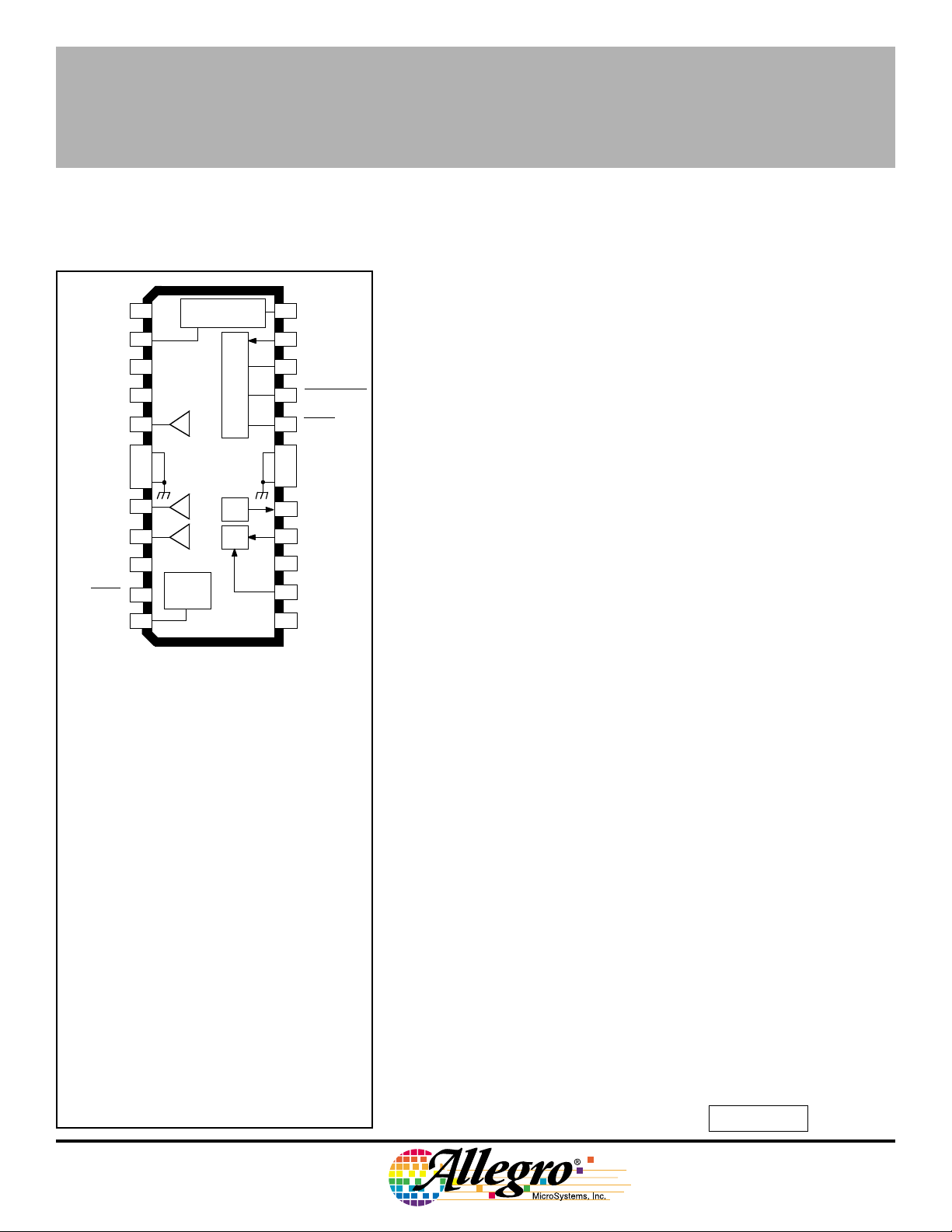

Allegro A8902CLBA Datasheet

LOAD

SUPPLY

C

D2

C

WD

C

ST

OUT

GROUND

GROUND

OUT

OUT

CENTERTAP

BRAKE

C

RES

8902–A

3-PHASE BRUSHLESS DC MOTOR

CONTROLLER/DRIVER WITH BACK-EMF SENSING

The A8902CLBA is a three-phase brushless dc motor controller/

V

BB

BOOST

CHARGE

PUMP

COMMUTATION

DELAY

SERIAL PORT

MUX

FLL

V

DD

1

2

3

4

5

A

6

7

8

B

9

9

C

10

11

24

23

22

21

20

19

18

17

16

15

14

1312

C

D1

DATA IN

CLOCK

CHIP SELECT

RESET

GROUND

GROUND

DATA OUT

OSCILLATOR

LOGIC

SUPPLY

SECTOR

DATA

FILTER

driver for use in 5 V or 12 V hard-disk drives. The three half-bridge

outputs are low on-resistance n-channel DMOS devices capable of

driving up to 1.25 A. The A8902CLBA provides complete, reliable,

self-contained back-EMF sensing motor startup and running algorithms.

A programmable digital frequency-locked loop speed control circuit

together with the linear current control circuitry provides precise motor

speed regulation.

A serial port allows the user to program various features and

modes of operation, such as the speed control parameters, startup

current limit, sleep mode, diagnostic modes, and others.

The A8902CLBA is fabricated in Allegro’s BCD (Bipolar CMOS

DMOS) process, an advanced mixed-signal technology that combines

bipolar, analog and digital CMOS, and DMOS power devices. The

A8902CLBA is provided in a 24-lead wide-body SOIC batwing package.

It provides for the smallest possible construction in surface-mount

applications.

