查询ATS612LSG供应商

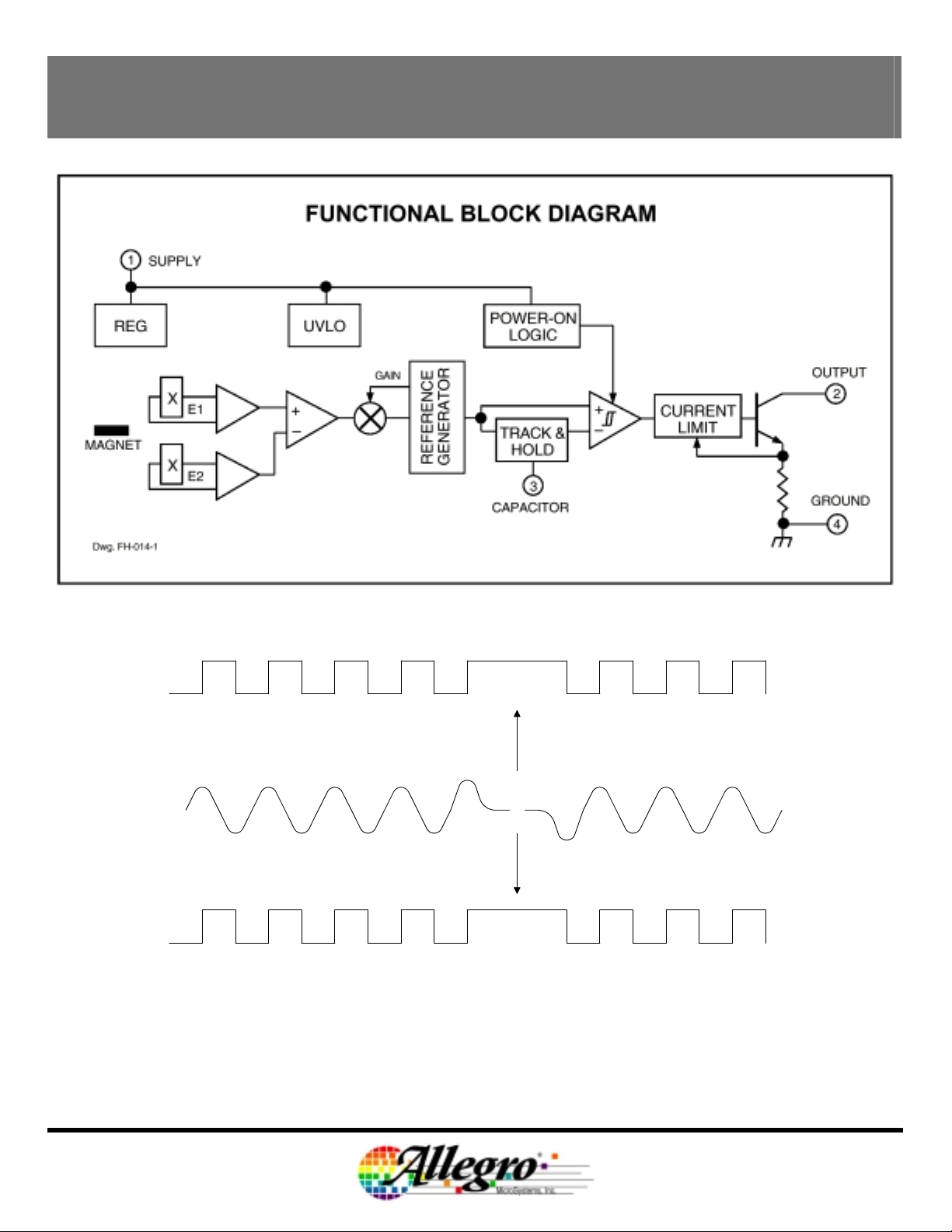

Pin 1: Supply

Pin 2: Output

Pin 3: Capacitor

Pin 4: Ground

ATS612LSG

DYNAMIC, SELF-CALIBRATING,

The ATS612LSG gear-tooth sensor is a peak-detecting device

that uses automatic gain control to provide extremely accurate gear

edge detection down to low operating speeds. Each sensor module

consists of an over-molded package, which holds together a

samarium-cobalt magnet, a pole piece and a differential opencollector Hall IC that has been optimized to the magnetic circuit.

