Page 1

Installation Instructions

Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

WARNING: Electrostatically sensitive sub-assemblies can be destroyed by voltages far below the human perception threshold. These voltages already occur if you touch a component

or electrical terminals of a sub-assembly without being electrostatically discharged. The damage of a sub-assembly caused by an overvoltage is often not immediately

recognised, but will be noticed only after a longer operating time.

Mounting or actuation of the 1694 connector arm must only be effected at dead-voltage. For start-up the 1694 connector arm must be closed.

Device to be installed, operated and maintained by trained personnel only.

To secure device properly against unintended access, product shall be mounted in locked cabinet.

The device can’t be serviced or repaired.

Do not open device’s enclosure.

Table of contents

1. Bulletin 1694 Electronic circuit protection modules for 24V DC with IO-Link communication ................................................................... 2

1.1. 1694-PMD* and 1694-PMD2A10 Circuit Protection Module Technical data............................................................................... 3

2. Bulletin 1694. Power Feed 1694-PFD1244 with IO-link communication ................................................................................................... 8

2.1. 1694-PFD1244 Power Feed Module Technical data .................................................................................................................. 9

3. IO-Link technology review ....................................................................................................................................................................... 15

3.1. Accessing IO-Link Data............................................................................................................................................................. 16

4. IO-Link connector description used for 1694-PFD1244 .......................................................................................................................... 16

5. Signaling of operating status on 1694-PFD1244 Power Feed Module.................................................................................................... 17

6. Signaling of operating status on 1694-PMD* Protection Modules........................................................................................................... 18

7. Installation and configuration of 1694-PFD1244 and 1694-PMD* in Studio5000.................................................................................... 19

7.1. AOP Installation......................................................................................................................................................................... 19

7.2. Creating a Project...................................................................................................................................................................... 19

7.3. Adding a Controller.................................................................................................................................................................... 19

7.4. Adding a Point IO (Ethernet Adapter)........................................................................................................................................ 20

7.5. Adding an IO-Link Master.......................................................................................................................................................... 21

7.6. Registration of IODD file for Power Feed 1694-PFD1244......................................................................................................... 23

7.7. Connect the 1694-PFD1224 to the IO-Link Master ................................................................................................................... 25

7.8. Download the Project to Allen-Bradley Logix Controller............................................................................................................ 26

7.9. Exploring the 1694-PMD1244 Parameters in AOP ................................................................................................................... 28

7.9.1. Common Tab .................................................................................................................................................................. 30

7.9.2. Identification Tab ............................................................................................................................................................ 31

7.9.3. Observation Tab ............................................................................................................................................................. 32

7.9.4. Parameters Tab .............................................................................................................................................................. 34

7.9.5. Diagnosis Tab................................................................................................................................................................. 36

8. Device Parameters Details ...................................................................................................................................................................... 39

8.1. Cyclic Data ................................................................................................................................................................................ 39

8.2. Non-Cyclic Data ........................................................................................................................................................................ 43

9. Rockwell Automation Support ................................................................................................................................................................. 47

Page 2

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

2

1. Bulletin 1694 Electronic circuit protection modules for 24V DC with IO-Link communication

Bulletin 1694 Electronic Circuit Protection is a modular solution with a max. system capacity of 40A. The protection modules come in fix and adjustable current

rating in a range from 1A…10A. Designed for 24V DC circuits, the 1694 provides comprehensive protection against short circuit and overcurrent conditions

while allowing for inrush current. 1694-PMD* and 1694-PFD1244 Provides IO-Link communication capability.

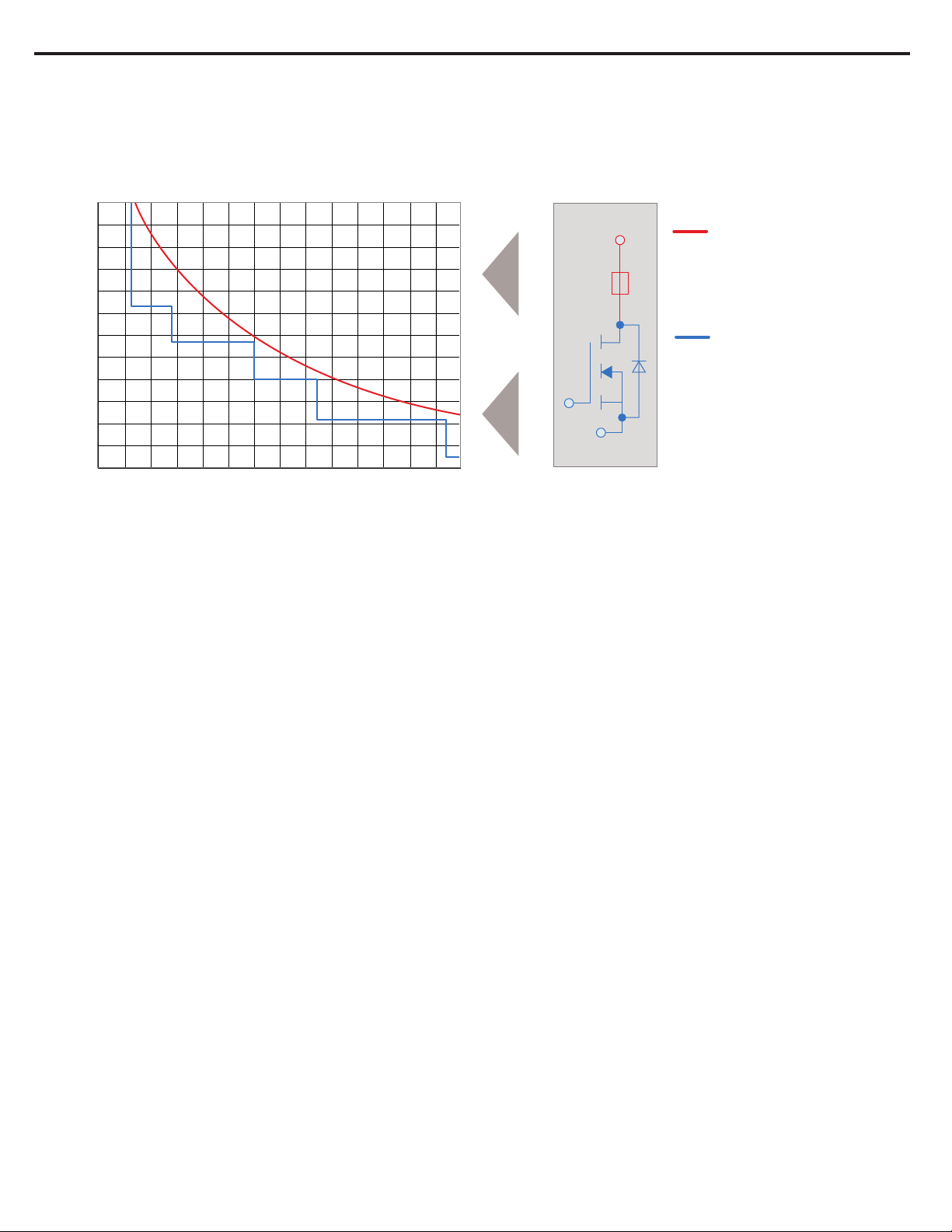

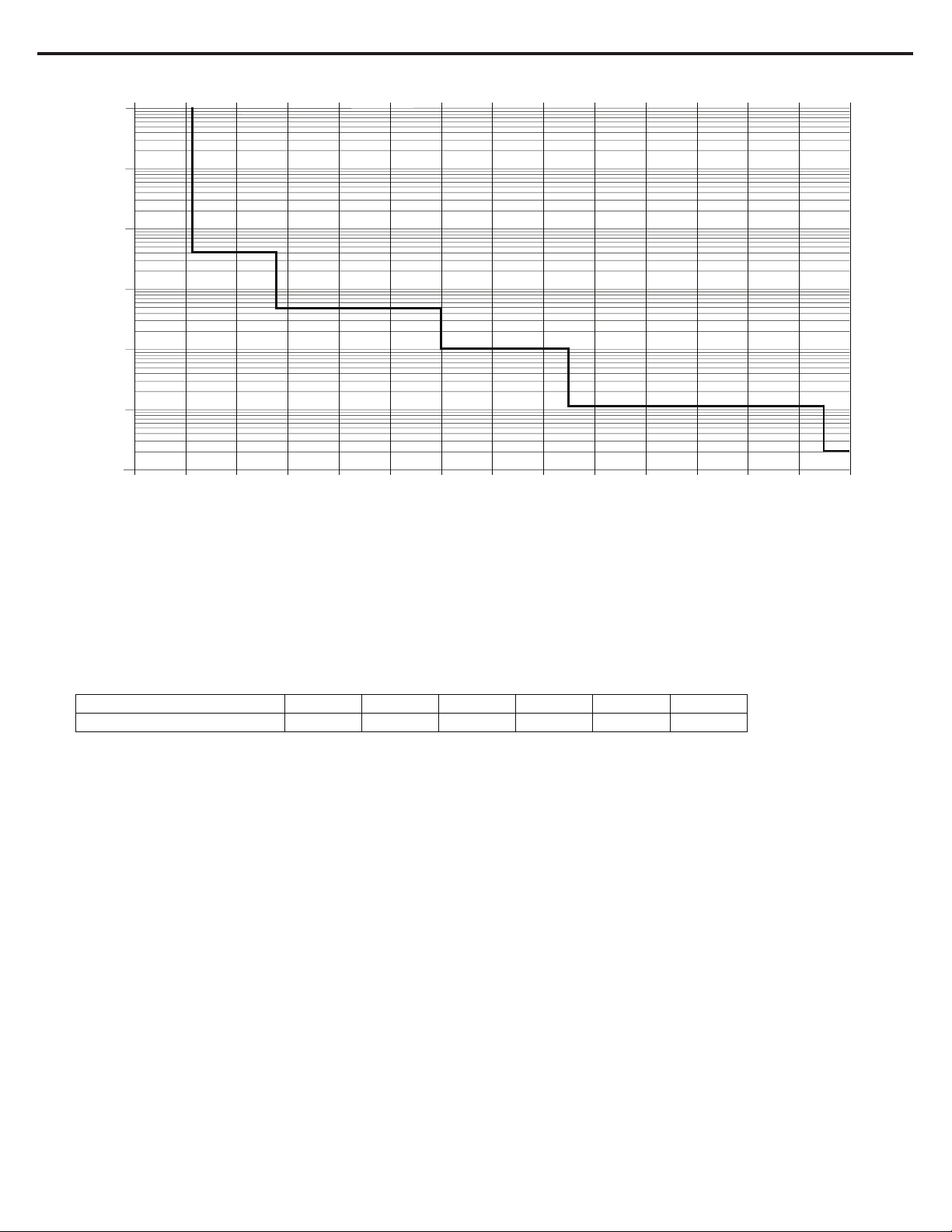

Basic trip curve and schematic diagram 1694-PMD

Schematic diagram

1.000

4 A

LINE

blade fuse

100

10

1

semiconductor

0,1

0,01

trip time in seconds

0,001

0,8 1,0 1,2 1,4 1,6 1,8 2,0 2,2 2,4 2,6 2,8 3,0 3,2 3,4 I

KS

4 A

LOAD

times rated current trip curve

Features

• Combination of supply modules, circuit protection and power distribution

• IO-Link communication to Logix Controller via Power Feed 1694-PFD1244 module. Main features:

- Current and Voltage monitoring,

- Statistics,

- Remote control,

- Error massaging.

• Selective load protection by means of electronic trip curve

• No accessories required for connecting the modules

• Width per channel only 12.5 mm (1-channel) or 6.25mm (2-channel)

• Integral fail-safe element, adjusted to current rating

• Switching capacitive loads up to 20,000 μF (at IN > 6A)

• Manual ON/OFF/reset momentary switch

• Clear status indication by means of LED and auxiliary contact (1694-PF power feed module)

• Wire connection via push-in terminals

• 1694-PMD* available in Class 2 version in nominal currents: 1A, 2A, 3A, 4A

• Adjustable circuit protection module 1694-PMD2A10 with trip current range from 1A to 10A.

