查询A3250供应商查询A3250供应商

Package UA, 3-pin SIP

A3250 and A3251

Field-Programmable, Chopper-Stabilized

Unipolar Hall-Effect Switches

The A3250 and A3251 are field-programmable, chopper-stabilized, unipolar Halleffect switches designed for use in high-temperature applications. These devices

use a chopper-stabilization technique to eliminate offset inherent in single-element

devices.

The A3250 and A3251 are externally programmable devices. The devices have a

wide range of programmability of the magnetic operate point (B

teresis remains fixed. This advanced feature allows for optimization of the sensor

switchpoint and can drastically reduce the effects of variations found in a production environment, such as magnet and device placement tolerances.

These devices provide on-chip transient protection. A Zener clamp on the power

supply protects against overvoltage conditions on the supply line. These devices

also include short-circuit protection on the output.

) while the hys-

OP

TL Option

231

1. VCC

2. GND

3. VOUT

AB SO LUTE MAX I MUM RAT INGS

Supply Voltage, VCC ......................................26.5 V

Reverse-Supply Voltage, V

Zener Overvoltage, V

Output Current, I

Magnetic Flux Density, B.........................Unlimited

Operating Temperature

Ambient, T

Ambient, T

Maximum Junction, T

Storage Temperature, T

Z

.........................................20 mA

OUT

, Range J................. –40ºC to 115ºC

A

, Range L................–40ºC to 150ºC

A

........................–18 V

RCC

.......................................30 V

........................165ºC

J(max)

.................. –65ºC to 170ºC

S

The output of the A3250 switches LOW when subjected to a south-polarity magnetic field with a flux density that exceeds the threshold for B

HIGH when the field drops below the magnetic release point, B

, and switches

OP

. The output of

RP

the A3251 has the opposite polarity, switching HIGH in a south-polarity magnetic

field that B

, and switching LOW when the field drops below B

OP

RP

.

The other differences in the devices are the power-on state. The A3250 powers-on

in the HIGH state, while the A3251 powers-on in the LOW state.

These devices are available in a TO-92 three-lead ultra-mini SIP (Single In-line

Package), with either straight or formed and trimmed lead configuration.

Features and Benefits

Chopper stabilization for stable switchpoints

throughout operating temperature range

Externally programmable operate point

(through VCC pin)

On-board voltage regulator for 4.2 V to 24 V

operation

Use the following complete part numbers when ordering:

T

Part Number Package

A3250JUA

A3250JUATL

A3250LUA

A3250LUATL

A3251JUA

A3251JUATL

A3251LUA

A3251LUATL

*In south polarity magnetic field of sufficient strength.

Straight lead

Formed lead

Straight lead

Formed lead

Straight lead

Formed lead

Straight lead

Formed lead

A

(ºC)

–40 to 115 18

–40 to 150 13

–40 to 115 18

–40 to 150 13

On-chip protection against:

Supply transients

Output short-circuits

Reverse-battery condition

B

hys(typ)

(G)

