查询A3966SLB-T供应商

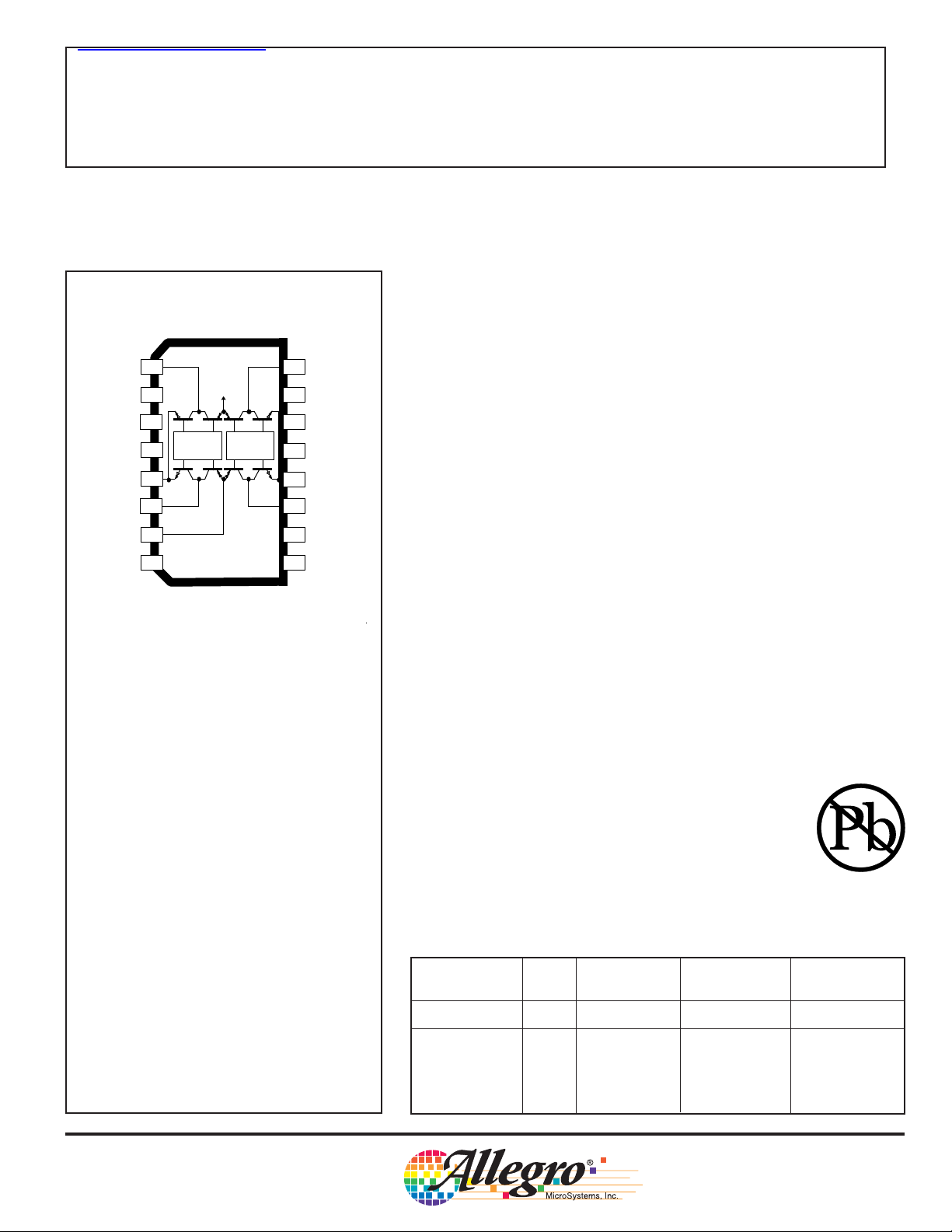

A3966SLB (SOIC)

OUT

PHASE

ENABLE

GROUND

SENSE

OUT

LOAD

SUPPLY

REFERENCE

1

1A

V

2

1

3

1

4

5

1

6

1B

710

V

89

REF

BB

LOGICLOGIC

V

BB

16

OUT

2A

PHASE

15

14

13

12

11

V

CC

RC

ENABLE

GROUND

SENSE

OUT

2B

LOGIC

SUPPLY

RC

Dwg. PP-066-1

2

2

2

ABSOLUTE MAXIMUM RATINGS

Load Supply Voltage, VBB...................... 30 V

Output Current, I

(continuous) .............................. ±650 mA

Logic Supply Voltage, V

Input Voltage, V

Sense Voltage, V

Package Power Dissipation (T

A3966SA ..................................... 2.08 W*

A3966SLB ................................... 1.87 W*

Operating Temperature Range,

T

..................................... -20°C to +85°C

A

Junction Temperature,

T

.................................................. +150°C

J

Storage Temperature Range,

T

................................... -55°C to +150°C

S

Output current rating may be limited by duty cycle,

ambient temperature, and heat sinking. Under any set

of conditions, do not exceed the specified current rating

or a junction temperature of 150°C.

