A3930 and A3931

Automotive 3-Phase BLDC Controller and MOSFET Driver

Features and Benefits

High current 3-phase gate drive for N-channel MOSFETs

Synchronous rectification

Cross-conduction protection

Charge pump and top-off charge pump for 100% PWM

Integrated commutation decoder logic

Operation over 5.5 to 50 V supply voltage range

Extensive diagnostics output

Provides +5 V Hall sensor power

Low-current sleep mode

Package: 48 Lead LQFP with exposed

thermal pad (suffix JP)

Description

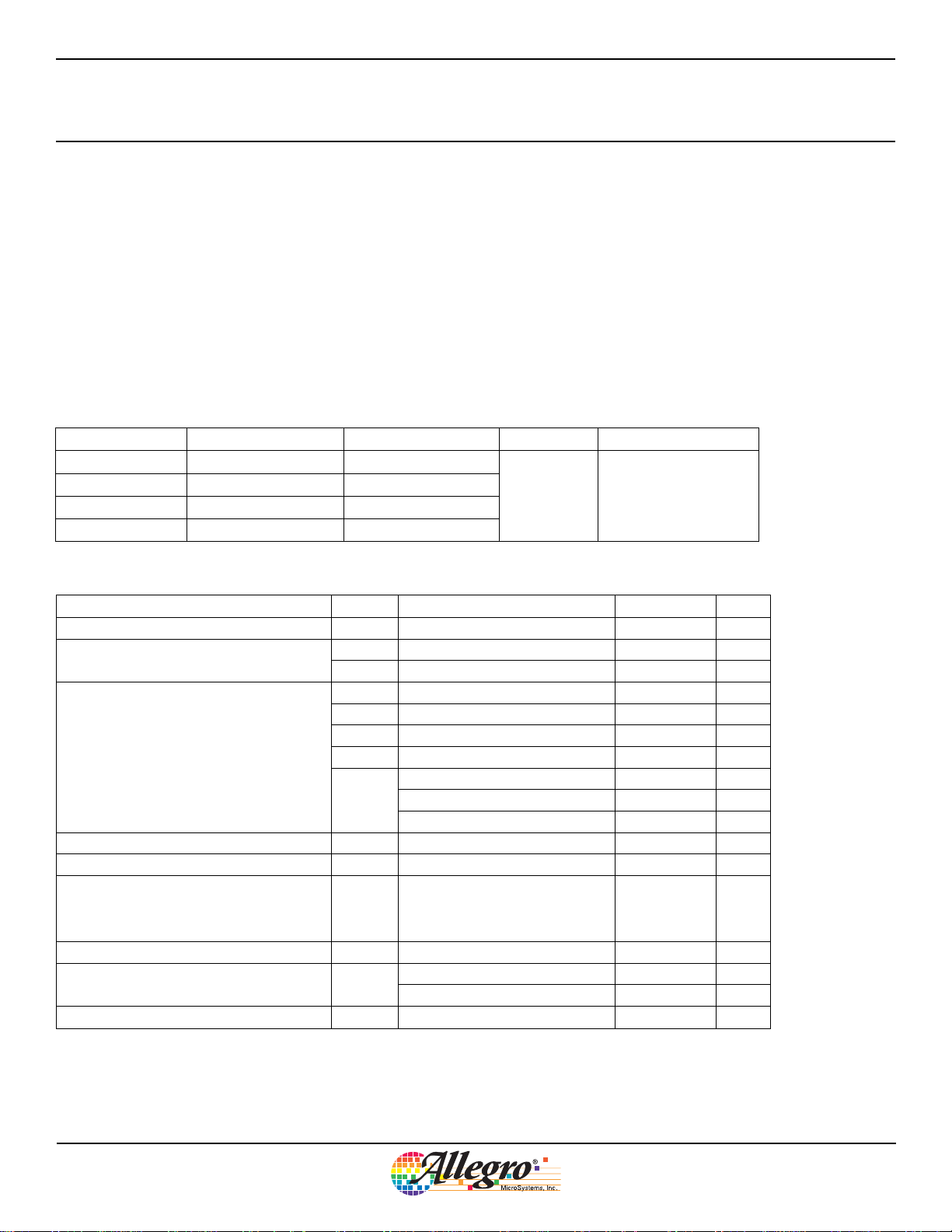

The A3930 and A3931 are 3-phase brushless DC (BLDC) motor

controllers for use with N-channel external power MOSFETs.

They incorporate much of the circuitry required to design a

cost effective three-phase motor drive system, and have been

specifically designed for automotive applications.

A key automotive requirement is functionality over a wide

input supply range. A unique charge pump regulator provides

adequate (>10 V) gate drive for battery voltages down to 7 V,

and allows the device to operate with a reduced gate drive at

battery voltages down to 5.5 V. Power dissipation in the charge

pump is minimized by switching from a voltage doubling mode

at low supply voltage to a dropout mode at the nominal running

voltage of 14 V.

A bootstrap capacitor is used to provide the above-battery

supply voltage required for N-channel MOSFETs. An internal

charge pump for the high-side drive allows for DC (100% duty

cycle) operation.

Internal fixed-frequency PWM current control circuitry can

be used to regulate the maximum load current. The peak

load current limit is set by the selection of an input reference

voltage and external sensing resistor. The PWM frequency is

set by a user-selected external RC timing network. For added

flexibility, the PWM input can be used to provide speed and

Approximate Scale 1:1

Continued on the next page…

T ypical Application

3930-DS Rev. 2

A3930 and

Automotive 3-Phase BLDC Controller

A3931

Description (continued)

torque control, allowing the internal current control circuit to set

the maximum current limit.

Efficiency is enhanced by using synchronous rectification. The

power FETs are protected from shoot-through by integrated

crossover control with dead time. The dead time can be set by a

single external resistor.

The A3930 and A3931 only differ in their response to the all-zero

Selection Guide

Part Number Option Packing Terminals Package

A3930KJP-T Hall short detection 250 pieces/tray

A3930KJPTR-T Hall short detection 1500 pieces/reel

A3931KJP-T Pre-positioning 250 pieces/tray

A3931KJPTR-T Pre-positioning 1500 pieces/reel

combination on the Hall inputs. In this state, the A3930 indicates

a logic fault, but the A3931 pre-positions the motor in an unstable

starting position suitable for start-up algorithms in microprocessordriven “sensor-less” control systems.

Both devices are supplied in a 48-pin LQFP with exposed thermal

pad. This is a small footprint (81 mm2) power package, that is lead

(Pb) free, with 100% matte tin leadframe plating.

