E

查询3936供应商

3936

DMOS THREE-PHAS

ABSOLUTE MAXIMUM RATINGS

at TA = +25°C

Load Supply Voltage, VBB........................... 50 V

Output Current, I

Logic Supply Voltage, VDD......................... 7.0 V

Logic Input Voltage Range, VIN

(tW>30 ns) .......... -0.3 V to V

(tW<30 ns) ................ -1.0V to VDD +1V

Sense Voltage, V

Reference Voltage, V

Package Power Dissipation,

P

Operating Temperature Range,

T

Junction Temperature, TJ......................... +150°C

Storage Temperature Range,

T

* Output current rating may be limited by duty cycle,

ambient temperature, and heat sinking. Under any set of

conditions, do not exceed the specified current rating or a

junction temperature of 150°C.

D

A

S

................................... ±3 A*

OUT

+ 0.3 V

DD

................................. 0.5 V

SENSE

................................ VDD

REF

............................................... 3.9 W

................................ -20°C to +85°C

............................... -55°C to +150°C

PWM MOTOR DRIVER

Designed for pulse-width modulated (PWM) current control of threephase brushless dc motors, the A3936SED is capable of peak output currents

to ± 3 A and operating voltages to 50 V. Internal fixed off-time PWM currentcontrol timing circuitry can be configured to operate in slow-, fast- and mixeddecay modes.

Internal synchronous rectification control circuitry is provided to

improve power dissipation during PWM operation.

Internal circuit protection includes thermal shutdown with

hysteresis, and crossover current protection. Special power up sequencing is

not required.

The A3936 is supplied in a 44-pin plastic PLCC with a copper

batwing tabs (suffix ‘ED’). The power tabs are at ground potential and need

no electrical isolation. This device is also available in a lead-free version

(100% matte tin leadframe).

Features

±3 A, 50 V Continuous Output Rating

Low

Configurable Mixed, Fast and Slow Current-Decay Modes

Synchronous Rectification for Low Power Dissipation

Internal UVLO and Thermal Shutdown Circuitry

Crossover-Current Protection

Tachometer Output for External Speed Control Loop

Always order by complete part number

Part Number Package

A3936SED 44-pin PLCC

A3936SED-T 44-pin PLCC, Lead-free

r

Outputs (typically 500 mΩ source, 315 mΩ sink)

DS(on)

