Allegro A3951SW, A3951SB Datasheet

29319.4†

3951

FULL-BRIDGE PWM MOTOR DRIVER

Data Sheet

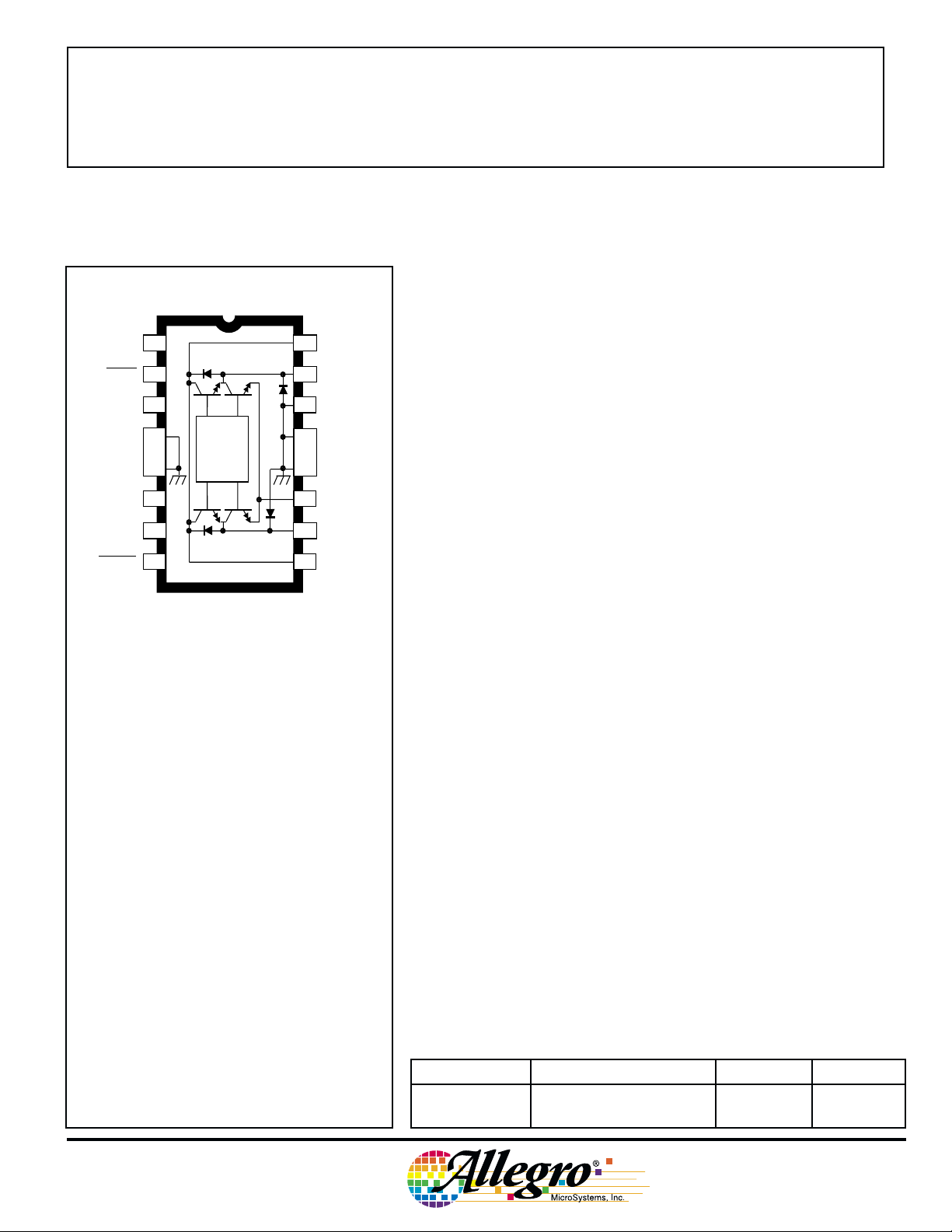

A3951SB

LOAD

1

REF/

BRAKE

GROUND

GROUND

LOGIC

SUPPLY

PHASE

ENABLE

NC

RC

2

3

4

5

6

V

CC

7

8

LOGIC

V

BB

V

BB

ABSOLUTE MAXIMUM RATINGS

Load Supply Voltage, V

Output Current, I

(tw ≤ 20 µs) .................................. ±3.5 A

(Continuous) ............................... ±2.0 A

Logic Supply Voltage, VCC.................. 7.0 V

Logic Input Voltage Range,

........................ -0.3 V to VCC + 0.3 V

V

IN

Sense Voltage, V

Reference Voltage, V

Package Power Dissipation,

PD ....................................... See Graph

Operating Temperature Range,

............................... –20°C to +85°C

T

A

Junction Temperature, TJ ............. +150°C*

Storage Temperature Range,

TS ............................. –55°C to +150°C

Output current rating may be limited by duty cycle,

ambient temperature, heat sinking and/or forced

cooling. Under any set of conditions, do not

exceed the specified current rating or a junction

temperature of +150°C.

* Fault conditions that produce excessive junction

temperature will activate device thermal shutdown

circuitry. These conditions can be tolerated but

should be avoided.

BB

OUT

........................ 1.5 V

SENSE

....................... V

REF

16

SUPPLY

15

OUT

B

14

GROUND

13

GROUND

12

GROUND

11

SENSE

10

OUT

A

LOAD

9

SUPPLY

Dwg. PP-056-1

................... 50 V

CC

Designed for bidirectional pulse-width modulated current control of

inductive loads, the A3951SB and A3951SW are capable of continuous

output currents to ±2 A and operating voltages to 50 V. Internal fixed

off-time PWM current-control circuitry can be used to regulate the

maximum load current to a desired value. The peak load current limit is

set by the user’s selection of an input reference voltage and external

sensing resistor. The fixed off-time pulse duration is set by a userselected external RC timing network. Internal circuit protection includes

thermal shutdown with hysteresis, transient suppression diodes, and

crossover-current protection. Special power-up sequencing is not

required. The A3951SB and A3951SW are improved replacements for

the UDN2953B and UDN2954W, respectively. For new system designs, the A3952SB/SEB/SLB/SW are recommended.

With the ENABLE input held low, the PHASE input controls load

current polarity by selecting the appropriate source and sink driver pair.

A user-selectable blanking window prevents false triggering of the PWM

current control circuitry. With the ENABLE input held high, all output

drivers are disabled.

When a logic low is applied to the BRAKE input, the braking

function is enabled. This overrides ENABLE and PHASE to turn off

both source drivers and turn on both sink drivers. The brake function

can be safely used to dynamically brake brush dc motors.

