ALLEGRO ACS712 User Manual

ACS712

Fully Integrated, Hall Effect-Based Linear Current Sensor

with 2.1 kVRMS Voltage Isolation and a Low-Resistance Current Conductor

Features and Benefits

Low-noise analog signal path

Device bandwidth is set via the new FILTER pin

5 s output rise time in response to step input current

50 kHz bandwidth

Total output error 1.5% at TA = 25°C, and 4% at –40°C to 85°C

Small footprint, low-profile SOIC8 package

1.2 m internal conductor resistance

2.1 kV

minimum isolation voltage from pins 1-4 to pins 5-8

RMS

5.0 V, single supply operation

66 to 185 mV/A output sensitivity

Output voltage proportional to AC or DC currents

Factory-trimmed for accuracy

Extremely stable output offset voltage

Nearly zero magnetic hysteresis

Ratiometric output from supply voltage

Package: 8 pin SOIC (suffix LC)

Description

The Allegro® ACS712 provides economical and precise

solutions for AC or DC current sensing in industrial, automotive,

commercial, and communications systems. The device

package allows for easy implementation by the customer.

Typical applications include motor control, load detection and

management, switched-mode power supplies, and overcurrent

fault protection.

The device consists of a precise, low-offset, linear Hall

sensor circuit with a copper conduction path located near the

surface of the die. Applied current flowing through this copper

conduction path generates a magnetic field which is sensed

by the integrated Hall IC and converted into a proportional

voltage. Device accuracy is optimized through the close

proximity of the magnetic signal to the Hall transducer. A

precise, proportional voltage is provided by the low-offset,

chopper-stabilized BiCMOS Hall IC, which is programmed

for accuracy after packaging.

The output of the device has a positive slope (>V

when an increasing current flows through the primary copper

conduction path (from pins 1 and 2, to pins 3 and 4), which

is the path used for current sensing. The internal resistance of

this conductive path is 1.2 m typical, providing low power

IOUT(Q)

)

