Allegro A3968SLB, A3968SA Datasheet

3968

Data Sheet

29319.29

ADVANCE INFORMATION

(subject to change without notice)

September 3, 1999

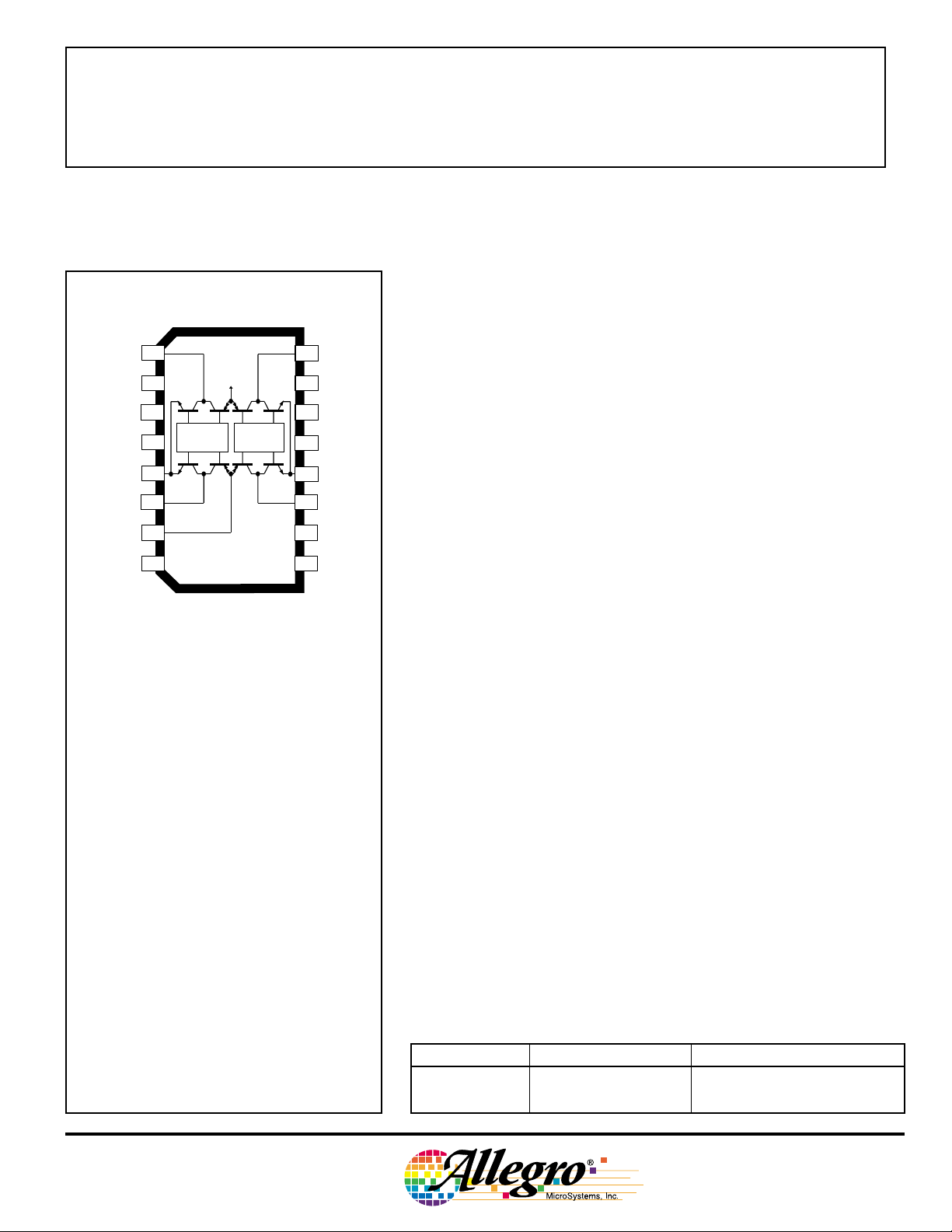

A3968SLB

OUT

INPUT

INPUT

GROUND

SENSE

OUT

SUPPLY

REFERENCE

1

1A

V

2

1A

3

1B

4

5

1

6

1B

LOAD

710

89

REF

BB

LOGICLOGIC

V

BB

ABSOLUTE MAXIMUM RATINGS

Load Supply Voltage, VBB................... 30 V

Output Current, I

(continuous) .............................. ±650 mA

Logic Supply Voltage, VCC................. 7.0 V

Input Voltage, Vin..... -0.3 V to VCC + 0.3 V

Sense Voltage, VS................................ 1.0 V

Package Power Dissipation

A3968SA ................................... 2.08 W*

A3968SLB ................................. 1.87 W*

Operating Temperature Range,

TA................................... -20°C to +85°C

Junction Temperature,

TJ................................................. +150°C

Storage Temperature Range,

TS................................. -55°C to +150°C

Output current rating may be limited by duty

cycle, ambient temperature, and heat sinking.

Under any set of conditions, do not exceed the

specified current rating or a junction temperature

of 150°C.

* Per SEMI G42-88 Specification, Thermal Test

Board Standardization for Measuring Junctionto-Ambient Thermal Resistance of Semiconductor

Packages.

(peak) .......... ±750 mA

OUT

16

15

14

13

12

11

V

CC

RC

Dwg. PP-066

(TA = 25°C)

OUT

INPUT

INPUT

GROUND

SENSE

OUT

LOGIC

SUPPLY

RCV

, P

DUAL FULL-BRIDGE PWM

MOTOR DRIVER WITH BRAKE

The A3968SA and A3968SLB are designed to bidirectionally control two

dc motors. Each device includes two H-bridges capable of continuous output

currents of ±650 mA and operating voltages to 30 V. Motor winding current

can be controlled by the internal fixed-frequency, pulse-width modulated

2A

2A

2B

2

2B

D

(PWM), current-control circuitry. The peak load current limit is set by the

