查询A8450供应商查询A8450供应商

Package LB 24-pin SOIC

VBB

1

CP2

2

CP1

VCP

VREG11

GND

GND

ENB

CPOR

CLADJ

VADJBD

FB

Charge

3

4

5

6

7

8

9

10

1.2Vto

3.3 V

11

Lin Reg

12

Control

Approximate Scale 1:1

Converter

Pump

Buck

Soft

Start

Dig/Anlg

Lin Reg

5 V Reg

Control

5V

Track

3.3 V

Lin Reg

Control

A8450

Automotive Multioutput Voltage Regulator

The A8450 is a multioutput power supply intended for automotive

applications. The A8450 operates from a wide input supply range and

is designed to satisfy the requirements of high ambient temperature

environments.

Four regulated voltage outputs provide multiple options. The 3.3 V

regulator and the 1.2 to 3.3 V adjustable regulator can be used to power

24

23

22

21

20

19

18

17

16

15

14

13

LX

ENBAT

V33

V33BD

CL33

GND

GND

VREG

V5D

NFAULT

NPOR

V5A

microcontroller or DSP cores, or for I/O, sensing, and A-to-D conversion. Two 5 V outputs, one digital and the other analog, feature output

tracking within 0.5% of each other over the operating temperature

range. In addition, the analog regulator is protected against short-tobattery conditions. All four regulators feature foldback current limit

protection.

The device can be enabled or disabled using two input pins. The

high voltage input, on the ENBAT pin, allows enable/disable using an

engine ignition or battery switch signal. The logic-level input, on the

ENB pin, allows enable/disable by microcontroller or DSP signals.

When disabled, the A8450 draws less than 10 µA of current. A POR

(power-on-reset) block monitors the supply voltages and provides a

reset signal, with an adjustable delay, for microcontroller or DSP resets.

A separate fault pin signals TSD (thermal shutdown), 5 V analog shortto-supply, and 5 V analog or digital undervoltage.

The A8450 is supplied in a 24-pin SOIC package (part number

suffix LB) with fused power ground pins for enhanced thermal performance. This provides an R

of 35°C/W on a 4-layer board (see chart

θJA

on p. 4).

AB SO LUTE MAX I MUM RAT INGS

Load Supply Voltage, V

Analog Output, Pin V5A........................–1 V to 45 V

Logic Input Signal

Pin ENBAT .................................–0.3 V to 45 V

Pin ENB .....................................–0.3 V to 6.5 V

Pin LX.................................................... –2 V to V

Operating Temperature Range

Ambient Temperature, T

Junction Temperature, T

Storage Temperature, TS.................... –55°C to 150°C

A8450KLB-DS, Rev. 1

..................................45 V

BB

............ –40°C to 135°C

A

.....................150°C

J(MAX)

FEATURES

6 V to 45 V input range

dc-to-dc buck converter with 5.7 V output

Overcurrent protection with foldback, and undervoltage lockout (UVLO)

Dual 5 V outputs

– Digital 5 V ±2%, 200 mA

– Analog 5 V, 200 mA

– Short-to-supply protection on analog regulator

– Analog to digital regulator output tracking < 0.5%, throughout

operating temperature range

3.3 V linear regulator, with foldback current limit

Adjustable 1.2 V to 3.3 V linear regulator, adjustable foldback current limit

BB

Ignition switch enable; Sleep mode

100% duty cycle operation for low input voltages

Power OK output

–40°C to 135°C ambient operating temperature range

Use the following complete part number when ordering:

Part Number Package Description

A8450KLB 24-pin, SOIC Webbed Leadframe

Automotive Multioutput Voltage Regulator

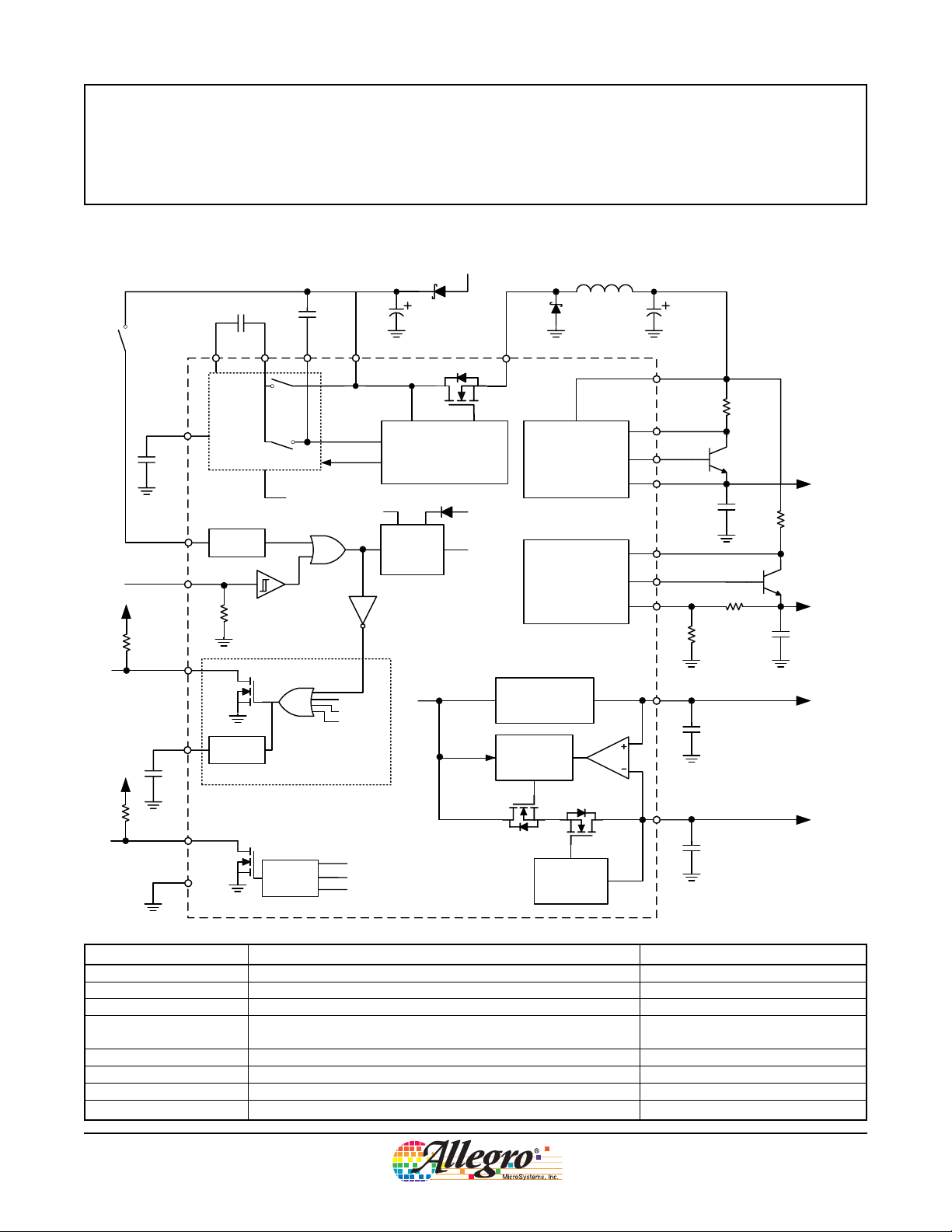

Functional Block Diagram

VIN

D2

A8450

L1

High

Voltage

Switch

VREG11

ENBAT

C10

ENB

NPOR

CPOR

C9

Charge Pump

High V

Protection

Adjustable

Delay

POR Block

C8

CP2CP1 VCP

CPOK

C7

Soft Start

V

UVLOREG

V

UVLOADJ

V

UVLO33

VBB

VBB

Reference

CIN

Buck Converter with

Switching Regulator

Internal

VREG

Current

Limiting

VREG

V

REF

LX

3.3 V Linear

Regulator Control

1.2 V to 3.3 V

Adjustable Linear

Regulator Control

5 V Digital Linear

Regulator

5V Analog

Linear Regulator

and V5D to V5A

Tracking Control

D1

COUT

VREG

CL33

V33BD

V33

CLADJ

VADJBD

FB

V5D

R3

Q1

C3

R1

R2

C1

R4

Q2

VADJ

C4

V5A

NFAULT

GND

Fault

TSD Warning

V5A Short to Supply

UVLO V5D, V5A

Short-to-Supply

Protection

C2

ID Characteristics Representative Device

C1, C2, C3, C4 1 µF, 25 V ceramic X7R

COUT 100 µF, 35 V low-ESR electrolytic UHC1V101M, Nichicon

CIN 47 µF, 63 V electrolytic

C7, C8

0.1 µF, 50 V ceramic X7R (for 14 V applications), or

0.1 µF, 100 V ceramic X7R (for 42 V applications)

C10 0.22 µF, 10 V X7R

D1, D2 1 A, 40 V Schottky (for 14 V applications) EKO4, Sanken

L1 100 µH, 1.2 A D03316HT, Coilcraft

Q1, Q2 pass transistors npn transistor, h

A8450KLB-DS, Rev. 1

> 50 MPSW06

FE

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

2

A8450

Automotive Multioutput Voltage Regulator

ELECTRICAL CHARACTERISTICS at T

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Supply Quiescent Current I

Regulated Output Voltage V

Buck Switch On-Resistance R

Buck Switch Current Limit I

dc-to-dc Fixed Off-Time t

Soft Start Time t

Logic Inputs

ENBAT Logic Input Voltage V

ENBAT Input Current I

ENB Logic Input Voltage V

ENB Input Current I

Linear Regulator Outputs

*

V5D Output Voltage V

V5A Output Voltage V

V33 Output Voltage V

V5A to V5D Tracking V

V5D Current Limit I

V5A Current Limit I

Base Drive Output Current I

Feedback Voltage V

Feedback Input Bias Current I

Continued on next page

BB

REG

DSON

DSLIM

OFF

SS

ENBAT

ENBAT

ENB

ENB

OUTV5D

OUTV5A

OUTV33

TRACK

OUTV5DLIM

OUTV5ALIM

BD

FB

FB

= –40ºC to 135°C, V

A

Enabled mode: V

I

= 0 mA: V

OUT

BB

Enabled mode: V

I

= 0 mA; VBB = 6 V

OUT

Disabled mode: V

I

= 550 mA = I

LOAD

+ I

LOADVADJ

; VBB > 6.5 V

BB

ENBAT

= 14 V

ENBAT

ENBAT

LOADV5D

or V

or V

= 6 to 45 V, V

= HIGH,

ENB

= HIGH,

ENB

and V

= LOW – – 10 µA

ENB

+ I

LOADV5A

= 5 V, unless otherwise noted

ENB

– 6 10 mA

–1015mA

+ I

LOADV33

5.50 – 5.80 V

Dropout: 6 V ≤ VBB < 6.5 V 5.00 – 5.80 V

TJ = 25°C – 415 500 mΩ

TJ = 135°C – 650 750 mΩ

1.0 1.2 1.8 A

VBB = 14 V – 4.75 – µs

VBB = 14 V 5 10 15 ms

HIGH input level 2.7 – 45 V

LOW input level –0.3 – 0.8 V

HIGH input level, V

HIGH input level, V

LOW input level, V

= 45 V – – 300 µA

ENBAT

= 14 V – – 70 µA

ENBAT

= 0.8 V –1 – 10 µA

ENBAT

HIGH input level 2.7 – 6.5 V

LOW input level –0.3 – 0.8 V

HIGH input level, V

LOW input level, V

1 mA ≤ I

1 mA ≤ I

LOADV5D

LOADV5A

≥ 2.7 V – – 50 µA

ENB

≤ 0.8 V –1 – 10 µA

ENB

≤ 200 mA 4.9 5.0 5.1 V

≤ 200 mA 4.9 5.0 5.1 V

3.234 3.300 3.366 V

50 mA ≤ I

V

> 6.5 V

BB

LOADV5A

, I

LOADV5D

≤ 200mA;

–25 – 25 mV

200 300 – mA

200 300 – mA

1 V ≤ V

OUTVADJ

, V

≤ 4 V 5.0 10.0 16.0 mA

OUTV33

1.16 1.20 1.24 V

–400 –100 100 nA

A8450KLB-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

3

A8450

Automotive Multioutput Voltage Regulator

ELECTRICAL CHARACTERISTICS (continued) at T

otherwise noted

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Protection

NFAULT, NPOR Output Voltage V

NFAULT, NPOR Leakage Current I

POR Delay t

V33 Undervoltage Threshold V

V33 Hysteresis V

V5A, V5D Undervoltage Threshold V

V5A, V5D Hysteresis V

VADJ Undervoltage Threshold V

VADJ Hysteresis V

VADJ, V33 Overcurrent Threshold V

VREG Undervoltage Threshold V

Thermal Warning Threshold T

Thermal Shutdown Threshold T

Thermal Shutdown Hysteresis T

*

Linear regulator output specifications are only valid when V

ERRON

ERROFF

POR

UVLOV33

HYSV33

UVLOV5

HYSV5

UVLOVADJ

HYSVADJ

OC

UVLOVREG

JTW

JTSD

HYSTSD

Fault asserted;

I

NFAULT

V

NFAULT

C9 = 0.47 µF 65 100 135 ms

V33 rising 2.80 2.95 3.10 V

V

falling 2.75 2.90 3.05 V

33

–80–mV

V

REG

V

REG

VFB rising 1.02 1.07 1.12 V

V

FB

At FB pin – 70 – mV

TJ rising – 160 – °C

TJ rising – 175 – °C

Recovery period = T

is in regulation (VBB ≥ 6.5).