Approximate Scale 1:1

Continued on the next page…

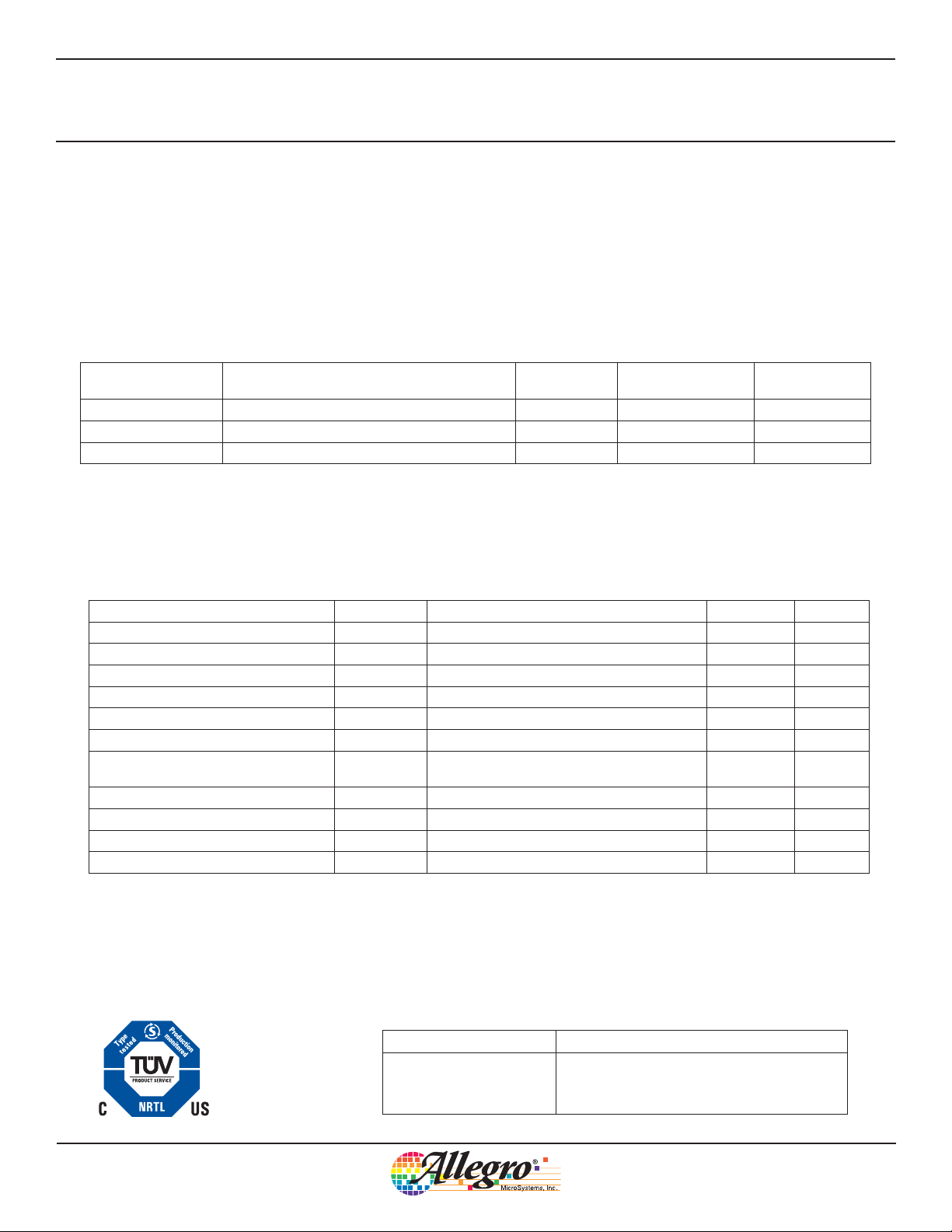

Typical Application

VCC

VIOUT

FILTER

GND

8

7

6

5

1

IP+

2

IP+

I

ACS712

P

3

IP–

4

IP–

Application 1. The ACS712 outputs an analog signal, V

that varies linearly with the uni- or bi-directional AC or DC

primary sensed current, IP , within the range specified. CF

is recommended for noise management, with values that

depend on the application.

V

OUT

C

1 nF

+5 V

C

BYP

0.1 μF

F

OUT

.

ACS712-DS, Rev.1

ACS712

Fully Integrated, Hall Effect-Based Linear Current Sensor with

2.1 kVRMS Voltage Isolation and a Low-Resistance Current Conductor

Description (continued)

loss. The thickness of the copper conductor allows survival of

the device at up to 5× overcurrent conditions. The terminals of

the conductive path are electrically isolated from the sensor leads

(pins 5 through 8). This allows the ACS712 current sensor to be

used in applications requiring electrical isolation without the use

of opto-isolators or other costly isolation techniques.

The ACS712 is provided in a small, surface mount SOIC8 package.

The leadframe is plated with 100% matte tin, which is compatible

with standard lead (Pb) free printed circuit board assembly processes.

Internally, the device is Pb-free, except for flip-chip high-temperature

Pb-based solder balls, currently exempt from RoHS. The device is

fully calibrated prior to shipment from the factory.

Selection Guide

Part Number Packing*

ACS712ELCTR-05B-T Tape and reel, 3000 pieces/reel –40 to 85 ±5 185

ACS712ELCTR-20A-T Tape and reel, 3000 pieces/reel –40 to 85 ±20 100

ACS712ELCTR-30A-T Tape and reel, 3000 pieces/reel –40 to 85 ±30 66

*Contact Allegro for additional packing options.

TOP

(°C)

Optimized Range, I

(A)

P

Absolute Maximum Ratings

Characteristic Symbol Notes Rating Units

Supply Voltage V

Reverse Supply Voltage V

Output Voltage V

Reverse Output Voltage V

Output Current Source I

Output Current Sink I

Overcurrent Transient Tolerance I

Maximum Transient Sensed Current I

Nominal Operating Ambient Temperature T

Maximum Junction TJ(max) 165 ºC

Storage Temperature T

CC

RCC

IOUT

RIOUT

IOUT(Source)

IOUT(Sink)

P

(max) Junction Temperature, TJ < TJ(max) 60 A

R

A

stg

100 total pulses, 250 ms duration each, applied

at a rate of 1 pulse every 100 seconds.