* Per SEMI G42-88 Specification, Thermal Test Board

Standardization for Measuring Junction-to-Ambient

Thermal Resistance of Semiconductor Packages.

(peak) ........... ±750 mA

OUT

.................... 7.0 V

CC

........ -0.3 V to VCC + 0.3 V

in

................................ 1.0 V

S

= 25°C), P

A

D

29319.25C

3966

DUAL FULL-BRIDGE PWM

MOTOR DRIVER

The A3966SA and A3966SLB are designed to drive both windings of a twophase bipolar stepper motor. Each device includes two H-bridges capable of

continuous output currents of ±650 mA and operating voltages to 30 V. Motor

winding current can be controlled by the internal fixed-frequency, pulse-width

modulated (PWM), current-control circuitry. The peak load current limit is set

by the user’s selection of a reference voltage and current-sensing resistors.

Except for package style and pinout, the two devices are identical.

The fixed-frequency pulse duration is set by a user-selected external RC timing

network. The capacitor in the RC timing network also determines a userselectable blanking window that prevents false triggering of the PWM currentcontrol circuitry during switching transitions.

To reduce on-chip power dissipation, the H-bridge power outputs have been

optimized for low saturation voltages. The sink drivers feature the Allegro

patented Satlington® output structure. The Satlington outputs combine the low

voltage drop of a saturated transistor and the high peak current capability of a

Darlington.

For each bridge, a PHASE input controls load-current polarity by selecting the

appropriate source and sink driver pair. For each bridge, an ENABLE input, when

held high, disables the output drivers. Special power-up sequencing is not

required. Internal circuit protection includes thermal shutdown with hysteresis,

ground-clamp and flyback diodes, and crossover-current protection.

The A3966SA is supplied in a 16-pin dual in-line plastic package. The

A3966SLB is supplied in a 16-lead plastic SOIC with copper heat sink tabs. The

power tab is at ground potential and needs no electrical isolation. The A3966SLB

is also available in a lead (Pb) free version, with 100% matte tin leadframe plating.

FEATURES

■ ±650 mA Continuous Output Current

■ 30 V Output Voltage Rating

■ Internal Fixed-Frequency PWM Current Control

■ Satlington Sink Drivers

■ User-Selectable Blanking Window

■ Internal Ground-Clamp & Flyback Diodes

■ Internal Thermal-Shutdown Circuitry

■ Crossover-Current Protection and UVLO Protection

Always order by complete part number:

Part Number Pb-free Packing Package R

A3966SA – Bulk 16-pin DIP 60 38 —

A3966SLB – Bulk

A3966SLB-T Yes Bulk 16-lead SOIC 67 — 6

A3966SLBTR – Tape and Reel with internally

A3966SLBTR-T Yes Tape and Reel fused leads

R

θθ

θJA

θθ

(°C/W)

