查询A3938供应商查询A3938供应商

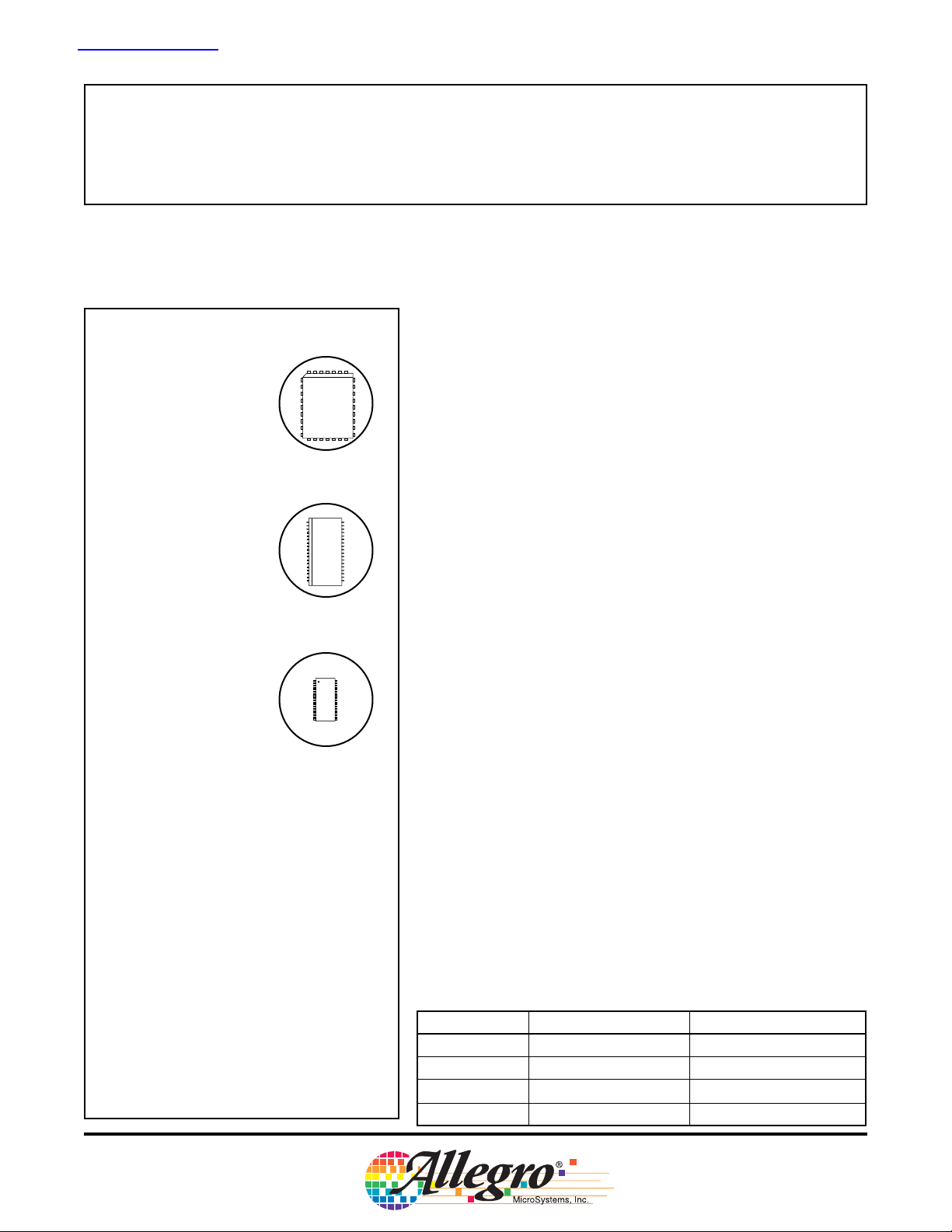

A3938EQ, 32-pin PLCC

A3938LQ, 36-pin QSOP

A3938

Three-Phase Power MOSFET Controller

The A3938 is a three-phase, brushless dc motor controller. The A3938

high-current gate drive capability allows driving of a wide range of

power MOSFETs and can support motor supply voltages to 50 V. The

A3938 integrates a bootstrapped high-side driver to minimize the external component count required to drive N-channel MOSFET drivers.

Internal fi xed off-time, PWM current-control circuitry can be used to

regulate the maximum load current to a desired value. The peak load

current limit is set by the user’s selection of an input reference voltage and external sensing resistor. A user-selected external RC timing

network sets the fi xed off-time pulse duration. For added fl exibility, the

PWM input can provide speed/torque control where the internal current

control circuit sets a limit on the maximum current.

The A3938 includes a synchronous rectifi cation feature. This shorts out

the current path through the power MOSFET reverse body diodes during PWM off-cycle current decay. This can minimize power dissipation

in the MOSFETs, eliminate the need for external power clamp diodes,

and potentially allow a more economical choice for the MOSFET drivers.