48 LQFP surface mount

and MOSFET Driver

Absolute Maximum Ratings

Parameter Symbol Conditions Rating Units

Load Supply Voltage V

V

Logic Input/Output Voltage

Output Voltage Range

Operating Temperature Range (K) T

Junction Temperature T

Transient Junction Temperature T

Storage Temperature Range T

ESD Rating, Human Body Model

ESD Rating, Charged Device Model AEC-Q100-011, all pins 1050 V

RESET

V

V

V

V

VBB pin –0.3 to 50 V

BB

RESET pin input –0.3 to 6 V

Remaining logic pins –0.3 to 7 V

GHA, GHB, and GHC pins VSx to VSx+ 15 V

GHx

GLA, GLB, and GLC pins –5 to 16 V

GLx

CA, CB, and CC pins VSx+ 15 V

Cx

SA, SB, and SC pins –5 to 55 V

Sx

CSP, CSN, and LSS pins –4 to 6.5 V

CSO, VDSTH pins –0.3 to 6.5 V

VDRAIN pin –0.3 to 55 V

A

J

Overtemperature event not exceeding 1 s, lifetime duration not exceed-

tJ

ing 10 hr; guaranteed by design

characterization

S

AEC-Q100-002, all pins except CP1 2000 V

AEC-Q100-002, pin CP1 1000 V

–40 to 150 °C

–55 to 150 °C

150 °C

175 °C

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

2

A3930 and

Automotive 3-Phase BLDC Controller

A3931

QV5

VBAT+

V5BD

CV5

MODE

COAST

BRAKE

RESET

DIR

and MOSFET Driver

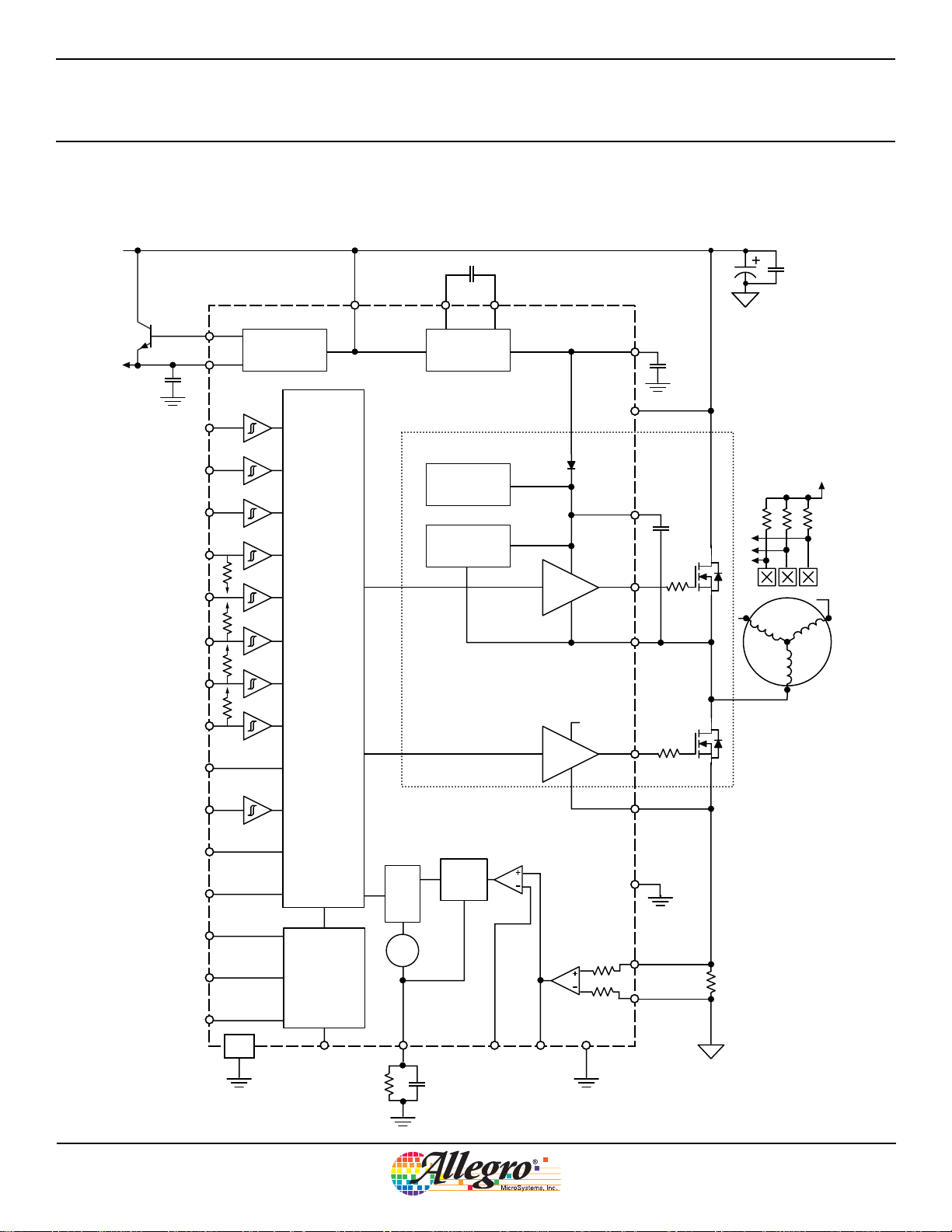

Functional Block Diagram

CP

VBB

V5

H1

+5V Ref

Control

Logic

Phase A of three phases

CP1CP2

Charge

Pump

Regulator

Charge

Pump

Boostrap

Monitor

High-Side

Drive

VREG

VDRAIN

CA

GHA

SA

CREG

CBOOTA

RGHA

P

V5

H1

H2

H3

&C

&B

H2

H3

RDEAD

PWM

TACHO

DIRO

ESF

FF1

FF2

Pad

Diagnostics and

Protection

–UVLO

–TSD

–Short to Supply

–Short to Ground

–Shorted Winding

–Low Load

VDSTH

RC

Q

OSC

VREG

Low-Side

Drive

R

Blanking

S

REF

CSOUT

CTRT

AGND

GLA

RGLA

LSS

TEST

CSP

CSN

P

&A

RSENSE

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

3

A3930 and

Automotive 3-Phase BLDC Controller

A3931

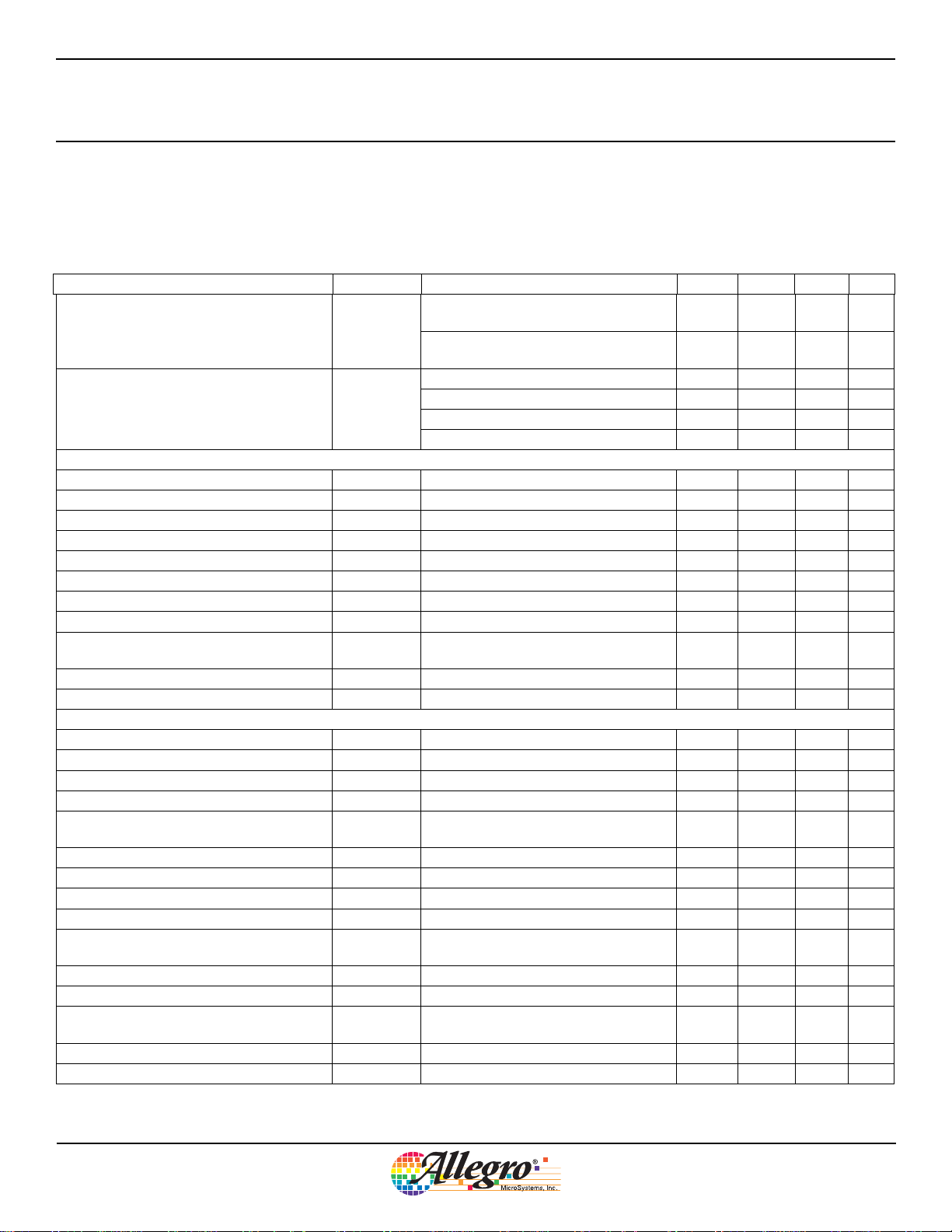

ELECTRICAL CHARACTERISTICS at T

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Supply and Reference

VBB Functional Operating Range

VBB Quiescent Current

V5 Quiescent Current I

VREG Output Voltage V

Bootstrap Diode Forward Voltage V

Bootstrap Diode Resistance r

Bootstrap Diode Current Limit I

Top-off Charge Pump Current Limit I

High-Side Gate Drive Static Load

Resistance

V5 Output Voltage V

VBE of External Transistor QV5 V

V5BD Base Drive Capability for QV5

Gate Output Drive

Turn-On Rise Time t

Turn-Off Fall Time t

Pull-Up On Resistance R

Pull-Down On Resistance R

Short-Circuit Current – Source

Short-Circuit Current – Sink I

GHx Output Voltage V

GLx Output Voltage V

6

2

2

= –40°C to 150°C, V

J

DS(on)UP

DS(on)DN

I

SC(source)TJ

SC(sink)

V

BB

I

BBQ

I

BBS

V5Q

REG

fBOOT

D

DBOOT

TOCPM

R

GSH

5

BEEXT

I

5BD

r

f

GHx

GLx

and MOSFET Driver

= 7 to 45 V, unless otherwise noted

BB

Function correct, parameters not

guaranteed

RESET = High, outputs = Low – 11 14 mA

RESET = Low, sleep mode – – 10 A

RESET = High, outputs = Low – – 5 mA

V

7.4 V, I

BB

6 V < V

BB

I

= 0 to 15 mA

REG

5.5 V < VBB < 6 V, I

= 0 to 15 mA 12.10 13 13.75 V

REG

< 7.4 V

< 10 mA 9 10 – V

REG

ID = 10 mA 0.4 0.7 1.0 V

ID = 100 mA 1.5 2.2 2.8 V

r

D(100 mA)

V

C

LOAD

C

LOAD

TJ = 25°C, I

TJ = 150°C, I

TJ = 25°C, I

TJ = 150°C, I

= (V

fBOOT(150 mA)

fBOOT(50 mA)

–

) / 100 mA

= 3300 pF, 20% to 80% points – 60 – ns

= 3300 pF, 80% to 20% points – 40 – ns

= –150 mA 3 4 5

GHx

= –150 mA 4.6 5.6 6.6

GHx

= 150 mA 1 1.5 2

GLx

= 150 mA 1.5 2.3 3

GLx

= 25°C – –500 – mA

TJ = 25°C – 850 – mA

tw < 10 s

Bootstrap capacitor fully charged

1

5.5 – 50 V

2 × V

BB

–2.7

––V

61020

250 500 750 mA

– 200 – A

250 – – k

4.75 5 5.25 V

––1V

– – –2 mA

V

– 0.2 – – V

Cx

V

–

REG

0.2

––V

Continued on the next page...

