Page 1

A8601

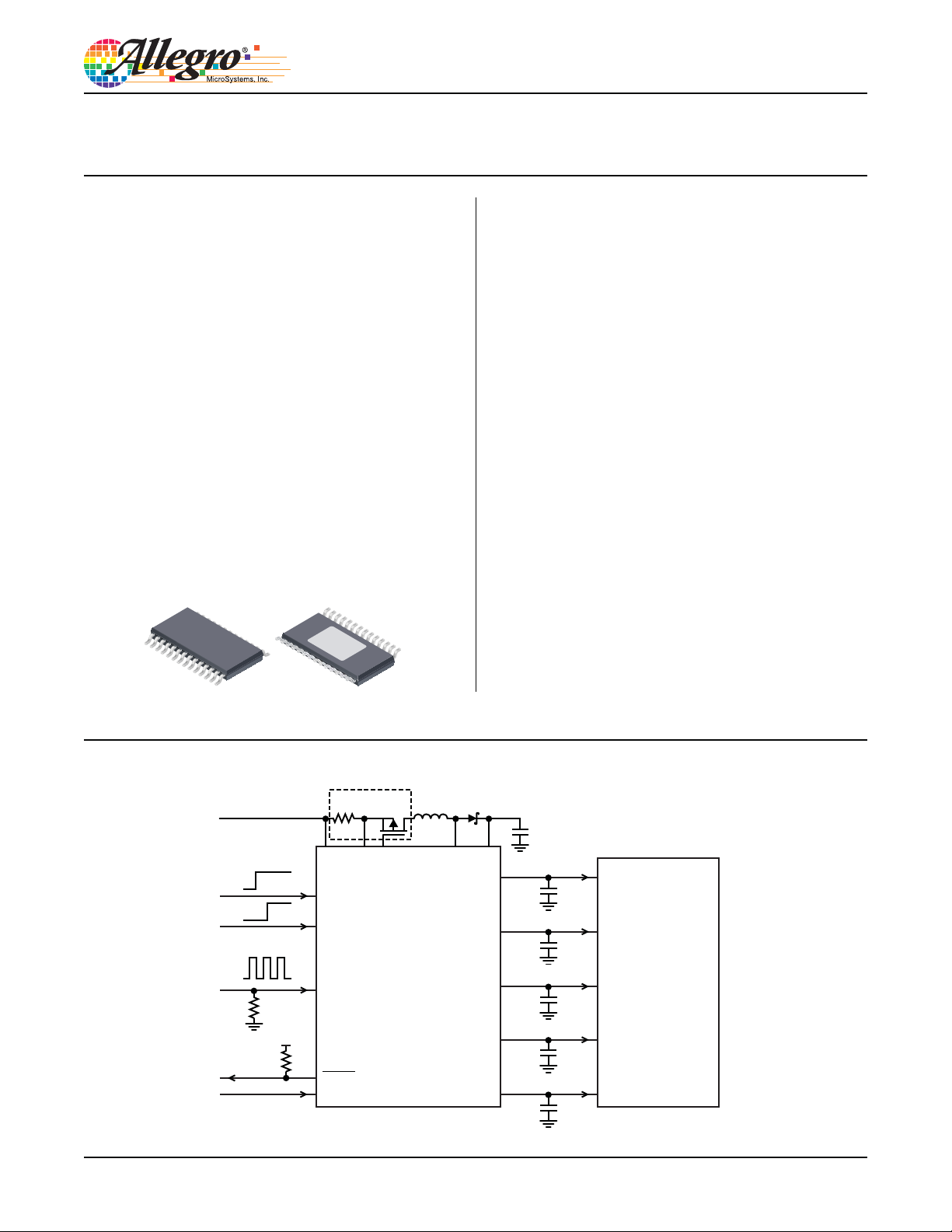

Multiple-Output Regulator for Automotive LCD Displays

Features and Benefits

• Automotive Grade AEC-Q100 qualified

• Five individual output supplies

• Independent control of each output voltage

• 350 kHz to 2.25 MHz switching frequency with external

synchronization capability

• <10 μA shutdown current

• Preprogrammed power-up and shutdown sequences

• Overcurrent, overvoltage, short circuit, and thermal

overload protection

Applications:

• GPS

• Infotainment

• Medium LCDs

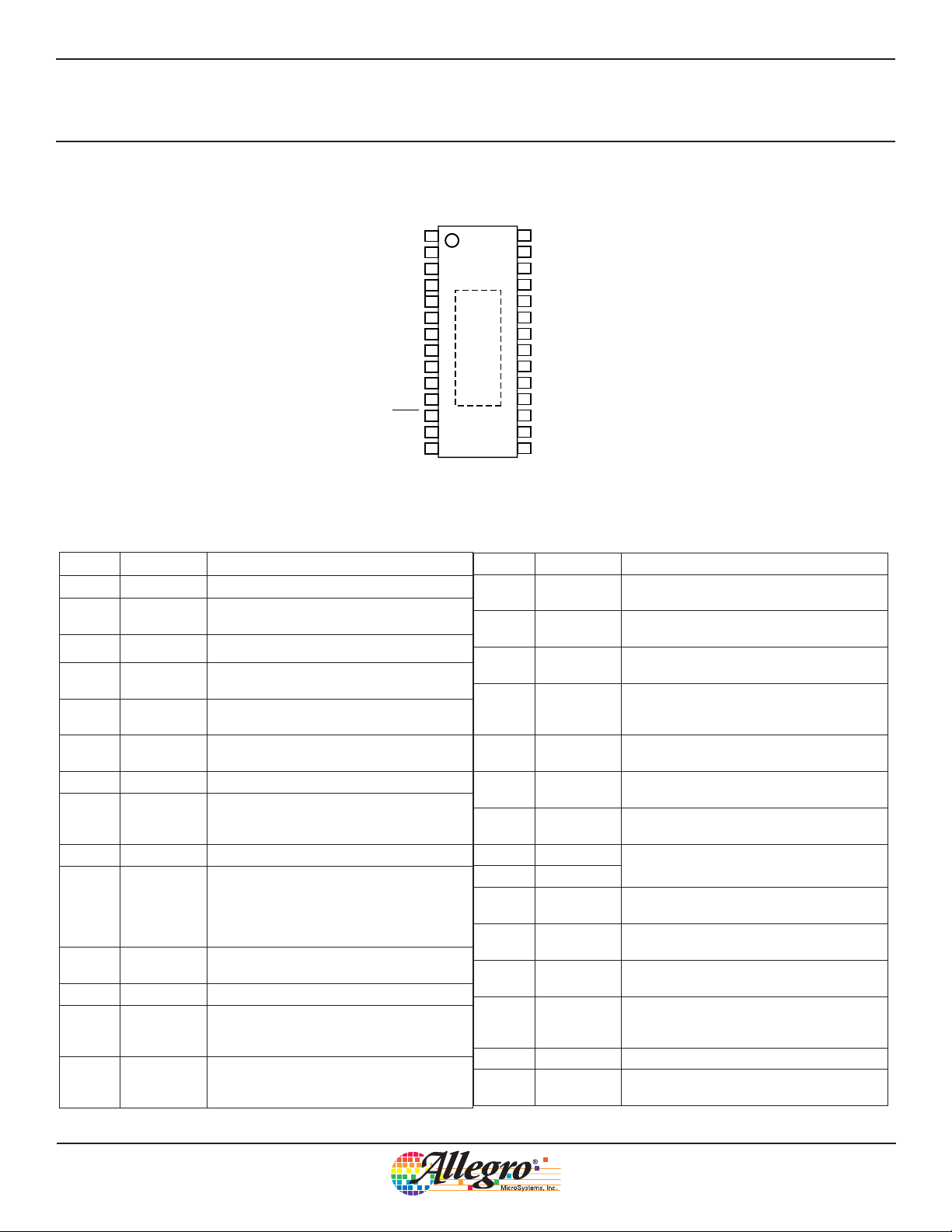

Package: 28-pin TSSOP with exposed

thermal pad (suffix LP)

Description

The A8601 is a fixed frequency, multiple-output supply for

LCD bias. Its switching frequency can be either programmed

or synchronized with an external clock signal between 350 kHz

and 2.25 MHz, to minimize interference with AM and FM

radio bands.

A total of five output voltages are provided, from three linear

regulators and two charge-pump regulators. Each output

voltage can be adjusted independently. During power-up and

shutdown, the outputs are turned on and off in preprogrammed

sequences, to meet the sequencing requirements for specific

LCD panels.

Short circuit protection is provided for all outputs. The boost

switch is protected against overcurrent and overvoltage. Input

disconnect protection is achieved by driving an external

P-MOSFET.

28-pin exposed thermal pad TSSOP package allows operation

at high ambient temperatures. It is lead (Pb) free with 100%

matte-tin leadframe plating.

Not to scale

VIN

External Sync

1.5 to 3.2 V

System Block Diagram

Optional

R

SC

Q1

INS GATE SW

VIN

EN1

EN2

FSET_SYNC

V

VIN

FAULT

VINAMP

A8601

D1L1

OUT

DVDD

AVDD

VGH

VGL

VCOM

V

DVDD

V

AVDD

V

VGH

V

VGL

V

VCOM

3.3 V

5 to 14 V

LCD Panel

10 to 25 V

+

– 5 to –12 V

+

3 to 6 V

+

Output voltages shown are

for typical LCD Panel

A8601-DS, Rev. 1

Page 2

A8601

Multiple-Output Regulator for Automotive LCD Displays

Selection Guide

Part Number Packing* Programming

A8601KLPTR-T 4000 pieces per 13-in. reel

*Contact Allegro

®

for additional packing options.

Contact Allegro Sales for

VCOM regulator factory trim option

Absolute Maximum Ratings

1,2

Characteristic Symbol Notes Rating Unit

VIN and INS Pin Voltage V

SW Pin Voltage

3,4

VIN

V

OUT Pin Voltage V

AVDD and FB2 Pin Voltage V

AVDD

CP11 Pin Voltage V

CP12 Pin Voltage V

VGH Pin Voltage V

FB4 Pin Voltage V

CP21 Pin Voltage V

V

V

CP22

EN1

V

V

CP22, VGL and FB3 Pin Voltage

EN1, EN2, and ¯F¯ ¯A

¯¯¯U ¯¯L¯ ¯T¯

Pin Voltage

BIAS Pin Voltage V

VCOM Pin Voltage V

V

PGND and GNDVCOM Pin Voltage

All other pins

5

PGND

V

GNDVCOM

Operating Ambient Temperature T

, V

SW

OUT

, V

CP11

CP12

VGH

FB4

CP21

, V

FB3

, V

FAULT

BIAS

VCOM

– –0.3 to 7 V

A

All voltages measured with respect to GND –0.3 to 6.5 V

INS

Continuous –0.6 to 22 V

Voltage spikes (pulse width < 100 ns) –1 to 40 V

–0.3 to 22 V

FB2

Positive charge pump

–0.3 to

V

OUT

–0.3 to

V

CP12

Positive charge pump –0.3 to 27 V

Positive charge pump –0.3 to 27 V

Positive charge pump

–0.3 to

V

VGH

Negative charge pump –0.3 to 14 V

,

VGL

Negative charge pump –14 to 0.3 V

,

EN2

–0.3 to 5.5 V

–0.3 to lower of:

5.5 or V

–0.3 to lower of:

7 or V

AVDD

,

–0.3 to 0.3 V

K temperature range –40 to 125 ºC

+ 0.3

+ 0.3

+ 0.3

VIN

+ 0.3

+ 0.3

V

V

V

V

V

Maximum Junction Temperature TJ(max) 150 ºC

Storage Temperature T

1

Stresses beyond those listed in this table may cause permanent damage to the device. The Absolute Maximum ratings are stress ratings

stg

–55 to 150 ºC

only, and functional operation of the device at these or any other conditions beyond those indicated in the Electrical Characteristics table is

not implied. Exposure to Absolute Maximum-rated conditions for extended periods may affect device reliability.

2

All voltages referenced to AGND.

3

The SW pin has internal clamp diodes to GND. Applications that forward bias this diode should take care not to exceed the IC package

power dissipation limits. Note: Exact energy specification to be determined.

4

The switch DMOS is self-protected. If voltage spikes exceeding 40 V are applied, the device would conduct and absorb the energy safely.

5

When V

= 0 (no power), all inputs are limited by -0.3 to 5.5 V.