26301.104B

Data Sheet

A3938LD, 38-pin TSSOP

AB SO LUTE MAX I MUM RAT INGS

Load Supply Voltage, VBB...................................50 V

VREG (Transient)...............................................15 V

Logic Input Voltage Range, V

Sense Voltage, V

Pins: SA, SB, SC................................... –5 V to 50 V

Pins: GHA, GHB, GHC.................. –5 V to V

Pins: CA, CB, CC ...........................SA/SB/SC + 17 V

Operating Temperature Range

Ambient Temperature, T

Junction Temperature, T

Storage Temperature, TS..........–55°C to +150°C

Thermal Impedance (Typical), at T

measured on a JEDEC-standard "High-K" PCB

A3938EQ, R

A3938LD, R

A3938LQ, R

SENSE

........................................37°C/W

θJA

........................................38°C/W

θJA

........................................44°C/W

θJA

...–0.3 V to V

IN

........................... –5 V to 1.5 V

.............–20°C to +85°C

A

............................+150°C

J

= +25ºC;

A

LCAP

+0.3 V

+ 17 V

BB

The A3938 provides commutation logic for Hall sensors confi gured for

120-degree spacing. The Hall input pins are pulled-up to an internallygenerated 5 V reference. Power MOSFET protection features include:

bootstrap capacitor charging current monitor, regulator undervoltage

monitor, motor lead short-to-ground, and thermal shutdown.

The LD package is available in a lead-free version (100% matte tin

plated leadframe).

FEATURES

Drives wide range of N-channel MOSFETs

Low-side synchronous rectifi cation

Power MOSFET protection

Adjustable dead time for cross-con-

duction protection

Selectable coast or dynamic brake on

power-down or RESET input

Fast/slow current decay modes

Use the following complete part numbers when ordering:

Part Number Pins Package

A3938SEQ 32 PLCC

A3938SLQ 36 QSOP

A3938SLD 38 TSSOP

A3938SLD-T 38 TSSOP, Lead-free

Internal PWM current control

Motor lead short-to-ground

protection

Internal 5 V regulator

Fault diagnostic output

Thermal shutdown

Undervoltage protection

A3938

Three-Phase Power MOSFET Controller

Functional Block Diagram

(This diagram shows only one of the three outputs)

26301.104B

Data Sheet

Short to GND

Logic

TSD

Invalid Hall

VREG Undervoltage

High-Side

Protection

Logic

Low-Side

Protection

Logic

Regulator

Charge Pump

Turn-On

Delay

Turn-On

Delay

VREG

High-Side

Driver

Low-Side

Driver

FAULT

LCAP

+

0.1 uF

H1

H2

H3

PWM

DIR

RESET

BRAKE

MODE

RC

C

T

R

T

O.D.

Control

RC Blanking

Fixed Off-Time

VBB

VREG

CA

GHA

SA

GLA

SENSE

A

C

BOOT

0.1 uF

+

0.1 uF

+

10 uF

To Phase C

To Phase B

REF

DEAD

AGND

VREG

Dead-Time

Adjust

A

For 12 V applications, VBB must be shorted to VREG. For this condition, the absolute

V

REG

RESET

UVLO

Power Loss

Brake

PGND

BRKCAP

BRKSEL

maximum rating of 15 V on VREG must be maintained to prevent damage to the A3938.