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

4

A3930 and

Automotive 3-Phase BLDC Controller

A3931

ELECTRICAL CHARACTERISTICS (continued) at T

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Turn-Off Propagation Delay t

Dead Time (turn-off to turn-on delay) t

Logic Inputs and Outputs

FFx Fault Output (Open Drain) V

FFx Fault Output Leakage Current

2

TACHO and DIRO Output High Voltage V

TACHO and DIRO Output Low Voltage V

Input Low Voltage V

Input High Voltage (Except RESET) V

RESET Input High Voltage V

Input Hysteresis V

Input Current (Except H1, H2, H3, and

RESET)

2

RESET Input Pull-Down Resistor R

Hx Input Pull-Up Resistor R

Current Sense Differential Amplifier

Input Bias Current

Input Offset Current

2

2

CSP Input Resistance R

CSN Input Resistance R

Differential Input Voltage V

Output Offset Voltage V

Output Offset Voltage Drift V

Input Common Mode Range V

Differential Input Voltage Gain A

Low Output Voltage Error V

DC Common Mode Gain A

Source Resistance r

Output Dynamic Range V

Output Current – Sink I

Output Current – Source

2

p(off)

DEAD

OL

I

OH

OH

OL

IL

IH

IHR

IHys

I

IN

PD

PU

I

IBS

I

IOS

CSP

CSN

ID

OOS

OOS(t)

CM

V

err

CMdc

CSOUT

CSOUT

CSOUT(sink)VCSOUT

I

CSOUT(source)VCSOUT

and MOSFET Driver

= –40°C to 150°C, V

J

From Hall input change to unloaded

gate output change

From other control input change to

unloaded gate output change

R

= 5 k – 180 – ns

DEAD

R

= 50 k 835 960 1090 ns

DEAD

R

= 400 k – 3.3 – s

DEAD

= 7 to 45 V, unless otherwise noted

BB

300 500 700 ns

– 150 200 ns

RDEAD = tied to V5 – 6 – s

I

= 1 mA, fault asserted – – 0.4 V

OL

VO = 5 V, fault not asserted –1 – 1 A

I

= –1 mA V5 – 1 V – – V

OH

I

= 1 mA – – 0.4 V

OL

– – 0.8 V

2––V

2.2 – – V

300 500 – mV

–1 – 1 A

V

= 5 V – 50 – k

IN

V

= 0 V – 100 – k

IN

CSP = CSN = 0 V –250 –200 –150 A

CSP = CSN = 0 V –10 – 10 A

Measured with respect to AGND – 80 – k

Measured with respect to AGND – 4 – k

V

= CSP – CSN, –1.3 V < CSP < 4 V,

ID

–1.3 V < CSN < 4 V

0 – 200 mV

CSP = CSN = 0 V 100 320 550 mV

CSP = CSN = 0 V – 100 – V/°C

CSP = CSN –1.5 – 4 V

40 mV < V

0 < V

V

CSOUT

< 175 mV, VCM in range 18.5 19 19.5 V/V

ID

< 40 mV,

ID

= (19 × VID) + V

OOS

+ V

err

–20 – 20 mV

CSP = CSN = 200 mV – –30 – dB

V

–100 A < I

= 2 V, –2 mA < I

CSOUT

< 0.5 mA – 80 –

CSOUT

< 100 A 0.1 –

CSOUT

= 2 V ±5% – 1 – mA

= 2 V ±5% – –19 – mA

1

– 0.2

V5

V

Continued on the next page…

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

5

A3930 and

Automotive 3-Phase BLDC Controller

A3931

ELECTRICAL CHARACTERISTICS (continued) at T

= –40°C to 150°C, V

J

= 7 to 45 V, unless otherwise noted

BB

and MOSFET Driver

1

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Supply Rejection PSRR CSP = CSN = AGND, 0 to 300 kHz – 45 – dB

Small Signal 3 dB Bandwidth Frequency f

Settling Time t

AC Common Mode Gain A

Common Mode Recovery Time t

3dB

SETTLE

CMac

CMrec

Output Slew Rate SR

Input Overload Recovery Time t

IDREC

VID=10 mV

To within 10%, V

PP

= 1 VPP square

CSOUT

wave

V

= 250 mVPP, 0 to 1 MHz – –28 – dB

ICR

To within 100 mV, V

= +4.1 to 0 V

ICR

step

10% to 90% points, VID= 0 to 175 mV

step

– 1.6 – MHz

– 400 – ns

–1–s

–20–V/s

To within 10%, VID=250 mV to 0 V step – 500 – ns

Current Limit

Reference Comparator Input Offset Voltage V

Reference Input Clamp Voltage V

Comparator Blank Time t

REF Input Bias Current I

RC Charge Current

2

RC HIgh Voltage Threshold V

RC Low Voltage Threshold V

IOC

REFC

RC

IBREF

I

RC

RCH

RCL

External pull-up to 5 V R

= 200 k 3.75 4 4.2 V

REF

RT= 56 k, CT = 470 pF – 650 – ns

–15 0 15 mV

–0–A

–1.15 –1 –0.85 mA

1.7 1.9 2.1 V

0.6 0.7 0.8 V

Protection

V

rising 7.5 8 8.5 V

VREG Undervoltage Lockout V

Bootstrap Capacitor Undervoltage Lockout V

Bootstrap Capacitor Undervoltage Lockout

Hysteresis

V5 Undervoltage Lockout V

V5 Undervoltage Lockout Hysteresis V

VDSTH Input Voltage Range V

VDSTH Input Current

2

VDRAIN Input Voltage Range V

Short-to-Ground Threshold Offset

Short-to-Battery Threshold Offset

3,5

4,5

Low Load Current Detection Voltage V

Overtemperature Flag T

Overtemperature Flag Hysteresis T

1

Parameters are tested at 135°C. Values at 150°C are guaranteed by design or correlation.

2

For input and output current specifications, negative current is defined as coming out of (sourcing) the specified device pin.

3

High side on. As VSX decreases, fault occurs if V

4

Low side on. As VSX increases, fault occurs if V

5

V

threshold is V

STG

6

Function is correct but parameters not guaranteed above or below general limits (7 to 45 V).

DTSTH

+ V

STGO

. V

STB

threshold is V

REGUV

BOOTUVVBOOT

V

BOOTUVHysVBOOTUVHys

5UV

5UVHys

DSTH

I

DSTH

DRAIN

V

STGO

V

STBO

CSOL

JF

JFHys

– V

– V

SX

LSS

DTSTH

> V

> V

BAT

SX

REG

V

falling 6.75 7.25 7.75 V

REG

falling, VCx – V

= %V

REG

Sx

59 – 69 %

–13–%

V5 falling 3.4 3.65 4.0 V

300 400 500 mV

0.3 – 4 V

–1 – 1 A

7VBB45 V

V

> 1 V – ±300 – mV

DSTH

V

1 V, 7 V V

DSTH

V

> 1 V – ±300 – mV

DSTH

V

1 V, 7 V V

DSTH

30 V –150 – 150 mV

DRAIN

30 V –150 – 150 mV

DRAIN

– 500 – mV

Temperature increasing – 170 – ºC

Recovery = T

.

STG

.

STB

+ V

STBO

.

JF

– T

JFHys

–15–ºC

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

6

A3930 and

Automotive 3-Phase BLDC Controller

A3931

and MOSFET Driver

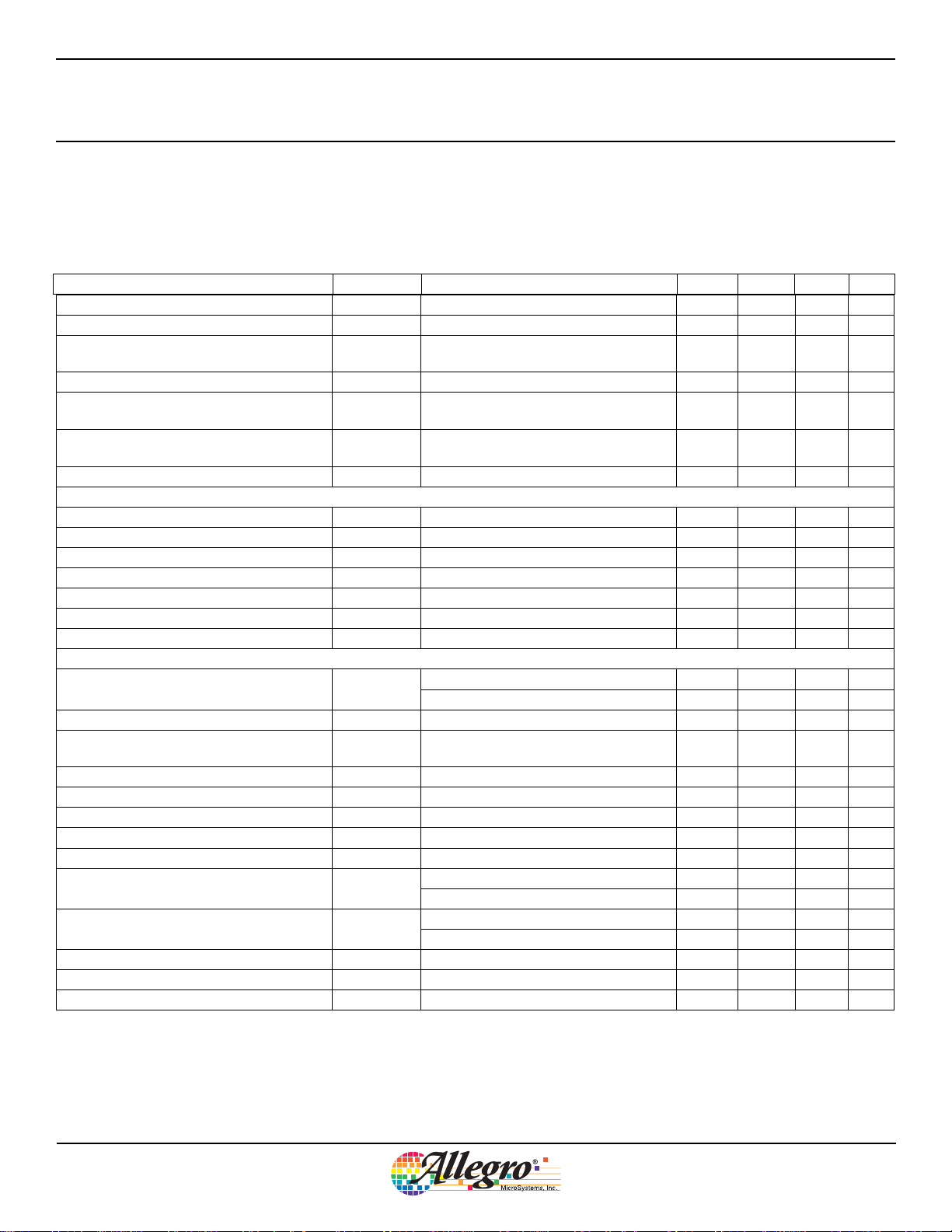

Thermal Characteristics

THERMAL CHARACTERISTICS may require derating at maximum conditions, see Applications Information section

Characteristic Symbol Test Conditions* Value Units

4-layer PCB, based on JEDEC standard 23 ºC/W

Package Thermal Resistance R

Die-to-Exposed Pad Thermal Resistance

*Additional thermal information available on Allegro Web site.