θθ

θJC

θθ

R

θθ

θJT

θθ

Data Sheet

®

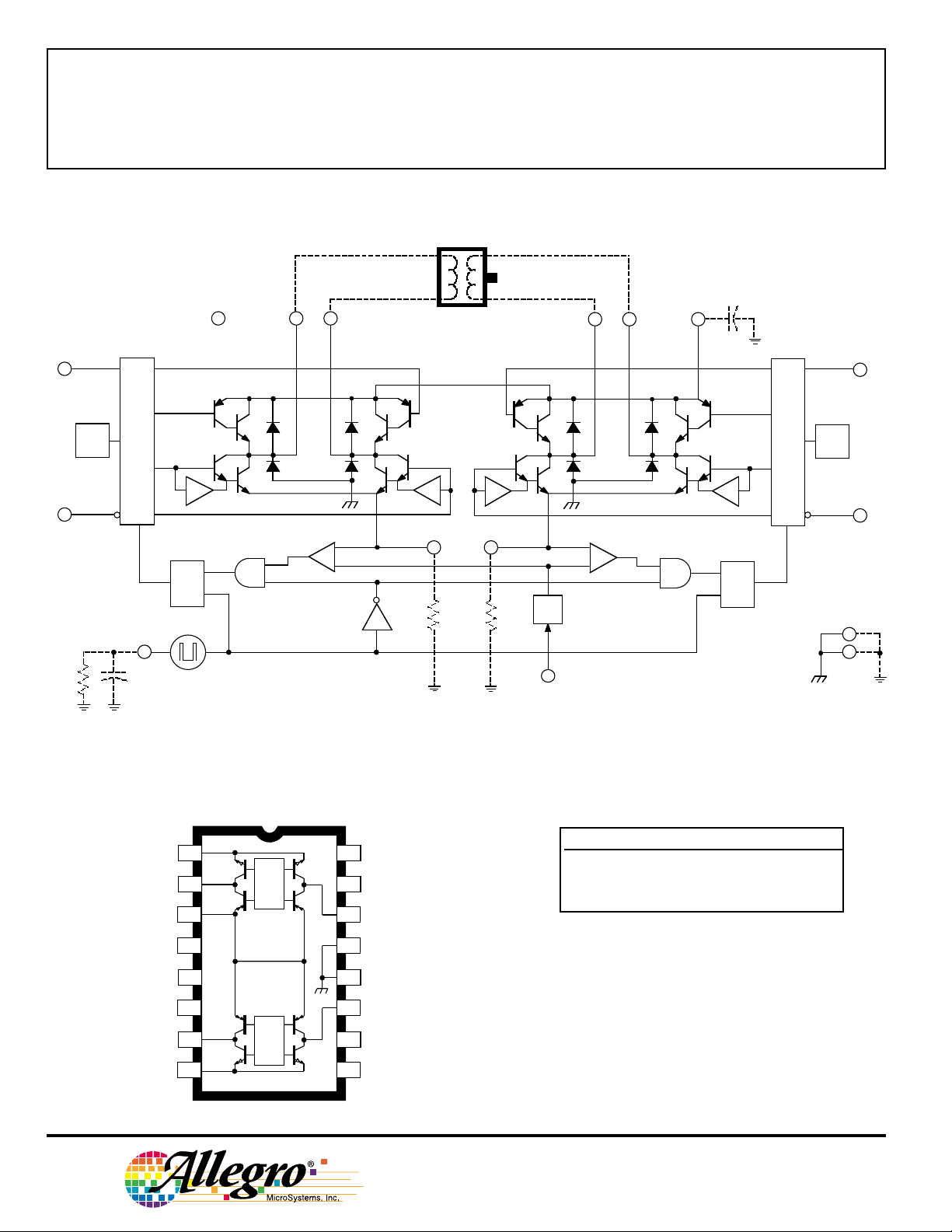

3966

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

LOGIC

SUPPLY

V

CC

PHASE

1

1

FUNCTIONAL BLOCK DIAGRAM

1A

1B

OUT

OUT

V

BB

2A

OUT

2B

OUT

LOAD

SUPPLY

+

PHASE

2

2

ENABLE

R

T

UVLO

& TSD

1

CONTROL LOGIC

1

SOURCE

ENABLE

RC

C

T

SENSE

OUT

LOAD

SUPPLY

REFERENCE

RC

LOGIC

SUPPLY

OUT

SENSE

PWM LATCH

Q

OSC

BLANKING

1

R

S

A3966SA (DIP)

1

1

2

1B

3

V

4

REF

RC

5

V

6

CC

7

2B

8

2

GATE

CURRENT-SENSE

1

LOGIC

V

BB

LOGIC

COMPARATOR

+

–

16

15

14

13

12

11

10

9

1

ENABLE

PHASE

OUT

GROUND

GROUND

OUT

PHASE

ENABLE

UVLO

& TSD

CONTROL LOGIC

ENABLE

2

÷4

REFERENCE

CURRENT-SENSE

COMPARATOR

+

–

2

BLANKING

GATE

2

PWM LATCH

R

S

2

2

SOURCE

ENABLE

Q

GROUND

Dwg. FP-036-6

SENSE

R

1S

SENSE

1

2

R

2S

TRUTH TABLE

PHASE ENABLE OUT

1

1

1A

XH OffOff

HL H L

LL L H

X = Irrelevant

2A

2

2

OUT

A

B

Dwg. PP-066-2

2

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 1998, 2003 Allegro MicroSystems, Inc.

