查询ATS642LSH供应商

ATS642LSH

Two-Wire True Zero Speed Miniature Differential

Peak-Detecting Gear Tooth Sensor with Continuous Calibration

The ATS642LSH is an optimized Hall effect sensing integrated circuit and magnet

combination that provides a user-friendly solution for true zero-speed digital

gear-tooth sensing in two-wire applications. The sensor consists of a single-shot

Package SH, 4-pin Module

1

2

3

4

1. VCC

2. No connection

3. Test pin (fl oat or tie to GND)

4. GND

molded plastic package that includes a samarium cobalt magnet, a pole piece,

and a Hall effect IC that has been optimized to the magnetic circuit. This small

package, with optimized two-wire leadframe, can be easily assembled and used in

conjunction with a wide variety of gear shapes and sizes.

The integrated circuit incorporates a dual element Hall effect sensor and signal

processing that switches in response to differential magnetic signals created

by ferrous gear teeth. The circuitry contains a sophisticated digital circuit to

reduce magnet and system offsets, to calibrate the gain for air gap independent

switchpoints, and to achieve true zero-speed operation. Signal optimization occurs

at power-up through the combination of offset and gain adjust and is maintained

throughout the operating time with the use of a running mode calibration. The running mode calibration allows immunity to environmental effects such as microoscillations of the target or sudden air gap changes.

The regulated current output is configured for two wire applications and the

sensor is ideally suited for obtaining speed and duty cycle information in ABS

(antilock braking systems). The 1.5 mm Hall element spacing is optimized for fine

pitch gear-tooth-based configurations. The package is lead (Pb) free, with 100%

matte tin leadframe plating.

AB SO LUTE MAX I MUM RAT INGS

Supply Voltage, V

Reverse-Supply Voltage, V

Operating Temperature

Ambient, T

Maximum Junction, T

Storage Temperature, T

ATS642LSH-DS

..........................................28 V

CC

,............................... –40ºC to 150ºC

A

........................–18 V

RCC

........................165ºC

J(max)

.................. –65ºC to 170ºC

S

Features and Benefi ts

• Running mode calibration for continuous optimization

• Single chip IC for high reliability

• Internal current regulator for 2-wire

operation

• Small mechanical size (8 mm

diameter x 5.5 mm depth)

• Precise duty cycle signal over

operating temperature range

Use the following complete part numbers when ordering:

Part Number ICC Typical Packing*

ATS642LSHTN-I1-T 6.0 Low to 14.0 High mA

ATS642LSHTN-I2-T 7.0 Low to 14.0 High mA

*Contact Allegro for additional packing options.

• Large operating air gaps

• Automatic Gain Control (AGC)

gap independent switchpoints

• Automatic Offset Adjustment (AOA)

