查询ATS665LSG供应商

ATS665LSG

Pin 1: V

Pin 2: V

Pin 3: Tie to Gnd or Float

Pin 4: Gnd

CC

OUT

ABSOLUTE MAXIMUM RATINGS

Supply Voltage1,

VCC . . . . . . . . . . . . . . . . . . . . . . . . . . 26.5 V

Reverse Supply Voltage,

V

Reverse Output Current

I

Continuous Output Current,

I

Ambient Operating Temperature Range,

T

Storage Temperature,

T

Maximum Junction Temperature,

T

Maximum Junction Temperature – 100 Hours,

T

1

Refer to power de-rating curve

2

V

. . . . . . . . . . . . . . . . . . . . . . . . . . –18 V

RCC

. . . . . . . . . . . . . . . . . . . . . . . . . . . 50 mA

RCC

. . . . . . . . . . . . . . . . . . . . . . . . . . 20 mA

OUT

. . . . . . . . . . . . . . . . . . -40° C to 150°C

A

. . . . . . . . . . . . . . . . . . . . -65° C to 170°C

S

. . . . . . . . . . . . . . . . . . . . . . . . . 165° C

Jmax

. . . . . . . . . . . . . . . . . . . . . . . . . 185° C

Jmax

≥ -0.5V

OUT

2

,

True Zero Speed,

High Accuracy, Gear Tooth Sensor

The ATS665 true zero-speed gear tooth sensor is an optimized

Hall IC/magnet configuration packaged in a molded module that

provides a user-friendly solution for digital gear tooth sensing

applications. The sensor module consists of an over-molded

package, which holds together a samarium cobalt magnet, a pole

piece and a true zero-speed Hall IC that has been optimized to the

magnetic circuit. This small package can be easily assembled and

used in conjunction with gears of various shapes and sizes.

The sensor incorporates a dual element Hall IC that switches in

response to differential magnetic signals created by a ferrous

target. The IC contains a sophisticated compensating circuit

designed to reduce the detrimental effects of magnet and system

offsets. Digital processing of the analog signal provides zero speed

performance independent of air gap and also dynamic adaptation of

device performance to the typical operating conditions found in

automotive applications (reduced vibration sensitivity). Highresolution peak detecting DACs are used to set the adaptive

switching thresholds of the device. Hysteresis in the thresholds

reduces the negative effects of any anomalies in the magnetic

signal associated with the targets used in many automotive

applications.

This sensor’s ability to provide tight duty cycle at high speeds

and over a wide temperature range makes it ideal for transmission

and industrial speed applications. The ATS665 is available in the

SG package in the automotive temperature range, -40° to 150° (L).

FEATURES & BENEFITS

True zero-speed operation

Switchpoints independent of air gap

High vibration immunity

Precise duty cycle signal over operating temperature range

Large operating air gaps

Defined power-on state

Wide operating voltage range

Digital output representing target profile

Single-chip sensing IC for high reliability

Small mechanical size

Optimized Hall IC magnetic system

200 µs power-on time at gear speed < 100 rpm

AGC and reference adjust circuit

Under-voltage lockout

Use complete part number when ordering: ATS665LSG.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

OPERATING CHARACTERISTICS

Valid at TA = -40oC to 150oC over air gap, unless otherwise noted

Typical operating parameters: V

Characteristics Symbol Test Conditions

ELECTRICAL CHARACTERISTICS

Supply Voltage VCC Operating; Tj < Tjmax 3.3 – 24 V

Under Voltage Lockout V

Reverse Supply Current I

Supply Zener Clamp Voltage VZ Icc = I

Supply Zener Current IZ Test only; VCC = 28V, Tj < Tj(max) – –

Supply Current ICC

– –

CC(UV)

