查询A3950供应商查询A3950供应商

Preliminary Data Sheet

Subject to Change without Notice

November 4, 2005

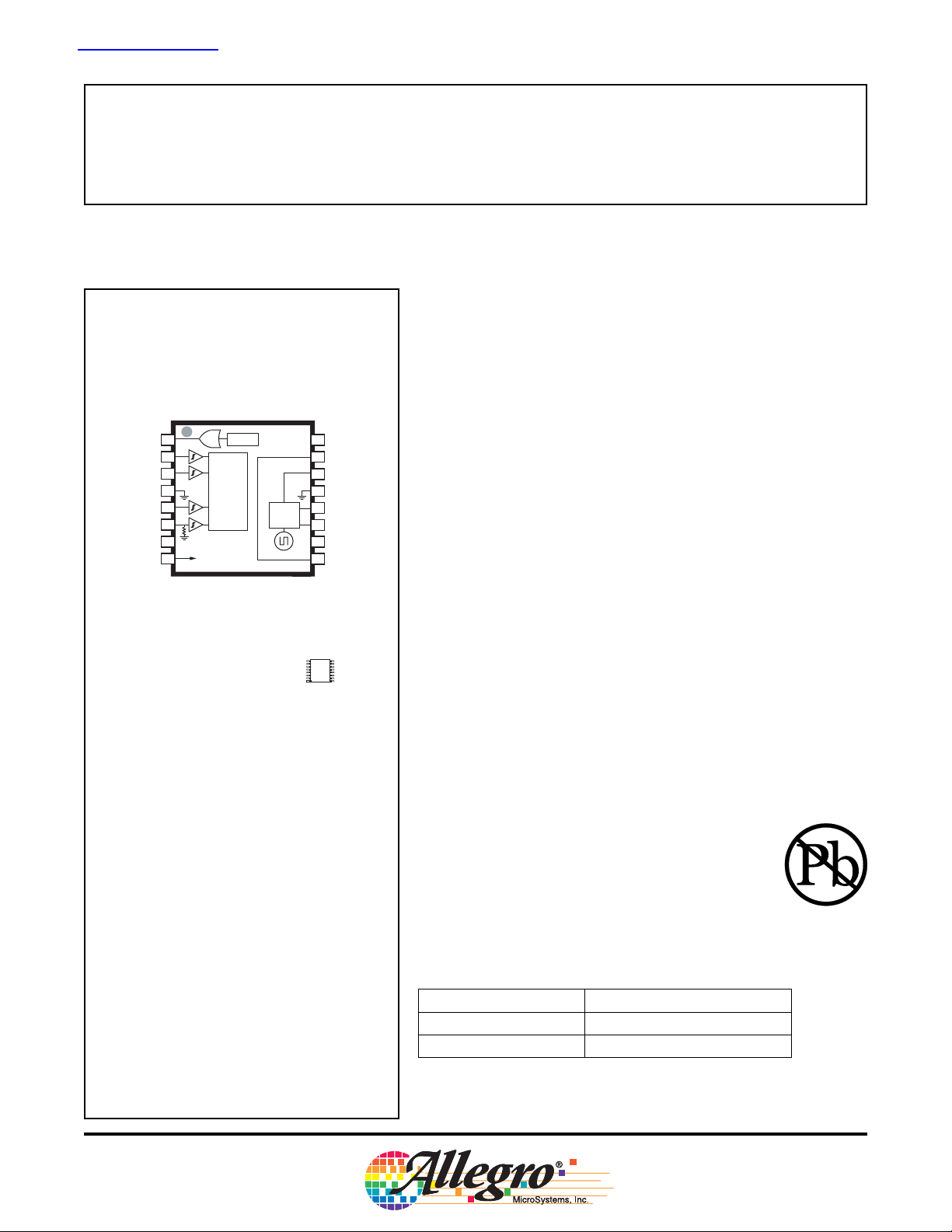

Package LP, 16-pin TSSOP

with Exposed Thermal Pad

Control

Logic

Fault

Charge

Pump

NFAULT

MODE

PHASE

GND

SLEEP

ENABL

OUTA

SENSE

1

2

3

4

5

6

7

8

A3950

DMOS Full-Bridge Motor Driver

Designed for PWM (pulse width modulated) control of dc motors, the

A3950 is capable of peak output currents to ±2.8 A and operating voltages to 36 V.

