Page 1

A8500

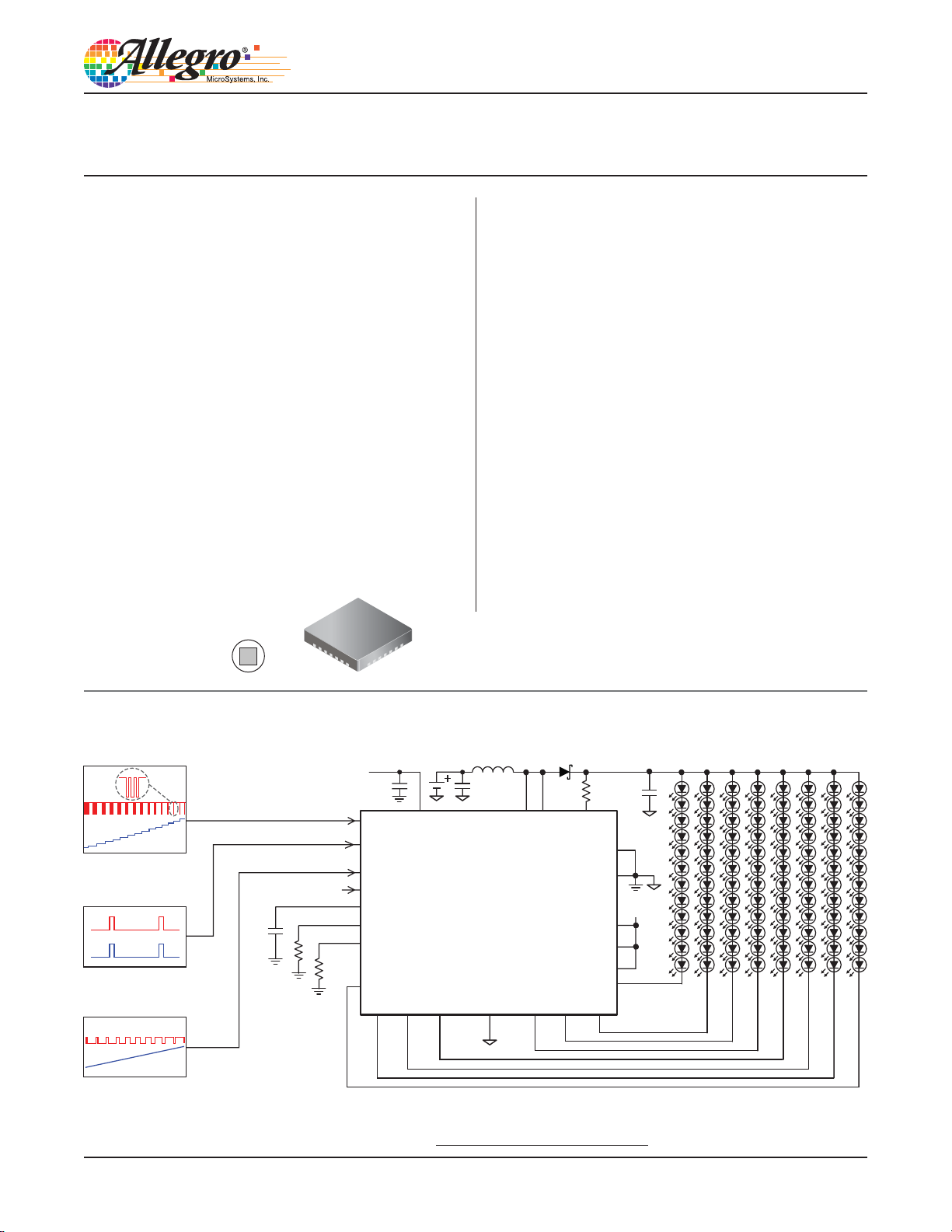

Flexible WLED/RGB Backlight Driver for Medium Size LCDs

Features and Benefits

▪ Active current sharing between LED strings for ±1.5%

typical current matching and ±1.2% typical accuracy

▪ Drive up to 12 series × 8 parallel = 96 LEDs

(Vf = 3.2 V, If = 20 mA)

▪ Flexible dimming, using alternative methods:

▫ LED duty cycle control (PWM pin)

▫ DC current using serial programming (EN pin)

▫ DC current using external PWM signal (APWM pin)

▫ An external resistor

▪ Boost converter with integrated 50 V, 2 A DMOS

▪ LED sinks rated for 25 mA

▪ 200 kHz to 2 MHz switching frequency

▪ Open LED disconnect

▪ Boost current limit, thermal shutdown, and soft start

▪ No audible ceramic capacitor noise during PWM dimming

▪ Adjustable overvoltage protection (OVP)

▪ No pull-up resistors required for LED modules that use

ESD capacitors

Package: 26 pin QFN/MLP (suffix EC)

Approximate Scale 1:1

Description

The A8500 is a multi-output WLED driver for medium display

backlighting. The A8500 integrates a boost converter and eight

current-sinks to provide a flexible WLED/RGB backlight

driver. The boost converter can provide output voltage up to

47 V. The flexible channel selection control and high voltage

capability allow a wide range of LED backlight applications.

The A8500 can support any application requiring 4 to 96

WLEDs. The boost converter is a constant frequency currentmode converter.

Each LED channel can sink 25 mA, and channels can be

paralleled for higher currents. Flexible dimming allows output

channels to either run at an adjustable DC value or with

externally controlled PWM duty cycles.

The A8500 is available in a 26 pin, 4 mm × 4 mm QFN/MLP

package that is only 0.75 mm nominal in height. Applications

include:

▪ Thin notebook displays

▪ LCD TV

▪ RGB backlight

▪ GPS systems

▪ Portable DVD players

EN pin dimming:

serial pulse train input

V

EN

I

OUT

PWM pin dimming:

digital PWM input

V

PWM

I

OUT

APWM pin dimming:

analog PWM input

V

APWM

I

OUT

Figure 1. LCD monitor backlight, driving 96 LEDs. LED Vf = 3.2 V, 20 mA per LED string. Overvoltage

protection set to 45 V nominal (40.5 V minimum). Alternative dimming control pulse trains illustrated

for EN, PWM, and APWM control. See also: Recommended Components table, page 14.

8500-DS, Rev. 2

T ypical Application

V

IN

5 V ±10%

C

0.1 μF/ 10 V

EN

PWM

APWM

SKIP

COMP

C

C

RFSET

FSET

ISET

RISET

LED1

LED3 LED5 LED7 LGND

V

BAT

5 to 25 V

IN

VIN SW SW OVP

L1

10 μH

C

BAT

1 μF/ 25 V

A8500

D1

ROVP

AGND

PGND

SEL3

SEL2

SEL1

LED2

LED8 LED6 LED4

COUT

2.2 μF

50 V

V

IN

Page 2

Flexible WLED/RGB Backlight Driver

A8500

for Medium Size LCDs

Selection Guide

Part Number Package Packing*

A8500EECTR-T 4 mm × 4 mm QFN/MLP 1500 pieces / 7-in. reel

*Contact Allegro for additional packing options

Device package is lead (Pb) free, with 100% matte tin leadframe plating.