VCC = –18 V – – –10 mA

RCC

+ 3mA,TA = 25°C 26.5 – – V

cconMAX

Output OFF – 8 14 mA

Output ON – 8 14 mA

= 12 V and TA = 25°C

cc

Limits

Min. Typ. Max. Units

< Vcc

min

Iccon

+ 3

max

mA

V

POWER-ON STATE CHARACTERISTICS

Power-On State SPO – High –

Power-On Time t

PO

Gear Speed < 100 RPM; VCC > VCC min – – 200

µs

OUTPUT STAGE

Low Output Voltage V

Output Current Limit I

Output Leakage Current I

Output Rise Time t

Output Fall Time t

Output = ON, I

Sat

V

lim

OFF

r

f

= 12 V, Tj < Tj(max) 25 45 70 mA

OUT

Output = OFF, V

R

= 500 Ω, C

LOAD

R

= 500 Ω, C

LOAD

= 20 mA – 225 400 mV

SINK

= 24 V – – 10

OUT

LOAD

LOAD

= 10 pF

= 10 pF

– 1.0 2

– 0.6 2

µA

µs

µs

SWITCH POINT CHARACTERISTICS

Target Speed S

Reference target 0 – 12000 rpm

Bandwidth f-3dB – 20 – kHz

Operate Point BOP % of peak-to-peak signal, AG < AG

Release Point BRP % of peak-to-peak signal, AG < AG

– 70 – %

(max)

– 30 – %

(max)

Final Version, Rev 1.0; DSD; 01Aug03

Page 2

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

CALIBRATION

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

Initial Calibration

Calibration Update

Start-up3 – 2 6 Edges

Running mode operation Continuous

OPERATING CHARACTERISTICS (with 60-0 reference target)

Operational Air Gap AG

Duty Cycle

Operating Signal

Measured from sensor face to top of

target tooth

AG < AG

Duty cycle spec compliance 60 – – G

, reference target 42 47 52 %

(max)

