查询A1180供应商查询A1180供应商

Sensitive Two-Wire Field-Programmable Chopper-Stabilized

Package LH, 3-pin SOT

1. VCC

2. No connection

3. GND

Package UA, 3-pin SIP

A1180/81/82/83

Unipolar Hall-Effect Switches

The A1180, A1181, A1182, and A1183 devices are sensitive, two-wire, unipolar,

Hall effect switches. The operate point, BOP, can be fi eld-programmed, after fi nal

3

NC

packaging of the sensor and placement into the application. This advanced feature

allows the optimization of the sensor switching performance, by effectively

accounting for variations caused by mounting tolerances for the device and the

target magnet.

This family of devices are produced on the Allegro MicroSystems advanced

BiCMOS wafer fabrication process, which implements a patented, high-frequency,

chopper-stabilization technique that achieves magnetic stability and eliminates

the offsets that are inherent in single-element devices exposed to harsh application environments. Commonly found in a number of automotive applications,

the A1180-83 family of devices are utilized to sense: seat track position, seat belt

buckle presence, hood/trunk latching, and shift selector position.

1. VCC

2. GND

3. GND

1 2 3

AB SO LUTE MAX I MUM RAT INGS

Supply Voltage, V

Reverse-Supply Voltage, V

Magnetic Flux Density, B.........................Unlimited

Operating Temperature

Ambient, T

Ambient, T

Maximum Junction, T

Storage Temperature, T

..........................................28 V

CC

, Range E..................–40ºC to 85ºC

A

, Range L................–40ºC to 150ºC

A

........................–18 V

RCC

........................165ºC

J(max)

.................. –65ºC to 170ºC

S

Two-wire unipolar switches are particularly advantageous in price-sensitive applications, because they require one less wire than the more traditional open-collector output switches. Additionally, the system designer gains inherent diagnostics

because output current normally fl ows in either of two narrowly-specifi ed ranges.

Any output current level outside of these two ranges is a fault condition. The

A1180-83 family of devices also features on-chip transient protection, and a Zener

clamp to protect against overvoltage conditions on the supply line.

The output currents of the A1181 and A1183 switch

HIGH in the presence of a south

polarity magnetic fi eld of suffi cient strength; and switch LOW otherwise, including

when there is no signifi cant magnetic fi eld present. The A1180 and A1182 have

inverted output current levels: switching LOW in the presence of a south polarity

magnetic fi eld of suffi cient strength, and HIGH otherwise. The devices also differ in

their specifi ed LOW current supply levels.

Both devices are offered in two package styles: LH, a SOT-23W miniature lowprofi le package for surface-mount applications, and UA, a three-lead ultramini

Single Inline Package (SIP) for through-hole mounting. Each package is available

in a lead (Pb) free version (suffi x, –T) with 100% matte tin plated leadframe.

Factory-programmed versions are also available. Refer to: A1140, A1141, A1142,

A1143, A1145, and A1146.

