Page 1

A6285

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

Features and Benefits

▪ 3.0 to 5.5 V logic supply range

▪ Schmitt trigger inputs for improved noise immunity

▪ Power-On Reset (POR)

▪ Up to 80 mA constant-current sinking outputs

▪ LED open circuit detection (LOD)

▪ Dot correction (DC) for adjusting LED light intensity on

each channel with 7-bit resolution

▪ Low-power CMOS logic and latches

▪ High data input rate up to 30 MHz

▪ Active output pull-ups with enable/disable

▪ 20 ns typical staggering delay between outputs

▪ Internal UVLO and thermal shutdown (TSD) circuitry

▪ Fault output flags for an LED open circuit (LOD) or a

thermal shutdown (TSD) condition

Package: 32 Contact QFN (suffix ET)

5 mm × 5 mm

0.90 mm nominal overall height

Description

The A6285 is designed for LED display applications. This

BiCMOS device includes an On/Off shift register, a Dot

Correction (DC) shift register, accompanying data latches, and

16 MOS constant-current sink drivers with active pull-ups that

can be enabled or disabled as required by the application.

The CMOS shift registers and latches allow direct interfacing

with microprocessor-based systems. With a 3.3 or 5 V logic

supply, typical serial data input rates can reach up to 30 MHz.

The LED drive current level can be set by a single external

resistor, selected by the application designer. A CMOS serial

data output permits cascading of multiple devices in applications

requiring additional drive lines.

Individual LED light intensity can be adjusted to correct for light

intensity variations by using the Dot Correction feature.

Open LED connections can be detected, and then signaled back

to the host microprocessor through the serial data output (SDO

pin). The FAULT output flags an LED open circuit (LOD)

condition or a thermal shutdown (TSD) condition. A staggering

delay on the load outputs during ON/OFF transitions helps to

reduce ground bounce.

Continued on the next page…

Not to scale

Controller

T ypical Application

V

DD

100 KΩ

SDI SDI

FAULT

CLK

LE

MODE

OE

SDO

FAULT

CLK

LE

MODE

OE

V

LED

PE

OUT0 OUT15

A6285

V

LED

10 μF

SDO

V

DD

100 nF

REXT

6285-DS, Rev. 1

Page 2

16-Channel Constant-Current Latched LED Driver

A6285

with Open LED Detection and Dot Correction

Description (continued)

The device is available in a 32-lead QFN (package ET), with an

exposed thermal pad. It is lead (Pb) free with 100% matte tin

leadframe plating.

Selection Guide

Part Number Package Packing (estimated)

A6285EET-T 5×5 mm QFN, 32 pin, exposed thermal pad 73 pieces per tube

A6285EETTR-T 5×5 mm QFN, 32 pin, exposed thermal pad 1500 pieces per 7-in reel

Applications include the following:

▪ Display backlighting

▪ Monocolor, multicolor, or full-color LED display

▪ Monocolor, multicolor, LED Signboard

▪ Multicolor LED lighting

Absolute Maximum Ratings

Characteristic Symbol Notes Min. Max. Unit

Supply Voltage* V

OUTx Current (any single output) I

Input Voltage Range* V

LED Load Supply Range* V

ESD Rating

Operating Temperature Range (E) T

Junction Temperature T

Storage Temperature Range T

*With respect to ground (GND, PGND).

DD

O

VOE, VLE, V

I

LED

HBM (JEDEC JESD22-A114, Human Body Model) – 1.5 kV

CDM (JEDEC JESD22-C101, Charged Device Model) – 1.0 kV

A

(max) – 150 °C

J

stg

CLK

, V

SDI

, V

MODE

–0.3 5.5 V

–90mA

–0.3 VDD + 0.3 V

–0.3 13.2 V

–40 85 °C

–55 150 °C

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

2

Page 3

A6285

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

Functional Block Diagram

MODE

CLK

SDI

OE

REXT

GND

LE

TSD

UVLO

01 15

1

MODE

0

1

MODE

0

1

ON/OFF Shift Register

0

MODE

015

1

0

MODE

ON/OFF

Register

0

LOD

0

Io

Regulator

LE

DC Register

06

7-Bit

DC

015

LOD

1

Status Info:

LOD

ON/OFF

Register

1

TSD

LOD

VDD

DC Shift Register

0 111

DC Register

713

7-Bit

DC

ON/OFF

Register

LOD

15

FAULT

UVLO

POR

1

0

DC Register

15

105 111

7-Bit

DC

VDD

SDO

MODE

PAD

PE

OUT0 OUT1

Inputs and Outputs Equivalent Circuits

(Note: Resistor values are equivalent resistance and not tested.)

