Page 1

Bulletin

1391

Servo

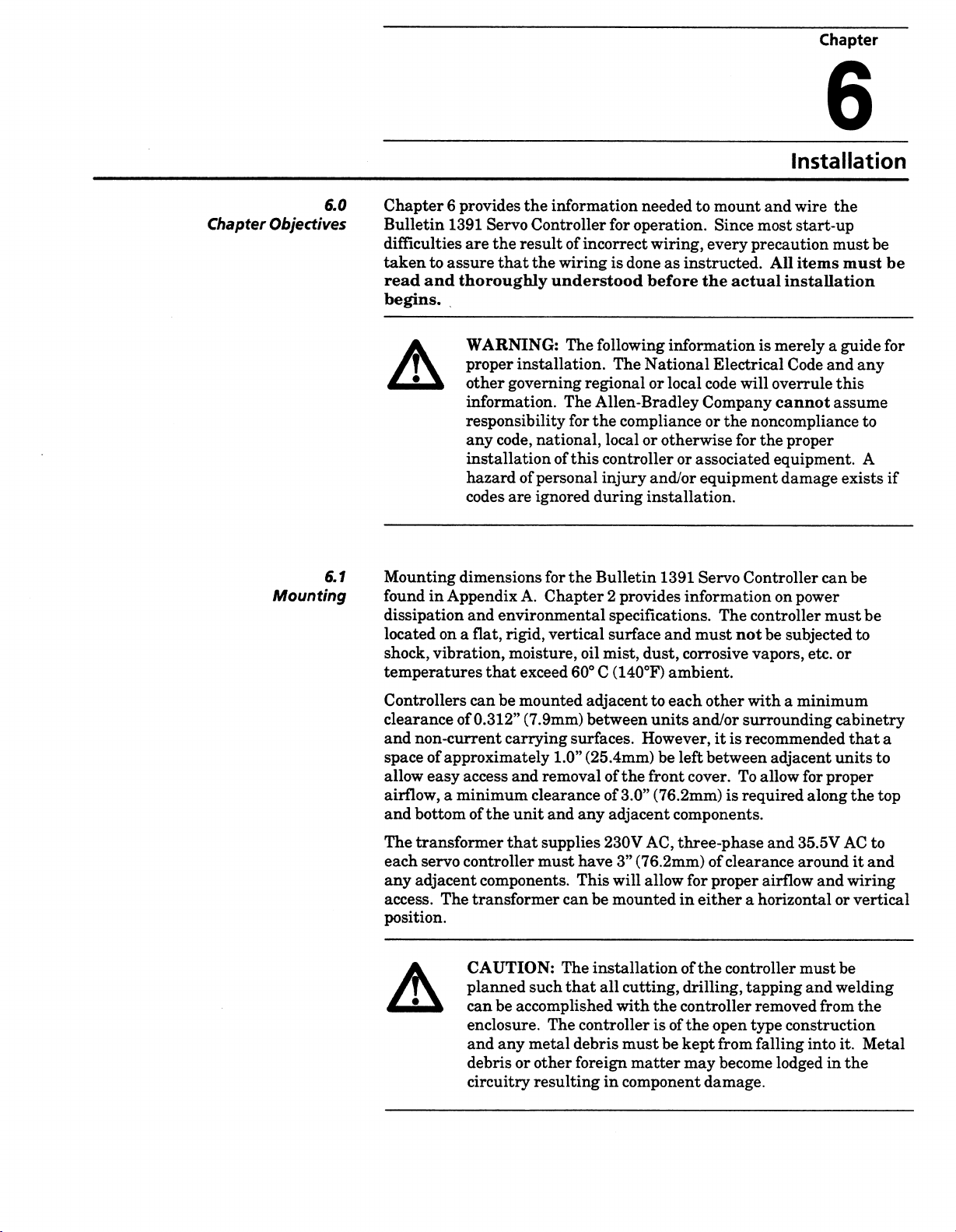

AC

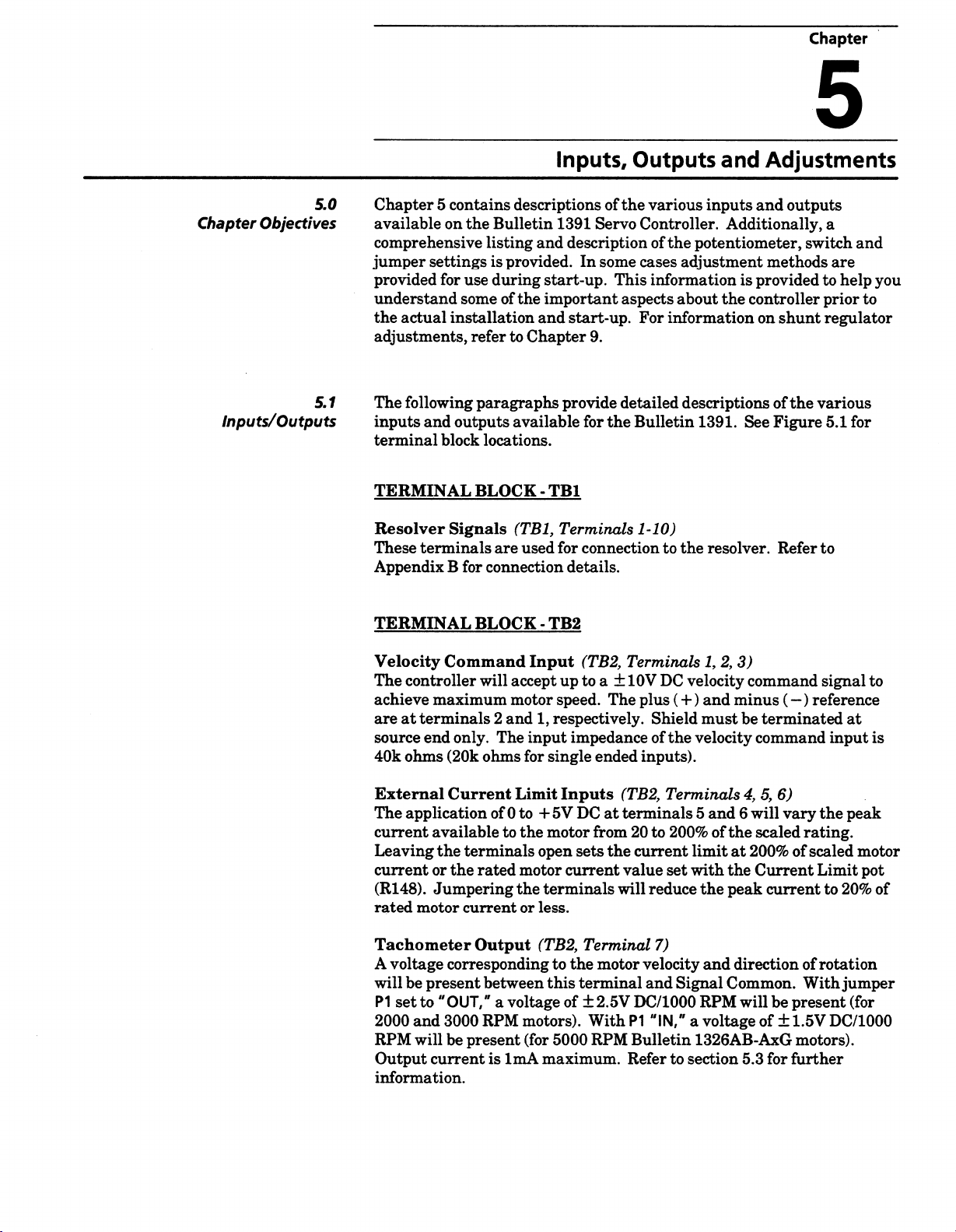

(Series

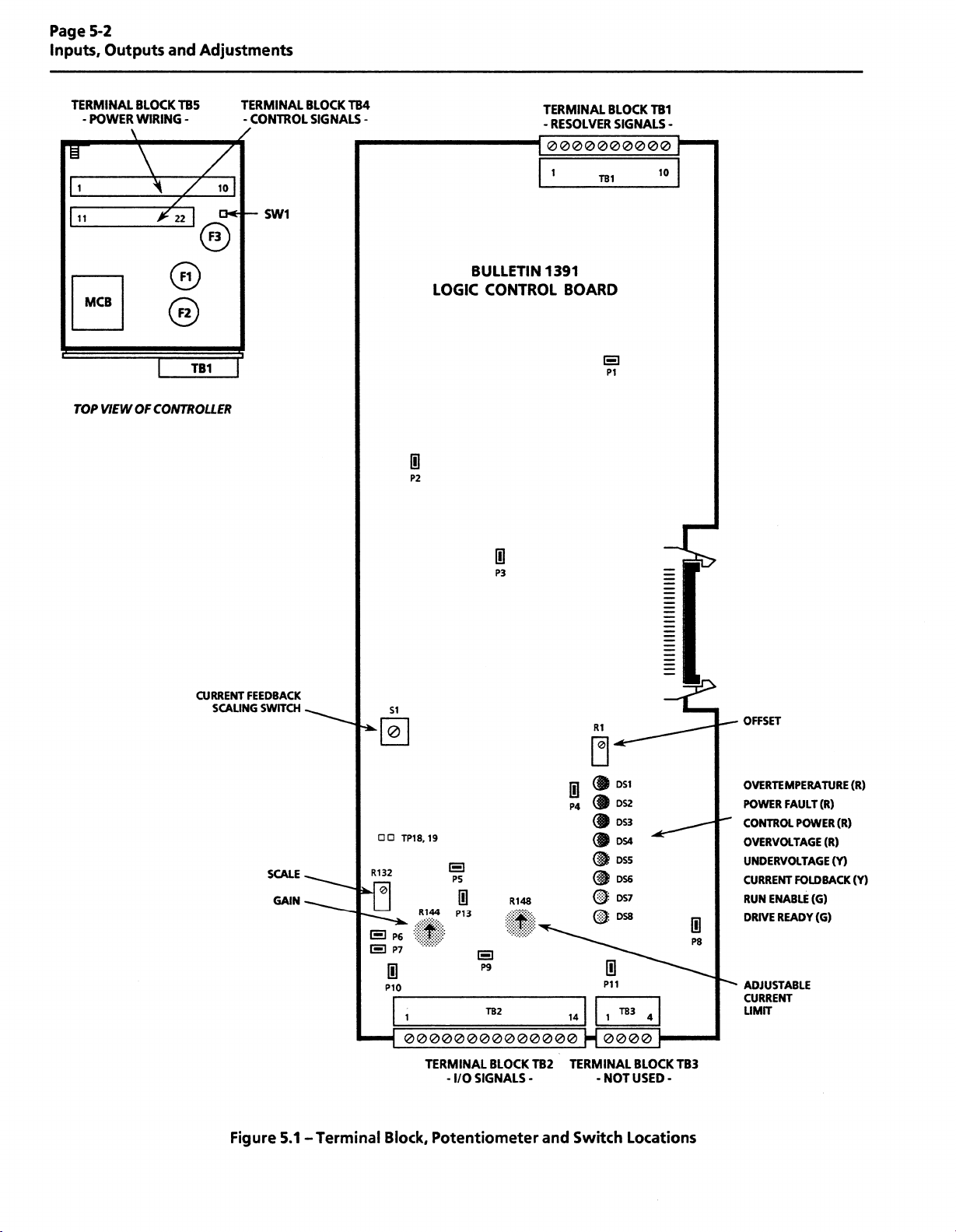

A.

Controller

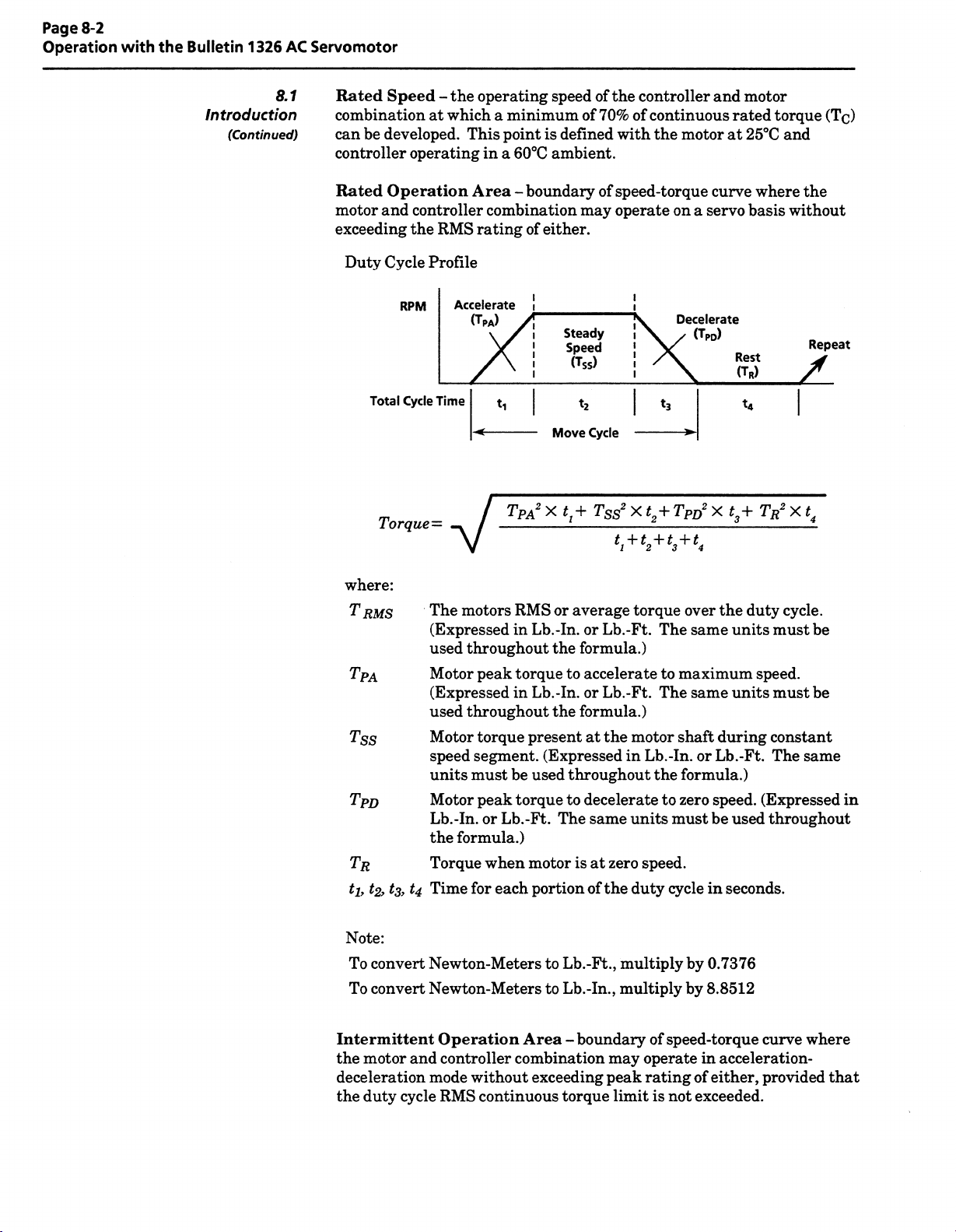

ts)

ana

1

a;aaaa*-

dm

W&l

lnstruction

Manual

|i

'

i'V:

:

mm

m

mi

mm

1

1

p

i

iiiai

4

a

’

V

\

%

sa

m

\

:

%

I

%

1

p

:a-a/;

|

aSlflii

.a

illilSl

a'-aa-aa-

IBliiHIMliiiil

:Va:

aa-;

Wi:.

my.

W:0:

%

a-

1

MMI

'

fig

-

%

'ÿ

my

mi

aa.

\-yy

wwM

%

MSI

siiii

.........

........

mm

iiiiiiiil

iMiM

a

a

I

;-a

%

1

1

agaga

"

;

.

.

5

'.a.'

g

a-"

a

&

a

a

mm

M

a'

i

§

.a.

