Page 1

Bulletin 1395 Digital DC Drive

USER MANUAL

Firmware Versions 5.xx to 10.10/9.30

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

www.rockwellautomation.com/literature) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for solid

state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect

or consequential damages resulting from the use or application of this

equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with any

particular installation, Rockwell Automation, Inc. cannot assume responsibility

or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use

of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

http://

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING: Identifies information about practices or

circumstances that can cause an explosion in a hazardous

!

environment, which may lead to personal injury or death, property

damage, or economic loss.

Important: Identifies information that is critical for successful application and

understanding of the product.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

!

damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard, and recognize the consequences.

Shock Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that dangerous voltage may be

present.

Burn Hazard labels may be located on or inside the equipment

(e.g., drive or motor) to alert people that surfaces may be at

dangerous temperatures.

CENTERLINE, PLC, PLC-5 and PLC-3, DH+, PLC-5/250, PLC-5/15, PLC-5/25, PLC-5/40, and PLC-5/60, ControlView, Data Highway

Plus, DriveTools are either trademarks or registered trademarks of Rockwell Automation, Inc.

Page 3

Summary of Changes

The information below summarizes the changes to the Bulletin 1395 User

Manual, publication 1395-5.40 since the last release (February, 2004).

Change Page(s)

Added control power spec 1-4

Updated Figure 2.5 2-6

Updated Figure 2.7 2-8

Updated Figure 2.9 & Removed Control Voltage Common description 2-11

Updated Figure 3.1 3-2

Updated Figure 3.12 3-14

Removed Control Common description 3-15

Updated Figure 3.13 3-16

Updated Figure 4.1 4-2

Updated Figure 4.12 & Removed Control Common description 4-15

Updated Figure 5.5 5-36, 5-37

Updated Figure 6.3 6-4

Updated Table 6.N 6-25

Updated Figure 6.23 6-35

Corrected Default Value for Parameter 632 7-41

Added Appendix - Understanding EEPROM functions A-1

SOC-1

Page 4

Summary of Changes

Notes

SOC-2

Page 5

Summary of Changes

Firmware Revision History

1.00: First Release.

2.30: Enhanced noise immunity.

3.01: Released Trending and VP and CP Autotune.

4.01: Enhanced EEprom fault reporting for SP-83 and SP30 SEEG device, VP

4.02: Consolidate 1396 and 1395 board assemblies.

4.03: Enhanced Feedback calculation on first pulse, CP phase loss updated for

5.01: Released Tach recovery algorithm, EH E-step micro-processor, changed

The following is a brief description of the MCB Firmware Revision

History:

indirects added, check for Ia with contactor open.

HKVA, software change for BH processor.

checksum routine VP and CP, added noise filter caps for CP-101-106.

• Added P688 Tach Switch Tolerance. Note: P688 used on 5.01 FW

only. P731 and P732 used on all other FW.

• Added P689 Tach Switch Ki

• Added P690 Tach Switch Kp

• Added P691 Tach Switch Select

• Rev 18 = Enhanced 24VDV Fault Reporting

• Rev 19 = Enhanced CP-06 Phase Loss Reporting

6.01 and 7.01: Both released and recalled.

8.02: Rev 4 = Further Enhanced 24VDV Fault Reporting.

Rev 5 = Further Enhanced CP-06 Phase Loss Reporting.

8.03: VP:

1. Motor Thermal Overload — Modified algorithm for self ventilated

motor options to work above 150% of base motor speed, P629 = 3 or

4.

2. Process Trim — Enhanced process trim regulator for enable/disable

from logic command when using process trim velocity limiter

function. The Process Trim Select (P628 = 0) had to be used instead of

Logic Command bit to disable Process Trim.

3. Velocity Regulator — Modified integrator in the PI regulator for

current limit switching. Example: switch from motoring to regen or

vice versa.

4. CEMF regulator — Modify IR compensation so that 1PU CEMF is

now equal to 100% at FULL LOAD. Previously, 1PU was the motor

nameplate voltage at no load.

Old: CEMF = Terminal Volts - IR

New: CEMF = (Terminal Volts - IR)/(1 - R)

5. Field Flux Auto Tune Enhanced

a. Allow CEMF regulator to trim flux reference to near zero (formerly

limited to 10% minimum) during autotune.

Page 6

Summary of Changes

b. Increase wait time for each flux table measurement from 5 seconds

to 15 seconds.

c. Change test for up to speed (during field flux autotune) to use a

constant 5% instead of being tied to the speed tolerance parameter,

to reduce the occurrence of “Motor not up to speed” faults.

SP:

1. Slave percent 2 (P670) — Enhanced EEprom Save and Recall

function for this parameter.

2. CEMF feedback (P120) — Change conversion formula and units

display from volts to percent (4096 = 100%) to accommodate CEMF

regulator change (see #4 under VP).

CP:

1. Auto tune test — Modified autotune to work with a wider range of

motors (inductance related).

2. Change diode to enhance CP-15 24V PS Loss reporting.

3. Change diodes to enhance CP-06 Phase Loss reporting.

8.10: Rev. 1 = Released. Note: 8.03 to 8.10 only updated the micro’s.

Functionality did not change.

Rev. 2 = N/A (change diode tape/loose insertion).

Rev. 3 = Change diode to enhance Vel and Armature Voltage readout

stability on the terminal.

9.20: Rev. 1 = New features added:

1. Added P744 — Bridge Switch Delay (for electro-magnet

applications).

2. Increased P617 — Rated AC Voltage Maximum to 690 VAC.

3. Increased P610 — Rated Motor Voltage Maximum to 850 VDC.

4. Enhanced df/dt functions to accommodate motor/generator

switchover.

5. Enhanced Encoder Feedback processing.

10.10: Rev. 1 = Enhanced Autotune feature to work with higher inductance

motors.

• Added P745 — K disc Fraction for increased resolution.

• Added P746 — Arm Volt Offset to calibrate Arm Volts Zero +/-20

volts.

• Changed P734 — K disc default from 1024 to 288 and minimum

value from 33 to 4.

• Changed P735 — KP Armature Loop default from 710 to 2330.

• Changed P736 — KI Armature Loop default from 90 to 386.

• Changed P741 and P742 Current Loop BW minimum from 100 to 40.

9.30: Rev. 1 = Renumbered 10.10 firmware to 9.30 to accommodate ITS and

DriveTools32. No functional changes.

Page 7

Introduction, Inspection & Storage,

and Publication References Chapter 1

Manual Objectives 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Who Should Use This Manual 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Objective 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Drive Features 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storing 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog Number Explanation 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication References 1-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Hardware Description

1 – 30 HP, 230VAC Series B

2 – 60 HP, 460VAC Series B Chapter 2

Introduction 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminology 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Overview 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Armature Bridge Components 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Bridge Components 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Board 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PSI/Switcher Board 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Control Board 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relay Logic (1 – 30 HP 230VAC) (2 – 60 HP 460VAC) 2-12. . . . . . . . .

Options 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete Adapter Board 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Reference Adapter Board 2-16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Adapter Board 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi-Communication Board 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ControlNet Adapter Board 2-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 8

Table of Contents

Hardware Description

40 – 100 HP, 230VAC Series A

75 – 200 HP, 460VAC Series A Chapter 3

Introduction 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminology 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Overview 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Armature Bridge Components 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Bridge Components 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Boards 3-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Peripheral Devices 3-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relay Logic 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete Adapter Board 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Reference Adapter Board 3-21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Adapter Board 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi-Communication Board 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ControlNet Adapter Board 3-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Description

125 – 300 HP, 230VAC Series B

600 HP, 460VAC Series B

250 –

Medium KVA (MKVA) Chapter 4

Introduction 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminology 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Overview 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Armature Bridge Components 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Bridge Components 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Boards 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Peripheral Devices 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Distribution 4-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relay Logic 4-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Options 4-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete Adapter Board 4-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Reference Adapter Board 4-20. . . . . . . . . . . . . . . . . . . . . . . . . . .

Node Adapter Board 4-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Multi-Communication Board 4-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ControlNet Adapter Board 4-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Page 9

Functional Description Chapter 5

Introduction 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminology 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functional Overview 5-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Auto-tuning 5-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Loop Tuning 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Velocity Loop Tuning 5-16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Field Flux Tuning 5-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trending 5-18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming a Trend Buffer 5-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trend Setup 5-24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Trending To Aid Troubleshooting 5-25. . . . . . . . . . . . . . . . . . . . . . . . . . .