VDD

CLK, SDI, LE,

MODE, O¯ ¯ E¯

500 Ω

10 Ω

10 Ω

VDD

SDO

FAULT

OUT15

Active Pull-up Cell

(1 of 16 Outputs)

5 mA

ON

VLED

PE

OUTx

V

LED

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

3

Page 4

16-Channel Constant-Current Latched LED Driver

A6285

with Open LED Detection and Dot Correction

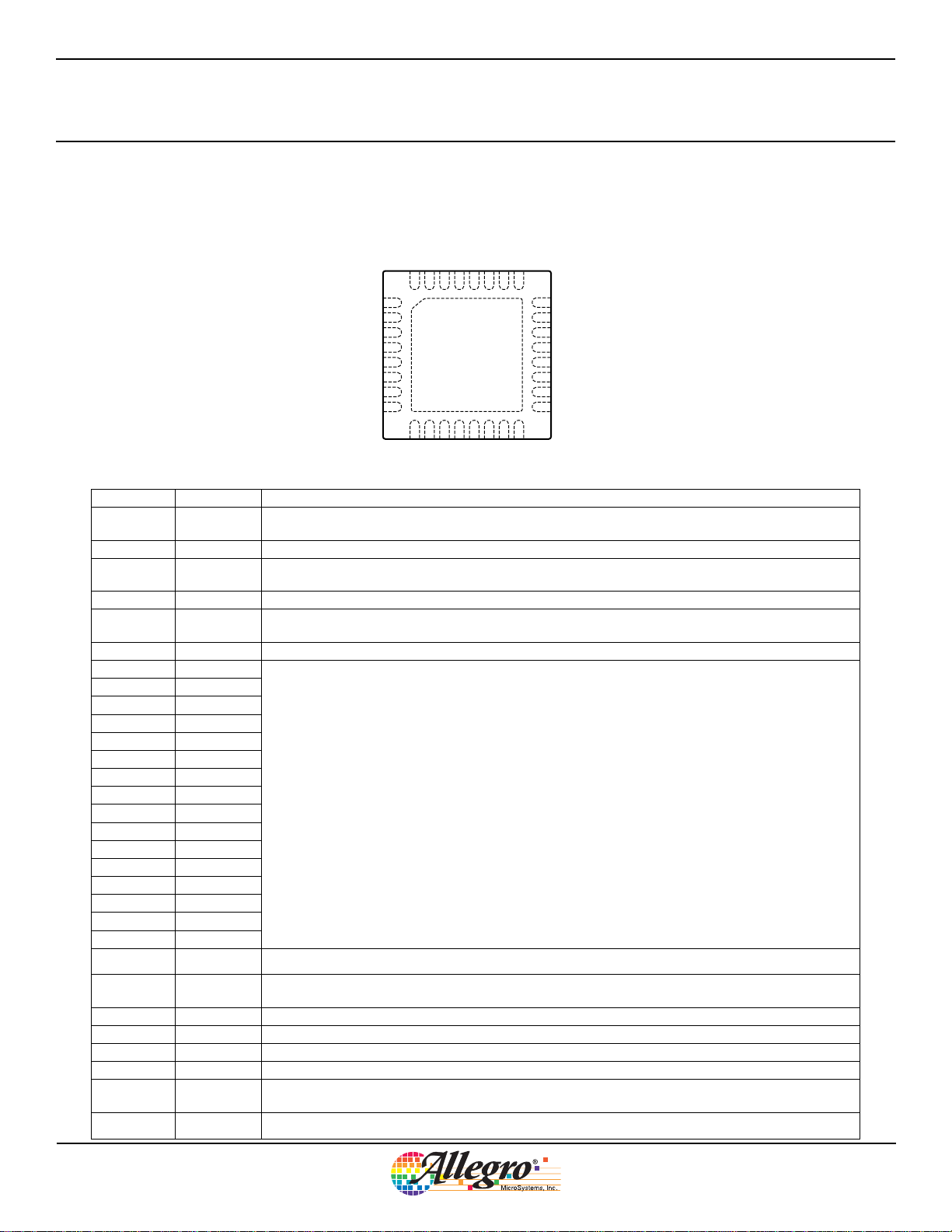

Pin-out Diagram

CLKLEOE

GND

VDD

REXT

MODE

FAULT

32313029282726

1

SDI

2

NC

3

OUT0

4

Terminal List Table

OUT1

PGND

OUT2

OUT3

OUT4

5

6

7

8

PAD

9

10111213141516

OUT5

OUT6

OUT7

PGND

Name Number Description

O¯ ¯E¯ 30

Output Enable input. Active low. When O¯ ¯E¯ = High, all OUTx outputs are forced OFF. When O¯ ¯E¯ = Low,

ON/OFF of OUTx outputs are controlled by input data.

GND 29 Logic supply ground.

PE 23

Active Pull-up Enable. When connected to LED Load Supply (V

= disabled.

REXT 27 Reference current input/output terminal.

MODE 26

Logic input, Mode select. When MODE = Low, then SDI, SDO, CLK, LE are connected to ON/OFF control

logic. When MODE = High, SDI, SDO, CLK, LE are connected to dot-correction logic.

NC 2 No connection. Not internally connected.

OUT0 3

OUT1 4

OUT2 6

OUT3 7

OUT4 8

OUT5 9

OUT6 11

OUT7 12

OUT8 13

Constant current outputs.

OUT9 14

OUT10 16

OUT11 17

OUT12 18

OUT13 19

OUT14 21

OUT15 22

PGND 5, 10, 15, 20 Power ground.

CLK 32

Data shift clock input. Note that the internal connections are switched by input at MODE pin. At CLK, the

shift-registers selected by MODE shift the data.

SDI 1 Serial Data In. Data input of serial data interface.

SDO 24 Serial Data Out. Data output of serial data interface.

VDD 28 Logic Supply.

FAULT 25 Error output. FAULT is open drain terminal. FAULT goes low when LOD or TSD detected.

LE 31

