Page 1

User Manual

Original Instructions

PowerMonitor 500 Unit

Catalog Numbers 1420-V1, 1420-V1P, 1420-V1A, 1420-V1-ENT, 1420-V1-485, 1420-V1P-ENT, 1420-V1P-485, 1420-V1AENT, 1420-V1A-485, 1420-V2, 1420-V2P, 1420-V2A, 1420-V2-ENT, 1420-V2-485, 1420-V2P-ENT, 1420-V2P-485, 1420V2A-ENT, 1420-V2A-485

Page 2

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Page 3

Summary of Changes

This manual contains new and updated information as indicated in the following

table

New and Updated Information

This table contains the changes made to this revision.

Top ic Pag e

Updated wiring diagrams in Chapter 2. 19…22

Added CIP message examples to Appendix C 75…82

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 3

Page 4

Summary of Changes

Notes:

4 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 5

PowerMonitor 500 Unit Overview

Installation and Wiring

Table of Contents

Preface

About This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Intended Audience . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

About the PowerMonitor 500 Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PowerMonitor 500 Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . 10

Front Panel Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Display Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Selecting Data to Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Unit Configuration

Communication

PowerMonitor 500 Unit Data Tables

Technical Specifications

Chapter 3

Configure with the Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

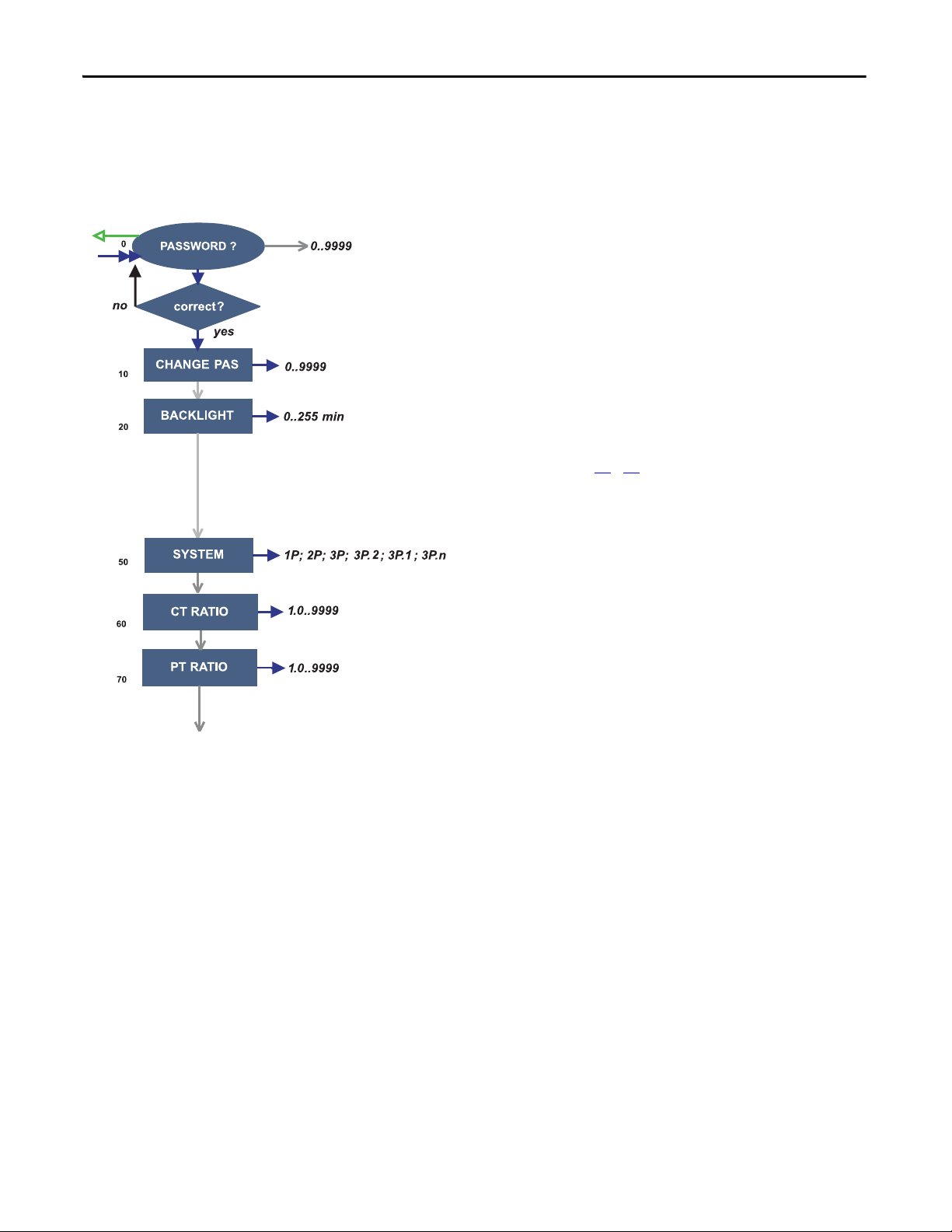

Configuration Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Digital Filtering Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Analog Output Configuration Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Alarm Configuration Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 4

EtherNet/IP Communication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Modbus Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Appendix A

Summary of Data Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Geometric Representation of Power and Power Factor . . . . . . . . . . . . . . 48

Data Tables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Appendix B

List of Connectable Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

PowerMonitor 500 EtherNet/IP

Device Profile

Appendix C

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Object Model and Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Identity Object - CLASS CODE 0x0001 . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Assembly Object - CLASS CODE 0x0004 . . . . . . . . . . . . . . . . . . . . . . . . . 80

Technical Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 5

Page 6

Table of Contents

Index

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

6 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 7

Preface

About This Manual

Intended Audience

Catalog Number Explanation

This manual contains detailed information on these topics:

• Mounting and wiring of the unit

• Wiring to native and optional communication port

• Set-up and use of the display module

• Information on metering functionality and measurements

• Use of the display module for configuration, monitoring, and commands

• Discussion of communication options, functionality, configuration, and

operation

• Alarm configuration and operation

• PowerMonitor™ 500 data tables

This manual is intended for qualified personnel. You need a basic understanding

of electric power and energy theory and terminology, and alternating-current

(AC) metering principles.

Bulletin Number

1420 - PowerMonitor 500

1420

Voltage

V1 - 240V AC V-LL

120V AC V-LN/208V AC V-LL

V2 - 400V AC V-LN and

690V AC V-LL

-V1 P -485

Auxiliary

P - Pulse (Digital) Output

A - Analog Output

Blank - No Output

Optional Comms

485 - Serial RS-232,

RS-485, Modbus RTU

ENT - EtherNet/IP

and Modbus TCP/IP

Blank - No Comm

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 7

Page 8

Preface

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Product Certifications website, http://www.ab.com Provides declarations of conformity, certificates, and

Provides general guidelines for installing a Rockwell

Automation industrial system.

other certification details.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley distributor or

Rockwell Automation sales representative.

8 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 9

PowerMonitor 500 Unit Overview

Chapter 1

About the PowerMonitor 500 Unit

The PowerMonitor™ 500 unit is an AC power monitor with a built-in advanced

configuration system and LCD data display. The unit is designed for

measurement of electrical parameters in various three-phase, single-phase

(2-wire European), and split-phase (3-wire North American single phase)

circuits. The unit modular housing can be mounted in a panel that provides IP65

degree protection from the front. The power monitor can be provided with

analog or digital (relay) outputs. These outputs can be selected to output a pulse

proportional to the real and reactive energy that is measured, or to annunciate

alarms. The instrument can also be equipped with a serial RS-485/RS-232 port

or an EtherNet/IP port.

Equipped with an optional communication port, the unit communicates power

and energy parameters to applications, such as FactoryTalk® EnergyMetrix™

software. The power monitor works with these software applications to address

these key customer applications:

• Load profiling - log power parameters such as real energy, apparent power,

and demand, for analysis of power usage by loads over time

• Cost allocation - report actual energy cost by department or process to

integrate energy information into management decisions

• Billing and sub billing - charge users of energy the actual usage cost rather

than allocating by square footage or other arbitrary methods

• Power system monitoring and control - display and control power flow and

energy utilization

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 9

Page 10

Chapter 1 PowerMonitor 500 Unit Overview

PowerMonitor 500 Features and Functions

The power monitor connects to your three-phase, split-phase (3-wire North

American single phase), or single-phase (2-wire European) AC power system

directly or through instrument transformers (PTs and CTs). It converts

instantaneous voltage and current values to digital values, and uses the resulting

digital values in calculations of voltage, current, power, energy, and demand.

The power monitor family includes several models that combine the following

basic components:

• A panel-mounted power monitor in one of two AC voltage ranges:

120/208V or 400/600V

• An optional pair of digital (relay) outputs

• An optional pair of 0…20 mA analog outputs

• Optional serial RS-232/RS-485 communication supporting Modbus

RTU

• Optional Ethernet port supporting EtherNet/IP and Modbus TCP/IP

• Front protection degree: IP65, NEMA 4X, NEMA 12

• Up to four configurable virtual alarms

• Class 1 (kWh) according to EN62053-21

• Class B (kWh) according to EN50470-3

• Class 2 (kVARh) according to EN62053-23

• Accuracy ±0.5% of reading (current/voltage)

• Metering values display: Four rows x 4 digit

• Energy value display: Ten digit plus sign

• Three-phase (system) variables: V(L-L), V(L-N), A, VA, W, VAR, power

factor, frequency

• Single phase variables: V(L-L), V(L-N), A(L), An (calculated), VA, W,

VAR , pow er f ac tor

• System and single phase average and maximum variables

• Energy measurements (imported/exported): kWh and kVARh

• Revenue grade energy measurements per ANSI C12.1 Class 1.0, ANSI

C12.1

• Run hours counter (8+2 digit)

• Real-time clock function

• Universal power supply: 120/240V AC 50/60 Hz, or 120/240V DC

• Front dimensions: 96 x 96 mm (3.78 x 3.78 in)

10 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 11

PowerMonitor 500 Unit Overview Chapter 1

PowerMonitor 500

1

2

3

4

5

6

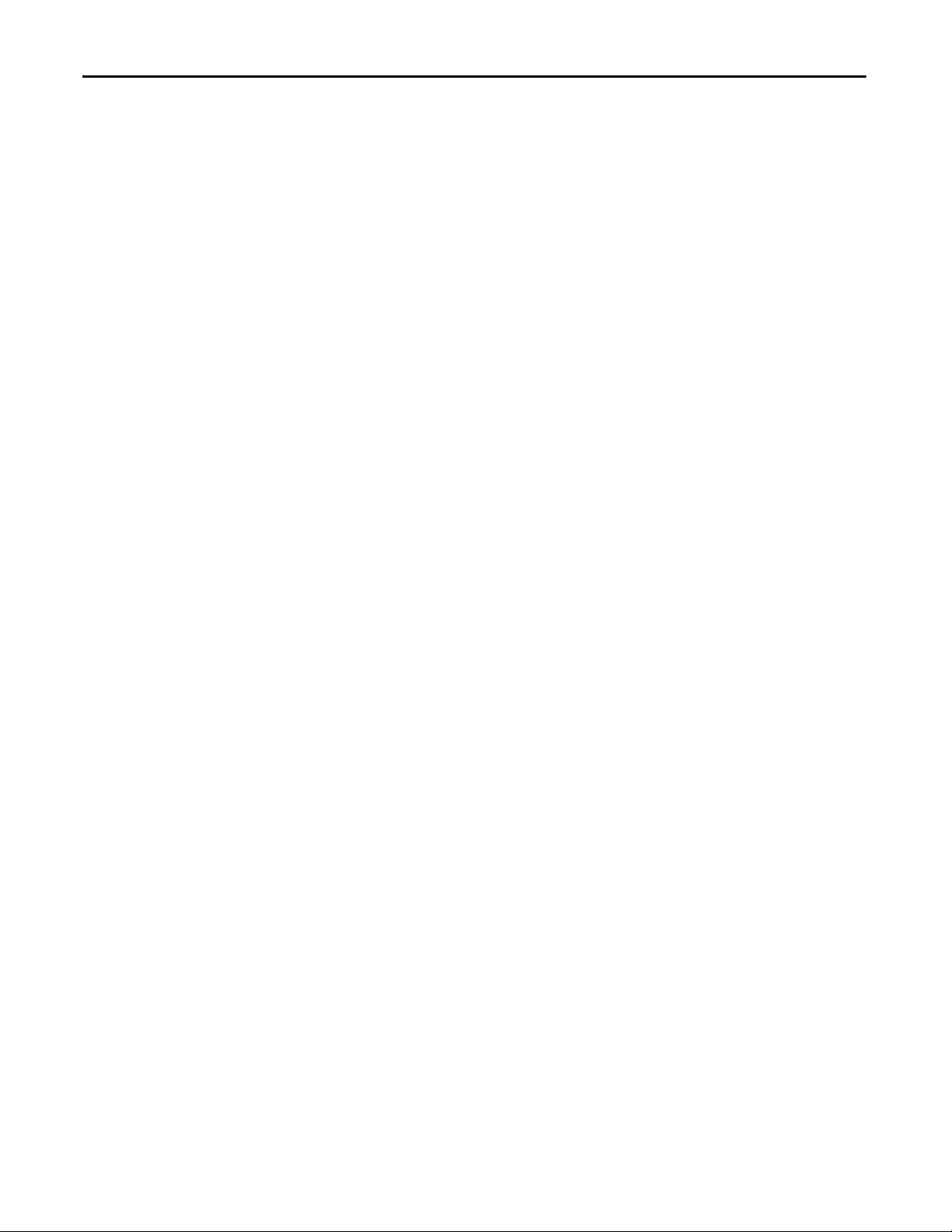

Front Panel Features

This section describes the front panel of the unit.

Front Panel Indicators and Control Buttons

The buttons are enhanced touch buttons. The touch icon turns on each time a

button is pressed. We recommend using your forefinger to activate the touch

buttons.

In Metering mode, buttons 4 and 5 (shown in Figure 1

maximum and demand (average) values of the displayed measurements.

Figure 1 - Front Panel

) are used to display the

Display Item Description

1 Active Alarms AL1…AL4 status indicators.

2 Real Energy consumption rate status indicator. Faster flashing indicates higher rate of consumption. Maximum frequency 16 Hz per EN5047-1.

3 Exit Button - Press quickly to exit submenus, or to exit the programming menus in Programming mode.

When in the programming menu, press and hold Exit for at least 2 seconds to exit the programming menu. Press Program/select to confirm and return to the

metering display and exit the programming menu without saving your changes.

To save changes, use the Up and Down arrows to go to the End menu, then press Program/Select.

When not in the programming menu, press and hold for more than 2 seconds to view the information pages.

In Metering mode, press quickly to scroll through the energy co unters.

4 Up Button - Press the Up button to browse menus and to increase values to be set.

5 Down Button - Press the Down button to browse menus and to decrease values to be set.

6 Program/select Button - Press and hold the Program/select button for at least 2 seconds to access the programming menu.

When in the programming menu, press Program/select to confirm the programmed values in the active page. Press Program/select to enter and exit edit mode on

the active page.

When not in the programming menu, press Program/select to select measured values for display. Press quickly to scroll through the metering display pages.

See Tab le 1

and Tab le 2 for a list of the measurement screens.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 11

Page 12

Chapter 1 PowerMonitor 500 Unit Overview

Additional Button Functions

Certain buttons have two functions. To access the second function, press and

hold the button for more than 2 seconds.

Displays PowerMonitor 500 information screens, which provide reference

standards, firmware revision, and year of manufacture.

Resets the max (maximum) of the displayed variables. You must press Program/

select to confirm the reset.

Resets the dmd (demand) of the displayed variables. You must press Program/

select to confirm the reset.