A3936-DS Rev. 1

3936 Three Phase PWM Motor Driver

FUNCTIONAL BLOCK DIAGRAM

.22uf/100V

.22uf/50V

VREG

V

DD

REGULATOR CHARGE PUMP

CP2

CP1

VCP

HALL

HALL

HALL

TACH

HBIAS

HA+

HB+

HC+

SLEEP

DIR

EXTMODE

BRAKE

ENABLE

HA-

HB-

HC-

SR

Comm

Logic

Control

Logic

BANDGAP

GATE

DRIVE

OVERVOLTAGE

UNDERVOLTAGE

AND FAULT

DETECT

VCPVREG

ZERO

DETECT

+-

CURRENT

VBB1

VBB2

OUTA

OUTB

OUTC

LSS2

LSS1

SENSE

R

GND

.22uf/50V

.1uF

S

VDD

BLANK

OSC

PFD1

PFD2

PWM

TIMER

+-

SENSE

CURRENT

BUFFER/

DIVIDER

REF

3936 Three Phase PWM Motor Driver

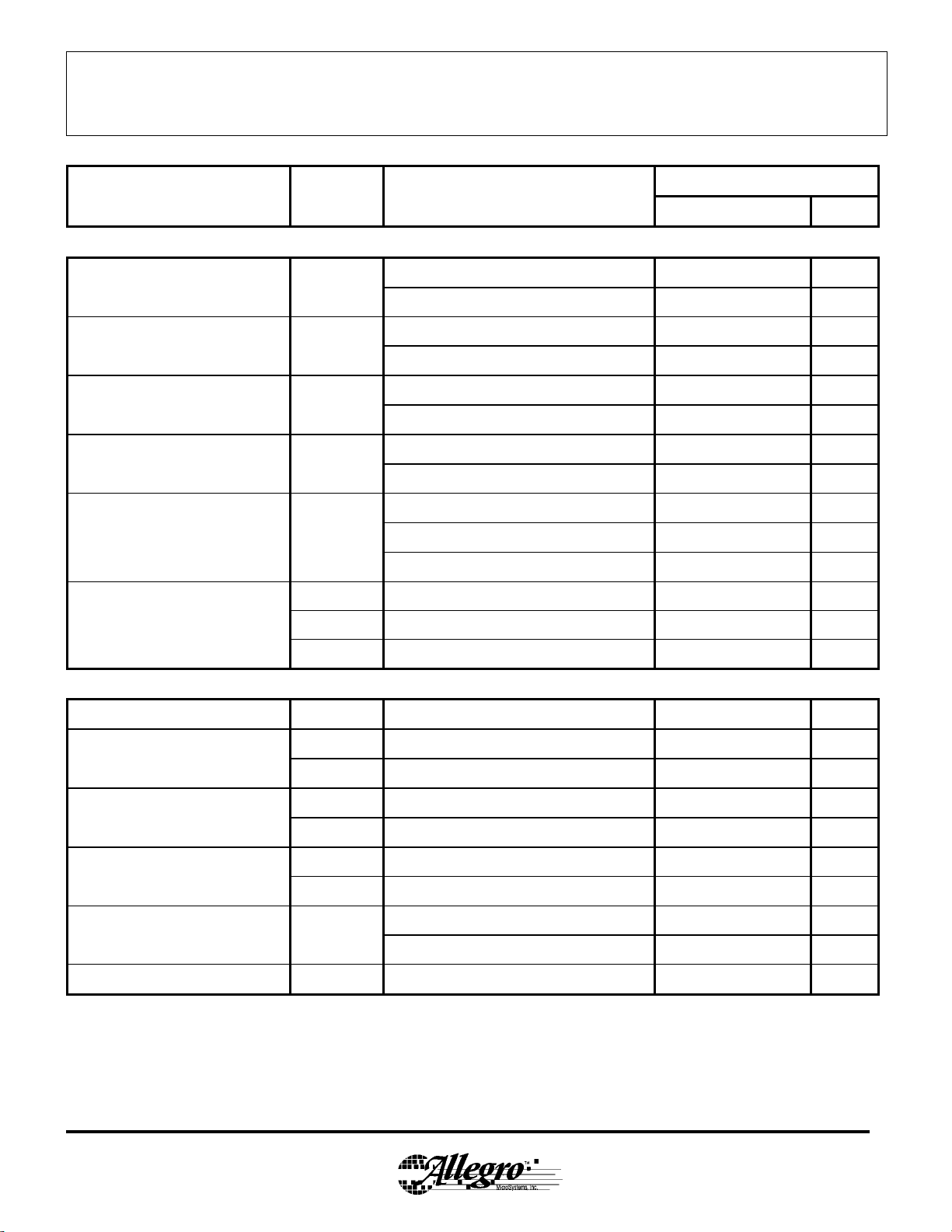

ELECTRICAL CHARACTERISTICS at TJ= +25°C, VBB = 50 V, VDD=5.0V,f

< 50KHz (unless noted otherwise)

PWM

Limits

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Output Drivers

Load SupplyVoltage Range VBB Operating 9 – 50 V

During Sleep Mode 0 50 V

Output Leakage Current I

Output On Resistance R

BodyDiodeForward Voltage V

Motor Supply Current I

Logic Supply Current

DSS

DSON

F

BB

I

DD

V

OUT=VBB

V

= 0 V – <–1.0 -20 µA

OUT

SourceDriver, I

Sink Driver, I

= -3A – .55 Ω

OUT

=3A – .35 Ω

OUT

–<1.020 µA

Source Diode, IF= -3A – – 1.4 V

Sink Diode, IF=3A – – 1.3 V

f

<50kHz – 4 7 mA

PWM

Charge Pump On, Outputs Disabled – 2 5 mA

Sleep Mode – – 20 uA

f

<50kHz – 10 mA

PWM

Control Logic

Logic Supply Voltage Range V

Logic Input Voltage V

Logic Input Current I

(except ENABLE) I

Logic Input Current I

ENABLE Input I

Outputs Off – 8 mA

Sleep Mode (Inputs belo w.5V) 100 µA

DD

IN(1)

V

IN(0)

IN(1)

IN(0)

IN(1)

IN(0)

OSC

Operating 3 5.0 5.5 V

VDD*.5 – – V

––V

*.2 V

DD

VIN=VDD*.5 -20 <1.0 20 µA

VIN=VDD*.2 -20 <-1.0 20 µA

VIN=VDD*.5 – 100 µA

VIN=VDD*.2 – 30 µA

OSC shorted to GND 3 4 5 MHzInternalOscillator f

R

= 51K 3.4 4 4.6 MHz

OSC

3936 Three Phase PWM Motor Driver

ELECTRICAL CHARACTERISTICS at TJ= +25°C, VBB=50V,VDD= 5.0 V, f

< 50KHz (unless noted

PWM

otherwise)

