Allegro A4255CLN, A4255CA Datasheet

Data Sheet

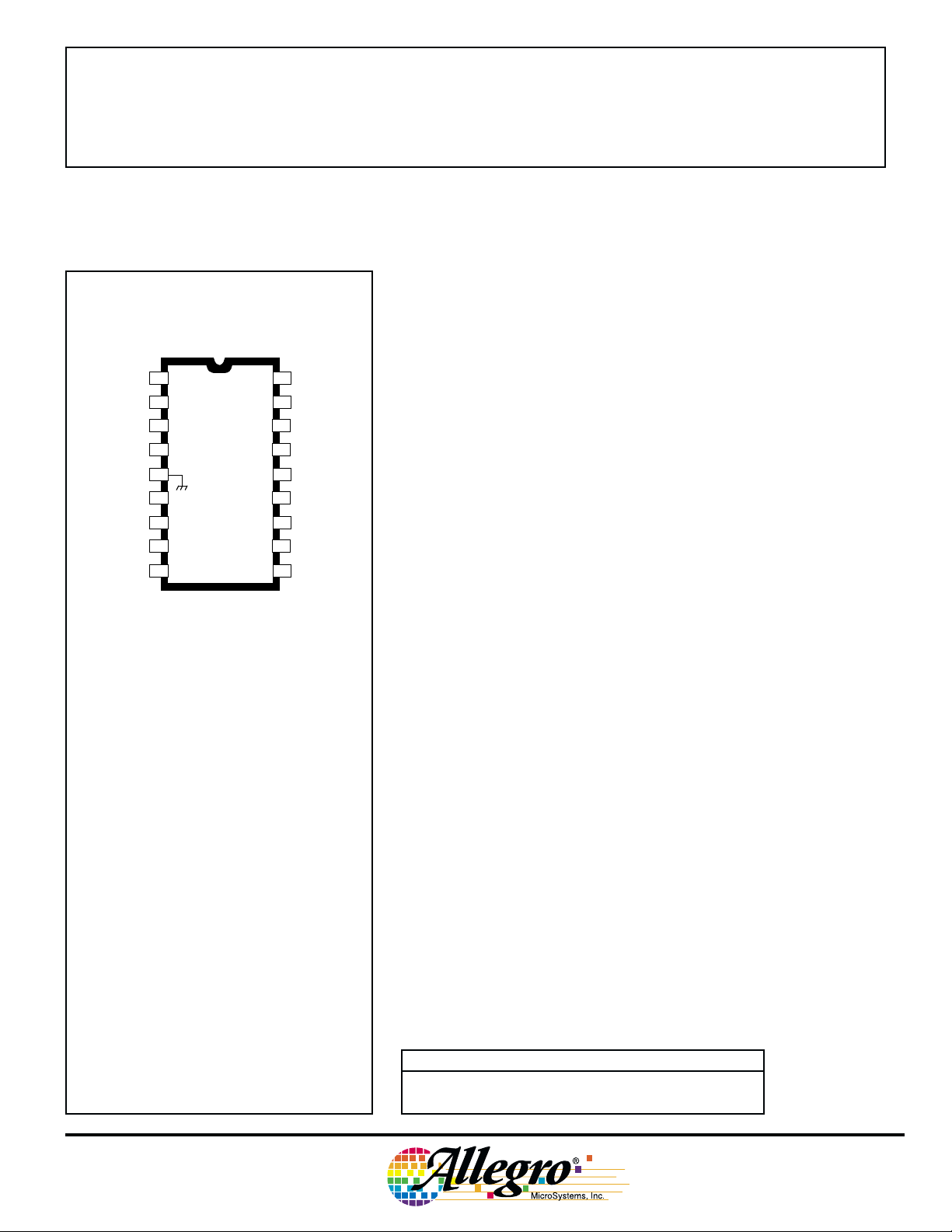

MODE SELECT

MODE SELECT

STEP IN

RESET

GROUND

MONITOR OUT

SHIFT CLOCK

SERIAL DATA OUT

STROBE OUT

1

1

2

2

3

4

5

6

7

8

9

A4255CA

DD

18

MODE SELECT

DIRECTION

17

CONTROL IN

16

OSC/CLOCK IN

15

OSC/CLOCK OUT

14

SUPPLYV

13

PFD

12

PHASE

11

PFD

10

PHASE

A

A

B

B

Dwg. PP-071A

4255

MICROCONTROLLER

The A4255CA and A4255CLN microcontrollers make designing

with step motors easy, inexpensive, and productive. A reference design

technique is integral to the implementation of a system that includes the

power circuitry, a low-cost, 8-bit, preprogrammed microcontroller and

the other components needed to complete the control hardware. The

0

A4255Cx eliminates the need for software development, expedites the

product creation, and hastens the time to market.

The reference design can be utilized directly or integrated into a

larger printed wiring board. A further benefit is the compactness of the

circuit layout. Power-driver output ratings presently available with these

devices are 50 V and ±1.5 A (with the A3955 or A3957). A similar

device for 46 V and either 1.5 A (with the SLA7042M) or 3 A (with the

SLA7044M) is planned. The reference design supports stepping formats

that include full-step, half-step, quarter-step, eighth-step, and sixteenthstep (microstepping) increments for a two-phase stepping motor.