PHASE and ENABLE input terminals are provided for use in controlling the speed and direction of a dc motor with externally applied PWM

control signals. Internal synchronous rectification control circuitry is

provided to lower power dissipation during PWM operation.

16

NC

15

VREG

14

VCP

13

GND

12

CP2

11

CP1

10

OUTB

9

VBB

Internal circuit protection includes motor lead short-to-supply / short-toground, thermal shutdown with hysteresis, undervoltage monitoring of

VBB and VCP, and crossover-current protection.

The A3950 is supplied in a thin profile (<1.2 mm overall height) 16-pin

TSSOP package with exposed thermal pad (package LP). It is lead (Pb)

free with 100% matte tin leadframe plating.

Approximate Scale 1:1

AB SO LUTE MAX I MUM RAT INGS

Load Supply Voltage, V

Output Current, I

Sense Voltage, V

BB.............................................

OUT.......................................................

.................................±500 mV

SENSE

VBB to OUTx.................................................... 36 V

OUTx to SENSE ................................................ 36 V

Logic Input Voltage, V

..........................–0.3 to 7 V

IN

Operating Temperature Range

Ambient, T

Junction Temperature, T

Storage Temperature, T

, Range S .................... –20°C to 85°C

A

............................ 150°C

J(MAX)

................. –40°C to 125°C

S

36 V

2.8 A

FEATURES

Low R

Overcurrent protection

Motor lead short-to-supply protection

Short-to-ground protection

Sleep function

Synchronous rectification

Diagnostic output

Internal UVLO

Crossover-current protection

Use the following complete part numbers when ordering:

Part Number Packing

A3950SLP-T 96 pieces / tube

A3950SLPTR-T 13-in. reel, 4000 pieces / reel

DS(on)