Features and Benefi ts

Chopper stabilization

Low switchpoint drift over operating

temperature range

Low stress sensitivity

Field-programmable for optimized

switchpoints

On-chip protection

Supply transient protection

Reverse-battery protection

On-board voltage regulator

3.5 V to 24 V operation

A1180-DS, Rev. 2

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

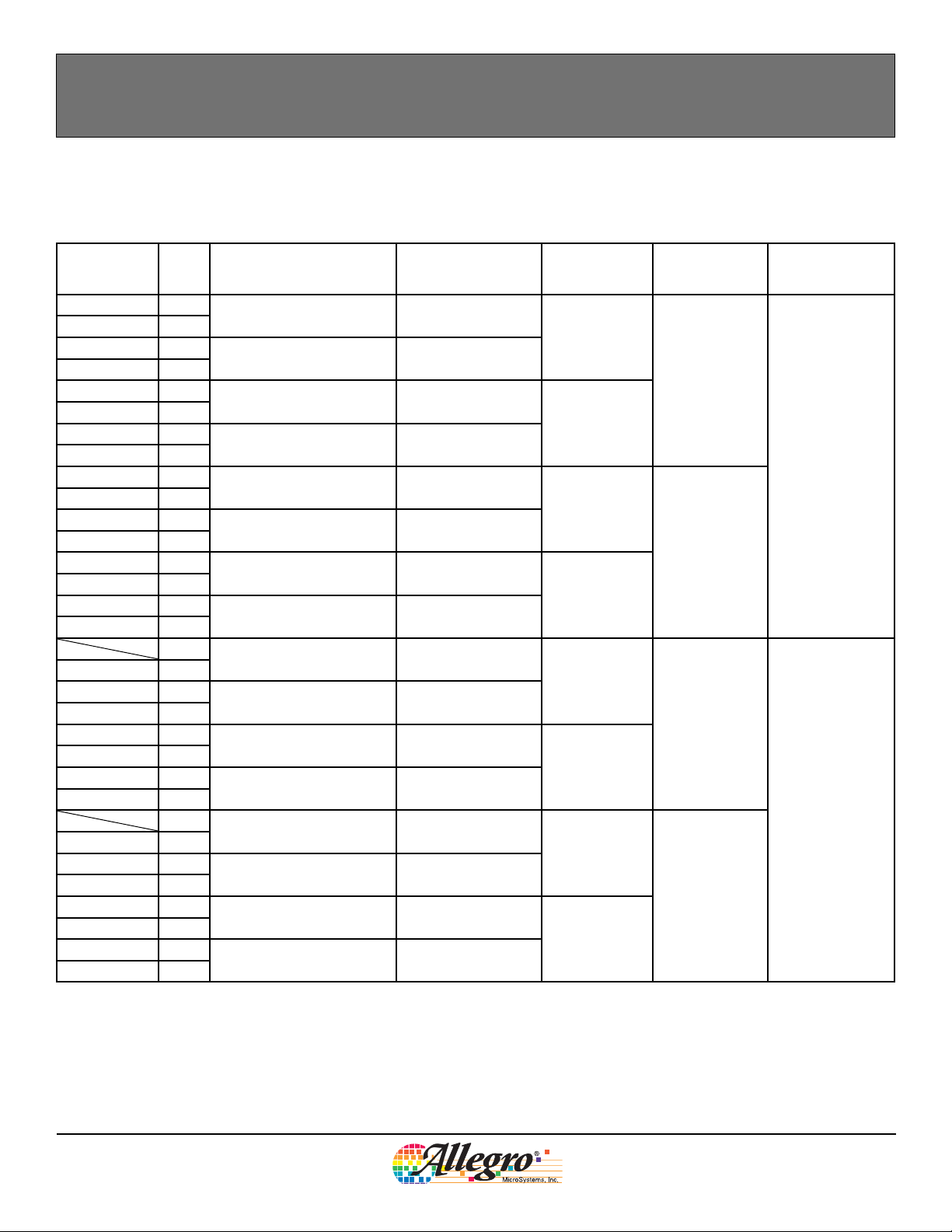

Product Selection Guide

Part Number

A1180ELHLT –

A1180ELHLT-T Yes

A1180EUA –

A1180EUA-T Yes

A1180LLHLT –

A1180LLHLT-T Yes

A1180LUA –

A1180LUA-T Yes

A1181ELHLT –

A1181ELHLT-T Yes

A1181EUA –

A1181EUA-T Yes

A1181LLHLT –

A1181LLHLT-T Yes

A1181LUA –

A1181LUA-T Yes

A1182ELHLT

A1182ELHLT-T Yes

A1182EUA –

A1182EUA-T Yes

A1182LLHLT –

A1182LLHLT-T Yes

A1182LUA –

A1182LUA-T Yes

A1183ELHLT

A1183ELHLT-T Yes

A1183EUA –

A1183EUA-T Yes

A1183LLHLT –

A1183LLHLT-T Yes

A1183LUA –

A1183LUA-T Yes

1

Contact Allegro for additional packing options.

2

South (+) magnetic fields must be of sufficient strength.

3

These variants are in production but have been determined to be NOT FOR NEW DESIGN. This classification indicates that sale of this device is cur-

Pb-

free

7-in. reel, 3000 pieces/reel Surface mount

Bulk, 500 pieces/bag 4-pin SIP through hole

7-in. reel, 3000 pieces/reel Surface mount

Bulk, 500 pieces/bag 4-pin SIP through hole

7-in. reel, 3000 pieces/reel Surface mount

Bulk, 500 pieces/bag 4-pin SIP through hole

7-in. reel, 3000 pieces/reel Surface mount

Bulk, 500 pieces/bag 4-pin SIP through hole

3

–

7-in. reel, 3000 pieces/reel Surface mount

Bulk, 500 pieces/bag 4-pin SIP through hole

7-in. reel, 3000 pieces/reel Surface mount

Bulk, 500 pieces/bag 4-pin SIP through hole

3

–

7-in. reel, 3000 pieces/reel Surface mount

Bulk, 500 pieces/bag 4-pin SIP through hole

7-in. reel, 3000 pieces/reel Surface mount

Bulk, 500 pieces/bag 4-pin SIP through hole

Packing

1

Mounting

Ambient, T

(°C)

–40 to 85

–40 to 150

–40 to 85

–40 to 150

–40 to 85

–40 to 150

–40 to 85

–40 to 150

A

Output

South (+) Field

Low

High

Low

High

Supply Current at

Low Output, I

2

(mA)

2 to 5

5 to 6.9

CC(L)

rently restricted to existing customer applications. The device should not be purchased for new design applications because obsolescence in the near

future is probable. Samples are no longer available. Status date change May 2, 2005.

