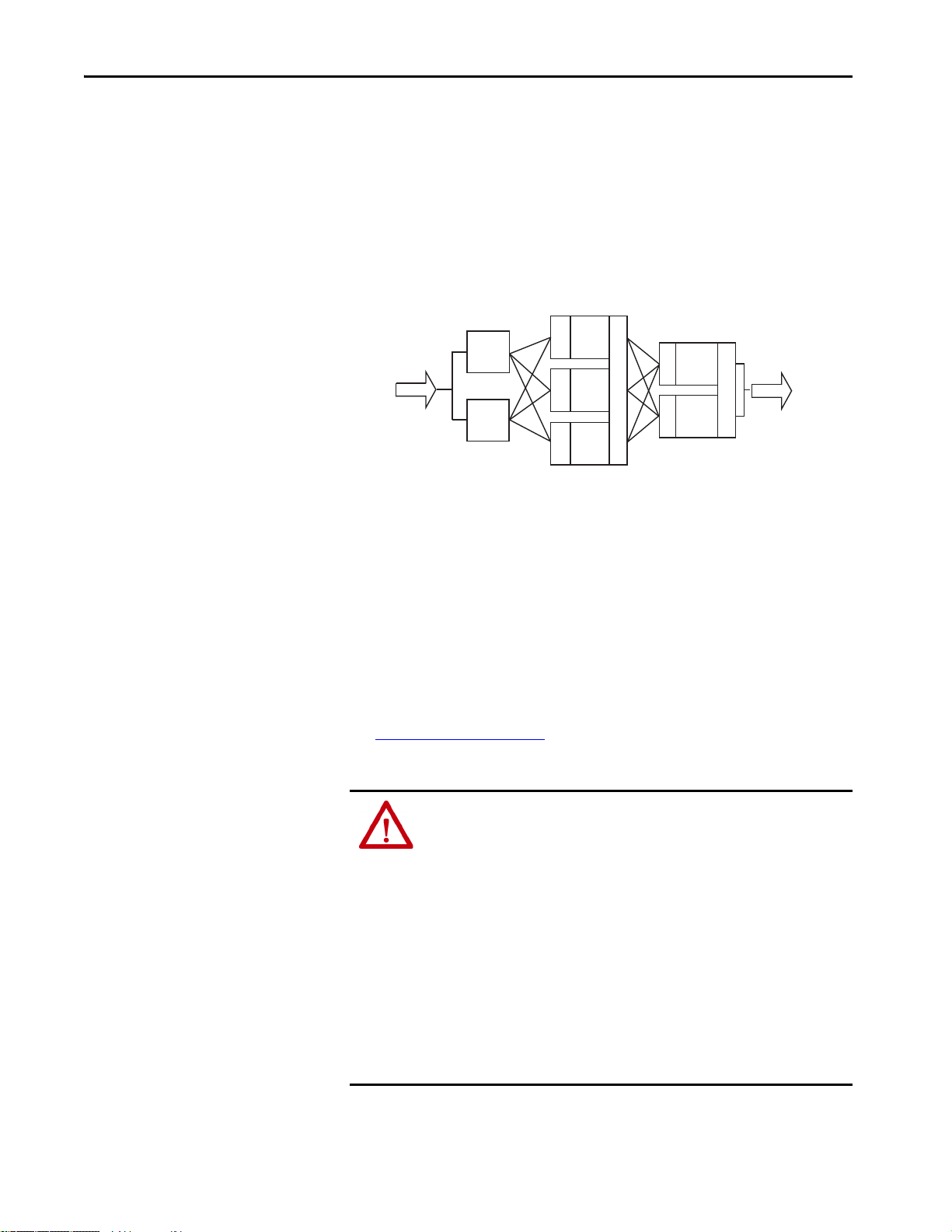

Maintenance

Display

(Controller)

IO

Confi

Password

Control

Confi

Load/Save

Navigation

Operation

Commands

Alarms /

Warnings

Alarm

Display

Warning

Display

Help Screen

(Info)

Maintenance/

Security

Blank

Cause & Eect 5

Display

Cause & Eect 9

Display

Cause & Eect 8

Display

Cause & Eect 7

Display

Cause & Eect 6

Display

Cause & Eect 2

Display

Cause & Eect 3

Display

Cause & Eect 4

Display

Cause & Eect 10

Display

Cause & Eect 1

Display

IO Confi

Faceplates

IO Confi

Overlay

Module

Faceplates

LEGEND

System Home Screen

Screen can navigate directly

to top-level screens

Screen can NOT navigate directly

to top-level screens

Faceplates (popups)

MAIN ICON

TOOLBAR

Navigation (on-screen object)

Navigation

(Navigation / arrows)

Operator

Display

(Overview)

For simple and quick navigation, you can access and progress through multiple

pages of a display by pressing the arrows at the bottom of the display. Notice

the green dot at the center bottom of each display for orientation. Navigation

arrows are available on most displays and loop at end of sequence.

