Allegro A3976KLB, A3973KB Datasheet

ADVANCED DATASHEET - 02/19/99

(Subject to change without notice)

Page 1 of 5

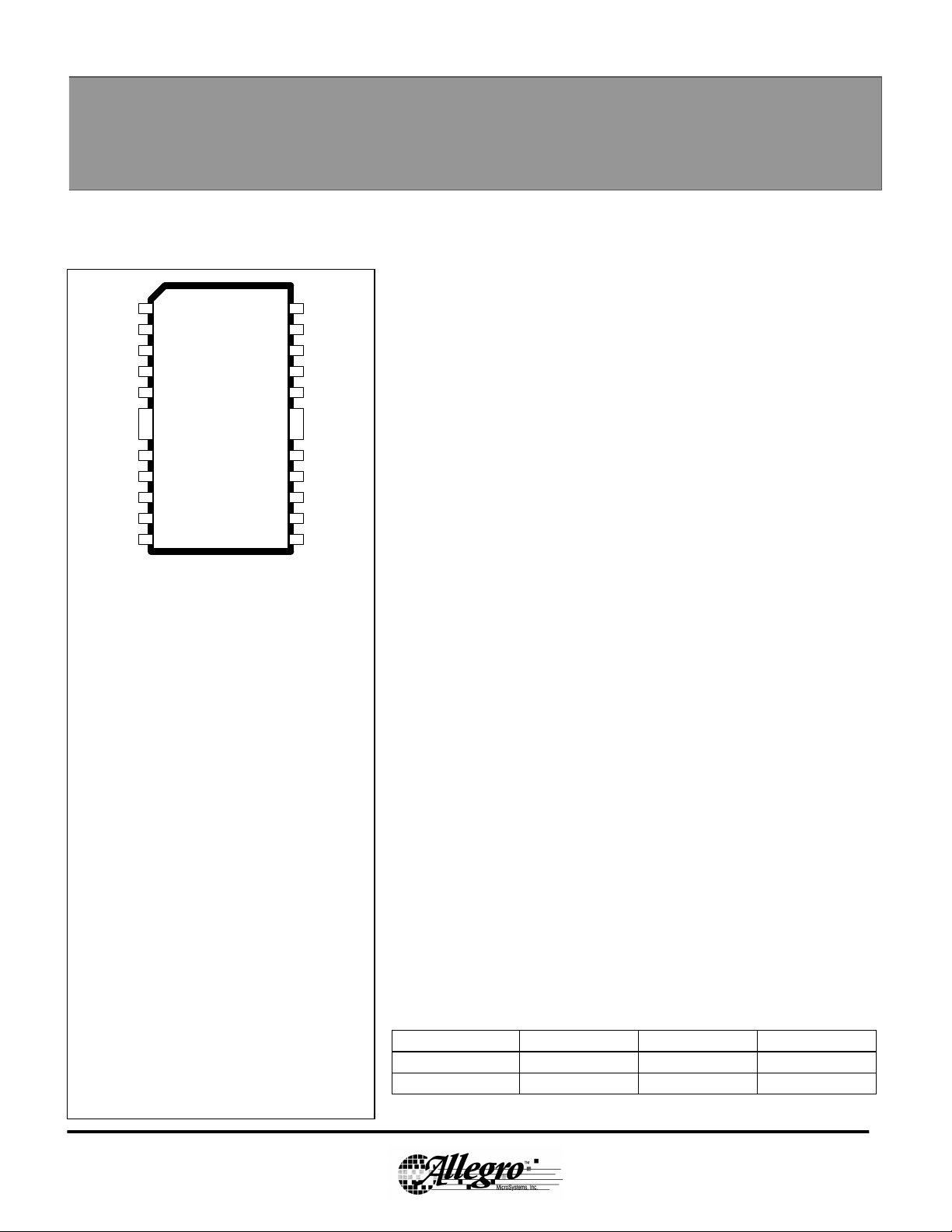

3976

DUAL FULL BRIDGE

PROTECTED MOTOR DRIVER

ENABLE1

PHASE1

GROUND

GROUND

OUT1A

FAULT1

OUT1B

1

V

BB

2

3

4

n/c

5

n/c

A3976KLB

6

7

8

n/c

9

10

n/c

11

12

24

23

22

21

20

19

18

17

16

15

14

13

V

CC

ENABLE2

PHASE2

n/c

n/c

GROUND

GROUND

n/c

OUT2A

n/c

FAULT2

OUT2B

ABSOLUTE MAXIMUM RATINGS

at TA = +25°C

Operating Supply Voltage, VBB....................30 V

Non-Operating Supply Voltage.....................35 V

Output Current, I

Logic Supply Voltage, VCC..........................7.0 V

Fault Output Voltage ...................................7.0 V

Logic Input Voltage Range,

VIN..........................-0.3 V to V

Package Power Dissipation (TA = +25°C), P

A3976KLB..................................2.2 W

A3976KB....................................2.9 W

Operating Temperature Range,

TA..............................-40°°C to +125°°C

Junction Temperature, TJ.........................+150°°C

Storage Temperature Range,

TS...............................-55°°C to +150°°C

* Output current rating may be limited by duty cycle,

ambient temperature, and heat sinking. Under any set of

conditions, do not exceed the specified current rating or a

junction temperature of 150°C.

............................±±500 mA*

OUT

CC

+ 0.3 V

D

The A3976 is designed to drive both windings of a bipolar stepper

motor or bidirectionally control two DC Motors. Both H-Bridges are capable

of continuous output currents of up to +/- 500 mA and operating voltages to

30V. Free wheeling, substrate isolated diodes are included for output transient

suppression when switching motors or other inductive loads. For each bridge

the PHASE input controls load current polarity by selecting the appropriate

source and sink driver pair. The ENABLE input, when held high, enables the

respective output H-bridge. When both ENABLE pins are held low the device

will enter SLEEP mode and consume less than 100µA.

The 3976 is protected to ensure safe operation in harsh operating

environments and was designed specifically for automotive applications.

Protection circuitry will check for open or shorted load, motor lead short to

ground or supply, VBB overvoltage, VCC undervoltage, and thermal

shutdown. If any of these conditions are detected the outputs will be disabled

and fault information will be output to diagnostic pins FAULT1 and FAULT2.

The 3976 is supplied in a choice of two power packages, a 16-lead

plastic DIP with a copper batwing tab (suffix ‘B’), and a 24-lead plastic SOIC

with a copper batwing tab (suffix ‘LB’). In both cases, the power tab is at

ground potential and needs no electrical isolation.