12 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 13

PowerMonitor 500 Unit Overview Chapter 1

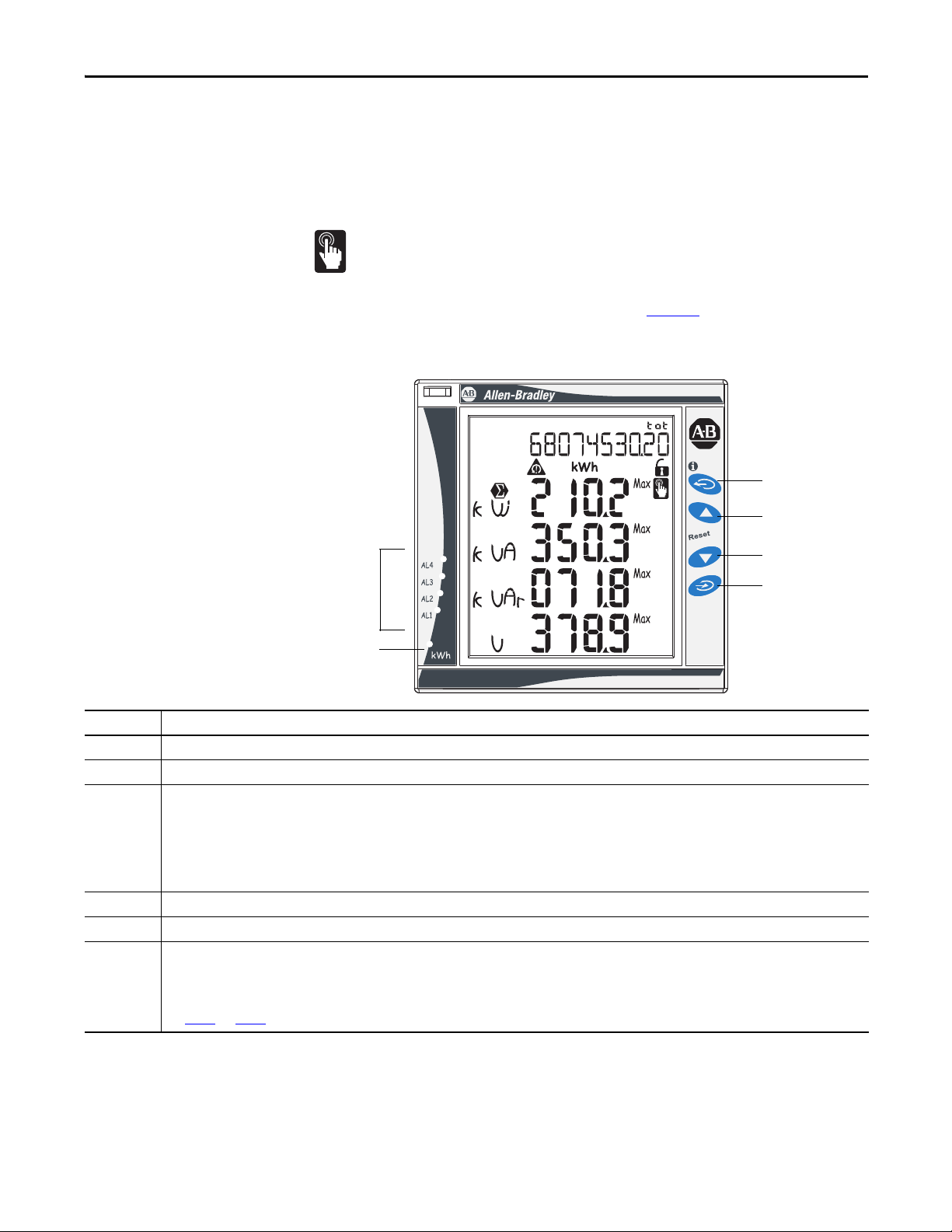

ROW 1ROW 2ROW 3ROW 4ROW 5

1

2

3

4

5

10

9

6

7

11

8

12

9

10

11

12

Display Features

Display Item Description

1 Phase displacement indicator: inductive L, -L, or capacitive C, -C.

The sign is based on the direction of real power flow.

Positive = consuming power, negative = generating power.

See the Geometric Representation of Power and Power Factor

In Programming mode, the indicator displays E when a parameter can be edited.

2 Indicates the measured value phase (line-to-neutral L1 or line-to-line L12).

3 Indicates the measured value phase (line-to-neutral L2 or line-to-line L23).

4 Indicates the measured value phase (line-to-neutral L3 or line-to-line L31).

5 Engineering unit and multiplier indicator (k, M, V, W, A, var, PF, Hz, An).

6 ALR: the alarm display function is active. PROG: the programming function is active.

7 Area set aside for energy counters (see Tabl e 1

8 Indicates that metering values are dmd (demand) or MAX (maximum) values.

Figure 2 - Features

in Appendix A for more information.

), text messages, date and time (format: dd.mm.yy/hh:mm).

Display Icons

Display Item Description

9 Indicates that the metering values displayed are system (three-phase) values.

10 Indicates a phase sequence error alarm for Voltage rotation.

11 Configuration lock switch is not active. Always indicates unlocked.

12 Indication of serial RS-485/RS-232 data transmission (TX) and reception (RX).

Alarm Icons

• Indicates a high value alarm

• Indicates a low value alarm

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 13

Page 14

Chapter 1 PowerMonitor 500 Unit Overview

IMPORTANT

Selecting Data to Display

Ta b l e 1 and Ta b l e 2 provide a guide to navigation through the metering data

displays available on the front panel display. Row 1…Row 5 indicate the rows of

the display (see Figure 2 on page 13

).

Press for <2 seconds to cycle through the data that is displayed in Row 1

of the display.

Selected data for Row 1 remains displayed until is pressed.

Table 1 - Row 1 Data

Parameters123456789 10

Row 1 Tot al kWh

(+)

Tot al kVARh

(+)

Tot al kWh (-)Tot al kVARh

(-)

kWh (+)

part.

kVARh (+)

part.

kWh (-)

part.

kVARh (-)

part.

Run Hours

(99999999.99)

RTC

Press for <2 seconds to cycle through the data that is displayed in Rows

2…5 of the display.

Selected data for Rows 2…5 displays momentarily and then returns to the default

display.

Use and to cycle through the max, instantaneous, and demand

(dmd) values.

The appropriate data is displayed based on the configured system. For

example, for delta (3P) systems, individual line data is not displayed for lineto-neutral voltage, VA, VAR, W, and power factor.

Table 2 - Rows 2…5 Data

Parameters Set01234567

Row 2 V LN Σ V LL Σ An Hz VA Σ VAR Σ W Σ PF Σ

Row 3 V L1 V L1-2 A L1 - VA L1 VAR L1 W L1 PF L1

Row 4 V L2 V L2-3 A L2 - VA L2 VAR L2 W L2 PF L2

Row 5 V L3 V L3-1 A L3 - VA L3 VAR L3 W L3 PF L3

14 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 15

PowerMonitor 500 Unit Overview Chapter 1

IMPORTANT

To access information pages, press and hold for more than 2 seconds,

then press and to select information items, as shown in Ta b l e 3

After a period of inactivity, the information pages close, and the display returns to

the default screen.

Information items are not displayed for options that are not installed. For

example, a module that does not have the analog output option does not

display analog parameters (columns 11 and 12 in Tabl e 3

Table 3 - Rows 1…5 Information Pages

Page

No.

Row 1 Serial

Row 2 Yr. xx CT.rA 0.001…

Row 3 rEL 1.0…9

Row 4 A.10 Pt.rA Out2 Set 2 Set 2 Set 2 Set 2 Hi.A

Row 5 1…60

123 456789101112131415

Number

(9

digits)

Conn.

xxx

(3PN/

3P/3P1/

3P2/1P/

Status

Indicator

Pulse

kWh

Pulse

OUT1

kWh/

kVARh

(1)

Pulse

OUT2

kWh/

kVARh

Remote

out

(1)

AL1 AL2 AL3 AL4 Analog

(1)

2P)

1000

kWh per

pulse

0.001

…1000

kWh/

kVARh

per

xxxx

kWh/

kVARh

per

pulse

Out 1 Variable Variable Variable Variable Hi.E

pulse

(min)

9.99k

1.0…9

999

+/- tot/

PAr

+/- tot/

PAr

on/oFF Set 1 Set 1 Set 1 Set 1 0.0…

on/oFF (measur

ement)

(measur

ement)

(measur

ement)

(measur

ement)

‘dmd’

(1)

1

(2)

9999k

(3)

0.0…

100.0%

Analog2

(1)

(2)

Hi.E

0.0…

9999k

(3)

Hi.A

0.0…

100.0%

).

COM

port

Add XXX XXX dAtE

1…247 XXX tiME

bdr XXX

9.6/

19.2/

38.4/

115.2

IP

(1)

Address

XX•XX•X

X XX:XX

(Realtime

clock)

XXX

.

(1) If ap propriate option is selected.

(2) Hi.E corresponds to the configured Max Input for the analog output.

(3) Hi.A corresponds to the configured Max Output for the analog output.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 15

Page 16

Chapter 1 PowerMonitor 500 Unit Overview

PowerMonitor 500

Row 1

Row 2

Row 3

Row 4

Row 5

PowerMonitor 500

Row 5

Row 4

Row 3

Row 2

Row 1

Figure 3 and 4 are examples of how the information pages are displayed.

Figure 3 - Information Page 2

Figure 4 - Information Page 15

16 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 17

Installation and Wiring

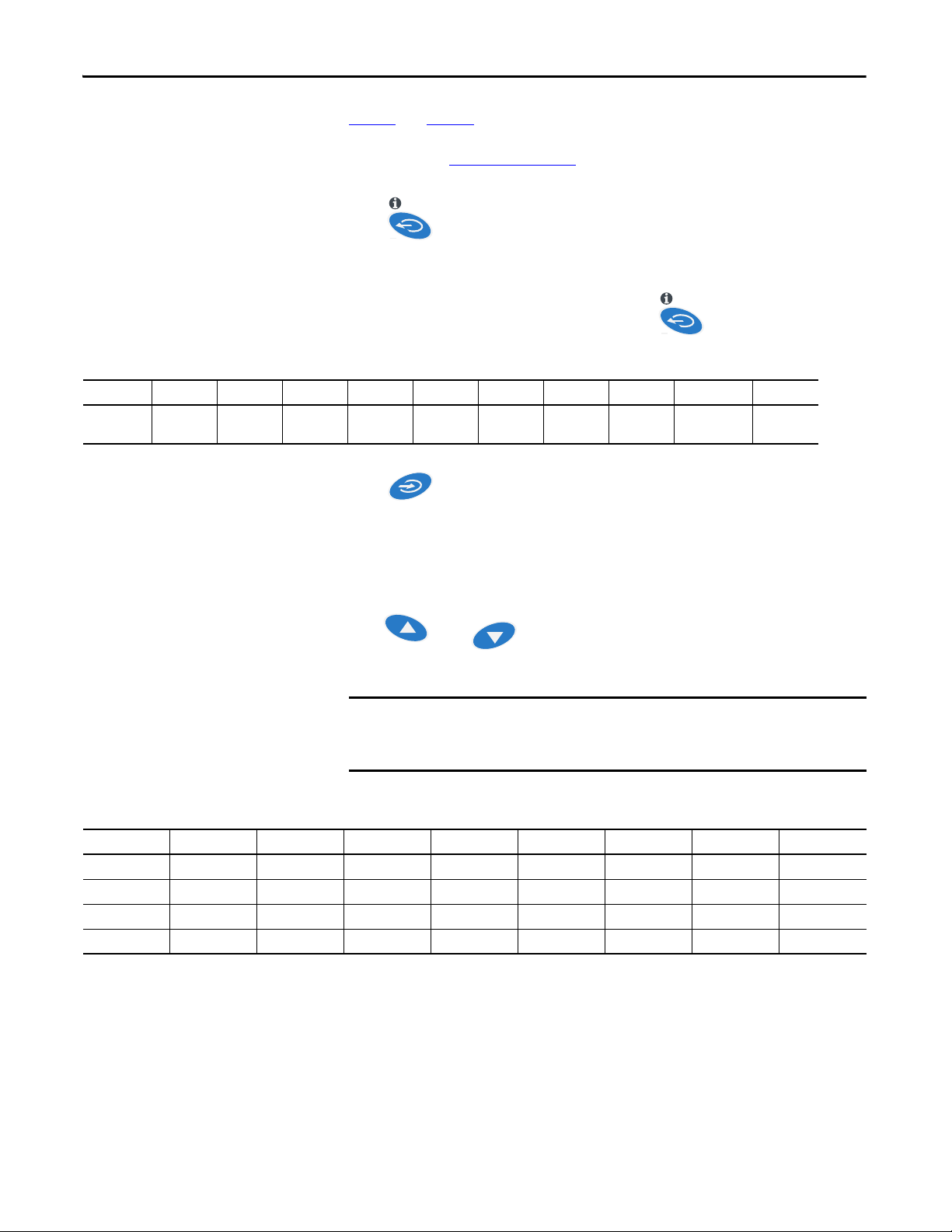

96.00 mm

(3.78 in.)

96.00 mm

(3.78 in.)

93.00 mm

(3.66 in.)

20.20 mm

(0.80 in.)

29.70 mm

(1.17 in.)

89.97 mm

(3.54 in.)

91.00 mm

(3.58 in.)

62.99 mm

(2.48 in.)

89.49 mm

(3.52 in.)

62.99 mm

(2.48 in.)

89.49 mm

(3.52 in.)

16.00 mm

(0.63 in.)

20.00 mm

(0.79 in.)

Digital and Analog Output Modules

Serial and Ethernet Communication Modules

Chapter 2

Installation

This section shows the dimensions of the unit for installation in a panel.

