查询ATS625LSG供应商

Package SG, 4-pin Through Hole

ATS625LSG

True Zero-Speed Low-Jitter

High Accuracy Gear Tooth Sensor

The ATS625 true zero-speed gear tooth sensor is an optimized Hall IC and magnet

configuration packaged in a molded module that provides a manufacturer-friendly

solution for digital gear tooth sensing applications. The sensor assembly consists

of an over-molded package that holds together a samarium cobalt magnet, a

pole piece concentrator, and a true zero-speed Hall IC that has been optimized

to the magnetic circuit. This small package can be easily assembled and used in

conjunction with gears of various shapes and sizes.

The sensor incorporates a dual-element Hall IC that switches in response to

differential magnetic signals created by a ferrous target. Digital processing of the

analog signal provides zero-speed performance independent of air gap as well

as dynamic adaptation of device performance to the typical operating conditions

found in automotive applications (reduced vibration sensitivity). High-resolution

peak detecting DACs are used to set the adaptive switching thresholds of the

device. Switchpoint hysteresis reduces the negative effects of any anomalies in the

magnetic signal associated with the targets used in many automotive applications.

This sensor system is optimized for crank applications that utilize targets that

possess signature regions.

1

2

3

4

1. VCC

2. VOUT

3. AUX

4. GND

AB SO LUTE MAX I MUM RAT INGS

Supply Voltage*, VCC.......................................26.5 V

Reverse-Supply Voltage, V

Reverse-Supply Current, I

Reverse-Output Voltage, V

Continuous Output Current, I

Output Sink Current, I

Operating Temperature

Ambient, T

Maximum Junction, T

Maximum Junction ≤100 hr, T

Storage Temperature, T

*See the Power Derating section.

OUT

, Range L................–40ºC to 150ºC

A

........................–18 V

RCC

........................50 mA

RCC

.....................–0.5 V

ROUT

...................25 mA

OUT

............................. 10 mA

........................165ºC

J(max)

.................. –65ºC to 170ºC

S

J(max100)

......180ºC

TheATS625 is provided in a 4-pin SIP. The Pb (lead) free option, available by

special request, has a 100% matte tin plated leadframe.

Features and Benefits

Highly repeatable over operating temperature range

Tight timing accuracy over operating temperature range

True zero-speed operation

Air-gap–independent switchpoints

Vibration immunity

Large operating air gaps

Defined power-on state

Wide operating voltage range

Digital output representing target profile

Single-chip sensing IC for high reliability

Small mechanical size

Optimized Hall IC magnetic system

Fast start-up

AGC and reference adjust circuit

Undervoltage lockout

Use the following complete part numbers when ordering:

Part Number Pb-free Packing

ATS625LSGTN –

ATS625LSGTN-T Yes

1

Contact Allegro for additional packing options.

2

Available by special request only.

2

Tape and Reel 13-in. 800 pcs./reel

1

ATS625LSG-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

V+

0.1 F

C

BYPASS

VCC

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Functional Block Diagram

Voltage

Regulator

Threshold

Comparator

Threshold

Logic

Hall

Amp

Automatic

Gain

Control

PPeak

PDAC

V

PROC

NDAC

NPeak

Reference

Generator

PThresh

NThresh

GND

(Recommended)

AUX

Current

Limit

Output

Transistor

VOUT

ATS625LSG-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

2

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

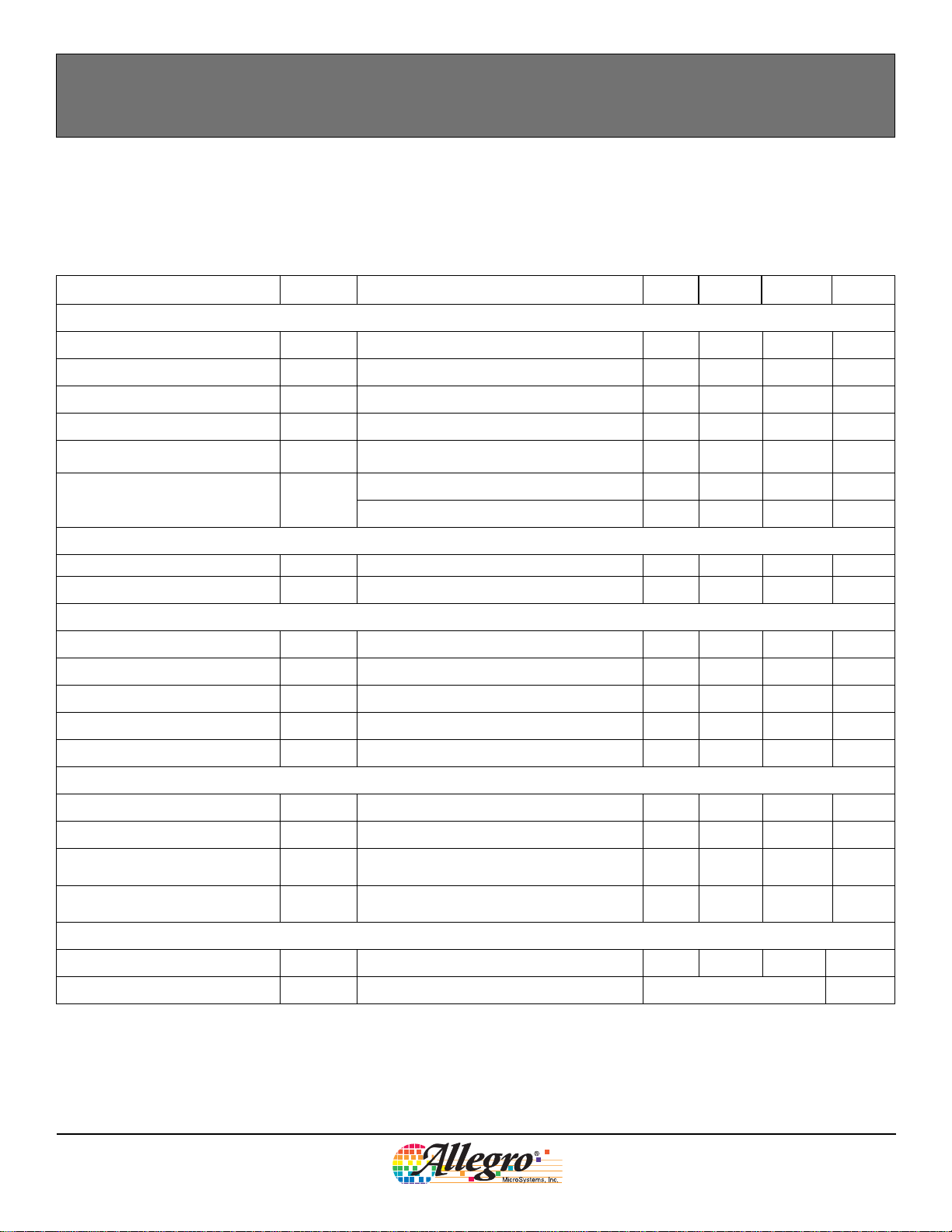

Operating Characteristics Valid at T

= –40°C to 150°C, TJ ≤ T

A

operating parameters: VCC = 12 V and TA = 25°C

Characteristic Symbol Test Conditions Min. Typ. Max. Units

ELECTRICAL CHARACTERISTICS

Supply Voltage V

Undervoltage Lockout V

Reverse Supply Current I

Supply Zener Clamp Voltage

Supply Zener Current

1

2

Supply Current I

CC

CCUV

RCC

V

Z

I

Z

CC

POWER-ON CHARACTERISTICS

Power-On State S

Power-On Time t

PO

PO

OUTPUT STAGE

Low Output Voltage V

Output Current Limit I

Output Leakage Current I

Output Rise Time t

Output Fall Time t

OUT(SAT)ISINK

OUT(LIM)VOUT

OUT(OFF)

r

f

SWITCHPOINT CHARACTERISTICS

, over full range of AG, unless otherwise noted; typical

J(max)