Absolute Maximum Ratings

Characteristic Symbol Notes Rating Units

SW and OVP Pins –0.3 to 50 V

LED1 through LED8 Pins –0.3 to 23 V

VIN Pin V

IN

Remaining Pins –0.3 to V

Operating Ambient Temperature T

Maximum Junction Temperature T

(max) 150 ºC

J

Storage Temperature T

A

stg

Range E –40 to 85 ºC

–0.3 to 6 V

+ 0.3 V

IN

–55 to 150 ºC

Package Thermal Characteristics*

Characteristic

Package Thermal Resistance

*Additional information is available on the Allegro website

Symbol

R

JA

Note Rating Units

Measured on 3 in. × 3 in., 2-layer PCB 48.5 °C/W

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

2

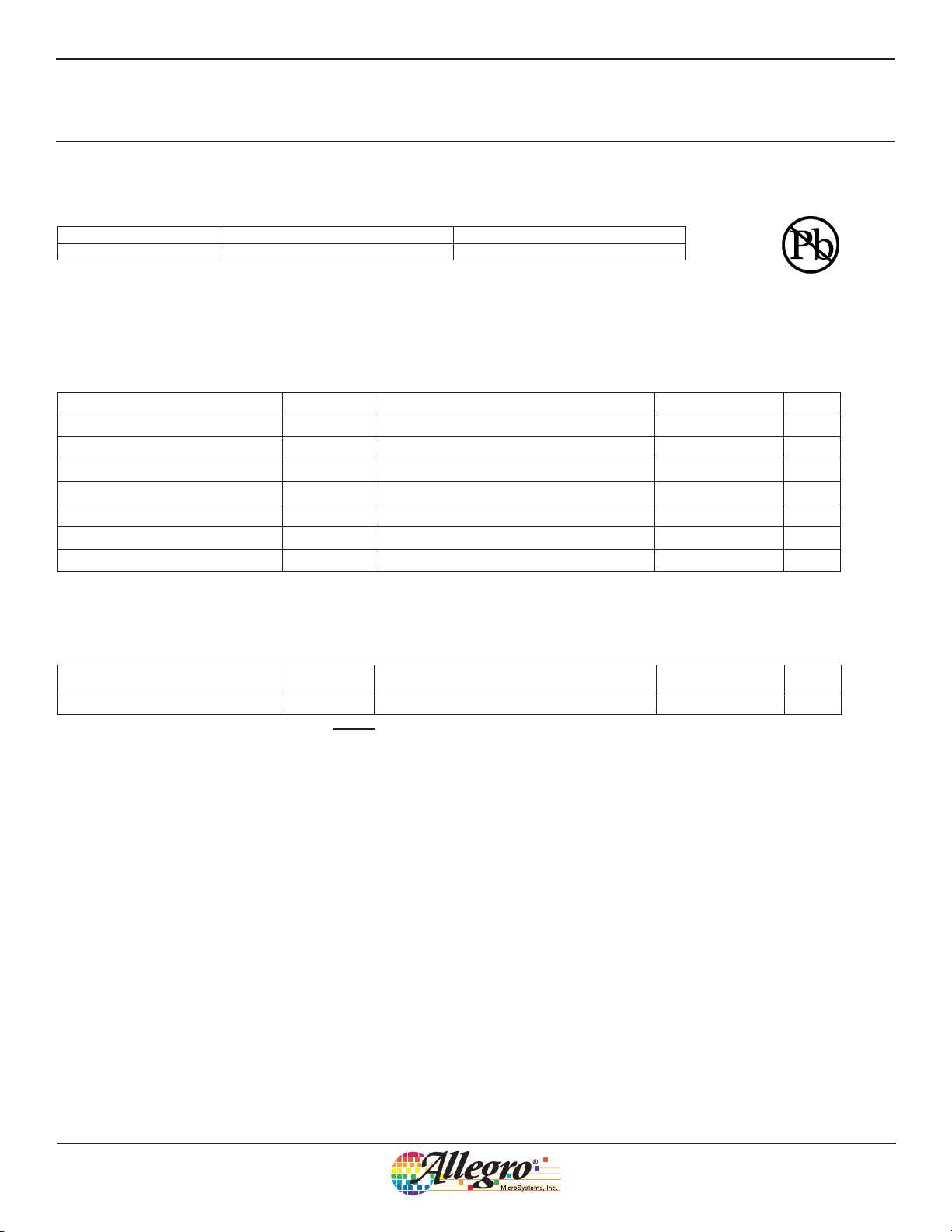

Page 3

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

Functional Block Diagram

V

IN

5 V ±10%

C

IN

R

R

FSET

ISET

COMP

C

C

AGND

APWM

SKIP

FSET

EN

SEL1

SEL2

SEL3

PWM

ISET

Reference

100 kΩ

100 kΩ

100 kΩ

Amp

VIN

and

Soft Start

On/Off

Serial Interface

PWM Generator

I

OUT_SET

100 kΩ

+

–

Feedback

Loop

L1

10 μH

SW

SW

D1

V

OUT

COUT

C

BAT

V

BAT

5 to 25 V

+

–

QSR

ROVP

+

∑

OSC

Current Sinks

–

PGND

OVP

LED1

LED2

LED3

LED4

LED5

LED6

LED7

LED8

LGND PGND

LGND

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

3

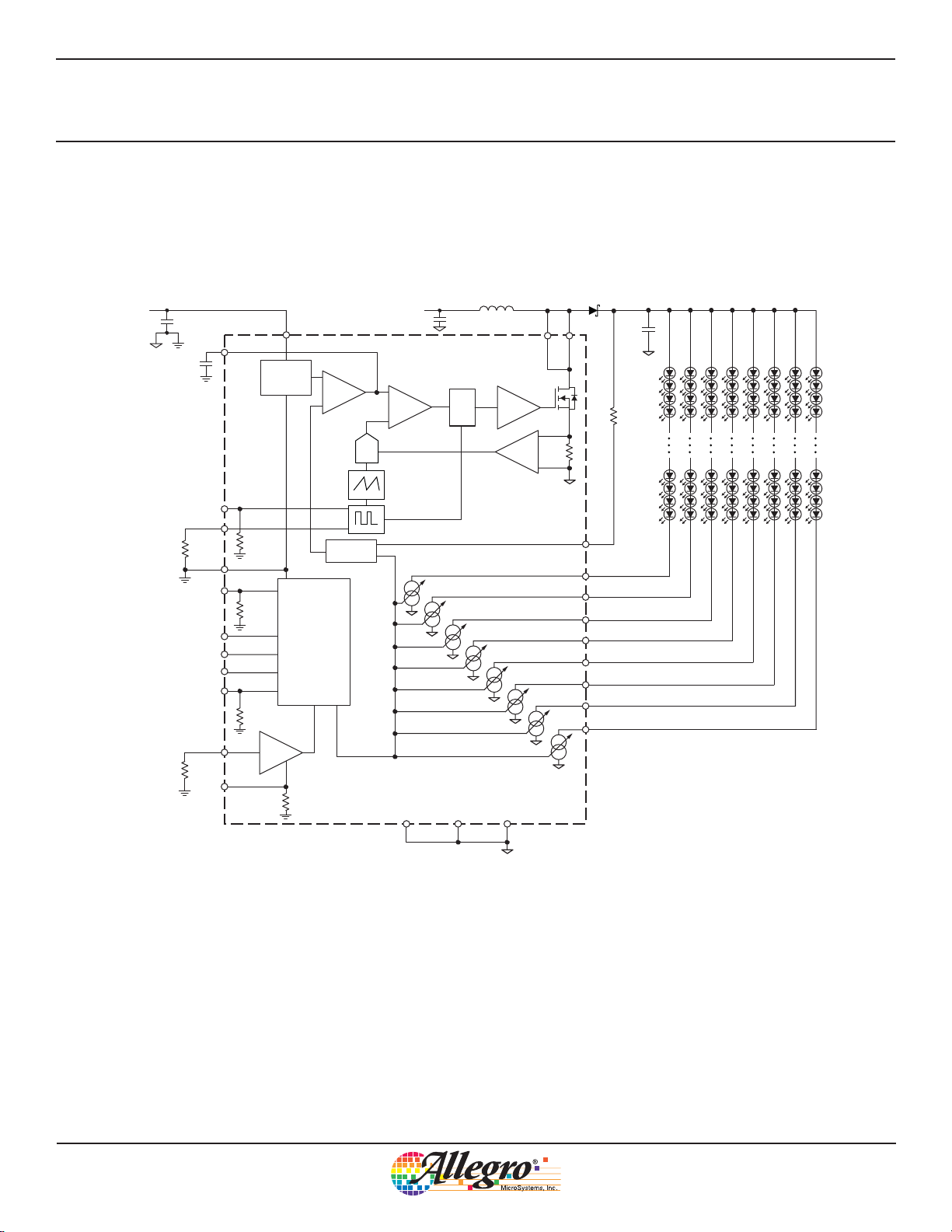

Page 4

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

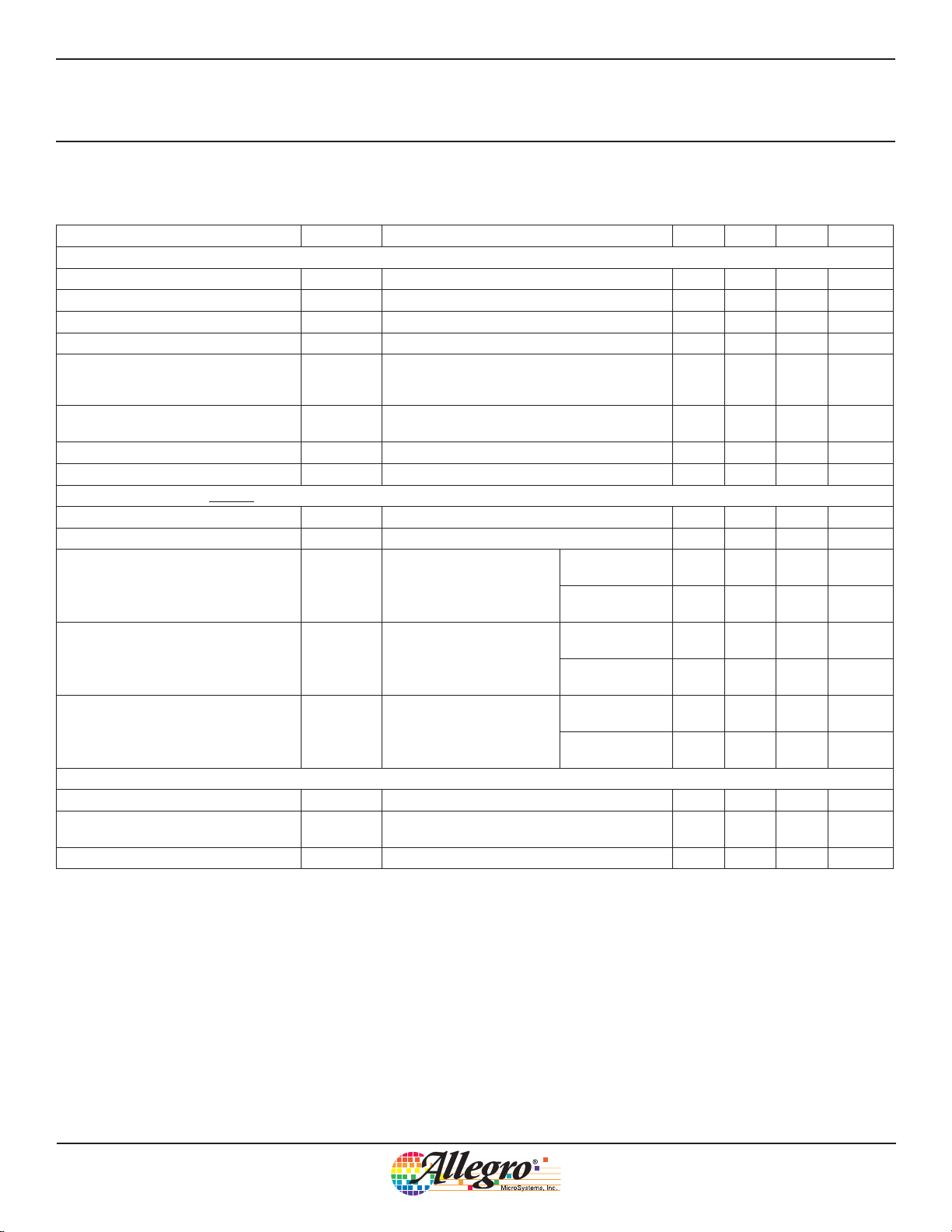

ELECTRICAL CHARACTERISTICS, valid at T