Figure 5 - Base Unit Dimensions

Figure 6 - Panel Cut-out

Figure 7 - Factory-installed Optional Modules

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 17

Page 18

Chapter 2 Installation and Wiring

Power Supply

Figure 8 - Installation in Panel

Figure 9 - Rear View of Unit Showing Wiring Terminals

18 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 19

Installation and Wiring Chapter 2

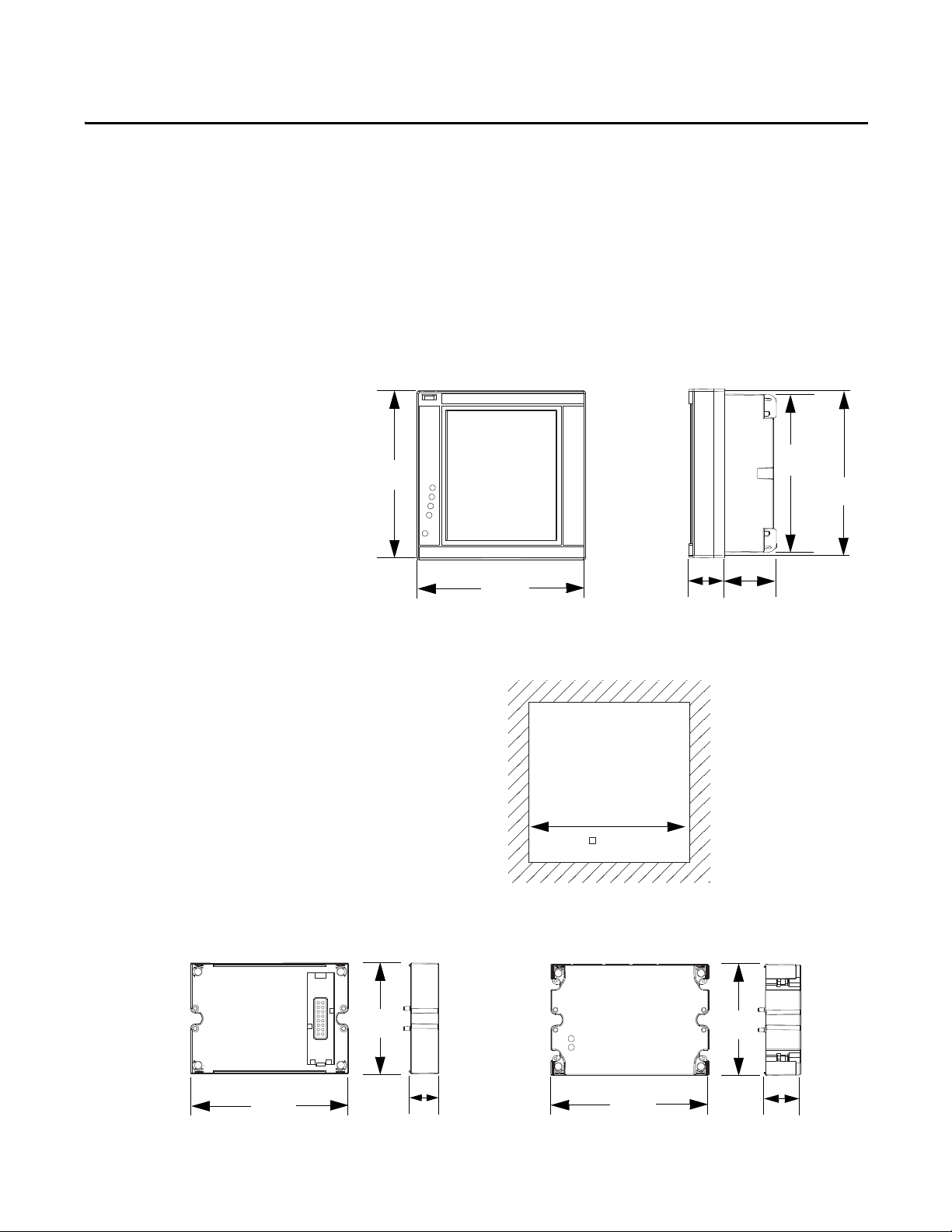

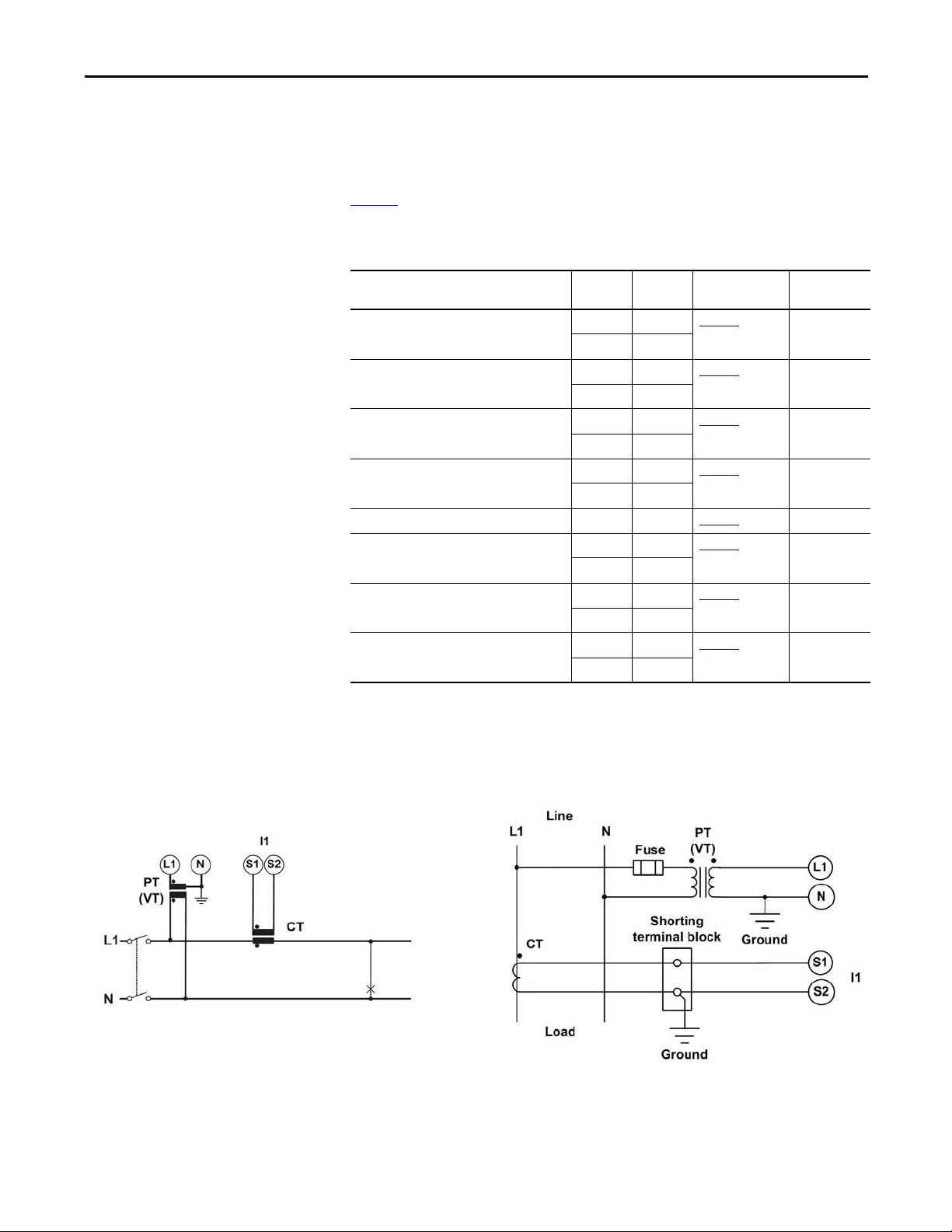

Wiring Diagrams

The PowerMonitor™ 500 unit can monitor various three-phase, single-phase, and

split-phase circuits. Select the voltage connections, current wiring, and system

metering mode to match the configuration of the circuit being monitored.

Ta b l e 4

provides a key for you to select the proper wiring diagrams and system

metering modes.

Table 4 - Wiring Diagram Explanation

Circuit type No. of CTs No. of PTs Wiring Diagram System

3-phase, 4-wire Wye Unbalanced load 3 - Figure 1 2

33

3-phase, 2-wire Wye Balanced load 1 - Fig ure 11 3P.2

11

3-phase, 3-wire Delta Unbalanced load 3 - Fig ure 13

2-

Open Delta Unbalanced load 3 2 Figure 13

22

Open Delta Balanced load 1 2 Figure 14 3P.1

3-phase, Single CT Balanced load 1 - Fig ure 14

13

Split-phase 2 - Fi gure 15 2P

22

Single phase 1 - Fi gure 16

11

Configuration

3P.n

3P

3P

3P.1

1P

The wiring diagrams in this manual are drawn with U.S. (NEMA) conventions.

For convenience, a connection diagram is shown in IEC style on the left and in its

corresponding NEMA style (used in the U.S.) on the right.

Figure 10 - Wiring Diagram Interpretation

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 19

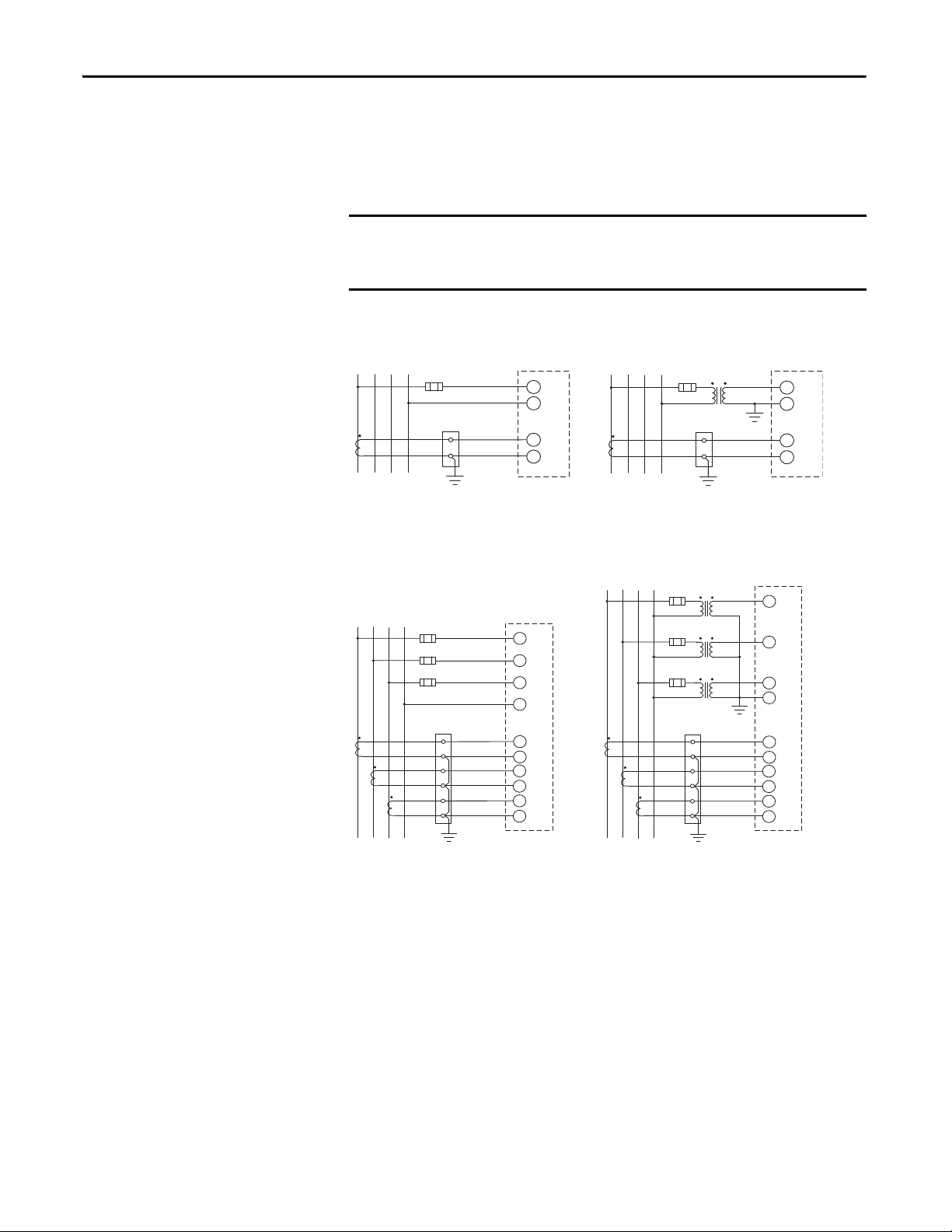

Page 20

Chapter 2 Installation and Wiring

IMPORTANT

Line

L1 N

Fuse

PT 1

(VT1)

Load

Ground

Shor ti ng

terminal block

S1

I1

Ground

CT

1

L2

L3

L1

S2

PM 500

3-CT and 3-PT/VT Connec tions

S1

I2

CT

2

S2

S1

I3

CT

3

S2

Fuse

PT 2

(VT2)

L2

Fuse

PT 3

(VT3)

L3

N

Line

L1 N

Fuse

Load

Ground

Shorting

terminal block

S1

I1

CT

1

L2

L3

L1

S2

PM 500

3-CT Connection

S1

I2

CT

2

S2

S1

I3

CT

3

S2

Fuse

L2

Fuse

L3

N

Meter Configuration: System = 3P.n

These diagrams are simplified. Wiring of the power monitor must comply with

all applicable codes, standards, and regulations. Protect voltage and control

power wiring with suitable overcurrent protection. Connect current transformer

(CT) secondary wiring through a suitable shorting terminal block.

In these diagrams, ‘balanced load’ configurations permit 3-phase

measurement by using only one phase connection. Unbalance in the measured

circuit affects the accuracy of the measurements.

Figure 11 - 3-phase, 2-wire Wye, Balanced Load

Meter Configuration: System = 3P.2

Line

L2

L1 N

L3

CT

1

Load

Fuse

Shorting

terminal block

Ground

1-CT Connection

PM 500 PM 500

L1

N

S1

I1

S2

Line

L2

L1 N

L3

Fuse

Shorting

terminal block

CT

1

Load

1-CT and 1-PT/VT Connections

Groun d

(VT)

PT

L1

N

Groun d

S1

I1

S2

Figure 12 - 3-phase, 4-wire Wye, Unbalanced Load

20 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 21

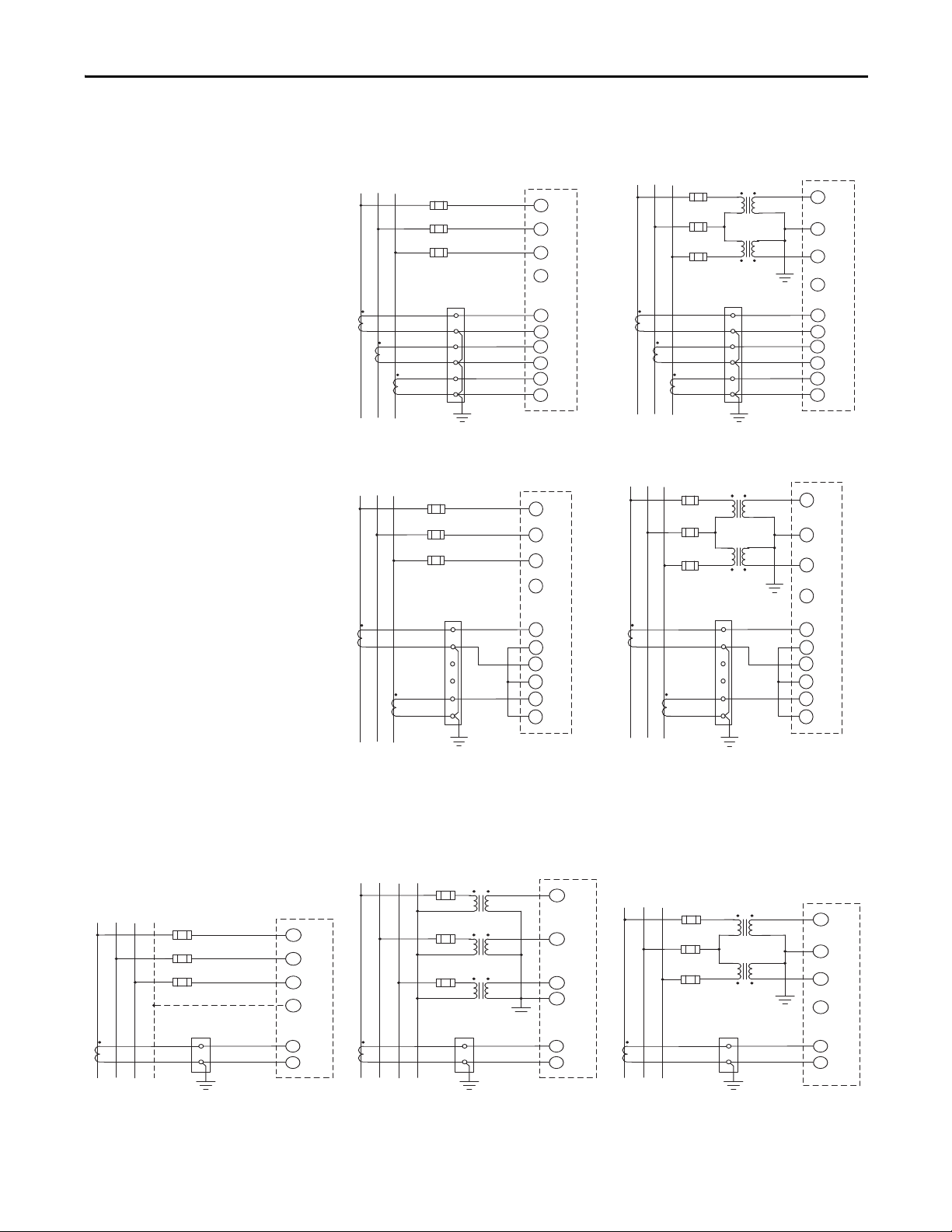

Figure 13 - 3-phase, 3-wire Delta, Unbalanced Load

Line

L1

Fuse

PT 1

(VT1)

