Allegro ATS632LSC Datasheet

ATS632LSC

HALL-EFFECT

GEAR-TOOTH SENSOR

SUBASSEMBLY

NON-ORIENTED, HALL-EFFECT GEAR-TOOTH SENSOR

1 = Supply

2 = Output

3 = Ground

PRELIMINARY INFORMATION

(subject to change without notice)

April 8, 1998

ABSOLUTE MAXIMUM RATINGS

1

2

Dwg. AH-008

3

ATS632LSC

ZERO-SPEED, SELF-CALIBRATING,

The ATS632LSC gear-tooth sensor is an optimized Hall-effect IC/

magnet combination that provides tooth/valley recognition and extremely accurate tooth edge detection when used with large-pitch

targets. The sensor subassembly consists of a high-temperature

plastic shell that holds together a compound samarium-cobalt magnet,

a single-element self-calibrating Hall-effect IC that has been optimized

to the magnetic circuit, and a voltage regulator. This small package,

with its non-oriented operation, can be easily assembled and used in

conjunction with a number of gear configurations.

The gear sensing technology used for this sensor subassembly is

Hall-effect based. The sensor incorporates a single-element Hall IC

that switches in response to absolute magnetic signals created by a

ferrous target. The digital output is LOW over a tooth and HIGH over a

valley. The sophisticated processing circuitry contains self-calibrating

6-bit A/D circuitry that adapts the thresholds to the peak-to-peak

signals to minimize the effects of variation in application air gap on

switch-point timing accuracy. The effects of system and device offsets

are minimized by using active offset cancellation circuitry. The digital

algorithm provides zero-speed detection capabilities without the

associated running jitter inherent in classical digital solutions.

The sensor system is ideal for use in gathering speed, position and

profile information of ferrous objects. The device is particularly suited

to large tooth/valley sensing applications where accurate timing

accuracy is a desired feature. For applications requiring the sensing of

fine-pitch gears, the ATS611LSB is recommended.

Data Sheet

27627.126

Supply Voltage, VCC......................... 24 V

Reverse Supply Voltage,

V

(1 minute max.)................ -24 V

RCC

Output OFF Voltage, V

Output Current, I

Reverse Output Current, I

Package Power Dissipation,

PD.................................... See Graph

Operating Temperature Range,

TA........................... -40°C to +150°C

Storage Temperature, T

OUT

................ 24 V

OUT

.. Internally Limited

........ 50 mA

OUT

............ +170°C

S

continued next page…

Always order by complete part number, e.g., ATS632LSC .