= –40°C to 85°C, typical values at TA = 25°C, VIN = 5 V, unless otherwise noted

A

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Input Voltage Range V

Undervoltage Lockout Threshold V

UVLO Hysteresis Window V

Supply Current I

APWM Frequency Range f

IN

UVLO

UVLOhys

SUP

APWM

VIN falling – – 4 V

Switching at no load, TA = 25°C – 5 – mA

Shutdown EN = PWM = APWM = V

IL

Error Amplifier

Error Amplifier Open Loop Gain A

Error Amplifier Unity Gain Bandwidth UGB

Error Amplifier Transconductance Gm

Error Amplifier Output Sink Current I

Error Amplifier Output Source Current I

VEA

EA

EA

EAsink

EAsource

I

= ±10 A – 850 – A/V

COMP

V

= 1 V – 280 – A

LED1-8

V

= 0 V – –280 – A

LED1-8

Boost Controller

R

= 13 k, SKIP = VIL 1.8 2 2.2 MHz

FSET

Switching Frequency f

Minimum Switch Off-Time t

SW

OFFmin

R

= 26.1 k, SKIP = VIL –1–MHz

FSET

R

= 32.4 k, SKIP = V

FSET

IH

Logic Input Levels (APWM , EN, MODE, PWM, SELx, and SKIP pins unless otherwise specified)

Input Voltage Level Low V

Input Voltage Level High V

Input Leakage Current (APWM, EN,

PWM, and SKIP pins)

Input Leakage Current (SELx pins) I

IL

IH

I

Ileak

SELleak

V

= 5 V, TA = 25°C – – 100 A

I(pin)

Over Voltage Protection (OVP)

Output Overvoltage Rising Limit V

OVP Sense Current I

OVP Release Current I

OVP Leakage Current I

OVP

OVPH

OVPL

OVPleak

V

= 21 V – 0.1 – A

VOP

Boost Switch

Switch On Resistance R

Switch Leakage Current I

Switch Current Limit I

ds(on)

