查询A3959供应商查询A3959供应商

3959

DMOS FULL-BRIDGE PWM

29319.37E

MOTOR DRIVER

Data Sheet

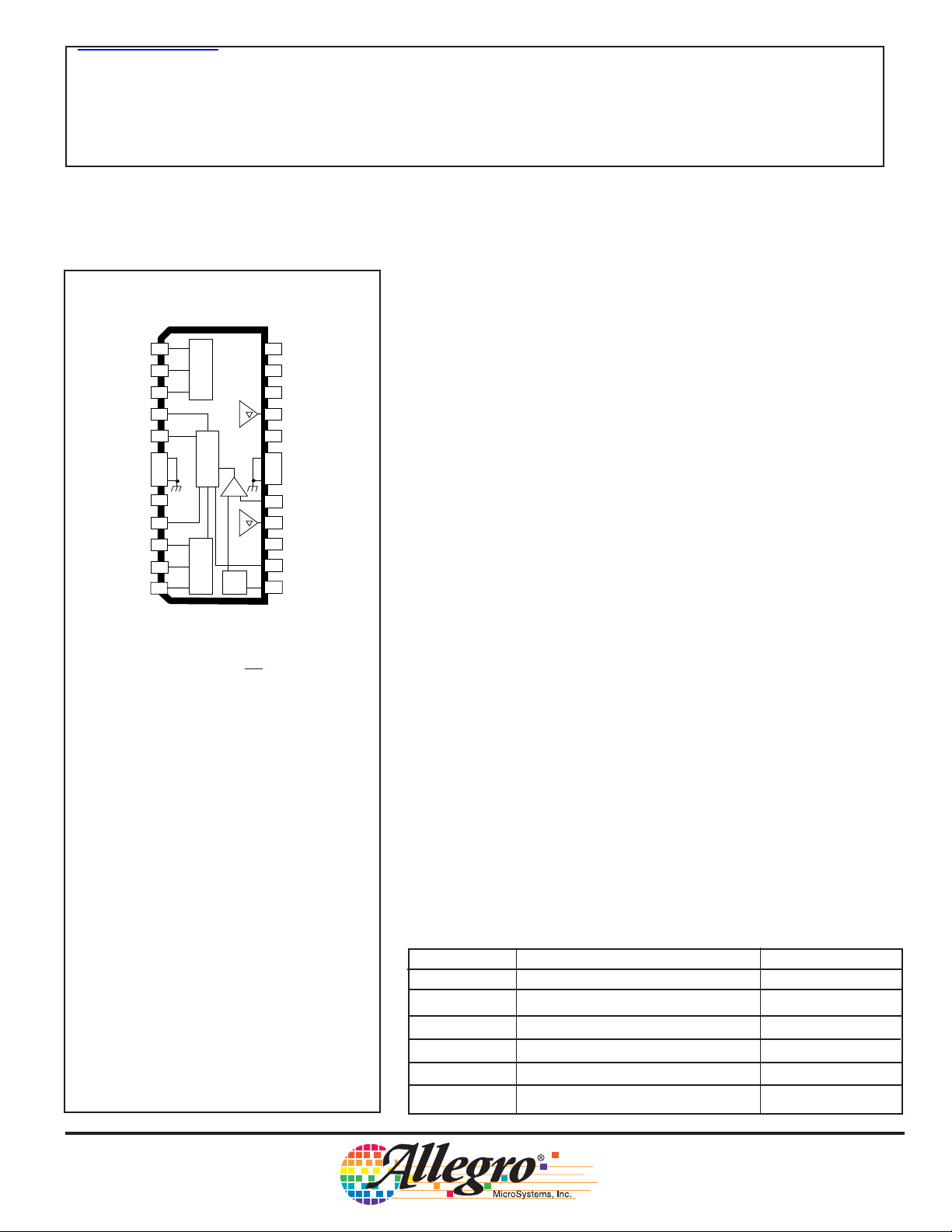

A3959SLB (SOIC)

Designed for pulse-width modulated (PWM) current control of dc

motors, the A3959SB, A3959SLB, and A3959SLP are capable of

output currents to ±3 A and operating voltages to 50 V. Internal fixed

V

24

REG

23

SLEEP

NO

NC

22

CONNECTION

21

B

OUT

V

20

LOAD SUPPLY

BB

19

GROUND

18

GROUND

SENSE

17

A

OUT

16

NO

NC

15

CONNECTION

EXT MODE

14

REF

13

Dwg. PP-069-4

CP

PHASE

ROSC

GROUND

GROUND

LOGIC SUPPLY

ENABLE

PFD

BLANK

PFD

CP

1

2

2

CP

1

3

4

5

6

7

8

9

9

2

10

11

1

12

θ

V

DD

CHARGE PUMP

LOGIC

÷

10

PWM TIMER

Note that the A3959SLB(SOIC), A3959SB (DIP),

and A3959SLP (TSSOP) do

not share a common

terminal assignment.

off-time PWM current-control timing circuitry can be adjusted via

control inputs to operate in slow, fast, and mixed current-decay modes.

PHASE and ENABLE input terminals are provided for use in

controlling the speed and direction of a dc motor with externally

applied PWM-control signals. Internal synchronous rectification

control circuitry is provided to reduce power dissipation during PWM

operation.