M

§§g

«B8r

,

,

>

,'a.

a':'a

MM

II

aa-

\

aaa

:

m

1

,

a

—

Page 2

Important

User

Information

Because

differences

equipment,

must

of

or

application

The

text

associated

cannot

illustrative

No

use

of

satisfy

the

equipment.

liable

for

illustrations

this

of

assume

patent

information,

of

the

variety

between

user

the

themselves

In

indirect

of

this

equipment.

shown

manual.

with

any

responsibilityorliability

uses

and

liability

is

uses

of

this

solid-state

of

and

those

as

to

no

event

or

consequential

this

in

Because

particular

applications.

assumed

circuits

or

this

for

equipment

responsible

the

acceptability

Allen-Bradley

will

manual

many

of

the

installation,

by

Allen-Bradley

equipment

equipment

and

for

applying

of

damages

are

resulting

intended

variables

the

Allen-Bradley

for

actual

Company

describedinthis

and

becauseofthe

electromechanical

this

equipment

each

application

Company

solely

and

use

be

responsible

the

from

to

illustrate

requirements

Company

upon

based

with

respect

text.

and

use

the

use

or

the

to

Reproduction

written

The

each

to

procedures.

permission

information

chapter

so.

Do

do

WARNING:

injured

A

CAUTION:

economic

A

These

reader-alerts

The

•

•

•

•

probability

The

probability

The

consequences

How

to

avoid

of

the

in

in

sequence

not

proceed

if

these

content

the

Allen-Bradley

of

this

manual

and

the

to

tells

procedures

tells

readers

can

you

severity

severity

of

improper

occur

loss

help

and

and

consequences.

of

this

is

organized

perform

next

readers

are

not

if

identify:

hazards.

of

damage.

of

use.

manual,

chapter

about

where

procedures

in

Company

in

procedures

until

hazards

followed

machinery

or

whole

prohibited.

is

numbered

when

you

have

and

properly.

may

are

not

in

part,

chapters.

are

you

completed

where

prople

damaged

be

followed

without

Read

instructed

all

may

or

properly.

be

Hazard

alert

labels

are

on

the

product.

Page 3

Table

Contents

of

Table

Contents

of

Page

1

Chapter/

Section

1

1.0

1.1

1.2

1.3

1.4

1.5

1.6

2

2.0

2.1

2.2

2.3

2.4

3

3.0

3.1

3.2

3.3

3.4

Manual

General

Controller

Series

Standard

Objectives

Precautions

Description

A,

and

B

Features

Controllers

D

Options/Modifications

Controller

Chapter

Controller

Environmental

Controller

Transformer

Chapter

Receiving

Unpacking

Inspection

Storing

Layout

Objectives

Specifications

Specifications

Power

Dissipation

Power

Objectives

Dissipation

.

.

Receiving,

Title

Introduction

Specifications

Unpacking

and

Page

1-1

1-1

1-2

1-3

1-4

1-4

1-5

2-1

2-1

2-2

2-2

2-2

Inspection

3-1

3-1

3-1

3-1

3-1

4

4.0

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.8

4.9

4.10

4.11

4.12

4.13

5

5.0

5.1

5.2

5.3

Chapter

Objectives

General

300V

DC

Power

PWM

Operation

Shunt

Controller/System

Starting

Regulator

Logic

Power

Logic

Control

Isolated

Integral

Line/DB

Power

Power-Up/Down

Chapter

Inputs/Outputs

Supply

Current

Circuit

Contactor

Driver

Stopping

and

Objectives

Board

Board

Potentiometer

Switch

and

Jumper

Supply

Bus

Operation

Monitor

Fault

Sensing

Breaker

Sequence

Adjustments

Settings

Description

and

Inputs,

Detection

Outputs

Operation

of

Adjustments

and

4-1

4-1

4-1

4-1

4-2

4-2

4-2

4-3

4-4

4-4

4-4

4-4

4-5

4-5

5-1

5-1

5-4

5-5

Page 4

Page

Table

II

Contents

of

Chapter/

Section

6

6.0

6.1

6.2

6.3

7

7.0

7.1

8

8.0

8.1

8.2

8.3

9

9.0

9.1

9.2

9.3

Chapter

Mounting

Wiring

Wiring

Chapter

Start-Up

Chapter

Objectives

Recommendations

Objectives

Procedure

Objectives

Introduction

Bulletin

Motor

Chapter

Bulletin

Shunt

Shunt

1326AB

Maintenance

Objectives

1391

Regulator

Regulator

Operation

Motor

Options

Transformers

Operation

Installation

with

the

Transformers

Title

Installation

Start-Up

Bulletin

Shunt

and

1326

Regulators

Servomotor

AC

Page

6-1

6-1

6-2

6-3

7-1

7-1

8-1

8-1

8-3

8-5

9-1

9-1

9-4

9-6

10

10.0

10.1

10.2

Appendix

A

B

c

Chapter

System

Test

Objectives

Troubleshooting

Point

Controller

Interconnect

Cable

Information

Descriptions

Dimensions

Drawings

...

—

.

Troubleshooting

10-1

10-1

10-4

A-1

B-1

C-1

Page 5

Chapter

1

Introduction

Manual

1.0

Objectives

This

manual

troubleshooting

arranged

troubleshooting

operation,

understood

Caution,

the

IMPORTANT:

Only.

Refer

information

Important

This

single

to

limitationsofthis

installation,

points:

is

It

to

the

manual

controller

help

the

This

equipment

component

While

when

same

meant

is

order

in

the

material

before

Warning

not

intended

Bulletin

the

on

Information

has

user

setup

controller

potential

the

used

considerations

solid-state

Manufacturers

design

standards

requirements.

In

the

compliance

regulations

control

electrical

of

and

actual

factory

with

which'

guide

to

Bulletin

of

a

from

a

and

maintenance.

presented

proceeding.

and

This

manual

for

1391B-ES

Bulletin

prepared

been

application.

understand

equipment

and

maintenance

has

been

in

hazards

system

a

in

to

are

be

equipment

engineering

and

control

codes

for

environment,

applicable

beyond

are

the

1391

general

Particular

Important

is

use

with

Instruction

1391B-ES

about

It

the

including

designed

integrated

an

associated

environment,

given

equipment

specific

machine

interface,

AC

description

To

must

statements

standard

for

the

Servo

ensure

thoroughly

be

attention

Bulletin

Manual

installation,

Controller.

the

of

successful

contained

Bulletin

1391B-ES

Controller.

this

Manual

primarily

standard

is

a

individual

procedures.

to

to

characteristicsofother

and

the

groups

safety

the

scope

the

support

to

document

operating

hazards

meet

the

controller

with

the

it

cumulative

responsible

refer

must

guidelines

user

is

operator

and

purpose

and

associated

Note

requirements

must

responsible

setup

The

controller

installation

read

and

must

be

1391

directed

within.

Controllers

Controller.

further

for

product

this

is

that

characteristics

with

following

the

system.

controller

be

noted

peripheral

impact

to

and

on

specification

for

applicable

interface

to

safety

codes

this

of

and

contents

to

and

to

in

a

intended

and

of

a

remain

that

the

special

safety.

industry

ensure

or

document.

are

or

General

1.1

Precautions

addition

In

following

and

understood.

A

A

to

precautions

the

statements

WARNING:

Servo

Controller

implement

maintenance

personal

in

CAUTION:

result

can

Wiring

life.

motor,

ent

incorrect

temperatures

which

Only

installation,

the

of

the

injury

An

component

in

application

or

throughout

listed

general

are

personnel

and

associated

controller.

and/or

incorrectly

inadequate

or

may

to

familiar

start-up

equipment

applied

damage

errors,

resultinmalfunction

this

the

controller

machinery

and

Failure

damage.

or

reduction

or

a

such

supply,

AC

manual,

with

the

should

subsequent

comply

to

installed

undersizing

as,

or

of

the

must

be

Bulletin

plan

may

controller

product

in

excessive

the

controller.

read

1391

or

result

the

ambi¬

Page 6

1-2

Page

Introduction

General

1.1

Precautions

(Continued)

A

CAUTION:

Discharge)

precautions

repairing

or

ESD

familiar

Allen-Bradley

sensitive

control

with

Electrostatic

Handbook.

controller

This

required

are

assembly.

this

procedures

control

static

publication

Damage

parts

are

or

any

may

assemblies.

and

installing,

when

Component

not

followed.

procedures,

8000-4.5.2,

other

contain

damage

reference

Guarding

applicable

ESD

Static

testing,

you

If

ESD

(Electrostatic

control

servicing

may

result

not

are

Against

Protection

if

Controller

1.2

Description

IMPORTANT:

Controllers,

Servo

Transformer.

The

user

accordance

codes

The

Bulletin

dedicated,

require

number

a

equipment

The

Bulletin

positioning

various

components

All

front

enclosure

included

is

The

Bulletin

voltage

AC

which

speed

responsible

is

with

may

that

single

minimum

a

of

industries.

system

machine

cover.

and

to

with

proportional

is

and/or

features

The

servomotor.

RMS

with

all

Transformer,

complete

the

order

In

the

of

Use

the

apply.

Pulse

1391

axis,

1391

is

to

members

are

controller

ventilated

circulate

1391

converts

controlled

current

The

controller

package

Bulletin

system.

servo

to

user

any

other

for

National

Width

servo

AC

amount

required

generally

control

mounted

with

air

user

a

to

(torque)

sizes

1326

maintain

provide

must

transformer

providing

Electrical

Modulated

controller.Ithas

space

panel

of

by

the

with

used

position

the

on

automated

an

open

in

an

is

intended

filtered

power

the

over

three-phase,

a

supplied

of

Bulletin

a

available

is

being

Servomotor

AC

amplitude

identical.

phase,

listing

UL

power

motor

overload

Code

Servo

while

machine

computer

a

and

framed

to

be

and/or

heat

50/60

analog

1326

ratings

in

on

from

voids

the

(NEC),

Controller

been

containing,

tool

and

linear

machine.

package

panel

mounted

cooled

sink.

Hz

frequency.

and

command,

permanent

of

Bulletin

A

and

Bulletin

Allen-Bradley

Isolation

1391

a

listing.

UL

protection

and

packaged

any

is

as

in

other

a

automated

aided,

or

rotary

closed

motion

withaslide-on

an

in

An

to

regulates

22.5

1391

1326

internal

variable

a

The

magnet

and

Cables

air.

input,

15,

1391

local

to

standard,

loop

of

fan

output

the

AC

45A

Page 7

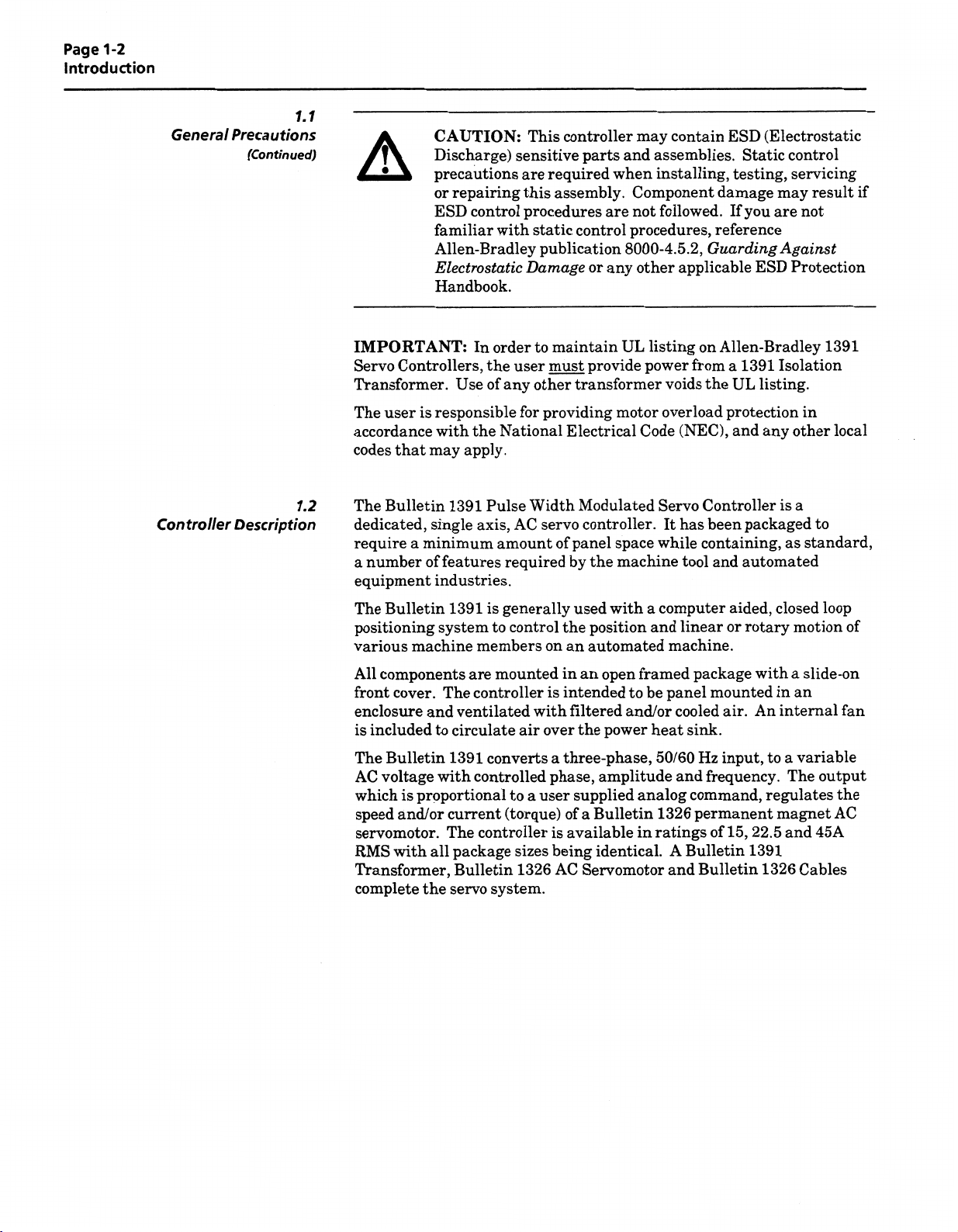

Series

A,

Page

1-3

Introduction

1.3

and

B

D

Controllers

"B"

BULLETIN

1391

AC

SERVO

CONTROLLER

SERIES

B

CAT

l

INST

MAN

VOLTS

V.C.T.

VOLTS

OWII.y

The

Bulletin

Series

and

functionally

are

identical,

Bulletin

unit.

In

providing

A

Series

catalog

the

carton

Series

necessary.

as

B.

as

1391

addition,

improved

B

controller

number

product

or

and

A

1391

are

Series

IMPORTANT:

controller,

used

controller

Series

in

a

B

Series

Logic

however,

may

1391B-AA45

1391-5.1

1

230

l

|

36

MAX

210

ALLEN

A

ROCKWELL

Figure

AC

In

most

equivalent.

the

user

integrated

has

some

methods

can

or

nameplate

B

Series

The

it

B

controller.

result

Board,

AC

|

PH

l

l

SYM

PH

Servo

3

PH

1

l

RMS

SHORT

AC

HZ

[T]

BRADLEY

INTERNATIONAL

1.1-

Bulletin

Controller

installations,

Mounting

interconnects

some

internal

of

manufacture.

be

identified

by

referencing

(see

controller

Logic

B

is

recommended

Use

in

loss

of

a

including

INPUT

|

[

50/60

HZ

|

|

HZ

CKT

50/60

CURRENT

OUTPUT

AMPS

0-200

I

l

COMPANY

1

391

exists

the

Series

and

and

the

of

former

design

will

the

Figure

be

Board

changes

by

the

“Series”

1.1).

identified

can

that

Series

of

a

additional

some

undervoltage

SER

1

S/N[

|

|

[

Nameplate

in

A

physical

terminations.

addition

Differences

be

Series

a

Logic

A

sensing.

|

AMPS

|

AMPS

|

AMPS

j

KW

45

MADE

two

versions;

Series

and

dimensions

options

have

been

of

fieldonthe

throughout

used

A

Board

features

38

5.5

1300

]

IN

The

into

letter

a

between

a

in

Logic

provided

*

B

1

|

|

|

|

14

U.S.A

Series

B

controllers

Series

the

made,

shipping

the

Series

Board

Series

a

in

A

are

B

standard

“B”

in

the

manual

A

not

by

the

be

B

Series

improvement

D

-

Controller.

unchanged,

|

CAT

13918-xxx

This

new

increases

versions

This

Control

same.

of

enhancement

Board(s)

The

information

Allen-Bradley’s

has

led

to

catalog

The

however,

series

manufacturing

the

1391

adjustment,

presented

the

incorporates

that

totally

is

and

all

commitment

the

introductionofthe

number

string

controller

re-designed

a

quality

are

now

and

in

transparent

components

other

connection,

this

in

manual

continuing

to

the

|

Series

SER

for

nameplate

Power

provides

a

development.

to

the

of

the

diagnostic

remains

and

product

Series

1391

will

D

will

appear

D

-

Driver

platform

of

user

this

controller

troubleshooting

correct.

