查询ATS635LSE供应商

ATS635LSE and ATS636LSE

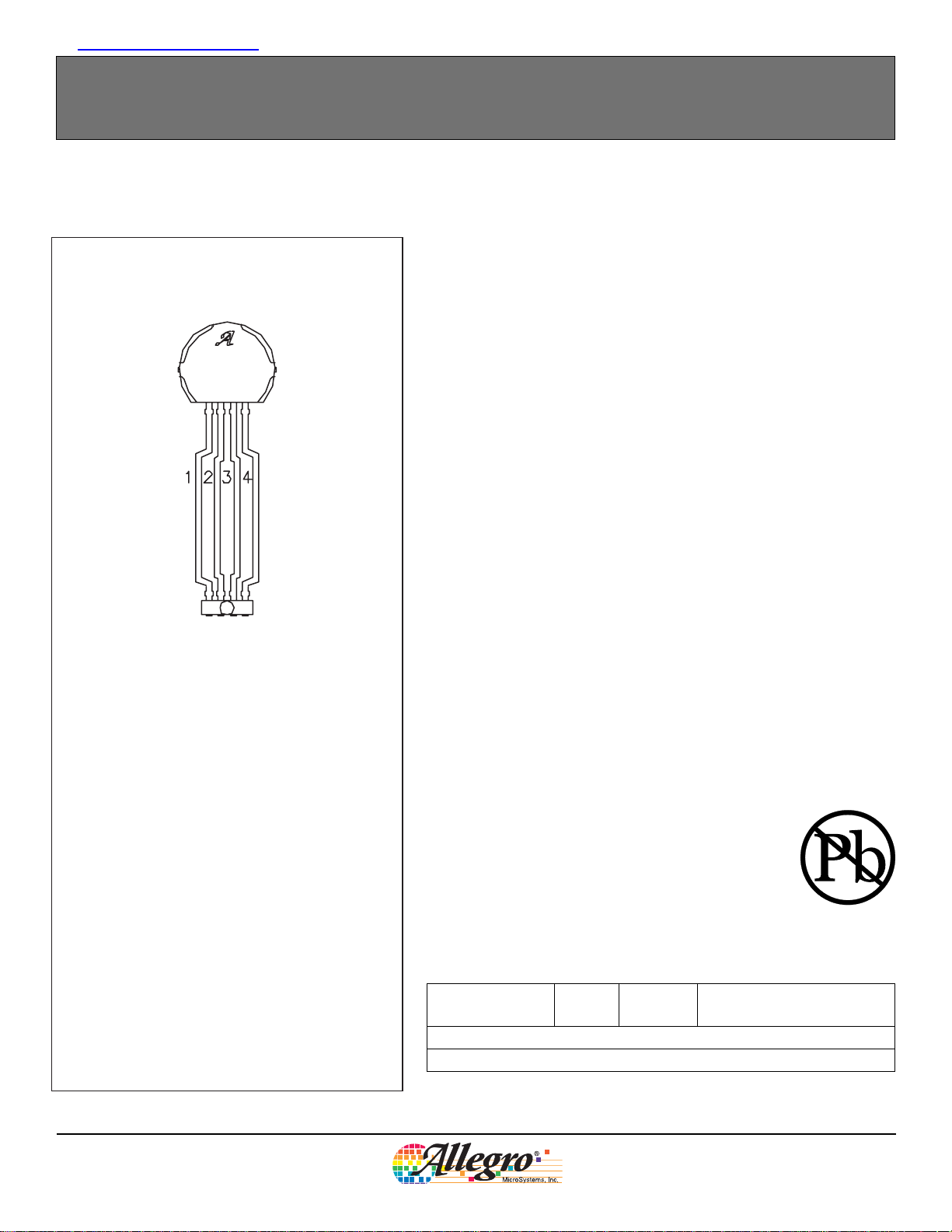

PACKAGE DIAGRAM

Pin 1 = VCC

Pin2=VOUT

Pin3=NoConnect

Pin 4 = GND

ABSOLUTE MAXIMUM RATINGS

Supply Voltage, VCC………………….…….. 28 V*

Reverse Supply Voltage, V

Overvoltage Supply Current, I

Output Off Voltage, V

Output Sink Current, I

OUT……

OUT

Magnetic Flux Density, B…………… Unlimited

Package Power Dissipation, P

Operating Temperature Range, T

Suffix “L”………...……….. -40°Cto+150°C

Junction Temperature, T

Storage Temperature Range

………………………… -65°Cto+170°C

T

S

…………… -18 V

RCC

…..……100 mA

CC

……………… 26.5V

…...…………. 20 mA

….. See Graph

D

A

……..…………..165 °C

J

†

Programmable Back Biased Hall-Effect

Switch with TPOS Functionality

The ATS635LSE and ATS636LSE programmable, true power-on state

(TPOS), sensors are an optimized Hall-effect IC and magnet combination

that switch in response to magnetic signals created by ferrous targets in

gear-tooth sensing and proximity applications.

The devices are externally programmable. A wide range of

programmability is available on the magnetic operate point (B

hysteresis remains fixed. This advanced feature allows for optimization of

the sensor switch point and can drastically reduce the effects of

mechanical placement tolerances found in production environments .