Internal circuit protection includes thermal shutdown with

hysteresis, undervoltage monitoring of supply and charge pump, and

crossover-current protection. Special power-up sequencing is not

required.

The A3959SB/SLB/SLP is a choice of three power packages, a

24-pin plastic DIP with a copper batwing tab (package suffix ‘B’), a

24-lead plastic SOIC with a copper batwing tab (package suffix ‘LB’),

and a thin (<1.2 mm) 28-lead plastic TSSOP with an exposed thermal

pad (suffix ‘LP’). In all cases, the power tab is at ground potential and

needs no electrical isolation.

free version (100% matte tin leadframe).

ABSOLUTE MAXIMUM RATINGS

Load Supply Voltage, VBB......................... 50 V

Output Current, I

(Repetitive) ........... ±3.0 A

OUT

(Peak, <3 µs) ................................... ±6.0 A

Logic Supply Voltage, VDD....................... 7.0 V

Logic Input Voltage Range, V

IN

(Continuous) ............ -0.3 V to VDD + 0.3 V

<30 ns) ............... -1.0 V to VDD + 1.0 V

(t

w

Sense Voltage, VS (Continuous) .............. 0.5 V

(tw <3 µs) ........................................... 2.5 V

Reference Voltage, V

Package Power Dissipation (TA = 25°C), P

............................ V

REF

DD

D

A3959SB ........................................ 3.3 W*

A3959SLB ...................................... 2.5 W*

A3959SLP ...................................... 3.1 W*

Operating Temp. Range, T

.... -20°C to +85°C

A

Junction Temperature, TJ..................... +150°C

Storage Temp. Range, TS..... -55°C to +150°C

Output current rating may be limited by duty cycle,

ambient temperature, and heat sinking. Under any

set of conditions, do not exceed the specified

current rating or a junction temperature of 150°C.

* Double-sided board, one square inch copper each side. See also, Layout, page 7.

FEATURES

■ ±3 A, 50 V Output Rating

■ Low

■ Mixed, Fast, and Slow Current-Decay Modes

■ Synchronous Rectification for Low Power Dissipation

■ Internal UVLO and Thermal-Shutdown Circuitry

■ Crossover-Current Protection

■ Internal Oscillator for Digital PWM Timing

Always order by complete part number:

Part Number Package R

A3959SB-T 24-pin batwing DIP; Lead-free 38°C/W 6°C/W

A3959SLB 24-lead batwing SOIC 50°C/W 6°C/W

A3959SLB-T 24-lead batwing SOIC; Lead-free 50°C/W 6°C/W

A3959SLP 28-lead thin shrink SOIC 40°C/W —

A3959SLP-T 28-lead thin shrink SOIC; Lead-free 40°C/W —

r

Outputs (270 mΩ, Typical)

DS(on)

