SEPW Series

Multi Chip White LED Modules

Features and Benefits

▪ High efficiency, 100 1m/W (20 mA ) with all LEDs

illuminated; equivalent to fluorescent lamps (HCFL)

▪ Low thermal resistance, R

= 6°C/W

θJC

▪ High optical, 50 lm, output with all LEDs illuminated

▪ Superior directivity

▪ 5.23 mm × 13.7 mm case footprint, and

low 2.5 mm overall package height

▪ Silver plating on leadframe

▪ 8 LED configuration

Package:

16-pin, 1.27 mm pitch, surface mount

Description

The SEPW series of LEDs provides a range of high-powered

InGaN blue LEDs producing brilliant white light that can be

used in general lighting applications, amusement and gaming

equipment, and for backlighting TFT displays. Each module

combines 8 LEDs in 2 separate channels.

Modular design allows the SEPW devices to be easily assembled

into string arrays by simply connecting the modules in series.

The devices also provide superior color balance throughout

the display because of the high density of LEDs that can be

achieved. This also minimizes the distance that power and

control lines must run between LEDs and from the LEDs to

the control electronics.

The white thermoplastic case is an innovative Sanken original

design with exceptional heat dissipation properties. The white

resin compound is especially formulated for superior reflectance

and transmittance of the generated light. Enhanced thermal

dissipation is achieved through the incorporated heatsink on the

bottom of the package. The heatsink can be mated directly to an

external radiator through the PCB for superior heat conduction

allowing dense placement of modules.

The leadframe is plated with silver, providing a highly-reflective

surface for the bottom and sides of the emitting area. The

terminals and heatsink are also silver-plated.

Not to scale

V

B

5 to 20 V

5 V

Use only

one dimming

method

C

COMP

48100.000, Rev. 4

R

0.1 μF

10 V

FSET

L1

10 μH

1 μF

35 V

R

ISET

SW SW OVP

SEL1

SEL2

SEL3

VIN

LED Driver

EN

PWM

APWM

SKIP

COMP

FSET

ISET

AGND

PGND LGND

D1

Allegro

A8500

IC

R

OVP

C

O

2.2 μF/50 V

LED1

LED2

LED3

LED4

LED5

LED6

LED7

LED8

T ypical Application

8 SEPW modules, 8 LEDs each

SEP8W

SEP8W

SEP8W

SEP8W

SEP8W

SEP8W

SEP8W

SEP8W

R

C

R

R

The SEPW devices can be mounted in tight

arrays on a single PCB substrate for ease of

manufacture and to provide a dense, uniform

appearance when illuminated.

The application shown here uses eight

SEP8Wx2001 LED modules, each populated

by eight LEDs connected in series.

OVP

COMP

ISET

FSET

100 kΩ

0.1 μF / 6.3 V

12.7 kΩ (for 20.3 mA)

26.1 kΩ (for 1 MHz

switching frequency)