VIN

Thermal Characteristics may require derating at maximum conditions, see application information

Characteristic Symbol Test Conditions* Value Unit

Package Thermal Resistance

*Additional thermal information available on the Allegro website.

R

θJA

On 4-layer PCB based on JEDEC standard 28 ºC/W

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

2

Page 3

A8601

Multiple-Output Regulator for Automotive LCD Displays

Table of Contents

Characteristic Performance 10

Functional Description 15

Linear Regulators 15

VCOM Regulator 15

Charge Pumps 16

Boost Controller 18

Switching Frequency 19

Continuous Conduction Mode Operation 20

Input Disconnect Switch 21

FAULT Conditions 22

Pre-Output Fault Detection 23

General Fault Detection 23

Application Information 24

Output Voltage Selection 24

Output Capacitance 25

Operating with Separate VIN and

Boost Supplies 26

Thermal Analysis 26

Component Selection Recommendations 28

I/O pin Equivalent Circuit Diagrams 29

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

3

Page 4

A8601

Multiple-Output Regulator for Automotive LCD Displays

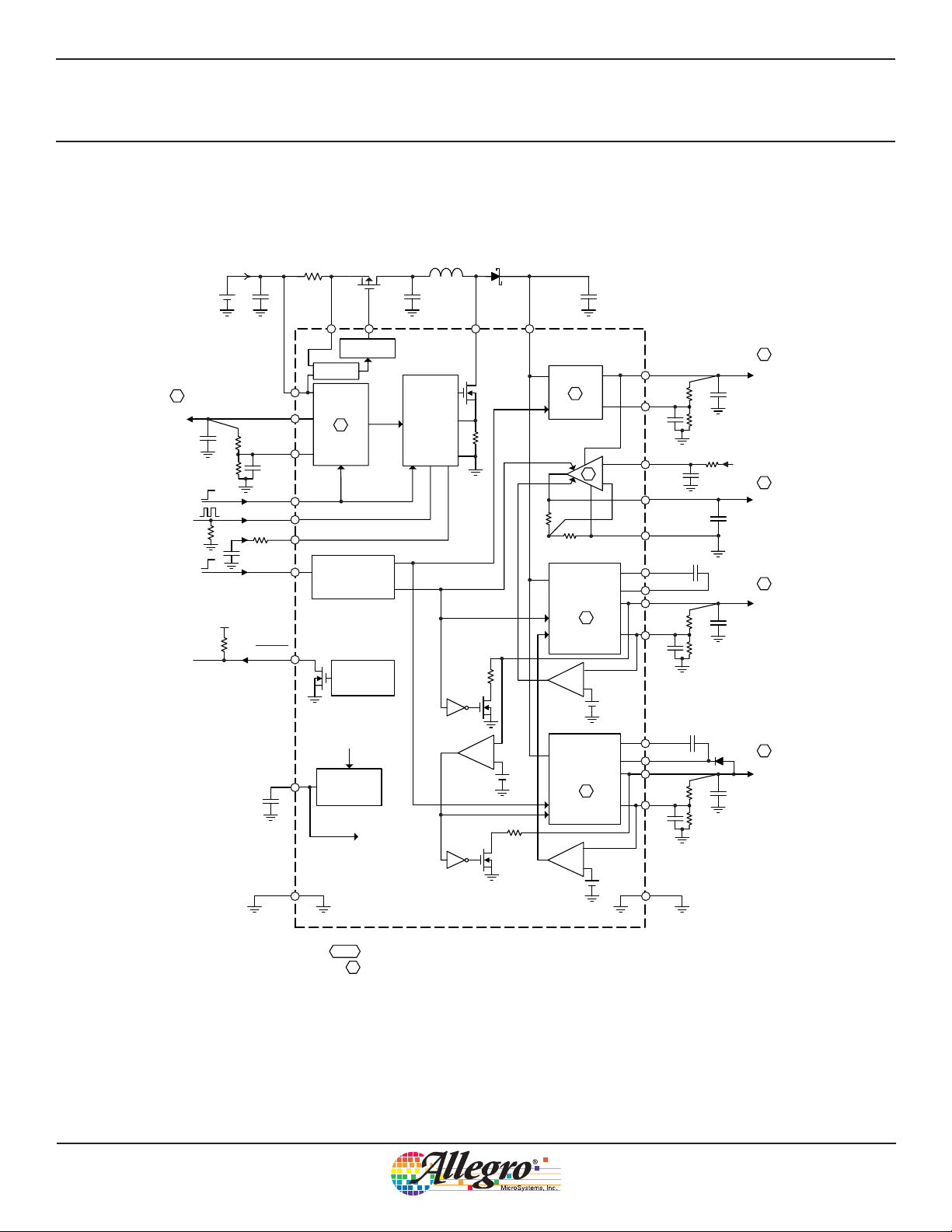

Functional Block Diagram

5 V DC to DC

Converter

(

4V )

min.

6

V

DVDD

3.3V

External

.

Sync

FSET_SYNC

C

COMP

V

VIN

FAULT

VIN

DVDD

FB1

EN1

COMP

EN2

R

INS

SC

OCP

LDO

1

Enable/

Disable

Fault

Q1

Drive

GATE

REG

Boost

Regulator

with

Soft

Start

SW

OFF

OFF

ON

OFF

D1L1

ON

OFF

ON

ON

OUT

X1.9 4

OP AMP

ON

+

LDO

2

+

5

2x

Charge

Pump

4

–

–

90%

C

OUT

6

+

C

Microprocessor

+

C

+

V

AVDD

10V

AVDD

1.5 to 3.2 V

from

6

V

VCOM

3 to6 V

VCOM

6

V

VGH

18 V

AVDD

FB2

VINAMP

VCOM

GNDVCOM

C

FLY1

CP11

CP12

VGH

FB4

BIAS

AGND

V

IN

BIAS

Regulat or

3.6 V

See Terminal List Table

1 to 5

6

Output voltages shown are for a typic

ON

OFF

OFF

C

FLY2

+

10%

-

Inverted

Charge

Pump

3

+

–

al LCD panel

90 %

CP21

CP22

VGL

FB

3

+

PGND

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

V

-8 V

6

VGL

4

Page 5

A8601

Multiple-Output Regulator for Automotive LCD Displays

Pin-out Diagram

GATE

INS

VIN

DVDD

FB1

COMP

VINAMP

VCOM

GNDVCOM

FSET_SYNC

BIAS

FAULT

EN1

EN2

Terminal List Table

Number Name Function

1 GATE Gate driver for input disconnect P-MOSFET

2 INS

3 VIN Input supply voltage (4.0 to 5.5 V) for the IC

4 DVDD

5

FB1

(DVDD)

6 COMP

7 VINAMP Control voltage from external microprocessor

8 VCOM

9 GNDVCOM Ground reference for VCOM

10 FSET_SYNC

11 BIAS

12 ¯F¯ ¯A

¯¯¯U ¯¯L¯ ¯T¯

13 EN1

14 EN2

High-side sense for input overcurrent

detection

Output from internal LDO (item 1 in Functional

Block Diagram) powered by VIN

Connect to resistor divider network to set

DVDD

Compensation pin, connect to external COMP

capacitor

Output from operational amplifier (item 5 in

Functional Block Diagram), controlled by

VINAMP

Input for synchronizing boost and charge

pump signals switching frequency to external

clock signal; alternatively, it can be connected

to an external resistor to set the switching

frequency

Output from internal 3.6 V bias regulator;

connect to GND via 0.1 μF ceramic capacitor

Open-drain output, pulls low in error condition

Enable pin for DVDD output; system can only

be enabled after V

(refer to Startup Timing Diagram)

is above UVLO level

VIN

Enable pin for the voltage outputs other than

DVDD; it can be activated only after V

above UVLO and EN1 = high.

VIN

28

1

2

3

4

5

6

PAD

7

8

9

10

11

12

13

14

SW

27

PGND

26

OUT

25

AVD D

24

FB2

23

CP11

22

CP12

21

VGH

20

FB4

19

CP21

18

CP22

17

VGL

16

FB3

15

AGND

Number Name Function

15 AGND

16

FB3

(VGL)

17 VGL

Analog GND reference for signals; connect to

ground plane

Connect to resistor divider network to set V

VGL

Inverted charge pump output

(item 3 in Functional Block Diagram)

Capacitor terminal for inverted charge pump

18 CP22

(item 3 in Functional Block Diagram); refer to

Negative Charge Pump section for usage

19 CP21

20

FB4

(VGH)

21 VGH

22 CP12

23 CP11

24

FB2

(AVDD)

25 AVDD

26 OUT

Capacitor terminal for inverted charge pump

(item 3 in Functional Block Diagram)

Connect to resistor divider network to set V

VGH

2x charge pump (item 4 in Functional Block

Diagram) output

Capacitor terminals for charge pump

(item 4 in Functional Block Diagram)

Connect to external resistor network to set

V

AVDD

Output from internal LDO (item 2 in Functional

Block Diagram) powered by V

OUT

Connect to boost output for internal LDO and

charge pump regulators

Power ground for internal boost switch;

27 PGND

connect this pin to ground terminal of

output ceramic capacitor(s)

28 SW Boost converter switch node

is

– PAD

Exposed pad (substrate of IC); solder to GND

plane for better thermal conduction

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

5

Page 6

A8601

Multiple-Output Regulator for Automotive LCD Displays

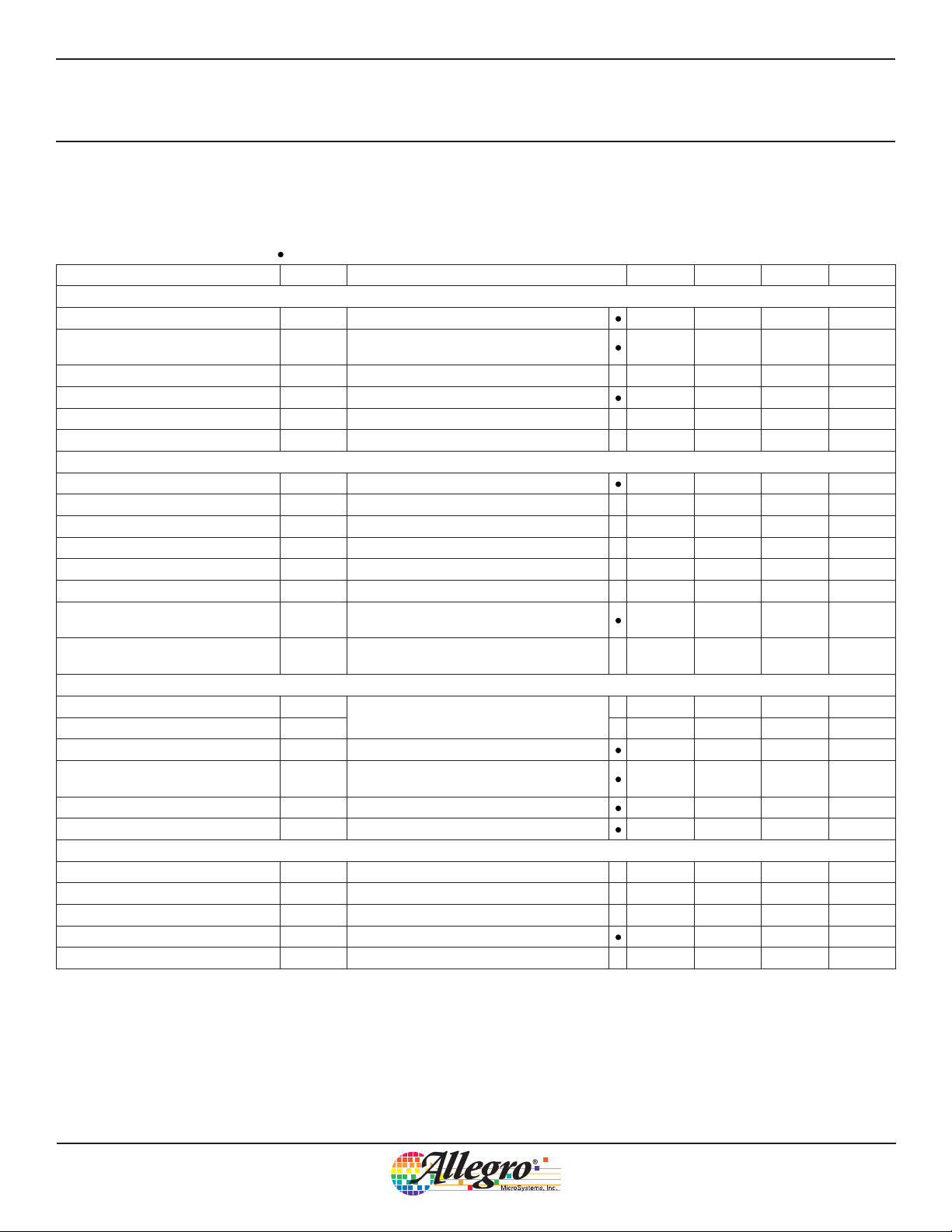

ELECTRICAL CHARACTERISTICS

V

= –8 V, TJ = TA = 25°C, except indicates specifications guaranteed for TJ = TA = −40°C to 125°C; unless otherwise specified

