Page 1

1305 Adjustable

Frequency AC Drive

(Series C)

0.37 - 4 kW (0.5 - 5 HP)

FRN 6.01 and Up

User

Manual

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Page 2

PLEASE READ!

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

IMPORTANT USER INFORMATION

This manual is intended to guide qualified personnel in the

installation and operation of this product.

Because of the variety of uses for this equipment and because of

the differences between this solid-state equipment and

electromechanical equipment, the user of and those responsible

for applying this equipment must satisfy themselves as to the

acceptability of each application and use of the equipment. In no

event will Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or

application of this equipment.

The illustrations shown in this manual are intended solely to

illustrate the text of this manual. Because of the many variables

and requirements associated with any particular installation, the

Allen-Bradley Company cannot assume responsibility or liability

for actual use based upon the illustrative uses and applications.

No patent liability is assumed by Allen-Bradley Company with

respect to use of information, circuits or equipment described in

this text.

Reproduction of the content of this manual, in whole or in part,

without written permission of the Allen-Bradley Company is

prohibited.

The information in this manual is organized in numbered

chapters. Read each chapter in sequence and perform procedures

when you are instructed to do so. Do not proceed to the next

chapter until you have completed all procedures.

Throughout this manual we use notes to make you aware of

safety considerations:

ATTENTION: Identifies information about

practices or circumstances that can lead to personal

!

injury or death, property damage or economic loss.

Attentions help you:

D identify a hazard

D avoid the hazard

D recognize the consequences

Important: Identifies information that is especially important

for successful application and understanding of the product.

Page 3

Summary of Changes

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

BULLETIN 1305 PERFORMANCE ENHANCEMENTS

New features in Firmware Revision 6.01 include:

D Increased Low Speed Torque.

The parameter [IR Comp %] was added, allowing

adjustment of the amount of IR compensation desired. This

is used to compensate for stator resistance and allows much

higher levels of starting torque. The default levels of [Start

Boost] and operation of the [Compensation] parameter

have changed. The default setting for [Compensation] is

now “Comp” and functions from 1.1 to 120 Hertz.

D Improved Acceleration.

The acceleration current ramp regulator has been retuned

and the current feedback filter time constant was reduced,

allowing improved performance with short acceleration

times under all load conditions. The drive power-up

diagnostics were also shortened considerably, which

improves response time to a START signal. The parameter

[Adaptive I Lim] was also added for very quick

accelerations with low system inertias.

D Robust Current Limit.

A fast frequency foldback was added to operate with the

lower hardware current limit. This allows the drive to

continue operating under adverse conditions.

D Improved Speed Regulation.

The parameter [Rated Slip] was added, which compensates

for inherent slip in an induction motor. This assists in

maintaining an induction motor shaft frequency under

heavy loading conditions. The actual frequency value added

may be viewed in [Slip Comp Adder].

D Reduced Voltage Ring-up.

Voltage Ring-up Reduction Software is enabled when

[Cable Length] = “Long”. This software attempts to limit

voltage ring-up.

D Improved Drive Functionality.

The [Analog Filter] parameter was added. This allows

selection of the amount of software filtering applied to the

0-10 Volt and Potentiometer inputs in 25% increments. The

lower the percentage, the less filtering applied.

The Stop Mode “DC Brake” has been greatly improved by

incorporating a current limit function into this stopping

mode.

The parameter [DC Hold Time] is now settable up to 150

seconds in 0.1 second increments and [Maximum Voltage]

is now settable to 110% of the drive rating. Several

additional parameters now have new factory default values.

Page 4

Summary of Changes

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

SUMMARY OF DRIVE ENHANCEMENTS

Refer to the following references in this manual:

Firmware Compatibility Chart 1-4

New Adaptive Current Limit Parameter 5-14

DC Hold Time Improvements 5-22

Compensation Improvements 5-24

New Preset Speed Defaults 5-27

New Analog Filter Parameter 5-31

Slip Compensation 5-35 & 5-36

IR Compensation 5-36

Updated Drive Specifications A-2 through A-6

Updated Drive Accessories C-1 & C-2

Page 5

Notes

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Page 6

Notes

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Page 7

Table of Contents

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Chapter 1 – Information and Precautions

Chapter Objectives 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Objectives 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving, Unpacking, Inspection, Storing 1-2. . . . . . . . . . . . . . . .

General Precautions 1-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions Used In This Manual 1-3. . . . . . . . . . . . . . . . . . . . . .

Nameplate Location 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Firmware Compatibility 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Catalog Number Code Explanation 1-5. . . . . . . . . . . . . . . . . . . . . .

Chapter 2 – Installation/Wiring

Chapter Objectives 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Block Access 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Devices 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Power Conditioning 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Fusing 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Interference – EMI/RFI 2-7. . . . . . . . . . . . . . . . . . . . . . .

RFI Filtering 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CE Conformity 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Wiring 2-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drive Operation without a Human Interface Module (HIM) 2-17. . . . .

Control Wiring 2-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Devices 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cable Termination 2-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adapters 2-23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 – Human Interface Module

Chapter Objectives 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIM Description 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIM Operation 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HIM Removal and Installation 3-4. . . . . . . . . . . . . . . . . . . . . . . . . .

HIM Modes 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program and Display Modes 3-7. . . . . . . . . . . . . . . . . . . . . . . . . .

Process Mode 3-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EEprom Mode 3-11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Search Mode 3-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control Status Mode 3-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Password Mode 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 – Start–Up

Chapter Objectives 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Start-up Procedure 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5 – Programming

Chapter Objectives 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Conventions 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Function Index 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parameter Flow Chart 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Example 5-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Metering 5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set Up 5-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Advanced Setup 5-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

ii

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Frequency Set 5-25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feature Select 5-32. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Configuration 5-37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Faults 5-39. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics 5-42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Masks 5-47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Owners 5-50. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adapter I/O 5-54. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Process Display 5-55. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linear List 5-56. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Chapter 6 – Toubleshooting and Fault Information

Chapter Objectives 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fault Information 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A – Block Diagram And Specifications

Appendix B – Serial Communications

Appendix C – Drive Accessories

Appendix D – CE Conformity

Page 9

Information and Precautions

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Chapter

1

CHAPTER OBJECTIVES

Chapter 1 provides information on the general intent of this

manual, gives an overall description of the Bulletin 1305

Adjustable Frequency AC Drive (herein called “the drive”) and

provides a listing of key drive options. Additionally, this

chapter provides information on receiving and handling the

drive.

MANUAL OBJECTIVES

The purpose of this manual is to provide the user with the

necessary information to install, program, start up and maintain

the Bulletin 1305 drive. To assure successful installation and

operation, the material presented must be thoroughly read and

understood before proceeding. Particular attention must be

directed to the ATTENTION and Important statements

contained within.

Chapter 2 provides instructions on how to mount and wire the

drive. It also describes how to operate the drive without a Human Interface Module. Read the Motor Cable Length section

on pages 2-13 – 2-16, and the contact closure inputs information in the Control Terminal Block descriptions on pages

2-19 – 2-21.

Chapter 3 defines the display and control panel keys on the

optional Human Interface Module. A flowchart is provided to

guide the user through the key strokes of the various menu

levels.

Chapter 4 describes the steps to start up the drive. It includes

a typical start up routine defining the adjustments and checks to

assure proper operation.

Chapter 5 outlines the parameter information of the drive such

as description, number, type, units, factory default, minimum

and maximum settings.

Chapter 6 defines the various drive faults and the appropriate

action to take as well as general troubleshooting information.

Appendix A contains a block diagram and general specifications of the drive.

Appendix B provides the necessary information for drive set up

using a PLC

provided that lists each parameter by parameter group with

space for the user to record any custom parameter settings.

Appendix C lists the accessories and their catalog number.

Appendix D lists requirements for CE conformity.

Index – A comprehensive index is provided to assist the user in

locating specific information. All parameters and fault information are listed alphabetically under parameters and faults

respectively.

PLC is a registered trademark of Allen-Bradley Company.

SLC is a trademark of Allen-Bradley Company.

R

, SLC or other logic controller. A table is

Page 10

1-2

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Information and Precautions

Receiving – It is the responsibility of the user to thoroughly

inspect the equipment before accepting the shipment from the

freight company. Check the item(s) received against the

purchase order. If any items are obviously damaged, it is the

responsibility of the user not to accept delivery until the freight

agent has noted the damage on the freight bill. Should any

concealed damage be found during unpacking, it is again the

responsibility of the user to notify the freight agent. The

shipping container must be left intact and the freight agent

should be requested to make a visual inspection of the

equipment.

Unpacking – Remove all packing material from within and

around the drive.

Important: Before the installation and start-up of the drive,

a general inspection of the mechanical integrity (i.e. loose

parts, wires, connections, etc.) should be made.

Inspection – After unpacking, check the item(s) nameplate

catalog number against the purchase order. An explanation of

the catalog numbering system for the Bulletin 1305 drive is

included as an aid for nameplate interpretation. Refer to the

following pages for complete nomenclature.

Storing – The drive should remain in its shipping container

prior to installation. If the equipment is not to be used for a

period of time, it must be stored according to the following

instructions in order to maintain warrranty coverage:

D Store in a clean, dry location.

D Store within an ambient temperature range of –40_ to

+70_C.

D Store within a relative humidity range of 0% to 95%,

noncondensing.

D Do not store equipment where it could be exposed to a

corrosive atmosphere.

D Do not store equipment in a construction area.

GENERAL PRECAUTIONS

In addition to the precautions listed throughout this manual, the

following statements which are general to the system must be

read and understood.

The DC Bus Charge Indicator is a neon bulb that will be

illuminated when power is applied to the drive.

Page 11

Information and Precautions

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

1-3

ATTENTION: This drive contains ESD

(Electrostatic Discharge) sensitive parts and

!

assemblies. Static control precautions are

required when installing, testing, or servicing this

assembly. Component damage may result if ESD

control procedures are not followed. If you are

not familiar with static control procedures,

reference A-B publication 8000-4.5.2, ‘‘Guarding

Against Electrostatic Damage ” or any other

applicable ESD protection handbook.

ATTENTION: An incorrectly applied or

installed drive can result in component damage or

!

a reduction in product life. Wiring or application

errors, such as, undersizing the motor, incorrect or

inadequate AC supply, or excessive ambient

temperatures may result in malfunction of the

system.

ATTENTION: Only personnel familiar with the

the drive and associated machinery should plan or

!

implement the installation, start-up and subsequent

maintenance of the system. Failure to comply may

result in personal injury and/or equipment damage.

CONVENTIONS USED IN THIS MANUAL

Programmer Terminal will appear as Human Interface Module or HIM.

To help differentiate parameter names, display text, and control

keys from other text in this manual, the following conventions

will be used:

Parameter Names will appear in [brackets]

Display Text will appear in ‘‘quotes”.

Control Key Names will appear as depicted on the control key, if the key is

labeled with letters or numbers (i.e., JOG, SEL) or if

the key depicts an icon, its operative term appear with

initial capitalization (i.e., Stop, Increment, Enter).