Operating; TJ < T

Jmax

4.0 – 24 V

– – < V

CC(min)

V

VCC = –18 V – – –10 mA

ICC = 17 mA 28 – – V

VS = 28 V – – 17 mA

Output OFF – 8.5 14 mA

Output ON – 8.5 14 mA

– High – V

Gear Speed < 100 RPM; VCC > VCC min – – 200 µs

= 20 mA, Output = ON – 200 450 mV

= 12 V, TJ < T

Output = OFF, V

Jmax

= 24 V – – 10 µA

OUT

25 45 70 mA

RL = 500 Ω, CL = 10 pF – 1.0 2 µs

RL = 500 Ω, CL = 10 pF – 0.6 2 µs

Speed S Reference target 60+2 0 – 12000 rpm

Bandwidth BW Corresponds to switching frequency – 3 dB – 20 – kHz

Operate Point B

Release Point B

% of peak-to-peak signal, AG < AG

OP

BIN transitioning from LOW to HIGH

% of peak-to-peak signal, AG < AG

RP

BIN transitioning from HIGH to LOW

max

max

;

;

–60 – %

–40 – %

CALIBRATION

Initial Calibration

3

Cal

Start-up – 1 6 edges

PO

Calibration Update Cal Running mode operation continuous –

Continued on the next page...

Allegro MicroSystems, Inc.

ATS625LSG-DS, Rev. 1

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

3

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Operating Characteristics, continued Valid at T

= –40°C to 150°C, TJ ≤ T

A

, over full range of AG, unless otherwise noted;

J(max)

typical operating parameters: VCC = 12 V and TA = 25°C

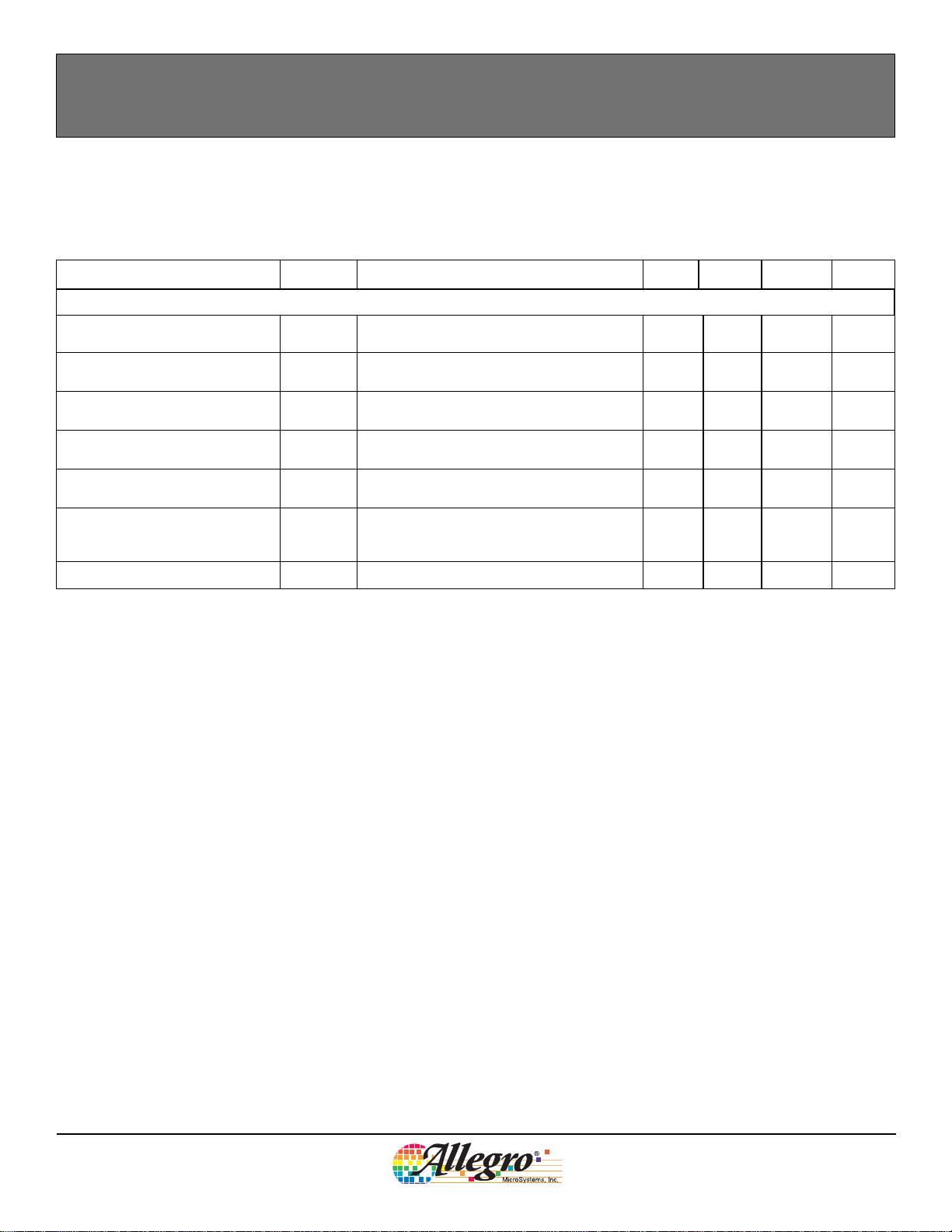

Characteristic Symbol Test Conditions Min. Typ. Max. Units

OPERATING CHARACTERISTICS with 60+2 reference target

Operational Air Gap AG

Relative Timing Accuracy, Sequential Mechanical Rising Edges

Relative Timing Accuracy, Sequential Mechanical Falling Edges

Relative Timing Accuracy, Signature Mechanical Rising Edge

4

Relative Timing Accuracy, Signature Mechanical Falling Edge

5

Relative Repeatability, Sequential

Rising and Falling Edges

Operating Signal

1

Test condition is I

2

Upper limit is I

3

Power-on speed ≤ 200 rpm. Refer to the Sensor Description section for information on start-up behavior.