A1180-DS, Rev. 2

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

2

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

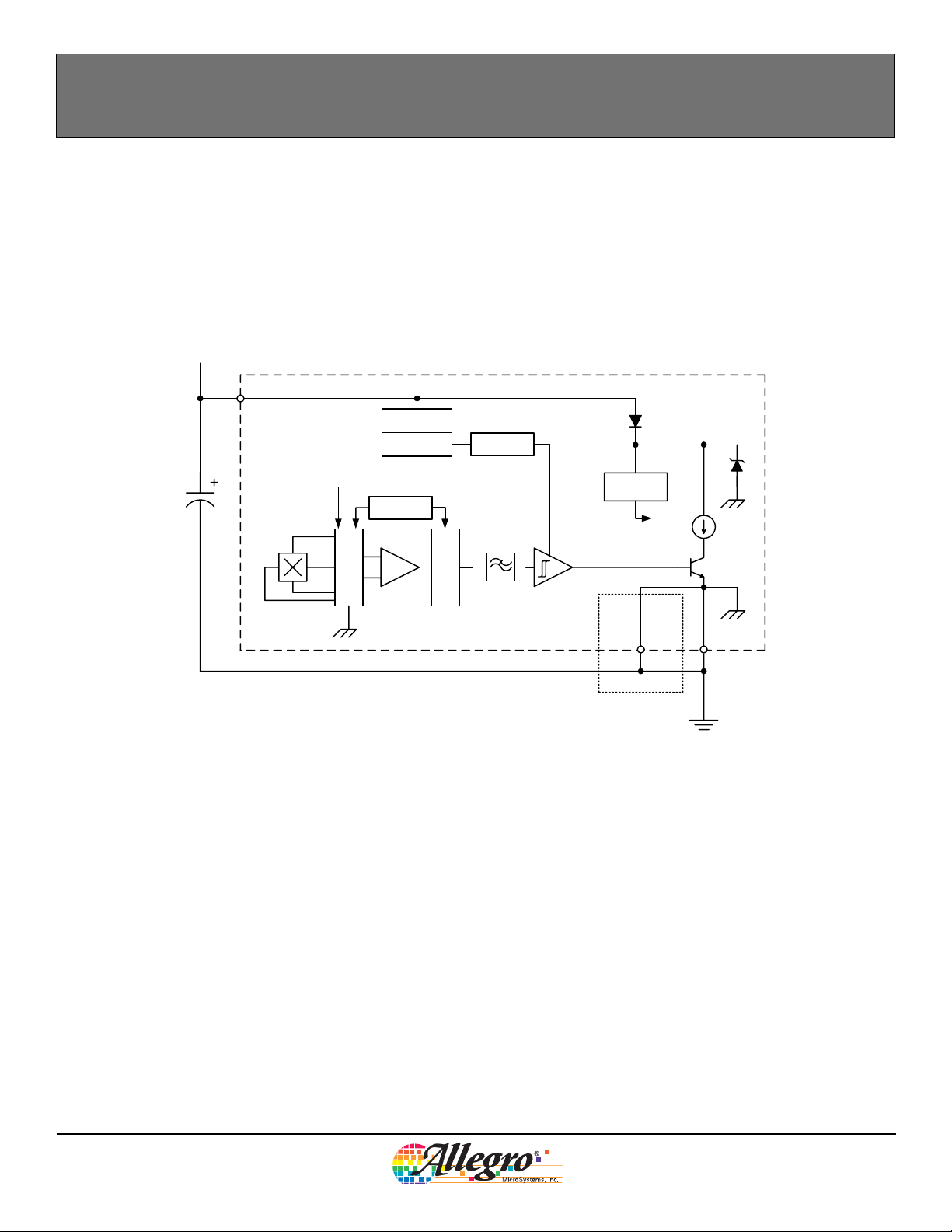

Functional Block Diagram

V+

VCC

Program/Lock

0.01 uF

Dynamic Offset

Cancellation

Programming

Logic

Clock/Logic

Amp

Offset

Regulator

Low-Pass

Filter

Sample and Hold

GND

Package UA Only

GND

A1180-DS, Rev. 2

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

3

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

ELECTRICAL CHARACTERISTICS over the operating voltage and temperature range, unless otherwise specifi ed

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Supply Voltage

Supply Current

1

2

Supply Zener Clamp Voltage V

Supply Zener Clamp Current I

Reverse Supply Current I

Output Slew Rate

3

Chopping Frequency f

Power-On Time

Power-On State

1

VCC represents the generated voltage between the VCC pin and the GND pin.

2

Relative values of B use the algebraic convention, where positive values indicate south magnetic polarity, and negative values indicate north magnetic

polarity; therefore greater B values indicate a stronger south polarity fi eld (or a weaker north polarity fi eld, if present).

3

Measured without bypass capacitor between VCC and GND. Use of a bypass capacitor results in slower current change.

4Measured with and without bypass capacitor of 0.01 μF. Adding a larger bypass capacitor causes longer Power-On Time.

5

POS is defi ned as true only with a VCC slew rate of 25 mV / μs or greater. Operation with a VCC slew rate less than 25 mV / μs can permanently harm

device performance.

6

POS is undefi ned for t > ton or BRP < B < BOP .

4

5,6

V

CC

Device powered on 3.5 – 24 V

B >BOP for A1180; B <BRP for A1181 2 – 5 mA

I

CC(L)

I

CC(H)

Z(supply)ICC

Z(supply)VZ(supply)

RCC

B >B

OP

B >BOP for A1181, A1183

B <B

RP

= I

CC(L)(max)

V

= –18 V – – –1.6 mA

RCC

No bypass capacitor; capacitance of the

di/dt

oscilloscope performing the measurement

= 20 pF

C

t

on

POS ton ≤ t

After factory trimming; with and without

bypass capacitor (C

on(max)

for A1182; B <BRP for A1183 5 – 6.9 mA

for A1180, A1182

12 – 17 mA

+ 3 mA; TA = 25°C 28 – 40 V

= 28 V – –

CC(L)(max)

+ 3 mA

mA

I

– 36 – mA/μs

– 200 – kHz

= 0.01 μF)

BYP

; V

slew rate ≥ 25 mV/μs – HIGH – –

CC

––25μs

MAGNETIC CHARACTERISTICS

1

over the operating voltage and temperature range, unless otherwise specifi ed

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Programmable Operate Point Range B

Initial Operate Point Range B

Switchpoint Step Size

2

OPrange

OPinitVCC

B

RES

ICC = I

ICC = I

VCC = 5 V, TA = 25°C 4 8 12 G

for A1180 and A1182

CC(H)

for A1181 and A1183

CC(L)

60 – 200 G

= 12 V – 33 60 G

Switchpoint setting – 5 – Bit

Number of Programming Bits

Temperature Drift of B

OP

Hysteresis B

1

Relative values of B use the algebraic convention, where positive values indicate south magnetic polarity, and negative values indicate north magnetic

polarity; therefore greater B values indicate a stronger south polarity fi eld (or a weaker north polarity fi eld, if present).

2

The range of values specifi ed for B

A1180-DS, Rev. 2

is a maximum, derived from the cumulative programming bit errors.