Servo

D

be

as

SERIES

Board

new

for

product.

remain

follows:

D

that

The

the

Page 8

1-4

Page

Introduction

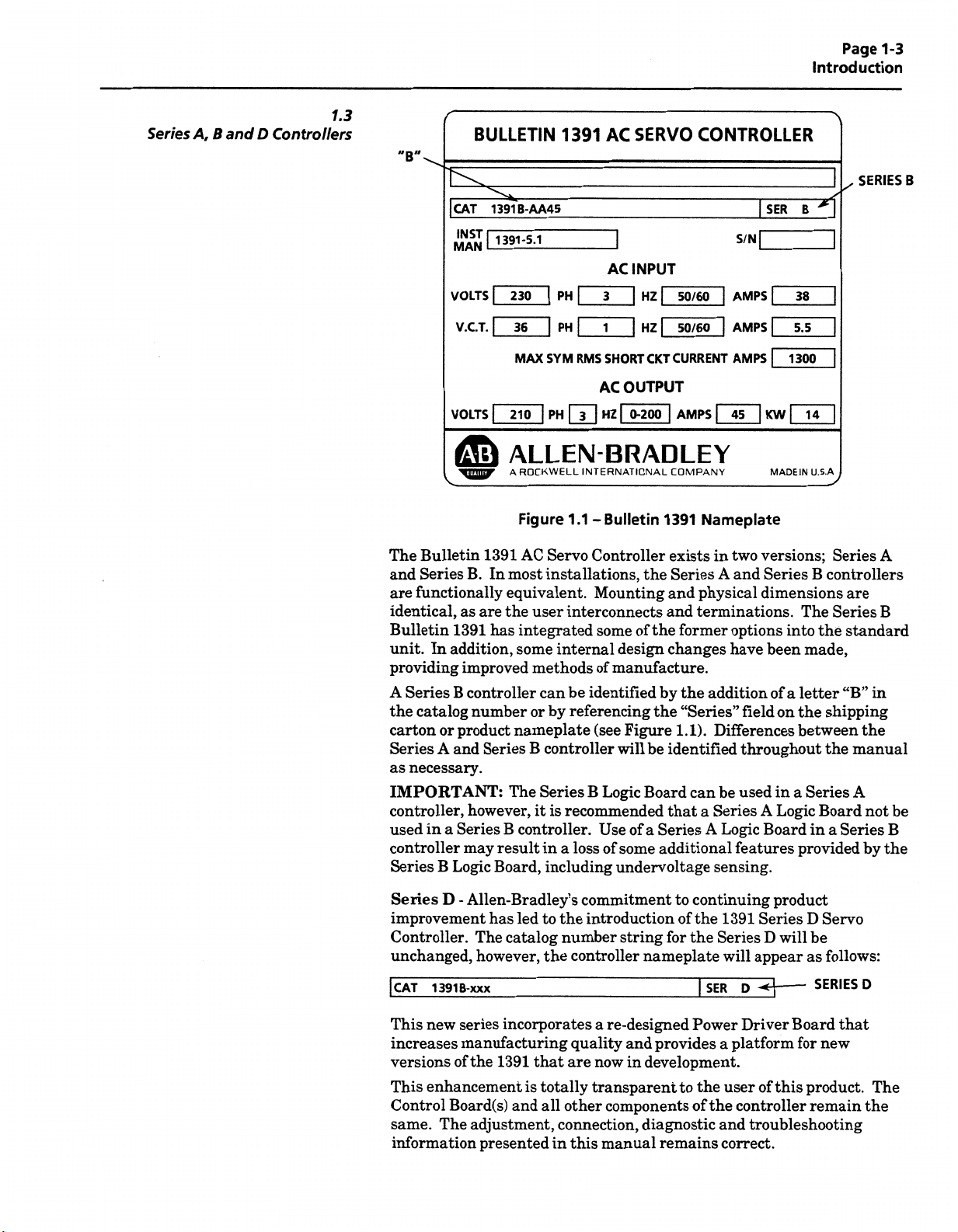

Standard

1.4

Features

The

Bulletin

typical

a

in

Input

A

and

protected

power

inserts

•

•

contactor

integral

An

•

the

event

standard

A

•

regulator.

A

shunt

•

motor

Velocity

•

between

Logic

•

troubleshooting

Three

•

have

UL

•

Transformers),

during

Board

controller

identical

listed

contains

1391

automated

against

line/DB

shunt

a

de-energized.

is

circuit

of

short

a

300V

regulator

regenerative

components

loop

to

0.03

1.0

that

and

mounting

per

UL

CSA

a

machine

transient

contactor

regulator

breaker

circuit

power

DC

resistor

in.-lbs.-sec2.

can

ratings

508

quickly

be

diagnostics.

that

dimensions.

(file

general

standard

number

which

which

conditioninthe

bus

to

braking.

compensate

to

#E59272

of

system.

servo

voltage.

opens

resistor

dissipate

are

file

across

will

open

supply

the

removed

the

in

volume1,section

-

LR32334-23,C22.2

the

that

for

and

same

features

AC

the

three

all

power

includes

energy

system

a

easily

physical

to

line

DC

bus

AC

circuitry.

an

generated

interchanged

and

required

the

controller

whenever

line

integral

inertia

package

10,

IEC

leads

by

the

range

and

Drives

146.

the

in

shunt

for

and

Options/

1.5

Modifications

The

Bulletin

following

The

Contactor

-

N.O.

Two

power

to

the

brake

control

Current

-

When

the

system,

torque

External

-

On

the

power.

regenerative

shunt

for

the

integral

The

amplifier

and

15

DC

bus

regulator

user

jumper

45A

Some

IMPORTANT:

standard

1391

are

Auxiliary

contacts

terminal

circuit

Torque

or

velocity

the

controller

Shunt

22.5A

voltage

applications

energy

mounting

on

TB5

fusing

controller

equipment

most

at

the

These

an

being

configured

be

the

of

Resistor

regulator

such

rated

controllers.

5A

from

externally

units.

45A

functions

user's

on

indicator

Operation

closed

plug

as

386

at

external

an

the

shunt

contains

selectable

Switch

mounted

are

block.

or

as

Amplifier

loop

is

can

by

use

Regulator

controllersaninternal

shunt

dissipate.

to

resistor

22.

on

using

and

accessible

has

an

external

An

on

needed

option:

the

main

contacts

that

part

as

operate

to

jumpers.

power

dissipate

can

overhauling

an

For

these

watts

Thisisselectable

resistor.

outside

regulator

An

of

mounted

additional

servo

a

in

power

contactor

be used

can

contactor

the

position

the

of

as

resistor

125

load

applications,

continuous

The

and

15

22.

resistor

resistor

unit

in

a

current

that

watts

have

can

shunt

5A

and

included

is

not

is

has

an

system.

wired

and

motor

a

closed.

control

or

part

is

continuous

excessive

external

supplied

be

removing

by

has

controllers.

fuse.

as

required.

of

Page 9

Options/

1.5

Modifications

(Continued)

-

Tach

A

voltage

1.5V

Output

equal

DC/1000

to

RPM

2.5V

on

DC/1000

units

set

RPM

for

5000

is

available

RPM

TB2.

at

operation.

Page

1-5

Introduction

Controller

1.6

Layout

Torque

-

A

voltage

Anti-Backlash

-

Current

or

equal

Provisions

provided.

In

additiontothe

hasalimited

type

is

This

per

option

of

followed

code

customer

by

sequentially

is

IMPORTANT:

on

Series

all

appear

Example:

The

“A10”

undervoltage

jumper

undervoltage

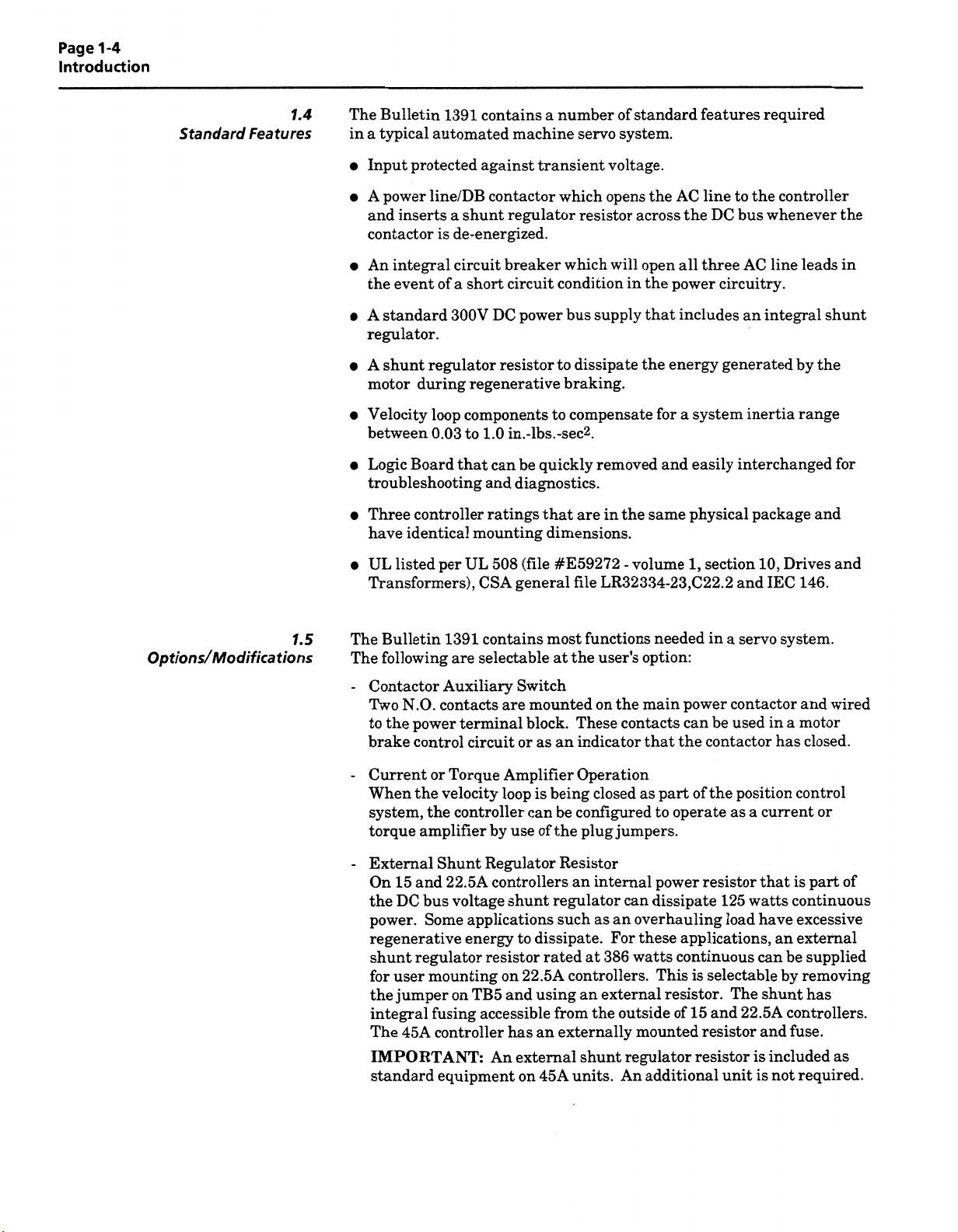

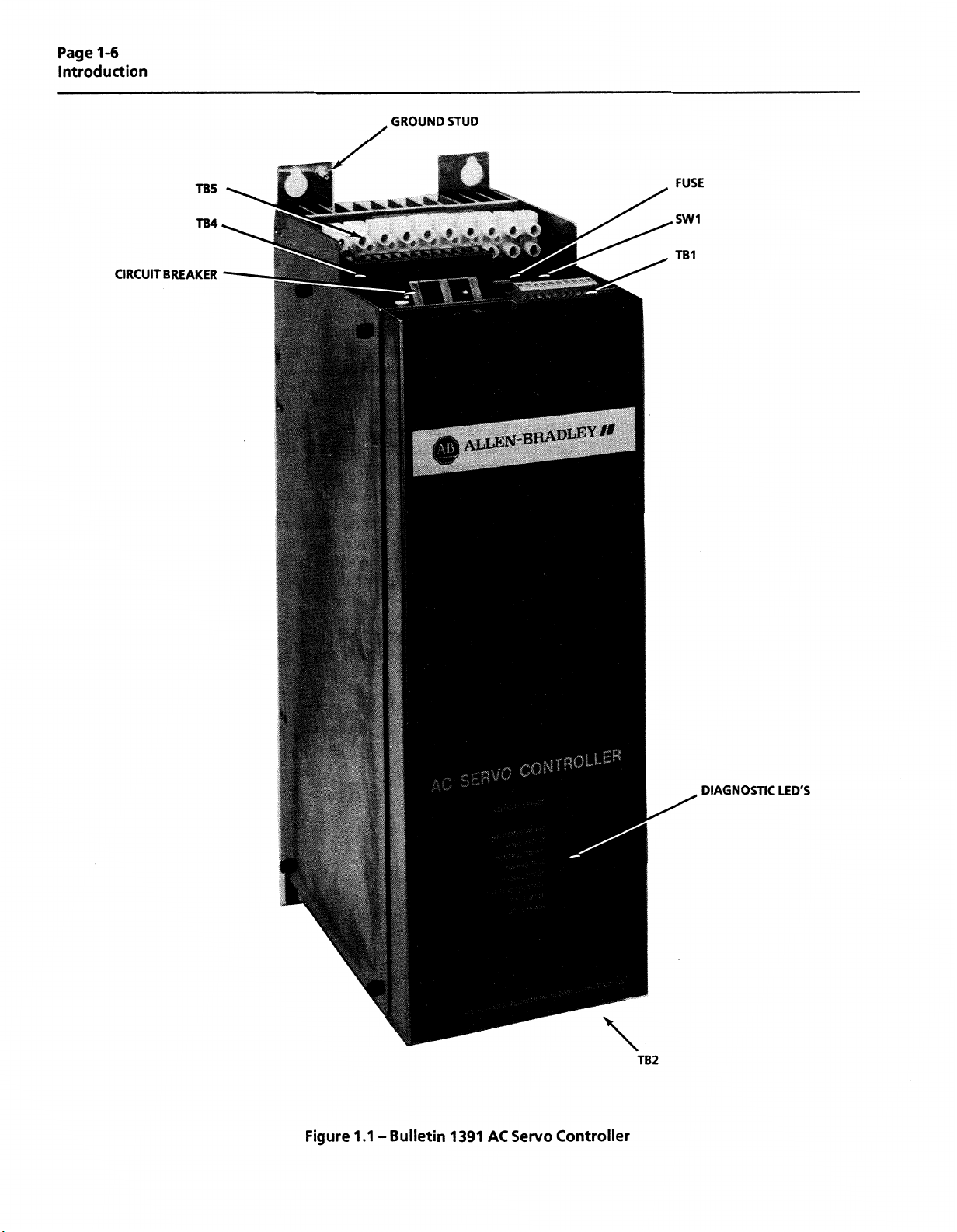

Figure

Controller,

B

in

the

1391-AA45N-A10

modification

P8.

It

provides

1.2

showing

Monitor

3.0V

to

to

the

use

Bulletin

selectable

custom

identified

be

three

The

fault,

a

provides

an

accessibility

of

character

assigned

Series

1391

number.

provides

without

resulting

exterior

number

can

a

specifications.