4

Detection accuracy of the update algorithm for the first rising mechanical edge following a signature region can be adversely affected by the magnetic

bias of the signature region. Please consult with Allegro field applications engineering for aid with assessment of specific target geometries.

5

Detection accuracy of the update algorithm for the falling edge of the signature region is highly dependent upon specific target geometry. Please consult

with Allegro field applications engineering for aid with assessment of specific target geometries.

6

The repeatability specification is based on statistical evaluation of a sample population.

7

Peak-to-peak magnetic flux strength required at Hall elements for complying with operational characteristics.

7

CC(max)

CC(max)

6

+ 3 mA.

+ 3 mA.

ERR

ERR

ERR

ERR

T

B

Measured from sensor branded face to

target tooth

Relative to measurement taken at

RR

AG = 1.5 mm

Relative to measurement taken at

FF

AG = 1.5 mm

Relative to measurement taken at

SIGR

AG = 1.5 mm

Relative to measurement taken at

SIGF

AG = 1.5 mm

360° Repeatability, 1000 edges; peak-peak

sinusoidal signal with B

θE

PEAK

6° period

AG

IN

< AG < AG

(min)

(max)

≥ B

IN(min)

and

0.5 – 2.5 mm

– – ±0.4 deg.

– – ±0.4 deg.

– – ±0.4 deg.

– – ±1.5 deg.

– – 0.08 deg.

60 – – G

ATS625LSG-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

4

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

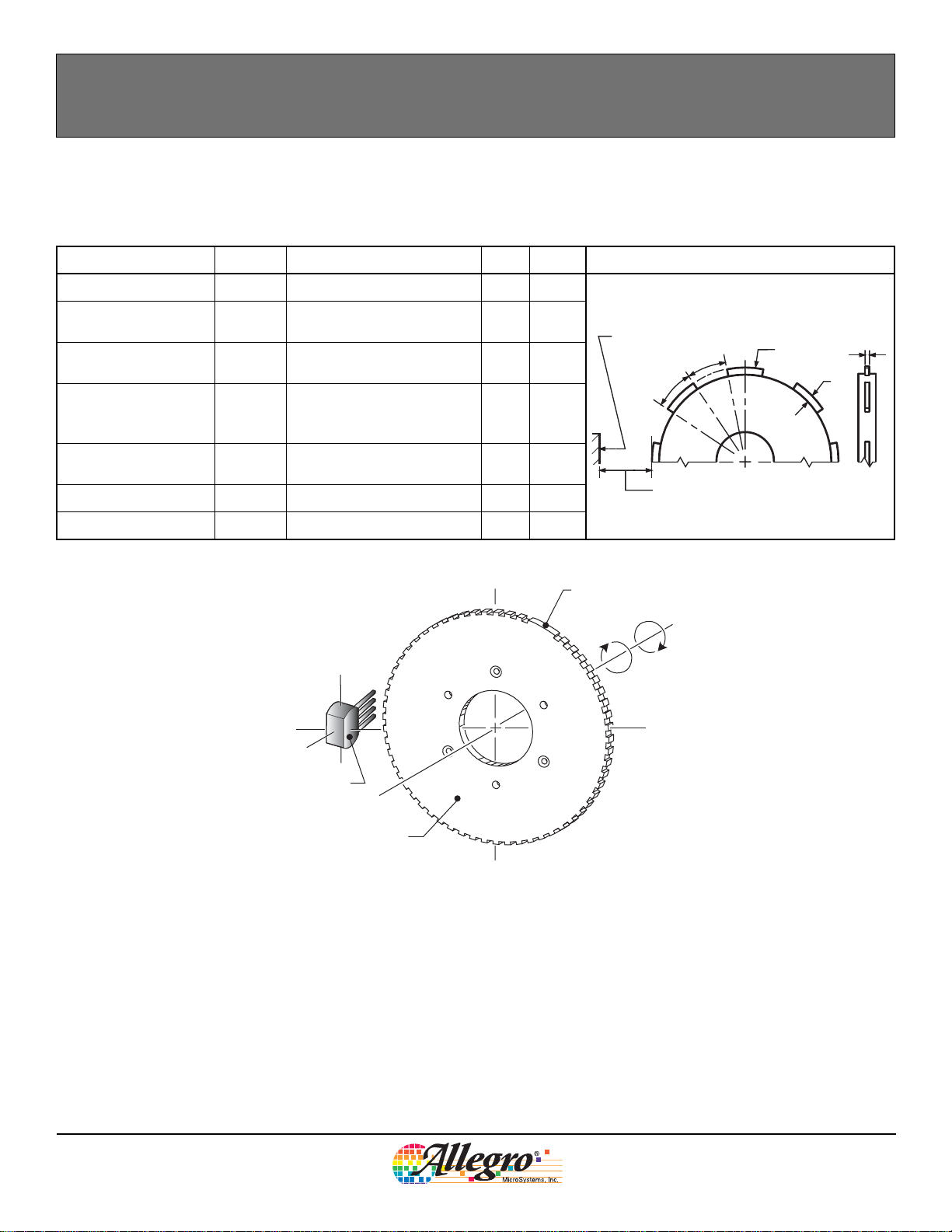

Reference Target (Gear) Information

REFERENCE TARGET 60+2

Characteristics Symbol Test Conditions Typ. Units Symbol Key

Outside Diameter D

Face Width F

Circular Tooth Length t

Signature Region Circular Tooth Length

Circular Valley Length t

Tooth Whole Depth h

Material Low Carbon Steel – –

t

SIG

Outside diameter of target

o

Breadth of tooth, with respect

to sensor

Length of tooth, with respect

to sensor; measured at D

Length of signature tooth,

with respect to sensor; measured at D

Length of valley, with respect

v

to sensor; measured at D

t

o

Pin 4

120 mm

6mm

3mm

o

15 mm

3mm

o

3mm

Branded Face

of Sensor

t,t

Air Gap

Signature Region

SIG

Ø

D

O

V

t

F

h

t

Pin 1

Branded Face

of Sensor

Reference Target

60+2

Figure 1. Configuration with Spur Gear Reference Target

For the generation of adequate magnetic field levels, the following recommendations should be followed in the design and

specification of targets:

• 2 mm < tooth width, t < 4 mm

• Valley width, tv > 2 mm

• Valley depth, ht > 2 mm

• Tooth thickness, F ≥ 3 mm

• Target material must be low carbon steel

ATS625LSG-DS, Rev. 1

Although these parameters apply to targets of traditional

geometry (radially oriented teeth with radial sensing, shown in

figure 1), they also can be applied in applications using stamped

targets (an aperture or rim gap punched out of the target mate-

rial) and axial sensing. For stamped geometries with axial sens-

ing, the valley depth, ht, is intrinsically infinite, so the criteria for

tooth width, t, valley width, tv, tooth material thickness, F, and

material specification need only be considered for reference. For

example, F can now be < 3 mm.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