user’s selection of a reference voltage and current-sensing resistors. Except

for package style and pinout, the two devices are identical.

The fixed-frequency pulse duration is set by a user-selected external

RC timing network. The capacitor in the RC timing network also determines

a user-selectable blanking window that prevents false triggering of the PWM

current-control circuitry during switching transitions.

To reduce on-chip power dissipation, the H-bridge power outputs have

been optimized for low saturation voltages. The sink drivers feature Allegro’s

patented Satlington™ output structure. The Satlington outputs combine the

low voltage drop of a saturated transistor and the high peak current capability

of a Darlington.

For each bridge, the INPUT

and INPUTB terminals determine the load

A

current polarity by enabling the appropriate source and sink driver pair.

When a logic low is applied to both INPUTs of a bridge, the braking function

is enabled. In brake mode, both source drivers are turned OFF and both sink

drivers are turned ON, thereby dynamically braking the motor. When a logic

high is applied to both INPUTs of a bridge, all output drivers are disabled.

Special power-up sequencing is not required. Internal circuit protection

includes thermal shutdown with hysteresis, ground-clamp and flyback diodes,

and crossover-current protection.

The A3968SA is supplied in a 16-pin dual in-line plastic package. The

A3968SLB is supplied in a 16-lead plastic SOIC with copper heat sink tabs.

The power tab is at ground potential and needs no electrical isolation.

FEATURES

■ ±650 mA Continuous Output Current

■ 30 V Output Voltage Rating

■ Internal Fixed-Frequency PWM Current Control

■ Satlington™ Sink Drivers

■ Brake Mode

■ User-Selectable Blanking Window

■ Internal Ground-Clamp & Flyback Diodes

■ Internal Thermal-Shutdown Circuitry

■ Crossover-Current Protection and UVLO Protection

Always order by complete part number:

Part Number Package R

θJA

A3968SA 16-pin DIP 60°C/W 38°C/W —

A3968SLB 16-lead batwing SOIC 67°C/W — 6°C/W

R

θJC

R

θJT

3968

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

WITH BRAKE

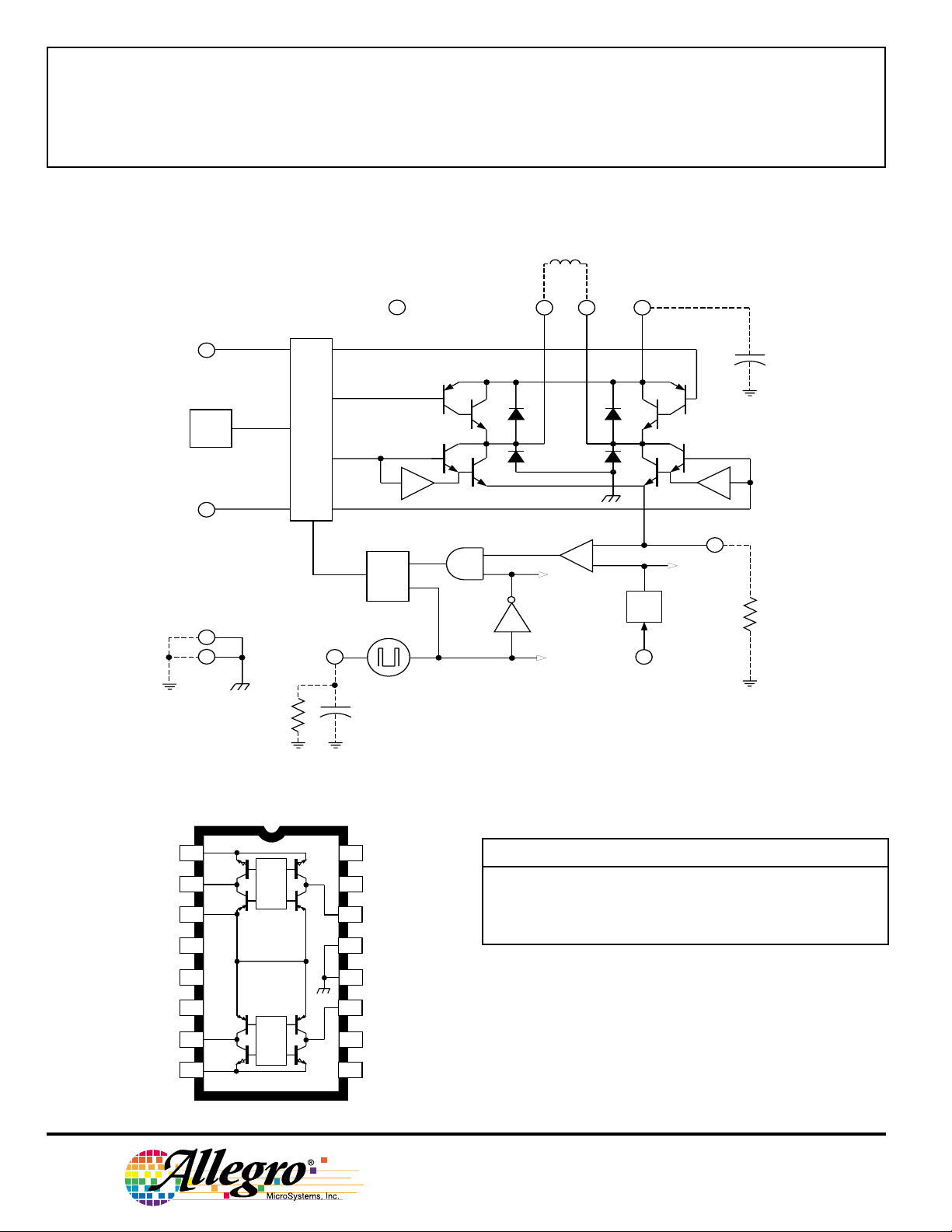

FUNCTIONAL BLOCK DIAGRAM

(one-half of circuit shown)

INPUT

UVLO

& TSD

INPUT

GROUND

A

LOGIC

SUPPLY

V

A

CC

OUT

V

BB

B

OUT

LOAD

SUPPLY

+

CONTROL LOGIC

B

R

T

SOURCE

ENABLE

RC

PWM LATCH

Q

C

T

OSC

BLANKING

GATE

R

S

CURRENT-SENSE

COMPARATOR

TO OTHER

BRIDGE

TO OTHER

BRIDGE

SENSE

+

–

TO OTHER

BRIDGE

÷4

REFERENCE

R

S

Dwg. FP-036-4

SENSE

OUT

LOAD

SUPPLY

REFERENCE

RC

LOGIC

SUPPLY

OUT

SENSE

A3968SA

TRUTH TABLE

INPUT

1

1

2

1B

3

V

4

REF

RC

5

V

6

CC

7

2B

8

2

V

LOGIC

BB

LOGIC

16

15

14

13

12

11

10

9

Dwg. PP-066-3

INPUT

OUT

1B

1A

1A

INPUTAINPUT

OUT

B

LLLLBrake mode

L H L H “Forward”

H L H L “Reverse”

H H Z Z Disable

GROUND

GROUND

OUT

2A

INPUT

2A

INPUT

2B

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1998, Allegro MicroSystems, Inc.

