查询A1373供应商查询A1373供应商

Package KB, 3-pin SIP

1

2

3

1. VCC

2. GND

3. VOUT (Programming)

A1373 and A1374

High Precision, Output Pin Programmable

Linear Hall Effect Sensors

The A1373 and A1374 high precision linear Hall effect sensors are sensitive, temperature stable, linear devices with externally programmable features. This device

family incorporates a chopper-stabilized amplifier, voltage regulator, programming logic, and an output amplifier on a single IC. The patented dynamic offset

cancellation used with a chopper-stabilization technique provides extremely low

offset and minimal temperature drift. A high frequency clock is used for chopping,

to ensure high frequency signal processing capability. The A1373 and A1374 are

ideal for use in automotive and industrial linear position-sensing applications that

require increased reliability and accuracy over conventional contacting-potentiometer solutions. Key applications include: throttle position sensors, pedal position

sensors, and suspension height sensors.

The design and manufacturing flexibility of the A1373 and A1374 complement

the Allegro linear Hall effect family of devices by offering programmable gain,

quiescent offset voltage for unipolar or bipolar operation, temperature coefficient, clamps, and polarity. The device can be set up in a magnetic circuit

and programmed with a train of serial pulses via the output pin. Once the right

combination of gain, quiescent output voltage, and temperature coefficient has

been selected, the codes can be locked for one-time programming. In this manner,

manufacturing tolerances can be reduced and the assembly process can be simplified.

These devices are available in the KB package, a 3-pin SIP (single inline package). The lead (Pb) free version has a 100% matte tin plated leadframe.

AB SO LUTE MAX I MUM RAT INGS

Supply Voltage, V

Reverse-Supply Voltage, V

Output Voltage

Reverse-Output Voltage, V

Output Current

Source, I

Sink, I

Operating Temperature

Ambient, T

Ambient, T

Maximum Junction, T

Storage Temperature, T

1

When blowing fuses during device programming, a

voltage of 28 V may be applied to VOUT.

A1373-DS, Rev. 3

OUTSOURCE

OUTSINK

..........................................16 V

CC

1

, V

OUT

.......................................... 10 mA

, Range E..................–40ºC to 85ºC

A

, Range L................–40ºC to 150ºC

A

........................ –16 V

RCC

....................................... 16 V

.....................–0.1 V

ROUT

................................... 3 mA

........................165ºC

J(max)

.................. –65ºC to 170ºC

S

Features and Benefits

Output pin programming

Field-programmable for optimal application integration

Selectable coarse and fine gain and quiescent output voltage

Selectable sensitivity temperature coefficient

Selectable output clamp voltage level, including no-clamp (rail-to-rail)

Selectable output polarity

Unipolar or bipolar operation

Ratiometric sensitivity, clamps, and quiescent output voltage

Chopper-stabilized Hall technique

Wide operating temperature range

On-chip regulator for over/under voltage protection

On-chip regulator provides EMI robustness

Wide lead-spacing with KB package

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

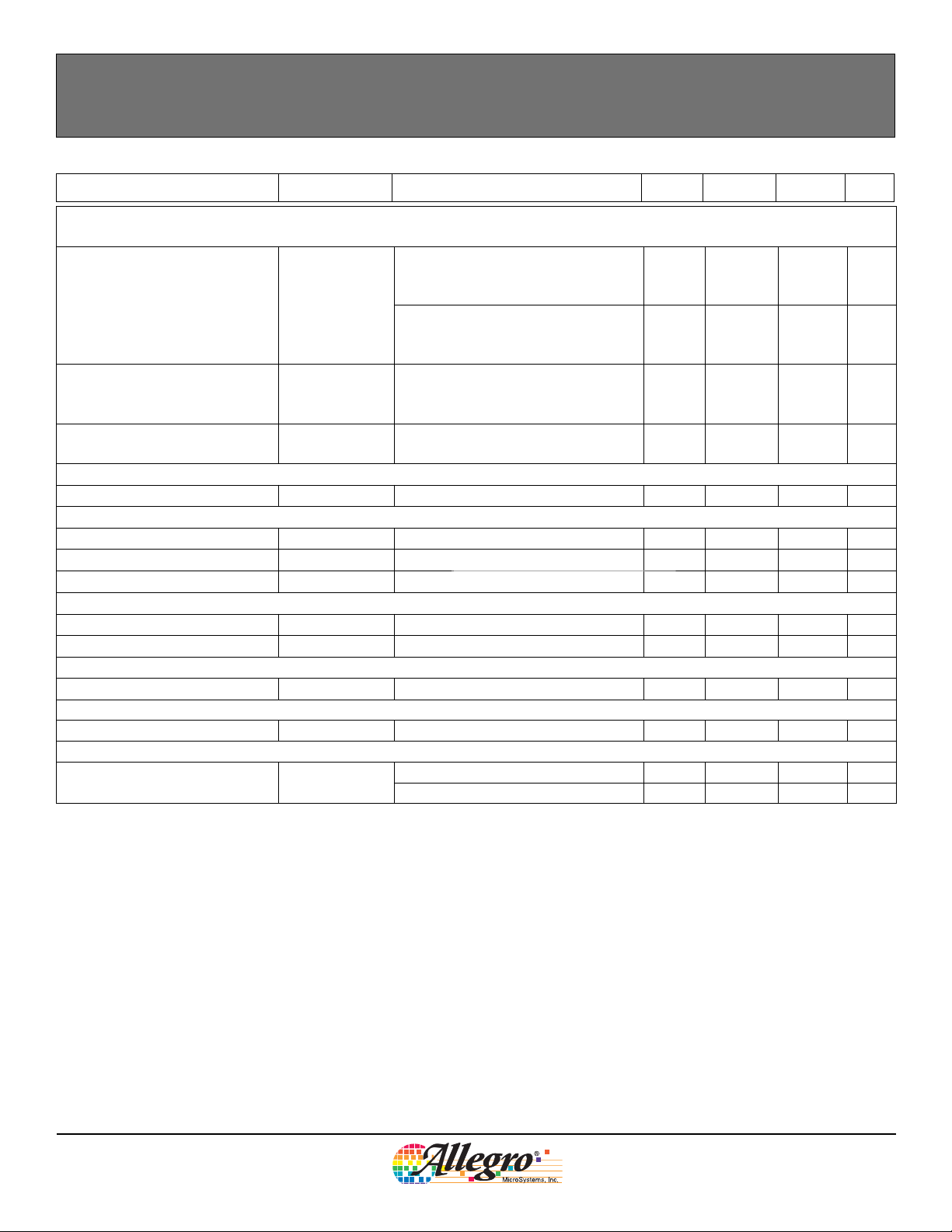

Product Selection Guide

Part Number

A1373EKB –

A1373EKB–T Yes –40 to 85

A1373EKBTI –

A1373EKBTI–T Yes

A1373LKB –

A1373LKB–T Yes –40 to 150

A1373LKBTI –

A1373LKBTI–T Yes

A1374EKB –

A1374EKB–T Yes –40 to 85

A1374EKBTI –

A1374EKBTI–T Yes

A1374LKB –

A1374LKB–T Yes –40 to 150

A1374LKBTI –

A1374LKBTI–T Yes

*Contact Allegro for additional packing options

Pb-

free Packing*

Bulk, 500 pcs./bag

14.24-in. reel, 2000 pcs/reel

Bulk, 500 pcs./bag

14.24-in. reel, 2000 pcs/reel

Bulk, 500 pcs./bag

14.24-in. reel, 2000 pcs/reel

Bulk, 500 pcs./bag

14.24-in. reel, 2000 pcs/reel

Ambient, T

(ºC)