5

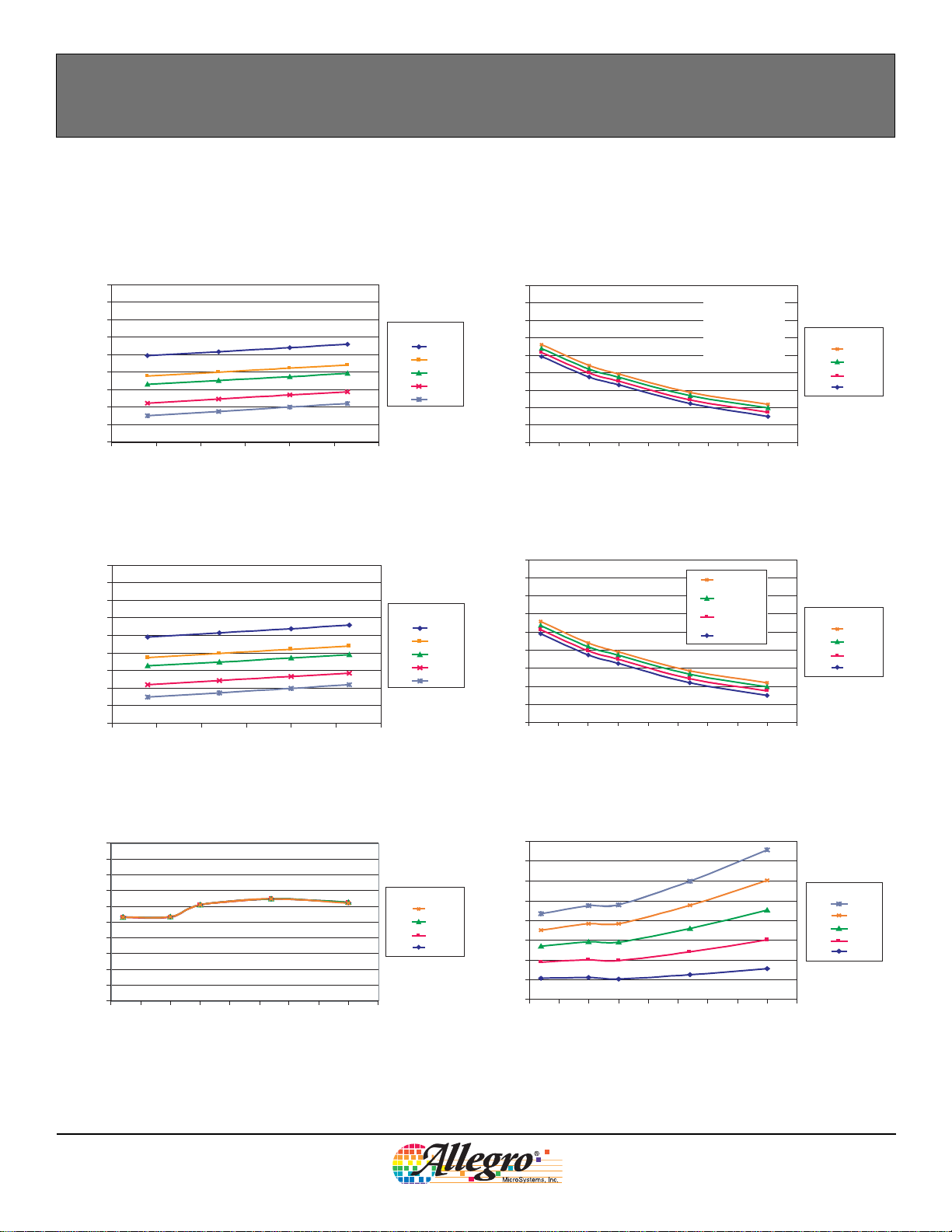

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

I

Versus V

CC(ON)

14

13

12

11

10

9

8

Current (mA)

7

6

5

0 5 10 15 20 25 30

Voltage (V)

CC

ATS625LSG

Characteristic Data: Electrical

14

13

TA (°C)

-40

0

25

85

150

12

11

10

9

8

Current (mA)

7

6

5

-50 -25 0 25 50 75 100 125 150 175

I

Versus T

CC(ON)

Temperature (°C)

A

Vcc = 26.5V

Vcc = 20V

Vcc = 12V

Vcc = 4V

(V)

V

CC

26.5

20.0

12.0

4.0

I

Versus V

CC(OFF)

14

13

12

11

10

9

Current (mA)

8

7

6

5

0 5 10 15 20 25 30

CC

Voltage (V)

I

10

8

6

4

2

0

-2

Current (uA)

-4

-6

-8

-10

-50 -25 0 25 50 75 100 125 150 175

OUT(OFF)

Versus T

A

Temperature (°C)

TA (°C)

V

OUT

150

(V)

26.5

20.0

12.0

4.0

-40

I

Versus T

CC(OFF)

14

13

12

11

0

25

85

10

9

8

Current (mA)

7

6

5

-50 -25 0 25 50 75 100 125 150 175

A

Vcc = 24V

Vcc = 20V

Vcc = 12V

Vcc = 4V

VCC (V)

24.0

20.0

12.0

4.0

Temperature (°C)

V

400

350

300

250

200

150

Voltage (mV)

100

50

0

-50 -25 0 25 50 75 100 125 150 175

Temperature (°C)

OUT(SAT)

Versus T

A

I

(mA)