www.allegromicro.com

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

R

S

+

4.7uF

2

A3938

Three-Phase Power MOSFET Controller

26301.104B

Data Sheet

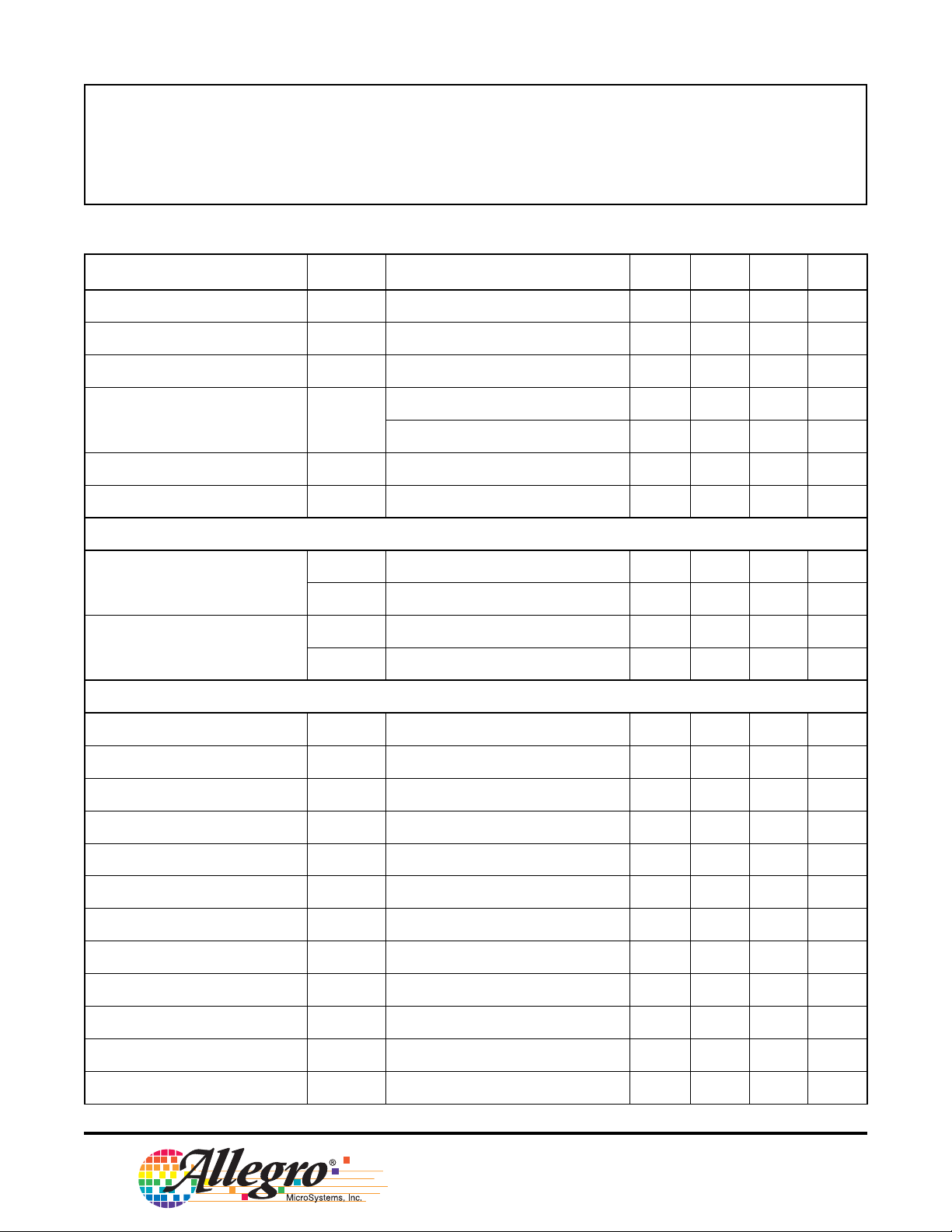

ELECTRICAL CHARACTERISTICS

C

= 10 µF, PWM = 22.5 kHz, square wave, two phases active

VREG

1,2

Unless otherwise noted: T

Characteristics Symbol Test Conditions Min. Typ.

Quiescent Current I

LCAP Regulator V

VREG =VBB Supply Voltage Range V

VBB

LCAP

REG

RESET = 1, Coast mode, stopped – – 8.0 mA

I

lcap

VREG = VBB, observe maximum rating = 15 V 10.8 – 13.2 V

VBB = 13.2 V to 18 V, I

VREG Output Voltage V

VREG Load Regulation V

VREG Line Regulation V

REG

REGLOADIvreg

REGLIN

VBB = 18 V to 50 V, I

I

vreg

Control Logic

Logic Input Voltage

Logic Input Current

V

IN(1)

V

IN(0)

I

IN(1)

I

IN(0)

Minimum high level for logical 1 2.0 – – V

Maximum low level for logical 0 – – 0.8 V

VIN = 2.0 V –30 – –90 µA

VIN = 0.8 V –50 – –130 µA

= 25°C, V

A

= 18 V to 50 V, C

BB

= 0.1 µF, C

LCAP

1

= 0.1 µF,

BOOT

Max. Units

= –3.0 mA 4.75 5 5.25 V

= –10 mA – VBB – 2.5 – V

vreg

= –10 mA 12.4 13 13.6 V

vreg

= –1 mA to –30 mA, Coast mode – 25 – mV

= –10 mA, Coast mode – 40 – mV

Gate Drive

Low-Side Drive, Output High V

High-Side Drive, Output High V

Pull-Up Switch Resistance R

Pull-Down Switch Resistance R

Low-Side Switching, 10/90 Rise Time tr

Low-Side Switching, 10/90 Fall Time tf

High-Side Switching, 10/90 Rise Time tr

High-Side Switching, 10/90 Fall Time tf

Propagation Delay; GHx,GLx Rising T

Propagation Delay; GHx,GLx Falling T

Dead Time, Maximum t

Dead Time, Minimum t

Continued on next page...

HGL

HGH

DS(ON)

DS(ON)