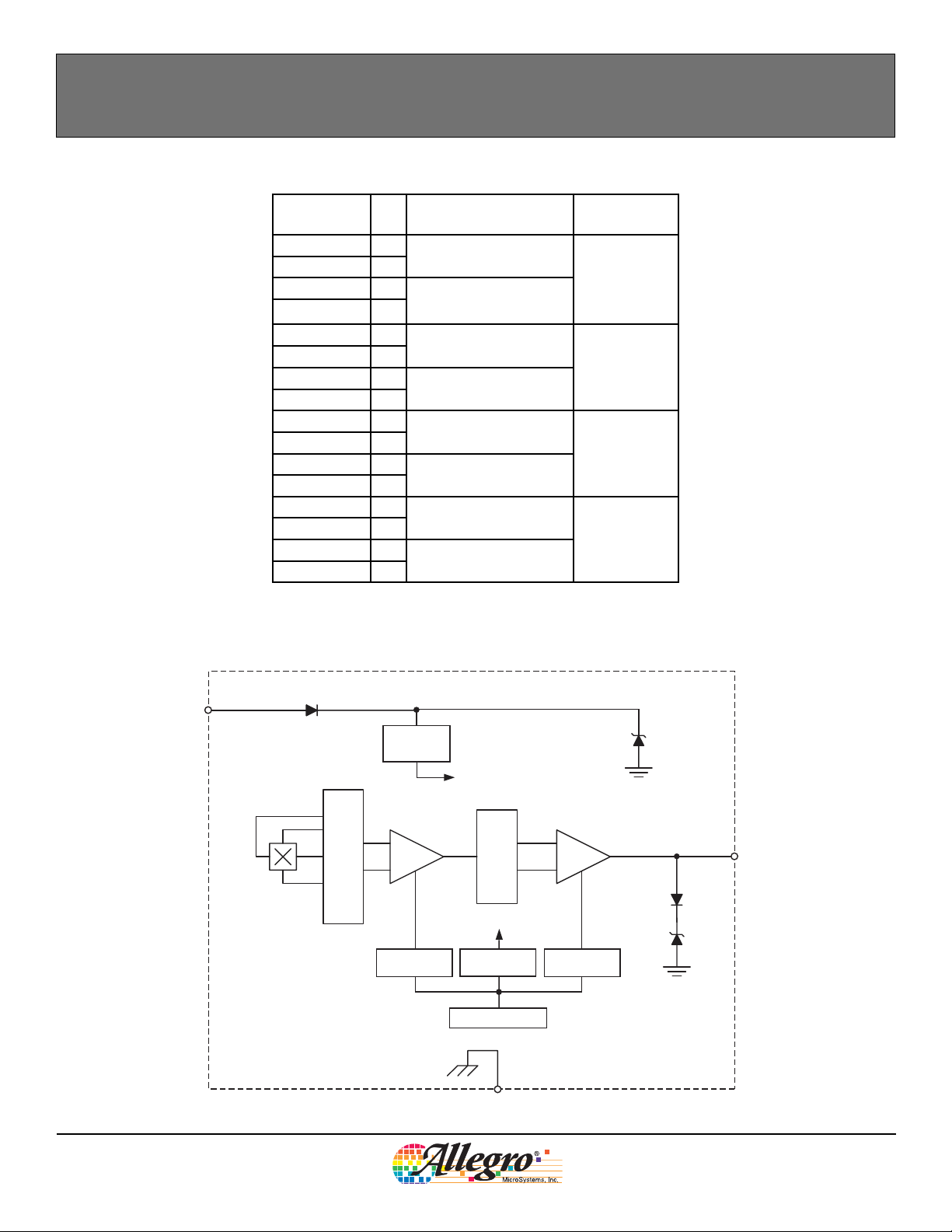

Functional Block Diagram

A

A1373-DS, Rev. 3

VCC

Pin 1

Cancellation

Dynamic Offset

Voltage

Regulator

To all subcircuits

Amp Out

Gain

Filter

Hall drive circuit

Temperature

Coefficient

Trim Control

GND

Pin 2

Offset

VOUT

Pin 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

2

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

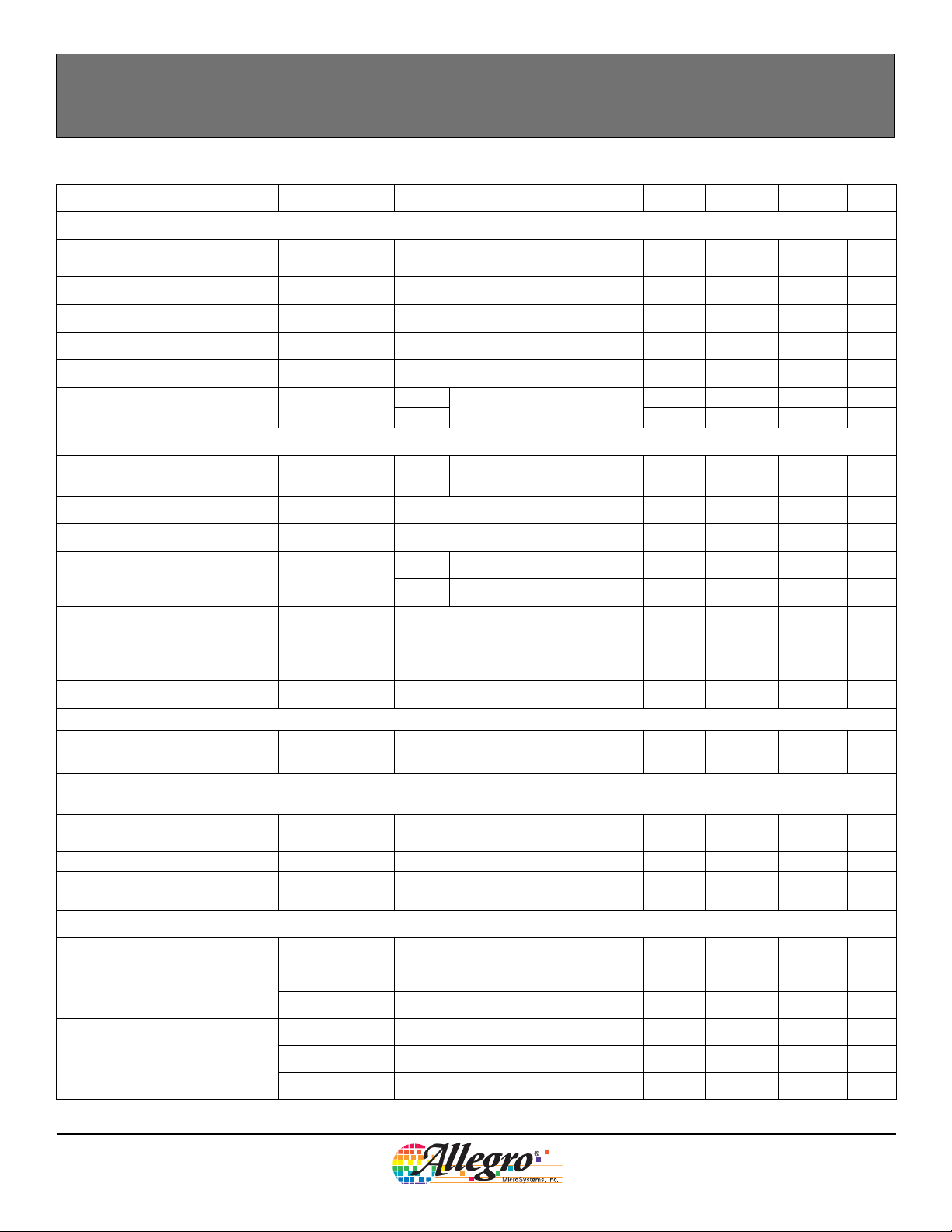

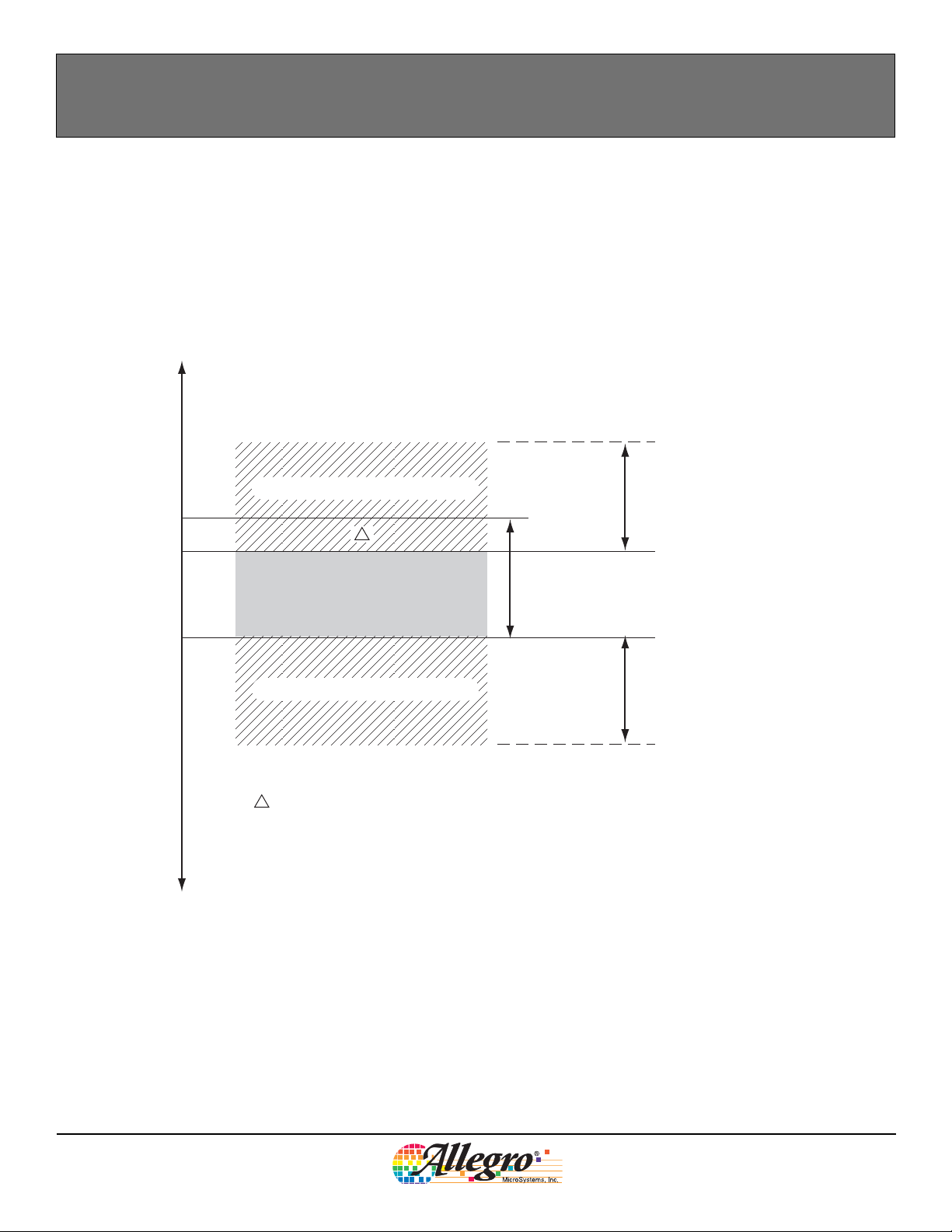

CHARACTERISTIC PARAMETERS

Characteristic Symbol Test Conditions Min. Typ. Max Units

A1373 and A1374

ELECTRICAL CHARACTERISTICS

Supply Voltage V

Supply Current I

Reverse-Supply Current I

Power-On Time

1

Chopping Frequency f

over operating temperature range, VCC= 5.0 V, unless otherwise noted

CC

CC

RCC

t

PO

C

Internal Bandwidth BW

OUTPUT CHARACTERISTICS

2,3

Noise

Output Capacitance Load C

Output Resistive Load R

over operating temperature range, VCC= 5.0 V, unless otherwise noted

V

LOAD

LOAD

Phase Shift ΔΦ

V

OUT(Sat)HIGH

Output Voltage

V

OUT(Sat)LOW

Output Resistance R

OUT

MAGNETIC CHARACTERISTICS

Operation within specification,

< 165°C

T

j

4.5 5.0 5.5 V

– 8.2 10 mA

VCC = –16 V, TA = 25°C – – 16 mA

C

= 10 nF, 90% full scale V

LOAD

OUT

– – 300 μs

– 200 – kHz

A1373

A1374 – 20 – kHz

A1373

N

A1374 – 14 26 mV

Small signal -3 dB

peak-to-peak, C

LOAD

2.5 mV/G

> 1 nF,

– 2.5 – kHz

– 6 16 mV

VOUT pin to GND pin – – 10 nF

4700 – – Ω

A1373 Magnetic signal freq. = 100 Hz – 3 – (°)

A1374 Magnetic signal freq. = 1000 Hz – 3 – (°)

I

OUTSINK

B(kG) > (VCC–V

I

OUTSOURCE

B(kG) < V

= 1.2 mA,

OUT(Q)

= 1.2 mA,

/ Sens (mV/G)

OUT(Q)

) / Sens (mV/G)

4.65 4.7 – V

– 0.2 0.25 V

– 1.5 – Ω

Magnetic Slew Rate SLR V / ms / Sens – 20 –

PRE-PROGRAMMING TARGET (Prior to coarse and fine trim) over operating temperature range, V

= 5.0 V, unless

CC

otherwise noted

Pre-Programming Quiescent

Output Voltage

Pre-Programming Sensitivity Sens