The A4255CA is furnished in an 18-pin dual in-line plastic package

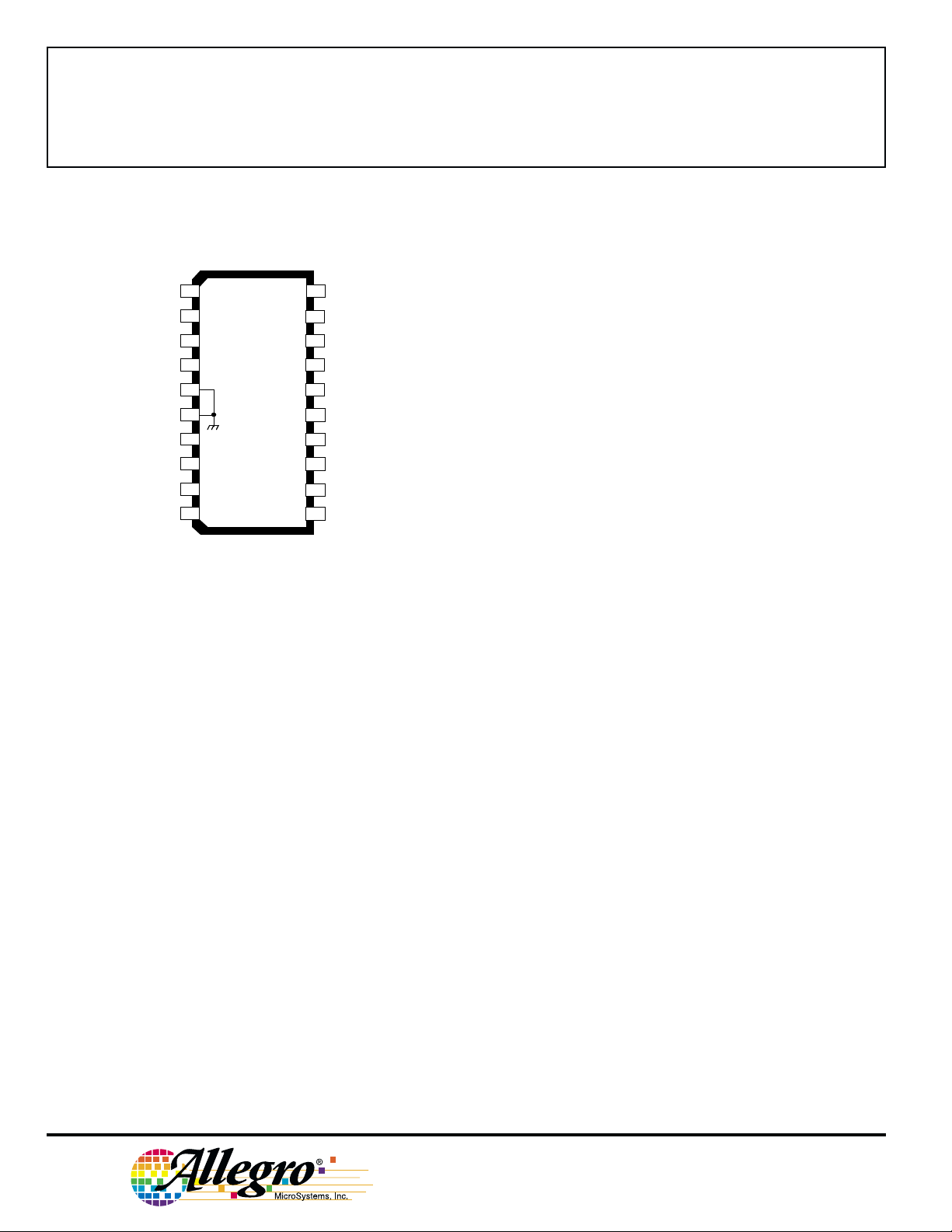

for through-hole applications. The A4255CLN is furnished in a 20-lead

wide-body, shrink-pitch, small-outline plastic package (SSOP) with gullwing leads for minimum area, surface-mount applications.

26113

8-BIT

ABSOLUTE MAXIMUM RATINGS

Supply Voltage, VDD.......................... 7.0 V

Input Voltage Range,

VI........................ -0.3 V to VDD + 0.6 V

RESET Voltage, V

Input Clamp Current, IIK............... ±20 mA

Output Clamp Current, IOK............ ±20 mA

Operating Temperature Range,

TA.................................... 0°C to +70°C

Storage Temperature Range,

TS.............................. -55°C to +150°C

Caution: These CMOS devices have input

static protection (Class 3) but are still

susceptible to damage if exposed to extremely

high static electrical charges.