General Logic Description 5-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1395 Block Description 5-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Installation Chapter 6

Chapter Objectives 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environment 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cooling Airflow 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

NEMA Type 12 Enclosures 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Clearance 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disconnect 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wire Size and Type 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding Procedures 6-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Wiring 6-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Wiring Procedure 6-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Circuit Board Jumper Connections 6-18. . . . . . . . . . . . . . . . . . . . . . . . . .

Control Connections 6-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adapter Boards 6-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Armature Current Ratings 6-40. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Parameters Chapter 7

Introduction 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminology 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Table Structure 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Types 7-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Table Storage 7-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Descriptions 7-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameters (Numerical) 7-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

Page 10

Table of Contents

8 retpahCpU-tratS

1-8noitcudortnI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8ygolonimreT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8tnempiuqE dna slooT deriuqeR . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2-8tnempiuqE dna slooT dednemmoceR . . . . . . . . . . . . . . . . . . . . . . . .

2-8lareneG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3-8skcehC rewoP-erP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5-8tnemerusaeM egatloV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-8skcehC O/I lortnoC dradnatS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8-8serudecorP gnimmargorP retemaraP . . . . . . . . . . . . . . . . . . . . . . . . .

01-8srotsiseR nedruB tnerruC erutamrA/eniL . . . . . . . . . . . . . . . . . . . . .

41-8sretemaraP retpadA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61-8skcehC ytiraloP kcabdeeF dna rotoM . . . . . . . . . . . . . . . . . . . . . . . .

71-8noitarbilaC evirD fo noitacifireV . . . . . . . . . . . . . . . . . . . . . . . . . . . .

91-8)tnerruC/enutotuA/puteS evirD( gninuT evirD . . . . . . . . . . . . . . . . .

22-8puteS noitacilppA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reference Materials Chapter 9

Renewal Parts Chapter 10

1 – 30HP, 230VAC; 2 – 60HP, 460VAC SERIES B 10-1. . . . . . . . . . . . .

40 – 100HP, 230VAC; 75 – 200HP, 460VAC SERIES A 10-5. . . . . . . . .

125 – 300HP, 230VAC; 250 – 600HP, 460VAC SERIES B 10-8. . . . . . .

Appendix

Understanding EEPROM Functions A-1

Initialize, Restore Old & Save Change A-1

Index

1-9noitcudortnI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-9tsiL retemaraP noitarugifnoC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-9tsiL eulaV retemaraP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

01-9gnitsiL ecnerefeR retemaraP lacitebahplA . . . . . . . . . . . . . . . . . . . .

41-9yrassolG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1-01noitcudortnI . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

iv

Page 11

Chapter

Introduction, Inspection and Storage, and Publication References

Manual Objectives The purpose of this manual is to provide the user with the necessary

information to install, program, start up and maintain the1395 DC Drive.

This manual should be read in its entirety before operating, servicing or

initializing the 1395 Drive. This manual must be consulted first, as it

will reference other 1395 manuals for troubleshooting or option

initialization. This manual covers three different series of 1395 Drive

and is organized with each topic broken down by horsepower range.

Who Should Use This Manual This manual is intended for qualified service personnel responsible for

setting up and servicing the 1395 DC Drive. You must have previous

experience with and a basic understanding of electrical terminology,

programming procedures, required equipment and safety precautions, as

typical applications will consist of a properly rated DC motor, with or

without feedback based on performance requirements, a line impedance

device (line reactor or isolation transformer) and the 1395. A

programming terminal is required to set up the drive and for enhanced

monitoring and diagnostics.

WARNING: Only personnel familiar with the 1395 Drive

!

!

!

and the associated machinery should plan or implement the

installation, start-up, and subsequent maintenance of the

Drive. Failure to comply may result in personal injury

and/or equipment damage.

CAUTION: An incorrectly applied or installed Drive can

result in component damage or a reduction in product life.

Wiring or application errors such as undersizing the motor,

incorrect or inadequate AC supply or excessive ambient

temperatures may result in damage to the Drive or motor.

CAUTION: This Drive contains ESD (Electrostatic

Discharge sensitive parts and assemblies. Static control

precautions are required when installing, testing, servicing

or repairing this assembly. Component damage may result

if ESD control procedures are not followed. If you are not

familiar with static control procedures, reference

Allen-Bradley Publication 8000-4.5.2, Guarding against

Electrostatic Damage or any other applicable ESD

protection handbook.

Chapter Objective Chapter 1 in addition to detailing drive features and specifications, also

supplies the information needed to unpack, properly inspect and if

necessary, store the 1395 Drive. A complete explanation of the catalog

numbering system is also included at the back of this chapter.

1-1

Page 12

Chapter 1

Introduction, Inspection & Storage, and

Publication References

Standard Drive Features The 1395 is a microprocessor Digital DC Drive available in;

• Four quadrant, armature regenerative, two quadrant field:

– 1 – 300 HP @ 230VAC in standard 1395 enclosures

– 400 – 700 HP @ 230VAC in Bulletin 2100 CENTERLINE motor

control centers (MCCs)

– 2 – 600 HP @ 460VAC in standard 1395 enclosures

– 700 to 1750 HP @ 460VAC in MCCs

– 750 to 2250 HP @ 575VAC in MCCs

– 750 to 2500 HP @ 660VAC in MCCs

• Non–regenerative:

– 1 – 30 HP and 125 to 300 HP @ 230VAC in standard 1395

enclosures; 400 to 700 HP @ 230VAC in MCCs.

– 2 to 60 HP and 250 to 600 HP @ 460VAC in standard 1395

enclosures; 700 to 1750 HP @ 460 VAC in MCCs.

– 750 to 2250HP @ 575VAC in MCCs

– 750 to 2500HP @ 660VAC in MCCs

NOTE: For information on high horsepower 1395 drives packaged in

MCCs, refer to publication 2361–5.01. This publication contains:

– hardware descriptions of 1395 drives rated at or above 700 HP @

460VAC, 750HP @ 575/660VAC.

• Fused AC input

• DC Contactor

• Field regulation over a 6 to 1 speed range.

• Programmable Functions:

– Independent Acceleration/Deceleration adjustment

– Preset Speeds, Jog Speeds

– Current Limit, Tapered Current Limit

• Protective Features:

– Instantaneous Overcurrent, Motor Overload

– Feedback Loss, Field Loss, Field Economy

• Open Chassis Construction

• UL Listed/CSA Approved

• Basic Input/Outputs

Options

1-2

• Discrete Adapter Board Provides:

– 4 Digital Inputs, 120VAC

– 2 Digital Outputs, Contact type 125VAC

– 4 Analog Inputs, 4 Analog Outputs, +/– 10VDC

• Discrete Adapter Board Provides:

– 4 Digital Inputs, 24VDC

– 2 Digital Outputs, Contact type 24VDC

– 4 Analog Inputs, 4 Analog Outputs +/– 10VDC

• Digital Reference Adapter Board Provides:

– 1 Digital Reference Input

– 10 Discrete Inputs, 5 Discrete Outputs, 24VDC

– 2 Analog Inputs +/–10VDC, 2 Analog Outputs +/–10VDC

Page 13

Accessories

Chapter 1

Introduction, Inspection & Storage, and

Publication References

• Node Adapter Board

Provides an interface between external (push buttons, pots) devices

and the Bulletin 1395.

The board allows the Bulletin 1395 to be controlled using an

Allen-Bradley PLC

PLC5

family.

Programmable Controller from the PLC3 or

• Multi-Communications Adapter Board

Contains the hardware necessary to connect the 1395 to

Allen-Bradley’s RIO or Data Highway Plus

communication links.

• ControlNet Adapter Board contains the hardware necessary to

connect the 1395 to a ControlNet Network.

• Normally Closed DB contact on the main motor contactor.

• Auxiliary Contact on the motor contactor for special interlocks

(1 – N.O., 1 – N.C.).

• Line Reactors

• Dynamic Braking

Receiving It is the responsibility of the user to thoroughly inspect the equipment

before accepting the shipment from the freight company. Check the

item(s) received against the purchase order. If any items are obviously

damaged, it is the responsibility of the user not to accept delivery until

the freight agent has noted the damage on the freight bill. Should any

concealed damage be found during unpacking, it is again the

responsibility of the user to notify the freight agent. The shipping

container must be left intact and the freight agent should be requested to

make a visual inspection of the equipment.