Power-On Running*

V

OUT

High Low

Low High

A3250-DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

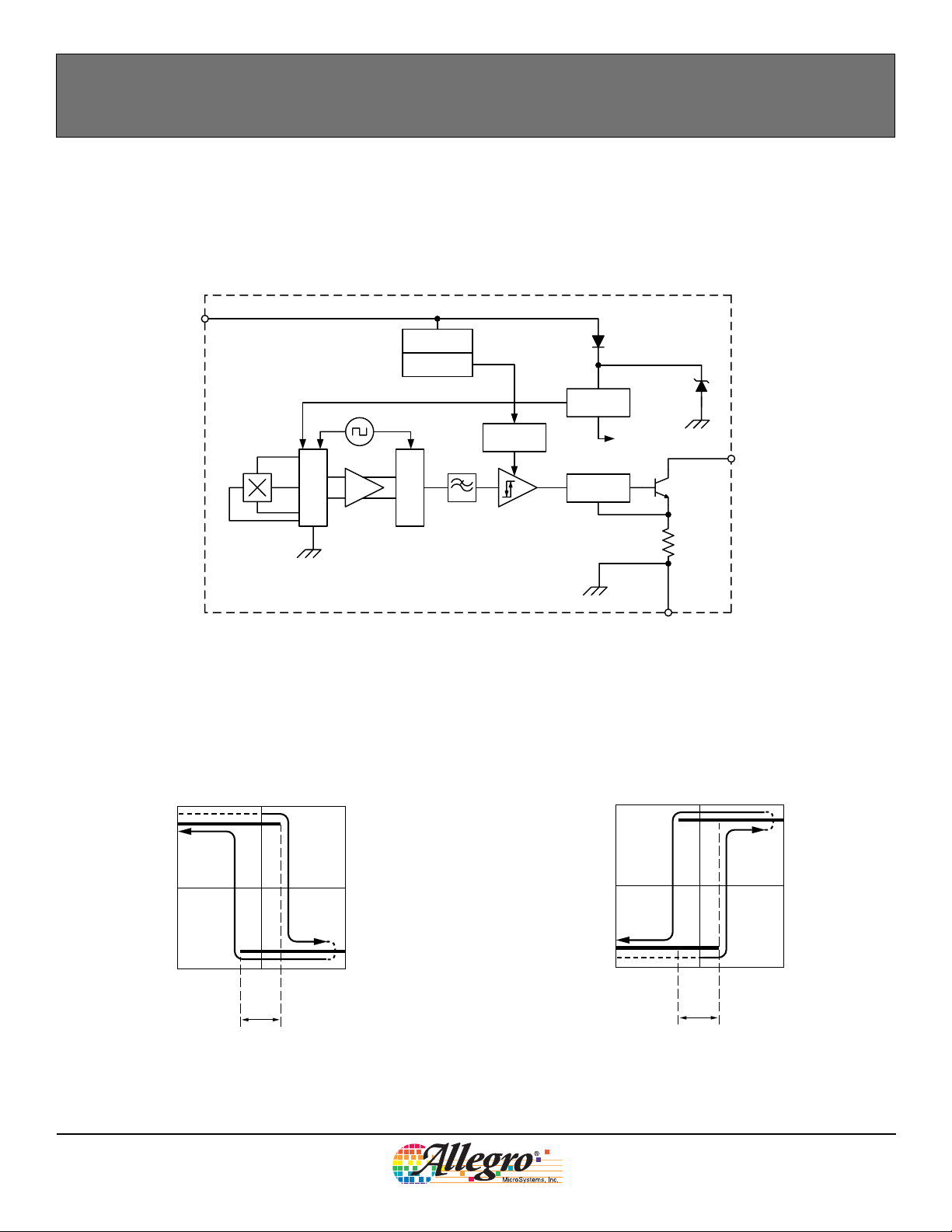

A3250 and A3251

B

OP

B

RP

B

HYS

Switch to High

Switch to Low

B+

V

OUT(off)

V

OUT

V

OUT(on)(sat)

V+

Hysteresis of ∆V

OUT

Switching Due to ∆B

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

Functional Block Diagram

VCC

Program/Lock

Programming

Logic

Regulator

A3250

Hysteresis of ∆V

Switching Due to ∆B

V+

OUT

Switch to Low

Offset Adjust

Amp

Cancellation

Dynamic Offset

Low-Pass

Sample and Hold

Filter

Current Limit

GND

VOUT

Hysteresis Curves

A3251

V

OUT(off)

A3250-DS

OUT

V

Switch to High

RP

B

B

HYS

V

OUT(on)(sat)

B

OP

B+

Output voltage in relation to sensed magnetic flux density in a

south polarity magnetic field of sufficient strength. Transition

through B

must precede transition through BRP.

OP

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

2

A3250 and A3251

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

OPERATING CHARACTERISTICS valid over operating TA and VCC, unless otherwise specified

Characteristic Symbol Test Conditions Min. Typ. Max. Units

ELECTRICAL CHARACTERISTICS

Supply Voltage

1

Output Saturation Voltage V

Output Leakage Current I

Supply Current

Output Rise Time t

Output Fall Time t

Chopping Frequency f

Power-Up Time t

Output Current Limit

1,2

Power-On State POS

MAGNETIC CHARACTERISTICS

V

CC

OUT(sat)IOUT

OFF

Running mode 4.2 – 24 V

V

A3250; B < BRP; V

I

CC(off)

A3251; B > B

A3250; B > BOP; V

I

CC(on)

r

f

C

on

I

OUT(lim)

A3251; B < B

R

R

V

Short-circuit protection 60 90 120 mA

A3250; B < B

A3251; B < B

= 20 mA; Switch state = ON – 175 400 mV

= 24 V; Switch state = OFF – – 10 µA

OUT

= HIGH – 4.0 7.0 mA

OUT

; V

OP

RP

= 820 Ω, C

LOAD

= 820 Ω, C

LOAD

= HIGH – 20 50 µs

OUT

RP

RP

= HIGH – 4.0 7.0 mA

OUT

= LOW – 6.0 10.0 mA

OUT

; V

= LOW – 6.0 10.0 mA

OUT

= 10 pF – – 5.0 µs

LOAD

= 10 pF – – 5.0 µs

LOAD

, t > t

on

, t > t

on

– 340 – kHz

– HIGH – mV

– LOW – mV

Initial Operate Point B

Temperature Drift of B

OP

∆B

OP

BOP ≤ 500 gauss –35 – 35 G

OP

–20 13 50 G

Package TA range = J 5.0 18 35 G

Hysteresis (B

– BRP)B

OP

hys

Package T

range = L 5.0 13 35 G

A

PROGRAMMING CHARACTERISTICS

Programmable B

OP

Values

3

B

OP(prog)

50 – ≥350 G

Switchpoint set – 6 – Bit

Number of Programming Bits –

Programming lock – 1 – Bit

Resolution B

RES

– 7.0 – G

TRANSIENT PROTECTION CHARACTERISTICS

Supply Zener Voltage V

Supply Zener Current I

Reverse Battery Current I

1

Do not exceed TJ(max): Additional information on power derating is provided in the applications section.

2

Short-circuit protection is not intended for continuous operation; permanent damage may result.