REG

= –40ºC to 135°C, V

A

, I

= 1 mA

NPOR

, V

= 5 V – – 1 µA

NPOR

= 6 to 45 V, V

BB

= 5 V, unless

ENB

– – 400 mV

rising 4.36 4.50 4.75 V

falling 4.24 4.38 4.63 V

– 125 – mV

falling 0.97 1.02 1.07 V

175 200 225 mV

4.94 5.15 5.36 V

JTSD

– T

JTW

–15–°C

A8450KLB-DS, Rev. 1

Power Dissipation Versus Ambient Temperature

4.5

4.0

3.5

(W)

D

3.0

2.5

2.0

1.5

4-Layer PCB*

(R

=35ºC/W)

θJA

Power Dissipation, P

1.0

0.5

0.0

20 40 60 80 100 120 140 160

Ambient Temperature (°C)

*In still air; mounted on PCB based on JEDEC high-conductance standard PCB

(JESD51-7; High Effective Thermal Conductivity Test Board for Leaded Surface Mount

Packages); data on other PCB types is provided on the Allegro Web site.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

4

V

REG

V

OUTV33

V

OUTVADJ

V

OUTVADJ

V

ENBAT

V

ENBAT

V

ENB

V

ENB

V

NPOR

V

NPOR

V

NPOR

V

BB

V

REG

V

OUTV33

V

OUTV5A/V5D

VREG Monitor

V

CP

V

REG

V

OUTV33

V

OUTVADJ

V

UVLOV33

t

POR

t

POR

t

POR

t

POR

V

HYSV33

V

UVLOV33

VBB>6V

V

REG

= 1.8 V

V

UVLOVREG

V

UVLOVADJ

V

HYSVADJ

AB

POR event initiates

+7 V

Slope of V

OUTV33

and V

OUTVADJ

from A to B determined by I

LOAD

and output capacitor (C3, C4).

ENBAT signals power-on

Charge pump ramping

Charge pump OK flag set

V

UVLOV33

exceeded; VADJ enabled

V

UVLO(33)

ENB signals power-off

V33 can sustain regulation with normal load by bulk capacitor (COUT) on V

REG

.

Slope of V

REG

(which controls V

OUTV5A/V5D

,V

OUTV33

, and V

OUTVADJ

) from A to B determined by I

LOAD

and COUT.