OUT

25

20

15

10

5

ATS625LSG-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

6

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

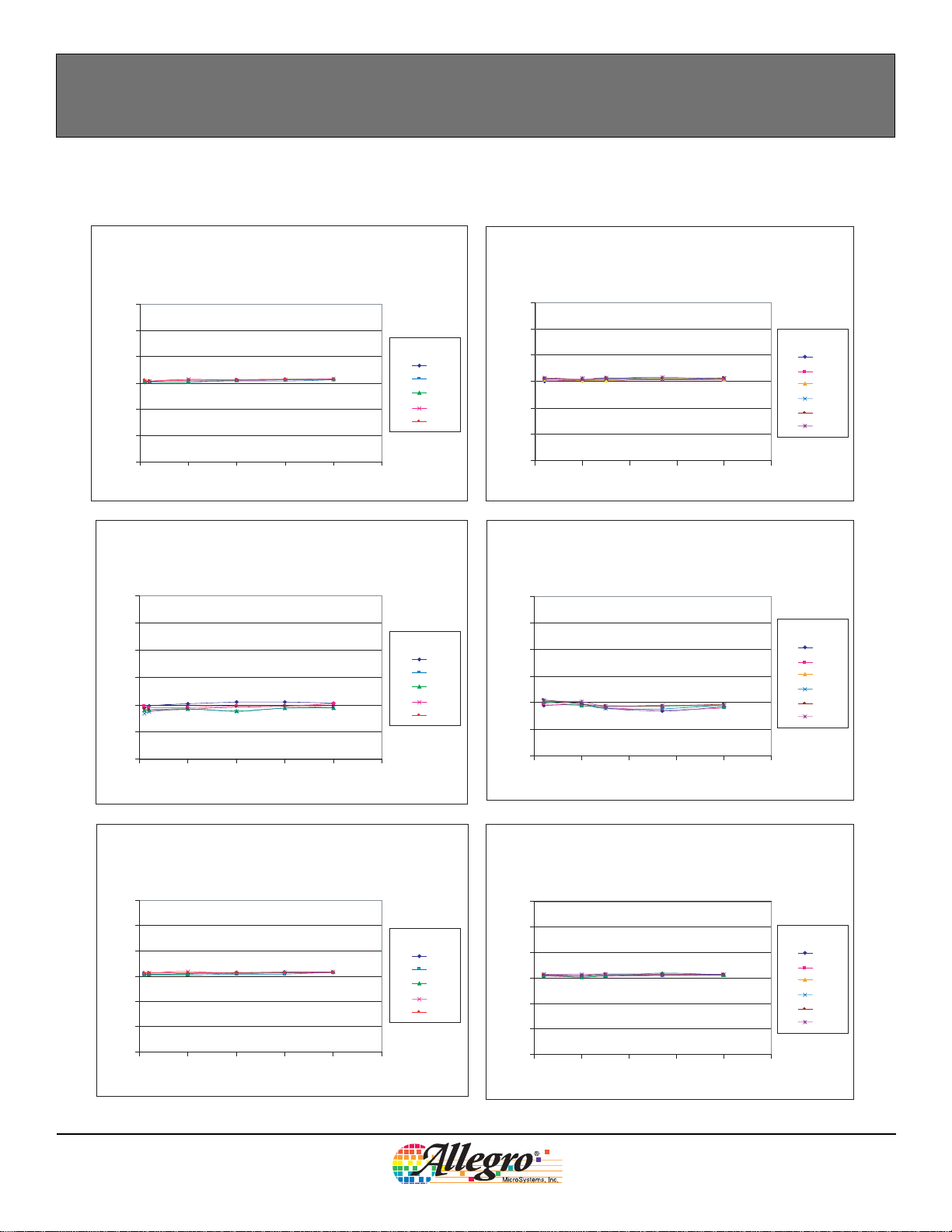

Characteristic Data: Relative Timing Accuracy

Relative Timing Accuracy Versus Speed

Signature Tooth Rising Edge

0.5 mm Air Gap

1.5

1.0

0.5

0.0

-0.5

Edge Position (°)

-1.0

-1.5

500 1000 1500 2000 2500

0

Target Speed, S (rpm)

Relative Timing Accuracy Versus Speed

Signature Tooth Falling Edge

0.5 mm Air Gap

1.5

1.0

0.5

0.0

-0.5

Edge Position (°)

-1.0

-1.5

0 500 1000 1500 2000 2500

Target Speed, S (rpm)

TA (°C)

–40

150

TA (°C)

–40

150

Relative Timing Accuracy Versus Ambient

Signature Tooth Rising Edge

0.5 mm Air Gap

1.5

1.0

0.5

0

25

85

0.0

-0.5

Edge Position (°)

-1.0

-1.5

-50 0 50 100 150 200

S (rpm)

50

100

500

1000

1500

2000

Tem perature, TA (°C)

Relative Timing Accuracy Versus Ambient

Signature Tooth Falling Edge

0.5 mm Air Gap

1.5

1.0

0.5

0

25

85

0.0

-0.5

Edge Position (°)

-1.0

-1.5

-50 0 50 100 150 200

Tem perature, TA (°C)

S (rpm)

50

100

500

1000

1500

2000

Relative Timing Accuracy Versus Speed

Rising Edge Follow ing Signature Tooth

1.5

1.0

0.5

0.0

-0.5

Edge Position (°)

-1.0

-1.5

0 500 1000 1500 2000 2500

ATS625LSG-DS, Rev. 1

0.5 mm Air Gap

Target Speed, S (rpm)

TA (°C)

–40

150

Relative Timing Accuracy Versus Ambient

Rising Edge Follow ing Signature Tooth

0.5 mm Air Gap

1.5

1.0

0.5

0

25

85

0.0

-0.5

Edge Position (°)

-1.0

-1.5

-50 0 50 100 150 200

Tem perature, TA (°C)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

S (rpm)

50

100

500

1000

1500

2000

7

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Relative Timing Accuracy Versus Speed

Signature Tooth Rising Edge

2.5 mm Air Gap

1.5

1.0

0.5

0.0

-0.5

Edge Position (°)

-1.0

-1.5

500 1000 1500 2000 2500

0

Target Speed, S (rpm)

Relative Timing Accuracy Versus Speed

Signature Tooth Falling Edge

2.5 mm Air Gap

1.5

1.0

0.5

0.0

-0.5

Edge Position (°)

-1.0

-1.5

0 500 1000 1500 2000 2500

Target Speed, S (rpm)

TA (°C)

–40

150

TA (°C)

–40

150

Relative Timing Accuracy Versus Ambient

Signature Tooth Rising Edge

2.5 mm Air Gap

1.5

1.0

0.5

0

25

85

0.0

-0.5

Edge Position (°)

-1.0

-1.5

-50 0 50 100 150 200

S (rpm)

50

100

500

1000

1500

2000

Tem perature, TA (°C)

Relative Timing Accuracy Versus Ambient

Signature Tooth Falling Edge

2.5 mm Air Gap

1.5

1.0

0.5

0

25

85

0.0

-0.5

Edge Position (°)

-1.0

-1.5

-50 0 50 100 150 200

Tem perature, TA (°C)

S (rpm)

50

100

500

1000

1500

2000

Relative Timing Accuracy Versus Speed

Rising Edge Follow ing Signature Tooth

1.5

1.0

0.5

0.0

-0.5

Edge Position (°)

-1.0

-1.5

0 500 1000 1500 2000 2500

ATS625LSG-DS, Rev. 1

2.5 mm Air Gap

Target Speed, S (rpm)

TA (°C)

–40

150

Relative Timing Accuracy Versus Ambient

Rising Edge Follow ing Signature Tooth

2.5 mm Air Gap

1.5

1.0

0.5

0

25

85

0.0

-0.5

Edge Position (°)

-1.0

-1.5

-50 0 50 100 150 200

Tem perature, TA (°C)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

S (rpm)

50

100

500

1000

1500

2000

8

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Relative Timing Accuracy Versus Air Gap

Signature Tooth R ising Edge

= –40, 0, 25, 85, 150 (°C)

T

A

S = 50, 100, 500, 1000, 1500, 2000 (rpm)

2.0

1.5

1.0

0.5

0.0

-0.5

-1.0

Edge Position (°)

-1.5

0.0 0.5 1.0 1.5 2.0 2.5 3.0

Air Gap (mm)

2.0

1.5

1.0

0.5

0.0

-0.5

Edge Position (°)

-1.0

-1.5

0 0.5 1.0 1.5 2.0 2.5 3.0

Relative Timing Accuracy Versus Air Gap

2.0

1.5

1.0

0.5

0.0

-0.5

-1.0

Edge Position (°)