Pre-Programming Sensitivity

Temperature Coefficient

INITIAL COARSE PROGRAMMING

Initial Coarse Quiescent Output

Voltage

Initial Coarse Sensitivity

V

OUT(Q)PRE

TC

PRE

PRE

B = 0 G, TA = 25°C 1.62 1.80 1.98 V

TA = 25°C 1.05 1.31 1.75 mV/G

TA relative to 25°C –0.016 0.05 0.104 %/°C

over operating temperature range, VCC= 5.0 V, unless otherwise noted

V

OUT(Q)INITLOWTA

V

OUT(Q)INITMID

V

OUT(Q)INITHIGHTA

Sens

INITLOW

Sens

INITMID

Sens

INITHIGHTA

= 25°C – 0.55 – V

Reference V

OUT(Q)PRE

––- –V

= 25°C – 3.25 – V

Reference Sens

PRE

– – – mV/G

TA = 25°C – 2.8 – mV/G

= 25°C – 5.5 – mV/G

Continued on the next page...

Allegro MicroSystems, Inc.

A1373-DS, Rev. 3

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

G/μs

3

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

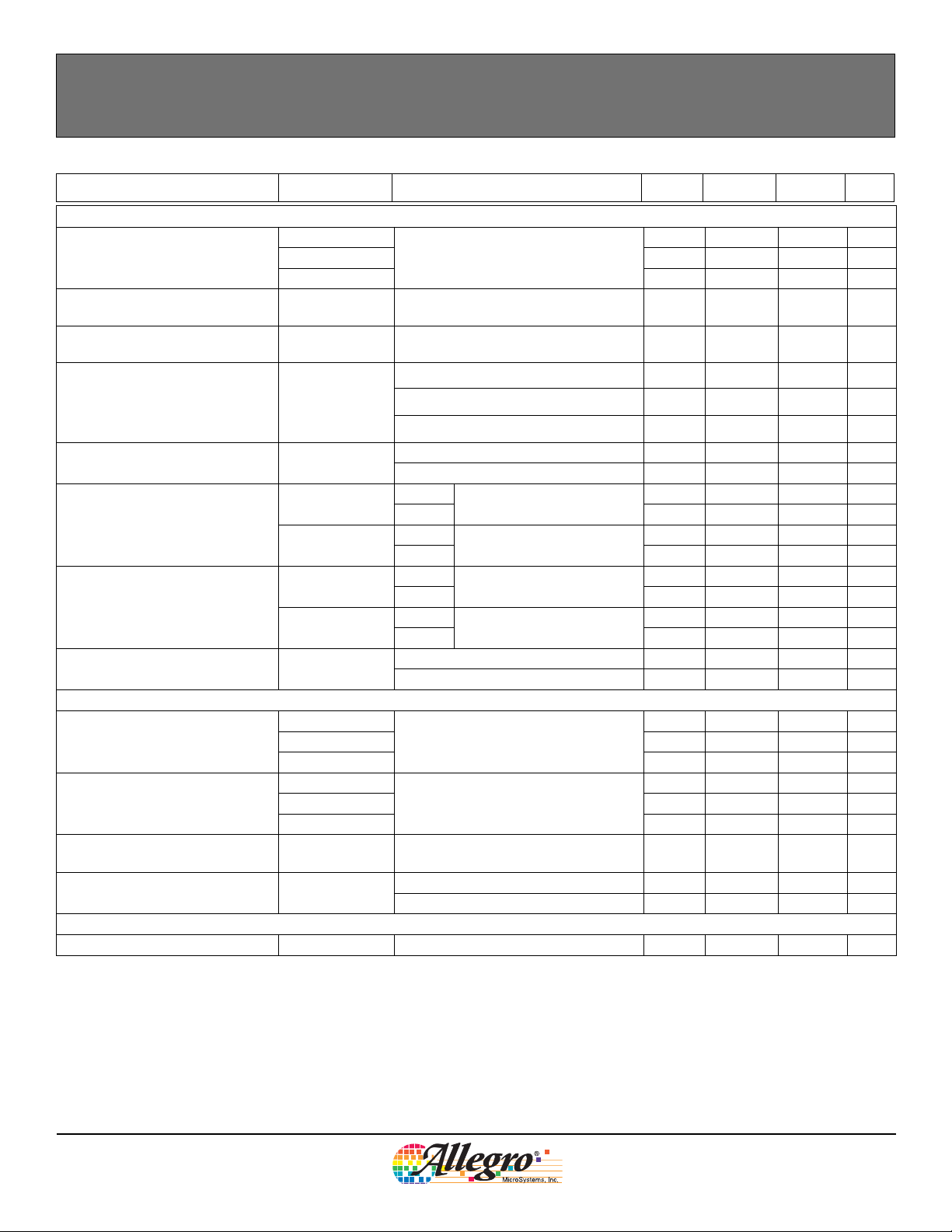

CHARACTERISTIC PARAMETERS (continued)

Characteristic Symbol Test Conditions Min. Typ. Max Units

QUIESCENT OUTPUT VOLTAGE PROGRAMMING over operating temperature range, V

V

OUT(Q)LOW

Quiescent Output Voltage Range

Average Quiescent Output Voltage

Step Size

4,5,6

Quiescent Output Voltage

Programming Resolution

V

OUT(Q)MID

V

OUT(Q)HIGH

Step

Err

PROGVOUT(Q)

Quiescent Output Voltage Drift

Over Operating Temperature

ΔV

Range

Quiescent Output Voltage

Programming Bits

V

10% Output Clamp Option

20% Output Clamp Option

7

7

Delay to Clamp t

SENSITIVITY PROGRAMMING

Sensitivity Range

Average Sensitivity Step Size

8

4,5,6

Sensitivity Programming

Resolution

Sensitivity

Programming Bits

OUTCLP10HIGH

V

OUTCLP10LOW

V

OUTCLP20HIGH

V

OUTCLP20LOW

over operating temperature range, VCC= 5.0 V, unless otherwise noted

Sens

Sens

Sens

Step

Step

Step

Err

VOUT(Q)

OUT(Q)

–

CLP

LOW

MID

HIGH

SENSLOW

SENSMID

SENSHIGH

PROGSENS

–

B = 0 G, TA = 25°C

TA = 25°C 3.0 3.275 3.5 mV

Fine programming value selection

accuracy

V

= V

OUT(Q)

V

OUT(Q)

V

OUT(Q)