Range E –40 to 85 ºC

8V

–0.1 V

8V

–0.1 V

3mA

10 mA

60 A

–65 to 170 ºC

Sensitivity, Sens

(Typ) (mV/A)

TÜV America

Certificate Number:

U8V 06 05 54214 010

Parameter Specification

CAN/CSA-C22.2 No. 60950-1-03

Fire and Electric Shock

UL 60950-1:2003

EN 60950-1:2001

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

2

ACS712

Fully Integrated, Hall Effect-Based Linear Current Sensor with

2.1 kVRMS Voltage Isolation and a Low-Resistance Current Conductor

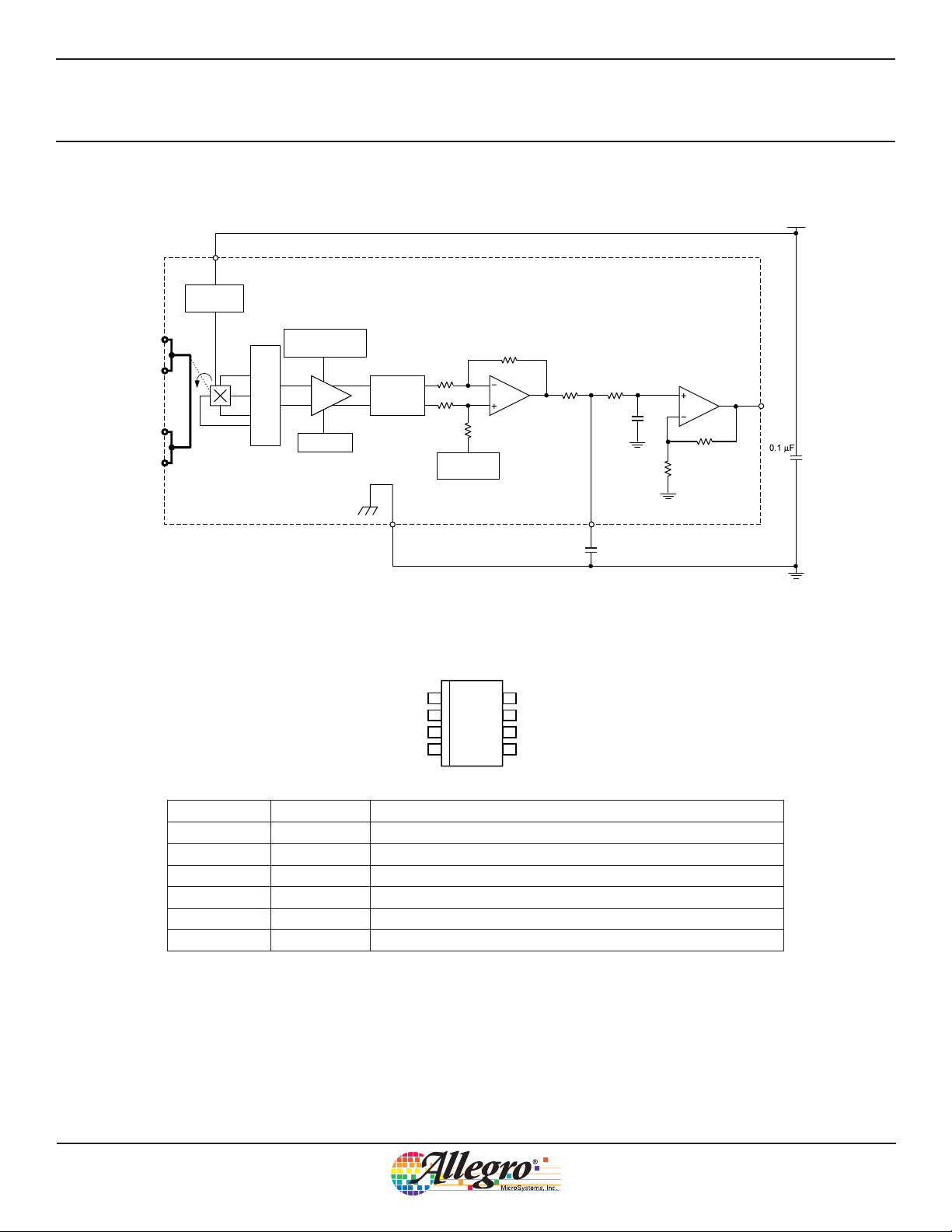

Functional Block Diagram

IP+

(Pin 1)

IP+

(Pin 2)