-1.5

0.0 0.5 1.0 1.5 2.0 2.5 3.0

Relative Timing Accuracy Versus Air Gap

Rising Edge Following Signature Tooth

TA = –40, 0, 25, 85, 150 (°C)

S = 50, 100, 500, 1000, 1500, 2000 (rpm)

Air Gap (mm)

Signature Tooth Fa lling Edge

TA = –40, 0, 25, 85, 150 (°C)

S = 50, 100, 500, 1000, 1500, 2000 (rpm)

Air Gap (mm)

ATS625LSG-DS, Rev. 1

Characteristic Data: Repeatability

360° Repeatability Versus Air Gap

Sequential Tooth Falling Edge

S = 1000 rpm

0.25

(°C)

T

0.20

0.15

0.10

Repeatabilty (°)

0.05

0

0 1.0 2.0 3.0 4.0

A

–40

25

150

Air Gap (mm)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

9

ATS625LSG

(

)(

)

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Sensor Description

Assembly Description

The ATS625LSG true zero-speed gear tooth sensor is a combined Hall IC-magnet configuration that is fully optimized to

provide digital detection of gear tooth edges. This sensor is

integrally molded into a plastic body that has been optimized for

size, ease of assembly, and manufacturability. High operating

temperature materials are used in all aspects of construction.

Sensing Technology

The gear tooth sensor contains a single-chip differential Hall

effect sensor IC, a 4-pin leadframe, a samarium cobalt magnet,

and a flat ferrous pole piece. The Hall IC consists of two Hall

elements spaced 2.2 mm apart, and each independently measures

Target (Gear)

Element Pitch

Hall Element 2

Dual-Element

Hall Effect Device

Pin n >1 Side

Figure 2. Device Cross Section. Relative motion of the target is detected

by the dual Hall elements mounted on the Hall IC. This view is from the

side opposite the pins.

South Pole

North Pole

Hall Element 1

Hall IC

Pole Piece

(Concentrator)

Back-biasing Magnet

Plastic

Pin 1 Side

the magnetic gradient created by the passing of a ferrous object.

This is illustrated in figures 2 and 3. The differential output of

the two elements is converted to a digital signal that is processed

to provide the digital output.

Switching Description

After proper power is applied to the component, the sensor is

then capable of providing digital information that is representative of the profile of a rotating gear, as illustrated in figure 4.

No additional optimization is needed and minimal processing

circuitry is required. This ease of use reduces design time and

incremental assembly costs for most applications.

Rotating Target

1

4

Figure 3. This left-to-right (pin 1 to pin 4) direction of target rotation

results in a high output signal when a tooth of the target gear is centered

over the face of the sensor. A right-to-left (pin 4 to pin 1) rotation inverts

the output signal polarity.

Branded Face

of Sensor

Target

Mechanical Profile

Target

Magnetic Profile

Sensor Output

Switch State

Sensor Output

Electrical Profile

Target Motion from

Pin 1 to Pin 4

Sensor Output

Electrical Profile

Target Motion from

Pin 4 to Pin 1

Figure 4. The magnetic profile reflects the geometry of the target, allowing the device to present an accurate digital output response.

ATS625LSG-DS, Rev. 1

B+

B

IN

On Off On Off On Off On Off On OffOn OffOn OffOn Off

V+

V

OUT

V+

V

OUT

Signature Tooth

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

10

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Undervoltage Lockout

When the supply voltage falls below the undervoltage lockout

level, V

, the device switches to the OFF state. The device

CCUV

remains in that state until the voltage level is restored to to the

VCC operating range. Changes in the target magnetic profile

have no effect until voltage is restored. This prevents false signals caused by undervoltage conditions from propagating to the

output of the sensor.

Power Supply Protection

The device contains an on-chip regulator and can operate over

a wide range of supply voltage levels. For applications using an

unregulated power supply, transient protection must be added

externally. For applications using a regulated supply line, EMI

and RFI protection may still be required. The circuit shown in

V

S

C

BYPASS

0.1 µF

3

figure 5 is the basic configuration required for proper device

operation. Contact Allegro field applications engineering for

information on the circuitry required for compliance to various

EMC specifications.

Internal Electronics

The ATS625LSG contains a self-calibrating Hall effect IC

that possesses two Hall elements, a temperature compensated

amplifier and offset cancellation circuitry. The IC also contains

a voltage regulator that provides supply noise rejection over the

operating voltage range. The Hall transducers and the electronics are integrated on the same silicon substrate by a proprietary

BiCMOS process. Changes in temperature do not greatly affect

this device due to the stable amplifier design and the offset rejection circuitry.

1

VCC

ATS625

2

VOUTAUX

R

PU

Sensor Output

ATS625LSG-DS, Rev. 1

GND

4

Figure 5. Power Supply Protection Typical Circuit

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

11

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Sensor Operation Description

Power-On State

At power-on, the device is guaranteed to initialize in the OFF

state, with V

OUT

high.

First Edge Detection

The device uses the first two mechanical edges to synchronize

with the target features (tooth or valley) and direction of rotation

of the target. The device is synchonized by the third edge. The

actual behavior is affected by: target rotation direction relative to

Sensor

Pin 4 Side

Target Mechanical Profile

Target Magnetic Profile

(A) Target relative movement

as shown in figure 3. Output

signal is high over the tooth.

Sensor Output, V

(Start-up over rising edge)

OUT

(Start-up over valley)

(Start-up over tooth)

the, target feature (tooth, rising edge, falling edge, or valley) that

is centered on the device at power-on, and fact that the sensor

powers-on in the OFF state,with V

high, regardless of the

OUT

eventual direction of target rotation. The interaction of these factors results in a number of possible power-on scenarios. These

are diagrammed in figure 6. In all start-up scenarios, the correct

number of output edges is provided, but the accuracy of the first

two edges may be compromised.

Target Motion Relative to Sensor

Sensor

Pin 1 Side

(Start-up over falling edge)

Sensor s tart-up location

Sensor

Pin 4 Side

(B) Target relative movement

Sensor

Pin 1 Side

Target Mechanical Profile

Target Magnetic Profile

Sensor Output, V

OUT

(Start-up over valley)

Target Motion Relative to Sensor

opposite that shown in figure 3.

Output signal is low over the tooth.

(Start-up over rising edge)

(Start-up over tooth)

(Start-up over falling edge)

Sensor start-up location

Figure 6. Start-up Position And Relative Motion Effects on First Device Output Switching. Panel A shows the effects when the

target is moving from pin 1 toward pin 4 of the device; V

in the opposite direction, as in panel B, the polarity of the device output inverts; V

goes high at the approach of a tooth. When the target is moving

OUT

goes low at the approach of a tooth.