Data Sheet

26301.2

Dwg. PP-040B

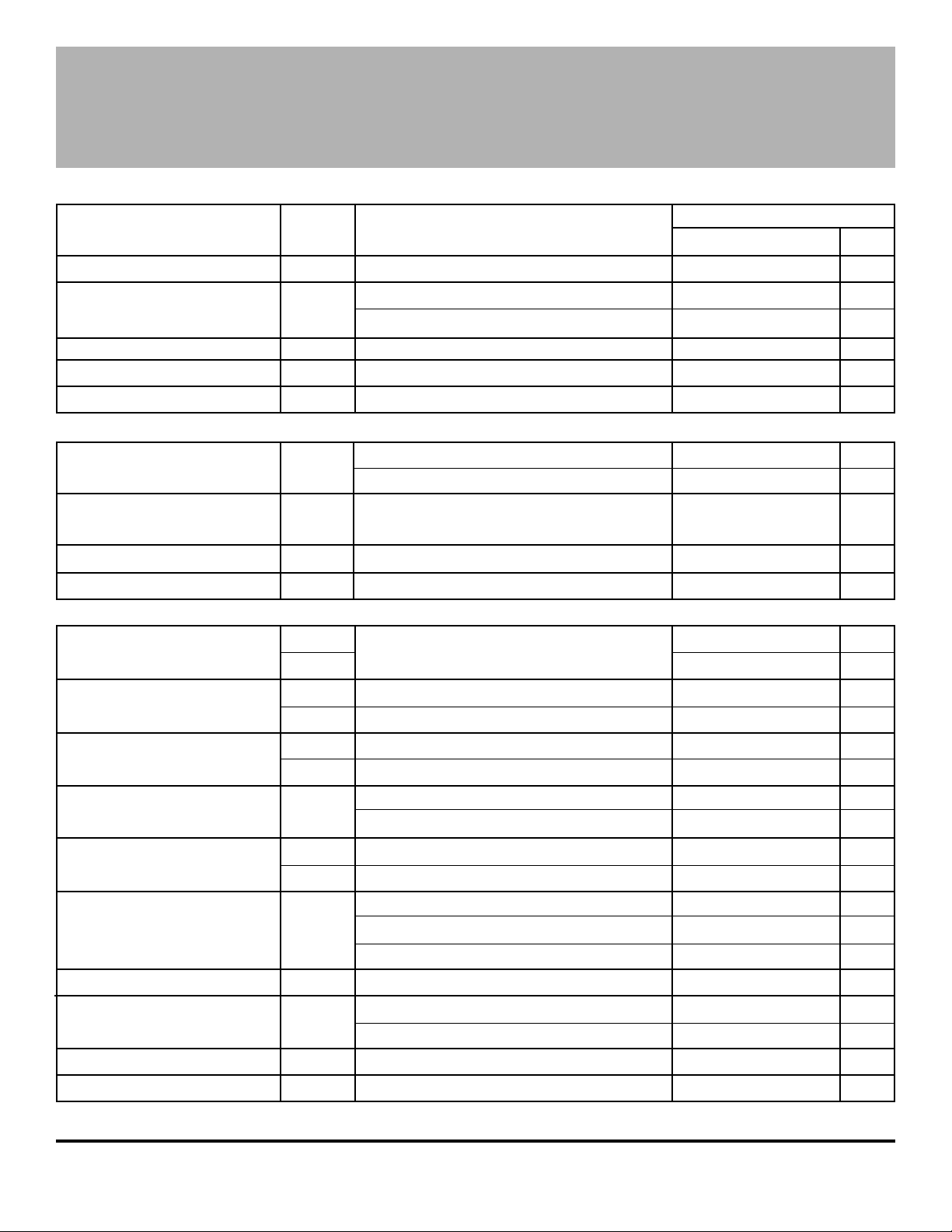

ABSOLUTE MAXIMUM RATINGS

at T

= +25°C

A

Load Supply Voltage, VBB. . . . . . . . . . 14 V

Output Current, I

Logic Supply Voltage, V

Logic Input Voltage Range,

VIN. . . . . . . . . . . -0.3 V to VDD + 0.3 V

Package Power Dissipation, P

Operating Temperature Range,

TA. . . . . . . . . . . . . . . . . . 0°C to +70°C

Junction Temperature, T

Storage Temperature Range,

TS. . . . . . . . . . . . . . . -55°C to +150°C

† Fault conditions that produce excessive junction

temperature will activate device thermal shutdown

circuitry. These conditions can be tolerated, but

should be avoided.

Output current rating may be restricted to a value

determined by system concerns and factors.

These include: system duty cycle and timing,

ambient temperature, and use of any heatsinking

and/or forced cooling. For reliable operation, the

specified maximum junction temperature should

not be exceeded.

. . . . . . . . . . . . ±1.25 A

OUT

. . . . . . . . . 6.0 V

DD

See Graph

D

. . . . . . . +150°C†

J

FEATURES

■ DMOS Outputs

■ Low r

■ Startup Commutation Circuitry

■ Back-EMF Commutation Circuitry

■ Serial Port Interface

■ Frequency-Locked Loop Speed Control

■ Sector Data Tachometer Signal Input

■ Programmable Start-Up Current

■ Diagnostics Mode

■ Sleep Mode

■ Linear Current Control

■ Internal Current Sensing

■ Dynamic Braking Through Serial Port

■ Power-Down Dynamic Braking

■ System Diagnostics Data Out

■ Data Out Ported in Real Time

■ Internal Thermal Shutdown Circuitry

Always order by complete part number, e.g., A8902CLBA .

DS(on)