3

Device can be used below 50 G but is not guaranteed to be a unipolar switch. It is the responsibility of the programmer to verify that the desired

switchpoint has been achieved.

Z

Z

RCC

VCC = 28 V – – 13 mA

V

= –18 V, TJ < T

RCC

J(max)

28 – – V

– – –5.0 mA

A3250-DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

3

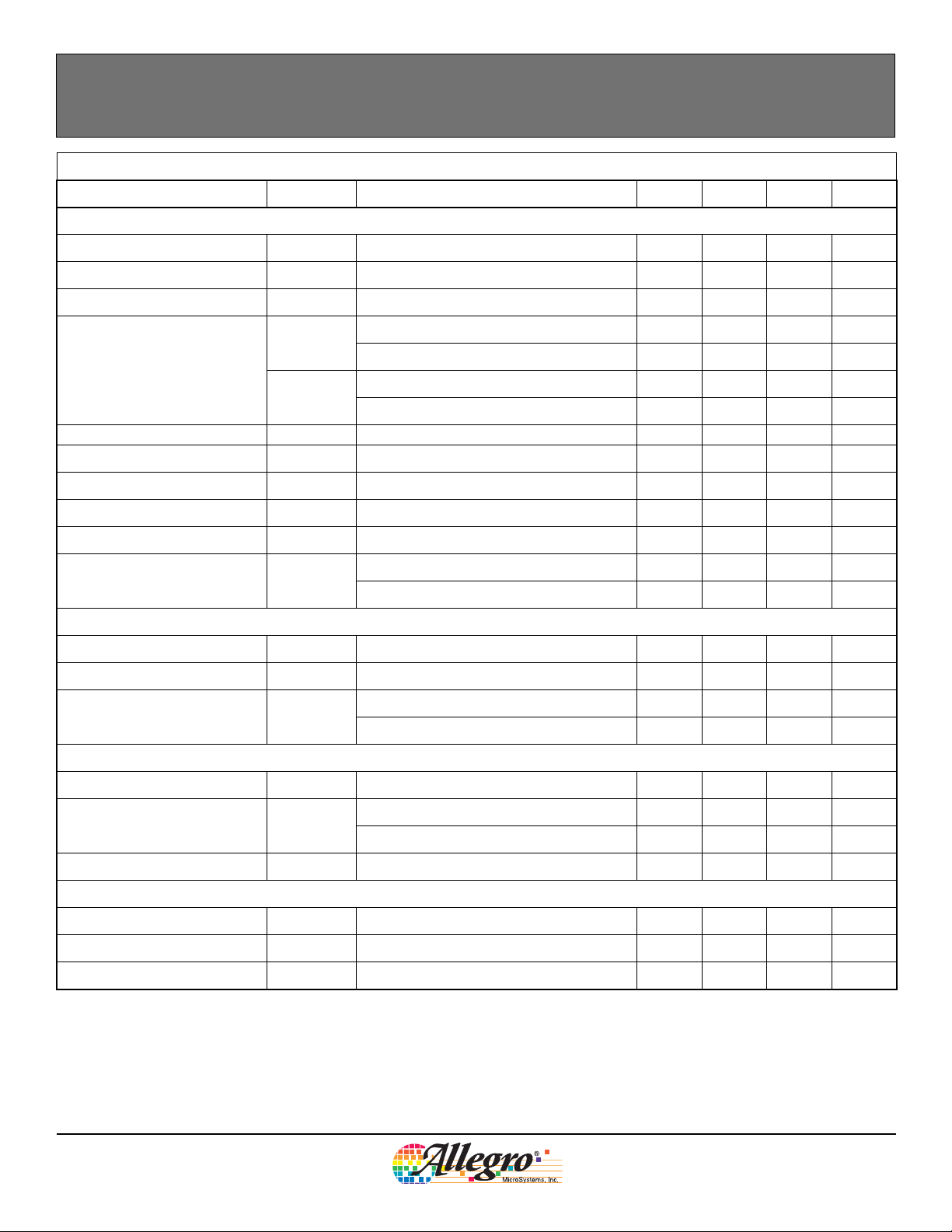

A3250 and A3251

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

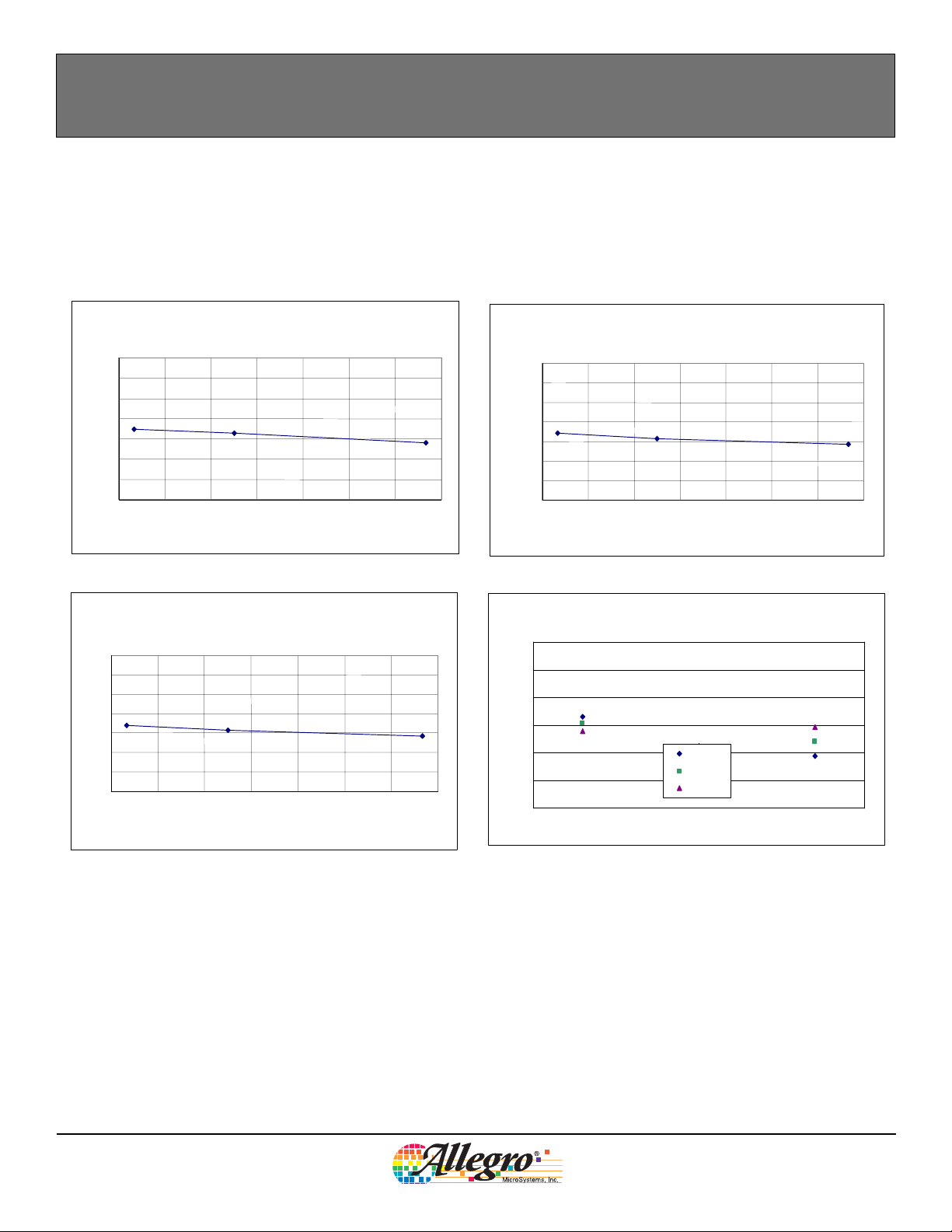

Typical Characterization Data

All data are taken with A3250 devices, the average of 3 lots, 30 pieces per lot

Average BOPvs. T

A

Program Code: 1, VCC=12V

30

25

(G)Average B

20

OP

15

10

5

Average B

0

-5

-50 -20 10 40 70 100 130 160

T

(°C)

A

Average BOPvs. T

A

Program Code: 8, VCC=12V

75

70

(G)Average B

65

OP

60

55

50

45

40

-50 -20 10 40 70 100 130 160

(°C)

T

A

Average BRPvs. T

A

Program Code: 1, VCC=12V

10

5

(G)Average B

0

RP

-5

-10

Average B

-15

-20

-50 -20 10 40 70 100 130 160

TA(°C)

Average BRPvs. T

A

Program Code: 8, VCC=12V

60

50

(G)Average B

RP

40

30

20

-50 -20 10 40 70 100 130 160

T

(°C)

A

130

125

(G)

120

OP

115

110

105

100

A3250-DS

Average BOPvs. T

A

Program Code: 16, VCC=12V

-50 -20 10 40 70 100 130 160

T

(°C)

A

Average BRPvs. T

A

Program Code: 16, VCC=12V

110

105

(G)

100

RP

95

90

85

80

-50 -20 10 40 70 100 130 160

(°C)