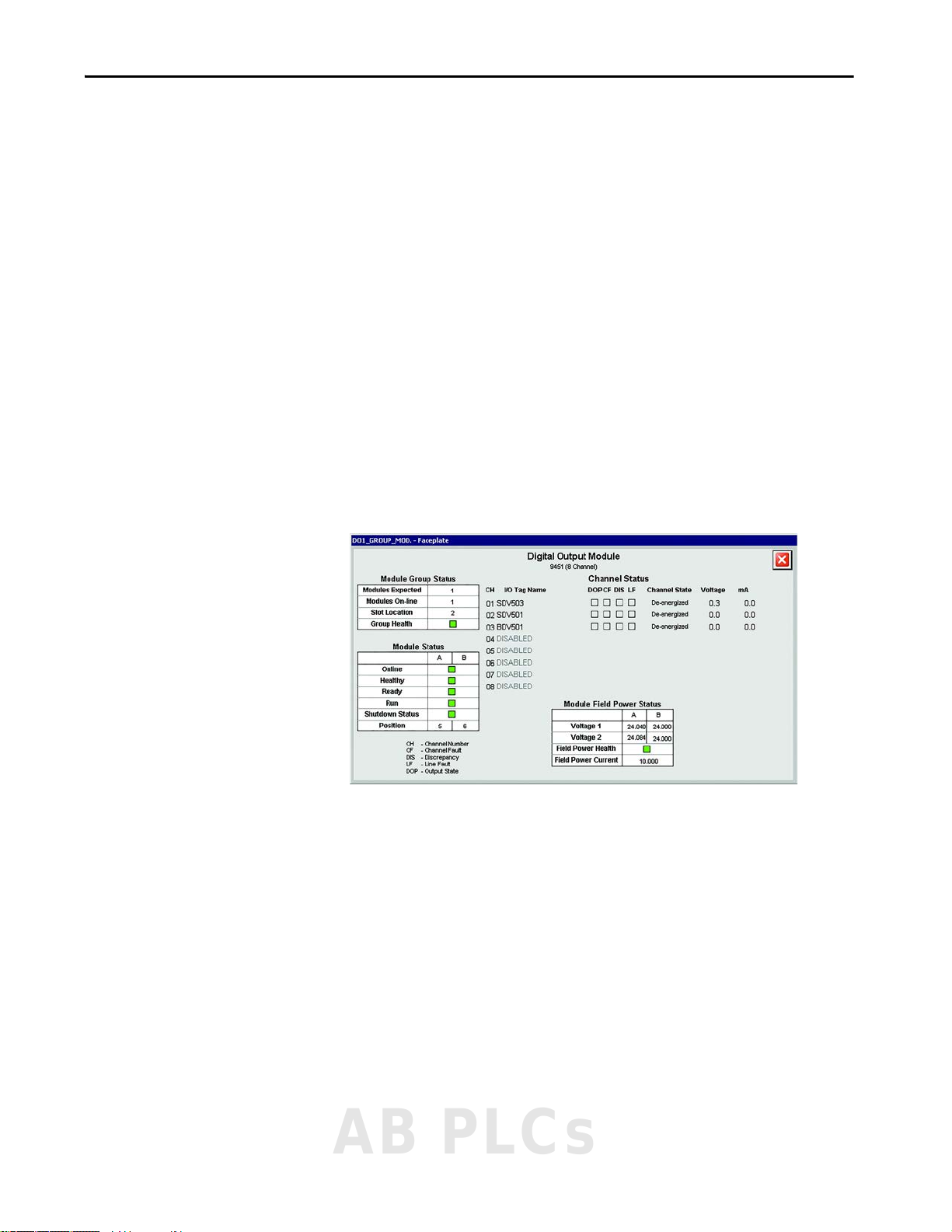

Figure 19 - Navigation Arrows and Page Dots

Figure 20 is a navigational hierarchy structure of the basic displays.

Figure 20 - HMI Displays Navigational Hierarchy Structure

36 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 37

Startup Chapter 5

Operator

The Operator display is the first display that appears. You can access and

progress through the Cause and Effect charts by pressing the arrows at the

bottom of the display. You can also press a specific chart navigation button to

go to that Cause and Effect chart.