IP−

(Pin 3)

IP−

(Pin 4)

VCC

(Pin 8)

Hall Current

Drive

Sense Temperature

Coefficient Trim

Cancellation

Dynamic Offset

Sense

Trim

GND

(Pin 5)

Signal

Recovery

Offset Adjust

Pin-out Diagram

0 Ampere

R

F(INT)

FILTER

(Pin 6)

VIOUT

(Pin 7)

+5 V

IP+

IP+

IP–

IP–

1

2

3

4

8

7

6

5

VCC

VIOUT

FILTER

GND

Terminal List Table

Number Name Description

1 and 2 IP+ Terminals for current being sensed; fused internally

3 and 4 IP– Terminals for current being sensed; fused internally

5 GND Signal ground terminal

6 FILTER Terminal for external capacitor that sets bandwidth

7 VIOUT Analog output signal

8 VCC Device power supply terminal

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

3

ACS712

Fully Integrated, Hall Effect-Based Linear Current Sensor with

2.1 kVRMS Voltage Isolation and a Low-Resistance Current Conductor

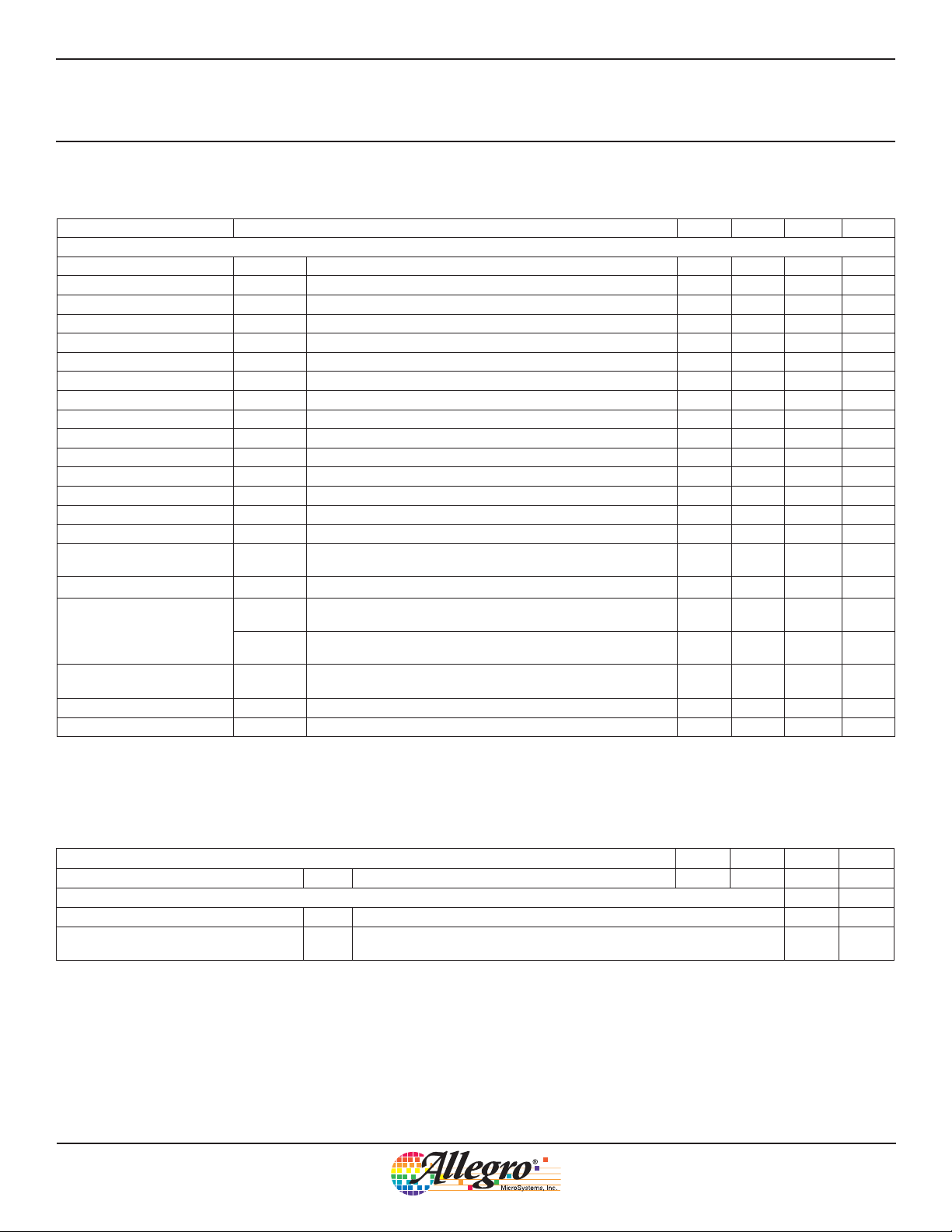

COMMON OPERATING CHARACTERISTICS

1

over full range of T

, CF = 1 nF, and VCC = 5 V, unless otherwise specified

OP

Characteristic Symbol Test Conditions Min. Typ. Max. Units

ELECTRICAL CHARACTERISTICS

Supply Voltage V

Supply Current I

Output Zener Clamp Voltage V

Output Resistance R

Output Capacitance Load C

Output Resistive Load R

Primary Conductor Resistance R

RMS Isolation Voltage V

PRIMARYTA

ISORMS

DC Isolation Voltage V

Propagation Time t

Response Time t

PROPIP

RESPONSEIP

Rise Time t

CC

VCC = 5.0 V, output open 6 8 11 mA

CC

ICC = 11 mA, TA = 25°C 6 8.3 – V

Z

IOUTIIOUT

LOAD

LOAD

VIOUT to GND – – 10 nF

VIOUT to GND 4.7 – – k

Pins 1-4 and 5-8; 60 Hz, 1 minute, TA=25°C 2100 – – V

ISODC

Pins 1-4 and 5-8; 1 minute, TA=25°C – 5000 – V

IP = IP(max), TA = 25°C, C

r

= 1.2 mA, TA=25°C – 1 2

= 25°C – 1.2 – m

= IP(max), TA = 25°C, C

= IP(max), TA = 25°C, C

= open – 3 – s

OUT

= open – 7 – s

OUT

= open – 5 – s

OUT

4.5 5.0 5.5 V