Limits

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Control Logic

Buffer Input Offset Volt. V

V

Input Voltage Range Operating 0.0 – V

REF

Reference Input Current I

Comparato rInput Offset Volt. V

IO

REF

IO

ERR

(Note3)

V

REF=VDD,VBB

V

=0V ±5 mV

REF

V

REF=VDD

=.5V -14 14 %

V

REF

=0 to 50V -.5 0 0.5 µA

-4 4 %GMError V

Propagatio nDelay Times tpd 50% TO 90%, SR Enabled

PWM CHANGE TO SOURCE ON 600 750 1000 ns

PWM CHANGE TO SOURCE OFF 50 150 350 ns

PWM CHANGE TO SINK ON 600 750 1000 ns

PWM CHANGE TO SINK OFF 50 100 150 ns

±10 mV

DD

V

Crossover Delay t

Thermal Shutdown Temp. T

Thermal Shutdown Hysteresis ∆T

COD

J

J

UVLO EnableThresho ld Rising V

SR Enabled 300 600 1000 ns

– 165 – °C

–15– °C

DD

2.45 2.7 2.95 V

UVLO Hysteresis 0.05 0.10 – V

NOTES: 1. Typical Data is for design information only.

2. Negative current is defined as coming out of(sourcing) the specified device pin.

3.

V

=((V

ERR

REF

/10) – V

SENSE

)/(V

REF

/10)

3936 Three Phase PWM Motor Driver

ELECTRICAL CHARACTERISTICS at TA= +25°C, VBB=50V,VDD=5.0Vf

< 50KHz (unless noted

PWM

otherwise)

Limits

Characteristics Symbol Test Conditions Min. Typ. Max. Units

Hall Logic

Hall Input Current I

Common Mode Input Range VCMR .3 2.5 V

AC Input VoltageRange V

Hysteresis V

Pulse Reject Filter 35.58 µs

Hall Bias Output Sat Voltage V

Tach Output V

HALL

HALL

HYS

HB

I

HB

OL

VIN=1.2V -1 0 1 µA

.120 Vp-p

TA= -20 to 85 deg C. 10 30 mV

I

=40mA, TA= -20 to 85 deg C. .4 .5 V

OUT

40 mA

I

= 500uA .5 V

OUT

NOTES: 1. Typical Data is for design information only.