3966

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

ELECTRICAL CHARACTERISTICS at T

V

= 0 V, 56 kΩ & 680 pF RC to Ground (unless noted otherwise)

S

= +25°C, V

A

= 30 V, VCC = 4.75 V to 5.5 V, V

BB

REF

= 2 V,

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Output Drivers

Load Supply Voltage Range V

Output Leakage Current I

Output Saturation Voltage V

CE(SAT)

Clamp Diode Forward Voltage V

Motor Supply Current I

(No Load)

BB(ON)

I

BB(OFF)

BB

CEX

F

Operating, I

V

= 30 V — <1.0 50 µA

OUT

V

= 0 V — <-1.0 -50 µA

OUT

Source Driver, I

Source Driver, I

Sink Driver, I

Sink Driver, I

= ±650 mA, L = 3 mH V

OUT

= -400 mA — 1.7 2.0 V

OUT

= -650 mA — 1.8 2.1 V

OUT

= +400 mA, VS = 0.5 V — 0.3 0.5 V

OUT

= +650 mA, VS = 0.5 V — 0.7 1.3 V

OUT

CC

—30 V

IF = 400 mA — 1.1 1.4 V

IF = 650 mA — 1.4 1.6 V

V

V

ENABLE1

ENABLE1

= V

= V

= 0.8 V — 3.0 5.0 mA

ENABLE2

= 2.4 V — <1.0 200 µA

ENABLE2

Control Logic

Logic Supply Voltage Range V

Logic Input Voltage V

V

Logic Input Current I

I

Reference Input Volt. Range V

Reference Input Current I

Reference Divider Ratio V

REF/VTRIP

Current-Sense Comparator V

CC

IN(1)

IN(0)

IN(1)

IN(0)

REF

REF

IO

Operating 4.75 — 5.50 V

V

IN

V

IN

Operating 0.1 – 2.0 V

V

REF

Input Offset Voltage

Current-Sense Comparator V

S

Operating -0.3 — 1.0 V

Input Voltage Range

Sense-Current Offset I

SO

IS – I

NOTES: 1. Typical Data is for design information only.

2. Negative current is defined as coming out of (sourcing) the specified device terminal.

2.4 — — V

— — 0.8 V

= 2.4 V — <1.0 20 µA

= 0.8 V — <-20 -200 µA

-2.5 0 1.0 µA

3.8 4.0 4.2 —

= 0 V -6.0 0 6.0 mV

, 50 mA ≤ I

OUT

≤ 650 mA 12 18 24 mA

OUT

www.allegromicro.com

3

3966

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

ELECTRICAL CHARACTERISTICS at T

V

= 0 V, 56 kΩ & 680 pF RC to Ground (unless noted otherwise) (cont.)

S

= +25°C, V

A

= 30 V, VCC = 4.75 V to 5.5 V, V

BB

REF

= 2 V,

Limits

Characteristic Symbol Test Conditions Min. Typ. Max. Units

Control Logic (continued)

PWM RC Frequency f

PWM Propagation Delay Time t

Cross-Over Dead Time t

PWM

codt

Propagation Delay Times t

Thermal Shutdown Temp. T

Thermal Shutdown Hysteresis ∆T

UVLO Enable Threshold V

UVLO Hysteresis V

Logic Supply Current I

T(UVLO)+

T(UVLO)hys

CC(ON)

I

CC(OFF)

osc

pd

J

J

CT = 680 pF, R

= 56 kΩ 22.9 25.4 27.9 kHz

T

Comparator Trip to Source OFF — 1.0 1.4 µs

Cycle Reset to Source ON — 0.8 1.2 µs

1 kΩ Load to 25 V 0.2 1.8 3.0 µs

I

= ±650 mA, 50% to 90%:

OUT

ENABLE ON to Source ON — 100 — ns

ENABLE OFF to Source OFF — 500 — ns

ENABLE ON to Sink ON — 200 — ns

ENABLE OFF to Sink OFF — 200 — ns

PHASE Change to Sink ON — 2200 — ns

PHASE Change to Sink OFF — 200 — ns

PHASE Change to Source ON — 2200 — ns

PHASE Change to Source OFF — 200 — ns

— 165 — °C

—15—°C

Increasing V

CC

— 4.1 4.6 V

0.1 0.6 — V

V

ENABLE 1

V

ENABLE 1

= V

= V

ENABLE 2

ENABLE 2

= 0.8 V — — 50 mA

= 2.4 V — — 9.0 mA

NOTES: 1. Typical Data is for design information only.