The A3951SB is supplied in a 16-pin dual in-line plastic package

with copper heat-sink contact tabs. The lead configuration enables

easy attachment of a heat sink while fitting a standard printed wiring

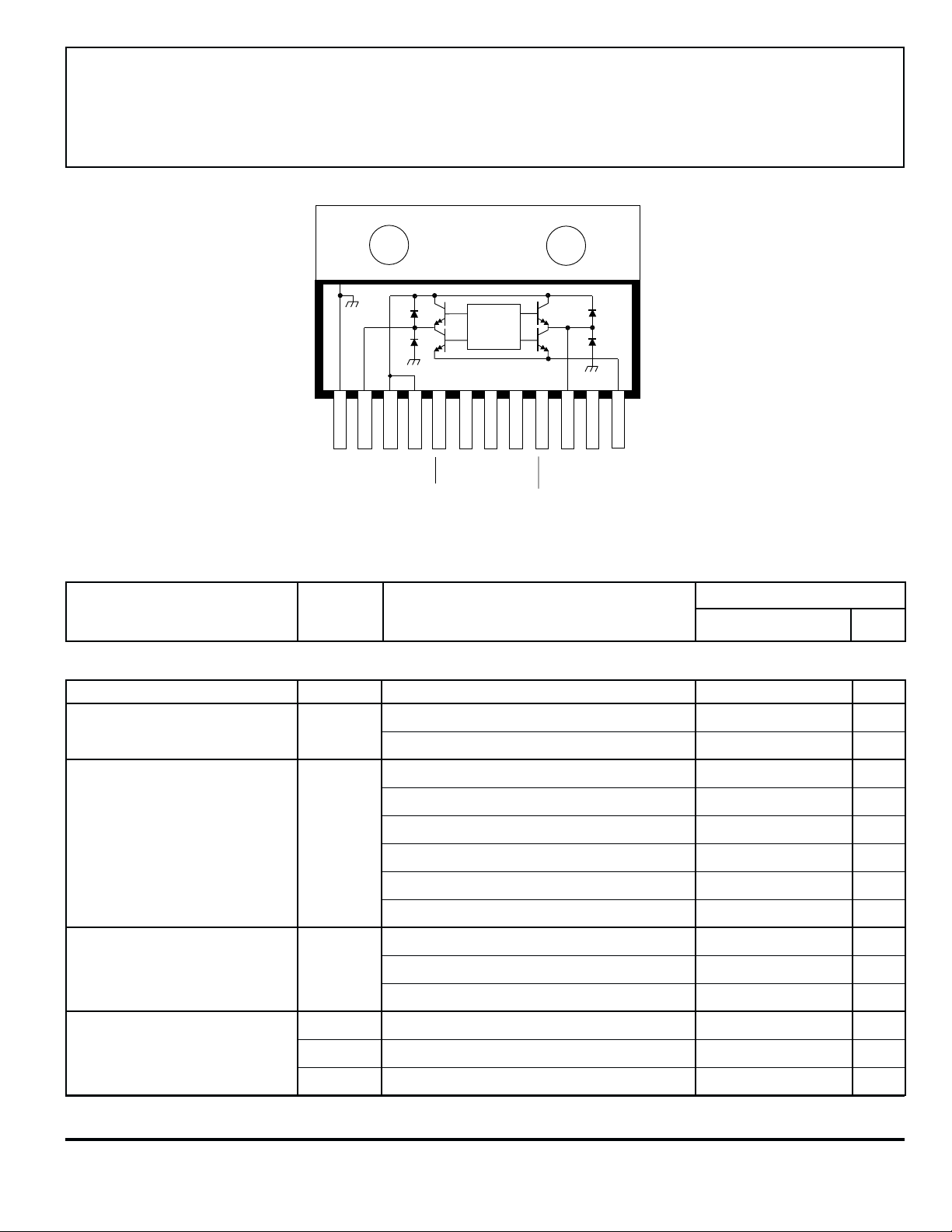

board layout. The A3951SW, for higher package power dissipation

requirements, is supplied in a 12-pin single in-line power-tab package.

In either package style, the batwing/power tab is at ground potential

and needs no isolation.

FEATURES

■ ±2 A Continuous Output Current Rating

■ 50 V Output Voltage Rating

■ Internal PWM Current Control

■ Internal Transient Suppression Diodes

■ Under-Voltage Lockout

■ Internal Thermal Shutdown Circuitry

■ Crossover-Current Protection

■ Default Brake Current Limit

Always order by complete part number:

Part Number Package R

θJA

A3951SB 16-Pin DIP 43°C/W 6.0°C/W

A3951SW 12-Pin Power-Tab SIP 36°C/W 2.0°C/W

R

θJT

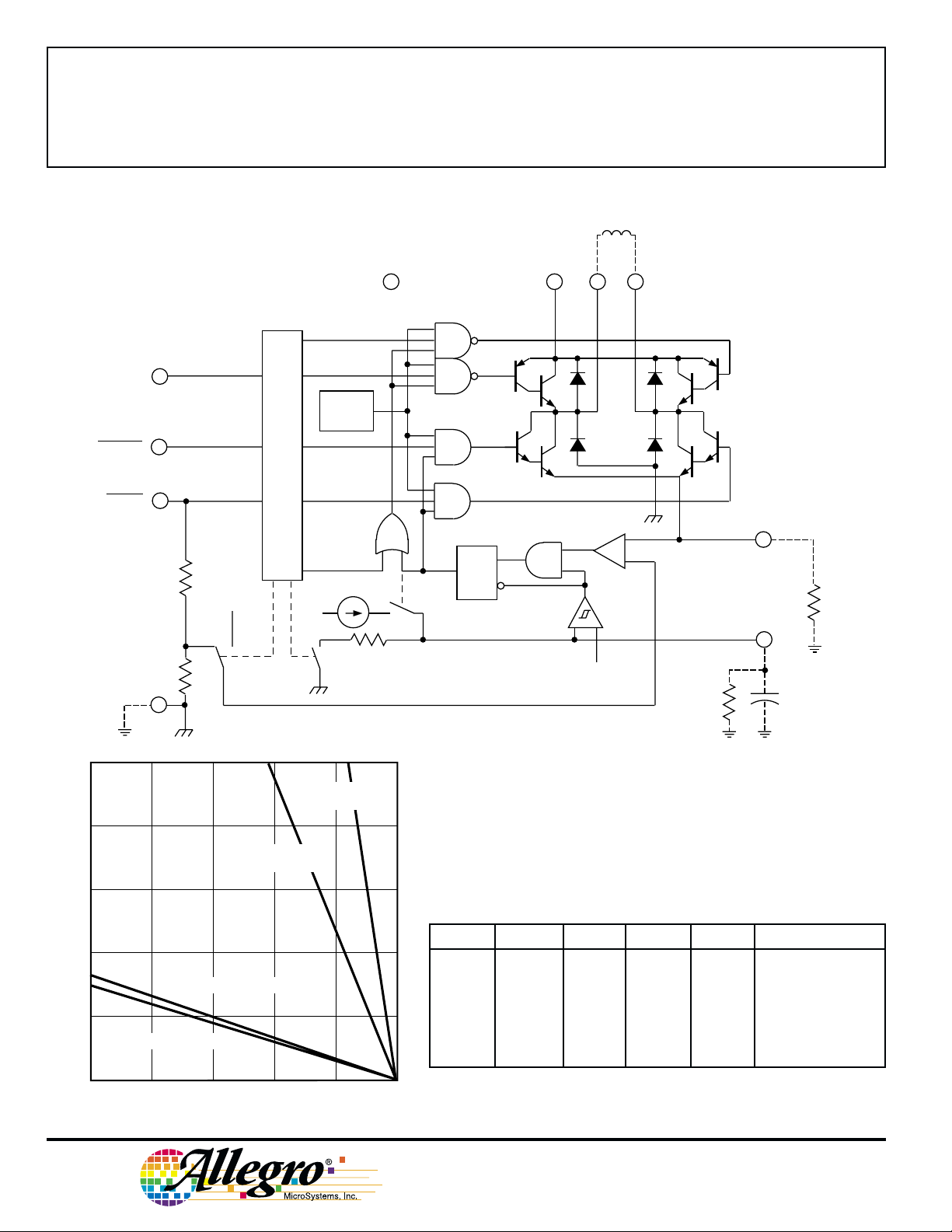

3951

FULL-BRIDGE

PWM MOTOR DRIVER

FUNCTIONAL BLOCK DIAGRAM

ENABLE

REF/

GROUND

PHASE

BRAKE

9R

A

LOGIC

SUPPLY

CC

V

UVLO

& TSD

INPUT LOGIC

R

Q

1.5 V

R

BLANKING

V

CC

S

PWM LATCH

LOAD

SUPPLY

BB

V

+ –

OUT

V

TH

B

OUT

+

–

SENSE

RC

R

S

10

SUFFIX 'W',

R = 2.0°C/W

θJT

8

SUFFIX 'B',

R = 6.0°C/W

θJT

6

4

SUFFIX 'W', R = 38°C/W

2

SUFFIX 'B', R = 43°C/W

0

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

25

θJA

50 75 100 125 150

TEMPERATURE IN °C

θJA

2

TRUTH TABLE

BRAKE ENABLE PHASE OUT

H H X Z Z Outputs Disabled

H L H H L Forward

H L L L H Reverse

L X X L L Brake, See Note

X = Irrelevant Z = High Impedance (source and sink both off)

NOTE: Includes internal default V

Dwg. GP-032A

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1994, 2000 Allegro MicroSystems, Inc.