Unpacking Remove all packing material, wedges, or braces from within and around

the drive. Remove all packing material from the cooling fans (when

equipped) and the heat sink.

IMPORTANT: Before the installation and start-up of the drive, a

general inspection of the mechanical integrity (i.e. loose parts, wires,

connections, etc.) should be made.

Inspection After unpacking, check the item(s) nameplate catalog number against the

purchase order. An explanation of the catalog numbering system for the

1395 drive is included as an aid for nameplate interpretation. Refer to the

following pages for complete nomenclature.

Storing The drive should remain in its shipping container prior to installation. If

the equipment is not to be used for a period of time, it must be stored

according to the following instructions in order to maintain warranty

coverage:

• Store in a clean, dry location.

• Store within an ambient temp. range of 0° to 65°C (32° to 149°F).

• Store within a humidity range of 5% to 95%, non-condensing.

• Do not store equipment in a corrosive atmosphere.

• Do not store equipment in a construction area.

1-3

Page 14

Chapter 1

Introduction, Inspection & Storage, and

Publication References

Specifications

Type Drive:

Electrical:

Input Voltages –

Input Power –

Input Frequency –

Max Rate of Change of

Input Frequency –

Output Voltage –

Output Horsepower

(Continuous) –

Output Current–

Field Voltage–

Field Current–

Field Control–

Field Economy–

Armature Firing–

Output Waveform–

Controller Current

Output –

Armature Control –

Speed Regulation:

Encoder –

Full Wave Regen, 12 SCR w/Full Wave 1

∅ Field Regulator

150 – 460VAC +/– 10%, 3 phase

115VAC Control Power, +/– 10%, 1 phase

1.5 kVA to 660 kVA

50/60Hz +/– 3 Hz.

3.5 Hz/Sec.

240VDC (230VAC Input)

400VDC (380 – 415 AC Input)

500VDC (460VAC Input)

1 to 300 HP, 240VDC

1.5 to 500 HP, 400VDC

2 to 600 HP, 500VDC

3.6 to 980A

120 – 150VDC, 230VAC

200 – 250VDC, 380VAC

220 – 270VDC, 415VAC

240 – 300VDC, 460VAC

Field Voltage Source is selectable between

internal or external supply.

1 – 30HP, 230V; 2 – 60HP, 460V Drive:

150mA – 10 Amperes Continuous

40 – 100HP, 230V; 75 – 200HP, 460V

Drive: 650mA – 20 Amperes (continuous)

125 – 300HP, 230V; 250 – 600HP, 460V

Drive: 650mA – 40 Amperes (continuous)

A 6:1 speed range with an encoder or DC

tach feedback

Programmable enable, time delay, power on

standby

Phase sequence insensitive, Regenerative/

Non–regenerative

6 pulse, full wave, NEMA Code C

150% for one minute, 200% for 10 seconds,

260% for 5 seconds

Tapered current limit, di/dt limit, Instantaneous overcurrent, Programmable motor

overload

0.01% of set speed (over a 10:1 speed

range); 0.001% of top speed (over a 100:1

speed range).

1-4

DC Tachometer –

Armature Voltage –

0.5% of top speed with 5PY tachometer;

0.1% of top speed with BC42 tachometer.

2% of top speed

Page 15

Chapter 1

Introduction, Inspection & Storage, and

Publication References

Feedback Devices:

DC Tachometer – 5 PY, BC42 or equal

Encoder –

Incremental, dual channel; 12 volts,

500mA, isolated with differential transmitter, 102.5 kHz max. Quadrature : 90°± 27°

@ 25°C, Duty Cycle: 50% ± 10% Source/

Sink capable, A–B 845H or equal.

External Inputs:

Enable/Contingency

Coast Stop –

System Reset –

Motor Thermostat –

Communication Port –

24VDC/115VAC, hard–wired to DC

contactor

24VDC/115VAC, Isolated

24VDC/115VAC, Isolated

RS–422 for programming terminal

External Outputs:

Drive Ready/Faulted–

N.O. relay contact, open when drive faulted

or de–energized, closed when ready. Contact rating – 1 ADC @ 24 VDC or 0.5A @

120VAC

Environmental

Ambient Operating

Temperature

Relative Humidity

Altitude

Standard Features

Accel/Decel

Preset Speeds

Jog Speeds

“S” Ramp

Motor Operated Pot

(MOP)

Options

Discrete Adapter

Board;

Digital Inputs (4) –

Digital Outputs (2) –

Analog Inputs (4) –

Analog Outputs (4) –

Power Supply (For

external use) –

0° to 55°C (32° – 130° F)

5% to 95%, non–condensing

3,300 feet (1,000 meters)

0.1 to 6554 seconds, independently

programmable.

5 adjustments, programmable

2 adjustments, programmable

Programmable

10 adjustments, programmable

24VDC or 120VAC, 10 mA. NOTE: A

separate board and part number is used for

each voltage rating.

Dry relay contacts rated at 0.6 amps at

125VAC or 2.0 amps at 30VDC.

0 to +/– 10 VDC, differential input impedance – 20K ohms.

–10 to + 10VDC, 1mA minimum output

impedance – 200 ohms.

+10VDC, 4mA maximum, –10VDC,

4mA maximum.

1-5

Page 16

Chapter 1

Introduction, Inspection & Storage, and

Publication References

Digital Reference

Board;

Digital Reference Input (1) –

Digital Inputs (10) –

Discrete Outputs (5) –

Analog Inputs (2) –

Analog Outputs (2) –

Power Supply –

(for external use)

Node Adapter Board;

Current source and sink input for high

common mode noise immunity. Nominal

5VDC or 12VDC interface (internal hardware configurable), + 10mA nominal current source/sink requirements.

24VDC Nominal; 18VDC minimum,

28VDC maximum; 10 mA nominal.

-25%, +16.6%, 24VDC nominal; Current

sourcing type driver; Diode clamped for

inductive load; 18VDC minimum,

28VDC maximum; 1.5VDC saturation,

100mA maximum load.

0 to +/– 10 VDC, differential input impedance– differential > 1m ohm; 20K ohms

(single ended to analog common).

–10 to +10VDC, 2.5mA maximum output

impedance – 200 ohms.

+10VDC, 4mA maximum, –10VDC, 4mA

maximum.

This board allows the Bulletin 1395 to be

controlled using an Allen-Bradley PLC

controller from either the PLC3 or PLC5

family. The +5V Node Adapter board

power is generated internally in the Drive.

1-6

Multi-Communications

Adapter Board;

Power Supply –

Communications

Channels (2) –

Function Blocks (4)

Discrete Input (1)

Board power provided by Drive discrete

input, 24VDC or 115VAC, jumper selectable.

Each channel can be configured as either

Allen-Bradley Remote I/O (RIO) or

Allen-Bradley Data Highway + (DH+) interfaces.

Compatible with PLC3, PLC250,

PLC5/15, PLC5/25, PLC5/40, PLC5/60

and Controlview.

These programmable function blocks can

be used to manipulate data.

One programmable discrete input is available (24VDC or 115VAC).

Page 17

Chapter 1

Introduction, Inspection & Storage, and

Publication References

ControlNet Adapter

Board;

Rev Requirement – Requires Main Control Board Revision

8.10 or greater.

Catalog Number Explanation

230 Volt AC Input (1–100HP)

A611395

First Position

Bulletin No.

1395

Second Position

Horsepower

Non–Regenerative

Letter

A61N – 1HP

A62N – 1.5 HP

A63N – 2HP

A64N – 3HP

A65N – 5HP

A66N – 7.5HP

A67N – 10HP

A68N – 15HP

A69N – 20HP

A70N – 25HP

A71N – 30HP

Regenerative

A61 – 1HP

A62 – 1.5 HP

A63 – 2HP

A64 – 3HP

A65 – 5HP

A66 – 7.5HP

A67 – 10HP

A68 – 15HP

A69 – 20HP

A70 – 25HP

A71 – 30HP

A72 – 40HP

A73 – 50HP

A74 – 60HP

A75 – 75HP

A76 – 100HP

HP Letter HP Letter Description

Communication

Channel –

C1

Third Position

Contactor Type

Standard

C1 – 1 – 15HP

C2 – 20 – 30HP

C3 – 40 – 50HP

C4 – 60 – 75HP

C5 – 100HP

Dynamic Braking

D1 – 1 – 15HP

D2 – 20 – 30HP

D3 – 40 – 50HP

D4 – 60 – 75HP

D5 – 100HP

One ControlNet channel with a redundant

connector to allow for backup connection

in case one fiber optic cable fails.