VGL

1

Valid at V

= 5 V, EN1 = EN2 = high, fSW = 2 MHz, V

VIN

DVDD

= 3.3 V, V

AVDD

= 10 V, V

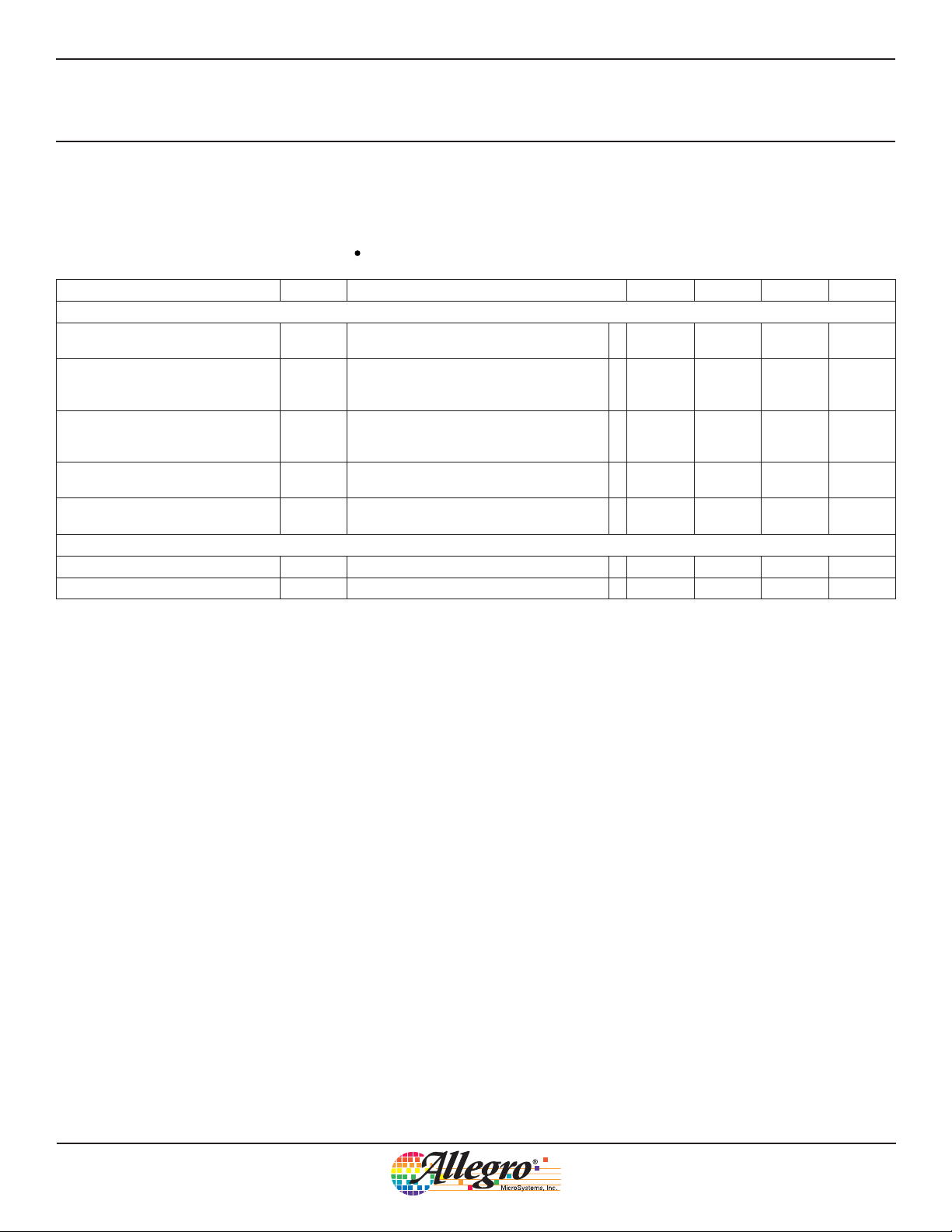

Characteristics Symbol Test Conditions Min. Typ. Max. Unit

Input Voltage and Current

Input Voltage V

VIN Pin Undervoltage Lockout

(UVLO) Threshold

VIN Pin UVLO Hysteresis V

Shutdown Bias Current I

Standby Bias Current I

Operating Bias Current I

V

UVLO(HYS)

VINBIAS(SD)

VINBIAS(STB)

VINBIAS(OP)

VIN

UVLO

V

rising 3.6 – 4.0 V

VIN

Current into VIN pin, EN1 = low –550μA

EN1 = high, EN2 = low, no load at DVDD pin – 2 – mA

EN1 = high, EN2 = high – 6.5 – mA

4.0 – 5.5 V

– 0.15 0.25 V

Boost Switch

Switch Peak Current Limit I

Switch On-Resistance R

Switch Minimum On-Time t

Switch Minimum Off-Time t

SW Pin Leakage Current I

OUT Pin Leakage Current I

SW Pin Secondary Overvoltage

Protection (OVP)

SW Pin Secondary OVP Minimum

Pulse Width

4

V

t

SW(MAX)

DS(on)ISW

ON(MIN)

OFF(MIN)

SW(LKG)VSW

OUT(LKG)VOUT

SW(OVP)

SW(OVP)VSW

Cycle-by-cycle current limit 1.3 – 2.0 A

= 0.5 A – 0.5 – Ω

50 72 95 ns

33 50 75 ns

= 5 V, EN1 = low – 0.1 – μA

= 5 V, EN1 = low – 0.1 – μA

17.4 19.2 21.2 V

≥ OVP level – 40 – ns

Switching Frequency / Synchronization

FSET_SYNC Pin Voltage V

FSET_SYNC Pin Current I

FSETSYNC

FSETSYNC

Switching Frequency f

Synchronization Frequency f

Synchronization Minimum On-Time t

Synchronization Minimum Off-Time t

SYNC(ON)

SYNC(OFF)

SW

SYNC

Without using external synchronization signal

R

FSET_SYNC

= 5.1 kΩ 1.81 2.0 2.17 MHz

External logic signal connected to

FSET_SYNC pin

– 1.0 – V

34 – 220 μA

0.35 – 2.25 MHz

150 – – ns

150 – – ns

Input Disconnect

= V

GATE Pin Sink Current I

GATE Pin Source Current I

GATE Voltage at Off Condition V

INS Trip Point V

INS Trip Blanking Time t

GATE(SNK)VGATE

GATE(SRC)VGATE

GATE(OFF)

INS(TRIP)

INS(BLANK)

EN1 = EN2 = low, or fault tripped – V

Between VIN and INS pins 85 100 115 mV

Sensed voltage = 2 × input current limit 1.5 – 3 μs

, no fault – 100 – μA

VIN

= 0 V, fault tripped – 130 – mA

VIN

= 20 V,

VGH

–V

Continued on the next page…

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

6

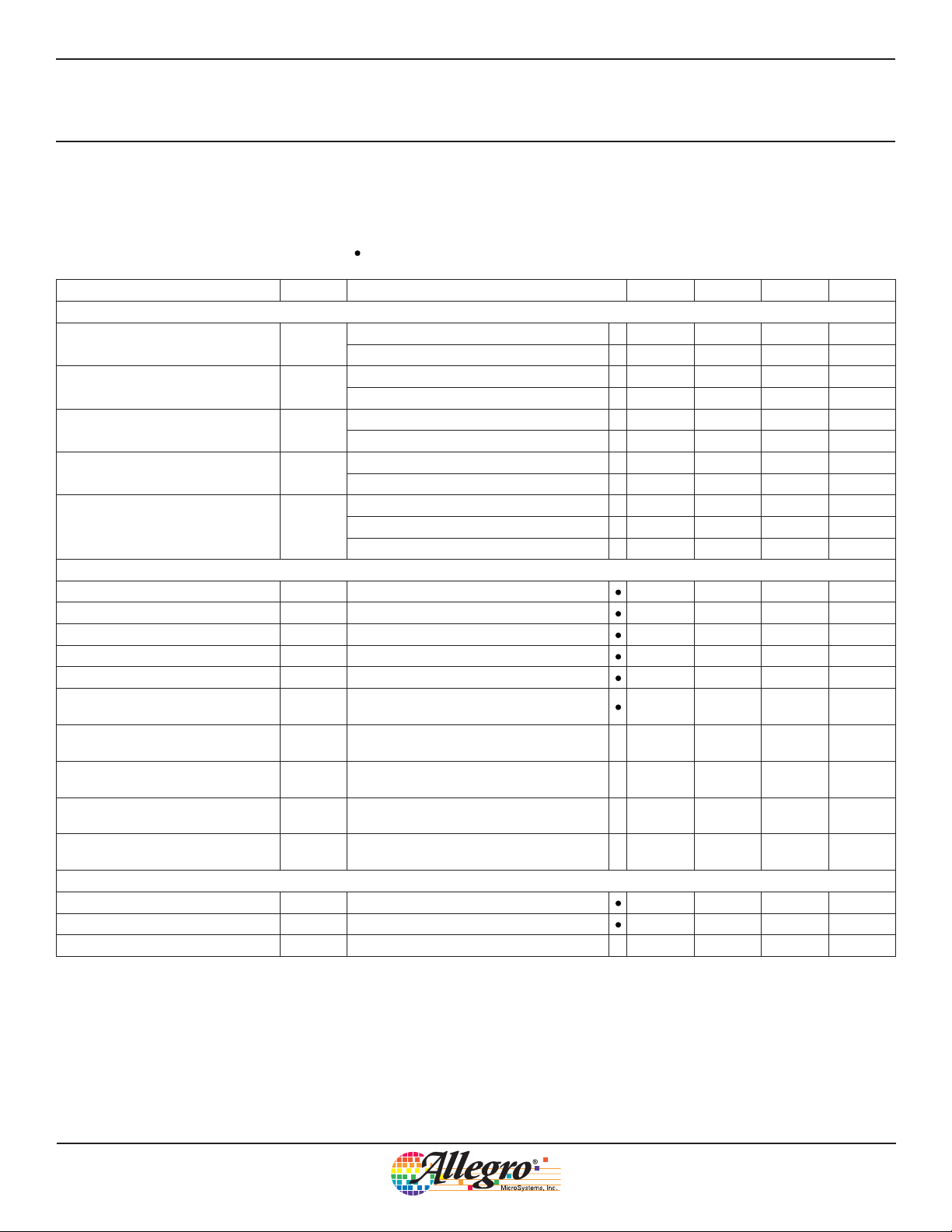

Page 7

A8601

Multiple-Output Regulator for Automotive LCD Displays

ELECTRICAL CHARACTERISTICS

V

= 20 V, V

VGH

otherwise specified

Feedback Pins

Feedback Sense Voltage V

Output Overvoltage Fault Threshold V

Output Undervoltage Fault Threshold V

Feedback Input Currents I

Feedback Load Resistance

Output Regulators

DVDD Output Voltage V

AVDD Output Voltage V

VCOM Output Voltage V

VGH Output Voltage V

VGL Output Voltage V

Dropout for DVDD Regulator V

Boost Minimum Headroom for AVDD

Regulator

Boost Minimum Headroom for VGH

Regulator

Boost Minimum Headroom for VGL

Regulator

Output Pull-Down Resistor During

Shutdown (AVDD, VCOM, VGH, VGL)

Logic Inputs

Input Logic High V

Input Logic Low V

Internal Pull-Down Resistance to AGND R

= –8 V, TJ = TA = 25°C, except indicates specifications guaranteed for TJ = TA = −40°C to 125°C; unless

VGL

Characteristics Symbol Test Conditions Min. Typ. Max. Unit

2

V

V

V

R

1

(continued) Valid at V

FB1, FB2, and FB4 pins – 2.40 – V

FBx

FB3 pin – –1.8 – V

FB1, FB2, and FB4 pins; V

FBx(OV)