GL

GL

GH

GH

pr

pf

DEAD

DEAD

Igx = 0 V

– 0.8 V

REG

– 0.5 – V

REG

Igx = 0 10.4 11.6 12.8 V

Igx = –50 mA – 14 – Ω

Igx = 50 mA – 4 – Ω

C

= 3300 pF – 120 – ns

load

C

= 3300 pF – 60 – ns

load

C

= 3300 pF – 120 – ns

load

C

= 3300 pF – 60 – ns

load

PWM to gate drive out, C

PWM to gate drive out, C

V

= 0, GHx to GLx, C

dead

I

= 780 µA, GLx to GHx, C

DEAD

= 3300 pF – 220 – ns

load

= 3300 pF – 110 – ns

load

= 0 3.5 5.6 7.6 µs

load

= 0 50 100 150 ns

load

www.allegromicro.com

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

3

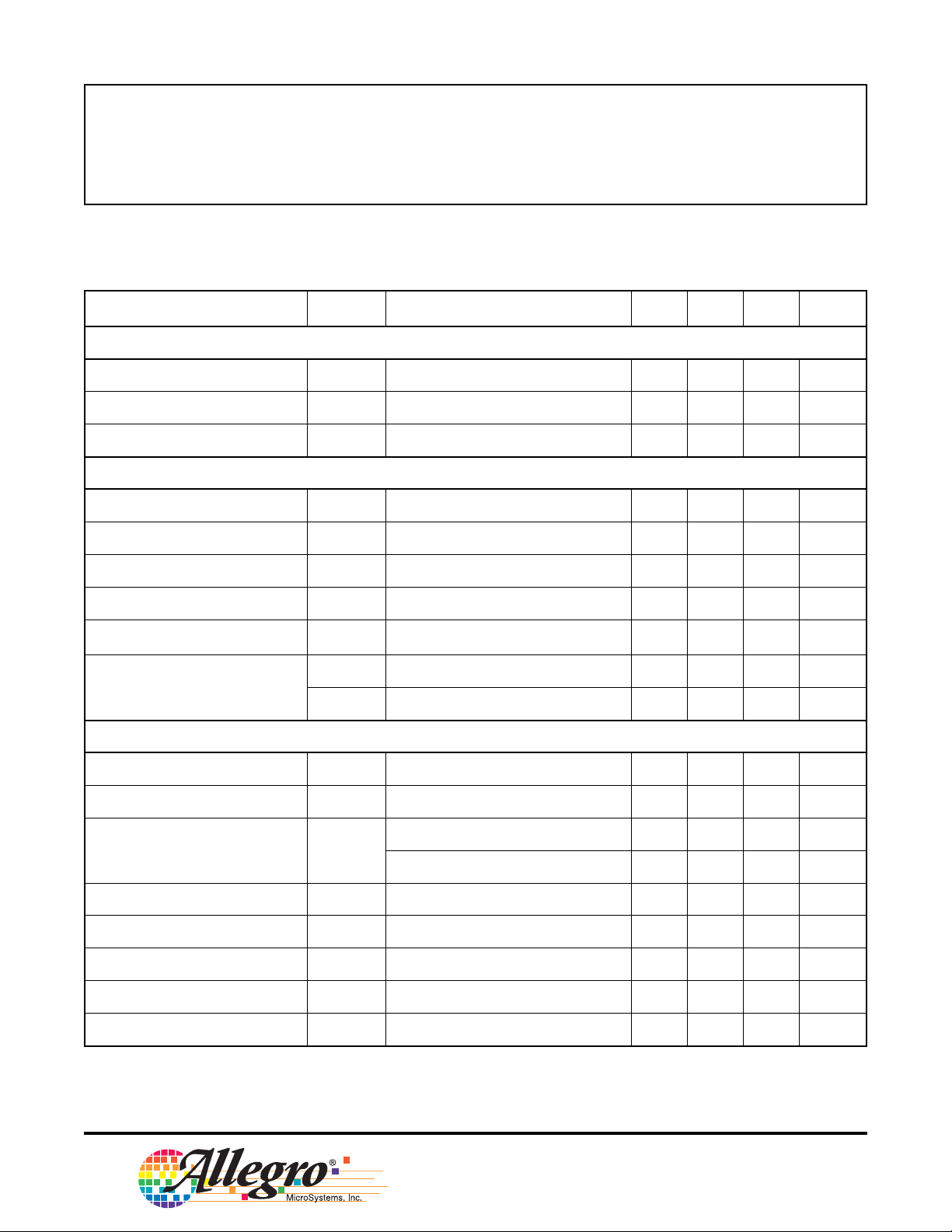

A3938

Three-Phase Power MOSFET Controller

26301.104B

Data Sheet

ELECTRICAL CHARACTERISTICS

C

= 0.1 µF, C

BOOT

Characteristics Symbol Test Conditions Min. Typ.

Bootstrap Capacitor

Bootstrap Capacitor Voltage V

Bootstrap R

OUT

Charge Current (Source) I

Current Limit Circuitry

Input Offset Voltage V

Input Current , Sense pin I

Input Current , Reference pin I

Blank Time t

RC Charge Current I

RC Voltage Threshold

= 10 µF, PWM = 22.5 kHz, square wave, two phases active

VREG

1,2

(continued) Unless otherwise noted: T

R

BLANK

V

V

CX

RC

RCL

RCH

Icx = 0, Vsx = 0, V

CX

Icx = –50 mA – 9 12 Ω

CX

0 V < V

IO

B

B

cmr

0 V < Vcm, V

0 V < Vcm, V

R = 56 kΩ, C = 470 pF – 0.91 – µs

= 13 V 10.4 11.6 12.8 V

reg

< 1.5 V – – ± 5 mV

< 1.5 V – –25 – µA

diff

< 1.5 V – 0 – µA

diff

= 25°C, V

A

= 18 V to 50 V, C

BB

1

= 0.1 µF,

LCAP

Max. Units

100 – – mA

–0.9 –1 –1.1 mA

1.0 1.1 1.2 V

2.7 3.0 3.3 V

Protection Circuitry

Bootstrap Charge Threshold I

Short to Ground, Drain-Source Monitor V

VREG Undervoltage Threshold

Fault Output Voltage

Brake Capacitor Supply Current I

Low Side Gate Voltage V

cx

dsh

UVLO

V

OUT

BRAKE

GLBH

Thermal Shutdown Temperature T

Thermal Shutdown Hysteresis ∆T

1

Typical data are for initial design estimations only, and assume optimum manufacturing and application conditions. Performance may vary for

individual units, within the specifi ed maximum and minimum limits.