This small package can be easily assembled and used in

conjunction with a wide variety of gear shapes and sizes.

The sensor incorporates a dual-element Hall IC that switches in

response to differential magnetic signals created by ferrous targets.

The sophisticated processing circuitry contains a 5-bit D/A

converter that self-calibrates (normalizes) the internal gain of the

device to minimize the effect of air-gap variations. The patented

peak-detecting filter circuit eliminates magnet and system offsets

and has the ability to discriminate relatively fast changes such as

those caused by tilt, gear wobble, and other eccentricities, yet

provides stable operation to extremely low RPM.

This sensor system is ideal for use in gathering speed, position,

and timing information using gear-tooth-based configurations. The

ATS612 is particularly suited to those applications that require

extremely accurate duty cycle control or accurate edge detection

such as in automotive crankshaft applications. The lower vibration

sensitivity also makes this device extremely useful for transmission

speed sensing.

PEAK-DETECTING, DIFFERENTIAL

HALL-EFFECT GEAR-TOOTH SENSOR

ABSOLUTE MAXIMUM RATINGS

Supply Voltage, V

Reverse Supply Voltage, V

Output OFF Voltage, V

Continuous Output Current, I

Reverse Output Current, I

Package Power Dissipation, P

Operating Temperature Range,

T

.............................. –40°°°°C to +150°°°°C

A

Storage Temperature, T

Maximum Junction Temperature,

T

.................................................. 165°°°° C

J

..............................…. 24 V

CC

OUT

................. –16 V

RCC

......................... 24 V

............ 25 mA

OUT

............... 50 mA

ROUT

...... See Graph

D

...................... +170°°°°C

S

FEATURES AND BENEFITS

Fully Optimized Differential Digital Gear-Tooth Sensor

Single-Chip Sensing IC for High Reliability

Digital Output Representing Target Profile

Extremely Low Timing Accuracy Drift with Temperature

Large Operating Air Gaps

Small Mechanical Size

Optimized Magnetic Circuit

Patented Peak-Detecting Filter:

80 µs Typical Power-On Time

<10 RPM Operation (single-tooth target)

Uses Small Value Ceramic Capacitors

Under-Voltage Lockout

Wide Operating Voltage Range

Defined Power-On State

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

Timing Diagrams

MECHANICAL PROFILE

SIG TOOTH

MAGNETIC PROFILE

SENSOR ELECTRICAL OUTPUT PROFILE

NOTE: Output polarity is dependent upon sensor orientation and target rotation. See Output Polarity

description on page 9.

115 Northeast Cutoff, Box 15036

Page 2 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

ELECTRICAL CHARACTERISTICS over operating voltage and temperature range,

C3 = 0.1 µF to 0.47 µF.

Limits

Characteristic Symbol Test Condition

Supply Voltage VCC

Power-On State POS

Under-Voltage Lockout V

Under-Voltage Hysteresis V

Low Output Voltage V

Supply Zener Clamp Voltage

Output Current Limit I

Output Leakage Current I

CC(UV)

CC(hys)

OUT(SAT)

VZ

OUTM

OFF

Operating, T

V

CC

V

CC(UV)

V

– V

I

CC

CC(SD)

OUT

ICC = 18 mA 24 — —

V

OUT

V

OUT

< 165°C

J

= 0 → 5 V

= 0 → 5 V

(see NOTE below) — 0.2 — V

= 20 mA — 185 400 mV

= 12 V 25 45 55 mA

= 24 V — 0.2 15 µA

Min. Typ. Max. Units

3.6 — 24 V

HIGH HIGH HIGH —

2.5 — 3.6 V

Output OFF 6.0 8.7 13 mA

Supply Current ICC

Output ON 8.0 10.7 15 mA

Power-On Delay t

on

Output Rise Time tr

Output Fall Time tf

R

R

VCC > 5 V — 80 500 µs

= 500 Ω, C

L

= 500 Ω, C

L

= 10 pF

L

= 10 pF

L

— 0.2 5.0 µs

— 0.2 5.0 µs

NOTES: Typical data is at VCC = 8 V and T

V

= shutdown voltage, V

CC(SD)

= +25°C and is for design information only.