OUT(Q)LOW

= V

OUT(Q)MID

= V

OUT(Q)HIGH

Coarse (Range selection) – 2 – Bit

Fine (Value selection) – 9 – Bit

A1373

A1374 4.300 – 4.650 V

A1373

A1374 0.3 – 0.6 V

A1373

A1374 3.900 – 4.200 V

A1373

A1374 0.8 – 1.1 V

High-side output clamp

Low-side output clamp

High-side output clamp

Low-side output clamp

A1373 – – 2 μs

A1374 – – 100 μs

TA = 25°C

TA = 25°C

Fine programming value selection

accuracy

Coarse (Range selection) – 2 – Bit

Fine (Value selection) – 8 – Bit

POLARITY PROGRAMMING

Polarity

Programming Bit

– Negative Sensitivity – 1 – Bit

= 5.0 V, unless otherwise noted

CC

0.7 – 1.9 V

2.0 – 3.2 V

3.5 – 4.5 V

–

±0.5 ×

Step

VOUT(Q)

–mV

– – ±40 mV

– – ±40 mV

– – ±55 mV

4.350 – 4.565 V

0.4 – 0.6 V

3.925 – 4.125 V

0.9 – 1.1 V

1.75 – 2.8 mV/G

3.5 – 5.7 mV/G

7.0 – 11.25 mV/G

6 9.5 14 μV/G

12 18.7 28 μV/G

22 37.0 56 μV/G

–

±0.5 ×

Step

SENS

– μV/G

Continued on the next page...

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

4

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

CHARACTERISTIC PARAMETERS (continued)

Characteristic Symbol Test Conditions Min. Typ. Max Units

SENSITIVITY TEMPERATURE COEFFICIENT PROGRAMMING over operating temperature range, V

= 5.0 V, unless

CC

otherwise noted

Sensitivity T/C codes 0 to 11,

Sensitivity Temperature

Coefficient Range

TC

minimum (absolute) positive

temperature coefficient attainable

Sensitivity T/C codes 16 to 27,

minimum (absolute) negative

–

–

0.07

–

0.016 – %/°C

–

%/°C

temperature coefficient attainable

Average Sensitivity

Temperature Coefficient Step

6

4,5,

Size

Sensitivity Temperature

Coefficient Programming Bits

Step

TC

TA = 150°C

––

–

0.01

5

–

%/°C

– Bit

ONE-TIME PROGRAMMING

Device Programming Lock Bit

RATIOMETRY over operating temperature range, V

Quiescent Voltage Error

Sensitivity Error

Clamp Error Rat

LINEARITY

over operating temperature range, VCC= 5.0 V, unless otherwise noted

Positive Linearity Error Lin+ VCC at V

Negative Linearity Error

SYMMETRY

over operating temperature range, VCC= 5.0 V, unless otherwise noted

Symmetry Error

ADDITIONAL CHARACTERISTICS

Sensitivity Drift

9

FAULT CONDITIONS over operating temperature range, V

Shorted Output Wire

1

tPO does not include t

2

Peak to peak value exceeded: 0.3% (6σ).

3

For A1373, no digital noise is present at the output.

4

Step size is larger than required for the specified range, to take into account manufacturing spread.

5

Individual code step sizes can be greater than 2× larger than the step size at each significant bit rollover.

6

Average fine code step size in a given range = (Output value at highest fine code in the range – Output value at code 0 of the range) / Total quantity of

steps (codes) in the range.

7

Values indicated are valid if any additional magnetic field does not exceed B(kG)= ±2 (V) / Sens (mv/G), after V

8

Program the Sensitivity T/C register before programming Sensitivity Coarse and Sensitivity Fine, due to a worst case shift of ±3% in sensitivity at 25°C

at the maximum values for Sensitivity T/C: Positive T/C and Sensitivity T/C: Negative T/C. The Programming Guidelines section in this document lists a

complete recommended order for programming individual values.

9

Drift due to temperature cycling is due to package effects on the Hall transducer. The stress is reduced when the package is baked. However, it will

recover over time after removal from the bake.

, specified in the Quiescent Programming sectio n of this table.

CLP

– – 1 – Bit

= 5.0 V, unless otherwise noted

CC

Rat

Rat

VOUTCLP

VOUT(Q)

SENS

Lin–

Sym

VCC at V

VCC at V

VCC at V

VCC at V

VCC at V

OPERATING

OPERATING

OPERATING

OPERATING

OPERATING

OPERATING

– V

CC

–

–

–

–

–

–

±0.25

±1.0

±1.5

±0.5

±0.5

±0.35 –

–%

–%

–%

–%

–%

ΔSens – – ±2 %

= 5.0 V, unless otherwise noted

CC

I

OUTSHT

VOUT pin to VCC pin – – 18 mA

VOUT pin to GND pin – – 4 mA

is reached.

OUTCLP

%

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

5

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Typical Characteristics

Temperature Coefficient Code Profile

TA = 150°C, Magnetically Back-Biased

3.4

V

3.2

Positive Programming Codes

OUT(Q)

= V

OUT(Q)PRE

, Sens = 5 mV/G

3.0

Negative Programming Codes

(V)

2.8

OUT(Q)

2.6

V

2.4

2.2

2.0

0 5 10 15 20 25 30

Sensitivity TC Code

Code Application

0 Initial code

1 – 11 Positive TC codes, use to increase TC value

12 – 15 [Unused, same effect as 4 – 7, respectively]

16 – 27 Negative TC codes, use to decrease TC value

28 – 31 [Unused, same effect as 20 – 23, respectively]

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

6

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

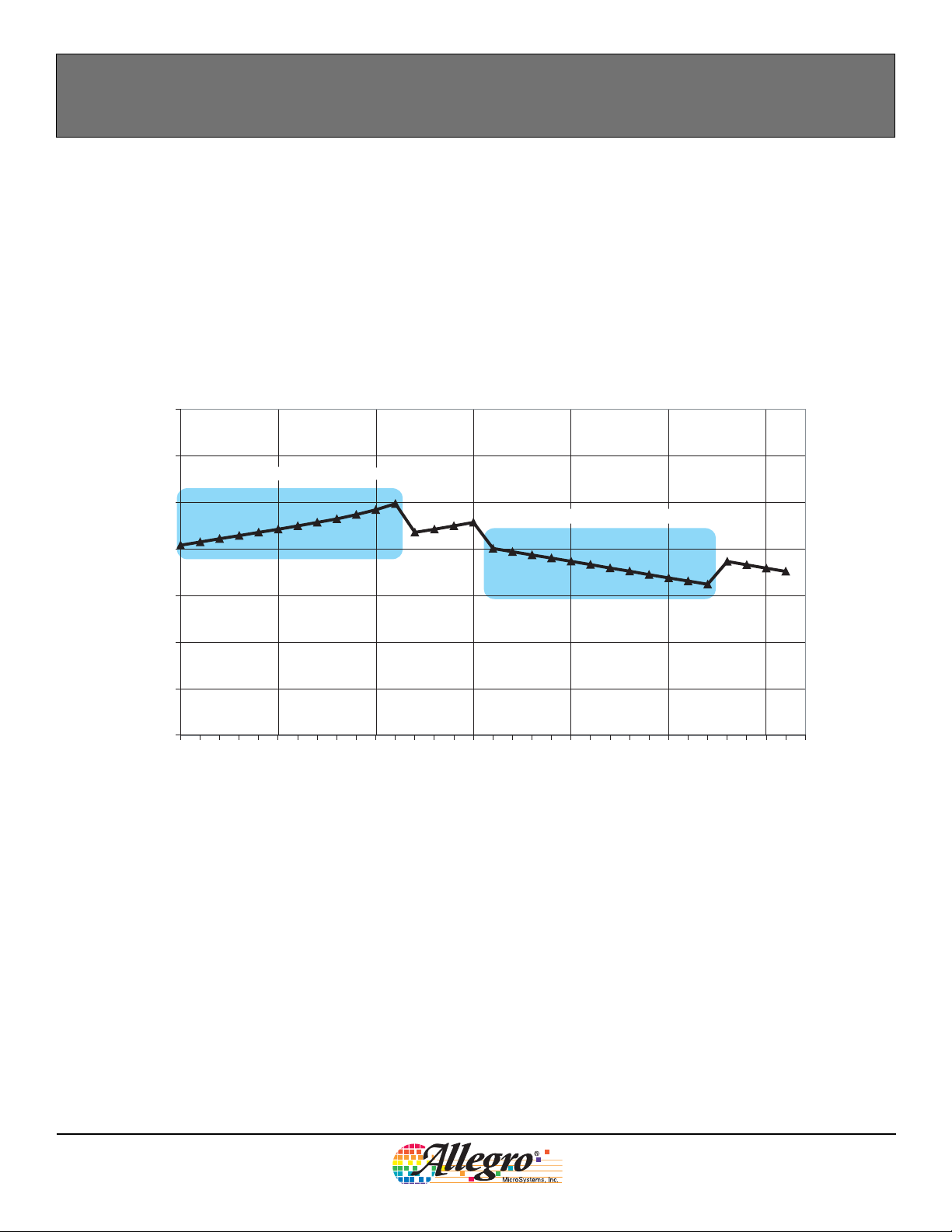

Sensitivity Temperature Coefficient Range, TC

0.25

0.20

0.15

0.10

0.05

0

TC (% / °C)