2. Negative current is defined as coming out of (sourcing) the specified device terminal.

4

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

FUNCTIONAL DESCRIPTION

3966

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

Internal PWM Current Control. The A3966SA and

A3966SLB dual H-bridges are designed to drive both

windings of a bipolar stepper motor. Load current can be

controlled in each motor winding by an internal fixedfrequency PWM control circuit. The current-control

circuitry works as follows: when the outputs of the Hbridge are turned on, current increases in the motor winding. The load current is sensed by the current-control

comparator via an external sense resistor (R

). Load

S

current continues to increase until it reaches the predetermined value, set by the selection of external currentsensing resistors and reference input voltage (V

REF

)

according to the equation:

I

where I

= I

TRIP

is the sense-current error (typically 18 mA) due

SO

+ ISO = V

OUT

REF

/(4 RS)

to the base-drive current of the sink driver transistor.

At the trip point, the comparator resets the sourceenable latch, turning off the source driver of that H-bridge.

The source turn off of one H-bridge is independent of the

other H-bridge. Load inductance causes the current to

recirculate through the sink driver and ground-clamp

diode. The current decreases until the internal clock

oscillator sets the source-enable latches of both H-bridges,

turning on the source drivers of both bridges. Load current

increases again, and the cycle is repeated.

V

PHASE

The frequency of the internal clock oscillator is set by

the external timing components R

. The frequency can

TCT

be approximately calculated as:

f

where t

osc

is defined below.

blank

= 1/(RT CT + t

blank

)

The range of recommended values for RT and CT are

20 kΩ to 100 kΩ and 470 pF to 1000 pF respectively.

Nominal values of 56 kΩ and 680 pF result in a clock

frequency of 25 kHz.

Current-Sense Comparator Blanking. When the

source driver is turned on, a current spike occurs due to

the reverse-recovery currents of the clamp diodes and

switching transients related to distributed capacitance in

the load. To prevent this current spike from erroneously

resetting the source enable latch, the current-control

comparator output is blanked for a short period of time

when the source driver is turned on. The blanking time is

set by the timing component C

according to the equa-

T

tion:

t

= 1900 CT (µs).

blank

A nominal C

value of 680 pF will give a blanking

T

time of 1.3 µs.

The current-control comparator is also blanked when

the H-bridge outputs are switched by the PHASE or

ENABLE inputs. This internally generated blank time is

approximately 1 µs.

V

BB

BRIDGE

+

I

0

OUT

–

www.allegromicro.com

ON

OSCILLATOR

BRIDGE

INTERNAL

ON

BRIDGE ON

ALL

OFF

SOURCE

I

TRIP

OFF

t

d

R C

T T

t

blank

Dwg. WM-003-2

R

S

SOURCE OFF

ALL OFF

Dwg. EP-006-16

5

3966

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

FUNCTIONAL DESCRIPTION (continued)

Load Current Regulation. Due to internal logic and

switching delays (t

slightly higher than the I

), the actual load current peak will be

d

value. These delays, plus the

TRIP

blanking time, limit the minimum value the current control

circuitry can regulate. To produce zero current in a

winding, the ENABLE terminal should be held high,

turning off all output drivers for that H-bridge.

Logic Inputs. A logic high on the PHASE input results

in current flowing from OUT

to OUTB of that H-bridge.

A

A logic low on the PHASE input results in current flowing

from OUTB to OUTA. An internally generated dead time

(t

) of approximately 1 µs prevents cross-over current

codt

spikes that can occur when switching the PHASE input.

A logic high on the ENABLE input turns off all four

output drivers of that H-bridge. This results in a fast

current decay through the internal ground clamp and

flyback diodes. A logic low on the ENABLE input turns

on the selected source and sink driver of that H-bridge.

The ENABLE inputs can be pulse-width modulated for

applications that require a fast current-decay PWM. If

external current-sensing circuitry is used, the internal

current-control logic can be disabled by connecting the

RTCT terminal to ground.

The REFERENCE input voltage is typically set with a

resistor divider from V

. This reference voltage is

CC

internally divided down by 4 to set up the current-comparator trip-voltage threshold. The reference input voltage

range is 0 to 2 V.

Output Drivers. To minimize on-chip power dissipation,

the sink drivers incorporate a Satlington structure. The

Satlington output combines the low V

features of a

CE(sat)

saturated transistor and the high peak-current capability of

a Darlington (connected) transistor. A graph showing

typical output saturation voltages as a function of output

current is on the next page.