Bulletin

catalog

as

also

conditions,

100%

DC

options

A,

=

by

“A10”

scaled

Anti-Backlash

1388

listed

options/modifications

noting

alphanumeric

at

the

option/modification

controllers.

now

is

an

extended

the

latching,

in

of

view

various

of

controller

an

1391B-AA45N

the

current

above,

the

if

controller

code

factory

The

“A10”

with

depending

bridge

enable

extended

Bulletin

components.

available

is

module

the

Bulletin

available.

1391-AA22-A03)

(i.e.

options

as

designation

the

on

during

regeneration

1391

catalog

are

now

is

ability

the

setting

AC

at

are

1391

The

number

provided

standard

will

to

bus

time.

Servo

TB2.

also

.

not

sense

of

Page 10

Page

1-6

Introduction

CIRCUIT

TB5

TB4

BREAKER

m

fit

mi

,1111

m

m

§j|g|gg

§§11

\<

WM

1|

GROUND

‘

i

STUD

tL

ALLEN-BRApLEY#f

;

h:

j

FUSE

SW1

TB1

|

a

SI

WBm

umm

mSS§Wm

I

v,

:

m

*

:

f'.

50

I

III

DIAGNOSTIC

LED'S

Figure

1.1-

Bulletin

1

391

AC

Servo

\

TB2

Controller

Page 11

Chapter

2

Specifications

Controller

NOMINAL

CONTINUOUS

PEAK

CONTINUOUS

PEAK

INPUT

CIRCUIT

(SYMM

STATIC

UNIT

BUS

CURRENT

POWER

CIRCUIT

BREAKER

ETRICAL

(A/RPM)

GAIN

WEIGHT

Chapter

OUTPUT

CURRENT

(RMS)

OUTPUT

POWER

OUTPUT

BREAKER

INTERRUPT

AMPERES)

IN

LBS.

8.

Objectives

Specifications

VOLTAGE

(RMS)

RATING

RATING

(KG)

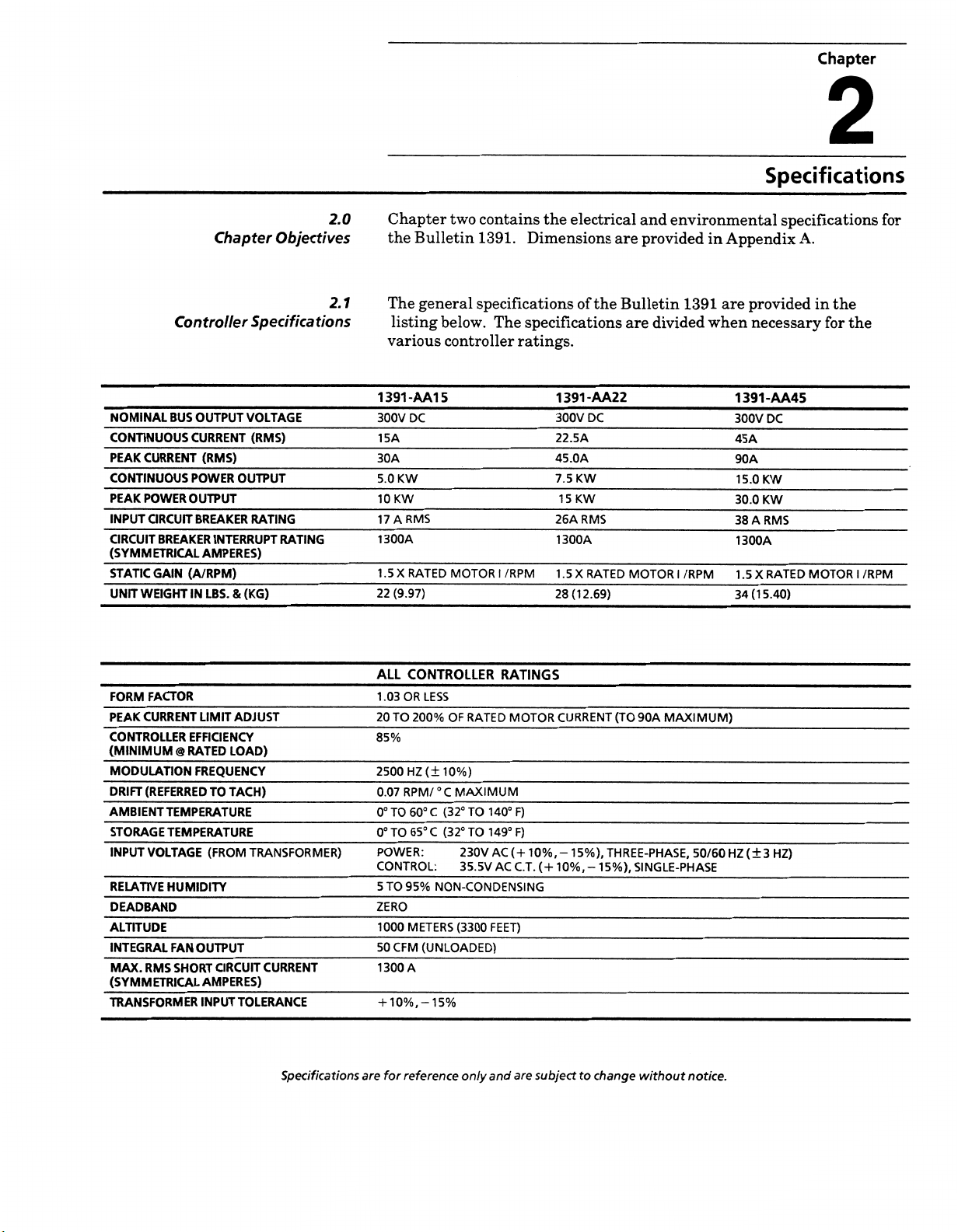

2.0

2.1

Chapter

the

Bulletin

The

general

listing

various

1391-AA1

DC

300V

15A

30A

KW

5.0

KW

10

RMS

17

A

1300A

1.5

X

RATED

(9.97)

22

two

contains

1391.

specifications

below.

controller

5

MOTOR

Dimensions

specifications

The

ratings.

I

/RPM

the

electrical

of

1391-AA22

300V

DC

22.5A

45.0A

KW

7.5

KW

1

5

26ARMS

1300A

1.5

X

RATED

28(12.69)

the

and

provided

are

Bulletin

are

MOTOR

environmental

in

1391

divided

/RPM

I

when

Appendix

provided

are

necessary

1391-AA45

300V

DC

45A

90A

KW

15.0

KW

30.0

A

RMS

38

1300A

1.5

RATED

X

(1

5.40)

34

specifications

A.

in

the

the

for

MOTOR

I

for

/RPM

FORM

FACTOR

PEAK

CURRENT

CONTROLLER

(MINIMUM

MODULATION

DRIFT

AMBIENT

STORAGE

INPUT

RELATIVE

DEADBAND

ALTITUDE

INTEGRAL

MAX.

(SYMM

TRANSFORMER

EFFICIENCY

@

RATED

FREQUENCY

(REFERRED

TEMPERATURE

TEMPERATURE

VOLTAGE

HUMIDITY

OUTPUT

FAN

RMS

SHORT

ETRICAL

ADJUST

LIMIT

LOAD)

TACH)

TO

(FROM

CIRCUIT

AMPERES)

INPUT

TOLERANCE

TRANSFORMER)

CURRENT

Specifications

ALL

1.03

TO

20

85%

2500

0.07

0°TO60°

0°TO65°

POWER:

CONTROL:

TO

5

ZERO

1000

CFM

50

1300

+10%,

are

for

OR

RPM/

reference

CONTROLLER

LESS

200%

OF

RATED

(±10%)

HZ

°C

MAXIMUM

(32°

C

C

95%

NON-CONDENSING

METERS

(UNLOADED)

A

-15%

(32°

TO

TO

230V

35.5V

(3300

only

140°

149°F)

and

RATINGS

MOTOR

F)

(+

10%,

AC

AC

C.T.

FEET)

are

CURRENT

-

(+

10%,-

subject

15%),

THREE-PHASE,

15%),

change

to

(TO

MAXIMUM)

90A

SINGLE-PHASE

without

50/60

notice.

HZ

(±3

HZ)

Page 12

Page

2-2

Specifications

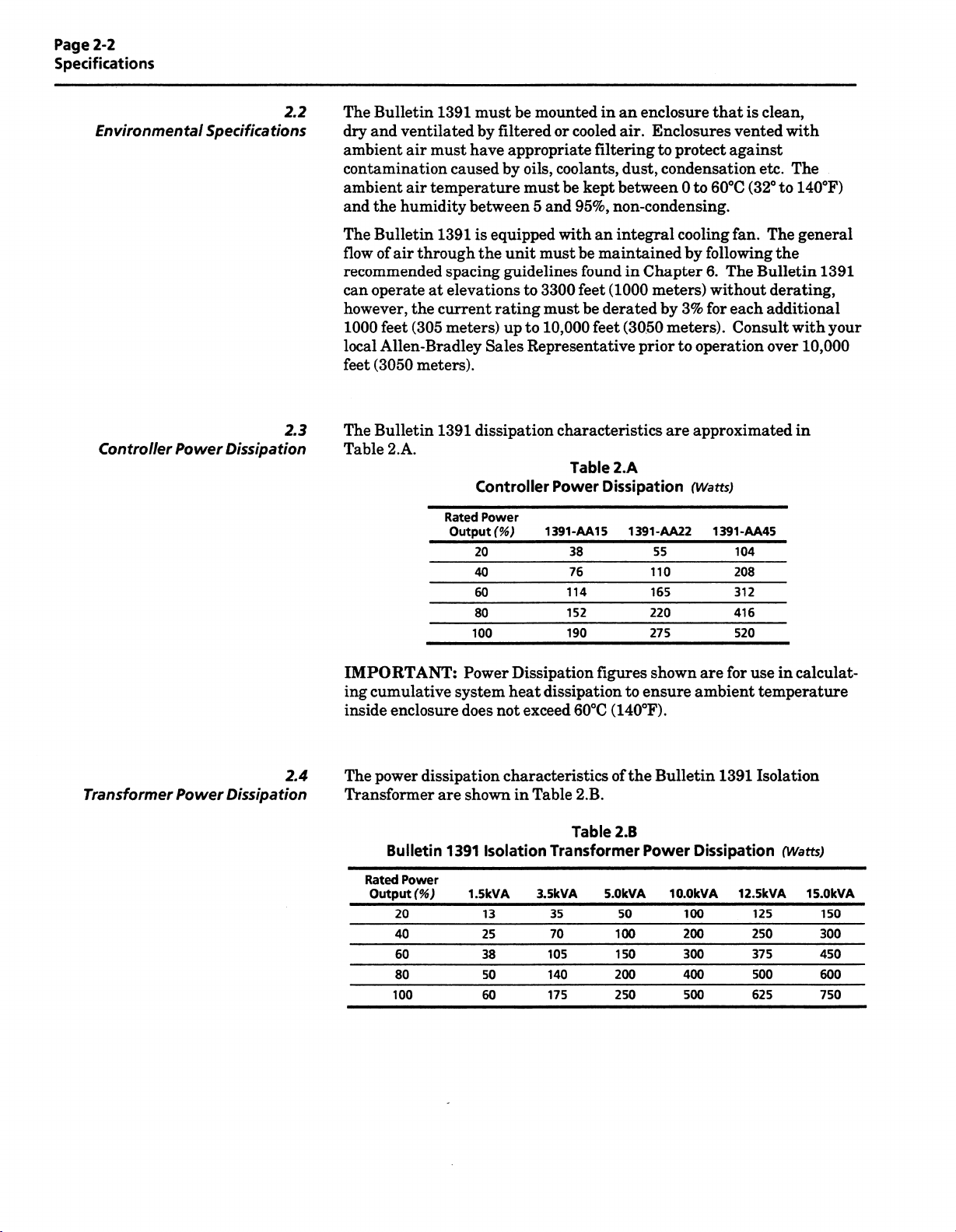

Environmental

Controller

Power

2.2

Specifications

2.3

Dissipation

Bulletin

The

dry

and

ventilatedbyfiltered

ambient

air

contamination

ambient

and

the

The

Bulletin

flow

of

temperature

air

humidity

through

air

recommended

operate

can

however,

feet

1000

Allen-Bradley

local

(3050

feet

The

Bulletin

Table

at

the

(305

meters).

2.A.

1391

must

have

caused

between

1391

spacing

elevations

current

meters)

1391

Rated

Output

100

must

mounted

be

appropriate

by

oils,

must

5

equipped

is

the

unit

guidelines

to

rating

up

to

Representative

Sales

dissipation

Controller

Power

(%)

20

40

60

80

in

or

cooled

filtering

coolants,

kept

be

95%,

and

with

an

must

be

maintained

found

(1000

feet

3300

be

must

10,000

derated

feet

characteristics

Table

Power

1391-AA15

Dissipation

38

76

114

152

190

an

enclosure

Enclosures

air.

to

dust,

condensation

between

protect

60°C

to

0

that

non-condensing.

integral

in

(3050

cooling

by

following

Chapter

meters)

priortooperation

6.

without

3%

by

for

meters).

approximated

are

2.A

(Watts)

1391-AA22

55

110

165

220

275

1391-AA45

is

vented

against

etc.

(32°

fan.

The

Bulletin

each

Consult

104

208

312

416

520

clean,

with

The

140°F)

to

general

The

the

derating,

additional

with

10,000

over

in

1391

your

Transformer

Power

2.4

Dissipation

IMPORTANT:

ing

cumulative

inside

enclosure

dissipation

power

The

Transformer

are

Bulletin

Rated

Power

(%)

Output

20

40

60

80

100

Power

system

does

shown

1391

1.5kVA

Dissipation

dissipation

heat

exceed

not

characteristics

Table

in

Isolation

3.5kVA

13

25

38

50

60

105

140

175

figures

to

(140°F).

60°C

of

2.B.

Table

2.B

Transformer

5.0kVA

35

70

50

100

150

200

250

shown

ensure

the

Power

are

ambient

Bulletin

Dissipation

IQ.OkVA

100

200

300

400

500

for

1391

12.5kVA

in

calculat¬

use

temperature

Isolation

(Watts

15.0kVA

125

250

375

500

625

)

150

300

450

600

750

Page 13

Chapter

3

Chapter

3.0

Objectives

3.1

Receiving

3.2

Unpacking

Chapter3provides

necessary,

and

if

catalog

the

is

it

agent

damage

of

must

inspection

packing

Remove

Inspection

the

against

the

be

section

Bulletin

It

before

item(s)

damaged,

the

concealed

responsibility

container

make

Remove

the

sink

entitled

1391

responsibility

the

is

accepting

received

freight

visual

a

all

controller.

etc.

Receiving,

the

information

store

the

Bulletin

provides

numbering

of

the

shipment

the

responsibility

has

noted

the

be

found

to

user

left

intact

of

material,

packing

all

user

from

purchase

of

damage

during

notify

and

the

equipment.

the

wedges,

Unpacking

needed

1391

a

system.

thoroughly

to

the

the

unpacking,

the

freight

material

to

and

complete

freight

order.

not

user

on

the

freight

agent

or

braces

unpack,

related

explanation

inspect

company.

any

If

items

accept

to

freight

again

is

it

agent.

should

from

from

the

Inspection

and

properly

equipment.

of

equipment

the

Check

are

delivery

Should

bill.

the

shipping

The

be

within

cooling

inspect

The

the

the

obviously

until

any

requested

and

around

fans,

heat

to

3.3

Inspection

3.4

Storing

IMPORTANT:

general

connections,

After

the

included

The

installation.

must

•

•

•

•

•

inspection

unpacking,

purchase

on

the

controller

be

stored

Store

Store

Store

not

Do

atmosphere.

Do

not

clean,

a

in

within

within

store

store

packing

order.

If

Before

mechanical

of

materials,

check

An

following

equipment

the

dry

an

ambient

relative

a

remain

should

according

equipment

equipment

the

installation

item(s)

the

explanation

pages

in

is

to

the

location.

temperature

humidity

where

in

construction

a

integrity

etc.)

must

nameplate

of

the

as

aid

an

shipping

its

not

to

be

following

range

it

could

start-up

and

(i.e.

loose

be

made.

catalog

catalog

nameplate

for

container

for

used

instructions:

range

of

5%

of

to

exposed

be

area.

of

the

parts,

number

numbering

interpretation.

prior

period

a

to

0

65°

non-condensing.