outputs

A3950DS

Preliminary Data Sheet

Subject to Change without Notice

November 4, 2005

DMOS Full-Bridge Motor Driver

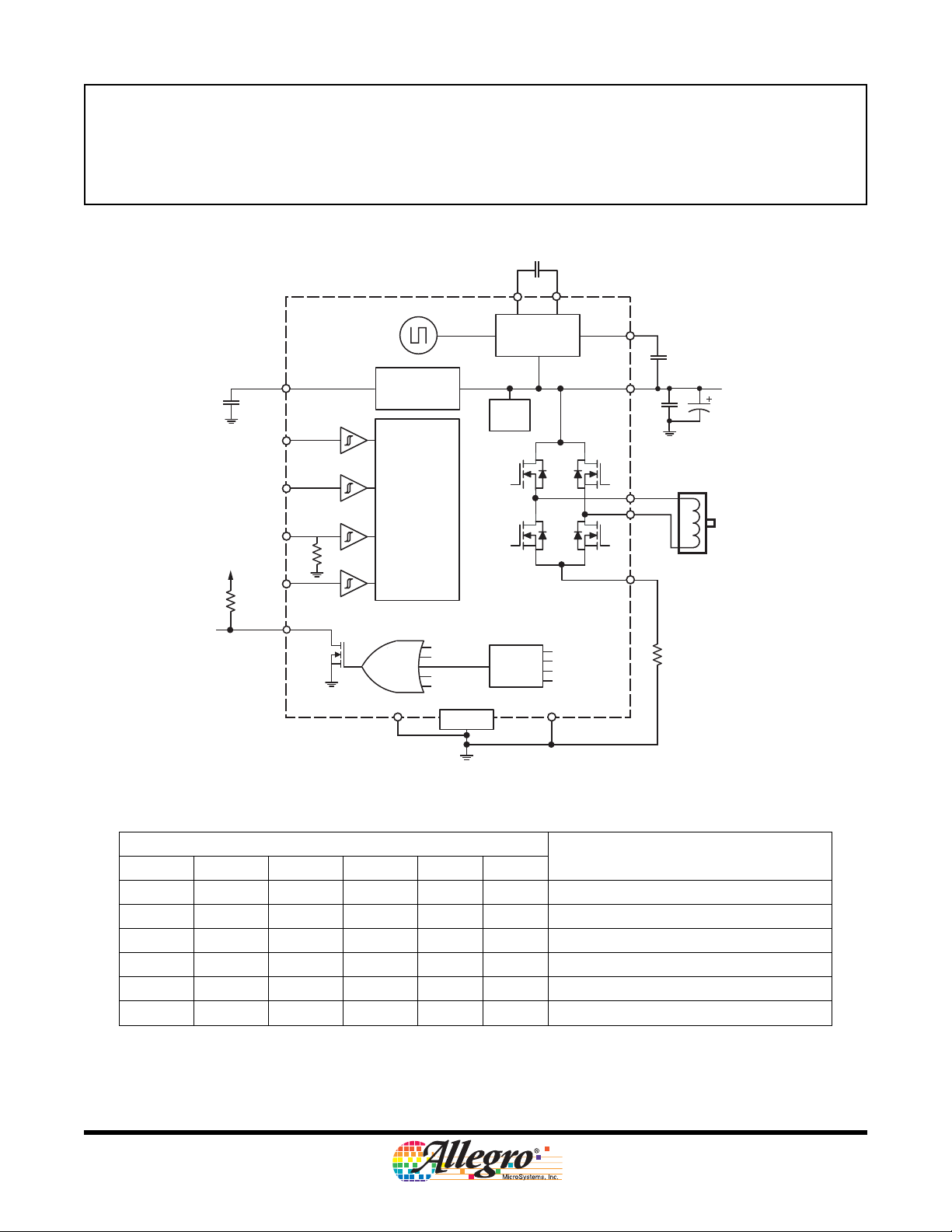

Functional Block Diagram

0.1 µF

CP2

CP1

A3950

VREG

22 µF

25 V

MODE

PHASE

ENABLE

SLEEP

NFAULT

Charge

Pump

Low-Side

Gate Supply

Bias

Supply

Control Logic

UVLO

STB

STG

TSD Warning

GND GND

Pad

Motor Lead

Protection

VBB

OUTA

OUTB

SENSE

VCP

VBB

0.1 µF

OUTA

OUTB

SENSE

0.1 µF

Load Supply

R

SENSE

100 µF

Control Logic Table

PHASE ENABLE MODE SLEEP OUTA OUTB

1

Pin

Function

1 1 X 1 H L Forward

0 1 X 1 L H Reverse

X 0 1 1 L L Brake (slow decay)

1001LHFast Decay Synchronous Rectification

0001HLFast Decay Synchronous Rectification

XXX0ZZ

1X iindicates “don’t care,” Z indicates high impedence.

2To prevent reversal of current during fast decay synchronous rectification, outputs go to the high impedance state as the current approaches 0 A.