V

falling – –2.16 – V

FB3

FB1, FB2, and FB4 pins; V

FBx(UV)

V

rising – –1.44 – V

FB3

FB1, FB2, and FB4 pins; V

FBx

V

= –1.8 V – 0.5 – μA

FB3

FB1 pin 9 10 11 kΩ

R

FB2 pin 24 25 26 kΩ

FBx

FB3 and FB4 pins 49 50 51 kΩ

DVDDVVIN

AVDD

VCOMVVIN

VGH

VGL

DVDD(DO)

AVDD(DO)

VGH(DO)

VGL(DO)

OUTPD

IH

IL

ENx(PD)

= 4.0 to 5.5 V 2.4 – V

V

= 4.0 to 5.5 V 4.4 – 14.8 V

VIN

= 4.0 to 5.5 V, V

V

= 4.0 to 5.5 V 2.4 – 26 V

VIN

V

= 4.0 to 5.5 V –12.9 – –5 V

VIN

Between VIN and DVDD pins;

V

= 2.33 V, I

FB1

Defined as V

I

= 100 mA

OUT

Defined as V

V

= 2.33 V, I

FB4

Defined as V

= –1.75 V, I

V

FB3

EN1 = high, EN2 = low – 250 – Ω

EN1, EN2, FSET_SYNC pins 1.8 – – V

EN1, EN2, FSET_SYNC pins – – 0.8 V

EN1, EN2 pins – 100 – kΩ

OUT

OUT

OUT

= 5 V, EN1 = EN2 = high, fSW = 2 MHz, V

VIN

rising – 2.88 – V

FBx

falling – 1.92 – V

FBx

= 2.4 V – –0.5 – μA

FBx

OUT

– V

– V

OUT

– (–V

OUT

> V

AVDD

= 50 mA

; V

AVDD

/ 2;

VGH

= 8 mA

VGL

= –8 mA

);

+ 1.5 V 2.9 – 6.8 V

VCOM

= 2.33 V,

FB2

DVDD

= 3.3 V, V

VIN

= 10 V,

AVDD

– 0.6 V

– – 0.6 V

–2–V

– 2.4 – V

– 3.6 – V

Continued on the next page…

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

7

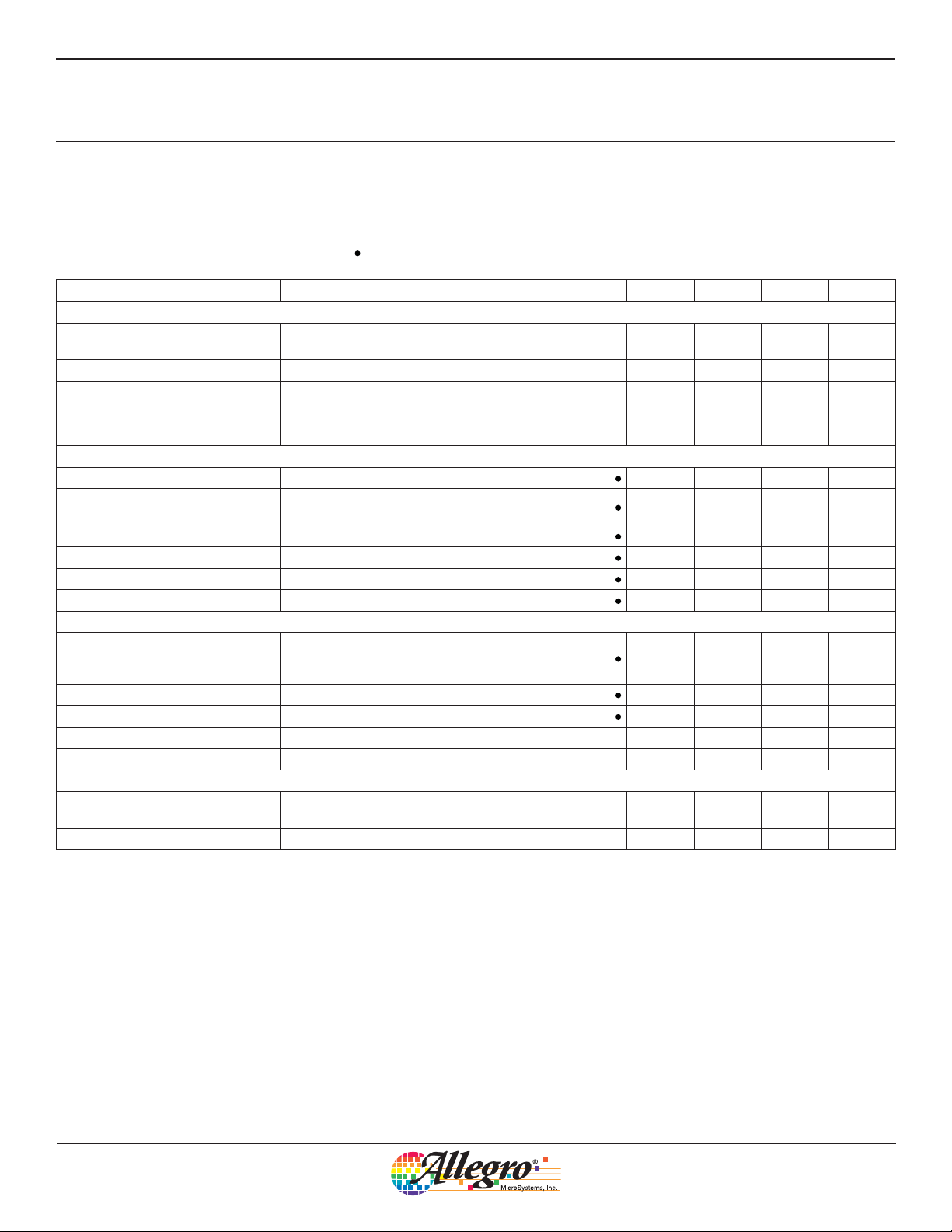

Page 8

A8601

Multiple-Output Regulator for Automotive LCD Displays

ELECTRICAL CHARACTERISTICS

V

= 20 V, V

VGH

otherwise specified

Output Current Capacity

DVDD Overcurrent Protection (OCP)

Trip Level

AVDD OCP Trip Level I

VCOM OCP Trip Level i

VGH OCP Trip Level i

VGL OCP Trip Level i

Output Voltage Accuracy

DVDD Load Regulation V

AVDD, VGL and VGH Load

Regulation

DVDD Accuracy

AVDD Accuracy

VGH Accuracy

VGL Accuracy

VCOM Operational Amplifier

VCOM Gain

VCOM Load Regulation

VCOM Temperature Coefficient

Input Resistance to AGND R

Dropout for VCOM from AVDD V

¯F¯ ¯

¯¯¯U ¯¯L¯ ¯T¯

A

Pin

¯F¯ ¯

¯¯¯U ¯¯L¯ ¯T¯

A

Pull-Down Voltage V

¯F¯ ¯

¯¯¯U ¯¯L¯ ¯T¯

A

Pin Leakage Current V

= –8 V, TJ = TA = 25°C, except indicates specifications guaranteed for TJ = TA = −40°C to 125°C; unless

VGL

Characteristics Symbol Test Conditions Min. Typ. Max. Unit

I

DVDD(OCP)

AVDD(OCP)

3

3

3

3

4

4

4

err

err

V

TC

VINAMP(PD)

VCOM(DO)VAVDD

FAULT(PD)

FAULT(LKG)

1

(continued) Valid at V

Includes i

VCOM

VGH

VGL

DVDDregVDVDD

V

err

err

Current into VGL pin 14 – 32 mA

xregILOAD

DVDDVDVDD

AVDDVAVDD

VGHVVGH

V

VGL

VCOM

= 3.3 V, I

= 10% to 100% of I

= 3.30 V –2.5 – 2.5 %

= 10.0 V –2.1 – 2.1 %

= 20.0 V –2.5 – 2.5 %

= –8.0 V –2.5 – 2.5 %

VGL

Defined as V

A

VCOM

VCOMregILOAD

1.5 V < V

85°C, I

–30°C < TA < 85°C, I

VCOM

VINAMP

LOAD

= 5 to 50 mA –5 – 5 mV

VINAMP pin – 100 – kΩ

= 7 V, I

Fault condition asserted,

pull-up current = 1 mA

Fault condition cleared, pull-up to 5 V – – 1 μA

= 5 V, EN1 = EN2 = high, fSW = 2 MHz, V

VIN

DVDD

= 3.3 V, V

50 – 90 mA

200 – 350 mA

60 – 110 mA

14 – 32 mA

= 10 to 50 mA –0.1 – 0.1 V

LOAD

(min) –0.1 – 0.1 V

x(OCP)

/ V

VCOM

< 3.21 V, –30°C < TA <

VINAMP

;

1.92 1.94 1.96 V / V

= 25 mA

= 25 mA –50 – 50 μV/°C

LOAD

= 60 mA – – 1.5 V

VCOM

– – 0.4 V

AVDD

= 10 V,

Continued on the next page…

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

8

Page 9

A8601

Multiple-Output Regulator for Automotive LCD Displays

ELECTRICAL CHARACTERISTICS

V

VGH

= 20 V, V

= –8 V, TJ = TA = 25°C, except indicates specifications guaranteed for TJ = TA = −40°C to 125°C; unless

VGL

1

(continued) Valid at V

= 5 V, EN1 = EN2 = high, fSW = 2 MHz, V

VIN

DVDD

= 3.3 V, V

AVDD

otherwise specified

Characteristics Symbol Test Conditions Min. Typ. Max. Unit

Fault Timers

Soft Start Time-Out t

SS(TO)

Maximum time allowed for any output to

reach 90% of its target

Maximum time allowed for VGH to fall to

Shutdown Time-Out t

Overcurrent Protection (OCP)

Time-Out

Restart Delay t

t

RESTART

Fault Counter Reset Time t

SDN(TO)

OCP(TO)

fault

10% and VGL to 30% of their respective

targets; EN1 = high, EN2 = low

Maximum time allowed for any output to

stay in an overcurrent fault condition before

shutdown

Delay time after fault shutdown until the next

retry (repeats until Fault counter = 8)

Time required after setting EN1 = low until

Fault counter clears

Thermal Shutdown (TSD) Protection

TSD Threshold T

TSD Hysteresis

1

For input and output current specifications, negative current is defined as coming out of the node or pin (sourcing), positive current is defined as

going into the node or pin (sinking).

2

Net parallel resistance required at FBx pin in order to meet accuracy.

3

Output voltage is set to required nominal value using external sense resistor network. Output current at 50% of minimum OCP trip level. Accuracy

does not include mismatch error caused by external sense resistor network.

4

Ensured by design and characterization, not production tested.