for signal processing optimization

• True zero-speed operation

• Undervoltage lockout

• Wide operating voltage range

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

for air

Tape and reel,

13-inch reel

800 pieces/reel

ATS642LSH

C

D

True Zero Speed Miniature Differential Peak-Detecting Gear Tooth Sensor

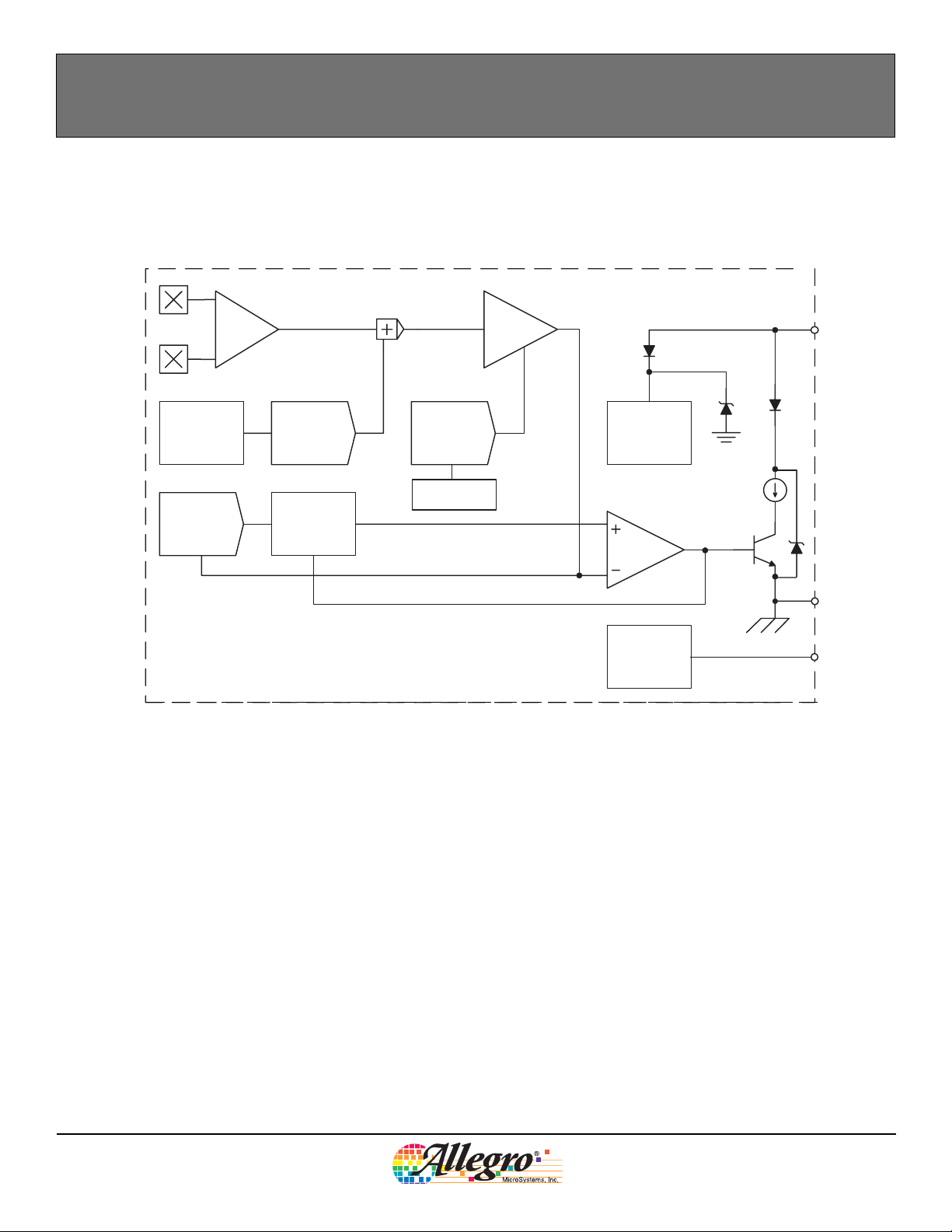

Functional Block Diagram

Amplifier

Automatic Offset

Control

Tracking

DAC

Hall

AOA DAC

Peak Hold

AGC DAC

Gain Control

Gain

Internal Regulator

Test Signals

VC

GN

Test

ATS642LSH-DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

2

ATS642LSH

True Zero Speed Miniature Differential Peak-Detecting Gear Tooth Sensor

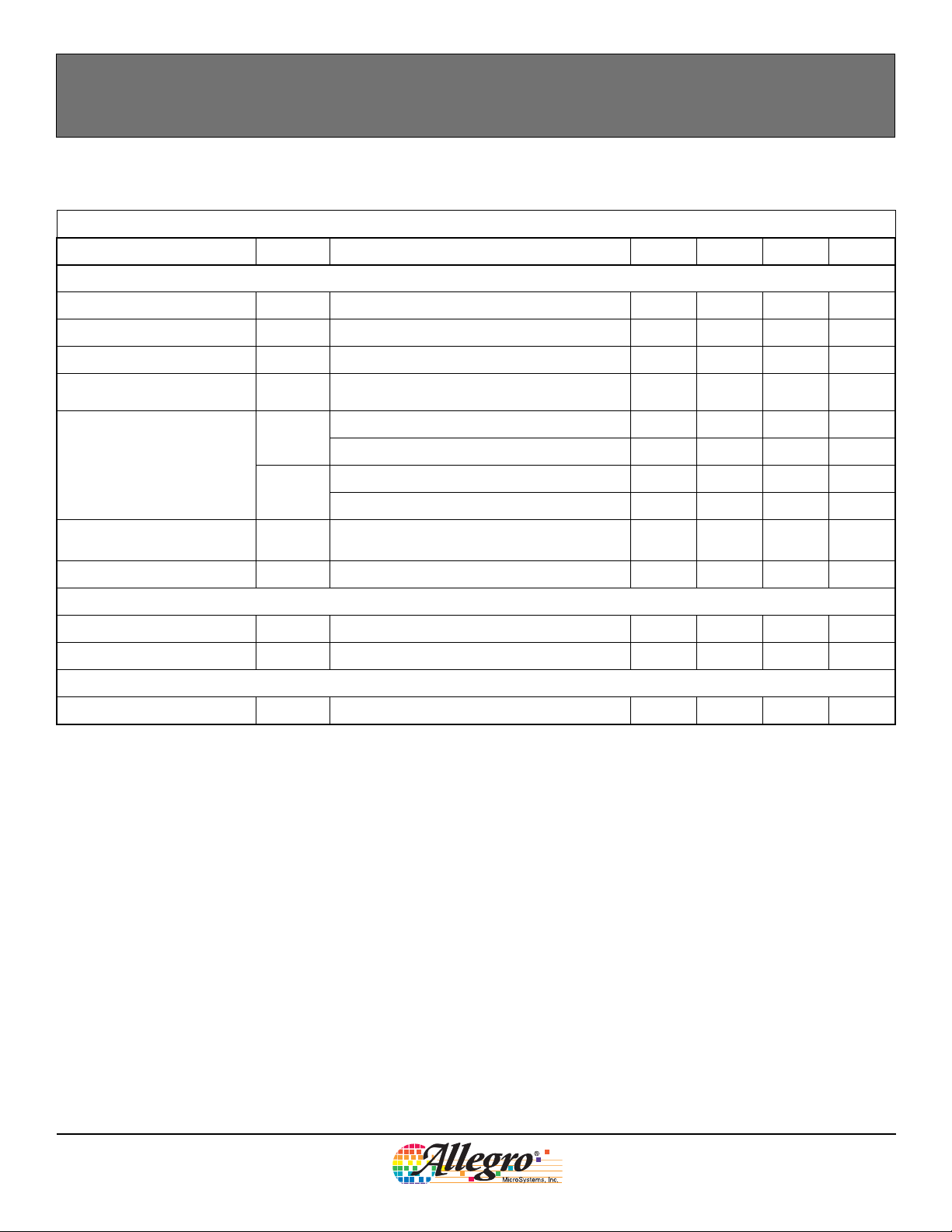

OPERATING CHARACTERISTICS using reference target 60-0, T

and VCC within specifi cation, unless otherwise noted

A

CHARACTERISTIC Symbol Test Conditions Min. Typ.