Page 12

1-4

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Information and Precautions

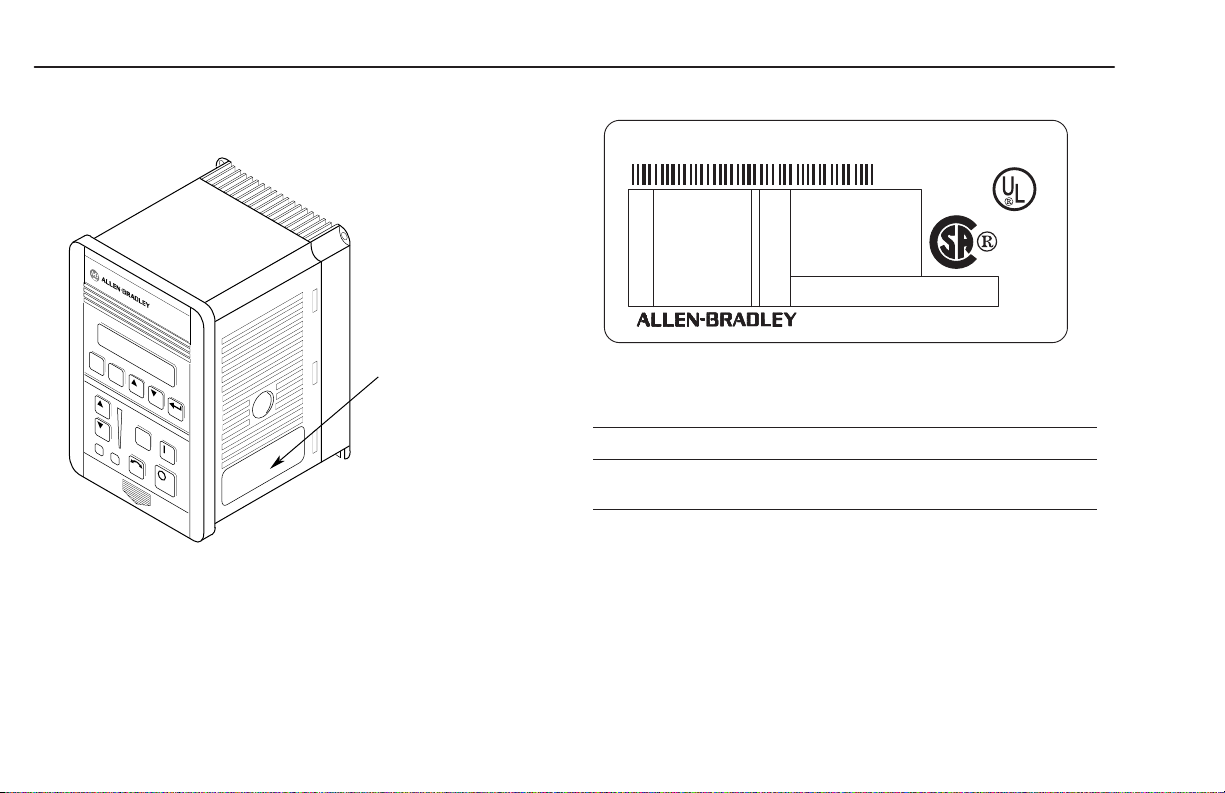

NAMEPLATE LOCATION

Figure 1.1 Bulletin 1305 Nameplate Location

ESC

SEL

JOG

Nameplate

Located

on Exterior

of Enclosure

Figure 1.2 Nameplate Information

CAT 1305-BA03A-HAP SER C

I

V: 380-460

N

A: 2.2

P

Hz: 50/60

U

T

VA: 1800

O

V: 380-460 3Φ

U

A: 2.3

T

P

Hz: 0-400

U

Motor

Rating:

T

0.75KW / 1 HP

MADE IN U.S.A.

AB0516C

FIRMWARE COMPATIBILITY

➀

Drive: Series C, FRN 6.01 and up

HIM: Series A, FRN 1.0 through 3.0

Series B, FRN 1.0

➀ Specific Firmware versions are identified by digits to the right/left of decimal.

Example 1.01, 2.01.

Firmware version can be found on the drive carton label, on

integrated circuits found on the Control Board (see Figure 2.3),

or can be viewed in Drive Diagnostics (see Chapter 5).

Page 13

CATALOG NUMBER CODE EXPLANATION

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Information and Precautions

1-5

1305 – A02 AA

First

Position

BulletinNumber

Code Description

A 200-240V , Single-Phase

B 380-460V, Three-Phase

Second

Position

200-230V, Three-Phase

–

Third

Position

Nominal

Current Rating

A01

A02

A03

A04

A06

A08

A09

A12

Language Code (English language is included in base catalog number.

To order a second language, add the appropriate suffix to the drive

catalog number.)

DE German

ES Spanish

IT Italian

FR French

Code Enclosure Type

A IP 30 (NEMA Type 1)

Human Interface Modules, NEMA Type 1 (IP 30) To order installed in the

drive, add the appropriate suffix to the drive catalog number.

HAP Programmer Only

HA1 HIM with Analog Speed Pot

HA2 HIM with Digital Up-Down Keys

Fourth

Position

Enclosure TypeRating

DE

Fifth

Position

–

Options

HA1

Sixth

Position

Page 14

1-6

Number

(

)

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Information and Precautions

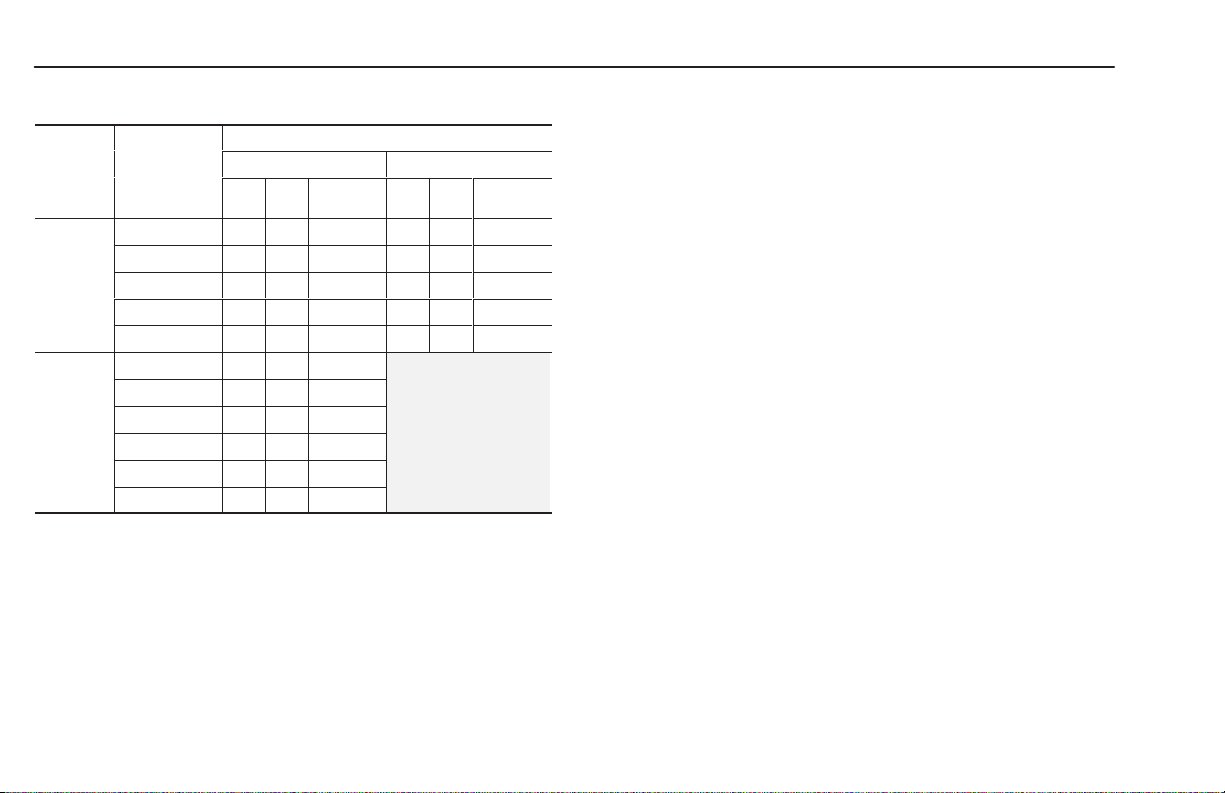

Table 1.A Drive Rating and Derating Guidelines

Motor Rating

Three-Phase Input Single-Phase Input

HP kW

1 0.75 4.5 0.75 0.55 3

1 0.75 2.3

Output ➀➁

Current (A)

Voltage

Rating

200-230V

50/60 Hz

380-460V

50/60 Hz

Catalog

IP30

NEMA Type 1

1305-AA02A 0.5 0.37 2.3 0.25 0.19 1.2

1305-AA03A 0.75 0.55 3 0.5 0.37 2.3

1305-AA04A

1305-AA08A 2 1.5 8 1 0.75 4.5

1305-AA12A 3 2.2 12 ➂ 2 1.5 8 ➂

1305-BA01A 0.5 0.37 1.3

1305-BA02A 0.75 0.55 1.6

1305-BA03A

1305-BA04A 2 1.5 4

1305-BA06A 3 2.2 6 ➃

1305-BA09A 5 4.0 9 ➄

HP kW

Not Available

Output ➀➁

Current (A)

In general:

➀ Motor Full Load Amps (FLA) should not exceed the drive output current rating.

➁ If the [PWM Frequency] is set above 4kHz, the output current must be derated per

the chart on page 5-20.

When operating the drive in an ambient temperature at or near

the maximum operating temperature (50°C), the following

derating guidelines are recommended to guard against

overheating depending on application and operating conditions.

➂ Output current value listed for 200V input voltage. At 230V input voltage, output

current is 9.6A for 3 phase and 6.8A for single phase.

➃ Output current value listed for 380V input voltage. At 415V input voltage, output

current is 5.3A. At 460V input voltage, output current is 4.8A.

➄ Output current value listed for 380V input voltage. At 415V input voltage, output

current is 8.4A. At 460V input voltage, output current is 7.6A.

For derating guidelines at ambient temperatures between 40°C

and 50°C, consult Allen-Bradley.

Page 15

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Chapter

2

CHAPTER OBJECTIVES

Chapter 2 provides the information needed to properly mount

and wire the drive. Since most start-up difficulties are the

result of incorrect wiring, every precaution must be taken to

assure that the wiring is done as instructed. All items must be

read and understood before the actual installation begins.

ATTENTION: The following information is

merely a guide for proper installation. The National

!

Electrical Code and any other governing regional

or local code will overrule this information. The

Allen-Bradley Company cannot assume

responsibility for the compliance or the

noncompliance to any code, national, local or

otherwise for the proper installation of this drive or

associated equipment. A hazard of personal injury

and/or equipment damage exists if codes are

ignored during installation.