–0.05

–0.10

–0.15

–0.20

–0.25

Extended Range Not Guaranteed

TC

A

Guaranteed Programmable Range

Extended Range Not Guaranteed

A

Units with a TC in the range TC

< TC < TC

(min)

PRE(max)

TC Range Before Programming

PRE(max)

before programming may not be programmable

to the maximum attainable negative TC programming value

Typical maximum attainable

positive TC programming range

TC

(typ)

, for positive programming

TC

, for negative programming

(typ)

TC

PRE(min)

Typical maximum attainable

negative TC programming range

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

7

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Average Supply Current (Icc) vs Temperature

10.0

9.5

9.0

8.5

8.0

7.5

7.0

6.5

6.0

Average Supply Cur rent ( mA)

5.5

5.0

-50 -25 0 25 50 75 100 125 150

Average Ratiometry, Voq

101.0

100.8

100.6

100.4

100.2

100.0

99.8

99.6

99.4

Average Ratiom etry (Voq) (%)

99.2

99.0

-50-250255075100125150

4.5 to 5. 0 V

5.5 to 5. 0 V

Temperature (°C)

Vcc = 5V

Temperature ( °C)

101.0

100.8

100.6

100.4

100.2

100.0

99.8

99.6

99.4

99.2

Average Ratiom etry (Sens) (%)

99.0

-50-250255075100125150

Average Ratiometry, Sens

4.5 to 5. 0 V

5.5 to 5. 0 V

Temperature (°C)

101.0

100.8

100.6

100.4

100.2

100.0

99.8

99.6

99.4

Average Symmet ry (%)

99.2

99.0

-50 -25 0 25 50 75 100 125 150

A1373-DS, Rev. 3

Average Symmetry vs Temperature

Temperature (°C)

Average Linearity vs Temperature

101.0

100.8

100.6

100.4

100.2

100.0

99.8

99.6

Average Linear ity ( %)

99.4

99.2

99.0

-50 - 25 0 25 50 75 100 125 150

Temperature (°C)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

Lineari ty +

Lineari ty -

8

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Average Delta Sensit ivity

(percent change relative to 25°C)

8

6

4

2

0

-2

Average Delta Sensiti vity ( %)

-4

-6

-50 -25 0 25 50 75 100 125 150

Sensitivity Low

Sensitivity Mid

Sensitivity High

Temperature ( °C)

Average Delta Sensit ivity

(percent per degree Celsius change relative to 25°C)

0.08

0.06

0.04

0.02

0

-0.02

-0.04

Average Delta Sensitvi ty (%/ °C)

-0.06

-0.08

-50 - 25 0 25 50 75 100 125 150

Sensitivity Low

Sensitivity Mid

Sensitivity High

Temperature ( °C)

Average Delta Sensit ivity over TC Codes

(percent change relative to 25°C)

Initial Coarse Ran ge

25

20

15

10

5

0

-5

Initial Delta Sensitivity (%)

-10

-15

-50 - 25 0 25 50 75 100 125 150

Sensitivity Low - TC Code 0

Sensitivity Low - TC Code 11

Sensitivity Low - TC Code 27

Temperature ( °C)

Average Delta Sensitivity

(percent per degree Celsius change relative to 25°C)

Initial Coarse Low

0.20

0.15

0.10

0.05

-0.05

-0.10

Average Delta Sensitvi ty (%/ °C)

-0.15

-0.20

Sensitivity Low - TC Code 0

Sensitivity Low - TC Code 11

Sensitivity Low - TC Code 27

0

-50 -25 0 25 50 75 100 125 150

Temperature ( °C)

15

10

5

0

TC Contribution to

Delta Sensitivity (%)

-5

-10

-50 -25 0 25 50 75 100 125 150

A1373-DS, Rev. 3

Positive TC Contribution to Delta Sensitivity

TC Code 1

TC Code 2

TC Code 4

TC Code 8

TC Code 11

Temperature (°C)

Negative TC Contribution to Delta Sensitivity

10

5

0

-5

-10

Sensitivity (%)

TC Contribution to Delta

-15

-20

-50 -25 0 25 50 75 100 125 150

TC Code 16

TC Code 17

TC Code 18

TC Code 20

TC Code 24

TC Code 27

Tem perature (°C)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

9

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Average Quiescent Output Voltage

3.5

3.0

2.5

2.0

1.5

Average Vout(q) (V)

1.0

0.5

0

-50 -25 0 25 50 75 100 125 150

Average Quiescent Output Voltage

Max Code (511)

6

5

4

3

2

1

Average Vout(q) (max Code - 511) (V)

0

-50 -25 0 25 50 75 100 125 150

Vout(q)Low - Initial

Vout(q)Mid - Initial

Vout(q)High - Initial

Temperature (°C )

Vout(q)Low - Max Code

Vout(q)Mid - Max Code

Vout(q)High - Max Code

Temperature ( °C)

Average Delta Quiescent Output Voltage

Relative to 25°C, Initial Sensitivity

6

4

2

0

-2

-4

-6

Average Delta Vout(q) (mV)

-8

-10

-50 -25 0 25 50 75 100 125 150

Average Init ial Quiescent Output Voltage vs Supply Voltage

4.0

3.5

3.0

2.5

2.0

1.5

Average Vout(q) (V)

1.0

0.5

0

4 4.5 5 5.5 6

Temperature (°C)

= 25°C

T

A

Supply Voltage (V)

Vout(q)Low

Vout(q)Mid

Vout(q)High

Vout(q)Low - Initial

Vout(q)Mid - Initial

Vout(q)High - Initial

A1373-DS, Rev. 3

1.85

1.83

1.81

1.79

Average Vout(q) (V)

1.77

1.75

Average Quiescent Output Voltage over Sensitivity

Vout(q)Mid - SensLow

Vout(q)Mid - SensMid

Vout(q)Mid - SensHigh

-50 -25 0 25 50 75 100 125 150

Tempe rature (°C)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

10

A1373 and A1374

p

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

5

Average Saturation Voltage

4

(V)

3

V

2

OUT(sat)

V

1

0

-50 -25 0 25 50 75 100 125 150

Temperature (°C)

OUT(sat)+

V

OUT(sat)–

5

Average Clamp Values

4

3

2

1

Average Clamp Vo ltage (V)

0

-50 -25 0 25 50 75 100 125 150

10% High Clamp

10% Low Clamp

20% High Clamp

20% Low Clam

Temperature (° C)

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

11

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Chopper Stabilization Technique

Chopper stabilization is a unique approach used to minimize

Hall offset on the chip. The patented Allegro technique, namely

Dynamic Quadrature Offset Cancellation, removes key sources

of the output drift induced by thermal and mechanical stresses.

This offset reduction technique is based on a signal modulationdemodulation process. The undesired offset signal is separated

from the magnetic field-induced signal in the frequency domain,

through modulation.

The subsequent demodulation acts as a modulation process for

the offset, causing the magnetic field-induced signal to recover

its original spectrum at baseband, while the dc offset becomes

a high-frequency signal. The magnetic-sourced signal then can

pass through a low-pass filter, while the modulated dc offset is

suppressed.

The chopper stabilization technique uses a 200 kHz high

frequency clock. For demodulation process, a sample and hold

technique is used, where the sampling is performed at twice the

chopper frequency (400 kHz). This high-frequency operation

allows a greater sampling rate, which results in higher accuracy

and faster signal-processing capability.

This approach desensitizes the chip to the effects of thermal and

mechanical stresses, and produces devices that have extremely

stable quiescent Hall output voltages and precise recoverability after temperature cycling. This technique is made possible

through the use of a BiCMOS process, which allows the use of

low-offset, low-noise amplifiers in combination with high-density logic integration and sample-and-hold circuits.

A1373-DS, Rev. 3

Hall Element

Regulator

Clock/Logic

Amp

Concept of Chopper Stabilization Technique

Low-Pass

Filter

Hold

Sample and

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

12

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Definitions of Terms

Linear: A type of Hall-Effect sensor that produces an analog output voltage proportional to the strength of a sensed magnetic field.

Ratiometric: A linear Hall-Effect sensor that, when not subjected to a significant magnetic field, has an output that is a ratio of its supply voltage.

A ratiometric performance of 100% indicates the output follows the supply with no percentage error.

Gauss: Standard unit of measuring magnetic flux density. 1 gauss is equal to 1 Maxwell per square centimeter or 10

earth’s magnetic field is approximately 0.5 gauss.)

-4

tesla. (For reference, the

Blowing: Applying a pulse of sufficient voltage and duration to permanently set a bit, by blowing a fuse internal to the device. Once a bit (fuse)

has been blown, it cannot be reset. The terms trimming and programming can be used interchangeably with blowing in this context.

Programming modes: Testing the results is the only valid method to guarantee successful programming, and multiple modes are provided to

support this. The programming modes are described in the section Mode Selection State.

Code: The number used to identify the register and the bitfield to be programmed, expressed as the decimal equivalent of the binary value. The LSB

of a register is denoted as bit 0.