FEATURES

n 30 V , ±500 mA Continuous Output Rating

n 35V Load Dump Survival

n Output Short Circuit Protection

n Coded Fault Diagnostic Outputs

n Low Current Standby Mode

n Open Load Monitor

n Low Current Standby Mode

n VBB Over Voltage Shutdown

n Internal Thermal Shutdown Circuitry

n Internal Low Parasitic Free Wheeling Diodes

n Crossover Current Protection

PART NUMBER PACKAGE R

ØJA

A3976KLB 24 Lead SOIC 56°°C/W 6°°C/W

A3973KB 16 Lead DIP 43 °°C/W 6°°C/W

R

ØJT

Page 2 of 5

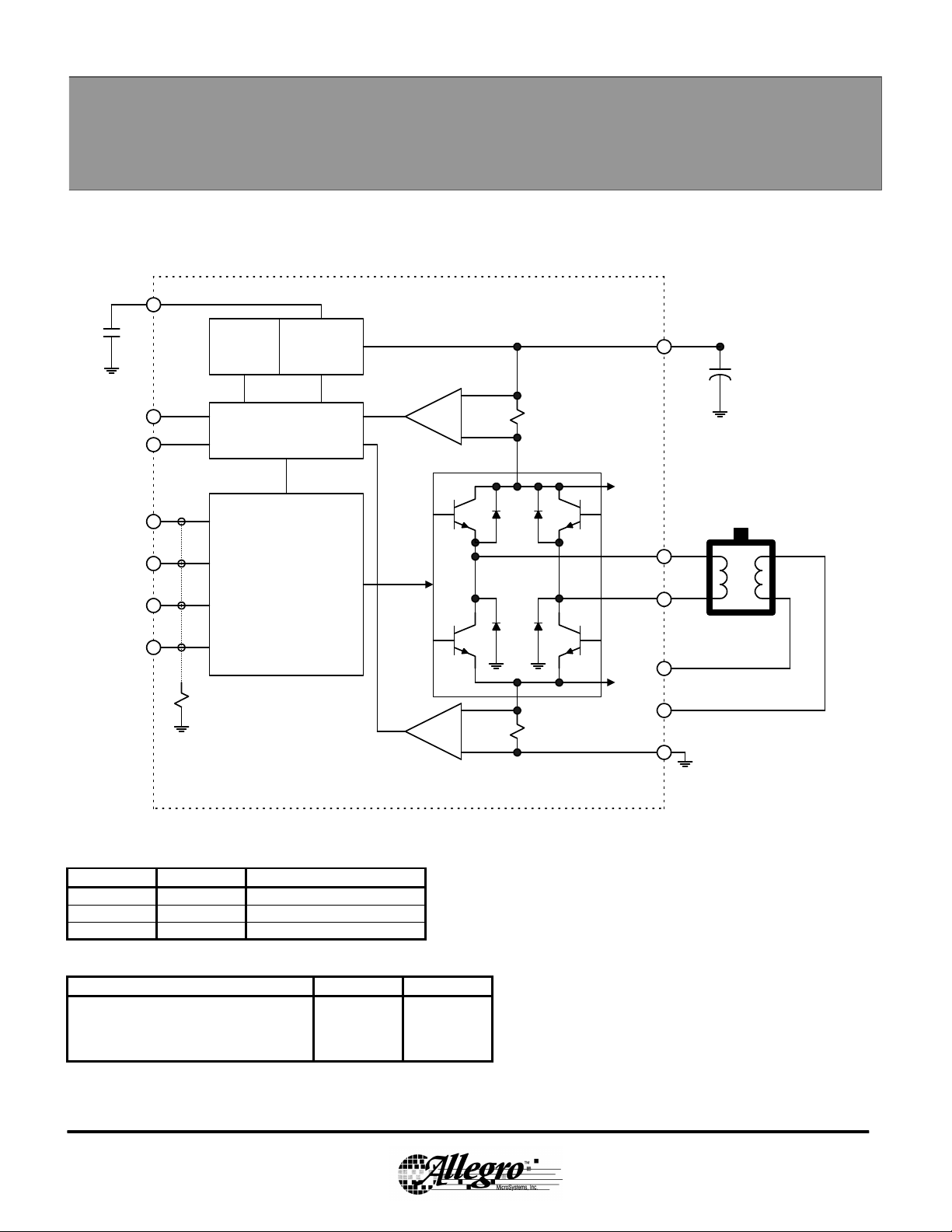

3976 Dual Protected PWM Motor Driver

Functional Block Diagram

(one of two bridges shown)

V

CC

FAULT1

FAULT2

PHASE1

ENABLE1

PHASE2

ENABLE2

Thermal

Shutdown

Diagnostic Logic

Input Pull Down

Over/Under

Voltage

Monitor

CONTROL

LOGIC

Short to Supply

Monitor

Short to Ground

Monitor

To Bridge 2

To Bridge 2

V

BB

OUT1A

OUT1B

OUT2A

OUT2B

GROUND

Input Logic

PHASE ENABLE OUTA OUTB

X 0 Off Off

0 1 Low High

1 1 High Low

Fault Logic

Fault Condition FAULT1 FAULT2

Thermal Shutdown Low Low

Short to Battery or Open Load Low High

Short to Ground High Low

Normal Operation High High

Loading...

Loading...