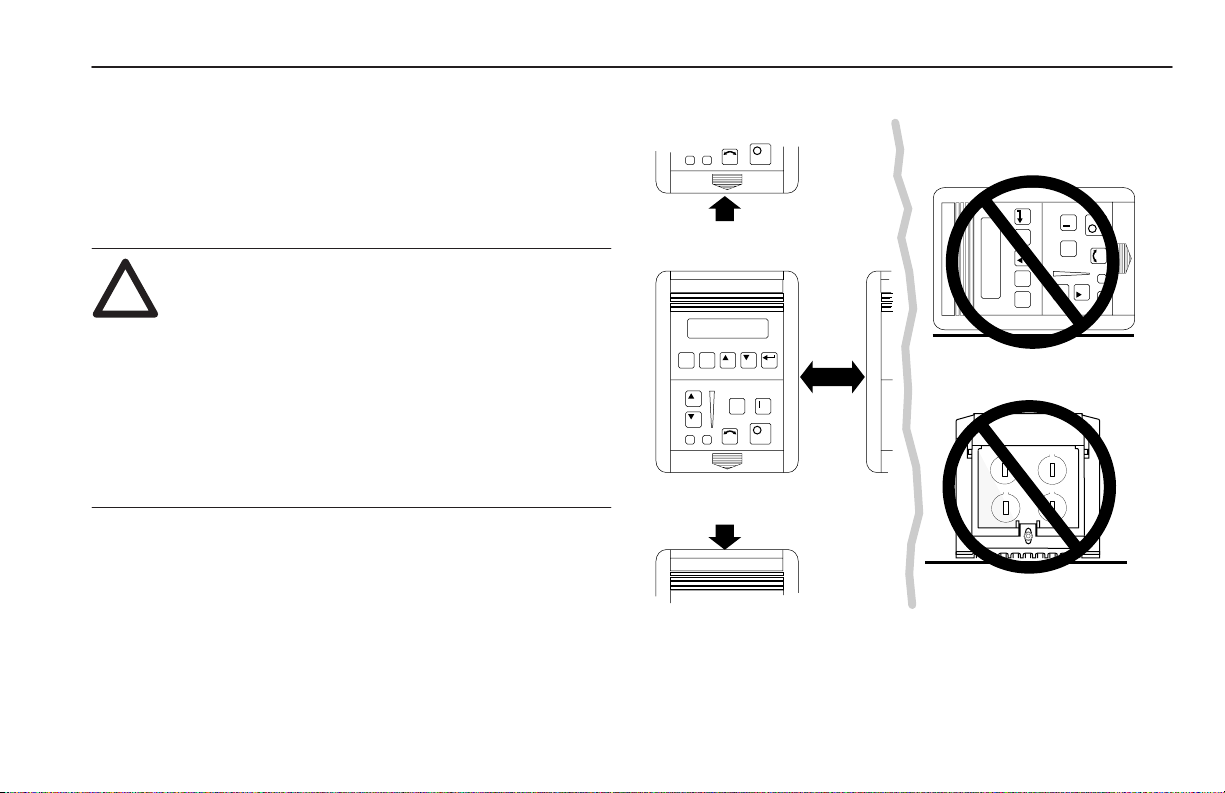

Figure 2.1 Mounting Requirements

50.8 mm

(2.0 in.)

ESC SEL

50.8 mm

(2.0 in.)

76.2 mm

(3.0 in.)

JOG

JOG

ESC SEL

Important: The drive must be mounted to a metallic surface.

Page 16

2-2

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Installation/Wiring

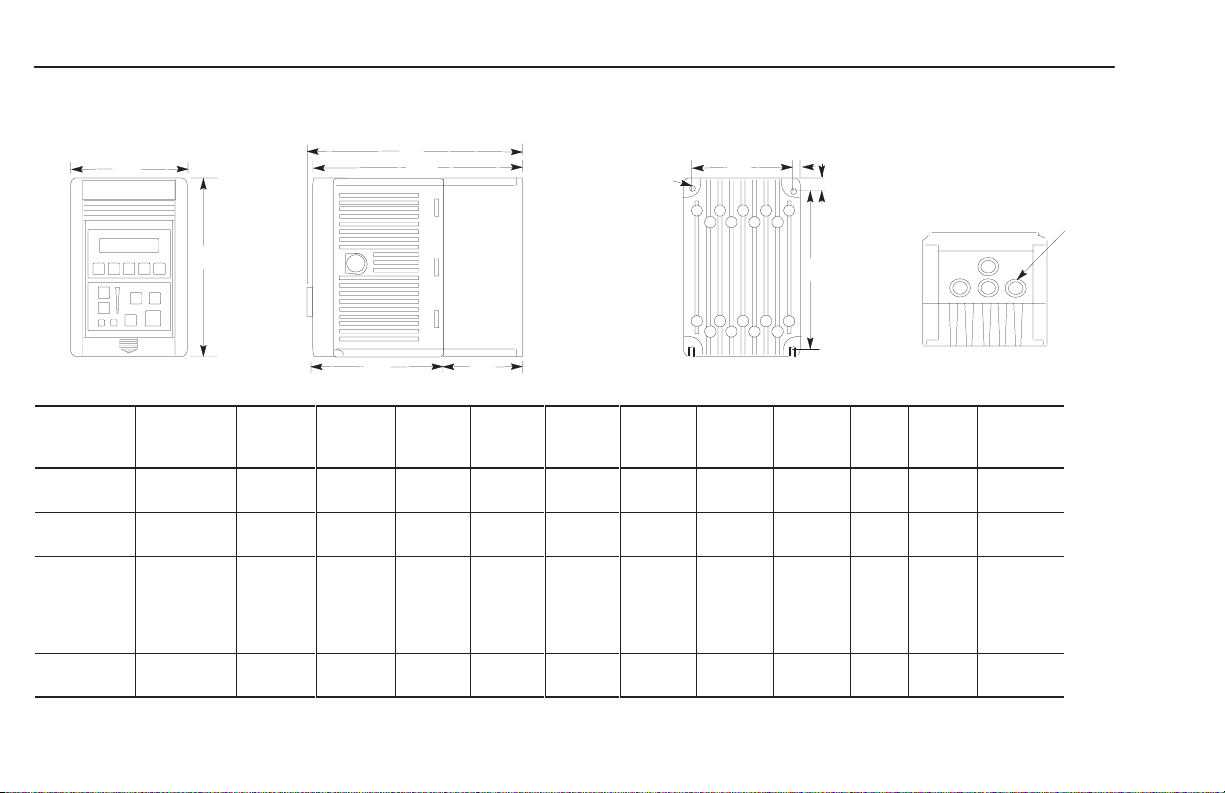

Figure 2.2 Bulletin 1305 Approximate Dimensions

Dimensions shown are in millimeters (inches). Shipping weights are in kilograms (pounds).

C’

A

B

C

FG

O 5.5

(7/32)

H

D

J

O 22.5

(7/8)

E

200/230 V

Cat. No.

1305- . . .

AA02A

AA03A

AA04A 120

AA08A BA01A

AA12A BA09A 210

380/460 V

Cat. No.

1305- . . .

BA02A

BA03A

BA04A

BA06A

A

Width

120

(4-23/32)

(4-23/32)

170

(6-11/16)

(8-1/4)

B

Height

195

(7-11/16)

195

(7-11/16)

195

(7-11/16)

195

(7-11/16)

C

Depth

w/o Pot.

122

(4-13/16)

140

(5-1/2)

179

(7-1/16)

179

(7-1/16)

C’

Depth

w/ Pot.

127.1

(5)

145.1

(5-23/32)

184.1

(7-1/4)

184.1

(7-1/4)

D E F G H J

110

(4-11/32)

110

(4-11/32)

160

(6-5/16)

200

(7-7/8)

180

(7-1/16)9(11/32)

180

(7-1/16)27(1-1/16)

180

(7-1/16)66(2-19/32)

180

(7-1/16)66(2-19/32)

113

(4-7/16)5(7/32)

113

(4-7/16)5(7/32)

113

(4-7/16)5(7/32)

113

(4-7/16)5(7/32)

7.5

(5/16)

7.5

(5/16)

7.5

(5/16)

7.5

(5/16)

Approx.

Shipping

Weight

1.6

(3.5)

1.9

(4.2)

3.6

(8.0)

4.2

(9.2)

Page 17

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

2-3

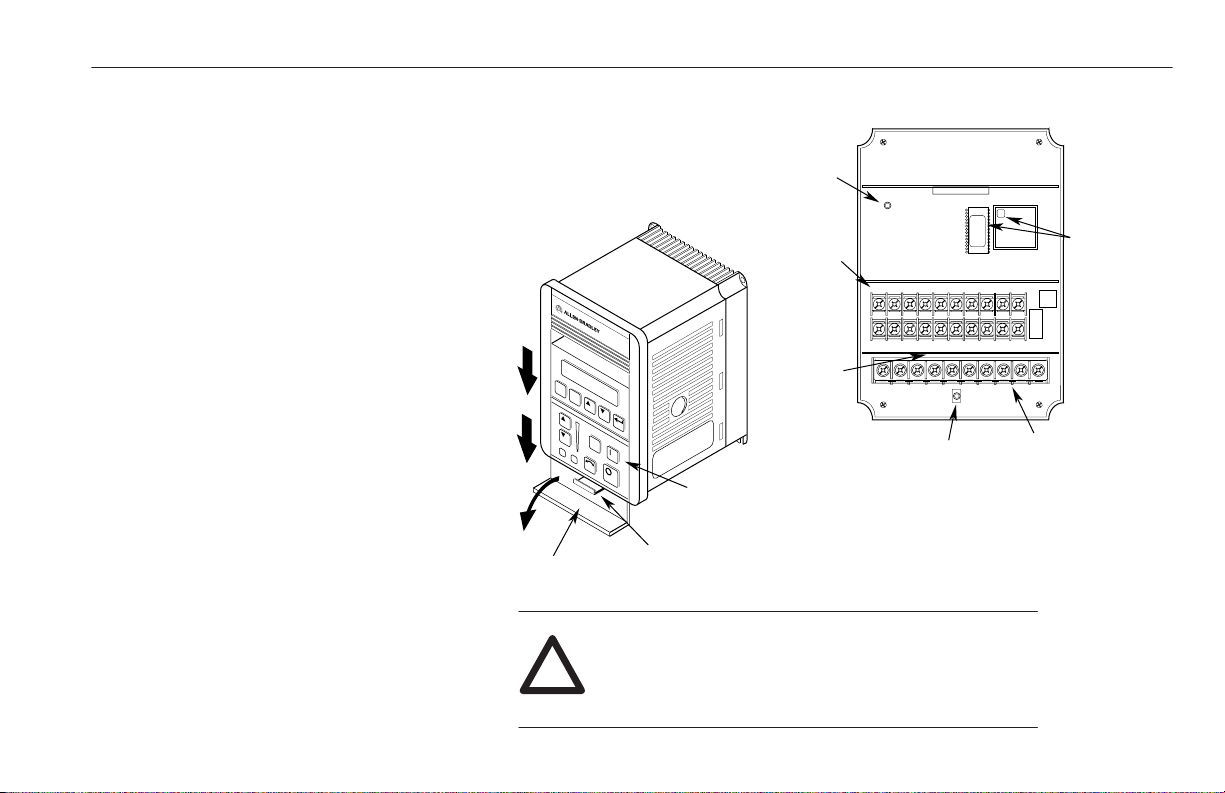

TERMINAL BLOCK ACCESS

To access the power and control terminal

blocks, perform the following procedure:

1. Remove power from the drive.

2. Lower the hinged panel located below the

HIM or blank front panel.

3. For drives equipped with a blank front

panel, slide the panel downward and

remove it from the drive. Skip to Step 5.

4. For drives equipped with a HIM, press the

retaining lever directly beneath the HIM

and slide the HIM downward to remove it

from drive.

5. Remove the drive front cover by grasping

the upper corners of the cover and pulling

at a 90-degree angle to the drive. Lift the

cover off.

ESC

SEL

J

O

G

Hinged Cover

!

Figure 2.3 Terminal Block Access

LED Fault

Indicator

Drive with HIM Removed

TB2

Control Terminal

Block

11 12 13 14 15 16 17 18 19 20

1 23456

87

Serial

Number

DC Bus Charge

HIM – See back for

Indicator

Series Letter and

Firmware Revision Level

Retaining Lever

ATTENTION: Proceed with caution. A DC Bus

Voltage may be present at the Power Terminal

Block (TB1) even when power is removed from

the drive.