Figure 21 - Operator Display

Figure 22 - Cause and Effect Chart - Online Mode

Figure 23 - Cause and Effect Chart - Configuration Mode

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 37

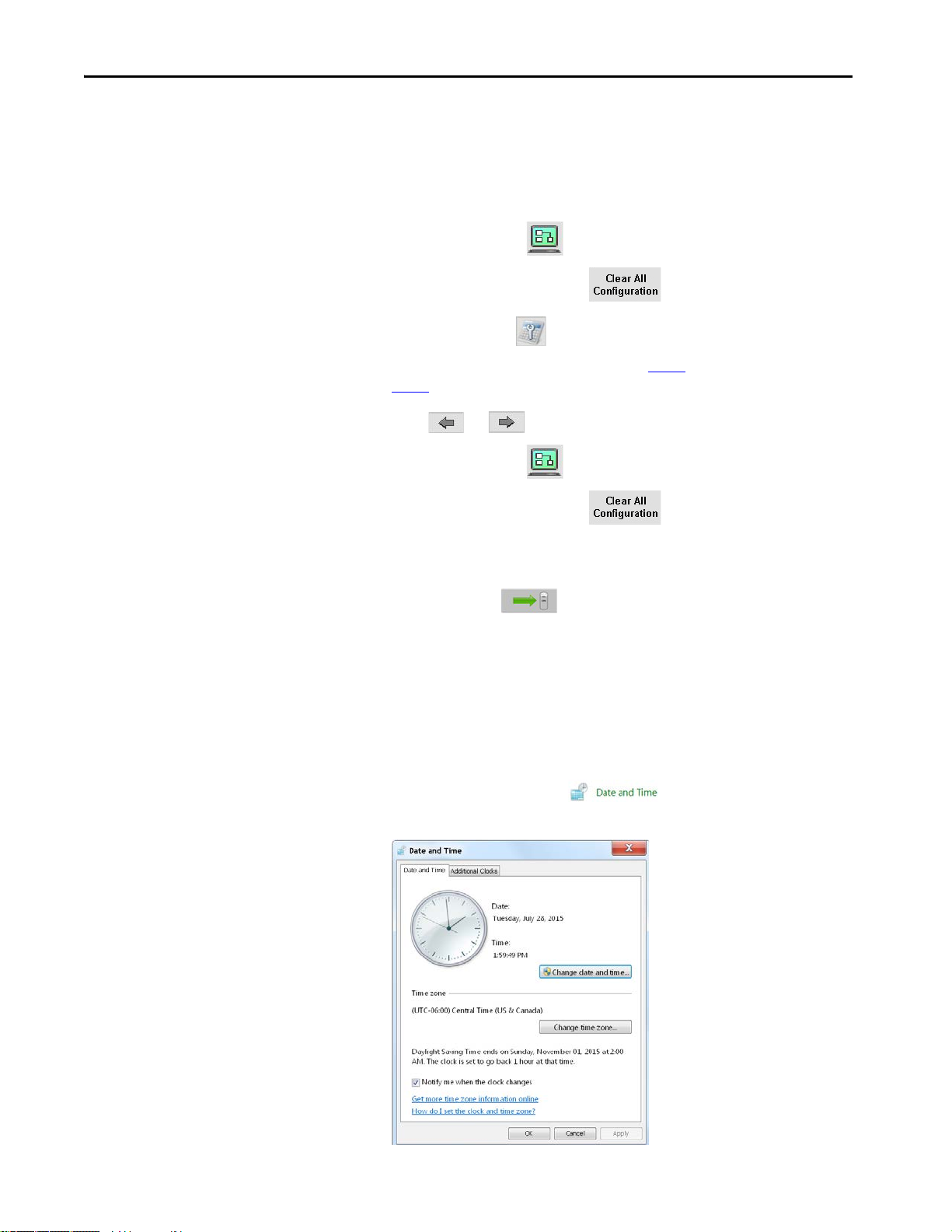

Page 38

Chapter 5 Startup

Maintenance

This Maintenance display has four pages. Access and progress through multiple

pages of a display by pressing the arrows at the bottom of the display.

Figure 24 - Maintenance Display – System Status

Figure 25 - Maintenance Display – I/O Configuration

Figure 26 - Maintenance Display – User Accounts

38 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 39

Figure 27 - Maintenance Display – Configuration Load/Save

Alarm

Use the Alarm display to view the unit alarms.

Startup Chapter 5

Figure 28 - Alarm Display

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 39

Page 40

Chapter 5 Startup

1

2

Warning

Use the Warning display to view a listing of all unit warnings.

• Level 1 Warnings: Conditions are preventing unit operation.

• Level 2 Warnings: Unit functions are disabled or bypassed. These

include suppressed alarms and trips, forced inputs, and forced outputs.

Figure 29 - Warning Display

Help

The Help display has five pages. You can progress through the pages of the

Help display by pressing the arrows at the bottom of the display. The Help

display pages provide information regarding application information, screen

navigation, logic functions, color keys for system icons, and more.

Figure 30 - Help Display – Application Information

Item Description

1 HMI Version - Current version of the OptiSIS HMI application.

PLC Version - Current version of the OptiSIS controller application.

2 Config CRC - Error-checking code configured in the OptiSIS HMI application. This value must match the

Running CRC.

Running CRC - Error-checking code running in the OptiSIS controller application. This value must match the

Config CRC.

40 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 41

Startup Chapter 5

Figure 31 - Help Display – Screen Navigation and Logic Functions

Figure 32 - Help Display – Alarm, Warning, Maintenance, and Security Symbols

Connect Peripherals

You can connect peripherals, such as a keyboard and mouse, to the

corresponding USB ports on the bottom side of the HMI. The USB ports are

covered by a hinged door. See Figure 6 on page 21

ATTENTION: The bottom side USB ports on the 6181X HMI are functionally

hot-pluggable in an environment that is known to be nonhazardous. For

European Zone 2 applications, do not use the USB ports unless the area is

known to be nonhazardous.

.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 41

Page 42

Chapter 5 Startup

Application Accounts

The OptiSIS solution initially loads and is operational without logging in. On

load, the initial user account is ‘Default’.

TIP On the main icon toolbar, the Current User is listed.

See Configure User Accounts on page 44

your password. The user roles are defined in Tabl e 2 o n pa ge 16

To change your current user login, follow these steps.