A3950DS

Sleep Mode

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

2

2

2

Preliminary Data Sheet

Subject to Change without Notice

November 4, 2005

DMOS Full-Bridge Motor Driver

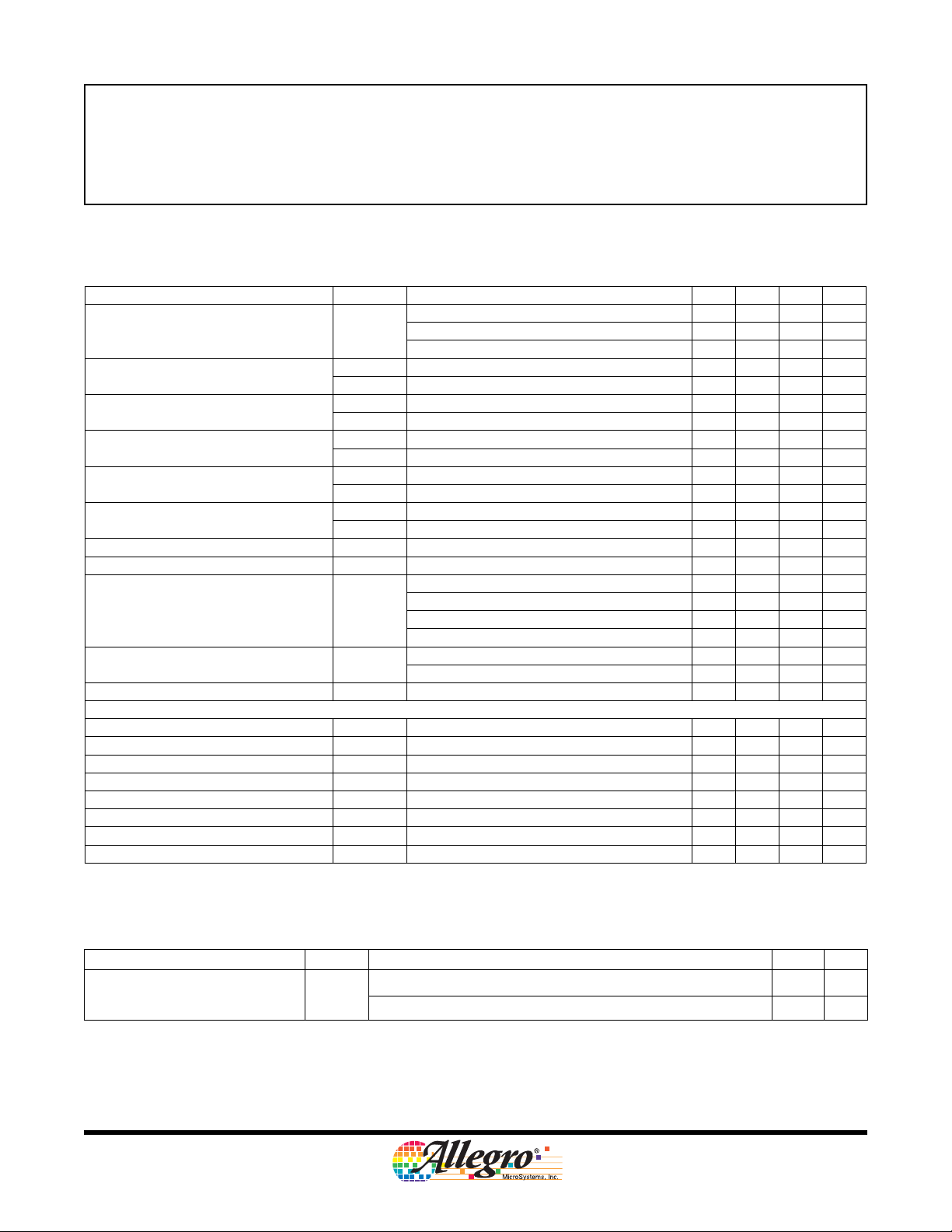

ELECTRICAL CHARACTERISTICS at TJ = 25°C, VBB = 8 to 36 V, unless noted otherwise

Characteristics Symbol Test Conditions Min. Typ. Max. Units

f

< 50 kHz – 6 8.5 mA

Motor Supply Current I

PHASE, ENABLE, MODE Input

Voltage

SLEEP Input Voltage

PHASE, MODE Input Current

1

ENABLE Input Current

SLEEP Input Current

BB

V

V

V

V

I

I

I

I

I

I

NFAULT Output Voltage V

Input Hysteresis, except SLEEP V

Output On Resistance R

IHys

DS(on)

Propagation Delay Time t

Crossover Delay t

COD

Protection Circuitry

UVLO Threshold V

UVLO Hysteresis V

Overcurrent Threshold

2

Overcurrent Protection Period t

UVHys

I

OCP

OCP

Thermal Warning Temperature T

Thermal Warning Hysteresis T

Thermal Shutdown Temperature T

Thermal Shutdown Hysteresis T

1

For input and output current specifications, negative current is defined as coming out of (sourcing) the specified device pin.