Miscellaneous Information. Thermal protection

circuitry turns off all output drivers should the junction

temperature reach +165 °C (typical). This is intended

only to protect the device from failures due to excessive

junction temperatures and should not imply that output

short circuits are permitted. Normal operation is resumed

when the junction temperature has decreased about 15°C.

The A3966 current control employs a fixed-frequency, variable duty cycle PWM technique. As a result,

the current-control regulation may become unstable if the

duty cycle exceeds 50%.

To minimize current-sensing inaccuracies caused by

ground trace I

drops, each current-sensing resistor

R

should have a separate return to the ground terminal of

the device. For low-value sense resistors, the I x R drops

in the printed-wiring board can be significant and should

be taken into account. The use of sockets should be

avoided as their contact resistance can cause variations in

the effective value of RS.

The LOAD SUPPLY terminal, VBB, should be

decoupled with an electrolytic capacitor (47 µF recommended) placed as close to the device as physically

practical. To minimize the effect of system ground I x R

drops on the logic and reference input signals, the system

ground should have a low-resistance return to the load

supply voltage.

The frequency of the clock oscillator will determine

the amount of ripple current. A lower frequency will

result in higher current ripple, but reduced heating in the

motor and driver IC due to a corresponding decrease in

hysteretic core losses and switching losses respectively.

A higher frequency will reduce ripple current, but will

increase switching losses and EMI.

6

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Typical output saturation

voltages showing Satlington

sink-driver operation.

3966

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

2.5

TA = +25°C

2.0

SOURCE DRIVER

1.5

1.0

56 kW

PH2

TYPICAL APPLICATION

(A3966SLB)

0.5 W

680 pF

+3.3 V

28272625242322

1

2

3

4

LOGIC

5

6

7

8

9

1011121314

+24 V

LOGIC

V

BB

0.5

SINK DRIVER

OUTPUT SATURATION VOLTAGE IN VOLTS

+3.3 V

47 µF

20 kW

10 kW

0

200

OUTPUT CURRENT IN MILLIAMPERES

The products described here are manufactured under one or more

500

600

007004300

Dwg. GP-064-1A

U.S. patents or U.S. patents pending. Satlington® is a registered

21

20

0.5 W

19

18

17

16

15

EN1EN2

PH1

trademark of Allegro MicroSystems, Inc. (Allegro), and Satlington

devices are manufactured under U. S. Patent No. 5,684,427.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be

required to permit improvements in the performance, reliability, or

manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components

in life-support devices or systems without express written approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringement of patents or other rights of

third parties which may result from its use.

www.allegromicro.com

7

3966

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

16

0.280

0.240

A3966SA

Dimensions in Inches

(controlling dimensions)

9

0.014

0.008

0.430

MAX

0.300

BSC

0.210

MAX

7.11

6.10

0.015

MIN

1

0.070

0.045

16

1

1.77

1.15

0.022

0.014

0.100

0.775

0.735

BSC

Dimensions in Millimeters

(for reference only)

2.54

19.68

18.67

BSC

8

0.005

MIN

0.150

0.115

Dwg. MA-001-16A in

0.355

9

8

0.13

MIN

0.204

10.92

MAX

7.62

BSC

5.33

MAX

0.39

MIN

0.558

0.356

3.81

2.93

NOTES: 1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative.

3. Lead thickness is measured at seating plane or below.

4. Supplied in standard sticks/tubes of 25 devices.

8

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Dwg. MA-001-16A mm

A3966SLB

Dimensions in Inches

(for reference only)

16 9

3966

DUAL FULL-BRIDGE

PWM MOTOR DRIVER

0.0125

0.0091

0.2992

0.2914

0.020

0.013

0.0926

0.1043

7.60

7.40

1 2

0.0040

MIN.

3

0.4133

0.3977

Dimensions in Millimeters

(controlling dimensions)

0.419

0.394

0.050

0.016

0.050

BSC

916

0° TO 8°

Dwg. MA-008-16A in

0.32

0.23

10.65

10.00

0.51

0.33

2.65

2.35

1 2

0.10

3

10.50

10.10

MIN.

1.27

BSC

NOTES: 1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative.

3. Webbed lead frame. Leads 4 and 13 are internally one piece.

4. Supplied in standard sticks/tubes of 47 devices or add “TR” to part number for tape and reel.

www.allegromicro.com

1.27

0.40

0° TO 8°

Dwg. MA-008-16A mm

9

Loading...

Loading...