A proprietary dynamic offset cancellation technique, with an internal

high-frequency clock, reduces the residual offset voltage, which is normally

caused by device overmolding, temperature dependencies, and thermal

stress. Having the Hall element and amplifier in a single chip minimizes

many problems normally associated with low-level analog signals.

This sensor system is ideal for use in gathering speed or position

information using gear-tooth-based configurations, or for proximity sensing

with ferrous targets.

The ATS635LSE switches HIGH in the presence of a ferrous target or

tooth and switches LOW in the presence of a target valley, window, or

when the ferrous target is removed. The ATS636LSE has the opposite

polarity and switches LOW in the presence of a ferrous target or tooth and

switches HIGH in the presence of a target valley, window, or when the

ferrous target is removed.

These devices are available in lead (Pb) free versions, with 100%

matte tin leadframe plating.

FEATURES

Chopper Stabilization

Extremely low switch-point drift over temperature

On-chip Protection

Supply transient protection

Output short-circuit protection

Reverse-battery protection

True Zero-Speed Operation

True Power-On State

Single-chip Sensing IC for High Reliability

Optimized Magnetic Circuit

Wide Operating Voltage Range

Internal Regulator

Use the following complete part numbers when ordering:

) while the

OP

*Fault conditions that produce supply voltage transients will

be clamped by an internal Zener diode. These conditions

can be tolerated but should be avoided.

†

Internal current limiting is intended to protect the device

from output short circuits, but is not intended for continuous

operation.

ATS635LSE-DS

Part Number Pb-Free Output

Packing*

(Tooth)

ATS635LSETN-T Yes High 13-in. reel, 450 pieces/reel

ATS636LSETN-T Yes Low 13-in. reel, 450 pieces/reel

*Contact Allegro for additional packing options.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

CHARACTERISTICS

ELECTRICAL CHARACTERISTICS over operating voltage and junction temperature range

(unless otherwise noted)

Characteristics Symbol Test Conditions

Limits

Min. Typ. Max. Units

Supply Voltage1 VCC Operating 4.2 – 24 V

After programming

Power-Up State POS

V

= 0 à V

CC

B < BOP ATS636

CC(min)

, t > t

:

ON

HIGH HIGH HIGH –

B < BOP ATS635 LOW LOW LOW –

Low Output Voltage V

Output Current Limit2 I

Output Leakage Current I

OUT(SAT)

Output on, I

OUTM

Output off, V

OFF

Pulse test method

= 20 mA – 175 400 mV

OUT

Output on

OUT

30 50 90 mA

= 24 V – – 10 µA

Output off (HIGH) – 2.5 5.5 mA

Supply Current I

CC

Output on (LOW) – 2.5 5.5 mA

Reverse Supply Current I

Power-On Delay3 tON Output off; VCC > V

V

RCC

= -18V – – -5 mA

RCC

– 35 50 µs

CC(min)

Output Rise Time tr RL = 820 Ω, CL = 10 pF – 1.2 5 µs

Output Fall Time tf RL = 820 Ω, CL = 10 pF – 1.2 5 µs

Sampling Frequency f

Supply Zener Voltage V

Output Zener Voltage V

Supply Zener Current4 I

Output Zener Current I

- – 250 - kHz

Sample

Zsupply

ZOutput

VS = 28 V – –

Zsupply

VO = 30 V – –

ZOutput

ICC = I

I

+ 3 mA

CC(max)

TA = 25°C

= 3 mA

OUT

TA = 25°C

28 – – V

30 – – V

8.5 mA

3

mA

Note: Typical data is at VCC = 12 V and TA = +25°C.

1

Do not exceed the maximum thermal junction temperature: see power de-rating curve.

2

Short circuit protection is not intended for continuous operation and is tested using pulses.

3

The power on delay is the time that is necessary before the output signal is valid

4

The maximum spec limit for this parameter is equivalent to I

CC(max)