ELECTRICAL CHARACTERISTICS

Supply Voltage

2

Undervoltage Lockout V

Supply Zener Clamp Voltage V

Supply Zener Current I

V

CC(UV) VCC

Operating; TJ < 165 °C 4.0 – 24 V

CC

I

Z

CC

Test conditions only; VZ = 28 V – –

Z

0 → 5 V and 5 → 0 V – – 4.0 V

= I

+ 3 mA; TA = 25°C 28 – – V

CC(max)

ATS642LSH-I1 4.0 6.0 8.0 mA

I

CC(Low)

ATS642LSH-I2 5.9 7.0 8.4 mA

Supply Current

ATS642LSH-I1 12.0 14.0 16.0 mA

I

I

Supply Current Ratio

CC(High)

I

Reverse Battery Current I

CC(High)

CC(Low)

RCC

ATS642LSH-I2 11.8 14.0 16.8 mA

/

Ratio of high current to low current 1.85 – 3.05 –

V

= –18 V – – –5 mA

RCC

POWER-ON STATE CHARACTERISTICS

Power-On State

Power-On Time

3

4

POS t > t

t

Target gear speed < 100 rpm – 1 2 ms

PO

PO

OUTPUT STAGE

Output Slew Rate

5

dI/dt R

= 100 Ω, C

LOAD

= 10 pF – 10 – mA/μs

LOAD

–I

CC(High)

1

Max. Units

I

CC(max)

3 mA

+

mA

––

Continued on the next page.