1. To navigate to the Operator display, press .

The Operator display appears.

2. To log in, press .

The Login dialog box appears.

for instructions on how to change

.

3. Press in the User name field.

A keyboard appears.

42 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 43

4. Type the User name and press Enter on the keyboard.

The keyboard disappears.

TIP User names are not case-sensitive.

5. Press in the Password field.

A keyboard appears.

6. Type the Password and press Enter on the keyboard.

The keyboard disappears.

TIP Passwords are case-sensitive.

7. Press OK.

Startup Chapter 5

If the User name and password are incorrect, an error appears.

TIP You are allowed unlimited login attempts.

If you entered your account information correctly, the current user name

appears in the header.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 43

Page 44

Chapter 5 Startup

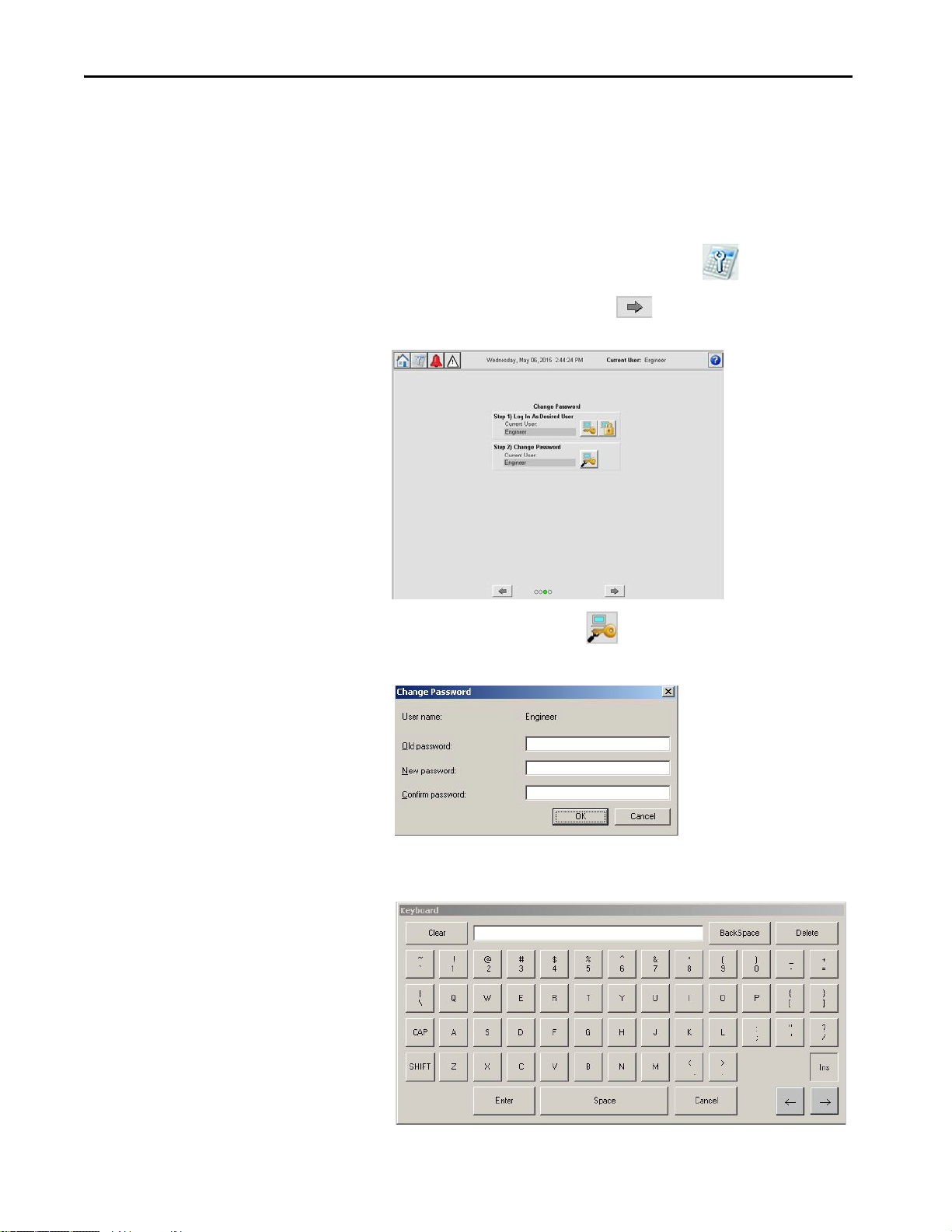

Configure User Accounts

The HMI application has default user account information, however, it is

possible to change the password for a specific user role. To update the

password, follow these steps.

1. Navigate to the Maintenance display by pressing .

2. On the Maintenance display, press until you reach the User

Accounts display.

3. To change the password, press .

The Change Password dialog box appears.

4. Press the Old password field.

A keyboard appears.

44 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 45

Startup Chapter 5

5. Type the old password and press Enter on the keyboard.

6. Press the New password field.

A keyboard appears.

7. Type the new password and press Enter on the keyboard.

8. Press the Confirm password field.

A keyboard appears.