Typical Application Drawing

V

REG

A1373-DS, Rev. 3

C

BYPASS

0.1 µF

VCC

A1373

A1374

GND

1

2

VOUT

3

R

LOAD

4.7 kΩ

Sensor Output

C

LOAD

1nF

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

13

A1373 and A1374

V

CC

5V

=

× 100%

RAT

Sens

Sens

(VCC)

Sens

(5V)

=

× 100%

Lin+

2 (V

OUT(+B½)

–V

VOUTQ

)

–

V

OUT(+B)VOUTQ

=

× 100%

Lin–

2(V

OUT(–B½)–VOUTQ

)

–

V

OUT(–B)VOUTQ

–

=

× 100%

Sym

V

OUT(+B)

V

OUTQ–VOUT(–B)

V

OUTQ

=

RAT

VCLP

V

CC

5V

V

CLP(VCC)VCLP(5V)

× 100%

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Characteristic Definitions

Quiescent Output Voltage. In the quiescent state (no signifi-

cant magnetic field: B = 0), the output, V

, equals a ratio of

OUTQ

the supply voltage, VCC, throughout the entire operating ranges

of VCC and ambient temperature, TA. Due to internal component tolerances and thermal considerations, however, there is

a tolerance on the quiescent output voltage, ΔV

OUTQ

, which is

a function of both ΔVCC and ΔTA. For purposes of specification, the quiescent output voltage as a function of temperature,

ΔV

OUTQ(ΔTA)

, is defined as:

ΔV

OUTQ(ΔΤΑ)

V

OUTQ(ΤΑ)VOUTQ(25ºC)

=

Sens

–

(25ºC)

(1)

where Sens is in mV/G, and the result is the device equivalent

accuracy, in gauss (G), applicable over the entire operating temperature range.

Sensitivity. The presence of a south-polarity (+B) magnetic

field, perpendicular to the branded face of the device package,

increases the output voltage, V

field applied, from V

toward the VCC rail. Conversely, the

OUTQ

, in proportion to the magnetic

OUT

application of a north polarity (–B) magnetic field, in the same

orientation, proportionally decreases the output voltage from its

quiescent value. This proportionality is specified as the magnetic

sensitivity of the device and is defined as:

Sens

V

=

–

OUT(–B)VOUT(+B)

2B

(2)

The stability of the device magnetic sensitivity as a function of

ambient temperature, Δ Sens

ΔSens

(ΔΤΑ)

Sens

=

(%) is defined as:

( ΔTA)

Sens

–

(ΤΑ)

Sens

(25ºC)

(25ºC)

× 100%

(3)

proportional to the supply voltage, V

CC

.

The ratiometric change in the quiescent output voltage,

RAT

VOUT(Q)

RAT

(%), is defined as:

V

VOUT(Q)

=

OUTQ(VCC)

V

CC

V

OUTQ(5V)

5V

× 100%

(4)

the ratiometric change in sensitivity is defined as:

(5)

and the ratiometric change in clamp voltage is defined as:

(6)

Note that clamping effect is applicable only when clamping is

enabled by programming of the device.

Linearity and Symmetry. The on-chip output stage is

designed to provide linear output at a supply voltage of 5 V.

Although the application of very high magnetic fields does not

damage these devices, it does force their output into a nonlinear

(7)

(8)

region. Linearity in percent is measured and defined as:

(9)

Ratiometric. The A1373 and A1374 feature ratiometric

output. This means that the quiescent voltage output, V

magnetic sensitivity, Sens, and clamp voltage, V

A1373-DS, Rev. 3

OUTCLP

OUTQ

, are

,

and output symmetry as:

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

14

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Pulse Generation

Several parameters can be field-programmed. To do so, a coded

series of voltage pulses through the VOUT pin is used to set

bitfields in onboard registers. The effect on the device output can

be monitored, and the registers can be cleared and set repeatedly until the required output results are achieved. To make the

setting permanent, bitfield-level solid state fuses are blown, and

finally, a device-level fuse is blown, blocking any further coding.

Although any programmable variable power supply can be used

to generate the pulsed waveforms, Allegro highly recommends

using the Allegro Sensor Evaluation Kit, available on the Allegro

Web site On-line Store. The manual for that kit is available for

download free of charge, and provides additional information on

programming these devices.

There are four relative nominal voltage levels that must be taken

into account when programming. For purposes of explanation

in this document, the signal levels are referred to simply as high

programming voltage, V

, midrange, VPM, and low, VPL. The

PH

V

PH

Change State

1 < ΔtPH < 35 µs

fourth voltage level, V

, is a very low level, near zero volts, used

R

to reset the bitfields that have not yet been isolated by blown

fuses.

The high level, VPH, pulse is maintained either for short duration

(ΔtPH = 1 to <<35 μs), acting as a strobe to signal the transition

between states, or for long duration (ΔtPH ≥ 35 μs) and used for

fuse-blowing. The device generates an internal pulse beginning

at the leading (rising) edge of a VPH pulse. The duration of the

internal pulse is the duration of the external VPH pulse, ΔtPH,

plus 15 μs. The added time is a buffer to compensate for voltage drop when the high current is sourced, ensuring that there

is sufficient power to blow the fuse completely. Before sending

another pulse, an additional guard band of 5 μs is recommended

to allow the signal to decay, for a total of at least 20 μs after the

end of any VPH pulse. ΔtPH is measured from the time when the

external signal voltage rises above 23.6 V to the time when it

falls below 19.4 V. The nominal level for VPH is 28 V.

Blow Fuse

Δt

> 35 µs

PH

External Pulses

on VOUT Pin

Internal Pulses

Programming Pulse Waveforms

A1373-DS, Rev. 3

V

PM

V

PL

V

R

Logic 1

Logic 0

Guard

Band

(20 µs)

State Change or Blow pulse = ΔtPH +15 µs

Note: Spurious bit-setting pulses are generated on first V > V

Guard Band (6 µs)

Bit setting pulses = 5 µs

Blowing fuse

t

≥ 50 µs

min

after VR, and at last VPL.

PL

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

15

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

The midrange voltage level, VPM, is a neutral level, used to

separate both VPH and VPL pulses from each other. The nominal

level for VPM is 15 V.

The low level, VPL, pulse is used to indicate bitfield addresses

that are to be set. The device generates an internal pulse beginning at the leading (falling) edge of a VPL pulse. The duration

of the internal pulse is 5 μs. Before allowing the voltage to

rise again, an additional guard band of 1 μs is recommended to

ensure that the pulse completes, for a total of at least 6 μs after

the start of any VPL pulse. The duration of the VPL pulse, ΔtPL ,

is measured from the time when the external signal voltage falls

into the range 0 to 7.5 V to the time when it rises above 10 V. If

the voltage rises above 10 V before the 5 μs period expires, then

the VPL pulse will immediately end, with undefined results. The

nominal level for VPH is 5 V.

VPL must always be maintained high enough above VR (nominally 0 V) to maintain the settings provisionally latched into

registers. Note that, when the external voltage rises from VR

through the VPL range, a spurious internal pulse is generated,

making Code 0 not available in Mode Selection state. A spurious

internal pulse also is generated when the external voltage falls

through the VPL range at the end of a code sequence. For that

reason, it is mandatory to ensure that the voltage is dropped fully

to VR, before every Blow Fuse mode operation, to ensure that

the spurious pulse does not affect the next code sequence.