SEPW Series

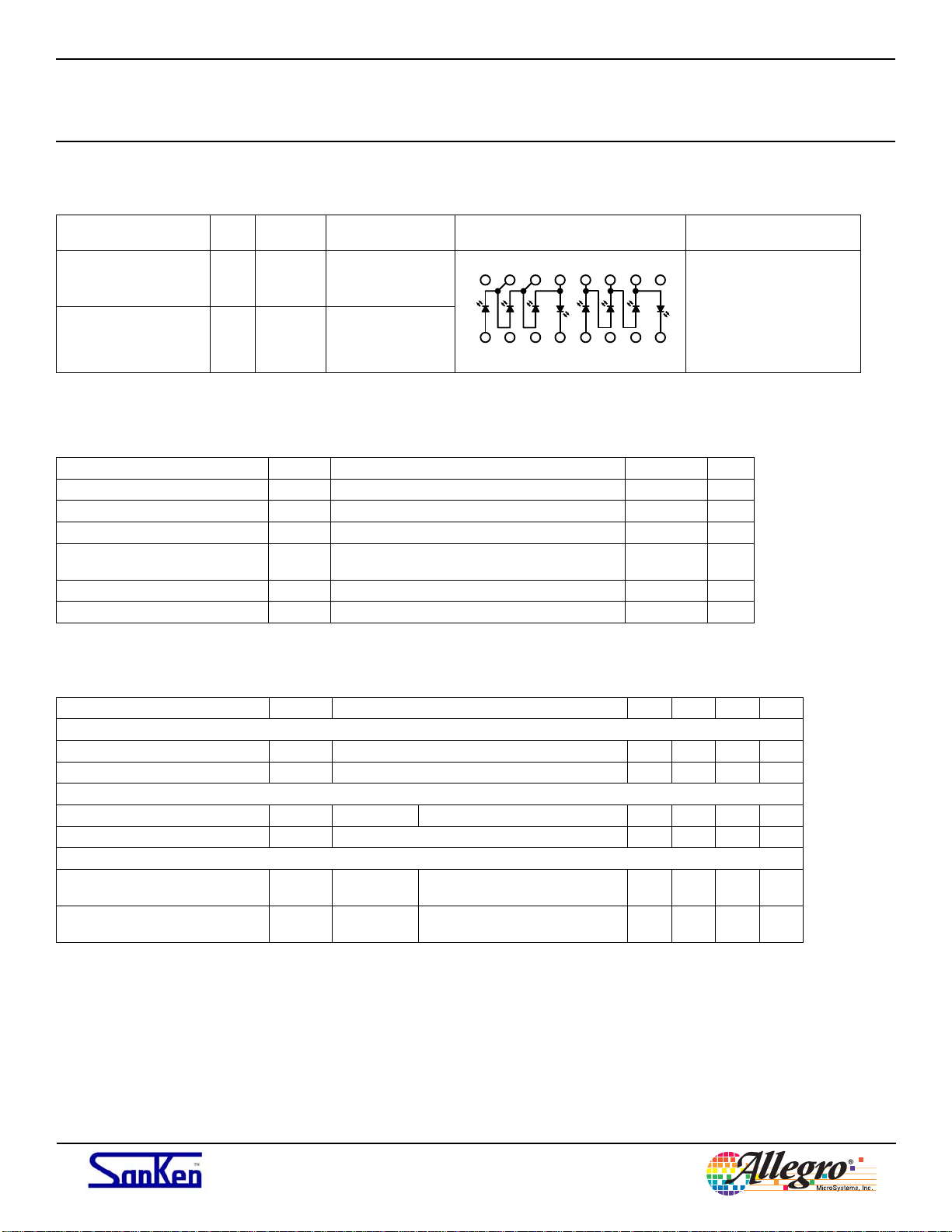

Selection Guide

Part Number LEDs Channels Color Temperature

Multi Chip White LED Modules

Internal Circuit Diagram

(Pin Numbers Shown)

Packing

SEP8WL2001 8 2 Bulb Light (2900)

16 15 14 13 12 11 10 9

B BBB BB

SEP8WN2001 8 2 Day White (5000)

12345678

Absolute Maximum Ratings (electrical characteristics at TA=25°C)

Characteristic Symbol Notes Rating Units

Forward Current (Continuous) I

Forward Current (Pulsed) I

Reverse Voltage V

Isolation Voltage V

Operating Temperature T

Storage Temperature T

Per element 40 mA

f

Frequency, f = 1 kHz, pulse width, tw = 100 μs 100 mA

fp

R

Measured from device pins to heatsink, with DC

IS

voltage applied

opr

stg

Operating Characteristics

Characteristic Symbol Conditions Min. Typ. Max. Units

Electrical

Forward Voltage (per LED channel) V

Reverse Current (per LED channel) I

Optical

Luminous Flux (all channels) Φ SEP8Wx 8 LEDs, I

Peak Wavelength λ

Thermal

Thermal Resistance (junction to

exposed thermal pad)

Thermal Resistance (junction to

ambient)

R

R

If = 20 mA, TA = 25˚C 2.6 3.1 3.8 V

f

VR = 5 V – – 10 μA

R

= 20 mA / LED 25 40 – lm

f

If = 20 mA TA = 25°C – 460 – nm

P

SEP8Wx 8 LEDs – 6 – °C/W

θJC

All SEPxWx – 120 – °C/W

θJA

BB

5V

±60 V

–40 to 85 °C

–40 to 90 °C

1000 pieces per reel

All performance characteristics given are typical values for circuit or

system baseline design only and are at the nominal operating voltage and

an ambient temperature, T

, of 25°C, unless oth er wise stated.