ATS632LSC

1

2

3

HALL-EFFECT

GEAR-TOOTH SENSOR

SUBASSEMBLY

FEATURES AND BENEFITS

■ Non-Oriented Installation

■ Fully Optimized Gear-Tooth Sensors

■ Single-Chip Sensing IC for High Reliability

■ Zero-Speed Digital Output Representing Target

Profile

■ Extremely Low Timing Accuracy Drift with Temperature

■ Large Operating Air Gaps

■ Optimized Magnetic Circuit

■ Self-Calibrating Circuitry

with Integrated Offset Cancellation

6-bit A/D Converters to Capture Peaks

Thresholds Proportional to Peak-to-Peak Signals

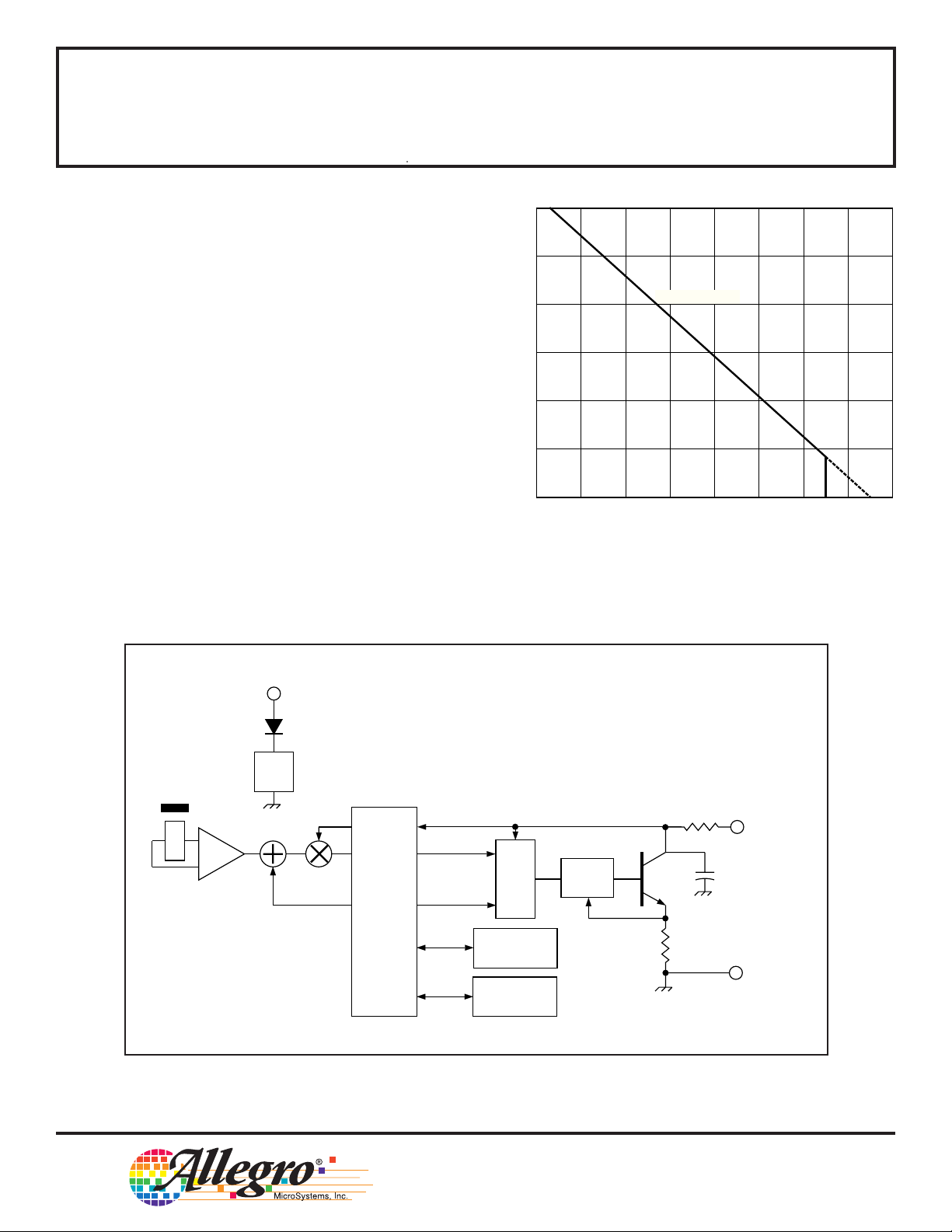

1200

1000

800

600

400

200

0

ALLOWABLE PACKAGE POWER DISSIPATION IN mW

40 80 120 160

RθJA = 119°C/W

60 100 140 18020

AMBIENT TEMPERATURE IN °C

Dwg. GH-065-2

MAGNET

X

FUNCTIONAL BLOCK DIAGRAM

SUPPLY

REG

GAIN

–

+

OFFSET

REFERENCE

GENERATOR

THRESHOLD

PEAK

LOGIC

OUTPUT

POSITIVE PEAK

TRACK & HOLD

NEGATIVE PEAK

TRACK & HOLD

CURRENT

LIMIT

100 Ω

OUTPUT

330 pF

GROUND

Dwg. FH-015-3

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

W

Copyright © 1998, Allegro MicroSystems, Inc.