RES

ΔB

–

Programming locking – 1 – Bit

OP

HYS

B

HYS

= BOP – B

RP

– – ±20 G

51530G

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

4

A1180/81/82/83

10

12

14

16

18

20

3.5

12

24

3.5

12

24

3.5

12

24

3.5

12

24

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

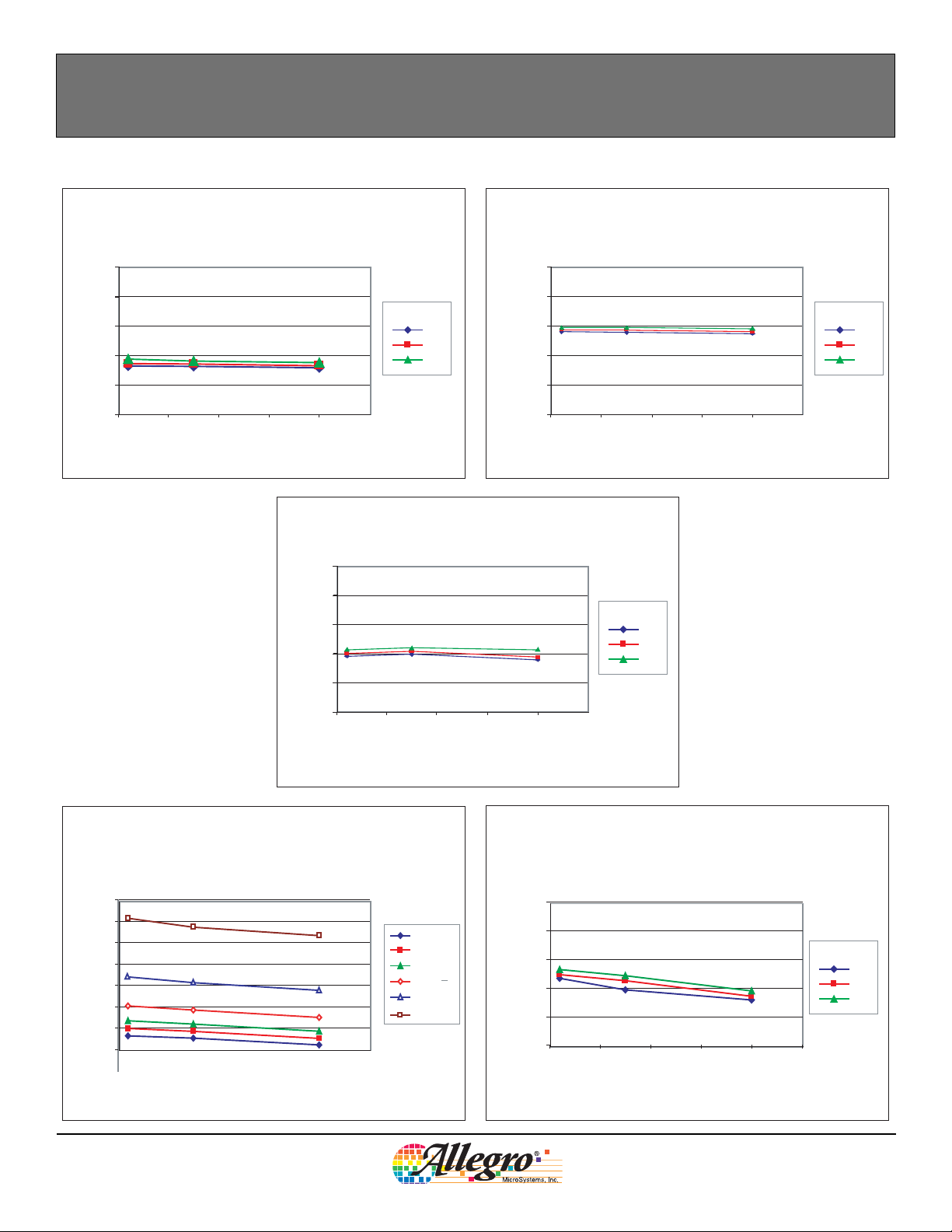

Characteristic Data

I

versus Ambient Temperature

CC(L)

at Various Levels of V

CC

(A1180, A1181)

10

10

I

versus Ambient Temperature

CC(L)

at Various Levels of V

(A1182, A1183)

CC

8

6

(mA)

4

CC(L)

I

2

0

-50 0 50 100 150 200

Ambient Temperature, TA(°C)

(mA)

CC(H)

I

-50 0 50 100 150 200

VCC(V)

I

versus Ambient Temperature

CC(H)

at Various Levels of V

(A1180, A1181, A1182, A1183)

8

6

(mA)

4

CC(L)

I

2

0

-50 0 50 100 150 200

Ambient Temperature, TA(°C)

CC

VCC(V)

VCC(V)

200

175

(G)

150

OP

125

100

75

Average B

50

25

A1180-DS, Rev. 2

Ambient Temperature, T

Average BOPBits versus Ambient Temperature

(A1180, A1181, A1182, A1183)

(°C)

A

Hysteresis versus Ambient Temperature

at Various Levels of V

CC

(A1180, A1181, A1182, A1183)

30

(G)

HYS

B

25

20

15

10

5

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

B

OPinit

B

it 1

B

it 2

B

it 3

B

it 4

B

it 5

0

-50 0 50 100 150 200 -50 0 50 100 150 200

Ambient Temperature, T

(°C) Ambient Temperature, TA(°C)

A

VCC(V)

5

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

Device Qualifi cation Program

Contact Allegro for information.

EMC (Electromagnetic Compatibility) Requirements

Contact your local representative for EMC results.