SWleak

SWlim

I

= 1.5 A – 225 – m

SW

V

= 5 V, TA = 25°C – – 1 A

SW

V

= 21 V – 1 – A

SW

4.2 – 5.5 V

– 0.2 – V

– 0.1 1 A

20 – 2000 kHz

–60– dB

–3–MHz

– 200 – kHz

–70– ns

– – 0.4 V

1.5 – – V

––1 A

28 – 32 V

– 54.9 – A

– 47.8 – A

1.8 2 – A

Continued on the next page…

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

4

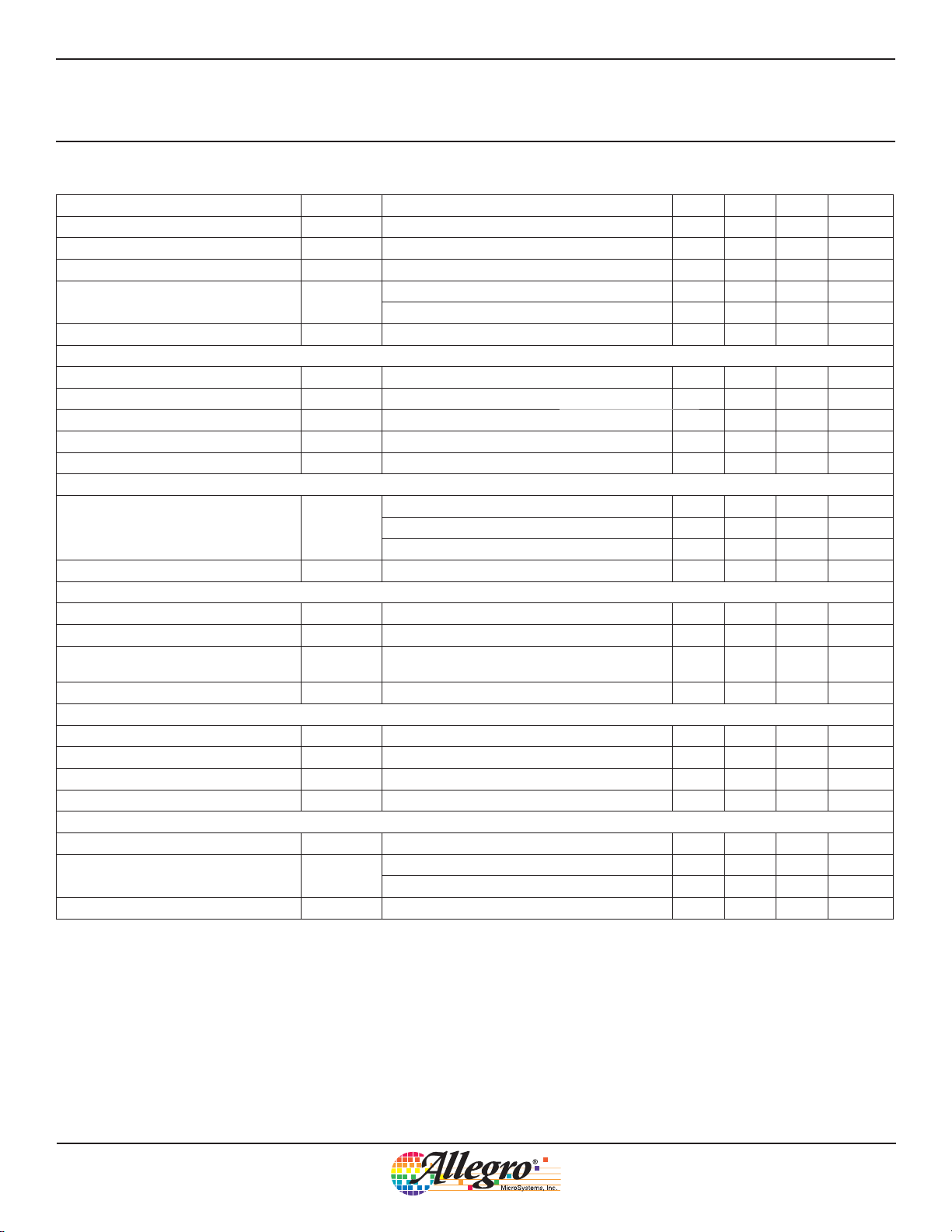

Page 5

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

ELECTRICAL CHARACTERISTICS (continued), valid at T

otherwise noted

Characteristics Symbol Test Conditions Min. Typ. Max. Units

LED Current Sinks

LEDx Regulation Voltage V

I

to I

SET

Current Gain A

LEDx

Voltage on ISET Pin V

I

Allowable Current Range I

SET

LEDx Accuracy Err

LEDx Matching

LEDx Switch Leakage Current I

LEDx Switch Leakage Current I

Serial Pulse Timing (see figure 4 for further explanation)

EN Pulse Low Time t

EN Pulse High Time t

Initial EN or APWM Pulse High Time (relative to switching period)

Level Change Delay (relative to switching

period)

Shutdown Delay (relative to switching

period on EN or APWM)

Soft Start

Soft Start Boost Current Limit I

Soft Start LEDx Current Limit I

Thermal Shutdown Threshold T

LEDx

I

ISET

ISET

SET

LEDx

LEDx

LSleak5

LSleak21

LO

HI

t

HI(init)

t

HID

t

SHDN

SWSS

LEDSS

40°C hysteresis – 165 – °C

SHDN

= 100 A – 210 – –

SET

R

= 12 k; 100% current ratio,

ISET

measured as average of LED1 to LED8;

LED1 to LED8 = 0.5 V

I

= 100 A , 100% current ratio;

SET

LED1 to LED8 = 0.5 V

V

= 5 V, EN = PWM = APWM = 0, TA = 25°C – – 1 A

LEDx

V

= 21 V, EN = PWM = APWM=0 – 1 – A

LEDx

First EN or APWM pulse after

shutdown

Falling edge of EN or APWM

pulse

Initial soft start current for boost switch - 1 - A

Current through enabled LEDx pins during soft

start, R

= –40°C to 85°C, typical values at TA = 25°C, VIN = 5 V, unless

A

– 500 – mV

– 1.23 – V

40 – 120 A

– ±1.2 – %

– ±1.5 – %

0.5 – 100 s

0.5 – 100 s

SKIP = Low – 256 –

SKIP = High – 64 –

SKIP = Low – 256 –

SKIP = High – 64 –

SKIP = Low – 256 –

SKIP = High – 64 –

ISET

=12 k

- 1.25 - mA

Switching

Pulses

Switching

Pulses

Switching

Pulses

Switching

Pulses

Switching

Pulses

Switching

Pulses

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

5

Page 6

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

Performance Characteristics

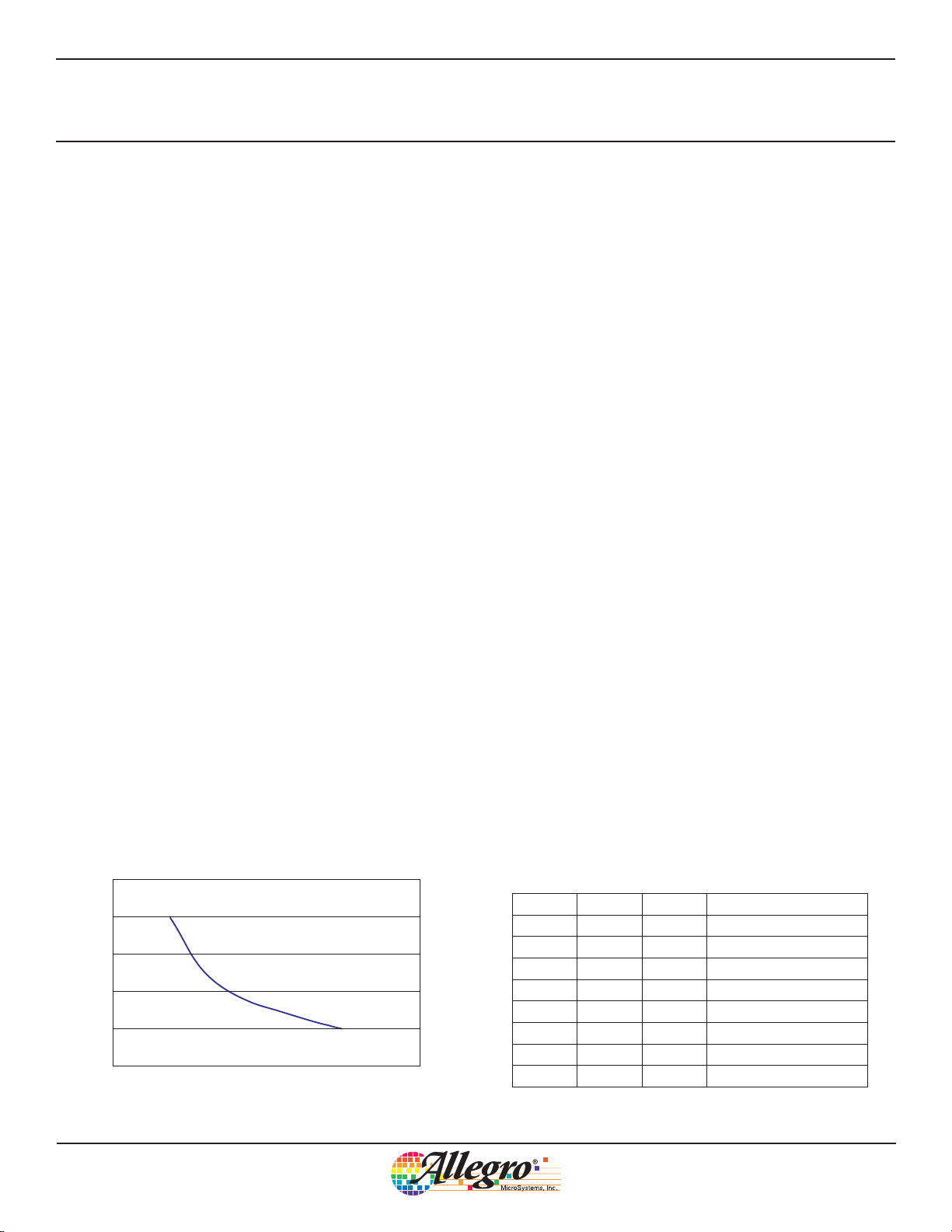

Efficiency with EN dimming is similar to that with APWM dimming. APWM light load

efficiency can be improved by reducing boost switching frequency with SKIP set high.