10

9

TB1

Power Terminal

Block

Firmware

Revision

Level

Page 18

2-4

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

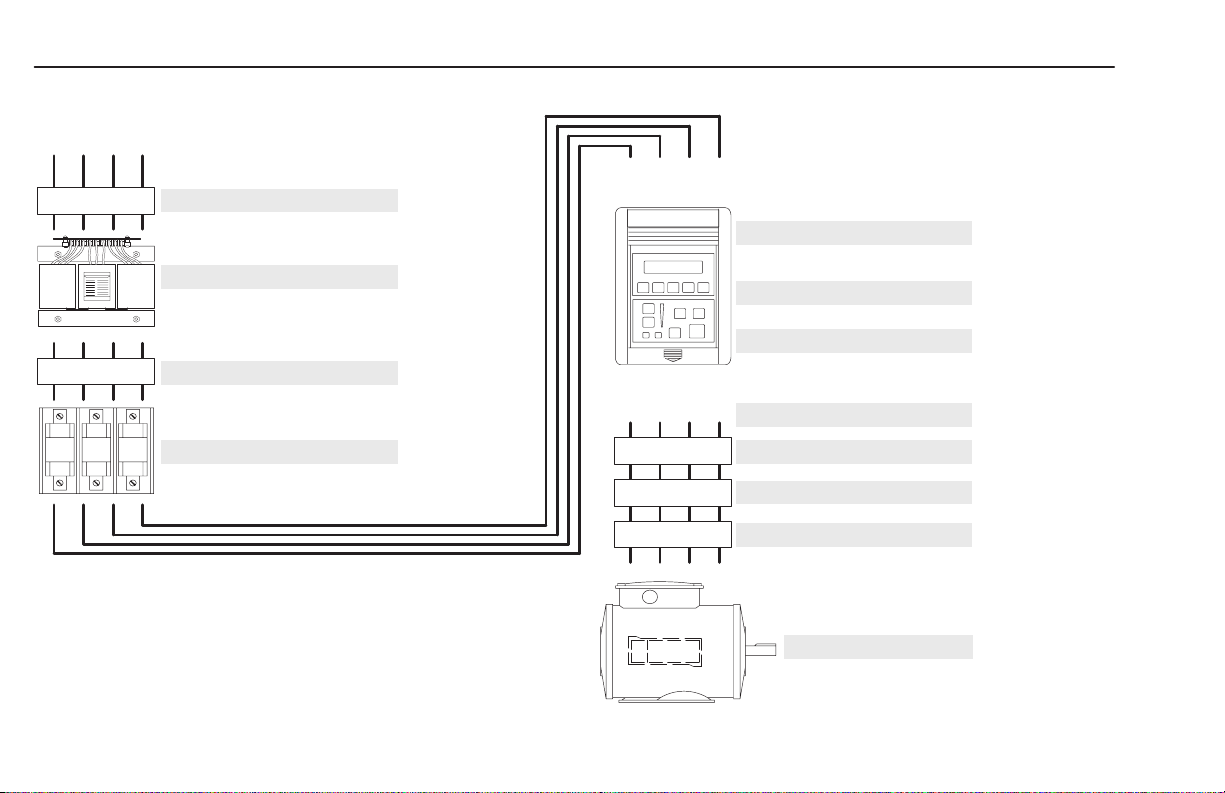

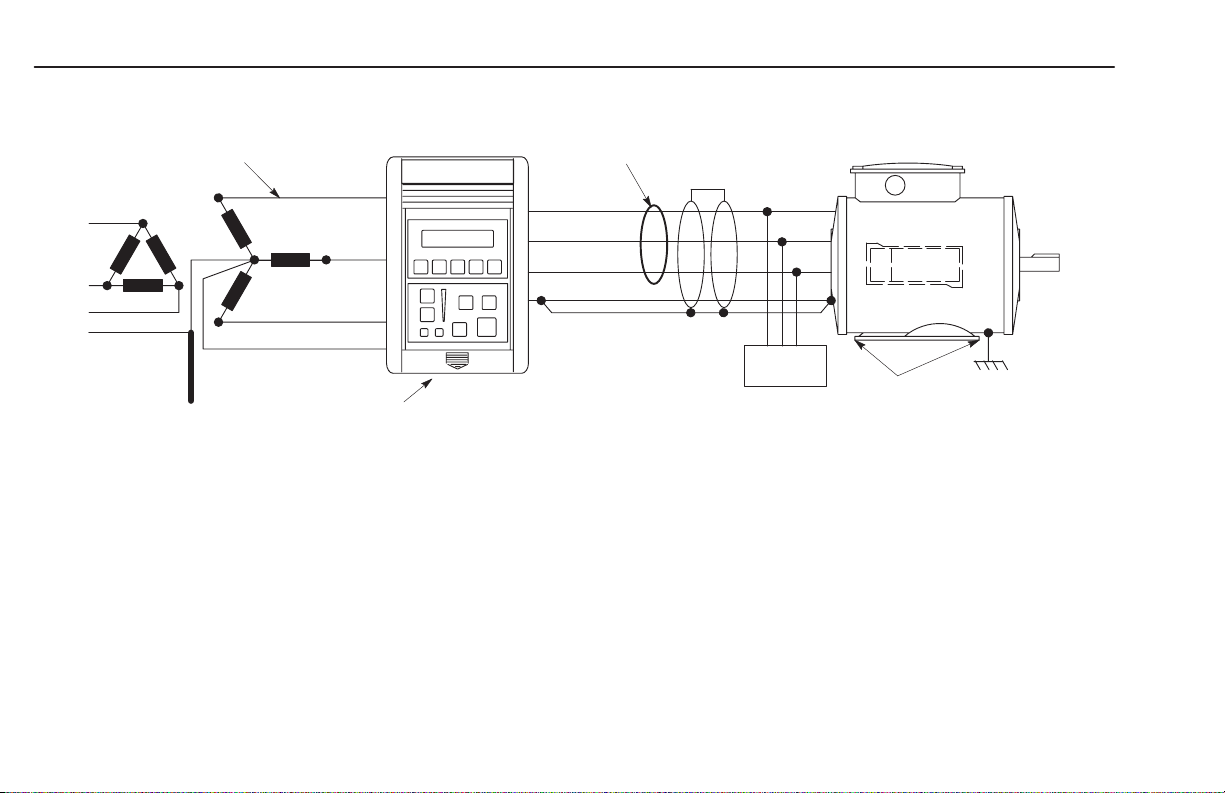

Figure 2.4 Installation Guidelines

GRD

Installation/Wiring

Input Devices Page 2-5

GRD R S T

GRD (L1) (L2) (L3)

Electrical Interference Page 2-7

Input Power Conditioning Page 2-6

Input Filters Page 2-8

GRD (T1) (T2) (T3)

GRD U V W

Input Fusing Page 2-6

Grounding Page 2-9

Power Wiring Page 2-11

Control Wiring Page 2-17

Output Filters Page 2-8

Output Devices Page 2-22

Cable Termination Page 2-22

Motor

Page 19

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

2-5

INPUT DEVICES

Starting and Stopping the Motor

ATTENTION: The drive start/stop control circuitry

includes solid-state components. If hazards due to

!

accidental contact with moving machinery or

unintentional flow of liquid, gas or solids exist, an

additional hardwired stop circuit is required to remove

AC line power to the drive. When AC input power is

removed, there will be a loss of inherent regenerative

braking effect and the motor will coast to a stop. An

auxiliary braking method may be required.

Repeated Application/Removal of Input Power

ATTENTION: The drive is intended to be controlled

by control input signals that will start and stop the motor.

!

A device that routinely disconnects then reapplies line

power to the drive (input contactor, etc.) for the purpose

of starting and stopping the motor should not be used. If it

is necessary to use this method for starting and stopping or

if frequent cycling of power is unavoidable, make sure

that it does not occur more than once

Input Contactor

ATTENTION: An incorrectly applied or installed

system can result in component damage or reduction in

!

product life. Follow these recommendations for

application of an input contactor to a 1305 drive.

a minute.

Normal Operation: After the input contactor is closed, the

enable, start, and stop signals may be applied. These control

signals must be removed before opening the input contactor.

The input contactor must not be opened and closed more than

once a minute.

Bypass Contactors

ATTENTION: An incorrectly applied or

installed system can result in component damage

!

or reduction in product life. The most common

causes are:

D

Wiring AC line to drive output or control terminals.

D Improper voltage placed on control terminals.

D Improper bypass or output circuits not approved by

Allen-Bradley.

D Output circuits which do not connect directly to the

motor.

D Incorrect or inadequate AC supply.

D Excessive ambient temperature.

Contact Allen-Bradley for assistance with

application or wiring.

Page 20

2-6

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Installation/Wiring

INPUT POWER CONDITIONING

The drive is suitable for direct connection to a correct voltage,

single phase or three-phase, AC power line. However, there are

certain power line conditions which may introduce the

possibility of drive input power component malfunction. To

reduce the possibility of these malfunctions, a line reactor or

isolation type transformer with an input impedance of 3% of

the drive input VA rating may be required.

The basic rules for determining if a line reactor or isolation

type transformer is required are as follows:

1. If the AC line supplying the drive has power factor

correction capacitors that are switched in and out, installing

an AC line reactor or isolation type transformer between the

capacitor bank and the drive input may be required. Damage

to drives can occur from the extreme current spikes caused

by capacitor switching.

2. If the AC line frequently experiences transient power

interruptions or significant voltage spikes, an AC line

reactor or isolation type transformer may be required.

Damage to drives can occur from extreme current spikes.

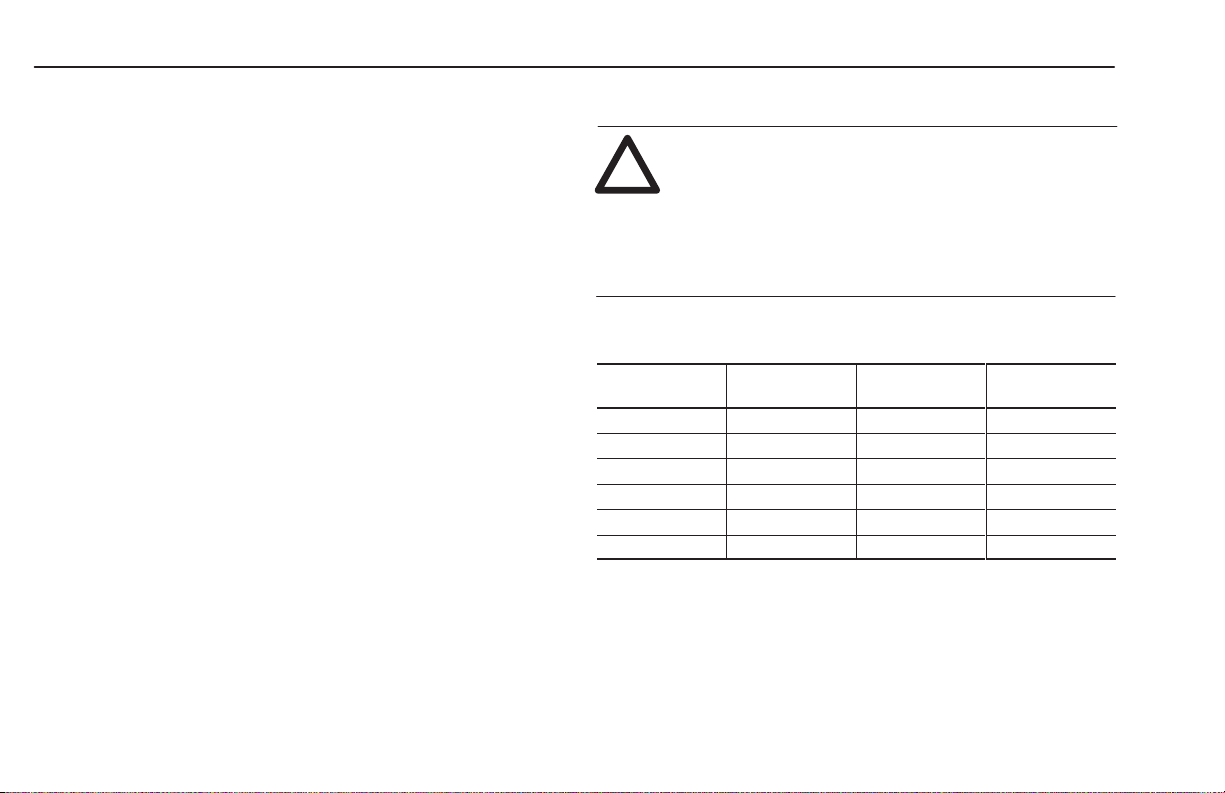

INPUT FUSING

ATTENTION: The drive does not provide

!