One Network Access PortPort –

P10 – X1

Fourth Position

Options*

P10 Discrete Adapter 115 VAC (Port A)

P11 Discrete Adapter 24VDC (Port A)

P12 Digital Reference Adapter (Port A)

P50 Node Adapter (Port B)

P51 Multi–Communication Adapter (Port B)

P54EN ControlNet Adapter Board (Port A or B)

PZ No Adapter

Other Options

X1 – Auxiliary Contact (1–N.O – 1–N.C.)

(standard on 100 HP)

* Multiple options are separated by dashes

* Limited to one adapter in port A and one adapter in Port B.

1-7

Page 18

Chapter 1

Introduction, Inspection & Storage, and

Publication References

460 Volt AC Input (2–200HP)

First Position

Bulletin No.

1395

B631395

Second Position

Horsepower

Non–Regenerative

Letter

B63N – 2HP

B64N – 3HP

B65N – 5HP

B66N – 7.5HP

B67N – 10HP

B68N – 15HP

B69N – 20HP

B70N – 25HP

B71N – 30HP

B72N – 40HP

B73N – 50HP

B74N – 60HP

Regenerative

B63 – 2HP

B64 – 3HP

B65 – 5HP

B66 – 7.5HP

B67 – 10HP

B68 – 15HP

B69 – 20HP

B70 – 25HP

B71 – 30HP

B72 – 40HP

B73 – 50HP

B74 – 60HP

B75 – 75HP

B76 – 100HP

B77 – 125HP

B78 – 150HP

B79 – 200HP

HP Letter HP Letter Description

C1

Third Position

Contactor Type

Standard

C1 – 2 – 30HP

C2 – 40 – 60HP

C3 – 75 – 100HP

C4 – 125 – 150HP

C5 – 200HP

Dynamic Braking

D1 – 2 – 30HP

D2 – 40 – 60HP

D3 – 75 – 100HP

D4 – 125 –150HP

D5 – 200HP

P10 – X1

Fourth Position

Options*

P10 Discrete Adapter 115 VAC (Port A)

P11 Discrete Adapter 24VDC (Port A)

P12 Digital Reference Adapter (Port A)

P50 Node Adapter (Port B)

P51 Multi–Communication Adapter (Port B)

P54EN ControlNet Adapter Board (Port A or B)

PZ No Adapter

Other Options

X1 – Auxiliary Contact (1–N.O – 1–N.C.)

(standard on 200 HP)

* Multiple options are separated by dashes

* Limited to one adapter in port A and one adapter in Port B.

1-8

Page 19

230 Volt AC Input (125 –300HP)

Chapter 1

Introduction, Inspection & Storage, and

Publication References

First Position

Bulletin No.

No

1395

460 Volt AC Input (250 – 600HP)

Second Position

Horsepower

Letter

A77N – 125HP

A78N – 150HP

A79N – 200HP

A80N – 250HP

A81N – 300HP

A77 – 125HP

A78 – 150HP

A79 – 200HP

A80 – 250HP

A81 – 300HP

HP Type Type Letter

A771395

230V Non–Regen

230V Non–Regen

230V Non–Regen

230V Non–Regen

230V Non–Regen

230V Regenerative

230V Regenerative

230V Regenerative

230V Regenerative

230V Regenerative

E1

Third Position

Armature Shunt

Letter

No Shunt

EN

1000A for

E1

125HP

1500A for

E2

150 – 200HP

2000A for

E3

250 – 300HP

P30 – P50 – X2

Fourth Position

Options*

P30 Discrete Adapter115VAC (Port A)

P31 Discrete Adapter 24VDC (Port A)

P32 Digital Reference Adapter 24VDC

(Port A)

P50 Node Adapter (Port B)

P52 Multi–Communications Adapter

P54EN ControlNet Adapter Board

PZ No Adapter

X2 Lug Kit

* Multiple Options are separated by dashes

* Limited to one adapter in Port A and one

adapter in Port B

Type

(Port B)

(Port A or B)

First Position

Bulletin No.

1395

B82N1395

Second Position

Horsepower Options*

Letter

B80N – 250HP

B81N – 300 HP

B82N – 400HP

B83N – 500HP

B84N – 600HP

B80 – 250HP

B81 – 300HP

B82 – 400HP

B83 – 500HP

B84 – 600HP

HP

Type No

460V Non–Regen

460V Non–Regen

460V Non–Regen

460V Non–Regen

460V Non–Regen

460V Regenerative

460V Regenerative

460V Regenerative

460V Regenerative

460V Regenerative

E2

Third Position

Armature Shunt

Letter

EN

E1

E2

E3

Type

No Shunt

1000A for

250HP

1500A for

300 – 400HP

2000A for

500 – 600HP

P30 – P50 – X2

Fourth Position

Letter

P30 Discrete Adapter 115VAC (Port A)

P31 Discrete Adapter 24VDC (Port A)

P32 Digital Reference Adapter 24VDC

(Port A)

P50 Node Adapter (Port B)

P52 Multi–Communications Adapter

P54EN ControlNet Adapter Board

PZ No Adapter

X2 Lug Kit

* Multiple Options are separated by dashes

* Limited to one adapter in Port A and one

adapter in Port B

Type

(Port B)

(Port A or B)

1-9

Page 20

Chapter 1

Introduction, Inspection & Storage, and

Publication References

Publication References

This update provides you with a list of user manuals for 1395 and 2361

drives and their current status. If a firmware version or date is not shown

with a publication, it indicates that the publication is the current version,

which will be updated until the firmware version changes.

Bulletin 1395 HKVA Drives

(Early Design)

230 Volt AC Input (400 – 600 HP

(1350 – 2250 AMP))

For 1395 drives in this horsepower range, refer to publication 1395-5.70

for catalog number explanation.

460 Volt AC Input (700 – 1250 HP)

(1350 – 2250 AMP) For 1395 drives in this horsepower range, refer to publication 1395-5.70

for catalog number explanation.

660 Volt AC Input (900 – 2000 HP)

(1350 – 2250 AMP) For 1395 drives in this horsepower range, refer to publication 1395-5.70

for catalog number explanation.

Bulletin 2361 HKVA Motor Control Center (MCC)

Drives (Later Design)

460 Volt AC Input (700 – 1750 HP)

(1250 AMP)

For 1395 drives in this horsepower range, refer to publication 2361-5.01

for catalog number explanation.

575 Volt AC Input (750 – 2250 HP)

(1650 AMP) For 1395 drives in this horsepower range, refer to publication 2361-5.01

for catalog number explanation.

660 Volt AC Input (750 – 2500 HP)

(3000 AMP) For 1395 drives in this horsepower range, refer to publication 2361-5.01

for catalog number explanation.

Important: These drives are commonly referred to as “HIGH KVA

(HKVA)” in this and other publications.

1-10

Page 21

List of User Manuals for 1395 and 2361 Drives

Chapter 1

Introduction, Inspection & Storage, and

Publication References

PUB NO. PUB DATE

1395 – 5.6

1395 – 5.11

1395 – 5.11 DU1

1395 – 5.40

1395 – 5.70

2361–5.01

1395 – 5.1

1395 – 5.7

1395 – 5.12

1395 – 5.12

1395 – 5.12

1395 – 5.12

1395 – 5.2

1395 – 5.9

1395 – 5.9

1395 – 5.9

1395 – 5.9

1395 – 5.23

1395 – 5.33

1395 – 5.33

1395 – 5.33

1395 – 5.22

1395 – 5.55

1395 – 5.45 Jul. 1997 Troubleshooting Manual Ver. 1.X – 8.X CURRENT

Feb. 1989

Aug. 1989

Oct. 1991

Oct. 2002

Nov . 1995

Jul. 1998

Sep. 1988

Apr. 1989

Aug. 1989

Apr. 1993

May 1994

Feb. 1995

Jul. 1989

Aug. 1989

May 1994

Feb. 1995

Oct. 1995

Apr. 1995

March, 1992

March, 1995

Apr. 1996

Jan. 1991

Apr. 1996

DESCRIPTION

User Manual, Current Rated Drives

User Manual, Current Rated Drives

User Manual Supplement, HP Rated Drives

User Manual, HP Rated Drives

User Manual, HP Rated Drives 800 – 1250

HP (2250 A), Series A.