A

B

t

POR

t

SS

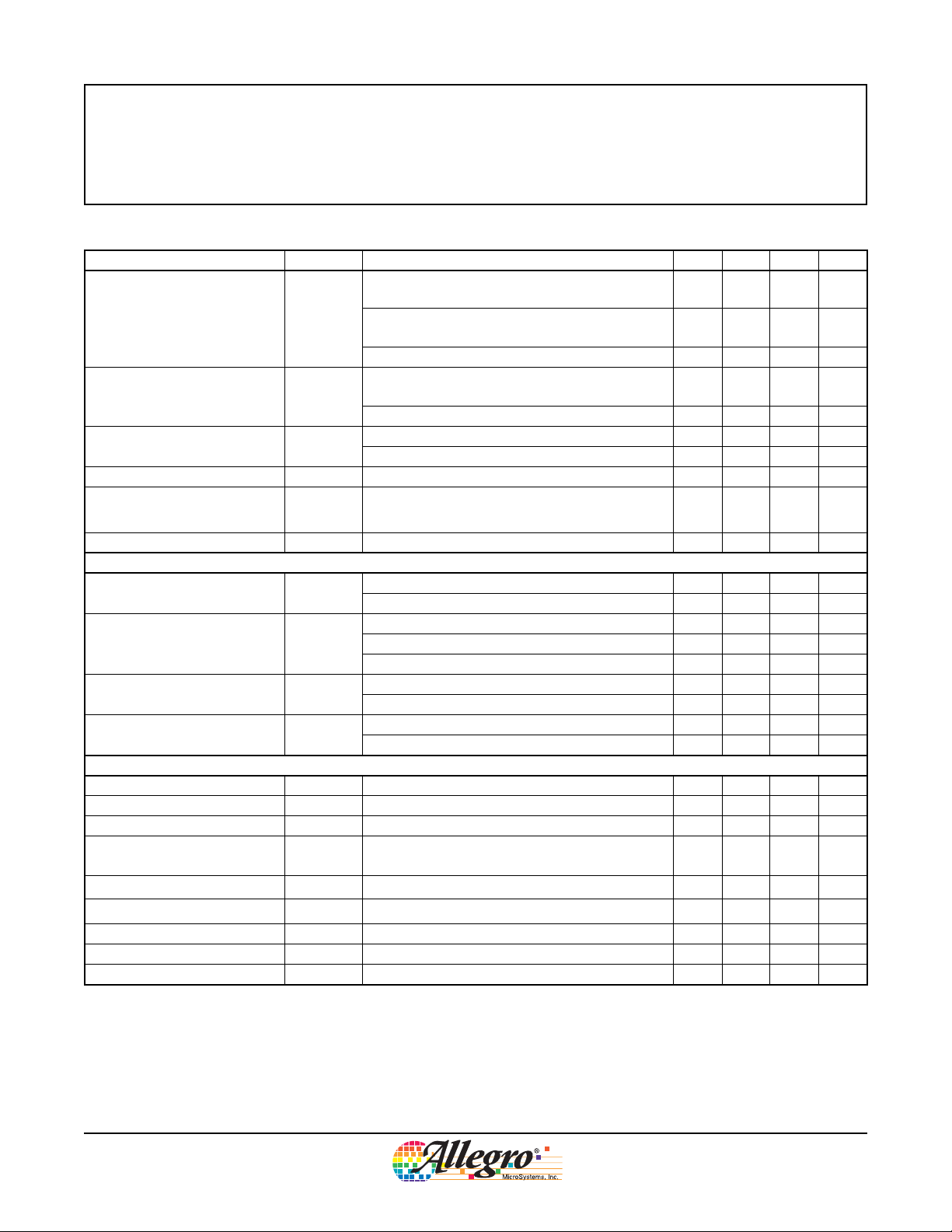

Figure 1a. NPOR fault due to undervoltage lockout on the V33 or FB pins

A8450

Automotive Multioutput Voltage Regulator

Timing Diagrams

Figure 1b. Power-off using V

Figure 1c. Power-on using ENBAT, followed by power-off using ENB

A8450KLB-DS, Rev. 1

BB

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

5

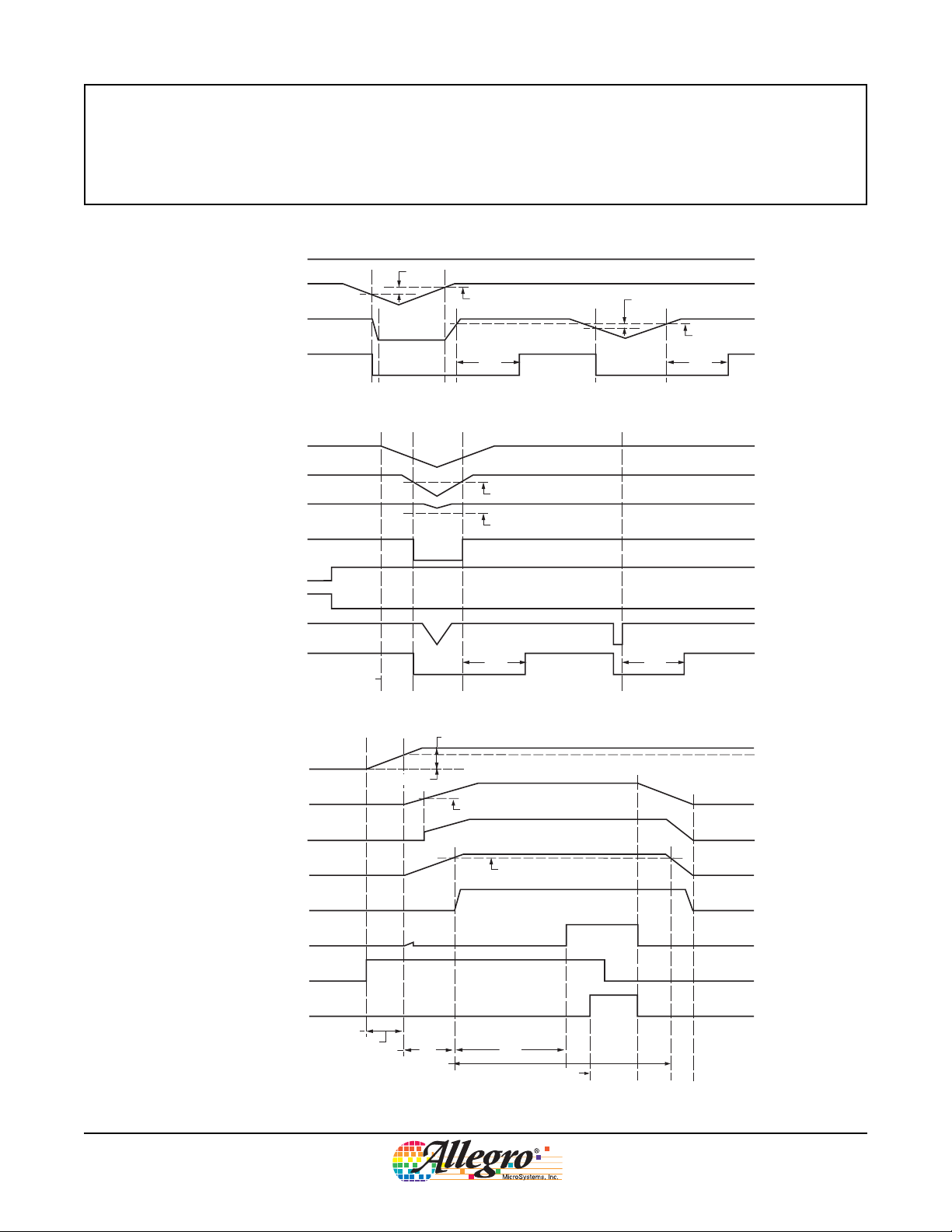

VIN = 12 V; I

I

LOAD

Automotive Multioutput Voltage Regulator

Load Transients Diagrams

= 100 mA; TA = 25°C; ac-coupled; C1, C2, C3 and C4 = 1 µF

LOAD

3.3 V Regulator

90%

A8450

= 5 to 100 mA

LOAD

I

(50 mV / Div.)

OUT

V

10%

t

RISE

t (0.2 µs/Div.)

V5D Regulator

t (50 µs/Div.)

V5A Regulator

(50 mV / Div.)

OUT

V

t (50 µs/Div.)

Adjustable Regulator, at 1.8 V*

(50 mV / Div.)

OUT

V

t (50 µs/Div.)

*For the adjustable regulator, the transient load response

is improved as the voltage is reduced. This is due to the

ability of the regulator to provide more base drive (V

because of more available voltage. When the adjustable

ADJBD

regulator approaches 3.3 V, its transient load response is

equivalent to the response of the V33 regulator.

)

(50 mV / Div.)

OUT

V

A8450KLB-DS, Rev. 1

t (50 µs/Div.)

For all regulators, load transients can be improved by

increasing the output capacitance (C1, C2, C3, and C4).

In order to keep ESR down it is best to use ceramic type

capacitors. However, large values in ceramic type capacitors

are either not available or very expensive. If larger values are

needed, above 22 µF, electrolytic capacitors with low ESR

ratings can be used. Performance can be improved further

by adding a 1 µF ceramic in parallel with the electrolytic.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

6

Automotive Multioutput Voltage Regulator

VBB

LX

D1

L1

100 µH

COUT

100 µF

VREG

Switching

Regulator

Control

Clock

Counter

Soft Start

Ramp

Generation

Error

Bandgap

1.22 V

Clamp

t

OFF

VCP

Compensation

1.2 A Limit

I

PEAK

I

DEMAND

ENB

Buck Converter

Buck Switch

5.5

5 7 9 11 13 15

5.0

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0.0

t

OFF

by V

BB

VBB(V)

t

OFF

(µs)

4.75 µs

12 V

2.05 µs

11 V

0.58 µs

6.02 V

Functional Description

Buck Converter with Switching Regulator. A current-mode, variable frequency buck dc-to-dc converter and

switching regulator are integrated in the A8450, as shown in

figure 2. This feature allows the device to efficiently handle

power over a wide range of input supply levels. The dc-to-dc

converter outputs 5.7 V typical, and has an overcurrent limit

of 1.2 A typical.