T

A

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

4

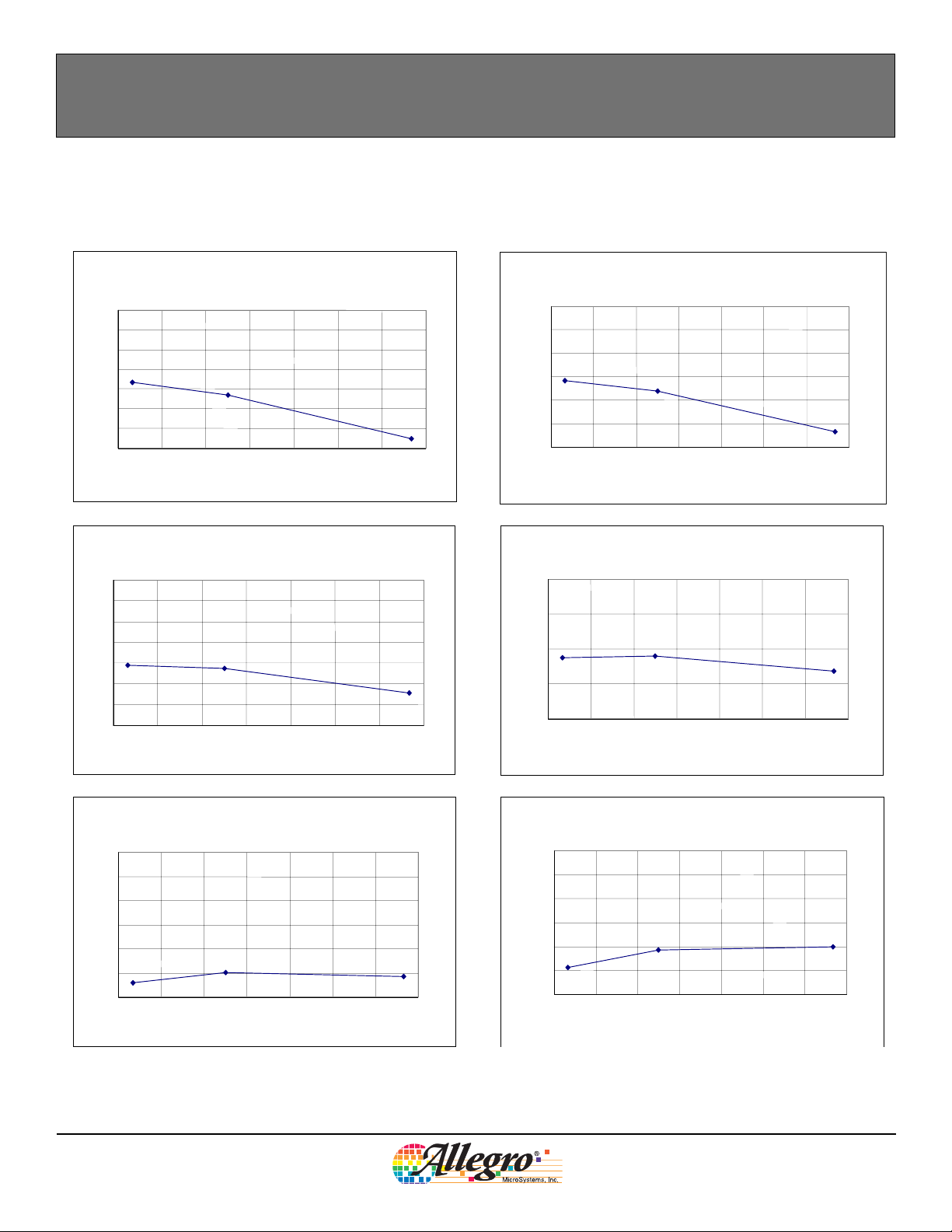

A3250 and A3251

-40°C to 25°C and 150°C to 25°C

-30

-20

-10

0

10

20

30

Code 1

Code 8

Code 16

-40°C to 25°C

150°C to 25°C

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

Typical Characterization Data

All data are taken with A3250 devices, the average of 3 lots, 30 pieces per lot

Average B

Program Code: 1, V

vs. Temperature

hys

CC

=12V

35

30

(G)

25

HYS

20

15

10

Average B

5

0

-50 -20 10 40 70 100 130 160

T

(°C)

A

Average B

Program Code: 8, V

vs. Temperature

hys

CC

=12V

35

30

(G)

25

HYS

20

15

10

Average B

5

0

-50 -20 10 40 70 100 130 160

(°C)

T

A

Average B

Program Code: 16, V

vs. Temperature

hys

CC

=12V

35

30

(G)

25

HYS

20

15

10

Average B

5

0

-50 -20 10 40 70 100 130 160

TA(°C)

Average BOPvs. Temperature

(G)

OP

Average B

(°C)

T

A

A3250-DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

5

A3250 and A3251

(

)

(

)

(

)

(

)

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

Typical Characterization Data

All data are taken with A3250 devices, the average of 3 lots, 30 pieces per lot

Average I

vs. Temperature

CC(on)

10

8

6

mA

on

4

CC

I

2

I

CC(on)

I

CC(on)

I

CC(on)

@3.8V

@12.0V

@26.5V

0

-50 -20 10 40 70 100 130 160

T

(°C)

A

Average V

V

CC

280

260

240

(mV)

220

200

OUT(SAT)

180

V

160

140

-50 -20 10 40 70 100 130 160

OUT(SAT)

= 3.8 V, I

T

10

8

6

mA

off

4

CC

I

2

0

-50 -20 10 40 70 100 130 160

vs. Temperature

=20mA

out

(°C)

A

Average I

vs. Temperature

CC(off)

TA(°C)

I

CC(off)

I

CC(off)

I

CC(off)

@3.8V

@12.0V

@26.5V

A3250-DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

6

A3250 and A3251

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

THERMAL CHARACTERISTICS may require derating at maximum conditions, see application information

Characteristic Symbol Test Conditions Min. Typ. Max Units

Package Thermal Resistance

R

θJA

25

24

23

22

21

(V)

20

CC

19

18

17

16

15

14

13

12

11

10

9

Maximum Allowable V

8

7

6

5

4

3

2

20 40 60 80 100 120 140 160 180

Package UA, minimum-K PCB (single-sided with

copper limited to solder pads)