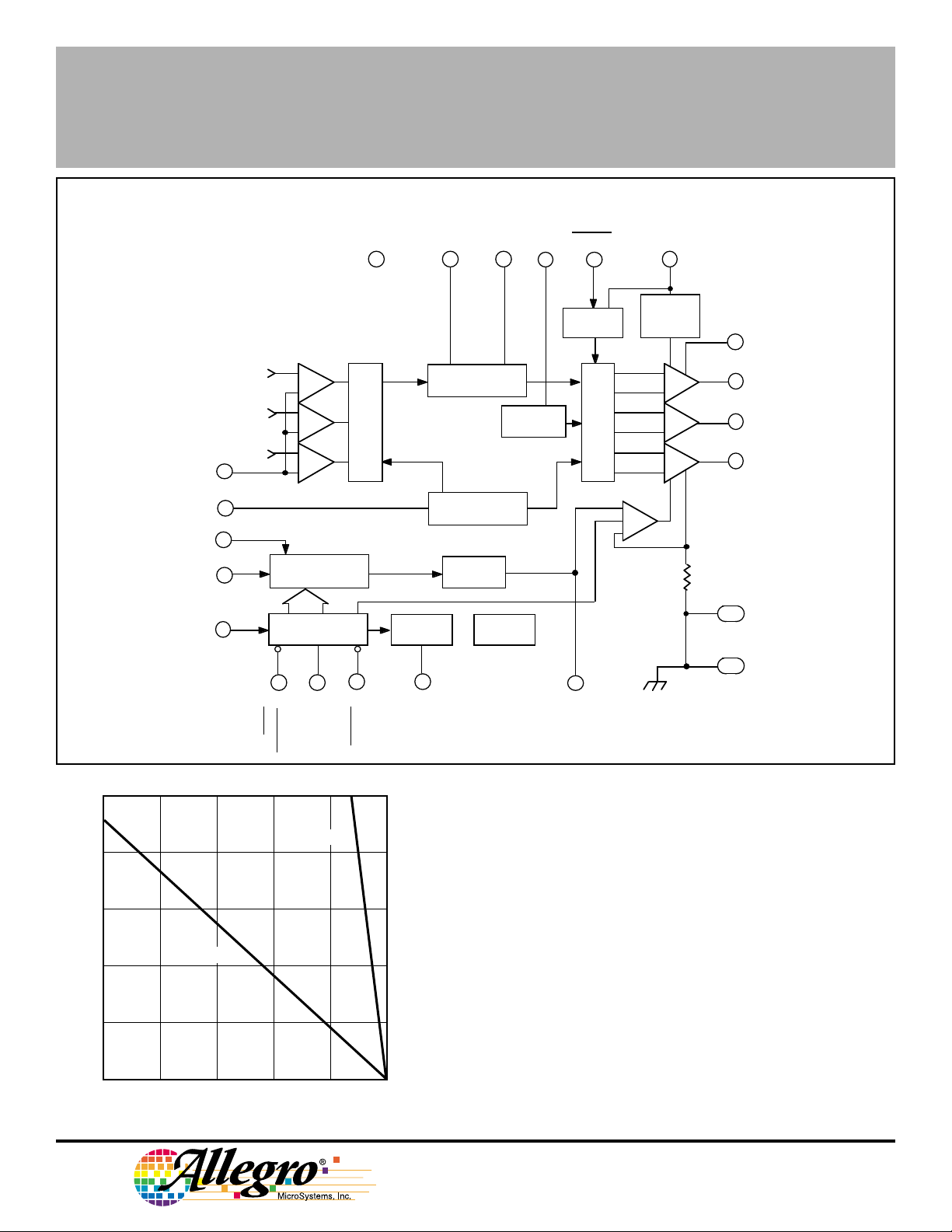

8902–A

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

FUNCTIONAL BLOCK DIAGRAM

LOGIC

SUPPLY

15

V

DD

CENTERTAP

10

OUT

OUT

OUT

A

B

C

FCOM

LOGIC

BLANK

COMMUTATION

C

D1

24

C

D2

2

COMMUTATION

DELAY

START-UP

C

OSC.

ST

4

BRAKE

11

BRAKE

SEQUENCE

LOGIC

C

RES

12

BOOST

CHARGE

PUMP

V

BB

1

5

8

9

LOAD

SUPPLY

OUT

A

OUT

B

OUT

C

2.5

2.0

1.5

1.0

C

WD

SECTOR

DATA

OSC

DATA IN

R = 55°C/W

θJA

3

14

16

23

FREQUENCY-

LOCKED LOOP

SERIAL PORT MUX

22

21

WATCHDOG

CHARGE

1720

TIMER

PUMP

TSD

13

CURRENT

CONTROL

R

S

6-7

GROUND

18-19

GROUND

FILTER

CHIP

SELECT

R = 6°C/W

θJT

CLOCK

RESET

OUT

DATA

Dwg. FP-034

0.5

0

25

ALLOWABLE PACKAGE POWER DISSIPATION in WATTS

50 75 100 125 150

TEMPERATURE in °C

Dwg. GP-019B

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1992, 1995 Allegro MicroSystems, Inc.