The converter employs a soft-start feature. This ramps the

converter output voltage and limits the maximum demand on

by controlling the inrush current required at power-on

V

REG

to charge the external capacitor, COUT, and any dc load.

An internal charge pump provides gate drive for the

N-channel MOSFET buck switch. A 100% duty cycle is

implemented when using low VBB input voltages.

A8450

At VBB lower than 12 V, off-time, t

in figure 3. This reduction keeps the switching frequency,

f

, within a reasonable range and lowers the ripple cur-

PWM

rent. Lowering the ripple current at low VBB levels prevents

degradation of linear regulator headroom due to V

voltage.

5 V Linear Regulators. Two 5 V medium-power linear regulators are provided. These low-dropout regulators feature foldback

current limiting for short-to-supply protection. When a direct

Figure 2. Buck converter with switching regulator

A8450KLB-DS, Rev. 1

, is reduced, as shown

OFF

Figure 3. When VBB falls below 12 V, t

ripple

REG

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

decreases

OFF

7

A8450

Automotive Multioutput Voltage Regulator

short is applied to the regulator output, either V5A or V5D,

the current folds back to 0 V at 50 mA, as shown in figure 4a.

The voltage recovers to its regulated output when the short is

removed.

The V5A and V5D regulators track each other during poweron, and when the device is enabled and ramped up out of

disabled mode, the regulators will start to track when V

REG

reaches approximately 1.8 V. These regulators are guaranteed

to track to within 0.5% of each other under normal operating

conditions.

3.3 V and Adjustable Linear Regulators. Two additional

linear regulators, one that outputs at 3.3 V, and another that has

a 1.2 V to 3.3 V adjustable output, can be implemented using

external npn pass transistors. The output voltage of the adjustable regulator, V

OUTVADJ

(V), is set by the values of the output

resistors, R1 and R2 (Ω). It can be calculated as

V

OUTVADJ

= VFB (1+R1 ⁄ R2)

where VFB (V) is the voltage on the feedback pin, FB.

Additional pins, CL33 and CLADJ, are provided for setting

current limits. These are used to protect the external pass transis-

tors from a short-to-ground condition. The current limit setting,

I

(mA), is calculated using the formula

CL

ICL = VOC ⁄ R

RCL

where RCL (Ω) is the current-limiting resistor corresponding to

that regulator (R3 for the 3.3 V regulator, and R4 for the adjustable regulator). When ICL is exceeded, the maximum load current

through that regulator is folded back to 40% of ICL ±10%, as

shown in figure 4b. If current limiting is not needed, the CL33

and CLADJ pins should be shorted to the VREG pin.

Disabled Mode. When the two input signal pins, ENBAT

and ENB, are pulled low, the A8450 enters disabled mode.

This is a sleep mode, in which all internal circuitry is disabled in order to draw a minimal current from VBB. When

either of these pins is pulled high, the device is enabled.

When emerging from disabled mode, the buck converter

switching regulator does not operate until the charge pump

has stabilized (≈ 300 µs).

Enabled Mode. When one or both of the signal input

pins, ENBAT and ENB, are in the high state, the A8450 is

enabled.

6

5

4

(V)

3

OUT

V

2

1

0

0 50 100 150

Figure 4a. Linear foldback to 50 mA. Foldback occurs at the

typical current limit for the 5 V regulator.

5V Regulators Overcurrent Foldback

I

OUT

I

and I

OUTV5DLIM

200 250 300

(mA)

OUTV5ALIM

A8450KLB-DS, Rev. 1

1600

3.3 V and Adjustable Regulators Overcurrent Foldback

6

5

4

(V)

3

OUT

V

2

1

0

0

Figure 4b. Linear foldback to a percentage of ICL . Foldback

occurs at the current limit setting for the regulator.

V

V

OUTVADJ(min)

0.4 ICL±10%

and V

OUTV33

OUTVADJ(max)

I

(mA)

OUT

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

I

CL

1600

8

A8450

Automotive Multioutput Voltage Regulator

ENBAT is an edge-triggered enable (logic 1 ≥ 2.7 V), which

is used to enable the A8450 in response to a high-voltage

signal, such as from an automobile ignition or battery switch.

In this capacity, ENBAT is used only as a momentary switch

to wake up the device. If there is no need for a high-voltage

signal, ENBAT can be pulled low continuously.

ENB is used to initiate the reset of the device. If ENBAT is

pulled low, ENB acts as a single reset control.

Diagnostics. An open drain output, through the NFAULT

pin, is pulled low to signal to a DSP or microcontroller any of

the following fault conditions:

• V5A, the 5 V analog regulator output, is shorted to supply

• Either or both of the V5A and the V5D regulator outputs

are below their UVLO threshold, V

UVLOV5

• Device junction temperature, TJ, exceeds the Thermal

Warning threshold, T

JTW

Charge Pump. The charge pump generates a voltage above

VBB in order to provide adequate gate drive for the N-channel

buck switch. A 0.1 µF ceramic monolithic capacitor, C7, should

be connected between the VCP pin and the VBB pin, to act as

a reservoir to run the buck converter switching regulator.

V

is internally monitored to ensure that the charge pump is

CP

disabled in the case of a fault condition. In addition, a 0.1 µF

ceramic monolithic capacitor, C8, should be connected between

CP1 and CP2.

Power On Reset Delay. The POR block monitors the sup-

ply voltages and provides a signal that can be used to reset a

DSP or microcontroller. A POR event is triggered by any of

the following conditions:

• Either V33 or VADJ is pulled below its UVLO threshold,

V

UVLOV33

or V

UVLOVADJ

. This occurs if the current limit

on either regulator,

the VREG voltage falls below V

exceeding I

DSLIM

V

, is exceeded. It also occurs if

OC

REGMON

.

, due to current

• Both input signal pins, ENB and ENBAT, are pulled low.

This immediately pulls the NPOR pin low, indicating that

the device is beginning a power-off sequence. In addition,

the buck converter switching regulator is disabled, and

the VREG supply begins to ramp down. The rate at which

V

decays is dependent on the total current draw, I

REG

LOAD

and value of the output capacitors (C1, C2, C3, and C4).