2

Negative current is defi ned as conventional current coming out of (sourced from) the specifi ed device terminal.

GHx turns on, and GLx turns off, at I

V

– VSX, high side on 1.3 2.0 2.7 V

BB

V

increasing 9.2 9.7 10.2 V

REG

decreasing 8.6 9.1 9.6 V

V

REG

cx

– –9 – mA

IOL = 1 mA – – 0.5 V

VBB = 8 V, BRKSEL = 1 – 30 – µA

VBB=0, BRKCAP = 8V – 6.6 – V

J

J

– 165 – °C

–10– °C

www.allegromicro.com

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

4

Three-Phase Power MOSFET Controller

Pin Descriptions

RESET. A logic input that enables the device. Has internal

50 kΩ pull-up to LCAP. Setting RESET to 1 coasts or brakes

the motor, depending on the state of the BRKSEL pin. Setting RESET to 0 enables the gate drive to follow commutation logic. Setting RESET to 1 overrides the BRAKE pin.

GLA/GLB/GLC. Low-side gate drive outputs for external

MOSFET drivers. External series gate resistors can be used

to control slew rate seen at the power driver gate, thereby

controlling the di/dt and dv/dt of Sx outputs.

SA/SB/SC. Directly connected to the motor terminals,

these pins sense the voltages switched across the load. The

pins are also connected to the negative side of the bootstrap

capacitors and the negative supply connections for the fl oat-

ing high-side drivers.

GHA/GHB/GHC. High-side gate drive outputs for

N-channel MOSFET drivers. External series gate resistors

can be used to control slew rate seen at the power driver

gate, thereby controlling the di/dt and dv/dt of Sx outputs.

CA/CB/CC. High-side connections for bootstrap capaci-

tors, providing positive supply for high-side gate drivers. The

bootstrap capacitors are charged to approximately VREG

when the output Sx terminals go low. When the outputs

swing high, the voltages on these pins rise with the outputs to

provide the boosted gate voltages needed for the N-channel

power MOSFETs.

MODE. Logic input to set current-decay mode. In response

to a PWM Off command, Slow Decay mode (MODE = 1)

switches off the high-side FET, and Fast Decay mode

(MODE = 0) switches off the high-side and low-side FETs.

Has an internal 50 kΩ pull-up to LCAP.

H1/H2/H3. Hall sensor inputs with internal, 50 kΩ pull-ups

to LCAP. Confi gured for 120-degree electrical spacing.

DIR. Logic input to reverse rotation (see the table Commu-

tation Truth Table, on the next page). Has internal, 50 kΩ

pull-up to LCAP.

FAULT. Open-drain output to indicate fault condition. Will

be pulled high (usually by 5.1 kΩ external pull-up) for any of

the following fault conditions:

• Invalid Hall sensor input code (coasts the motor).

• Undervoltage condition detected at VREG (coasts or brakes

A3938

the motor depending on stored setting for BRKSEL).

• Thermal shutdown (coasts the motor).

• Motor lead (SA/SB/SC) connected to ground (turns off

only the high-side power MOSFETs).

Only the “short-to-ground” fault is latched, but it is cleared

at each commutation. If the motor has stalled due to a shortto-ground being detected, toggling the RESET pin or repeating a power-up sequence clears the fault.

BRAKE. Logic input for braking function. Setting BRAKE

to 1 turns on low-side MOSFETs, and turns off the high-side

MOSFETs. This effectively shorts the BEMF in the windings

and brakes the motor. Internal 50 kΩ pull-up to LCAP. Setting RESET to 1 overrides this BRAKE pin. See also BRKSEL.

BRKCAP. This pin is for connection of the reservoir

capacitor used to provide the positive power supply for the

sink drive outputs for a power-down condition. This allows

predictable braking, if desired. Using a 4.7 µF capacitor will

provide 6.5 V gate drive for 300 ms. If the power-down braking option is not needed (i.e., BRKSEL = 0), then this pin

should be tied to VREG.

BRKSEL. Logic input to enable/disable braking upon

power-down condition or RESET = 1. Internal 50 kΩ pull-up

to LCAP. Setting BRKSEL to 0 enables Coast mode. Setting

BRKSEL to 1 enables Brake mode.

PWM. Speed control input. Setting PWM to 1 turns on

MOSFETs selected by Hall input logic. Setting PWM to 0

turns off the selected MOSFETs. Keep the PWM input held

high to utilize internal current control circuitry. Internal

50 kΩ pull-up to LCAP.

RC. Analog input. Connection for R

fi xed off-time. CT also sets the BLANK time (see the section

Application Information). It is recommended that the fi xed

off-time should not be less than 10 µs. The resistor should be

in the range between 10 kΩ and 500 kΩ.

VREG. Regulated 13 V supply for the low-side gate drive

and the bootstrap capacitor charge circuit. As a regulator, use

a 10 µF decoupling/storage capacitor (ESR < 1 Ω) from this

pin to AGND, as close to the device pins as possible.

Note: For 12 V applications, the VREG pin should be

shorted to VBB.

and CT to set the

T

26301.104B

Data Sheet

www.allegromicro.com

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

5

A3938

Three-Phase Power MOSFET Controller

26301.104B

Data Sheet

VBB. Motor power supply connection for the A3938 and

for power MOSFETs. It is good practice to connect a decoupling capacitor from this pin to AGND, as close to the device

pins as possible.