A

= 5 V → 0.

CC

V

115 Northeast Cutoff, Box 15036

Page 3 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

OPERATION over operating voltage and temperature range with reference target

(unless otherwise specified).

Limits

Characteristic Symbol Test Condition

Air Gap Range AG

Calibration Cycle n

Calibration Mode Disable n

Relative Timing Accuracy,

Sequential

Allowable User Induced

Differential Offset

cal

dis

t

θ

Operating within specification,

Target Speed > 20 RPM

Output edges before which

Calibration is completed*

Output falling edges for startup

calibration to be complete

Target Speed = 1000 RPM,

0.4 mm ≤ AG ≤ 2 mm

Output switching only; may not

meet data sheet specifications

Min. Typ. Max. Units

0.4 — 2.25 mm

1 1 1 Edge

64 64 64 Edges

— ±0.3 ±0.9

— — ±50 G

* Non-uniform magnetic profiles may require additional output pulses before calibration is complete.

°

115 Northeast Cutoff, Box 15036

Page 4 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

REFERENCE TARGET / GEAR INFORMATION

Diameter 120 mm

Thickness 6 mm

Sequential Tooth Width 3 mm

Sequential Valley Width 3 mm

Sequential Valley Depth 3 mm

Signature Tooth Width 9 mm

Material Low carbon steel

ATS612LSG

115 Northeast Cutoff, Box 15036

Page 5 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

POWER DE-RATING

Due to internal power consumption, the temperature of

the IC (junction temperature, T

ambient environment temperature, T

the device does not operate above the maximum rated

junction temperature use the following calculations:

∆T = PD × R

θJA

Where: P

= VCC × ICC

D

∴ ∆T=V

× ICC × R

CC

θJA

Where ∆T denotes the temperature rise resulting from

the IC’s power dissipation.

= TA + ∆T

T

J

For the sensor :

T

= 165°C

J(max)

R

= 126°C/W

θJA

Typical T

calculation:

J

T

V

I

= 25 °C

A

= 5 V

CC

= (I

CC

CC(ON)typ

+ I

CC(OFF)typ

8.7 mA) / 2 = 9.7 mA

P

= VCC × ICC = 5 V × 9.7 mA = 48.5 mW

D

∆T = P

D

× R

= 48.5 mW × 165°C/W = 8.0°C

θJA

T

= TA + ∆T = 25°C + 8.0°C = 33.0°C

J

Maximum Allowable Power Dissipation Calculation

for ATS612LSG:

Assume:

T

T

Icc = (I

= T

A

J(max)

= 150 °C

A(max)

= 165°C

ON(max)

+ I

OFF(max)

= (15 mA + 13 mA) / 2 = 14 mA

If:

T

= TA + ∆T

J

) is higher than the

J

. To ensure that

A

) / 2 = (10.7 mA +

) / 2

Then:

= T

∆T

(max)

If:

∆T = P

D

then:

= ∆T

P

D(max)

If:

P

= VCC × ICC

D

then the maximum V

V

CC(max)

= P

This value applies only to the voltage drop across the

ATS612 chip. If a protective series diode or resistor is

used, the effective maximum supply voltage is

increased.

For example, when a standard diode with a 0.7 V drop is

used:

V

S(max)

SG Package Power De-Rating Curve

Thermal Resistance = 126°C/Wat t , T

30.0

28.0

26.0

24.0

22.0

20.0

18.0

16.0

14.0

12.0

10.0

8.0

6.0

4.0

Maximum Supply Voltage [Volt s ]

2.0

0.0

20 40 60 80 100 120 140 160 180 200

× R

J(max)

θJA

(max)

D(max)

– T

/ R

CC

= 165°C - 150°C = 15°C

A(max)

= 15°C / 126°C/W = 119 mW

θJA

at 150°C is therefore:

/ ICC = 119 mW / 15 mA = 7.9 V

= 7.9 V + 0.7 V = 8.6 V

Ambient Temperature [°C]

jmax

= 165°C

115 Northeast Cutoff, Box 15036

Page 6 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

DEVICE DESCRIPTION

Assembly Description. The ATS612 gear-tooth sensor

is a Hall IC/magnet configuration that is fully optimized to

provide digital detection of gear tooth edges. This

sensor is packaged in a molded miniature plastic body

that has been optimized for size, ease of assembly, and

manufacturability. High operating temperature materials

are used in all aspects of construction.