ATS642LSH-DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

3

ATS642LSH

True Zero Speed Miniature Differential Peak-Detecting Gear Tooth Sensor

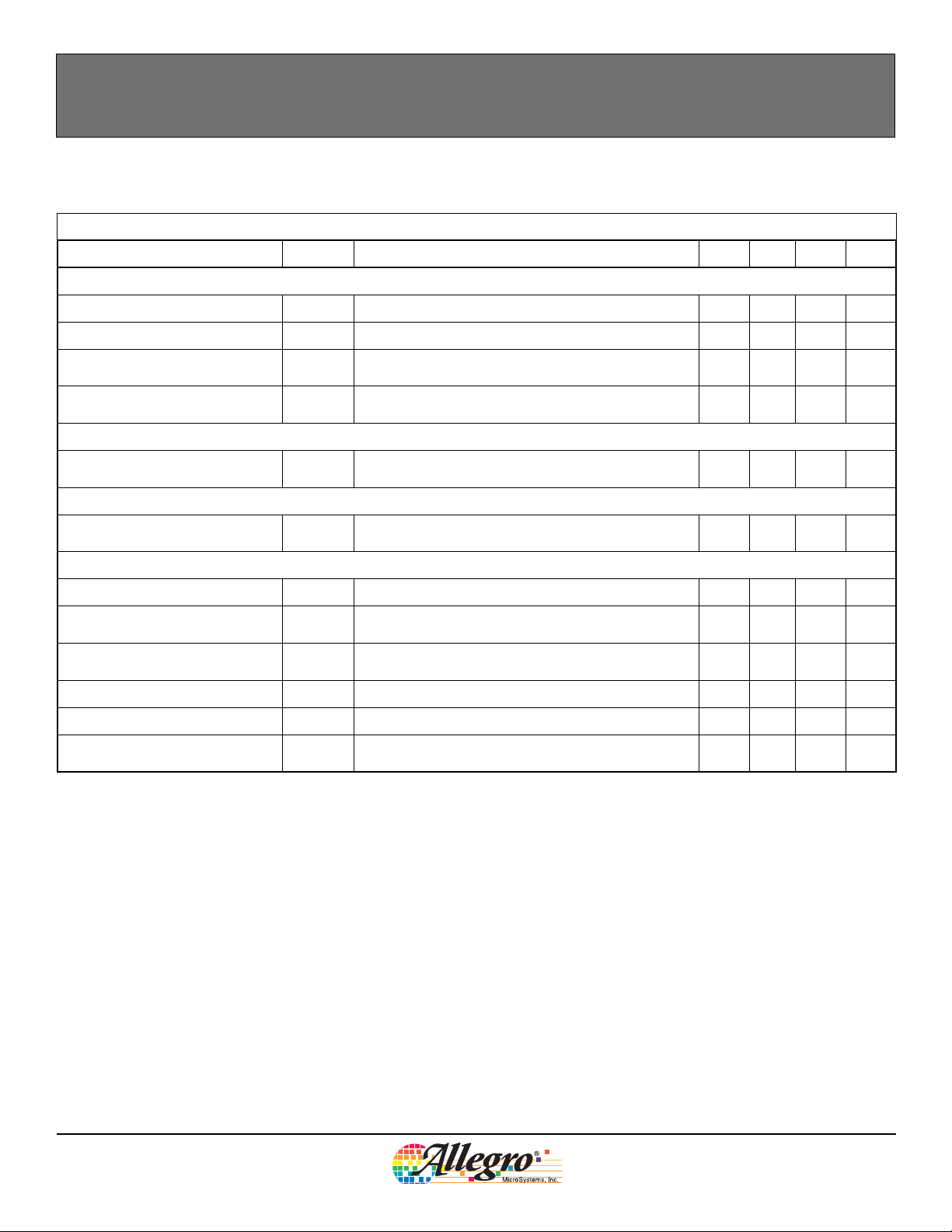

OPERATING CHARACTERISTICS (continued) using reference target 60-0, T

Characteristic Symbol Test Conditions Min. Typ.