Table 2.A Maximum Recommended AC Input Line Fuse

UL Class J, T, CC, or BS88 (or equivalent)

Three-Phase

Rating – kW (HP)

0.37 (0.25) 0.19 (0.25) 6A 3A ➀

0.55 (0.75) 0.37 (0.5) 6A 3A ➀

0.75 (1) 0.55 (0.75) 10A 6A ➁

1.5 (2) 0.75 (1) 15A 10A ➁

2.2 (3) 1.5 (2) 25A 15A ➁

4.0 (5) –– –– 20A ➁

➀ Must be dual element time delay, Bussmann LPJ or equivalent.

➁ If fuse blowing is a problem, use dual element type fuses.

branch circuit protection. Specifications for the

recommended fuse size and type which provide

branch circuit protection against short circuits are

provided in Table 2.A. Branch circuit breakers or

disconnect switches cannot provide this level of

protection for drive components.

Single-Phase

Rating – kW (HP)

Fuse

200-230V Rating

Fuse

380-460V Rating

Page 21

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

2-7

ELECTRICAL INTERFERENCE – EMI/RFI

Immunity

The 1305 drive is designed for immunity to most externally

generated interference. Usually, no special precautions are

required beyond the installation practices provided in this

publication.

It is recommended that the coils of DC energized contactors

associated with drives be suppressed with a diode or similar

device, since they can generate severe electrical transients.

In areas subject to frequent lightening strikes, additional surge

suppression is advisable.

Emission

Careful attention must be given to the arrangement of power

and ground connections to the drive to avoid interference with

nearby sensitive equipment. The cable to the motor carries

switched voltages and should be routed well away from

sensitive equipment.

The ground conductor of the motor cable should be connected

to the drive ground (GRD) terminal directly. Connecting this

ground conductor to a cabinet ground point or ground bus bar

may cause high frequency current to circulate in the ground

system of the enclosure. The motor end of this ground

conductor must be solidly connected to the motor case ground.

Shielded or armored cable may be used to guard against

radiated emissions from the motor cable. The shield or armor

should be connected to the drive ground terminal and the

motor ground as outlined in the Grounding section of this

Installation chapter.

Common mode chokes are recommended at the drive output to

reduce the common mode noise.

An RFI filter can be used and in most situations provides an

effective reduction of RFI emissions that may be conducted

into the main supply lines.

If the installation combines a drive with sensitive devices or

circuits, it is recommended that the lowest possible drive PWM

frequency be programmed.

Page 22

2-8

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Installation/Wiring

RFI FILTERING

1305 drives can be installed with an RFI filter, which controls

radio–frequency conducted emissions into the main supply

lines and ground wiring.

If the cabling and installation recommendation precautions

described in this manual are adhered to, it is unlikely that

interference problems will occur when the drive is used with

conventional industrial electronic circuits and systems.

However, a filter is recommended if there is a likelihood of

sensitive devices or circuits being installed on the same AC

supply or if the motor cable exceeds 75 meters (250 feet).

Beyond this length, capacitance to ground will increase the

supply emissions.

Where it is essential that very low emission levels must be

achieved or if conformity with standards is required the

optional RFI filter should be used. Refer to Appendix D and

instructions included with the filter for installation and

grounding information.

RFI Filter Leakage Current

The optional RFI filter may cause ground leakage currents.

Therefore a solid ground connection must be provided.

ATTENTION: To guard against possible

!

equipment damage, RFI filters can only be used

with AC supplies that are nominally balanced

with respect to ground. In some installations,

three–phase supplies are occasionally connected

in a 3-wire configuration with one phase

grounded (Grounded Delta). The filter must not

be used in Grounded Delta supplies.

CE Conformity

Refer to Appendix D.

Page 23

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

2-9

GROUNDING

Refer to the grounding diagram on the following page. The

drive must be connected to system ground at the power ground

(GRD) terminal provided on the power terminal block (TB1).

Ground impedance must conform to the requirements of

national and local industrial safety regulations (NEC, VDE

0160, BSI, etc.) and should be inspected and tested at

appropriate and regular intervals. In any cabinet, a single,

low–impedance ground point or ground bus bar should be used.

All circuits should be grounded independently and directly.

The AC supply ground conductor should also be connected

directly to this ground point or bus bar.

Sensitive Currents

It is essential to define the paths through which the high

frequency ground currents flow. This will assure that sensitive

circuits do not share a path with such current, and to minimize

the area enclosed by these paths. Current carrying ground

conductors must be separated. Control and signal ground

conductors should not run near or parallel to a power ground

conductor.

Motor Cable

The ground conductor of the motor cable (drive end) must be

connected directly to the ground terminal, not to the enclosure

bus bar. Grounding directly to the drive (and filter, if installed)

provides a direct route for high frequency current returning

from the motor frame and ground conductor. At the motor end,

the ground conductor should also be connected to the motor

case ground. If shielded or armored cables are used, the same

grounding methods should be used for the shield/armor as well.

Discrete Control and Signal Wiring

DO NOT connect drive Common terminals (TB2) to ground.

DO NOT switch these inputs using non-isolated TTL type

circuits. Use dry relay contacts to switch signal inputs to

Common. Only isolated 4-20mA sources are recommended.

There must be no ground potential difference between source

and drive.

Safety Ground

This is the safety ground required by code. The ground bus can

be connected to adjacent building steel (girder, joist) or a floor

ground loop, provided grounding points comply with NEC

regulations.

RFI Filter

Important: Using an optional RFI filter may result in

relatively high ground leakage currents. The filter must be

permanently installed and solidly grounded. Grounding must

not rely on flexible cables and should not include any form of

plug or socket that would permit inadvertent disconnection.

The integrity of this connection should be periodically

checked.

Page 24

2-10

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

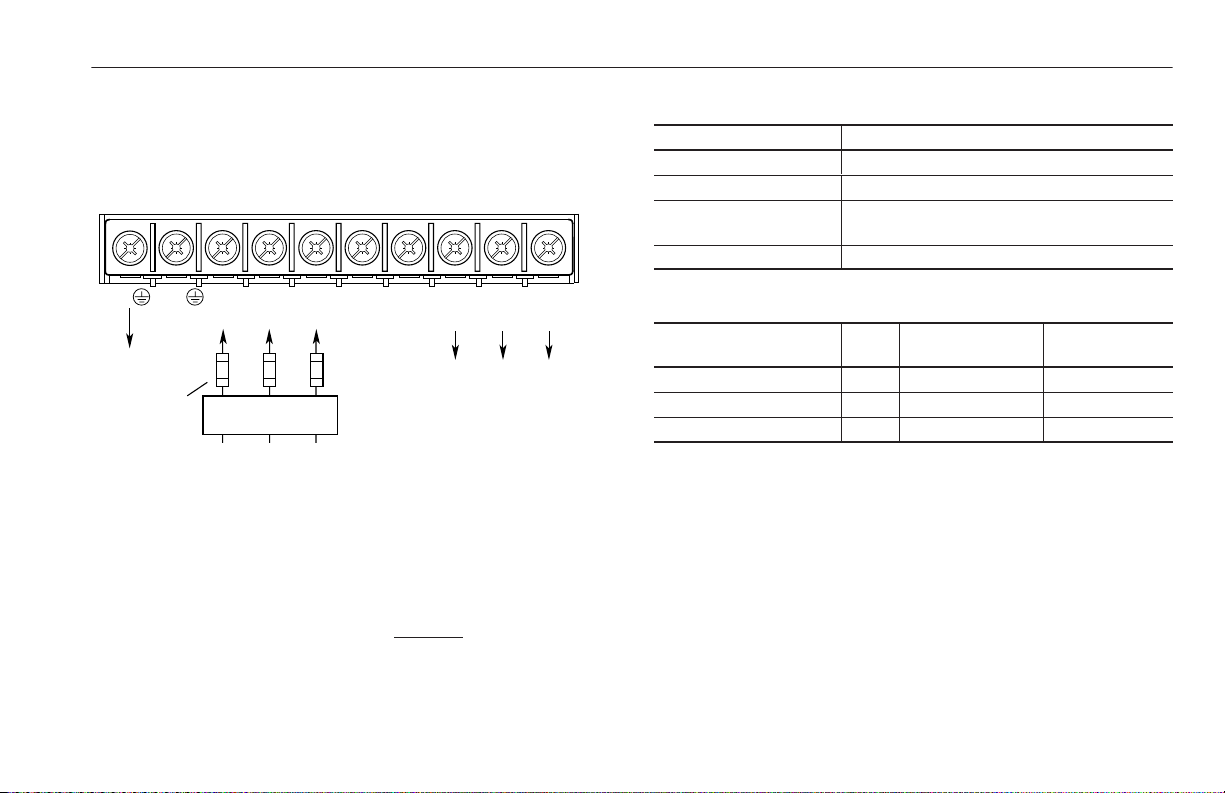

Figure 2.5 Recommended 1305 Grounding for Installation Without EMI Filter (Non–CE)

Installation/Wiring

Conduit/4-Wire Cable

Ground Rod

R(L1)

S(L2)

T(L3)

GRD

Standard unit has plastic conduit

entry. For installation with EMI

filter (CE), see Appendix D.

Common

Mode Core*

U(T1)

V(T2)

W(T3)

GRD

* These are options that can be installed as needed.

Shield*

Shield

Motor

Terminator*

Motor

Frame

Ground Per

Local Codes

Page 25

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

2-11

POWER WIRING

Input and output power connections are performed through a

ten position terminal block, TB1 (see page 2-3 for location).

Figure 2.6 Power Terminal Block Designations (TB1)

Option

➀

(–DC)

T1UT2VT3

➂

To Motor

for single motor

W

GRD

GRD

➃

To Motor

Required

Input Fusing

➀ Connection for Dynamic Brake Resistors for all models except the 200-230 Volt,

0.37 to 0.75 kW (0.5 to 1 HP) drive. Important: The [DB Enable] parameter must

be enabled for proper operation.

➁ For single phase applications, the AC input line can be connected to any two of

the three input terminals R, S, T (L1, L2, L3).

➂ 1305 drives are UL and cUL listed, and CSA certified as a motor overload

protective device. An external overload relay is not required

applications. Important: This drive is not intended for use with single phase

motors.

➃ Ground from drive to motor frame must be an independent continuous insulated

wire run.