95%,

to

corrosive

a

controller,

wires,

against

system

to

of

time,

(32

to

C

a

is

it

149°F).

Page 14

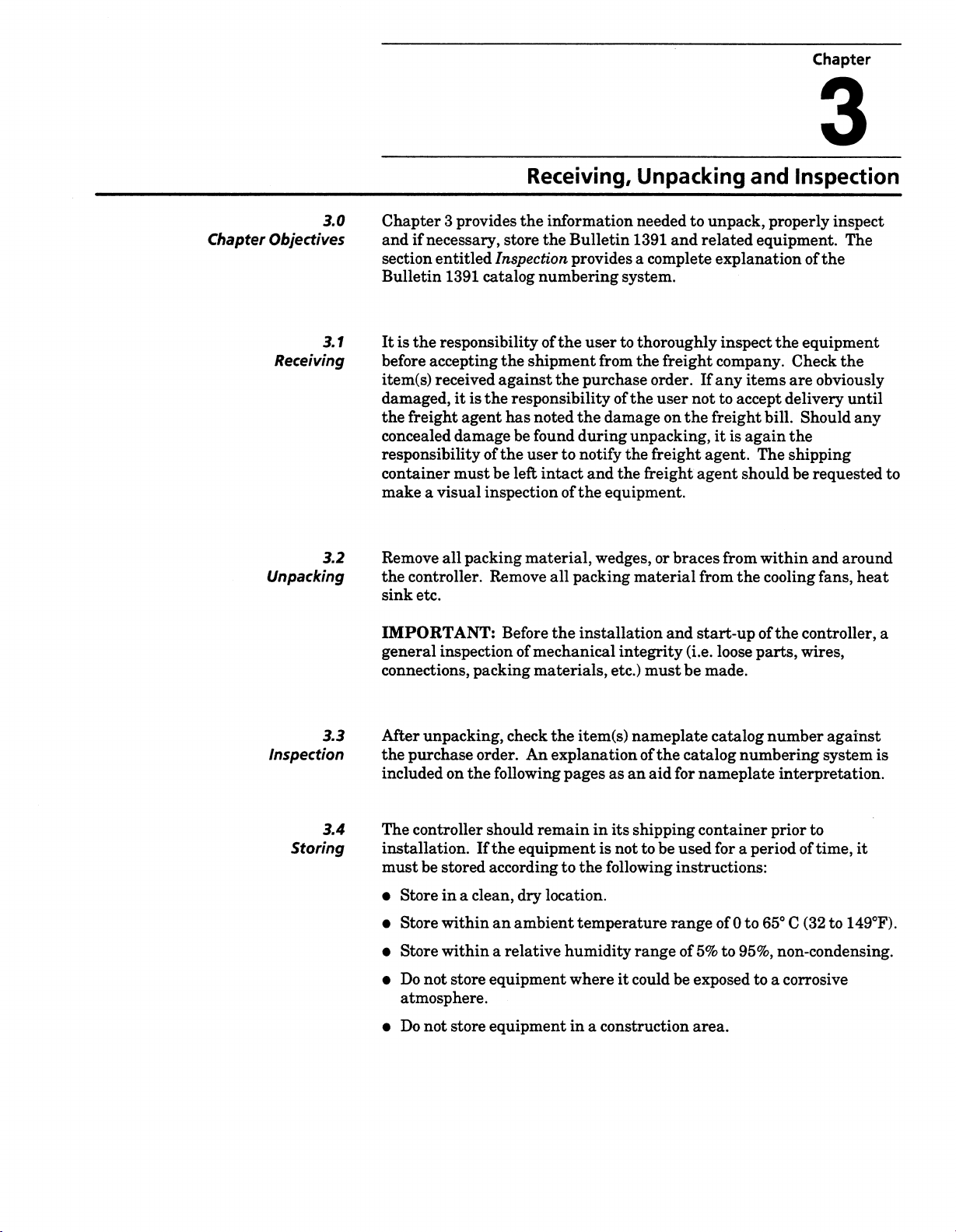

Page

3-2

Receiving,

Unpacking

and

Inspection

1391

First

Position

Bulletin

Number

Code

T

T

Second

Position

Type

Description

Transformer

Open

&

Coil

ISOLATION

015

Third

Position

Rating

kVA

No.

Core

015

035

050

100

125

150

TRANSFORMER

D

Fourth

Position

kVA

1.5

3.5

5.0

10.0

12.5

15.0

Primary

Code

D

E

N

Frequency

&

input

240/480

3-ph..

240/380/415/

480V

ph..

208/230/460/

575V

3-ph.,

Voltage

VAC,

60Hz

AC,

50/60

AC,

60Hz

T

Fifth

Position

Secondary

Voltage

Description

Code

AC,

35.5V

windings

CT

3-ph.

AC

&

1-

230V

T

four

ph.,

3-

Hz

NEMA

TYPE

1

1391

First

Position

Bulletin

Number

TRANSFORMER

TA2

Second

Position

Accessory

Module

TA2

Description

all

Fits

Bulletin

Isolation

Letter

ENCLOSURE

Ratings

1389

on

and

1391

kVA

1388.

Transformers

KIT

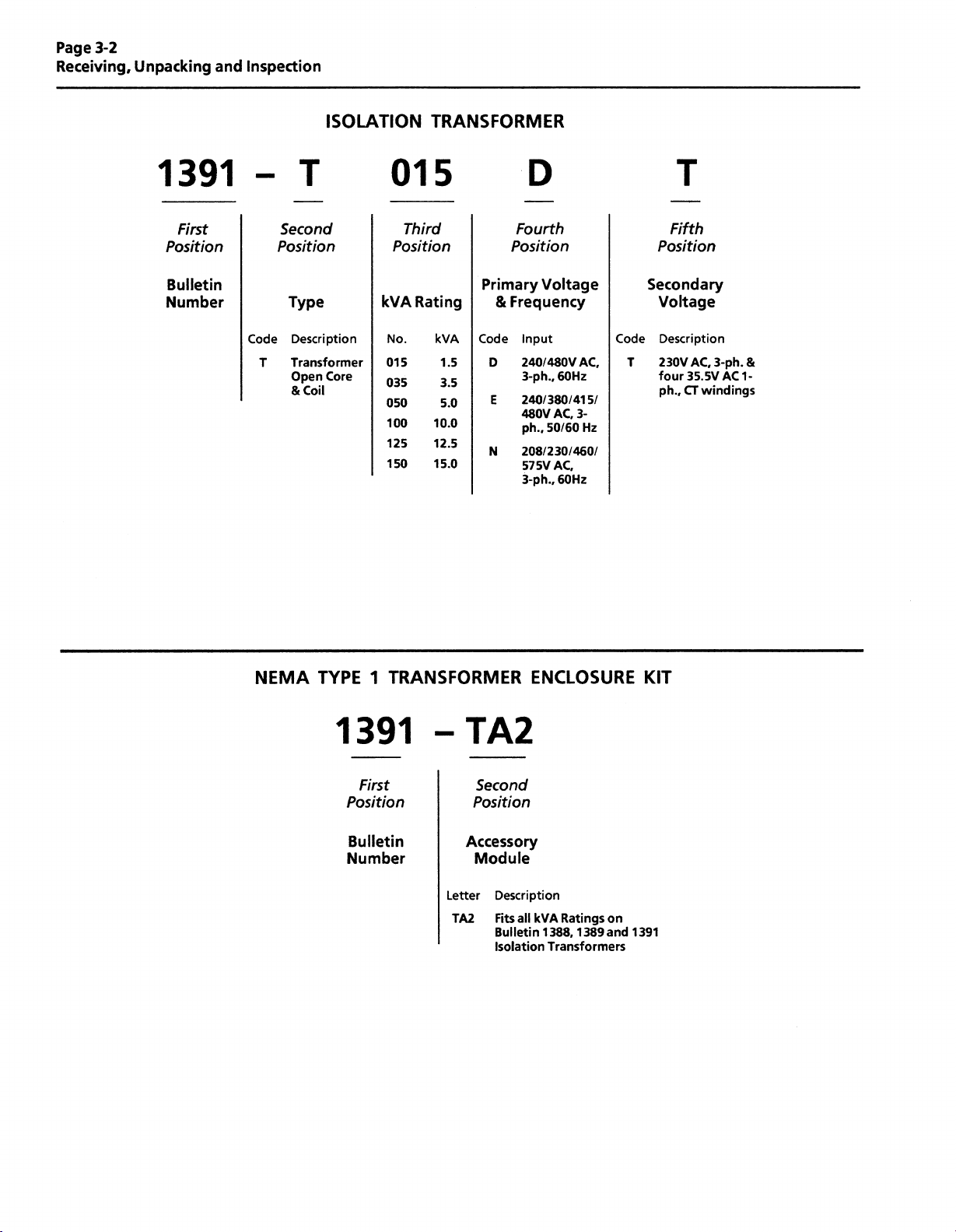

Page 15

Receiving,

Unpacking

and

Page

3-3

Inspection

1391B

First

Position

Bulletin

Number

Description

A

=

=

Series

Series

B

1391

1391B

A

-

Second

Position

Type

and

Construction

A

Description

Open

Frame

Internal

Heat

Letter

BULLETIN

Nominal

Letter

A

Sink

1391

A

Third

Position

Output

Voltage

Description

230V

Three-Phase

CONTROLLER

Position

Current

Code

AC,

15

22

45

1

30

22.5A

45A

45A

90A

45

Fourth

Rating

Description

RMS

5A

Peak

A

RMS

Peak

RMS

Peak

Cont./

Cont./

Cont./

XXX

Fifth

Position

Options

(if

required)

Description

three

character

A

alphanumeric

assigned

modifications.

Contact

Allen-Bradley

Representative

further

Code

A07

A08

your

information.

Description

24V

Contactor

240V

Contactor

to

DC

field

special

local

Sales

for

Coil

AC

Coil

ACCESSORIES

1388

First

Position

Bulletin

Number

-

X

Second

Position

Accessory

Module

MODULES

A

Third

Position

Accessory

Letter

A

B

C

Description

Anti-Backlash

Accel/Decel

Velocity

Reference

Module

Board

w/Mounting

w/Mounting

w/Mounting

Board

Assem.

Rack

Rack

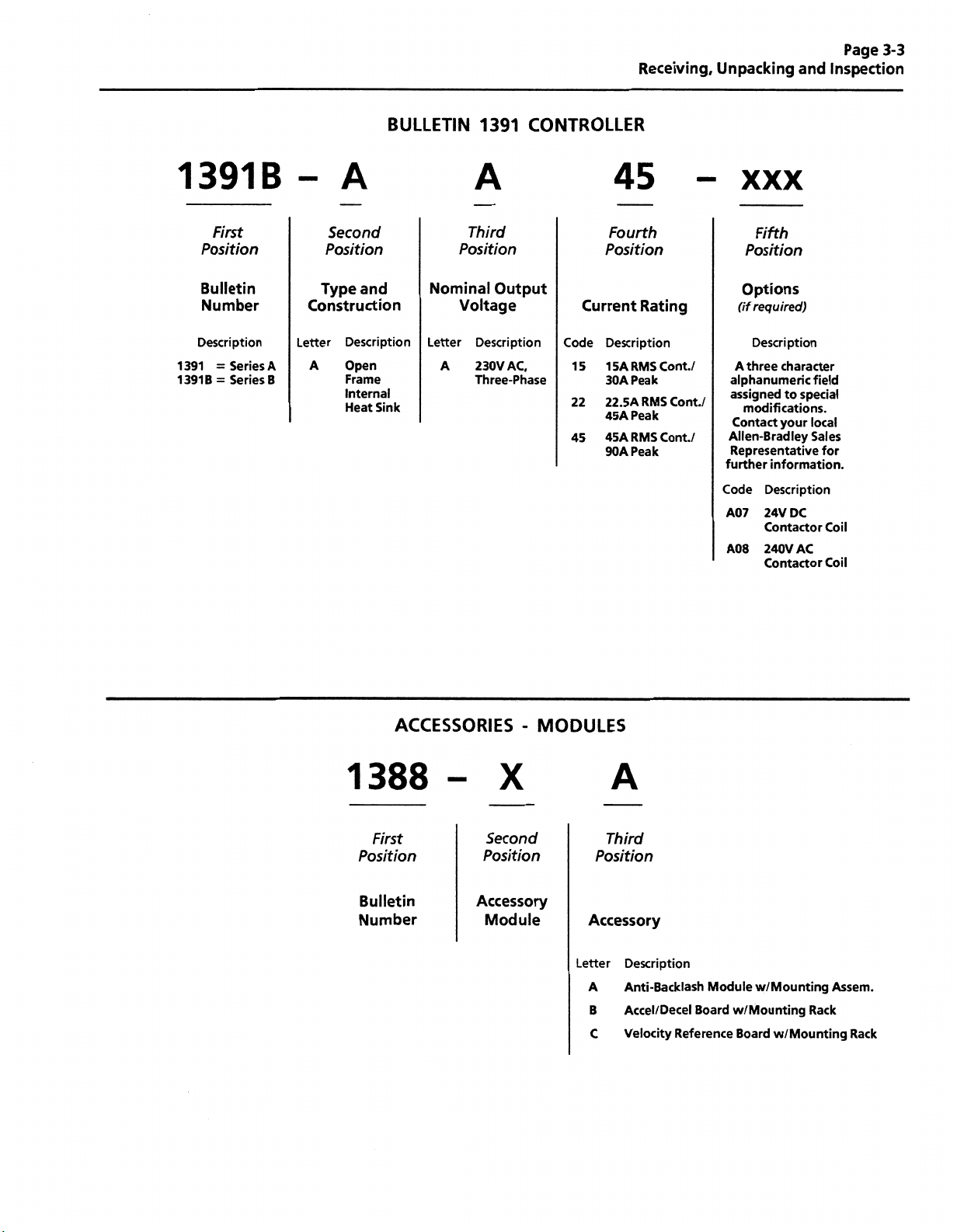

Page 16

Page

3-4

Receiving,

Unpacking

and

Inspection

AC

SERVOMOTOR

1326

First

Position

Bulletin

No.

Code

B

D

Second

Position

Code

A

A

Type

Type

AC

Servo¬

motor

Type

PM

Description

General

Ceramic

High

Performance

Inertia

Low

Purpose

Magnet

B

Third

Position

Design

See

Below

A

Fourth

Position

Series

Sequentially

lettered

designate

frame

diameters.

Code

A

(108mm)

B

(149mm)

C

(194mm)

to

Dia.

4.25"

5.88"

7.63"

3

Fifth

Position

Motor

Length

Sequentially

numbered

to

indicate

length

stack

within

a

frame

given

size.

E

Sixth

Position

Maximum

Operating

Speed

Code

B

C

E

G

Code

A4

A5

A7

K4

K5

K7

72

120

360

72

120

360

RPM

1600

2000

3000

5000

in.-lb.

in.-lb.

in.-lb.

in.-lb.

in.-lb.

in.-lb.

Mounting

Code

11

21

(8.1

N-m),

(13.6

(40.7

(8.1

N-m).

(1

3.6

(40.7

11

Seventh

Position

Description

Description

Inch

Combination

Face/flange

way

Key

NEMA/IEC

Flange

Description

DC

90V

N-m),

90V

N-m),

90V

DC

24V

N-m),

24V

N-m),

24V

&

with

Brake

DC

DC

Brake

DC

DC

Shaft

with

Metric

Keyway

Brake

Brake

Brake

Brake

1

326AB-A

1326AB-B

1

326AB-C

1

326AB-A

1

326AB-B

1

326AB-C

A4

Eighth

Position

Standard

Options

See

Table

Below

Series

Series

Series

Series

Series

Series

1326AB

First

Position

Bulletin

No.

MOD

-

Second

Position

Type

Code

MOD

Description

Modifica¬

tion

Kit

SHAFT

SS

Third

Position

Shaft

Seal

OIL

SEAL

Letter

V

KIT

V

Fourth

Position

Material

Type

Viton

Letter

A

B

C

A

Fifth

Position

Motor

Series

For

1

-A

Series

-B

Series

Series

-C

326AB

Mounting

Number

1

2

1

Sixth

Position

Motor

Description

Std.