• V

• During any normal power-on, V

drops below its UVLO threshold, V

REG

V

UVLOVADJ

, triggering a POR.

OUTVADJ

UVLOVREG

falls below

.

An open drain output, through the NPOR pin, is provided to

signal a POR event to the DSP or microcontroller. The reset

occurs after an adjustable delay, t

tor, C9, connected to the CPOR pin. The value of t

, set by an external capaci-

POR

POR

(ms) is

calculated using the following formula

= 2.13×105 × C

where C

t

POR

(µF) is the value of the C9 capacitor.

CPOR

CPOR

A POR can be forced without a significant drop in the supply

voltage, V

, by pulsing low both the ENB and the ENBAT

REG

pins. However, pulse duration should be short enough so that

V

does not drop significantly.

REG

Thermal Shutdown. When the device junction temperature,

, is sensed to be at T

T

J

warning temperature, T

(≈15°C higher than the thermal

JTSD

), a fault is indicated at the NFAULT

JTW

pin. At the same time, a thermal shutdown circuit disables the

buck converter, protecting the A8450 from damage.

,

A8450KLB-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

9

Automotive Multioutput Voltage Regulator

Application Information

A8450

Component Selection

Output Inductor (L1). This inductor must be rated to handle

the total load current, I

. In addition, the value chosen

LOAD

must keep the ripple current to a reasonable level. A typical

selection is a power inductor rated at 100 µH and 1.3 A.

The worse case ripple current, I

RIPPLE(max)

(mA), can be

calculated as

I

RIPPLE(max)

= V

L1OFF

×

t

OFF

⁄ LL1

where LL1 (µH) is the inductance for the selected component,

and V

is the voltage (V) through the inductor when the

L1OFF

A8450 is in the quiescent state

= V

V

L1OFF

REG(max)

where VD1 (V) is the voltage drop on diode D1, I

+ VD1 + (I

LOAD

×

RL1)

LOAD

(mA)

is the total load current, and RL1 is the specified dc resistence

(Ω) for the selected inductor at its rated temperature.

The frequency, f

(Hz), of the switching regulator in the

PWM

buck converter can then be estimated by

f

= 1/(tON + t

PWM

OFF

)

where tON (µs) is calculated as

tON = I

and V

V

L1ON

(V) as

= VBB – (I

L1ON

RIPPLE(max)

LOAD

×

×

R

LL1 ⁄ V

DSON(max)

– (I

LOAD

L1ON

)

×

RL1) – V

REG(max)

Example

Given a typical application with VBB = 14 V, t

and I

= 550 mA. (Note that the value for t

LOAD

= 4.75 µs,

OFF

is con-

OFF

stant for VBB > 12 V, as shown in figure 3.)

Given also a 100 µH power inductor rated at 400 mΩ for

125ºC. (Note that temperature ratings for inductors may

include self-heating effects. If a 125ºC rating includes a selfheating temperature rise of 20ºC at maximum current, then

the actual ambient temperature, T

, cannot exceed 105ºC.)

A

V

I

V

= 5.8 + 0.8 + (0.550

L1OFF

RIPPLE(max)

L1ON

= 6.821

= 14 – (0.550

0.400) = 6.821 V

×

4.75 ⁄ 100 = 0.324 A

×

0.750) – (0.550

×

×

0.400)

– 5.8 = 7.56 V

tON = 0.324

f

= 1/(4.3 + 4.75) = 111 kHz

PWM

100 ⁄ 7.56 = 4.3 µs

×

In the case of a shorted output, the buck converter could

reach its internal current limit, I

ensure safe operation, the I

SAT

rating for the selected induc-

, of 1.2 A typical. To

DSLIM

tor should be greater than 1.4 A. However, if the external

current limit resistors, R3 and R4, selected for the 3.3 V and

adjustable (1.2 V to 3.3 V) regulators, are rated such that the

total inductor current, I

, could never reach that inter-

LOAD

nal current limit, then an inductor can be selected that has

an I

rating closer to the calculated output current of the

SAT

device, I

Higher inductor values can be chosen to lower I

, plus the maximum ripple current, I

LOAD

RIPPLE(max)

. This

RIPPLE

may be an option if it is desired to increase the total maximum current that is drawn from the switching regulator. The

maximum total current available, I

I

LOAD

= I

DSLIM

– (I

(mA), is calculated as

LOAD

RIPPLE(max)

⁄ 2)

Catch Diode (D1). The Schottky catch diode should be

rated to handle 1.2 times the maximum load current, I

LOAD

,

because the duty cycle at low input voltages, VBB, can be

very close to 100%. The voltage rating should be higher than

the maximum input voltage, V

, expected during any

BB(max)

operating condition.

VREG Output Capacitor (COUT). Voltage ripple in the

VREG output is the main consideration when selecting the

VREG output capacitor, COUT. The peak-to-peak output

voltage ripple, V

V

RIPPLE(p-p)

RIPPLE(p-p)

(mV), is calculated as

= I

RIPPLE

×

ESR

COUT

with ESR in ohms. It is recommended that the maximum

level of V

RIPPLE(p-p)

be less than 200 mV.

.

A8450KLB-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

10

A8450

Automotive Multioutput Voltage Regulator

For electrolytic output capacitors, a low-ESR type is recommended, with a minimum voltage rating of 10 V. However,

because ESR decreases with voltage, the most cost-effective

choice may be a capacitor with a higher voltage rating.

Regulator Output Capacitors (C3 and C4). The output

capacitors used with the 3.3 V regulator (C3) and the 1.2 V

to 3.3 V adjustable regulator (C4), should be 1 µF or greater

X7R (5% tolerance) ceramic or equivalent capacitors, with

a maximum capacitance change of ±15% over a temperature

range of –55ºC to 125ºC.

The ESR of these capacitors does not affect the outputs of

the corresponding regulators. If a greater capacitance is used,

the regulators have improved ripple rejection at frequencies

greater than 100 kHz.

Pass Transistors (Q1 and Q2). The pass transistors

used to implement the 3.3 V regulator and the 1.2 V to 3.3 V

adjustable regulator must ensure the following:

• Stable operation. The cutoff frequency for the control

loops of the regulators is 100 kHz. Transistors must be

selected that have gain bandwidth product, f

(kHz), and

T

beta, hFE (A), ratings such that

fT ⁄ hFE > 100 kHz

• Adequate base drive. It is acceptable to use a lower level

of current gain, hFE, for lower total load currents, I

The lower limit for I

current for the A8450, I

is limited by the minimum base

LOAD

, and the minimum hFE of

BD(min)

LOAD

.

the pass transistor, such that

For a typical application where V

2.5 V, and I

= 190 mA

LOAD

PD = (5.8 – 2.5)

×

= 5.8 V, V

REG

190 = 627 mW

OUT

=

Adjusting Pass Transistor Power Dissipation

Transistors are manufactured in a wide variety of package types, and the thermal dissipation efficiencies of the

packages can vary greatly. In general, increasing thermal

efficiency can also increase cost substantially. Selecting the

package to closely match operating conditions is important to

optimizing application design and cost.