L1RL2SL3

Required Branch

Circuit Disconnect

AC Input Line

➁

+DC BRK

T

Dynamic Brake

Table 2.B Power Block Terminal (TB1)

Terminals Description

GRD Earth Ground

R, S, T (L1, L2, L3) AC Input Line Terminals

+DC, BRK (or –DC) Dynamic Brake Option - Refer to instructions in-

U, V, W (T1, T2, T3) Motor Connection

cluded with option

Table 2.C Screw Size, Wire Size and Torque Specifications

Screw

Max./Min. Wire Size

mm

2

(AWG )

Terminal

TB1 (0.37-0.75 kW/0.5-1HP) M4 3.5/0.75 (12/18) 0.90 (8)

TB1 (All except above) M4 4/0.75 (10/18) 1.81 (16)

TB2 (All) M3.5 1.5/0.20 (14/24) 0.90 (8)

Size

Maximum Torque

N-m ( lb-ins. )

Page 26

2-12

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Installation/Wiring

Motor Cables

A variety of cable types are acceptable for drive installations.

For many installations, unshielded cable is adequate, provided

it can be separated from sensitive circuits. As an approximate

guide, allow a spacing of 1 meter (3.3 feet) for every 10 meters

(33 feet) of length. In all cases, long parallel runs must be

avoided.

The cable should be 4-conductor with the ground lead being

connected directly to the drive ground terminal (GRD) and the

motor frame ground terminal.

Shielded Cable

Shielded cable is recommended if sensitive circuits or devices

are connected or mounted to the machinery driven by the

motor. The shield must be connected to the drive ground and

motor frame ground. The connection must be made at both

ends to minimize the external magnetic field.

If cable trays or large conduits are to be used to distribute the

motor leads for multiple drives, shielded cable is recommended

to reduce or capture the noise from the motor leads and

minimize “cross coupling” of noise between leads of different

drives. The shield should be connected to the ground

connections at both the motor and drive end.

Armored cable also provides effective shielding. Ideally, it

should be grounded only at the drive (GRD) and motor frame.

Some armored cable has a PVC coating over the armor to

prevent incidental contact with grounded structure. If, due to

the type of connector, the armor must be grounded at the

cabinet entrance, shielded cable should be used within the

cabinet to continue as far as possible to the coaxial

arrangement of power cable and ground.

In some hazardous environments it is not permissible to ground

both ends of the cable armor. This is because of the possibility

of high current circulating at the input frequency if the ground

loop is cut by a strong magnetic field. This only applies in the

proximity of powerful electrical machines. In such case, the

ground connection at one end may be made through a

capacitance, which will block the frequency current but present

a low impedance to RF. Because of the highly pulsed nature of

the circulating current, the capacitor type used must be rated

for AC-to-ground voltage. Consult factory for specific

guidelines.

Page 27

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

2-13

Conduit

If metal conduit is preferred for cable distribution, the

following guidelines must be followed.

1. Drives are normally mounted in cabinets and ground

connections are made at a common ground point in the

cabinet. If the conduit is connected to the motor junction

box and at the drive end, no further conduit connections are

necessary.

2. No more than three sets of motor leads can be routed

through a single conduit. This will minimize “cross talk”

that could reduce the effectiveness of the noise reduction

methods described. If more than three drive/motor

connections per conduit are required, shielded cable as

described above must be used. If practical, each conduit

should contain only one set of motor leads.

ATTENTION: To avoid a possible shock hazard

caused by induced voltages, unused wires in the

!

conduit must be grounded at both ends. For the

same reason, if a drive sharing a conduit is being

serviced or installed, all drives using this conduit

should be disabled. This will eliminate the

possible shock hazard from “cross coupled” drive

motor leads.

Motor Lead Lengths

Installations with long cable lengths between the 1305 drive

and motor may require the use of an output reactor or

Terminator. The following guidelines allow for selection of the

appropriate drive HP rating (and output reactor or Terminator,

if required) to work with an existing motor, and provide

motor-lead length solutions for new installations.

Voltage doubling at motor terminals, known as reflected wave

phenomenon, standing wave or transmission line effect, can

occur when using long motor cables with drives. Long motor

cables can cause capacitive charging current in excess of the

rating of a smaller drive. To ensure proper installation, follow

the guidelines provided.

All cabling and distances are based on using 14 AWG,

4-conductor type cabling.

In general, motors designed and built without phase separating

insulation paper between motor windings should be classified

as 1000V

Section A: No Output Reactor or Terminator

Table 2.D lists the maximum cable lengths permitted when

applying a 460V, 1305 drive to a 460V motor for motor

insulation ratings of 1000V, 1200V, and 1600V without an

output reactor or Terminator. Shielded and unshielded

maximum cable lengths also are listed. Tables are based on

operation at nominal line condition (480V).

P-P insulation design.

Page 28

2-14

HP

1

1

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Installation/Wiring

1000V and 1200V Motor Insulation Ratings: Cable lengths

listed in Table 2.D are for operating the 1305 drive at a

maximum carrier frequency of 4 kHz on motor insulation

ratings of 1000V and 1200V. Consult the factory regarding

operation above 4 kHz carrier frequency. Multiply listed

distances by 0.85 for operation at high line conditions (above

480V). If the maximum cable length used exceeds the

distances indicated, refer to Section B.

1600V Motor Insulation Ratings: Cable lengths listed in

Table 2.D are based on operating the 1305 drive at a maximum

carrier frequency of 2 kHz on motor insulation ratings of

1600V. Consult the factory regarding operation above 2 kHz

carrier frequency. Multiply listed distances by 0.55 for

operation at high line conditions (above 480V). If the

maximum cable length used exceeds the distances indicated,

refer to Section B.

The Allen-Bradley 1329-HR is representative of 1600V

P-P

insulation rating designs and is recommended in applications

where long cable lengths are required.

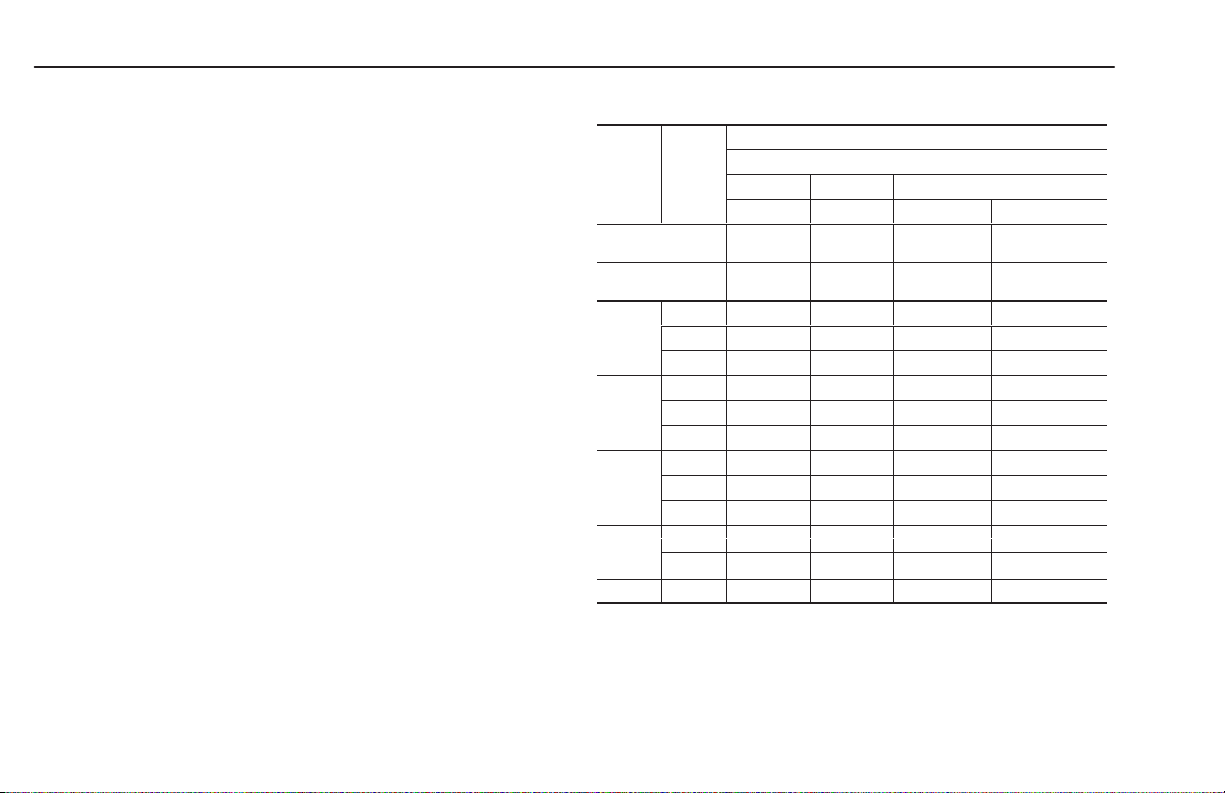

Table 2.D Maximum Motor Cable Length Restrictions

No External Devices or Reactor at the Motor

Drive

(460V)HP(460V)

Maximum Carrier

Frequency

High-Line Derate

Multiplier

5 5 9m (30ft) 30m (100ft) 121m (400ft) 121m (400ft)

3 3 9m (30ft) 30m (100ft) 91m (300ft) 121m (400ft)

2 2 9m (30ft) 30m (100ft) 76m (250ft) 121m (400ft)

1

0.5 0.5 9m (30ft) 30m (100ft) 45m (150ft) 106m (350ft)

Motor

3 9m (30ft) 30m (100ft) 121m (400ft) 121m (400ft)

2 9m (30ft) 30m (100ft) 121m (400ft) 121m (400ft)

2 9m (30ft) 30m (100ft) 121m (400ft) 121m (400ft)

1 9m (30ft) 30m (100ft) 121m (400ft) 121m (400ft)

1 9m (30ft) 30m (100ft) 121m (400ft) 121m (400ft)

0.5 9m (30ft) 30m (100ft) 121m (400ft) 121m (400ft)

0.5 9m (30ft) 30m (100ft) 121m (400ft) 121m (400ft)

Using a Motor with Insulation V

1000 Volt 1200 Volt 1600 Volt 1329 HR

Any Cable Any Cable Shielded Cable Unshielded Cable

4 kHz 4 kHz 2 kHz 2 kHz

0.85 0.85 0.55 0.55

9m (30ft) 30m (100ft) 68m (225ft) 121m (400ft)

P-P

Page 29

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

2-15

Section B: Use of Output Reactor or Terminator

For longer motor-lead length applications, an output reactor or

Terminator is required to ensure proper drive operation, and for

the motor to operate within its specified insulation rating. The

guidelines in Table 2.E are required for proper drive and motor

operation, or motor designs without phase-separating insulation

paper between motor windings.

Applications with non-inverter duty rated motors, with long

lead lengths, require an output reactor or Terminator. An output

reactor or Terminator helps reduce voltage reflection to the

motor to levels which are less than the motor insulation rating.

Table 2.E lists maximum cable lengths that can be run when

using an output reactor, or one of two available Terminators,

for motor insulation ratings of 1000V, 1200V, and 1600V.

Shielded and unshielded maximum cable lengths also are

listed.

When an output reactor is required, locate the reactor at the

drive if possible. Consult the factory for applications which

require mounting the reactor at the motor.

1000V and 1200V Motor Insulation Ratings: Cable lengths

listed in Table 2.E are for operating the 1305 drive at a

maximum carrier frequency of 2 kHz on motor insulation

ratings of 1000V and 1200V when used with an output reactor

or Terminator. Consult the factory regarding operation above 2

kHz carrier frequency. Multiply listed distances by 0.85 for

operation at high line conditions (above 480V).

1600V Motor Insulation Ratings: Cable lengths listed in

Table 2.E are based on operating the 1305 drive at a maximum

carrier frequency of 2 kHz on motor insulation ratings of

1600V. Consult the factory regarding operation above 2 kHz

carrier frequency.