Notes

• Connection to a higher or not reliably disconnected voltage can cause hazardous conditions or damages

• Only the intended Bulletin 1694 circuit protectors must be used

• The technical data of the circuit protectors used must be observed

• The entire power distribution system must only be installed by qualified personnel

• Only after expert installation must the device be supplied with power

• After tripping of the circuit protector and before reset, the cause of the anomaly (short circuit or overload) must be remedied

• The national standards must be observed for installation and selection of feed and return cables.

• Circuit protection modules 1694-PMD* must be operated with 1694-PFD1244.

• Circuit protection modules 1694-PMD2A10 can be operated with 1694-PFD1244 or 1694-PF* (Line +). Module is recognized automatically.

• IO-Link communication is provided by Power Feed 1694-PFD1244 to Protection Modules. Protection Modules cannot communicate directly with Logix Controller

and IO-Link master.

• Standard Protection Modules should not be used in IO-link configuration (for 1694-PMD2A10 see note above).

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 3

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

3

1.1. 1694-PMD* and 1694-PMD2A10 Circuit Protection Module

Technical data (Tamb = +23 °C, UB = DC 24 V)

Operating voltage

Closed current I

1694-PM1 (1-channel)

1694-PM2 (2-channel)

U

B

0

DC 24 V (min. 18 V, max. 30 V)

(no battery-buffered applications)

in ON condition:

typically 5 mA

typically 8 mA

Reverse polarity protection Yes, without load

Rated current IN

1694-PM1 (1-channel)

1694-PM2 (2-channel)

Visual status indication

current ratings:

1 A, 2 A, 3 A, 4 A, 6 A, 8 A, 10 A

1A/1A, 2A/2A, 3A/3A, 4A/4A, 6A/6A

Green: Load circuit connected

by means of LED:

flashing

orange Load current warning limit reached

green:

orange: Overload or short circuit until disconnection

red: After disconnection (trip condition) due to overload or short circuit

after undervoltage release of operating voltage in ON condition with autoreset

OFF: Device switched off by means of ON/OFF

Non Illuminated momentary switch or no operating voltage

For additional information about LED singling related communication with Logix Controller (PLC)

by IO-Link technology please refer to chapter: Signalling of operating conditions on 1694-PMD* Protection Module (Page 18).

Load current warning limit (IWLimit)

1694-PMD2A10

1694-PMD

Hysteresis

Overload disconnection (I

with trip times (t

)

OL

short circuit trip time (t

)

OL

)

KS

typically 0.9 x IN (0.5 ... 1.0 x IN configurable)

typically 0.9 x IN (0.5 ... 1.0 x IN configurable)

typically 5%

typically I

typically I

typically I

typically I

typically at (I

see time/current characteristics

: IN x 1.05 tOL: 3s

OL

: IN x 1.35 tOL: 0.5s

OL

: IN x 2.00 tOL: 0.1s

OL

: IN x 2.50 tOL: 0.012s

OL

KS

) tKS: 0.002s

1

1

depending on power source

Influence of ambient temperature

on overload trip and load current

warning limit

Leakage current in load circuit

in OFF condition

Voltage drop in load circuit

1694-PMD

between LINE+ and LOAD+

Voltage drop in load circuit at I

1694-PMD2A10

N

between LINE+ and LOAD+

for

see temperature factor table

typically <1 mA

: 1A (CL2) typically 180 mV

• I

N

: 2A (CL2) typically 110 mV

• I

N

: 3A typically 120 mV

• I

N

: 3A- CL2 typically 130 mV

• I

N

: 4A typically 115 mV

• I

N

: 4A- CL2 typically 180 mV

• I

N

: 6A typically 170 mV

• I

N

: 8A typically 160 mV

• I

N

: 10A typically 180 mV

• I

N

: 1A typically 30 mV

• I

N

: 2A typically 39 mV

• I

N

: 3A typically 48 mV

• I

N

: 4A typically 57 mV

• I

N

: 5A typically 66 mV

• I

N

: 6A typically 74 mV

• I

N

: 7A typically 83 mV

• I

N

: 8A typically 92 mV

• I

N

: 9A typically 101 mV

• I

N

: 10A typically 110 mV

• I

N

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 4

4

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Fail-safe element

integrated fuse

Adjusted to the corresponding rated current IN

: 1A (CL2) fail-safe IN: 1A

• I

N

: 2A (CL2) fail-safe IN: 2A

• I

N

: 3A fail-safe IN: 3.15A

• I

N

: 3A-CL2) fail-safe IN: 4A

• I

N

: 4A fail-safe IN: 4A

• I

N

: 4A-CL2 fail-safe IN: 4A

• I

N

: 6A fail-safe IN: 6.3A

• I

N

: 8A fail-safe IN: 8A

• I

N

: 10A fail-safe IN: 10A

• I

N

Low voltage monitoring

of operating voltage

OFF at typically U

ON at typically U

Hysteresis typically 2 V with automatic OFF and ON operation

< 16.0 V

B

> 19.0 V

B

ON delay

- with power ON

channel 1: typically 100 ms (1694-PMD)

channel 2: typically 200 ms (1694-PMD)

channel 1: typically 1,500 ms (1694-PMD2A10, depending on slot)

channel 2: typically 1,600 ms (1694-PMD2A10, depending on slot)

- when switching on via ON/OFF

momentary switch

- after an undervoltage

channel 1: typically 5 ms

channel 2: typically 100 ms

channel 1: typically 5 ms

channel 2: typically 5 ms

Disconnection of the load circuit - manually on the device with the ON/OFF momentary switch

- after an overload / short circuit disconnection with storage (no automatic reset)

- temporarily at undervoltage

- at no operating voltage

- remote control via the Logix Controller and IO-Link master control unit

Switching on the load circuit

- Momentary switch ON/OFF

Unit can only be switched ON when operating voltage was applied

The circuit protector can be switched ON by the Logix Controller and IO-Link master or otherwise directly on the

device. These two options are linked with AND. Switch ON is only possible if switched ON from both positions. If the

circuit protector was switched OFF either by the control unit or by the momentary switch directly on the device, switch

ON must be affected also from the corresponding position.

- Apply operating voltage

Read currently adjusted rated

current of 1694-PMD2A10

The device re-starts with the last stored condition.

Reading the currently adjusted current rating is, independent of the operating mode (COM or standard), possible for

each channel directly on the 1694-PMD2A10.

Enquiry mode is started by pushing the button between >= 2 seconds and < 5 seconds After releasing the button, the

LED is RED for 333 ms to indicate start of enquiry. Afterwards, the LED flashes ORANGE in a puls/break ratio of 1/2

with a frequency of 1 Hz to indicate the adjusted current value. When the adjusted current rating is reached, signaling

re-starts after the RED LED re-lights for 333 ms. The enquiry mode is left after the adjusted current rating was signaled

5 times or by pressing the button. Visual indication will now show again the current operating condition.

The enquiry mode is possible in all operating conditions (ON, OFF, UNDERVOLTAGE and TRIPPED).

Setting the current ratings of

1694-PMD2A10

The adjustment mode directly on the 1694-PMD2A10 can only be activated in standard mode.

The adjustment mode is started per channel by pushing the button for >= 5 seconds. After releasing the button, the

LED is RED for 333 ms to indicate start of adjustment. The LED is blinking GREEN with a pulse/break ratio of 1/4 at a

frequency of 0.6 Hz for visual indication. GREEN After reaching the max. adjustment value, signaling re-starts. Overrun

of the max. adjustment value after 1 Ampere is indicated by the RED LED (333 ms). The current rating to be adjusted

is adopted by pushing the button during the blinking period of 1 A up to the max. adjustment value. If for instance the

button is pushed after the 7th illumination of the GREEN LED, 7A is adopted as current rating and visual indication

again shows the current operating condition. If the button is not pressed, the adjustment mode is left after 5 times

signaling the current rating range without a new current rating being adopted and the visual indication returns to current

status indication.

The adjustment mode is possible in all operating conditions (ON, OFF, UNDERVOLTAGE and TRIPPED).

Reset function for 1694-PMD* and

1694-PMD2A10

Capacitive loads

(Depending on: cable attenuation,

power supply used, load current

and current rating)

A blocked load output (blocked by overload / short circuit) can be reset or switched

on manually by the momentary ON/OFF switch (LED button).

: 1A DC24V up to 5,000µF

at I

N

: 2A, 3A DC24V up to 10,000µF

at I

N

: 4A DC24V up to 12,000µF

at I

N

: > 6A DC24V up to 20,000µF

at I

N

Free-wheeling circuit external free-wheeling circuit at inductive load (rating according to load) is recommended.

Parallel connection

of several load outputs

not permitted

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 5

5

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

General data 1694-PMD*

Housing material

Mounting method

Ambient temperature (T

) -25°...+60 °C (without condensation, cf. EN 60204-1)

amb

plastic

symmetrical rail to EN 60715-35x7.5

Storage temperature -30°...+70 °C

Mounting temperature +5°… +60°C

Humidity: 96 hrs / 95% RH RH/40 °C to IEC 60068-2-78-Cab climate class 3K3 to EN 60721

Vibration resistance 3 g, test to IEC 60068-2-6 test Fc

Degree of protection

Operating area 1694-PMD*

EMC requirements

(EMC Directive, CE Logo)

Insulation co-ordination

IEC 60529, DIN VDE 0470

IP30

Emitted interference: EN 61000-6-3

Noise immunity: EN 61000-6-2

0.5 kV / pollution degree 2

(IEC 60934)

Dielectric strength max. DC 30 V (load circuit)

Insulation resistance

n/a, only electronic disconnection

(OFF condition)

Modules mountable side by side

Terminals

Push-in terminal PT 2.5

wire stripping length

max. 16 channels

0.14mm2

to 2.5mm2, flexible

AWG24 – AWG14 str.

8mm to 10mm

Rockwell Automation recommends to use ferrules for smaller diameter cables.

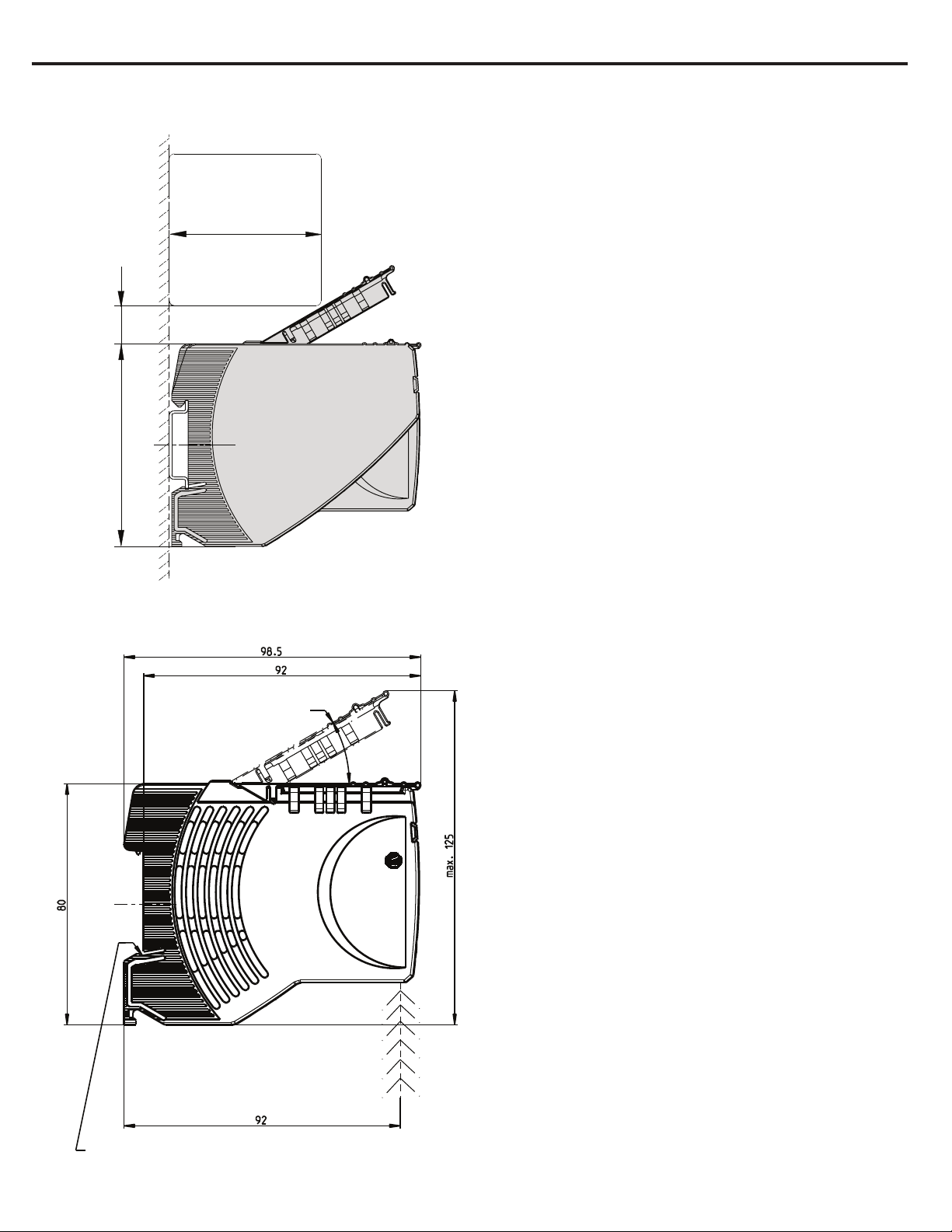

Dimensions (h x w x d) 12.5 x 80 x 98.5 mm

Weight approx. 60 g

Conformity and approvals for 1694-PMD* with 1694-PFD1244

Conformity CE Marking

Approvals UL 2367 RA File # E350272 current rating range: 1A… 10A

3

Class 2 only for Protection Modules

RoHS compliant

China RoHS

WEEE

Morocco EMC

UL 1310 current rating range:

NEC Class2

3

1A, 2A, 3A, 4A

cULus508 RA RA File # E56639 current rating range: 1A… 10A

listed

At the End of its life, this equipment should be collected separately from any unsorted municipal waste.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 6

6

ambient temperature [°C]

0

10

23

40

50

60

temperature factor

1 1 1

0.95

0.90

0.85

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

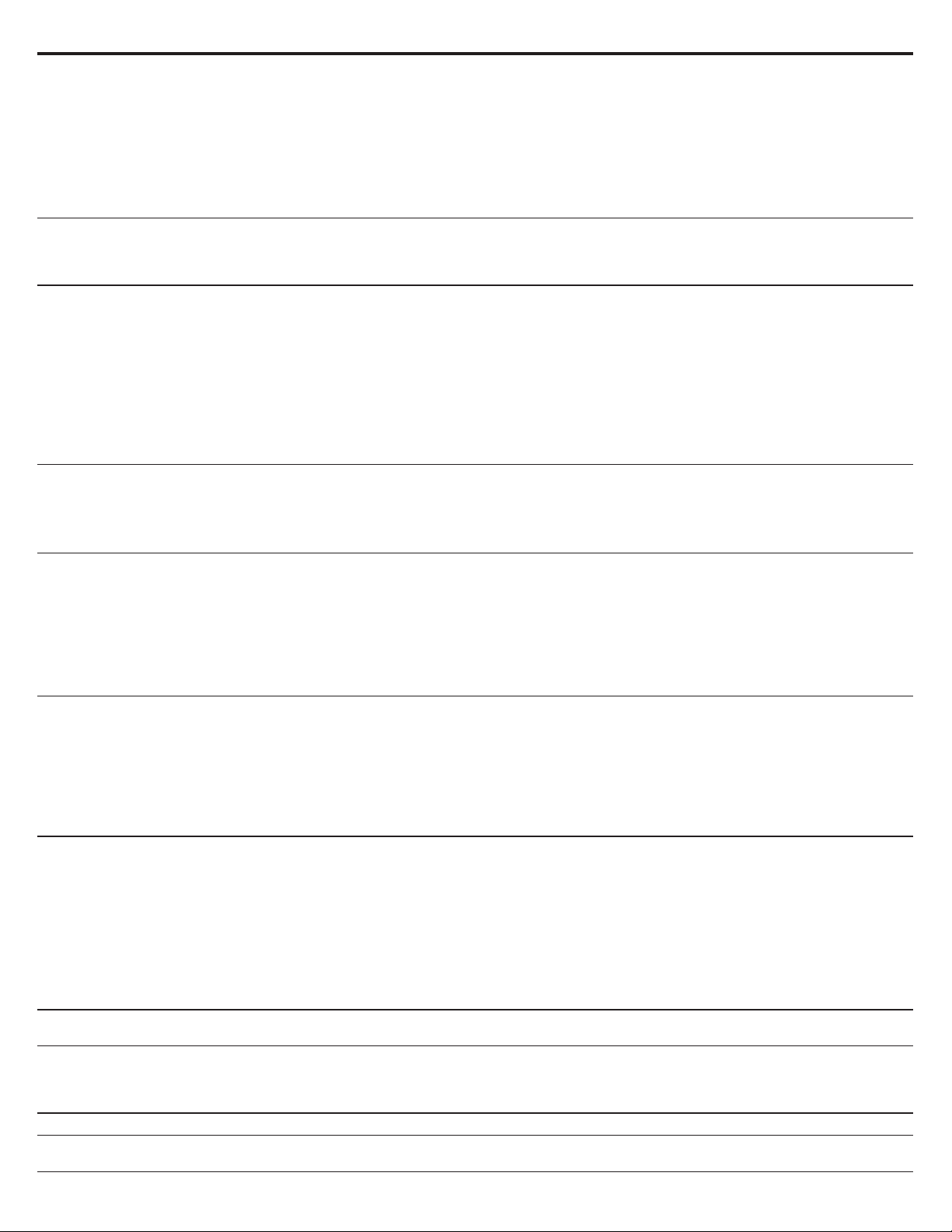

Typical time/current characteristic (T

1000

100

10

1

0.1

trip time in seconds

0.01

0.001

0.8 1 1.2 1.4 1.6 1.8 2 2.2 2.4 2.6 2.8 3 I

= +23 °C, UB = DC 24 V)

amb

SC

times rated current

ISC - short circuit current

Temperature factor / continuous duty

The time/current characteristic depends on the ambient temperature. In order to determine the max. load current,

please multiply the current rating with the temperature factor and consider the factor for side-by-side mounting.

Temperature factor table:

Please note

- When mounted side-by-side, the devices can carry max. 80 % of their rated load or a different rating has to be selected.

- With high temperatures, the load current warning threshold “warn limit typically 0.9 x I

with the temperature factor.

- Selection of current rating of the circuit protector ≤ rating of power supply.

” will be reduced in accordance

N

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 7

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Catalog Code

Description

1694-PMD110

Electronic Circuit Protection, Protection Module, IO-Link, 1-Channel, Fix Current, 10A

1694-PMD18

Electronic Circuit Protection, Protection Module, IO-Link, 1-Channel, Fix Current, 8A

1694-PMD211

Electronic Circuit Protection, Protection Module, IO-Link, 2-Channels, Fix Current, 1A, 1A

1694-PMD211-CL2

Electronic Circuit Protection, Protection Module, IO-Link, 2-Channels, Fix Current, 1A, 1A, Class 2

1694-PMD222

Electronic Circuit Protection, Protection Module, IO-Link, 2-Channels, Fix Current, 2A, 2A

1694-PMD222-CL2

Electronic Circuit Protection, Protection Module, IO-Link, 2-Channels, Fix Current, 2A, 2A, Class 2

1694-PMD233

Electronic Circuit Protection, Protection Module, IO-Link, 2-Channels, Fix Current, 3A, 3A

1694-PMD233-CL2

Electronic Circuit Protection, Protection Module, IO-Link, 2-Channels, Fix Current, 3A, 3A, Class 2

1694-PMD244

Electronic Circuit Protection, Protection Module, IO-Link, 2-Channels, Fix Current, 4A, 4A

1694-PMD244-CL2

Electronic Circuit Protection, Protection Module, IO-Link, 2-Channels, Fix Current, 4A, 4A, Class 2

1694-PMD266

Electronic Circuit Protection, Protection Module, IO-Link, 2-Channels, Fix Current, 6A, 6A

1694-PMD2A10

Electronic Circuit Protection, Protection Module, IO-Link, 2-Channels, Adjustable Current, 1A to 10A