Even when using a thermally-enhanced package, it remains

difficult to provide high current to a load at high ambient

operating temperatures. Depending on the load requirements,

using drop resistors, as shown in figure 5, may be necessary

to protect the pass transistor from overheating.

The output current-limiting resistors, RCL (corresponding

to R3 and R4), will drop between 175 mV and 225 mV at

the highest current output, I

resistance, the voltage dropped, V

VREG

CL33

. Assuming no additional

LOAD

(mV), on each pass

DROP

RCL

I

LOAD

= I

BD(min)

×

h

FE(min)

Note that hFE is dependant on operating temperature.

Lower temperatures decrease hFE, affecting the current

capacity of the transistor.

• Packaged for sufficient power dissipation. In order to

ensure appropriate thermal handling, the design of the application must take into consideration the thermal characteristics of the PCB where the A8450 and pass transistors

are mounted, the ambient temperature, and the power

dissipation characteristics of the transistor packages. In

general, the power dissipation, PD (mW), is estimated by

PD = (V

A8450KLB-DS, Rev. 1

REG

– V

OUT

)

I

LOAD

×

I

A8450

V33BD

V33

Figure 5. Placement of drop resistors for thermal protection; example

shown is for the 3.3 V regulator.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

V

V

DROP

CE

LOAD

V

OUTV33

11

A8450

Automotive Multioutput Voltage Regulator

transistor is

V

DROP

= V

REG

– V

RCL

– V

OUT

This can be substituted into the power dissipation formula

PD = V

DROP

Given a typical application where V

0.175 V, V

= 3.3 V, and I

OUT

I

×

LOAD

= 5.8 V, V

REG

= 350 mA, then PD is

LOAD

RCL

=

approximately 814 mW.

PD can be used to estimate the minimum required operating

temperature rating for the transistor. The ability of a package

to dissipate heat is approximated by the thermal resistance

from the die (junction) to the ambient environment, R

θJA

(°C/W). This includes the significant effect of dissipation through the package leads and the PCB on which the

transistor is mounted, and the state of the ambient air. The

typical rating for a DPAK package is 32˚C/W. The expected

self-induced temperature rise in the package, ∆TJ (°C), given

PD = 0.814 W, is approximated as

∆TJ = P

R

= 26°C

×

D

θJA

In automotive applications, where under-the-hood ambient

temperatures can exceed 125˚C, the pass transistor would

have to be rated to provide the required beta at ≥ 151°C, plus

a safe operating margin.

Assume that V

REG(max)

= 5.8 V and V

OUT(max)

= 3.3 V.

Assume also that TA = 125°C, and VCE = 1V (as specified for

the MPSW06 npn transistor, beta = 300 at 125˚C).

In order to determine the resistance values for the currentlimiting and drop resistors, V

in terms of I

V

Assume a typical I

LOAD(lim)

RCL

V

RDROP

LOAD

= (I

= (I

= 350 mA. However, under normal

and V

RCL

LOAD(lim)

LOAD(lim)

×

×

can be expressed

DROP

RCL)

R

RDROP

)

operating conditions, the current limit set by RCL would

be higher than the expected normal current, so assume

I

LOAD(lim)

mine V

We can now solve for R

= 0.400 A and RCL = 44 Ω. Substituting to deter-

RCL

V

= 0.400

RCL

V

– V

REG

RCL

– (I

5.8 – 0.176 – (0.4 × R

RDROP

LOAD

×

×

0.44 = 0.176 V

and then V

R

RDROP

DROP

) – V

RDROP

) – 1 ≥ 3.30 V

CE

≥ V

OUT

therefore

R

RDROP

≥ 3.31 Ω

and

For a selected transistor, VCE can change depending on current, temperature, and transistor beta. Typically, transistors

are rated at a minimum beta at a defined VCE. However, VCE

should be calculated with some margin so there is always

enough headroom to drive the device at the desired load.

To provide an operating margin, or if a lower-value RCL is

required, voltage drop resistors, RDROP, can be added to

the circuit, between the RCL and the transistor (figure 5). It

is also important to consider tolerances in resistance values

and V

. The level of V

REG

REG(min)

is 5.6 V, at which level PD

is reduced, but also the voltage available for VCE is reduced.

Calculating maximum and minimum voltage drops is useful

in determining the values of the drop resistors.

The required drop resistor value, R

, can be determined

RDROP

in terms of the voltage drops across each component of the

circuit, as shown in the following formula

V

DROP

≥ V

OUT

where

V

= V

DROP

A8450KLB-DS, Rev. 1

REG

– V

RCL

– V

RDROP

– VCE

V

= 0.4 × 3.31 = 1.3 V

RDROP

Using four 0.25 W resistors valued at 14.7 Ω in parallel will

drop 1.3 volts.

Using the drop resistors as calculated above, the power dissipation in the transistor, P

= I

P

D

LOAD(lim)

(W) is reduced to

D

(V

×

REG

– V

RCL

– V

RDROP

– V

OUT

)

= 0.400× (5.8 – 0.176 – 1.3 – 3.3) = 0.410 W

and

∆TJ = PD

×

R

θJA

= 13°C

The power dissipated in the transistor is significantly

reduced. A transistor in a power package with an R

θJA

of

32˚C/W at 400 mA (a 50 mA margin) undergoes a temperature rise of 13˚C with the drop resistors, as opposed to a

similar transistor at 350 mA rising 26˚C without drop resistors. At high output currents, properly selected drop resistors

can protect the external pass transitor from overheating.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

12

Automotive Multioutput Voltage Regulator

A8450 Power Dissipation. The A8450 is designed to

operate in applications with high ambient temperatures. The

total power dissipated in the device must be considered in

conjunction with the thermal dissipation capabilities of the

PCB where the A8450 is mounted, as well as the capabilities

of the device package itself.