OUTBDESCRIPTION

A

level for over-current protection.

sense

Dwg. FP-036-1

PWM MOTOR DRIVER

A3951SW

LOGIC

BB

V

CC

V

1 2 3 4 5 6 7 8 9 10 11 12

OUT

GROUND

B

LOAD

LOAD

SUPPLY

SUPPLY

BRAKE

REF/

RC

LOGIC

PHASE

SUPPLY

ENABLE

A

OUT

NC

Dwg. PP-058-1

3951

FULL-BRIDGE

SENSE

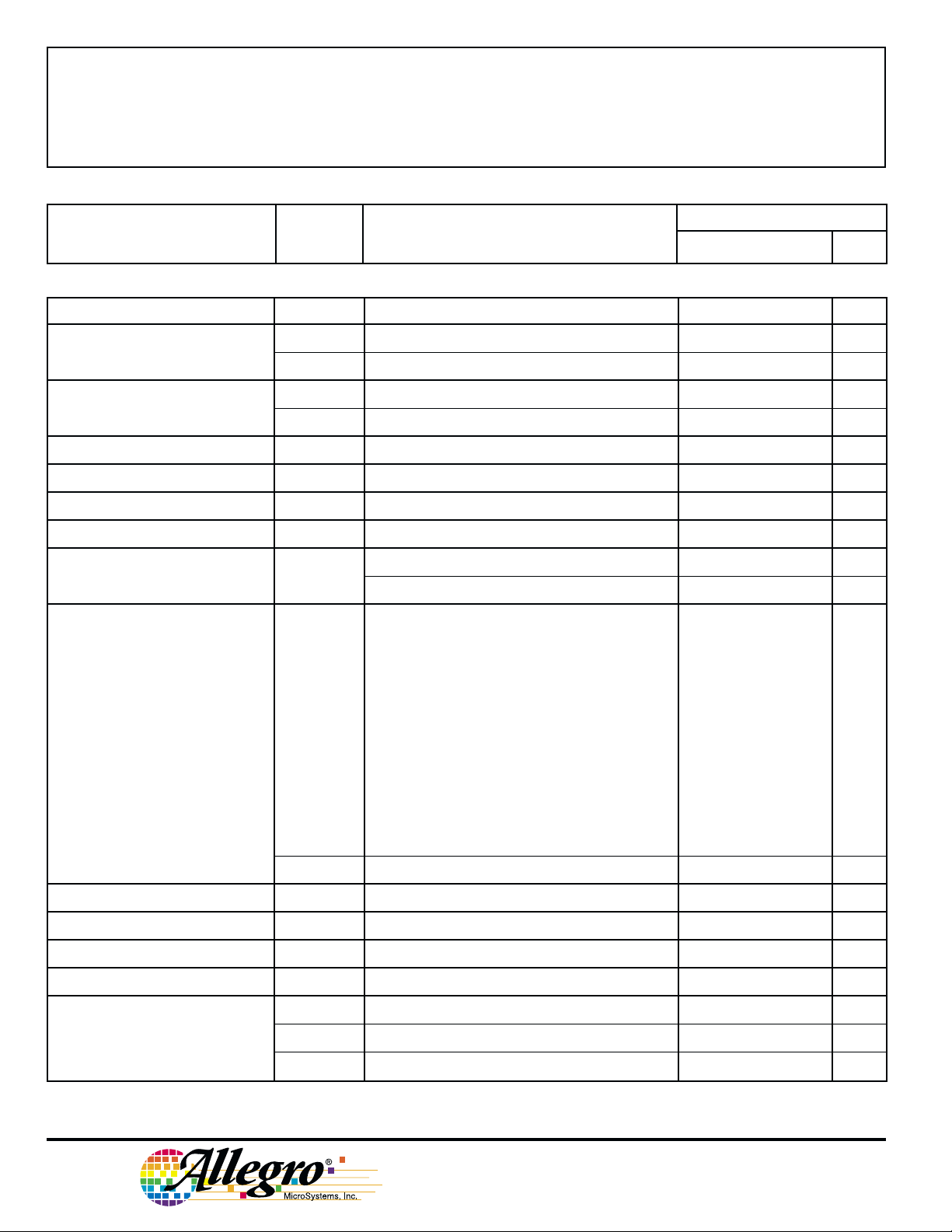

ELECTRICAL CHARACTERISTICS at TA = +25°C, VBB = 50 V, VCC = 5.0 V,

V

= 2.0 V, V

REF

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Output Drivers

Load Supply Voltage Range V

Output Leakage Current I

Output Saturation Voltage V

Clamp Diode Forward Voltage V

(Source or Sink) IF = 1.0 A – 1.1 1.6 V

= 0 V, RC = 20 kΩ/1000 pF to Ground (unless noted otherwise).