REFERENCE TARGET/GEAR INFORMATION

3

Power-on speed ≤ 200 rpm

Diameter 120 mm

Thickness 6 mm

Tooth Width 3 mm

0.5 – 2.5 mm

Valley Width 3 mm

Valley Depth 3 mm

Material Low carbon steel

Final Version, Rev 1.0; DSD; 01Aug03

Page 3

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

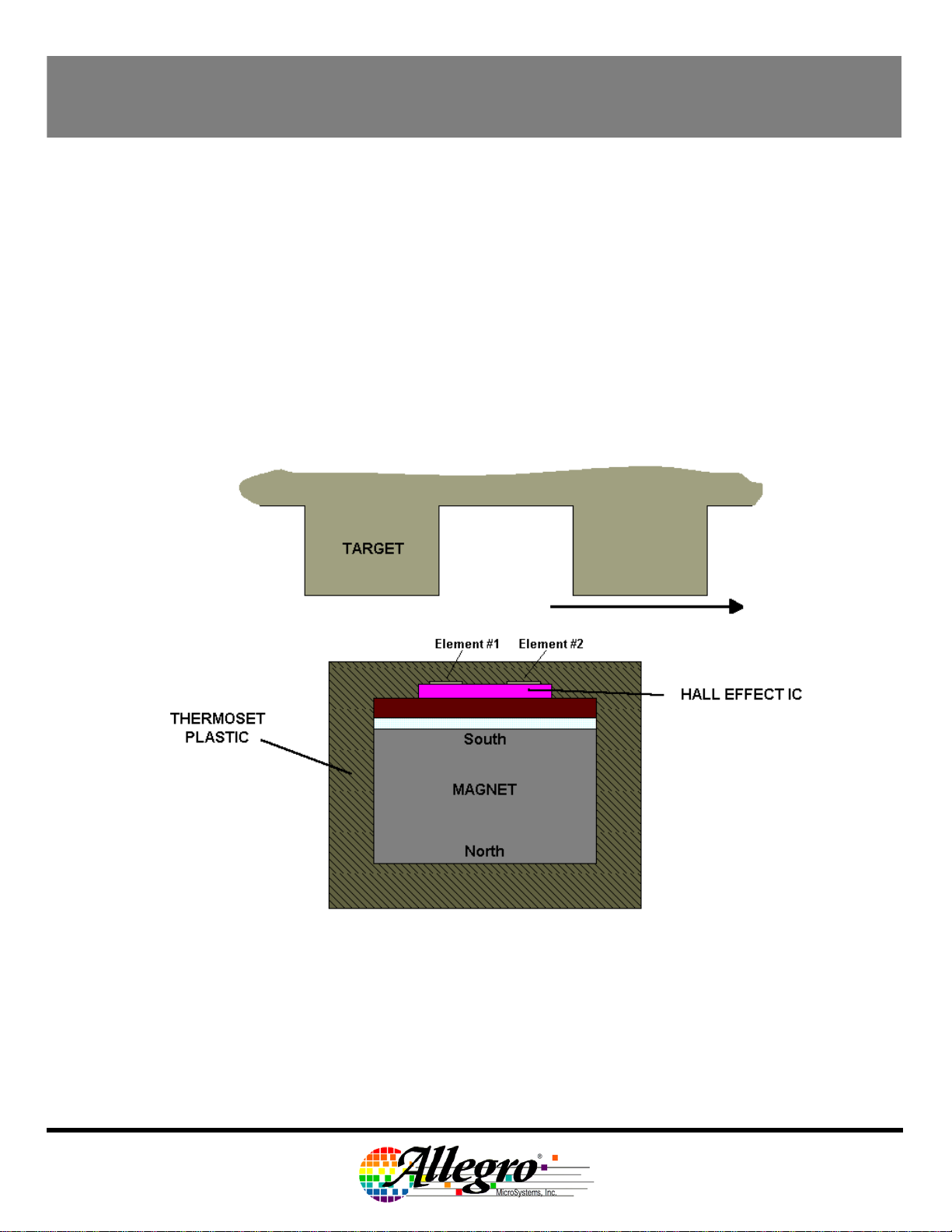

SENSOR DESCRIPTION

Assembly Description:

The ATS665 true zero speed gear tooth sensor is a Hall IC/magnet configuration that is fully optimized to provide digital

detection of gear tooth edges. This sensor is integrally molded into a plastic body that has been optimized for size, ease of

assembly, and manufacturability. High operating temperature materials are used in all aspects of construction.

Sensing Technology:

The gear tooth sensor sub-assembly contains a single-chip differential Hall effect sensor IC, a Samarium Cobalt magnet,

and a flat ferrous pole piece. The Hall IC consists of two Hall elements spaced 2.2 mm apart which measure the magnetic

gradient created by the passing of a ferrous object. The gradient is converted to an analog voltage that is then processed

to provide a digital output signal.

Final Version, Rev 1.0; DSD; 01Aug03

Page 4

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

Operation:

After proper power is applied to the component the sensor is then capable of providing digital information that is

representative of the profile of a rotating gear. No additional optimization is needed and minimal processing circuitry is

required. This ease of use should reduce design time and incremental assembly costs for most applications. The following

output diagram is indicative of the sensor performance for the polarity indicated in the figure at the bottom of the page.

MECHANICAL PROFILE

MAGNETIC PROFILE

SENSOR ELECTRICAL OUTPUT PROFILE

Output Polarity:

The output of the sensor will switch from LOW to HIGH as the leading edge of the tooth passes the sensor face in the

direction indicated in the figure below. In this system configuration, the output voltage will be high when the sensor is facing

a tooth. If rotation occurs in the opposite direction, the output polarity will invert.

High over Tooth

Power-On State Operation:

The device is guaranteed to power up in the OFF state (logic high output).

Final Version, Rev 1.0; DSD; 01Aug03

Page 5

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

Start-up Detection:

Since the sensor powers up in the OFF state (logic high output), the first edge seen by the sensor can be missed if the

switching induced by that edge reinforces the OFF state. Therefore, the first edge that can be guaranteed to induce an

output transition is the second detected edge. This device has accurate first electrical falling edge detection. The tables

below show various start-up schemes.

MECHANICAL

TARGET PROFILE

MAGNETIC PROFILE

(High over Tooth)

SENSOR OUTPUT

(Start-up over Valley)

High over Tooth

SENSOR OUTPUT

(Start-up over Rising Edge)

Low over Tooth

SENSOR OUTPUT

(Start-up over Tooth)

SENSOR OUTPUT

(Start-up over Falling Edge)

MECHANICAL

TARGET PROFILE

MAGNETIC PROFILE

(Low over Tooth)

SENSOR OUTPUT

(Start-up over Valley)

SENSOR OUTPUT

(Start-up over Rising Edge)

Sensor start-up location

Final Version, Rev 1.0; DSD; 01Aug03

Page 6

SENSOR OUTPUT

(Start-up over Tooth)

SENSOR OUTPUT

(Start-up over Falling Edge)

Sensor start-up location

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

N

TRUE ZERO-SPEED GEAR TOOTH SENSOR

Under-Voltage Lockout:

When the supply voltage falls below the minimum operating voltage (Vcc

irrespective of the state of the magnetic field. This prevents false signals caused by under-voltage conditions from

propagating to the output of the sensor.