Latch Enable input. Note that the internal connections are switched by input at the MODE pin. At LE, the

latches selected by MODE get new data.

PAD – Exposed pad for enhanced thermal dissipation; not connected internally, connect to power ground plane.

OUT8

OUT9

25

PGND

24

23

22

21

20

19

18

17

OUT10

SDO

PE

OUT15

OUT14

PGND

OUT13

OUT12

OUT11

) = enabled, when connected to PGND

LED

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

4

Page 5

A6285

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

Operating Characteristics

ELECTRICAL CHARACTERISTICS at T

Characteristic Symbol Test Conditions Min. Typ.

Logic Supply Voltage Range V

LED Load Supply Output Voltage V

Undervoltage Lockout V

Output Current I

Output to Output Matching Error

Load Regulation I

Output Leakage Current I

Logic Input Voltage

Logic Input Voltage Hysteresis V

Logic Input Current I

SDO Voltage

Supply Current

3

FAULT Output

Active Pull-up I

Thermal Shutdown Temperature T

Thermal Shutdown Hysteresis T

Open LED Detection Threshold V

Reference Voltage at R

1

Tested at 25°C. Specifications are assured by design and characterization over the operating temperature range of –40°C to 85°C.

2

Typical data are for initial design estimations only, and assume optimum manufacturing and application conditions. Performance may vary for

individual units, within the specified maximum and minimum limits.

3

Recommended operating range: VO = 1.0 to 3.0 V.

4

Err = (IO(min or max) – IO(av)) / IO(av).

EXT

4

1

= 25°C, VDD = 3.0 to 5.5 V, unless otherwise noted

A

Operating 3.0 5.0 5.5 V

DD

Operating – – 12.0 V

LED

VDD 0 5.0 V 2.5 2.7 2.95 V

DD(UV)

VDD 5 0.0 V 2.3 2.5 2.75 V

VDS = 1 V, R

O

VDS = 1 V, R

1 V = V

Err

All outputs on

1 V = V

All outputs on

V

Oreg

All outputs on

DSS

V

V

V

V

I

DD(OFF)