9. Type the new password again and press Enter on the keyboard.

10. To confirm the password change, press OK.

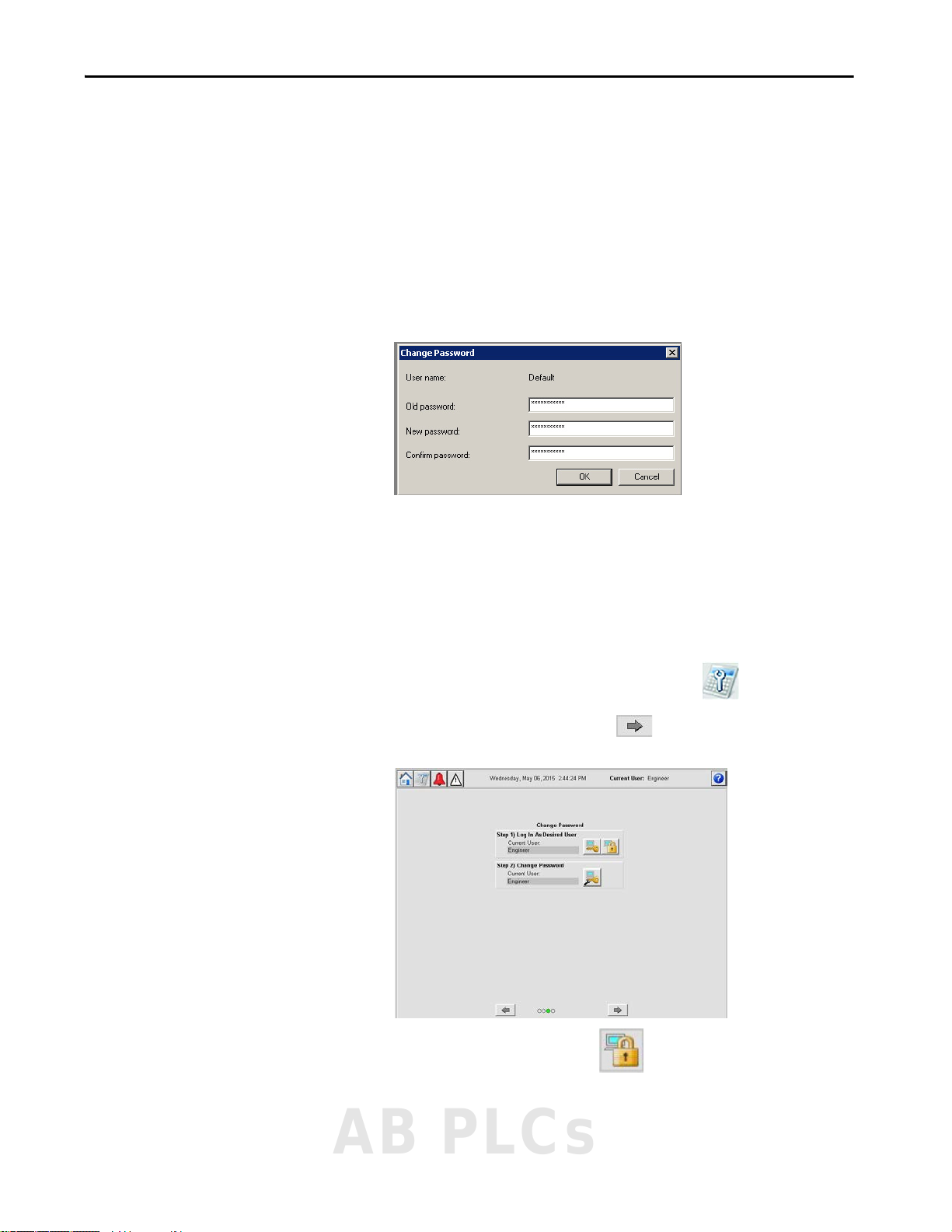

Log Out Current User

To help prevent unauthorized access to your system, we recommend that you

log out when you are done working with the system. To log out of a user

account, follow these steps.

1. Navigate to the Maintenance display by pressing .

2. On the Maintenance display, press until you reach the User

Accounts display.

3. To log off the current user, press .

4. The Current User in the header reverts to Default.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 45

Page 46

Chapter 5 Startup

Notes:

46 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 47

Configure I/O

ATTENTION: If I/O configuration or Cause and Effect logic changes are

performed while process is operational (online changes), then a formal

Management of Change (MOC) process must be followed. The process

includes, but is not limited to, an impact analysis of the change, documented

implementation and test procedures, and identification of any additional

measures that are required while the change is made.