Z = High impedance

OUT

A

B

Description

3968

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

WITH BRAKE

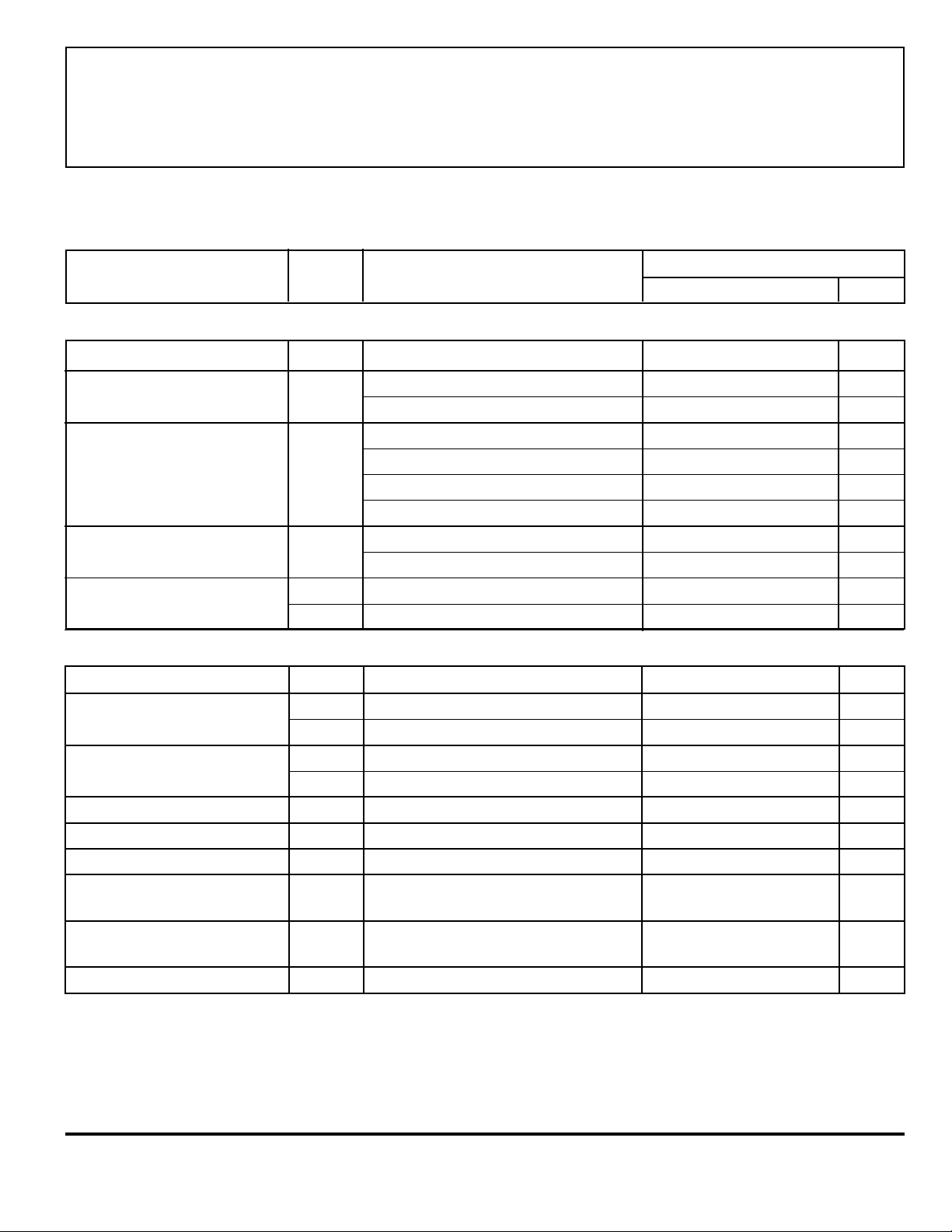

ELECTRICAL CHARACTERISTICS at T

V

= 0 V, 56 kΩ & 680 pF RC to Ground (unless noted otherwise)