JA

R

JP

Power Dissipation versus Ambient Temperature

2-layer PCB, with 3 in.

by thermal vias

2

of copper area each side connected

44 ºC/W

2 ºC/W

6.0

5.0

4.0

R

R

QJA

Q

JA

= 23°C/W

= 44°C/W

3.0

2.0

1.0

0

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

50 75 100 125 15025

AMBIENT TEMPERATURE IN °C

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

7

A3930 and

Automotive 3-Phase BLDC Controller

A3931

Functional Description

Basic Operation

The A3930 and A3931 devices provide commutation and current

control for 3-phase brushless DC (BLDC) motors with integrated

Hall-effect (HE) sensors. The motor current is provided by an

external 3-phase N-channel MOSFET bridge which is controlled

by the A3930/A3931, using fixed-frequency pulse width modulation (PWM). The use of PWM with N-channel MOSFETs

provides the most cost-effective solution for a high-efficiency

motor drive.

The A3930/A3931 provides all the necessary circuits to ensure

that the gate-source voltage of both high-side and low-side external MOSFETs are above 10 V, at supply voltages down to 7 V.

For extreme battery voltage drop conditions, functional operation

is guaranteed down to 5.5 V but with a reduced gate drive. The

A3930/A3931 also decodes the commutation sequence from three

HE sensors spaced at 120° in the electrical cycle, and ensure no

cross-conduction (shoot through) in the external bridge. Individual pins provide direction, brake and coast control.

Motor current can be sensed by a low-value sense resistor,

RSENSE, in the ground connection to the bridge, amplified and

compared to a reference value. The A3930/A3931 then limits the

bridge current on a cycle-by-cycle basis. Bridge current can also

be controlled using an external PWM signal with the internal current control either disabled or used to set the absolute maximum

motor current. Specific functions are described more fully in the

following sections.

Power Supplies

Only one power connection is required because all internal

circuits are powered by integrated regulators. The main power

supply should be connected to VBB through a reverse battery

protection circuit.

V5 and V5BD A 5 V supply for external pull-up and bias cur-

rents is provided by an integrated 5 V regulator controller and an

external NPN transistor, QV5. The A3930/A3931 provides the

base drive current on the V5BD pin, and the 5 V reference on the

V5 pin. This regulator is also used by the internal logic circuits

and must always be decoupled by at least a 200 nF capacitor,

CV5, between the V5 pin and AGND. For stability, a 100 nF

capacitor, C5BD, also should be connected between V5BD and

and MOSFET Driver

AGND. If an external 5 V supply is not required, the V5BD pin

and the V5 pin should be connected together.

CP1, CP2, and VREG The gate drive outputs are powered by

an internal charge pump, which requires a pump capacitor, typically 470 nF, CP, connected between the CP1 and CP2 pins. The

output from the charge pump, 13 V nominal, is used to power

each of the three high- and low-side driver pairs and is also

available on the VREG pin. A sufficiently large storage capacitor, CREG, must be connected to this pin to provide the transient charging current to the low-side drivers. The charge pump

also provides the charging current for the bootstrap capacitors,

CBOOTx.

An additional “top-off” charge pump is provided for each highside drive which allows the high-side drive to maintain the gate

voltage on the external FET indefinitely, ensuring so-called 100%

PWM if required. This is a low-current trickle charge pump

(< 100 A typical), and is only operated after a high-side driver

has been signaled to turn on. There is a small amount of bias

current (< 20 A) drawn from the Cx pin to operate the floating

high-side circuit, and the charge pump simply provides enough

drive to ensure that the bootstrap voltage, and hence the gate voltage, will not droop due to this bias current. The charge required

for initial turn-on of the high-side gate is always supplied by

bootstrap capacitor charge cycles.

Hall Effect Sensor Inputs

H1, H2, and H3 Hall-effect sensor inputs are configured for

motors with 120° electrically-spaced HE sensors, but may be

used for 60° electrical spacing with an external inverter. HE sensors usually require an additional pull-up resistor to be connected

between the sensor output and 5 V. This 5 V can be provided by

the integrated 5 V regulator. HE inputs have a hysteresis of typically 500 mV to reduce the effects of switching noise on the HE

connections to the motor. These inputs are also filtered to further

reduce the effects of switching noise. The HE inputs are pulledup to 5 V inside the A3930/A3931 through a high value (100

k typical) resistor in series with a diode. This internal pull-up

makes the HE input appear high if the Hall sensor signal is missing, allowing detection of an HE input logic fault.

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

8

A3930 and

Automotive 3-Phase BLDC Controller

A3931

In order to provide a known start-up position for the motor, an

optional prepositioning function is available in the A3931. When

the Hall inputs are all driven low (H1 = H2 = H3 = 0), the power

FETs in the A phase source current from the supply, and those in

both the B and C phases sink current. This forces the motor to

move to an unstable position midway between two detent points

and allows any start-up algorithm to ensure correct initial direction of rotation. Note that this is only available in the A3931. The

A3930 will indicate a logic fault when all Hall inputs are driven

low. The commutation truth table for these inputs is shown in

table 2. The inputs can also be driven directly from a microcontroller or similar external circuit.

Gate Drive

The A3930/A3931 is designed to drive external N-channel power

MOSFETs. They supply the large transient currents necessary to

quickly charge and discharge the gate capacitance of the external

FETs in order to reduce dissipation in the external FETs during

switching. The charge and discharge rate can be controlled using

external resistors in series with the connections to the gate of the

FETs.

RDEAD Cross-conduction is prevented by the gate drive circuits

which introduce a dead time, t

off and the complementary FET on. The dead time is derived

from the value of a resistor, RDEAD, connected between the

RDEAD pin and AGND. If RDEAD is connected to V5, t

defaults to 6 s typical.

GLA, GLB, and GLC Low-side gate drive outputs for external

NMOS drivers. External series-gate resistors, RGATE, (as close

as possible to the NMOS gate) can be used to control the slew

rate seen at the power-driver gate, thereby controlling the di/dt

and dv/dt of the Sx outputs. Referring to table 2, GLx = 1 (high)

means that the upper half (PMOS) of the driver is turned on, and

that its drain will source current to the gate of the low-side FET

in the external motor-driving bridge. GLx = 0 (low) means that

the lower half (NMOS) of the driver is turned on, and that its

drain will sink current from the corresponding external FET gate

circuit to the LSS pin.

, between switching one FET

DEAD

DEAD

and MOSFET Driver

which should have low-impedance traces to the FET bridge.

GHA, GHB, and GHC High-side gate drive outputs for exter-

nal NMOS drivers. External series-gate resistors, RGATE, can

be used to control the slew rate seen at the power-driver gate,

thereby controlling the di/dt and dv/dt of the Sx inputs. Referring

to table 2, GHx = 1 (high) means that the upper half (PMOS) of

the driver is turned on, and that its drain will source current to the

gate of the high-side FET in the external motor-driving bridge.

GHx = 0 (low) means that the lower half (NMOS) of the driver

is turned on, and that its drain will sink current from the corre-

sponding external FET gate circuit to the respective Sx pin.

CA, CB, and CC High-side connections for the bootstrap

capacitors and positive supply for high-side gate drivers. The

bootstrap capacitors, CBOOTx, are charged to approximately

V

when the corresponding Sx terminal is low. When the Sx

REG

output swings high, the voltage on the Cx pin rises with the out-

put to provide the boosted gate voltage needed for the high-side

N-channel power MOSFETs.

VDRAIN High impedance sense input (Kelvin connection) to

the top of the external FET bridge. This input allows accurate

measurement of the voltage at the drain of the high-side FETs and

should be connected directly to the bridge, close to the drain connections of the high-side FETs, with an independent trace.

LSS Low-side return path for discharge of the gate capacitors.

It is connected to the common sources of the low-side external

FETs through an independent low-impedance trace.

Logic Control Inputs

Additional logic-level inputs are provided to enable specific

features described below. These logic inputs all have a nominal

hysteresis of 500 mV to improve noise performance.

RESET Allows minimum current consumption from the VBB

supply. When RESET is low, all internal circuitry is disabled

including the V5 output. When coming out of sleep state, the

protection logic ensures that the gate drive outputs are off until

the charge pump reaches proper operating conditions. The charge

pump stabilizes in approximately 3 ms under nominal conditions.

SA, SB, and SC Directly connected to the motor, these

terminals sense the voltages switched across the load. These

terminals are also connected to the negative side of the bootstrap

capacitors and are the negative supply connections for the

floating high-side drivers. The discharge current from the highside FET gate capacitance flows through these connections,

RESET has an internal pull-down resistor, 50 k typical.

However, to allow the A3930/A3931 to start-up without the

need for an external logic input, the RESET pin can be pulled

to the battery voltage with an external pull-up resistor. Because

RESET also has an internal clamp diode, 6 V typical, to limit the

input current, the value of the external pull-up resistor should be

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

9

A3930 and

Automotive 3-Phase BLDC Controller

A3931

greater than 20 k. The upper limit for the resistor must be low

enough to ensure that the input voltage reaches the input high

threshold, V

COAST An active-low input which turns all FETs off without

disabling the supplies or control logic. This allows the external

FETs and the motor to be protected in case of a short circuit.

MODE Sets the current-decay method. Referring to table 3, when

in slow-decay mode, MODE = 1, only the high-side MOSFET

is switched off during a PWM-off cycle. In the fast-decay mode,

MODE = 0, the device switches both the high-side and low-side

MOSFETs.