Test Name Reference Specifi cation

ESD – Human Body Model AEC-Q100-002

ESD – Machine Model AEC-Q100-003

Conducted Transients ISO 7637-1

Direct RF Injection ISO 11452-7

Bulk Current Injection ISO 11452-4

TEM Cell ISO 11452-3

A1180-DS, Rev. 2

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

6

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

THERMAL CHARACTERISTICS may require derating at maximum conditions, see application information

Characteristic Symbol Test Conditions* Value Units

Package LH, 1-layer PCB with copper limited to solder pads 228 ºC/W

Package Thermal Resistance

R

θJA

Package LH, 2-layer PCB with 0.463 in.

connected by thermal vias

Package UA, 1-layer PCB with copper limited to solder pads 165 ºC/W

*Additional thermal information available on Allegro Web site.

Power Derating Curve

25

24

23

22

21

(V)

20

CC

19

18

17

16

15

14

13

12

11

10

9

Maximum Allowable V

8

7

6

5

4

3

2

2-layer PCB, Package LH

(R

= 110 ºC/W)

θJA

1-layer PCB, Package UA

(R

= 165 ºC/W)

θJA

1-layer PCB, Package LH

(R

= 228 ºC/W)

θJA

20 40 60 80 100 120 140 160 180

Temperature (ºC)

2

of copper area each side

V

CC(max)

V

CC(min)

110 ºC/W

A1180-DS, Rev. 2

Power Dissipation versus Ambient Temperature

1900

1800

1700

1600

1500

1400

1300

(mW)

D

Power Dissipation, P

1200

1100

1000

900

800

700

600

500

400

300

200

2-layer PCB, Package LH

(R

θJA

= 110 ºC/W)

1-layer

(R

PCB, Pa

θ

JA

= 165 ºC/W)

1-lay

e

rP

(R

θ

J

=

A

22

ckage

UA

CB, Package LH

8ºC

/

W

)

100

0

20 40 60 80 100 120 140 160 180

Temperature (°C)

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

7

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

Functional Description

Operation

The output, I

, of the A1180 and A1182 devices switch low

CC

after the magnetic fi eld at the Hall sensor exceeds the oper-

ate point threshold, BOP. When the magnetic fi eld is reduced to

below the release point threshold, BRP, the device output goes

high. The differences between the magnetic operate and release

point is called the hysteresis of the device, B

. This built-

HYS

I+

I

CC(H)

I

Switch to Low

CC

Switch to High

I

CC(L)

0

B–

RP

B

B

OP

B+

in hysteresis allows clean switching of the output even in the

presence of external mechanical vibration and electrical noise.

The A1181 and A1183 devices switch with opposite polarity for

similar BOP and BRP values, in comparison to the A1180 and

A1183 (see fi gure 1).

I+

I

CC(H)

I

Switch to Low

CC

Switch to High

I

CC(L)

0

B–

RP

B

B

B+

OP

B

HYS

(A) A1180 and A1182

Figure 1. Alternative switching behaviors are available in the A118x device family. On the horizontal axis, the B+ direction indicates

increasing south polarity magnetic fi eld strength, and the B– direction indicates decreasing south polarity fi eld strength (including the

case of increasing north polarity).

A1180-DS, Rev. 2

(B) A1181 and A1183

B

HYS

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

8

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

Chopper Stabilization Technique

A limiting factor for switchpoint accuracy when using Hall

effect technology is the small signal voltage developed across

the Hall element. This voltage is proportionally small relative to

the offset that can be produced at the output of the Hall sensor

device. This makes it diffi cult to process the signal and maintain

an accurate, reliable output over the specifi ed temperature and

voltage range.

Chopper stabilization is a unique approach used to minimize

Hall offset on the chip. The Allegro patented technique, dynamic

quadrature offset cancellation, removes key sources of the output

drift induced by temperature and package stress. This offset

reduction technique is based on a signal modulation-demodulation process. The undesired offset signal is separated from the

magnetically induced signal in the frequency domain through

modulation. The subsequent demodulation acts as a modulation

process for the offset causing the magnetically induced signal

to recover its original spectrum at base band while the dc offset

becomes a high frequency signal. Then, using a low-pass fi lter,

the signal passes while the modulated dc offset is suppressed.

The chopper stabilization technique uses a 200 kHz high frequency clock. For demodulation process, a sample-and-hold

technique is used, where the sampling is performed at twice

the chopper frequency (400KHz). The sampling demodulation

process produces higher accuracy and faster signal processing

capability. Using this chopper stabilization approach, the chip is

desensitized to the effects of temperature and stress. This technique produces devices that have an extremely stable quiescent

Hall output voltage, is immune to thermal stress, and has precise

recoverability after temperature cycling. This technique is made

possible through the use of a BiCMOS process which allows the

use of low-offset and low-noise amplifi ers in combination with

high-density logic integration and sample-and-hold circuits.

The repeatability of switching with a magnetic fi eld is slightly

affected using a chopper technique. The Allegro high frequency

chopping approach minimizes the affect of jitter and makes it

imperceptible in most applications. Applications that may notice

the degradation are those that require the precise sensing of alternating magnetic fi elds such as ring magnet speed sensing. For

those applications, Allegro recommends the “low jitter” family

of digital sensors.

A1180-DS, Rev. 2

Regulator

Clock/Logic

Low-Pass

Hall Element

Amp

Figure 2. Chopper stabilization circuit (dynamic quadrature offset cancellation)