A3959SB 24-pin batwing DIP 38°C/W 6°C/W

Each package is available in a lead-

* R

θθ

θJA

θθ

θθ

θJT

θθ

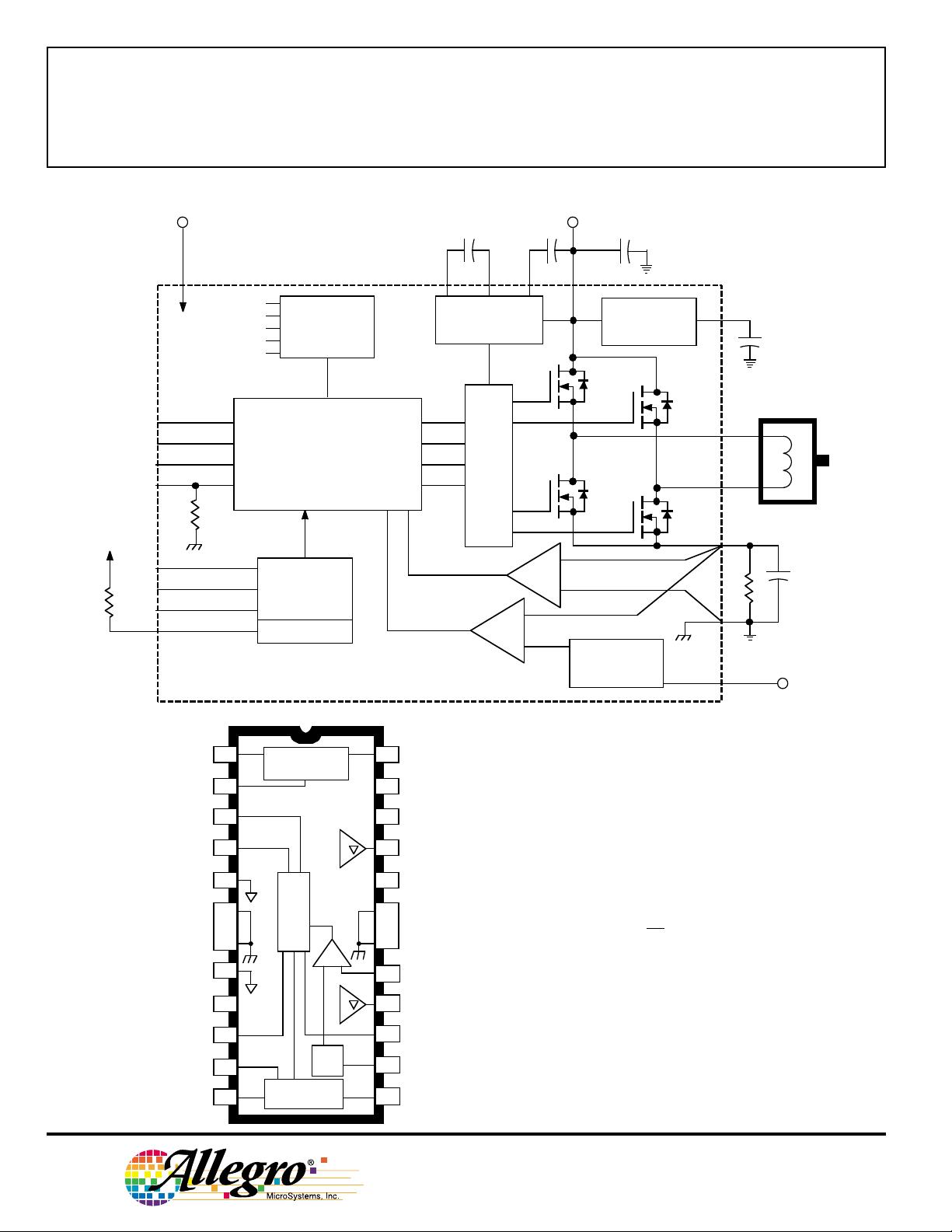

3959

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

V

DD

LOGIC

SUPPLY

FUNCTIONAL BLOCK DIAGRAM

VBB

CP1

CP2

CP

LOAD

SUPPLY

+

SLEEP

EXT MODE

PHASE

ENABLE

TO VDD

BLANK

PFD1

PFD2

ROSC

CHARGE PUMP

CP

PHASE

2

1

BANDGAP

V

C

REG

TSD

1

2

θ

3

VOLTAGE &

DD

FAULT DETECT

CONTROL LOGIC

PWM

TIMER

OSC

CHARGE PUMP

UNDER-

CHARGE

PUMP

BANDGAP

REGULATOR

VREG

OUTA

GATE DRIVE

OUTB

SENSE

ZERO

CURRENT

DETECT

CURRENT

SENSE

CPCP

24

REG

V

23

SLEEP

22

REFERENCE

BUFFER &

÷10

REF

CS

RS

V

Dwg. FP-048-2A

REF

ROSC

GROUND

GROUND

GROUND

GROUND

LOGIC

SUPPLY

ENABLE

BLANK

2

PFD

4

5

6

7

8

9

V

9

10

2

11

12

LOGIC

DD

PWM TIMER

V

BB

÷

10

21

20

19

18

17

16

15

14

13

OUT

B

LOAD

SUPPLY

GROUND

GROUND

SENSE

OUT

A

EXT MODE

REF

PFD

1

Dwg. PP-069-5A

A3959SB (DIP)

Note that the A3959SLB (SOIC), A3959SB (DIP),

and A3959SLP (TSSOP) do

terminal assignment.

not share a common

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Copyright © 2001, 2003 Allegro MicroSystems, Inc.