PWM Efficiency

V

= 5 V, 6 ch. with 7 LEDs per ch., 20 mA per ch., fSW = 1 MHz

IN

95

90

85

V

(V)

Eff (%)

80

75

70

0 20406080100

BAT

5

8.5

17.6

Duty Cycle (%)

APWM Efficiency

V

= 5 V, 6 ch. with 7 LEDs per ch., 20 mA per ch., fSW = 1 MHz

IN

100

90

80

V

70

Eff (%)

60

50

40

30

0 20406080100

(V)

BAT

5

8.5

17.6

Duty Cycle (%)

PWM Efficiency

V

= 5 V, 6 ch. with 7 LEDs per ch., 20 mA per ch., fSW = 2 MHz

IN

95

90

85

Eff (%)

80

75

70

0 20406080100

V

BAT

(V)

5

8.5

17.6

Duty Cycle (%)

APWM Efficiency

V

= 5 V, 6 ch. with 7 LEDs per ch., 20 mA per ch., fSW = 2 MHz

IN

100

90

80

V

70

Eff (%)

60

50

40

30

0 20406080100

(V)

BAT

5

8.5

17.6

Duty Cycle (%)

Efficiency versus Input Voltage with EN Dimming

V

= V

IN

95

90

85

80

Eff (%)

75

70

65

4.5 4.7 4.9 5.1 5.3 5.5

, 8 ch. with 8 LEDs per ch., fSW = 1 MHz

BAT

VIN (%)

I

LED

(mA)

1

10

20

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

6

Page 7

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

Performance Characteristics

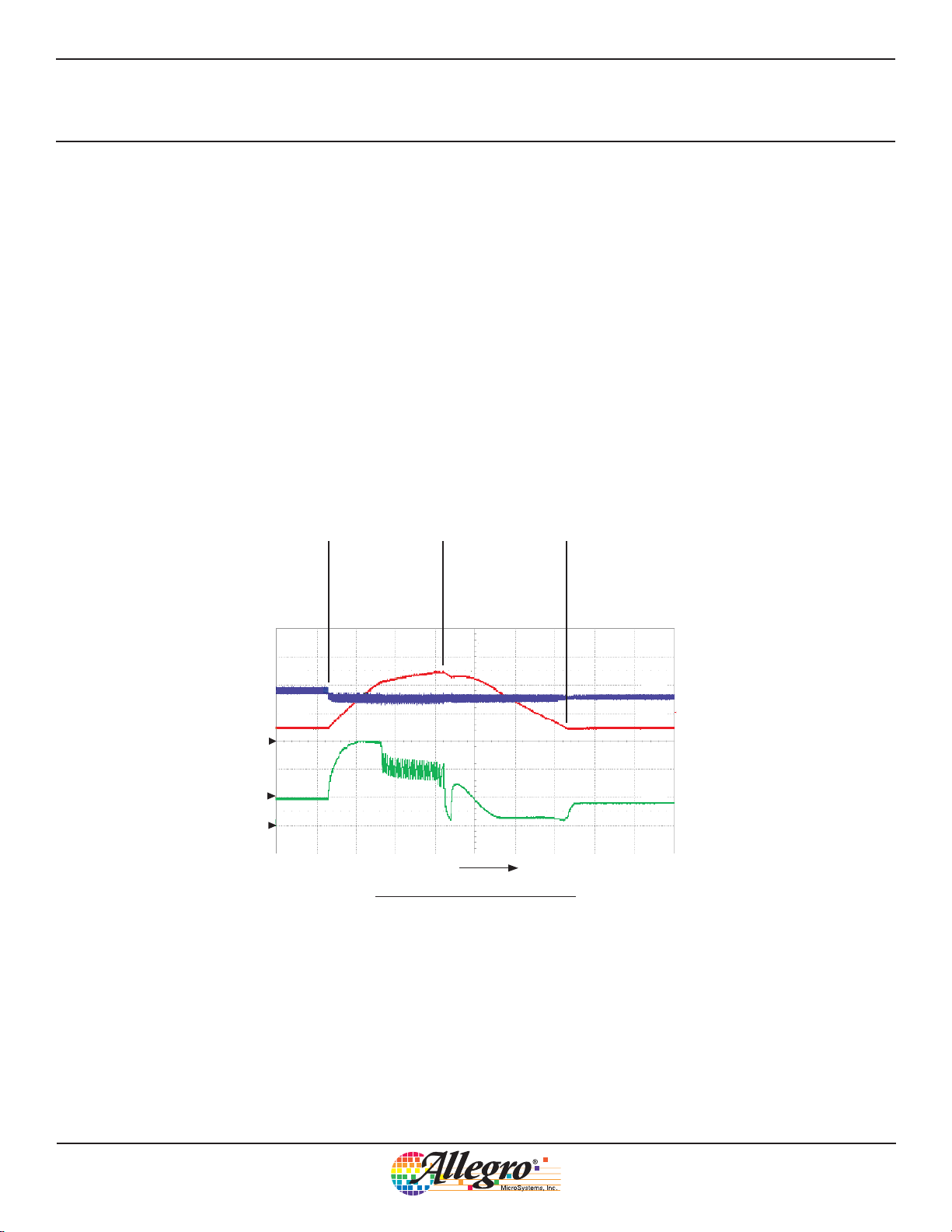

EN Pin Turn On

V

= V

IN

C1

C2

C3

C4

= 5 V; 8 ch., 8 LEDs per ch.

BAT

Symbol Parameter Units/Division

t t

C1 EN 5 V

C2 I

C3 V

C4 I

t time 500 s

OUT

OUT

IN

100 mA

10 V

1 A

EN

I

OUT

V

OUT

I

IN

C1

C2

C3

C4

PWM Turn On at 50% Duty Cycle

V

= V

IN

C1

C2

= 5 V; 8 ch., 8 LEDs per ch.

BAT

PWM

I

OUT

V

OUT

C1

C2

V

IN

PWM Turn On at 5% Duty Cycle

V

IN

EN Pin Turn Off

= V

= 5 V; 8 ch., 8 LEDs per ch.

BAT

Symbol Parameter Units/Division

C1 EN 5 V

C2 I

C3 V

C4 I

t time 100 s

= V

= 5 V; 8 ch., 8 LEDs per ch.

BAT

OUT

OUT

IN

100 mA

10 V

1 A

I

V

PWM

I

OUT

V

OUT

EN

OUT

OUT

I

IN

C3

C4

Symbol Parameter Units/Division

t t

C1 PWM 5 V

C2 I

C3 V

C4 I

t time 5 ms

OUT

OUT

IN

100 mA

10 V

1 A

I

IN

C3

C4

Symbol Parameter Units/Division

C1 PWM 5 V

C2 I

C3 V

C4 I

t time 10 ms

OUT

OUT

IN

100 mA

10 V

1 A

I

IN

APWM Turn On at 50% Duty Cycle

F

=100 kHz

APWM

C1

C2

C3

C4

Symbol Parameter Units/Division

t

C1 APWM 5 V

C2 I

C3 V

C4 I

t time 200 s

OUT

OUT

IN

100 mA

10 V

1 A

APWM

I

OUT

V

OUT

I

IN

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

7

Page 8

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

Functional Description

The A8500 is a multioutput WLED driver for medium display

backlighting. The A8500 works with 4.2 to 5.5 V input supply,

and it has an integrated boost converter to boost a 5 V battery

voltage up to 47 V, to drive up to 12 WLEDs in 6 series (Vf =

3.2 V, If = 20 mA), or 8 WLEDs in 8 series at 20 mA per LED

string. For higher LED power or more LEDs, an inductor can be

connected to a separate power supply, V

, from 5 to 25 V, with

BAT

the A8500 IC powered from a 5 V source. The LED sinks can

sink up to a 25 mA current.