OUT

ATS625LSG-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

12

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

AGC (Automatic Gain Control)

The AGC feature is implemented by a unique patented selfcalibrating circuitry. After each power-on, the device measures

the peak-to-peak magnetic signal. The gain of the sensor is then

Differential Electrical Signal versus Target Rotation

at Various Air Gaps, Without AGC

1000

800

600

(mV)

400

PROC

200

0

-200

-400

-600

Differential Signal, V

-800

-1000

0 3 6 9 12 15 18 21 24

AG:

0.25 mm

0.50 mm

1.00 mm

1.50 mm

2.00 mm

Target Rotation (°)

adjusted, keeping the internal signal amplitude constant over the

air gap range of the device, AG. This feature ensures that operational characteristics are isolated from the effects of changes in

AG. The effect of AGC is shown in figure 7.

Differential Electrical Signal versus Target Rotation

at Various Air Gaps, With AGC

1000

800

600

(mV)

400

PROC

200

0

-200

-400

-600

Differential Signal, V

-800

-1000

0 3 6 9 1215182124

AG:

0.25 mm

0.50 mm

1.00 mm

1.50 mm

2.00 mm

Target Rotation (°)

Figure 7. Effect of AGC. The left panel shows the process signal, V

AGC. The result is a normalized V

, which allows optimal performance by the rest of the circuits that reference this signal.

PROC

Offset Adjustment

In addition to normalizing performance over varying AG, the

gain control circuitry also reduces the effect of chip, magnet,

and installation offsets. This is accomplished using two DACs

(D to A converters) that capture the peaks and valleys of the

ATS625LSG-DS, Rev. 1

, without AGC. The right panel shows the effect with

PROC

processed signal, V

, and use it as a reference for the Thresh-

PROC

old Comparator subcircuit, which controls device switching. If

induced offsets bias the absolute signal up or down, AGC and

the dynamic DAC behavior work to normalize and reduce the

impact of the offset on sensor performance.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

13

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

SWITCHPOINTS

Switchpoints in the ATS625 are a percentage of the amplitude of

the signal, V

, after normalization with AGC. In operation,

PROC

the actual switching levels are determined dynamically. Two

DACs track the peaks of V

(see the Update subsection).

PROC

The switching thresholds are established at 40% and 60% of the

values held in the two DACs. The proximity of the thresholds

near the 50% level ensures the most accurate and consistent

switching, because it is where the slope of V

is steepest and

PROC

least affected by air gap variation.

The low hysteresis, 20%, provides high performance over various air gaps and immunity to false switching on noise, vibration,

backlash, or other transient events.

Figure 8 graphically demonstrates the establishment of the

switching threshold levels.Because the thresholds are established

dynamically as a percentage of the peak-to-peak signal, the

effect of a baseline shift is minimized. As a result, the effects of

offsets induced by tilted or off-center installation are minimized.

UPDATE

The ATS625 incorporates an algorithm that continuously monitors the system and updates the switching thresholds accordingly.

The switchpoint for each edge is determined by the signal result-

ing from the previous two edges. Because variations are tracked

in real time, the sensor has high immunity to target run-out and

retains excellent accuracy and functionality in the presence of

both run-out and transient mechanical events. Figure 9 shows

how the sensor uses historical data to provide the switching

threshold for a given edge.

Dynamic BOP Threshold Determination

V+

100

(%)Device

PROC

V

60

0

On Off

B

OP

State

Switching Threshold Levels

V+

100

(%)Device

60

40

PROC

V

0

At Constant V

Off On Off On

PROC

Level

B

OP

B

RP

State

Figure 8. Switchpoint Relationship to Thresholds.The device switches

when V

corresponding direction: increasing for a B

for a BRP switchpoint.

passes a threshold level, BOP or B

PROC

, while changing in the

RP

switchpoint, and decreasing

OP

(A)

Dynamic B

V+

100

Threshold Determination

RP

(%)Device

B

RP

Off On

PROC

V

40

0

State

(B)

Figure 9. Switchpoint Determination. The two previous V

used to determine the next threshold level: panel A, operate point, and

panel B, release point.

PROC

peaks are

ATS625LSG-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

14

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Sensor and Target Evaluation

Magnetic Profile

In order to establish the proper operating specification for a

particular sensor and target system, a systematic evaluation of

the magnetic circuit should be performed. The first step is the

generation of a magnetic map of the target. By using a calibrated

device, a magnetic profile of the system is made. Figure 10 is a

magnetic map of the 60+2 reference target.

300

250

200

150

(G)

IN

100

50

0

-50

-100

-150

-200

Differ ential Flux Density, B

-250

-300

-350

-400

0 30 60 90 120 150 180

Magnetic Map, Reference Target 60+2 with ATS625

Target Rotation (°)

A single curve can be derived from this map data, and be used to

describe the peak-to-peak magnetic field strength versus the size

of the air gap, AG. This allows determination of the minimum

amount of magnetic flux density that guarantees operation of the

sensor, B

, so the system designer can determine the maximum

IN

allowable AG for the sensor and target system. Referring to figure 11, a BIN of 60 G corresponds to a maximum AG of approximately 2.5 mm.

AG

(mm)

0.75

1.00

1.50

2.00

2.50

3.00

Air Gap Versus Magnetic Field, Reference Target 60+2 with ATS625

800

(G)

IN

700

600

500

400

300

200

100

Peak-Peak Differential Flux Densit y, B

0

0.5 1.0 1.5 2.0 2.5 3.0 3.5

AG (mm)

Figure 10. Magnetic Data for the Reference Target 60+2 with ATS625. In the top panel, the Signature Region appears in the center of the plot.

Allegro MicroSystems, Inc.

ATS625LSG-DS, Rev. 1

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

15

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

ACCURACY

While the update algorithm will allow the sensor to adapt to

typical air gap variations, major changes in air gap can adversely

affect switching performance. When characterizing sensor

performance over a significant air gap range, be sure to re-power

the device at each test at different air gaps. This ensures that

self-calibration occurs for each installation condition. See the

Operating Characteristics table and the charts in the Characteristic Data: Relative Timing Accuracy section for performance

information.

REPEATABILITY

Repeatability measurement methodology has been formulated to

minimize the effect of test system jitter on device measurements.

By triggering the measurement instrument, such as an oscillo-

Target Mechanical Profile

Low Resolution Encoder

scope, close to the desired output edge, the speed variations that

occur within a single revolution of the target are effectively nullified. Because the trigger event occurs a very short time before

the measured event, little opportunity is given for measurement

system jitter to impact the time-based measurements.

After the data is taken on the oscilloscope, statistical analysis

of the distribution is made to quantify variability and capability. Although complete repeatability results can be found in the

Characteristic Data: Repeatability section, figure 11 shows the

correlation between magnetic signal strength and repeatability.

Because an direct relationship exists between magnetic signal

strength and repeatability, optimum repeatability performance

can be attained through minimizing the operating air gap and

optimizing the target design.