Filter

Hold

Sample and

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

9

A1180/81/82/83

GND

A118x

VCC

V+

0.01 uF

A

B

B

GND

ECU

Package UA Only

A

B

Maximum separation 5 mm

R

SENSE

C

BYP

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

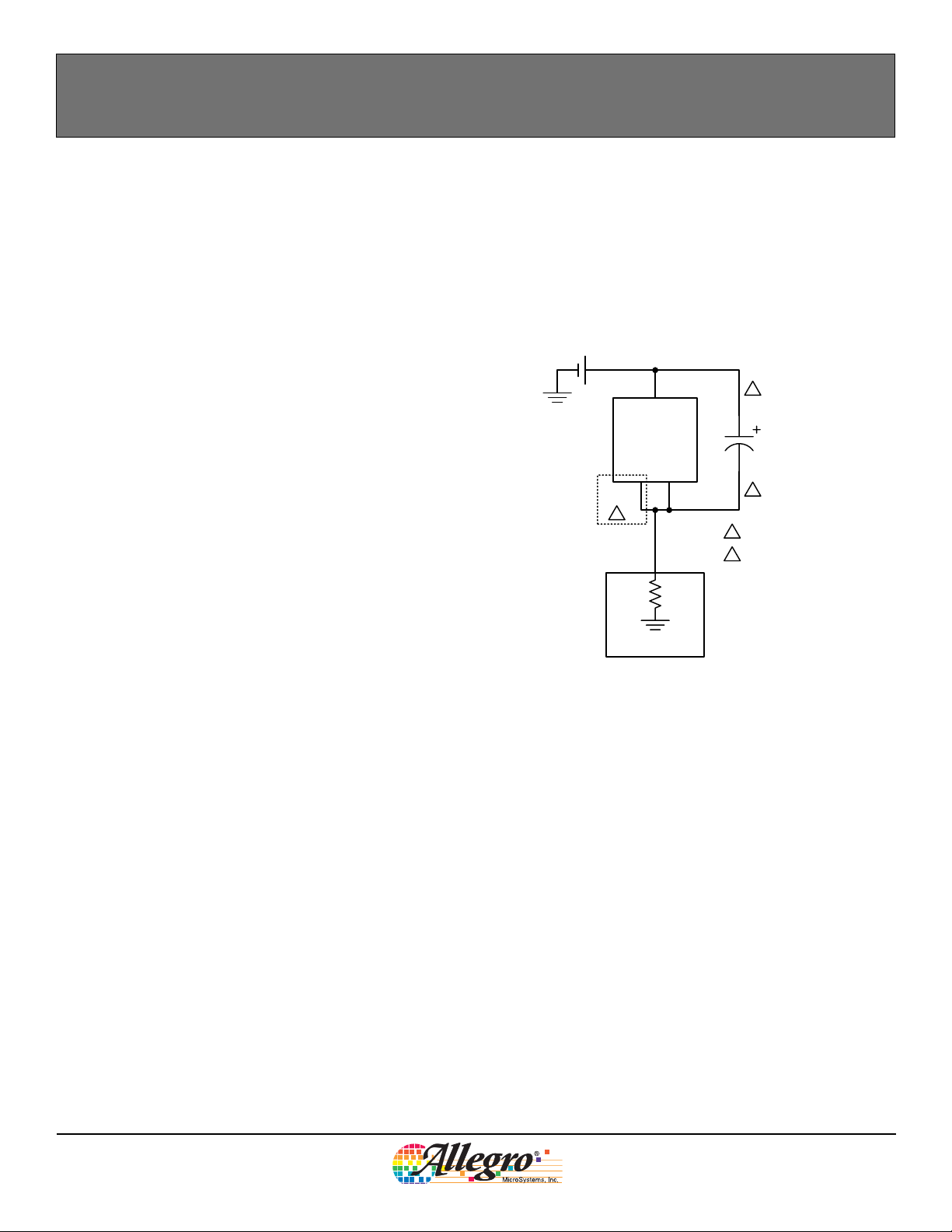

Application Information

For additional general application information, visit the Allegro

MicroSystems Web site at www. allegromicro.com.

Typical Application Circuit

The A118x family of devices must be protected by an external

bypass capacitor, C

and the ground, GND, of the device. C

noise and the noise generated by the chopper-stabilization function. As shown in fi gure 3, a 0.01 μF capacitor is typical.

, connected between the supply, VCC,

BYP

reduces both external

BYP

Installation of C

must ensure that the traces that connect it to

BYP

the A118x pins are no greater than 5 mm in length.

All high-frequency interferences conducted along the supply

lines are passed directly to the load through C

, and it serves

BYP

only to protect the A118x internal circuitry. As a result, the load

ECU (electronic control unit) must have suffi cient protection,

other than C

, installed in parallel with the A118x.

BYP

A series resistor on the supply side, RS (not shown), in combination with C

, creates a fi lter for EMI pulses. (Additional

BYP

information on EMC is provided on the Allegro MicroSystems

Web site.)

When determining the minimum VCC requirement of the A118x

device, the voltage drops across RS and the ECU sense resistor,

R

, must be taken into consideration. The typical value for

SENSE

R

is approximately 100 Ω.

SENSE

Figure 3. Typical application circuit

A1180-DS, Rev. 2

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

10

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

Power Derating

The device must be operated below the maximum junction

temperature of the device, T

. Under certain combinations of

J(max)

peak conditions, reliable operation may require derating supplied power or improving the heat dissipation properties of the

application. This section presents a procedure for correlating

factors affecting operating TJ. (Thermal data is also available on

the Allegro MicroSystems Web site.)

The Package Thermal Resistance, R

, is a fi gure of merit sum-

θJA

marizing the ability of the application and the device to dissipate

heat from the junction (die), through all paths to the ambient air.

Its primary component is the Effective Thermal Conductivity,

K, of the printed circuit board, including adjacent devices and

traces. Radiation from the die through the device case, R

relatively small component of R

. Ambient air temperature,

θJA

θJC

, is

TA, and air motion are signifi cant external factors, damped by

overmolding.

The effect of varying power levels (Power Dissipation, PD), can

be estimated. The following formulas represent the fundamental

relationships used to estimate TJ, at PD.

PD = VIN × I

ΔT = PD × R

IN

(2)

θJA

(1)

Example: Reliability for V

minimum-K PCB.