S

= +25°C, V

A

= 30 V, VCC = 4.75 V to 5.5 V, V

BB

REF

= 2 V,

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Output Drivers

Load Supply Voltage Range V

Output Leakage Current I

Output Saturation Voltage V

CE(SAT)

Clamp Diode Forward Voltage V

Motor Supply Current I

(No Load)

BB(ON)

I

BB(OFF)

BB

CEX

F

Operating, I

V

= 30 V — <1.0 50 µA

OUT

V

= 0 V — <-1.0 -50 µA

OUT

Source Driver, I

Source Driver, I

Sink Driver, I

Sink Driver, I

= ±650 mA, L = 3 mH V

OUT

= -400 mA — 1.7 2.0 V

OUT

= -650 mA — 1.8 2.1 V

OUT

= +400 mA, VS = 0.5 V — 0.3 0.5 V

OUT

= +650 mA, VS = 0.5 V — 0.4 1.3 V

OUT

CC

—30 V

IF = 400 mA — 1.1 1.4 V

IF = 650 mA — 1.4 1.6 V

Both bridges ON (forward or reverse) — 3.0 5.0 mA

All INPUTs = 2.4 V — <1.0 200 µA

Control Logic

Logic Supply Voltage Range V

Logic Input Voltage V

V

Logic Input Current I

Reference Input Volt. Range V

Reference Input Current I

Reference Divider Ratio V

REF/VTRIP

Current-Sense Comparator V

IN(1)

I

IN(0)

REF

CC

IN(1)

IN(0)

REF

IO

Operating 4.75 — 5.50 V

V

IN

V

IN

Operating 0.1 – 2.0 V

V

REF

Input Offset Voltage

Current-Sense Comparator V

S

Operating -0.3 — 1.0 V

Input Voltage Range

Sense-Current Offset I

SO

IS – I

NOTES: 1. Typical Data is for design information only.