...................... 14 V

RESET

FEATURES

■ Full-, Half-, Quarter-, Eighth-, or Sixteenth-Step Increments

■ DC to 20 MHz Clock Input

■ Power-On Reset

■ Brown-Out Reset

■ High-Speed CMOS Technology

■ Low Power, <20 mA @ 5 V, 20 MHz

(Typically 9 mA)

Always order by complete part number:

Part Number Package

A4255CA 18-pin DIP

A4255CLN 20-lead shrink-pitch SOIC

4255

8-BIT

MICROCONTROLLER

A4255CLN

0.65 mm (0.026”) pitch

MODE SELECT

MODE SELECT

STEP IN

RESET

GROUND

GROUND

MONITOR OUT

SHIFT CLOCK

SERIAL DATA OUT

STROBE OUT

1

1

2

2

3

4

5

7

9

8

9

10

DD

DD

MODE SELECT

20

DIRECTION

19

CONTROL IN

18

OSC/CLOCK IN

17

OSC/CLOCK OUT

SUPPLYV

16

156

SUPPLYV

14

PFD

13

PHASE

PFD

12

PHASE

11

0

A

A

B

B

Dwg. PP-071-1

FUNCTIONAL DESCRIPTION

To ease and simplify the design effort, the user only

provides the following signals: (a) direction, (b) stepping

clock (8x the full-step frequency), (c) mode logic (three

inputs determine the operation for full, half, quarter, or

eighth stepping), (d) reset input (initiates a ‘detent’

position), and (e) recirculation control (this allows establishing the percent of fast- vs slow-decay in the phase

winding). The microcontroller program providess automatic recirculation control. This eliminates the need for

evaluating the impact of stepping rate vs the sinusoidal

current profile.

Although recirculation control can provide slight

improvements (i.e., lower current ripple, reduced motor

heating [a few degrees], and diminish audible noise levels

[minimal differences]), this entails an evaluation of the

motor (and step frequencies) to determine the proper ratio

of fast- and slow-decay. The benefits of tuning the

recirculation ratios are small, and the time and effort

required can be considerable. Hence, the uninitiated user

should opt for the automatic recirculation control, and

avoid the essentially unnecessary activity.

RECOMMENDED OPERATING CONDITIONS

over operating temperature range

Logic Supply Voltage Range, VDD............... 4.5 V to 5.5 V

High-Level Input Voltage, VIH............................ ≥ 0.85V

Low-level input voltage, VIL................................. ≤0.15V

MICROCONTROLLER OPERATION

Although ‘hardware’ control of the microstepping ICs

is feasible, without a specific (ASIC), monolithic IC

controller the prime solution becomes a ‘software’ option.

From the user’s perspective, a ‘preprogrammed’ microcontroller appears little, or no, different than a ‘dedicated’

controller and sequencer IC expressly created for microstepping applications of the power-driver ICs. Further,

the flexibility of a software-based drive is certainly a basic

benefit (high-volume production of 8-bit microcontrollers

transposes to low-cost circuitry).

As an indicator of the logic signals needed to control

the power ICs, Table 1 lists the required A3955 inputs to

the 3-bit DAC for eighth-step operation (the similar

A3957 uses a 4-bit DAC for sixteenth-step operation).

These I/O signals are serial data from the microcontroller,

then converted to a parallel mode by a 74HC595 as the

‘interface’ between the microcontroller and the two

microstepping power ICs.

The versatility offered by software control allows the

operating modes listed in Table 1. This table itemizes the

various logic inputs that determine direction, stepping

DD

DD

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2000, Allegro MicroSystems, Inc.

FUNCTIONAL DESCRIPTION (cont’d)

format, reset, 1/8th vs 1/16th sub-steps, etc. Note that

during power up, shift clock (SCLK) is sampled for a pullup or pull-down resistor to establish the fractional step

limit. A pull up sets up a 1/8th-step format (for the

A3955) and pull down sets up 1/16th-operation (for the

A3957).

Table 2 lists the microcontroller terminal descriptions

and provides the essence of the circuit operation (a

schematic illustrating a typical stepper design follows). A

brief description of the microcontroller I/O should clarify

the connections of the various elements of the drive

electronics.

4255

8-BIT

MICROCONTROLLER

Table 1 — Controller/sequencer IC operational logic

Binary inputs Operating mode Comments

DIR MS2 MS1 MS0 (Command executed on L → H of CLK) (Applicable power ICs)

0000 CW, Full step (single-phase) A3955/57

0001 CW, Half step (constant torque) A3955/57

0010 CW, 1/4 step (constant torque) A3955/57

0011 CW, 1/8th step (constant torque) A3955/57

0100 CW, 1/16th step (constant torque) A3957 only

0101 Disable A3955/57 holding torque At present position

0110 Enable A3955/57 holding torque From present position

0111 Reset A4255 sequencer IC A3955/57

1000 CCW, full step (single-phase) A3955/57

1001 CCW, half step (constant torque) A3955/57

1010 CCW, 1/4 step (constant torque) A3955/57

1011 CCW, 1/8th step (constant torque) A3955/57

1100 CCW, 1/16th step (constant torque) A3957 only

1101 Disable A3955/57 holding torque At present position

1110 Enable A3955/57 holding torque From present position

1111 Reset A4255 sequencer IC A3955/57

www.allegromicro.com

Loading...

Loading...