REF. Analog input to current limit comparator. Voltage

applied here sets the peak load current according to the following equation:

I

= V

TRIP

REF

/ R

SENSE

LCAP. 5 V reference to power internal logic and provide

low current for DEAD pin and FAULT pin. Connection for

0.1 µF external capacitor for decoupling.

Commutation Truth Table

H1 H2 H3 DIR GLA GLB GLC GHA GHB GHC SA SB SC

1011001100HI ZLO

1001001010 Z HILO

1101100010LOHIZ

0101100001LOZHI

0111010001 ZLOHI

0011010100HILOZ

1010100001LOZHI

1000010001 ZLOHI

1100010100HILOZ

0100001100HI ZLO

0110001010 Z HILO

0010100010LOHIZ

DEAD. Analog input. A resistor between DEAD and LCAP

is selected to adjust turn-off time to turn-on time. This

delay is needed to prevent cross-conduction in the external

power MOSFETs. See the section Application Information

for details on setting dead time.

SENSE. Analog input to the current limit comparator.

Voltage representing load current appears on this pin. Voltage

transients that are seen at this pin when the drivers turn on

are ignored for period of time, t

BLANK

.

AGND. Analog reference ground.

PGND. Return for low-side gate drivers. This should be

connected to the PCB power ground.

Input Logic

MODE PWM RESET Quadrant Mode of Operation**

0* 0 0 Fast decay

0* 1 0 Fast Decay

1 0 0 Slow decay PWM chop – current decay with both low-side drivers ON.

1 1 0 Slow Decay Selected drivers ON. If current limiting, both low-side drivers ON.

XX 1 X

* Low-side, only, Synchronous Rectifi cation mode.

**See Commutation Truth Table for meaning of “both” and "selected."

PWM chop – current decay with opposite of selected lowside drivers ON.

Selected drivers ON. If current limiting, opposite of selected

low-side drivers ON.

All high-side drivers OFF, low-sides see BRKSEL stored.

Clears storable faults.

www.allegromicro.com

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

6

A3938

Three-Phase Power MOSFET Controller

Application Information

26301.104B

Data Sheet

Synchronous Rectifi cation. To reduce power con-

sumption in the external MOSFETs, during the load current

recirculation PWM-off cycle, the A3938 control logic turns

on the appropriate low-side driver only. The reverse body

diode of the power MOSFET conducts only during the dead

time required at each PWM transition, as usual. However,

unlike full synchronous rectifi cation, the opposite high-side

FET’s body diode (not the RdsON) will carry the re-circulating current, be self-extinguishing, and not force the motor to

reverse direction.

Dead Time. To prevent cross-conduction, it is required to

have a delay between a high-side or low-side turn-off, and

the next turn-on event. The potential for cross-conduction

occurs with synchronous rectifi cation, direction changes,

PWM, or after a bootstrap capacitor charging cycle. This

dead-time is set via a resistor from the DEAD pin to LCAP

and can be varied from 100 ns to 5.5 µs.

For a nominal case, given:

• 25°C ambient temperature, and

• 5.6 kΩ < R

For predicting worst-case overvoltage and temperature

extremes, use the following equations:

t

t

For nominal comparison with I

ambient temperature:

where V

Rather than use R

which activates an internal (I

The choice of power MOSFET and external gate resistance

determines the selection of the dead-time resistor. The dead

time should be made long enough to cover the variation of

the MOSFET capacitance and gate resistor tolerances (both

external and internal to the A3938).

< 470 kΩ,

dead

t

dead (nom,ns)

dead (min,ns)

lcap

= 37 + [(11.9 ×10-3) × (R

= 10 + [(6.55 ×10-3) × (R

dead (max,ns)

= 63 + [(17.2 ×10-3) ×(R

I

dead

= (V

– Vbe) / (R

lcap

= 5 V, Vbe = 0.7 V, and R

values near 470 kΩ, set V

dead

+ 500)]

dead

+ 350)]

dead

+ 650)]

dead

currents, also at 25°C

dead

+ R

dead

= 500 Ω.

int

= 10 µA) current source.

dead

)

int

dead

= 0 V,

Decoupling. The internal reference VREG supplies

current for the gate drive circuit. As the gates are driven

high, they will require current from an external decoupling

capacitor to support the transients. This capacitor should be

placed as close as possible to the VREG pin. The value of the

capacitor should be at least 20 times larger than the bootstrap

capacitor. Additionally, a 1 nF (or larger) ceramic monolithic

capacitor should be connected between LCAP and AGND, as

close to the device pins as possible.

Protection Circuitry. The A3938 has several protection

features:

• Bootstrap Monitor. The bootstrap capacitor is charged

whenever a sink-side MOSFET is on, an Sx output goes low,

or load current recirculates. This happens constantly during

normal operation.

Note: The high side will not be allowed to turn on before the

charging has decayed to less than approximately 9 mA.

• Undervoltage. VREG supplies the low-side gate driver

and the bootstrap charge current. It is critical to ensure that

the voltages are at a proper level before enabling any of the

outputs. The undervoltage circuit is active during power-up

and signals a fault, and also coasts or brakes (depending

on the stored BRKSEL setting) the motor during that time

period, until VREG is greater than approximately 10 V. On

powering down, a fault is signaled and the motor is coasted

or braked, depending on the stored setting for BRKSEL.