+ 3 mA

Page 2 of 15

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

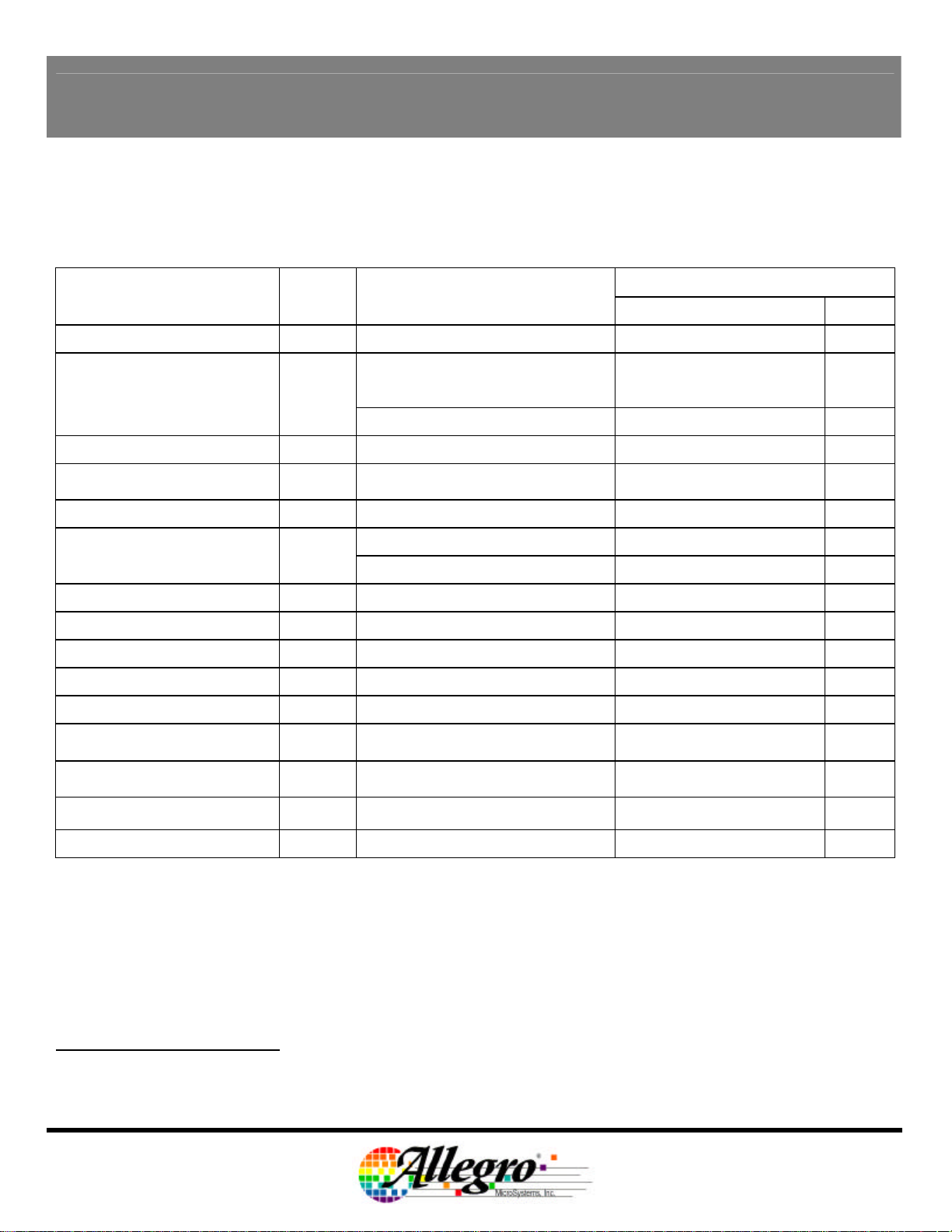

MAGNETIC CHARACTERISTICS over operating voltage and junction temperature range using

reference target (Unless otherwise noted)

Limits

Characteristics Symbol Test Conditions

Switch Point – 7 – Bit

Number of Programming

Bits

-

Switch Point Polarity – 1 – Bit

Programming Lock – 1 – Bit

Gear Tooth Sensor / Proximity Sensing Characteristi cs (Low Switchpoint Only)

1

Programming Air Gap

Range

Programming Resolution

2

Air Gap Drift Over Full

Temperature Range

AG

AG

AG

Range

Res

Drift

Temp: 25°C Code –127

Temp: 25°C Code +127

Temperature: 25°C

Program Air Gap = 2.5 mm

Device Programmed

to 2.5 mm

Over Tooth (ATS635LSE) – HIGH – –

Over Valley (ATS635LSE) – LOW – –

Polarity P

Over Tooth (ATS636LSE) – LOW – –

Over Valley (ATS636LSE) – HIGH – –

1400

1200

1000

800

600

400

Flux Density (Gauss)

200

0

0 30 60 90 120 150 180 210 240 270 300 330 360

Reference Target Flux Density vs. Position: Typical

Reference Target Flux Density vs. Position

Position (º)

0.25

0.50

0.75

1.00

1.25

1.50

1.75

2.00

2.25

2.50

2.75

3.00

3.25

3.50

3.75

4.00

4.25

4.50

4.75

5.00

5.25

5.50

5.75

6.00

1400

1200

1000

800

600

400

Flux Density [Gauss]

200

0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

Reference Target Tooth and Valley Field vs. Air Gap

Min. Typ. Max. Units

2.5 – – mm

– – 1.5 mm

– 0.05 – mm

– 0.2 – mm

Tooth and Valley Field vs. Air Gap

Reference Target

Reference Target Tooth

Reference Target Valley

Air Gap [mm]

1

The switch point will vary over temperature. A sufficient margin obtained through customer testing is required to guarantee functionality over

temperature. Programming at larger air gaps leaves no safety margin for switchpoint drift. See the applications note: “Proximity Sensing

Programming Technique” http://www.allegromicro.com/techpub2/proximity_sensing/ or visit the Allegro website at http://www.allegromicro.com

for additional information.