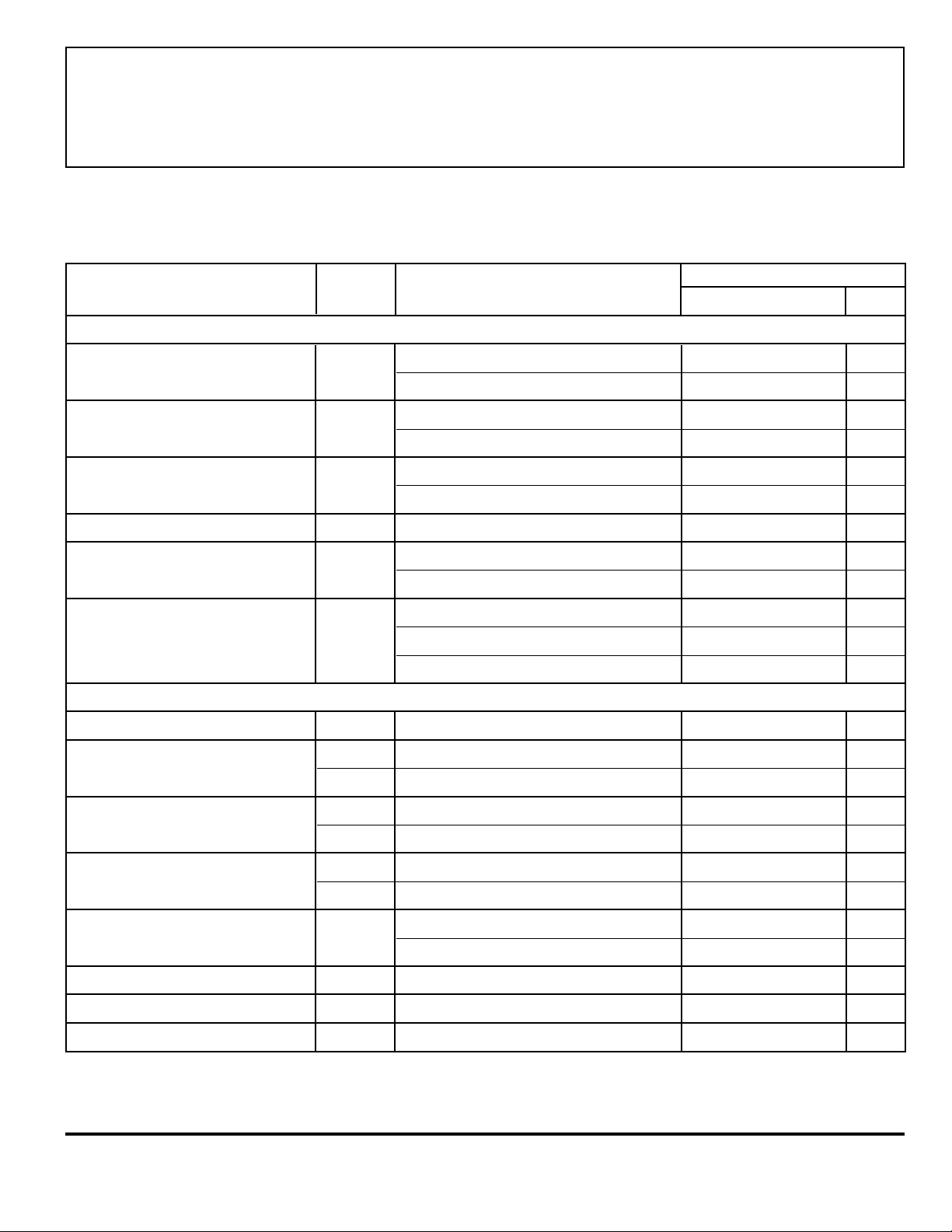

3959

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

ELECTRICAL CHARACTERISTICS at T

f

< 50 kHz (unless noted otherwise)

PWM

= +25°C, V

A

= 50 V, VDD = 5.0 V, V

BB

SENSE

= 0.5 V,

Limits

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Output Drivers

Load Supply Voltage Range V

BB

Operating 9.5 – 50 V

During sleep mode 0 – 50 V

Output Leakage Current I

Output On Resistance r

DSS

DS(on)

V

= V

OUT

V

OUT

Source driver, I

Sink driver, I

BB

= 0 V – <-1.0 -20 µA

= -3 A – 270 300 mΩ

OUT

= 3 A – 270 300 mΩ

OUT

– <1.0 20 µA

Crossover Delay 300 600 1000 ns

Body Diode Forward Voltage V

Source diode, IF = -3 A – – 1.6 V

F

Sink diode, IF = 3 A – – 1.6 V

Load Supply Current I

BB

f

< 50 kHz – 4.0 7.0 mA

PWM

Charge pump on, outputs disabled – 2.0 5.0 mA

Control Logic

Logic Supply Voltage Range V

Logic Input Voltage V

V

Logic Input Current I

(all inputs except ENABLE)

I

ENABLE Input Current I

I

Internal OSC frequency f

Reference Input Volt. Range V

Reference Input Current I

Comparator Input Offset Volt. V

DD

IN(1)

IN(0)

IN(1)

IN(0)

IN(1)

IN(0)