8902–A

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

ELECTRICAL CHARACTERISTICS at T

= +25°C, V

A

= 5.0 V

DD

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Logic Supply Voltage V

Logic Supply Current I

DD

DD

Operating 4.5 5.0 5.5 V

Operating — 7.5 10 mA

Sleep Mode — 250 500 µA

Load Supply Voltage V

Thermal Shutdown T

Thermal Shutdown Hysteresis ∆T

BB

J

J

Operating 4.0 — 14 V

— 165 — °C

— 20 — °C

Output Drivers

Output Leakage Current I

Total Output ON Resistance r

DSX

DS(on)

VBB = 14 V, V

V

= 14 V, V

BB

I

= 600 mA — 1.0 1.4 Ω

OUT

= 14 V — 1.0 300 µA

OUT

= 0 V — -1.0 -300 µA

OUT

(Source + Sink + RS)

Output Sustaining Voltage V

DS(sus)

Clamp Diode Forward Voltage V

F

V

= 14 V, I

BB

OUT

= I

(MAX), L = 3 mH 14 ——V

OUT

IF = 1.0 A — 1.25 1.5 V

Control Logic

Logic Input Voltage V

Logic Input Current I

DATA Output Voltage V

C

Current I

ST

C

Threshold V

ST

Filter Current I

Filter Threshold V

CD Current I

IN(0)

V

IN(1)

IN(0)

I

IN(1)

OUT(0)

V

OUT(1)

CST

CSTH

V

CSTL

FILTER

FILTERTH

CD

(CD1 or CD2)

C

Current Matching — I

D

CD Threshold V

CDTH

SECTOR DATA, RESET, CLK, -0.3 — 1.5 V

CHIP SELECT, OSC 3.5 — 5.3 V

VIN = 0 V ——-0.5 µA

VIN = 5.0 V ——1.0 µA

I

= 500 µA ——1.5 V

OUT

I

= -500 µA 3.5 —— V

OUT

Charging -9.0 -10 -11 µA

Discharging — 500 — µA

2.25 2.5 2.75 V

0.85 1.0 1.15 V

Charging -9.0 -10 -11 µA

Discharging 9.0 10 11 µA

Leakage, V

= 2.5 V ——5.0 nA

FILTER

1.57 1.85 2.13 V

Charging -18 -20 -22 µA

Discharging 32 40 48 µA

CD(DISCHRG)/ICD(CHRG)