ATS632LSC

HALL-EFFECT

GEAR-TOOTH SENSOR

SUBASSEMBLY

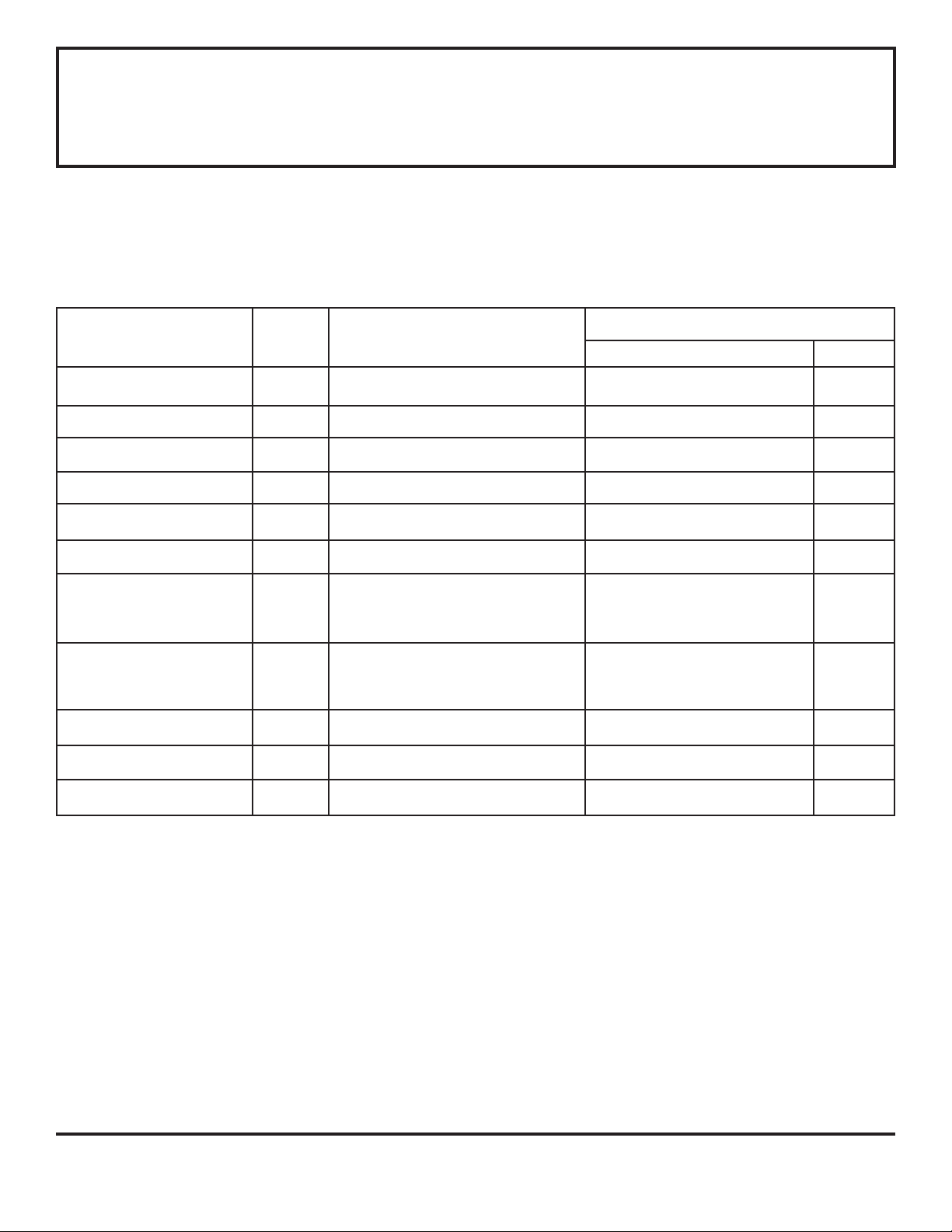

ELECTRICAL CHARACTERISTICS over operating voltage and temperature range (unless

otherwise specified).

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Supply Voltage V

Under-Voltage Lockout V

Low Output Voltage V

Output Current Limit I

CC(UV)

OUT(L)

OUTM

Output Leakage Current I

Supply Current I

Calibration Count n

Calibration Update n

Power-On Time t

Output Rise Time t

Output Fall Time t

CC

OFF

CC

cal

up

po

Operating, TJ < 165°C 6.0 12 24 V

I

= 5 mA, VCC = 0 → 6 V – 5.0 – V

OUT

I

= 5 mA, Output ON – 0.7 1.6 V

OUT

V

= 12 V 25 45 55 mA

OUT

V

= 24 V, Output OFF – 5.0 10 µA

OUT

Output OFF, Target Speed = 0 RPM – 9.0 15 mA

Output falling mechanical edges 16 16 16 Pulses

after power on for startup calibration

to be complete

Output falling mechanical edges 64 64 64 Pulses

for the threshold calibration to be

complete

VCC > 6 V – 200 500 µs

r

f

RL = 2.5 kΩ, CL = 10 pF – 3.0 6.0 µs

RL = 2.5 kΩ, CL = 10 pF – 1.0 3.0 µs

NOTE: Typical data is at VCC = 12 V and TA = +25°C and is for design information only.