2. Negative current is defined as coming out of (sourcing) the specified devicepin.

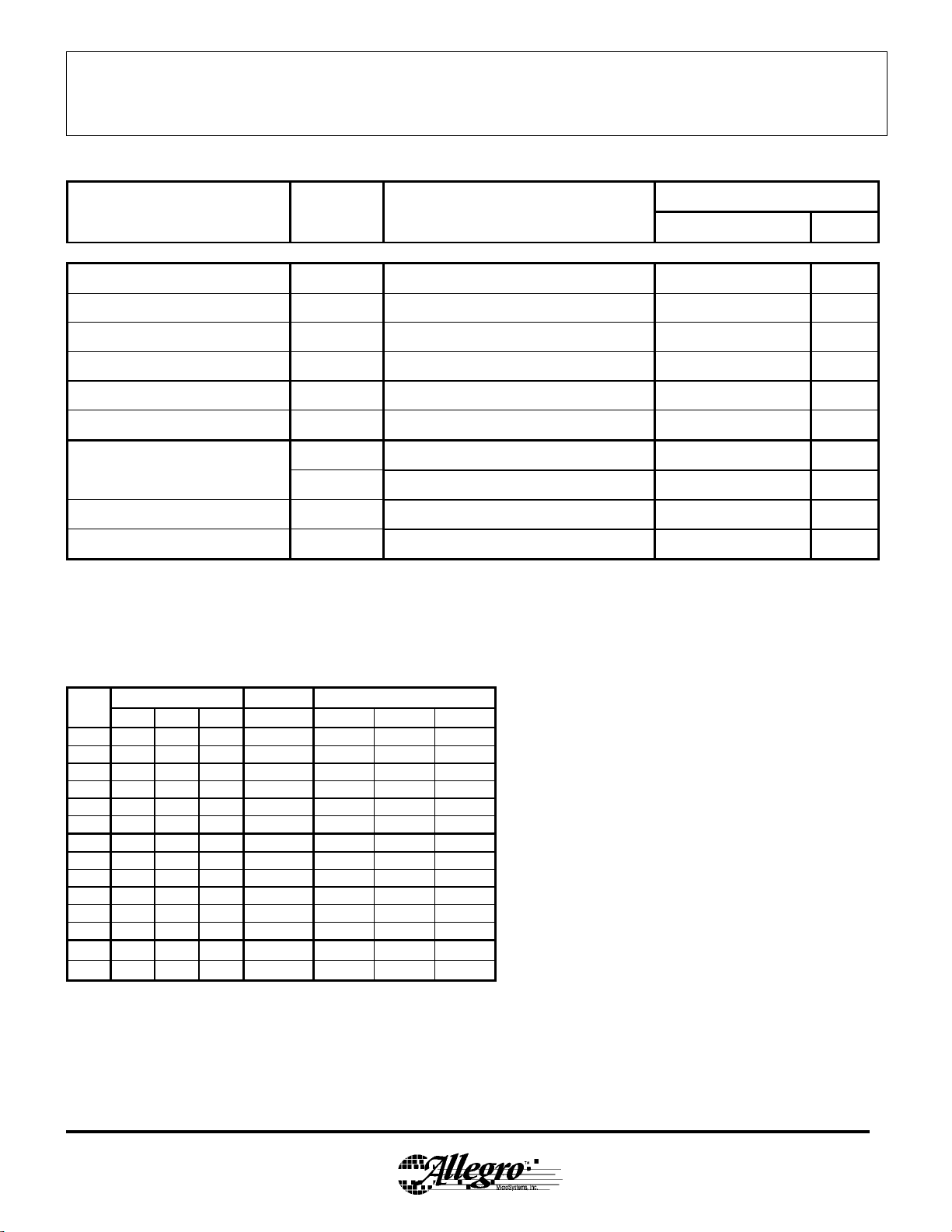

Commutation Truth Table

120 spacing

HA

HB HC DIR OUTA OUTB OUTC

1+-+FOR HI LO Z

2+-- FOR HI Z LO

3++- FOR Z HI LO

4-+-FOR LO HI Z

5-++FOR LO Z HI

6--+FOR Z LO HI

1+-+REV LO HI Z

2 + - - REV LO Z HI

3 + + - REV Z LO HI

4-+- REV HI LO Z

5-++REV HI Z LO

6 - - + REV Z HI LO

--- X Z Z Z

+++ X Z Z Z

Outputs

3936 Three Phase PWM Motor Driver

Functional Description

VREG. Th e VREG pin should be decoupled with a 0.22

µF capacitor to gr ound. This supplyvoltage is used to run

the sink side DMOS outputs. VREG is internally monitored

and in the case ofa fault condition, the outputs of the device

are disabled.

Charge Pump.The Charge Pump is used to generate a

supply above VBB to drive the source side DMOS gates. A

0.22 uF ceramic monolithic capacitor should be connected

between CP

and CP2for pumping purposes. A 0.22 uF

1

ceramic monolithic capacitor should beconnected between

V

and VBBto act as a reservoir to run the high side

CP

DMOS devices. The V

Voltageis internally monitored

CP

and in the case ofa fault condition the outputs of the device

are disabled.

Shutdown. In the event of a fault due to excessive

junction temperature, or lowvoltage on V

outputs of the device ar e disabled until the fault condition is

removed. At power up, and in the event of low V

UVLO circuit disables the drivers.

or V

CP

REG

DD

,the

,the

Current Regulation. Load current is regulated by an

internal fixed off time PWM control circuit. When the

outputs of the DMOS H-bridge are turned on, current

increases in the motor winding until it reaches a value given

by:

I

TRIP=VREF

At the trip point, the sensecomparator resets the source

enable latch, turning offthe source driver. At th is point,

load inductance causes the current to recirculate for the

fixed off time period. The current path during recirculation

is determined by the configuration of slow/mixed decay

mode and the synchronous rectification control setting.

/(10*R

SENSE

)

Extmode Logic. When using external PWM current

control, the EXTMODE input determines the current path

during the chopped cycle. With EXTMODE set low, fast

decaymode, both the source and sink drivers are chopped

OFF during the decaytime (ENABLE=0). With

EXTMODE high, slow decay mode, only the source driver

turns off during the current decay time.

EXTMODE Decay

0Fast

1Slow

Sleep Mode. The input pin SLEEP is dedicated to put

the device into a minimum current draw mode. When

asserted low, all circuits are disabled.