Power Derating Curve

T

= 165ºC; ICC=I

J(max)

Minimum-K PCB, Package UA

(R

= 165 ºC/W)

θJA

CC(max)

V

V

165 – – ºC/W

CC(max)

CC(min)

A3250-DS

Maximum Power Dissipation, P

1900

J(max)

CC(max);ICC=ICC(max)

T

= 165ºC; VCC=V

1800

1700

1600

1500

1400

1300

1200

(mW)

1100

D

Power Dissipation, P

1000

900

800

700

600

500

400

300

Minimum-K P

(R

θ

JA

=165

CB, Pac

º

C

/W)

kag

eUA

200

100

0

20 40 60 80 100 120 140 160 180

Temperature (°C)

D(max)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

7

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

Chopper-Stabilized Technique

A3250 and A3251

Functional Description

The Hall sensor is based on a Hall element, a small sheet of

semiconductor material in which a constant bias current flows

when a constant voltage source is applied. The output takes the

form of a voltage measured across the width of the Hall element,

and has negligible value in the absence of a magnetic field.

When a magnetic field is applied with flux lines at right angles

to the current in the Hall element, a small signal voltage directly

proportional to the strength of the magnetic field occurs at the

output of the Hall element.

This small signal voltage is disproportionally small relative to

the offset produced at the input of the device. This makes it very

difficult to process the signal and maintain an accurate, reliable

output over the specified temperature and voltage range. Therefore, it is important to reduce any distortion of the signal that

could be amplified when the signal is processed.

Chopper stabilization is a unique approach used to minimize

input offset on the Hall IC. This technique removes a key

source of output drift due to temperature and mechanical stress,

and produces a 3X reduction in offset in comparison to other,

conventional methods.

This offset reduction chopping technique is based on a signal modulation-demodulation process. The undesired offset

signal is separated from the magnetically-induced signal in the

frequency domain. The offset (and any low-frequency noise)

component of the signal can be seen as signal distortion added

after the signal modulation process has taken place. Therefore,

the dc offset is not modulated and remains a low-frequency

component. Consequently, the signal demodulation process acts

as a modulation process for the offset, causing the magneticallyinduced signal to recover its original spectrum at baseband while

the dc offset becomes a high-frequency signal. Then, the signal

passes using a low-pass filter, while the modulated dc offset is

suppressed.

The advantage of this approach is significant offset reduction,

which desensitizes the Hall IC against the effects of temperature

and mechanical stress. The disadvantage is that this technique

features a demodulator that uses a sample-and-hold block to

store and recover the signal. This sampling process can slightly

degrade the SNR (signal-to-noise ratio) by producing replicas of

the noise spectrum at the baseband. This degradation is a function

of the ratio between the white noise spectrum and the sampling

frequency. The effect of the degradation of the SNR is higher

jitter, also known as signal repeatability. However, the jitter in a

continuous-time device can be 5X that of the A3250/A3251.

A3250-DS

Regulator

Amp

Hold / LPF

Sample and

Chopper stabilization circuit (dynamic quadrature offset cancellation)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

8

A3250 and A3251

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

Programming Protocol

The operate switchpoint, B

, can be field-programmed. To do

OP

so, a coded series of voltage pulses through the VCC pin is used

to set bitfields in onboard registers. The effect on the device

output can be monitored, and the registers can be cleared and

set repeatedly until the required BOP is achieved. To make the

setting permanent, bitfield-level solid state fuses are blown, and

finally, a device-level fuse is blown, blocking any further coding. It is not necessary to program the release switchpoint, BRP ,

because the difference between BOP and BRP , referred to as the

hysteresis, B

The range of values between B

HYS

, is fixed.

OP(min)

and B

OP(max)

is scaled to

64 increments. The actual change in magnetic flux (G) represented by each increment is indicated by B

(see the Operating

RES

Characteristics table; however, testing is the only method for

verifying the resulting B

). For programming, the 64 incre-

OP

ments are individually identified using 6 data bits, which are

physically represented by 6 bitfields in the onboard registers.

By setting these bitfields, the corresponding calibration value is

programmed into the device.

Three voltage levels are used in programming the device: a low

voltage, V

, a minimum required to sustain register settings; a

PL

mid-level voltage, VPM , used to increment the address counter

in the device; and a high voltage, VPH , used to separate sets of

VPM pulses (when short in duration) and to blow fuses (when

long in duration). A fourth voltage level, essentially 0 V, is used

to clear the registers between pulse sequences. The pulse values

are shown in the Programming Protocol Characteristics table and

in figure 1.

V+

V

PH

V

PM

V

PL

T

0

T

d(1)

Figure 1. Pulse amplitudes and durations

d(P)

T

d(0)

t

Additional information on device programming and programming products is available on www. allegromicro.com. Programming hardware is available for purchase, and programming

software is available free of charge.

Code Programming. Each bitfield must be individually set. To

do so, a pulse sequence must be transmitted for each bitfield that

is being set to 1. If more than one bitfield is being set to 1, all

pulse sequences must be sent, one after the other, without allowing VCC to fall to zero (which clears the registers).