7

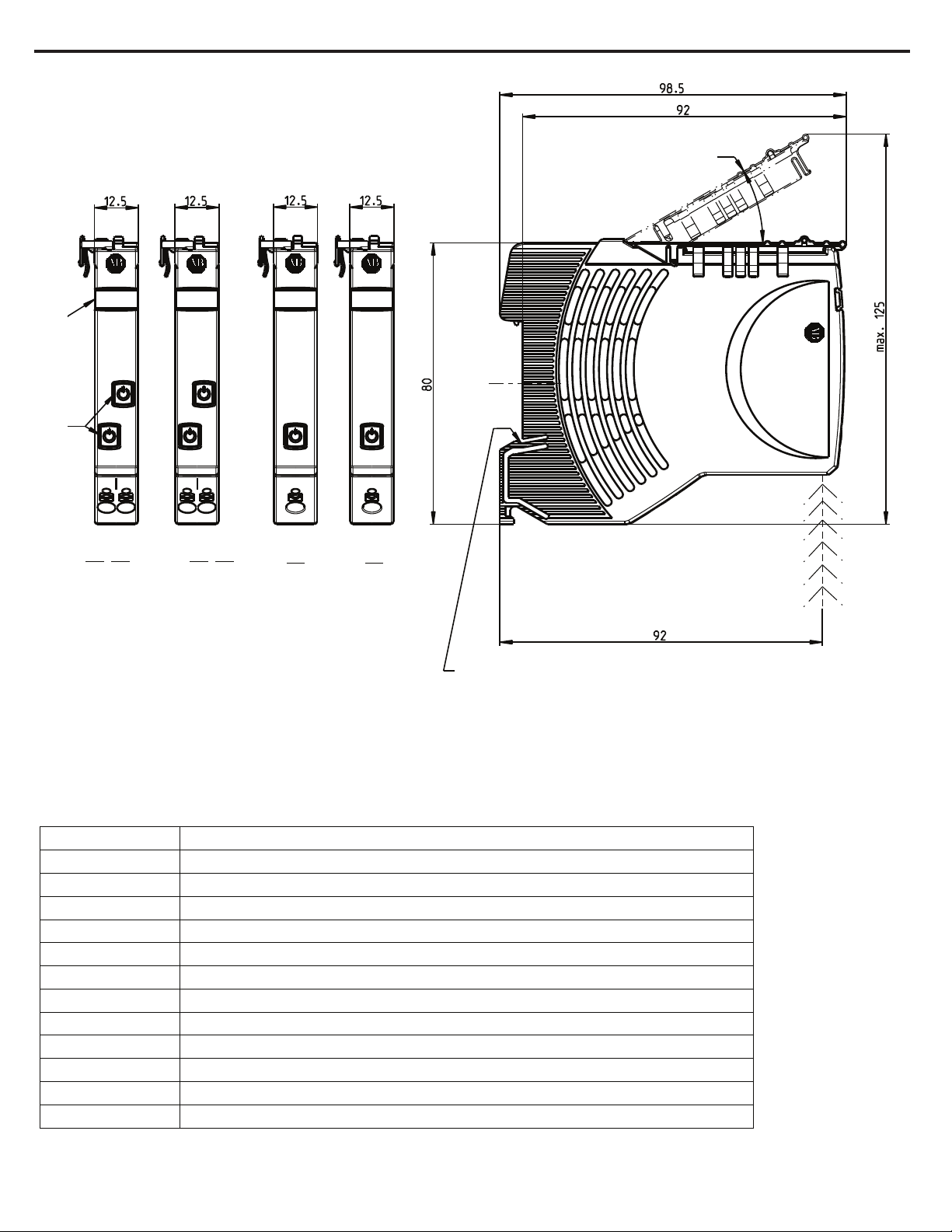

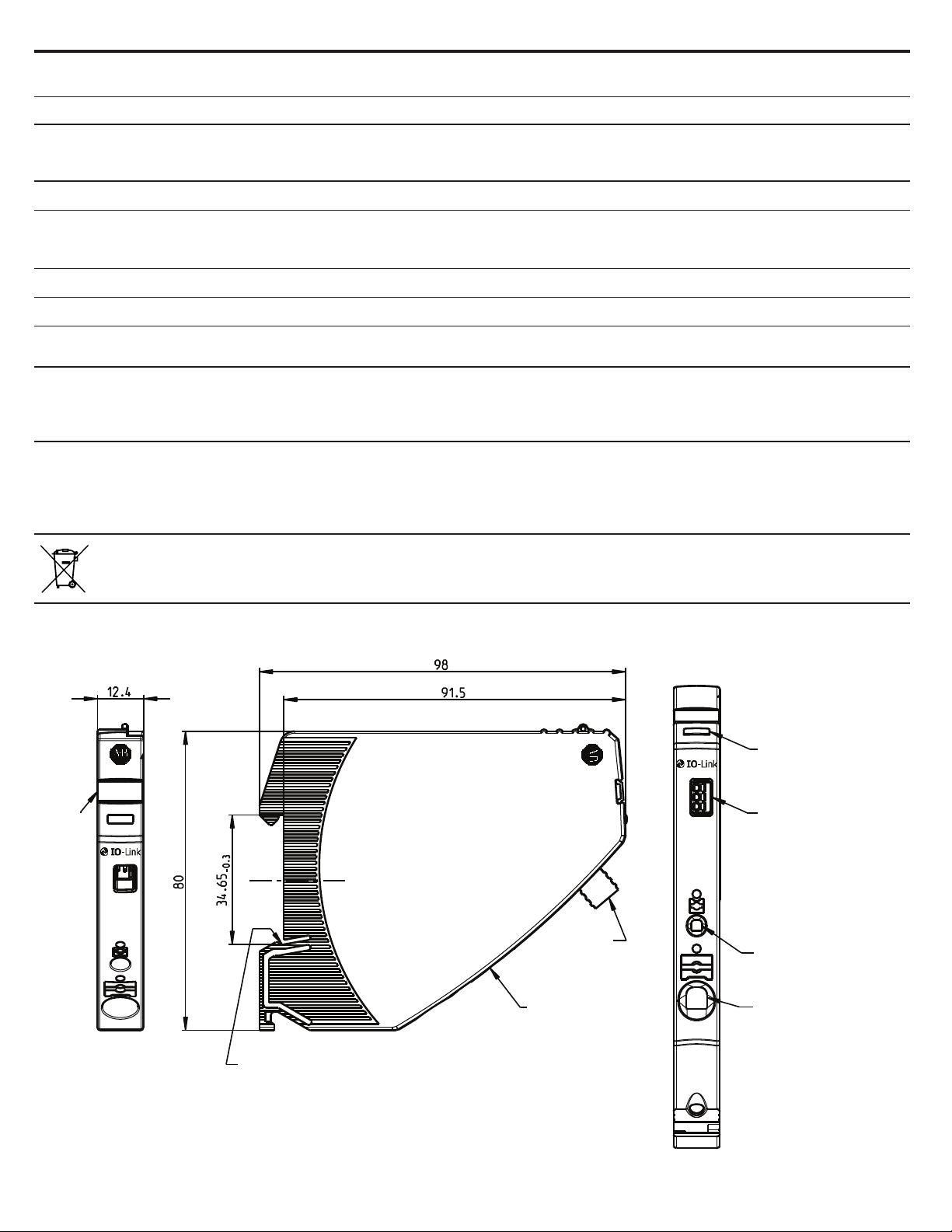

Dimensions 1694-PMD*

Contact arm

1694-PM2

DC24V

Class 2

Marker

xA

xA

2.1 2.2 2.1 2.1 2.12.2

LOAD + LOAD + LOAD + LOAD +

Button for ON / OFF or Reset

with integrated status indication (LED)

1694-PM2

DC24V

xA

xA xAxA

1694-PM1

DC24V

Class 2

1−channel2−channel

1694-PM1

DC24V

snap−on socket for DIN rail EN 60715−35x7.5

Small opening above the screwdriver insert (marked as 2.1 and 2.2) = voltage measuring point.

Larger opening under the screwdriver insert (marked as LOAD +) = wire connection area.

General recommendation for all 1694 modules installation.

For installation instructions please refer to item: Mounting on or removing of 1694-* from symmetrical rail (Page 11)

CAT 1694−PMDxy−zzz SER X

Protection Module IO xxxA xxx

Allen-Bradley

Instalation area

Operating area

Product selection list - 1694-PMD*

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 8

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

8

2. Bulletin 1694. Power Feed 1694-PFD1244 with IO-link communication

The 1694-PFD1244 Power Feed module receives the DC 24 V supply voltage, e.g. from a switched mode power supply, and distributes it to the mounted circuit

protectors via the integral connector arm of the 1694-PMD. Build-in LED provides information about setup status. Build-in IO-Link communication offers control

and monitoring by Logix Controller of each attached electronic circuit protection module 1694-PMD1244. One IO-Link Power Feed can control max 16

channels.

• Main Communication features:

• Current monitoring for each attached channel

• Voltage monitoring foe each attached channel

• Input voltage monitoring

• Statistics for each attached output channel

◦ Max, min, average current value

◦ Max, min, average voltage vale

• Remote control,

◦ Remote switch ON and switch OFF

◦ Remote trip reset

◦ Channel monitoring parameters change (warning limits)

◦ Trip current limit change for adjustable module (1694-PMD2A10)

• Error massaging.

◦ Protection module errors massaging

◦ Power feed errors massaging

• Last trip information for each channel.

◦ Trip counter

◦ Last trip reason

◦ Trip current

Provided features significantly helps for quick troubleshooting.

User need to use IO-Link master in the setup to build communication capable configuration

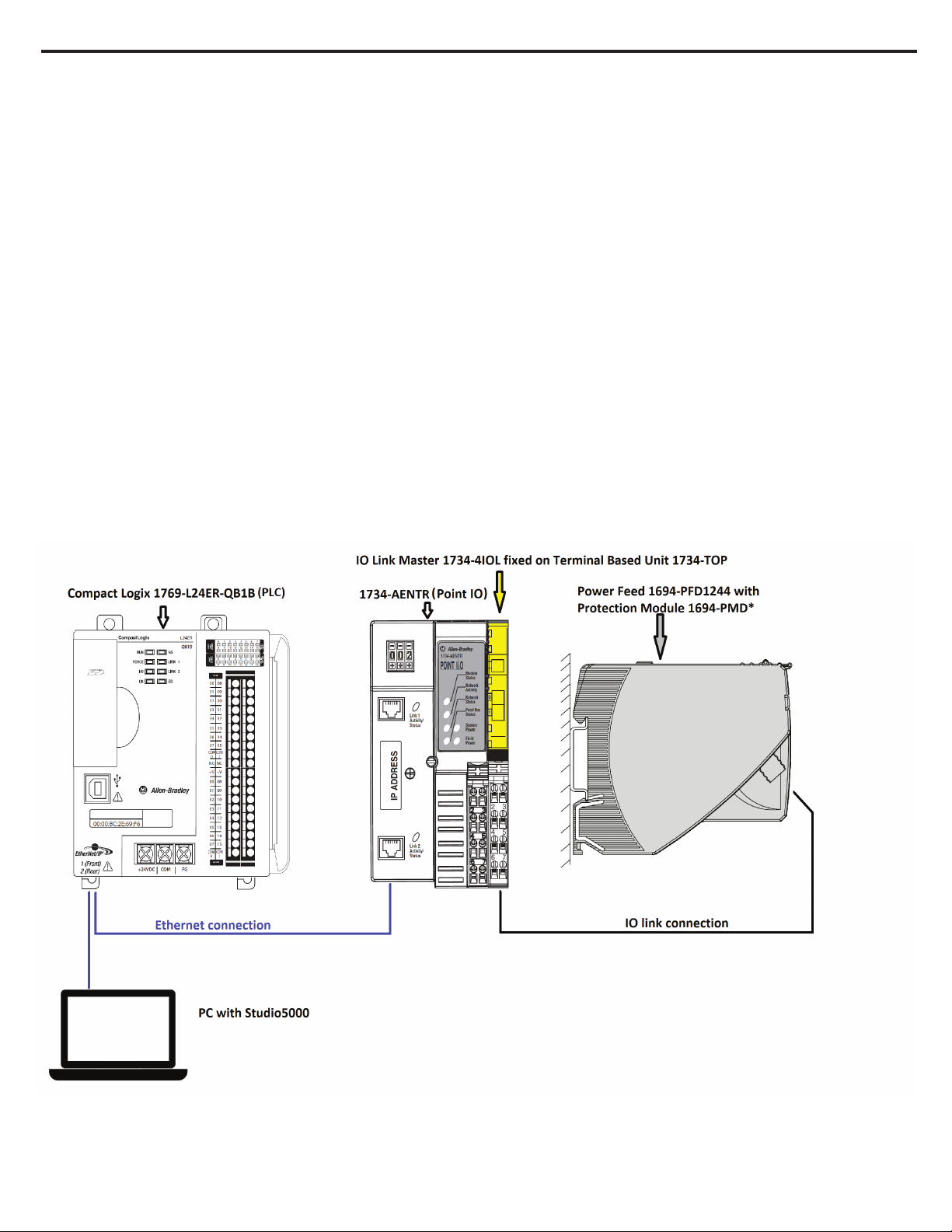

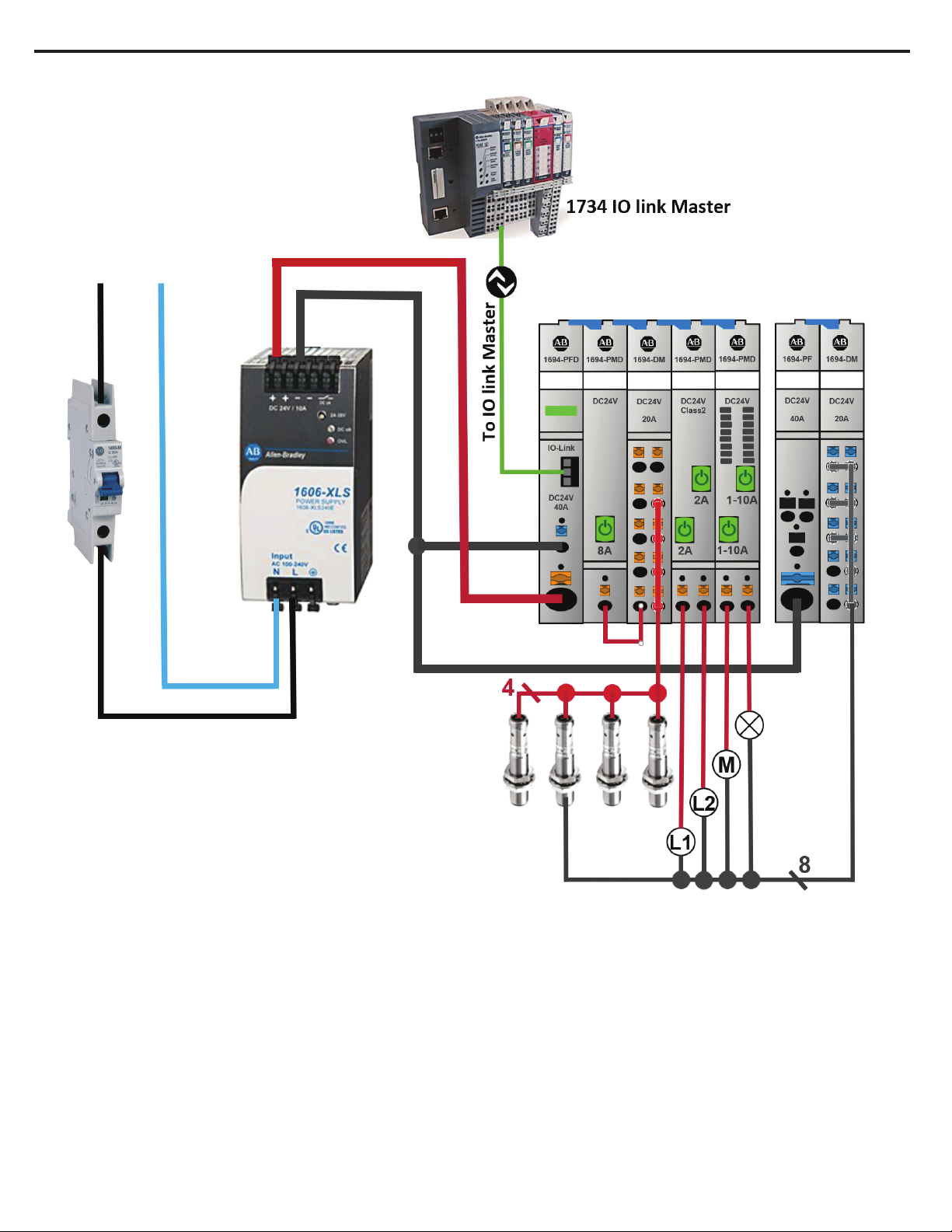

Sample schematic data connection of IO-Link bulletin 1694 devices to ethernet network and Logix Controller

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 9

9

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

2.1. 1694-PFD1244 Power Feed Module

Technical data (Tamb = +23 °C, UB = DC 24 V)

Operating voltage UB

Operating current IB

Reverse polarity protection Yes, without load

Closed current I0 normal condition: typically 20 mA

Circuit protectors can be mounted

side-by-side

1694-PMD1* 1-channel or

1694-PMD2* 2-channels or

1694-PMD2A10 2-channels

Visual status indication

by means of LED:

DC 24 V (min. 18 V, max. 30 V)

(no battery-buffered applications)

Max. 40 A

max. 16 pieces

Green: Faultless operations

Blinking Independent operations

green:

Red: Critical Anomaly

Orange Uncritical Anomaly (communication available)

Blinking Uncritical Anomaly (communication not available)

Orange

OFF: Device switched off.