The boost converter is a constant frequency current-mode converter. The integrated boost DMOS switch is rated for 50 V at

2 A. This switch has pulse-by-pulse current limiting, with the current limit independent of duty cycle. The switch also has output

overvoltage protection (OVP), with the OVP level adjustable,

typically from 30 to 47 V, as described in the Device Internal

Protection section.

The A8500 has individual open LED detection. If any LED

opens, the corresponding LED pin is removed from regulation

logic. This allows the remaining LED strings to function normally, without excessive power dissipation.

The switching frequency, fSW, can be set from 600 kHz to 2 MHz

by a single resistor, RFSET, connected across the FSET and

AGND pins, and with the SKIP pin set to logic low (see figure 2).

The switching frequency is set as:

FSW = 26.03 / R

where FSW is in MHz and R

is in kΩ When the SKIP pin is

FSET

FSET

,

connected to logic low, switching frequency is as set by RFSET.

When the SKIP pin is connected to logic high, the switching

frequency is divided by 4. The SKIP pin can be used to reduce

switching frequency in order to reduce switching losses and

improve efficiency at light loads.

The IC offers a wide-bandwidth transconductance amplifier with

external COMP pin. External compensation offers optimum performance for the desired application.

The A8500 has eight well-matched current sinks to provide regulated current through LEDs for uniform display brightness. The

quantity of LEDx pins used is determined by the SELx pins. Refer

to table 1 for further description.

The boost converter is controlled such that the minimum voltage

on any LEDx pin is 500 mV. In a typical application, the LEDx

pin connected to the LED string with the maximum voltage drop

controls the boost loop, so the remaining pins will also have the

higher voltage drop. All LED sinks are rated for 21 V, to allow

PWM dimming control.

LED Current Setting

The maximum LED current can be set at up to 25 mA per channel, by using the ISET pin. To set the reference current, I

SET

,

connect a resistor, RISET, between this pin and ground, valued

according to the following formula:

I

where I

is in mA and R

SET

= 1.23 / R

SET

ISET

is in kΩ.

ISET

,

2.5

2.0

1.5

(MHz)

SW

1.0

f

0.5

0

010 20304050 60 70

(kΩ)

R

FSET

Figure 2. Switching frequency setting by value of RFSET.

Table 1. LEDx Channel Enable Table

SEL1 SEL2 SEL3 LEDx Outputs

0 0 0 Only LED1 on

1 0 0 LED1 through LED2 on

0 1 0 LED1 through LED3 on

1 1 0 LED1 through LED4 on

0 0 1 LED1 through LED5 on

1 0 1 LED1 through LED6 on

0 1 1 LED1 through LED7 on

1 1 1 LED1 through LED8 on

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

8

Page 9

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

This current is multiplied internally with a gain of 210, and then

mirrored on all enabled LEDx pins. This sets the maximum current through the LEDs, referred to as “100% current.” The effects

of the value of R

are shown in figure 3.

ISET

The LED current can be reduced from 100% by any of three

alternative methods. These modes are:

serial dimming through the EN pin,

•

on/off control (PWM) with an external PWM signal on the

•

PWM pin, and

analog dimming with an external PWM signal on the APWM pin.

•

Note: Only one dimming technique can be used at a time.

Serial Dimming Through the EN Pin. When the EN pin is pulled

high with PWM, and the APWM pin is low, the A8500 starts

up in serial programming mode. In this mode, series of pulses

applied to the EN pin are used to adjust the output current level,

I

, to a proportion of the ISET current, in equal increments, as

LEDx

listed in table 2.

As shown in the timing diagram in figure 4, serial dimming is

disabled during startup, for the t

Table 2. Serial Dimming Levels

Pulse Count I

0 100% 8 100%×8/16

1 100%×15/16 9 100%×7/16

2 100%×14/16 10 100%×6/16

3 100%×13/16 11 100%×5/16

4 100%×12/16 12 100%×4/16

5 100%×11/16 13 100%×3/16

6 100%×10/16 14 100%×2/16

7 100%× 9/16 15 100%×1/16

*The counter resets on the sixteenth pulse.

Pulse Count I

LEDx

period. After that, the

HI(init)

16* 100%

LEDx

A8500 begins evaluating pulse patterns applied on the EN pin.

Until a valid series is evaluated, the count remains 0 and the

default I

level remains at “100% current.” A count in the

LEDx

range 1 to 15 is evaluated proportionately; for example, when

a series of 12 pulses is evaluated, I

4/16) of 100% current

. At a 16th pulse, the counter resets to 0 and

is set to 25% (100% ×

LEDx

continues to count if additional pulses are applied.

25

20

15

(mA)

10

OUT

I

5

0

010 20304050 60 70

R

(kΩ)

R

ISET

ISET

(kΩ)

V

(V)

IN

4.5

5.0

5.5

(A)

212

211

210

209

208

207

Gain

206

205

204

203

202

010 20304050 60 70

(B)

Figure 3. Effect of value of RISET on (A) “100% current” level, and

(B) LEDx gain.

t

Pulses

EN

I

LEDX

0

HI(init)

1234

t

LO

100% as set by R

100% ×1/16 level

Shutdown

Figure 4. Timing diagram for serial dimming.

ISET

123

81.2%

t

SHDN

Dimming

Counter

Reset

9

t

HID

Dimming

Counter

Reset

t

HI

75%

t

HID

Dimming

Counter

Reset

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

Page 10

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

To indicate the end of a programming sequence, set the EN pin

high for a period, t

, which is either (a) greater than 256 oscil-

HID

lator periods when the SKIP pin is high, or (b) greater than 64

oscillator periods when SKIP is low. When the A8500 evaluates

the end of a programming sequence, it changes the current level

to match the existing count (per table 2). The counter is then reset

to 0 and begins counting pulses again at the next valid pulse.

If the EN pin, along with the PWM and APWM pins, is pulled

low for period greater than t

, the A8500 shuts down. When

SHDN

the IC enters shutdown, LED1 through LED8 and the boost

switch turn off after the t

period. During t

SHDN

SHDN

, the con-

verter continues to work in normal fashion.

When enabled through the EN pin, internal references ramp up

during the t

period. The boost converter starts with soft

HI(init)

start to limit input inrush current. During soft start, the boost

stage is peak current limited to 1 A. All enabled LEDx sinks are

set to 1/16 of the set 100% current level, as V

and the volt-

OUT

age on the LEDx pins increases. When all LEDx pins reach the

regulation level of 0.5 V, the IC comes out of soft start, resuming

normal operation with 2 A current limit on boost and 100% current through LEDx pins. A typical step response in steady state is

shown in figure 5.

On/off Control (PWM) with an External PWM Signal on the

PWM Pin.

When the PWM pin is pulled high with the EN and

APWM pins low, the A8500 turns on and all enabled LEDx pins

sink 100% current. When the PWM pin is pulled low, the IC

EN

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 1 2 3 4 5 6 7 8 9 10 11 12 13 14 151

I

OUT

Figure 5. Serial dimming response. The numbers indicate the

quantity of EN pulses at each step.

shuts down with the LEDx pins disabled. External PWM applied

to the PWM pin should be in the range of 100 to 400 Hz for

optimal accuracy.

V

C1

C2

C3

t

Symbol Parameter Units/Division

C1 V

C2 I

C3 V

t time 1.00 ms

Figure 7. PWM pin dimming f

180

160

140

120

100

(mA)

80

OUT

I

60

40

20

0

0 20406080

f

PWM

OUT

OUT

PWM

PWM

(Hz)

100

500

Duty Cycle (%)

= 200 Hz, Duty Cycle =10%.

5.00 V

100 mA

1.00 V

Figure 8. PWM pin dimming linearity.

OUT

I

OUT

V

PWM

100

PWM

I

LEDx

6 μs

100% Current level

Figure 6. Timing diagram for dimming using the PWM pin.