The same pulse sequence is used to provisionally set bitfields as

is used to permanently set bitfield-level fuses. The only difference is that when provisionally setting bitfields, no fuse-blowing

pulse is sent at the end of the pulse sequence.

PROGRAMMING PROTOCOL CHARACTERISTICS, TA = 25ºC, unless otherwise noted

Characteristic Symbol Test Conditions Min. Typ. Max. Units

V

Programming Voltage

1

V

V

Programming Current

2

t

Pulse Width

t

t

Pulse Rise Time t

Pulse Fall Time t

1

Programming voltages are measured at the VCC pin.

2

A bypass capacitor with a minimum capacitance of 0.1 µF must be connected from VCC to the GND pin of the device in order to provide

Minimum voltage range during programming 4.5 5.0 5.5 V

PL

PM

PH

I

Maximum supply current during programming – 500 – mA

PP

OFF time between programming bits 20 – – µs

d(0)

Pulse duration (ON time) for enable, address, fuse

d(1)

blowing or lock bits

Pulse duration (ON time) for fuse blowing 100 300 – µs

d(P)

VPL to VPM; VPL to V

r

VPM to VPL; VPH to V

f

PH

PL

10 11 12 V

23 25 26 V

20 – – µs

11 – – µ s

5––µs

the current necessary to blow the fuse.

Allegro MicroSystems, Inc.

A3250-DS

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

9

A3250 and A3251

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

The pulse sequences consist of the following groups of pulses:

1. An enable sequence.

2. A bitfield address sequence.

3. When permanently setting the bitfield, a long V

fuse-blow-

PH

ing pulse. (Note: Blown bit fuses cannot be reset.) When

provisionally trying a value, a short VPH pulse.

4. When permanently setting the bitfield, the level of V

CC

must

be allowed to drop to zero between each pulse sequence, in

order to clear all registers. However, when provisionally setting bitfields, VCC must be maintained at VPL between pulse

sequences, in order to maintain the prior bitfield settings while

preparing to set additional bitfields.

Bitfields that are not set are evaluated as zeros. The bitfield-level

V+

V

PH

V

PM

V

PL

0

Figure 2. Pulse sequence to provisionally try calibration value 5 (101 binary, or bitfield

address 3 and bitfield address 1).

7 pulses

Enable

Address

Try 001002 (410)

fuses for 0 value bitfields are never blown. This prevents inadvertently setting the bitfield to 1. Instead, blowing the devicelevel fuse protects the 0 bitfields from being accidentally set in

the future.

Two pulse sequences for provisionally trying the calibration

value 5 are shown in figure 2. Because the bitfields must be set

individually, 510 must be programmed as binary 101. Bit 3 is

set to 1 (0001002, which is 410), then bit 1 is set to 1 (0000012,

which is 110). Bit 2 is ignored, and so remains 0.

Two pulse sequences for permanently setting the calibration

value 5 are shown in figure 3. The final VPH pulse, which was

used as a short delimiter when trying values, is maintained for a

longer period, enough to blow the corresponding bitfield-level

fuse.

Optional

Monitoring

7 pulses

Try 00001

(110)

2

Address

Optional

Monitoring

ClearEnable

t

A3250-DS

V+

V

PH

V

PM

V

PL

0

7 pulses

Enable

Address

Encode 001002 (410)

Blow BlowEnable

7 pulses

Encode 00001

Figure 3. Pulse sequence to permanently encode calibration value 5 (101 binary, or

bitfield address 3 and bitfield address 1).

Address

(110)

2

t

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

10

A3250 and A3251

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

Enabling Addressing Mode. The first segment of code is a

keying sequence used to enable the bitfield addressing mode. As

shown in figure 4, this segment consists of one short VPH pulse,

seven or more VPM pulses, and one VPH pulse, with no supply

interruptions. This sequence is designed to prevent the device

from being programmed accidentally, such as by noise on the

supply line.

Address Selection. After addressing mode is enabled, the

target bitfield address, is indicated by a series of VPM pulses,

as shown in figure 3. When provisionally trying a value, this

sequence is followed by a short VPH pulse, which serves to

delimit the address and set the corresponding bitfield. When

permanently setting a bitfield, the VPH pulse is continued for a

longer period of time, suffienct to not only set the bitfield to 1,

but also to blow the bitfield fuse.

V+

V

PH

V

PM

V

PL

0

Minimum 7 pulses

Figure 4. Addressing mode enable pulse sequence

V+

V

PH

V

PM

V

PL

0

Address 1

Address 2

Address n ( ≤ 63)

t

Lock Bit Programming. After the desired B

calibration value

OP

is programmed, and all of the corresponding bitfield-level fuses

are blown, the device-level fuse should be blown. To do so, the

lock bit (bitfield address 65) should be encoded as 1 and have

its fuse blown. This is done in the same manner as permanently

setting the other bitfields, as shown in figure 6.