Oscilloscope triggers at

n events after low-resolution pulse

High Resolution Encoder

Sensor Output

Electrical Profile

(target movement

from pin 1 to pin 4)

Oscilloscope trace

of 1000 sweeps for

the same output edge

Statistical distribution

of 1000 sweeps

Figure 11. Repeatability Measurement Methodology

Next high-resolution encoder pulse

(at target edge)

X

ATS625LSG-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

16

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Power Derating

THERMAL CHARACTERISTICS may require derating at maximum conditions, see application information

Characteristic Symbol Test Conditions* Value Units

Minimum-K PCB (single layer, single-sided, with copper limited to

Package Thermal Resistance

R

θJA

solder pads)

Low-K PCB (single-layer, single-sided with copper limited to

solder pads and 3.57 in.2 (23.03 cm2) of copper area each side)

*Additional information is available on the Allegro Web site.

Power Derating Curve

30

25

(V)

CC

20

T

J(max)

= 165ºC

V

CC(max)

126 ºC/W

84 ºC/W

15

Low-K PCB

(R

= 84 ºC/W)

θJA

Minimum-K PCB

(R

= 126 ºC/W)

10

Maximum Allowable V

5

0

20 40 60 80 100 120 140 160 180

θJA

Power Dissipation Versus Ambient

1900

for Sample PCBs

1800

1700

1600

1500

1400

1300

n

imum-K PCB

θJA

=

126 ºC/

Low-K PCB

(

R

θJ

A

=84

W)

ºC/W)

(mW)

D

1200

1100

1000

900

800

700

Mi

(R

600

500

400

Power Dis s ipation, P

300

200

100

0

20 40 60 80 100 120 140 160 180

Temperature, T

(°C)

A

V

CC(min)

ATS625LSG-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

17

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

The device must be operated below the maximum junction

temperature of the device, T

. Under certain combinations of

J(max)

peak conditions, reliable operation may require derating supplied power or improving the heat dissipation properties of the

application. This section presents a procedure for correlating

factors affecting operating TJ. (Thermal data is also available on

the Allegro MicroSystems Web site.)

The Package Thermal Resistance, R

, is a figure of merit sum-

θJA

marizing the ability of the application and the device to dissipate

heat from the junction (die), through all paths to the ambient air.

Its primary component is the Effective Thermal Conductivity,

K, of the printed circuit board, including adjacent devices and

traces. Radiation from the die through the device case, R

relatively small component of R

. Ambient air temperature,

θJA

θJC

, is

TA, and air motion are significant external factors, damped by

overmolding.

The effect of varying power levels (Power Dissipation, P

), can

D

be estimated. The following formulas represent the fundamental

relationships used to estimate TJ, at PD.

PD = VIN × I

∆T = PD × R

T

= TA + ∆T (3)

J

IN

(2)

θJA

(1)

Example: Reliability for VCC at TA = 150°C, package SG, using

minimum-K PCB.

Observe the worst-case ratings for the device, specifically:

R

126°C/W, T

θJA =

I

CC(max) = 8

the I

CC(max)

mA. Note that I

at TA = 25°C given in the Operating Characteristics

J(max) =

165°C, V

CC(max)

CC(max) =

26.5 V, and

at TA = 150°C is lower than

table.

Calculate the maximum allowable power level, P

D(max)

. First,

invert equation 3:

∆T

max

= T

– TA = 165 °C – 150 °C = 15 °C

J(max)

This provides the allowable increase to TJ resulting from internal

power dissipation. Then, invert equation 2:

P

D(max)

= ∆T

max

÷ R

= 15°C ÷ 126 °C/W = 119 mW

θJA

Finally, invert equation 1 with respect to voltage:

V

CC(est)

= P

D(max)

÷ I

= 119 mW ÷ 8 mA = 14.9 V

CC(max)

The result indicates that, at TA, the application and device can

dissipate adequate amounts of heat at voltages ≤V

Compare V

able operation between V

R

. If V

θJA

V

is reliable under these conditions.

CC(max)

CC(est)

CC(est)

to V

≥ V

. If V

CC(max)

CC(est)

CC(max)

CC(est)

and V

CC(max)

, then operation between V

≤ V

CC(max)

requires enhanced

.

CC(est)

, then reli-

CC(est)

and

For example, given common conditions such as: T

V

= 12 V, I

IN

P

= VIN × I

D

∆T = PD × R

= 4 mA, and R

IN

= 12 V × 4 mA = 48 mW

IN

= 48 mW × 140 °C/W = 7°C

θJA

= 140 °C/W, then:

θJA

TJ = TA + ∆T = 25°C + 7°C = 32°C

A worst-case estimate, P

able power level, without exceeding T

, represents the maximum allow-

D(max)

, at a selected R

J(max)

and TA.

ATS625LSG-DS, Rev. 1

= 25°C,

A

θJA

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

18

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Sensor Evaluation: EMC

Characterization Only

Test Name* Reference Specification

ESD – Human Body Model AEC-Q100-002

ESD – Machine Model AEC-Q100-003

Conducted Transients ISO 7637-1

Direct RF Injection ISO 11452-7

Bulk Current Injection ISO 11452-4

TEM Cell ISO 11452-3

*Please contact Allegro MicroSystems for EMC performance

Mechanical Information

Component Material Description Value

Element Spacing Hall sensing element spacing 2.2 mm

Back-biasing Magnet Rare Earth South pole behind IC

Sensor Package Material Thermoset Epoxy Maximum Temperature 170°C

Leads Copper Solder, Tin/Lead 90/10

a

Temperature excursions of up to 260°C for 2 minutes or less are permitted (based on delamination studies).

b

Industry accepted soldering techniques are acceptable for this package as long as the indicated maximum temperature is not exceeded.

a

b

ATS625LSG-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

19

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

Package SG, 4-Pin SIP

5.5 .217

20.95 .825

5.8 .228

4.7 .185

15.3 .602

8.0 .315

2.9 .114

E

0.6

1.7 .067

.024

A

B

C

D

E

2431

A

Dimensions in millimeters. Untoleranced dimensions are nominal.

U.S. Customary dimensions (in.) in brackets, for reference only

Dambar removal protrusion

Metallic protrusion, electrically connected to pin 4 and substrate (both sides)

Active Area Depth, 0.43 [.017]

Thermoplastic Molded Lead Bar for alignment during shipment

Hall elements, controlling dimension inches

1.10 .04331.10 .0433

0.4 .016

C

E

A

1.27 .050

B

0.38 .015

1.08 .043

D

D

ATS625LSG-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

20

ATS625LSG

True Zero-Speed Low-Jitter High Accuracy Gear Tooth Sensor

ATS625LSG-DS, Rev. 1

The products described herein are manufactured under one or more of

the following U.S. patents: 5,045,920; 5,264,783; 5,442,283; 5,389,889;

5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719; 5,686,894;

5,694,038; 5,729,130; 5,917,320; and other patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such de par tures from the detail spec i fi ca tions as may be required

to permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to

verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components in

life-support devices or sys tems without express written approval.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable.

How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty for its

use; nor for any in fringe ment of patents or other rights of third parties

which may result from its use.

Copyright © 2005, Allegro MicroSystems, Inc.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

21

Loading...

Loading...