For additional information about LED singling related to IO-Link communication please refer to chapter:

Signaling of operating conditions on 1694-PFD1244 Power Feed Module (Page 17).

IO-Link Connection 3 pins communication interface to IO-Link master.

For more information please refer to chapter: IO-Link connector description (Page 16).

General data 1694-PFD1244

Housing material

Mounting method

Ambient temperature (T

Storage temperature -30°...+70 °C

Mounting temperature +5°… +60°C

Corrosion 96hrs. in 5% salt mist to IEC 60068-2-11 test Ka

Humidity: 96 hrs / 95% RH RH/40 °C to IEC 60068-2-78-Cab climate class 3K3 to EN 60721

Vibration resistance 3 g, test to IEC 60068-2-6 test Fc

Degree of protection

terminal

EMC requirements

(EMC Directive, CE Logo)

) -25°...+60 °C (without condensation, cf. EN 60204-1)

amb

plastic

symmetrical rail to EN 60715-35x7.5

IEC 60529, DIN VDE 0470

IP20

Emitted interference: EN 61000-6-3

Noise immunity: EN 61000-6-2

Insulation co-ordination

(IEC 60934)

Dielectric strength max. DC 30 V (load circuit)

0.5 kV / pollution degree 2

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 10

10

Insulation resistance

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

n/a, only electronic disconnection

(OFF condition)

Terminals LINE+

Push-in terminal PT 10

0.5mm2 to 10mm2, flexible

AWG20 – AWG8 stranded

wire stripping length

18mm

Terminals 0V

Push-in terminal PT 2.5 (0V)

0.14mm2 to 2.5mm2, flexible

AWG24 – AWG14 stranded

wire stripping length

8mm to 10mm

Dimensions (h x w x d) 12.5 x 80 x 98.5 mm

Weight approx. 56 g

Conformity and approvals for 1694-PFD1244 with 1694-PMD*

Conformity CE Marking

Approvals UL 2367 RA File # E350272 current rating range: 1A… 10A

China RoHS

WEEE

Morocco EMC

cULus508 RA File # E56639 current rating range: 1A… 10A

listed

At the End of its life, this equipment should be collected separately from any unsorted municipal waste.

Dimensions 1694-PFD1244

1694-PFD

Marker

L+

C/Q

L-

X81

DC24V

40A

0V

LINE +1

snap-on socket for rail EN 60715-35x7.5

CAT 1694-PFD1244 SER X

Power Feed IO 40A

Allen-Bradley

connector

3-pole

view: X

view: X

L+

C/Q

L-

X81

DC24V

40A

0V

+ 1

LINE

status indication

LED

IO-link master

COM

interface

bushing 1 (L+)

bushing 2 (C/Q)

bushing 3 (L-)

0V DC

LINE + 1

DC 24V - 40A

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 11

11

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Configuration example

Module configuration in sample schematic diagram

Starting from left position:

• 1694-PFD1244

• 1694-PMD18

• 1694-DM1L2

• 1694-PMD222-CL2

• 1694-PMD2A10

• 1694-PF1G4

• 1694-DM3G2

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 12

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

12

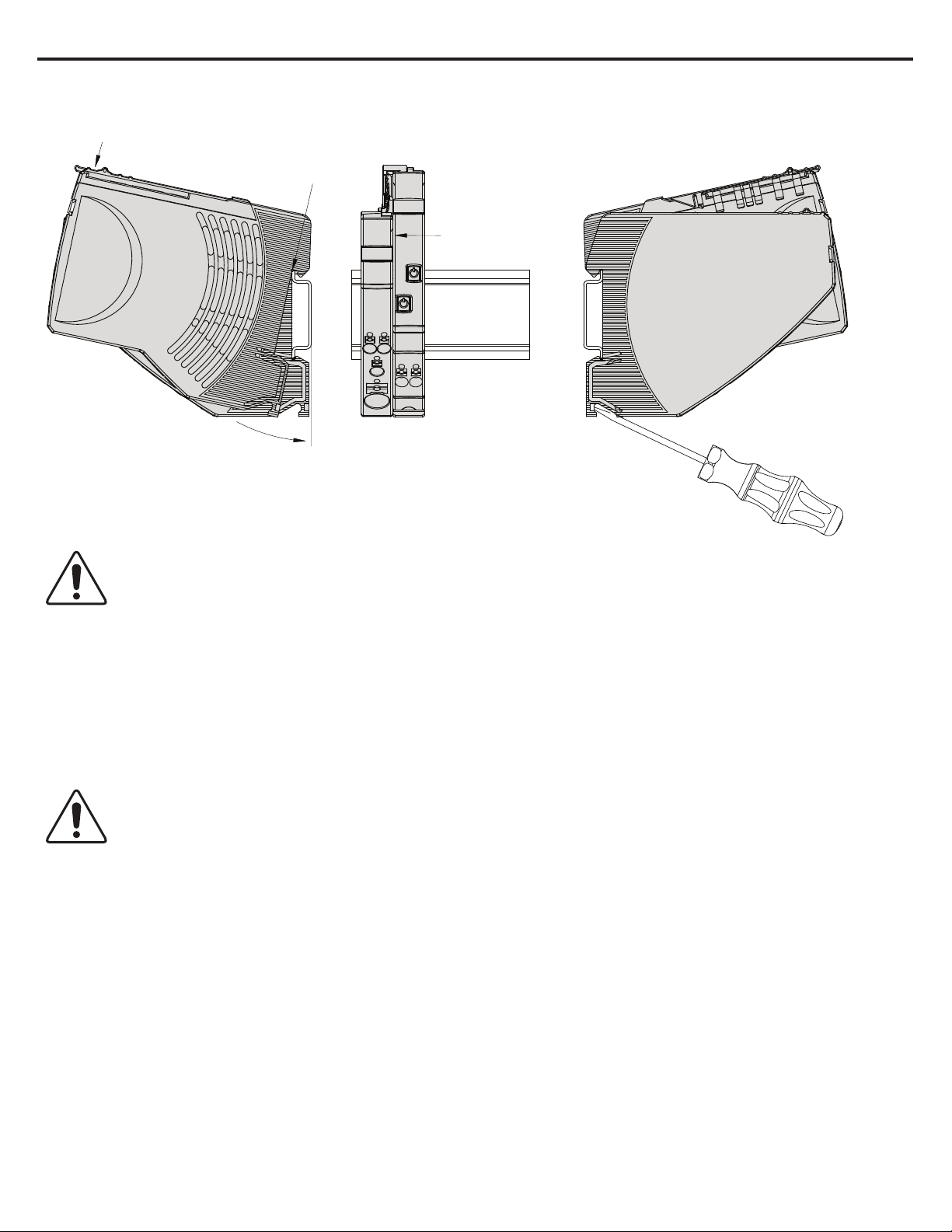

Mounting on or removing of 1694-* from symmetrical rail

Connector arm

can be closed

Push 1694 PM...

towards rail

Mount 1694 PM...

side-by-side

with 1694 PF…

Latch on enclosure

downwards

Remove 1694 PM... from rail

Unlatch with srewdriver,

tilt upwards and remove

(connector arm can be closed)

Please note

Sliding on DIN rail is not permitted.

Open connector arm carefully to avoid damage

General recommendation for all 1694 modules installation.

Screwdriver for installation:

- blade-style screwdriver size 1 for smaller Push-in terminal (PT 2.5) inserts

- blade-style screwdriver size 4 for larger Push-in terminal (PT 10) inserts

Mounting position:

- horizontal mounting position is preferred

Hot swap of circuit protectors is not permitted

Opening under load can damage the device or cause undefined system conditions.

The electronic circuit protection module can at any time be mounted side by side with a supply module or an existing system.

Opening the connector arm is only permitted in the OFF (No input voltage) condition. After plugging in a circuit protector, it will automatically be identified

and parameterized if parameters are available for the slot. During this procedure, the cyclical data will be marked as invalid for a short period of time.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 13

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

13

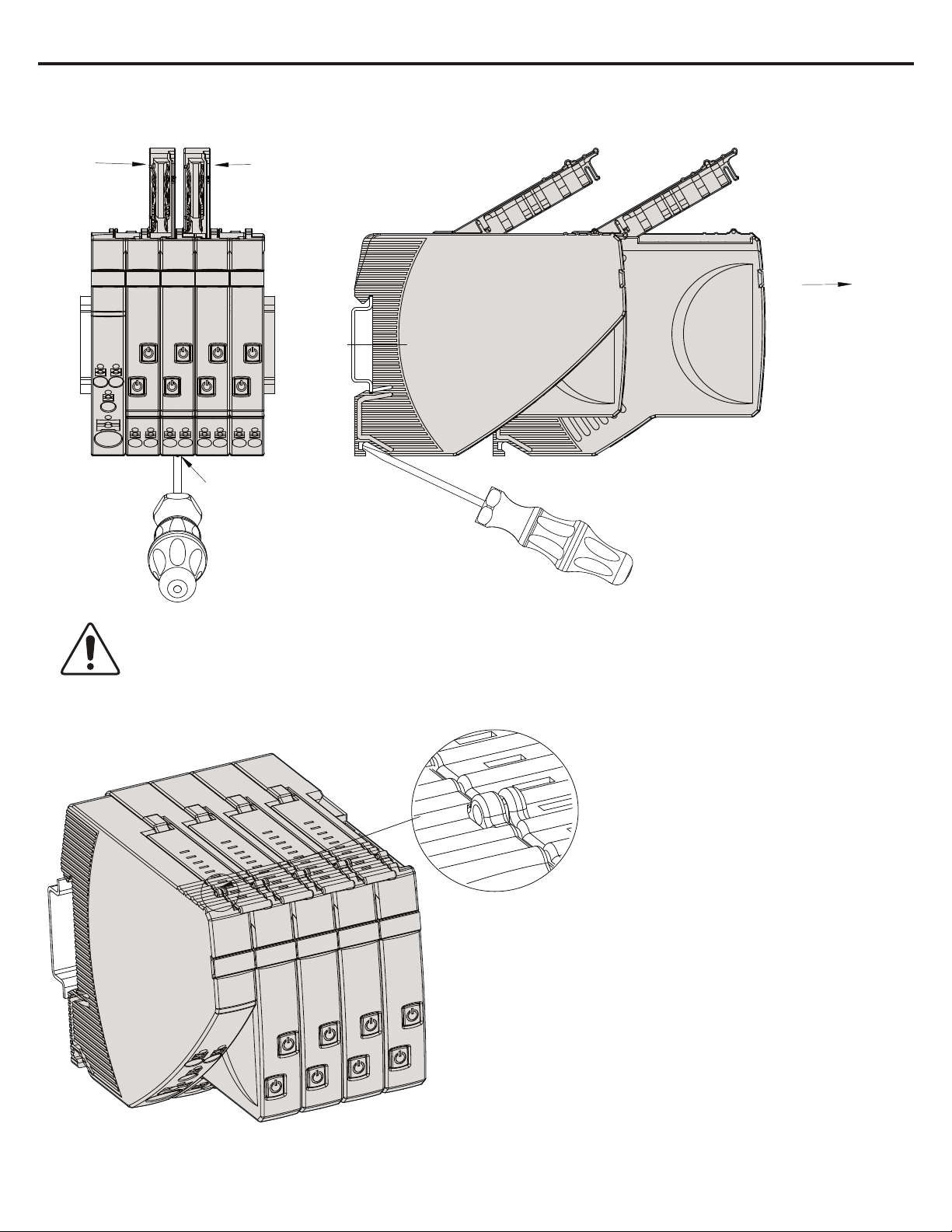

Removing 1694-* devices from DIN rail

Open connector

arm

Open connector

arm

Pull out at right

angles to the rail

Unlatch with screwdriver

Caution

:

Exchange/disassembly only in dead-voltage condition! Potentials will be interrupted.