OSC

REF

REF

IO

Sleep Mode – – 20 µA

Operating 4.5 5.0 5.5 V

2.0 – – V

– – 0.8 V

V

= 2.0 V – <1.0 20 µA

IN

V

= 0.8 V – <-2.0 -20 µA

IN

V

= 2.0 V – 40 100 µA

IN

V

= 0.8 V – 16 40 µA

IN

R

shorted to GROUND 3.25 4.25 5.25 MHz

OSC

R

= 51 kΩ 3.65 4.25 4.85 MHz

OSC

Operating 0.0 – V

V

= V

V

REF

REF

DD

= 0 V – ±5.0 – mV

––±1.0 µA

Continued next page …

DD

V

www.allegromicro.com

3

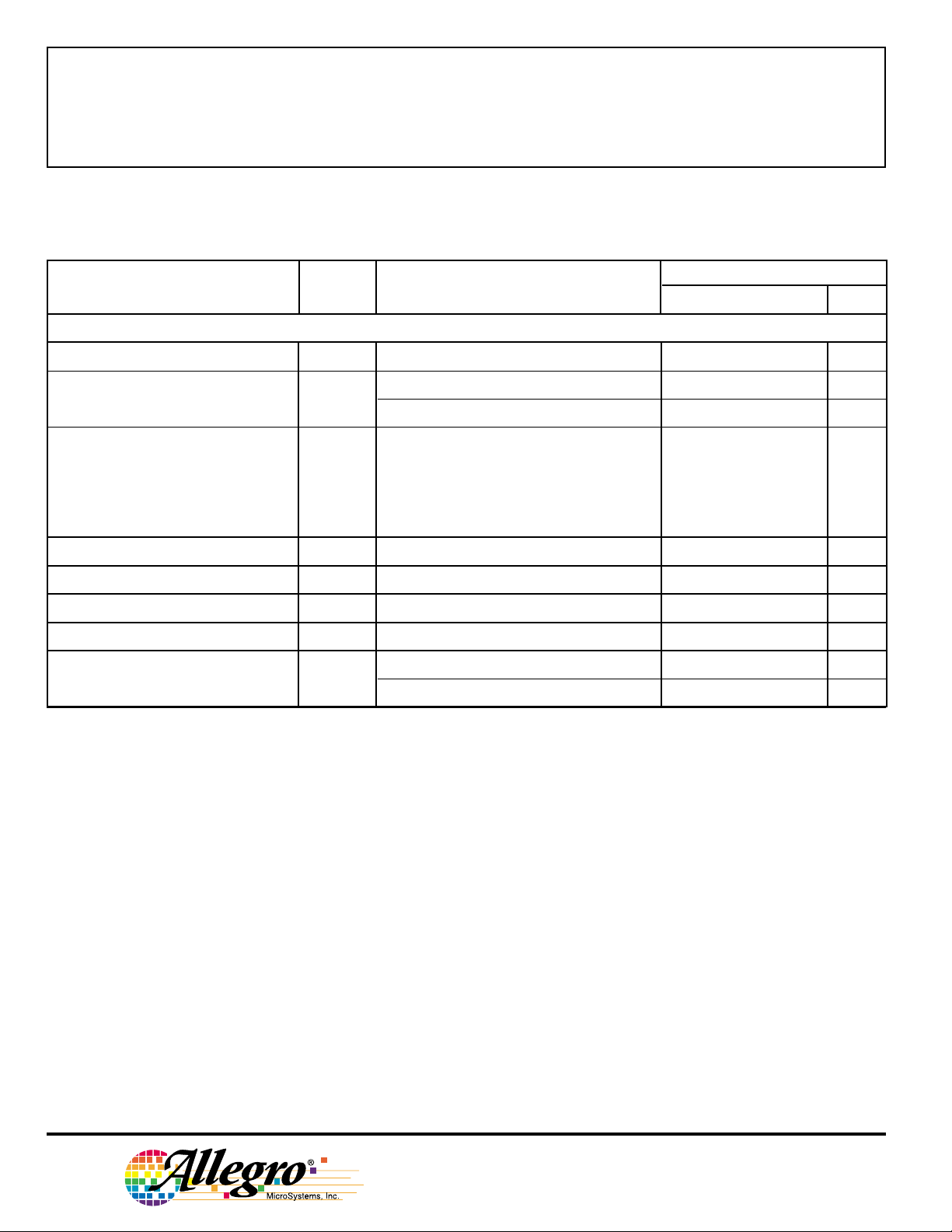

3959

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

ELECTRICAL CHARACTERISTICS at T

f

< 50 kHz (unless noted otherwise), continued.

PWM

= +25°C, V

A

= 50 V, VDD = 5.0 V, V

BB

SENSE

= 0.5 V,

Limits

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Control Logic

Reference Divider Ratio – – 10 – –

Gm Error E

Gm

(Note 3) V

Propagation Delay Times t

pd

V

= V

REF

REF

0.5 Ein to 0.9 E

DD

= 0.5 V – – ±14 %

:

out

––±4.0 %

PWM change to source on 600 750 1200 ns

PWM change to source off 50 150 350 ns

PWM change to sink on 600 750 1200 ns

PWM change to sink off 50 100 150 ns

Thermal Shutdown Temp. T

Thermal Shutdown Hysteresis ∆T

J

J

UVLO Enable Threshold UVLO Increasing V

DD

– 165 – °C

–15– °C

3.90 4.2 4.45 V

UVLO Hysteresis ∆UVLO 0.05 0.10 – V

Logic Supply Current I

DD

f

< 50 kHz – 6.0 10 mA

PWM

Sleep Mode – – 2.0 mA

NOTES: 1. Typical Data is for design information only.

2. Negative current is defined as coming out of (sourcing) the specified device terminal.

3. Gm error = ([V

4

/10] – V

REF

SENSE

)/(V

REF

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

/10) where V

SENSE

= I

TRIP•RS

.

FUNCTIONAL DESCRIPTION

3959

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

V

. This internally generated voltage is used to operate

REG

the sink-side DMOS outputs. The V

be decoupled with a 0.22 µF capacitor to ground. V

terminal should

REG

REG

is

internally monitored and in the case of a fault condition,

the outputs of the device are disabled.

Charge Pump. The charge pump is used to generate a

gate-supply voltage greater than V

to drive the source-

BB

side DMOS gates. A 0.22 µF ceramic capacitor should be

connected between CP1 and CP2 for pumping purposes.

A 0.22 µF ceramic capacitor should be connected between

CP and V

to act as a reservoir to operate the high-side

BB

DMOS devices. The CP voltage is internally monitored

and, in the case of a fault condition, the source outputs of

the device are disabled.

PHASE Logic. The PHASE input terminal determines if

the device is operating in the “forward” or “reverse” state.

PHASE OUT

A

OUT

B

0 Low High

1 High Low

ENABLE Logic. The ENABLE input terminal allows

external PWM. ENABLE high turns on the selected sinksource pair. ENABLE low switches off the source driver

or the source and sink driver, depending on EXT MODE,

and the load current decays. If ENABLE is kept high, the

current will rise until it reaches the level set by the internal

current-control circuit.

ENABLE Outputs

0 Chopped

1On

EXT MODE Logic. When using external PWM current

control, the EXT MODE input determines the current path

during the chopped cycle. With EXT MODE low, fast

decay mode, the opposite pair of selected outputs will be

enabled during the off cycle. With EXT MODE high,

slow decay mode, both sink drivers are on with ENABLE

low.

EXT MODE Decay

0 Fast

1 Slow

Current Regulation. Load current is regulated by an

internal fixed off-time PWM control circuit. When the

outputs of the DMOS H bridge are turned on, the current

increases in the motor winding until it reaches a trip value

determined by the external sense resistor (R

applied analog reference voltage (V

I

= V

TRIP

REF

/10R

REF

S

):

) and the

S

At the trip point, the sense comparator resets the sourceenable latch, turning off the source driver. The load

inductance then causes the current to recirculate for the

fixed off-time period. The current path during

recirculation is determined by the configuration of slow/

mixed/fast current-decay mode via PFD1 and PFD2.