User Manual, 1250, 1650, 3000A, Series C

Discrete Adapter Manual

Discrete Adapter Manual

Discrete Adapter Manual

Discrete Adapter Manual

Discrete Adapter Manual

Discrete Adapter Manual

Node Adapter I&O Manual

Node Adapter I&O Manual

Node Adapter I&O Manual

Node Adapter I&O Manual

Node Adapter I&O Manual

Encoder Drive Module

Multi Comm Hardware & Software Manual

Multi Comm Hardware & Software Manual

Multi Comm Hardware & Software Manual

Digital Reference Adapter Board

Digital Ref Adapter Hardware & Software

Reference Manual

F/W VER

Ver. 2.3

Ver. 3.XX

Ver 4.XX

Ver 5.X

–10.10/9.30

Ver 5.X – 8.X

Ver. 2.XX

Ver. 2.3

Ver. 3.XX

Ver. 4.XX

Ver. 4.XX

Ver. 4.10

Ver. 2.3

Ver. 3.XX

Ver. 3.XX

Ver. 3.XX

Ver. 3.01

N/A

Ver. 1.XX

Ver. 1.XX

Ver. 1.06

Ver. 1.XX

Ver. 1.02

ST ATUS

OBSOLETE FIRMWARE

OBSOLETE FIRMWARE

OBSOLETE FIRMWARE

CURRENT

OBSOLETE FIRMWARE

CURRENT

OBSOLETE FIRMWARE

OBSOLETE FIRMWARE

OBSOLETE (Use Current)

OBSOLETE (Use Current)

OBSOLETE (Use Current)

CURRENT

OBSOLETE FIRMWARE

OBSOLETE (Use Current)

OBSOLETE (Use Current)

OBSOLETE (Use Current)

CURRENT

CURRENT

OBSOLETE (Use Current)

OBSOLETE (Use Current)

CURRENT

OBSOLETE (Use Current)

CURRENT

1300 – 5.4 Aug. 1989

1300 – 5.5 Aug. 1989 1300 – DMT CURRENT

1395 – 5.37 Sep. 1998 ControlNet Adapter Manual Ver. 1.5 CURRENT

1395 – 6.0 Mar. 2002 Renewal Parts All CURRENT

RENEWAL PARTS: A current renewal parts publication is packaged with each unit at the time of shipment. Contact your

Rockwell Automation sales/support office if additional renewal parts information is needed.

IMPORTANT: Drives with Motor Control Center (MCC) Construction have a different User manual configuration. Contact

your local Rockwell Automation sales/support office for more information.

NOTE: Publication Date information is as of date of this manual. Manuals may be updated and have newer Publication

Dates than what is shown above.

1300 – EHT

CURRENT

1-11

Page 22

Chapter 1

Introduction, Inspection & Storage, and

Publication References

This Page Intentionally Left Blank

1-12

Page 23

Chapter

Hardware Description

1 – 30 HP; 230VAC

2 – 60 HP; 460VAC

(3.6 – 110 A)

Series B

Introduction Chapter 2 contains both a general description of the major hardware

components of the1395 Series B drive, and background information to

support the procedures detailed in other chapters of this manual. You

should use this chapter in conjunction with the installation Chapter when

installing 1 – 30HP, 230VAC and 2 – 60HP, 460VAC Series B Drive.

Terminology A brief description of new terms and concepts covered in Chapter 2 is

presented here:

Adapter Board – Circuit board containing hardware and software required

to interface external devices such as Allen-Bradley PLC or Discrete I/O

devices to the 1395 drive.

Interface – Hardware and associated software required to transfer

information and/or control signals from one device to another.

Microbus – Hardware and associated software designed by Allen-Bradley

for the exchange of digital information at the microprocessor level. The

microbus is used for the transfer of information between adapter boards

and the main control board.

Port – Hardware located on the main control board which allows for

connection of an adapter board to the microbus. There are two ports on the

main control board.

Programming Terminal – Device used for programming and monitoring

operation on the 1395 drive. The programming terminal is provided in two

packages: digital handheld terminal and door mounted terminal.

Hardware Overview Figure 2.1 provides an overview of the hardware components associated

with the 1 – 30 HP, 230VAC and 2 – 60 HP, 460VAC drives.

This chapter describes in general all of the major hardware components.

Figures provided in this chapter are drawn based on hardware

functionality. Some components may be repeated in several different

diagrams.

Important: Refer to Chapter 1, “Publication References” for manuals

describing larger horsepower and current ratings at other line

voltages.

2-1

Page 24

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Figure 2.1

Hardware Overview

3 Phase AC

L1 L2 L3

Fuses

J7 J6

Main

Control

Board

J4 J1

Programming

T erminal

DHT/DMT

TB3

J5

J2

1 Phase

115 V AC

TB2

J13

J10

PSI

Switcher

Board

J5

J5

J9

J5

J6

Power

Board

M1

ACT-1

Encoder

3 Phase

SCR

Bridge

TD1

Armature

TB1

ACT-2

FCT

M1

Field

Bridge

CONTROL CONTROL/POWER INTERFACE

2-2

Field

Page 25

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Armature Bridge Components A general description of the components in the armature bridge (Figures

2.2 and 2.3) and their operation is detailed here:

AC Line Reactor – When connecting the drive directly to the main

distribution system an AC line reactor must be used to protect the power

bridge from rapid rate of current changes (di/dt).

When an isolation transformer matched to the unit rating is used, an AC

line reactor is not required.

Fast acting semiconductor fuses F1, F2 and F3 are standard on all drives.

Synchronization – The three-phase input to the drive is fed directly to the

Power Board. The Power Board scales down the voltage and develops the

synchronization information to be used by the Main Control Board.

AC Current Feedback – Current Transformers ACT-1 and ACT-2

(Figure 2.2) are used to provide current feedback information to the

PSI/Switcher Board. The PSI/Switcher Board rectifies the feedback and

scales a DC voltage representing the current feedback. This signal is then

sent to the Main Control Board.

Isolation

Transformer

or

Line

Reactor

L1

L2

L3

Figure 2.2

Armature Bridge Components (INPUT)

F1

F2

F3

To TB1

Power Board

Field Bridge

ACT-1

To PSI/Switcher

Board

ACT-2

To Power Board

2-3

Page 26

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Surge Suppression – Surge suppressor MOV1 to MOV4 on the Power

Board protects the armature power bridge from line voltage spikes and line

surges.

Line Reactor – A reactor mounted outside the drive is used to protect the

power bridge SCRs from rapid rate of current changes (di/dt).

SCR Packaging – SCR packaging in the 1395 in bridge ratings 3.6 – 110A

(1 – 60 HP) consists of 2 SCRs per module. The regenerative construction

has 6 SCR blocks PM1 through PM6. The non regenerative construction

has 3 SCR blocks PM1, PM3 and PM5. Refer to Figure 2.3.

Pulse Transformers – Pulse Transformers on the Power Board provide

the gate firing pulses and voltage isolation for the armature SCRs.

Voltage Transient Protection – RC networks contained on the Power

Board are used to protect the SCRs against voltage transients (dv/dt).

DC Bus Snubbers – DC Bus Snubbers are used on 3.6 – 19 A units only.

DC Current Sensing – DC overcurrent sensing is provided using DC

transducer TD1.

G1

G2

L1 L2

PM1

1F

4F

1R

4R

PM2

G2

G1

To Power

Board

Figure 2.3

Armature Bridge Components (OUTPUTS)

PM3 PM4

G1

3F

G2

6F

6R

3R

G2

G1

PM5 PM6

G1

G2

To Power

Board

5F

2F

L3

5R

2R

G2

G1

TD–1

To PSI/

Switcher

Board

M1

DB1

DB Resistor

DB2

A1

A1

A2

A2

2-4

DC Contactor – Output of the armature bridge is connected to the DC

motor through the main DC contactor M1 (Fig. 2.3). Coil voltage to M1 is

controlled by contacts from the pilot relay K3 (on PSI/Switcher board) and

external 115VAC control input entering at TB2-2 and 3.