The use of this sensor is simple. After proper power is

applied to the component the sensor is then capable of

instantly providing digital information that is

representative of the profile of a rotating gear. No

additional optimization or processing circuitry is required.

This ease of use should reduce design time and

incremental assembly costs for most applications.

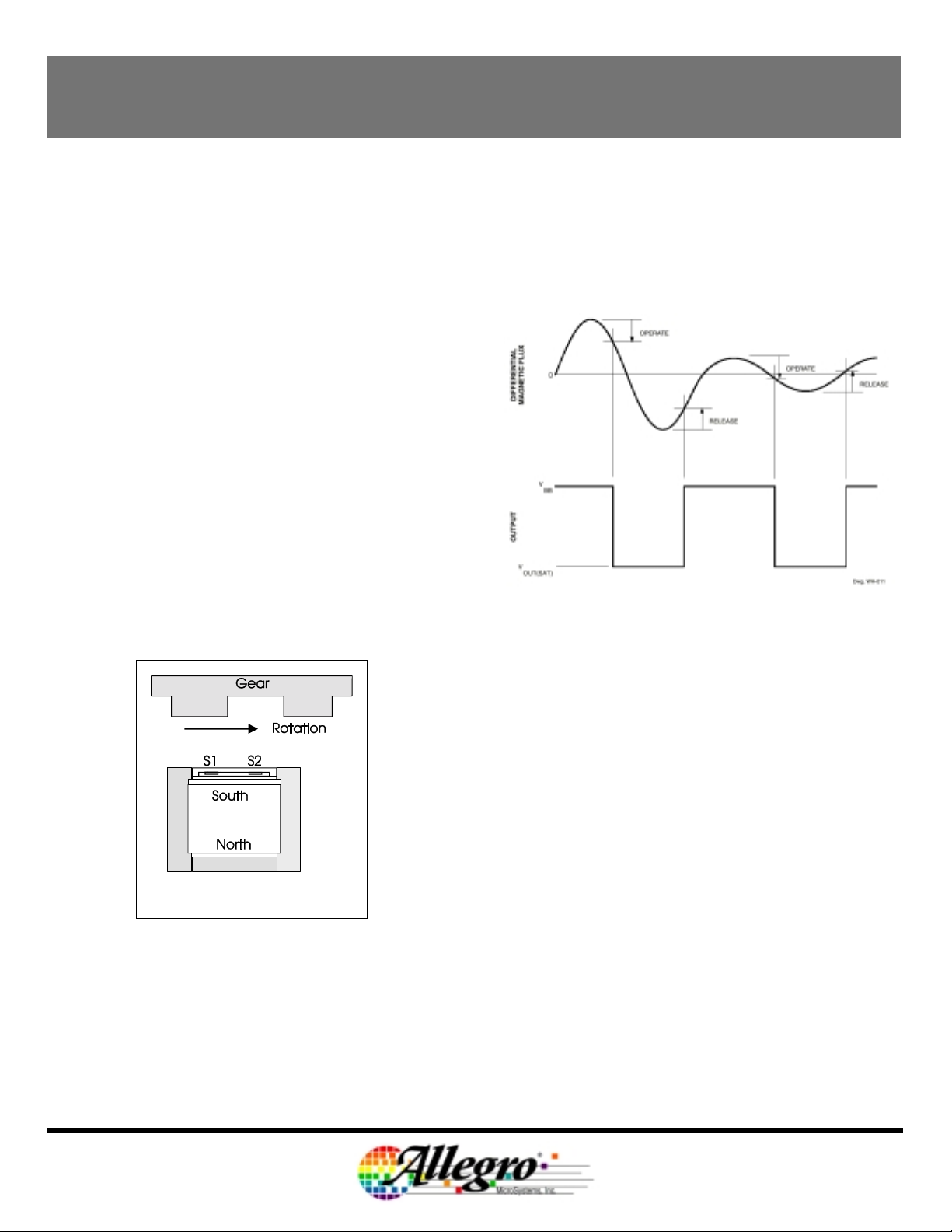

Sensing Technology. The gear tooth sensor module

contains a single-chip differential Hall effect sensor IC, a

Samarium Cobalt magnet, and a flat ferrous pole piece

(Figure 2). The Hall IC consists of 2 Hall elements

(spaced 2.2 mm apart) located so as to measure the

magnetic gradient created by the passing of a ferrous

object. The two elements measure the magnetic

gradient and convert it to an analog voltage that is then

processed in order to provide a digital output signal.

Magnetic Circuit

Figure 2

Internal Electronics. The processing circuit uses a

patented peak detection scheme to eliminate magnet

and system offsets. This technique allows dynamic

coupling and filtering of offsets without the power-up and

settling time disadvantages of classical high-pass

filtering schemes. The peak signal of every tooth and

valley is detected by the filter and is used to provide an

instant reference for the operate and release point

comparator. In this manner, the thresholds are adapted

and referenced to individual signal peaks and valleys,

providing immunity to zero line variation from installation

inaccuracies (tilt, rotation, and off center placement), as

well as for variations caused by target and shaft

eccentricities. The peak detection concept also allows

extremely low speed operation for small value filter

capacitors.

The ATS612 also includes self-calibration circuitry that is

engaged at power on. The signal amplitude is measured

and the device gain is normalized. In this manner,

switch-point drift versus air gap is minimized and

excellent timing accuracy can be achieved. The AGC

(Automatic Gain Control) circuitry, in conjunction with a

unique hysteresis circuit, also eliminates the effect of

gear edge overshoot as well as increases the immunity

to false switching caused by gear tooth anomalies at

close air gap. The AGC circuit sets the gain of the

device after power on. Up to 0.25 mm air gap change

can occur after calibration is complete without significant

performance impact.

Superior Performance. The ATS612 peak-detecting

differential gear-tooth sensor module has several

advantages over conventional Hall-effect gear-tooth

sensors. The signal-processing techniques used in the

ATS612 solve the catastrophic issues that affect the