SENSE

BB

CEX

CE(SAT)

F

Operating, I

V

= V

OUT

V

= 0 V – <-1.0 -50 µA

OUT

Source driver, I

Source driver, I

Source driver, I

Sink driver, I

Sink driver, I

Sink driver, I

IF = 0.5 A – 1.0 1.4 V

= ±2.0 A, L = 3 mH V

OUT

BB

= -0.5 A – 0.9 1.2 V

OUT

= -1.0 A – 1.0 1.4 V

OUT

= -2.0 A – 1.2 1.8 V

OUT

= +0.5 A – 0.9 1.2 V

OUT

= +1.0 A – 1.0 1.4 V

OUT

= +2.0 A – 1.3 1.8 V

OUT

Limits

CC

– 50 V

– <1.0 50 µA

Load Supply Current I

(No Load) I

I

www.allegromicro.com

BB(ON)

BB(OFF)

BB(BRAKE)

IF = 2.0 A – 1.4 2.0 V

V

V

V

= 0.8 V, V

ENABLE

= V

ENABLE

BRAKE

REF

= 0.8 V – 3.1 6.5 mA

= 2.0 V – 2.9 6.0 mA

REF

= 2.0 V – 3.1 6.5 mA

Continued next page …

3

3951

FULL-BRIDGE

PWM MOTOR DRIVER

ELECTRICAL CHARACTERISTICS (Continued)

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Control Logic

Logic Supply Voltage Range V

Logic Input Voltage V

Logic Input Current I

Reference Voltage Range V

Reference Input Current I

V

IN(1)

I

IN(0)

REF

CC

IN(1)

IN(0)

REF

Reference Voltage Divider Ratio – V

PWM RC Fixed Off Time t

PWM Minimum On Time t

Propagation Delay Time t

off

on(min)

pd

Operating 4.5 5.0 5.5 V

2.0 ––V

––0.8 V

VIN = 2.0 V – <1.0 20 µA

VIN = 0.8 V – <-2.0 -200 µA

Operating 2.0 – V

2.0 V ≤ V

= 5 V 9.5 10.0 10.5 –

REF

REF

≤ V

CC

25 40 55 µA

CC

V

CT = 1000 pF, RT = 20 kΩ 18 20 22 µs

CT = 820 pF, RT ≥ 12 kΩ – 1.7 3.0 µs

CT = 1200 pF, RT ≥ 12 kΩ – 2.5 3.8 µs

I

= ±2.0 A, 50% EIN to 90% E

OUT

transition:

OUT

ENABLE on to source driver on – 2.9 – µs

ENABLE off to source driver off – 0.7 – µs

ENABLE on to sink driver on – 2.4 – µs

ENABLE off to sink driver off – 0.7 – µs

PHASE change to source driver on – 2.9 – µs

t

pd(pwm)

Thermal Shutdown Temperature T

Thermal Shutdown Hysteresis ∆T

UVLO Disable Threshold V

UVLO Hysteresis ∆V

Logic Supply Current I

(No Load) I

J

J

CC(UVLO)

CC(UVLO)

CC(ON)

CC(OFF)

I

CC(BRAKE)

NOTES: 1. Typical Data is for design information only.

2. Each driver is tested separately.

3. Negative current is defined as coming out of (sourcing) the specified device terminal.

4

PHASE change to source driver off – 0.7 – µs

PHASE change to sink driver on – 2.4 – µs

PHASE change to sink driver off – 0.7 – µs

Comparator trip to sink driver off – 0.8 1.5 µs

– 165 – °C

– 15 – °C

3.15 3.50 3.85 V

300 400 500 mV

V

V

V

= 0.8 V, V

ENABLE

= V

ENABLE

REF

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

REF

= 0.8 V – 26 40 mA

= 2.0 V – 20 30 mA

REF

= 2.0 V – 12 18 mA

Loading...

Loading...