Load

Groun d

Shorting

terminal block

S1

I1

Ground

CT

1

L2

L3

L1

S2

PM 500

3-CT and 2-PT/VT Connections (Open Delta)

S1

I2

CT

2

S2

S1

I3

CT

3

S2

Fuse

L2

PT 3

(VT3)

L3

N

Line

L1

Fuse

Load

Groun d

Shorting

terminal block

S1

I1

CT

1

L2

L3

L1

S2

PM 500

3-CT Connection

S1

I2

CT

2

S2

S1

I3

CT

3

S2

Fuse

L2

Fuse

L3

N

Fuse

Meter Configuration: System = 3P

Line

Load

Groun d

PM 500

2-CT and 2-PT/VT Connections (ARON) (Open Delta)

Line

L1

Fuse

Load

Ground

Shorting

terminal block

S1

I1

CT

1

L2

L3

L1

S2

PM 500

2-CT Connection (ARON)

S1

I2

S2

S1

I3

CT

3

S2

Fuse

L2

Fuse

L3

N

Shor ti ng

terminal block

S1

I1

CT

1

S2

S1

I2

S2

S1

I3

CT

3

S2

L1

Fuse

PT 1

(VT1)

Groun d

L2

L3

L1

Fuse

L2

PT 3

(VT3)

L3

N

Fuse

Line

L1 N

Fuse

PT 1

(VT1)

Groun d

L2

L3

L1

PM 500

1-CT and 3-PT/VT Connec tions

Fuse

PT 2

(VT2)

L2

Fuse

PT 3

(VT3)

L3

N

Line

L1 N

Fuse

L2

L3

L1

PM 500

1-CT Connection

Fuse

L2

Fuse

L3

N

Line

PM 500

1-CT and 2-PT/VT Connec tions

(Open Delta with balanced load)

Load

Groun d

Shorting

terminal block

S1

S2

I1

CT

Load

Groun d

Shorting

terminal block

S1

S2

I1

CT

Load

Groun d

Shorting

terminal block

S1

S2

I1

CT

L1

Fuse

PT 1

(VT1)

Groun d

L2

L3

L1

Fuse

L2

PT 3

(VT3)

L3

N

Fuse

Meter Configuration: System = 3P.1

Installation and Wiring Chapter 2

Figure 14 - 3-phase, Single CT, Balanced Load

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 21

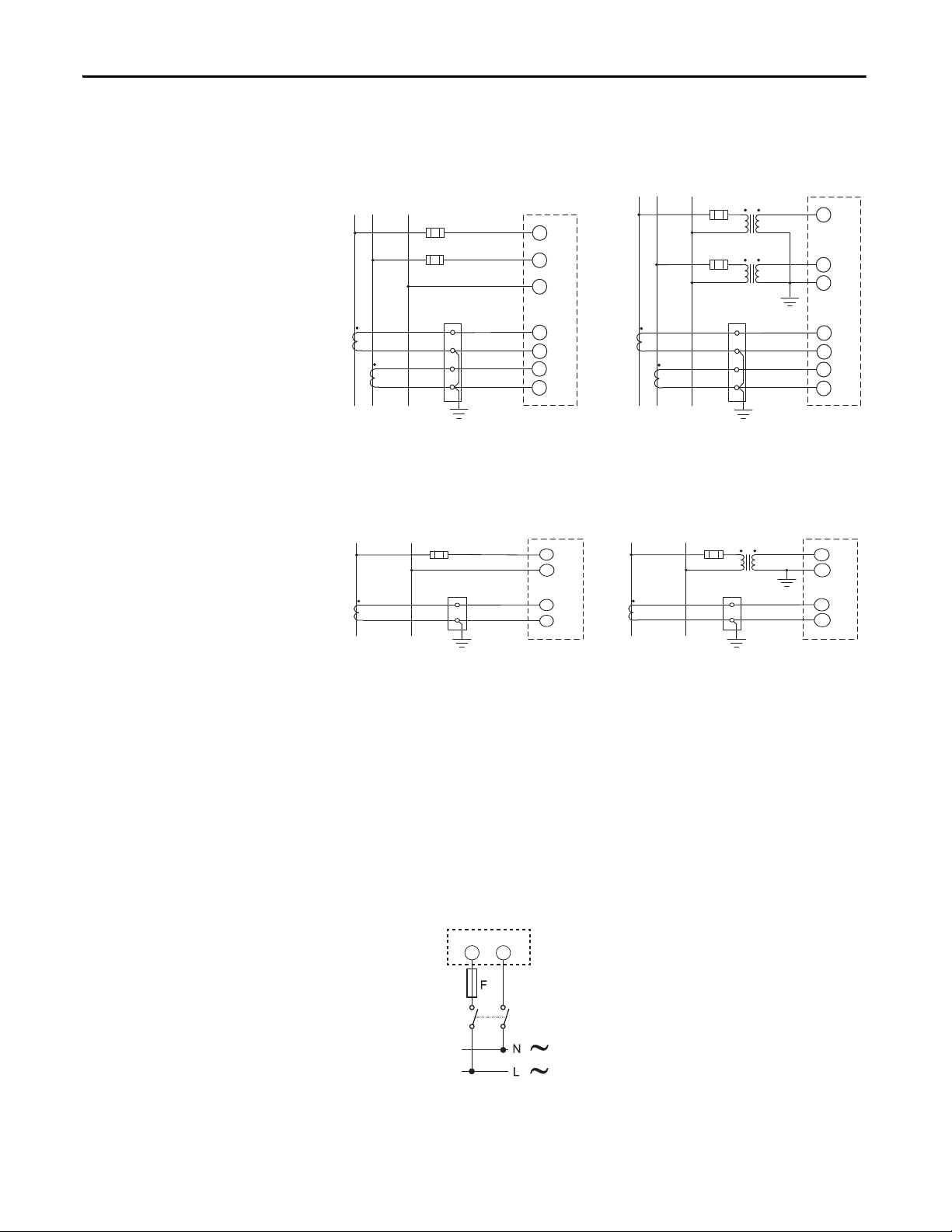

Page 22

Chapter 2 Installation and Wiring

Line

L1 N

Fuse

PT 1

(VT1)

Groun d

L2

L1

PM 500

2-CT and 2-PT/VT Conn ection s

Fuse

PT 2

(VT2)

L2

Line

L1 N

Fuse

Load

Groun d

Shorting

terminal block

S1

I1

CT

1

L2

L1

S2

PM 500

2-CT Connection

S1

I2

CT

2

S2

Fuse

L2

N

Load

Groun d

Shorting

terminal block

S1

I1

CT

1

S2

S1

I2

CT

2

S2

N

Meter Configuration: System = 2P

Line

L1 N

Fuse

PT

(VT)

Load

Groun d

Shorting

terminal block

L1

N

S1

S2

I1

Groun d

CT

Line

L1 N

Fuse

Load

Groun d

Shorting

terminal block

L1

N

S1

S2

I1

CT

PM 500 PM 500

1-CT Connection

1-CT and 1-PT/VT Connection s

Meter Configuration: System = 1P

Figure 15 - Split-phase

Figure 16 - Single-phase

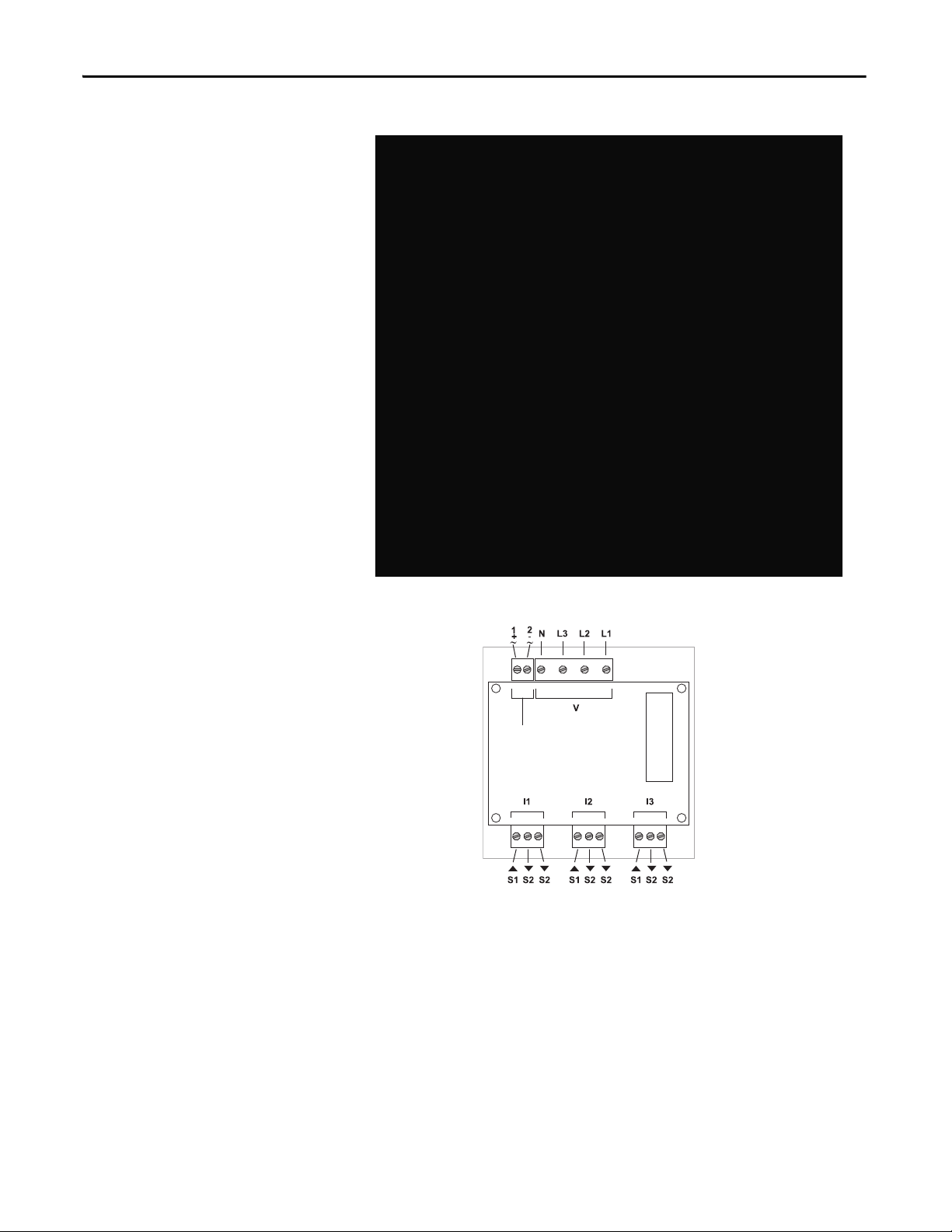

Supply Power

Connect the PowerMonitor™ 500 unit to a source of supply power through userprovided disconnecting means, such as a switch or circuit breaker close to the

power monitor. Provide overcurrent protection that is sized to protect the wiring.

Apply supply power only after all wiring connections are made to the unit.

Figure 17 - Supply Power

120/240V AC 50/60Hz, or 120/240V DC

22 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

F = 250V (T) 630 mA

PowerMonitor 500

+--

1

2

+

Page 23

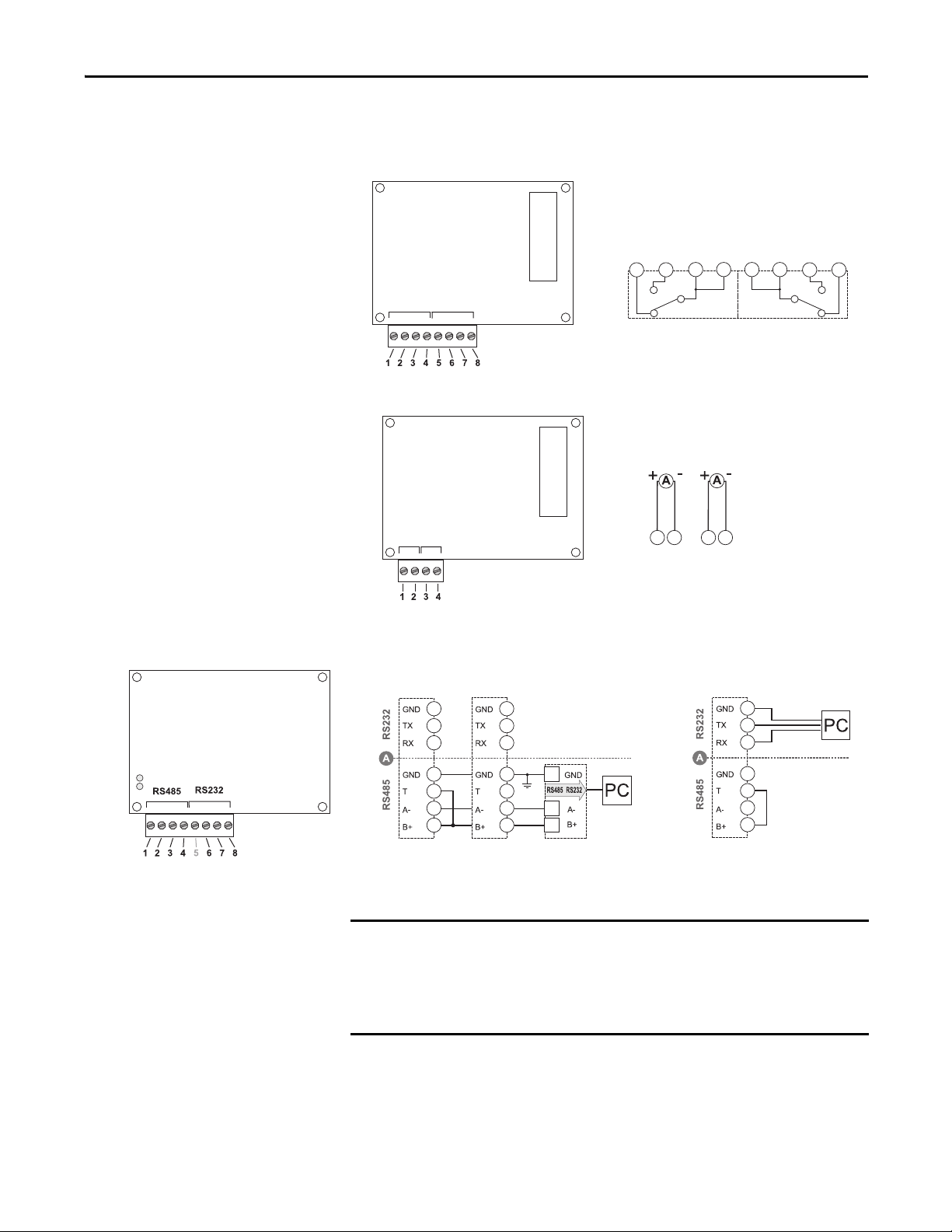

Factory Installed Option Wiring

1432

Out 1 Out 2

Out 1

Out 2

Analog 20 mA DC

RS-485 Port RS-232 Port

6

7

8

1

2

3

4

6

7

8

1

2

3

4

6

7

8

1

2

3

4

Mandatory

Termination

T = Termination

A- = Transmit minus

B+ = Transmit plus

IMPORTANT

Figure 18 - Pulse (digital) Outputs (P option)

Installation and Wiring Chapter 2

2143

Out 1 Out 2

Out 1 Out 2

Figure 19 - Analog Outputs (A option)

Figure 20 - Serial RS-485 and RS-232 Communication Wiring (485 option)

6587

Additional devices that are provided with RS-485 are connected in parallel. The

termination of the serial output is implemented only on the last instrument of

the network, with a jumper between (B+) and (T). The jumper applies an

internal termination resistance between (A-) and (B+). The RS-232 and

RS-485 communication ports cannot be connected and used simultaneously.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 23