VOH = 12 V – – 0.5 A

IH

IL

All digital inputs 250 – 900 mV

Ihys

All digital inputs –1 – 1 A

I

IOL = 1 mA – – 0.5 V

OL

OHIOH

R

R

All outputs on, R

I

DD(ON)

data transfer 30 MHz

All outputs on, R

data transfer 30 MHz

V

OUT(0)IOUT

I

OUT(1)VOUT

OUT(0)VLED

JTSD

JTSDhys

V

Temperature increasing – 165 – °C

LOD

R

EXT

2

Max. Unit

= 600 Ω 70 80 90 mA

EXT

= 1.2 kΩ 35 40 45 mA

EXT

, R

, R

= 600 Ω;

EXT

= 1.2 kΩ;

EXT

= 600 ;

EXT

= 1.2 kΩ, VO = 1 V,

EXT

= 600 Ω, VO = 1 V,

EXT

– +1.0 +4.4 %

– +1.0 +4.4 %

– – +6.0 %

0.8×V

DD

GND – 0.2×V

– 0.5 – – V

DD

–VDDV

DD

– – 25 mA

–2640mA

DS(x)

DS(x)

= 1 to 3 V, R

DS(X)

= –1 mA V

= 9.6 kΩ, VOE = 5 V – – 6 mA

EXT

= 1.2 kΩ, VOE = 5 V – – 17 mA

EXT

= 5 mA; faults asserted – – 0.4 V

= 5.5 V, open drain; faults negated – – 1 A

= 1 V, all outputs off – 2.8 – mA

–15–°C

– 0.30 0.40 V

= 600 Ω 1.19 1.23 1.28 V

EXT

V

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

5

Page 6

A6285

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

SWITCHING CHARACTERISTICS at T

1

= 25°C, VDD = VIH = 3.0 to 5.5 V, VDS = 1 V, VIL = 0 V, R

A

= 1.2 k, IO = 40 mA,

EXT

VL = 3 V, RL = 51 , CL = 15 pF (see table 9)

Characteristic Symbol Test Conditions Min. Typ.

Clock Frequency f

Clock Pulse Duration t

Clock Frequency (cascaded) f

LE Pulse Duration t

Setup Time

Hold Time

Rise Time

Fall Time

Propagation Delay Time

LOD Sample and Read Time t

wh0/twl0

CLKC

t

t

t

t

t

t

t

t

t

t

LOD

CLK – – 30 MHz

CLK

CLK = High/Low 16 – – ns

CLK – – 25 MHz

LE = High 20 – – ns

wh1

SDI to CLK 10 – – ns

su0

CLK to LE 10 – – ns

su1

MODE to CLK 10 – – ns

su2

MODE to LE 10 – – ns

su3

CLK to SDI 10 – – ns

t

h0

t

LE to CLK 10 – – ns

h1

t

CLK to MODE 10 – – ns

h2

t

LE to MODE 10 – – ns

h3

t

SDO, 10/90% points (see figure 1) – – 16 ns

r0

OUTx, VDD = 5 V, DC = 127, 10/90% points

t

r1

(see figure 2)

t

SDO, 10/90% points (see figure 1) – – 16 ns

f0

OUTx, VDD = 5 V, DC = 127, 10/90% points

t

f1

(see figure 2)

CLK to SDO (see figure 1) – – 30 ns

pd0

MODE to SDO (see figure 1) – – 30 ns

pd1

O¯ ¯E¯ to OUT0 (see figure 2) – – 60 ns

pd2

LE to OUT0 (see figure 2) – – 60 ns

pd3

OUTx to FAULT (see figures 2 and 3) – – 1000 ns

pd4

pd5

LE to I

(DC) (see figure 2) – – 200 ns

OUT

–1030ns

–1030ns

LE1 to LE2 1660 – – ns

Output Delay Time td OUTx to OUT(x+1) (see figure 2) 10 20 40 ns

1

Tested at 25°C. Specifications are assured by design and characterization over the operating temperature range of –40°C to 85°C.

2

Typical data are for initial design estimations only, and assume optimum manufacturing and application conditions. Performance may vary for

individual units, within the specified maximum and minimum limits d maximum and minimum limits.

2

Max. Unit

A6285

SDO

Figure 1. Test circuit for tr0, tf0, td0,

and t

d1

Parameter Measurement Information

15 pF

A6285

OUTx

Figure 2. Test circuit for tr1, tf1, t

t

, t

pd5

, and t

pd6

pd3

pd2

51 7

,

15 pF

A6285

FAULT

Figure 3. Test circuit for t

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

pd4

1.2 k7

6

Page 7

A6285

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

Operating Characteristics

100

VDS= 1 V

DC= 127

10

(kΩ)

EXT

R

1

0.1

IO(max) (mA)

Figure 4. Value of external reference resistor, REXT, versus

channel Constant Output Current

Thermal Characteristics

Characteristic Symbol Test Conditions

Package Power Dissipation

Package Thermal Resistance R

1

Additional thermal information available on Allegro website.