• Hall Invalid. Illegal codes for the Hall sensor inputs (0,0,0

or 1,1,1) force a fault and coast the motor. Noisy Hall lines

may cause Hall code errors, and therefore faults. Additional

external pull-up loading and fi ltering may be required in

some systems.

Hint: Use dividers to the VREG terminal, than to the LCAP

terminal, because the VREG terminal has more current

capability.

• Thermal Shutdown. Junction temperatures greater than

165°C cause the A3938 to signal a fault and coast the motor.

• Motor Lead. The A3938 signals a fault if the motor lead

is shorted to ground. A short-to-ground is assumed after a

high- side is turned on and greater than 2 V is measured

between the drain (VBB) and source (Sx) of the high-side

power MOSFET. This fault is cleared at the beginning of

www.allegromicro.com

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

7

A3938

Three-Phase Power MOSFET Controller

26301.104B

Data Sheet

each commutation. If a stalled motor results from a fault, the

fault can only be cleared by toggling the RESET pin or by a

power-up sequence.

Current Regulation. Load current can be regulated by

an internal fi xed off-time, PWM-control circuit. When the

outputs of the MOSFETs are turned on, current increases in

the motor winding until it reaches a value given by:

I

= V

TRIP

At the trip point, the sense comparator resets the source

enable latch, turning off the source driver. At this point, load

inductance causes the current to recirculate for the fi xed off-

time period. The current path during recirculation is determined by the confi guration of the MODE and SR input pins.

The fi xed off-time is determined by an external resistor, R

and capacitor, CT, connected in parallel from the RC terminal

to AGND. The fi xed off-time is approximated by:

t

OFF

t

should be in the range between 10 µs and 50 µs. Larger

OFF

values for t

could result in audible noise problems. For

OFF

proper circuit operation, 10 kΩ < R

Torque control can be implemented by varying the REF input

voltage as long as the PWM input stays high. If direct control

of the torque/current is desired by PWM input, a voltage can

be applied to the REF pin to set an absolute maximum current limit.

PWM Blank. The capacitor C

to set the BLANK time duration. At the end of a PWM

off-cycle, a high-side gate selected by the commutation logic

turns on. At this time, large current transients can occur during the reverse recovery time, trr, of the intrinsic body diodes

/ R

REF

SENSE

= RT × C

T

< 500 kΩ.

T

also serves as the means

T

,

T

of the power MOSFETs. To prevent false tripping of the

sense comparator, the BLANK function disables the comparator for a time period defi ned by:

t

BLANK

= 1.9 × C

/ (1 × 10-3 – [2 / RT])

T

The user must ensure that CT is large enough to cover the

current spike duration.

Braking. The A3938 dynamically brakes the motor by

forcing all low-side power MOSFETs on, and all high-side

power MOSFETs off. This effectively short-circuits the

BEMF and brakes the motor. During braking, the load current can be approximated by:

I

BRAKEPEAK

= V

BEMF

/ R

LOAD

As the current does not fl ow through the sense resistor dur-

ing a dynamic brake, care should be taken to ensure that the

maximum ratings of the power MOSFETs are not exceeded.

Note: On its rising edge, a RESET setting of 1 overrides the

BRAKE input pin and latches the condition selected by the

BRKSEL pin.

Power Loss Brake. The BRKCAP and BRKSEL pins

provide a power-down braking option. A Power-Loss Brake

Trigger Event, which is either an undervoltage on VREG

or a RESET = 1 rising edge, is sensed by the A3938, which

then dynamically brakes or coasts (depending on the stored

BRKSEL setting) the motor. The reservoir capacitor on the

BRKCAP pin provides the positive voltage that forces the

low-side gates of the power MOSFETs high, keeping them

on, even after supply voltage is lost. A stored setting of BRKSEL = 1 brakes the motor, but a stored setting of BRKSEL = 0

coasts it. The combined effect of these settings is shown in the

table Brake Control.

Brake Control

BRAKE BRKSEL Before Power Loss Brake Trigger Event After Power Loss Brake Trigger Event

0 0 Normal run mode Coast mode – All gate drive outputs OFF

0 1 Normal run mode Brake mode – All low-side gate drivers ON

1 0 Brake mode – All low-side gate drivers ON Coast mode – All gate drive outputs OFF