Metric

Inch

Page 17

Receiving,

Unpacking

and

Page

3-5

Inspection

1

326AB

Bulletin

BRAKE

1326

Bulletin

Number

No.

BLOWER

MOD-

Code

MOD

POWER

MOD

MOD

Type

Description

Modifica¬

tion

Kit

SUPPLY

Type

KIT

G3

Description

Code

Motor

Rear

G3

for

G4

side

for

RECTIFIER

-

BPS

Description

Mount

C

Series

Mount

"C"

Series

Series

Blower

Motors

Blower

Motors

Standard

Motor

H

Motor

Junction

with

Box

Kit

r\

1326AB

Bulletin

Alternate

(Customer

Position

Selected)

IMPORTANT:

mounted

axially

out

MOTOR

No.

The

radially

motor

to

to

the

motor

Code

MOD

JUNCTION

MOD

-

Type

Code

MOD

standard

comes

the

motor.

without

This

further

Description

Modifica¬

tion

Kit

BOX

Description

Modifica¬

*

tion

Kit

with

allows

kit

wiring.

Code

BPS

KIT*

RJAB

-

Description

Code

RJAB

RJBC

IP65

plug

the

connectors

Description

Single-Phase,

Rectifier.

Supplies

brakesonBulletin

Description

All

For

AB-B

Series

For

AB-B4

AB-Cx

style

Full-Wave,

5V

11

power

AB-Aand

Motors

and

Series

Motors

connectors

brought

to

be

AC

for

Input,

up

1

326AB

to

Panel

90V

four

or

Mounted

Output

DC

90V

AD

motors.

DC

*

Kit

includes

Motor

Junction

Box

and

Mounting

Hardware

Page 18

Page

3-6

Receiving,

Unpacking

and

Inspection

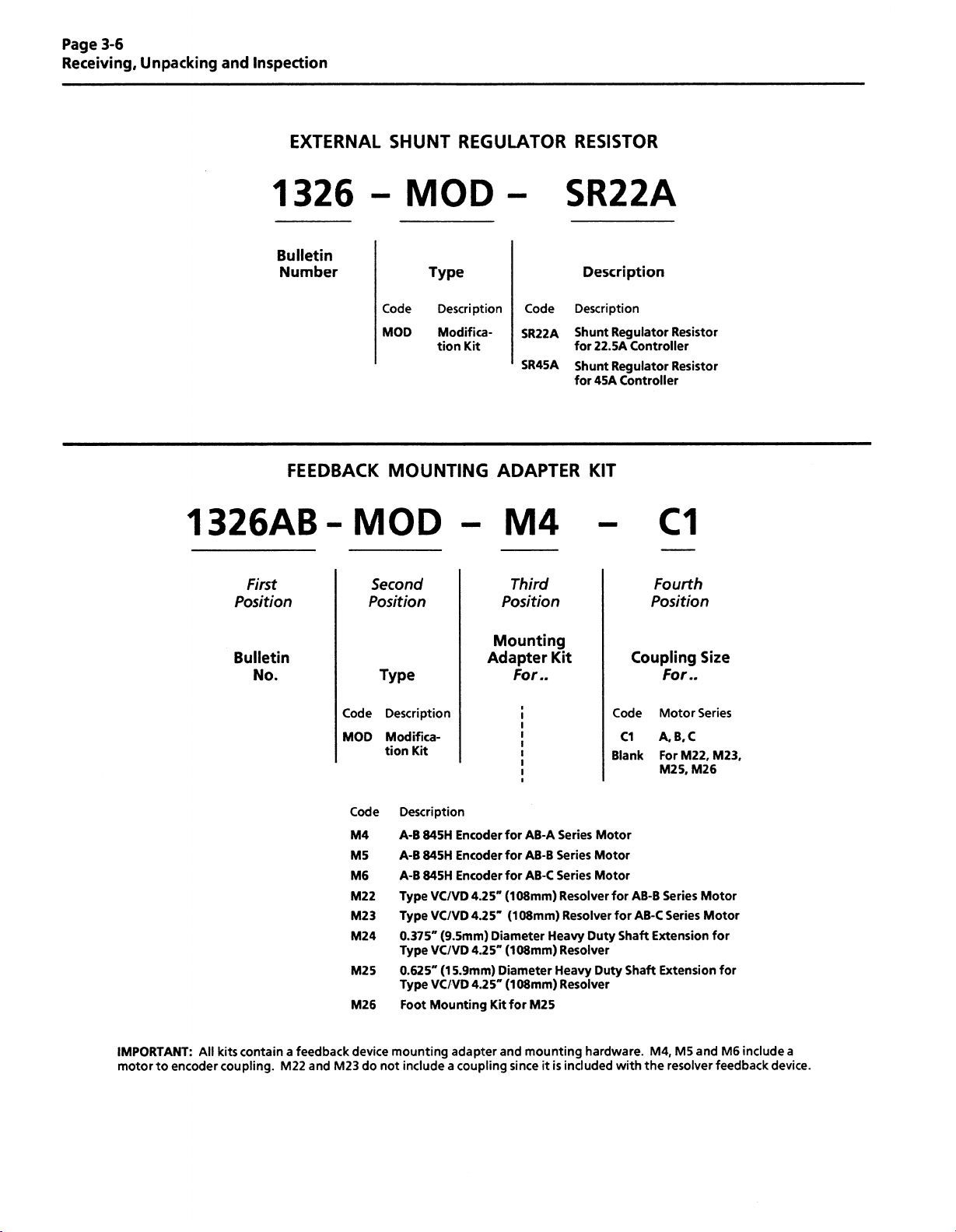

EXTERNAL

1326

Bulletin

Number

FEEDBACK

1326AB

First

Position

MOD

-

Second

Position

SHUNT

REGULATOR

MOD

Type

Code

MOD

MOUNTING

Description

Modifica¬

Kit

tion

RESISTOR

-

SR22A

Code

SR22A

SR45A

Description

Shunt

for

Shunt

for

ADAPTER

M4

Third

Position

Description

Regulator

Controller

22.5A

Regulator

Controller

45A

KIT

Resistor

Resistor

C1

Fourth

Position

IMPORTANT:

motor

encoder

to

All

Bulletin

No.

kits

contain

coupling.

a

feedback

M22

and

Code

MOD

M23

Code

M4

M5

M6

M22

M23

M24

M25

M26

device

do

Type

Description

Modifica¬

tion

Kit

Description

845H

A-B

845H

A-B

A-B

845H

Type

Type

0.375"

Type

0.625"

Type

Foot

mounting

not

include

Encoder

Encoder

Encoder

VC/VD

VC/VD

(9.5mm)

VC/VD

(1

5.9mm)

VC/VD

Mounting

adapter

coupling

a

Mounting

Adapter

for

4.25"

4.25'

Diameter

4.25"

Diameter

4.25"

Kit

and

For..

AB-A

for

AB-B

AB-C

for

(108mm)

(108mm)

(108mm)

(108mm)

for

M25

mounting

since

it

Kit

Series

Series

Series

Resolver

Resolver

Heavy

Resolver

Heavy

Resolver

is

included

Code

C1

Blank

Motor

Motor

Motor

for

for

Duty

Shaft

Duty

Shaft

hardware.

with

Coupling

For..

Motor

A,

B.C

M22, M23,

For

5,

M2

Series

AB-B

Series

AB-C

Extension

Extension

M4,

M5

resolver

the

Size

Series

M26

Motor

Motor

and

for

for

M6

include

feedback

a

device.

Page 19

Receiving,

Unpacking

and

Page

3-7

Inspection

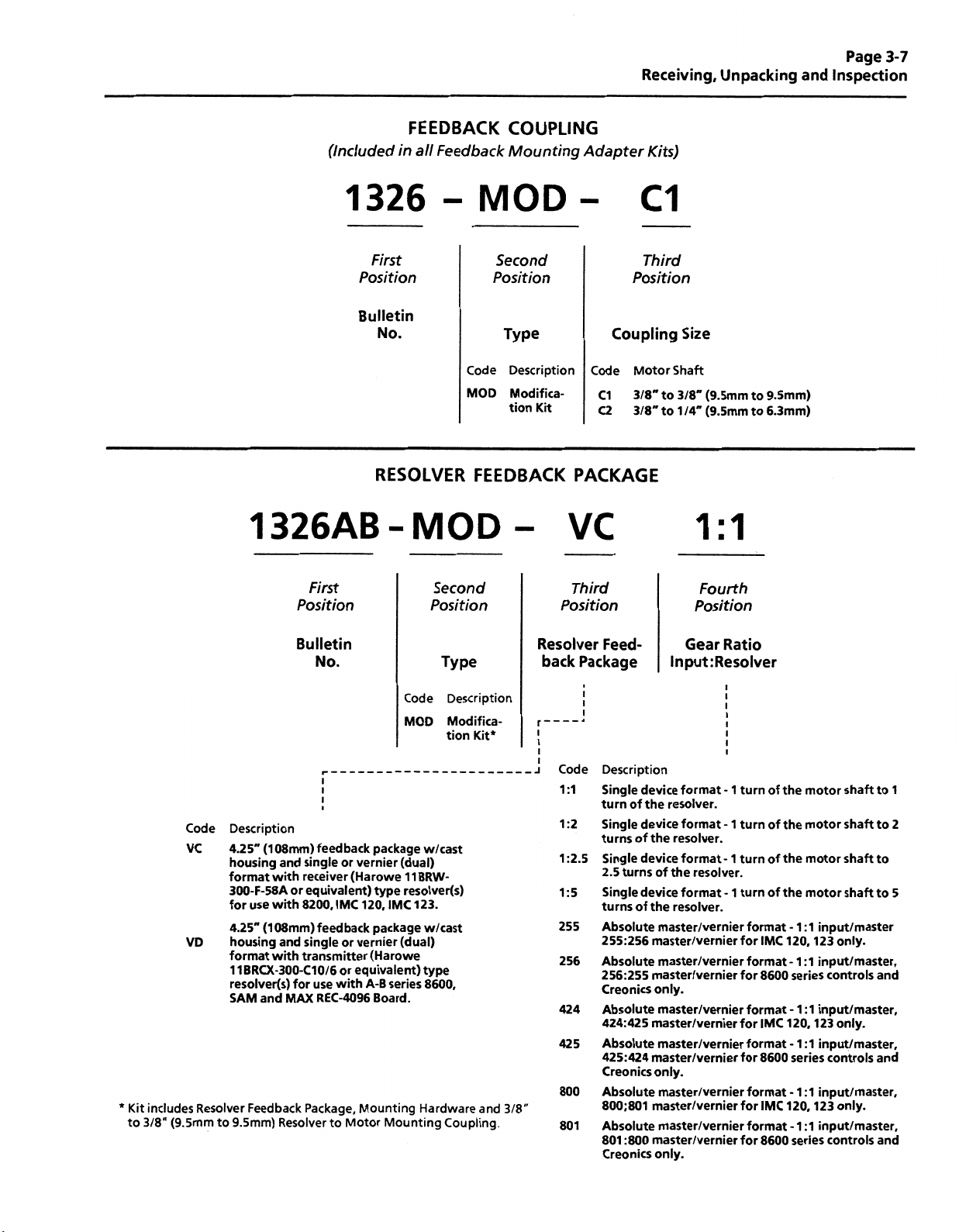

(Included

1326

First

Position

Bulletin

1326AB

FEEDBACK

in

Feedback

all

-

No.

RESOLVER

MOD

-

COUPLING

Mounting

MOD

Second

Position

Type

Description

Code

MOD

Modifica¬

tion

Kit

FEEDBACK

Adapter

C1

Position

Coupling

Motor

Code

C1

3/8"to3/8"

C2

3/8"

PACKAGE

VC

Kits)

Third

to

Size

Shaft

(9.5mmto9.5mm)

(9.5mmto6.3mm)

1/4"

1:1

*

Kit

includes

(9.5mmto9.5mm)

3/8"

to

Code

VC

VD

Resolver

First

Position

Bulletin

Description

(108mm)

4.25"

housing

format

300-F-58A

use

for

4.25"

housing

format

1BRCX-300-C10/6

1

resolver(s)

SAM

Feedback

(1

and

with

with

08mm)

with

single

and

receiver

equivalent)

or

8200,

single

and

transmitter

for

MAX

Package,

Resolver

No.

i

i

i

feedback

or

vernier

(Harowe

IMC

feedback

or

vernier

equivalent)

or

use

with

REC-4096

Mounting

Motor

to

package

type

120,

package

(Harowe

A-B

Board.

Code

MOD

w/cast

(dual)

11BRW-

resolver(s)

IMC

123.

w/cast

(dual)

type

8600,

series

Hardware

Mounting

Second

Position

Type

Description

Modifica¬

tion

Kit*

Coupling

and

3/8"

Third

Position

Resolver

Package

back

r~~

i

i

i

i

J

Code

1:1

:2

1

1

:2.5

:

1

5

255

256

424

5

42

800

801

Feed¬

i

i

i

Description

Single

turn

Single

turns

Single

2.5

Single

turns

Absolute

255:256

Absolute

256:255

Creonics

Absolute

424:425

Absolute

425:424

Creonics

Absolute

800:801

Absolute

801

Creonics

device

of

the

device

of

the

device

turns

of

device

the

of

master/vernier

master/vernier

master/vernier

master/vernier

only.

master/vernier

master/vernier

master/vernier

master/vernier

only.

master/vernier

master/vernier

master/vernier

:800

master/vernier

only.

Fourth

Position

Gear

Ratio

lnput:Resolver

format

resolver.

format

resolver.

format

resolver.

the

format

resolver.

-

-

-

-

1

1

1

1

turn

turn

turn

turn

format

for

format

for

format

for

format

for

format

for

format

for

of

of

of

of

IMC

8600

IMC

8600

IMC

8600

the

the

the

the

-1:1

120,

-1:1

series

-1:1

120.

-

series

-1:1

120.

-1:1

series

motor

motor

motor

motor

1:1

shaft

shaft

shaft

shaft

input/master

only.

123

input/master,

controls

input/master.

only.

123

input/master,

controls

input/master,

only.

123

input/master,

controls

to

to

to

to

and

and

and

1

2

5

Page 20

Page

3-8

Receiving,

Unpacking

and

Inspection

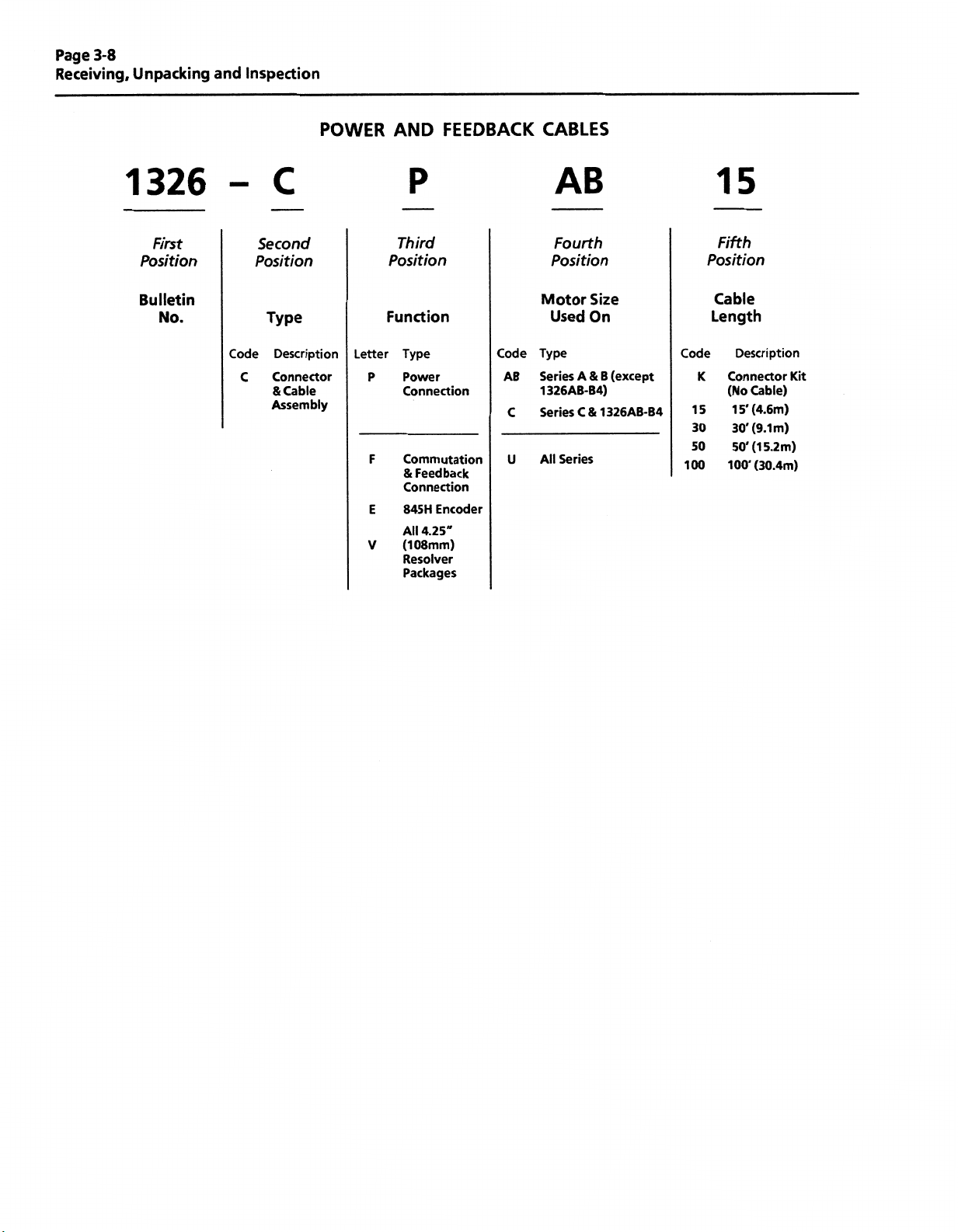

1326

First

Position

Bulletin

No.