functionality of conventional digital gear-tooth sensors.

• Temperature drift. Changes in temperature do not

greatly affect this device due to the stable amplifier

design and the offset rejection circuitry.

• Timing accuracy variation due to air gap. The

accuracy variation caused by air gap changes is

minimized by the self-calibration circuitry. A 2x-to-3x

improvement can be seen.

115 Northeast Cutoff, Box 15036

Page 7 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

• Dual edge detection. Because this device switches

from the positive and negative peaks of the signal,

dual edge detection is guaranteed.

• Tilted or off-center installation. Traditional

differential sensors will switch incorrectly due to

baseline changes versus air gap caused by tilted or

off-center installation. The peak detector circuitry

references the switch point from the peak and is

immune to this failure mode. There may be a timing

accuracy shift caused by this condition.

• Large operating air gaps. Large operating air gaps

are achievable with this device due to the sensitive

switch points after start up. (dependent on target

dimensions, material, and speed).

• Immunity to magnetic overshoot. The air gap-

independent hysteresis minimizes the impact of

overshoot on the switching of device output.

• Response to surface defects in the target. The

gain-adjust circuitry reduces the effect of minor gear

anomalies that would normally cause false

switching.

• Immunity to vibration and backlash. The gain-

adjust circuitry keeps the hysteresis of the device

roughly proportional to the peak-to-peak signal. This

allows the device to have good immunity to vibration

even when operating at close air gaps.

• Immunity to gear run out. The differential sensor

configuration eliminates the baseline variations

caused by gear run out.

Differential vs. Single-Element Sensing. The

differential Hall-effect configuration is superior in most

applications to the classical single-element gear-tooth

sensor. As shown in the flux maps on this page, the

single-element configuration commonly used (Hall-effect

sensor mounted on the face of a simple permanent

magnet) requires the detection of a small signal (often

<100 G) that is superimposed on a large back-biased

field, often 1500 G to 3500 G. For most gear/target

configurations, the back-biased field values change due

to concentration effects, resulting in a varying baseline

with air gap, with valley widths, with eccentricities, and

with vibration. The differential configuration cancels the

effects of the back-biased field and avoids many of the

issues presented by the single Hall element.