2. Negative current is defined as coming out of (sourcing) the specified device terminal.

2.4 — — V

— — 0.8 V

= 2.4 V — <1.0 20 µA

= 0.8 V — <-20 -200 µA

-2.5 0 1.0 µA

3.8 4.0 4.2 —

= 0.1 V -6.0 0 6.0 mV

, 50 mA ≤ I

OUT

≤ 650 mA 12 18 24 mA

OUT

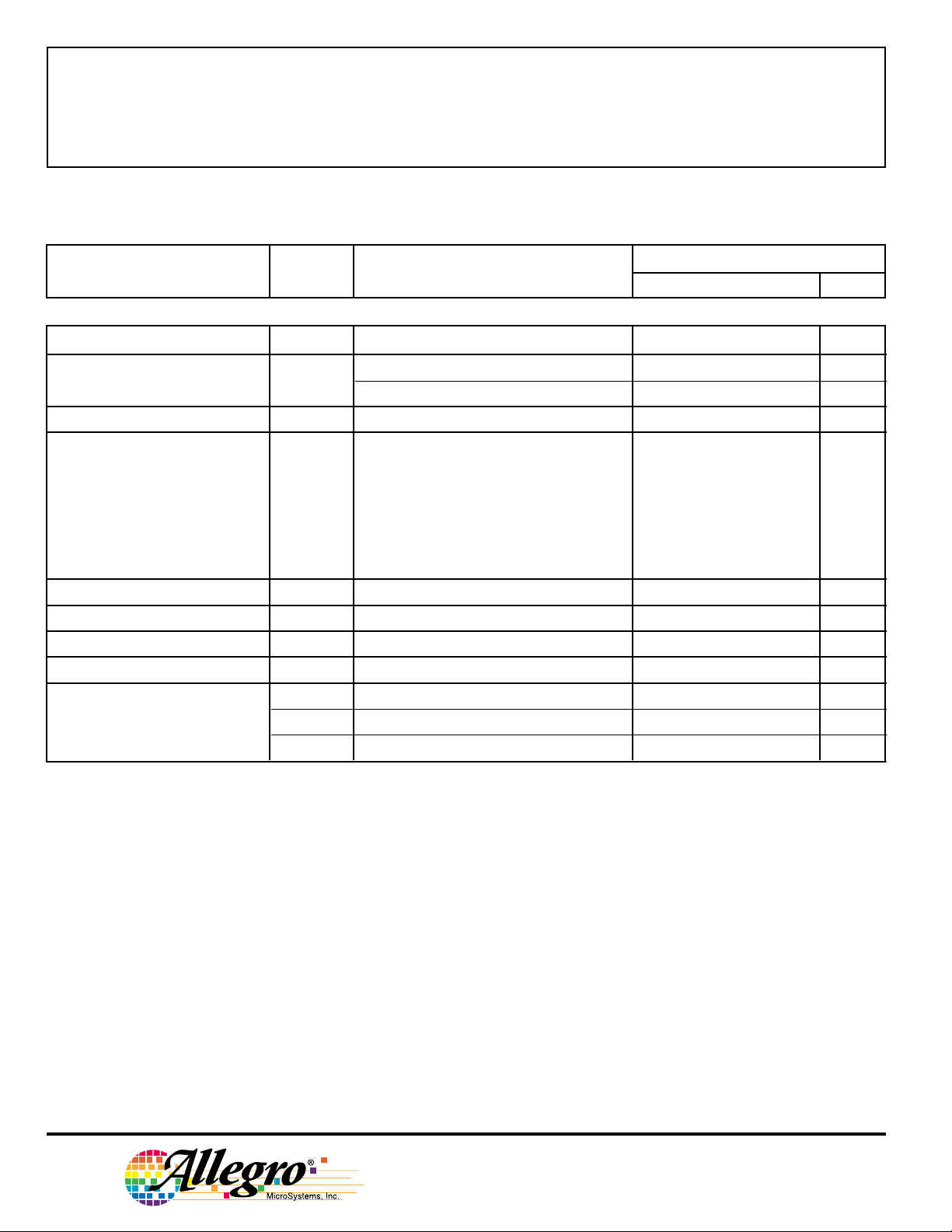

3968

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

WITH BRAKE

ELECTRICAL CHARACTERISTICS at T

V

= 0 V, 56 kΩ & 680 pF RC to Ground (unless noted otherwise) (cont.)

S

= +25°C, V

A

= 30 V, VCC = 4.75 V to 5.5 V, V

BB

REF

= 2 V,

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Control Logic (continued)

PWM RC Frequency f

PWM Propagation Delay Time t

Cross-Over Dead Time t

Propagation Delay Times t

Thermal Shutdown Temp. T

Thermal Shutdown Hysteresis ∆T

UVLO Enable Threshold V

UVLO Hysteresis V

Logic Supply Current I

osc

PWM

codt

T(UVLO)+

T(UVLO)hys

CC(ON)

I

CC(OFF)

I

CC(BRAKE)

pd

J

J

CT = 680 pF, R

Comparator Trip to Source OFF — 1.0 1.4 µs

Cycle Reset to Source ON — 0.8 1.2 µs

1 kΩ Load to 25 V 0.2 1.8 3.0 µs

I

= ±650 mA, 50% to 90%:

OUT

Disable OFF to Source ON — 100 — ns

Disable ON to Source OFF — 500 — ns

Disable OFF to Sink ON — 200 — ns

Disable ON to Sink OFF — 200 — ns

Brake Enable to Sink ON — 2200 — ns

Brake Enable to Source OFF — 200 — ns

Increasing V

Both bridges ON (forward or reverse) — — 50 mA

All INPUTs = 2.4 V — — 9.0 mA

All INPUTs = 0.8 V — — 95 mA

= 56 kΩ 22.9 25.4 27.9 kHz

T

— 165 — °C

—15—°C

CC

— 4.1 4.6 V

0.1 0.6 — V

NOTES: 1. Typical Data is for design information only.

2. Negative current is defined as coming out of (sourcing) the specified device terminal.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...