Bridge Output Connections – Bridge output connections labeled A1 and

A2 (Fig. 2.3) correspond to the NEMA standards for connection to the A1

and A2 leads of the DC motor. If dynamic braking is used, the dynamic

braking resistor bank is connected to terminals DB1 and DB2.

Page 27

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Field Bridge Components A general description of the components in the field bridge (Fig. 2.4) and

their operation is covered here:

Supply Voltage – Two of the three supply voltage phases are routed to the

input of the field supply power bridge (TB1-1 and TB1-2).

Field Current Feedback – Current at transformer FCT provides field

current feedback information to the PSI/Switcher board. The PSI/Switcher

board rectifies the single phase feedback and scales the DC voltage using a

burden resistor selected by the position of Jumper J1 on this board. The

DC voltage representing field current feedback is sent to the main control

board.

Surge Suppression – Surge suppressor MOV5 protects the field power

bridge from high voltage line spikes and line surges on the incoming AC

line. MOV6 protects the motor field windings from line spikes on the

output of the field bridge.

Inductor – Inductor L1 protects the field power bridge SCRs from rapid

rate of current changes (di/dt).

SCR Modules – Field bridge SCRs are contained in one single phase full

wave module (PM7).

Field Pulse Transformer – The Field Pulse Transformers on the Power

Board provide the gate firing pulses for the field SCRs.

Voltage Transient Protection – RC networks contained on the power

board are used to protect the SCRs against voltage transients (dv/dt).

Bridge Output Connections – The output of the field bridge is connected

to the Power Board. Connections of the motor field is at TB1-3 and TB1-4

on the Power Board.

TB1

F(–)

F(+)

L3

L1

See Figures 6.8 and 6.1 1

4

3

2

1

On Power Board

F2

F1

J1 J2

To PSI

/

Figure 2.4

Field Bridge Components

MOV5

L1

FCT

FCT–2FCT–1

1 2

Switcher Bd J5

2

7

4

8

1

9

3

On

Power

Board

MOV6

6

2-5

Page 28

Chapter 2

Hardware Description

1 – 30 HP, 230VAC 2 – 60 HP, 460VAC

Power Board The operation of the Power Board components (Figures 2.5 and 2.6) is

detailed here:

Gate Firing Pulses – The function of the Power Board is to provide the

gate firing pulses for the armature and field bridges.

Transient Voltage Protection – The Power Board provides protection

against line voltage spikes and transients (dv/dt) for the armature and field

SCRs.

Bus Bar – The Power Board acts as an interface board between the SCRs

and the Bus Bar. All armature SCR connections terminate at the bus bar

mounted on the power board.

Feedback Circuitry – All voltage related feedback circuitry is contained

on the Power Board. All signals are attenuated to logic level voltage.

Field Connections – All user motor field connections are located on

TB1on the bottom left edge of the Power Board (Fig. 2.6).

Figure 2.5 shows the location of the power board in the drive, while Figure

2.6 illustrates the power board layout outlining the relevant components for

user interface.

Figure 2.5

Power Board Location

PSI/Switcher Board

Main Control Board

Power Board

2-6

Page 29

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Figure 2.6

Switch and Hardware Location on Power Board

– J4

ARMATURE

VOLTS

SENSING

J3

+

C7 C8

1

23

500 240

500V 240V

1

23

500 240

J27

ARMATURE

VOLTS

SELECTION

J28

MOV6

MOV5

CHASSIS

GND

J5

3 PHASE LINE

VOLTAGE SELECTION

230V 460V

3

230 460

3

230 460

3

230 460

MOV4

21

21

21

J31

J30

J29

R1 R2

C1 C2

MOV1 MOV2

R3

R4

C4

C3

Torque Bus Bar

Screws to 28 in/lbs

C5

MOV3

C6

J2

FCT

J1

F1

F2

1L1 2L3 3F+ 4

TB1

F-

Motor Field Connection

J6

Connection to PSI/Switcher

2-7

Page 30

Chapter 2

Hardware Description

1 – 30 HP, 230VAC 2 – 60 HP, 460VAC

PSI/Switcher Board The primary function of the board (Figure 2.7) is to provide interface

between the Main Control Board, and the Power Board. The PSI/Switcher

board also provides the following:

• Distribution of DC logic power to the Main Control Board.

• Three-Phase line synchronization signals to the Main Control Board.

• Contactor and other logic control interface with the Main Control

Board.

• Rectification and Regulation of the external 115VAC power supply to

produce 5VDC and +/–12VDC control voltage.

• All current related feedback scaling circuitry.

• Customer basic interface for 115VAC.

• Field Current Range jumpers.

• Jumper selection for 24VDC or 115VAC for reset, motor thermal and

ECOAST.

Figure 2.7

PSI/Switcher Board Hardware Location

F2

T1

J2

1 M1–AUX1

2 M1–AUX2

3 M1–COIL1

4 M1–COIL2

5 Chassis

J14

1 COM–IN

2 MOTOR TMP

3 RESET

4 E–COAST1

5 E–COAST2

6 COM–OUT

7 RDY/FLT1

8 RDY/FLT2

9 E–COAST+

10 E–COAST–

11 +24V

12 24VCOM

F1

J11

J12

J10

F3

MOTOR TEMP

1 2 3

115V24V

RESET

1 2 3

115V24V

TB2

J5

1 2 3 4 5 6 7

J3

HST1

J4

HST2

FCT–1

FIELD

CURRENT

SCALING

1

4.5 – 10.6A

2

2.0 – 4.6A

3

0.5 – 2.1A

4

TP25

115

CON

1 2 3 4 5 6 7

0.15 – 0.6A

ARMATURE ARMATURE

TB1 FEEDBACK

BURDEN

115

115

RTN

PWR

TD1–1

ACT1–1

FCT–2

TD1–2

ACT2–2

ACT1&2 RTN

J1

TB3 TRIP

BURDEN

TP24

TP22 TP23 TP2 TP6 TP1 TP3 TP4 TP5

+5V COM +12V –12V +12VSO ICOM

J13

TP17 TP19 TP18 TP15 TP12 TP10 TP9

5R 1R 6F FLD2 2R 4R 3F

TP20 TP14 TP16 TP13 TP11 TP8 TP7

3R 2F 4F FLD1 6R 5F 1F

J9

PRM1PETE

Q1

C10

T2

J6

J8

FAN1 FAN2

J7

COM

2-8

Customer Interface 115 VAC Control

Page 31

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Table 2.A

PSI/Switcher Board Jumper Settings

Jumper

J11 MotorTemp

J12

Function Position 1–2

24VDC 120VAC

Reset 24VDC

Position 2–3

120V AC

Table 2.B

Field Current Range Jumper Selections (see Table 8.J)

Jumper Position

J1

1

2

3

4

1–30HP 240VDC; 2–60HP 500VDC

Field Current Range

4.5 – 10.6A

2.0 – 4.6A

0.5 – 2.1A

0.15 – .6A

Note: See T able 8.J for additional high horsepower settings

2-9

Page 32

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Main Control Board The Main Control Board (Figure 2.8) performs all control functions of the

1395 drive. Hardware located on the board is used to support operation of

the microprocessor firmware. The primary functions performed include:

• Microbus interface.

• Control Firmware

• Analog signal interface

• Develop gate firing signals sent to the PSI/Switcher Board

Figure 2.8

Main Control Board Hardware Location

Main Control

Board

IMPORTANT: Do not install jumpers on

J12, J13, J15

J2 J4 J5

Connection to Power Connection to

Stage Interface Board Programming Terminal

TP2 TP5

TP13

123

TP12

Connection

To

Encoder

J1

TP11

TP15

TP23

TP32

TP35

123

1

23

5V 12V

J10

J9

J8

Encoder

Voltage

Selection

TP24

TP17 TP8 TP39

J12

1 2

34

TP42

TP50

VP

TP45

TP46

SP

Port A Port B

TP9 TP6

TP21

TP25

TP33

TP34

TP38 TP30

TP43

TP1

UMC8

123

J15

(T o Adapter Board)(T o Adapter Board)

J6J7

Connection To Power

Stage Interface Board

TP27 TP26

TP31TP29

J13

1 2

34

CP

TP47 TP44

TP20

TP49

TP58

1

J14

2

3

TP54

ISO+12V ISO+5VIGND

TP51

+5V –12V+12VDGND AGND

TP53 TP58

TP52 TP56TP55TP57

TP41

TP20

TP28

TP19

TP10

2-10

AB0665A

Page 33

Chapter 2

Hardware Description

1 – 30 HP, 230VAC 2 – 60 HP, 460VAC

Power Distribution 115VAC Control Voltage – Figure 2.9 illustrates the distribution of

115VAC control voltage within the Bulletin 1395. Single phase 115VAC

control voltage, provided from an external source by the user enters the

drive at TB2-2 and 3. Fuse F3 provides protection against short circuits on

the 115VAC input to the drive.