2

Overcurrent protection is tested at 25°C in a restricted range and guaranteed by characterization.

JWHys

JTSD

JTSDHys

PWM

Charge pump on, outputs disabled – 3 4.5 mA

Sleep mode – – 10 μA

IH

IL

IH

IL

VIN = 2.0 V – <1.0 20 μA

IH

V

IL

IH

IL

IH

IL

OL

= 0.8 V – <–2.0 –20 μA

IN

VIN = 2.0 V – 40 100 μA

VIN = 0.8 V – 16 40 μA

VIN = 2.7 V – 27 50 μA

VIN = 0.8 V – <1 10 μA

I

= 1.0 mA – – 0.4 V

sink

2.0 – – V

– – 0.8 V

2.7 – – V

– – 0.8 V

100 150 200 mV

Source driver, I

Source driver, I

Sink driver, I

Sink driver, I

= -2.8 A, TJ=25°C – 0.35 0.48 Ω

OUT

= -2.8 A, TJ=125°C – 0.55 0.8 Ω

OUT

= 2.8 A, TJ=25°C – 0.3 0.43 Ω

OUT

= 2.8 A, TJ=125°C – 0.45 0.7 Ω

OUT

PWM, change to source or sink ON – 600 – ns

pd

PWM, change to source or sink OFF – 100 – ns

– 500 – ns

VBB increasing – 6.5 – V

UV

– 250 – mV

3––A

– 1.2 – ms

Temperature increasing – 160 – °C

JW

Recovery = TJW – T

JWHys

–15–°C

Temperature increasing – 175 – °C

Recovery = T

JTSD

– T

JTSDHys

–15–°C

A3950

THERMAL CHARACTERISTICS may require derating at maximum conditions, see application information

Characteristic Symbol Test Conditions* Value Units

Package Thermal Resistance R

*Additional thermal data available on the Allegro Web site.

A3950DS

4-layer PCB based on JEDEC standard 34 ºC/W

θJA

2-layer PCB with 3.8 in.

2

copper both sides, connected by thermal vias 43 ºC/W

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

3

Preliminary Data Sheet

Subject to Change without Notice

November 4, 2005

SLEEP

ENABLE

PHASE

MODE

V

BB

V

OUTA

0

A3950

DMOS Full-Bridge Motor Driver

Timing Diagram: PWM Control

V

OUTB

I

OUTX

V

BB

0

0

A 1 2 3 4 5 6 7 98

V

BB

1

5

234

V

BB

6

7

OutBOutAOutA OutB

8

9

A3950DS

A

Charge pump and VREG power-on delay (≈200 µs)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

4

Preliminary Data Sheet

Subject to Change without Notice

November 4, 2005

Timing Diagram: Overcurrent Control

V

OUTA

High-Z

V

OUTB

A3950

DMOS Full-Bridge Motor Driver

I

OUTx

ENABLE,

Source

or Sink

BLANK

Charge Pump

Counter

NFAULT

I

PEAK

I

OCP

t

BLANK

Motor lead

short condition

t

OCP

Normal dc

motor capacitance

A3950DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

5

Preliminary Data Sheet

Subject to Change without Notice

November 4, 2005

A3950

DMOS Full-Bridge Motor Driver

Functional Description

VREG. This supply voltage is used to run the sink-side

DMOS outputs. VREG is internally monitored and in the

case of a fault condition, the outputs of the device are disabled. The VREG pin should be decoupled with a 0.22 μF

capacitor to ground.

Charge Pump. The charge pump is used to generate a

supply above VBB to drive the source-side DMOS gates. A

0.1 μF ceramic monolithic capacitor should be connected

between CP1 and CP2 for pumping purposes. A 0.1 μF

ceramic monolithic capacitor should be connected between

VCP and VBB to act as a reservoir to run the high-side

DMOS devices. The VCP voltage level is internally monitored and, in the case of a fault condition, the outputs of the

device are disabled.