Oscillator. The PWM timer is based on an internal

oscillator set by a resistor connected from the R

OSC

terminal to VDD. Typical value of 4 MHz is set with a

51 kΩ resistor. The allowable range of the resistor is from

20 kΩ to 100 kΩ.

f

If R

= 204 x 109/R

OSC

is not pulled up to VDD, it must be shorted to

OSC

OSC

.

ground.

www.allegromicro.com

Fixed Off Time. The A3959 is set for a fixed off time of

96 cycles of the internal oscillator, typically 24 µs with a

4 MHz oscillator.

5

3959

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

FUNCTIONAL DESCRIPTION (continued)

Internal Current-Control Mode. Inputs PFD1 and

PFD2 determine the current-decay method after an

overcurrent event is detected at the SENSE input. In

slow-decay mode, both sink drivers are turned on for the

fixed off-time period. Mixed-decay mode starts out in

fast-decay mode for a portion (15% or 48%) of the fixed

off time, and then is followed by slow decay for the

remainder of the period.

PFD2 PFD1 % t

off

Decay

0 0 0 Slow

0 1 15 Mixed

1 0 48 Mixed

1 1 100 Fast

PWM Blank Timer. When a source driver turns on, a

current spike occurs due to the reverse-recovery currents

of the clamp diodes and/or switching transients related to

distributed capacitance in the load. To prevent this current

spike from erroneously resetting the source-enable latch,

the sense comparator is blanked. The blank timer runs

after the off-time counter to provide the blanking function.

The blank timer is reset when ENABLE is chopped or

PHASE is changed. For external PWM control, a PHASE

change or ENABLE on will trigger the blanking function.

The duration is determined by the BLANK input and the

oscilator.

BLANK t

0 6/f

1 12/f

blank

osc

osc

Synchronous Rectification. When a PWM off cycle

is triggered, either by an ENABLE chop command or

internal fixed off-time cycle, load current will recirculate

according to the decay mode selected by the control logic.

The A3959 synchronous rectification feature will turn on

the appropriate pair of DMOS outputs during the current

decay and effectively short out the body diodes with the

low r

driver. This will reduce power dissipation

DS(on)

significantly and can eliminate the need for external

Schottky diodes.

Synchronous rectification will prevent reversal of load

current by turning off all outputs when a zero-current level

is detected.

Shutdown. In the event of a fault (excessive junction

temperature, or low voltage on CP or V

) the outputs of

REG

the device are disabled until the fault condition is

removed. At power up, and in the event of low V

DD

, the

UVLO circuit disables the drivers.

Braking. The braking function is implemented by

driving the device in slow-decay mode via EXTMODE

and applying an enable chop command. Because it is

possible to drive current in either direction through the

DMOS drivers, this configuration effectively shorts out

the motor-generated BEMF as long as the ENABLE chop

mode is asserted. It is important to note that the internal

PWM current-control circuit will not limit the current

when braking, because the current does not flow through

the sense resistor. The maximum brake current can be

approximated by V

BEMF/RL

. Care should be taken to

ensure that the maximum ratings of the device are not

exceeded in worst-case braking situations of high speed

and high inertial loads.

SLEEP Logic. The SLEEP input terminal is used to

minimize power consumption when when not in use. This

disables much of the internal circuitry including the

regulator and charge pump. Logic low will put the device

into sleep mode, logic high will allow normal operation.

6

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

FUNCTIONAL DESCRIPTION (continued)

3959

Current Sensing. To minimize inaccuracies in sensing

the I

current level, which may be caused by ground

TRIP

trace IR drops, the sense resistor should have an

independent ground return to the ground terminal of the

device. For low-value sense resistors the IR drops in the

PCB sense resistor’s traces can be significant and should

be taken into account. The use of sockets should be

avoided as they can introduce variation in R

due to their

S

contact resistance.

The maximum value of R

where I

TRIP

≤ 3.0 A.

is given as RS ≤ 0.5/I

S

TRIP

Thermal Protection. Circuitry turns off all drivers

when the junction temperature reaches 165°C typically. It

is intended only to protect the device from failures due to

excessive junction temperatures and should not imply that

output short circuits are permitted. Thermal shutdown has

a hysteresis of approximately 15°C.

5

SUFFIX 'B', R

SUFFIX 'LP', R

4

SUFFIX 'LB', R

MULTI-LAYER HIGH-K BOARD

θJA

= 26°C/W

θJA

θJA

= 28°C/W

= 35°C/W

Layout. A star ground system located close to the driver

is recommended. The printed wiring board should use a

heavy ground plane. For optimum electrical and thermal

performance*, the driver should be soldered directly onto

the board. The ground side of R

should have an indi-

S

vidual path to the ground terminals of the device. This

path should be as short as is possible physically and

should not have any other components connected to it. It

is recommended that a 0.1 µF capacitor be placed between

SENSE and ground as close to the device as possible; the

load supply terminal, V

, should be decoupled with an

BB

electrolytic capacitor (> 47 µF is recommended) placed as

close to the device as is possible. On the 28-lead TSSOP

package, the copper ground plane located under the

exposed thermal pad is typically used as a star ground.