and VCC within specifi cation, unless otherwise noted

A

1

Max. Units

SWITCHPOINT CHARACTERISTICS

Rotation Speed S

Reference Target 60-0 0 – 8,000 rpm

ROT

Analog Signal Bandwidth BW Equivalent to f – 3 dB 20 40 – kHz

Operate Point B

Release Point B

Transitioning from I

OP

referenced; AG < AG

Transitioning from I

RP

referenced; AG < AG

CC(High)

MAX

CC(Low)

MAX

to I

to I

CC(Low)

CC(High)

; positive peak

; negative peak

– 120 – mV

– 120 – mV

CALIBRATION

Initial Calibration C

Quantity of rising output (current) edges required for

I

accurate edge detection

– – 3 Edge

DAC CHARACTERISTICS

Allowable User-Induced Differential

Offset

FUNCTIONAL CHARACTERISTICS

Operational Air Gap Range

7

Maximum Operational Air Gap

Range

6

AG ΔDC within specifi cation 0.5 – 2.75 mm

AG

OP(max)

Duty Cycle Variation ΔDC

Duty Cycle Pitch Variance

Operating Signal Range

Minimum Operating Signal Sig

1

Typical values are at TA = 25°C and VCC = 12 V. Performance may vary for individual units, within the specifi ed maximum and minimum limits.

2

Maximum voltage must be adjusted for power dissipation and junction temperature; see Power Derating section.

3

Please refer to Sensor Operation section, page 13.

4

Power-On Time includes the time required to complete the internal automatic offset adjust. The DACs are then ready for peak acquisition.

5

dI is the difference between 10% of I

Note: di/dt is dependent upon the value of the bypass capacitor, if one is used.

6

Functional characteristics valid only if magnetic offset is within the specifi ed range for Allowable User Induced Differential Offset.

7

AG is dependent on the available magnetic fi eld. The available fi eld is dependent on target geometry and material, and should be independently

characterized. The fi eld available from the reference target is given in the reference target parameter section of the datasheet.

8

E

represents the difference between consecutive duty cycles, DC(n) - DC(n-1); Mean ± 3-sigma.

DC

9

In order to remain in specifi cation, the magnetic gradient must induce an operating signal greater than the minimum value specifi ed. This includes the

effect of target wobble.

8

9

E

Sig Operating within specifi cation 30 – 1000 G

OP(min)

and 90% of I

CC(Low)

Output switching only; may not meet datasheet specifi cations

Output switching (no missed edges); ΔDC not

guaranteed

Wobble < 0.5 mm; Typical value at AG = 1.5 mm, for

max., min., AG within specifi cation

AG = 1.5 mm – ±1.5 – %

DC

Output switching (no missed edges); ΔDC not

guaranteed

, and dt is time period between those two points.

CC(High)