A

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

2

SEPW Series

Chromaticity and Color Temperature (JIS Z9112-2004) at TA = 25°C, If= 20 mA

Day White WN Yes

Bulb Light WL Yes

Color Symbol JIS Compliant

Multi Chip White LED Modules

x

(±0.01)

0.3616 0.3875

0.3552 0.3476

0.3324 0.3296

0.3326 0.3635

0.4834 0.4382

0.4594 0.3971

0.4153 0.3862

0.4305 0.4218

y

(±0.01)

Color Temperature (Center)

(K)

4600 to 5500

(5000)

2600 to 3250

(2900)

Chromaticity Diagram (Compliance with CIE1931)

0.50

0.45

0.40

Y

0.35

0.30

0.25

0.20

0.20 0.25 0.30 0.35 0.40 0.45 0.50

:1

Planckian Locus

X

:/

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

3

SEPW Series

Short Axis

Long Axis

Module

Top View

–50

Multi Chip White LED Modules

SEPW Series Directivity

TA= 25°C, If = 20 mA

0

–10

–20

–30 30

–40

10

20

Degrees from Normal

40

Common in Long and Short Axes

50

–80

–90

–70

–60

60

70

80

90

050100

Relative Emission Intensity

Emission Color Mixing

Additive white light

Silicone resin

with mixed

fluorescent material

Blue LED

Emission Spectrum (Typical)

TA= 25°C, If = 20 mA

Day White (WN) Bulb Light (WL)

1.2

1.0

0.8

0.6

0.4

0.2

Relative Emission Intensity Factor

0

380 480 580 680 780

Emission Wavelength (nm) Emission Wavelength (nm)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

1.2

1.0

0.8

0.6

0.4

0.2

Relative Emission Intensity Factor

0

380 480 580 680 780

4

SEPW Series

Multi Chip White LED Modules

Forward Current versus Foward Voltage

T

= 25°C

A

100

(mA)

f

I

10

2.70 2.90 3.10 3.30 3.50 3.70 3.90

(V)

V

f

Forward Voltage versus Ambient Temperature

= 20 mA

I

f

3.10

3.00

2.90

(V)

f

V

2.80

slope = –17 mV/°C

Relative Luminous Flux versus

Forward Current, T

3.50

3.00

2.50

2.00

1.50

1.00

Relative & Factor

0.50

0

020406080100

= 25°C

A

If (mA)

Relative Luminous Flux versus

Ambient Temperature, I

1.00

80

60

40

Relative & (%)

20

= 20 mA

f

2.70

0 20 40 60 80 100 120

TA (°C)

Forward Current versus Duty Cycle

T

= 25°C, tw≤ 100 μs

A

120

100

80

60

(mA)

f

40

I

20

0

110100

Duty Cycle (% On)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

0

020406080100120

TA (°C)

Allowable Forward Voltage versus Ambient

Temperature at Various Thermal Resistances

50

40

30

(V)

f

V

20

R

θ

JA

R

θJA

= 30°C/W

=50°C/W

R

θJA

= 15°C/W

Without Heatsink

R

θJA

10

0

= 120°C/W

020406080100

TA (°C)

5

SEPW Series

Multi Chip White LED Modules

Chromaticity versus Forward Current (Typical)