Shutdown (0 μA)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

10

Page 11

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

At startup, the output capacitor is discharged and the IC enters

soft start. The boost current is limited to 1 A, and all active LEDx

pins sink 1/16 of the set 100% current until all of the enabled

LEDx pins reach 0.5 V. After the IC comes out of soft start, the

boost current and the LEDx pin currents are set to 100% current.

The output capacitor charges to the voltage level required to supply full LEDx current within a few cycles. The IC is shut down

immediately when PWM goes low.

Analog Dimming with an External PWM Signal on the APWM

Pin.

When the APWM pin is pulled high, with the EN and PWM

pins low, the A8500 turns on in this mode. The first pulse after

shutdown should be greater than t

signal applied to the APWM pin multiplies I

. The logic level PWM

HI(init)

by the duty cycle

SET

to set the reference current level for the LED pins. The typical

range for the APWM signal frequency is 20 kHz to 2 MHz. The

output current ripple at 20 kHz, 50% duty cycle, is less than 5%

of the set value. The LED current accuaracy at 2 MHz, 50% duty

180

160

140

120

100

(mA)

80

OUT

I

60

40

20

0

0 20406080

Figure 9. APWM pin dimming linearity.

f

APWM

(kHz)

20

100

500

100

Duty Cycle (%)

cycle, is less than 3%. In this mode, the A8500 goes through a

soft start routine similar to serial dimming.

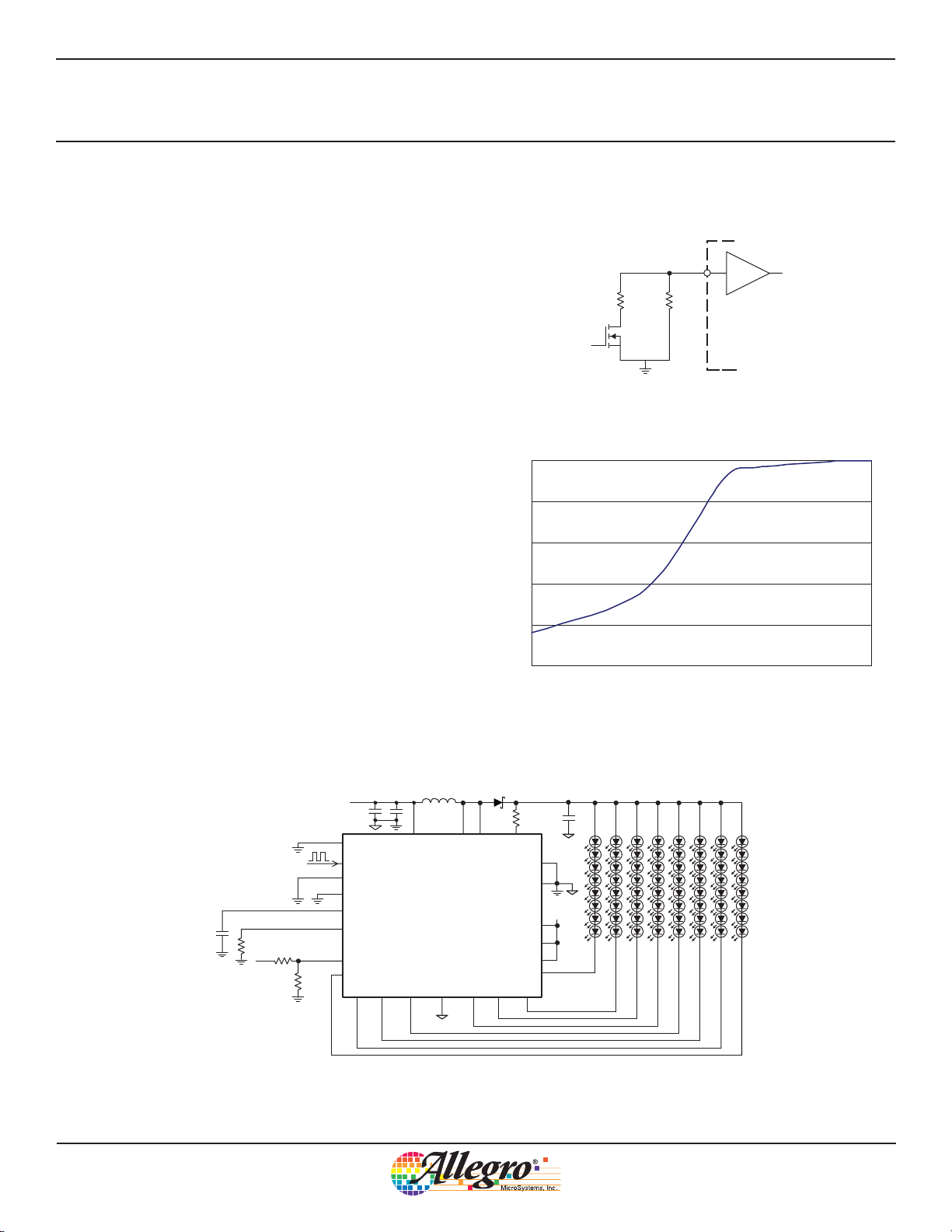

Device Internal Protection

Overcurrent Protection (OCP). The A8500 has a pulse-by-pulse

current limit of 2 A on the boost switch. This current limit is

independent of duty cycle.

Thermal Shutdown Protection (TSD). The IC shuts down when

junction temperature exceeds 165°C and restarts when the junction temperature falls by 40°C.

Overvoltage Protection (OVP). The A8500 has overvoltage

protection to protect the IC against output overvoltage. The overvoltage level can be set, from 30 to 45 V typical, with an external

resistor, ROVP, as shown in figure 10. When the current though

the OVP pin exceeds 54.9 μA, the OVP comparator goes high.

When the OVP pin current falls below 47.8 μA, OVP is reset.

22 kΩ

4.4 kΩ

D1

OVP

ROVP

V

OUT

DZ

A

COUT

V

IN

SW SW

OVP

Disable

28.8 V

–

+

1.23 V

Figure 10. Overvoltage protection circuit. Three alternative

configurations at (A) are available, as follows:

External Component OVP Rating

ROVP only up to 45 V

DZ only up to 47 V

both ROVP and DZ redundancy

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

11

Page 12

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

Calculate the value for R

R

OVP

where V

is the desired typical OVP level in V, and R

OVP

= (V

as follows:

OVP

– 30) / 54.9 μA ,

OVP

OVP

is

in Ω. For tighter OVP limits, a low–leakage-current Zener diode,

DZ, can be used, instead of ROVP, to set OVP at up to 47 V. For

redundancy, DZ can be connected across ROVP to provide additional protection, if ROVP should open. Select a 17 V low-leakage Zener diode for DZ.

Open LED Protection. The A8500 has protection against open

LEDs. If any enabled LED string opens, voltage on the corresponding LEDx pin goes to zero. The boost loop operates in open

loop till the OVP level is reached. The A8500 identifies the open

I

LED string

opens

OUT

Overvoltage

detected,

OVP begins

LED string when overvoltage on the OVP pin is detected. This

string is then removed from the boost controlling loop. The boost

circuit is then controlled in the normal manner, and the output

voltage is regulated, to provide the output required to drive the

remaining strings. If the open LED string is reconnected, it will

sink current up to the programmed current level.

Note: Open strings are removed from boost regulation, but not

disabled. This keeps the string in operation if LEDs open for only

a short length of time, or reach OVP level on a transient event.

The disconnected string can be restored to normal mode by reenabling the IC. It can also restored to normal operation if the

fault signal is removed from the corresponding LEDx pin, but an

OVP event occurs on any other LEDx pin.

Normal operation

resumes with open

LED string removed

from control loop

I

OUT

V

OUT

C1

I

IN

C2

C3

Symbol Parameter Units/Division

C1 I

C2 V

C3 I

t time 200 s

Figure 11. Open LED fault protection.