NOTE: 10 G = 1 mT, exactly.

115 Northeast Cutoff, Box 15036

Page 8 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

Peak Detecting vs. AC-Coupled Filters. High-pass

filtering (normal AC coupling) is a commonly used

technique for eliminating circuit offsets. AC coupling has

errors at power on because the filter circuit needs to hold

the circuit zero value even though the circuit may power

on over a large signal. Such filter techniques can only

perform properly after the filter has been allowed to

settle, which is typically greater than one second. Also,

high-pass filter solutions cannot easily track rapidly

changing baselines such as those caused by

eccentricities. Peak detection switches on the change in

slope of the signal and is baseline independent at power

up and during running.

Peak Detecting vs. Zero-Crossing Reference. The

usual differential zero-crossing sensors are susceptible

to false switching due to off-center and tilted installations

which result in a shift of the baseline that changes with

air gap. The track-and-hold peak-detection technique

ignores baseline shifts versus air gaps and provides

increased immunity to false switching. In addition, using

track-and-hold peak-detecting techniques, increased air

gap capabilities can be expected because a peak

detector utilizes the entire peak-to-peak signal range as

compared to zero-crossing detectors that switch on onehalf the peak-to-peak signal.

NOTE – “Baseline” refers to the zero-gauss differential

field where each Hall-effect element is subject to the

same magnetic field strength.

Power-On Operation. The device will power on in the

OFF state (output high) irrespective of the magnetic field

condition. The power-up time of the circuit is no greater

than 500 µs. The circuit is then ready to accurately

detect the first target edge that results in a HIGH-toLOW transition.

Under-Voltage Lockout. When the supply voltage is

below the minimum operating voltage (V

CC(UV)

), the

device is OFF and stays OFF irrespective of the state of

the magnetic field. This prevents false signals, which

may be caused by under-voltage conditions (especially

during turn on), from appearing at the output.

Output. The device output is an open-collector stage

capable of sinking up to 20 mA. An external pull-up

(resistor) to a supply voltage of not more than 24 V must

be supplied.

Output Polarity. The output of the unit will switch from

HIGH to LOW as the leading edge of the tooth passes

the unit in the direction indicated in figure 3 which means

that in this configuration, the output voltage will be high

when the unit is facing a tooth. If rotation is in the

opposite direction, the output polarity will be opposite as

well, with the unit switching LOW to HIGH as the leading

edge passes the unit.

Figure 3

115 Northeast Cutoff, Box 15036

Page 9 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

TYPICAL ELECTRICAL CHARACTERISTICS

I

CC

13

I

CC

13

11

SUPPLY CURRENT IN mA

Output On

9

7

Output Off

V

CC

11

9

7

SUPPLY CURRENT IN mAA

Output On

Output Off

= 8V

5

-40

0

40

AMBIENT TEMPER ATUR E IN

80

120

o

C

160 200

5

2 6 10

SUPPLY VOLTAGE IN VOLT S

14 18 22 26

TA =

o

C

25

V

OUT(SAT)

250

I

=

225

200

175

OUTPUT SATURATION VOLTAGE IN mV

150

OUT

20mA

-40 0 40 80 120 160

AMBIE NT TEMPERATU RE IN oC

115 Northeast Cutoff, Box 15036

Page 10 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

TYPICAL OPERATING CHARACTERISTICS

(Relative Accuracy data presented has been normalized to 1.5 mm air gap at 1000 RPM)