A3250-DS

Figure 5. Pulse sequence to select addresses

V+

V

PH

V

PM

V

PL

0

Falling edge of final BOP address digit

7 pulses 65 pulses

Enable

Address Blow

Encode Lock Bit

Figure 6. Pulse sequence to encode lock bit

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

t

t

11

A3250 and A3251

GND

A3250/A3251

VCC

V

Supply

0.1 µF

A

R

L

C

BYP

R

S

100 Ω

1.2 kΩ

5V

VOUT

A

A

Maximum separation 5 mm

from C

BYP

to device

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

Application Information

For additional general application information, visit the Allegro

MicroSystems Web site at www. allegromicro.com.

Typical Application Circuit

It is strongly recommended that an external ceramic bypass

capacitor, C

between the VCC pin and the supply and GND pin to reduce

both external noise and noise generated by the chopper-stabilization technique. (The diagram at the right shows C

C

should be installed so that the traces that connect it to the

BYP

A3250/A3251 are no greater than 5 mm in length.

, in the range of 0.01 µF to 0.1 µF be connected

BYP

at 0.1 µF.)

BYP

The series resistor RS, in combination with C

creates a filter

BYP

for EMI pulses. (Additional information on EMC is provided

on the Allegro MicroSystems Web site.) RS will have a drop

of approximately 800 mV. This must be taken into consideration when determining the minimum VCC requirement for the

A3250/A3251. The pull-up resistor, RL, should be chosen to

limit the current through the output transistor; do not exceed the

maximum continuous output current of the device.

Typical application circuit

A3250-DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

12

A3250 and A3251

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

Power Derating

The device must be operated below the maximum junction

temperature of the device, T

peak conditions, reliable operation may require derating supplied power or improving the heat dissipation properties of the

application. This section presents a procedure for correlating

factors affecting operating TJ. (Thermal data is also available on

the Allegro MicroSystems Web site.)

The Package Thermal Resistance, R

marizing the ability of the application and the device to dissipate

heat from the junction (die), through all paths to the ambient air.

Its primary component is the Effective Thermal Conductivity,

K, of the printed circuit board, including adjacent devices and

traces. Radiation from the die through the device case, R

relatively small component of R

TA, and air motion are significant external factors, damped by

overmolding.

The effect of varying power levels (Power Dissipation, PD), can

be estimated. The following formulas represent the fundamental

relationships used to estimate TJ, at PD.

P

= VIN × I

D

∆T = PD × R

. Under certain combinations of

J(max)

, is a figure of merit sum-

θJA

. Ambient air temperature,

θJA

IN

(2)

θJA

(1)

θJC

, is

Example: Reliability for VCC at TA = 150°C, package UA, using

minimum-K PCB.

Observe the worst-case ratings for the device, specifically:

R

165°C/W, T

θJA =

I

CC(max) = 10

mA.

Calculate the maximum allowable power level, P

J(max) =

165°C, V

CC(max) =

24 V, and

D(max)

. First,

invert equation 3:

∆T

max

= T

– TA = 165 °C – 150 °C = 15 °C

J(max)

This provides the allowable increase to TJ resulting from internal

power dissipation. Then, invert equation 2:

P

D(max)

= ∆T

max

÷ R

= 15°C ÷ 165 °C/W = 91 mW

θJA

Finally, invert equation 1 with respect to voltage:

V

CC(est)

= P

D(max)

÷ I

= 91 mW ÷ 10 mA = 9 V

CC(max)

The result indicates that, at TA, the application and device can

dissipate adequate amounts of heat at voltages ≤V

Compare V

able operation between V

R

. If V

θJA

V

is reliable under these conditions.

CC(max)

CC(est)

CC(est)

to V

≥ V

. If V

CC(max)

CC(est)

CC(max)

CC(est)

and V

CC(max)

, then operation between V

≤ V

CC(max)

requires enhanced

.

CC(est)

, then reli-

CC(est)

and

T

= TA + ∆T (3)

J

For example, given common conditions such as: TA= 25°C,

V

= 12 V, I

CC

PD = VCC × I

∆T = PD × R

= 4 mA, and R

CC

= 12 V × 4 mA = 48 mW

CC

= 48 mW × 165 °C/W = 8°C

θJA

θJA

= 165 °C/W, then:

TJ = TA + ∆T = 25°C + 8°C = 33°C

A worst-case estimate, P

able power level (V

at a selected R

A3250-DS

θJA

CC(max)

and TA.

, represents the maximum allow-

D(max)

, I

), without exceeding T

CC(max)

J(max)

,

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

13

A3250 and A3251

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

Package UA, 3-Pin; (TO-92)

A3250-DS

The products described herein are manufactured under one or more of the following U.S. patents: 5,045,920;

5,264,783; 5,442,283; 5,389,889; 5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719; 5,686,894; 5,694,038;

5,729,130; 5,917,320; and other patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to time, such de par tures from the detail spec i fi ca tions as may be required to permit improvements in the per for mance, reliability, or manufacturability of its

products. Before placing an order, the user is cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components in life-support devices or sys tems without

express written approval.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable. How ev er, Allegro MicroSystems, Inc.

assumes no re spon si bil i ty for its use; nor for any in fringe ment of patents or other rights of third parties which may

result from its use.

Copyright © 2004 Allegro MicroSystems, Inc.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

14

A3250 and A3251

Field-Programmable, Chopper-Stabilized, Unipolar Hall-Effect Switches

A3250-DS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

15

Loading...

Loading...