Observe the worst-case ratings for the device, specifi cally:

R

165°C/W, T

θJA =

I

CC(max) = 17

J(max) =

mA.

Calculate the maximum allowable power level, P

invert equation 3:

ΔT

max

= T

– TA = 165 °C – 150 °C = 15 °C

J(max)

This provides the allowable increase to TJ resulting from internal

power dissipation. Then, invert equation 2:

P

D(max)

= ΔT

max

÷ R

Finally, invert equation 1 with respect to voltage:

V

CC(est)

= P

D(max)

÷ I

The result indicates that, at TA, the application and device can

dissipate adequate amounts of heat at voltages ≤V

Compare V

CC(est)

to V

able operation between V

R

θJA

V

CC(max)

. If V

is reliable under these conditions.

CC(est)

≥ V

CC(max)

at TA = 150°C, package UA, using

CC

165°C, V

= 15°C ÷ 165 °C/W = 91 mW

θJA

CC(max)

CC(max)

CC(est)

CC(max) =

= 91 mW ÷ 17 mA = 5 V

. If V

CC(est)

and V

24 V, and

≤ V

CC(max)

requires enhanced

CC(max)

, then operation between V

D(max)

CC(est)

, then reli-

. First,

.

CC(est)

and

TJ = TA + ΔT (3)

For example, given common conditions such as: T

V

= 12 V, I

CC

P

= VCC × I

D

ΔT = PD × R

= 4 mA, and R

CC

= 12 V × 4 mA = 48 mW

CC

= 48 mW × 140 °C/W = 7°C

θJA

θJA

= 140 °C/W, then:

TJ = TA + ΔT = 25°C + 7°C = 32°C

A worst-case estimate, P

able power level (V

at a selected R

A1180-DS, Rev. 2

and TA.

θJA

CC(max)

, represents the maximum allow-

D(max)

, I

), without exceeding T

CC(max)

= 25°C,

A

J(max)

,

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

11

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

Programming Protocol

The operate switchpoint, B

, can be fi eld-programmed. To do

OP

so, a coded series of voltage pulses through the VCC pin is used

to set bitfi elds in onboard registers. The effect on the device

output can be monitored, and the registers can be cleared and

set repeatedly until the required BOP is achieved. To make the

setting permanent, bitfi eld-level solid state fuses are blown, and

fi nally, a device-level fuse is blown, blocking any further coding. It is not necessary to program the release switchpoint, BRP ,

because the difference between BOP and BRP , referred to as the

hysteresis, B

The range of values between B

HYS

, is fi xed.

OP(min)

and B

OP(max)

is scaled to

31 increments. The actual change in magnetic fl ux (G) repre-

sented by each increment is indicated by B

(see the Operating

RES

Characteristics table; however, testing is the only method for

verifying the resulting B

). For programming, the 31 incre-

OP

ments are individually identifi ed using 5 data bits, which are

physically represented by 5 bitfi elds in the onboard registers.

By setting these bitfi elds, the corresponding calibration value is

programmed into the device.

Three voltage levels are used in programming the device: a low

voltage, V

, a minimum required to sustain register settings; a

PL

mid-level voltage, VPM , used to increment the address counter

in the device; and a high voltage, VPH , used to separate sets of

VPM pulses (when short in duration) and to blow fuses (when

long in duration). A fourth voltage level, essentially 0 V, is used

to clear the registers between pulse sequences. The pulse values

are shown in the Programming Protocol Characteristics table and

in fi gure 4.

V+

V

PH

V

PM

V

PL

T

0

T

d(1)

Figure 4. Pulse amplitudes and durations

d(P)

T

d(0)

t

Additional information on device programming and programming products is available on www. allegromicro.com. Programming hardware is available for purchase, and programming

software is available free of charge.

Code Programming. Each bitfi eld must be individually set. To

do so, a pulse sequence must be transmitted for each bitfi eld that

is being set to 1. If more than one bitfi eld is being set to 1, all

pulse sequences must be sent, one after the other, without allowing VCC to fall to zero (which clears the registers).

The same pulse sequence is used to provisionally set bitfi elds as

is used to permanently set bitfi eld-level fuses. The only differ-

ence is that when provisionally setting bitfi elds, no fuse-blowing

pulse is sent at the end of the pulse sequence.

PROGRAMMING PROTOCOL CHARACTERISTICS, over operating temperature range, unless otherwise noted

Characteristic Symbol Test Conditions Min. Typ. Max. Units

V

Programming Voltage

1

V

V

Programming Current

2

t

Pulse Width

t

t

Pulse Rise Time t

Pulse Fall Time t

1

Programming voltages are measured at the VCC pin.

2

A bypass capacitor with a minimum capacitance of 0.1 μF must be connected from VCC to the GND pin of the A118x device in order to

Minimum voltage range during programming 4.5 5.0 5.5 V

PL

PM

PH

I

PPtr

d(0)

d(1)

d(P)

r

= 11 μs; 5 V → 26 V; C

= 0.1 μF - 190 - mA

BYP

OFF time between programming bits 20 - - μs

Pulse duration for enable and addressing

sequences

Pulse duration for fuse blowing 100 300 - μs

VPL to VPM; VPL to V

VPM to VPL; VPH to V

f

PH

PL

11.5 12.5 13.5 V

25.0 26.0 27.0 V

20 - - μs

5-20μs

5 - 100 μs

provide the current necessary to blow the fuse.

Allegro MicroSystems, Inc.

A1180-DS, Rev. 2

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

12

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

The pulse sequences consist of the following groups of pulses:

1. An enable sequence.

2. A bitfi eld address sequence.

3. When permanently setting the bitfi eld, a long VPH fuse-blow-

ing pulse. (Note: Blown bit fuses cannot be reset.)