– ±60 – G

––3mm

41 – 61 %

20 – – G

ATS642LSH-DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

4

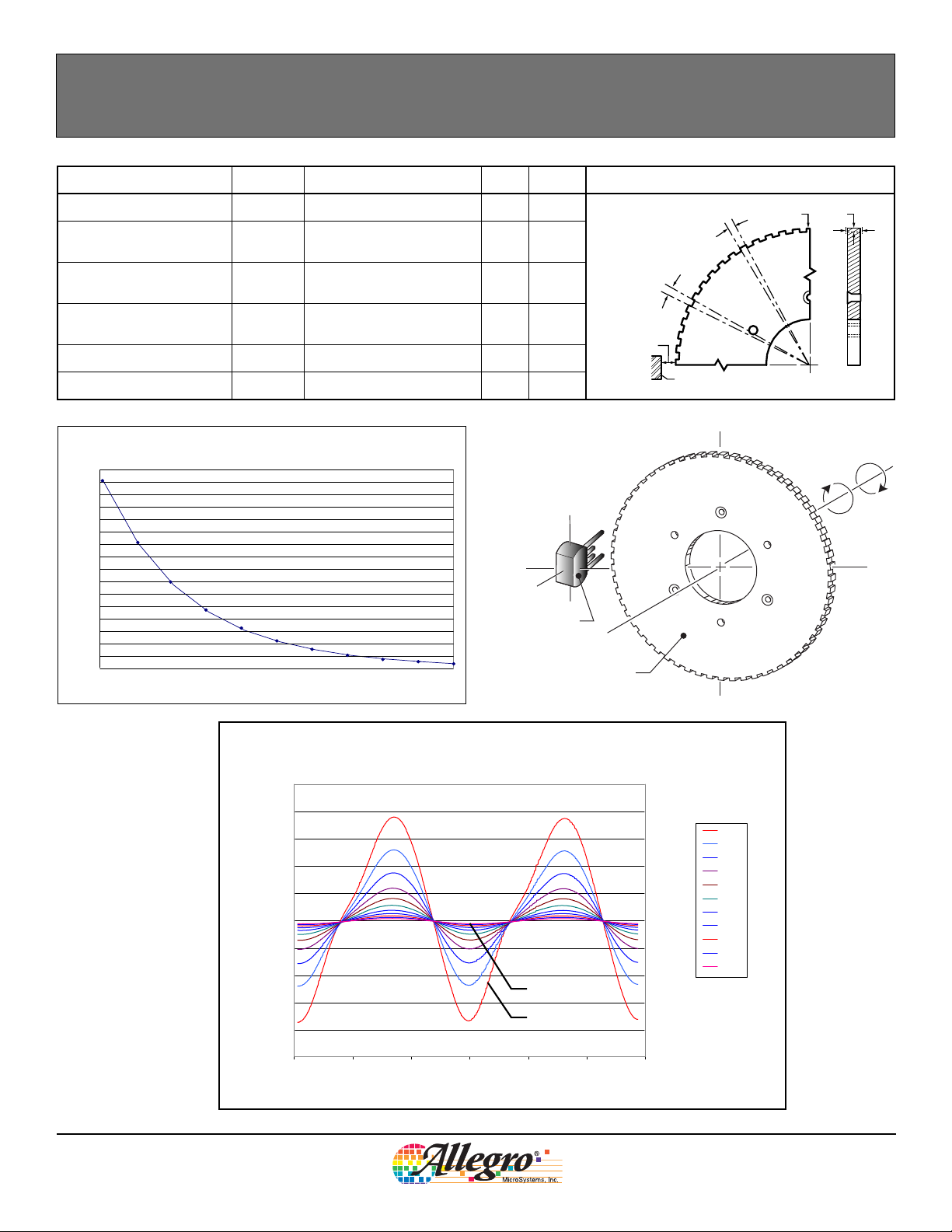

ATS642LSH

D

o

h

t

F

Air Gap

Branded Face of Sensor

t

t

v

Reference Target

60-0

of Sensor

Branded Face

True Zero Speed Miniature Differential Peak-Detecting Gear Tooth Sensor

REFERENCE TARGET, 60-0 (60 Tooth Target)

Characteristics Symbol Test Conditions Typ. Units Symbol Key

Outside Diameter D

Face Width F

Angular Tooth Thickness t

Angular Valley Thickness t

Tooth Whole Depth h

Outside diameter of target

o

Breadth of tooth, with

respect to sensor

Length of tooth, with

respect to sensor

Length of valley, with

v

respect to sensor

t

120 mm

6mm

3 deg

3 deg

3mm

Material Low Carbon Steel – –

Reference Gear Magnetic Gradient Amplitude

800

700

600

500

400

300

200

Peak-to-Peak Differential B (G)

100

0

With Reference to Air Gap

11.520.5 2.5 3

Air Gap (mm)

ATS642LSH-DS

Reference Gear Magnetic Profile

Two Tooth-to-Valley Transitions

500

400

300

200

100

0

-100

-200

Differential B* (G)

3.00 mm AG

-300

0.50 mm AG

-400

-500

024681012

Gear Rotation (°)

Air Gap

(mm)

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50

2.75

3.00

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

5

Loading...

Loading...