Shutdown. In the event of a fault due to excessive junction

temperature, or low voltage on VCP or VREG, the outputs of

the device are disabled until the fault condition is removed.

At power-on the UVLO circuit disables the drivers.

Sleep Mode. Control input SLEEP is used to minimize

power consumption when the A3950 not in use. This disables

much of the internal circuitry, including the regulator and

charge pump. A logic low setting puts the device into Sleep

mode, and a logic high setting allows normal operation. After

coming out of Sleep mode, provide a 1 ms interval before

applying PWM signals, to to allow the charge pump to

stabilize.

applying an enable chop command. Because it is possible to

drive current in both directions through the DMOS switches,

this configuration effectively shorts out the motor generated

BEMF as long as the ENABLE chop mode is asserted. The

maximum current can be approximated by V

BEMF/RL

. Care

should be taken to insure that the maximum ratings of the

device are not exceeded in worse case braking situations:

high speed and high-inertia loads.

Overcurrent Protection. The voltage on the output pins

relative to supply are monitored to ensure that the motor lead

is not shorted to supply or ground. If a short is detected, the

full-bridge outputs are turned off, flag NFAULT is driven

low, and a 1.2 ms fault timer is started.

After this 1.2 ms period, t

, the device will then be

OCP

allowed to follow the input commands and another turn-on is

attempted. If there is still a fault condition, the cycle repeats.

If, after t

expires, it is determined that the short condi-

OCP

tion is not present, the NFAULT pin is released and normal

operation resumes.

Diagnostic Output. The NFAULT pin signals a problem

with the chip via an open drain output. A motor fault, undervoltage condition, or TJ > 160°C will drive the pin active

low. This output is not valid when SLEEP puts the device

into minimum power dissipation mode.

MODE. Control input MODE is used to toggle between

fast decay mode and slow decay mode. A logic high puts

the device in slow decay mode. Synchronus rectification is

always enabled.

Braking. The braking function is implemented by driving

the device in slow decay mode via the MODE setting and

A3950DS

TSD. Two die temperature monitors are integrated on the

chip. As die temperature increases towards the maximum, a

thermal warning signal will be triggered at 160°C. This fault

drives the NFAULT low, but does not disable the operation of

the chip. If the die temperature increases further, to approximately 175°C, the full-bridge outputs will be disabled until

the internal temperature falls below a hysteresis of 15°C.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

6

P

Preliminary Data Sheet

Subject to Change without Notice

November 4, 2005

A3950

DMOS Full-Bridge Motor Driver

Applications Information

Power Dissipation. First order approximation of power

dissipation in the A3950 can be calculated by first examining

the power dissipation in the full-bridge during each of the

operation modes. The A3950 features synchronous rectification, a feature that effectively shorts out the body diode by

turning on the low R

DMOS driver during the decay

DS(on)

cycle. This significantly reduces power dissipation in the

full-bridge. In order to prevent shoot-through, where both

source and sink driver are on at the same time, the A3950

implements a 500 ns typical crossover delay time. For this

period, the body diode in the decay current path conducts

the current until the DMOS driver turns on. This does affect

VBB

1

3

2

1

Drive current

Fast decay with synchronous rectification (reverse)

2

Slow decay with synchronous rectification (brake)

3

Figure 1. Current Decay Patterns

power dissipation and may need to be considered in high

current, high ambient temperature applications. In addition,

motor parameters and switching losses can add power dissipation that could affect critical applications.

Drive Current. This current path is through source DMOS

driver, motor winding, and sink DMOS driver. Power dissipation is I2R loses in one source and one sink DMOS driver,

as shown in the following equation:

2

D

DS(on)Source DS(on)Sink

RRI

+=

)(

(1)

Fast Decay with Synchronous Rectification. This

decay mode is equivalent to a phase change where the opposite drivers are switched on. When in fast decay, the motor

current is not allowed to go negative (direction change).