Fixed Off-Time. The 3936 is set for a fixed off time of

96 counts of the intern al oscillator, typically24 µs with

4Mhz oscillator.

Internal Current Control Mode. Input pins PFD1

and PFD2 determine the current decay method after an

overcurrent event is detected at sense input. In slow decay

mode both sink side drivers are turned on for the fixed off

time period. Mixed decaymode starts out in fast decay

mode for the selected percentage of the fixed off time, and

then is followed by slow decay for the rest of the period.

PFD2 PFD1 % t

OFF

00 0Slow

0 1 15 Mixed

1 0 48 Mixed

1 1 100 Fast

Decay

Enable Logic. The Enable input terminal allows

external PWM. ENABLE high turns ON the selected sinksourcepair, enable low switches offthe appropriate drivers

and the load current decays. Ifthe ENABLEpin is held

high, the current will rise until it reaches the level set by the

internal current control circuit.

ENABLE Outputs

0 Source

Chopped

1ON

3936 Three Phase PWM Motor Driver

PWM Blank Timer. When a sourcedriver turnson, a

current spikeoccurs due to the reverserecovery currents of

the clamp diodes and/or switching transients related to

distributed capacitance in the load. To prevent this current

spike from erroneouslyresetting the source enable latch, the

sense comparator is blanked. The blank timer run s after the

offtime counter to provide the blanking function. The blank

timer is reset when ENABLE is chopped or DIRis changed.

For external PWM control, a DIR change or ENABLE ON

will trigger the blanking function. The duration is adjusted

by control input BLANK.

BLANK t

06/f

1 12/f

BLANK

OSC

OSC

Brake. Logic high to the brake terminal activates the

brake function, logic low allows normal operation. Brake

will turn all three sink dr ivers ON and effectively shorts out

the motor generated BEMF. It is important to note th at the

internal PWM current control circuit will not limit the

current when braking, sincethe current does not flow

through the sense resistor. Themaximum current can be

approximated by V

BEMF/RL

that the maximum ratings of the device ar e not exceeded in

worse case braking situations of h igh speed an d high

inertial loads.

. Care should be taken to insure

Synchronous Rectification. Logic high applied to

the SR terminal enables synchronous rectification. When a

PWM off cycle is triggered, either by an ENABLE chop

command or internal fixed off time cycle, load current will

recirculate according to the decay mode selected by control

logic. The A3936 synchronous rectification feature will turn

on the appropriate MOSFET(s)during the current decay and

effectivelyshort out the bodydiodes with the lowRdson

driver. This will lower power dissipation significantly and

can eliminate the need for external schottky diodes.

Reversal of load current is prevented by turning off

synchronous rectification when a zero current level is

detected.

Oscillator. The PWMtimer is based on an internal

oscillator set by a resistor connected from the OSC terminal

to V

. Typical value of 4Mhz is set with 51k resistor.

DD

F

OSC

= 204E9/R

OSC

.

Tach. A tachometer signal is available for speed

measurement. This open collector output toggles at each

Hall transition.

3936

Terminal List

Pin No. Pin Name Pin Description

1GND

2GND

3 HA+ Hall input

4 HA- Hall input

5 HB+ Hall input

6 HB- Hall input

7 HC+ Hall input

8 HC- Hall input

9V

10 REF GmReference Input Voltage

11 GND

12 GND

13 GND

14 BRAKE Logic Input

15 SENSE Sense Resistor Connection

16 SR Logic Input (Disabled = Low, Active SR = High)

17 OUTA DMOS H – Bridge A

18 HBIAS Connection for hall element neg side

19 VBB1 Load Supply Voltage

20 LSS1 Low Side Source connection

21 OUTB DMOS H – Bridge B

22 GND

23 GND

24 GND

25 LSS2 Low Side Source connection

26 VBB2 Load Supply Voltage

27 TACH Speed output

28 OUTC DMOS H – Bridge C

29 V

30 CP1 Charge Pump Capacitor Terminal

31 CP2 Charge Pump Capacitor Terminal

32 SLEEP Logic input for SLEEP mode

33 GND

34 GND

35 GND

36 OSC Oscillator Terminal

37 V

38 DIR Logic Input

39 ENABLE Logic Input

40 EXTMODE Logic Input

41 BLANK Logic Input

42 PFD2 Logic Input

43 PFD1 Logic Input

44 GND Power Ground Tab

DD

CP

REG

Logic Supply Voltage

Reservoir Capacitor Terminal

Regulator decoupling Terminal

3936

Loading...

Loading...