2

The switch point will vary over temperature, proportionally to the programmed air gap. This parameter is based on characterization data and is not

a tested parameter in production. Switch point air gap generally drifts downward as temperature increases.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

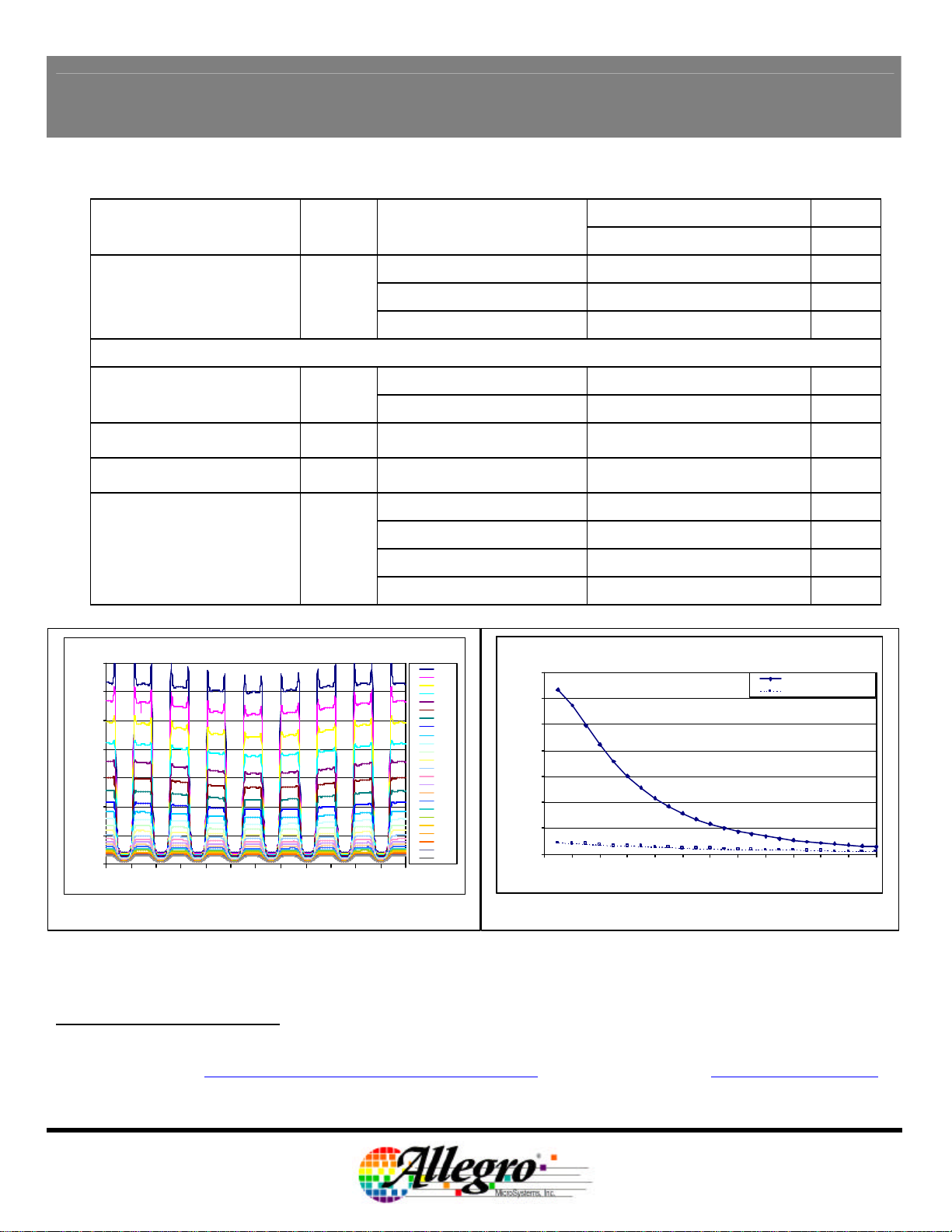

REFERENCE TARGET DIMENSIONS

Outside

Target

Reference Target 120mm 6mm 23.5mm 23.5mm 5mm

Diameter

(Do)

Face Width

(F)

Reference Target

Reference Target

GEAR PARAMETERS FOR CORRECT OPERATION

Characteristic Description

Tooth Whole Depth (ht) Depth of Target Valley 5 – – mm

Circular Valley Length (PC – T) Length of Target Valley 13 – – mm

Circular Tooth Length (T) Length of Target Tooth 5 – – mm

Face Width (F) Thickness or Width of Target Tooth 5 – – mm

MATERIAL: CRS 1018

Circular Tooth

Length

(T)

Circular Valley

Length

(PC – T)

Limits

Min. Typ. Max. Units

Tooth Whole

Depth

(ht)