Page 24

Chapter 2 Installation and Wiring

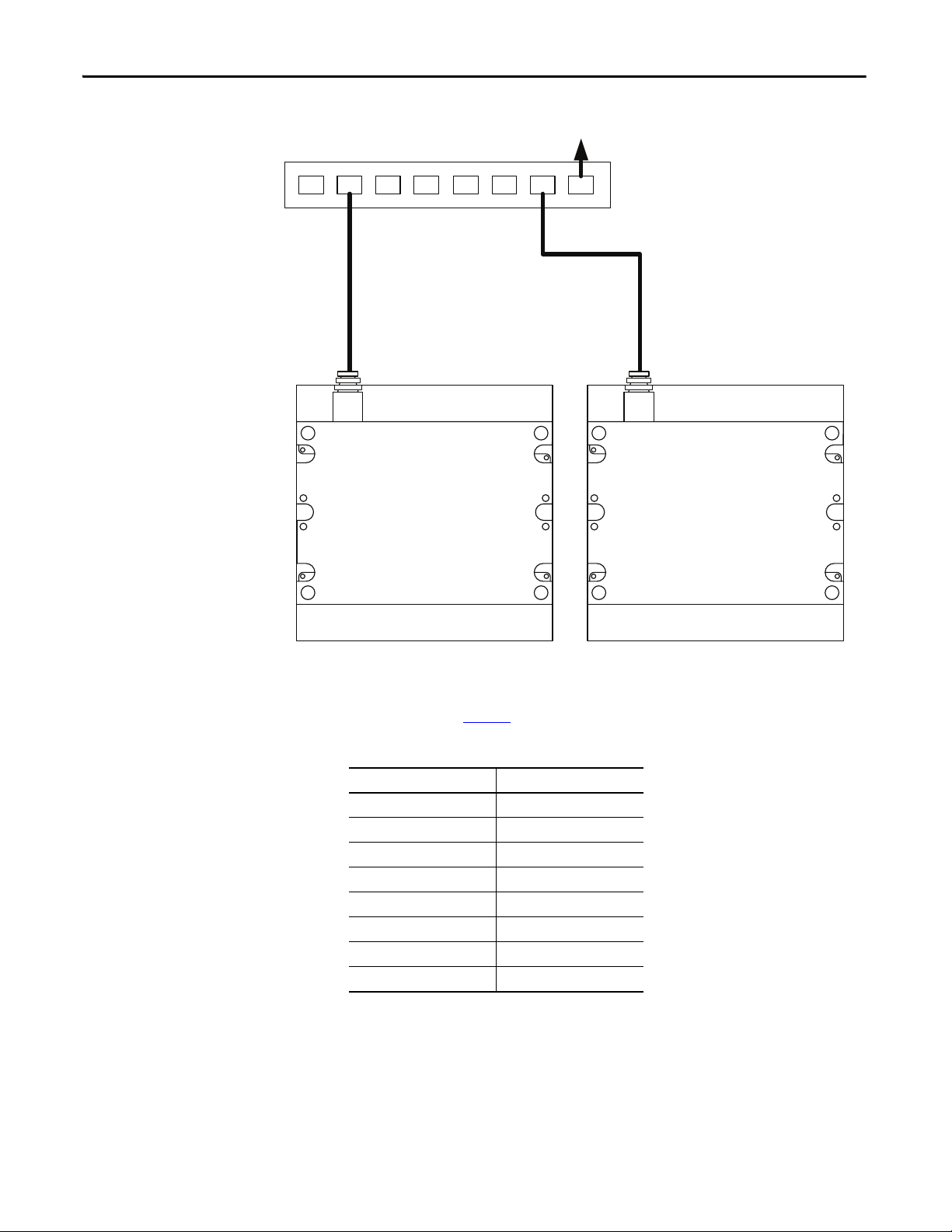

Ethernet Network Switch Uplink to LAN

PowerMonitor 500 PowerMonitor 500

Figure 21 - Ethernet Communication (ENT option)

The PowerMonitor 500 unit connects to industry-standard Ethernet hubs and

switches by using standard CAT-5 UTP (unshielded twisted-pair) cables with

RJ45 connectors. Ta b l e 5

Table 5 - Ethernet Network Connections

Terminal Signal

1TX+

2TX-

3RX+

4

5

6RX-

7

8

shows the cable and connector pin assignments.

24 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 25

Unit Configuration

Chapter 3

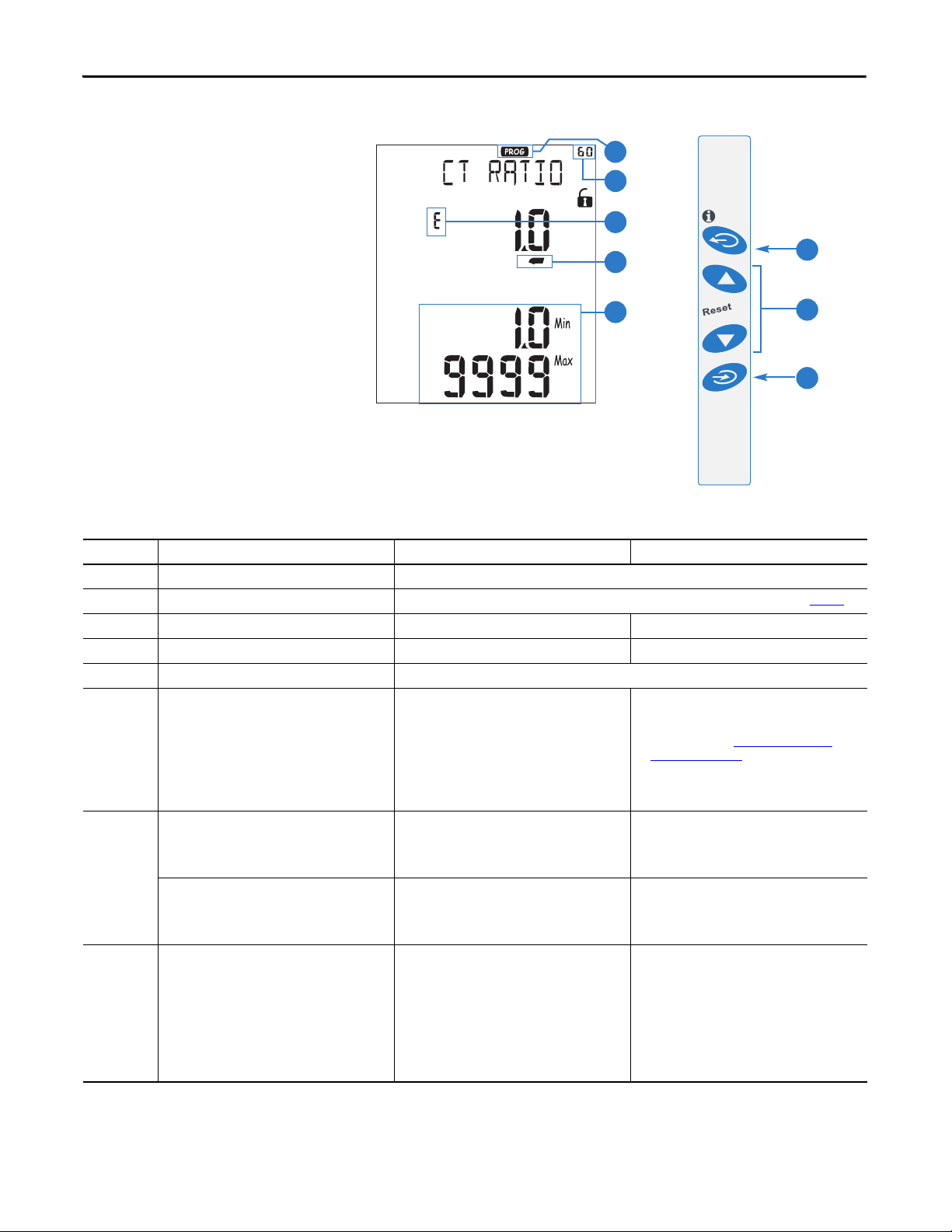

Configure with the Display

The PowerMonitor™ 500 unit provides menu-based configuration

(programming) by using its front panel display. The programming menus let you

select parameters to edit, select digits within parameters, and increase or decrease

the value of each digit.

Place the unit in Programming mode by pressing Program/select (8) for about

2 seconds. The front panel displays the PASSWORD? menu page 0 in Editing

mode. Enter the correct password by using the Up and Down arrows (the default

password is 0) and press Program/select. The front panel then displays the

CHANGE PAS menu page 10.

See the programming flowchart that begins on page 28

organization of programming menus and submenus. Each page is identified with

a number, which is displayed in the top right corner. Menu page numbers end in

zero, while submenu pages end in 1 through 9. For example, the Change

Password page is menu 10. Likewise, the Dmd page is menu 80, and the demand

interval Time page is menu 82.

While you are programming the power monitor, the display items and control

buttons function one way when you are navigating between menu or submenu

pages, and another way when you are editing a menu page.

for a view of the

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 25

Page 26

Chapter 3 Unit Configuration

Figure 22 - Front Panel Display

1

2

3

4

5

6

7

8

Table 6 - Front Panel Display Descriptions

Display Item Description Navigating Menus Editing a Menu

1 Programming mode indicator Indicates programming mode.

2 Programming menu page Identifies the current programming menu page. See the programming flowchart that begins on page 28

3 Editing mode indicator Does not appear. Indicates the parameter being edited.

4 Cursor Does not appear. Appears beneath the digit currently being edited.

5 Permitted range Displays the permitted range of values for the selected parameter.

6 Exit button • When in a menu page, exits Programming mode

without saving changes. Program/select button

confirms exit.

• When in a submenu page, exits to menu page.

7 Up button Selects the next higher-numbered menu or

submenu page.

Down button Selects the next lower-numbered menu of submenu

page.

8 Program/select button • Press and hold for 2 seconds to enter the Program

mode.

• Selects a menu page for editing.

• When in a menu page with submenus, displays

the first submenu page.

• After pressing the Exit button, confirms exit from

Programming mode without saving changes.

• From End menu page 260, saves new

configuration and exits Programming mode.

• Moves the cursor one digit to the left.

• When the leftmost digit is selected, dP is

indicated and you can change the decimal point

and multiplier (see Edit Decimal Point and

Multiplier on page 27).

• When held for at least 2 seconds, cancels the edit

and restores the previous value of the selected

parameter.

• Increments the value of the digit indicated by the

cursor.

• When dP is indicated, increments the decimal

point and multiplier.

• Decrements the value of the digit indicated by

the cursor.

• When dP is indicated, decrements the decimal

point and multiplier.

Stores the new value of the selected parameter, but

does not save the new configuration to the power

monitor.

.

26 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 27

Unit Configuration Chapter 3

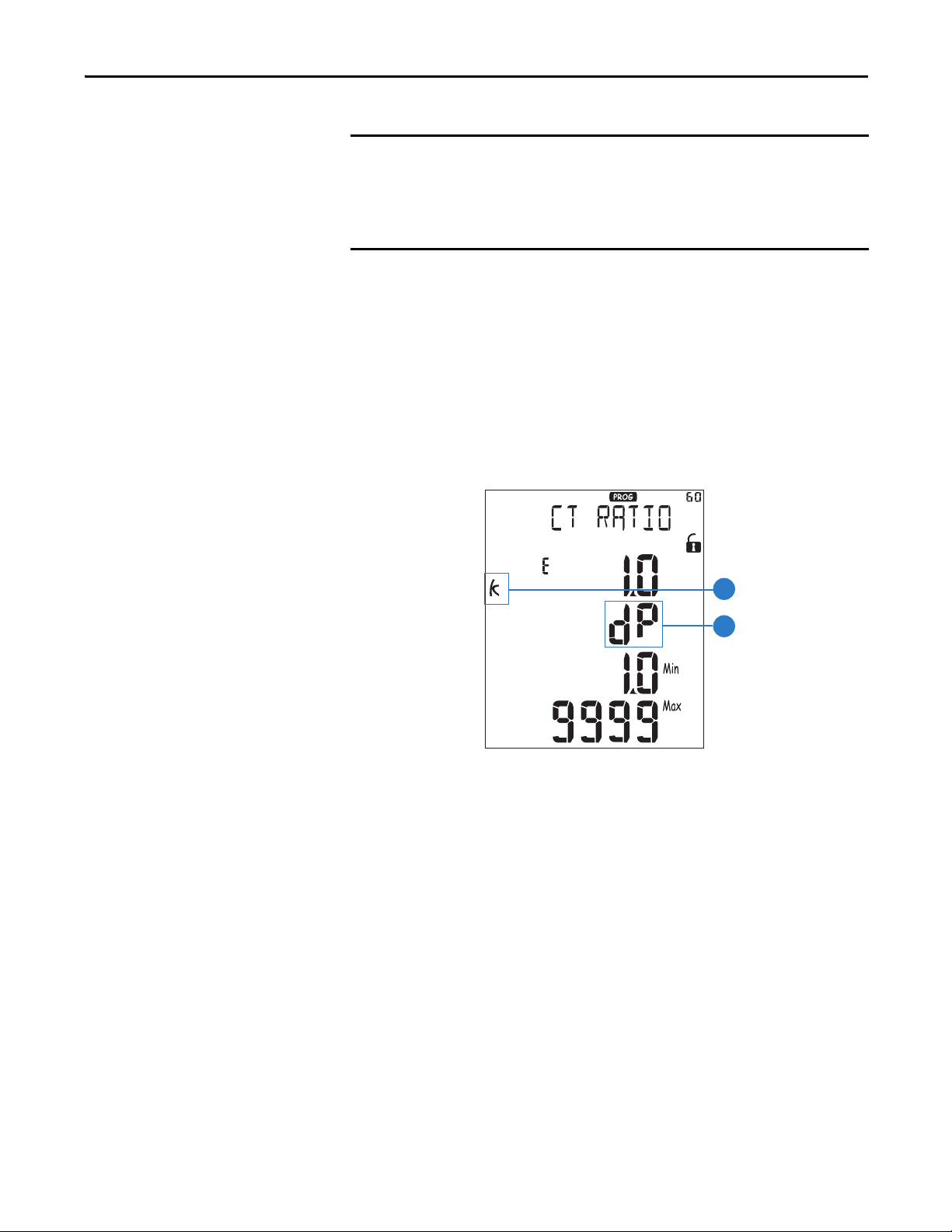

IMPORTANT

TIP

To save programming changes, navigate to the End menu page 260 and press

Program/select. To exit the Programming mode without saving any changes,

press Exit and confirm by pressing Program/select. If no buttons have been

pressed for 2 minutes, the power monitor exits Programming mode without

saving any changes.

You can make programming changes by using the PowerMonitor 500 software.

Edit Decimal Point and Multiplier

When the cursor is beneath the last digit on the left, pressing Exit (6) lets you

change the decimal point and the multiplier (9) (k or M). The blinking ‘dP’

(decimal point) text (10) indicates this capability.

9

10

To modify the decimal point position and the multiplier, use the Up and Down

arrow (7) to select the desired value.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 27

Page 28

Chapter 3 Unit Configuration

Configuration Flowchart

The following flowchart shows the configuration menus and submenus that are

accessed through the display. To navigate through the menu pages, use the up and

down arrows. To enter Edit mode or to access a submenu, press the Program/

select button. The menu pages available depend on your module type.

• 0 PASSWORD?: enter password by using up and

down arrows to change the digit. Use the Exit button

to move the cursor between digits. Press the

Program/select button to confirm password. The

default password is 0.

• 10 CHANGE PAS: this function lets you modif y the

PASS value with a new value (from 0…9999).

• 20 BACKLIGHT: adjusts backlight time from

0…255 minutes (0 = always on).

• 50 SYSTEM: this function lets you select the type of

electrical system.

See pages 19

diagrams that correspond to the system type

designations, such as, 3P and 3P.n.