Rising signature tooth edge 1000 RPM

Falling signature tooth edge 1000 R PM

1.5

-40oC

o

C

1

0.5

0

-0.5

-1

RELATIVE ACCURACY IN DE GREES

-1.5

0 0.5 1 1.5 2 2.5 3

AIR GAP IN MILLIMETERS

Rising signature tooth edge 10 RPM

1.5

1

25

150

-40oC

o

C

25

150

o

C

o

C

0.75

0.5

0.25

0

-0.25

-0.5

RELATIVE ACCURACY IN DEGREES

-0.75

0 0.5 1

AIR GAP IN MILLIM ETERS

1.5

o

-40

C

o

25

C

o

150

C

2 2.5 3

Falling signature tooth edge 10 RPM

0.75

0.5

-40

25

150

o

C

o

C

o

C

0.5

0

-0.5

-1

RELATIVE ACCURACY IN DE GREES

-1.5

0 0.5 1 1.5 2 2.5 3

AIR GAP IN MILLIMETERS

Page 11 of 15

0.25

0

-0.25

-0.5

RELATIVE ACCURACY IN DEGREES

-0.75

0 0.5 1

AIR GAP IN MILLIM ETERS

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

1.5

2 2.5 3

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

TYPICAL OPERATING CHARACTERISTICS

0.75

0.25

-0.25

-0.5

RELATIVE ACCURACY IN DEGREES

-0.75

Rising sequential tooth edge 1000 RPM

0.5

0

0

0.5

1

AIR GAP IN MILLIMETERS

1.5

-40

25

150

o

C

o

C

o

C

2

2.5 3

0.75

0.5

0.25

0

-0.25

-0.5

RELATIVE ACCURACY IN DEGREES

-0.75

Falling sequential tooth edge 1000 RPM

-40

25

150

0 0.5 1 1.5

AIR GAP IN MILLIM ETERS

o

C

o

C

o

C

2 2.5 3

Rising sequential tooth edge 10 RPM

Falling sequential tooth edge 10 RPM

RELATIVE ACCURACY IN DEGREES

0.75

0.5

0.25

-0.25

-0.5

-0.75

-40

25

150

o

C

o

C

o

C

0

0

0.5

1

AIR GAP IN MILLIMETERS

1.5

2

2.5 3

0.75

0.5

0.25

0

-0.25

-0.5

RELATIVE ACCURACY IN DEGREES

-0.75

0 0.5 1 1.5

o

-40

C

o

25

C

o

150

C

2 2.5 3

AIR GAP IN MILLIM ETERS

115 Northeast Cutoff, Box 15036

Page 12 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

MECHANICAL INFORMATION

Component

Material Function Value

Sensor Package Material Thermoset Epoxy Max. Temperature 170°C1

Leads Copper, 0.016” dia, 0.050” spacing

Lead Coating Solder, Tin / Lead 90/102

1

Temperature excursions of up to 225°C for 2 minutes or less are permitted.

2

Industry accepted soldering techniques are acceptable for this module as long as the indicated maximum temperatures for each component are not

exceeded. Please see the Allegro website (http://www.allegromicro.com/techpub2/an/an26009.pdf

) for soldering profile.

ELECTROMAGNETIC CAPABILITY (EMC) PERFORMANCE

Please contact Allegro MicroSystems for EMC performance.

Test Name Reference Specification

ESD – Human Body Model AEC-Q100-002

ESD – Machine Model AEC-Q100-003

Conducted Transients ISO 7637-1

Direct RF Injection ISO 11452-7

Bulk Current Injection ISO 11452-4

TEM Cell ISO 11452-3

115 Northeast Cutoff, Box 15036

Page 13 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

PACKAGE DRAWING

For Reference Only

NOTE: Metallic protrusion may be present, electrically connected to substrate and pin 4 (ground).

115 Northeast Cutoff, Box 15036

Page 14 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

ATS612LSG

DYNAMIC, SELF-CALIBRATING, PEAK-DETECTING,

DIFFERENTIAL HALL-EFFECT GEAR TOOTH SENSOR

The products described herein are manufactured under one or more

of the following U.S. patents: 5,045,920; 5,264,783; 5,442,283;

5,389,889; 5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719;

5,686,894; 5,694,038; 5,719,130; 5,917,320; and other patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be required to

permit improvements in the design of its products. Before placing an

order, the user is cautioned to verify that the information being relied

upon is current.

Allegro products are not authorized for use as critical components in

life-support applications, devices, or systems without express written

approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroS ystems, Inc. assumes no responsibility

for its use; nor for any infringements of patents or other rights of third

parties which may result from its use.

115 Northeast Cutoff, Box 15036

Page 15 of 15

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

Loading...

Loading...