2

Actual performance significantly affected by application.

P

D

JA

Continuous, TA = 25°C 3.9 W

4-layer PCB based on JEDEC standard 32 °C/W

90

90

R

= 600 Ω

80

80

70

70

60

60

(mA)

50

50

(mA)

OLC

O

40

40

I

I

30

30

20

20

10

10

0

0

0

0.3 0.6 0.9 1.2 1.5 1.8 2.1 2.4 2.7 3.00 1020304050607080

0 0.30.60.91.21.51.82.12.42.7 3

EXT

R

EXT

R

EXT

R

EXT

VO (V)

= 800 Ω

= 1.2 kΩ

= 2.4 kΩ

VO(V)

Figure 5. Output Voltage versus Output Current at various

levels of R

EXT

1

Value2Units

5.0

4.0

0

Package ET, R

QJA

= 32°C/W

50 75 100 125 15025

AMBIENT TEMPERATURE IN °C

3.0

2.0

1.0

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

Figure 6. Power Dissipation versus temperature

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

7

Page 8

A6285

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

Functional Description

Setting Maximum Channel Current The maximum output

current per channel is set by a single external resistor, REXT,

which is placed between the REXT pin and PGND. The voltage

on REXT, V

, is set by an internal band gap. The maximum

EXT

channel current is equivalent to the current flowing through

REXT multiplied by 38.4. The maximum channel output current

can be calculated as:

where:

V

EXT

R

EXT

IO(max) =

R

EXT

EXT

is 1.25 V typical, and

is the value of the user-selected external resistor, which

38.4 ,

×

(1)

V

should not be less than 600 Ω, corresponding to 80 mA.

Figure 4 shows the maximum per channel constant output current, IO(max), of OUT0 to OUT15, versus R

, the value of the

EXT

,

resistor between REXT terminal and ground.

Dot Correction The A6285 can independently fine-adjust

the current of each output channel, a feature referred to as dot

correction. This feature is used to compensate for the brightness

deviations of the LEDs connected to the output channels, OUT0

through OUT15.

Each of the 16 channels can be programmed with a 7-bit word.

The channel output can be adjusted in 128 steps from 0% to

100% of the maximum programmable per channel output current, IO(max). Equation 2 determines the output current for each

OUTx:

I

(max) × DC

IOx =

O

127

x

,

(2)

where DCx is the programmed dot-correction value (0, 1, …127)

for each output channel.

register. The timing sequence is shown in figure 9.

All Channel Output Enable-Disable All OUTx channels

of the A6285 can switched off using the O¯ ¯E¯ pin. When O¯ ¯E¯ is

set high, all OUTx outputs are disabled, regardless of the on/off

status of any OUTx. When O¯ ¯E¯ is set to low, the on/off status of

each OUTx is determined by the state of the latches in the On/Off

register. O¯ ¯E¯ can be PWMed to control the average current, which

controls the LED brightness of all outputs, in addition to the DC

function.

Individual Channel Output Enable-Disable Each OUTx

channel can be switched on or off independently. Each of the

channels can be programmed with a 1-bit word.

On/off data is entered for all channels at the same time. The

complete on/off data format consists of sixteen 1-bit words, which

form a 16-bit wide serial data packet. The data for each channel is

sent in a continuous sequence, and all data is clocked in with the

MSB first, as shown in figure 8.

To input data into the On/Off register, LE must be set low, and

MODE must be set low. LE allows on/off data to enter the input

shift register, and MODE sets the input shift register to 16-bit

width. After all serial data is clocked in, a rising edge on the LE

terminal latches the data into the On/Off register and moves the

LOD data at the Open Circuit Detector into the input shift register. The timing sequence is shown in figure 9.

LSB MSB

0

… … …

DC 0.0

DC

OUT0

Figure 7. Dot Correction (DC) data format

6

DC 0.6

7

DC 1.0

DC

OUT2

through DC

DC 14.6

OUT14

104

105

DC 15.0

111

DC 15.6

DC

OUT15

Dot correction data is entered for all channels at the same time.