The Allen-Bradley 1329-HR is representative of 1600V

P-P

insulation rating designs and is recommended in applications

where long cable lengths are required.

Example: An existing installation includes a 2 HP, 1200V

motor with a 84-meter (275-foot) cable-length requirement

between the 1305 drive and the motor. What are the possible

solutions to this installation?

1. Table 2.D indicates that either an output reactor or a

Terminator is required for this installation example. Consult

Table 2.E for output reactor, Terminator, and cable types.

2. Table 2.E suggests these possible solutions:

–

Install a 1305 2-HP drive with an output reactor installed at

the drive, and use unshielded cable.

– Install a 1305 3-HP drive with an output reactor installed at

the drive, and use shielded or unshielded cable.

– Install a 1305 2-HP drive with a 1204-TFA1 Terminator,

and use shielded or unshielded cable.

Contact Allen-Bradley for further assistance if required.

Page 30

2-16

Using a Motor with Insulation V

P-P

Drive HP

Motor HP

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Installation/Wiring

Table 2.E Maximum Motor Cable Length

Reactor➀ at the Drive With 1204-TFB2 Terminator With 1204-TFA1 Terminator

Using a Motor with Insulation V

Drive HP Motor HP

(460V)

Maximum Carrier Frequency 2 kHz 2 kHz 2 kHz 2 kHz 2 kHz 2 kHz 2 kHz 2 kHz 2 kHz

High-Line Derating Multiplier 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85 0.85

5 5 15m (50ft) 182m (600ft) 182m (600ft) NR NR 91m (300ft) 61m (200ft) 91m (300ft) 121m (400ft)

3 3 15m (50ft) 91m (300ft) 182m (600ft) NR NR 91m (300ft) 61m (200ft) 91m (300ft) 121m (400ft)

2 2 15m (50ft) 76m (250ft) 167m (550ft) NR NR 91m (300ft) 61m (200ft) 91m (300ft) 121m (400ft)

1 1 15m (50ft) 68m (225ft) 152m (500ft) NR NR 45m (150ft) 61m (200ft) 45m (150ft) 76m (250ft)

0.5 0.5 15m (50ft) 45m (150ft) 106m (350ft) NR NR NR NR NR NR

NR = Not Recommended.

➀ Important: A 3% reactor reduces motor stress but may cause a degradation of motor waveform quality. Reactors must have a turn-to-turn insulating rating of 2100 volts or higher.

Reactors are not recommended for lightly loaded applications because overvoltage trips may result at low output frequencies.

(460V)

3 15m (50ft) 182m (600ft) 182m (600ft) 91m (300ft) 121m (400ft) 99m (325ft) 61m (200ft) 152m (500ft) 121m (400ft)

2 15m (50ft) 182m (600ft) 182m (600ft) 121m (400ft) 182m (600ft) 99m (325ft) 61m (200ft) 182m (600ft) 121m (400ft)

2 15m (50ft) 182m (600ft) 182m (600ft) 91m (300ft) 121m (400ft) 99m (325ft) 61m (200ft) 152m (500ft) 121m (400ft)

1 15m (50ft) 182m (600ft) 182m (600ft) 91m (300ft) 182m (600ft) 99m (325ft) 61m (200ft) 182m (600ft) 121m (400ft)

1 15m (50ft) 182m (600ft) 182m (600ft) 61m (200ft) 61m (200ft) 99m (325ft) 61m (200ft) 121m (400ft) 121m (400ft)

0.5 15m (50ft) 182m (600ft) 182m (600ft) 91m (300ft) 121m (400ft) 99m (325ft) 61m (200ft) 152m (500ft) 121m (400ft)

0.5 15m (50ft) 121m (400ft) 182m (600ft) NR NR 76m (250ft) 61m (200ft) 76m (250ft) 121m (400ft)

1000 Volt 1200 Volt or 1600 Volt

Any Cable Shielded Unshielded Shielded Unshielded Shielded Unshielded Shielded Unshielded

P-P

Using a Motor with Insulation V

1000 Volt or 1200 Volt

Using a Motor with Insulation V

-

1000 Volt 1200 Volt

P-P

Page 31

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

2-17

DRIVE OPERATION WITHOUT A

HUMAN INTERFACE MODULE (HIM)

Bulletin 1305 drives are functional without the use of the

Human Interface Module (HIM). All control functions can be

performed from the control terminal block (TB2). See Table

2.F for control descriptions. Programming must be performed

using a HIM or PLC Remote I/O function. If operating without

a HIM, you must use an external Frequency Source on TB2.

Frequency Source

To control frequency from the control terminal block (TB2) an

input is required to SW3 at TB2. The input to SW3 changes the

frequency source from [Freq Select 1] to [Freq Select 2]. The

factory default setting for [Freq Select 2] is the “Remote Pot”.

If a 0 – 10 Volt or 4 – 20mA frequency source is required, then

the [Freq Select 1] or [Freq Select 2] parameters must be

programmed to select that source. These parameters can be

programmed using the optional Human Interface Module or

through serial communications when using an optional Bulletin

1203 Communication Module. See Appendix C for catalog

numbers of these accessories.

Refer to Chapter 5 for the factory default settings for all

parameters. Special attention should be paid to Table 5.A on

page 5-29 and Table 5.B on page 5-30. These tables

demonstrate what frequency source and accel and decel

parameters can be selected based on the inputs to SW1, SW2

and SW3 at TB2.

CONTROL WIRING

Important: All common terminals are tied together within the

drive and internally connected to chassis ground.

Recommended practice is to run all signal wiring in separate

steel conduit.

ATTENTION: Drive can be permanently

damaged if any EXTERNAL control voltage is

!

applied to terminals 5 – 8 and 11 – 18. DO NOT

connect drive Common terminals (TB2) to ground.

DO NOT switch these inputs using non-isolated

TTL type circuits. Use dry relay contacts to switch

signal inputs to Common. Only isolated 4-20mA

sources are recommended. There must be no

ground potential difference between source and

drive.

The factory default control wire scheme is ‘‘3 Wire” control.

The [Input Mode] parameter can be used to program the drive

to operate using a two wire ‘‘Run Forward/Run Reverse”

control wire scheme. Refer to Chapter 4, Step 10 for

programming instructions. Figures 2.7 through 2.10 show the

wiring diagrams for the different input modes.

Important: If the [Input Mode] is changed, power must be

cycled to the drive for the change to take effect. The Start and

Reverse functions operate differently for the two different

modes.

Page 32

2-18

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Installation/Wiring

Three Wire Control

When using this control scheme, the factory default for the

reverse function is controlled from TB2. To enable Reverse

operation from the HIM or other serial communication

adapters, Bit 0 of the [Direction Mask] parameter must be

changed from “1” to a “0”. See page 5-47. See Chapter 5 for

general programming instructions.

Two Wire “Run Forward/Run Reverse” Control

To use a two wire ‘‘Run Forward/Run Reverse” control

scheme, Bit 0 of the [Direction Mask] must be set to a ‘‘1.”

For proper operation of the “Run Forward/Run Reverse” mode,

install a jumper across terminals 7 and 8 (Stop) and terminals

11 and 12 (Enable).

3W/2nd Acc and Run F/R 2nd A Control

The HIM module is limited in the number of characters in the

LCD display. Definitions of these functions are as follows.

Refer to Chapter 5, Table 5.A for configuration of switches or

inputs to TB2.

3w/2nd Acc = Three Wire, 2nd Acceleration

Run F/R 2nd A = Run Forward/Reverse, 2nd Acceleration

MOP Function

The MOP function is a digital solid-state circuit that produces

the same effect as rotating a speed reference potentiometer

with a small DC motor. This permits local (HIM) or remote

(TB2) control of the command frequency.

Important: The drive can still be started from any adapter

(HIM or a serial device) and will run at the last commanded

direction unless the start, jog and reverse functions of that

adapter have been disabled (See [Start Mask], [Direction

Mask] and [Jog Mask]. See page 5-47 and 5-48.

Important: A stop command can be issued from any adapter

at all times.

Important: If a Jog is initiated, the drive will Jog in the

direction last traveled.

Page 33

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

2-19

Figure 2.7 TB2 Designations

[Input Mode] = “Three Wire” or [Input Mode]=“3 w/2nd Acc.”

Remote Pot

0-10V

➄

➀

User Side

➀➃

24VDC Source

(User Supplied)

1

2

3

4

5

6

7

8

9

10

Source

Wiper or 0-10V DC Input

Common

4-20mA Input

0-10V Output

➂

Start

Common

➂

Stop

Output #1

Enable

Common

Reverse

➂

Jog

Common

➂

SW1

➂

SW2

SW3

➂

(Sink)

Output #2

➂

➂

11

12

13

14

15

16

17

18

19

20

Momentary Input

Maintained Input

Wires must be shielded

Shield

Common

(connect to drive at TB2 Only)

See Table 2.F and

Notes on page 2-21

Figure 2.8 TB2 Designations – Two Wire Control Operation

[Input Mode]=“Run Fwd/Rev” or [Input Mode]=“Run F/R 2nd A”

Remote Pot

Run Forward

➀➁

Jumper

User Side

➀➃

Jumper

Run Reverse

24VDC Source

(User Supplied)

0-10V

1

2

3

4

5

6

7

8

9

10

Source

Wiper or 0-10V DC Input

Common

4-20mA Input

0-10V Output

➂

Start

Common

➂

Stop

Output #1

Enable

Common

Reverse

➂

Jog

Common

➂

SW1

➂

SW2

SW3

➂

(Sink)

Output #2

➂

➂

11

12

13

14

15

16

17

18

19

20

Page 34

2-20

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Installation/Wiring

Figure 2.9 TB2 Designations

[Input Mode] = “3 Wire/MOP”

Remote Pot

0-10V

➄

➀

User Side

1

2

3

4

5

6

7

8

9

10

➀➃

24VDC Source

(User Supplied)

Source

Wiper or 0-10V DC Input

Common

4-20mA Input

0-10V Output

➂

Start

Common

➂

Stop

Output #1

11

12

13

14

15

16

17

18

19

20

➂

Enable

Common

➂

Reverse

➂

Jog

Common

MOP Increment

MOP Decrement

Frequency Source

(Sink)

Output #2

➂➅

➂➅

➂➅

Momentary Input

Maintained Input

Wires must be shielded

Shield

Common

(connect to drive at TB2 Only)

See Table 2.F and

Notes on page 2-21

Figure 2.10 TB2 Designations – Two Wire Control Operation

[Input Mode] = “Run F/R MOP”

Remote Pot

Run Forward

➀➁

Jumper

User Side

➀➃

Jumper

Run Reverse

24VDC Source

(User Supplied)

0-10V

10

1

2

3

4

5

6

7

8

9

Source

Wiper or 0-10V DC Input

Common

4-20mA Input

0-10V Output

➂

Start

Common

➂

Stop

Output #1

11

12

13

14

15

16

17

18

19

20

➂

Enable

Common

➂

Reverse

➂

Jog

Common

MOP Increment

MOP Decrement

Frequency Source

(Sink)

Output #2

➂➅

➂➅

➂➅

Page 35

Installation/Wiring

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

2-21

Figure Notes:

➀ Required to operate drive. STOP also used to clear a fault.

➁ Use HIM Stop button to clear faults.

➂ Contact Closure Input. Internal 5V supply. DO NOT apply external voltage.

➃ When the ENABLE signal is lost, the drive output immediately shuts off and the

motor will coast to a stop.

➄ A Start command will override any Jog command.