Slow decay allows a lower ripple current in the motor at the

PWM frequency, but reduces the dynamic response of the current control. It is suitable for motors which run at a more-or-less

constant speed. Fast decay provides improved current-control

dynamic response, but increases the motor current ripple. It is

suitable for motors used in start-stop and positioning applications.

DIR Determines the direction of motor torque output, as shown in

table 2. For an unloaded, low-inertia motor, this will also usually

be the direction of mechanical rotation. With a motor that has a

high inertial load, the DIR input can be used to apply a controlled

breaking torque, when fast decay is used (MODE = 0).

BRAKE An active-low input that provides a braking function.

When BRAKE = 0 (see table 3), all the low-side FETs are turned

on and the high-side FETs are turned off. This effectively shortcircuits the back EMF in the windings, and brakes the motor.

The braking torque applied depends on the speed. RESET = 0 or

COAST = 0 overrides BRAKE and coasts the motor. Note that

when BRAKE is used to dynamically brake the motor, the windings are shorted with no control over the winding current.

ESF The state of the enable stop on fault (ESF) pin determines

the action taken when a short is detected. See the Diagnostics

section for details.

TEST Test is for Allegro production use and must be connected

to AGND.

Current Regulation

Load current can be regulated by an internal fixed frequency

PWM control circuit or by external input on the PWM pin.

Current Sense Amplifier: CSP, CSN, and CSOUT A dif-

ferential current sense amplifier with a gain, A

provided to allow the use of low-value sense resistors or current

shunts as the current sensing elements. Because the output of

this sense amplifier is available at CSOUT, it can be used for

either internal or external current sensing. With the sense resistor,

INR

.

, of 19 typical, is

V

and MOSFET Driver

RSENSE, connected between CSP and CSN, the output of the

sense amplifier will be approximately:

× A

OOS

) .

V

) .

,

CSOUT

V

where V

is the output offset voltage (the voltage at zero load

OOS

current), and A

(I

CSOUT

is the differential voltage gain of the sense

V

LOAD

× AV × R

SENSE

) + V

amplifier, 19 typical.

Internal Current Control: REF A fixed reference voltage

can be applied to provide a maximum current limit. A variable

reference voltage will provide a variable torque control. The

output voltage of the current sense differential amplifier, V

is compared to the reference voltage available on the REF

pin. When the outputs of the MOSFETs are turned on, current

increases in the motor winding until it reaches a trip point value,

I

, given by:

TRIP

I

TRIP

= (V

REF

– V

OOS

) / (R

SENSE

At the trip point, the sense comparator resets the source enable

latch, turning off the source driver. At this point, load inductance

causes the current to recirculate until the start of the next PWM

period.

The current path during recirculation is determined by the

configuration of the MODE pin. Torque control can therefore be

implemented by varying the voltage on the REF pin, provided

that the PWM input remains high. If direct control of the torque

or current by PWM input is desired, a voltage can be applied to

the REF pin to set an absolute maximum current limit. The REF

input is internally limited to 4 V, which allows the use of a simple

pull-up resistor to V5, RREF, to set the maximum reference

voltage, avoiding the need for an externally generated reference

voltage. RREF should have a value between 20 k and 200 k.

Internal PWM Frequency The internal oscillator frequency,

, is determined by an external resistor, RT, and capacitor, CT,

f

OSC

connected in parallel from the RC pin to AGND. The frequency

is approximately:

where f

1 / (RTCT + t

f

OSC

in the range 20 to 50 kHz.

OSC

BLANK

+ t

DEAD

PWM Input Can be used to control the motor torque by an exter-

nal control circuit signal on the PWM pin. Referring to table 3,

when PWM = 0, the selected drivers are turned off and the load

inductance causes the current to recirculate. The current path during recirculation is determined by the configuration of the MODE

pin. Setting PWM = 1 will turn on selected drivers as determined

by the Hx input logic. Holding PWM=1 allows speed and torque

control solely by the internal current-limit circuit, using the voltage on the REF pin.

,

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

10

A3930 and

Automotive 3-Phase BLDC Controller

A3931

In some circumstances, it may be desirable to completely disable

the internal PWM control. This can be done by pulling the RC

pin directly to AGND. This will disable the internal PWM oscillator and ensure that the output of the PWM latch is always high.

Blank Time When the source driver is turned on, a current spike

occurs due to the reverse-recovery currents of the clamp diodes

and switching transients related to distributed capacitance in the

load. To prevent this current spike from erroneously resetting

the source enable latch, the current-control comparator output

is blanked for a short period of time, t

driver is turned on.

The length of t

is different for internal versus external

BLANK

PWM. It is set by the value of the timing capacitor, CT, according

to the following formulas:

for internal PWM: t

for external PWM: t

A nominal C

value of 680 pF yields a t

T

(s) = 1260 × C

BLANK

(s) = 2000 × C

BLANK

external PWM, and 860 ns for internal PWM. The user must

ensure that CT is large enough to cover the current spike duration

when using the internal sense amplifier.

Diagnostics

Several diagnostic features integrated into the A3930/A3931

provide speed and direction feedback and indications of fault

conditions.

TACHO and DIRO These outputs provide speed and direction

information based on the HE inputs from the motor. As shown in

figure 1, at each commutation point, the TACHO output changes

state independent of motor direction. The DIRO output is updated

at each commutation point to show the motor direction. When

the motor is rotating in the “forward” or positive direction, DIRO

will be high. When rotation is in the “reverse” or negative direction, DIRO will be low. The actual direction of rotation is deter-

mined from the sequence of the three Hall inputs, Hx. Forward

is when the sequence follows table 2 top-to-bottom and reverse

when the sequence follows table 2 bottom-to-top.

DIRO

TACHO

Commutation

Points

"Forward" Motor Rotation "Reverse" Motor Rotation

Figure 1. Direction Indication Outputs

, when the source

BLANK

(F), and

T

(F) .

T

of 1.3 s for

BLANK

and MOSFET Driver

Note that there are some circumstances in which the direction

reported on the DIRO output pin and the direction demanded

on the DIR input pin may not be the same. This may happen if

the motor and load have reasonably high inertia. In this case,

changing the state of the DIR pin will cause the torque to reverse,

braking the motor. During this braking, the direction indicated on

the DIRO output will not change.

ESF The state of the enable stop on fault (ESF) pin will deter-

mine the action taken when a short is detected. For other fault

conditions, the action is defined by the type of fault. The action

taken follows the states shown in table 1.

When ESF = 1, any short fault condition will disable all the

gate drive outputs and coast the motor. This disabled state will

be latched until the next phase commutation or until COAST or

RESET go low.

When ESF = 0, under most conditions, although the fault flags,

FF1 and FF2, are still activated, the A3930/A3931will not disrupt

normal operation and will therefore not protect the motor or the

drive circuit from damage. It is imperative that the master control

circuit or an external circuit take any necessary action when a

fault occurs, to prevent damage to components.

If desired, the active low COAST input can be used as a crude

disable circuit by connecting the fault flags FF1 and FF2 to the

COAST input and a pull-up resistor to V5.

FF1, FF2, and VDSTH Fault conditions are indicated by the

state of two open drain output fault flags, FF1 and FF2, as shown

in table 1. In addition to internal temperature, voltage, and logic

monitoring, the A3930/A3931 monitors the state of the external

MOSFETs and the motor current to determine if short circuit

faults occur or a low load condition exists. In the event that two

or more faults are detected simultaneously, the state of the fault

flags will be determined by a logical AND of the fault states of

each flag.

• Undervoltage VREG supplies the low-side gate driver and the

bootstrap charge current. It is critical to ensure that the voltages

are sufficiently high before enabling any of the outputs. The

undervoltage circuit is active during power-up, and will pull

both fault flags low and coast the motor (all gate drives low)

until V

sufficient to turn on the external power FETs at a battery voltage

as low as 5.5 V, but will not normally provide the rated on-resistance of the FET. This could lead to excessive power dissipation

in the external FET.

is greater than approximately 8 V. Note that this is

REG

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

11

A3930 and

Automotive 3-Phase BLDC Controller

A3931

In addition to a monitor on VREG, the A3930/A3931 also

monitors both the bootstrap charge voltage, to ensure sufficient

high-side drive, and the 5 V reference voltage at V5, to ensure

correct logical operation. If either of these fall below the lockout voltage level, the fault flags are set.

• Overtemperature This event pulls both fault flags low but

does not disable any circuitry. It is left to the user to turn off

the device to prevent overtemperature damage to the chip and

unpredictable device operation.

• Logic Fault: Hall Invalid The A3930 and the A3931 differ

slightly in how they handle error conditions on the Hall inputs,

Hx. When all Hx are 1s, both devices evaluate this as an illegal

code, and they pull both fault flags, FFx, low and coast the mo-

tor. This action can be used, if desired, to disable all FET drives

under bridge or motor fault conditions. The Hall logic fault

condition is not latched, so if the fault occurs while the motor is

running, the external FETs will be reenabled, according to the

commutation truth table (table 2), when the Hx inputs become

valid.

When all Hx are 0s, the A3930 handles this in the same manner

as all 1s, described in the preceding paragraph. The A3931,

however, evaluates this as a prepositioning code, and does not

register it as a fault.

The Hx inputs have pull-up resistors to ensure that a fault condi-

tion will be indicated in the event of an open connection to a

Hall sensor.

• Short to Ground A short from any of the motor phase con-

nections to ground is detected by monitoring the voltage across

the top FETs in each phase using the appropriate Sx pin and the

voltage at VDRAIN. This drain-source voltage is then compared

to the voltage on the VDSTH pin. If the drain source voltage

exceeds the voltage at the VDSTH pin, FF2 will be pulled low.

• Short to Supply A short from any of the motor phase connec-

tions to the battery or VBB connection is detected by monitoring the voltage across the bottom FETs in each phase using the

appropriate Sx pin and the LSS pin. This drain-source voltage

is then compared to the voltage on the VDSTH pin. If the drain

source voltage exceeds the voltage at the VDSTH pin, FF2 will

be pulled low.