Code

C

C

Second

Position

Type

Description

Connector

Cable

&

Assembly

POWER

Letter

P

F

E

V

AND

P

Third

Position

Function

Type

Power

Connection

Commutation

&

Feedback

Connection

845

H

Encoder

4.25"

All

(108mm)

Resolver

Packages

FEEDBACK

Code

AB

C

U

CABLES

AB

Fourth

Position

Motor

Type

Series

1326AB-B4)

Series

All

Size

Used

On

&

A

C&1326AB-B4

Series

B

(except

Code

15

30

50

100

15

Fifth

Position

Cable

Length

K

Connector

(No

100'

Description

Cable)

(4.6m)

15'

(9.1m)

30'

(15.2m)

50’

(30.4m)

Kit

Page 21

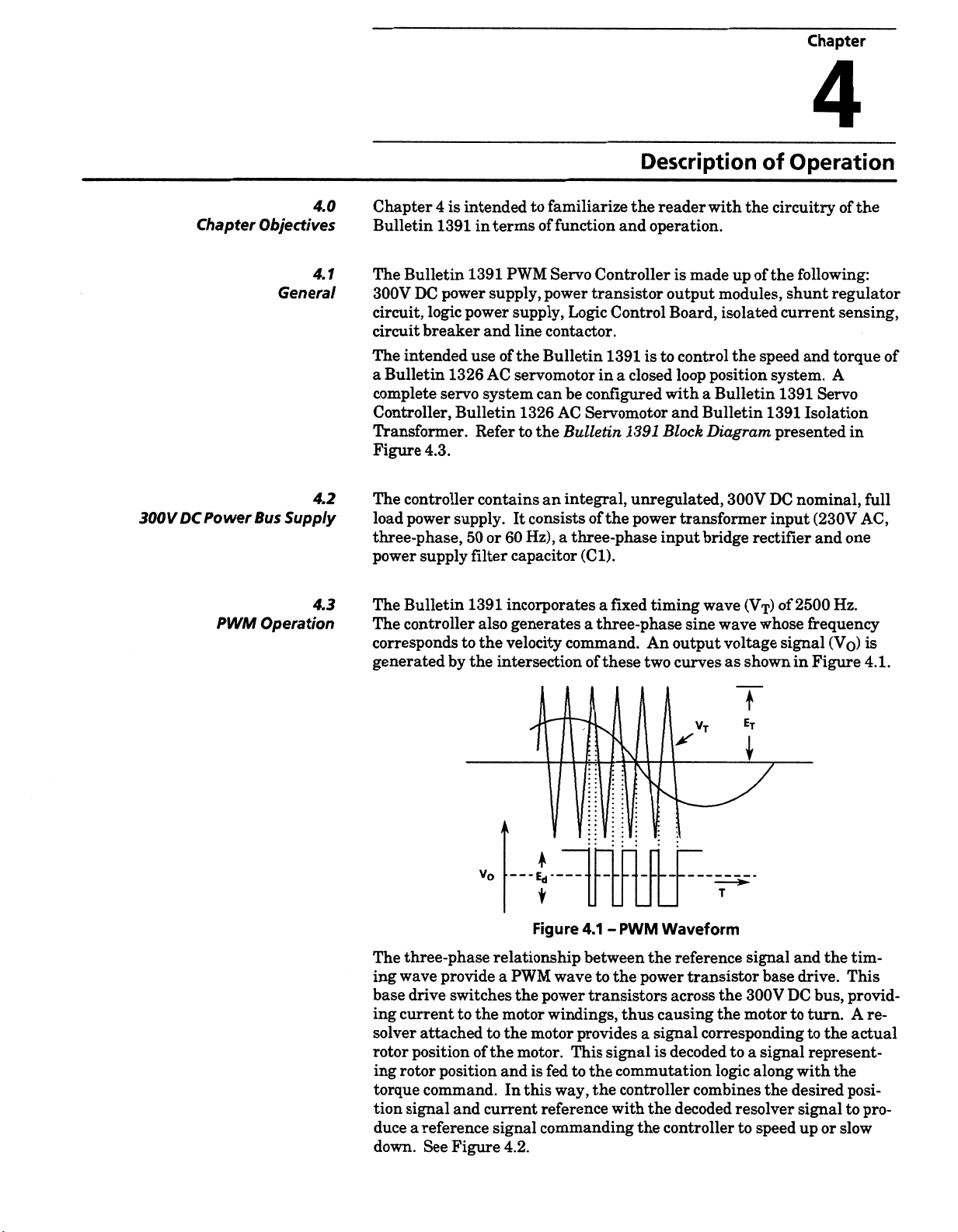

Chapter

4

300V

Chapter

DC

Power

PWM

4.0

Objectives

4.1

General

4.2

Supply

Bus

4.3

Operation

Chapter

Bulletin

The

300V

circuit,

circuit

The

Bulletin

a

complete

Controller,

4

is

1391

Bulletin

power

DC

logic

breaker

intended

1326

servo

Transformer.

Figure

The

load

three-phase,

power

The

The

corresponds

generated

4.3.

controller

power

supply.

supply

Bulletin

controller

by

intended

in

terms

1391

supply,

power

and

use

of

AC

system

Bulletin

Refer

contains

or

50

filter

1391

also

to

the

the

intersection

to

familiarize

of

function

Servo

PWM

power

supply,

line

the

Logic

contactor.

Bulletin

servomotor

can

be

AC

1326

to

the

Bulletin

integral,

an

consists

It

Hz),

three-phase

60

capacitor

incorporates

a

generates

velocity

command.

Description

the

and

Controller

transistor

Control

1391

is

closed

a

in

configured

Servomotor

1391

unregulated,

power

the

of

(Cl).

fixed

a

three-phase

a

An

two

these

of

reader

operation.

made

is

output

Board,

to

control

loop

with

a

and

Bulletin

Block

transformer

input

timing

wave

sine

output

curves

with

the

up

modules,

isolated

the

position

Bulletin

Diagram,

300V

bridge

(Vj)

wave

voltage

shown

as

Operation

of

circuitry

following:

the

of

shunt

current

speed

system.

1391

1391

presented

nominal,

DC

input

rectifier

of

2500

whose

signal

in

of

regulator

sensing,

torque

and

A

Servo

Isolation

in

(230V

and

one

Hz.

frequency

(Vo)

Figure

the

of

full

AC,

is

4.1.

three-phase

The

ing

wave

base

drive

ing

current

solver

rotor

position

ing

rotor

torque

signal

tion

duce

a

down.

V0

relationship

provide

switches

to

attached

position

command.Inthis

and

reference

Figure

See

a

the

to

the

of

and

current

signal

PWM

the

motor

the

motor.

4.2.

Figure

motor

4.1

between

wave

power

transistors

windings,

provides

to

This

to

fed

way,

the

the

is

reference

commanding

*

PWM

-

the

signal

with

Waveform

the

power

across

causing

thus

signal

a

decoded

is

commutation

controller

the

controller

the

VT

reference

transistor

the

the

corresponding

to

logic

combines

decoded

f

\

signal

base

300V

motor

signal

a

along

the

resolver

speed

to

the

and

drive.

bus,

DC

to

turn.

to

the

represent¬

with

desired

signal

up

or

tim¬

This

provid¬

A

actual

the

posi¬

to

slow

re¬

pro¬

Page 22

Page

4-2

DescriptionofOperation

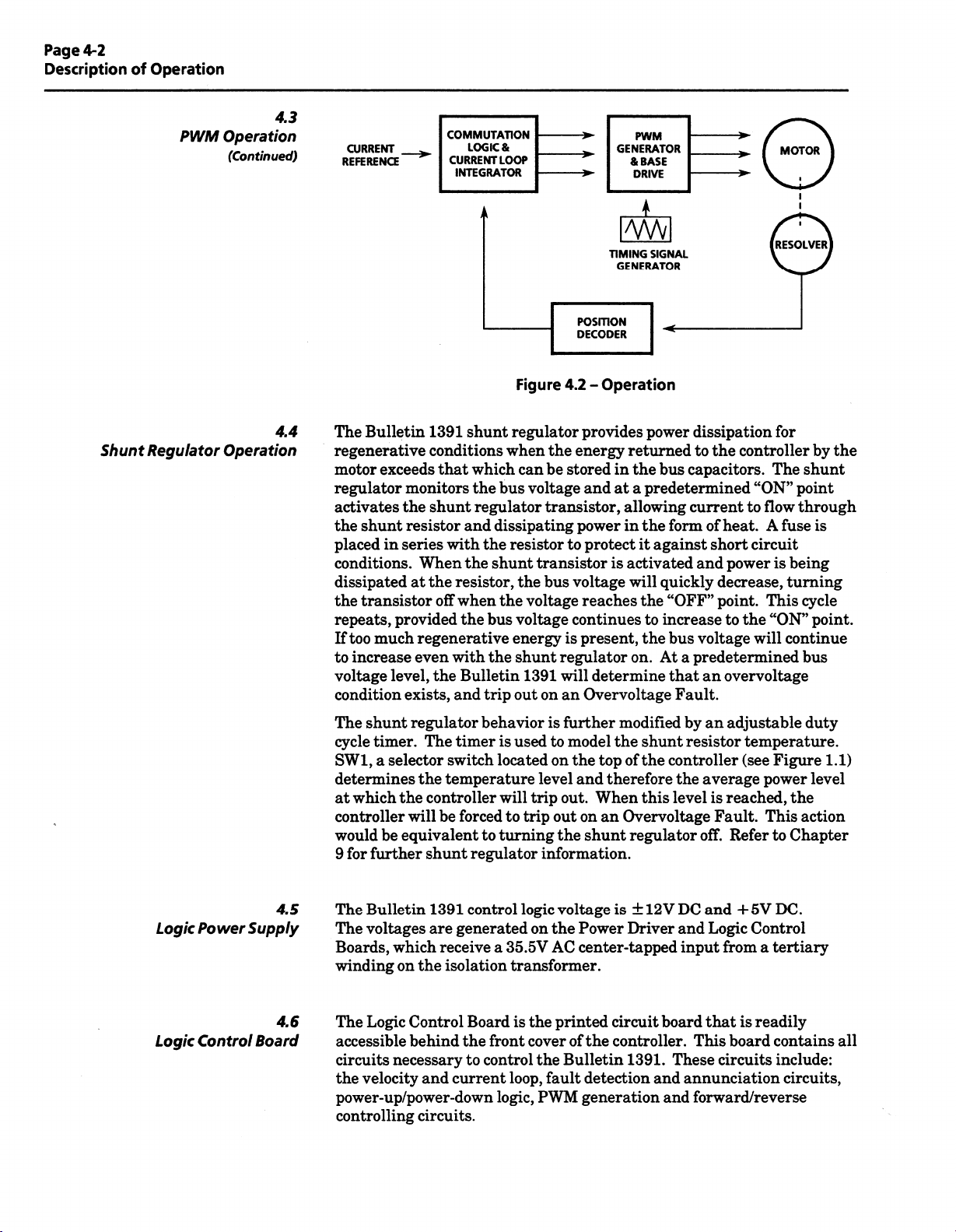

PWM

4.3

Operation

(Continued)

CURRENT

REFERENCE

COMMUTATION

LOGIC

CURRENT

&

LOOP

INTEGRATOR

Figure

POSITION

DECODER

4.2

-

PWM

GENERATOR

&BASE

DRIVE

IAM1

TIMING

SIGNAL

GENERATOR

Operation

Shunt

Regulator

4.4

Operation

The

Bulletin

regenerative

exceeds

motor

regulator

activates

the

placed

conditions.

dissipated

the

repeats,

too

If

increase

to

voltage

the

shunt

in

series

transistor

provided

much

level,

condition

The

shunt

cycle

timer.

SW1,

determines

at

a

which

selector

the

controller

would

for

9

equivalent

be

further

1391

shunt

conditions

which

that

monitors

resistor

When

at

shunt

with

the

off

the

regulator

and

the

the

resistor,

when

the

regenerative

even

with

the

Bulletin

exists,

and

regulator

The

timer

switch

temperature

the

behavior

controller

willbeforced

to

regulator

shunt

regulator

when

the

can

be

voltage

bus

transistor,

dissipating

resistor

shunt

transistor

the

bus

voltage

the

voltage

bus

energy

the

shunt

1391

trip

out

on

is

usedtomodel

is

locatedonthe

level

trip

will

trip

to

turning

out

information.

provides

energy

storedinthe

and

power

protect

to

voltage

reaches

continuestoincrease

present,

is

regulator

will

determine

Overvoltage

an

further

and

When

out.

on

the

shunt

power

returned

predetermined

at

a

allowing

in

the

it

activated

is

will

the

the

on.

modified

the

shunt

top

the

of

therefore

this

Overvoltage

an

regulator

bus

form

against

quickly

“OFF”

bus

At

that

Fault.

controller

the

level

dissipation

to

the

controllerbythe

capacitors.

“ON”

current

and

voltage

predetermined

a

by

resistor

to

heat.

of

short

power

decrease,

point.

the

to

overvoltage

an

adjustable

an

temperature.

(see

average

reached,

is

circuit

will

Fault.

Refer

off.

for

The

flow

fuse

A

being

is

turning

This

“ON”

continue

Figure

power

the

This

Chapter

to

shunt

point

through

is

cycle

point.

bus

duty

1.1)

level

action

Logic

Logic

wer

Po

Control

upply

5

Board

4.S

4.6

control

The

Bulletin

voltages

The

Boards,

winding

Logic

The

accessible

circuits

velocity

the

power-up/power-down

controlling

1391

are

which

receive

the

on

isolation

Control

behind

necessary

and

circuits.

generated

Board

the

to

current

logic

35.5V

a

transformer.

the

is

front

cover

control

loop,

logic,

on

the

AC

the

fault

PWM

voltage

is

Power

center-tapped

printed

of

the

circuit

controller.

Bulletin

detection

generation

12V

±

Driver

1391.

and

DC

and

Logic

and

input

from

that

board

This

These

and

circuits

annunciation

forward/reverse

5V

+

Control

readily

is

board

DC.

tertiary

a

contains

include:

circuits,

all

Page 23

Description

Page

Operation

of

4-3

Circ

S£[—

Brea

Isolation

Transformer

MPT

Primary

A

Y

Secondary

Line

AC

Input

TBS-4

TB5-5

Contactor

Contactor

35.5V

AC.