➅ See Table 5.C on Page 5-31 for more information.

The recommended control signal wire is:

2

D Belden 8760 (or equiv.) - 18 AWG (0.750 mm

), twisted

pair, shielded.

D Belden 8770 (or equiv.) - 18 AWG (0.750 mm

2

), 3

conductor, shielded.

2

D Belden 9460 (or equiv.) - 18 AWG (0.750 mm

), twisted

pair, shielded.

Important: Control inputs to two or more drives must NOT

be connected in parallel.

Table 2.F Control Terminal Block (TB2) Descriptions

Terminal Signal Specification

1, 2, 3

2,3

4,3

5, 3

6, 7

8, 7

9, 10

11, 12

13, 12

14, 15

16, 15

17, 15

18, 15

19, 20

External Speed Pot

0-10V Analog Input

4-20mA Analog Input

0-10V Analog Output

Start

Stop

Programmable Output 1

Drive Enable

Reverse

Jog

SW1

SW2

SW3

Programmable Output 2

10 kΩ Potentiometer, 2 Watts

Drive Input Impedance = 100 kΩ

Drive Input Impedance = 250 Ω

Meter Impedance ≥ 4 kΩ

Contact Closure Input ➂

Contact Closure Input ➂

Resistive Rating = 115 V AC/30 VDC, 5A

Inductive Rating = 115 V AC/30 VDC, 2A

Contact Closure Input ➂➃

Contact Closure Input ➂

Contact Closure Input ➂

Contact Closure Input ➂

Contact Closure Input ➂

Contact Closure Input ➂

24V DC "20%, 50 mA Max. (Sink)

Recommended practice is to run all signal wiring in a separate

steel conduit. The shield wire must only be connected at the

drive.

ATTENTION: Signal common is internally

connected to chassis ground. Do not use cable

!

shields as signal current paths.

Page 36

2-22

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Installation/Wiring

OUTPUT DEVICES

Drive Output Disconnection

ATTENTION: Any disconnecting means wired

to drive output terminals U, V and W must be

!

capable of disabling the drive if opened during

drive operation. If opened during drive operation,

the drive will continue to produce output voltage

between U, V, W. An auxiliary contact must be

used to simultaneously disable the drive or output

component damage may occur.

CABLE TERMINATION

Optional Cable Terminator

Voltage doubling at motor terminals, known as reflected wave

phenomenon, standing wave or transmission line effect, can

occur when using drives with long motor cables.

Inverter duty motors with phase-to-phase insulation ratings of

1600 volts or higher should be used to minimize effects of

reflected wave on motor insulation life.

Applications with non-inverter duty motors or any motor with

exceptionally long leads may require an output inductor or

cable terminator. An inductor or terminator will help limit

reflection to the motor, to levels which are less than the motor

insulation value.

Table 2.D lists the maximum recommended cable length for

unterminated cables, since the voltage doubling phenomenon

occurs at different lengths for different drive ratings. If your

installation requires longer motor cable lengths, a reactor or

cable terminator is recommended.

Optional Output Reactor

The reactors listed in Catalog A111 can be used for the drive

input and output. These reactors are specifically constructed to

accommodate IGBT inverter applications with switching

frequencies up to 20 kHz. They have a UL approved dielectric

strength of 4000 volts, opposed to a normal rating of 2500

volts. The first two and last two turns of each coil are triple

insulated to guard against insulation breakdown resulting from

high dv/dt. When using output line reactors, it is recommended

that the drive PWM frequency be set to its lowest value to

minimize losses in the reactors. See Table 2.E.

Important: By using an output reactor the effective motor

voltage will be lower because of the voltage drop across the

reactor – this may also mean a reduction of the motor torque.

Output Contactor

For application of an output contactor to a 1305 drive, please

contact Allen-Bradley.

Page 37

ADAPTERS

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

An adapter is any device connected to the drive’s serial port.

Typical devices include:

D Human Interface Modules

D Communication Modules

D Future adapter devices

Important: A maximum of five adapters can communicate to

the drive.

The total current draw of all adapters should not exceed

250mA. Refer to the data sheet or nameplate of each adapter

for the amount of current needed for the adapter to operate.

The Adapter address is determined as follows:

D Port 1 equals Adapter 1.

D Port 2 equals Adapter 2. However, if a splitter is used to

expand the number of Adapters to 3, 4 or 5 the splitter will

be marked with the appropriate Adapter numbers.

Adapter Mounting Distance

The maximum mounting distance between any two adapters

connected to the drive is 10 meters. Refer to Figure 2.11.

Installation/Wiring

2-23

Page 38

2-24

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Installation/Wiring

Figure 2.11 Adapter Mounting Distance and Cable Connections

Pull back connector to

disconnect cable from the

adapter device or Port 2

connection.

Maximum Distance

A + B ≤ 10 Meters (33 feet)

Refer to Appendix C for

Cable recommendations.

Maximum Distance

A + B + C ≤ 10 Meters (33 feet)

A + B + D ≤ 10 Meters (33 feet)

C + D ≤ 10 Meters (33 feet)

Port 2

Port 1

Male-Female

Cable

A

Male-Male Cable

B

ESC SEL

JOG

Adapter 1

HIM or Other

Remote Device

ESC SEL

JOG

Adapter 2

Port 1

A

ESC SEL

Adapter 1

Male-Female Cable

JOG

Port Expansion

C

Adapter 2

Communication

Module

Male-Male Cable

B

Option

Adapter 3

Communication

Port 2

Male-Male

Cables

D

Module

Page 39

Human Interface Module

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Chapter

3

CHAPTER OBJECTIVES

Chapter 3 describes the various controls and indicators found

on the optional Human Interface Module (HIM) of the Bulletin

1305 AC Drive. The material presented in this chapter must be

understood to perform the start-up procedure in Chapter 4.

HIM DESCRIPTION

When the drive mounted HIM is supplied, it will be connected

as Adapter 1 (see Adapter in Chapter 2) and visible from the

front of the drive. The HIM can be divided into two sections;

Display Panel and Control Panel. The Display Panel provides a

means of programming the drive and viewing the various

operating parameters. The Control Panel allows different drive

functions to be controlled. Refer to Figure 3.1 and the sections

that follow for a description of the panels.

Important: The operation of some HIM functions will depend

upon drive parameter settings. The default parameter values

allow full HIM functionality.

HIM OPERATION

When power is first applied to the drive, the HIM will cycle

through a series of displays. These displays will show drive

name, HIM ID number and communication status. Upon

completion, the Status Display will be shown. This display

shows the current status of the drive (i.e. “Stopped,”

“Running,” etc.) or any faults that may be present (“Serial

Fault,” etc.). If the HIM software is Series A version 3.00 and

above or Series B version 1.01 and above (see back of HIM),

the Status Display, Process Display or Password Login menu

can be selected as the power-up display or menu. See

appropriate sections on the following pages for more

information.

Figure 3.1 Human Interface Module

LCD Display

Display

Panel

Digital Speed

Control and

Indicator

(also available

with Analog

Speed Pot.)

Control

Panel

From this display, pressing any one of the five Display Panel

keys will cause “Choose Mode” to be displayed. Pressing the

Increment or Decrement keys will allow different modes shown

in Figure 3.3.

Page 40

3-2

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Human Interface Module

Display Panel Descriptions

Escape

When pressed, the ESC key will cause the

programming system to go back one level in the

menu structure.

Select

Pressing the SEL key alternately moves the cursor to

the next active area. A flashing first character

indicates which line is active.

Increment/Decrement

These keys are used to increment and

decrement a value or scroll through different

groups or parameters.

Enter

When pressed, a group or parameter will be selected

or a parameter value will be entered into memory.

After a parameter has been entered into memory, the

top line of the display will automatically become

active, allowing another parameter (or group) to be

chosen.

Control Panel Descriptions

Important: The following information is correct as shipped

from the factory. Reprogramming of mask parameters can mask

out control of some of these functions.

Start

The Start key will initiate drive operation if no other

control devices are sending a Stop command. This

key can be disabled by the [Logic Mask] or [Start

Mask].

Stop

If the drive is running, pressing the Stop key will

cause the drive to stop, using the selected stop

mode. Refer to the [Stop Select] in Chapter 5.

If the drive has stopped due to a fault, pressing this

key will clear the fault and reset the drive. Refer to

the [Flt Clear Mode], [Logic Mask] and [Fault

Mask] parameters.

Jog

When pressed, jog will be initiated at the frequency

set by the [Jog Frequency] parameter, if no other

control devices are sending a Stop command.

Releasing the key will cause the drive to stop, using

the selected stop mode. Refer to [Stop Select], [Logic

Mask] and [Jog Mask].

Important: If the drive is running prior to issuing a

jog command, the jog command will be ignored.

Important: A start command from another source

will override the jog command.

Page 41

Human Interface Module

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

3-3

Control Panel Descriptions (continued)

Change Direction

Pressing this key will cause the drive to ramp down to

0 Hz and then ramp up to set speed in the opposite

direction. The appropriate Direction Indicator will

illuminate to indicate the direction of motor rotation.

Refer to [Logic Mask] and [Direction Mask]. Note

that the factory default for control of the reverse

function is the reverse input at the TB2 control

terminal block. To enable the HIM control of the

reverse function, change Bit 0 of the [Direction

Mask] parameter to “0” to disable the reverse

function at TB2.

Direction LEDs (Indicators)

These LEDs illuminate to indicate the direction of

motor rotation.

OFF Steady ON

Steady ON OFF

Flashing Steady ON

Steady ON Flashing

Rotating "Forward"

Rotating "Reverse"

Changing Direction, Decelerating

"Reverse," will begin to Accelerate

"Forward."

Changing Direction, Decelerating

"Forward," will begin to Accelerate

"Reverse."

Increment/Decrement Arrows

(only available with digital speed control)

Pressing these keys will increase or decrease the HIM

frequency command. An indication of this command

will be shown on the visual Speed Indicator LEDs.

The drive will run at this command if the HIM is the

selected frequency reference. See [Freq Select 1/2].

Pressing both keys simultaneously stores the current

HIM frequency command in HIM memory. The

Speed Indicator LEDs will flash momentarily to

indicate a successful save (if speed is above 20

percent). Cycling power or connecting the HIM to the

drive will set the frequency command to the value

stored in HIM memory.

If the Analog Speed Potentiometer option has been

ordered, the Increment/Decrement keys and Speed

Indicator will be replaced by the pot.

Speed Indicator LEDs

(only available with digital speed control)

Illuminates in steps to give an approximate visual

indication of the commanded speed.

If the Analog Speed Potentiometer option has been

ordered, the Increment/Decrement keys and Speed

Indicator LEDs will be replaced by the pot.

Page 42

3-4

efesotomasyon.com - Allen Bradley,Rockwell,plc,servo,drive

Human Interface Module

HIM REMOVAL AND INSTALLATION

In addition to mounting directly on the drive, the HIM can be

used as a hand held programmer or it can be mounted on the

front of an enclosure. The HIM can be removed from the drive

in one of two methods:

A. Disconnect power from the drive and remove the HIM as

outlined in steps 1 and 2, or

B. Remove the HIM from the drive with the drive running, by

masking out the [Logic Mask] bit that identifies the adapter

address of the HIM. Refer to Figure 2.11 to identify the

adapter address for the HIM or view the HIM ID# on the

display as the unit is powered up. The ID # corresponds to the

adapter address. Refer to page 5-47 for programming

instructions on the [Logic Mask] parameter. For HIM

software, Series A version 3.00 and above or Series B version

1.01 and above, you can enter the Control Status menu and

Enable/Disable the Control Logic bit.