• Shorted Motor Winding A short across the motor phase

winding is detected by monitoring the voltage across both the

top and bottom FETs in each phase. This fault will pull FF2 low.

• Low Load Current The sense amplifier output is monitored

independently to allow detection of a low load current. This can

and MOSFET Driver

be used to detect if an open load condition is present. If, during

a commutation period, the output from the sense amplifier does

not go above a minimum value, V

further action will be taken.

Short Fault Operation Because motor capacitance may cause

the measured voltages to show a fault as the phase switches, the

voltages are not sampled until one t

nal FET is turned on.

If a short circuit fault occurs when ESF = 0, the external FETs

are not disabled by the A3930/A3931. Under some conditions,

some measure of protection will be provided by the internal current limit but in many cases, particularly for a short to ground,

the current limit will provide no protection for the external

FETs. To limit any damage to the external FETs or the motor, the

A3930/A3931 can either be fully disabled by the RESET input

or all FETs can be switched off by pulling the COAST input low.

Alternatively, setting ESF = 1 will allow the A3930/A3931 to disable the outputs as soon as the fault is detected. The fault will be

latched until any of the following conditions occur:

• a phase commutation

• RESET goes low

• COAST goes low

This will allow a running motor to coast to the next phase

commutation without the risk of damage to the external power

MOSFETs.

Low Load Current Fault Operation No action is taken for

a low load current condition. If the low load occurs due to an

open circuit on a phase connection while the motor is running,

the A3930/A3931 will continue to commutate the motor phases

according to the commutation truth table, table 2.

In some cases, this will allow the motor to continue operating at

a much reduced performance. The low load condition is checked

during a commutation period and is only flagged at the next commutation event. The flag is cleared at the end of any subsequentcommutation period where no low load current fault is detected.

If the motor stalls or is stationary, then the remaining phase connections will usually be insufficient to start rotating the motor. At

start-up or after a reset, the low load condition is flagged until the

first time the motor current exceeds the threshold value, V

This allows detection of a possible open phase from startup, even

if the motor is not able to start running.

Note that a low load current condition can also exist if the motor

being driven has no mechanical load.

, FF1 will go low. No

CSOL

interval after the exter-

DEAD

CSOL

.

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

12

A3930 and

Automotive 3-Phase BLDC Controller

A3931

and MOSFET Driver

Table 1. Fault Action Table

FF1 FF2 Fault

0 0 Undervoltage Disable Disable

0 0 Overtemperature No Action No Action

0 0 Logic Fault Disable Disable

1 0 Short to ground No Action Disable

1 0 Short to supply No Action Disable

1 0 Shorted motor winding No Action Disable

0 1 Low load current No Action No Action

1 1 None No Action No Action

*Disable indicates that all gate outputs are low and all MOSFETs are

turned off.

Action*

ESF = 0 ESF = 1

Table 2. Commutation Truth Table*

Device H1 H2 H3 DIR GLA GLB GLC GHA GHB GHC SA SB SC

Both 1 0 1 1001100High Z Low

Both 1 0 0 1001010ZHigh Low

Both 1 1 0 1100010LowHigh Z

Both 0 1 0 1100001LowZHigh

Both 0 1 1 1010001ZLowHigh

Both 0 0 1 1010100High Low Z

A3930 0 0 0 X 0 0 0 0 0 0 Z Z Z

A3931 0 0 0 X 0 1 1 1 0 0 High Low Low

Both 1 1 1 X 0 0 0 0 0 0 Z Z Z

Both 1 0 1 0100001LowZHigh

Both 1 0 0 0010001ZLowHigh

Both 1 1 0 0010100High Low Z

Both 0 1 0 0001100High Z Low

Both 0 1 1 0001010ZHigh Low

Both 0 0 1 0100010LowHigh Z

*X indicates “don’t care,” Z indicates high impedance state

Table 3. INPUT LOGIC

MODE PWM BRAKE COAST RESET Decay Mode of Operation

00111Fast PWM chop – current decay with opposite of selected drivers ON

01111Fast Peak current limit – selected drivers ON

10111Slow PWM chop – current decay with both low-side drivers ON

11111Slow Peak current limit – selected drivers ON

X X 0 1 1 n/a Brake mode - All low-side gates ON

X X X 0 1 X Coast mode - All gates OFF

XXXX0XSleep mode – All gates OFF, low power state, 5 V OFF

*X indicates “don’t care”

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

13

A3930 and

Automotive 3-Phase BLDC Controller

A3931

Applications Information

Power

All supply connections to the A3930/A3931 should have capacitors mounted between the supply pins and the ground pin. These

capacitors will provide the transient currents which occur during

switching and decouple any voltage transients on the pin from the

main supply.

VBB Decouple with at least a 100 nF ceramic capacitor mounted

between the VBB pin and the AGND pin. A larger electrolytic

capacitor, typically 10 F, in parallel with the ceramic capacitor

is also recommended.

VREG Supplies current for the gate-drive circuit. As the gates

are driven high, they require current from an external capacitor

connected to VREG to support the transients. This capacitor

should be placed as close as possible to the VREG pin with the

ground connection close to the AGND pin. Its value should be at

least 20 times larger than the bootstrap capacitor. The capacitor

should have a very low series resistance (ESR) and inductance

(ESL) to avoid large voltage drops during the initial transient.

The optimum capacitor type is a high quality ceramic such as

X7R. However, when the required capacitance is too large, an

aluminium electrolytic capacitor may be used, with a smaller

ceramic capacitor (100 nF) in parallel.

V5 When the 5V regulator is used with an external pass transistor

to provide power to other circuits, a 10 F decoupling capacitor

should be connected between the V5 pin and AGND as close to

the pins as possible. If an electrolytic capacitor is used, then a

100 nF ceramic capacitor should be added in parallel. To improve

stability, a 100 nF capacitor also should be connected between

the V5BD pin and AGND. If 5V is not required for external

circuits, the external pass transistor may be omitted, but in that

case, V5 must connected directly to V5BD and decoupled with at

least a 220 nF capacitor between V5 and AGND.

AGND The A3930/A3931 has a single ground connection at the

AGND pin. The design ensures that only the operating current

for the controller stage passes through this pin. The charge and

discharge current for the external FETs does not pass though this

pin. The AGND pin is the ground reference for the current trip

threshold, the V

It should therefor be kept as quiet as possible. A suggested ground

connection scheme is described in the layout section below.

monitor threshold, and the timing components.

DS

and MOSFET Driver

Power Dissipation In applications where a high ambient tem-

perature is expected the on-chip power dissipation may become

a critical factor. Careful attention should be paid to ensure the

operating conditions allow the A3930/A3931 to remain in a safe

range of junction temperature.

The power consumed, P

mated using the following formulas:

P

P

where I

P

where V

P

where V

IAV = Q

P

SWITCHING

= P

TOT

BIAS

is 3 mA, typical, and

BB

CPUMP

< 15 V, or

BB

CPUMP

> 15 V, and

BB

BIAS

= VBB × I

= (2 × VBB–V

= (VBB–V

GATE

= Q

GATE

where N = 2 for slow decay, or N = 4 for fast decay, and

Ratio = 10 / (R

Bootstrap Capacitors

Bootstrap Capacitor Selection The value for C

be correctly selected to ensure proper operation of the device. If

the value is too large, time will be wasted charging the capacitor,

resulting in a limit on the maximum duty cycle and PWM

frequency. If the value is too small, there can be a large voltage

drop at the time when the charge is transferred from C

MOSFET gate.

To keep the voltage drop small, Q

a reasonable value. To calculate C

can be used:

Q

= Q

therefore

C

The voltage drop on the Cx pin as the MOSFET is being turned

on can be approximated by:

V = Q

Bootstrap Charging It is good practice to ensure that the high-

side bootstrap capacitor, CBOOT, is completely charged before a

BOOT

BOOT

= C

= Q

BOOT

GATE

GATE

GATE

, by the A3930/A3931 can be esti-

TOT

+ P

BB

REG

× N × f

× V

GATE

× V

CPUMP

,

REG

) × I

PWM

REG

+ 10)

BOOT

+ P

SWITCHING

) × I

AV

AV

,

× N × f

BOOT

BOOT

× Ratio

PWM

Q

GATE

, the following formulas

,

,

. A factor of 20 is

× 20,

× 20 / V

/ C

BOOT

BOOT

BOOT

BOOT

must

to the

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

14

A3930 and

Automotive 3-Phase BLDC Controller

A3931

high-side PWM cycle is requested. The minimum time required

to charge the capacitor is approximated by:

t

CHARGE(min)

At power-on, and when the drivers have been disabled for a long

time, the CBOOT may be completely discharged. In these cases,

V can be considered to be the full high-side drive voltage,

12 V. Otherwise, V is the amount of voltage dropped during the

charge transfer, which should be 400 mV or less. The capacitor is

charged whenever the Sx pin is pulled low via a GLx PWM cycle,

and current flows from VREG through the internal bootstrap

diode circuit to CBOOT.

Bootstrap Charge Monitor The A3930 and A3931 provide

automatic bootstrap capacitor charge management. The bootstrap capacitor voltage for each phase, V

checked to ensure that it is above the bootstrap undervoltage

threshold, V

BOOTUV

A3930 and A3931 will turn on the necessary low-side FET until

the V

BOOT

exceeds V

The minimum charge time is typically 7 s, but may be longer for

very large values of the bootstrap capacitor (C

V

does not exceed V

BOOT

an undervoltage fault will be flagged, as shown in table 1.

PWM Control

The A3930 and A3931 have the flexibility to be used in many

different motor control schemes. The internal PWM control can

be used to provide fully integrated, closed-loop current control.

Alternatively, current-mode or voltage-mode control are possible

using external control circuits with either the DIR or the PWM

input pins.