Frequency Bandwidth f –3 dB, TA = 25°C; IP is 10 A peak-to-peak 50 – – kHz

Nonlinearity E

Symmetry E

Zero Current Output Voltage V

Magnetic Offset Error

IOUT(Q)

V

ERROMIP

V

Clamping Voltage

V

Power-On Time t

Magnetic Coupling

Internal Filter Resistance

1

Device may be operated at higher primary current levels, IP, and ambient, TA , and internal leadframe temperatures, T

2

3

R

F(INT)

Junction Temperature, TJ(max), is not exceeded.

2

1G = 0.1 mT.

3

R

F(INT)

forms an RC circuit via the FILTER pin.

Over full range of I

LIN

SYM

Over full range of I

P

P

Bidirectional; IP = 0 A, TA = 25°C –

= 0 A, after excursion of 5 A – 0 – mV

CH

CL

Output reaches 90% of steady-state level, TJ = 25°C, 20 A present

PO

on leadframe

– ±1 ±1.5 %

98 100 102 %

Typ. –110

Typ. –110

VCC ×

0.5

VCC ×

0.9375

VCC ×

0.0625

–V

Typ. +110 mV

Typ. +110 mV

–35–s

– 12 – G/A

1.7 k

, provided that the Maximum

OP

COMMON THERMAL CHARACTERISTICS

1

Min. Typ. Max. Units

Operating Internal Leadframe Temperature TOPE range –40 – 85 °C

Value Units

Junction-to-Lead Thermal Resistance

2

Junction-to-Ambient Thermal Resistance R

1

Additional thermal information is available on the Allegro website.

2

The Allegro evaluation board has 1500 mm2 of 2 oz. copper on each side, connected to pins 1 and 2, and to pins 3 and 4, with thermal vias connect-

R

Mounted on the Allegro ASEK 712 evaluation board 5 °C/W

JL

Mounted on the Allegro 85-0322 evaluation board, includes the power con-

JA

sumed by the board

23 °C/W

ing the layers. Performance values include the power consumed by the PCB. Further details on the board are available from the Frequently Asked

Questions document on our website. Further information about board design and thermal performance also can be found in the Applications Information section of this datasheet.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

4

Loading...

Loading...