Locked connector arms of 1694-PM…

Connector arms can

be sealed with

enclosure

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 14

14

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Distance between cable duct and connector arm of 1694-*

60

80 15

Installation area – operating area for 1694-*

Contact arm

ConformityConformity

ConformityConformity

CAT 1694−PMxyy−zzz SER X

Protection Module xxxA xxx

Allen-Bradley

snap−on socket for rail EN 60715−35x7.5

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Instalation area

Operating area

Page 15

15

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

3. IO-Link technology review

Please note: This is a very short overview of IO-Link technology. For more details please refer to IO-Link specification published on

IO-Link community webpage https://io-link.com.

What is IO-Link technology?

The IO-Link technology is an open point-to-point communication standard and was launched as (IS) IEC 61131-9. IO-Link is now the globally

standardized technology developed initially mainly for sensor and actuator communication with a field bus system. This technology provides

benefits to both OEMs and End Users.

IO-Link provides communications-capable devices to the control level by a cost-effective point-to-point connection. IO-Link provides a

point-to-point link between the I/O module and device that is used for transferring detailed diagnostics, device identity information, process

data, and parameterization.

IO-Link communication is based on a structure in which the master controls the interface access to the IO-Link device. The option of using the

intelligence that is integrated into the IO-Link device provides the user with new commissioning methods. Benefits range from reduced

installation time during startup to increased diagnostics over the lifetime of the machine. Benefits of IO-Link technology include:

• Reduced inventory and operating costs

• Increased uptime/productivity

• Simplified design, installation, set up and maintenance

• Enhanced flexibility and scalability

• Detailed diagnostic information for preventative maintenance

Why IO-Link?

IO-Link Offers a Full Range of Advanced Features and Functions

Seamless Integration

• Forward and backward compatible,

• No special cables required

• Connectivity options remain the same

• Access IO-Link functionality by simply connecting an IO-Link enabled device to an IO-Link master

Real-time Diagnostics and Trending

• Real-time monitoring of the entire machine down to the IO-Link device level

• Optimized preventative maintenance—identify and correct issues before Anomaly can occur

• Detect IO-Link device malfunctions/Anomalies

IO-Link Device Health Status

• Real-time monitoring helps ensure that IO-Link devices are operating correctly

• Detect damaged IO-Link device and pinpoint their exact location for quick troubleshooting through Application Specific Name parameter

Device Profiles and Automatic Device Configuration

• IO-Link technology provide user with quick IO-Link device configuration within minutes instead of hours,

Descriptive tags

• Faster programming during initial setup

• More efficient troubleshooting process-data tags are named based on the information they provide

• Easily monitor device data though intuitive tag names

How IO-Link works?

IO-Link delivers data over the same standard field cabling used today. By connecting an IO-Link device to an IO-Link master, the field-device

data and diagnostics are accessible. So go beyond detecting products on the machine—now the health of the machine can be MONITORED

as it runs.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 16

16

IO-Link Data Types

There are four data types available through IO-Link:

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Process Data (cyclic data)

The process data of the devices are transmitted cyclically in a data frame in which the size of the process data is specified by the

device. Depending on the device, 0...32 bytes of process data are possible (for each input and output). The consistency width of the

transmission is not fixed and is thus dependent on the master.

Value Status (cyclic data)

The value status indicates whether the process data is valid or invalid. The value status can be transmitted cyclically with the process data.

Device Data (acyclic data)

Device data supports device-specific configurable parameters, identification data, and diagnostic information. They are exchanged

acyclically and at the request of the IO-Link master. Device data can be written to the device (Write) and read from the device (Read)

Events (acyclic data)

When an event occurs, the device signals the presence of the event to the master. The master then reads out the event. Events can

be error messages and warnings/maintenance data. Error messages are transmitted from the device

3.1. Accessing IO-Link Data

Cyclic Data

To exchange the cyclic process data between an IO-Link device and a controller, the IO-Link data from the IO-Link master is placed on the

address ranges assigned beforehand. The user program on the controller accesses the process values using these addresses and processes

them. The cyclic data exchange from the controller to the IO-Link device is performed in reverse.

Acyclic data (Non-cyclic data)

Acyclic data, such as device parameters or events, are exchanged using a specified index range. The controller accesses these using Explicit

Messaging. The use of the index ranges allows targeted access.

4. IO-Link connector description used for 1694-PFD1244

IO-Link connector

Connection to IO-Link bus system.

This plug is delivered with Power Feed device.

Push-in terminals

Recommended cable parameters:

Cable length: max 20m

Cross section: 0.25 mm² to 0.5 mm²

stripping length = 6 mm

The cable does not have to be shielded specially.

Connector 1: IO-Link Terminal + (24V DC)

Connector 2: IO-Link Terminal C/Q (Data Cable to IO-Link master)

Connector 3: IO-Link Terminal L- (GROUND)

Connector 1 and 3 provide the energy for IO-Link control circuit in Power Feed

For wire connection please use 0 size flat-head screwdriver. By inserting the screwdriver into the rectangular openings of the connector plug,

the terminals are opening (for wire insert).

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 17

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

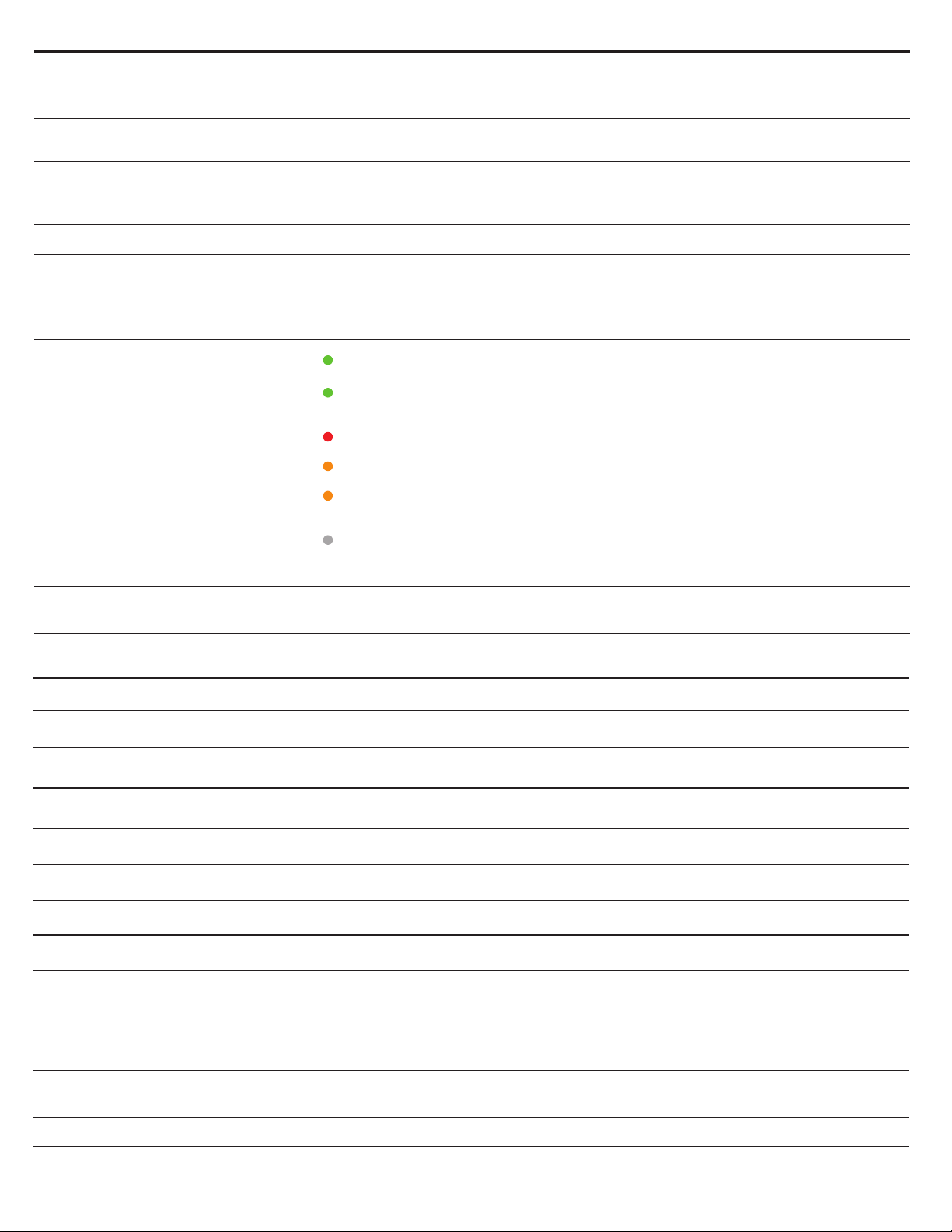

Operational status

LED button signal

IO-Link communication

System start

Orange (for approx. 1 sec)

Not available

Normal operations

Green

Available

Independent operations

Blinking green

Not available

Critical anomaly detected

Red

Not available

Non-critical anomaly detected

Orange

Available

Non-critical anomaly detected

Blinking orange

Not available

17

5. Signaling of operating status on 1694-PFD1244 Power Feed Module

LED button can signal following channel operational status:

Operating status: System start

When applying the supply voltage, the Power Feed will be initialized. The device will

carry out implemented program memory tests and self-test routines. During this time, a communication via the interfaces is not possible.

When system is starting, this operational status is indicated by orange color of LED for approximately 1 second.

Operational status: Normal operations.

If there is no fault and a connection to IO-Link master is established, the Power Feed will be into the operating mode “faultless operation”. The

parameters will be transmitted from the IO-Link master to the Power Feed and be saved there. Subsequently they will be forwarded to the

electronic circuit protectors. The configuration data and the parameters will be exchanged as non-cyclical data between the IO-Link master

and the Power Feed.

Operational status: Independent operations

If no connection to the IO-Link master is recognized after the supply voltage was applied, the module will change into the operating mode

“independent operations”.

The parameters stored in the Power Feed will be transmitted to the Protection Modules.

This operational mode will appear always when communication to IO-Link master is interrupted.

This operation mode will disappear always when communication to IO-Link master is restored.

If there is a connection between the Power Feed and IO-Link master and there is no critical anomaly, the Operational status: “independent

operations” will be quitted.

The behavior of the Power Feed and Protection Modules can be defined in the event of a communication interruption to IO-Link master. User

can choose if Protection Modules should work continuously or be switched OFF in case of communication lost.

Operational status: Critical anomaly.

If an anomaly is detected during the self-test routines, the Power Feed will change into status: “Critical anomaly”. In the event of a critical

anomaly this operating mode can only be discontinued re-starting the device and it prevents the data exchange via the interfaces. If the

Power Feed is in Critical anomaly status, then no communication is possible with control unit. The Protection Modules cannot be controlled by

it and remain OFF.

Operational status: Non-critical anomaly.

If there are invalid data or configuration data are not available, the Power Feed will go into Non-Critical anomaly mode. This mode allows only

restricted non-cyclical data exchange. Cyclical data exchange is prevented. Non-critical anomaly mode will be left when user setup the correct

module, slot parameters and configuration. The protection modules remain OFF.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 18

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Operational status

LED button signal

Condition of load output

Device switched off by means of ON/OFF

momentary switch or no operating voltage.