Figure 2.9

115 VAC Control Voltage Distribution

Power Ground

Chassis

TB2

115 CONTROL

115 PWR

115 RTN

TE

PE

M1

PR

NOTE: To provide DC Contactor

energization, a jumper or other

external circuitry must be connected to TB2-6 and 7.

TE

1

2

3

4

5

6

7

(TE) Signal GRND

TB4

PE

5

J2

Control Voltage Common

F3

PSI/Switcher Board

MOVI

J6 J7 J8

FA N

F1

115

VAC

H1

To M1 Relay

To PR Relay

X1

20

VAC

X2H2

T1

F2

To

Feedback

Circuitry

To Power Supply

DC Control Voltage Distribution – The Unit Power Supply located on

the PSI/Switcher converts 115VAC to +5VDC and to +/–12VDC control

voltages.

2-11

Page 34

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Relay Logic (1 – 30 HP 230VAC)

(2 – 60 HP 460VAC)

Main Contactor (M1) Control – Figure 2.10 illustrates the hardware

associated with the control of the coil voltage applied to the Main DC

contactor M1. The coil voltage originates at an external 115 VAC source

at TB2-1. The source voltage may be interrupted before being input to the

drive at TB2-1 by the use of externally controlled contacts. These external

contacts may include an external master coast stop, PLC controlled

contacts, permissive contacts, etc. Main contactor M1 coil voltage is

controlled within the 1395 through the PSI/Switcher Board.

Pilot Relay (PR) Control – K1 and K2 contacts in series with the 115VAC

Coast Stop input to the drive control coil voltage to the Pilot Relay K3.

ECOAST Stop – The “ECOAST Stop” as defined and illustrated, is a

contingency circuit designed to remove power from the motor in event of a

malfunction in the solid state interface drive software which

NEMA for

electromechanical E Stop of a micro controlled drive.

conforms to

When an ECOAST Stop is initiated, the DC loop contactor is de-energized

and the motor will coast to a stop unless the drive is equipped with

optional dynamic braking circuitry.

Relay K1 on the Power Stage Interface is the 24V ECOAST Stop relay and

is controlled by +24VDC. As shown in Figure 2.10, +24VDC from the

PSI/Switcher Board is connected to TB3-12 and 11. At this point, an

external (dry) 24 VDC ECOAST stop contact could be used to control the

application of 24VDC to K1 through TB3-9. TB3-12 and 10 should

always be jumpered together to provide a return path for 24VDC. If an

external 24VDC ECOAST Stop contact is not used, then TB3-9 and 11

must be jumpered.

In addition to the 24VDC ECOAST Stop, there is an 115VAC ECOAST

Stop circuit which is also provided as standard in the 1395. 115VAC

enters the PSI/Switcher Board at TB2. Between TB3-4 and 5, an external

(dry) ECOAST Stop contact may be connected. If an external 115 VAC

ECOAST stop circuit is not used, TB3-4 and 5 must be jumpered.

115VAC is returned to the Power Stage Interface from TB3-5 and sent to

contacts of K2. The 115VAC ECOAST Stop Signal is also sent to an

isolation circuit which converts the 115VAC to a +5VDC control Signal

ECOAST which is sent to the Main Control Board.

2-12

Main Control Relay – K2 on the PSI/Switcher is the main control relay

which controls turn on voltage to the coil of the pilot relay K3. K2 is

controlled by logic signals from the Main Control board entering the

PSI/Switcher through ribbon connector J10. The two signals which control

K2 are the SYSTRIP and the DCPILOT signals. In order for K2 to

energize PR, there must be no system fault and there must be a DC pilot

relay turn on command. If both these conditions are met, K2 is energized,

and the Pilot Relay is in turn energized.

Page 35

Optional

External

Control

Contacts

115

VAC

Common

NOTE: T o provide DC Contactor energization,

a jumper or other external circuitry must be

connected to

TB2-6 and 7.

(TE)

TB4

24VDC

ECOAST

(Optional)

External

Fault

Indication

ECOAST

24V DC

or

115 VAC

Common

NOTE: An

explanation

of terminals

1, 2 and 3 is

provided on

pg 6.22.

CHASSIS

PE

5

J2

TB2

1

2

F3

3

TE

4

PE

5

6

7

NOTE: 24 VDC must not be

used for any purpose other

than ECOAST

TB3

24 V – OUT

12

24 V + OUT

11

24 V ECOAST –

10

24 V ECOAST +

9

FLT2

8

FLT1

7

115V COMMON OUT

6

115V ECOAST 2

5

115V ECOAST 1 HOT

4

RESET IN

3

MOTOR TEMP IN

2

Common

1

From

Main

Control

Board

FAULTED

SYSTRIP

DCPILOT

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

The control voltage being applied to K2 may be monitored on the Power

Stage Interface at TP21. If K3 is being commanded to energize, the

voltage at TP21 will be 0VDC. If K3 is to be de-energized, the voltage at

TP21 will be +24VDC.

Figure 2.10

Relay Logic

M1

Armature

Bridge

J2

PR

34

15

K3

1

M1–X

12

16

K

J2-2

J2-4

HY1

ISO

+ 24 VDC

TP21

K2

61

HY4

ISO

J6

12

11

10

9

8

7

6

5

4

3

2

1

HST1 HST2

J3 J4

J14

+ 24 V

7

J10

SYSTRIP

DCPILOT

12

K1

HY2

HY3

Common

115 VAC

3 Phase

AC

712

K2

61

K1

12 7

K4

+ 24 VDC

6

3

K4

A1

To DC

Motor

A2

J2-1

CVERIFY

To Main

Board

ECOAST

To Main

Board

PSI/SWITCHER

2-13

Page 36

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Options Programming Terminal Interface – The Programming Terminal (shown

in Figure 2.11) is used to access information in the firmware of the 1395.

Keypads on both the handheld programming terminal and the door

mounted terminal can be used to perform the following functions:

• Monitor real time parameter values

• Change parameter values

• Start/Stop the drive (depending on Model of Programming Terminal)

• Program drive configuration

• Save parameter values to EEPROM

• Monitor fault information

• Clear faults, system reset

• Autotune

Interface between the 1395 Main Control Board and the handheld

Programming Terminal is accomplished using a 9 pin type connector

physically mounted on the end of TB3. The cable coming from the D-shell

connector is connected to J4 on the Main Control Board. For a detailed

description of the Programming Terminal, refer to the Programming

Terminal Installation and Operation Manual.

Figure 2.11

Programming Terminal

START

ALT

PRE 4

PRE 1

JOG

1

LOCAL

DEC

PRE 5

7

4

D

1

8

PRE 2

5

E

2

PROGRAMMING TERMINAL

JOG

2

REMOTE

INC

X REF

9

PRE 3

6

F

3

LOCAL

STOP

HOME

MENU

BASE

DEL

2-14

A

0

B

.

+/–

C

ENTER

AB0446A

Note: The Programming Terminal can be hand-held or door-mounted when used with the

mounting kit.

Page 37

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Adapter Boards – External control devices such as a PLC, discrete

operators devices, etc., are interfaced with the Main Control Board through

one of the two microbus ports, labeled Port A (J7) and Port B (J6) on the

Main Control Board. The microbus is a 60 line bus designed specifically

for the transfer of data between microprocessors. The microbus is used on

the Main Control Board to transfer data between devices on the board.

Additionally, hardware on the Main Control Board allows data transfer

between the microprocessor on the Main Control Board and external

devices through the two microbus Ports.

Information coming from external devices must be changed first to the

format required by the microbus before being input to the microbus Port.