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

ELECTROMAGNETC CAPABILITY (EMC) PERFORMANCE

Please contact Allegro MicroSystems for EMC performance

Test Name Reference Specification

ESD – Human Body Model AEC-Q100-002

ESD – Machine Model AEC-Q100-003

Conducted Transients ISO 7637-1

Direct RF Injection ISO 11452-7

Bulk Current Injection ISO 11452-4

TEM Cell ISO 11452-3

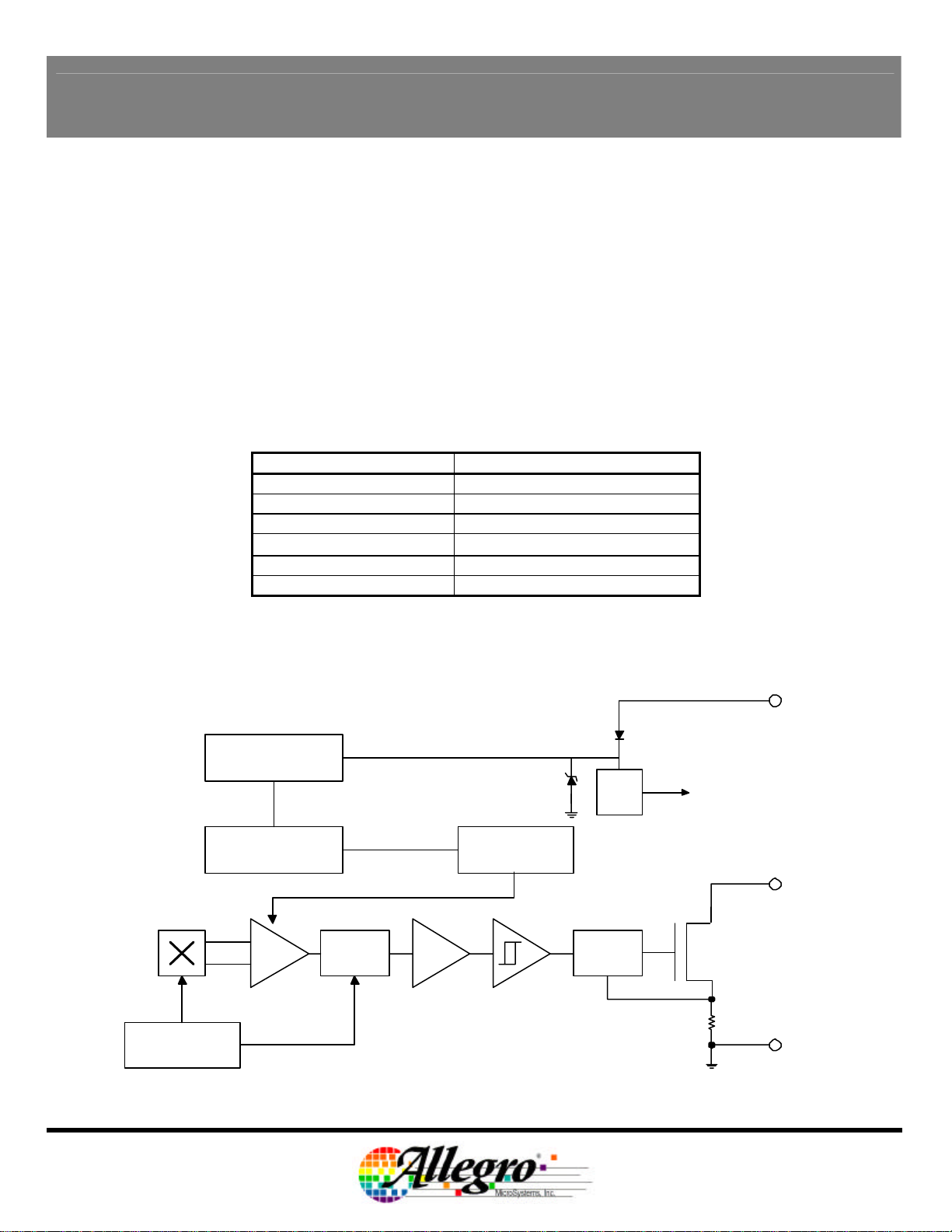

Clock/Logic

FUNCTIONAL BLOCK DIAGRAM

Program / Lock

Programmming

Logic

AMP S/H LPF

Offset Adjust

Reg

Current

Limit

VCC

To all

subcircuits

OUT

GND

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

FUNCTIONAL DESCRIPTION

Chopper-Stabilized Technique . The basic Hall sensor

is a small sheet of semiconductor material in which a

constant bias current will flow when a constant voltage

source is applied. The output will take the form of a

voltage measured across the width of the sheet and will

have negligible value in the absence of a magnetic field.

When a magnetic field with flux lines at right angles to

the Hall current is applied, a small signal voltage directly

proportional to the strength of the magnetic field will

occur at the output terminals.

This signal voltage is proportionally small relative to the

offset produced at the input of the chip. This makes it

very difficult to process the signal and maintain an

accurate, reliable output over the specified temperature

and voltage range. Therefore, it is important to reduce

any offset on the signal that could be amplified when the

signal is processed.

Chopper Stabilization is a unique approach used to

minimize input offset on the chip. This technique

removes a key source of output drift with temperature

and stress, and produces a 3X reduction in offset over

other conventional methods.

This offset reduction Chopping Technique is based on a

signal modulation-demodulation process. The undesired

offset signal is separated from the magnetically induced

Regulator

Hall Element

Figure 1 – Concept of Chopper -Stabilization Algorithm

signal in the frequency domain. The offset (and any low

frequency noise) component of the signal can be seen

as signal corruption added after the signal modulation

process has taken place. Therefore, the DC offset is not

modulated and remains a low frequency component.

Consequently, the signal demodulation process acts as

a modulation process for the offset causing the

magnetically induced signal to recover its original

spectrum at baseband while the DC offset becomes a

high frequency signal. Then, using a low pass filter the

signal passes while the modulated DC offset is

suppressed.

The advantage of this approach is significant offset

reduction, which de-sensitizes the chip against the

effects of temperature and stress. The disadvantage is

that this technique features a demodulator that uses a

sample and hold block to store and recover the signal.

This sampling process can slightly degrade the Signalto-Noise Ratio (SNR) by producing replicas of the noise

spectrum at the baseband. The degradation is a

function of the ratio between the white noise spectrum

and the sampling frequency. The effect of the

degradation of the SNR is higher jitter, a.k.a. signal

repeatability. In comparison to a continuous time device,

the jitter spec can be increased by a factor of five.