TA= 25°C

0.39

SEPxWN Target

Chromaticity Range

0.38

0.37

0.36

y

0.35

0.34

0.33

0.32

0.32 0.33 0.34 0.35 0.36 0.37 0.38

30 mA

10 mA

60 mA

40 mA

50 mA

20 mA

x

Chromaticity versus Ambient Temperature

If = 20 mA

0.45

0.44

0.43

0.42

y

0.41

0.4

0.39

0.38

SEPxWL Target

Chromaticity Range

60 mA

40 mA

20 mA

0.41 0.42 0.43 0.44 0.45 0.46 0.47 0.48 0.49

10 mA

50 mA

30 mA

x

y

0.39

0.38

0.37

0.36

0.35

0.34

0.33

0.32

SEPxWN Target

Chromaticity Range

50

60

°C

°C

40

70

°C

°C

25

0.45

0.44

0.43

0.42

°C

0.35 0.36 0.37 0.380.32 0.33 0.34

x

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

y

0.41

0.40

0.39

0.38

SEPxWL Target

Chromaticity Range

60°C

70°C

50°C

40°C

25°C

0.45 0.48 0.490.41 0.42 0.43 0.44 0.470.46

x

6

SEPW Series

Multi Chip White LED Modules

Package Outline Drawing

Device is lead (Pb) free.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

7

SEPW Series

Multi Chip White LED Modules

Solder Pad Layout

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

8

SEPW Series

Multi Chip White LED Modules

Embossed Tape and Reel Specifi cation

Taping reel dimensions (1/4)

Embossed taping outline dimensions (1/1)

330±2

8

.

0

±

0

.

1

2

φ

φ13.0±0.2

Label

29.4±1.0

25.4±1.0

100±1

Pull direction

No LEDsLEDs mounting partNo LEDs

Top cover tape

Reel Lead Min. 160 mm

Detailed drawing (1/1)

Anode mark

Tolerance ±0.2

P4.0

Embossed carrie r tape

φ1.5

2.0

φ1.5P12.0

1000 pcs/reel

0.34

1.75

11.5

14.5

3.7

9.2

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

Accmulative tol erance per 10 pitches shall be ±0.2 mm.

Adhesion streng th shall be 0.1-0.7 N when the cov er tape and

the carrier ta pe are torn o at the angle of 10 deg rees.

24.0

P/N, manufacturing date code number and quantitiy shall be indicated on

moist-proof package.

Reel Lead (No LEDs) Min. 320 mm

Reel Lead Min. 400 mm

9

SEPW Series

WARNING — These devices are designed to be operated at lethal voltages and energy levels. Circuit designs

that embody these components must conform with applicable safety requirements. Pre cau tions must be

taken to prevent accidental contact with power-line potentials. Do not connect ground ed test equipment.

The use of an isolation transformer is recommended during circuit development and breadboarding.

This product series emits high light output. Do NOT look directly into the light emitting area. Direct

exposure to the light over an extended time period may harm eyes.

Multi Chip White LED Modules

Because reliability can be affected adversely by improper storage

environments and handling methods, please observe the following:

Cautions for Storage

• Ensure that storage conditions are within 5°C to 40°C and relative

humidity < 30%; avoid storage locations that experience extreme

changes in temperature or humidity.

• Avoid locations where dust or harmful gases are present and

avoid direct sunlight.

• Reinspect for rust on leads and solderability of products that have

been stored for a long time.

Cautions for Testing and Handling

When tests are carried out during inspection testing and other

standard test periods, protect the products from power surges

from the testing device, shorts between adjacent products, and

shorts to the heatsink.

Precautions During Use

• Because the light generated inside the LED must be emitted

efficiently out of the module, a resin with high light transmittance

is used. Therefore, additives that are commonly used in

semiconductor devices to improve the heat resistance or moisture

resistance (such as silica glass) cannot be added to the resin.

Consequently, the ability of the resin to withstand heat is usually

low and the following precautions must be observed.

• Never apply an external force, stress, or excess vibration to resin

or terminals when at high temperature.

• Take particular care about heat dissipation when designing the

application. If dissipation is not adequate, the LEDs can reach

high temperatures, with resulting color change, luminous flux

reduction, and shortening of product lifetime.