Power Supply Protection:

The device contains an on-chip regulator and can operate over a wide supply voltage range. For devices that need to

operate from an unregulated power supply, transient protection must be added externally. For applications using a

regulated line, EMI/RFI protection may still be required. The following circuit is the most basic configuration required for

proper device operation. For EMC information, contact your Allegro representative.

), the device turns OFF and stays OFF

UV

Internal Electronics:

The ATS665 contains a self-calibrating Hall effect IC that possesses two Hall elements, a temperature compensated

amplifier and offset cancellation circuitry. The IC also contains a voltage regulator that provides supply noise rejection over

the operating voltage range. The Hall transducers and the electronics are integrated on the same silicon substrate using a

proprietary BiCMOS process. Changes in temperature do not greatly affect this device due to the stable amplifier design

and the offset rejection circuitry.

Vcc

Vsig

INTERNAL

HALL AMP

AUTOMAT IC

GAIN

CONTROL

THRESHP

REFERENCE

GENERATOR

PDAC

PPEAK

THRESHN

REGULATOR

THRESHOLD

COMPAR ATOR

THRESH

LOGIC

OUTPUT

Output

Transisto

Current

Limit

DAC

NPEAK

GND

Final Version, Rev 1.0; DSD; 01Aug03

Page 7

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

SENSOR OPERATION: AUTOMATIC GAIN CONTROL (AGC)

The patented self-calibrating circuitry is unique. After each power up, the device measures the peak-to-peak magnetic

signal. The gain of the sensor is then adjusted which keeps the internal signal amplitude constant over the air gap range of

the device. This feature provides operational characteristics independent of air gap.

MAGNETIC FLUX DENSITY

DIFFERENTIAL MAGNETIC SIGNAL

WITH INCREASING AIR GAP

1000

800

600

400

200

0

-200

[GAUSS]

-400

-600

-800

-1000

0123456789101112131415

TARGET POSITION [DEGREES]

0.25 mm

0.50 mm

1.00 mm

1.50 mm

2.00 mm

DIFFERENTIAL SIGNAL [mV]

DIFFERENT IAL ELECT RICAL SIGNAL

WIT H INCREASING AIR GAP

1000

800

600

400

200

0

-200

-400

-600

-800

-1000

0123456789101112131415

TARGET POSITION [DEGREES]

0.25 mm

0.50 mm

1.00 mm

1.50 mm

2.00 mm

Magnetic Signal with no Amplification

Electrical Signal after AGC

SENSOR OPERATION: OFFSET ADJUST

In addition to normalizing performance over air gap, the gain control circuitry also reduces the effect of chip, magnet, and

installation offsets. This is accomplished using two D/A converters that capture the peak and valley of the signal and use it

as a reference for the switching comparator. If induced offsets bias the absolute signal up or down, AGC and the dynamic

DAC behavior work to normalize and reduce the impact of the offset on sensor performance.

Final Version, Rev 1.0; DSD; 01Aug03

Page 8

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

SENSOR OPERATION: SWITCHPOINTS

Switchpoints in the ATS665 are established dynamically as a percentage of the amplitude of the normalized magnetic

signal. Two DACs track the peaks of the normalized magnetic signal (see the section on Update); the switching thresholds

are established at 30% and 70% of the two DAC’s values. The proximity of the thresholds near 50% ensures the most

accurate and consistent switching where the signal is steepest and least affected by air gap variation.

The hysteresis of 40% provides high air gap performance and immunity to false switching on noise, vibration, backlash and

other transient events. Since the hysteresis value is independent of air gap, it provides protection against false switching in

the presence of overshoot that can be induced on the edges of large teeth.

The figure below graphically demonstrates the establishment of the switching threshold levels.

Switching Threshold Levels

Bop

100 %

70 %

30 %

0 %

Brp

Because the threshold are established dynamically as a percentage of the peak-peak signal, the effect of a baseline shift is

minimized. As a result, the effects of offsets induced by tilted or off-center installation are minimized.