Amplifier

CLOCK

Sample/

Hold

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

FUNCTION DESCRIPTION: ADDRESSING / PROGRAMMING PROTOCOL

The ATS635LSE and ATS636LSE magnetic operate point (BOP) is programmed by serially addressing the devices

through the supply terminal (1). After the correct operate point is determined, the device programming bits are selected

and blown, then a lock bit is selected and blown to prevent any further (accidental) programming.

Addressing: Bop is programmable in both the positive and negative direction from its initial value. Addressing is used to

determine the desired code, while programming is used to lock the code. A unique key is needed to blow fuses, while

addressing as described below does not allow for the device to be programmed accidentally.

Addressing with positive polarity. The magnetic operate point (B

Addresses are sequentially selected (Figure 2) until the required operate point is reached. The first address must be

selected with a High voltage pulse (VPP), while the remaining pulses should be V

between BOP and the magnetic release point (BRP), the Hysteresis (B

) is adjustable using 7 bits or 128 addresses. The

OP

Pulses. Note that the difference

PH

), is fixed for all addresses.

HYS

V

PP

Code 2

Code 3

V

PH

V

PL

t

d(1)

t

d(0)

Code N-2

0

Code N

Code N-1

(Up to 127)

Figure 2 – Addressing Pulses: Positive Polarity

Code 1

Addressing with negative polarity. The magnetic operate point (B

128 addresses. To invert the polarity it is necessary to first apply a keying sequence (Figure 3). Th e polarity key contains

a VPP pulse and at least 1 VPH pulse, but no more than 6 VPH pulses; the key in Figure 3 shows 2 VPH pulses. The

addresses are then sequentially selected until the required operate point is reached. The first address must be selected

with a High voltage pulse (VPP), while the remaining pulses should be V

Key

Polarity

V

PP

V

PH

V

PL

0

Code -1

Code -2

t

d(1)

Code -3

Figure 3 – Addressing Pulses: Negative Polarity

) is adjustable with negative polarity using 7 bits or

OP

Pulses.

PH

Code -N

Code -(N-2)

Code -(N-1)

(Up to -127)

t

d(0)

Page 7 of 15

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

Program Enable. To program the device, a keying sequence is used to activate / enable the programming mode as

shown in Figure 4. This program key sequence consisting of a VPP pulse, at least seven VPH pulses, and a VPP pulse with

no supply interruptions. The sequence is designed to prevent the device from being programmed accidentally (e.g., as a

result of noise on the supply line).

t

PROGRAM ENABLE

7 or More Pulses

(8 Pulses Shown)

d(1)

t

d(0)

V

PP

V

PH

V

PL

t

d(1)

0

Figure 4 – Program Enable Pulse Sequence

Code Programming. After the desired switch point code is selected (0 through 127), each bit of the corresponding binary

address should be programmed individually, not at the same time. For example, to program code 5 (binary 000101), bits

1 and 3 need to be programmed. A bit is programmed by addressing the code and then applying a VPP pulse, the

programming is not reversible. An appropriate sequence for blowing code 5 is shown in Figure 5.

V

PP

V

PH

V

PL

0

t

d(1)

Program Enable

t

d(1)

Bit 3 Address

000100

Code 4

t

d(0)

t

dP

Bit 3 Program

Program Enable

000001

Code 1

Bit 1 Program

Bit 1 Address

Figure 5 – Code Programming Example

Polarity Bit Programming. If the desired switchpoint has negative polarity, the polarity bit must be programmed. To do

this it is necessary to first apply the polarity key sequence before the program key sequence (Figure 6). Finally a VPP

pulse of duration tdP must be applied to program this bit, the programming is not reversible. The polarity bit is for adjusting

programming range only and will not affect the output polarity. The proper output polarity device is determined by

ordering the correct part number (ATS635 or ATS636), as they are different ICs.

Key

Polarity

V

PP

Program

Polarity Bit

Program Enable

V

PH

V

PL

t

0

d(1)

Figure 6 – Polarity Bit Programming

Page 8 of 15

t

d(1)

t

d(0)

t

dP

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

Lock-Bit Programming. After the desired code is programmed, the lock bit (code 128), can be programmed (figure 7) to

prevent further programming of the device. Again; programming is not reversible.

V

PP

Program Enable

V

PH

V

PL

t

0

d(1)

t

d(1)

t

d(0)

Figure 7 – Lock -Bit Programming Pulse Sequence

See Allegro website at http://www.allegromicro.com for extensive information on device programming as well as

programming products. Programming hardware is available for purchase and programming software is available for free.

Valid over operating temperature range unless otherwise noted.

Lock Bit

Address

128 Pulses

t

dP

Lock Bit

Program

Part Number Characteristics Symbol Test Conditions

PROGRAMMING PROTOCOL (TA = +25°C)

Minimum voltage range

during programming

5,6

Programming Voltage

VPL

VPH 8.5 – 15 V

VPP 25 – 27 V

Maximum supply current

during programming

OFF time between bits 20 – – µs

Enable, address, program,

or lock bit ON time

ATS635 /

ATS636

Programming Current IPP

t

d(0)

t

d(1)

tdP Program pulse ON time 100 300 – µs

Pulse Rise Time tr VPL to VPH or VPP – – 11 µs

Pulse Fall Time tf VPH or VPP to VPL – – 5 µs

Limits

Min. Typ. Max. Units

4.5 5 5.5 V

– 500 – mA

20 – – µs Pulsewidth

5

Programming Voltages are measured at Pin 1 (VCC) of SIP. A minimum capacitance of 0.1 µF must be connected from VCC to GND

of the SIP to provide the current necessary to blow the fuse.