• 60 CT RATIO: this function lets you select the value

of the CT ratio (primary/secondary ratio of the

current transformer being used). Example: if the CT

primary (current transformer) has a current of 300 A

and the secondary a current of 5 A, the CT ratio

corresponds to 60 (300 divided by 5).

…22 for descriptions and wiring

• 70 PT RATIO: this function lets you select the value

of the PT (VT) ratio (primary/secondary ratio of the

potential/voltage transformer being used). Example:

if the primary of the connected PT is 20 kV and the

secondary is 100V, then the PT ratio corresponds to

200 (20,000 divided by 100). If the voltage level is

such that PTs are not required and are not in place,

configure the PT ratio to 1.0.

28 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 29

Unit Configuration Chapter 3

Where:

Pmax is the maximum power

Pc is the contractual power

t1 is the selected time period for the calculation of the AVG/DMD value

Fixed

Slide

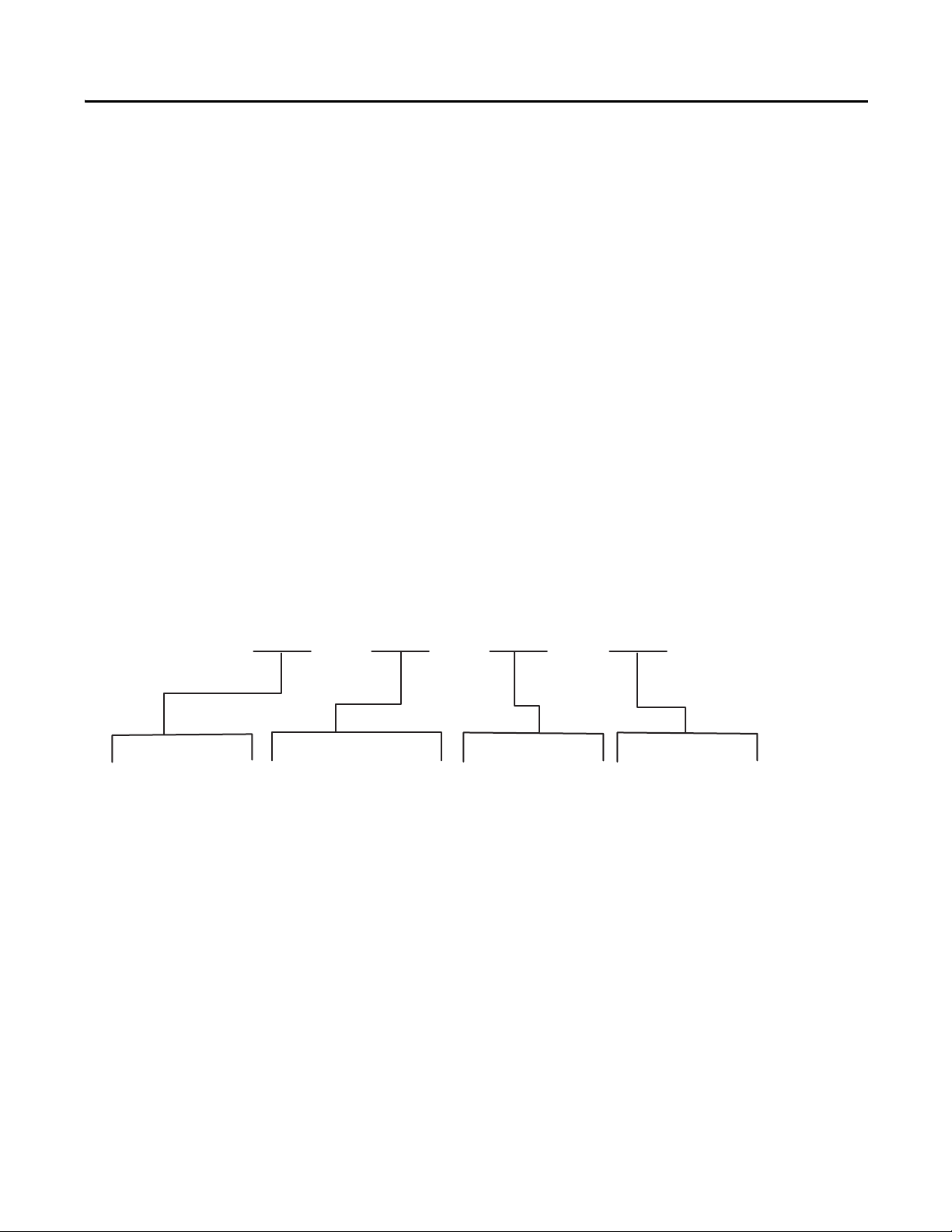

• 80 DMD: This function lets you select the

calculation method of the DMD/AVG value of the

selected variable.

– 81 TYPE: select the type of Calculation mode to be

used for the DMD/AVG calculation.

FIXED: The instrument calculates the

AVG/DMD value of the measured variable over the

selected interval, updates the AVG/DMD value at

the end of the interval, then resets and starts a new

calculation.

SLIDE: When first configured, the instrument

calculates the AVG/DMD value and updates its

value at the beginning after the first selected

interval. After the first interval, the instrument

calculates the AVG/DMD value every minute.

After the calculation, the instrument generates a

window whose width is the selected interval and

that moves forward every minute.

– 82 TIME: select the time interval for the DMD/

AVG calculation. Default is 15 minutes.

– 83 SYNC: select the Synchronization mode. That

mode is the method that controls the calculation

method of the average/demand according to the

selected time.

• 110 FILTER: The digital filter makes it possible to

stabilize the display of fluctuating measurements.

See Digital Filtering Operation

on page 32.

– 111 FILTER S: set the operating range (span) of the

digital filter. The value is expressed as a % (filter to

0.0 means filter excluded).

– 112 FILTER CO: set the filtering coefficient of the

instantaneous measures. By increasing the value, also

the stability and the settling time of the measures are

increased.

IMPORTANT: Some specific menus display only if

the relevant modules are installed.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 29

Page 30

list of available

variables

list of available

variables

Same as DIG OUT 1

Same as VIRT ALARM 1

Same as VIRT ALARM 1

list of available

variables

-IP ADDRESS

-SUBNET

-GATEWAY

-TCP IP PRT

-ACD

ETHERNET

www.xxx.yyy.zzz

www.xxx.yyy.zzz

www.xxx.yyy.zzz

1…9999 (default = 502)

yes/no (default = no)

Same as VIRT ALARM 1

Chapter 3 Unit Configuration

• 120 RS232-485: User settings for the RS-232 and

RS-485 serial communication ports.

• 130 ETHERNET: User settings for the Ethernet

communication port.

• 150 VIRT AL 1: This virtual alarm function lets you

set the alarm parameters.

– 151 ENABLE: enable (YES) or disable (NO) the

alarm.

– 152 VARIABLES: set the variable to be linked to

the alarm.

– 153 SET 1: set the on alarm set point of the variable.

– 154 SET 2: set the off alarm set point of the variable.

– 155 ON DELAY: set a delay on activation of the

alarm.

• 190 DIG OUT 1: This function lets you link a virtual

alarm to the digital relay output and to its working

parameters.

– 191 FUNCTION:

Alarm - the digital output is enabled when the

associated alarm status occurs.

Pulse - the measured energy is retransmitted by the

digital output with pulses.

Remote - the digital output can be controlled

through a command that is sent through the serial

communication port.

– 192 AL LINK: select the virtual alarm that it has to

be associated.

– 193 AL STATUS: ‘ND’ (normally de-energized

relay) or ‘NE’ (normally energized relay).

– 195 PULSE WEIG: selects the pulse weight (kWh

per pulse).

– 196 OUT TEST: Tests the digital output. YES

enables the test, No disables the test.

– 197 POWER TEST: sets a simulated power value

(kW) to test the energy pulse output. The function

remains active until you exit the programming

menu.

30 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 31

Save the set

parameters and come

back to the measuring

mode.

List of available

variables

Same as AN OUT 1

Unit Configuration Chapter 3

• 210 AN OUT 1: User programming of the analog

outputs (0…20 mA).

– 211 VARIABLES: selects the variable to be

retransmitted with the analog output.

– 212 MIN OUTPUT: sets the value that is expressed

as % of the output range (0…20 mA) that

corresponds to the minimum measured value.

– 213 MAX OUTPUT: selects the value that is

expressed as % of the output range (0…20 mA) that

corresponds to the maximum measured value.

– 214 MIN INPUT: minimum value of the variable

input range, corresponds to the ‘MIN OUTPUT’

value of the analog output.

– 215 MAX INPUT: maximum value of the variable

input range corresponds to the ‘MAX OUTPUT’

value of the analog output.

• 230 METERS: reset the ENERGY METERS.

Choose among the following:

– 231 TOTAL, 222 PARTIAL: resets all energy

meters, total and partial.

– 233 TOTAL +: resets the total meters of imported

energy.

– 234 TOTAL -: resets the total meters of exported

energy.

– 235 PARTIAL +: resets the partial meters of

imported energy.

– 236 PARTIAL -: resets the partial meters of

exported energy.

• 240 RESET: Resets the MAX or dmd stored values.

• 250 CLOCK:

– 251 FORMAT: UE, sets the European time format

as 24h (00:00) or sets the time format as 12h (12:00

AM/PM).

– 252 YEAR: sets the current year.

– 253 MONTH: sets the current month.

– 254 DAY: sets the current day.

– 255 HOUR: sets the current hour.

– 256 MINUTE: sets the current minute.

– 257 SECOND: sets the current second.

• 260 END:

– To save programming changes, press Program/select.

– To exit the Programming mode without saving any

changes, press Exit and confirm by pressing

Program/select.

– If no buttons are pressed for two minutes, the unit

exits Programming mode without saving changes.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 31

Page 32

Chapter 3 Unit Configuration

Digital Filtering Operation

Digital filtering smooths out the display of fluctuating values. The parameter

FILTER S defines the operating range of the filter. This operating range is

represented as a yellow band (each small square is one digit). While the measured

value (red curve in Figure 23

value exceeds the operating range, the filter is deactivated and a new band is active

around the new value. The range of fluctuation (in digits) is a good starting value

for such parameters.

The parameter FILTER CO represents the filtering coefficient. The higher the

FILTER CO, the smoother the curve of the displayed values (black in Figure 23

There is not a theoretical rule to define this parameter, it is set in the field. One

rule is to start with the value of the FILTER S coefficient and then increase

FILTER CO until the desired stability is reached.

The digital filter affects the values retransmitted both via serial communication

and analog output.

Figure 23 - Digital Filter

) is within this band, the filter is active. Once the

No lter action

).

Digital Fluctuation

Digital Filter Programming Examples

This section gives digital filter programming examples.

Example 1

This example describes how to stabilize the displayed value of the VL-N variable,

which fluctuates between 222V and 228V. The parameters of the digital filter

have to be programmed as follows.

FILTER S: The variable fluctuates within the mean value whose amplitude is

equal to ±0.75% of the full scale rated value of the variable itself, which is

obtained by the following calculation:

(228 - 222)/ 2= ±3V, then ±3*100/400V= ±0.75%

where 400V is the line-to-neutral rated value of a 1420-V2 unit input

32 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 33

Unit Configuration Chapter 3

The FILTER S parameter, which represents the action range of the digital filter, is

programmed to a value that must be slightly higher than the percentage

amplitude of the fluctuation, for example, 1.0%.

FILTER CO: if the new value that is measured by the instrument is within the

action range of the filter, the new displayed value is obtained by adding

algebraically the previous value to the variation divided by the filtering

coefficient. As a consequence, a value higher than this coefficient implies a longer

settling time and therefore better stability. You generally obtain the best result by

setting the filtering coefficient to a value equal to at least 10 times the range

parameter value.

In the following example, 1.0*10=10, the stability of the filtering coefficient can

be improved by increasing the filtering coefficient; the allowed values are

included within 1 and 255.

Example 2

This example describes how to stabilize the value of the displayed System Real

Power (W), which fluctuates 300...320 kW. In this example, the load is

connected to the instrument with a 300/5 A CT and a direct measure of the

voltage.

The parameters of the digital filter must be programmed as follows.

FILTER S: the variable fluctuates within the mean value whose amplitude is

equal to ±2.78% of the full scale rated value of this variable. This value is

obtained by the following calculation:

(320 - 300)/ 2= ±10 kW,

then ±10*100/360 kW= ±2.78%,

where 360 kW is the rated value of the System Real Power of a 1420-V2

unit input, at the CT and VT ratios and obtained with the following

formula:

VLN * VT * IN * CT * 3

Where:

VLN = rated input voltage (400V for the V1 input)

VT= primary/secondary ratio of the voltage transformer being used

IN = rated current (5 A)

CT = primary/secondary ratio of the voltage transformer being used (in

this example 400*1*5*60*3=360 kW).

The FILTER S parameter, which represents the digital filtering coefficient action

range, is programmed to a value that must be slightly higher than the percentage

of the fluctuation: for example 3.0%.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 33

Page 34

Chapter 3 Unit Configuration

FILTER CO: if the new value that is acquired by the unit is within the filtering

action range, the new displayed value is obtained by adding algebraically the

previous value to the variation divided by the filtering coefficient. As a

consequence, a value higher than this coefficient implies a higher settling time

and therefore better stability. Therefore, the best result is obtained by setting the

filtering coefficient to a value equal to at least 10 times the value of the range

parameters. In the example, 3.0*10=30. To improve the stability, you can increase

the filtering coefficient; the admitted values are included within

1 and 255.

Example 3

It is necessary to stabilize the value of the displayed variable A L1

(phase current 1), which fluctuates in the range 470 A and 486 A.

To be able to manage the alarm function and activation and deactivation of the

relay, this value is not to be subject to continuous fluctuations. In this example,

we have considered using a 500/5 A CT. Program the parameters of the digital

filter as follows:

FILTER S: the variable fluctuates within the mean value whose amplitude is

equal to ±1.60% of the full scale rated value of this variable (obtained with the

calculation:

(486 - 470)/ 2= ±8 A, then ±8*100/500 A= ±1.60%

where 500 A is the value referred to the primary of the transformer being

used).

The FILTER S parameter, which represents the action range of the digital filter, is

programmed to a value slightly higher than the percentage amplitude of the

fluctuation, for example 2.0%.

FILTER CO: if the new value that is acquired by the instrument is within the

filtering action range, the new displayed value is calculated algebraically adding to

the previous value the variation divided by the filtering coefficient. As a

consequence, a higher value of this coefficient implies a higher settling time and

therefore better stability. Therefore, the best result is obtained setting the filtering

coefficient at a value equal to at least 10 times the value of the range parameter. In

the example, 2.0*10=20. To improve the stability, you can increase the filtering

coefficient; the admitted values are within 1 and 255.

34 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 35

Unit Configuration Chapter 3

Analog Output Configuration Examples

These examples apply to units with catalog numbers 1420-V1A and 1420-V2A.

Example 1: Power value retransmission with a 0…20 mA analog output.

This example describes how to retransmit measured power up to

100 kW with a 4…20 mA signal. Program the unit as follows:

• VAR IA BL E: W

• MIN OUT: 20.0% means 4 mA. The calculation that is used is the

following:

(100*minimum output) / full scale output =100*4 mA/ 20 mA=20%

• MAX OUT: 100.0% means 20 mA. The calculation is the following:

(100*maximum output)/full scale output = 100*20 mA/20 mA= 100

• MIN INPUT: 0.0 k; the multiplier k, M, G can be selected on the unit

according to the chosen VT and CT values

• MAX INPUT: 100.0 k; the k, M, G multipliers can be selected on the unit

according to the selected VT and CT values

Example 2: Retransmission of the power factor (PF) value with the

0…20 mA analog output.