4. When permanently setting the bitfi eld, the level of VCC must

be allowed to drop to zero between each pulse sequence, in

order to clear all registers. However, when provisionally setting bitfi elds, V

must be maintained at VPL between pulse

CC

sequences, in order to maintain the prior bitfi eld settings while

preparing to set additional bitfi elds.

Bitfi elds that are not set are evaluated as zeros. The bitfi eld-level

fuses for 0 value bitfi elds are never blown. This prevents inad-

V+

V

PH

V

PM

V

PL

vertently setting the bitfi eld to 1. Instead, blowing the device-

level fuse protects the 0 bitfi elds from being accidentally set in

the future.

When provisionally trying the calibration value, one pulse

sequence is used, using decimal values. The sequence for setting

the value 5

is shown in fi gure 5.

10

When permanently setting values, the bitfi elds must be set indi-

vidually, and 510 must be programmed as binary 101. Bit 3 is

set to 1 (0001002, which is 410), then bit 1 is set to 1 (0000012,

which is 1

). Bit 2 is ignored, and so remains 0.Two pulse

10

sequences for permanently setting the calibration value 5 are

shown in fi gure 6. The fi nal V

pulse is maintained for a longer

PH

period, enough to blow the corresponding bitfi eld-level fuse.

0

Enable Address Clear

Try 5

10

Optional

Monitoring

t

Figure 5. Pulse sequence to provisionally try calibration value 5.

V+

V

PH

V

PM

V

PL

0

Enable

Address

Encode 001002 (410)

Blow BlowEnable

Encode 00001

Figure 6. Pulse sequence to permanently encode calibration value 5 (101 binary, or

bitfi eld address 3 and bitfi eld address 1).

Address

(110)

2

t

A1180-DS, Rev. 2

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

13

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

V+

V

Enabling Addressing Mode. The fi rst segment of code is a

keying sequence used to enable the bitfi eld addressing mode. As

shown in fi gure 7, this segment consists of one short VPH pulse,

one VPM pulse, and one short VPH pulse, with no supply interruptions. This sequence is designed to prevent the device from

being programmed accidentally, such as by noise on the supply

line.

PH

V

PM

V

PL

0

Address Selection. After addressing mode is enabled, the

target bitfi eld address, is indicated by a series of VPM pulses, as

shown in fi gure 8.

Figure 7. Addressing mode enable pulse sequence

t

V+

V

PH

V

PM

V

PL

0

Address 1

Address 2

Address n ( ≤ 31)

t

Figure 8. Pulse sequence to select addresses

V+

V

PH

Falling edge of final BOP address digit

Lock Bit Programming. After the desired B

calibration value

OP

is programmed, and all of the corresponding bitfi eld-level fuses

are blown, the device-level fuse should be blown. To do so, the

lock bit (bitfi eld address 32) should be encoded as 1 and have

its fuse blown. This is done in the same manner as permanently

setting the other bitfi elds, as shown in fi gure 9.

A1180-DS, Rev. 2

V

PM

V

PL

0

Enable

32 pulses

Address Blow

Encode Lock Bit

Figure 9. Pulse sequence to encode lock bit

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

t

14

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

Package LH, 3-Pin (SOT-23W)

3.10

.122

2.90

.114

1.49

3.00

2.70

.118

.106

2.10

1.85

0.55

REF

.083

.073

0.96

.038

NOM

0.50 .020

0.30

.012

.022

.059

3

NOM

0.28

.011

NOM

A

21

1.13

0.87

0.95

BSC

.037

0.15

0.00

.006

.000

.045

.034

8º

0º

0.20

0.13

0.25

MIN

0.25

.010

BSC

Seating Plane

Gauge Plane

.008

.005

.010

1.00

BSC

0.70

.028

BSC

.039

A

B

C

C

Dimensions in millimeters

U.S. Customary dimensions (in.) in brackets, for reference only

Hall element

Active Area Depth 0.28 [.011]

Fits SC–59A Solder Pad Layout

2.40

BSC

0.95

BSC

.094

.037

.122

.117

3.10

2.97

.640

.600

16.26

15.24

.0565

NOM

.085

MAX

Package UA, 3-Pin

.164

4.17

.159

4.04

45°

BSC

.0805

2.04

NOM

1.44

B

2.16

A

231

.019

0.48

.014

0.36

Dimensions in inches

Metric dimensions (mm) in brackets, for reference only

A

Dambar removal protrusion

B

Hall element

.050

BSC

.062

.058

1.27

.031

REF

.017

.014

1.57

1.47

0.79

0.44

0.35

.0195

NOM

0.50

45°

BSC

A1180-DS, Rev. 2

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

15

A1180/81/82/83

Sensitive Two-Wire Field-Programmable Chopper-Stabilized Unipolar Hall Effect Switches

A1180-DS, Rev. 2

The products described herein are manufactured under one or

more of the following U.S. patents: 5,045,920; 5,264,783; 5,442,283;

5,389,889; 5,581,179; 5,517,112; 5,619,137; 5,621,319; 5,650,719;

5,686,894; 5,694,038; 5,729,130; 5,917,320; and other patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such de par tures from the detail spec i fi ca tions as may be required

to permit improvements in the per for mance, reliability, or manufacturability of its products. Before placing an order, the user is cautioned to

verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components in

life-support devices or sys tems without express written approval.

The in for ma tion in clud ed herein is believed to be ac cu rate and reliable. How ev er, Allegro MicroSystems, Inc. assumes no re spon si bil i ty

for its use; nor for any in fringe ment of patents or other rights of third

parties which may result from its use.

Copyright © 2004, 2005 Allegro MicroSystems, Inc.

Allegro MicroSystems, Inc.

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

www.allegromicro.com

16

Loading...

Loading...