6

Testing is the only method that guarantees successful programming.

Page 9 of 15

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

FUNCTIONAL DESCRIPTION (CONT.): TYPICAL APPLICATION CIRCUIT

Applications. It is strongly recommended that an external ceramic bypass capacitor in the range of 0.01 µF to 0.1 µF be

connected between the supply and ground of the device to reduce both external noise and noise generated by the

chopper-stabilization technique. (The diagram below shows a 0.1 µF bypass capacitor.)

The series resistor RS in combination with the bypass capacitor creates a filter for EMC pulses. The series resistor will

have a drop of approximately 800 mV, this must be considered for the minimum VCC requirement of the ATS635LSE /

ATS636LSE. The small capacitor on the output of the device improves the EMC performance of the device.

The pull-up resistor should be chosen to limit the current through the output transistor; do not exceed the maximum

continuous output current of the device.

Note: This circuit cannot be used to program the device, as the series resistance is too large, and a minimum capacitance

of 0.1 µF must be connected from VCC to GND of the SIP to provide the current necessary to blow the fuse.

Typical Application:

R

S

100 Ohm

1

VCC

R

5V

L

1.2k Ohm

ATS635/636

V

Supply

Extensive applications information on magnets and Hall-effect sensors including Chopper-Stabilization is available in the

Allegro Electronic Data Book CD, or at the website: http://www.allegromicro.com .

0.1 µF

GND

4

2

VOUT

120 pF

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

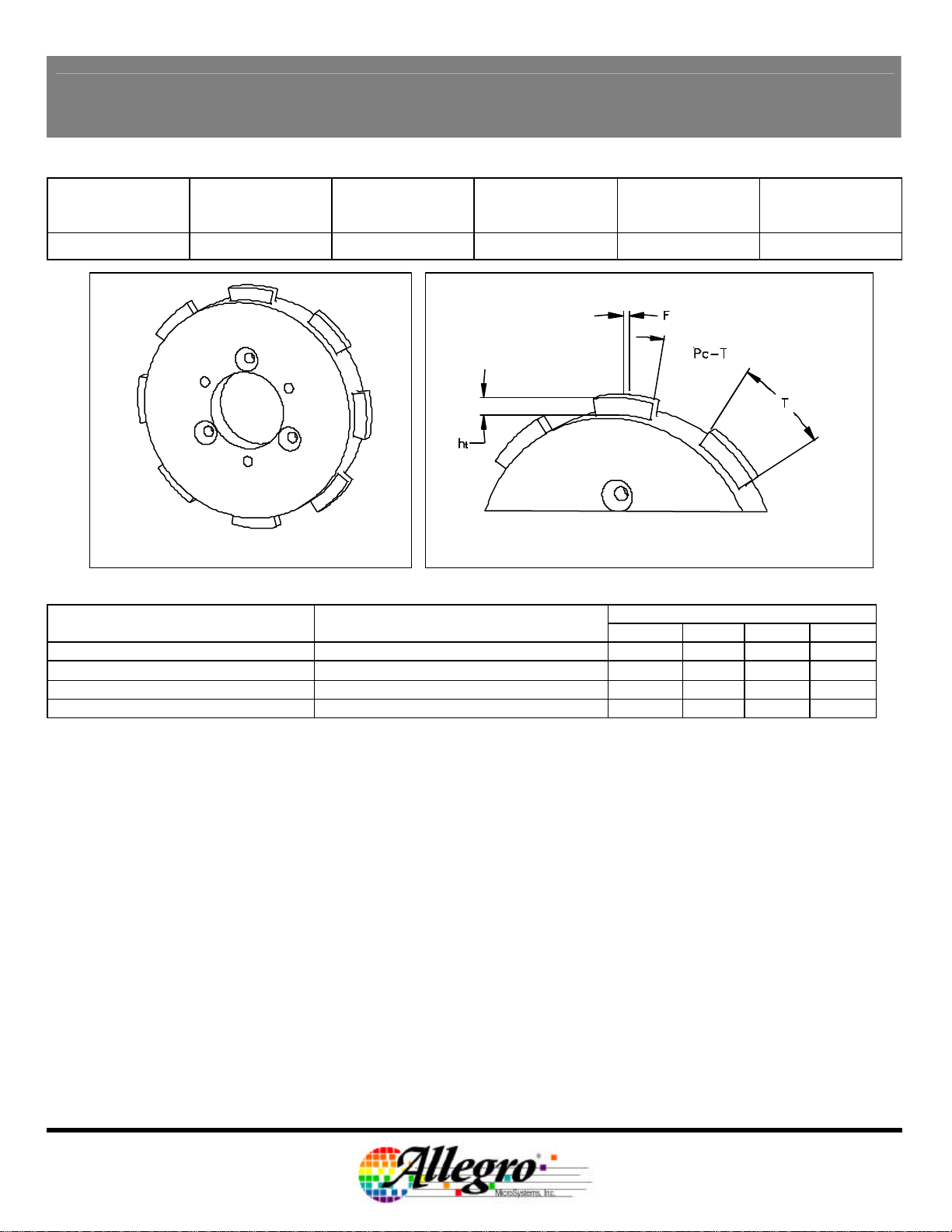

CHARACTERISTIC DATA

Data taken from 3 lots, 30 pieces/lot

Reference Target 8x

ICC ON

ICC OFF

6

5

4

3

(mA)