Dark

OFF

and OFF by IO-Link in PLC Control mode.

Orange

OFF

and IO-Link in PLC Control mode.

Green

ON

Load current warning limit reached.

Blinking green/orange

ON

Channel Overload detected.

Orange

ON

Trip by short circuit or overload.

Red

OFF

Low input voltage detected.

Red

OFF

18

6. Signaling of operating status on 1694-PMD* Protection Modules

LED button can signal following channel operational status:

Channel ON by momentary switch

Channel ON by momentary switch

Pay attention on specific signaling in PLC Control mode.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 19

19

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

7. Installation and configuration of 1694-PFD1244 and 1694-PMD* in Studio5000

7.1. AOP Installation

Add-on Profiles are files that users add to their Rockwell Automation® library. These files contain the pertinent information for configuring a

device that is added to the Rockwell Automation network. The Add-on Profile simplifies the setup of devices because it presents the necessary fields in an organized fashion. The Add-on Profile allows for set up and configuration of systems in a quick and efficient manner. The

Add-on Profile is a folder that contains numerous files for the device. It comes as an installation package.

Before start making a project in Studio5000 it is recommended to verify if proper and newest versions of AOP files are installed. In this

example you will need AOP for Point IO 1734-AENTR and IO-Link Master 1734-4IOL.

If the AOP is required to be downloaded and installed, then please use following link:

https://download.rockwellautomation.com/esd/download.aspx?downloadid=addonprofiles (registration required)

Extract the AOP zip file, open the folder, and execute the “MPSetup” application file.

7.2. Creating a Project

Following steps shows how to create simple configuration with 1694-PFD1244 and 1694-PMD* modules.

To begin a new project in Studio 5000, follow these steps.

1. Double Click the icon of Studio5000. In this example version 32 of Studio5000 is used.

2. Click New Project

7.3. Adding a Controller

3. To program the controller, select the controller that is used. In this example, it is used the “1769-L24ER-QB1B” CompactLogix.

4. After selecting the controller, name the project and click “Next” in the example, the project name is “ECP”.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 20

20

Depending on Studio5000 version you might be requested to set up some additional parameters as shown on below picture. Chose what you

need and press “Finish”.

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

7.4. Adding a Point IO (Ethernet Adapter)

5. Add Point IO to the project. In this project 1734-AENTR point IO is used.

To add device to the project, Studio500 must by in “Offline” mode as shown in the picture below

6. In the controller organizer tree, find Ethernet under I/O Configuration and right-click to “add new module”.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 21

21

7. The module window pops up and shows the available modules. Use the filter to

select “1734-AENTR” Point IO module and click “Create” button.

8. Name the Ethernet adapter (in this example we used name “Point IO”), set the chassis size, check the module revision, and set up the

adapter IP address. Click OK and Close.

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

9. The 1734 AENTR module is now visible in the Controller Organizer tree in the Ethernet section.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 22

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

22

7.5. Adding an IO-Link Master

10. Now IO-Link Master module must be added. Make sure that the controller is offline prior you start configuration. In the Controller Organizer tree, find Ethernet under I/O Configuration and right-click to “add new module” on Ethernet adapter 1734-AENTR.

11. The module window pops up and shows the available modules. Use the filter to select “1734-4IOL” module and click “Create” button.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 23

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

23

12. Another window appears to show the IO-Link Configuration screen.

Close selection pups up window if still visible.

13. The IO-Link Master can now be configured. To configure the device, a device specific IODD (IO Device Description) file is required. The

next steps show how to register the IODD file

7.6. Registration of IODD file for Power Feed 1694-PFD1244

To initialize a device on an IO-Link Master, register the IODD of the device. The IO Device Description (IODD) files contain the information

that is related to the device, integrated into the system environment.

By default, the IODDs are already located in the AOP Library.

If the IODD file for the 1694-PFD1244 cannot be located in the library, it can be downloaded from:

http://compatibility.rockwellautomation.com/Pages/MultiProductDownload.aspx.

And loaded manually to Studio5000. Once the IODD is registered, there is no need to register the IODD again unless it is manually deleted

from the Master Tree.

14. Double-click the 1734-4IOL in the Controller Organizer tree in the Ethernet section

15. Properties window will be opened. Click IO-Link on the left side of the window. Screen as shown below will be displayed.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 24

24

16. Right-click on the left section of the screen where the channel information is located and click “Register IODD”.

17. Select the IODD file that is needed for the device being configured and double click.

If there is no proper IODD file on the list, then press button “Register IODD” and select folder and file previously downloaded to your PC.

Selected IODD will be shown on the list.

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

18. Then Click “Exit”

19. The IODD registration is completed.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 25

25

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

7.7. Connect the 1694-PFD1224 to the IO-Link Master

Once the IODD file is registered, the device must be connected to the IO-Link master. The controller must always be offline to add a device to

the IO-Link Master.

20. Right-click the channel number where the power feed for electronic circuit protection is configured and click “Change”

21. Change Channel Configuration window will appear. Then click “…” on right side of the table.

Caution: Once you click “Create” you might be

required to wait longer time for configuration update.

In this time Studio5000 might not react.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 26

26

23. Click “Yes” to accept changes in module definition.

24. Press “Apply” and “OK” to accept configuration.

25. In IO-Link Tab, check if Data Storage mode for IO-Link channel is established as “Enable ADC”. This is not mandatory but might make

configuration process easier. If different mode is chosen, then user cannot see and cannot change device parameters values in offline mode.

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Caution: you might be required to wait longer time

for configuration update. In this time Studio5000

might not react.

Now you are almost ready to go online to download the project to controller.

Prior going online you must set up communication path

7.8. Download the Project to Allen-Bradley Logix Controller

26. Setup controller communication path. Click COMMUNICATION on the toolbar and then “Who Active”.

27. Select the controller that is being used for the project. In this example we are using “1769-L24ER-QB1B” CompactLogix. Once controller

is selected, click “Set Project Path” and then “Go online” to start communication.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 27

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

27

28. Download the project to controller. Click “Download” and then confirm downloading on the next window.

29. Project is loaded to the controller.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 28

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

28

7.9. Exploring the 1694-PMD1244 Parameters in AOP

To display parameters of Power Feed 1694-PFD1224 and Protection Modules 1694-PMD* in AOP you need to open IO-Link Master AOP.

Do to that:

1. in the Controller Organizer tree, find Ethernet under I/O Configuration and double click on IO-Link Master)

2. Properties window will be opened. Click IO-Link on the left side of the window on IO-Link description.

3. Then in IO-Link section click on proper channel of IO-link Master where 1694-PFD1244 module is installed (in this case this is Ch0) and

click on device attached to this channel.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 29

29

Tab

Description

Common

Tab

specifications and IO-link IODD Information.

Tab

Provides the device catalog number, series letter, general

and hardware revisions.

Tab

Provides device monitoring parameters for power feed 1694-

Protection device.

Parameter

Tab

offered by 1694 Electronic Circuit Protection system.

Diagnosis Tab displays the diagnostics parameters. Those

Factory Setting, etc.

4. IO-Link overcurrent protection system parameters will be displayed

The 1694-PMD1244 offers five different tabs to describe the device functionality and operations. These tabs are:

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Identification

Observation

Diagnosis

Tab

Provides general product information about the device

product description including the current product firmware,

PMD1244 and each channel controlled by Electronic Circuit

Displays and allows you to change the device parameters

parameters facilitate troubleshooting if device does not work

correctly. In this tab, user can find features common for the all

protection channels such as: Device Access Lock, Restore

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 30

30

Tab

Description

Vendor

Provides the vendor name assigned to Vendor ID.

Vendor Text

Field used to describe additional product information. In this case it

displays product Internet webpage address.

Vendor ID

Describes the vendor ID of the manufacturer of the product as

vendor’s identifier and is assigned by the IO-Link Consortium.

URL

Displays the vendor URL.

Device

Provides the specific catalog number of the product.

Description

This parameter displays the product description.

Device ID

The parameter Device ID contains the vendor internal unique

Automation.

Revision

Displays the IO-Link implemented revision of protocol supported by

Hardware

Revision

Displays the device hardware revision number. To confirm the latest

version of HW check value in Identification tab

Firmware

Revision

Displays the device firmware revision number. To confirm the latest

version of FW check value in Identification tab

Bitrate

Displays the IO-Link implemented communication speed supported

by the device.

Minimum

Cycle Time

This is device parameter to inform the master about the shortest

cycle time supported by the device. Value is given in microseconds

IODD

Displays an information about the IODD which has been used to

configure the IOLD

SIO mode

Displays the information whether the IOLD support the SIO

(Standard Input and Output).

Document

Version

Displays information about the IODD’s version which has been used

to configure the IOLD

Date of

Creation

This field displays date when the IODD file has been CRC stamped

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

7.9.1. Common Tab

Common tab contains the following device information:

IO-Link

designated in the IO-Link consortium. This is worldwide unique

device’s identifier. The Device ID is assigned by the Rockwell

the device.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 31

31

Parameter

Description

- Device Information Section

Vendor Name

Provides the vendor name of the product. For 1694PFD1244 this is Allen-Bradley.

Product Name

Provides the product catalog number information. For this

device this is 1694-PFD1244.

Product ID

Provides product catalog number information with series

letter. For this device is: 1694-PFD1244 Series A.

Product Text

Provides product (Power Feed) description.

Serial Number

Provides Power Feed serial number as unique numeric

value.

- User Specific Information Section

Device specific name assigned to device by user for device

populated and is Read/Write).

-

Revision Information Section

Hardware Version

Hardware version of Power Feed 1694-PFD1244 provided

as alphanumeric value

Firmware Version

Firmware version of Power Feed 1694-PFD1244 provided

as numeric value

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

7.9.2. Identification Tab

The Device Information shows us the Vendor Name, Product Name, Product Text, Product ID, and Serial Number of the exact device that is

configured.

These fields automatically populate according to the device information. These fields are read-only (RO).

The User Specific Information contains the Application-Specific Name (ASN) where you can name the device with a unique text string for

identification. The ASN allows a unique identity of each device. These fields can be custom (that is populated and is read/write).

Identification tab contains the following device information:

Application Specific

Tag

identification. The Application Specific Tag allows a unique

identity of each device. These fields can be custom (that is

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 32

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Parameter

Description

-

System Measurements Section

Process Data

In.InputVoltage

Provides power supply voltage value (line side). Unit V.

-

Channels Measurements

-

Measurements of ChXX (XX=01...16)

ChXX Voltage

Provides channel XX voltage value. Unit V.

Process Data

In.ChXXCurrent

Provides channel XX current value. Unit A.

-

Device Monitoring ChXX (XX=01…16)

- Device Details

Provides type of each type of Electronic Overcurrent Protection

- Adjustable current threshold module.

.Hardware Version

Firmware version of attached Overcurrent Protection Module

for channel XX control. This is provided as numeric value.

Software (Firmware) version of attached Overcurrent Protection

value.

.Serial Number

Serial number of attached Overcurrent Protection Module for channel

XX control. This is provided as unique numeric value.

32

7.9.3. Observation Tab

The Device Information shows us the Vendor Name, Product Name, Product Text, Product ID, and Serial Number of the exact device that is

configured.

These fields automatically populate according to the device information. These fields are read-only (RO).

The User Specific Information contains the Application-Specific Name (ASN) where you can name the device with a unique text string for

identification. The ASN allows a unique identity of each device. These fields can be custom (that is populated and is read/write).

Identification tab contains the following device information:

Module attached to Power Feed. It can be:

- No Device detected,

.Device Type

- 1-Channel module,

- 2-Channel module,

.Software Version

Module for channel XX control. This is provided as numeric

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 33

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

.Trip Counter

Provides number of trips for channel XX counted since first

device use or last reset.

.Last Trip Type

Provides reason of last trip for channel XX. Variable can

- Device Internal Fault

- Statistics

.Minimum Current

Provides value of lowest measured current for channel XX

since first power ON or last device/statistics reset. Unit A.

.Maximum Current

Provides value of highest measured current for channel XX

since first power ON or last device reset. Unit A.