4

T

TSD(HYS)

Temperature rising – 165 – °C

TSD

40 50 60 ms

40 50 60 ms

40 50 60 ms

80 100 120 ms

1––μs

–20–°C

= 10 V,

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

9

Page 10

A8601

Multiple-Output Regulator for Automotive LCD Displays

Characteristic Performance

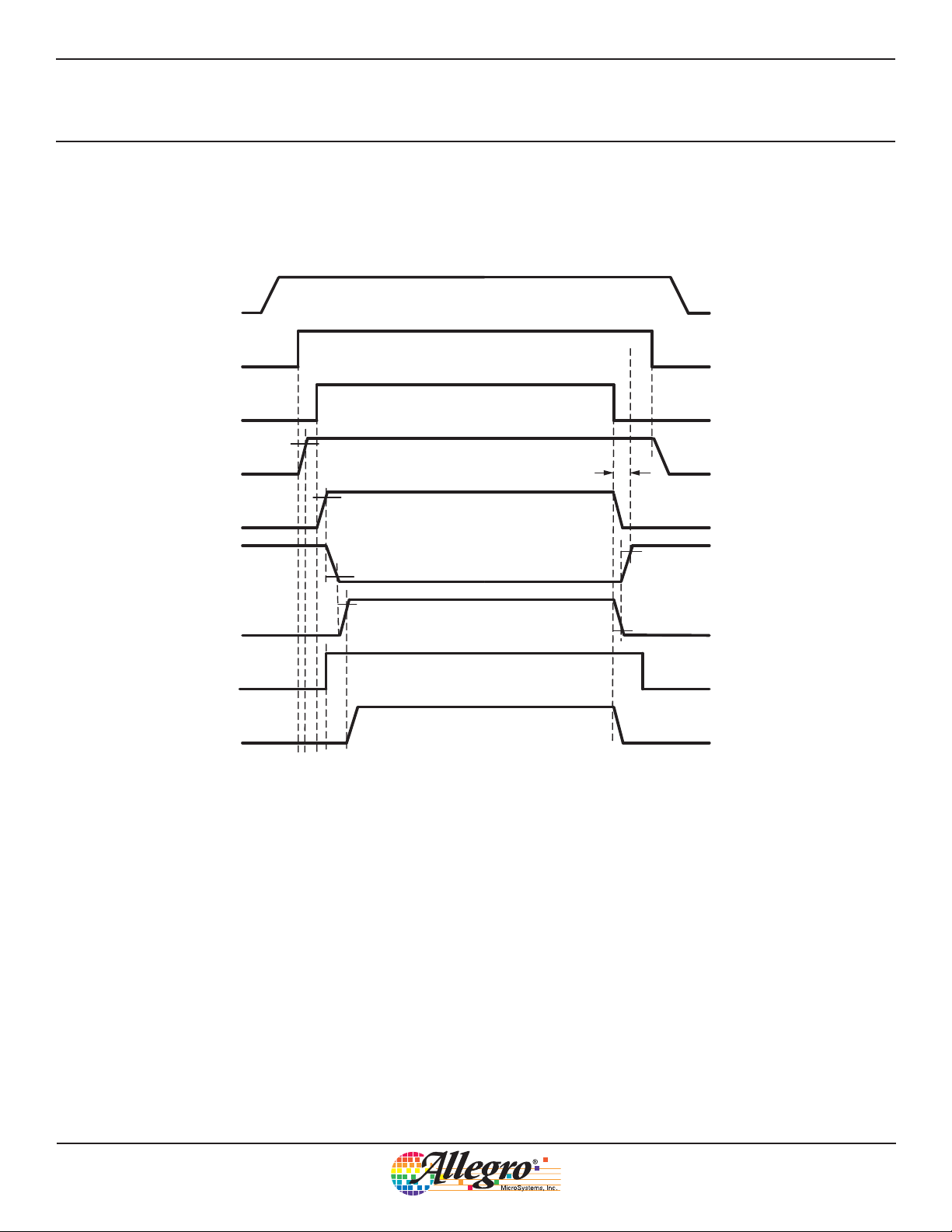

Startup and Shutdown Sequences (Normal Operation)

VIN

EN1

EN2

DVDD

AVDD

VGL

VGH

90%

t<100 ms

90%

30%

90%

90%

10%

VINAMP

VCOM

Notes:

• Normal system startup should follow the above sequence (VIN → EN1 → EN2).

• EN1 can only be asserted after VIN is above UVLO level, V

ignored until VIN rises above V

• EN2 can only be asserted when DVDD is >90% target voltage. If asserted before that, it is ignored

until the condition is met.

• VGH is enabled only after the magnitude of VGL has reached >90% of its target voltage.

• VCOM output is enabled only after VGH has reached >90% of its target voltage. (A valid VINAMP

must be asserted prior to this.)

• System shutdown should start with EN2 = low, followed by EN1 = low.

• VGL shutdown can only start after VGH has dropped to 10% its original target voltage, or the VGH

shutdown time-out interval has expired.

• EN1 = low can only be asserted when VGL has fallen below 30% of its target voltage. If asserted

before that, it is ignored until the condition is met or the VGL shutdown time-out interval has

expired.

UVLO

.

. If asserted before that, it is

UVLO

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

10

Page 11

A8601

VIN

Multiple-Output Regulator for Automotive LCD Displays

Startup and Shutdown Sequences (Irregular)

V

VIN

UVL O

VIN

EN1

EN2

DVDD

AVDD

VGL

VGH

VINAMP

VCOM

90%

90%

90%

90%

EN1

EN2

DVDD

AVDD

VGL

VGH

VINAMP

VCOM

90%

90%

90%

90%

EN1

EN2

DVDD

AVDD

VGL

VGH

VINAMP

VCOM

30%

10%

Case 1 (startup) Case 2 (startup) Case 3 (shutdown)

Notes:

• Case 1 (startup). During a startup sequence, if EN2 goes high before EN1 goes high, EN2 is

ignored until EN1 also goes high and DVDD has risen to 90% of its target voltage.

• Case 2 (startup). During a startup sequence, while VIN is below the UVLO level, V

in sleep mode. If either EN1 or EN2 goes high while the IC is still in sleep mode, they are ignored

until VIN exceeds V

UVLO

.

UVLO

, the IC is

• Case 3 (shutdown). During a shutdown sequence, if EN1 goes low before EN2 goes low, EN1

is ignored until EN2 also goes low and VGL has fallen to 30% of its target voltage, or the VGL

shutdown time-out interval has expired.

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

11

Page 12

A8601

Multiple-Output Regulator for Automotive LCD Displays

Startup Timing Diagram

>100 μs (determined by GATE pin capacitance)

IC waits until GATE pin < (V

– 3.5 V)

VIN

EN1

DVDD

EN2

AVDD

VGL

VGH

VCOM

≈ 4 ms for 48 μF

capacitor loading

12 ms for typical

≈

capacitor loading

EN2 ignored

≈

capacitor loading

90%

3 ms for 48 μF

4 ms for 24 μF

≈

capacitor loading

90%

≈

4 ms for 10 μF

capacitor loading

≈

2 ms for 10 μF

capacitor loading

EN1 ignored

90%

90%

90%

Notes:

• Startup ramps are based on internal timing and are assumed to have ± 20% variation.

• An internal pull-down resistor of 250 Ω is applied to each of the regulator outputs AVDD, VGL,

VGH, and VCOM as soon as EN1 = high. That means if any output capacitor was previously

charged, it would be discharged by this pull-down resistor. The pull-down is removed just

before each regulator is enabled.

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

12

Page 13

A8601

EN2

AVDD

VCOM

VGH

Multiple-Output Regulator for Automotive LCD Displays

Shutdown Timing Diagram

≈22 ms for 40 μF

capacitor discharge

10%

≈6 ms for 10 μF

capacitor discharge

10%

≈6 ms for 10 μF

capacitor discharge

10%

VGL

EN1

EN1 ignored

30%

7 ms for 24 μF

≈

capacitor discharge

Cumulative ≈

for 10 μF on VGH and 24 μF on VGL

EN1 active after AVDD, VGH, and VCOM

decay to <10%, and VGL decays to <30%,

of their target values

13 ms capacitor discharge

DVDD

Device enters

sleep mode

Notes:

• All exponential decays are based on external capacitance and internal pull-down resistance

(250 Ω each for AVDD, VCOM, VGH, and VGL). The external DC load is assumed to be off or

negligible.

• If any of the outputs AVDD, VCOM, or VGH does not decay to below 10% of target voltage

after 50 ms, starting from EN2 is low, it is by-passed and the rest of the shutdown sequence

continues without it.

• For VGL, the shutdown detection threshold is set at 30%. Only if the magnitude of VGL has

dropped below 30%, when EN1 goes low the IC will shut down completely. After shutdown, all

internal pull-down resistors are released, and output capacitor voltages will decay according to

external load resistances.

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

13

Page 14

A8601

Multiple-Output Regulator for Automotive LCD Displays

Typical Load Current during Normal Operation

500 mA

100 mA

30 mA

AVDD

I

AVDD(av)

= 140.25 mA

3.2 μs3.2 μs

31.8 μs

VGH

I

= 7.9 mA

VGH(av)

30 mA

4 mA

50 mA

VGL

I

= 8.9 mA

VGL(av)

6 μs6 μs

31.8 μs

VCOM

I

VCOM(av)

= 18.3 mA

4 mA

4.8 μs4.8 μs

31.8 μs

15 mA

6 μs6 μs

63.6 μs

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

14

Page 15

A8601

Multiple-Output Regulator for Automotive LCD Displays

Functional Description

The A8601 is a flexible multi-voltage regulator designed for

LCD panel bias applications. It utilizes a high-efficiency boost

converter, together with space-saving low-dropout regulator and

charge pump circuits to provide five independently-adjustable

voltage outputs:

• DVDD: Typically 3.3 V. Nominal output current 20 mA,

maximum 100 mA. This output is from a low-dropout regulator

(item 1 in the Functional Block Diagram) powered by VIN. It is

available while EN1 is high.

• AVDD: Typically between 5 and 13.3 V. Nominal current

100 mA. This output is from a low-dropout regulator (item 2 in

the Functional Block Diagram) powered by VOUT. It is only

available when both EN1 and EN2 are high.

• VCOM: Typically between 3 and 6 V at 50 mA. This voltage

is programmable by applying a control voltage at the VINAMP

pin (1.5 to 3.2 V from the application microprocessor). The

power supply of this regulator is internally connected to AVDD.

• VGL: Typically between –11 and –5.4 V at 4 mA. This voltage

is generated by an inverted charge pump, which is powered by

VOUT.

• VGH: Typically between 14.5 and 24.6 V at 4 mA. This voltage

is generated by a 2X charge pump, which is powered by VOUT.

Linear Regulators

The A8601 uses low-dropout linear regulators (LDO) to provide DVDD from VIN, and AVDD from boost output voltage. A

representative block diagram is shown in figure 1. Each LDO is

protected against output short or over-loading by its own internal

OCP limits. Refer to the Fault Conditions section for details.

The AVDD circuit monitors the voltage drop across its LDO

(item 2 in the Functional Block Diagram). If this voltage drop is

less than 2 V, the AVDD circuit sends a control signal to cause

the boost voltage to increase. This ensures there is always enough

headroom for regulation.

VCOM Regulator

The VCOM output voltage is determined by the input voltage of

VINAMP (see figure 2), according to the following relation:

V

VCOM

= V

× 1.94 (1)

VINAMP

FB2

A8601

AVD D Re gulator

5 kΩ

AGND

PMOS

Fr om boost out put

Rsc

250 Ω

To boost

controller

AVDD

Enable

V

VIN

Fold

back

30 kΩ

+

2.4 V

–

+

–

+

–

Discharge

OCP

VINAMP

A8601

VCOM R egulator

Trimmed

resistor

divider

100 kΩ

GNDVCOM

Enable

V

OUT

Fold

back

Figure 1. Representative linear regulator (AVDD shown) Figure 2. VCOM regulator

PMOS

From AVDD

Rsc

250 Ω

To boost

controller

OCP

+

–

+

–

Discharge

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

VCOM

15

Page 16

A8601

Multiple-Output Regulator for Automotive LCD Displays

The valid range for VINAMP is between 1.5 and 3.2 V, which

gives a V

least 1.5 V higher than V

range of 2.9 to 6.2 V (provided that AVDD is at

VCOM

). Beyond this range, the linearity

VCOM

of VCOM cannot be guaranteed.

The supply voltage of VCOM is taken from AVDD. In order to

ensure there is enough headroom, AVDD must be at least 1.5 V

higher than VCOM

.

During the startup sequence, VCOM is allowed to ramp up

only after VGH has reached 90% of its target voltage. A valid

VINAMP must be asserted prior to VCOM ramp up. If VINAMP

starts low (< 1.2 V), the A8601 waits as long as 50 ms for a valid

VINAMP to be asserted. If VINAMP is not asserted by that time

limit, a fault is generated.

If VCOM is not required, the VCOM pin can be left open, but a

small output capacitor (approximately 0.1 μF) must be present to

prevent oscillation. Make sure to connect VINAMP to a suitable

voltage such as DVDD at 3.3 V. The connection to DVDD can

be divided as shown in figure 3, according to the AVDD level

required.

Charge Pumps

The A8601 uses a 2X charge pump to generate VGH from boost

voltage, and an inverting charge pump to generate VGL . Representative block diagrams are shown in figure 4.

The frequency of the charge pumps is the same as the boost

switching frequency (or external SYNC frequency)

10 kΩ

40.2 kΩ

DVDD

3.3 V

VINAMP

DVDD

3.3 V

VINAMP

2.45 V

100 kΩ

100 kΩ

A8601

A8601

AVD D

>7 V

C

VCOM

0.1 μF

GNDVCOM

AVD D

5 V

C

VCOM

0.1 μF

GNDVCOM

When an external SYNC signal is used, it is internally converted

into a clock signal with the same frequency, but at 50% duty

cycle.