1.8 2.0 2.2 —

2.25 2.5 2.75 V

Continued next page …

8902–A

3-PHASE BRUSHLESS DC

MOTOR CONTROLLER/DRIVER

ELECTRICAL CHARACTERISTICS continued

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

C

Current I

WD

C

Threshold Voltage V

WD

Max. FLL Oscillator Frequency f

I

(MAX) — D3 = 0, D4 = 0 1.0 1.2 1.4 A

OUT

CWD

V

TH

OSC

TL

Charging -9.0 -10 -11 µA

0.22 0.25 0.28 V

2.25 2.5 2.75 V

VDD = 5.0 V, TA = 25°C12——MHz

D3 = 0, D4 = 1 0.9 1.0 1.1 A

D3 = 1, D4 = 0 0.5 0.6 0.7 A

D3 = 1, D4 = 1 — 250 — mA

BRAKE Threshold V

BRAKE Hysteresis Current I

Transconductance Gain g

Centertap Resistors R

BRK

BRKL

m

CT

Back-EMF Hysteresis — V

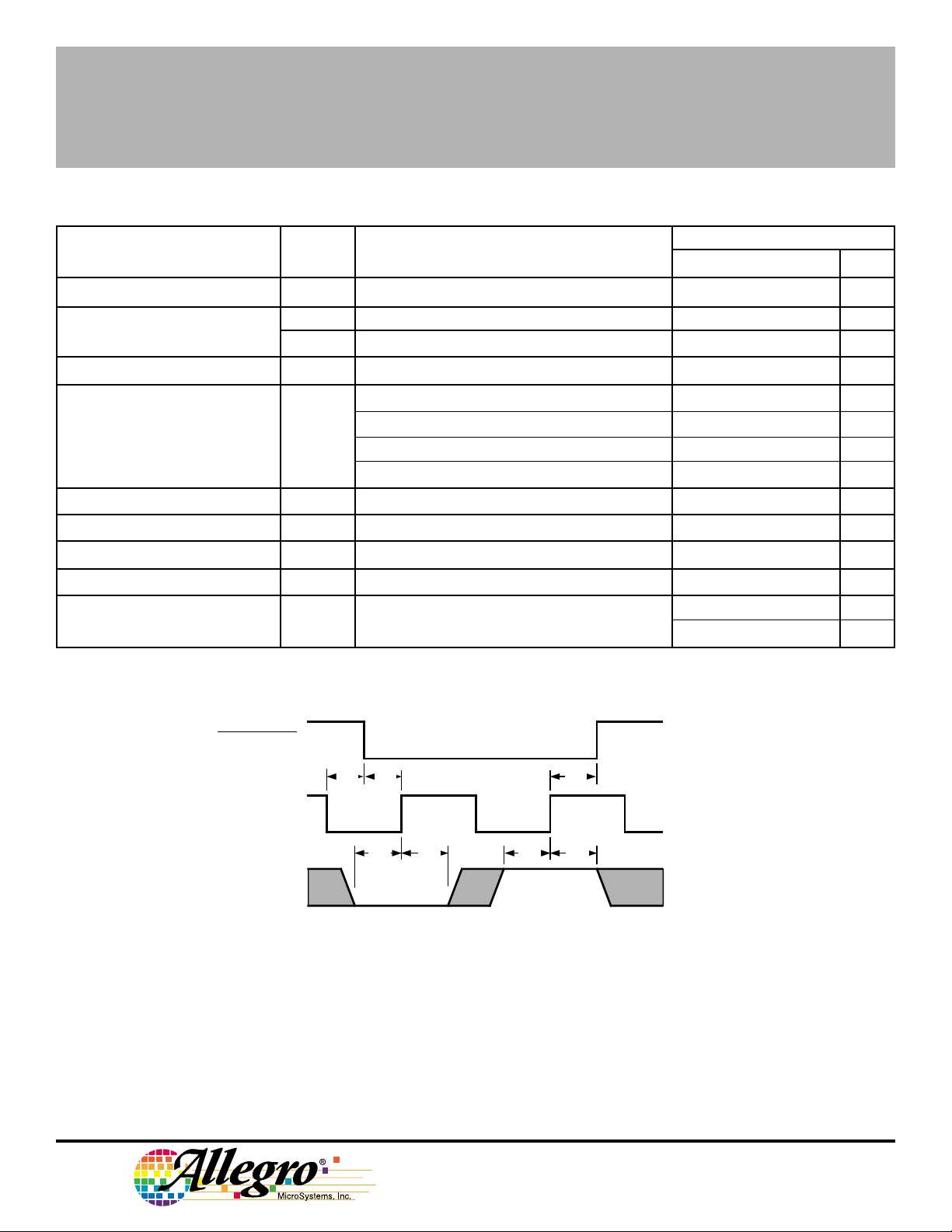

SERIAL PORT TIMING CONDITIONS

CHIP SELECT

E

CLOCK

DATA

1.5 1.75 2.0 V

V

= 750 mV — 20 — µA

BRK

0.42 0.50 0.58 A/V

5.0 10 13 kΩ

BEMF

- V

at 5.0 20 37 mV

CTAP

FCOM Transition -5.0 -20 -37 mV

A

C

D C D

B

Dwg. WP-019

A. Minimum CHIP SELECT setup time before CLOCK rising edge.......... 100 ns

B. Minimum CHIP SELECT hold time after CLOCK rising edge............... 150 ns

C. Minimum DATA setup time before CLOCK rising edge........................ 150 ns

D. Minimum DATA hold time after CLOCK rising edge............................. 150 ns

E. Minimum CLOCK low time before CHIP SELECT.................................. 50 ns

F. Maximum CLOCK frequency .............................................................. 3.3 MHz

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...