ATS632LSC

HALL-EFFECT

GEAR-TOOTH SENSOR

SUBASSEMBLY

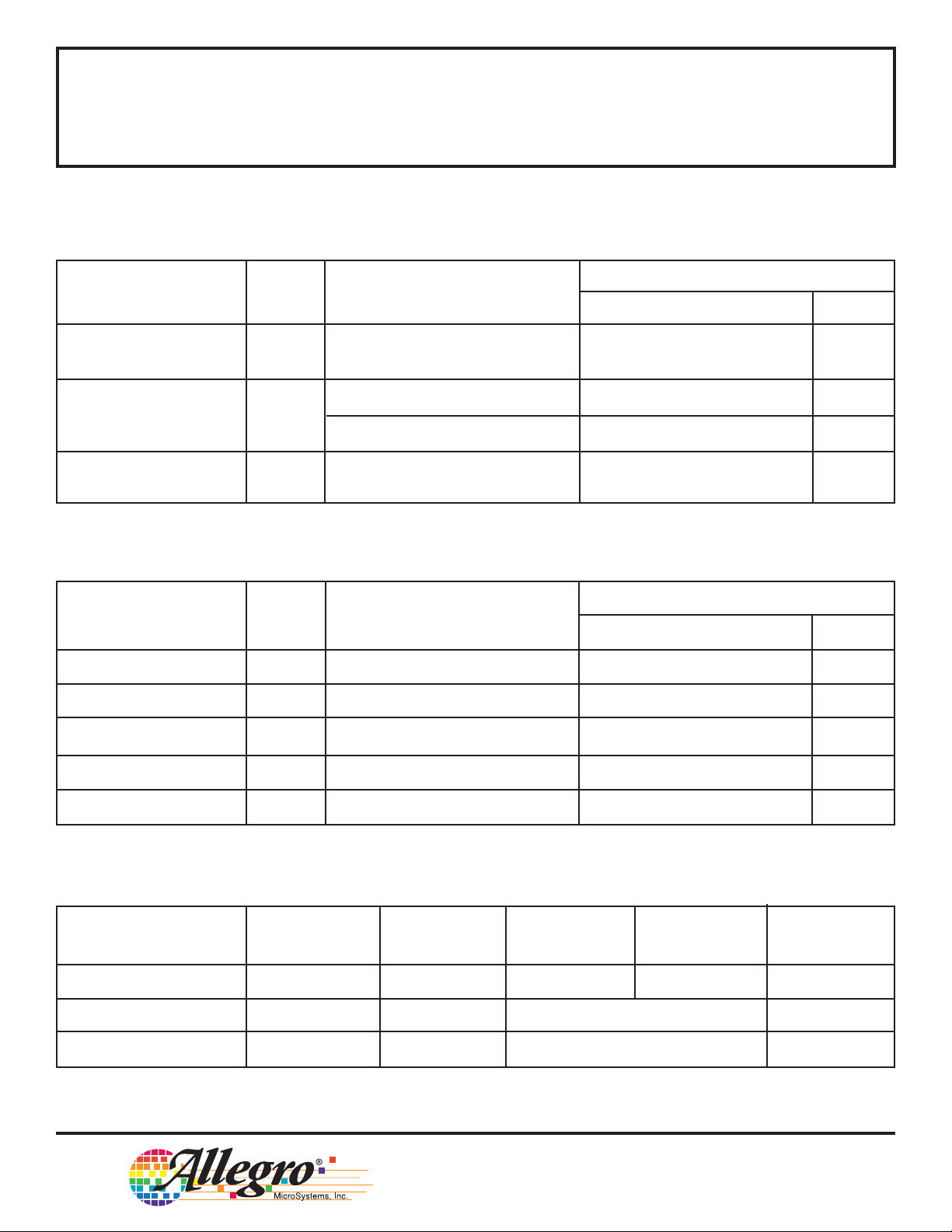

OPERATION over operating voltage and temperature range with reference target (unless otherwise specified).

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Operating Air Gap Range AG Operating, 0.3 – 1.9 mm

Target Speed > 20 RPM

Output Polarity – Operating, Over Tooth Low Low Low –

Operating, Over Valley High High High –

Timing Accuracy t

NOTE: Air Gap is defined as the distance from the face of the sensor subassembly to the target.

θ

Target Speed < 3500 RPM, – ±0.25 ±0.50 °

0.3 mm ≤ AG ≤ 1.9 mm

TARGET DESIGN CRITERIA

Limits

Characteristic Symbol Description Min. Typ. Max. Units

Valley Depth h

Valley Width (P

Tooth Width T – 5.0 – mm

Thickness F – 5.0 – mm

Eccentricity – Timing accuracy may change – – ±0.25 mm

t

- T) – 5.0 – mm

C

– 5.0 – mm

TARGET DIMENSIONS

Diameter Thickness Tooth Width Valley Width Valley Depth

Type (D

Reference Target 84 mm 16 mm 9 mm 13 mm 5 mm

Characterization Target #1 84 mm 16 mm 1 tooth, 180° 5 mm

Characterization Target #2 35 mm 7 mm 1 tooth, 180° 6 mm

NOTE: Timing accuracy data is taken by recalibrating the unit at each air gap.

) (F) (T) (PC - T) (ht)

o

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...