Recommended values of the external flying capacitor, C

FLYx

, on

Figure 3. Configuration for unused VCOM: (upper panel) V

(lower panel) V

AVDD

= 5 V.

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

AVDD

> 7 V, and

16

Page 17

A8601

Multiple-Output Regulator for Automotive LCD Displays

A8601

VGH R egulator

V

VIN

Enable

FB4

5 kΩ

55 kΩ

Figure 4A. 2X charge pump for VGH regulator

A8601

VGL R egulator

Enable

FB3

2.4 V

AGND

1.8 V

From boost output

+

–

Linear

Regula tor

From boost output

+

–

Linear

Regula tor

OCP

OCP

2X Charge

Pump

D1

S2

S1

Discharge

1X Charge

Pump

S1

S2

D1

Discharge

Switching Sequence:

To boost

controller

D2

250 Ω

To boost

controller

250 Ω

• S1 closed and D1 charges C

• S2 closed and D2 dumps C

C

FLY1

+

CP12

CP11

VGH

Switching Sequence:

• S1 closed and D1 charges C

• S2 closed and D2 dumps C

C

FLY2

+

CP21

D2

CP22

VGL

(Si)

FLY1

FLY1

FLY2

FLY2

to VGH

to VGL

AGND

Figure 4B. Inverting (negative) charge pump for VGL regulator, AC version

A8601

VGL Regulator

Enable

FB3

1.8 V

AGND

From boost output

+

–

Linear

Regula tor

OCP

Switching Sequence:

To boost

1X Charge

Pump

S1

S2

D1 D2

Di schar ge

controller

250 Ω

• S1 closed and D3 charges C

• S2 closed and D2 dumps C

CP21

CP22

VGL

FLY2

to VGL

FLY2

C

FLY2

+

D3

(Si)

(Si)

Figure 4C. Inverting (negative) charge pump for VGL regulator, AC version full output current (14 mA)

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

17

Page 18

A8601

Multiple-Output Regulator for Automotive LCD Displays

the CPxx pins depends on the switching frequency as shown in

the following table; a voltage rating of 25 V is sufficient:

Switching Frequency

(MHz)

2 ≈ 0.1

1 0.22

0.350 0.47

C

(μF)

FLYx

For the inverted (negative) charge pump, an external silicon diode

is used between the VGL and CP22 pins. However, at high temperatures and switching frequencies (such as 125°C and 2 MHz),

the maximum VGL output current is limited to about 8 mA. To

achieve the full output current, 14 mA, it is necessary to use two

external diodes, as shown in figure 4C.

The value of the flying capacitor can be calculates as follows:

1. The equivalent series resistance of the flying capacitor is:

ESR

= 1 / ( fSW × C

FLY2

) (2)

FLY2

2. Assuming a flying capacitor ripple voltage of 100 mV, and a

maximum output current of 20 mA, the series resistance is:

R

= 0.1 (V) / 0.02 (A) ≤ 5 Ω

FLY2

3. Therefore at an fSW of 2 MHz, the required capacitance,

C

, is 0.1 μF.

FLY2

Boost Controller

The A8601 contains an integrated DMOS switch and PWM

controller to drive a boost converter. The input voltage, V

(5 V nominal) is boosted to an intermediate voltage, V

OUT

,

VIN

, which

is the lowest voltage required to keep all outputs within regulation. That is, the effective boost voltage is the highest of the boost

requirement of the individual regulators, as illustrated in figure 5.

For example: assume the output requirements for a certain LCD

panel are: V

• AVDD (LDO 2): V

• VGH (2X Charge Pump): V

AVDD

= 10 V, V

≥ V

OUT

= 18.5 V and V

VGH

+ 2 (V) = 12 V

AVDD

≥ 0.5 × V

OUT

VGL

+ 2.4 (V) =

VGH

= –7 V, then:

11.65 V

• VGL (Inverted Charge Pump): V

OUT

≥ –V

+ 3.6 (V) =

VGL

10.6 V

In this example, AVDD has the highest requirement, so the

intermediate voltage will be regulated at a V

mately. However, if V

were increased to 23 V, it would be the

VGH

of 12 V approxi-

OUT

highest, and then the boost converter would increase the intermediate voltage to 13.9 V to satisfy the charge pump circuit.

16

14

(V)

12

10

BOOST

8

V

BOOST(VGL)

( –V

6

4

Boost Voltage, V

2

0

-12-10-8 -6 -4-2 0 2 4 6 8 101214161820222426

Figure 5. Boost voltage requirement with respect to VGL, AVDD, and VGH

VGL

+ 3.6 V)

V

BOOST(AVDD)

+ 2 V)

(V

AVDD

Regulated Output (V)

V

BOOST(VGH)

(V

VGH

/ 2 + 2.4 V)

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

18

Page 19

A8601

Multiple-Output Regulator for Automotive LCD Displays

A block diagram of the A8601 boost controller circuit is shown

in figure 6. The external COMP capacitor, C

, is typically a

COMP

0.1 to 1 μF MLCC.

The controller is protected against overvoltage and overcurrent

fault conditions.

• The OVP threshold, V

, is internally set at approximately

SW(OVP)

19 V typical. Under normal operating conditions, the boost voltage should always be lower than 16 V (as shown in figure 5), so

only in the event of a fault will OVP be tripped (for example:

output diode open, or wrong sense resistor values).

• The switching current limit,

I

, is protected by a pulse-

SW(MAX)

by-pulse OCP threshold (1.5 A typical). In the event of a heavy

load or during a transient, the SW peak current may reach OCP

level momentarily. In this case, the present on-time period

is terminated immediately, but no signal is generated on the

¯F¯ ¯A¯ ¯U¯ ¯L¯ ¯T¯

pin.

• In the event of a catastrophic failure (such as shorted inductor),

the SW current may exceed 150% of the OCP threshold. In this

case, the IC is shut down immediately.

Switching Frequency

The boost stage switching frequency, fSW , of the A8601 can

be programmed by using an external resistor between the

FSET_SYNC pin to GND, or it can be synchronized to an external clock frequency between 350 kHz and 2.25 MHz.

During startup, the A8601 senses the FSET_SYNC pin for any

external SYNC signal. If periodic logic transitions are detected

(Low < 0.8 V or High > 1.8 V), this is evaluated as an external

clock signal, and the boost switching frequency is synchronized

to it. If no periodic signal is detected, the bias current flowing

through FSET_SYNC pin is used to determine the switching frequency. The bias current is set by an external resistor, R

the FSET_SYNC pin. The relation between R

and switching

FSET

FSET

, on

frequency is given as:

R

where R

is in kΩ and fSW is in MHz.

FSET

= 10.21 / (f

FSET

– 0.0025) (3)

SW

This relationship is charted in figure 7. For example, to get a

switching frequency of 2 MHz requires an R

2.4

2.2

2.0

1.8

1.6

1.4

1.2

(MHz)

1.0

sw

f

0.8

0.6

0.4

0.2

0

0 5 10 15 20 25 30

Figure 7. Switching frequency versus FSET resistance

R

FSET

(kΩ)

of 5.11 kΩ.

FSET

C

A8601

AVDD

VGH

VGL

COMP

COMP

Figure 6. Boost controller circuit

Slope

Compensation

Oscillator

Transconductance

Multi-Input

Amplifier

G

m

Enable

PWM

Control

–

+

SW

DMOS

R

SC

PGND

OVP

OCP

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

19

Page 20

A8601

Multiple-Output Regulator for Automotive LCD Displays

Suppose the A8601 is started up with a valid external SYNC signal, but the SYNC signal is lost during normal operation. In that

case, one of the following happens:

• If the external SYNC signal is high impedance (open), the

A8601 continues normal operation, at the switching frequency

set by R

. No ¯F¯ ¯A¯ ¯U¯ ¯L¯ ¯T¯ flag is generated.

FSET

• If the external SYNC signal is low (shorted to ground), the

A8601 begins a shutdown sequence, at the switching frequency

set by the internal 1 MHz oscillator. The ¯F¯ ¯A¯ ¯U¯ ¯L¯ ¯T¯ pin is pulled

low and the internal error counter is increased by 1.

Note: If the outcome of the second scenario is not acceptable,

the circuit shown in figure 8 can be used to prevent generating a

fault when the external SYNC signal goes low. When the circuit

is used, after the external SYNC signal goes low, the A8601 will

continue to operate normally at the switching frequency set by

R

. No ¯F¯ ¯A¯ ¯U¯ ¯L¯ ¯T¯ flag is generated.

FSET

Continuous Conduction Mode Operation

It is often preferable for a boost converter to operate in continuous conduction mode (CCM) in order to reduce switching noise

and input ripple. However, whether the converter can operate in

CCM or discontinuous conduction mode (DCM) is determined by

many parameters, including input/output voltages, output current,

switching frequency, and inductor value. This is explained as follows, using simplified basic equations for a boost converter (refer

to figure 9):

During SW on-time, t

i

ON

:

ripple

= V

= V

/ L × t

VIN

/ L × T × D (5)

VIN

(4)

ON

where T is the switching period of the boost converter and D is

the duty cycle, t

ON

/ T.

During SW off-time, t

i

ripple

= (V

= (V

OFF

OUT

OUT

:

+ V

D1

+ VD1 – V

– V

) / L × t

VIN

) / L × T × (1 – D) (7)

VIN

(5)

OFF

therefore:

V

OUT

+ V

D1

= V

× 1 / (1 – D) (8)

VIN

In order to operate in CCM, the minimum inductor current must

be greater than zero amperes. This means:

i

i

(min) = iSW(av) – i

SW

≤ 2 × i

ripple

SW

(av)

/ 2 ≥ 0, or (9)

ripple

Average input current is directly related to the input power and

voltage, as given by:

iSW(av) = P

VIN

/ V

VIN

= (P

OUT

/ η ) / V

(10)

VIN

where η is the efficiency of the boost converter (typically around

80%). Ripple current is determined by inductance, period, and

duty cycle, as given by:

i

where D is 1 – V

V

OUT+VD

VIN

C

VIN

A8601

V

SW

ripple

/(V

= V

OUT

VIN

/ L × T × D (11)

VIN

+ VD1) from equation 8.

LD1

SW OUT

DMOS

PGND

V

OUT

C

OUT

i

SW

iSW(max)

(av)

i

SW

i

(min)

SW

0

i

ripple

t

t

Switching Period, T

t

ON

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

t

OFF

External

synchronization

signal

220 pF

Schottky

barrier

diode

Figure 8. Low FSET_SYNC signal fault counteraction circuit Figure 9. Continuous and discontinuous conduction mode factors

FSET_SYNC

R

10.2 kΩ

A8601

FSET

20

Page 21

A8601

Multiple-Output Regulator for Automotive LCD Displays

For a given V

VIN

and V

, the duty cycle is fixed. Furthermore,

OUT

for a given output power, the average input current also is fixed.

Therefore the only way to reduce ripple current is either to switch

at a higher frequency (a shorter period) or to use a larger inductance.

Figure 10 shows that the minimum inductance required to ensure

CCM operation increases with higher output voltage (hence also

with higher duty cycle), for a boost regulator with fixed input

voltage and output power. Note that the chart is calculated at an

of 1 MHz. If the frequency is reduced by half, to 500 kHz,

f

SW

the inductance requirement is doubled.

When selecting the boost inductor, pay attention to the following

parameters:

• Inductance. This usually determines whether the boost converter

operates in DCM or CCM. Refer to figure 10, or calculate minimum required inductance using the equations provided.

• DCR. Lower resistance is preferred to reduce conduction loss.

• Saturation current. I

should be greater than 1.5 A, and prefer-

SAT

ably 2 A.

• Heating current. I

HEATING

• Physical size. Smaller size typically means lower I

should be greater than 1.5 A

SAT

RMS

and

higher DCR.

The minimum SW on-time and off-time determine the range of

duty cycle, and hence the range of boost output voltage. They do

not affect whether the converter operates in CCM or DCM.

For example, assume fSW is 2 MHz (T = 500 ns), t

95 ns, and t

OFF(MIN)

D(min) = t

D(max) = 1 – t

Further, assume V

possible V

OUT

is 75 ns. Then:

/ T = 95 (ns)/ 500 (ns) = 19%

ON(MIN)

OFF(MIN)

VIN

/ T = 1 – 75 (ns)/ 500 (ns) = 85%

is 4.0 to 5.5 V and VD1 is 0.4 V. Then the

is between 6.4 and 20.7 V. This is wider than the

ON(MIN)

is

range required by individual regulators under all possible output

combinations. Therefore the minimum on-time and off-time are

not limiting factors in output regulation.