* The thermal resistance, R

, and absolute maximum

θJA

allowable package power dissipation specified on page 1

is measured on a typical two-sided PCB with one square

inch copper ground area on each side. With minimal

copper on a single-sided PCB (worst-case), the ‘B’

package R

is 40°C/W, ‘LB’ is 77°C/W, and ‘LP’ is

θJA

80°C/W. See also, Application Note 29501.5, Improving

Batwing Power Dissipation.

3

2

1

SUFFIX 'B', R

SUFFIX 'LP', R

SUFFIX 'LB', R

DOUBLE-SIDED BOARD,

1 SQ. IN. COPPER EA. SIDE

0

25

ALLOWABLE PACKAGE POWER DISSIPATION IN WATTS

www.allegromicro.com

θJA

= 38°C/W

θJA

= 40°C/W

θJA

= 50°C/W

50 75 100 125 150

TEMPERATURE IN °°°°C

Dwg. GP-049-6

For specification purposes, the multi-layer high-K board

performance graphed here is per JEDEC Standard

JESD51.

The products described here are manufactured under one or more

U.S. patents or U.S. patents pending.

Allegro MicroSystems, Inc. reserves the right to make, from time to

time, such departures from the detail specifications as may be

required to permit improvements in the performance, reliability, or

manufacturability of its products. Before placing an order, the user is

cautioned to verify that the information being relied upon is current.

Allegro products are not authorized for use as critical components

in life-support devices or systems without express written approval.

The information included herein is believed to be accurate and

reliable. However, Allegro MicroSystems, Inc. assumes no responsibility for its use; nor for any infringement of patents or other rights of

third parties which may result from its use.

7

3959

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

Terminal List

LB B LP

Terminal Name Terminal Description (SOIC) (DIP) (TSSOP)

CP Reservoir capacitor (typically 0.22 µF) 1 24 1

CP1 & CP2 The charge pump capacitor (typically 0.22 µF) 2 & 3 1 & 2 2 & 3

NC No (internal) connection — — 4

PHASE Logic input for direction control 4 3 5

ROSC Oscillator resistor 5 4 6

GROUND Grounds 6, 7 5, 6, 7, 8* 7, 8*

LOGIC SUPPLY V

ENABLE Logic input for enable control 9 10 10

NC No (internal) connection – – 11

PFD

2 Logic-level input for fast decay 10 11 12

BLANK Logic-level input for blanking control 11 12 13

PFD1 Logic-level input for fast decay 12 13 14

REF V

EXT MODE Logic input for PWM mode control 14 15 16

NO CONNECT No (Internal) connection 15 — 17

OUT

A

NC No (internal) connection – – 19, 20

SENSE Sense resistor 17 17 21

NC No (internal) connection – – 22

GROUND Grounds 18, 19 18, 19* —

LOAD SUPPLY V

OUT

B

NO CONNECT No (Internal) connection 22 — 25

SLEEP Logic-level Input for sleep operation 23 22 26

V

REG

GROUND Ground — — 28*

, the low voltage (typically 5 V) supply 8 9 9

DD

, the load current reference input voltage 13 14 15

REF

One of two DMOS bridge outputs to the motor 16 16 18

, the high-current, 9.5 V to 50 V, motor supply 20 20 23

BB

One of two DMOS bridge outputs to the motor 21 21 24

Regulator decoupling capacitor (typically 0.22 µF) 24 23 27

* For the A3959SB (DIP) only, there is an indeterminate resistance between the substrate grounds (pins 6, 7,

18, and 19) and the grounds at pins 5 and 8. Pins 5 and 8, and 6, 7, 18, or 19 must be connected together

externally. For the A3959SLP (TSSOP) the grounds at terminals 7, 8, and 28 should be connected together at

the exposed pad beneath the device.

8

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

0.280

0.240

24

NOTE 1

A3959SB

Dimensions in Inches

(controlling dimensions)

13

3959

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

0.014

0.008

0.430

MAX

0.300

BSC

0.210

MAX

7.11

6.10

0.015

MIN

16

0.070

0.045

0.022

0.014

24

1

1.77

1.15

7

NOTE 1

67

12

1.280

1.230

0.100

BSC

Dimensions in Millimeters

(for reference only)

13

12

32.51

31.24

2.54

BSC

0.005

0.150

0.115

0.13

MIN

MIN

0.355

0.204

Dwg. MA-001-25A in

10.92

MAX

7.62

BSC

5.33

MAX

0.39

MIN

0.558

0.356

NOTES: 1. Webbed lead frame. Leads 6, 7, 18, and 19 are internally one piece.

2. Exact body and lead configuration at vendor’s option within limits shown.

3. Lead spacing tolerance is non-cumulative.

4. Lead thickness is measured at seating plane or below.

5. Supplied in standard sticks/tubes of 15 devices.

www.allegromicro.com

3.81

2.93

Dwg. MA-001-25A mm

9

3959

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

A3959SLB

0.2992

0.2914

0.020

0.013

0.0926

0.1043

24 13

1

2

3

0.6141

0.5985

0.0040

MIN.

0.050

BSC

NOTE 1

NOTE 3

0.419

0.394

0° TO 8°

0.0125

0.0091

0.050

0.016

Dwg. MA-008-25A in

Dimensions in Inches

(for reference only)

0.32

0.23

7.60

7.40

0.51

0.33

2.65

2.35

1242

0.10

MIN.