• When the device is connected to an external radiator, please

coat the heatsink area with thermal conduction material such as

thermal conductive bond or thermal conductive grease.

• Extra attention should be paid to the sealing resin of the product,

which is rubber-like silicon resin. The surface of sealing resin is

slightly sticky (surface tack). Therefore, touching the emitting area

or exposing it to unclean conditions may cause dust or smudges

to adhere to it and possibly penetrate the resin. This could

cause deterioration of product characteristics when contacted by

materials such as epoxy resin.

• The silver plating of the leadframe may discolor if the product

comes into contact with material containing sulfides or if it is

exposed to an atmosphere containing sulfide gas.

• The emitting area of the LEDs contains fine gold wires. Touching

this area without care may add excess stress on the internal gold

wires and may result in disconnection of the internal wires.

Soldering

• The product is in a surface mount package. The product should

not be mounted on warped direction of the PCB.

• When the product is mounted by means of solder reflow and the

resin is unusually damp, solder dipping may cause interfacial

defoliation. This occurs when a drastic temperature change

causes moisture in the resin to evaporate and to swell. Therefore,

attention must be paid to the following:

• Examine the moisture-resistant packing before opening. If

the indicator color (blue) of the desiccant (such as silica gel)

has disappeared, the product must be prebaked as described

below.

• After the product packing is opened and staged for assembly,

soldering should be carried out as soon as practicable.

• During handling, ambient conditions should be 5°C to 30°C,

with relative humidity < 70%

• After 120 hours of exposure, prebake is recommended

before soldering; bake-out at 60±5°C for more than 10 hours

• After soldering, no mechanical force or excessive vibration should

be applied to the product until the product has cooled down to

normal room temperature. Quick cooling must be avoided.

• When soldering the products, please be sure to minimize the

working time, within the following limits:

Soldering Iron Temperature

(°C)

Time

(s)

350±10 3 (once only)

• Reflow soldering can be performed a maximum of 2 times, with

preheat conditions of 150°C to 180°C (at the device surface)

for 60 to 120 s, and soldering conditions less than 40 s at more

than 220°C, with a peak temperature less than 260°C, using the

following recommended profile:

Reflow Soldering Profile

300

260

220

180

140

100

60

20

Temperature of Device Package Surface (°C)

0 50 100 150 200 250 300

Peak 260°C Max

Pre-heat

60 to 120 sec

Soldering Time (s)

40 sec

Max

Between the first and second reflow sessions, follow the

guidelines in the Cautions for Storage section, above.

Electrostatic Discharge

• When handling the products, operator must be grounded.

Grounded wrist straps worn should have at least 1 MΩ of

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

10

SEPW Series

Multi Chip White LED Modules

resistance to ground to prevent shock hazard.

• Workbenches where the products are handled should be

grounded and be provided with conductive table and floor mats.

• When using measuring equipment such as a curve tracer, the

equipment should be grounded.

• When soldering the products, the head of soldering irons or the

solder bath must be grounded in other to prevent leak voltages

generated by them from being applied to the products.

• The products should always be stored and transported in our

shipping containers or conductive containers, or be wrapped in

Power Supply

Bypass

Capacitor

0.1 μF

R

10 kΩ

Protective Circuit

Reference Circuit Using Capacitor Reference Circuit Using Zener Diode

C

>0.01 μF

Resistor

aluminum foil.

• Exposure to any overvoltage exceeding the Absolute Maximum

Rating of the products may cause damage to, or possibly result in

destruction of, the products. Buyer shall take absolutely secured

countermeasures against static electricity and surge when

handling the products.

• Typical anti-static and anti-surge reference circuits are shown

below. The circuits shown are for reference only, and the buyer

must make a sufficient experimental verification of the static and

surge levels when employing the product.

Resistor

1X per LED

ZD

VR 7 to 8 V

Protective Circuit

Application and operation examples described in this document are quoted for the sole purpose of reference only, for the use of the products

herein, and Sanken can assume no responsibility for any infringement of industrial property rights, intellectual property rights, or any other rights

of Sanken or any third party which may result from its use.