1 1 Brake mode – All low-side gate drivers ON Brake mode – All low-side gate drivers ON

www.allegromicro.com

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

8

Three-Phase Power MOSFET Controller

Terminal List

32-Lead

Name Description

PGND Low-Side Gate Drive Return 1 36 36

RESET Control Input 2 1 1

GLC Low-Side Gate Drive Output, Phase C 3 2 2

SC Motor Connection, Phase C 4 3 3

GHC High-Side Gate Drive Output, Phase C 5 6 6

CC Bootstrap Capacitor, Phase C 6 7 7

GLB Low-Side Gate Drive Output, Phase B 7 8 8

SB Motor Connection, Phase B 8 9 9

GHB High-Side Gate Drive Output, Phase B 9 10 10

CB Bootstrap Capacitor, Phase B 10 11 11

GLA Low-Side Gate Drive Output, Phase A 11 12 12

SA Motor Connection, Phase A 12 13 13

GHA High-Side Gate Drive Output, Phase A 13 14 14

CA Bootstrap Capacitor, Phase A 14 15 15

VREG Gate Drive Supply 15 16 16

LCAP 5 V Output 16 17 17

FAULT Diagnostic Output 17 19 19

MODE Control Input 18 20 20

VBB Load Supply 19 21 21

H1 Hall Control Input 20 22 22

H3 Hall Control Input 21 24 24

H2 Hall Control Input 22 25 25

DIR Control Input 23 26 26

BRAKE Control Input 24 27 27

BRKCAP Power Loss Brake Reservoir Capacitor 25 28 28

BRKSEL Control Input 26 29 29

PWM Control Input 27 30 30

RC Connection for Fixed Off-Time R and C 28 31 31

SENSE Sense Resistor 29 32 32

REF Current Limit Adjust 30 33 33

DEAD Dead Time Adjust 31 34 34

AGND Ground 32 35 35

N/C Not Connected 4,5,18,23

A3938EQ

PLCC

36-Lead

A3938LQ

QSOP

A3938

38-Lead

A3938LD

TSSOP

4, 5, 18,

23, 37, 38

26301.104B

Data Sheet

www.allegromicro.com

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

9

SC

4

GLC

3

RESET

PGND

2

1

AGND

DEAD

323130

A3938

Three-Phase Power MOSFET Controller

A3938EQ, 32-pin PLCC

.495

12.57

.485

12.32

.453

11.51

.447

REF

11.35

132

.013

.008

0.32

0.19

26301.104B

Data Sheet

GHC

CC

GLB

SB

GHB

CB

GLA

SA

GHA

RESET

GLC

N/C

N/C

GHC

CC

GLB

GHB

GLA

GHA

VREG

LCAP

N/C

SC

SB

CB

SA

CA

5

6

7

8

9

10

11

12

13

14

CA

Control

Fault

1617181920

15

LCAP

VREG

FAULT

Logic

MODE

VBB

29

SENSE

28

RC

27

PWM

26

BRKSEL

25

BRKCAP

24

BRAKE

23

DIR

22

H2

21

H3

H1

.595

.585

15.11

14.86

.553

14.05

.547

13.89

.021

0.53

.013

0.33

.050

1.27

BSC

Dimensions in inches

Metric dimensions (mm) in brackets, for reference only

If unit is intended to be socketed, it is advisable to review lead profile with socket supplier

.095

.060

.140

.125

2.41

1.52

3.56

3.18

.015

0.38

MIN

Seating Plane

Base Plane

A3938LQ, 36-pin QSOP

.606

15.40

.598

0.80

REF

15.20

.031

0.30

0.10

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Control

Fault

Logic

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

PGND

AGND

DEAD

REF

SENSE

RC

PWM

BRKSEL

BRKCAP

BRAKE

DIR

H2

H3

N/C

H1

VBB

MODE

FAULT

10.51

10.11

0.85

BSC

0.51

0.28

.414

.398

36

.299

7.60

.291

7.40

21

.020

.011

.033

Dimensions in millimeters

U.S. Customary dimensions (in.) in brackets, for reference only

2.64

2.44

.012

.004

8º

0º

0.32

0.23

1.27

0.40

.355

BSC

Seating Plane

Gauge Plane

.104

.096

0.014

.013

.009

.050

.016

www.allegromicro.com

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

10

RESET

GLC

SC

N/C

N/C

GHC

CC

GLB

SB

GHB

CB

GLA

SA

GHA

CA

VREG

LCAP

N/C

FAULT

26301.104B

Data Sheet

A3938

Three-Phase Power MOSFET Controller

A3938LD, 38-pin TSSOP

9.8

0.386

9.6

.50

BSC

.020

0.378

0.75

0.45

0.030

0.018

0.15

0.05

1.10

MAX

0.006

0.002

0.043

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Control

Fault

Logic

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

N/C

N/C

PGND

AGND

DEAD

REF

SENSE

RC

PWM

BRKSEL

BRKCAP

BRAKE

DIR

H2

H3

N/C

H1

VBB

MODE

6.4

BSC

0.252

0.27

0.17

38

4.5

0.177

4.3

0.169

21

0.011

0.007

Dimensions in millimeters

U.S. Customary dimensions (in.) in brackets, for reference only

8º

0º

0.20

0.09

1

0.039

REF

.25

0.010

BSC

Seating Plane

Gauge Plane

0.008

0.004

The products described here are manufactured under one or

more U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time

to time, such de par tures from the detail spec i fi ca tions as may be

required to permit improvements in the per for mance, reliability,

or manufacturability of its products. Before placing an order, the

user is cautioned to verify that the information being relied upon is

current.

Allegro products are not authorized for use as critical components in life-support devices or sys tems without express written

approval.

The in for ma tion in clud ed herein is believed to be ac cu rate and

reliable. How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty for its use; nor for any in fringe ment of patents or other

rights of third parties which may result from its use.

Copyright©2003 AllegroMicrosystems, Inc.

www.allegromicro.com

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

11

Loading...

Loading...