3

15.60

15.20

1.27

BSC

NOTE 1

NOTE 3

10.65

10.00

NOTES: 1. Exact body and lead configuration at vendor’s option within limits shown.

2. Lead spacing tolerance is non-cumulative.

3. Webbed lead frame. Leads 6, 7, 18, and 19 are internally one piece.

4. Supplied in standard sticks/tubes of 31 devices or add “TR” to part number for tape and reel.

10

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Dimensions in Millimeters

(controlling dimensions)

1.27

0.40

0° TO 8°

Dwg. MA-008-25A mm

3959

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

A3959SLP

28-pin TSSOP

9.8

.386

9.6

.378

28

8”

0”

0.20

.008

0.09

.004

6.6

6.2

.260

.244

0.30

0.19

0.30

BSC

0.75

BSC

5

BSC

4.5

BSC

.200

0.65

BSC

0.65

BSC

A

.026

.026

.138

4.5

.177

4.3

.169

21

.012

.007

.012

6.6

.260

BSC

.030

Dimensions in millimeters

U.S. Customary dimensions (in.) in brackets, for reference only

A

Exposed thermal pad (bottom surface)

2.7

BSC

.106

0.75

0.45

3

BSC

.118

.030

.018

0.15

0.00

1.20

MAX

.006

.000

.047

1

.039

REF

0.25

.010

BSC

Seating Plane

Gauge Plane

www.allegromicro.com

11

3959

DMOS FULL-BRIDGE

PWM MOTOR DRIVER

MOTOR DRIVERS

Function Output Ratings* Part Number

INTEGRATED CIRCUITS FOR BRUSHLESS DC MOTORS

3-Phase Power MOSFET Controller — 28 V 3933

3-Phase Power MOSFET Controller — 40 V 3935

3-Phase Power MOSFET Controller — 50 V 3932 & 3938

3-Phase Back-EMF Controller/Driver ±900 mA 14 V 8904

3-Phase PWM Current-Controlled DMOS Driver ±3.0 A 50 V 3936

INTEGRATED BRIDGE DRIVERS FOR DC AND BIPOLAR STEPPER MOTORS

PWM Current-Controlled Dual Full Bridge ±500 mA 18 V 3965

Dual Full Bridge with Protection & Diagnostics ±500 mA 30 V 3976

PWM Current-Controlled Dual Full Bridge ±650 mA 30 V 3966

PWM Current-Controlled Dual Full Bridge ±650 mA 30 V 3968

Microstepping Translator/Dual Full Bridge ±750 mA 30 V 3967

PWM Current-Controlled Dual Full Bridge ±750 mA 45 V 2916

PWM Current-Controlled Dual Full Bridge ±750 mA 45 V 2919

PWM Current-Controlled Dual Full Bridge ±750 mA 45 V 6219

PWM Current-Controlled Dual Full Bridge ±800 mA 33 V 3964

PWM Current-Controlled Dual DMOS Full Bridge ±1.0 A 35 V 3973

PWM Current-Controlled Full Bridge ±1.3 A 50 V 3953

PWM Current-Controlled Dual Full Bridge ±1.5 A 45 V 2917

PWM Current-Controlled DMOS Full Bridge ±1.5 A 50 V 3948

PWM Current-Controlled Microstepping Full Bridge ±1.5 A 50 V 3955

PWM Current-Controlled Microstepping Full Bridge ±1.5 A 50 V 3957

PWM Current-Controlled Dual DMOS Full Bridge ±1.5 A 50 V 3972

PWM Current-Controlled Dual DMOS Full Bridge ±1.5 A 50 V 3974

PWM Current-Controlled Full Bridge ±2.0 A 50 V 3952

PWM Current-Controlled DMOS Full Bridge ±2.0 A 50 V 3958

Microstepping Translator/Dual DMOS Full Bridge ±2.5 A 35 V 3977

PWM Current-Controlled DMOS Full Bridge ±3.0 A 50 V 3959

UNIPOLAR STEPPER MOTOR & OTHER DRIVERS

Unipolar Stepper-Motor Translator/Driver 1.0 A 46 V 7050

Unipolar Stepper-Motor Translator/Driver 1.25 A 50 V 5804

Unipolar Stepper-Motor Quad Drivers 1.5 A 46 V 7024 & 7029

Unipolar Microstepper-Motor Quad Driver 1.5 A 46 V 7042

Unipolar Stepper-Motor Quad Driver 1.8 A 50 V 2540

Unipolar Stepper-Motor Translator/Driver 2.0 A 46 V 7051

Unipolar Stepper-Motor Quad Driver 3.0 A 46 V 7026

Unipolar Microstepper-Motor Quad Driver 3.0 A 46 V 7044

Unipolar Stepper-Motor Translator/Driver 3.0 A 46 V 7052

* Current is maximum specified test condition, voltage is maximum rating. See specification for sustaining voltage limits

or over-current protection voltage limits. Negative current is defined as coming out of (sourcing) the output.

† Complete part number includes additional characters to indicate operating temperature range and package style.

Also, see 3175, 3177, 3235, and 3275 Hall-effect sensors for use with brushless dc motors.

†

12

115 Northeast Cutoff, Box 15036

Worcester, Massachusetts 01615-0036 (508) 853-5000

Loading...

Loading...