In this example, the unit is configured to retransmit the whole range of the

allowed values for the PF with a signal from 0…20 mA. The value of the PF

variable can vary between C0.001 and L0.000 (for each phase); these values,

when retransmitted, correspond to 0 mA and 20 mA. When the PF value is equal

to 1, the analog output value corresponds to the middle of the scale,

which is 10 mA. Program the instrument as follows:

• VARIABLE: PF L1 (or L2 or L3 or PF

• MIN OUT: 0.0%

• MAX OUT: 100.0%

• MIN INPUT: C0.001 (the C symbol shows a CAPACITIVE value)

• MAX INPUT: L0.001 (the L symbol shows an INDUCTIVE value).

L0.001 has been chosen as minimum value to be set to avoid undesirable

rapid changes of the outputs

Σ (system real power)

Σ)

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 35

Page 36

Chapter 3 Unit Configuration

IMPORTANT

300 kW

295 kW

Alarm Configuration Example

These examples apply to units with catalog numbers 1420-V1P and 1420-V2P.

This example describes an alarm when a measured real power value exceeds a

programmed threshold. For example, when 300 kW are exceeded, the alarm

occurs and the load that is controlled by the relay output is disconnected.

The PowerMonitor 500 unit is not intended to be applied as a protective device.

An ‘UP’ alarm is selected. The recommended programming is the following:

• ENABLE: YES

• VAR IA BLE S: W sys tem ( W·)

• SET POINT 1: 300 kW

• SET POINT 2: 295 kW

• ON DELAY: set the desired number of seconds, for example 5 seconds

To program a ‘DOWN’ alarm, configure SET POINT 1 to be a lower value than

SET POINT 2.

36 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 37

Communication

TIP

IMPORTANT

Chapter 4

EtherNet/IP Communication

EtherNet/IP communication is supported in PowerMonitor™ 500 units that are

ordered with optional Ethernet communication. Communication parameters in

the power monitor must be configured. See Unit Configuration

Ethernet communication port supports 100 or 10 Mbps data rate, half-duplex, or

full-duplex.

The Ethernet hardware address (MAC ID) is printed on the unit label.

The PowerMonitor 500 unit provides nine Assembly Instances that contain realtime, maximum, demand, energy, and status data that can be read by a client by

using implicit messaging (Class 1) or Explicit Messaging (Class 3 or UCMM).

Appendix A

power monitor returns EtherNet/IP data as little-endian, the same byte order

that is used in the Logix family of programmable controllers.

Figure 24 - Byte Order Example

lists the Assembly Instances, sizes, data types, and other details. The

on page 25. The

Word

Low Byte (LSB)

High Byte (MSB)

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

MSb (Most Signicant Bit) (Least Signicant Bit) LSb

The power monitor supports the following communication commands:

• CIP Generic Assembly Object (Class 04), Get_Attribute_Single (Service

Code 0x0E) for Attribute 3 (data)

• CIP Generic Assembly Object (Class 04), Get_Attribute_Single (Service

Code 0x0E) for Attribute 4 (size in bytes)

The power monitor does not support configuration or commands on

EtherNet/IP network. To write the configuration of command data, refer to the

section on Modbus Communication

See Appendix C

implementation in the PowerMonitor 500 unit.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 37

for additional information on the EtherNet/IP communication

on page 43.

Page 38

Chapter 4 Communication

Electronic Data Sheet (EDS)

The EDS file is used to convey device configuration data that is provided by the

manufacturer. You can obtain EDS files for the PowerMonitor 500 unit by

downloading the file from the following website:

http://www.rockwellautomation.com/rockwellautomation/support/networks/eds.page

You can install EDS files on your computer by using the EDS Hardware

Installation Tool that comes with RSLinx® Classic software,

RSNetWorx™ for EtherNet/IP software, or other tools.

Explicit Messaging - Message Setup with CIP Generic

The following example shows how to configure your message instruction to read

from a data table in the power monitor by using a CIP Generic message type for

the Studio 5000 Logix Designer® application. This setup applies to

ControlLogix® and CompactLogix™ programmable logic controllers. The CIP

Generic message type does not support single element reads or writes. In this

example, we read the Real-time Metering Values (Voltage and Current) data table

from the power monitor.

38 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 39

Communication Chapter 4

We assume that you are familiar with basic message programming in a Logix

controller. Once you configure the logic, message tag, destination tag, and

message instruction, follow these steps to configure the message. This example

uses a CompactLogix™ controller, revision 20.

1. Choose the appropriate parameters in the Message Configuration window.

Parameter Choice

Message Type Choose message type CIP Generic.

Service Type Read: Select service type Get Attribute Single (E hex)

Instance See Appendix A

monitor Real-time Metering Values (Voltage and Current) data table is instance 101 (decimal).

Class 4 hex

Attribute 3 hex

Destination Get Attribute Single - This element is the first element of the controller tag that stores the data

being read. The tag is an array of the applicable data type the same length as the Assembly

Instance; in this example, 12 REAL elements.

Source Element Not applicable to a Read

Source Length Not applicable to a Read

for the CIP Instance of the data table to read. In this example, the power

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 39

Page 40

Chapter 4 Communication

2. Click the Communication tab and enter the path and method.

3. Click OK to complete message setup.

Path Method

<Ethernet Module, Port (always 2 for Ethernet), Power Monitor IP Address> CIP

Implicit Messaging - Generic Ethernet Module Input Data Connection

The PowerMonitor 500 unit with EtherNet/IP communication supports Class 1

connections to its nine Assembly Instances. To configure a Class 1 connection to

a selected Assembly Instance with a Logix controller, follow these steps.

1. Open the controller program offline in the Logix Designer application (or

online in Program mode if you are using a ControlLogix® controller).

2. In the I/O configuration tree, right-click the Ethernet communication

module (for example, 1756-EN2T), and choose New Module.

3. From the Communication pull-down menu, choose ETHERNETMODULE Generic Ethernet Module.

40 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 41

Communication Chapter 4

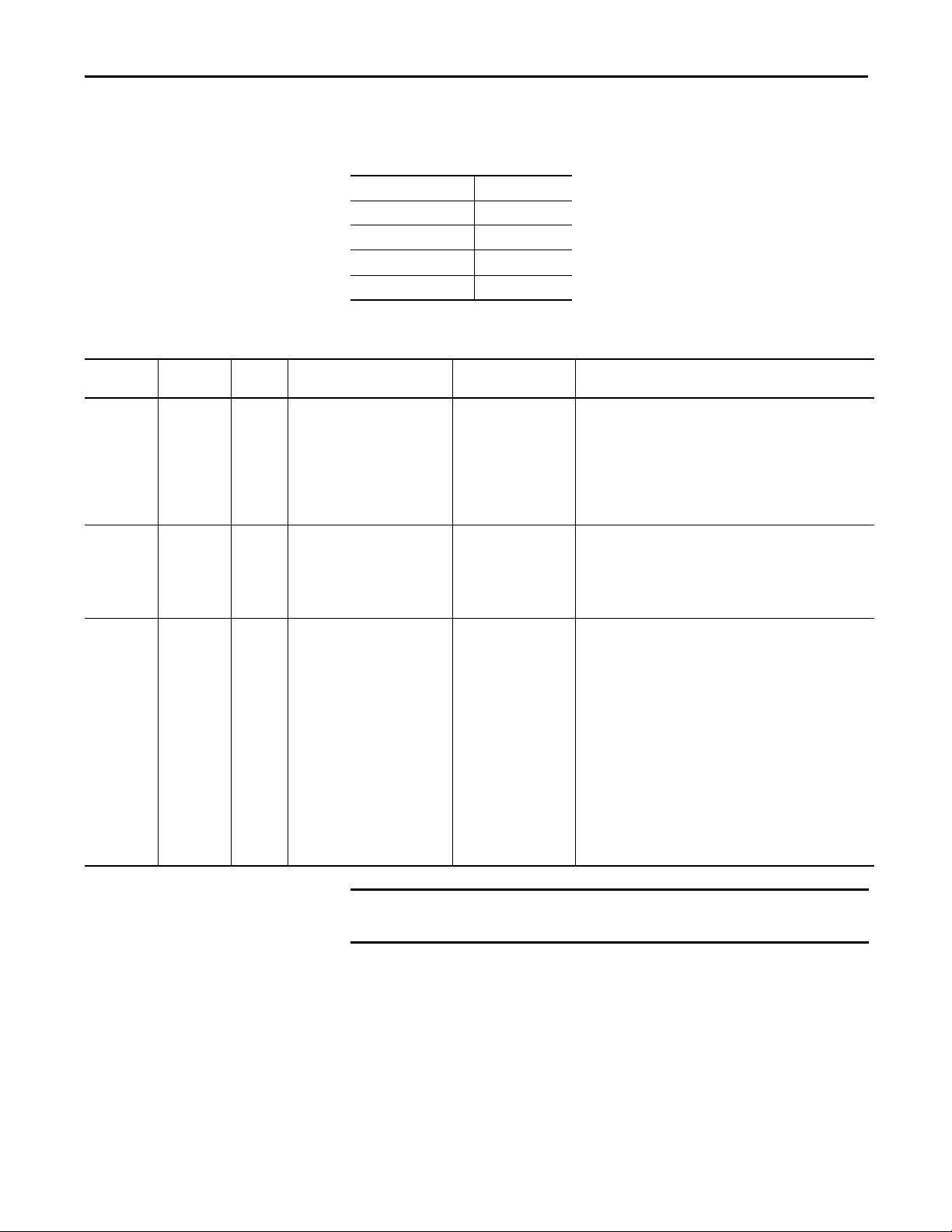

4. Enter the setup parameters as listed in this dialog box and explained in

Ta b l e 7

Table 7 - Module Properties Setup Parameters

Item Choices

General Tab

Name Required; must be IEC 1131-3 compliant

Description Optional

Comm Format Depends on selected Assembly Instance

Address/Host Name IP Address IP address of target PowerMonitor 500 unit

Host Name Not applicable

Connection Parameters Assembly Instance Size Comm Format Data Table Description

Input (select one) 100 20 Input Data - SINT Product Information

101 12 Input Data - REAL Real-time Voltage and Current

102 18 Input Data - REAL Real-time Power, PF, Frequency

103 12 Input Data - REAL Max Voltage and Current

104 17 Input Data - REAL Max Power, PF, Frequency

105 12 Input Data - REAL Dmd Voltage and Current

106 17 Input Data - REAL Dmd Power, PF, Frequency

107 18 Input Data - REAL Energy Meters

108 2 Input Data - INT Alarm and Output Status

Output 98 N/A Inst. 98 used for Input Only connection

99 N/A Inst. 99 used for Listen Only connection

Configuration 3 0 Instance 3 is a placeholder only

Connection Tab

RPI 100 ms or greater

Inhibit Module Optional - unchecked by default

Major Fault Optional - unchecked by default

Unicast Connection Optional - checked by default

.

(1)

(1)

(1) Use the Listen Only connection only when an Input Only connection exists with another controller.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 41

Page 42

Chapter 4 Communication

5. When finished, click OK to save the new module.

The module updates its input tag <Name>.I.Data at the Requested Packet

Interval (RPI).

You can use additional programming to show the data in another way. Instances

101…107 show data in the REAL, or floating point, format. However, Instance

100 combines ASCII characters with numeric byte (SINT) values.

This program displays the contents of Instance 100 in a more human-readable

fashion:

• The XIC instruction on tag ‘bool_Convert_i100’ enables the conversion.

• The first CPS instruction copies the first 6 bytes of the module input data

tag.

• The MOV instruction sets the serial number string length to 13.

• The last CPS instruction copies the serial number from the module input

data tag that starts at element (byte) 6.

42 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 43

Communication Chapter 4

IMPORTANT

The destinations of the CPS instructions are in a tag with a user-defined data

type.

The destination tag shows the data in this way.

Modbus Communication

For a complete description of the MODBUS protocol refer to the following

documents that can be downloaded from http://www.modbus.org

• Modbus_Application_Protocol_ V1_1a

• Modbus_Messaging_Implementation_Guide_V1_0a

:

Modbus Functions Supported

Modbus RTU is supported in PowerMonitor 500 units that are ordered with

optional RS-485/RS-232 communication. In addition, Modbus TCP/IP is

supported in units that are ordered with optional Ethernet communication.

Communication parameters in the power monitor must be configured. See the

Unit Configuration

section of this manual.

We recommend that you use Modbus TCP/IP to configure or write to the

PowerMonitor 500 unit and that you use Ethernet/IP to read the

PowerMonitor 500 unit.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 43

Page 44

Chapter 4 Communication

The PowerMonitor 500 unit supports the following Modbus functions:

• 0x03 - Read n Holding Registers

• 0x04 - Read n Input Register

• 0x06 - Write one Holding Register

• 0x10 - Write multiple registers

• 0x08 - Diagnostic (with subfunction code 0x00)

• 0x42 - Read n Special Registers (vendor specific)

• Broadcast mode (write command on address 00h)

In this section, Modbus addresses are indicated in two ways. The ‘Modbus

address’ is expressed as the 6-digit input register address (example: 300123), used

with Modbus function code 0x04. The ‘Physical address’ is the hexadecimal

representation of the word address that is included in the communication frame.

Modbus function 0x04 can be used with the Modbus address by substituting a 4

for the first digit (example: 400123). With that distinction, functions 0x03 and

0x04 return the same data.

To avoid errors due to signal reflections or line coupling, a termination resistor

must be connected at the RS-485 ports of the master station and of the furthest

power monitor from the master station. In the PowerMonitor 500, you can

implement a jumper between (B+) and (T) to apply the required termination

resistance between (A-) and (B+) internally. Termination on both ends is

necessary even in case of point-to-point connection, with short distances.

The GND connection is optional if a shielded cable is used. For connections

longer than 1000 m (3280 ft), a line amplifier is necessary.

Data Types Supported

Format Description Bits Range

INT Integer 16 -32768…32767

UNIT Unsigned Integer 16 0… 65535

31

DINT Double integer 32 -2

UDINT Unsigned Double Integer 32 0…2

ULINT Unsigned long Integer 64 0…2

REAL Single-precision Floating Point 32 -(1+[1-2

… 2

32-1

64-1

31-1

-23

])x2

127…2128

The IEEE754 representation of a 32-bit Floating Point number as an Integer is

defined as follows.

Bits

31 30…23 22…0

Sign Exponent Mantissa

Va l u e = (-1)

44 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

sign*2(Exponent-127)

*1.Mantissa

Page 45

Communication Chapter 4

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

MSb (Most Signicant Bit) (Least Signicant Bit) LSb

High Byte (MSB) Low Byte (LSB)

Holding Register (word)

Modbus Register Format

Modbus registers are 16-bit words that are organized as shown in the following

diagram.