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

16

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

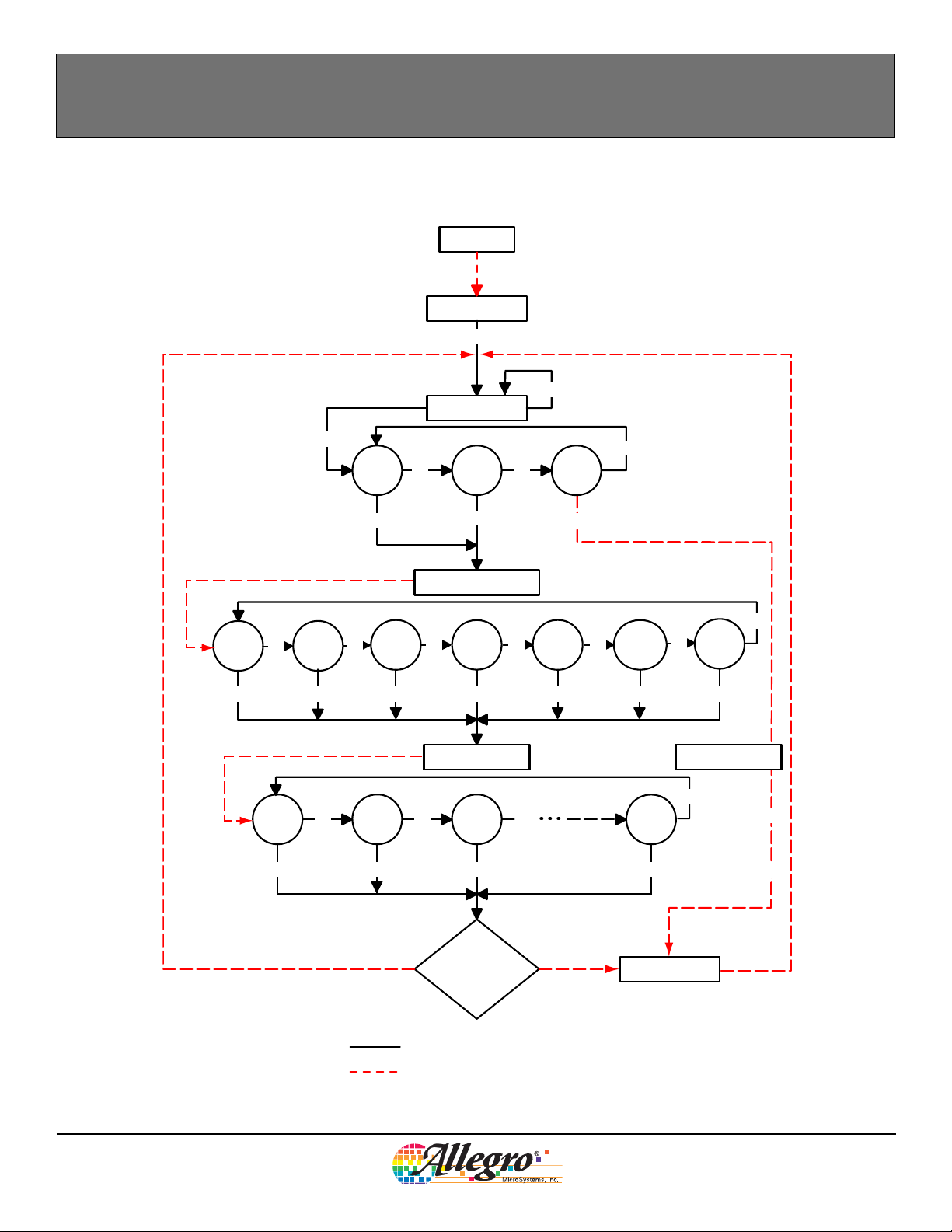

Programming State Machine

POWER UP

INITIAL STATE

V

PH

V

PH

MODE SELECT

V

PL

BLOWTRY LOCK

V

PL

V

PL

12 3

V

V

PH

PH

V

V

PL

PH

QVO

Coarse

01

V

PH

QVO

Fine

V

V

PH

V

PL

[Optional:

Measure]

V

PL

V

PH

REGISTER SELECT

SENS.

PL

Coarse

2

V

PH

[Optional:

Measure]

1 20 2^N -1

V

PH

No Yes

SENS.

V

PL

Fine

34 56

V

PH

BITFIELD SELECT BITFIELD SELECT

V

PL

SENS.

V

TC

V

PH

[Write Mode]

PL

[Optional:

Measure]

V

PL

V

V

PL

PH

BLOWING

MODE?

V

CLAMP

PL

V

PH

V

PL

V

PH

FUSE BLOWING

POLAR

V

PH

V

PL

V

PL

V

PH

A1373-DS, Rev. 3

User generated transition

Internally generated transition

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

17

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Programming Protocol and State Machine Description

INITIAL STATE

After system power-up, the programming logic is reset to a

known state. This is referred to as the Initial state. All the registers that have intact fuses are set to logic 0.

While in the Initial state, any VPL pulses on the VOUT pin are

ignored.

To enter the Mode Selection state, send one V

pulse on the

PH

VOUT pin.

MODE SELECTION STATE

This state allows the selection of the programming mode:

• Try Value Mode. In this mode, the user provisionally downloads

settings to the device registers, without blowing the bits. The user

can increment through the codes of each parameter, and evaluate the

results of various code settings.

• Blow Fuse Mode. In this mode, after downloading the settings, the

user can blow the fuses in specific registers.

• Lock Device Mode. This mode is similar to Blow Fuse mode, except

that the fuse that is blown permanently prevents any further programming of any bits in the device.

To select a mode, increment through the register bitfields by

sending VPL pulses on the VOUT pin, as follows:

0 pulses – No effect

1 pulse – Try Value mode

2 pulses – Blow Fuse mode

3 pulses – Lock Device mode

This register wraps by default. This means that sending additional VPL pulses traverses the register again.

Any VPH pulse sent before a VPL pulse has no effect.

To enter the Register Selection state, after sending a valid quantity of VPL pulses, send one VPH pulse on the VOUT pin.

REGISTER SELECTION STATE

This state allows the selection of the register containing the

bitfields to be programmed. Selecting the register corresponds to

selecting the parameter to be set. For bit codes, see the section

Programming Logic.

• QVO [V

ing dc point (2 bits)

• QVO Fine. Register for setting the value within the range set in the

QVO Coarse register (9 bits)

• Sens. [Sensivity] Coarse. Register for setting the overall gain of the

] Coarse. Register for setting the range of the operat-

OUT(Q)

device (2 bits)

• Sens. Fine. Register for setting the value within the range set in the

Sens. Coarse register (8 bits)

• [Sensitivity] TC Register. Register for setting the temperature coefficient for the device (5 bits).

• Clamp [V

the output (2 bits)

• Polarity Bit. Register setting the polarity of the output (1 bit)

] Bit. Register for setting the clamping voltage of

OUTCLP

To select a register, increment through the register bitfields by

sending V

pulses on the VOUT pin. Note that the program-

PL

ming of registers should follow the order shown in item 7 in the

section Programming Guidelines, not the bitfield selection order

shown here. The bitfield selection order is:

0 pulses – QVO Coarse register

1 pulse – QVO Fine register

2 pulses – Sens. Coarse register

3 pulses – Sense Fine register

4 pulses – TC Register register

5 pulses – Clamp Bit register

6 pulses – Polarity Bit register

This register wraps by default.

To enter the Register Selection state, send one VPH pulse on the

VOUT pin.

BITFIELD SELECTION STATE (Write Mode)

This state allows the selection of the individual bitfields to be

programmed, in the register selected in the Register Selection

state.

In Try Value mode, the total value of the bitfields selected increments by 1 with each VPL pulse on the VOUT pin. The parameter being programmed changes with each additional pulse, so

measurements can be taken after each pulse to determine if the

desired result has been acquired.

In Blow Fuses mode, each bitfield to be blown must be selected

individually.

For bit codes and wrapping for these registers, see the section

Programming Logic.

To leave this state, send one VPH pulse on the VOUT pin. If the

current mode is Try Value, the bitfields remain set and the device

reverts to the Mode Selection state. If the current mode is Blow

Fuse, the selected bitfield fuse is blown, and the device reverts to

the Mode Selection state.

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

18

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Programming Logic

Binary Bitfield Address Decimal Equivalent Code Description

QVO Coarse register

00 0 V

01 1 V

10 2 V

11 3 Register wraps to 00

QVO Fine register

000000000 0 Initial value in selected QVO Coarse range

111111111 511 Maximum value in selected QVO Coarse range

Sens. Coarse register

00 0 Sens low range

01 1 Sens mid range

10 2 Sens high range

11 3 Register wraps to 00

Sens. Fine register

00000000 0 Initial value in selected Sens. Coarse range

11111111 2 55 Maximum value in selected Sens. Coarse range

TC Register register (See also chart Sensitivity Temperature Coefficient Code Profile in Typical Characteristics section)

00000 0 initial TC

00001 through 01011 1 through 11 Positive TC programming range

01100 through 01111 1 2 through 15 Unused: equal to codes 4 to 7, respectively

10000 through 11011 16 through 27 Negative TC prgramming range; Value for 16 equals 1 step

11100 through 11111 28 through 31 Unused: equal to codes 20 to 23, respectively

Clamp Bit register

00 0 Rail-to-rail output swing

01 1 0.5 V and V

10 2 1 V and V

00 3 Register wraps to 00

Polarity Bit register

0 0 Positive (V

1 1 Negative (V

mid range

OUT(Q)

low range

OUT(Q)

high range

OUT(Q)

less than the value for the Initial TC Value (00000)

– 0.5V rails

CC

– 1 V rails

CC

increases when a positive (south) magnetic

field is applied to the device )

field is applied to the device )

OUT

increases when a negative (north) magnetic

OUT

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

19

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Programming Guidelines

• A bypass capacitor rated at 0.1μF must be mounted between

the VOUT pin and the GND pin during programming. The

power supply used for programming should be capable of delivering 28 V and 300 mA.

• Before beginning any Blow Fuse mode or Lock Device mode

code sequence, the device MUST be reset by cycling VCC

power-off and power-on again. Cycling power resets the device

by setting all bitfields that have intact fuses to 0. Bitfields with

blown fuses are unaffected.

In Try Value mode, to retain register settings from previous code

sequences, do not cycle power between sequences.

When a register is selected in Register Selection mode, when

the VPH pulse is sent to enter the Bitfield Selection mode, the

bitfields with intact fuses in that register are reset to 0.

• In Try Value mode, all bits in the register can be set in one

code sequence. For example, setting the binary value 0110 and

sending a VPH pulse sets code 6. However, because of the power

requirement, blowing fuses must be performed one bitfield at

a time. In order to program (blow fuses) for binary 0110, the

bitfields MUST be programmed (blown) in two different code

sequences:one setting the 0100 bit, and the other setting the 0010

bit (in either order). Power must be cycled before each of the

two sequences.

• Although a bitfield cannot be reset once its fuse is blown,

additional bitfields can be blown at any time, until the device is

locked by setting the Lock bit. For example, if bit 1 (0010) has

been blown, it is possible to blow bit 0 (0001). Because bit 1 was

already blown, the end result will be 0011 (code 3).