Chapter 6

Configure I/O Points

Table 4 - Configuration Parameters

Category Item Data Type Description

Input Conditioning Channel Enabled Boolean Channel enabled: 0 = disabled, 1 = enabled

Description String Device description

Tag Nam e St rin g Ta g na me

Channel Type Boolean Input mode: 0 = digital input, 1 = analog input

Switching Level Real Digital switching level value (V) [Range = 0…23V (digital only)]

Input Sense Boolean Digital input sense: 0 = normally closed, 1 = normally open (digital input only)

Line Monitoring Fitted Boolean Monitored DI: 0 = not monitored, 1 = line monitored (digital input only)

Units String Process variable engineering units (analog input only)

Maximum PV Real Process variable maximum value [Range = -999999.9…999999.9 (analog input only)]

Minimum PV Real Process variable minimum value [Range = -999999.9…999999.9 (analog input only)]

Alarm Unlatched Boolean Unlatch alarms: 0 = latched, 1 = not latched

Alarm on Fault Boolean Alarms on fault: 0 = no alarm on fault, 1 = alarm on fault

Alarm Enable 4x Boolean (1 per analog alarm) Analog alarm enabled: 0 = disabled, 1 = enabled

Alarm Limits 4x Real (1 per analog alarm) Analog alarm limit value (EU)

Digital Output

Conditioning

Channel Enabled Boolean Channel enabled: 0 = disabled, 1 = enabled

Description String Device description

Tag Nam e St rin g Ta g na me

Output Sense Boolean Digital output sense: 0 = normally de-energized, 1 = normally energized

Unlatch Output Boolean Output latch type: 0 = latched, 1 = not latched

Configuration parameters are accessible on the HMI or by using the offline

configuration tool (Appendix A

Configuration parameters consist of the following items.

on page 103) for initial development.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 47

Page 48

Chapter 6 Config ure I/O

7

6

12345

Item Description

1 Flexible inputs

2 Digital outputs

3Analog outputs

4 Internal paramete rs

5 Modbus inputs

6 Online/Configuration mode indicator

7 Online/Configuration toggle

Table 4 - Configuration Parameters

Category Item Data Type Description

Analog Output

Conditioning

Internal Parameters Description String Description

Modbus Inputs Description String Description

Channel Enabled Boolean Channel enabled: 0 = disabled, 1 = enabled

Description String Device description

Tag Nam e St rin g Ta g na me

Channel Type Boolean Analog output mode: 0 = AI repeat, 1 = Cause and Effect output

AI Repeat DINT AI channel to repeat

High Current Real High current value (mA), max 20 mA

Low Current Real Low current value (mA), min 0 mA

Output Sense Boolean Digital output sense: 0 = normally de-energized, 1 = normally energized