32-bit and 64-bit Data types that are presented as arrays of single registers in

LSW (least significant word) to MSW (most significant word) order.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 45

Page 46

Chapter 4 Communication

Notes:

46 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 47

PowerMonitor 500 Unit Data Tables

Appendix A

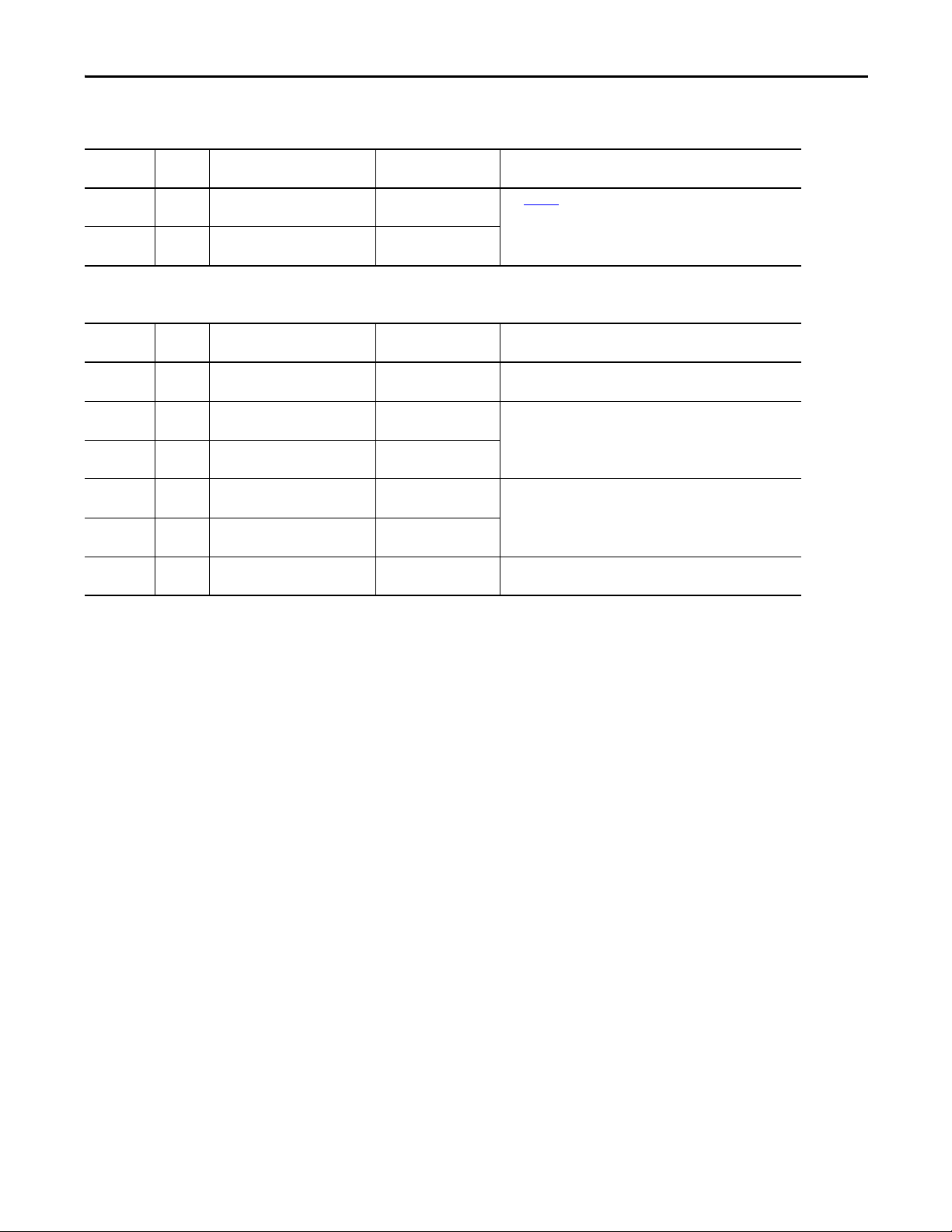

Summary of Data Tables

The Data Table Summary Index table summarizes all data tables available and

their general attributes.

Table 8 - Data Table Summary Index

Name of Data Table Read Write Modbus Starting

Product Information

Real-time Metering Values (voltage and current) X 300081 101 12 50

Real-time Metering Values (power, PF,

frequenc y)

Maximum Metering Values (voltage and current) X 300337 103 12 52

Maximum Metering Values (power, PF,

frequenc y)

DMD Metering Values (voltage and current) X 300849 105 12 54

DMD Metering Values (power, PF, frequency) X 300873 106 17 55

Total and Partial Energy Meters - EtherNet/IP

Data Table

Configuration - Base Unit: Read and Write X X 304097 - 79 57

Configuration - Alarms X X Varies - 16 58

Configuration - RS-485/RS-232 Communication X X 304356 - 17 58

Configuration - Analog Outputs: Read and Write X X 304609 - 32 59

Analog Output Configuration Parameters X X Varies - 16 59

Configuration - Digital Relay Outputs: Read and

Write

Commands: Write-only X 312369 - 45 61

Alarm and Output Status X 316385 108 2 63

X 300001

X 300105 102 18 51

X 300361 104 17 53

X 301281 107 9 56

X X 304865 - 12 60

Address

(1)

CIP Assy. Instance ID

(decimal)

100 10 49

No. of Elements See Page

(1) To obtain the physical address, subtract 300001 from the Modbus address, and convert the result to hexadecimal. Example: Physical address 0x000B corresponds to Modbus address

300012.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 47

Page 48

Appendix A PowerMonitor 500 Unit Data Tables

- W = Exported real power

+ W = Imported real power

+ VAR = Imported reactive

power

- VAR = Exported reactive

power

Geometric Representation of Power and Power Factor

Power and power factor values are signed values in accordance with EN 62053

and as indicated in the diagram. Inductive or lagging power factor (Quadrant I

and III) is indicated by a positive power factor value. Capacitive or leading power

factor (Quadrant II and IV) is indicated by a negative power factor value. The

PowerMonitor™ 500 unit indicates the quadrant by using +/- L or +/- C as

shown in Figure 25

Figure 25 - Power and Power Factor Diagram

+VAR

-VAR

PF > 0, ‘-L’ PF < 0, ‘C’

.

-W +W

PF > 0, ‘L’PF < 0, ‘-C’

Q

P

48 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 49

PowerMonitor 500 Unit Data Tables Appendix A

IMPORTANT

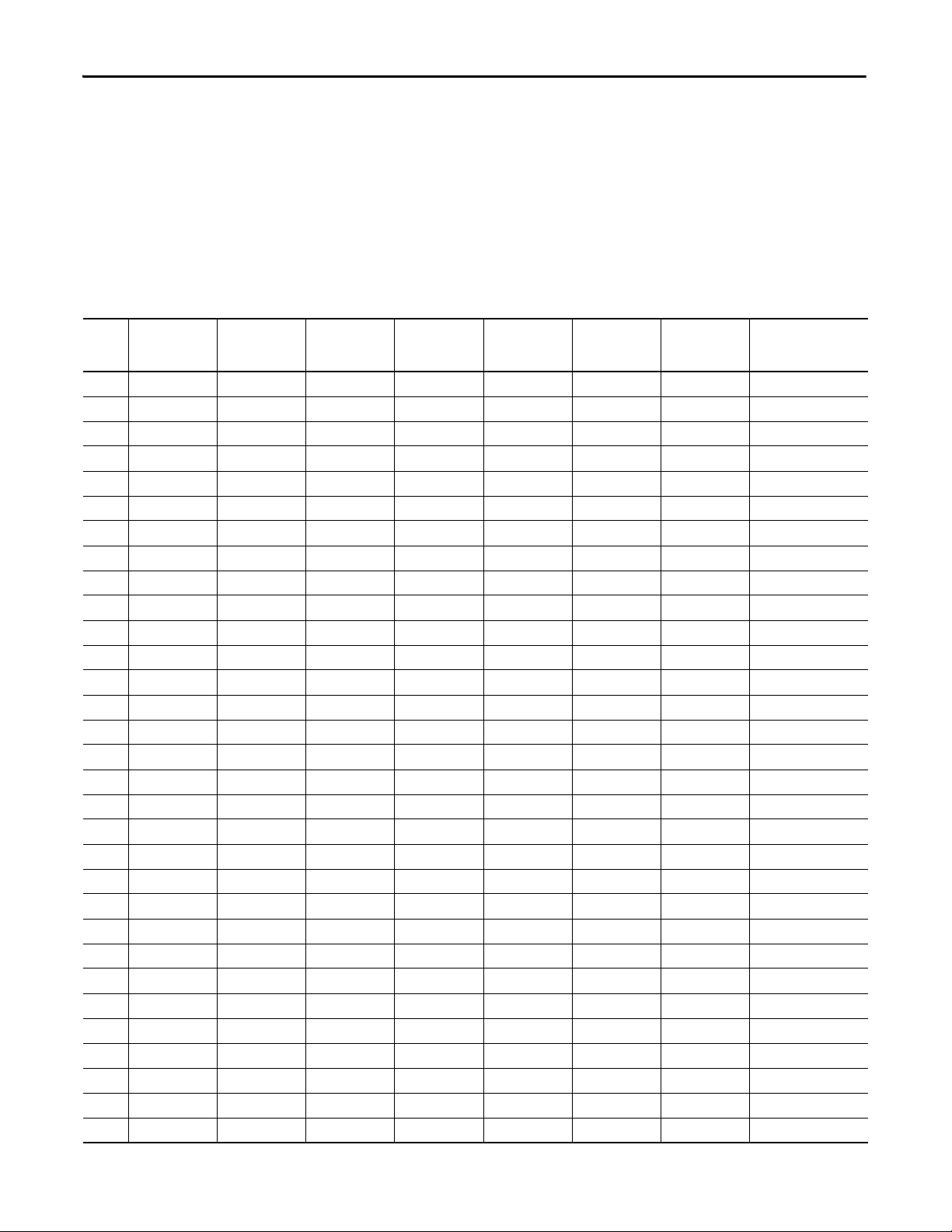

Data Tables

These tables detail each specific data table and its associated elements, such as

address, length, description, and format.

In the data tables, the symbol is used to indicate 3-phase or system values.

The context determines whether the symbol indicates average (for example,

voltage) or total (for example, power) values.

Product Information

Table 9 - Table Properties

CIP Assembly Instance 100

No. of Elements 10

Length in Words 10

Data Type UINT

Data Access Read Only

Table 10 - Product Information Data Table

Element Modbus

Address

1 300001 1 Base firmware revision UINT MSB: ASCII code for model (A = V2, B = V1)

2 300002 1 EtherNet/IP module firmware revision UINT MSB: ASCII code for model

3 300003 1 Analog output module firmware revision (if exists) UINT MSB: ASCII code for model

4 300033 1 Letter 1 (from SX)

5 300034 1 Letter 3 (from SX)

6 300035 1 Letter 5 (from SX)

7 300036 1 Letter 7 (from SX)

8 300037 1 Letter 9 (from SX)

9 300038 1 Letter 11 (from SX)

10 300039 1 Letter 13 (from SX) UINT MSB: ASCII code

Length

(words)

Description / Units Data

Form at

UINT MSB: ASCII code

Letter 2 (from SX)

UINT MSB: ASCII code

Letter 4 (from SX)

UINT MSB: ASCII code

Letter 6 (from SX)

UINT MSB: ASCII code

Letter 8 (from SX)

UINT MSB: ASCII code

Letter 10 (from SX)

UINT MSB: ASCII code

Letter 12 (from SX)

Notes

LSB: numeric number for revision

LSB: numeric number for revision

LSB: numeric number for revision

LSB: ASCII code

LSB: ASCII code

LSB: ASCII code

LSB: ASCII code

LSB: ASCII code

LSB: ASCII code

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 49

Page 50

Appendix A PowerMonitor 500 Unit Data Tables

Real-time Metering Values (voltage and current)

Table 11 - Table Properties

CIP Assembly Instance 101

No. of Elements 12

Length in Words 24

Data Type REAL

Data Access Read Only

Table 12 - Real-time Metering Values (voltage and current) Data Table

Element Modbus

Address

0 300081 2 V L1-N REAL

1 300083 2 V L2-N REAL

2 300085 2 V L3-N REAL

3 300087 2 V L-N REAL

4 300089 2 V L1-L2 REAL

5 300091 2 V L2-L3 REAL

6 300093 2 V L3-L1 REAL

7 300095 2 V L-L REAL

8 300097 2 A L1 REAL

9 300099 2 A L2 REAL

10 300101 2 A L3 REAL

11 300103 2 A N REAL Calculated by instrument base

Length

(words)

Description / Units Data Format Notes

50 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 51

Real-time Metering Values (power, PF, frequency)

Table 13 - Table Properties

CIP Assembly Instance 102

No. of Elements 18

Length in Words 36

Data Type REAL

Data Access Read Only

Table 14 - Real-time Metering Values (power, PF, frequency) Data Table

PowerMonitor 500 Unit Data Tables Appendix A

Element Modbus

Address

0 300105 2 W L1 REAL

1 300107 2 W L2 REAL

2 300109 2 W L3 REAL

3 300111 2 W REAL

4 300113 2 VA L1 REAL

5 300115 2 VA L2 REAL

6 300117 2 VA L3 REAL

7 300119 2 VA REAL

8 300121 2 VAR L1 REAL

9 300123 2 VAR L2 REAL

10 300125 2 VAR L3 REAL

11 300127 2 VAR REAL

12 300129 2 PF L1 REAL Negative values correspond to lead (C), positive values correspond

13 300131 2 PF L2 REAL

14 300133 2 PF L3 REAL

15 300135 2 PF REAL

16 300137 2 Hz REAL

17 300139 2 Voltage phase sequence REAL 1 = L1-L2-L3 voltage rotation

Length

(words)

Description / Units Data Format Notes

to lag (L)

-1 = Not L1-L2-L3 voltage rotation

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 51

Page 52

Appendix A PowerMonitor 500 Unit Data Tables

Maximum Metering Values (voltage and current)

Table 15 - Table Properties

CIP Assembly Instance 103

No. of Elements 12

Length in Words 24

Data Type REAL

Data Access Read Only

Table 16 - Maximum Metering Values (voltage and current) Data Table

Element Modbus

Address

0 300337 2 Max V L1-N REAL

1 300339 2 Max V L2-N REAL

2 300341 2 Max V L3-N REAL

3 300343 2 Max V L-N REAL

4 300345 2 Max V L1-L2 REAL

5 300347 2 Max V L2-L3 REAL

6 300349 2 Max V L3-L1 REAL

7 300351 2 Max V L-L REAL

8 300353 2 Max A L1 REAL

9 300355 2 Max A L2 REAL

10 300357 2 Max A L3 REAL

11 300359 2 Max A N REAL

Length

(words)

Description / Units Data Format Notes

52 Rockwell Automation Publication 1420-UM001E-EN-P - March 2016

Page 53

Maximum Metering Values (power, PF, frequency)

Table 17 - Table Properties

CIP Assembly Instance 104

No. of Elements 17

Length in Words 34

Data Type REAL

Data Access Read Only

Table 18 - Maximum Metering Values (power, PF, frequency) Data Table

PowerMonitor 500 Unit Data Tables Appendix A

Element Modbus

Address

0 300361 2 Max W L1 REAL

1 300363 2 Max W L2 REAL

2 300365 2 Max W L3 REAL

3 300367 2 Max W 3REAL

4 300369 2 Max VA L1 REAL

5 300371 2 Max VA L2 REAL

6 300373 2 Max VA L3 REAL

7 300375 2 Max VA REAL

8 300377 2 Max VAR L1 REAL Negative values correspond to lead (C), positive values correspond

9 300379 2 Max VAR L2 REAL

10 300381 2 Max VAR L3 REAL

11 300383 2 Max VAR REAL

12 300385 2 Max PF L1 REAL The Max PF displayed corresponds to the PF value with the largest

13 300387 2 Max PF L2 REAL

14 300389 2 Max PF L3 REAL

15 300391 2 Max PF REAL

16 300393 2 Max Hz REAL

Length

(words)

Description / Units Data Format Notes

to lag (L)

phase angle.

Rockwell Automation Publication 1420-UM001E-EN-P - March 2016 53

Page 54

Appendix A PowerMonitor 500 Unit Data Tables

DMD Metering Values (voltage and current)

Table 19 - Table Properties

CIP Assembly Instance 105

No. of Elements 12

Length in Words 24

Data Type REAL

Data Access Read Only

Table 20 - DMD Metering Values (voltage and current) Data Table

Element Modbus

Address

0 300849 2 DMD V L1-N REAL

1 300851 2 DMD V L2-N REAL

2 300853 2 DMD V L3-N REAL

3 300855 2 DMD V L-N REAL

4 300857 2 DMD V L1-L2 REAL

5 300859 2 DMD V L2-L3 REAL

6 300861 2 DMD V L3-L1 REAL

7 300863 2 DMD V L-L REAL

8 300865 2 DMD A L1 REAL

9 300867 2 DMD A L2 REAL

10 300869 2 DMD A L3 REAL