115V

1

$.CT

Coil

AC

Velocity

Command

Rectifier

TTi

Control

Protecti

Circuitry

Logic

Control

D1

Her

ion

External

Current

Limit

Board

Power

Control

Tach

Output

JS

Shunt

Regulator

Driver

Logic

I

Command

Output

External

Regulator

Transistor

Base

Board

Adjustments

Offset

0

I

0

Limit

Gain

0

Comr

0

Scale

Shunt

Resistor

mand

Enable

Drive

IBS.

Power

Logic

LED's

Overtemp

Power

Fault

Control

Power

Overvoltage

Undervoltage

Current

Foldback

Enable

Ready

Reset

Supply

Contact

Transistor

StS

DROK

Power

Protect

through

TB1-10

Output

Fault

Sion

lated

Iso

Cu

rrent

Sense

Board

Modules

Bulletin

1326

Permanent

MagnetAC

Servomotor

O

Brushless

Resolver

Controller/System

Fault

and

4.7

Monitor

Detection

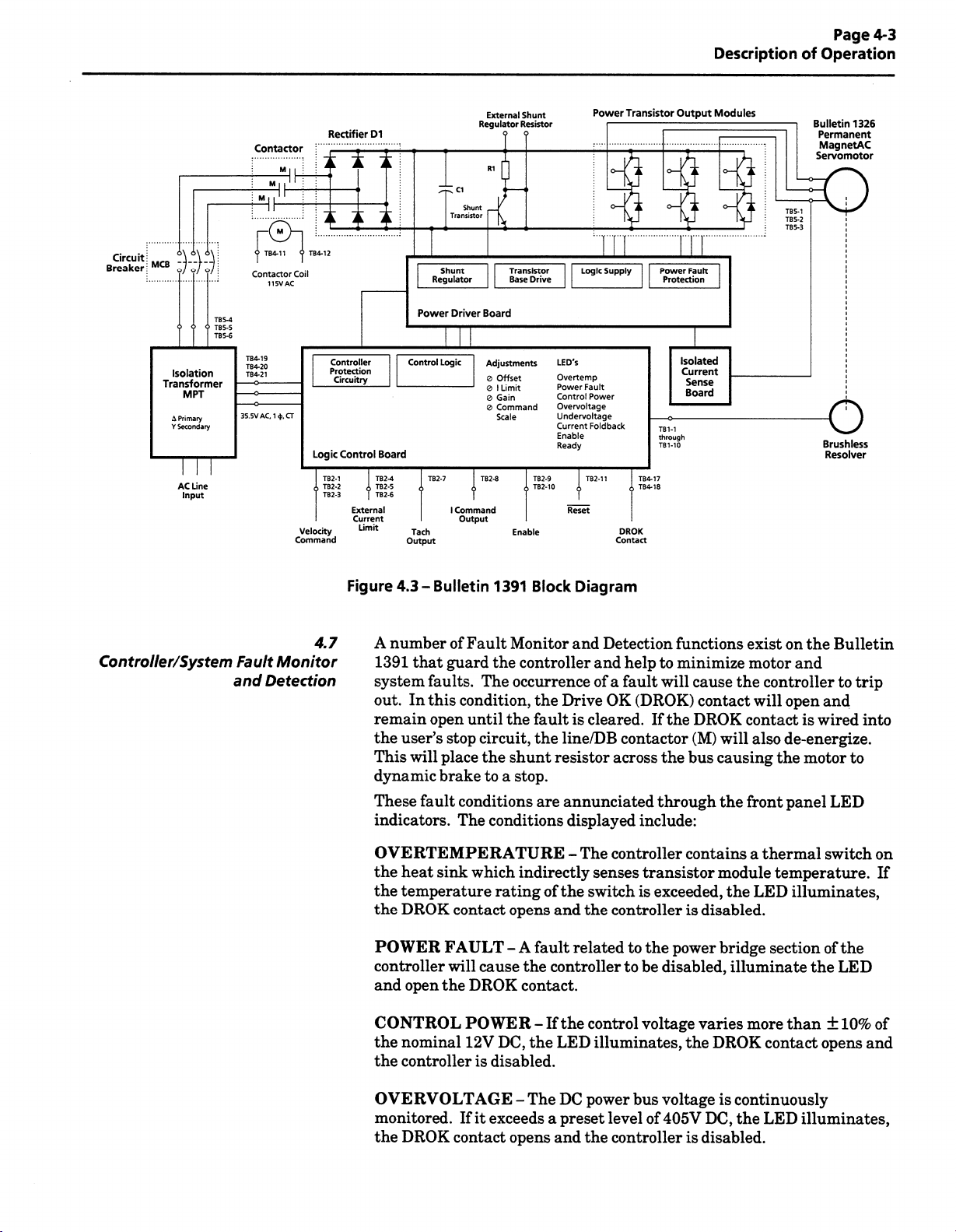

Figure

4.3-

A

number

1391

that

system

out.

remain

the

This

faults.

In

this

open

user’s

will

dynamic

These

fault

indicators.

Bulletin

of

Fault

guard

condition,

until

stop

circuit,

place

brake

conditions

The

1391

the

The

the

to

conditions

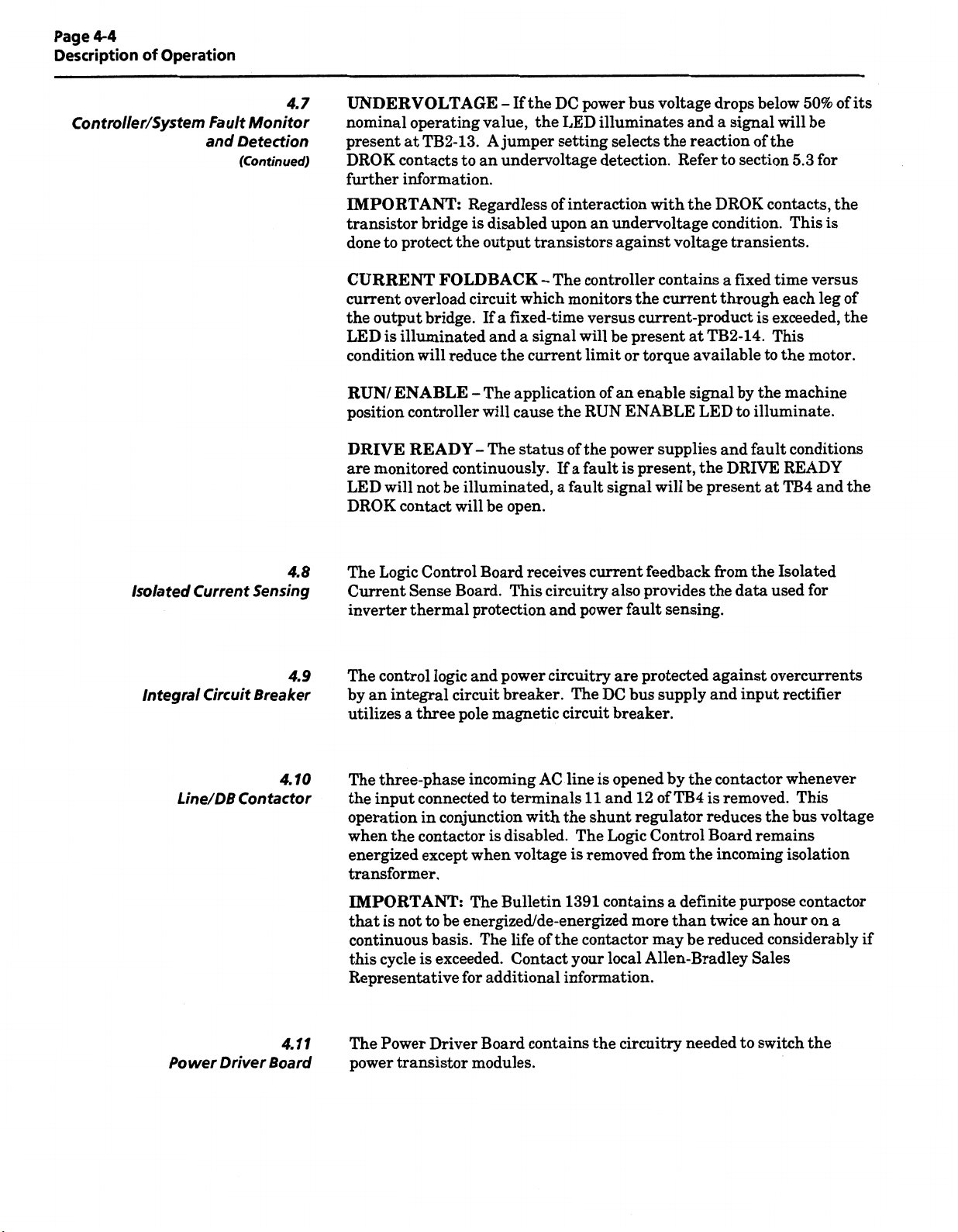

OVERTEMPERATURE

the

heat

sink

which

temperature

the

DROK

the

POWER

FAULT

controller

open

and

the

CONTROL

the

nominal

the

controllerisdisabled.

contact

will

cause

DROK

POWER

12V

rating

Block

Monitor

controller

occurrence

the

Drive

the

faultiscleared.

the

line/DB

shunt

resistor

stop.

a

are

annunciated

indirectly

of

the

opens

and

A

fault

-

the

controllertobe

contact.

If

the

-

DC,

the

LED

Diagram

and

Detection

help

fault

(DROK)

to

will

and

of

OK

a

If

contactor

across

the

through

displayed

The

-

switch

the

related

control

include:

controller

senses

transistor

exceeded,

is

controllerisdisabled.

to

the

voltage

illuminates,

functions

minimize

cause

contact

DROK

the

(M)

bus

contains

power

disabled,

varies

DROK

the

exist

motor

the

controller

will

contact

will

also

causing

the

front

a

thermal

module

the

LED

bridge

illuminate

more

contact

the

on

Bulletin

and

to

open

and

wired

is

de-energize.

the

motor

panel

LED

switch

temperature.

illuminates,

than

the

of

±

the

LED

10%

section

opens

trip

into

to

on

If

of

and

OVERV

OLTAGE

monitored.

DROK

the

If

exceeds

it

contact

The

-

opens

DC

preset

a

and

power

level

the

controllerisdisabled.

bus

voltage

405V

of

continuously

is

DC,

the

LED

illuminates,

Page 24

Page

4-4

Description

Operation

of

Controller/System

Fault

and

4.7

Monitor

Detection

(Continued)

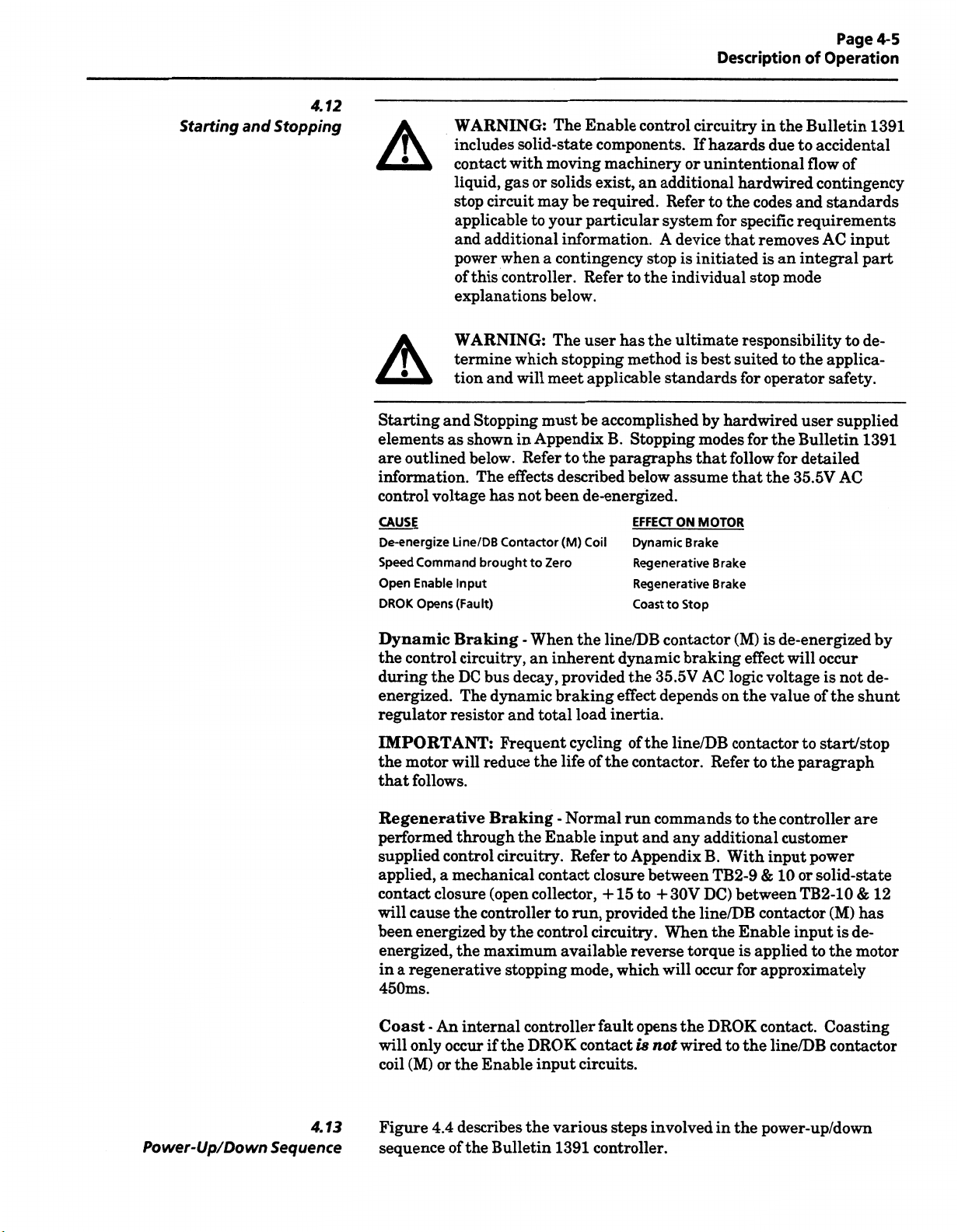

UNDER

nominal

present

DROK

further

VOLTAGE

operating

TB2-13.

at

contacts

information.

IMPORTANT:

transistor

done

CURRENT

current

output

the

LED

condition

RUN/

position

DRIVE

monitored

are

LED

DROK

bridge

protect

to

overload

bridge.

illuminated

is

will

ENABLE

controller

READY

not

will

contact

FOLDBACK

If

-

value,

jumper

A

undervoltage

to

an

Regardless

disabled

is

output

the

circuit

fixed-time

a

If

and

reduce

continuously.

be

the

application

The

-

cause

will

The

-

illuminated,

be

open.

will

the

DC

the

setting

of

upon

transistors

The

-

which

signal

a

current

the

status

If

a

power

LED

illuminates

selects

detection.

interaction

undervoltage

an

against

controller

monitors

versus

will

be

limit

of

an

RUN

power

the

of

fault

a

signal

fault

voltage

bus

and

the

reaction

Refer

with

the

voltage

contains

current

the

current-product

present

or

enable

ENABLE

present,

is

torque

supplies

will

at

availabletothe

signal

LED

the

be

drops

below

signal

a

of

to

section

DROK

condition.

transients.

fixed

a

through

is

TB2-14.

by

the

to

illuminate.

and

fault

DRIVE

present

50%

will

be

the

5.3

contacts,

This

time

each

exceeded,

This

motor.

machine

conditions

READY

TB4

at

of

for

the

is

versus

leg

and

its

of

the

the

Isolated

Integral

Current

Circuit

Line/DB

4.8

Sensing

4.9

Breaker

4.10

Contactor

Logic

The

Current

inverter

The

by

an

utilizes

The

the

operation

when

energized

Control

Sense

thermal

integral

three

a

connected

in

contactor

the

except

logic

control

three-phase

input

conjunction

transformer.

IMPORTANT:

not

is

that

continuous

cycle

this

Representative

be

to

basis.

exceeded.

is

receives

Board

Board.

circuit

pole

This

protection

power

and

breaker.

magnetic

incoming

to

terminals