The complete dot correction data format consists of sixteen 7-bit

words, which form a 112-bit (16 × 7) wide serial data packet. The

data for each channel is sent in a continuous sequence, and all

data is clocked in with the MSB first, as shown in figure 7.

To input data into the Dot Correction register, LE should be set

low, and MODE must be set high. MODE sets the input shift register to 112-bit width. After all serial data is clocked in, a rising

edge on the LE terminal latches the data into the Dot Correction

LSB MSB

On/Off On/Off

OUT

1

0

…

OUT1through OUT

0

14 15

On/Off On/Off

14

Figure 8. Individual output on-off data format

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

OUT

15

8

Page 9

A6285

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

Delay Between Outputs The A6285 has graduated delay

circuits between outputs. The fixed delay time is 20 ns (typical).

OUT0 has no delay, OUT1 has a 20 ns delay, OUT2 has a 40 ns

delay, and so forth. This delay prevents large in-rush currents

that create ground bounce, which reduces power supply bypass

capacitor requirements when the outputs turn on. The delays

work during switch on and switch off of each output channel.

Serial Interface Data Transfer Rate The A6285

includes a flexible serial data interface, which can be connected

to a microcontroller or a digital signal processor. Only 3 pins are

required to input data into the device. The rising edge of a CLK

signal shifts the data from SDI pin to the input shift register. After

all data is clocked in, a rising edge of LE latches the serial data

to the On/Off register. All data is clocked in with the MSB first,

while LE is set low.

Multiple A6285 devices can be cascaded by connecting the SDO-

pin of one device with the SDI pin of the following device. The

SDO pin can also be connected to the microcontroller or micro-

processor in order to transmit LOD information from the A6285.

Figure 9. Output on-off and Dot Correction timing

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

9

Page 10

A6285

f

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

Figure 10 shows an example application with n cascaded A6285

devices connected to a controller. The maximum number of

cascaded devices depends on the application system and the data

transfer rate. The minimum data input transfer rate is calculated

as follows:

= 112 × f

CLK

UPDATE

× n ,

(3)

where:

is the minimum data input frequency for CLK and SDI,

f

CLK

f

is the update rate of the entire cascaded system, and

UPDATE

n is the number of cascaded A6285 devices.

Operating Modes The A6285 has two operating modes, deter-

mined by the MODE signal:

• On-Off mode (MODE = low)

• Dot Correction mode (MODE = high)

Fault Output, FAULT The open-drain output FAULT is used

to report both of the fault flags, LOD and TSD. During normal

operating conditions, the internal transistor connected to the

FAULT pin is turned off. The voltage on FAULT is pulled up to

VDD through a external pull-up resistor.

If an LOD or TSD condition is detected, the internal transistor is

turned on, and FAULT is pulled to PGND. Because FAULT is an

open-drain output, multiple ICs can be ORed together and pulled-

up to VDD with a single pull-up resistor, as shown in figure 10.

This reduces the number of signals needed to report faults.

To determine whether the fault is a TSD or an LOD, LOD can be

masked by setting O¯ ¯E¯ = high. However, it cannot be determined

if both a TSD and an LOD condition are present. The FAULT

Truth Table is shown on page 11.

Active Pull-up Enable, PE The A6285 provides active

pull-ups on each output determined by the PE pin. When the

LED supply, V

, is tied to the PE pin, the active pull-ups are

LED

enabled. When the PE pin is tied to ground, the active pull-ups

are disabled. The Active Pull-up Enable is also current-limited to

2.8 mA typical, preventing possible damage to the device in the

event of a short-to-ground. This feature can eliminate ghosting in

multiplexing applications.

Undervoltage Lockout (UVLO) and Power-On Reset

(POR) The A6285 includes an internal undervoltage lockout

circuit that disables the outputs in the event that the logic supply

voltage drops below a minimum acceptable level. This feature

prevents the display of erroneous information, a function necessary for some critical applications. A Power-On Reset (POR)

is performed upon recovery of the logic supply voltage after a

UVLO event and at power-up. During POR, all internal shift

registers and latches are set to 0.