Tag Nam e St rin g Ta g na me

Tag Nam e St rin g Ta g na me

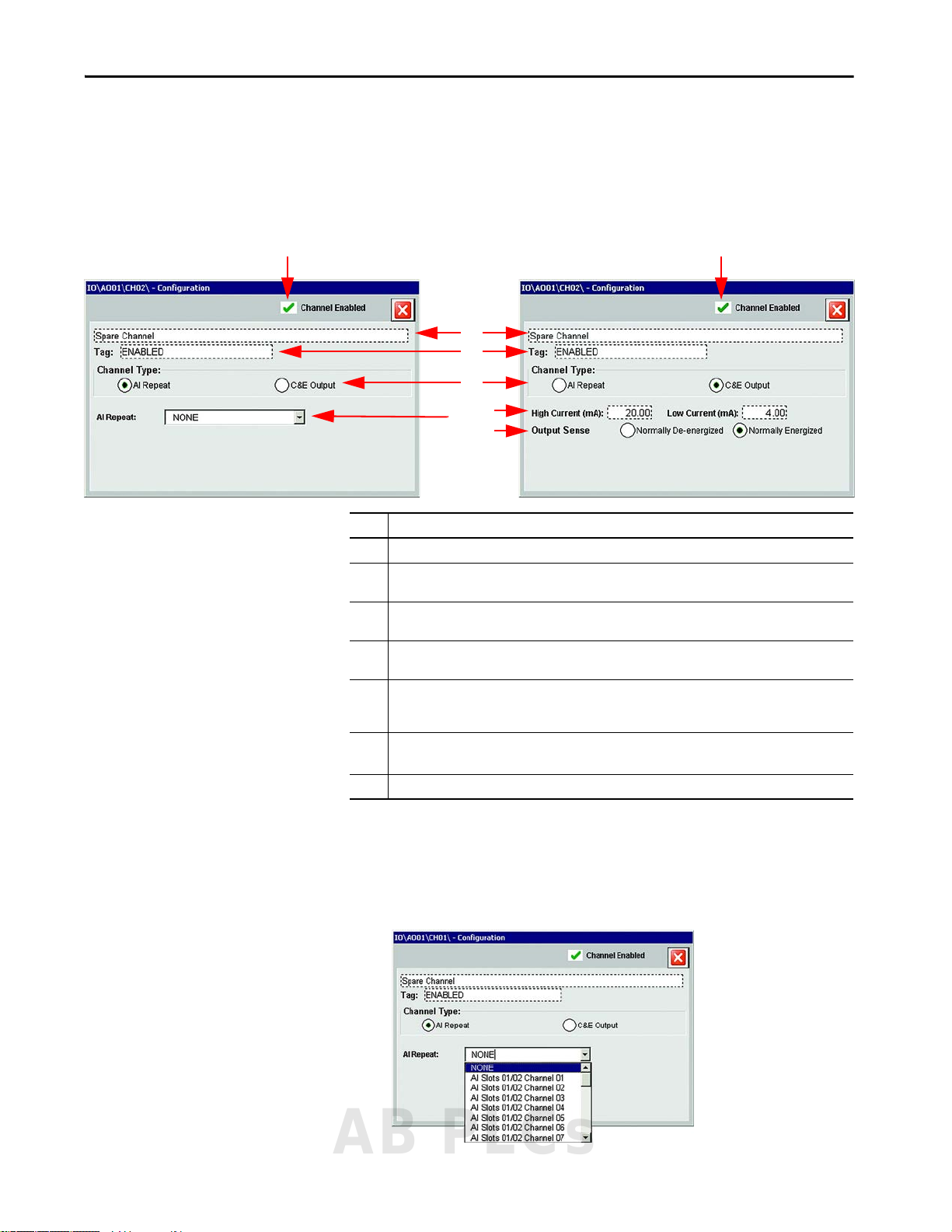

Figure 33 shows the I/O configuration display. The display shows a

representation of each I/O card and its channels. The channels are either green

to indicate that the channel configuration matches the runtime configuration,

or yellow to indicate that there is a difference between the configured I/O and

the runtime I/O. The Online/Configuration mode indicator shows if you are

in Online mode (view current controller variables) or Configuration mode

(configure then download configuration).

The configuration display is used to Enable, Disable, and Edit Channels.

When you press on the colored box to the right of the channel number, the

configuration display appears. Each configuration display is described later in

the chapter (starting on page 52

).

Users with a role other than Engineer can view status, but cannot edit the I/O

configuration.

Figure 33 - I/O Configuration Display

48 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 49

Configure I/O Chapter 6

Configure an I/O

IMPORTANT To configure your I/O with the Offline Configuration Tool, see Appendix A

These steps explain how to configure the fundamental characteristics for an

input, output, internal parameter, or Modbus input.

TIP You must be in Configuration mode to change characteristics.

IMPORTANT Internal parameters and Modbus inputs are enabled by default and are

selectable by the Cause and Effect charts. Modbus inputs are the only

parameters that can be written through Modbus.

1. Log in as Engineer.

See Application Accounts on page 42

2. To go to the Maintenance display, press .

3. From the Maintenance display, press until the I/O configuration

display appears.

4. To configure the I/O, press .

for login procedure.

.

The I/O Configuration display appears.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 49

Page 50

Chapter 6 Config ure I/O

5. To configure a particular channel, press the channel.

A configuration faceplate opens.

6. To enable the channel, check Channel Enabled.

IMPORTANT If Channel Enabled is not selected, then all other parameters are not seen.

Checking and clearing Channel Enable causes parameters to revert to a

default state.

50 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 51

Configure I/O Chapter 6

I/O Configuration

Modbus Input Configuration Internal Parameters Configuration

7. To configure a channel, follow these steps.

a. Press in the description field.

A keyboard appears.

IMPORTANT The keyboard is a standard FactoryTalk® keyboard. Update Field is not

configured for use in the OptiSIS solution. Press Enter to store parameter

values.

b. Type a description (maximum length 40 characters).

c. Press Enter on the keyboard.

IMPORTANT For internal parameters and Modbus inputs, no further configuration is

The keyboard disappears. The field updates with the description.

d. Repeat this process for Tag Name (maximum length 20 characters).

8. Continue to:

• Configure Analog Input Characteristics

• Configure Digital Input Characteristics

• Configure Analog Output Characteristics

• Configure Digital Output Characteristics.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 51

needed.

Page 52

Chapter 6 Config ure I/O

6

7

8

9

10

12

1 2

4

5

3

11

Configure Analog Input Characteristics

After the input is created by enabling the channel, entering a description, and

naming the tag, you can configure the characteristics of the analog input.

TIP Unconfigured points return a tag name of 'DISABLED' and a description of

'Spare Channel’. The tag name and descriptions reside in the HMI only.

Figure 34 - Analog Input Configuration Faceplates

Item Description

1 Device Configuration tab.

2 Channel Enabled - This feature controls the channel parameters configuration.

3 Description (maximum length 40 characters) - The description is shown in the Module Type faceplate to

describe the channel. Be descriptive for quick navigation and selection.

4 Tag Name (maximum length 20 characters) - The tag name is used in the Module Type faceplate to identify

the channel. Use field device names for Cause and Effect selection/presentation.

5 Channel Type (Analog or Digital) - The Flexible Input channel can be wired to either an analog input or

digital input (page 56

6 Process Variable (PV) Minimum/Maximum - Input process variable maximum and minimum value settings

in engineering units, as corresponding to 20 mA and 4 mA respectively (range = -999999.9…999999.9).

7 Units (maximum length 6 charac ters) - Engineering units relevant to the input that is configured (for

example, barg, degC, degF, %LEL, ppm).

8 Alarm Configuration tab.

9 Alarm Unlatched - With this box cleared, any configured input alarm latches when the alarm occurs. To

unlatch, the input first has to return to a normal value and then be reset (either by the HMI or by the

external Modbus Rese t being toggled to 1).

With this box checked, the analog input or digital input alarm resets once the input is at a normal value.

10 Alarm on Fault - With this box cleared, a field or module fault does not cause the input to generate any trip

alarms (although faults are still reported).

With this box checked, a field or module fault generates all trip alarms for the inputs affected.