When using the products herein, the applicability and suitability of such products for an intended purpose or object shall be reviewed at the

user’s responsibility.

Although Sanken undertakes to enhance the quality and reliability of its products, the occurrence of failure and defect of semiconductor products at a certain rate is inevitable. Users of Sanken products are requested to take, at their own risk, preventative measures including safety design

of the equipment or systems against any possible injury, death, fires or damages to the society due to device failure or malfunction.

Sanken products listed in this document are designed and intended for the use as components in general purpose electronic equipment or apparatus (home appliances, office equipment, telecommunication equipment measuring equipment, etc.). Before placing an order, the user’s written

consent to the specifications is requested.

When considering the use of Sanken products in the applications where higher reliability is required (transportation equipment and its control

systems, traffic signal control systems or equipment, fire/crime alarm systems, various safety devices, etc.), please contact your nearest Sanken

sales representative to discuss and obtain written confirmation of your specifications.

The use of Sanken products without the written consent of Sanken in the applications where extremely high reliability is required (aerospace

equipment, nuclear power control systems, life support systems, etc.) is strictly prohibited.

Anti radioactive ray design is not considered for the products listed herein.

If there is any discrepancy between English and Japanese versions of this datasheet, the Japanese version should take precedence over the

English one.

Please accept in advance that the content of this datasheet is subject to change without notice for the purpose of such as improvement of the

product.

Copyright © 2007-2008 Allegro MicroSystems, Inc. This datasheet is based on Sanken datasheet 92019.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

11

SEPW Series

Asia-Pacific

Multi Chip White LED Modules

Worldwide Contacts

China

Sanken Electric Hong Kong Co., Ltd.

Suite 1026, Ocean Centre, Canton Road

Tsimshatsui, Kowloon, Hong Kong

Tel: 852-2735-5262, Fax: 852-2735-5494

Sanken Electric (Shanghai) Co., Ltd.

Room 3202, Maxdo Centre, Xingyi Road 8

Changning District, Shanghai, China

Tel: 86-21-5208-1177, Fax: 86-21-5208-1757

Taiwan Sanken Electric Co., Ltd.

Room 1801, 18th Floor, 88 Jung Shiau East Road

Sec. 2, Taipei 100, Taiwan R.O.C.

Tel: 886-2-2356-8161, Fax: 886-2-2356-8261

India

Saket Devices Pvt. Ltd.

Office No. 13, First Floor, Bandal-Dhankude Plaza

Near PMT Depot, Paud Road

Kothrud, Pune 411 038, India

Tel: 91-20-5621-2340, 91-20-2528-5449

Fax: 91-20-2528-5459

Japan

Sanken Electric Co., Ltd.

Overseas Sales Headquarters

Metropolitan Plaza Building, 1-11-1 Nishi-Ikebukuro

Toshima-ku, Tokyo 171-0021, Japan

Tel: 81-3-3986-6164, Fax: 81-3-3986-8637

Korea

Sanken Electric Korea Co., Ltd.

Mirae Asset Life Building, 6F

168 Kongduk-dong, Mapo-ku

Seoul 121-705, Korea

Tel: 82-2-714-3700, Fax: 82-2-3272-2145

Singapore

Sanken Electric Singapore Pte. Ltd.

150 Beach Road, #14-03 The Gateway West

Singapore 189720

Tel: 65-6291-4755, Fax: 65-6297-1744

Europe

Sanken Power Systems (UK) Limited

Pencoed Technology Park

Pencoed, Bridgend CF35 5HY, United Kingdom

Tel: 44-1656-869-100, Fax: 44-1656-869-162

North America

United States

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01606, U.S.A.

Tel: 1-508-853-5000, Fax: 1-508-853-7895

Allegro MicroSystems, Inc.

14 Hughes Street, Suite B105

Irvine, California 92618, U.S.A.

Tel: 1-949-460-2003, Fax: 1-949-460-7837

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

12

Loading...

Loading...