Internal PWM Control The internal PWM current control

function is useful in applications where motor torque control

or simple maximum current limitation is required. However,

for motor speed control applications, it is usually better to use

external PWM control either as a closed- or open-loop system.

External PWM Control When external PWM control is used, it

is possible to completely disable the internal PWM control circuit

by connecting the RC pin to AGND.

With the internal control disabled, however, care should be taken

to avoid excessive current in the power FETs because the A3930/

. If V

BOOTUV

C

BOOT

× V /250 mA

BOOT

, is continuously

BOOTx

drops below this threshold, the

plus the hysteresis, V

BOOT

BOOTUV

within approximately 200 s,

BOOTUVHys

.

>1000 nF). If

and MOSFET Driver

A3931 will not limit the current. Short-circuit detection will still

be available in case of faults. The output of the sense amplifier is

also available, but provision must be made in the external control

circuits to ignore (blank) the transients at the switching points.

External and Internal Combined PWM Control Where

external PWM control is used but current limitation is still

required, internal PWM current control can be used at the

same time as external PWM control. To do so, usually the

internal PWM frequency is set lower than the external PWM

frequency. This allows the external PWM signal to dominate and

synchronize the internal PWM circuit. It does this by discharging

the timing capacitor, CT, when the PWM pin is low. When

internal and external PWM control are used together, all control

features of the A3930/A3931 are available and active, including:

dead time, current comparator, and comparator blanking.

PWM Frequency Should be set high enough to avoid any

audible noise, but low enough to ensure adequate charging of the

boot capacitor, CBOOT. The external resistor RT and capacitor

CT, connected in parallel from the RC pin to AGND, set the

PWM frequency to approximately:

f

1 / (RTCT + t

OSC

R

should be in the range of 5 to 400 k.

T

PWM Blank The timing capacitor, CT, also serves as the

means to set the blank time duration. t

PWM off-cycle, a high-side gate selected by the commutation

logic turns on. At this time, large current transients can occur

during the reverse recovery time of the intrinsic source drain

body diodes of the external power MOSFETs. To prevent false

tripping of the current-sense comparator, the output of the current

comparator is ignored during the blank time.

The length of t

is different for internal versus external

BLANK

PWM. It is set by the value of the timing capacitor, CT, according

to the following formulas:

for internal PWM: t

for external PWM: t

A nominal C

value of 680 pF will give a blanking time of 1.3 s

T

(s) = 1260 × C

BLANK

(s) = 2000 × C

BLANK

for external PWM and 860 ns for internal PWM. The user must

ensure that C

is large enough to cover the current-spike duration.

T

BLANK

BLANK

+ t

DEAD

) .

. At the end of the

(F), and

T

(F) .

T

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

15

A3930 and

Automotive 3-Phase BLDC Controller

A3931

Note that this blank time is only used to mask the internal current comparator. If the current sense amplifier output, CSOUT,

is being used in an external PWM control circuit, then it will

be necessary to externally generate a blank time for that control

loop.

Dead Time The potential for cross-conduction occurs with

synchronous rectification, direction changes, PWM, or after a

bootstrap capacitor charging cycle. To prevent cross-conduction

in any phase of the power FET bridge, it is necessary to have a

dead-time delay, t

the next turn-on event. t

6.3 s, and is set by the value of a resistor, RDEAD, between the

RDEAD pin and the GND pin. The maximum dead time of typically 6s can be set by leaving the RDEAD pin unconnected, or

connected to the V5 pin.

At 25°C, the value of t

t

I

where I

DEAD(nom)

DEAD

is in A, and R

DEAD

= 2000 / R

greatest accuracy is obtained with values of R

10 and 100 k.

The choice of power MOSFET and external series gate resistance

determines the selection of RDEAD. The dead time should be

made long enough to cover the variation of the MOSFET gate

capacitance and the tolerances of the series gate resistance, both

external and internal to the A3930/A3931.

Current

Trip Points

GHx

GLx

+V

V

RCH

RC

V

RCL

0

Figure 2. Internal PWM RC Timing

, between a high- or low-side turn-off and

DEAD

0.1 + 33 / (5 + I

t

DEAD

is in the range of between 96 ns and

DEAD

(s) can be approximated by:

DEAD

),

DEAD

DEAD

is between 5 and 400 k. The

DEAD

t

DEAD

t

t

RC

t

OSC

BLANK

between

DEAD

Note: For reasons of

clarity, t

DEAD

exaggerated.

is shown

and MOSFET Driver

Synchronous Rectification To reduce power dissipation in

the external MOSFETs, the A3930/A3931 control logic turns

on the appropriate low-side and high-side driver during the load

current recirculation PWM-off cycle. Synchronous rectification

allows current to flow through the FET selected by the MODE

pin setting during the decay time, rather than through the sourcedrain body diode. The body diodes of the recirculating power

FETs conduct only during the dead time that occurs at each PWM

transition. For internal current control using fast decay mode,

reversal of load current is prevented by turning off synchronous

rectification when a zero current level is detected. For external

PWM control using fast decay mode, the load current will not be

limited to zero but will rise to the set current limit in the reverse

direction before disabling synchronous rectification.

Braking. The A3930 and A3931 provide dynamic braking by

forcing all low-side MOSFETs on, and all high-side MOSFETs

off. This effectively short-circuits the back EMF of the motor,

which forces a reverse current in the windings, and creating a

breaking torque.

During braking, the load current can be approximated by:

I

V

BRAKE

Because the load current does not flow through the sense resistor,

RSENSE, during a dynamic brake, care must be taken to ensure

that the power MOSFET maximum ratings are not exceeded.

It is possible to apply a PWM signal to the BRAKE input to

limit the motor braking current. However, because there is

no measurement of this current, the PWM duty cycle must be

determined for each set of conditions. Typically the duty cycle

of such a brake PWM input would start at a value which limits

the current and then drops to 0%, that is, BRAKE goes to low, to

hold the motor stationary.

Setting RESET = 1 and COAST = 0 overrides BRAKE and turns

all motor bridge FETs off, coasting the motor.

Driving a Full-Bridge. The A3930 and A3931 may be used

to drive a full-bridge (for example, a brush DC motor load) by

hard-wiring a single state for the Hall inputs and leaving the

corresponding phase driver outputs floating. For example, with a

configuration of H1 = H2 = 1, and H3 = 0, the outputs CC, GHC,

SC, and GLC would be floated, according to the commutation

truth table, table3, which indicates a state of high-impedence (Z)

for SC with that Hall input configuration. The DIR input

controls the motor rotation, while the PWM and MODE

inputs control the motor current behavior, as described in the

input logic table, table 3.

BEMF

/ R

LOAD

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

16

A3930 and

Automotive 3-Phase BLDC Controller

A3931

Circuit Layout

Because this is a switch-mode application, where rapid current

changes are present, care must be taken during layout of the

application PCB. The following points are provided as guidance

for layout (refer to figure 3). Following all guidelines will not

always be possible. However, each point should be carefully

considered as part of any layout procedure.

Ground connection layout recommendations:

1. Sensitive connections such as RDEAD and VDSTH, which

have very little ground current, should be referenced to the

Quiet ground, which is connected independently closest to

the AGND pin. The components associated with these sensi-

tive pins should never be connected directly to the Supply

common or to the Power ground; they must be referenced

directly to the AGND pin.

2. Supply decoupling for the supply pins VBB, VREG, and

V5 should be connected to Controller Supply ground, which

is connected independently, close to the AGND pin. The

decoupling capacitors should also be connected as close as

possible to the corresponding supply pin.

3. The oscillator timing components can be connected to Quiet

ground or Controller Supply ground. They should not be

connected to the Supply common or the Power ground.

4. The exposed thermal pad on the package should be con-

nected to the AGND pin and may form part of the Controller

Supply ground.

5. If the layout space is limited, then the Quiet ground and the

Controller Supply ground may be combined, provided that

the ground return of the dead-time resistor, RDEAD, is close

to the AGND pin.

and MOSFET Driver

6. The AGND pin should be connected by an independent low

impedance trace to the Supply common at a single point.

7. Check the peak voltage excursion of the transients on the

LSS pin with reference to the AGND pin using a close-

grounded (tip and barrel) probe. If the voltage at LSS

exceeds the absolute maximum specified in this datasheet,

add additional clamping, capacitance or both between the

LSS pin and the AGND pin.

Other layout recommendations:

1. Gate charge drive paths and gate discharge return paths may

carry large transient current pulses. Therefore, the traces

from GHx, GLx, Sx, and LSS should be as short as possible

to reduce the inductance of the circuit trace.

2. Provide an independent connection from LSS to the common

point of the power bridge. It is not recommended to connect

LSS directly to the AGND pin, as this may inject noise into

sensitive functions such as the dead-timer. The LSS connec-

tion should not be used for the CSP connection.

3. The inputs to the sense amplifier, CSP and CSN, should be

independent traces and for best results should be matched in

length and route.

4. Minimize stray inductance by using short, wide copper runs

at the drain and source terminals of all power FETs. This

includes motor lead connections, the input power bus, and

the common source of the low-side power FETs. This will

minimize voltages induced by fast switching of large load

currents.

5. Consider the use of small (100 nF) ceramic decoupling

capacitors across the source and drain of the power FETs

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

17

A3930 and

r

Automotive 3-Phase BLDC Controller

A3931

to limit fast transient voltage spikes caused by trace induc-

tance.

6. Ensure that the TEST pin is connected to AGND. This pin is

used for production test only.