Thermal Shutdown Protection and Fault Flag (TSD) The

A6285 provides thermal protection when the device is overheated, typically a result of excessive power being dissipated in

the outputs. If the junction temperature exceeds the threshold

Controller

V

DD

100 k

SDI

FAULT

CLK

LE

MODE

OE OE OE

SDO

MODE

V

LED

PE

SDI SDO

FAULT

CLK

LE

OUT0 OUT15PE OUT0

A6285

V

LED

OUT15

V

DD

100 nF

REXT

5

SDI SDO

FAULT

CLK

LE

MODE

Figure 10. Schematic of cascaded A6285 devices

V

LED

V

LED

……

V

DD

A6285

IC nIC 1

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

100 nF

REXT

10

Page 11

A6285

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

temperature, T

, of 165°C (typical), all driver outputs will

TSDF

be turned off and a TSD fault will be flagged. The TSD flag will

pull the FAULT output pin to PGND (low). After a 15°C (typical) drop in junction temperature, the outputs will turn back on

and the FAULT pin will be pulled back to VDD (high). The input

shift register and the latch register will remain active during a

TSD event. Therefore, there is no need to reset the data in the

output latches. However, the TSD cycle will continue until the

thermal problem is corrected.

LED Open Detection (LOD) The A6285 provides LED open

circuit detection. This circuit flags a fault and pulls the FAULT

pin to PGND (low) if any of the 16 OUTx LEDs are open or

disconnected from the circuit.

The LOD circuit flags a fault when all of the following conditions

are met:

• O¯ ¯E¯ is set low

• The voltage at each OUTx pin is sampled after being turned on

• V

OUTx

< V

(0.3 V typical)

LOD

MODE may be set either high or low. However, to perform a

complete LOD cycle, which includes reading the LOD status of

each OUTx, MODE must be set low.

A complete LOD cycle is described as follows:

the input shift register every time On/Off data is moved into

the On/Off Register, although in reality, the previous LOD

status is being moved into the input shift register.

If an LOD condition was previously detected, a 1 for each

open LED will be moved from the Open Circuit Detector into

the input shift register, where it can be read on the SDO pin.

4. The existing LOD condition is sampled within 2 μs of the outputs turning on and the resulting status data waits at the Open

Circuit Detector until moved into the input shift register on the

rising edge of the next LE pulse.

5. The cycle is repeated when new On/Off data is clocked into

the input shift register. As new data is being clocked in, LOD

status data is being clocked out of the SDO pin, where it can

be read by a microprocessor.

Note: It is not necessary to load new On/Off data in order to view

the LOD status waiting at the Open Circuit Detector. A second

LE pulse will put the LOD data into the input shift register. However, LOD data that is presently in the input shift register will be

moved into the On/Off Register, generating a “blank” display.

Such a blank display may be undesirable; therefore, a second

LE pulse should not be applied without first clocking in useful

On/Off data for updating the display.

1. On/Off data is clocked into the input shift register.

2. LE is pulsed to move the On/Off data into the On/Off Register. The data is moved on the rising edge of LE. If an LOD

condition is present, the FAULT output is immediately pulled

to PGND (low).

3. Data present at the Open Circuit Detector (sampled when data

was moved into the On/Off Register on the previous transition

of LE) is immediately moved into the input shift register on

the same rising edge of LE.

If no LOD condition was previously detected, all 0s are present at the Open Circuit Detector. Thus, all 0s are moved into

the input shift register. This gives the appearance of “clearing”

FAULT Truth Table

Conditions

Junction Temperature Outx Voltage

TJ < T

TJ < T

TJ < T

T

< T

J

TJ > T

TJ > T

TJ > T

T

> T

J

TSD

TSD

TSD

TSD

TSD

TSD

TSD

TSD

Outx > V

Outx < V

Outx > V

Outx < V

Outx > V

Outx < V

Outx > V

Outx < V

LOD

LOD

LOD

LOD

LOD

LOD

LOD

LOD

The update interval between LE pulses ( LE1 to LE2 ), referred

to as the LOD Sample and Read Time, t

, must be at least

LOD

1660 ns to allow for settling and staggered delays. Figure 11

shows the LOD serial data format. The FAULT truth table is

shown below.