V

V

(min) = V

OUT

(max) = V

OUT

(max) × 1/(1 – D(min)) –VD1 = 6.4 V

VIN

(min) × 1/(1 – D(max)) –VD1 = 26.7 V

VIN

Input Disconnect Switch

The A8601 has a gate driver for an external PMOS, in order to

provide input disconnect protection function (figure11). During

normal startup, the PMOS is turned on gradually to avoid a large

inrush current. In the event there is a direct short at the boost

stage (either SW or OUT shorted to GND), a high input current

would cause the PMOS to turn off. See the Fault Conditions section for details.

The input disconnect current threshold is calculated by:

I

where V

= 100 mV typical.

INS(TH)

VIN(MAX)

= V

INS(TH)

/ R

(12)

INS

9

8

7

6

5

4

3

Inductance (μH)

2

1

0

10 11 12 13 14 15 16

(at V

= 5.5 V and fSW = 1 MHz)

VIN

P

= 1 W

OUT

P

= 1.33 W

OUT

= 2 W

P

OUT

Output Voltage (V)

R

100 mV

INS

VIN

+

–

+

–

Overcurrent

C

GS

(optional)

INS GATE SW OUT

Fault

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

V

S

A8601

Figure 11. Input disconnect switch circuitFigure 10. Minimum inductance for CCM as a function of output voltage

LD

V

IN

+

3.5 V

–

100 μA

+

–

Gate_OK

V

OUT

C

OUT

21

Page 22

A8601

Multiple-Output Regulator for Automotive LCD Displays

Under normal operation, the input current is protected by the

cycle-by-cycle boost switch current limit, I

SW(MAX)

,1.5 A (typ).

Only in the event of a direct short at the boost output (SW pin)

will the input disconnect switch be activated. Therefore the input

disconnect current threshold should be set slightly higher than the

switch current limit; for example, choose an R

set an I

VIN(MAX)

of 2 A approximately.

of 0.047 Ω to

INS

During a normal power-up sequence, as soon as EN1 reaches

high, the A8601 begins pulling the GATE pin low by a 100 μA

current. How quickly the external PMOS turns on depends on

the gate capacitance C

. If the gate capacitance is very low, the

GS

inrush current may momentarily exceed 2 A and trip the input disconnect protection. In this case, an external C

capacitor may be

GS

added to slow down the PMOS turn-on. A typical value of 4.7 nF

should be sufficient in most cases.

When selecting the external PMOS, check the following parameters:

• Drain-source breakdown voltage, V

(BR)VDSS

, should exceed

–20 V

• Gate threshold voltage should be fully conducting at VGS =

–4 V, and cut-off at –1 V

• R

is rated at VGS = –4.5 V or similar, not at –10 V; derate

DS(on)

for higher temperatures

FAULT Conditions

The A8601 has extensive fault detection mechanisms, to protect

against all perceivable faults at the IC level (pin open, pin short

to GND, pin short to neighboring pins, and so forth) and at the

system level (external component open/short, component value

changes from –50% to +100%, and so forth).

All feedback pins (FB1, FB2, FB3, and FB4) are monitored for

overvoltage and undervoltage faults during normal operation.

In case of an output short, or an open/short in the sense resistor

network, the magnitude of the sensed voltage may make a sudden

change that is either +20% over, or –20% under the target voltage. This will trigger the OVP/UVP fault and force the A8601 to

shut down.

OVP/UVP detections are disabled during the startup sequence. If

any output fails to reach 90% of its target voltage within a time-

t

out period,

(50 ms typical), a fault is generated and then the

SS(TO)

A8601 shuts down.

Each regulator output (DVDD, AVDD, VGH, VGL and VCOM)

is protected by its own independent overcurrent limit. When an

output current exceeds its limit, the corresponding regulator goes

into overcurrent protection mode to protect itself from damage.

See figure 11 for illustrations of the protection characteristics.

If the overcurrent condition persists for 50 ms, all regulators are

turned off following the normal shutdown sequence. The same

applies when there is an overvoltage fault detected at any of the

feedback pins, except that the offending regulator is turned off

immediately. The other outputs then shut down following normal

sequence.

In general, if a fault is detected, the A8601 halts operation and

pulls the ¯F¯ ¯A¯ ¯U¯ ¯L¯ ¯T¯

after a delay, t

pin low. It then attempts to restart operation

RESTART

, of 100 ms typical. Internally there is a

Fault counter that keeps track of how many times any fault has

occurred. If the Fault counter reaches eight, the A8601 is completely shut down. The Fault counter is cleared by a completed

shutdown sequence with EN1 = EN2 = low, or by a power reset

(V

drops below UVLO). During startup, all regulators go

VIN

through a soft-start process, to prevent excessive inrush current

from tripping OCP. The same applies to the turn-on of the external input disconnect PMOS.

V

,

DVDD

V

AVD D

Target

0

033 100

Output Current, I

Figure 11. Overcurrent protection characteristics for DVDD, AVDD, VCOM, VGH, and VGL

DVDD

, I

AVD D

(%)

V

VCOM

Ta rg e t

3 V

00

0 33 100

Output Current, I

VCOM

(%)

V

VGH,

V

VGL

Ta rg e t

0 100

Output Current, I

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

VGH

, I

(%)

VGL

22

Page 23

A8601

Multiple-Output Regulator for Automotive LCD Displays

Pre-Output Fault Detection

When EN1 turns on the A8601, a startup sequence is followed

before the regulators are powered up. The sequence checks for

General Fault Detection

The faults described in table 2 are continuously monitored,

whether during startup, normal operation, or shutdown.

extreme conditions and proceeds as described in table 1.

Table 1. Pre-Output Fault Detection Sequence

Step

Number

1 Check VIN UVLO A8601 remains powered-down until V

2 Power-up internal rail A8601 initializes. No

3 Check internal rail UVLO BIAS charges internal rail indefinitely, until V

Check all FBx pins for

4

short to GND

5 Turn on input disconnect Pull-down on GATE pin does not reach < V

6 Turn on DVDD FB1 pin does not reach >90% of target (2.4 V) after t

7 Turn on AVDD FB2 pin does not reach >90% of target (2.4 V) after t

8 Turn on VGL FB3 pin does not reach >90% of target (–1.8 V) after t

9 Turn on VGH FB4 pin does not reach >90% of target (2.4 V) after t

10 Turn on VCOM VCOM pin does not reach >90% of target (V

Step

Description

Fault Description

VIN

Any FBx pin is detected as shorted after t

is above V

BIAS

.Yes

SS(TO)

– 3.5 V after t

VIN

VINAMP

. No

UVLO

is above UVLO. No

.Yes

SS(TO)

.Yes

SS(TO)

.Yes

SS(TO)

.Yes

SS(TO)

.Yes

SS(TO)

× A

VCOM

) after t

.Yes

SS(TO)

Table 2. General Fault Detection

Fault Description A8601 Response to Fault Fault Tripped?

T

exceeded

TSD

V

, V

, V

, V

FB3

FB3

, or V

, or V

FB1

FB2

20% under target

V

, V

FB1

FB2

20% over target

V

reached

UVLO

BIAS UVLO

Overcurrent limit for i

i

, i

, i

AVDD

VCOM

exceeded

V

INS(TRIP)

V

SW(OVP)

I

SW(MAX) ×

exceeded

, or i

VGH

exceeded

exceeded

150% of OCP limit

FB4

FB4

DVDD

VGL

Shutdown using shutdown sequence.

Fault counter increased by one, retry after t

Shutdown using shutdown sequence.

Fault counter increased by one, retry after t

Over-target regulator rail shut down without shutdown sequence.

Other regulator rails shut down using shutdown sequence.

Fault counter increased by one, retry after t

RESET

RESET

RESET

.

.

.

Shutdown without using shutdown sequence.

Fault counter reset to 0, retry after t

RESET

.

Shutdown without using shutdown sequence.

Fault counter reset to 0, retry after t

,

Over-limit regulator rail goes into current fold-back or current limit.

Shutdown using shutdown sequence after t

Fault counter increased by one, retry after t

RESET

.

OCP(TO)

RESET

.

Shutdown without using shutdown sequence.

Fault counter increased by one, retry after t

RESET

.

Shutdown without using shutdown sequence.

Fault counter increased by one, retry after t

RESET

.

Shutdown without using shutdown sequence.

Fault counter increased by one, retry after t

RESET

.

Yes; ¯F¯ ¯A ¯U ¯¯L¯ ¯T¯ set during t

Yes; ¯F¯ ¯A ¯U ¯¯L¯ ¯T¯ set during t

Yes; ¯F¯ ¯A ¯U ¯¯L¯ ¯T¯ set during t

No

No

.

Yes; ¯F¯ ¯A ¯U ¯¯L¯ ¯T¯ set during t

Yes; ¯F¯ ¯A ¯U ¯¯L¯ ¯T¯ set during t

Yes; ¯F¯ ¯A ¯U ¯¯L¯ ¯T¯ set during t

Yes; ¯F¯ ¯A ¯U ¯¯L¯ ¯T¯ set during t

Fault

Tripped?

RESET

RESET

RESET

RESET

RESET

RESET

RESET

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

23

Page 24

A8601

Multiple-Output Regulator for Automotive LCD Displays

Application Information

Output Voltage Selection

Each output voltage of DVDD, AVDD, VGH, or VGL is selected

using a simple voltage-sensing (resistor divider) network, as

shown in figure 12.

In actual implementation there is a small bias current that is

flowing out from each positive FBx pin, and the direction is

reversed for any negative FBx pin. This is necessary to detect any

pin-open fault at an FBx pin. As shown in figure 13, a common

bias current is injected into both the (+) and the (–) terminals of

the operational-amplifier. Due to the principal of superposition,

the same set of equations as in figure 1 can be used to determine

values for R1 and R2 in figure 13.

VFB is the regulation voltage for the feedback pins, and it is specified as 2.40 V for FB1 (DVDD), FB2 (AVDD), and FB4 (VGH).

For FB3 it is specified as –1.80 V. The following considerations

affect voltage selection:

• To cancel the offset error introduced by input bias currents, and

to assure regulation loop stability, it is necessary to keep the

external equivalent resistance, that is, the parallel resistance of

R1 and R2, as follows:

Pin

FB1 (DVDD) 10 ± 1

FB2 (AVDD) 25 ± 1

FB3 (VGL) 50 ± 2.5

FB4 (VGH) 50 ± 2.5

Parallel Resistance

(kΩ)

• To reduce the mismatch error of the sensing network, consider

using 0.5% or 0.2% resistors for the resistor divider.

• To reduce effects of switching noises coupled into the FBx

pins, add an external filter capacitor (typically a 47 pF MLCC)

between the FBx pin and GND. The capacitor should be placed

as close as possible to the respective FBx pin.

Table 3 provides some examples of voltage sensing network

component values, using E96 1% resistors.

V

OUT

R2

V

R1

REF

R

Z

25 kΩ

FBx

FBx

A8601

A8601

5 kΩ

30 kΩ

V

AGND

5 kΩ

30 kΩ

V

AGND

REF

REF

Output voltage sensing network

V

= VFB × (R1 + R2) / R

+

–

+

–

OUT

where: VFB = V

Equivalent Circuit

R

= R1 × R2 / (R1 + R2)

Z

Combining the two equations:

= RZ × V

R

1

R

= R1 × V

2

where: RZ is 25 kΩ and

V

REF

/ V

OUT

/ (V

REF

is 2.4 V for AVDD

REF

REF

OUT

– V

2

REF

)

V

OUT

R1

R2

V

FBx

REF

FBx

R

Z

25 kΩ

A8601

A8601

i

BIAS

5 kΩ

30 kΩ

V

AGND

i

BIAS

5 kΩ

30 kΩ

V

AGND

REF

REF

V

V

BIAS

BIAS

i

BIAS

+

–

i

BIAS

+

–

Output voltage sensing network

V

= VFB × (R1 + R2) / R

OUT

where: i

Equivalent Circuit

R

Z

Based on the principle of

superposition, the same equations

can be used where i

R1 = RZ × V

R

2

where: RZ is 25 kΩ and

V

= 0 A

BIAS

= R1 × R2 / (R1 + R2)

/ V

OUT

= R1 × V

/ (V

REF

is 2.4 V for AVDD

REF

BIAS

REF

OUT

2

> 0 A:

– V

REF

)

Figure 12. The output voltage sensing network and the equivalent circuit Figure 13. The figure 12 circuits with the same bias current injected into

both inputs of the operational amplifier

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

24

Page 25

A8601

Multiple-Output Regulator for Automotive LCD Displays

Output Capacitance

The boost stage requires an output capacitor, C

OUT

. Use an

MLCC with a capacitance of approximately 4.7 to 10 μF and a

voltage rating of 25 V. The temperature rating should be either

X5R or X7R. Do not use Y5V, which has a very large variation

with temperature. Another point to note is the capacitance of

MLCC is specified at a 0 V bias. To account for the degradation

when the rated DC voltage is applied to an MLCC, the capacitance should be derated by as much as 50%. The derating factor

is typically less if the capacitor is physically larger (for example,

choose a 1206 package instead of an 0805) and has a higher voltage rating (for example, 50 V instead of 25 V).