11 Enable Alarms (High High, High, Low, and Low Low) - Enables (box checked)/disables (box cleared) the

selected alarm for the analog input.

12 Limits (High High, High, Low, and Low Low) - Configure the required alarm limits, within the configured

maximum and minimum process variable values, as defined on the Device Configuration tab.

). Required subparameters vary according to the option you choose here.

52 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 53

To configure the analog input, follow these steps.

1. In Channel Type, press Analog Input.

The analog input characteristics appear.

2. Configure the values for the analog input settings.

TIP Input Process Variable maximum and minimum settings correspond to

20 mA and 4 mA respectively.

a. Press in the Maximum PV field.

A numeric keypad appears.

Configure I/O Chapter 6

b. Enter a value by using the keypad.

c. Press Download.

d. Repeat steps a

e. Press in the Units field.

A keyboard appears.

f. Enter the units.

g. Press Enter on the keyboard.

3. To open the Alarm configuration tab, press .

…c for Minimum PV.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 53

Page 54

Chapter 6 Config ure I/O

4. Configure the Alarm Unlatched and Alarm On Fault settings as

required by pressing the required checkboxes.

5. To set the limit values for the alarms, follow these steps.

IMPORTANT You have to check an Alarm Enable box first before setting a limit value.

Four limits are available (High High, High, Low, and Low Low) to be

used in your specific installation. These instructions describe how to

configure one of these limits.

a. Under Enable, press the High High checkbox.

A green check mark and Limits field appear.

b. Press the High High Limits field.

A keypad appears.

c. Enter the limit.

d. Press Download.

The keypad disappears.

6. To close the configuration faceplate, press .

54 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 55

Configure I/O Chapter 6

7. To make your changes to the controller, you can download configuration

by using the logic write keyswitch at the front of the panel.

IMPORTANT On the I/O configuration display, the I/O channels that you configured or

changed appear as yellow. The yellow box indicates that there are

differences between what you configured and what the controller is

running.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 55

Page 56

Chapter 6 Config ure I/O

8

9

10

6

7

1

5

4

3

2

11

Configure Digital Input Characteristics

After the input is created by enabling the channel, entering a description, and

naming the tag, you can configure the digital input characteristics.

TIP Unconfigured points return a tag name of 'DISABLED' and a description of

'Spare Channel’. The tag name and descriptions reside in the HMI only.

Figure 35 - Digital Input Configuration Faceplates

Item Description

1 Device Configuration tab.

2 Channel Enabled - This feature controls the channel parameters configuration.

3 Description (maximum length 40 characters) - The description is shown in the Module Type faceplate to

describe the channel. Be descriptive for quick navigation and selection.

4 Tag Name (maximum length 20 characters) - The tag name is used in the Module Type faceplate to identify

the channel. Use field device names for Cause and Effect selection/presentation.

5 Channel Type (Analog or Digital) - The Flexible Input channel can be wired to either an analog input

6 Switching Level (V) - The level across which the input is deemed to be energized (above this value) or

7 Input Sense (Normally Open or Normally Closed) - Normal state of the field switch.

8 Line Monitoring Fitted - Check this box for line monitored switches/devices with End-of-Line (EOL)

9 Alarm Configuration tab.

10 Alarm Unlatched - With this box cleared, any configured digital input alarm latches when the alarm occu rs.

11 Alarm on Fault - With this box cleared, a field or module fault does not cause the input to generate any trip

) or digital input. Required subparameters vary according to the option you choose here.

(page 52

de-energized (below this value). Typically the default value (8.96V) is sufficient. (min 0V, max 23V)

resistors installed. Clear this box for non-line monitored devices.

With this box cleared, open circuit and short circuit faults are not generated.

With this box checked, open circuit and short circuit faults are generated.

To unlatch, the input first has to return to a normal value and then be reset (either by the HMI or by the

external Modbus Reset being toggled to 1).

With this box checked, the digital input alarm resets once the input is at a normal value.

alarms (although faults are still reported).

With this box checked, a field or module fault generates the configured trip alarm for the digital input.

56 Rockwell Automation Publication 1711-UM004B-EN-P - September 2016

Page 57

Configure I/O Chapter 6

To configure the digital input, follow these steps.

1. In Channel Type, press Digital Input.

The digital input characteristics appear.

2. Select the type of input sense required; press Normally Closed or

Normally Open.

3. To set the switching level, follow these steps.

a. Press the Switching Level field,

A keypad appears.

b. Enter the value.

c. Press Download.

The keypad disappears.

AB PLCs

Rockwell Automation Publication 1711-UM004B-EN-P - September 2016 57

Page 58

Chapter 6 Config ure I/O

4. Specify if line monitoring is configured for this input.

See Line Monitoring (Digital Inputs) on page 59

for more information.

5. To open the Alarm configuration tab, press .

6. Configure the Alarm Unlatched and Alarm On Fault settings as

required by pressing the required checkboxes.

7. To close the configuration faceplate, press .

8. To make your changes to the controller, you can download configuration

by using the logic write keyswitch at the front of the panel.

IMPORTANT On the I/O configuration display, the I/O channels that you configured

appear as yellow. The yellow box indicates that there are differences

between what you configured and what the controller is running.