• Before powering down the device after programming, observe

the recommended delay, to ensure that the last VPH pulse has

decayed before voltage drops to the VPL voltage. This will avoid

the generation of overlapping VPL and VPH pulses. At the end of

a Lock Device mode code sequence, the delay is not necessary.

• Programming order is important in both Try Value mode and

in Blow Fuse mode. There will be a slight parametric shift in

sensitivity after programming the temperature coefficient, and a

slight quiescent voltage shift with polarity. Subsequent changes

to sensitivity can cause a shift in the quiescent output voltage.

The following order is recommended:

a. Polarity

b. TC Register

c. Sens Coarse

d. QVO Coarse

e. Sens Fine

g. QVO Fine

The Clamp Bit register can be programmed at any point in the

order, as no parametric shift is observed due to clamps.

• The actual distribution of parametric programming ranges are

wider than the specified programming ranges, in order to take

in to account manufacturing spread. The maximum possible

attainable range can be used with the understanding that other

specified parameters might be out of datasheet specification in

the extended range. (For an example, see the chart Sensitivity

Temperature Coefficient Range, in the Typical Characteristics

section.)

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

20

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

Programming Example

This example demonstrates the programming of the devices by

setting the register for Sensitivity Temperature Coefficient to

00110.

1. Power-on the system. This will reset the unprogrammed bits

in all registers to 0. The device enters the Initial state.

2. Send one VPH pulse to enter the Mode Selection state.

3. Send one VPL pulse to select Try Value mode.

4. Send one V

pulse to enter the Register Selection state.

PH

5. Send four VPL pulses to select the TC register.

6. Send one VPH pulse to enter Bitfield Selection state (Write

mode). The TC register is reset to 00000 (assuming all of

those bitfields have intact fuses).

7. Send five V

pulses to set bitfields 0 and 2 (00101).

PL

Now we can measure the device output to see if this is the

desired value. We may find that the value we programmed is not

correct. So we will proceed to change it, as follows:

8. Send one V

pulse to increase the code to 6 (setting bitfields

PL

1 and 2: 00110).

We measure the device and find that this is the correct TC we

require. We are finished with trying values, and now want to set

the value permanently. In the following steps, remember that

blowing fuses is done one bit at a time.

9. Send one VPH pulse to exit Bitfield Selection mode. (The

device returns to the Mode Selection state.)

10. RESET the device by powering it off and on.

11. Send one VPH pulse to enter the Mode Selection state.

12. Send two VPL pulses to select Blow Fuse mode.

13. Send one VPH pulse to enter the Register Selection state.

14. Send four VPL pulses to select the TC register.

15. Send one VPH pulse to enter Bitfield Selection state (Write

Mode). The TC register is reset to 00000.

16. Send four VPL pulses to set bit 2 (00100, decimal 4).

17. Send one VPH pulse to exit Bitfield Selection state. The

bitfield fuse is blown, and the device returns to the Mode

Selection state.

One of the two bitfields is programmed. Now we program the

other bitfield.

18. Repeat steps 10 to 15 to select the TC register again. This

time, however, the register resets to 00100, because bit 2 has

been permanently set.

19. Send two VPL pulses to set bit 1 (00010, decimal 2).

20. Send one VPH pulse to exit Bitfield Selection state. The

bitfield fuse is blown, and the device returns to the Mode

Selection state.

After repeating the above steps to program all parameters, we

can lock the device:

21. RESET the device by powering it off and on.

22. Send one V

pulse to enter the Mode Selection state.

PH

23. Send three VPL pulses to select Lock Device mode.

24. Send one VPH pulse to enter the Bitfield Selection state. (We

do not need to select a register for locking the device).

25. Send one VPL pulse to set the Lock bit to 1.

26. Send one VPH pulse to exit Bitfield Selection state. The

bitfield fuse is blown, and the device returns to the Mode

Selection state.

27. Programming the device is complete. Optionally, test the

results, or power-off the device.

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

21

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

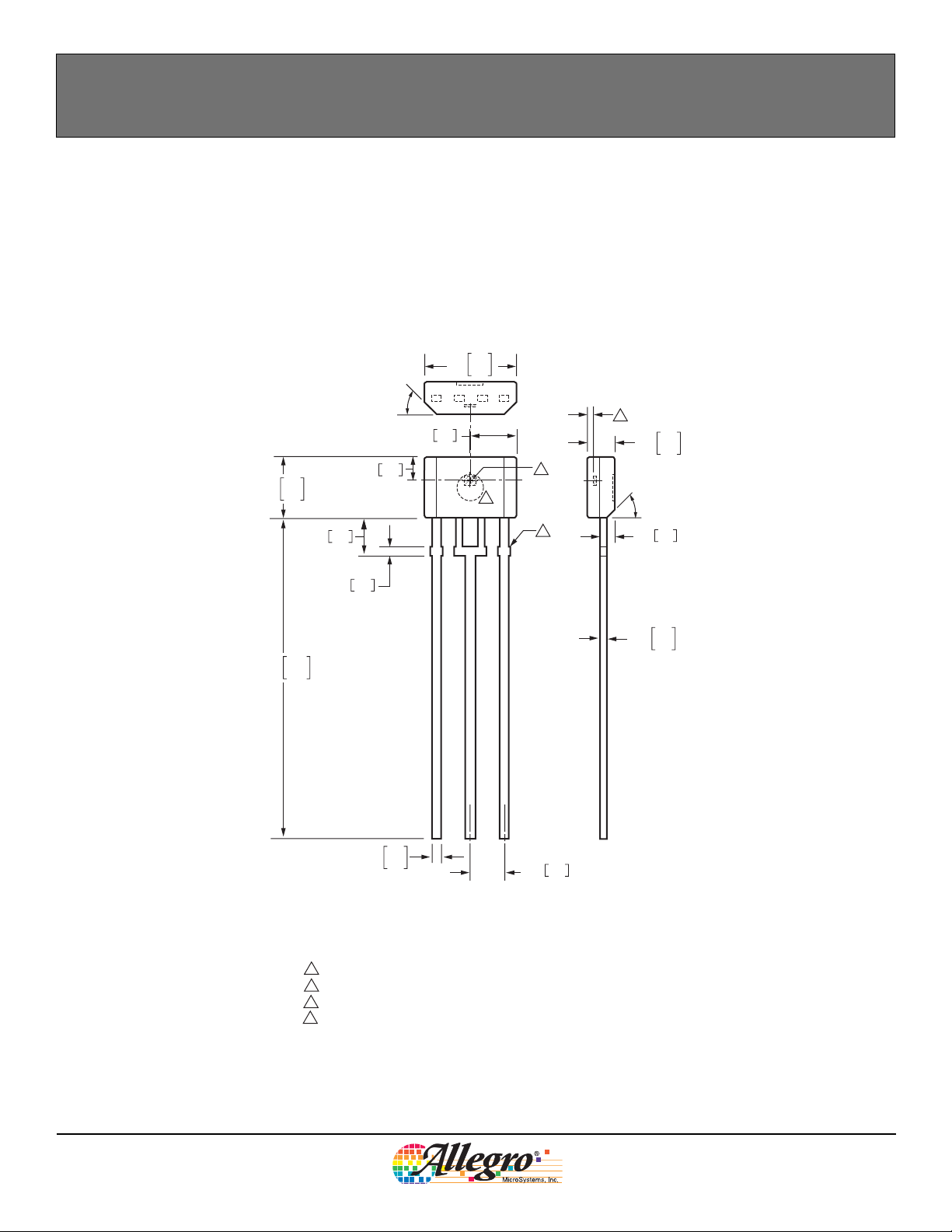

Package KB, 3-Pin SIP

.208

5.28

.203

5.16

45°

.138

.133

3.51

3.38

.085

MAX

2.16

.0520

NOM

BSC

1.32

.1025

NOM

2.60

D

B

A

C

.063

1.60

.059

1.50

45°

BSC

.033

0.84

REF

.020

0.51

REF

.600

15.24

.560

14.22

231

.023

0.58

.018

0.46

Dimensions in inches

Millimeters in brackets, for reference only

Dimensions exclusive of mold flash, gate burrs, or dambar protrusions

Exact case and lead configuration at supplier discretion within limits shown

A

Dambar removal protrusion (6X)

B

Ejector mark on opposite side

C

Active Area Depth .0165 [0.42] NOM

Hall element (not to scale)

D

.075

NOM

1.91

.0173

.0138

0.44

0.35

A1373-DS, Rev. 3

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

22

A1373 and A1374

High Precision, Output Pin Programmable, Linear Hall Effect Sensors

A1373-DS, Rev. 3

The products described herein are manufactured under one or more of

the following U.S. patents: 5,045,920; 5,264,783; 5,442,283; 5,389,889;

5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719; 5,686,894;

5,694,038; 5,729,130; 5,917,320; and other patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such de par tures from the detail spec i fi ca tions as may be required

to permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to

verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components in

life-support devices or sys tems without express written approval.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable.

How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty for its

use; nor for any in fringe ment of patents or other rights of third parties

which may result from its use.

Copyright © 2005, Allegro MicroSystems, Inc.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

23

Loading...

Loading...