Instead, as the current approaches zero, the drivers turn off.

The power calculation is the same as the drive current calculation, equation 1:

Slow Decay SR (Brake Mode). In this decay mode, both

sink drivers turn on, allowing the current to circulate through

2

the sink drivers and the load. Power dissipation is I

R loses

in the two sink DMOS drivers:

2

RIP=

2 ×

D

DS(on)Sink

)(

(2)

Layout. The printed circuit board should include a heavy

ground plane. For optimum electrical and thermal performance, the exposed thermal pad of the device should be soldered directly to an exposed copper area directly under the

device. The load supply pin, VBB, should be decoupled with

an electrolytic capacitor (typically 100 μF) in parallel with a

ceramic capacitor placed as close as possible to the device.

The ceramic capacitors between VCP and VBB, connected

to VREG, and between CP1 and CP2, should be as close to

the pins of the device as possible, in order to minimize lead

inductance.

A3950DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

7

Preliminary Data Sheet

Subject to Change without Notice

November 4, 2005

A3950

DMOS Full-Bridge Motor Driver

Ground. A star ground should be located as close to the

A3950 as possible. The copper ground plane directly under

the exposed thermal pad makes a good location for the star

ground point. The exposed pad can be connected to ground

for this purpose.

SENSE Pin. A low value resistor can be placed between

the SENSE pin and ground for current sensing purposes. To

minimize ground-trace IR drops in sensing the output current

Terminal List Table

Name Number Description

NFAULT 1 Fault output, open drain

MODE 2 Logic input

PHASE 3 Logic input for direction control

GND 4 Ground

SLEEP 5 Logic input

ENABLE 6 Logic input

OUTA 7 DMOS full-bridge output A

SENSE 8 Power return

VBB 9 Load supply voltage

OUTB 10 DMOS full-bridge output B

CP1 11 Charge pump capacitor terminal

CP2 12 Charge pump capacitor terminal

GND 13 Ground

VCP 14 Reservoir capacitor terminal

VREG 15 Regulator decoupling terminal

NC 16 No connection

Pad –

Exposed pad for thermal dissipation

connect to pins 4,13

level, the current sensing resistor should have an independent

ground return to the star ground point. This trace should be

as short as possible. For low value sense resistors, the IR

drops in the PCB can be significant, and should be taken into

account.

When selecting a value for the sense resistor be sure not to

exceed the maximum voltage on the SENSE pin of ±500 mV.

A3950DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

8

Preliminary Data Sheet

Subject to Change without Notice

November 4, 2005

LP Package, 16-Pin TSSOP with Exposed Thermal Pad

Preliminary dimensions, for reference only

Dimensions in millimeters

U.S. Customary dimensions (in.) in brackets, for reference only

(reference JEDEC MO-153 ABT)

Dimensions exclusive of mold flash, gate burrs, and dambar protrusions

Exact case and lead configuration at supplier discretion within limits shown

A

Terminal #1 mark area

B

Exposed thermal pad (bottom surface)

A3950

DMOS Full-Bridge Motor Driver

5.1

.201

4.9

16

A

.193

B

3

NOM

A

B

4.5

.177

4.3

.169

.118

6.6

6.2

.260

.244

8º

0º

0.75

0.45

0.20

0.09

1

REF

.030

.018

.039

.008

.004

16X

16X

0.30

0.19

0.10 [.004]

C0.10 [.004]

.012

.007

M C A B

21

0.65 .026

3

NOM

.118

0.15

0.00

SEATING

PLANE

1.20

MAX

.006

.000

.047

0.25 .010

C

SEATING PLANE

GAUGE PLANE

The products described here are manufactured under one or more U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such de par tures from the detail spec i fi ca tions as may be

required to permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components in life-support devices or sys tems without express written approval.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable. How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty

for its use; nor for any in fringe ment of patents or other rights of third parties which may result from its use.

Copyright©2005 AllegroMicr osystems, Inc.

A3950DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

9

Loading...

Loading...