The ability of a package to dissipate heat is approximated by

the thermal resistance from the die (junction) to the ambient environment, R

effect of dissipation through the package leads and the PCB

on which the package is mounted, and the temperature of the

ambient air. Test results for this 24-lead SOIC are approximately 35 °C/W when mounted on a high-thermally conductive PCB (based on the JEDEC standard PCB, having four

layers with buried copper areas).

The total power that can be applied to the device, P

(W), is affected by the maximum allowable device junction

temperature, T

ture, TA (°C), as shown in the following formula

P

can be estimated based on several parameters, using

D(lim)

the following formula

P

D(lim)

= P

+ P

where

(°C/W). This includes the significant

θJA

J(max)

P

D(lim)

D(Ibias)

(°C), R

= (T

+ P

, and the ambient air tempera-

θJA

– TA) ⁄ R

J(max)

D(V5A)

+ P

D(V5D)

θJA

+ P

D(buckdc)

D(buckac)

D(lim)

+ P

D(BD)

A8450

P

, the relationship can be assumed to be linear through-

D(lim)

out the practical TJ operating range (see test conditions for

R

in the Electrical Characteristics table).

DSON

DC (duty cycle) is a function of VBB and V

calculated precisely as

DC = V

REG(off)

⁄ (V

REG(on)

+ V

A rough estimate for DC is

DC = (V

I

V33BD(max)

is the maximum current drawn on the V33BD

pin. It is dependent on I

+ VLX) ⁄ V

REG

and the hFE of the pass tran-

OUTV33

sistor.

I

ADJBD(max)

pin. It is dependent on I

is the maximum current drawn on the VADJBD

OUTVADJ

and the hFE of the pass

transistor.

Overcurrent Protection

The current supplied by the 3.3 V and the 1.2 to 3.3 V adjust-

I

able regulators is limited to

. Current above ICL is folded

CL

back linearly, as shown in figure 4b. In the case of a shorted

load, the collector current is reduced to 40% of ICL ±10% ,

to ensure protection of the pass transistors. After the short is

removed, the voltage recovers to its regulated level.

The maximum power dissipated in the transistor during a

shorted load condition is:

REG

REG(off)

BB

. This can be

)

P

P

P

P

P

P

D(Ibias)

D(V5A)

D(V5D)

D(buckdc)

D(buckac)

= I

D(BD)

= V

= (V

= (V

= I

= I

I

×

BB

BB

– 5 V)

REG

– 5 V)

REG

2

×

LOAD

×

LOAD

V33BD(max)

×

×

R

DSON(TJmax)

[V

( 5 ns ⁄ 14 V)

BB

(V

×

I

LOAD(V5A)

I

LOAD(V5D)

– 4 V) + I

REG

×

×

DC

×

(V

and

I

R

A8450KLB-DS, Rev. 1

= I

LOAD

DSON

LOAD(V33)

is a function of TJ. For the purposes of estimating

+ I

LOAD(VADJ)

+ I

LOAD(V5D)

V

]

×

BB

VADJBD(max)

– V

REG

ADJ

+ I

0.5 f

PWM

– 0.7 V)

LOAD(V5A)

where V

OUT

PD ≈ (V

= 0 V.

REG

– V

OUT

) × (0.4

×

I

)

CL

Low Input Voltage Operation

When the charge pump has ramped enough to enhance

the buck switch, the buck converter switching regulator is

enabled. This occurs at VBB ≈ 5.7 V. At that point, the duty

cycle, DC, of the A8450 can be forced to 100% until VIN is

high enough to allow the switch to begin operating normally.

The point at which normal switching begins is dependent

on ambient temperature, TA. Increases in TA cause R

increase. Other significant factors are I

LOAD

, V

REG

to

DSON

, the ESR

of the output inductor (L1), and the forward biasing voltage

for the output Schottky diode (D1).

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

13

A8450

Automotive Multioutput Voltage Regulator

Regulator Bypass

Some applications may not require the use of all four regulators provided in the A8450. For the regulators that are not

used, the corresponding external components are not needed.

If either or both of the two 5 V regulators are not required by

the application, bypass an unused regulator by not connecting its output terminal, V5D or V5A. Also, the corresponding

output capacitor, C1 or C2, is not used.

For the 3.3 V regulator and the 1.2 V to 3.3 V adjustable

Pin List Table

Name Description Number

VBB Supply input 1

CP2 Charge pump capacitor, positive side 2

CP1 Charge pump capacitor, negative side 3

VCP

VREG11 Internal reference 5

GND Power ground 6

GND Power ground 7

ENB Logic control 8

CPOR Connection for POR adjustment 9

CLADJ Current limit for adjustable regulator 10

VADJBD Base drive for adjustable regulator pass transistor 11

FB Feedback for adjustable regulator 12

V5A 5 V analog regulator output 13

NPOR Power on Reset logic output 14

NFAULT Diagnostic output; open drain; low during fault condition 15

V5D 5 V digital regulator output 16

VREG dc-to-dc converter supply output 17

GND Power ground 18

GND Power ground 19

CL33 Current limit for 3.3 V regulator 20

V33BD Base drive for 3.3 V regulator pass transistor 21

V33 3.3 V regulator output 22

ENBAT High voltage logic control 23

LX Buck converter switching regulator output 24

Charge pump output used to drive N-channel buck converter

transistor

regulator, if either or both are not needed, the corresponding

external components are not used. In addition, if the 3.3 V

regulator is not used, CL33 and V33 are not connected. If the

adjustable regulator is not used, CLADJ and FB are not connected. However, to ensure stability of the A8450, the base

drive pin, V33BD or VADJBD, of any unused regulator must

be shorted to VREG.

4

A8450KLB-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

14

A8450

Automotive Multioutput Voltage Regulator

24-Pin SOIC

10.30 BSC

24 19 18

7.50 BSC

2176

0.51

0.31

0.64 BSC

Dimensions in millimeters

Conform to JEDEC MS-013AD

Actual dimensions may vary at vendor discretion

15.40 BSC

1.27 BSC

0.30

0.10

2.65

2.35

8º

0º

0.33

0.20

1.27

0.40

Leads 6, 7, 18, and 19 are internally fused ground leads, for enhanced thermal

dissipation. Exact external appearance subject to vendor discretion.

The products described here are manufactured under one or more U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such de par tures from the detail spec i fi ca tions as may be required

to permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned

to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components in life-support devices or sys tems without express written approval.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable. How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty for

its use; nor for any in fringe ment of patents or other rights of third parties which may result from its use.

Copyright©2004 AllegroMicrosystems, Inc.

A8450KLB-DS, Rev. 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

15

Loading...

Loading...