The above are only recommendations. Each application is different and may encounter different sensitivities. A driver running

with a few amperes will be less susceptible than one running with

150 A, and each design should be tested at the maximum current,

to ensure any parasitic effects are eliminated.

and MOSFET Driver

Quiet Ground

Controller Supply Ground

Figure 3. Supply and Ground Connections

VREG

V5

RC

VDSTH

RDEAD

VBB

A3930

A3931

AGND

VDRAIN

GHC

GHB

GHA

SA

SB

SC

GLA

GLB

GLC

LSS

Optional components

to limit LSS transients

RSENSE

Power Ground

+ Supply

Moto

Supply

Common

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

18

A3930 and

Automotive 3-Phase BLDC Controller

A3931

Gate Drive Outputs

Supplies

18 V

GHx

VREG

GLx

LSS

CP1

and MOSFET Driver

Sense Amplifier

V5BD

22V

VREG

22V

160μA

REF

160μA

32.4 k7

4.6 k7

2V

REF

4 k7

4 k7

72 k7

8 V

3 k7

8.5 V

76k

8.5 V

CSOUT

8.5 V

Cx

18 V

19 V

19 V

20 V

VBB

18 V

18 V

19 V

20 V

6 V

CSN

CSP

V5

10 V

18 V

18 V

Sx

18 V

20 V

VDRAIN

CP2

19 V

19 V

20 V

Logic Inputs

COAST

ESF

BRAKE

DIR

PWM

MODE

3 k7

8 V 8.5 V

VDS Monitor Threshold Input

1 k7

VDSTH

8 V

40 k7

8.5 V

RDEAD

2 V

RDEAD

8 V

100 7

8.5 V

Figure 4. Input and Output Structures

Hall Sensor Inputs

H1

H2

H3

8 V 8.5 V

Oscillator RC Pin

RC

8 V

Logic Output

TACHO

DIRO

8 V

100 k7

V5

V5

100 7

8 V

3 k7

1 k7

8.5 V

Reset Input

RESET

3 k7

6 V 6 V

50 k7

Fault Output

8 V

100 7

8 V

FF1

FF2

V5

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

19

A3930 and

Automotive 3-Phase BLDC Controller

A3931

NC

LSS

ESF

VREG

AGND

CP1

CP2

DIRO

VBB

COAST

NC

NC

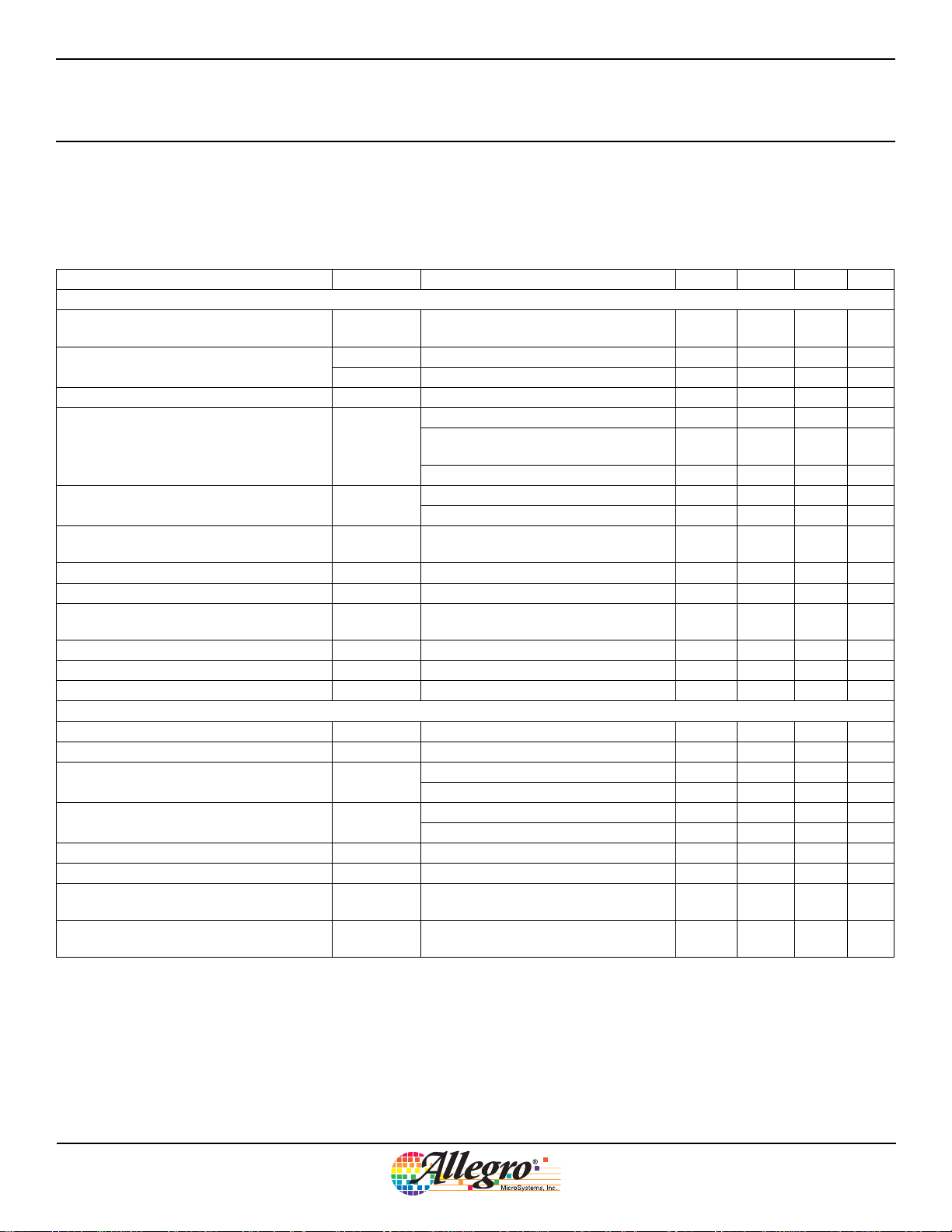

Pin-out Diagrams

JP Package

GLC

V5BD

CA

33

4

V5

GHASACB

31

32

Bootstrapped

High-Side Drives

Control

Logic

6

5

FF2

FF1

37

38

39

40

41

42

43

44

45

46

47

48

GLB

GLA

363534

Low

Side

Drives

Charge

Pump

123

NC

RESET

GHBSBCC

3029282726

Current

Sense

Hall

789

TACHO

DIR

BRAKE

101112

H1H2H3

GHC

and MOSFET Driver

SC

25

24

VDRAIN

23

VDSTH

22

CSP

21

CSN

20

REF

19

CSOUT

18

RDEAD

17

TEST

16

RC

15

MODE

14

PWM

13

NC

Terminal List Table

Number Name Description

1 N.C. No connection

2 RESET Control for sleep mode

3 V5BD 5V regulator base drive

4 V5 5V regulator reference

5 FF2 Fault flag 2

6 FF1 Fault flag 1

7 TACHO Speed output

8 BRAKE Brake input

9 DIR Direction control input

10 H1 Hall sensor input

11 H2 Hall sensor input

12 H3 Hall sensor input

13 N.C. No connection

14 PWM Control input

15 MODE Decay control input

16 RC PWM oscillator control input

17 TEST Test pin; tie to AGND

18 RDEAD Dead time setting

19 CSOUT Current sense output

20 REF Current limit setting

21 CSN Current sense input –

22 CSP Current sense input +

23 VDSTH Fault threshold voltage

24 VDRAIN High-side drain voltage sense

Number Name Description

25 SC Motor connection phase C

26 GHC High-side gate drive phase C

27 CC Bootstrap capacitor phase C

28 SB Motor connection phase B

29 GHB High-side gate drive phase B

30 CB Bootstrap capacitor phase B

31 SA Motor connection phase A

32 GHA High-side gate drive phase A

33 CA Bootstrap capacitor phase A

34 GLC Low-side gate drive phase C

35 GLB Low-side gate drive phase B

36 GLA Low-side gate drive phase A

37 N.C. No connection

38 LSS Low-side source

39 ESF Enable stop on fault input

40 VREG Gate drive supply output

41 AGND Analog ground

42 CP1 Pump capacitor

43 CP2 Pump capacitor

44 DIRO Direction output

45 VBB Supply voltage

46 COAST Coast input

47 N.C. No connection

48 N.C. No connection

– Pad Thermal dissipation, tie to AGND

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

20

A3930 and

Automotive 3-Phase BLDC Controller

A3931

9.00 ±0.20 7.00 ±0.20

48X

48

C0.08

0.22 ±0.05

and MOSFET Driver

Package JP, 48-pin LQFP with Exposed Thermal Pad

9.00 ±0.20

7.00 ±0.20

B

5.00

A

21

SEATING

PLANE

1.40 ±0.05

0.10 ±0.05

0.25

1.60 MAX

5.00

0.50

C

7º

4° ±4

0º

+0.05

0.15

–0.06

0.60 ±0.15

(1.00)

SEATING PLANE

GAGE PLANE

A

B

C

For Reference Only

(reference JEDEC MS-026 BBCHD)

Dimensions in millimeters

Dimensions exclusive of mold flash, gate burrs, and dambar protrusions

Exact case and lead configuration at supplier discretion within limits shown

Terminal #1 mark area

Exposed thermal pad (bottom surface)

Reference land pattern layout (reference IPC7351

QFP50P900X900X160-48M); adjust as necessary to meet

application process requirements and PCB layout

tolerances; when mounting on a multilayer PCB, thermal

vias at the exposed thermal pad land can improve thermal

dissipation (reference EIA/JEDEC Standard JESD51-5)

1.70

48

1

2

C

PCB Layout Reference View

0.30

0.50

C

5.00 8.60

5.00

8.60

Copyright ©2006-2008, Allegro MicroSystems, Inc.

The products described here are manufactured under one or more U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such de par tures from the detail spec i fi ca tions as may be required to permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to verify that the

information being relied upon is current.

Allegro’s products are not to be used in life support devices or systems, if a failure of an Allegro product can reasonably be expected to cause the

failure of that life support device or system, or to affect the safety or effectiveness of that device or system.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable. How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty for its use;

nor for any in fringe ment of patents or other rights of third parties which may result from its use.

For the latest version of this document, visit our website:

www.allegromicro.com

Allegro MicroSystems, Inc.

115 Northeast Cutoff

Worcester, Massachusetts 01615-0036 U.S.A.

1.508.853.5000; www.allegromicro.com

21

Loading...

Loading...