Final Version, Rev 1.0; DSD; 01Aug03

Page 9

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

SENSOR OPERATION: UPDATE

The ATS665 incorporates an algorithm that continuously monitors the system and updates the switching thresholds

accordingly. The switch point for each edge is determined by the previous two edges. Since variations are tracked in real

time, the sensor has high immunity to target run-out and retains excellent accuracy and functionality in the presence of

both run-out and transient mechanical events. The figures below show how the sensor uses historical data to provide the

switching threshold for a given edge.

Switching Level - Operate

Operate point

based on previous

two peaks

Final Version, Rev 1.0; DSD; 01Aug03

Page 10

Switching Level - Release

Release point

based on previous

two peaks

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

SENSOR/TARGET EVALUATION

In order to establish the proper operating specification for a particular sensor/target system, a systematic evaluation of the

magnetic circuit should be performed. The first step is the generation of a magnetic map of the target. By using a

calibrated device, a magnetic signature of the system is made. The following is a map of the 60-0 reference target. Flux

density shown is the differential of the magnetic fields sensed at the two Hall elements.

300

250

200

150

100

50

0

-50

-100

Flux Density [Gauss]

-150

-200

0.94mm

1.19mm

1.44mm

1.69mm

1.94mm

2.19mm

2.44mm

2.69mm

2.94mm

3.19mm

-250

-300

0 5 10 15 20 25 30 35

Position [º]

A single curve is distilled from this map data that describes the peak-peak magnetic field versus air gap. Knowing the

minimum amount of magnetic flux density that guarantees operation of the sensor, one can determine the maximum

operational air gap of the sensor/target system. Referring to the chart below, a minimum required peak-peak signal of 60G

corresponds to a maximum air gap of approximately 2.5 mm.

ATS665LSG 60-0 TARGET MAP

700

600

500

400

300

200

Peak-Peak Flux Density [Gauss]

100

0

0.511.522.533

Final Version, Rev 1.0; DSD; 01Aug03

Page 11

Air Gap [mm]

.5

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

TARGET DESIGN

For the generation of adequate magnetic field levels to maximize air gap performance, the following recommendations

should be followed in the design and specification of targets.

• Tooth width > 2 mm

• Valley width > 2 mm

• Valley depth > 2 mm

• Gear thickness > 3 mm

• Target material must be low carbon steel

Though these parameters apply to targets of traditional geometry (radially oriented teeth with radial sensing), they can be

applied to stamped targets as well. For stamped geometries with axial sensing, the valley depth is intrinsically infinite so

the criteria for tooth width, valley width, material thickness (can be < 3 mm) and material specification need only be

considered.

SENSOR EVALUATION: ACCURACY

While the update algorithm will allow the sensor the adapt to system changes (i.e. air gap increase), major changes in air

gap can adversely affect switching performance. When characterizing sensor performance over a significant air gap range,

be sure to re-power the device at each air gap. This ensures that self-calibration occurs for each installation condition.

See the section entitled Characteristic Data for typical duty cycle performance.

Final Version, Rev 1.0; DSD; 01Aug03

Page 12

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

POWER DE-RATING

Due to internal power consumption, the junction

temperature of the IC, Tj, is higher than the ambient

environment temperature, Ta. To ensure that the device

does not operate above the maximum rated junction

temperature use the following calculations:

∆T = PD * Rθja

Where: P

Where ∆T denotes the temperature rise resulting from

the IC’s power dissipation.

For the sensor :

Typical Tj calculation:

Vcc = 5 V

Icc = 7.0 mA

P

∆T = P

Tj = Ta + ∆T = 25 °C + 5.0°C = 30.0°C

Maximum Allowable Power Dissipation Calculation

for ATS665:

Assume:

Ta = Ta

Tj(max) = 165°C

Icc = 12.0 mA4

If:

4

max Icc @ 150C < max Icc @ 25C, see characteristic

data

= Vcc * Icc

D

∴ ∆T=Vcc * Icc * Rθja

Tj = Ta + ∆T

Tj(max) = 165°C

Rθja = 126°C/W

Ta = 25 °C

= Vcc * Icc = 5 V * 8.0 mA = 40.0 mW

D

* Rθja = 40.0 mW * 126°C/W = 5.0°C

D

= 165 °C

max

Tj = Ta + ∆T

Then, at Ta = 150 °C:

∆T

max

= Tj

max

– Ta

= 165°C - 150°C = 15°C

max

If:

∆T = P

* Rθja

D

Then, at Ta = 150°C:

P

Dmax

= ∆T

/ Rθja = 15°C / 126°C/W = 119 mW

max

If:

P

= Vcc * Icc

D

Then the maximum Vcc at 150°C is therefore:

Vccmax = P

/ Icc = 119 mW / 12.0 mA = 9.9 V

Dmax

This value applies only to the voltage drop across the

665 chip. If a protective series diode or resistor is used,

the effective maximum supply voltage is increased.

For example, when a standard diode with a 0.7 V drop is

used:

Vsmax = 9.9 V + 0.7 V = 10.6 V

ATS665LSG Package Power De-Rating Curve

The rm a l R e si st a nce = 126°C/ W a tt, T

30.0

28.0

26.0

24.0

22.0

20.0

18.0

16.0

14.0

12.0

10.0

8.0

6.0

4.0

Maximum Supply Voltage [Volts]

2.0

0.0

20 40 60 80 100 120 140 160 180

Ambient Temperature [°C]

c

jmax

= 165°C

Final Version, Rev 1.0; DSD; 01Aug03

Page 13

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

CHARACTERISTIC DATA

IccOn

14

12

10

8

6

Icc [mA]

4

2

0

0102030

Vcc [V]

IccOff

14

12

10

8

6

Icc [mA]

4

2

0

0102030

Vcc [V]

Vsat

400

350

°C

°C

-40

0

25

85

150

-40

0

25

85

150

IccOn

14

12

10

8

6

Icc [mA]

4

2

0

-50 0 50 100 150

Temperature [°C]

4.3

12

20

26.5

Vcc

IccOff

14

12

10

8

6

Icc [mA]

4

2

0

-50 0 50 100 150

Temperature [°C]

4.3

12

20

26.5

Vcc

300

250

200

150

Output Voltage [mV]

100

50

-50 0 50 100 150 200

Temperature [°C]

Final Version, Rev 1.0; DSD; 01Aug03

Page 14

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

CHARACTERISTIC DATA (Continued)

Duty Cycle 100 RPM

53

52

51

50

49

48

47

46

Duty Cycle [%]

45

44

43

-50 0 50 100 150

Temperature [°C]

Duty Cycle 1000 RPM

53

52

51

50

49

48

47

46

Duty Cycle [%]

45

44

43

-50 0 50 100 150

Temperature [°C]

Air

gap

Air

gap

0.4

0.5

0.8

1.5

2.35

2.5

0.4

0.5

0.8

1.5

2.35

2.5

Duty Cycle 100 RPM

53

52

51

50

49

48

47

46

Duty Cycle [%]

45

44

43

0123

Air Gap [mm]

-40

0

25

85

150

°C

Duty Cycle @ 1000 RPM

53

52

51

50

49

48

47

46

Duty Cycle [%]

45

44

43

0123

Air Gap [mm]

-40

0

25

85

150

°C

Final Version, Rev 1.0; DSD; 01Aug03

Page 15

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

PACKAGE DRAWING

Final Version, Rev 1.0; DSD; 01Aug03

Page 16

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

RELATED DOCUMENTS

Documents that can be found on the Allegro Microsystems web site: www.allegromicro.com :

• Definition of Terms (Pub 26004)

• Hall-Effect Devices: Soldering, Gluing, Potting, Encapsulating, and Lead Forming (AN27703.1)

• Storage of Semiconductor Devices (Pub 26011)

Hall Effect Applications Guide (Pub 27701)

•

Applications Note: Back-Biased Packaging Advances (SE, SG & SH versus SA & SB) •

Additional Applications Information on gear tooth and other Allegro sensors can be obtained at Allegro’s web

site, www.allegromicro.com

Final Version, Rev 1.0; DSD; 01Aug03

Page 17

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

ATS665LSG

TRUE ZERO-SPEED GEAR TOOTH SENSOR

Final Version, Rev 1.0; DSD; 01Aug03

Page 18

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1993, 1995 Allegro MicroSystems, Inc.

Loading...

Loading...