.Average Current

Provides value of average measured current for channel XX

since first power ON or last device reset. Unit A.

.Minimum Voltage

Provides value of lowest measured voltage for channel XX

since first power ON or last device reset. Unit V.

.Maximum Voltage

Provides value of highest measured voltage for channel XX

since first power ON or last device reset. Unit V.

.Average Voltage

Provides value of average measured voltage for channel XX

since first power ON or last device reset. Unit V.

33

display following massages:

- Not Triggered

- Channel Short Circuit

- Channel Overload

Remarks to statistical data:

- Power ON/OF cycle does not reset the statistical data.

- Statistical values are calculated only if channel is ON.

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 34

34

Parameter

Description

- System Configuration

.Output State During

Allows user to define the Electronic Overcurrent Protection System

OFF when communication is failed.

.Power Save

User can setup power save mode for Electronic Overcurrent Protection

System. If Power Save mode in ON then LEDs shining is reduced.

-

Parameters ChXX (XX=01…16)

-

Settings

Allows user to define Current Trip Limit value for adjustable

type, then system will refuse this demand. Unit A.

.Warning Limit

Allows user to define current value (warning limit) for channel XX

to 100% of Trip Limit/Nominal current. Unit %.

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

7.9.4. Parameters Tab

Parameters tab shows parameters that can be changed. User can define in this tab device behavior when communication is lost, warning

limits, trip current, PLC control. This tab provide user with reset functions for memory fault, trip counter, statistical measurements.

Parameters tab contains the following device information:

Communication Fail

.Trip Limit

behavior in case of communication failed.

If value is ON then outputs of all the Circuit Protectors remain in their

current condition when communication is failed.

If value is OFF then outputs of all the Circuit Protectors are switched

Electronic Overcurrent Protection module. When this value is

exceeded in the circuit (channel XX), then device will go into trip

state. For more information please refer to time/current characteristic

and temperature factor table. Parameter Range: 1 to I

(In – Module Nominal Current).

For non-adjustable modules, this value is read only (only for user

reference). If user tries to change this pa

when the LED starts blinking (green / orange). Parameter range: 50%

n.

rameter for non-adjustable

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 35

35

Controller Tag

ON/OFF

OFF

disconnected)

ON

(Green)

If in PLC

.On

Channel status: OFF

is in PLC control mode

Channel status: OFF

using LED button

- Commands

Channel Command: Reset

Trip Counter [Button]

Allows user to reset trip counter for channel XX. If cannel XX is controlled by 2channels module then both channels will be reset.

Channel Command: Reset

[Button]

Allows user to reset minimum value memory of voltage and current statistics for

be reset.

Channel Command: Reset

[Button]

Allows user to reset average value memory of voltage and current statistics for

be reset.

Channel Command: Reset

[Button]

Allows user to reset maximum value memory of voltage and current statistics for

be reset.

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Allows user to define if channel XX can be controlled by PLC.

When this parameter is setup as ON channel XX goes into status as described in

below table.

.PLC Control

.PLC Control= OFF

Initial

Channel

XX Status

ON

(Green)

.On relevant bit

value

responsible for

channel XX

Bit=0 Orange

Color of channel

XX LED button

after PLC

Control setup as

ON

.PLC Control= ON

Status of XX

channel after

PLC Control

setup as ON

(load

Remark

Bit=1 Green ON

Control mode,

user pushes

LED button to

switch channel

ON, then device

reaction will

depend on

OFF

(Dark)

Bit=0 or 1 Dark

OFF

(load

disconnected)

relevant bit

value in

Controller Tag

In PLC Control mode user can still control channel XX using LED module button.

Device behavior when LED button is pressed in PLC Control mode is described in

below table.

LED Status Channel status

Orange OFF

Device reaction while LED button is

pressed in PLC control mode = ON

LED status: DARK

PLC cannot control channel even if

LED status: DARK

Green ON

PLC cannot control channel even if

is in PLC control mode

Only user can switch channel ON

Comment: Channel trip reset can be done remotely from PLC independently on PLC

Control mode.

Minimum Value Memory

Average Value Memory

Maximum Value Memory

channel XX. If cannel XX is controlled by 2-channels module then both channels will

channel XX. If cannel XX is controlled by 2-channels module then both channels will

channel XX. If cannel XX is controlled by 2-channels module then both channels will

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 36

36

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

7.9.5. Diagnosis Tab

This tab provides user with device status information. User can check here potential device system faults and channel faults. In this place

reset to factory settings can be done and reset of all statistical data as well. Here, user can also block device parameter changes to protect

setup against unintended changes.

Diagnosis tab contains the following device information:

Parameter Description

- Device Access Locks

Device Access Locks.Data

Storage Lock

- Device Status

Device Status

Service Function

-

Standard Command: Reset

All Statistics [Button]

Standard Command: Restore

Factory Settings [Button]

By setting this parameter as "True", user can disable overwriting IO-link

device parameters by Data Storage mechanism defined by IO-Link

specification. Rockwell Automation does not recommend to control Data

Storage Lock in device by this parameter. To control Data Storage

mechanism user should use relevant function in IO-Link master settings.

If value is "True" then Data Storage in IO-Link Device is locked

If value is "False" then Data Storage in IO-Link Device is unlocked (can

be updated by IO-Link Master)

Displays the status of device.

- Device is OK.

- Maintenance required: The Process Data are valid, internal

diagnostics indicate that the Device is close to lose its ability

of correct functioning.

- Out of specification: The Process Data are valid, internal

diagnostics indicate that the Device is operating outside its

specified range or environmental conditions.

- Functiona

due to intended manipulations on the Device.

This is summary diagnosis status concerning all devices in the setup.

Provides reset function of all statistics for all protection modules in the

setup.

Provides reset to factory settings function for all devices in the setup.

l check: The Process Data are temporarily invalid

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 37

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

- Device System Fault

This parameter can provide following massages:

setup.

- Channel Fault

- ChXX Fault ( XX = 01…16)

Fault

This parameter provides massage concerning channel XX fault and can

- Device parameters changed.

Internal Fault

This parameter provides massage concerning channel XX internal fault

- Device is not available

Channel Command:

[Button]

Provides rest function of Internal Fault Memory for all channel ChXX

37

Device System Fault

- System is working normally.

- Fault in Internal Parameter Memory detected. Disconnect and

re-connect the Circuit Protector from Supply Voltage. If

problem persists, please contact Rockwell Automation for

further support.

- Detected Device is not supported.

- Internal communication was interrupted. Either there are no

devices connected or they are not powered.

- Watchdog Timer Reset occurred. Th

Strong Electromagnetic Interference. Try “Reset Error

Memory” command.

is could be caused due to

- The System has found a Fault in the Hardware. Please contact

Rockwell Automation for further support.

This is summary diagnostic information concerning all devices in the

provide following massage types:

- No Fault.

- Device is not available.

- Hardware switch is in OFF position.

- Undervoltage.

- Overheating.

- Output needs Reset.

- Internal Fault.

- Internal Communication Fault - Wrong Frame Length.

- Internal Communication Fault - Wrong Checksum.

Reset Internal Fault Memory

and can provide following massage types:

- No Fault

- Fault in Internal Parameter Memory detected. Disconnect and

re-connect the Circuit Protector from Supply Voltage. If

problem persists, please contact Rockwell Automation for

further support

- Checksum Fault in Parameters Memory. Disconnect and re-

connect the Circuit Protector from Supply Voltage. If problem

persists, please contact Rockwell Au

support

- Checksum Fault in Program Memory. Disconnect and re-

connect the Circuit Protector from Supply Voltage. If problem

persists, please contact Rockwell Automation for further

support

- Checksum Fault in Data Memory. Disconnect and re-connect

the Circuit Protector from Supply Voltage. If problem persists,

please contact Rockwell Automation for further support

- Internal M

Circuit Protector from Supply Voltage. If problem persists,

please contact Rockwell Automation for further support

- Watchdog Timer Reset occurred. This could be caused due to

Strong Electromagnetic Interference. Try “Reset Error

Memory” command

in the setup.

icrocontroller Fault. Disconnect and re-connect the

tomation for further

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 38

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

- Communication Characteristics

Direct Parameters 1.Min

This parameter shows a device (Power Feed) parameter to inform the

MinCycleTime. (Row 4136)

Direct Parameters 1.Master

This is IO-Link Master parameter and sets up the actual cycle time of a

MinCycleTime. (Row 4136)

Direct Parameters 1.IO-Link

Version ID

Provides IO-Link version supported by Power Feed.

38

Cycle Time

Cycle Time

Master about the shortest cycle time supported by this device (Power

Feed).

Value should be decoded by user according to IO-Link Interface and

System Specification Version 1.1.2. Chapter: MasterCycleTime and

particular port in IO-Link Master.

Value should be decoded by user according to IO-Link Interface and

System Specification Version 1.1.2. Chapter: MasterCycleTime and

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 39

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

39

8. Device Parameters Details

8.1. Cyclic Data

The IODD file defines the data communication between the IO link master and power feed. In detail these are the status and the load current

of the electronic circuit protectors. In addition, it is possible to switch the devices on or off or reset them in the event of an anomaly. These

parameters are available in Studio5000 Controller Tags. All Cyclic Data are available also using ISDU (Indexed Service Data Unit). Information required to use Cyclic Data in ISDU mode are provided in below table.

Parameter

Name

Index (Dec)

Place in the Index

/ Sub-Index (Dec)

.Ch01Current 40 1 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch02Current 40 2 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch03Current 40 3 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch04Current 40 4 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch05Current 40 5 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch06Current 40 6 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch07Current 40 7 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch08Current 40 8 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch09Current 40 9 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch10Current 40 10 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch11Current 40 11 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch12Current 40 12 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch13Current 40 13 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch14Current 40 14 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch15Current 40 15 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

.Ch16Current 40 16 RO 0 0…25.5A (0...255) UIntegerT (RecordT)

Access

Default

Value

Allowed

Value

Data Type

(length)

IODD

BitLenght=8

BitOffset=232

BitLenght=8

BitOffset=224

BitLenght=8

BitOffset=216

BitLenght=8

BitOffset=208

BitLenght=8

BitOffset=200

BitLenght=8

BitOffset=192

BitLenght=8

BitOffset=184

BitLenght=8

BitOffset=176

BitLenght=8

BitOffset=168

BitLenght=8

BitOffset=160

BitLenght=8

BitOffset=152

BitLenght=8

BitOffset=144

BitLenght=8

BitOffset=136

BitLenght=8

BitOffset=128

BitLenght=8

BitOffset=120

BitLenght=8

BitOffset=112

Data Type

Studio

5000

Int

Int

Int

Int

Int

Int

Int

Int

Int

Int

Int

Int

Int

Int

Int

Int

Publication 1694-IN001D-EN-E - August 2020 DIR 10005708550 (Version 03)

Page 40

40

.Status

40

17

RO 0 Bit 0 = Channel 01 On/Off

One bit each representing the status of a separate channel.

IntegerT (RecordT)

Int

.OverLoad

40

18

RO 0 Bit 0 = Channel 01 Overload

representing the status of a separate channel

IntegerT (RecordT)

Int

.ShortCircuit

40

19

RO 0 Bit 0 = Channel 01 Short Circuit

representing the status of a separate channel

IntegerT (RecordT)

Int

Installation Instructions: Bulletin 1694 Electronic circuit protection for 24V DC with IO-Link

Bit 1 = Channel 02 On/Off

Bit 2 = Channel 03 On/Off

Bit 3 = Channel 04 On/Off

Bit 4 = Channel 05 On/Off

Bit 5 = Channel 06 On/Off

Bit 6 = Channel 07 On/Off

Bit 7 = Channel 08 On/Off

Bit 8 = Channel 09 On/Off

Bit 9 = Channel 10 On/Off

Bit 10 = Channel 11 On/Off

Bit 11 = Channel 12 On/Off

Bit 12 = Channel 13 On/Off

Bit 13 = Channel 14 On/Off

Bit 14 = Channel 15 On/Off

Bit 15 = Channel 16 On/Off

For

Status=On Bit Value = 1

For Status=Off Bit value = 0

Comment: Shows the Channel Status of the Device installed.