LSB MSB

LOD LOD

OUT

Figure 11. Individual output LOD data format

Output Enable,

1

0

…

OUT1through OUT

0

Fault Output

O¯ ¯E¯

14 15

LOD LOD

14

OUT

SDO

15

HH

HH

LH

LL

HL

HL

LL

LL

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

11

Page 12

A6285

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

Application Information

Load Supply Voltage (V

LED

)

These devices are designed to operate with driver voltage drops

(VDS) of 1.0 to 3.0V, with one or more LED forward voltages,

VF , of 1.2 to 4.0 V. If higher voltages are dropped across the

driver, package power dissipation will increase significantly. To

minimize package power dissipation, it is recommended to use

the lowest possible load supply voltage, V

voltage dropping, V

with V

DROP

= IO× R

, according to the following formula:

DROP

V

= V

DROP

for a single driver or for a Zener diode

DROP

– VF – V

LED

, or to set any series

LED

DS ,

(VZ), or for a series string of silicon diodes (approximately 0.7 V

per diode) for a group of drivers (see figure 3). If the available

voltage source will cause unacceptable power dissipation and

series resistors or diodes are undesirable, a voltage regulator can

be used to provide V

LED

.

For reference, typical LED forward voltages are:

LED Type VF (V)

White 3.5 to 4.0

Blue 3.0 to 4.0

Green 1.8 to 2.2

Yellow 2.0 to 2.1

Amber 1.9 to 2.65

Red 1.6 to 2.25

Infrared 1.2 to 1.5

Pattern Layout

The logic and power grounds should be kept separate, terminated

at one location. The exposed metal pad must be connected to a

large power ground plane, allowing the copper to dissipate heat.

Where multiple devices are cascaded, multilayer boards are

recommended.

REXT should be placed as close as possible to the device, keeping a short distance between the REXT pin and ground.

Decoupling capacitors should be used liberally. 0.1 μF should

be placed on the logic supply pin, and 10 μF placed between

the common VLED line and the device ground at least at every

second device.

Package Power Dissipation (PD)

The maximum allowable package power dissipation based on

package type is determined by:

P

where R

= (150 – TA) / R

D(max)

is the thermal resistance of the package mounted on

θJA

θJA

,

the circuit board, determined experimentally. Power dissipation

levels based on the package are shown in the Package Thermal

Characteristics section (see page 7).

The actual package power dissipation is determined by:

P

= DC × (VDS × IO× 16) + (VDD× IDD) ,

D(act)

where DC is the duty cycle. The value 16 represents the maximum number of available device outputs.

When the load supply voltage, V

P

D(act)

> P

, an external voltage reducer (V

D(max)

, is greater than 3 to 5 V, and

LED

DROP

) must be

used (see figure 12).

Figure 12. Typical application voltage drops

Reducing the percent duty cycle, DC, will also reduce power dissipation.

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

12

Page 13

A6285

16-Channel Constant-Current Latched LED Driver

with Open LED Detection and Dot Correction

Package ET, 5 mm x 5 mm, 32-pin QFN with Exposed Thermal Pad

33X

0.40

5.00 ±0.15

32

1

2

A

5.00 ±0.15

D

C0.08

+0.05

0.25

+0.15

–0.10

–0.07

2

1

0.50

B

32

3.40

0.90 ±0.10

3.40

SEATING

PLANE

1.00

1

2

C

C

All dimensions nominal, not for tooling use

(reference JEDEC MO-220VHHD-6)

Dimensions in millimeters

Exact case and lead configuration at supplier discretion within limits shown

A

Terminal #1 mark area

Exposed thermal pad (reference only, terminal #1

B

identifier appearance at supplier discretion)

C

Reference land pattern layout (reference

IPC7351 QFN50P500X500X100-33V6M);

All pads a minimum of 0.20 mm from all adjacent pads; adjust as

necessary to meet application process requirements and PCB layout

tolerances; when mounting on a multilayer PCB, thermal vias at the

exposed thermal pad land can improve thermal dissipation (reference

EIA/JEDEC Standard JESD51-5)

D

Coplanarity includes exposed thermal pad and terminals

0.30

32

1

3.40

5.00

PCB Layout Reference View

0.50

3.40

5.00

Copyright ©2007-2008, Allegro MicroSystems, Inc.

The products described here are manufactured under one or more U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such de par tures from the detail spec i fi ca tions as may be required to permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to verify that the

information being relied upon is current.

Allegro’s products are not to be used in life support devices or systems, if a failure of an Allegro product can reasonably be expected to cause the

failure of that life support device or system, or to affect the safety or effectiveness of that device or system.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable. How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty for its use;

nor for any in fringe ment of patents or other rights of third parties which may result from its use.

For the latest version of this document, visit our website:

www.allegromicro.com

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

13

Loading...

Loading...