To ensure system stability, each output (DVDD, AVDD, VGL,

VGH, and VCOM) is required to have an external MLCC with

a minimum output capacitance of 2 ±0.1 μF. However, greater

capacitance may be required to satisfy transient current requirements. This is illustrated in figure 14. The AVDD load current

makes a step from 100 mA (steady state current) to 500 mA, for

a duration of 3.2 μs only. Because the linear regulator for AVDD

takes a finite time to respond to this load change, the voltage dip

is determined primarily by the output capacitance, C

AVDD

.

The corresponding voltage step, dV1, is determined by the

ESR of the output capacitor. When using an MLCC with very

low ESR (several mΩ), this drop is only several mV and can

be omitted.

AVDD

Current,

I

(mA)

AVDD

500

di = 400 mA

100

0

μs

dt = 3.2

AVDD

Voltage

Targ et

Figure 14. AVDD output voltage transient caused by a step change

in load current

dV1

dV2

Period = 31.8 μs

dV1 = di × × ESR

dV2 = di dt / C

AVDD

t

t

Table 3. Examples of Sensing Network Component Values

Goal Output Values

Output

[Pin]

DVDD

[FB1]

AVDD

[FB2]

VGH

[FB4]

VGL

[FB3]

Note: Use of series E96 1% resistors assumed.

V

FBx

(V)

2.4 10 3.3 13.75 36.67 13.7 36.5 9.96 3.3 0.02

2.4 25

2.4 50

–1.8 50

RZ

(kΩ)

V

12.8 133.33 30.77 133 30.9 25.07 12.73 –0.55

14.5 302.08 59.92 300 59 49.3 14.6 0.71

24.6 512.5 55.41 511 54.9 49.57 24.74 0.56

–5.4 150 75 150 75 50 –5.4 0.00

–11 305.56 59.78 309 60.4 50.52 –11.01 0.08

OUT

(V)

7 72.92 38.04 73.2 38.3 25.14 6.99 –0.19

Calculated Resistor

Divider Values

R

(kΩ)

1

R

(kΩ)

Actual Resistor

Divider Values

2

R

1

(kΩ)

R

2

(kΩ)

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

Calculated Output Values

RZ

(kΩ)

V

OUT

(V)

V

OUT

Resistor

Divider

Error

(%)

25

Page 26

A8601

Multiple-Output Regulator for Automotive LCD Displays

The second voltage step, dV2, is determined by the output

capacitance. For example, assume C

= 20 μF, then:

AVDD

dV2 = 0.4 (A) × 3.2 (μs) / 20 (μF) = 64 mV

Operating with Separate VIN and Boost Supplies

If necessary, the A8601 can be powered by a 5 V LDO for VIN,

while the boost stage can be powered by a different supply such

as 3.3 V. This is illustrated in figure 15.

The LDO for VIN should have an output voltage of 5 V ±10%.

The LDO supply current is the sum of the A8601 bias current

(approximately 6 mA at 2 MHz) and the DVDD output current.

The boost supply voltage is independent from the VIN voltage.

A reasonable range for the boost supply is between 3.3 and 10 V.

The boost supply current is determined by the output power of

boost stage, as outlined in the Thermal Analysis section.

The boost output voltage, V

V

. Therefore it is necessary to keep the boost supply

BOOSTS

, is always higher than its input,

OUT

voltage below a certain level. This can be determined for a boost

converter as follows:

V

OUT

= V

/ (1 – D) (13)

BOOSTS

where D is the duty cycle.

Assume a boost PWM frequency of 2 MHz (period = 500 ns).

The A8601 minimum on-time, t

, is 95 ns worst-case. That

ON(MIN)

results in a minimum PWM duty cycle of 19%.

For a V

of 12 V, and a D of 0.19, the calculated V

BOOSTS

OUT

would be 14.8 V. This is higher than the 14 V required by the

A8601 output regulators in figure 15. Higher V

levels result

OUT

in excessive power loss and may trigger OVP at the SW pin.

Thermal Analysis

The thermal resistance, R

, of the TSSOP-28 thermally

θJA

enhanced package is 28°C/W. For long term reliability, the

package junction temperature should be kept at 150°C or below.

Assuming a maximum ambient temperature of 85°C, the power

dissipation budget, PD(max), is:

PD(max) = (TJ(max) – TA(max)) / R

(14)

θJA

= (150 (°C) – 85 (°C)) / 28 (°C/W) = 2.3 W

The power losses of the IC come from two main contributors, the

boost stage and the linear regulators. These losses are calculated

separately, then summed, as follows.

To estimate the dissipation of the boost stage, calculate and sum

the losses due to switching losses, P

the switch, P

P

COND

:

D(BOOST)

= P

, and conduction losses in

SW

+ P

COND

(15)

SW

1. Estimate the maximum output power for boost stage:

P

I

OUT

OUT

(max) = V

= I

AVDD

+ I

OUT

VCOM

(max) × I

+ I

VGL

(max) (16)

OUT

+ 2 × I

(17)

VGH

Based on the average load current waveforms during normal

operation (see Characteristic Performance section), the average output current for the boost stage is estimated to be:

I

= 140 (mA) +18.3 (mA) + 8.9 (mA) + (2 × 7.9 (mA))

OUT

≈ 183 mA

V

INS

8 to 16 V

LDO

Enable

Figure 15. Typical dual supply application

EN1

EN2

DVDD

FB1

5 V

VIN

A8601

V

BOOSTS

3.3 to 10 V

INS SW OUT

LD1

V

OUT

≈ 14 V

C

OUT

AVDD

12 V

VGH

23 V

VGL

–7 V

VCOM

≈4.2 V

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

26

Page 27

A8601

Multiple-Output Regulator for Automotive LCD Displays

So at a maximum V

P

(max) = 16(V) × 0.183 (A) = 3 W

OUT

of 16 V, the maximum P

OUT

OUT

is:

2. Estimate the maximum input current:

I

P

VIN

VIN

= P

= P

/ V

VIN

OUT

(18)

VIN

/ η (19)

where η is efficiency (%). Substituting into equation 10:

I

= (3 (W) / 0.85) / 4 (V) = 0.88 A.

VIN

3. Estimate conduction loss for the internal switch:

P

COND

D = 1 – V

= I

2

VIN

× R

VIN

× D (20)

DS(on)

/ (V

OUT

+ V

) (21)

D1

where VD1 is the forward voltage drop of the external boost

diode. Subsituting into equation 20:

P

= (0.88 (A))2 × 0.7 (Ω) × [1 – 4 (V) / (16(V) + 0.4 (V))]

COND

= 0.78 × 0.7 × 0.756 = 0.41 W

where R

is 0.5 Ω typical, plus 40% of typical for tem-

DS(on)

perature compensation at 125°C.

4. Estimate switching loss for the internal switch:

PSW = ISW × VSW × ( tr + tf ) × f

where tr is the rise time, and tf the fall time, of V

/ 2 (22)

SW

. Subtitut-

SW

ing into equation 14:

PSW = 0.88 (A) × 16.4 (V) × (10 (ns) + 10 (ns)) × 2 (MHz) / 2

= 0.29 W

Assuming I

V

equals I

SW

SW

VIN

= V

and

OUT

+ V

(23)

D1

Substituting into equation 7:

P

D(BOOST)

= P

COND

+ P

SW

= 0.41 (W) + 0.29 (W) = 0.70 W

Therefore a total of 0.70W is dissipated on the boost stage.

Note that this analysis is done under the worst-case combination

(maximum V

, minimum V

OUT

, maximum f

VIN

, and so forth).

SW

Under typical operating conditions, the power loss is lower.

The linear regulator power dissipations are the sum of the individual linear regulators:

P

D(LINREG)

= P

LDO1

+ P

LDO2

+ P

LDO3

+ P

LDO4

+ P

LDO5

(24)

Referring to the Functional Block Diagram notes, LDO1 is the

regulator for DVDD, LDO2 is the regulator for AVDD, LDO3

is the regulator for VGL, LDO4 is the regulator for VGH, and

LDO5 is the regulator for VCOM.

Estimate the maximum output power for each regulator as follows, using the same worst-case values as for the boost stage

calculations:

1. For DVDD:

P

LDO1

= (V

VIN

– V

DVDD

) × I

(25)

DVDD

Substituting into equation 17:

P

= (4 (V) – 3.3 (V)) × 20 (mA) = 0.03 W

LDO1

2. For AVDD (which is usually the largest contributor of power

loss):

P

I

LDO2

LDO2

= (V

= I

OUT

AVDD

– V

+ I

) × I

AVDD

(27)

VCOM

(26)

LDO2

Substituting into equation 18:

P

= (16 (V) – 10 (V)) × (140 (mA) + 18.3 (mA))

LDO2

= 0.95 W

3. For VGL (magnitude of VGL):

P

LDO3

= (V

OUT

– |V

VGL

|) × |I

| (28)

VGL

Substituting into equation 20:

P

= (16 (V) – 12 (V)) × 8.9 (mA) = 0.036 W

LDO3

4. For VGH:

P

LDO4

= (2 × V

OUT

– V

VGH

) × I

(29)

VGH

Substituting into equation 29:

P

= (2 × 16 (V) – (18.5 (V)) × 7.9 (mA) = 0.107 W

LDO4

5. For VCOM:

P

LDO5

= (V

AVDD

– V

VCOM

) × I

(30)

VCOM

Substituting into equation 30:

P

= (10 (V) – (4.5 (V)) × 18.3 (mA) = 0.101 W

LDO5

6. Finally, the IC consumes a bias current of approximately

6 mA from VIN when EN1 and EN2 are both high. This adds

power consumption of approximately 0.024 W at minimum V

VIN

.

Substituting into equation 16, including the bias currrent factor:

P

D(LINREG)

= 0.03 (W) + 0.95 (W) + 0.036 (W) +

0.107 (W)+ 0.101 (W)+ 0.024 (W)

= 1.25 W

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

27

Page 28

A8601

Multiple-Output Regulator for Automotive LCD Displays

Therefore the sum of the power dissipations for all of the linear

Component Selection Recommendations

regulators is 1.25 W.

The total power dissipation if the IC is then the sum of the boost

stage and the linear regulators: 1.95 W (0.70 W plus 1.25 W).

This corresponds to a temperature rise of 60°C. At an ambient

temperature of 85°C, the junction temperature could reach 140°C

Final component selection is dependent on many system parameters, such as switching frequency, output power, and PCB area.

The following recommendations should be used as a starting

point only.

under the above worst-case conditions.

Table 4. External Component Recommendations

Component Manufacturer Description

Renesas uPA1830

External PMOS

Boost Inductor

Output Diode ON-Semi MBR130 30 V, 1 A, V

Boost Output

Capacitor

Negative

Charge Pump

External Diode

Toshiba TPC8125

Fairchild FDS6675

Vishay IHLP2020BZER3R3M01 L = 3.3 μH, DCR = 79 mΩ (typ), I

TOKO D63CB #A916CY-6R2M L = 6.2 μH, DCR = 29 mΩ (typ), I

TDK SLF6045T-100M1R6-3PF L = 10 μH, DCR = 39 mΩ (typ), I

Sumida CDR7D28MNNP-15Ø N L = 15 μH, DCR = 65 mΩ (typ), I

Murata GRM31CR61E106KA12L 10 μF, 25 V, X5R, 1206

1N4148W Switching diode, 100 V, 0.15 A, CT = 2 pF, SOD-123

Rohm DAN217 Dual Switching diode, 80 V, 0.1 A, CT = 3.5 pF, SOT-346

V

(BR)VDSS