CC

I

2

1

0

-50 -25 0 25 50 75 100 125 150 175

TEMPERATURE (°C)

4V

15V

24V

500

400

6

5

4

3

(mA)

CC

I

2

1

0

-50 -25 0 25 50 75 100 125 150 175

V

SAT

TEMPERATURE (°C)

4V

15V

24V

300

(mV)

SAT

V

200

20mA

100

0

-50 -25 0 25 50 75 100 125 150 175

TEMPERATURE (°C)

Page 11 of 15

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

CHARACTERISTIC DATA (continued)

Data taken from 3 lots, 30 pieces/lot

Reference Target 8x

BOP/BRP vs. Program Code

7

6

5

Code -8 BOP

Code -8 BRP

4

3

AIR GAP (mm)

Code 0 BOP

Code 0 BRP

Code +32 BOP

Code +32 BRP

Code +127 BOP

Code +127 BRP

2

1

0

-50 0 50 100 150 200

TEMPERATURE (°C)

Notes:

s Air gaps for Code 127 @ 150°C are interpolated due to test limitations at minimum air gap.

s These graphs are intended to provide an understanding of how the program codes affect the switch points. In a

production environment, individual devices would be programmed to individual codes to ensure all devices switch at

the same air gap.

Page 12 of 15

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

POWER DE-RATING – SE Package

Power De -Rating

Due to internal power consumption, the temperature of the

IC (junction temperature, TJ) is higher than the ambient

environment temperature, TA. To ensure that the device

does not operate above the maximum rated junction

temperature use the following calculations:

∆T=PD × R

Where PD = VCC × ICC

∴ ∆T = VCC × ICC × R

Where ∆T denotes the temperature rise resulting from the

IC’s power dissipation:

TJ = TA + ∆T R

Typical TJ Calculation:

TA = 25°C, V

PD = VCC × ICC

PD = 5 V × 5.5 mA = 27.5 mW

∆T = PD × R

TJ = TA + ∆T = 25°C + 2.0°C = 27.0°C

Maximum Allowable Power Dissipation Calculation

TJ = TA + ∆T

T

= 165°C, if TA = 150°C then:

J(max)

165 = 150 + ∆T

∆T = 15°C

DT = PD× R

\ P

D(max)

Maximum VCC for P

PD = VCC × ICC ICC = 10mA (max) at 150°C

VCC = PD / ICC = 195 mW / 5.5 mA = 35.4 V

θJA

θJA

= 77°C/W T

θJA

= 5 V, I

CC

= 27.5 mW × 77°C/W = 2.0°

θJA

(R

θJA

= 15°C / 77°C/W = 1 95 mW @ TA = 150°C

= 77°C/W)

θJA

D(max)

= 5.5 mA

CC(on)

=111 mW at TA=150°C

J(max)

= 165°C

Power Dissipation versus Ambient Temperature

4500

4000

3500

3000

(mW)

D

2500

2000

1500

1000

Power Dissipation, P

500

0

20 40 60 80 100 120 140 160 180

2-layer PCB

= 77 ºC/W)

(R

θJA

Temperature (°C)

Page 13 of 15

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

SE PACKAGE DIMENSIONS

Reference Dimensions Only

7 .276

20.95 .825

6.2 .244

11.6 .457

4.9 .193

10 .394

3.3 .130

0.6

1.3 .051

A

.240

C

B

E

A

2431

1.27 .050

2 .079

0.38 .015

1.08 .043

D

Dambar removal protrusion (16X)

Preliminary dimensions, for reference only

Untoleranced dimensions are nominal.

Dimensions in millimeters

U.S. Customary dimensions (in.) in brackets, for reference only

Dimensions exclusive of mold flash, burrs, and dambar protrusions

Exact case and lead configuration at supplier discretion within limits shown

Page 14 of 15

A

Metallic protrusion, electrically connected to pin 4 and substrate (both sides)

B

Active Area Depth, 0.43 mm [.017]

C

Thermoplastic Molded Lead Bar for alignment during shipment

D

Hall element (not to scale)

E

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

ATS635LSE and ATS636LSE

PROGRAMMABLE TRUE POWER-ON HALL-EFFECT GEAR-TOOTH SWITCHES

The products described herein are manufactured under one or more

of the following U.S. patents: 5,045,920; 5,264,783; 5,442,283;

5,389,889; 5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719;

5,686,894; 5,694,038; 5,719,130; 5,917,320; and other patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be required to

permit improvements in the design of its products. Before placing an

order, the user is cautioned to verify that the information being relied

upon is current.

Allegro products are not authorized for use as critical components in

life-support applications, devices, or systems without express written

approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility

for its use; nor for any infringements of patents or other rights of third

parties which may result from its use.

Page 15 of 15

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2005 Allegro MicroSystems, Inc.

Loading...

Loading...