The processing of data is accomplished through the use of the following

adapter boards:

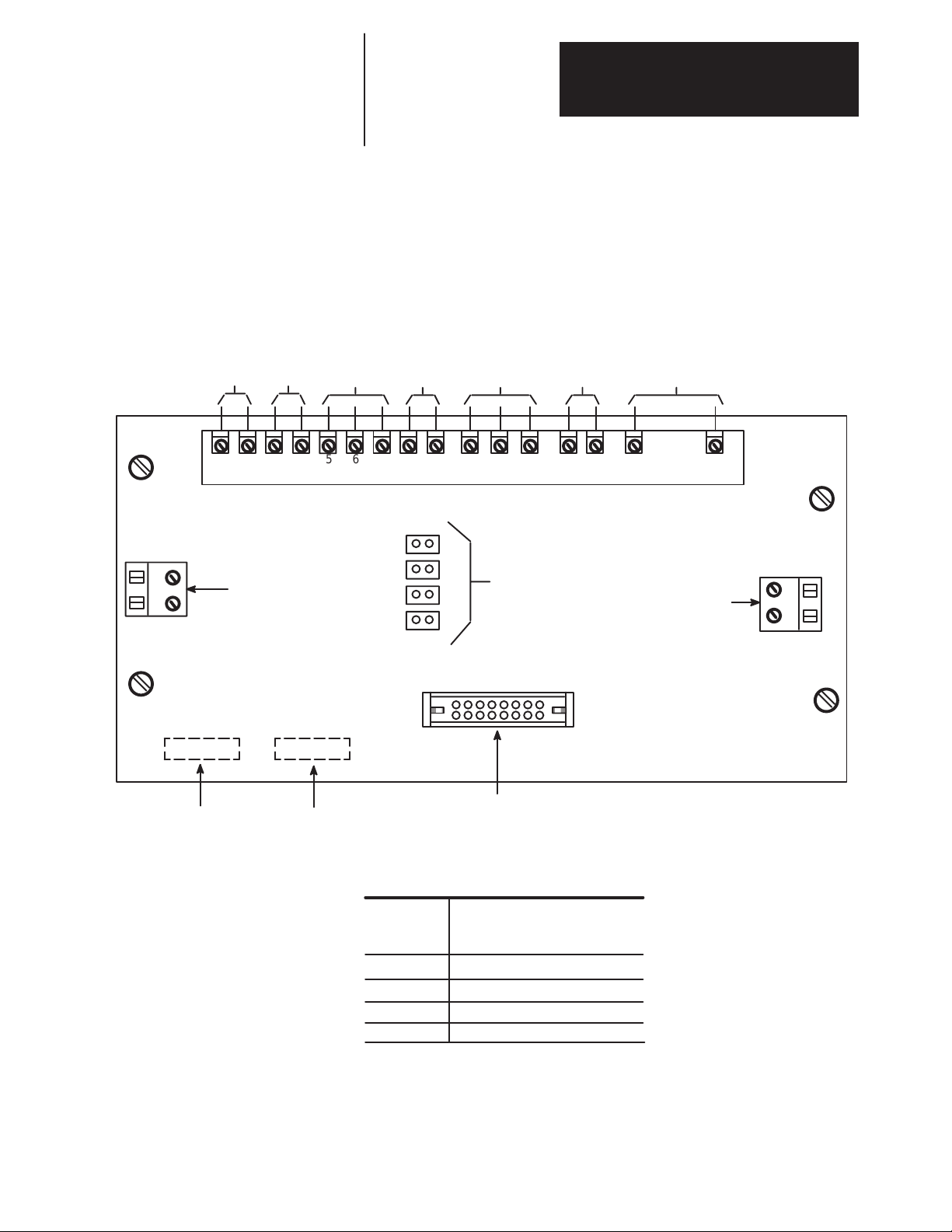

Figure 2.12

Construction and Location of Adapter Boards

AB0653A

2-15

Page 38

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

Discrete Adapter Board The Discrete Adapter Board connects directly to the Main Control Board

using Port A of the Microbus interface. All user connections to the board

are made at Terminal Block TB-3 located at the bottom of the 1395 Drive.

Digital Inputs – The Discrete Adapter Board contains four discrete inputs

and is available in 120VAC or 24VDC versions. These optically coupled

inputs provide a means for external control of the 1395 via pushbuttons,

relays, switches, etc.

The inputs are preconfigured for the following signals: STOP, JOG,

START, CLEAR FAULT.

Digital Outputs – Two discrete outputs are provided through control of

two on-board relays. The contact rating is 0.6A at 125VAC and 0.2A at

30VDC. These outputs allow the 1395 to signal various operating states of

the Drive.

The outputs are preconfigured for the following signals: DRIVE

RUNNING and AT ZERO SPEED.

Analog Inputs – Four preprogrammed 12-bit analog to digital inputs.

These inputs allow a +/– 10VDC analog signal to be converted to a +/–

2048 digital signal, thus providing 4.88 millivolts per bit resolution.

Through programming of associated Scale and Offset parameters the

effective range of the converted signal can be extended to +/–32767.

The analog inputs are preconfigured for the following signals:

VELOCITY REFERENCE, TACH VELOCITY, TRIM REFERENCE.

Analog Outputs – Four preprogrammed 11 bit digital to analog outputs.

These outputs allow a +/– 1024 drive signal to be converted to a

+/–10VDC analog output, thus giving 9.76 millivolts per bit resolution.

Through programming of associated Scale and Offset parameters the

effective range of the Drive signal can be extended to +/– 32767.

The analog outputs are preconfigured for the following signals:

VELOCITY FEEDBACK, FIELD CURRENT FEEDBACK,

ARMATURE CURRENT FEEDBACK and ARMATURE VOLTAGE

FEEDBACK.

All inputs and outputs have the flexibility to be reconfigured by the user

for other signals. For a detailed description of the Discrete Adapter, refer

to the Discrete Adapter manual.

Digital Reference Adapter Board The Digital Reference Adapter Board connects directly to the Main

Control Board using Port A of the Microbus interface. This interface

supplies the Adapter Board with all logic voltages and communication

capabilities. The Digital Reference Adapter has the following inputs and

outputs:

Digital Reference Input – One digital frequency reference input which

produces a digital velocity reference command for the Drive. The Adapter

Board is set up by default for the encoder input signal to be single channel

dual edge (ie. both the rising edge and falling edge are used by the

counting logic).

Digital Inputs – Ten programmable discrete inputs for 24VDC signals.

They can be connected to any Sink parameter such as the Logic command

word. All ten inputs are LED indicated for high input level visibility.

These optically coupled inputs provide a means for external control of the

1395 via pushbuttons, relays, switches, etc.

2-16

Page 39

Chapter 2

Hardware Description

1 – 30 HP, 230VAC2 – 60 HP, 460VAC

The inputs are preconfigured for the following signals: RUN

REFERENCE SELECT A,B,C, RAMP DISABLE, JOG 2, JOG1,

NORMAL STOP, START, CLOSE CONTACTOR, CLEAR FAULT.

Digital Outputs – Five programmable solid state outputs are provided.

These 24VDC outputs can be connected to any source parameter, such as

the logic status word. All five outputs have LEDs indicating the bits of the

state of the output (on or off).

These outputs are preconfigured for the following signals: ZERO SPEED,

DRIVE RUNNING, READY, AT CURRENT LIMIT, AT SET SPEED.

Analog Inputs – Two programmable analog inputs allow a +/– 10 Volt

signal through a 12 bit A to D converter, thus providing 4.88 millivolts per

bit resolution.

The inputs are preconfigured for the following signals: VELOCITY

REFERENCE, TACH VELOCITY.

Analog Outputs – Two programmable analog outputs allow a signal to be

converted to a +/– 10VDC analog output through a 11 bit digital to analog

converter, thus giving 9.76 millivolts per bit resolution. Through

programming of associated Scale and Offset parameters the effective range

of the Drive signal can be extended to +/– 32767. The digital drive signal

can be any of the 1395 run time sink parameters.

All user connections to the board are made at terminal block TB3 located

at the bottom of the 1395 Drive.

The outputs are preconfigured for the following signals, VELOCITY

FEEDBACK, ARMATURE CURRENT FEEDBACK.

All inputs and outputs have the flexibility to be reconfigured by the user

for other signals. For a detailed description of the Digital Reference

Adapter, refer to the Digital Reference Adapter manual.

Node Adapter Board The Node Adapter Board provides an interface between PLC family

devices and the Main Control Board of the 1395. The board allows the

1395 to be controlled using an Allen-Bradley PLC Controller from either

the PLC3 or PLC5 family.

The Node Adapter Board is not preconfigured. Refer to the Node Adapter

manual for hardware integration information.