V

OUT

I

IN

t

OUT

OUT

IN

50 mA

10 V

500 mA

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

12

Page 13

A8500

Application Information

A typical application circuit for dimming an LCD monitor

backlight with 96 LEDs is shown in figure 1. Figure 12 shows

two dimming methods: digital PWM control (PWM signal on the

PWM pin) and analog PWM control, with the analog signal, VA ,

applied to the ISET pin through a resistor, RA.

The current flowing through RA can be calculated as:

IA = VA/ RA .

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

ISET

RISETP

RISET

Q1

This current changes the reference current, I

I

SET

= V

SET

/ R

– (VA – V

SET

LED current can be changed by changing VA. I

SET

SET

) / RA .

, as follows:

can be

SET

changed in the range from 40 μA to 120 μA.

Application Circuit for 1000:1 Dimming Level

A wider dimming range can be achieved by changing the reference current, I

current levels turn on Q1. R

, while using PWM dimming. For higher output,

SET

ISET

and R

set the 100% current

ISETP

level. This current level can be set to 25 mA, and then it can be

dimmed by applying 100% to 0.32% duty cycle on the PWM pin.

The reference current can be reduced by turning off Q1. LED

current can be dimmed to 8 mA by reducing reference current

through ISET pin. This provides 1000:1 combined dimming level

range. Figure 14 shows the accuracy, Err

, results using this

LEDX

circuit.

V

IN

5 V ±10%

EN

PWM

APWM

SKIP

COMP

C

C

RFSET

RA

V

A

RISET

FSET

ISET

LED1

LED3 LED5 LED7 LGND

VIN SW SW OVP

A8500

Figure 13. Configuration for 1000:1 dimming.

100

95

90

85

Accuracy (%)

80

75

0.1 1.0 10.0 100.0

Dimming Level (%)

Figure 14. Typical accuracy, normalized to the 100% current level,

versus dimming level, with F

COUTROVP

AGND

PGND

V

SEL3

SEL2

SEL1

LED2

LED8 LED6 LED4

IN

PWM

= 100 Hz.

Figure 12. Typical application circuit for PWM dimming, using digital PWM (on the

PWM pin, with APWM high).

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

13

Page 14

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

V

5 to 25 V

V

IN

5 V ±10%

C

IN

EN

PWM

APWM

SKIP

C

C

RFSET

RISET

COMP

FSET

ISET

LED8

LED7 LED6 LED5 LGND

Figure 15. Typical application circuit for PWM dimming, using digital PWM (on the

PWM pin, with APWM high). Showing configuration of 16 WLEDs at 100 mA, in two

strings of 8 LEDs each.

BAT

C

BAT

VIN SW SW OVP

A8500

LED4 LED3 LED2

AGND

PGND

SEL3

SEL2

SEL1

LED1

COUTROVP

V

IN

C

C

0.1 μF

RFSET

RISET

V

IN

5 V ±10%

EN

PWM

APWM

SKIP

COMP

FSET

AGND

ISET

LED8

LED7 LED6 LED5 LGND

L1

10 μH

VIN SW SW OVP

D1

A8500

LED4 LED3 LED2

PGND

SEL3

SEL2

SEL1

LED1

All ESD capacitors across LED arrays are 0.1 μF

COUTROVP

1 μF

V

IN

Figure 16. Typical application circuit for LED modules with ESD capacitors.

Recommended Components Table (for application shown in figure 1)

Component

Capacitor C

Capacitor C

Capacitor CIN, C

Diode D1 60 V / 1.5 A IR 10MQ060NTRPBF International Rectifier

IC A8500 – A8500 Allegro MicroSystems

Inductor L1 10 H SLF6028T-100M1R3-PF TDK

Resistor RISET 12 k

Resistor RFSET 24 k

Resistor ROVP 270 k

Reference

Designator Value Part Number Vendor

BAT

OUT

C

1 F / 50 V C3216X7R1H105K TDK

1 F / 50 V C3216X7R1H105K TDK

0.1 F / 6.3 V

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

14

Page 15

Flexible WLED/RGB Backlight Driver

A8500

Pin-out Diagram

AGND

VIN

SW

SW

26

25

24

23

PGND

1

SKIP

2

COMP

3

FSET

4

ISET

5

APWM

6

LED1

7

Terminal List Table

Number Name Description

1 PGND Power ground pin.

2 SKIP

3 COMP Compensation pin; connect external compensation network for boost converter.

4 FSET Sets boost switching frequency. Connect RFSET from FSET to GND to set frequency. Range for RFSET is 13 to 40 k.

5 ISET Sets 100% current through LED string. Connect RISET from ISET to GND. Range for RISET is 10 to 30 k.

6 APWM

7 LED1

8 LED3

9 LED5

10 LED7

11 LGND Power ground pin for LED current sink.

12 LED8

13 LED6

14 LED4

15 LED2

16 SEL1

18 SEL3

19 EN

20 PWM

21 PGND Power ground pin.

22 OVP

23 SW

24 SW

25 VIN Input supply for the IC. Decouple with a 0.1 F ceramic capacitor.

26 AGND Circuit ground pin.

– EP Exposed pad. Electrically connectred to PGND and LGND; connect to PCB copper plane for heat transfer.

Reduces boost switching frequency in case of light load to improve frequency. Normally, this pin should be low; when

high, f

is divided by 4.

SW

On/off and analog LED current control with external PWM. Apply logic level PWM (1.2 V < V

dimming mode. When unused, connect to AGND.

LEDx capable of 25 mA.

LEDx capable of 25 mA.

SEL1, SEL2, and SEL3 decide active LED strings.17 SEL2

On/off and serial dimming control. EN high enables IC and EN low disables IC. This pin can also be used to program

LEDx current. When unused, connect to AGND.

On/off and on/off LED current control with external PWM. Apply logic level PWM for PWM controlled dimming mode.

When unused, connect to AGND.

Connect to this pin to output capacitor +Ve node through a resistor to enable OVP (overvoltage protection). Default OVP

level with 0 resistor is 30 V, and it can be programmed up to 47 V.

DMOS drain node.

EP

8

9

1011121314

LED3

LED5

LED7

(Top View)

LGND

LED8

LED6

OVP

22

LED4

for Medium Size LCDs

PGND

21

PWM

20

EN

19

SEL3

18

SEL2

17

SEL1

16

LED2

15

< 5 V) for PWM controlled

IH

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

15

Page 16

A8500

Flexible WLED/RGB Backlight Driver

for Medium Size LCDs

Package EC, 4 × 4 mm 26-Pin QFN/MLP

0.20

4.00

26

1

A

2

4.00 4.00

0.95

1

2

26

C

0.40

1.10

1.23

27X

(Top View)

D

C0.08

0.20

0.40

0.40

B

2

1

26

2.45

(Bottom View)

SEATING

PLANE

0.75

1.23

1.10

C

All dimensions nomianl, not for tooling use

(reference JEDEC MO-220WGGE)

Dimensions in millimeters

Exact case and lead configuration at supplier discretion within limits shown

A

Terminal #1 mark area

B

Exposed thermal pad (reference only, terminal #1

identifier appearance at supplier discretion)

C

Reference land pattern layout (reference IPC7351

QFN40P400X400X80-29M)

All pads a minimum of 0.20 mm from all adjacent pads; adjust as necessary

to meet application process requirements and PCB layout tolerances; when

mounting on a multilayer PCB, thermal vias at the exposed thermal pad land

can improve thermal dissipation (reference EIA/JEDEC Standard JESD51-5)

D

Coplanarity includes exposed thermal pad and terminals

(Pads on PCB)

2.45

4.00

Copyright ©2006, 2007, Allegro MicroSystems, Inc.

The products described here are manufactured under one or more U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such de par tures from the detail spec i fi ca tions as may be required to permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to verify that the

information being relied upon is current.

Allegro’s products are not to be used in life support devices or systems, if a failure of an Allegro product can reasonably be expected to cause the

failure of that life support device or system, or to affect the safety or effectiveness of that device or system.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable. How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty for its use;

nor for any in fringe ment of patents or other rights of third parties which may result from its use.

For the latest version of this document, visit our website:

www.allegromicro.com

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

16

Loading...

Loading...